Patents

Literature

33results about How to "Affect the clamping effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

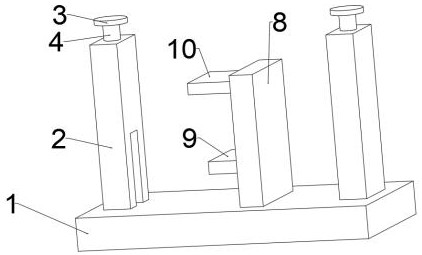

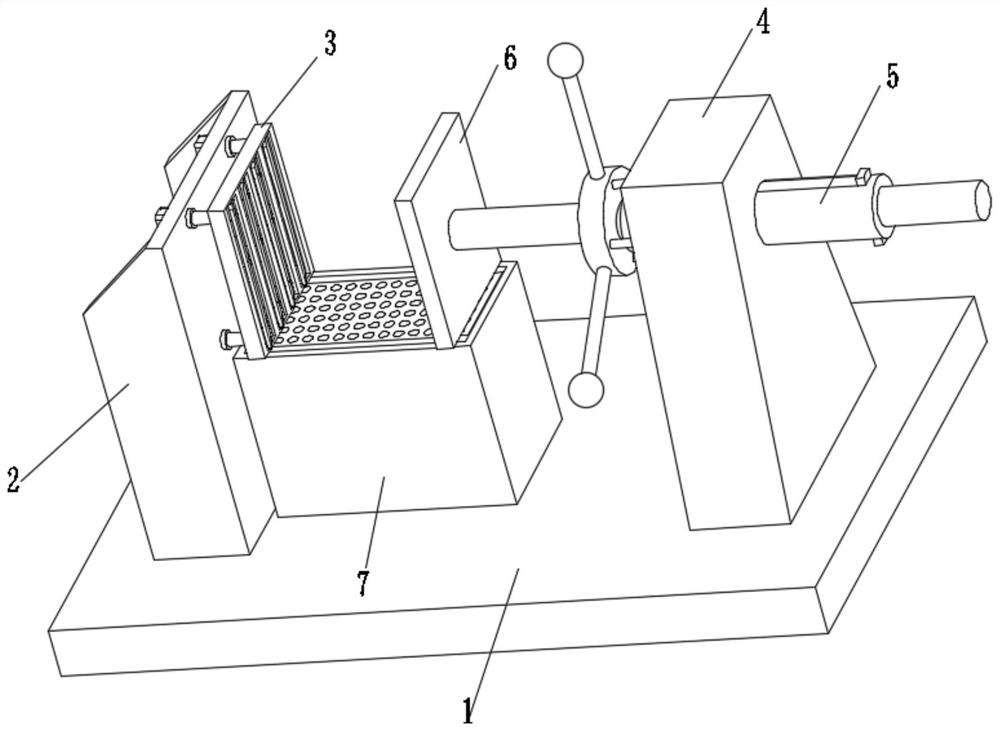

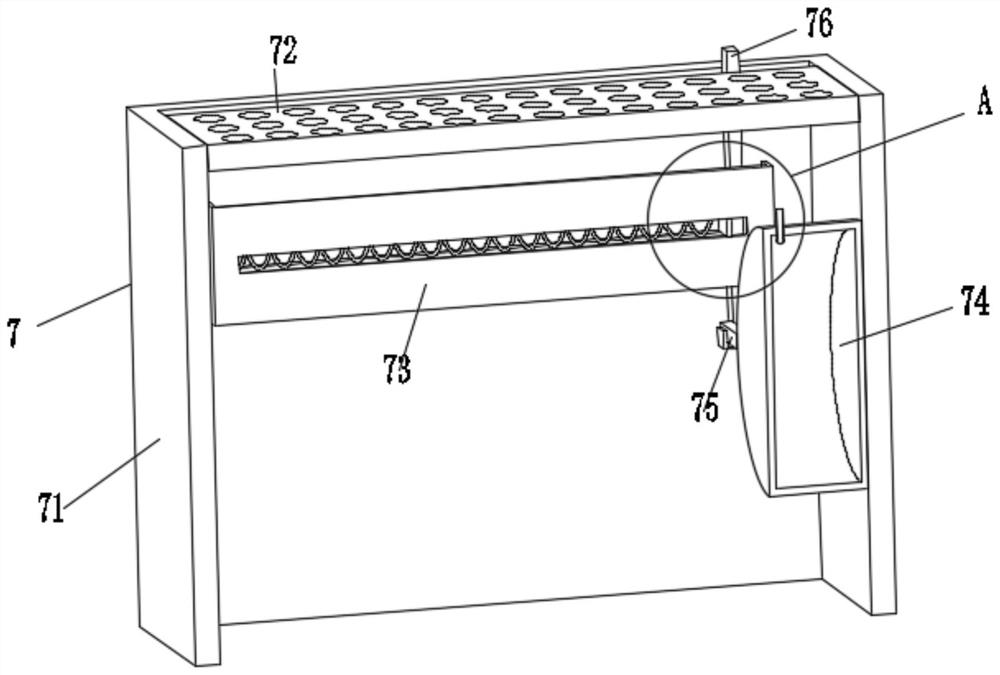

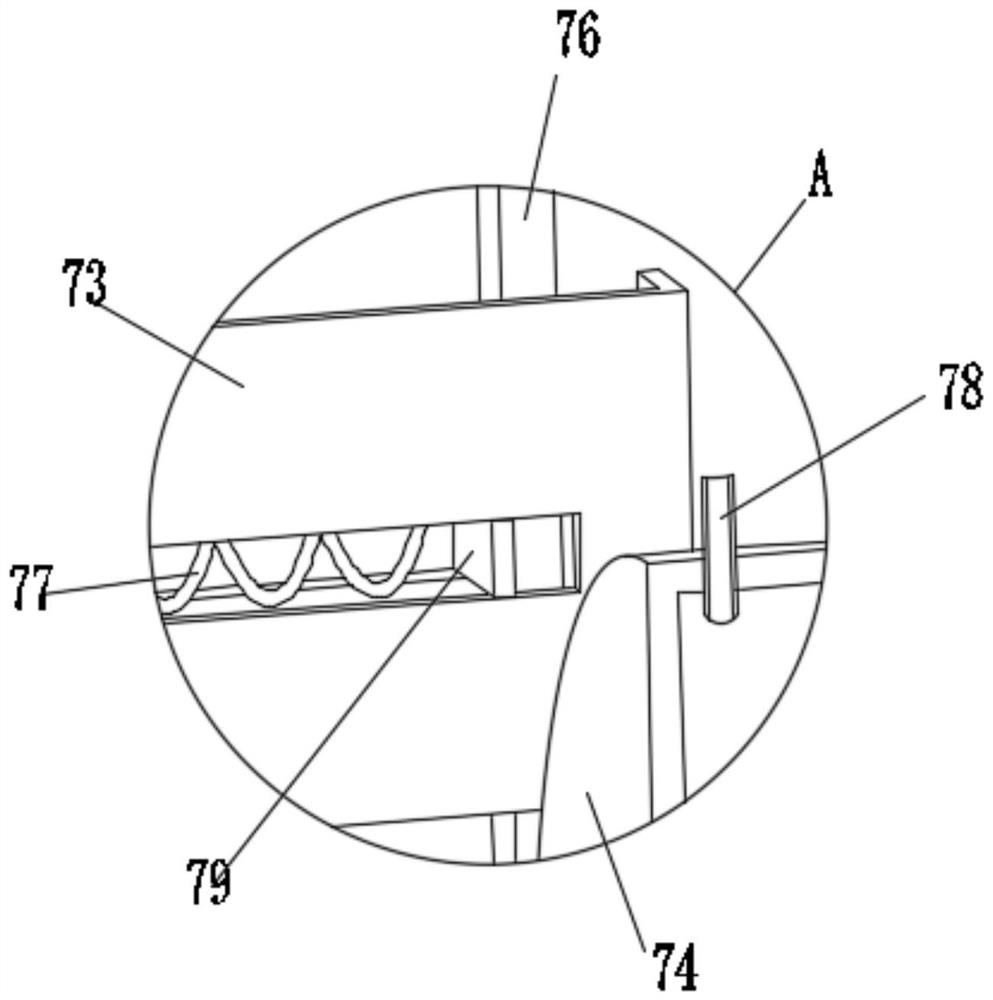

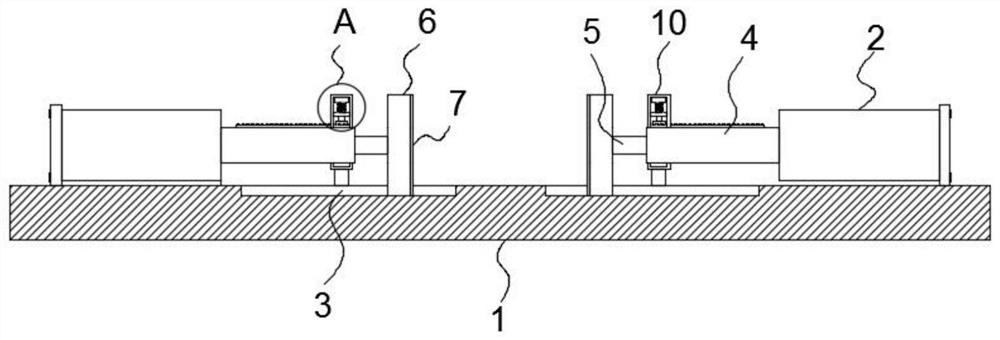

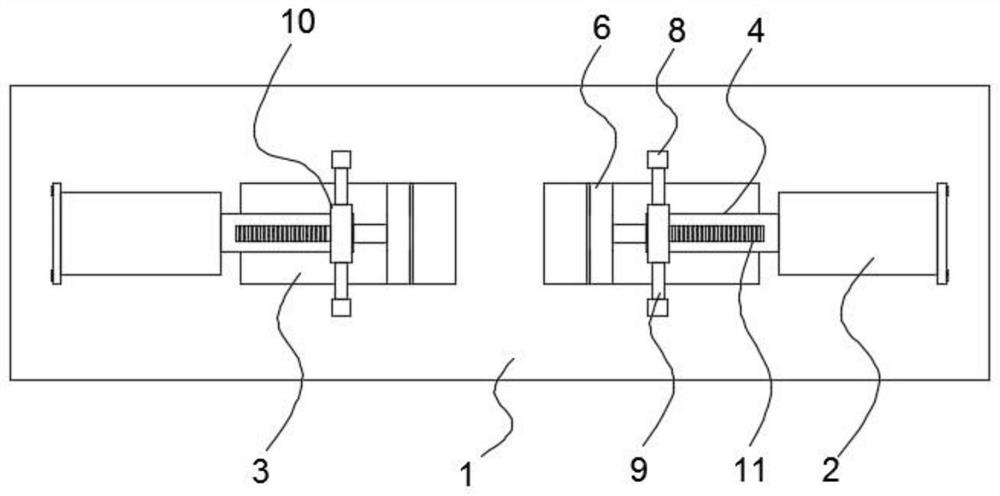

Machining fixture locking device

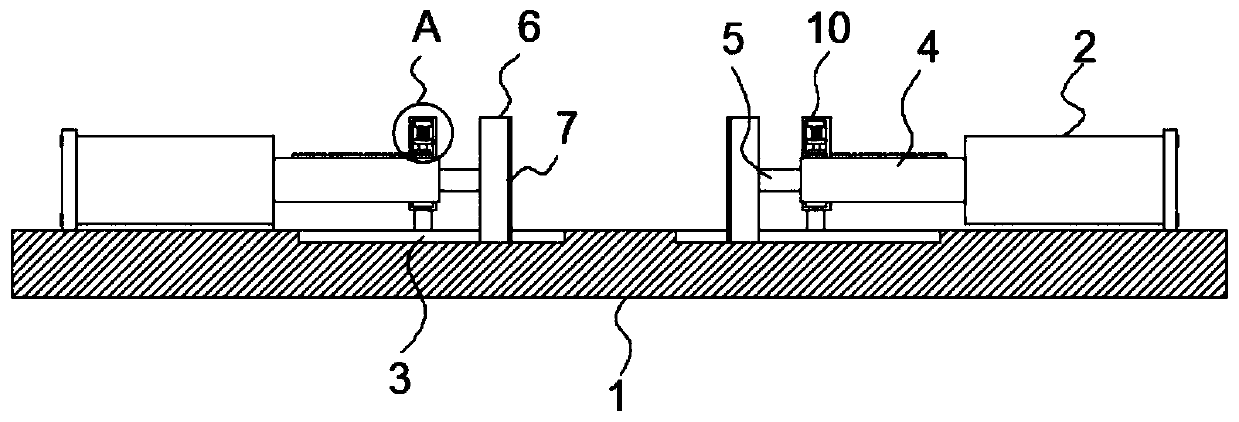

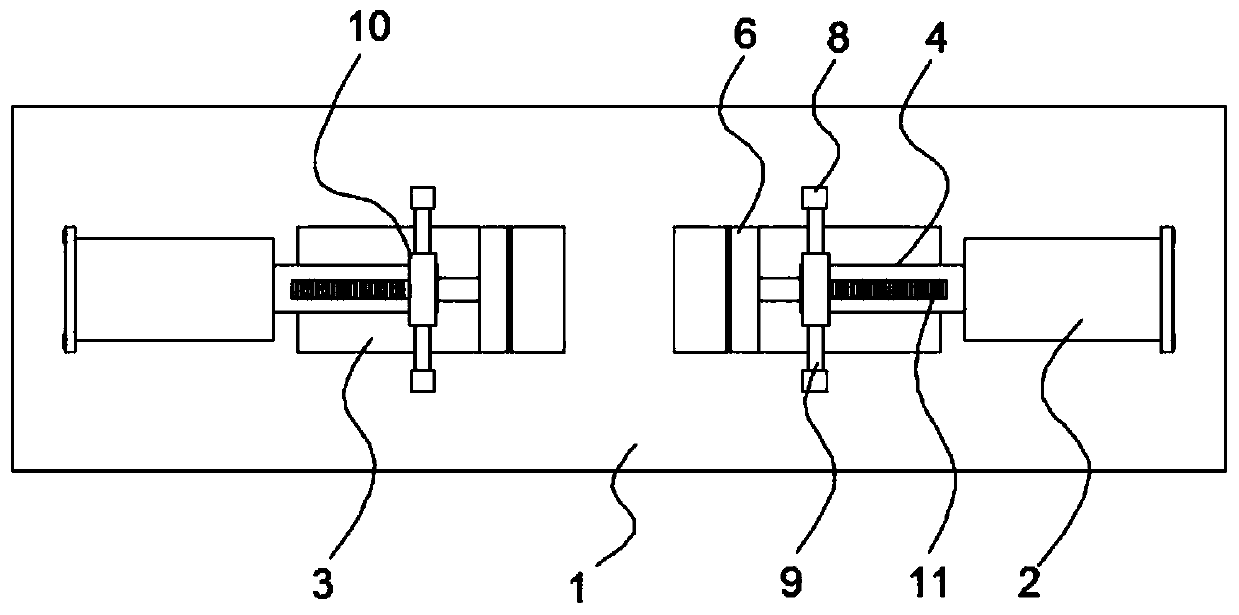

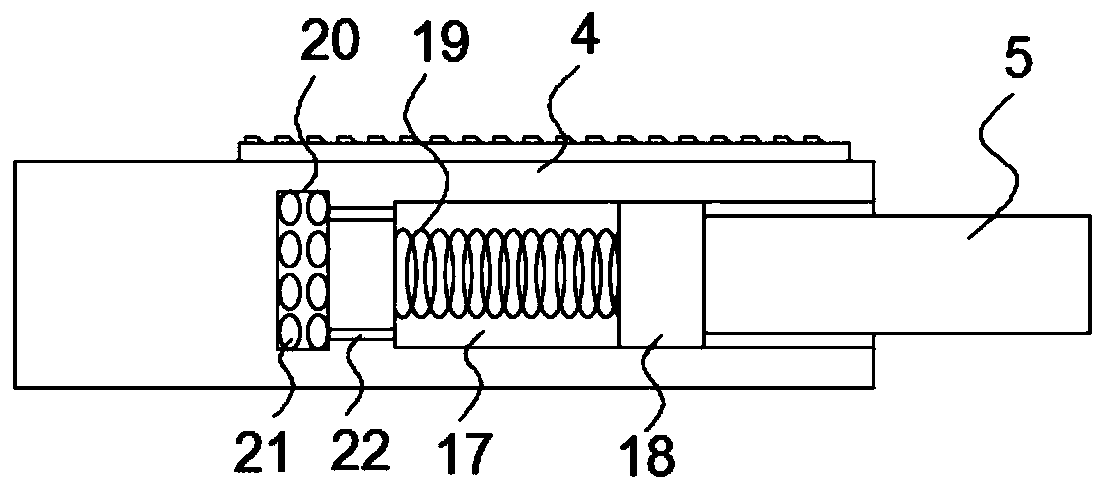

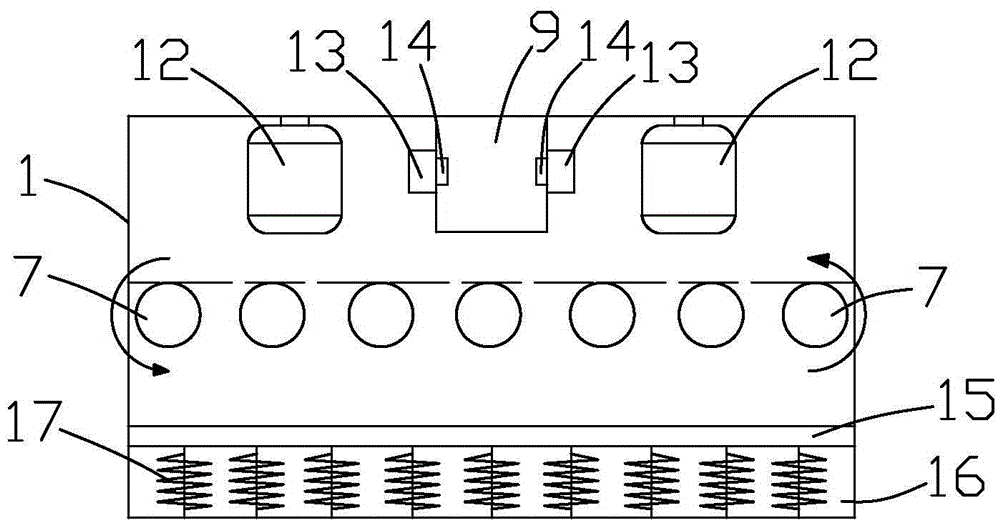

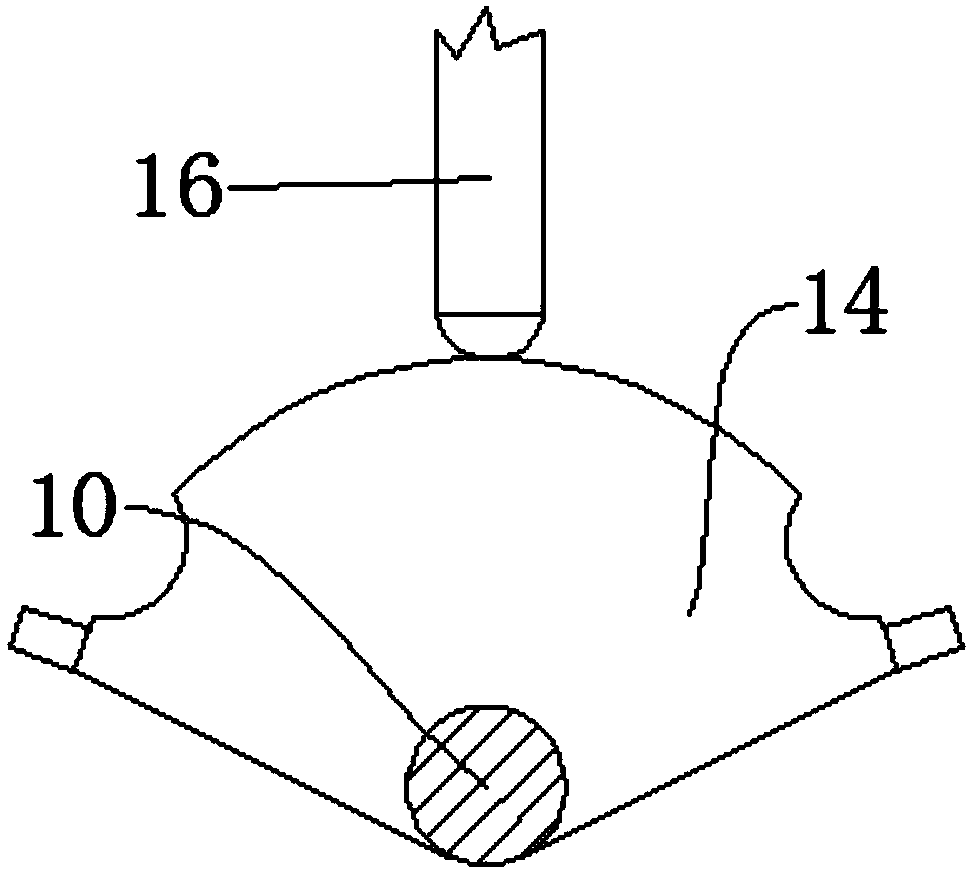

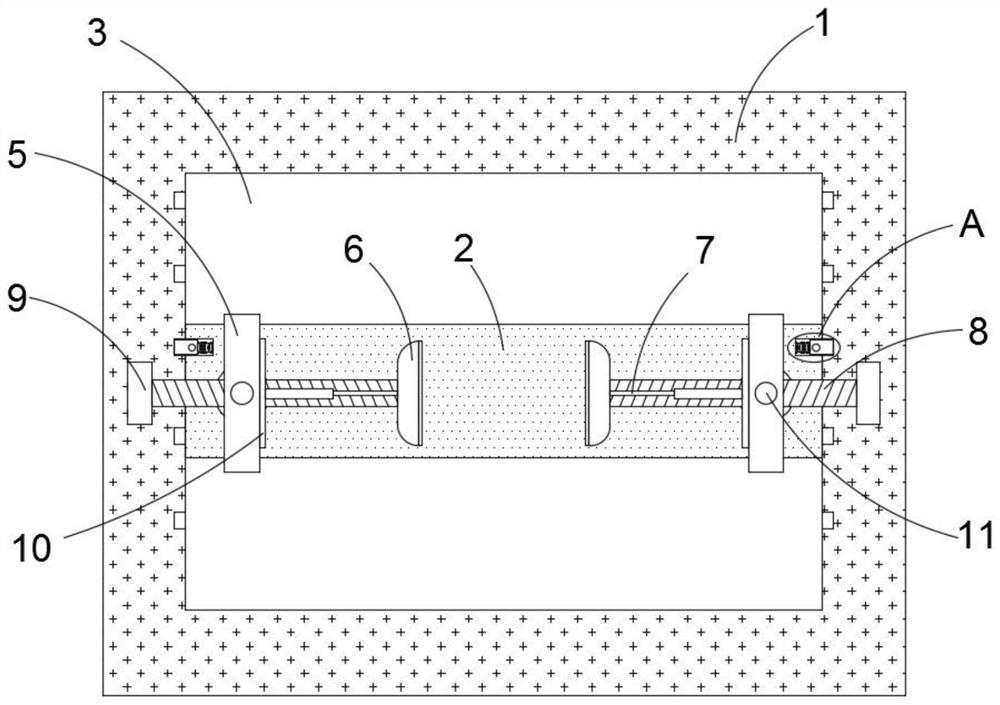

The invention discloses a machining fixture locking device. The machining fixture locking device comprises a base plate; two extension cylinders are symmetrically and fixedly mounted on the base plate; piston rods are arranged on the two extension cylinders, and are fixedly connected with tooth plates; buffer cavities are formed in the piston rods; piston blocks are slidingly connected into the buffer cavities; moving rods are fixedly connected to one sides of the piston blocks; the ends, far from the piston blocks, of the moving rods are fixedly connected with clamping plates; the other sidesof the piston blocks are fixedly connected with second springs; and the ends, far from the piston blocks, of the second springs are fixedly connected to the side walls of the buffer cavities. Tooth blocks adaptively slide up, and meanwhile, drive first springs to compress; and under the elastic effect of the first springs, the tooth blocks are engaged with the tooth plates again, and meanwhile, end surfaces B abut against the tooth plates to prevent retreating of the tooth plates, so that the locking effect on the piston rods is achieved, and the influence on the clamping effect of the pistonrods by instable air pressure of the extension cylinders is prevented.

