Machining fixture locking device

A locking device and machining technology, applied in the field of machining fixtures, can solve the problems of clamping block retraction, "unstable air pressure of the cylinder, not stable clamping enough, etc." The effect of preventing air pressure instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

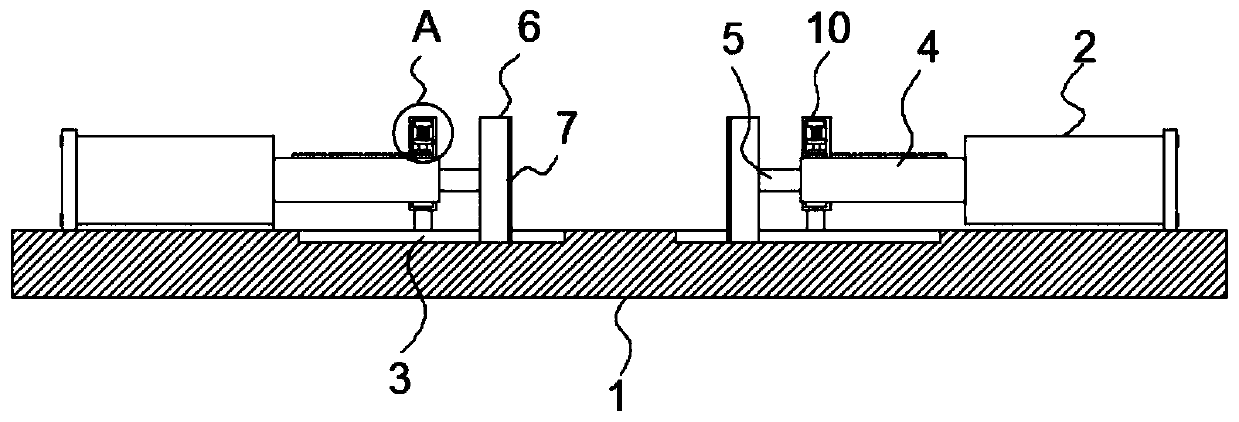

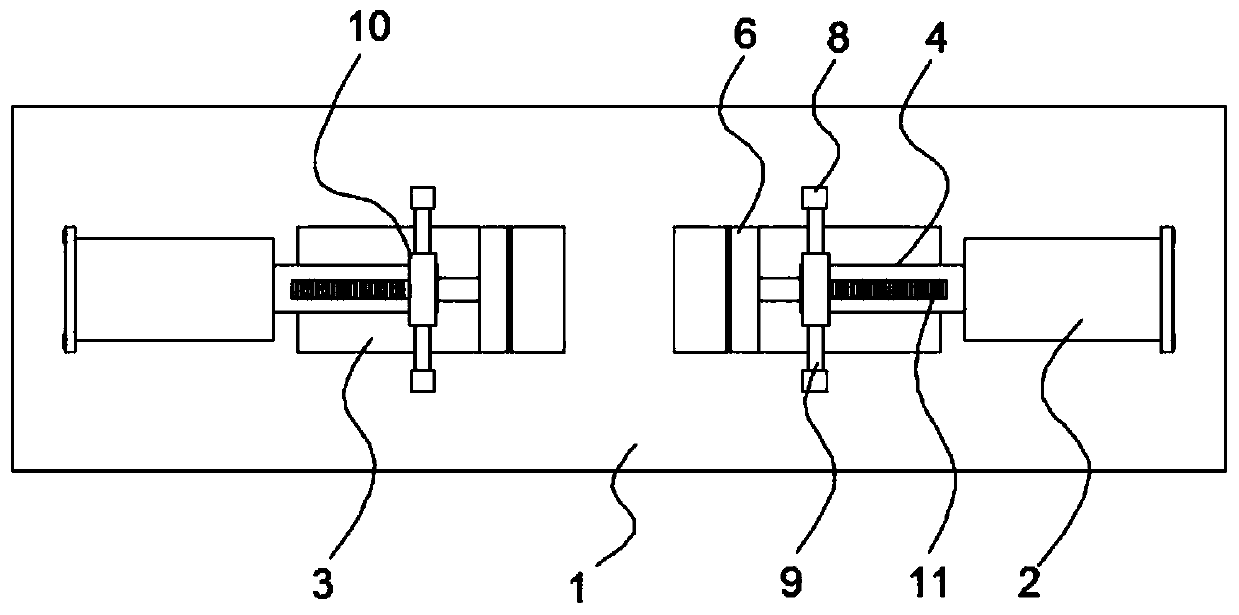

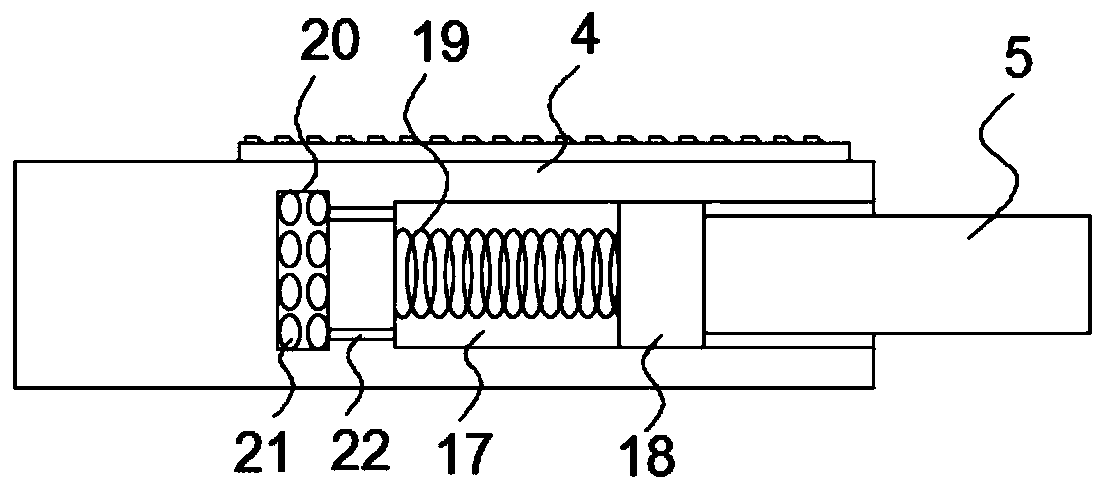

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0028] refer to Figure 1-5 , a machining fixture locking device, comprising a base plate 1, two telescopic cylinders 2 are symmetrically and fixedly installed on the base plate 1, piston rods 4 are arranged on the two telescopic cylinders 2, and the telescopic cylinders 2 drive the expansion and contraction of the piston rods 4, Belonging to the existing technical means, the specifications of the two telescopic cylinders 2 are the same, and the circuit can be controlled by the PLC controller, so that the working state of simultaneous start and simultaneous stop can be achieved. The piston rod 4 is fixedly connected with the tooth plate 11, the tooth plate 11 is an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com