Owner:浙江零捷网络科技有限公司

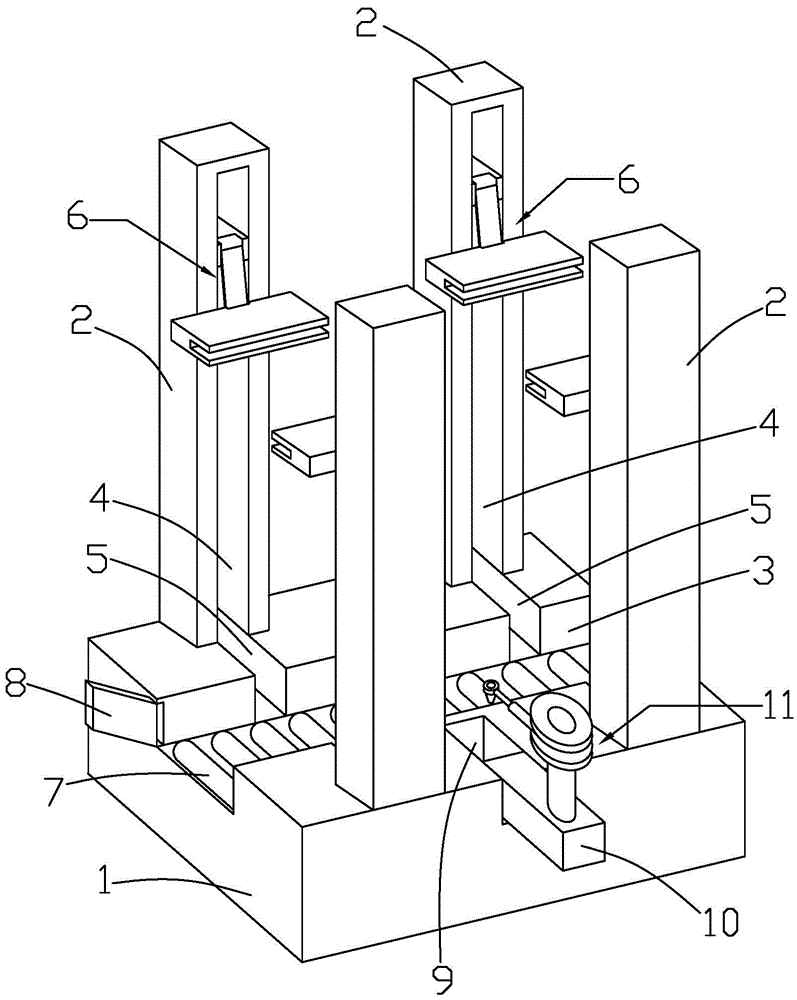

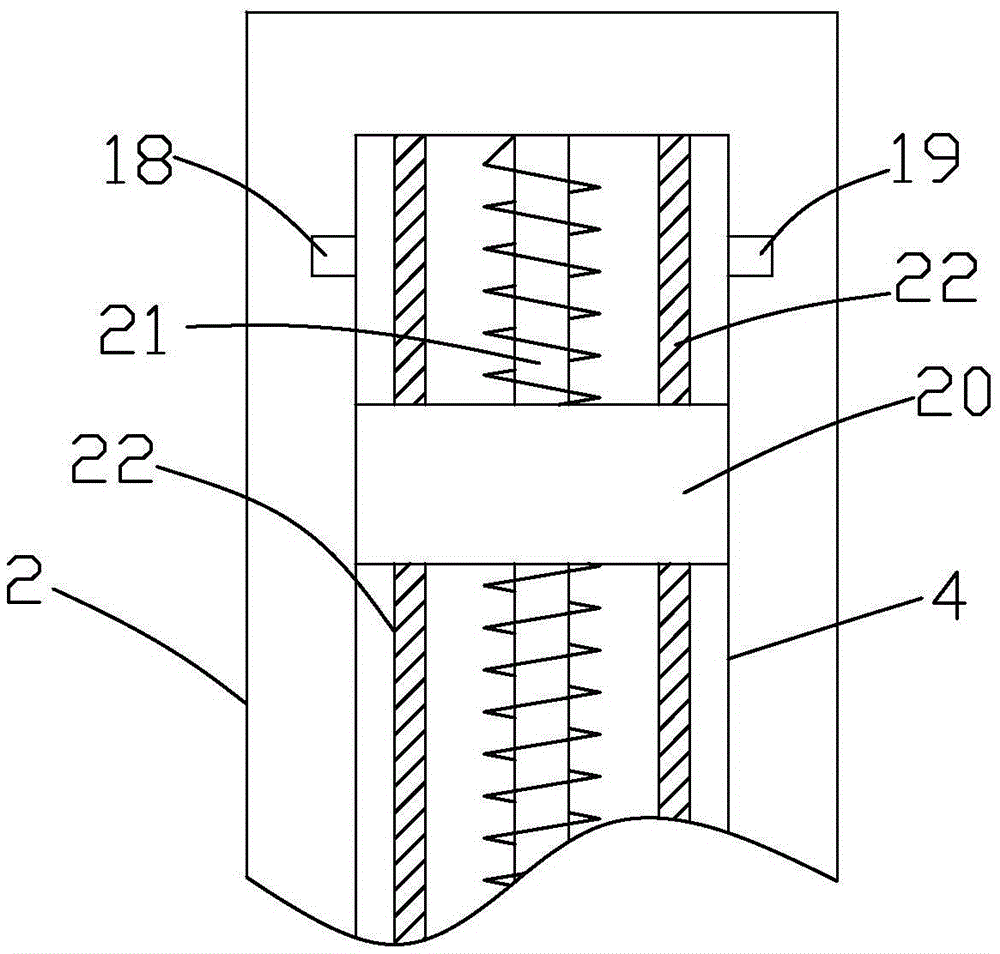

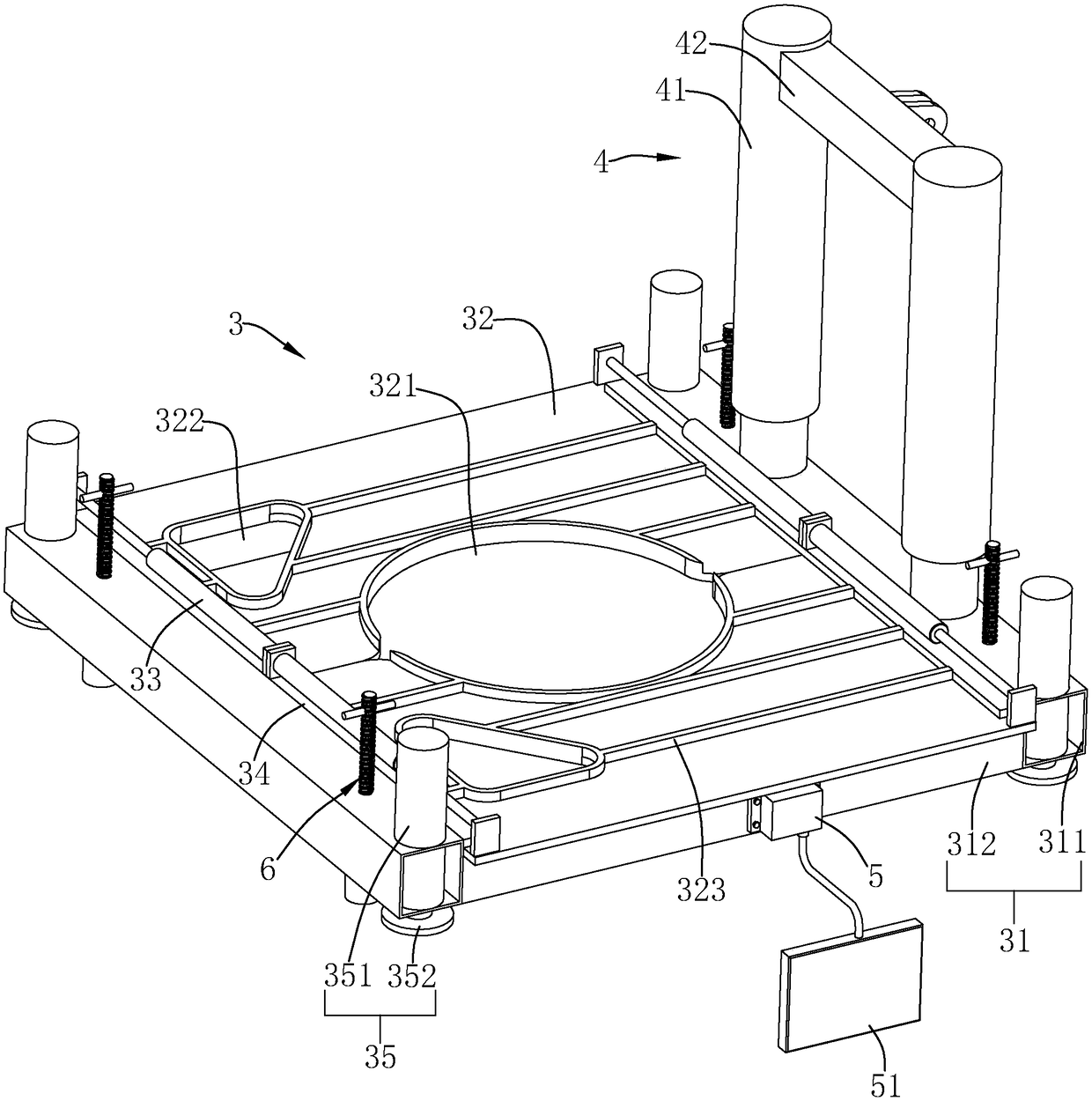

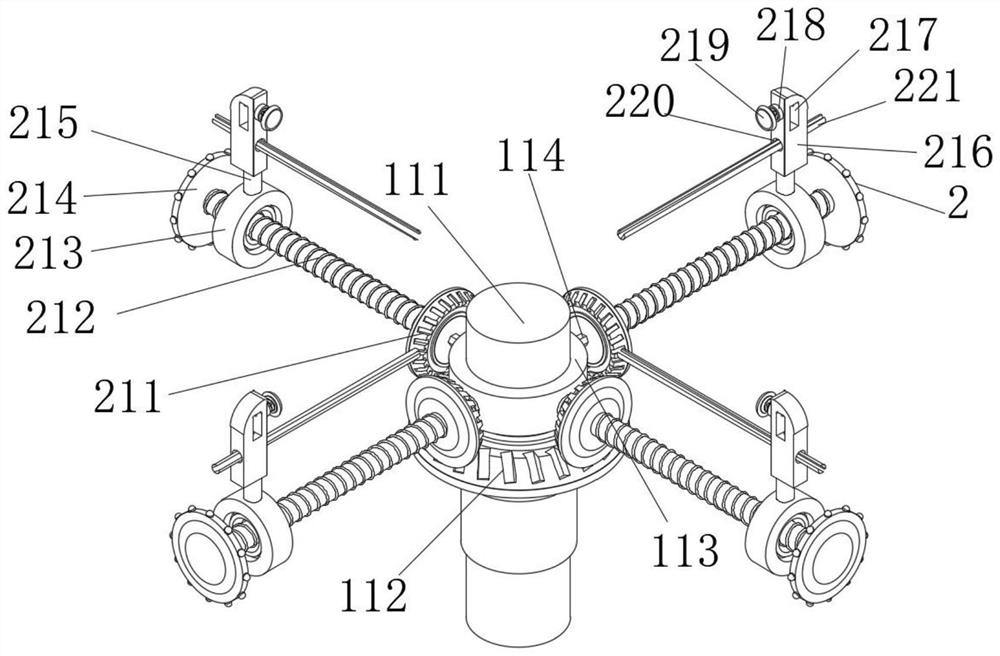

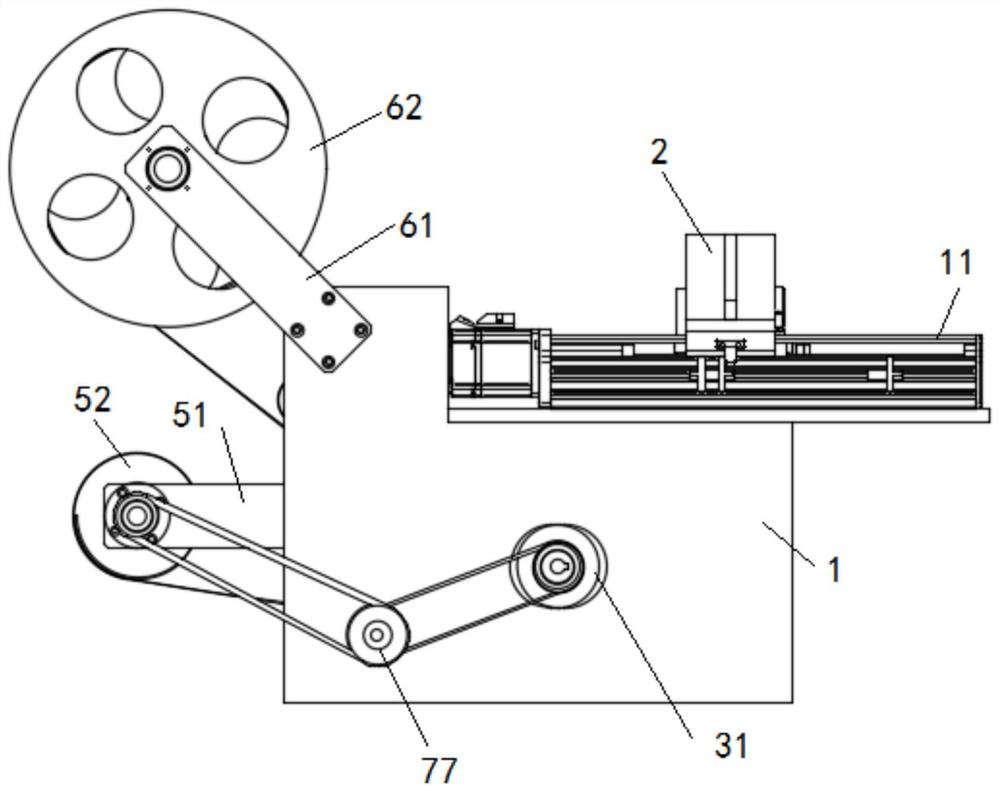

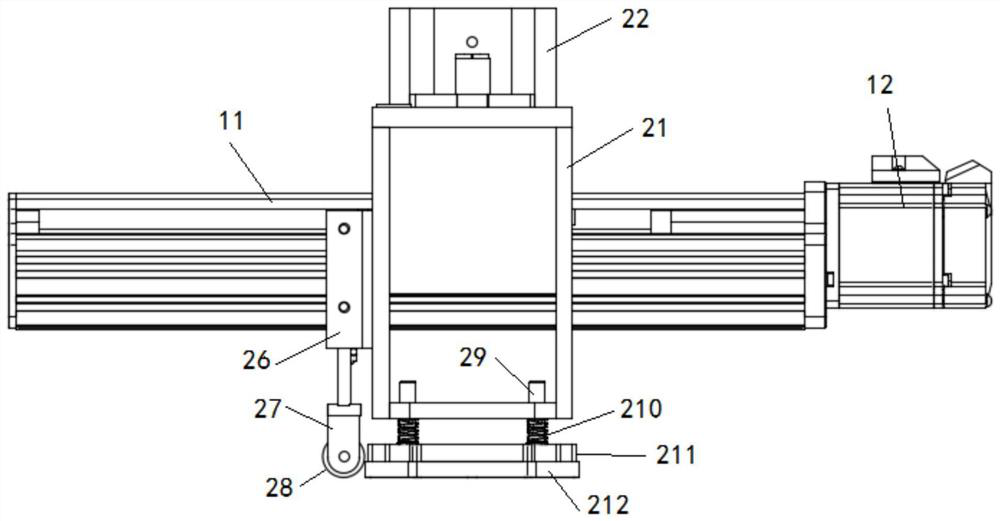

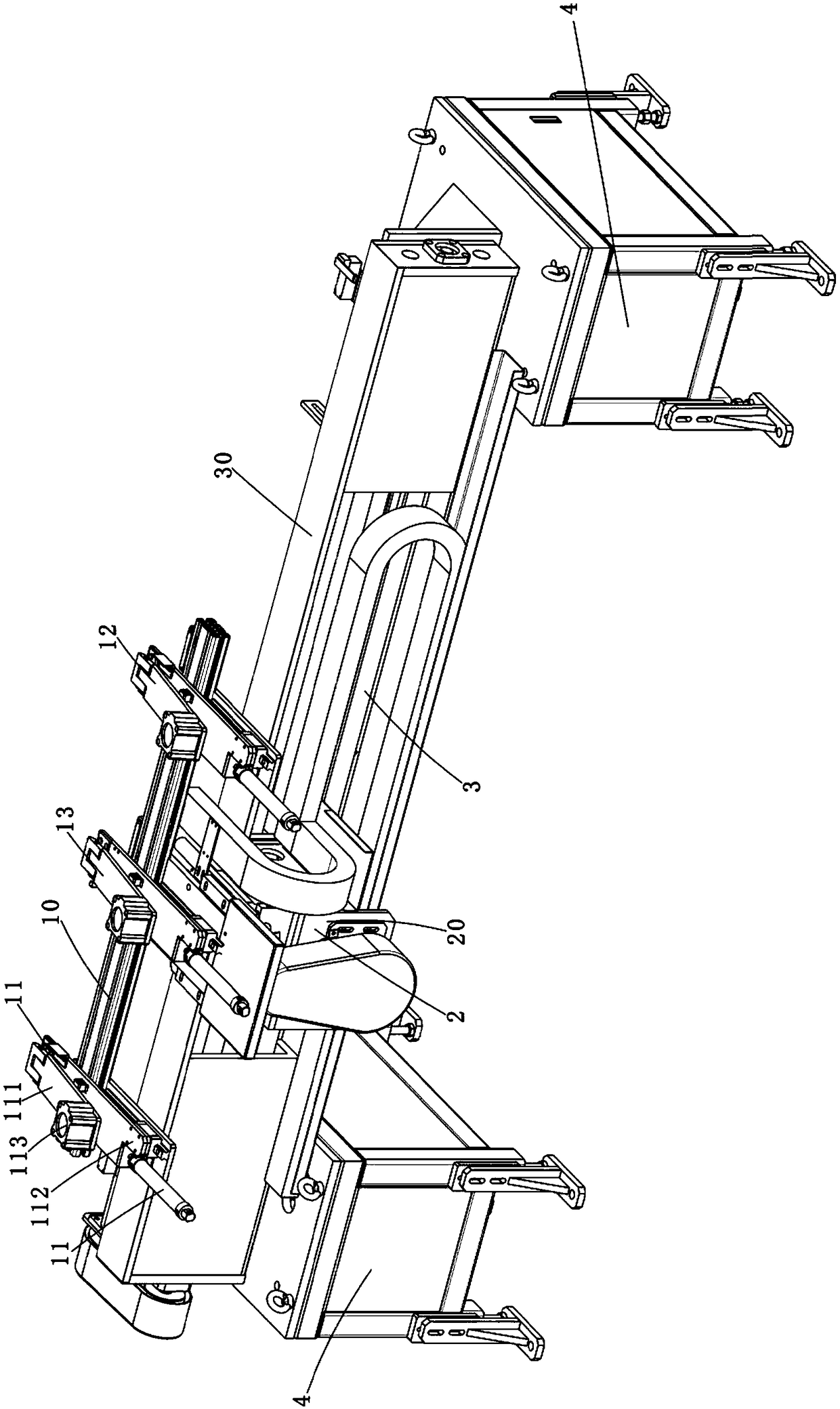

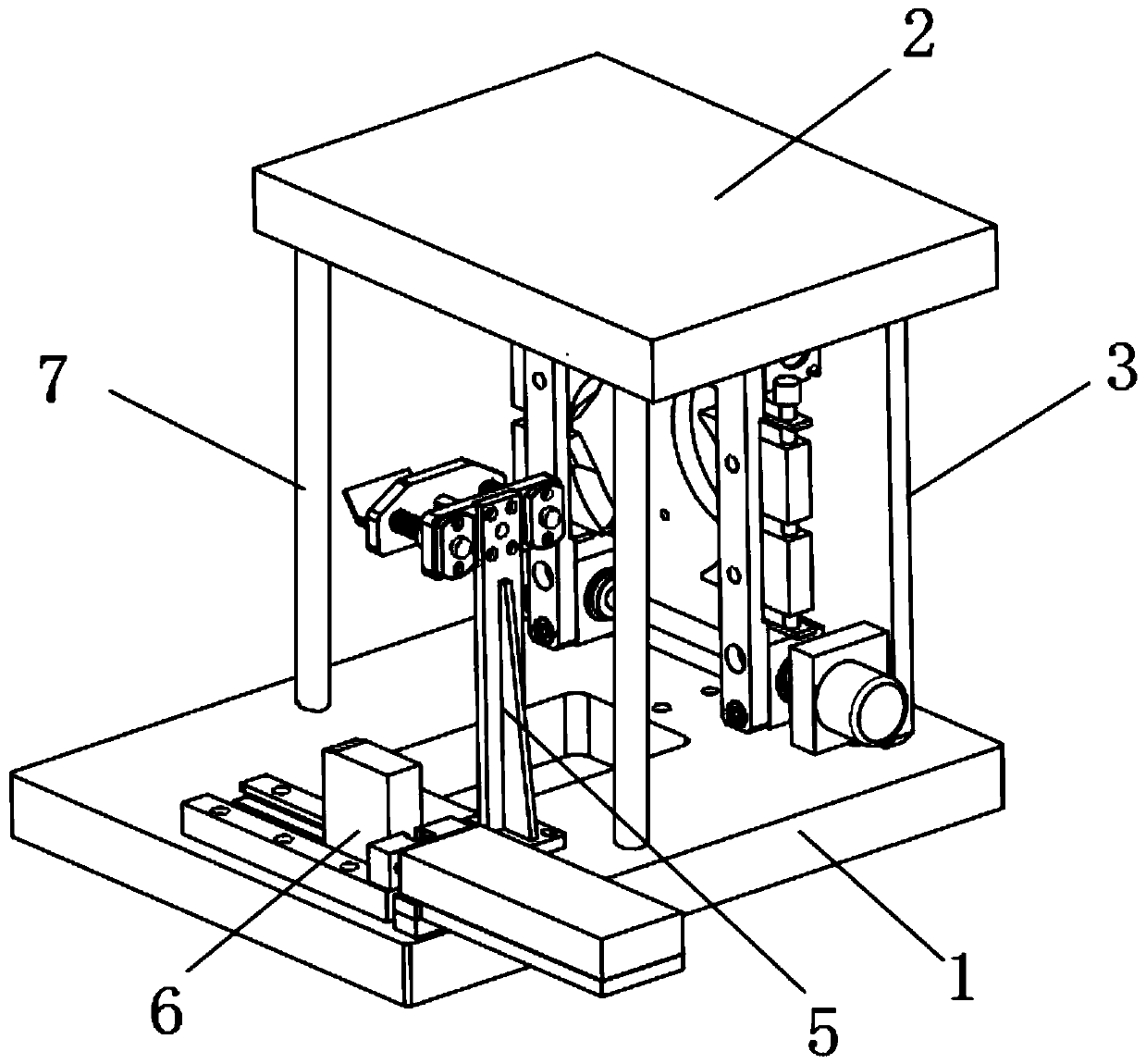

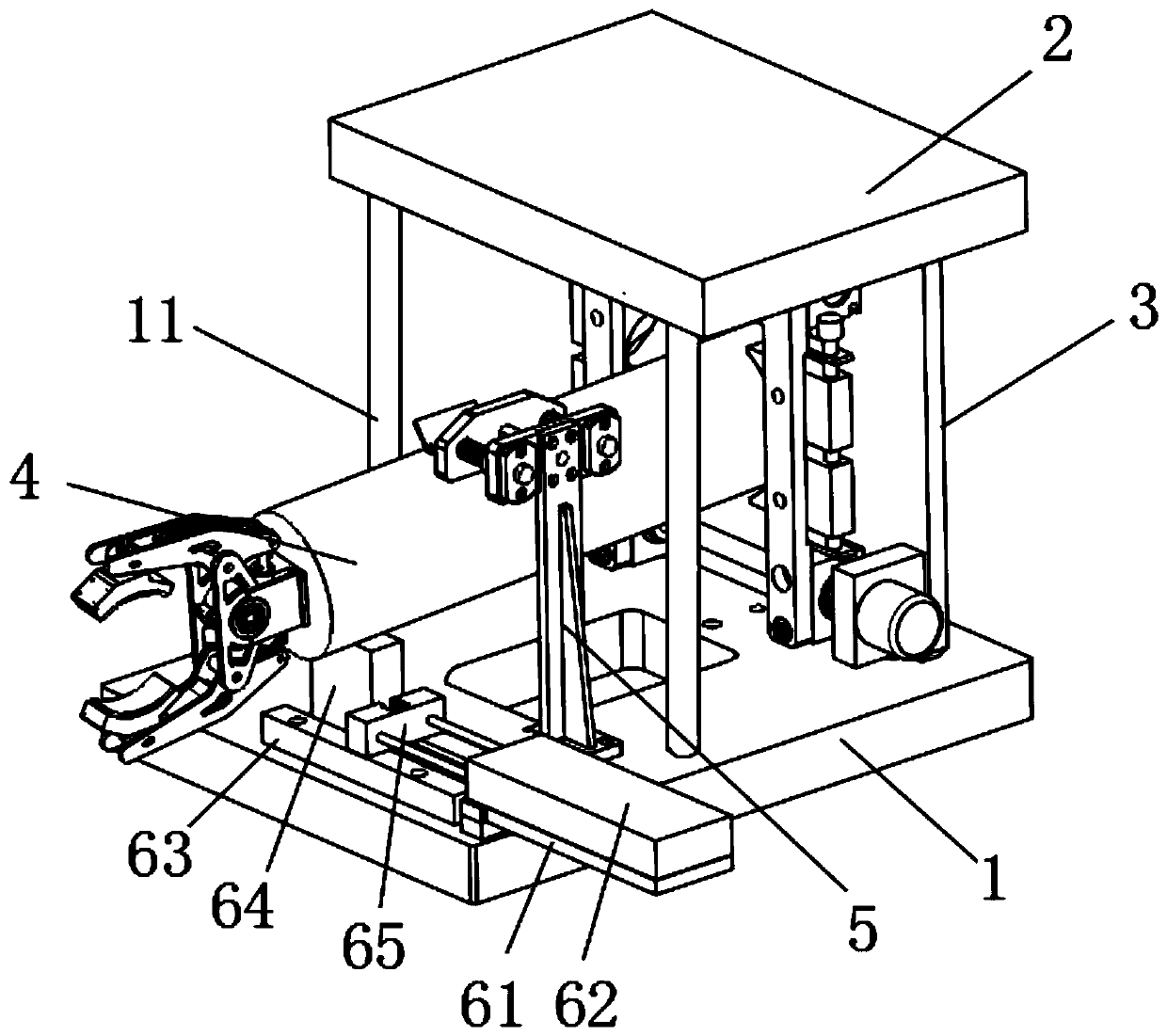

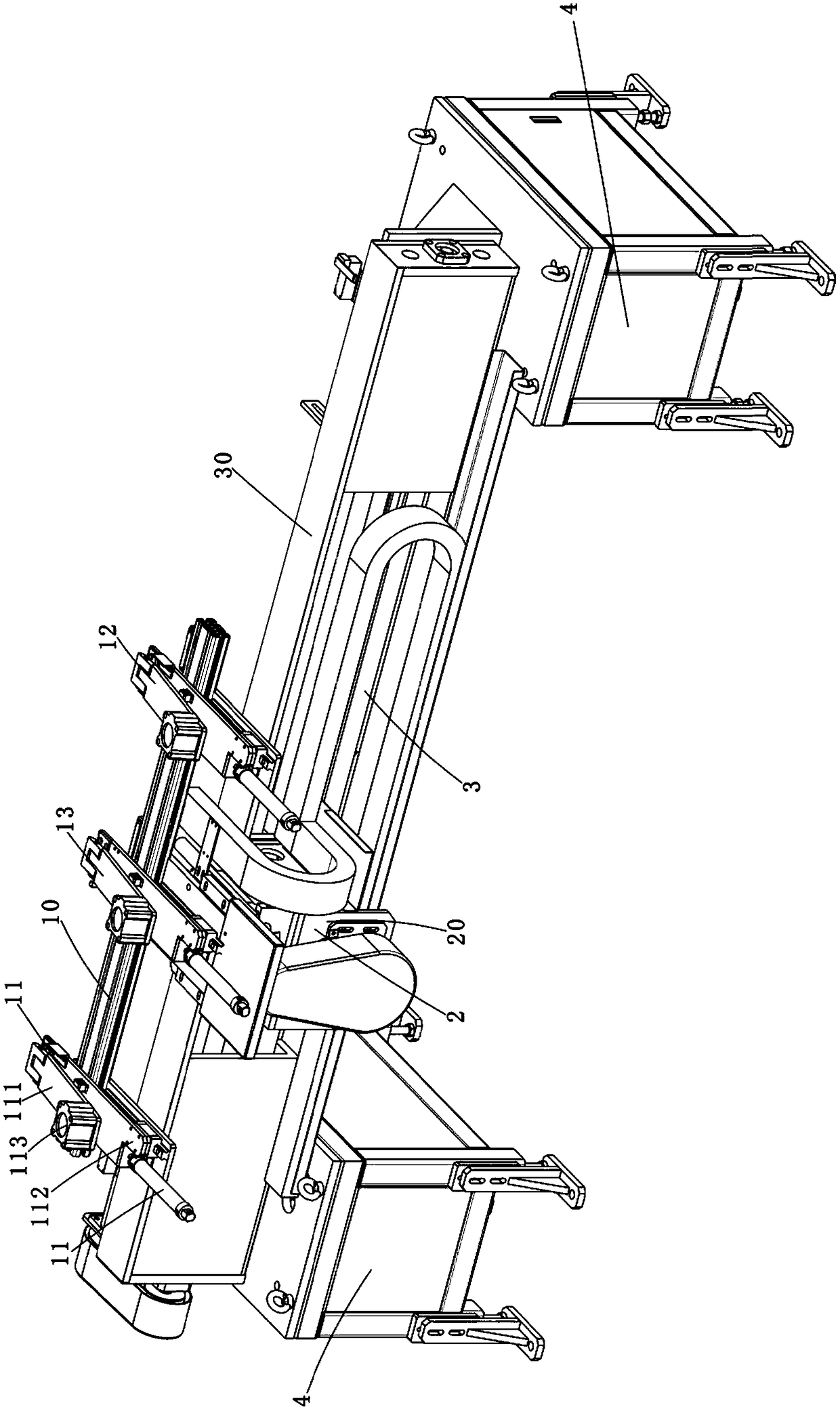

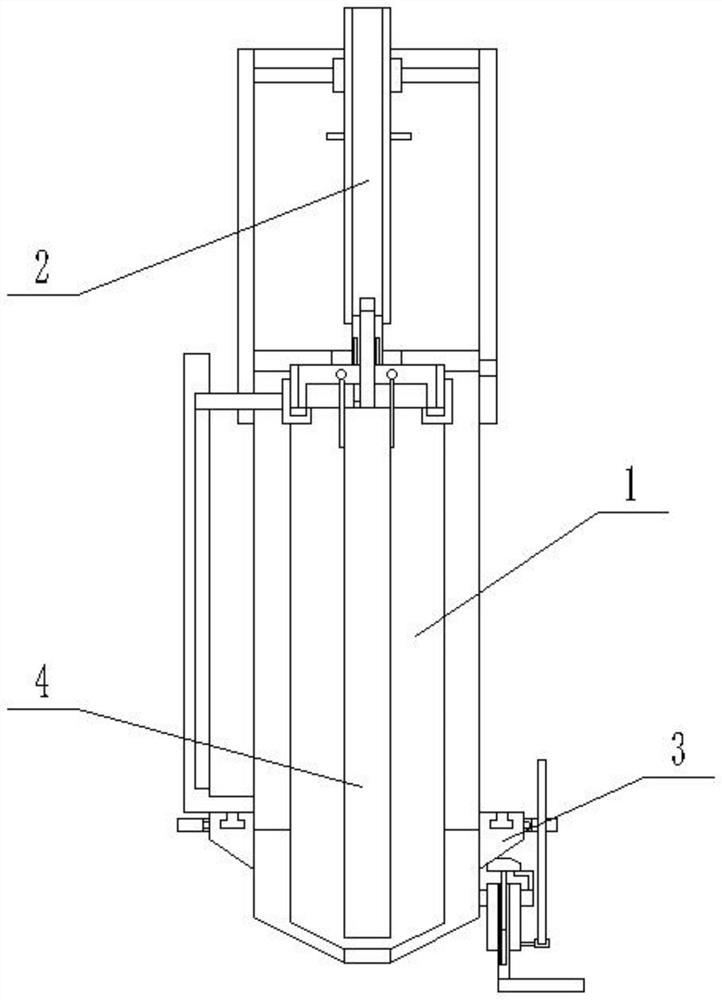

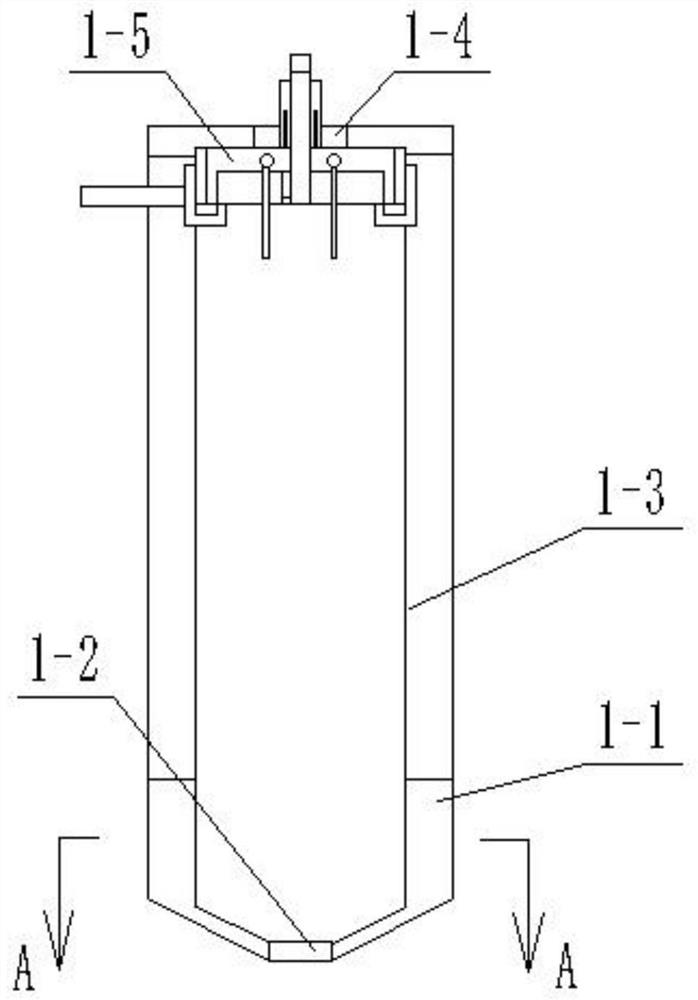

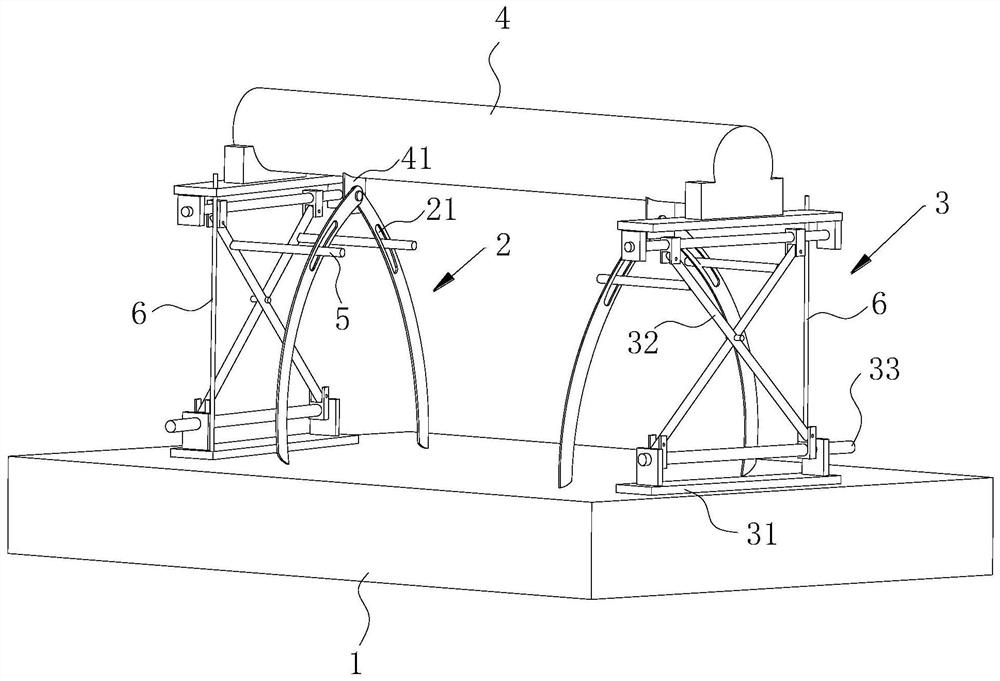

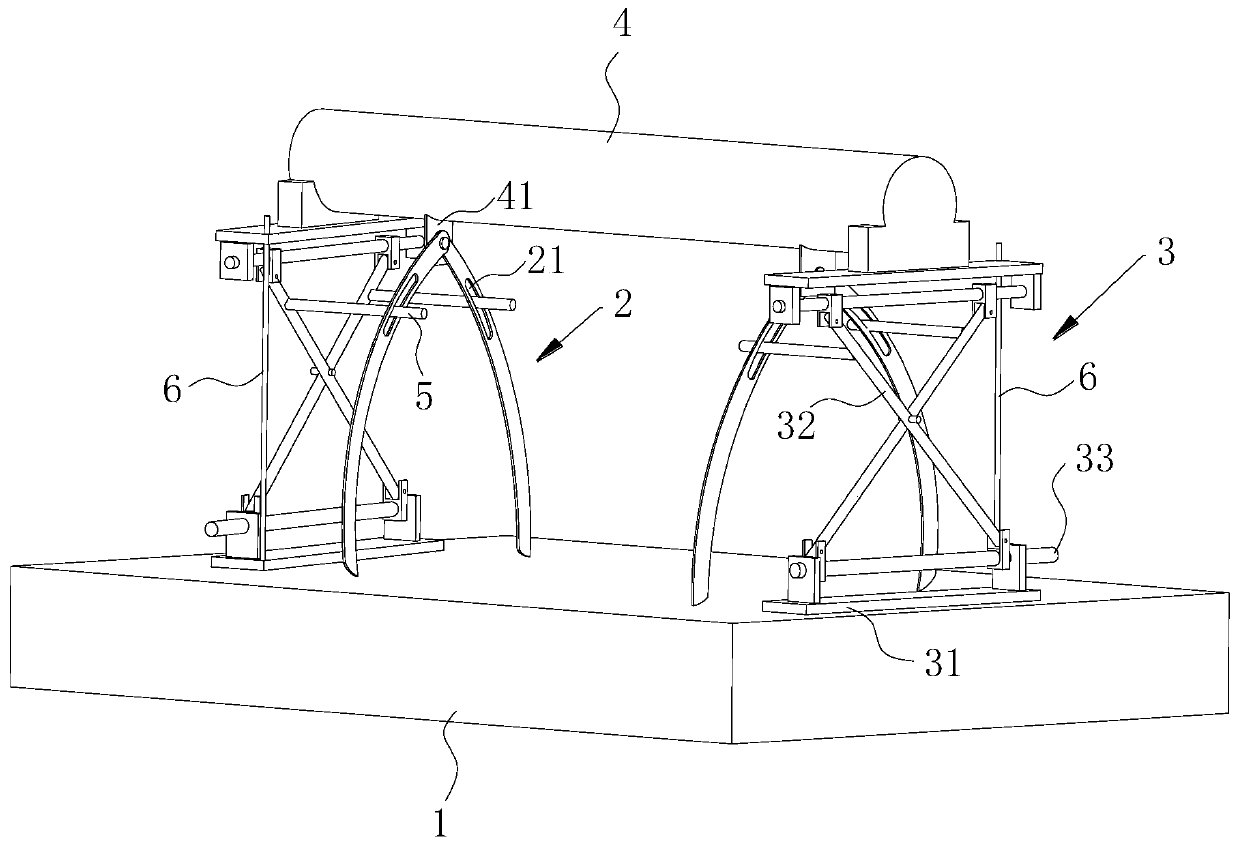

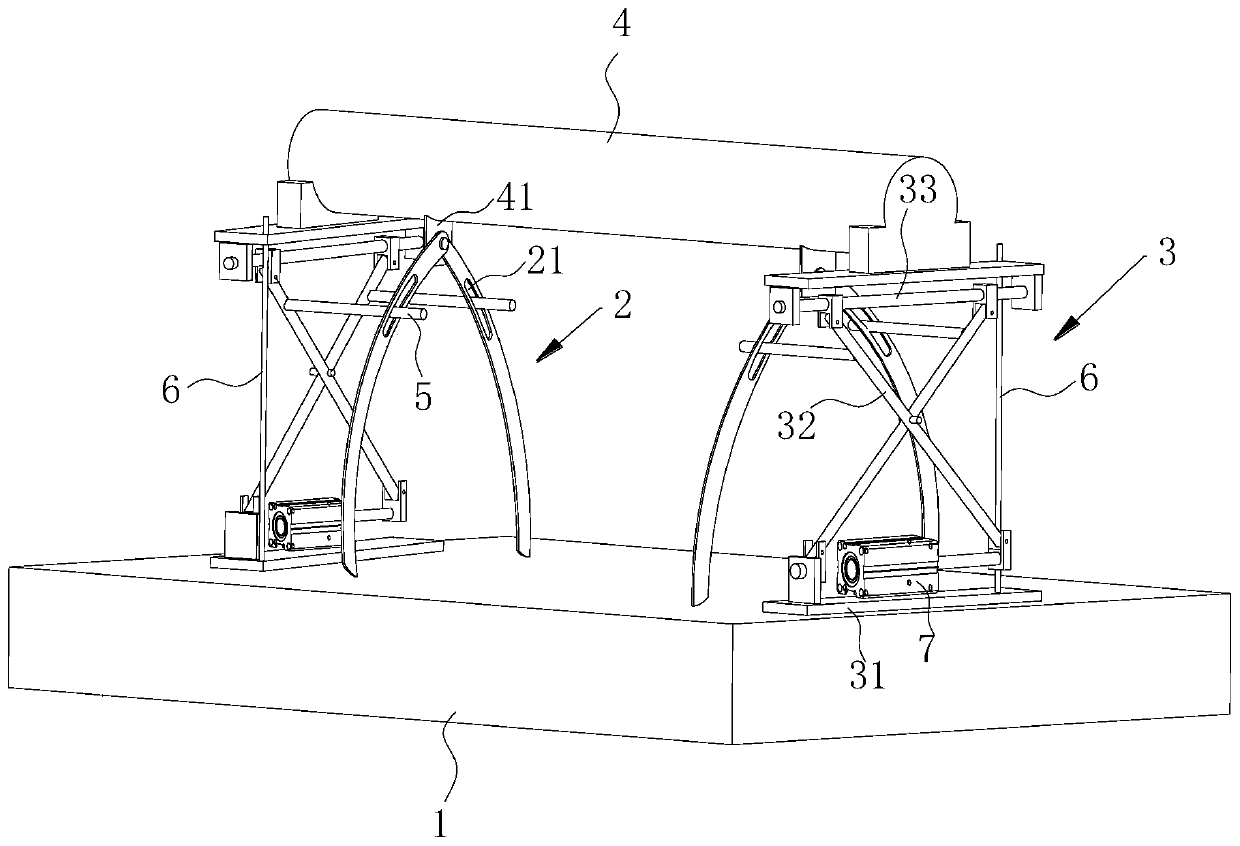

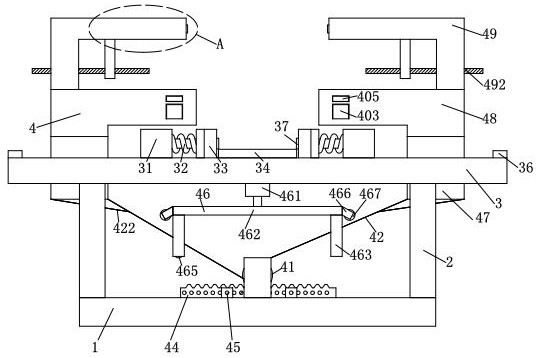

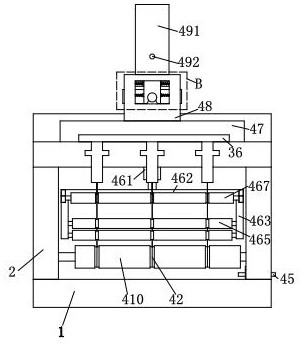

Lifting assembly mechanism for graphite boat loading and unloading wafers

InactiveCN105428286AGuaranteed stabilityExtended service lifeSolid-state devicesSemiconductor/solid-state device manufacturingSynchronous motorGraphite

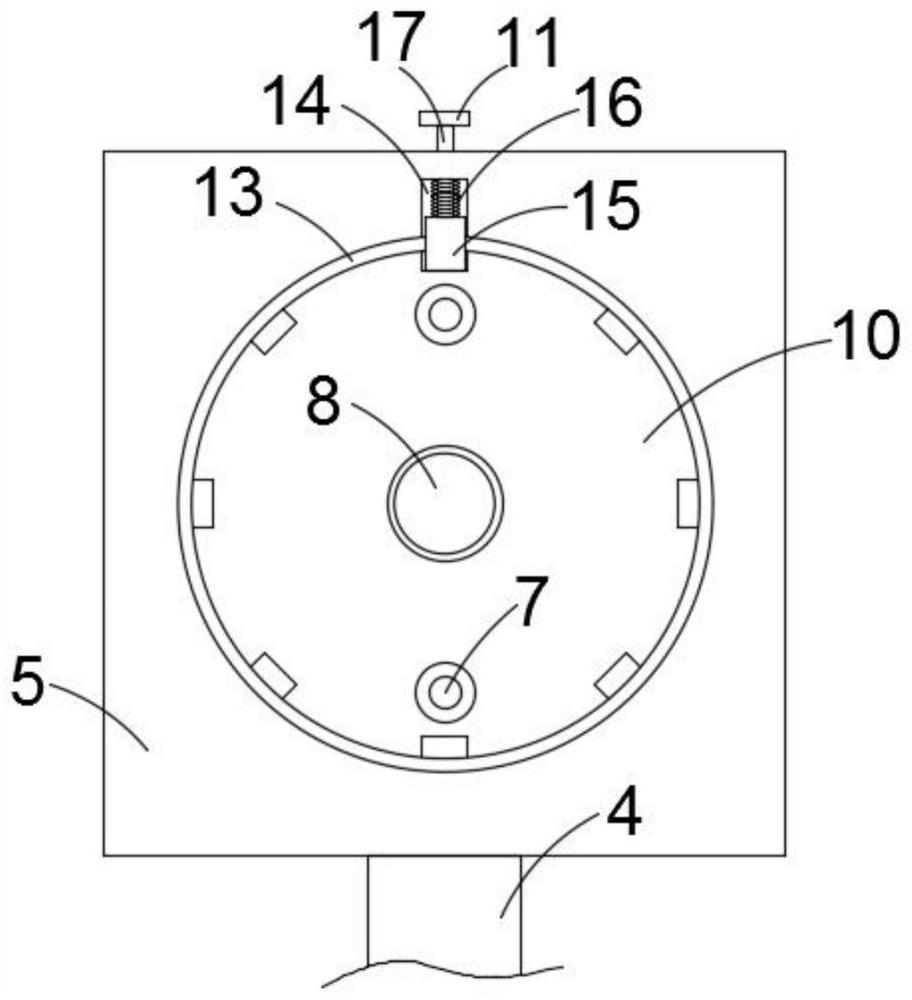

The invention discloses a lifting assembly mechanism for graphite boat loading and unloading wafers. The lifting assembly mechanism comprises a base, wherein support upright posts are symmetrically arranged on the top surface of the base; a lifting guide groove is formed in each support upright post; a lifting mechanism is movably connected with the inside of each lifting guide groove; a screw and auxiliary guide rods are arranged in each lifting guide groove; a synchronous motor is arranged at the bottom of each screw; positioning clamping grooves are formed in the top surface of the base; a mobile slide groove is formed in the side of the top surface of each positioning clamping groove; a support guide block is arranged in each mobile slide groove; boosters are arranged at two sides of each mobile slide groove and are connected with each support guide block through a first boosting block; each support guide block is rotationally connected with an assembly mechanism; and a damping device is arranged at the bottom of the base. The lifting assembly mechanism is simple in structure and high in practicability, and can meet the assembly requirements of the graphite boat loading and unloading wafers with different shapes and sizes; the assembly accuracy and quality of the loading and unloading wafers can be improved; the production technology is simplified; and the assembly efficiency is improved.

Owner:SHENGZHOU SIGMA TECH

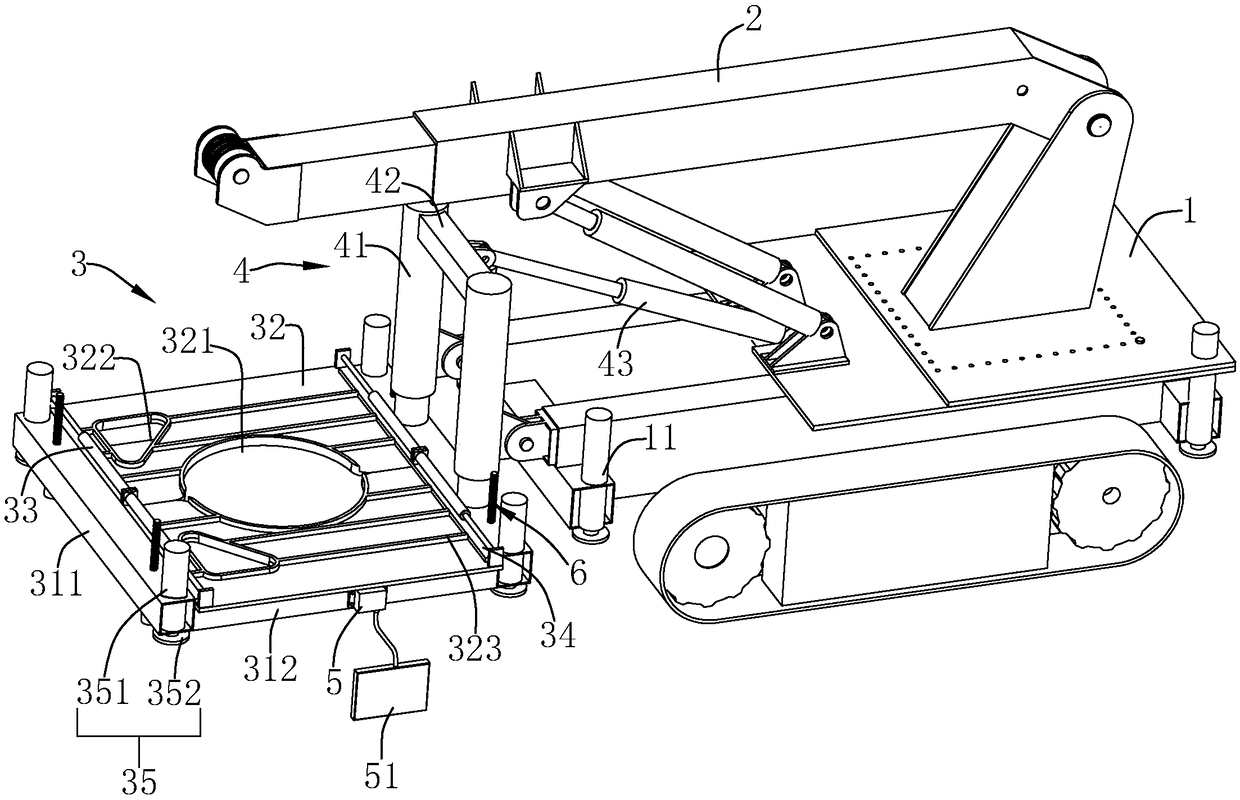

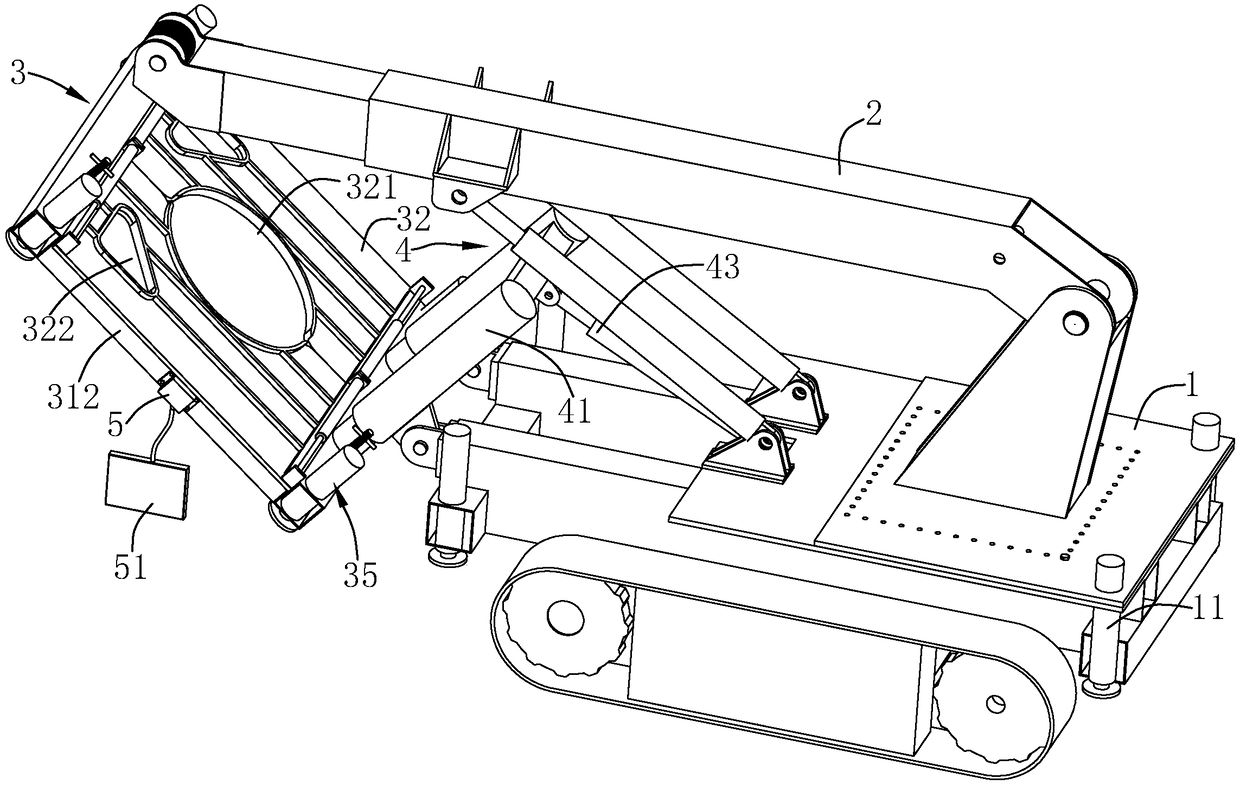

Multifunctional steel pipe column verticality adjusting machine for pile and column integral construction

ActiveCN108867647AHigh precisionShorten the construction periodBulkheads/pilesMechanical engineeringBuilding construction

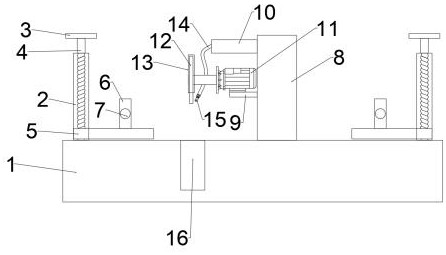

The invention discloses a multifunctional steel pipe column verticality adjusting machine for pile and column integral construction. The machine comprises a verticality adjusting machine body; a suspension device, extending to one side, is arranged above the verticality adjusting machine body; a clamping device is arranged on one side of the verticality adjusting machine body and positioned underthe extension end of the suspension device; the clamping device comprises a rectangular bracket horizontally arranged on one side of the verticality adjusting machine body and positioned under the extension end of the suspension device, clamping plates symmetrically and slidingly arranged on the rectangular bracket, and driving pieces arranged on the rectangular bracket and capable of driving theclamping plates to horizontally slide in an approaching or leaving direction to clamp or loosen lifted steel pipe columns; and the clamping device further comprises adjusting modules for leveling thebracket at four corners of the bracket. The machine has the following advantages: after the verticality adjusting machine body is leveled, the verticality of steel pipe columns is singly adjusted, sothat the verticality adjusting precision is improved, and meanwhile, the construction period is reduced.

Owner:BEIJING G&M ENG CONSTR CO LTD +1

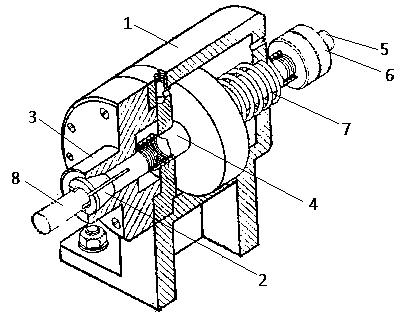

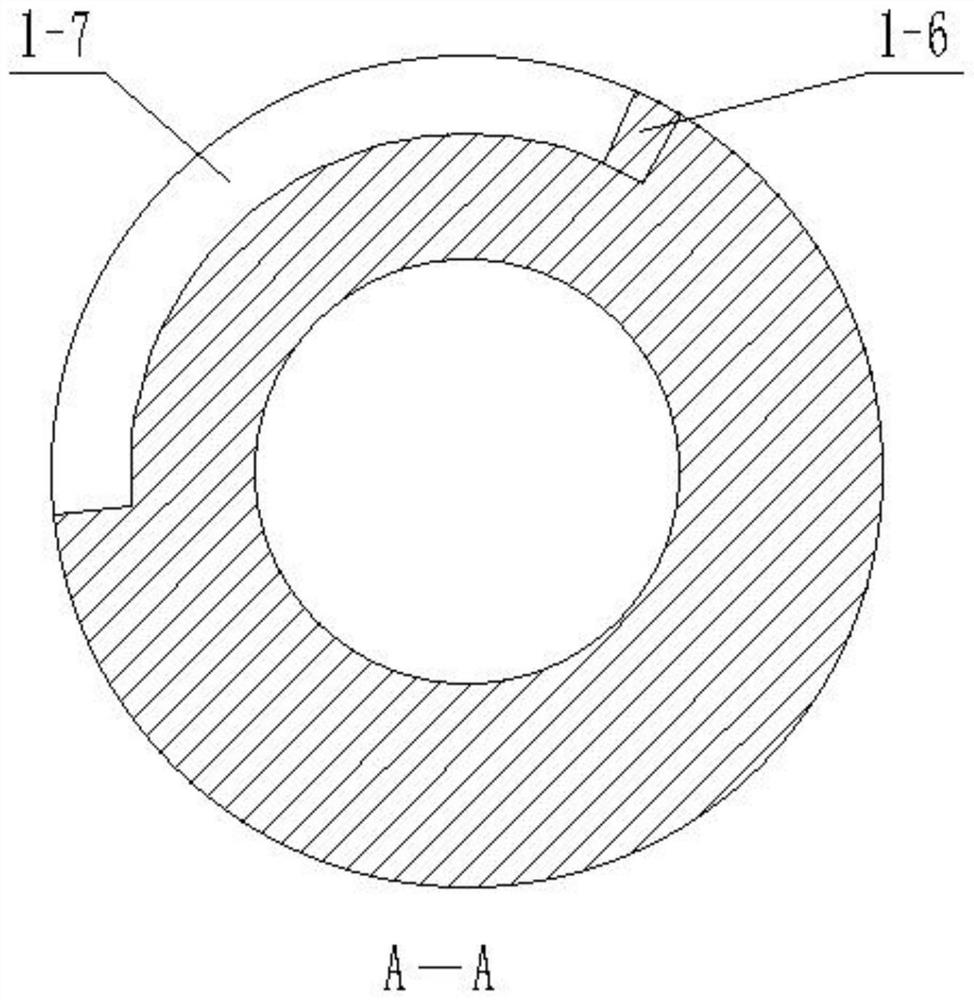

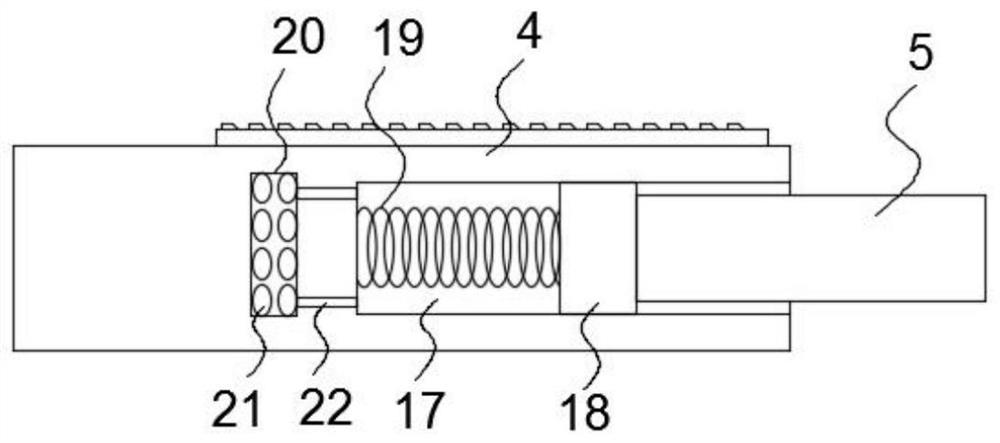

Simple elastic collet chuck

InactiveCN103639804AAffect the clamping effectSimple structureChucksPositioning apparatusEngineeringPiston rod

The invention discloses a simple elastic collet chuck which solves the problem in the existing collet chucks of being complex in structure. The collet chuck comprises a cylinder and a collet chuck body. An expanding sleeve is arranged at one end of the cylinder, the inner wall of the expanding sleeve is conical, the collet chuck body is attached to the inner wall of the expanding sleeve, sliding grooves are formed in the inner wall of the expanding sleeve and the outer wall of the collet chuck body, guiding pins are arranged in the two sliding grooves, the end portion of the collet chuck body is connected with one end of a cylinder piston, the other end of the cylinder piston rod is connected with a collet chuck pull rod, and a clamping adjusting nut is arranged on the collet chuck pull rod. The simple elastic collet chuck is simple in structure and convenient to operate.

Owner:CHONGQING BISHAN AIHUA

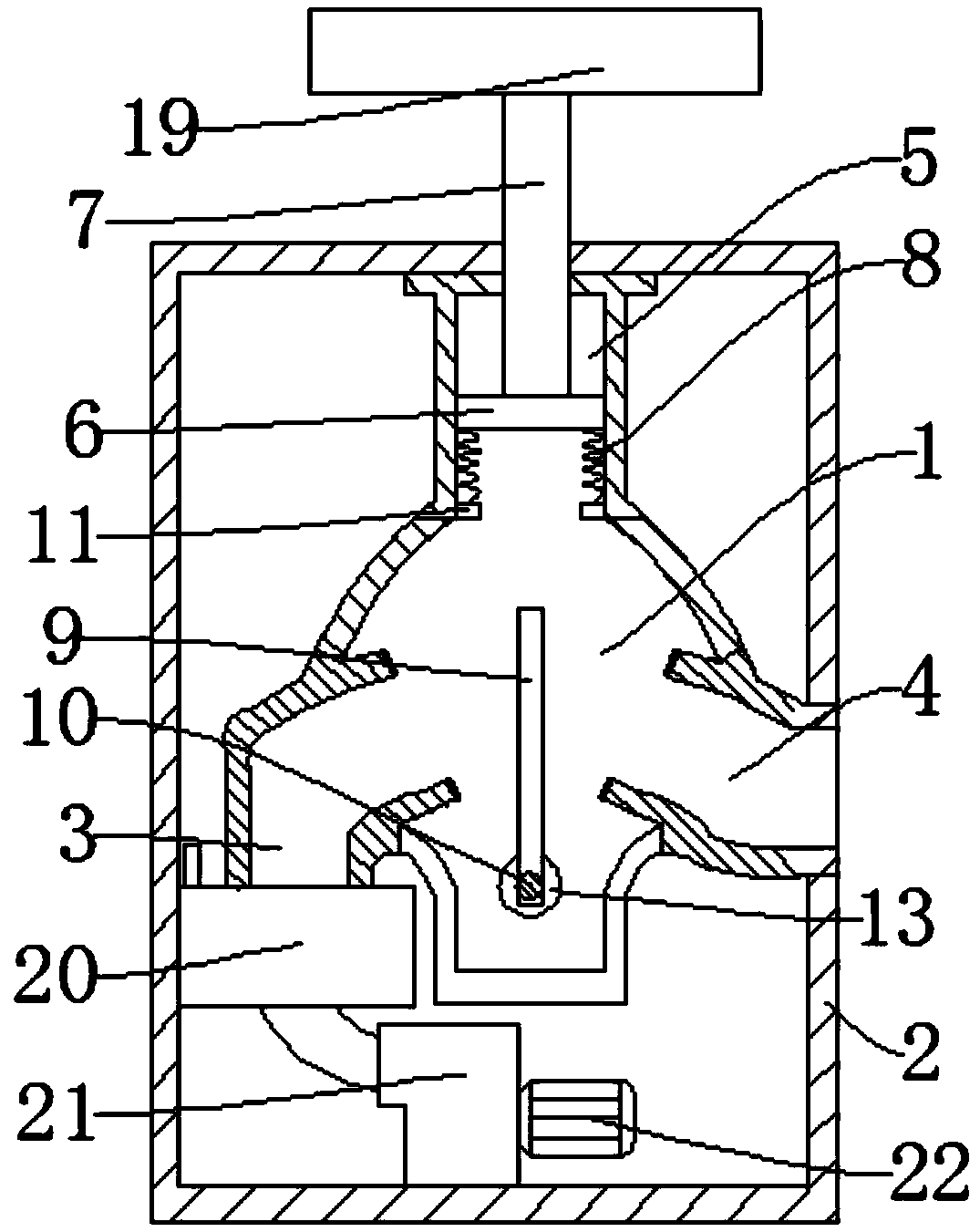

Garment shearing machine cloth negative pressure clamping device

The invention discloses a garment shearing machine cloth negative pressure clamping device, which comprises a case, wherein a work cavity is arranged inside the case. The garment shearing machine cloth negative pressure clamping device is characterized in that the cloth is clamped by using the negative pressure piston pulling principle; a device main body uses a first branch pipe, a second branchpipe and a work cavity for matching with a compression cavity for operation; through controlling the communication of the compression cavity with the first branch pipe or the second branch pipe, the movement mode of a piston inside the compression cavity is realized; when the pressure intensity inside the compression cavity is reduced, the piston can pull a pull rod to drive the press plate to move the work cavity; the spring is compressed; next, the press plate and the operation table are matched; the cloth can be fixed; when the pressure intensity inside the compression cavity starts to increase, the spring can extend; the spring an push the piston to a direction leaving far away from the work cavity; the extrusion of the press plate on the cloth can be relieved; an air extraction machine aims at completely extracting the air inside the compression cavity to make the negative pressure state; the rubber ring can be matched with the movable baffle plate; the air leakage is prevented; the structure and the principle are simple; the popularization and the use are facilitated.

Owner:安徽美裕集团有限公司

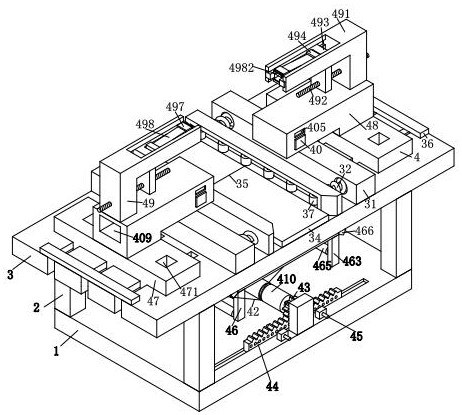

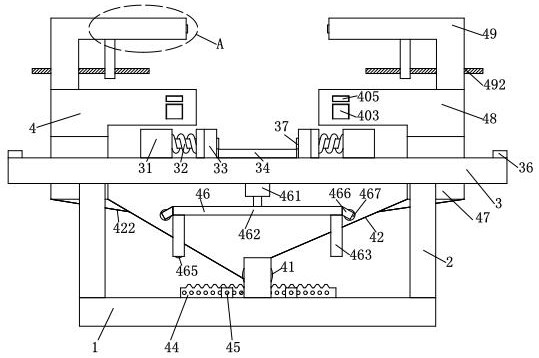

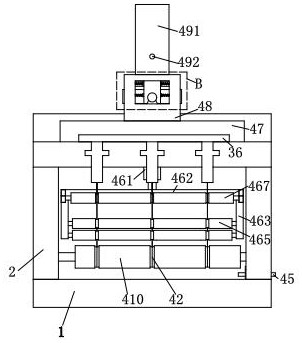

Positioning tool for new energy automobile part machining and manufacturing

InactiveCN114536252APlay a supporting roleAffect the clamping effectWork holdersCleaning using toolsMotor vehicle partNew energy

The invention discloses a positioning tool for new energy automobile part machining and manufacturing, and relates to the field of new energy automobile part machining. The positioning tool for new energy automobile part machining and manufacturing comprises a base, a fixing plate is fixedly mounted at the top of the base, a telescopic device is rotatably mounted on the left side of the fixing plate, a connecting plate is fixedly mounted at the output end of the telescopic device, and a contact plate is fixedly mounted on the left side of the connecting plate through an elastic telescopic rod. According to the positioning tool for new energy automobile part machining and manufacturing, a connecting plate and a contact plate can be pushed to move through a telescopic device, when the contact plate makes contact with a new energy automobile part, the contact plate can be pushed to move in the direction of the connecting plate, and a movable rod on the contact plate can be inserted into a concave part of the new energy automobile part; and a movable rod can support the new energy automobile part, and the situation that the clamping effect on the new energy automobile part is affected by the uneven surface of the new energy automobile part can be avoided.

Owner:LANZHOU INST OF TECH

Polishing device capable of protecting materials for die machining

InactiveCN112318345AAvoid damageImprove stabilityGrinding carriagesPolishing machinesPolishingProtective glasses

The invention discloses a polishing device capable of protecting materials for die machining, and belongs to the field of die machining. The polishing device capable of protecting the materials for die machining comprises a base, a polished piece and a polishing mechanism, wherein a supporting base is fixedly connected to the base; a connecting rod and a second threaded rod are rotatably connectedinto the base, and are rotatably connected with a driving mechanism; a first threaded rod is rotatably connected onto the connecting rod; a rotating sleeve is in threaded connection onto the first threaded rod; a jacket is fixedly connected onto the rotating sleeve; and a protective glass plate is fixedly connected onto the jacket. The polishing device capable of protecting the materials for diemachining provided by the invention is easy to use and convenient to operate; the stability of the polished piece is improved by fixing the polished piece, so that the movement of the polished piece in the polishing process is reduced; and meanwhile, the polishing process is protected, so that damage to the body of a worker due to splashing of chippings is reduced, and the operation safety of theworker is improved.

Owner:深圳利朋技术研发有限公司

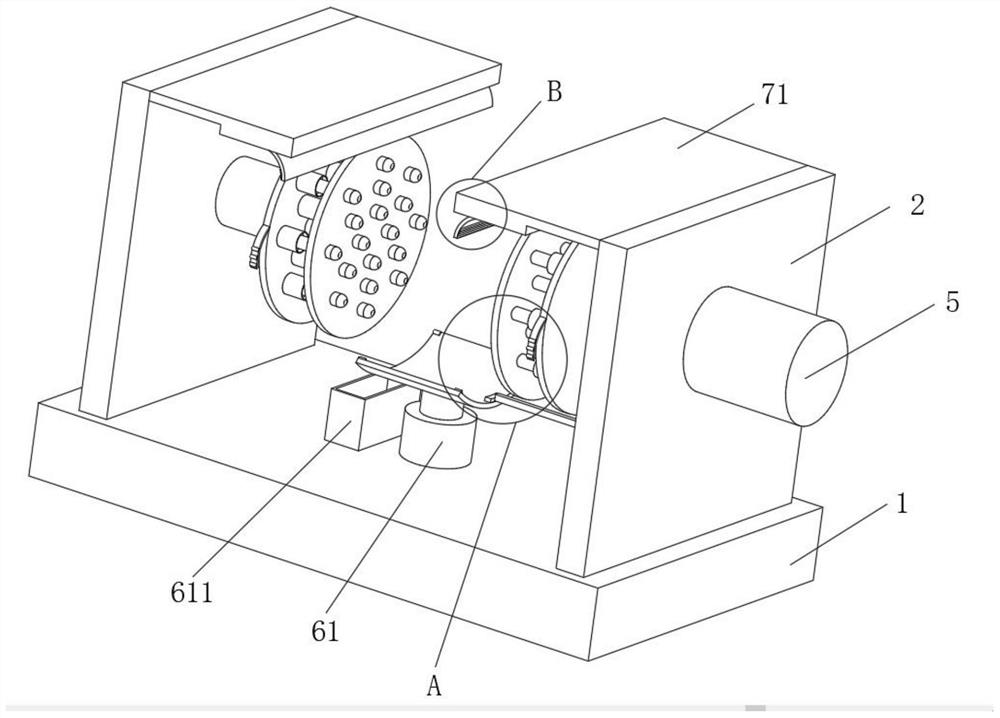

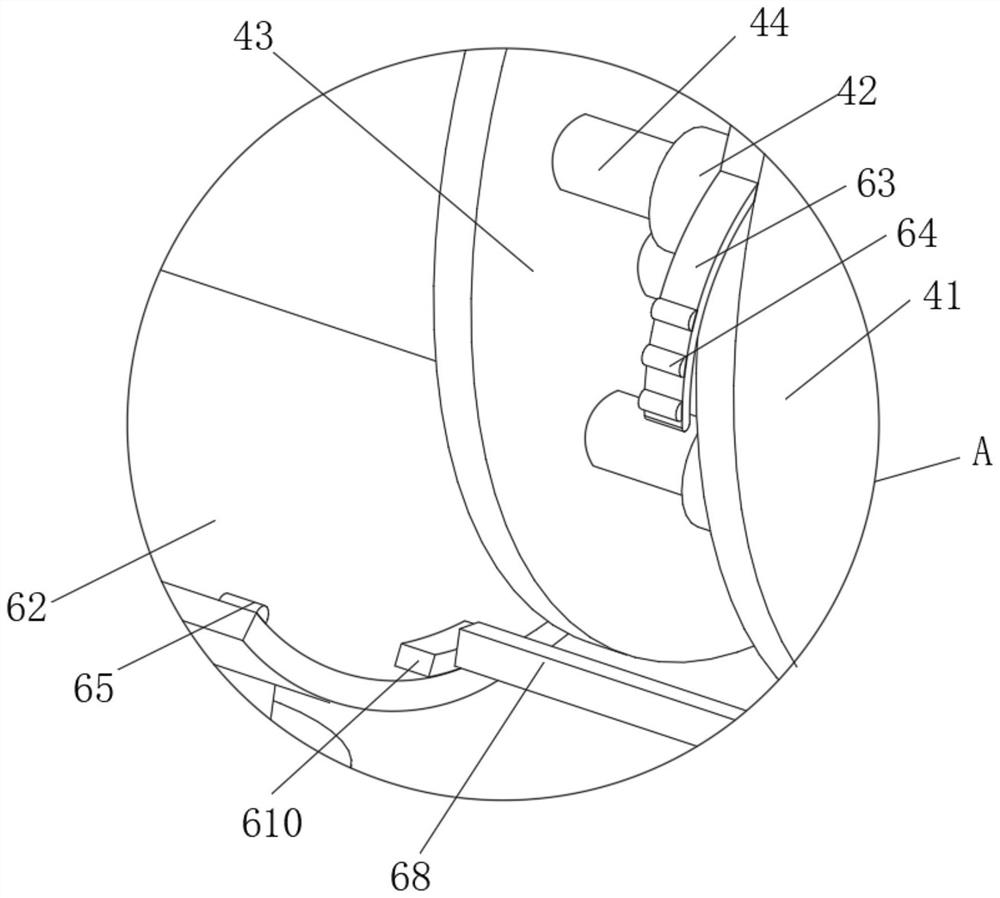

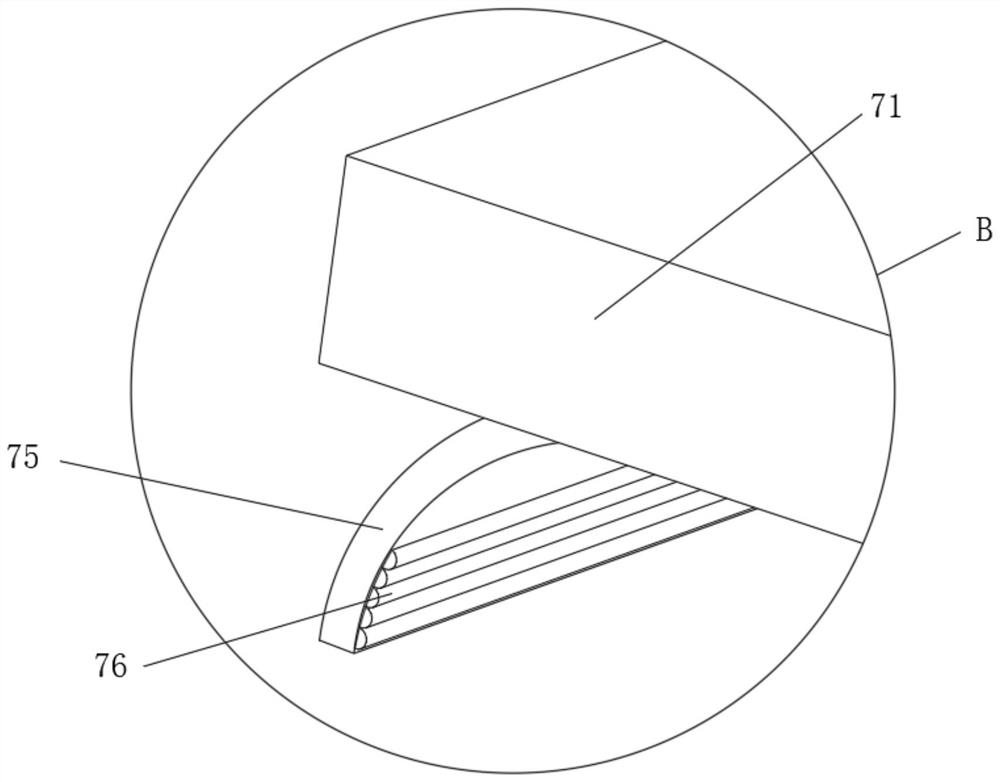

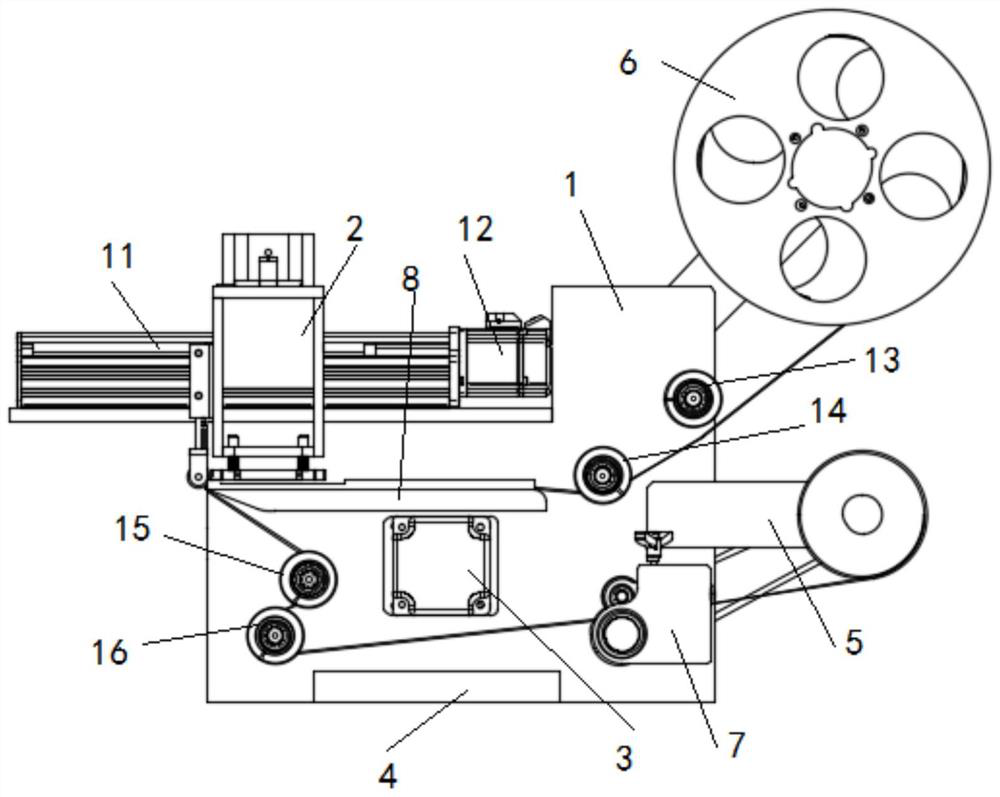

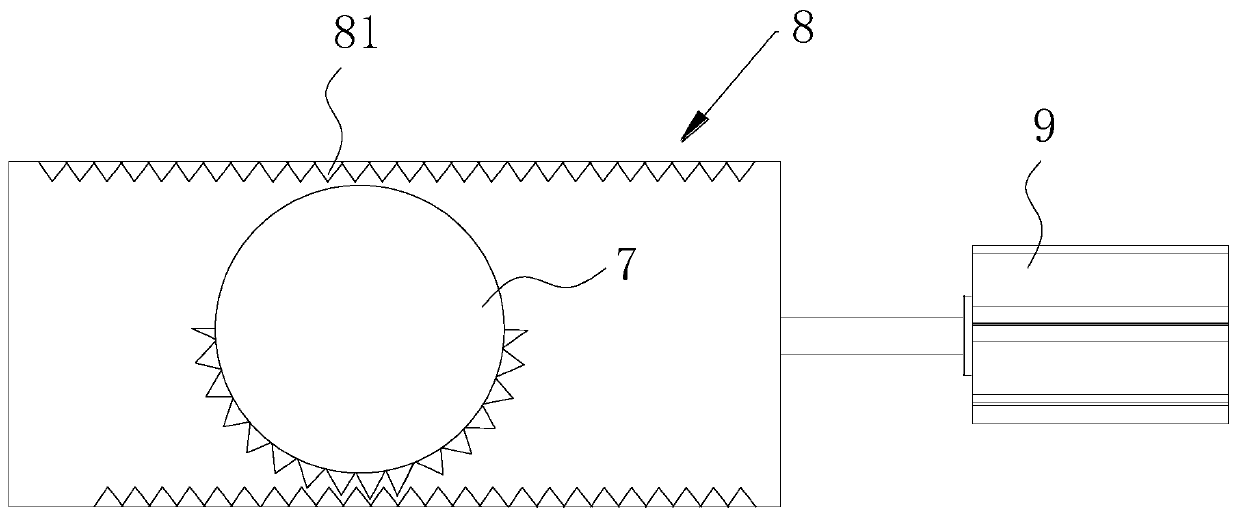

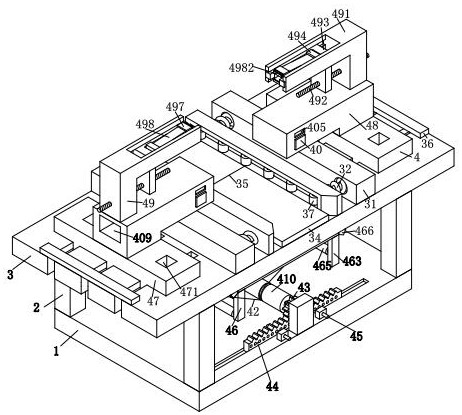

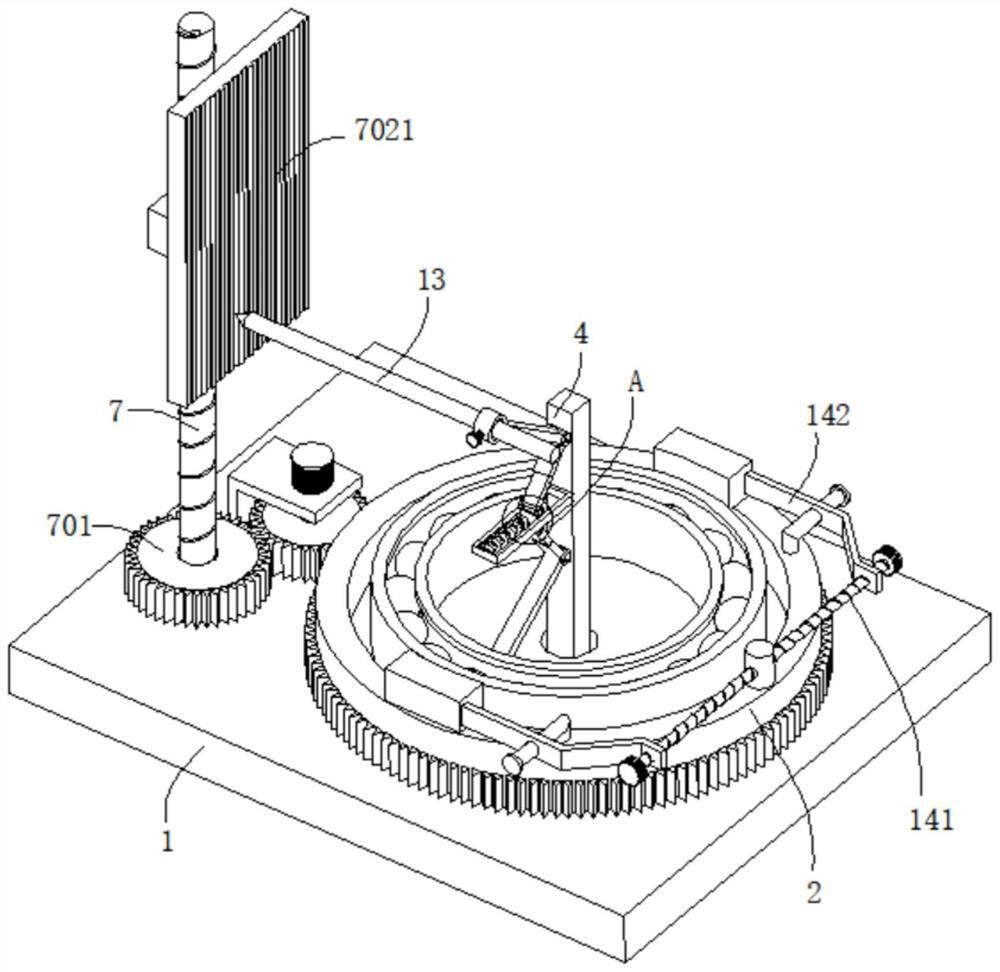

Automatic detection equipment for inner diameter of bearing

ActiveCN112414350AImprove detection efficiencyImprove detection accuracyMechanical measuring arrangementsGear wheelElectric machinery

The invention discloses automatic detection equipment for the inner diameter of a bearing, and belongs to the technical field of bearing detection. The automatic detection equipment for the inner diameter of the bearing comprises a workbench, the top of the workbench is rotatably connected with a storage table, a storage groove is dug in the outer wall of the storage table, the inner wall of the storage groove is connected with a bearing body, the outer wall of the workbench is connected with a fixing base, and a concave hole matched with the fixing base is dug in the inner wall of the storagegroove. The central axes of the fixing base and the storage groove are in the same straight line. The outer wall of the fixing base is connected with a detection mechanism and a recording mechanism,the top of the workbench is connected with a supporting base, the top of the supporting base is connected with a driving motor, the output end of the driving motor is connected with a rotating shaft,and the end, away from the driving motor, of the rotating shaft penetrates through the supporting base and is connected with a first gear. The bearing main body is detected through the detection mechanism, the detection efficiency and the detection precision are improved, the inner diameter detection condition can be converted into a fluctuation image through the recording mechanism, and visual understanding and observation are facilitated.

Owner:宁波川原精工机械有限公司

Rotary table tool clamp

InactiveCN113369932AAvoid displacement travelGuarantee processing qualityPositioning apparatusMetal-working holdersDrive shaftEngineering

The invention relates to the technical field of rotary table clamps, in particular to a rotary table tool clamp. The clamp comprises a device body, the device body comprises a rotary table body, a transmission shaft is installed at one end of the rotary table body, and the outer side of the transmission shaft is sleeved with a main bevel gear through a bearing. Through the arrangement of the transmission shaft, the main bevel gear, auxiliary bevel gears, threaded rods, movable lantern rings and chucks, the four auxiliary bevel gears are driven to rotate when the main bevel gear rotates, so that the four threaded rods can rotate at the same time, namely, the four chucks are driven to clamp a machined workpiece at the same time; and in addition, due to the fact that the four chucks move at the same time, it can be guaranteed that the four chucks can make contact with the workpiece at the same time, the situation that the workpiece generates a certain displacement stroke due to the fact that a single chuck makes contact with the workpiece is avoided, therefore the situation that the initial machining center of the workpiece is changed in the clamping process is avoided, and the workpiece machining quality of the device is guaranteed to a certain extent.

Owner:温州潭兴精密机械有限公司

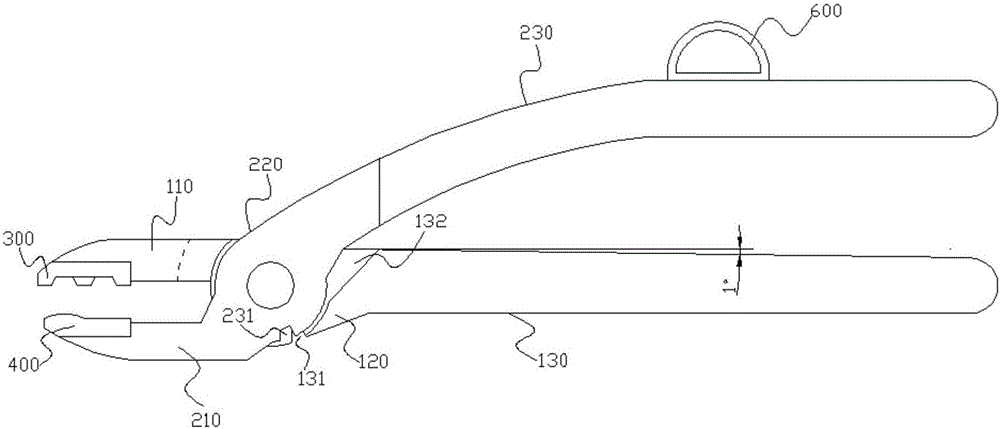

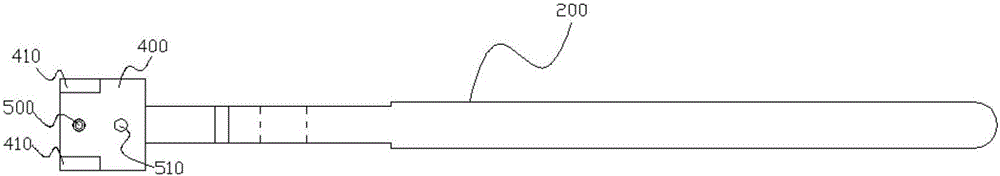

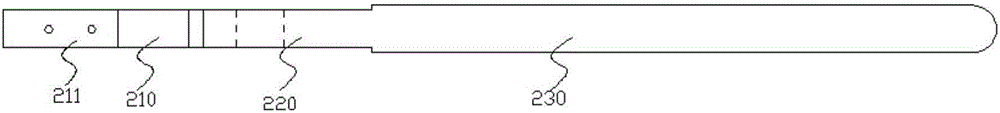

Forceps

The invention relates to forceps. The forceps comprise a first forceps body and a second forceps body, wherein the first forceps body comprises a first jaw section, a first forceps handle section and a first connecting part; the second forceps body comprises a second jaw section, a second forceps handle section and a second connecting part; a first clamping block and a second clamping block are respectively arranged on the first jaw section and the second jaw section; the first clamping block is connected with the first jaw section in a fastened manner by a screw; the second clamping block is also connected with the second jaw section in a fastened manner by a screw; the width of the first clamping block is greater than that of the first jaw section; the width of the second clamping block is greater than that of the second jaw section; a first shearing opening is formed in the first connecting part; a second shearing opening which is matched with the first shearing opening is formed in the corresponding position of the second connecting part; and a thumb sleeve is arranged on the second forceps handle section. The forceps have the beneficial effects that an object is clamped tightly, and is prevented from loosening, costs are saved, and waste of resources is reduced; and the forceps are multifunctional, and are convenient to grasp and convenient to open and close.

Owner:湖北大帆金属制品有限公司

Modified composite textile fabric and preparation method thereof

ActiveCN114274614AGood flexibilityGood antibacterial effectSynthetic resin layered productsPolyesterYarn

The invention discloses a modified composite textile fabric and a preparation method thereof.The composite textile fabric comprises a skin-friendly layer fabric and a reinforcing layer fabric which are bonded and compounded, the reinforcing layer fabric is formed by evenly mixing modified polyester fibers, spandex fibers and cotton fibers, spinning the mixture into yarn and then spinning the yarn, and when the yarn is compounded through a compounding device, the composite fabric is formed by blending the modified polyester fibers, the spandex fibers and the cotton fibers. Firstly, an enhancement layer fabric is unwound through an unwinding structure, the enhancement layer fabric is guided by a first guide roller and a second guide roller and then conveyed into a heating structure, and the enhancement layer fabric is heated through an electric heating pipe fixedly arranged on a pressing cover; according to the device, curing of adhesive particles can be accelerated, the situation that the adhesive particles are transferred in a large range, and the hand feeling of a formed fabric is affected is avoided, meanwhile, high-temperature and high-pressure gas is blown upwards from the hot air box, the adhesive particles can be prevented from being transferred downwards to the skin-friendly layer fabric under the influence of gravity, and the surface quality of the fabric is improved. Therefore, the softness of the composite textile fabric can be improved.

Owner:GUANGZHOU JACLYH UNDERWEAR

Multifunctional clamp for machine manufacturing

Owner:XUZHOU COLLEGE OF INDAL TECH

Cutting equipment for machining

InactiveCN112008451AAchieve clampingStable clampingLarge fixed membersPositioning apparatusEngineeringSlide plate

The invention discloses cutting equipment for machining. The cutting equipment comprises a bottom plate, first fixing plates are arranged on the left side and the right side of the upper portion of the bottom plate, first screw rods are arranged in the first fixing plates, the first lead screws penetrate through the upper side shell walls of the first fixing plates, rotating discs are arranged atthe ends, away from the bottom plate, of the first lead screws, sliding plates are arranged on the first lead screws and penetrate through the side shell walls, close to the center, of the first fixing plates, connecting plates are arranged above the sliding plates and are concave, and adjusting shafts are arranged in the centers of the front sides of the connecting plates. Before cutting, the cutting equipment enables a material to be clamped more stably, after clamping is completed, a cutting mechanism is started, the rotating discs are used for driving the first lead screws to rotate, and therefore the sliding plates drive the connecting plates to move up and down, and the material is cut; and after cutting is completed, the connecting plate on the right side is used for clamping the cut material, safety accidents caused by the fact that the cut material falls off are prevented, and the cutting equipment is suitable for large-scale popularization.

Owner:胡勇

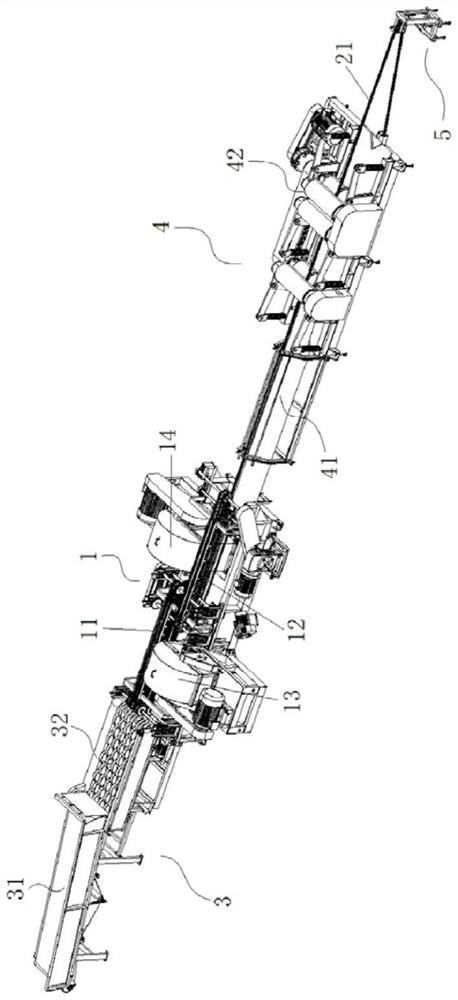

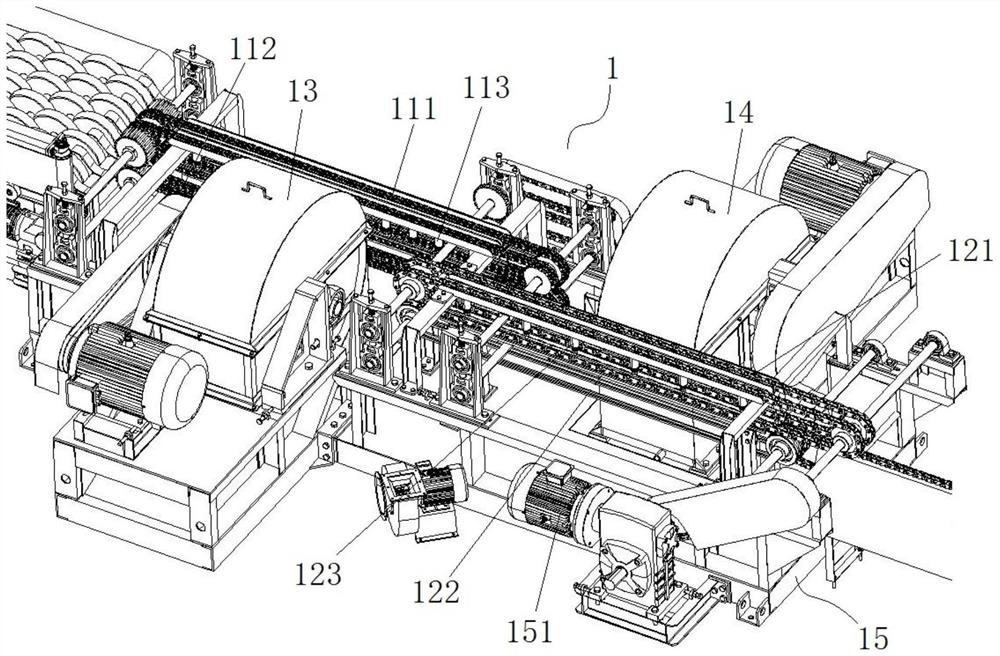

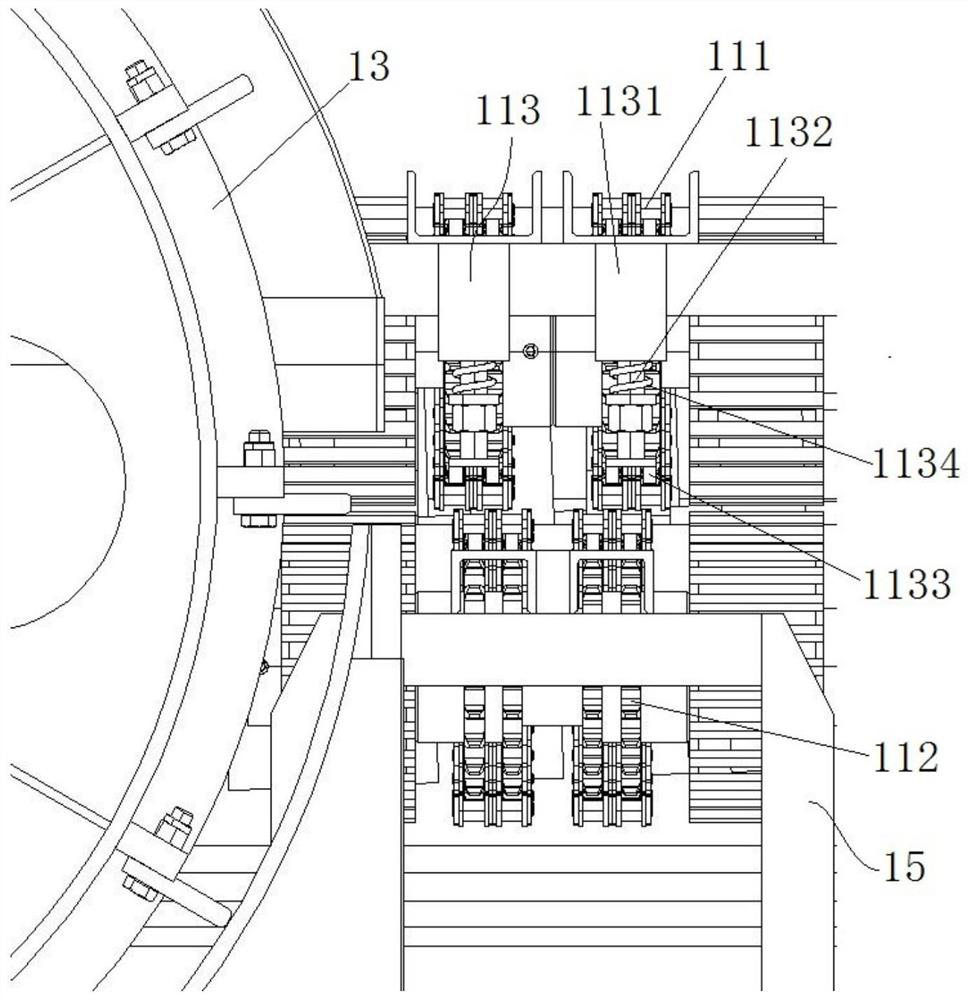

Hemp scraping device and plant fiber extraction equipment

PendingCN113136626AAffect the clamping effectStable and reliableMechanical fibre separationPlant fibreMechanical engineering

The invention belongs to the technical field of plant fiber extraction, and provides a hemp scraping device and plant fiber extraction equipment. The hemp scraping device mainly comprises a first hemp pressing chain group and a second hemp pressing chain group, wherein a first hemp scraping knife ball and a second hemp scraping knife ball are arranged corresponding to the first hemp pressing chain group and the second hemp pressing chain group, the raw material output end of the first hemp pressing chain group is connected with the raw material input end of the second hemp pressing chain group; the first hemp pressing chain group and the second hemp pressing chain group are arranged along the length direction of a straight line, and the projection of the raw material output end of the first hemp pressing chain group and the projection of the raw material input end of the second hemp pressing chain group on the straight line are overlapped. According to the hemp scraping device and plant fiber extraction equipment, the process integration of hemp scraping processing can be realized, the hemp scraping efficiency can be improved, the hemp scraping quality can be guaranteed, and the production economic benefits of plant fiber extraction can be improved.

Owner:ZHANJIANG WEIDA MACHINERY IND

Fixing tool clamp for welding forming of robot base

ActiveCN114273849AWide clamping limit rangeGood applicabilityWelding/cutting auxillary devicesAuxillary welding devicesPhysicsElectric machinery

The invention relates to the field of robot assembling and forming, in particular to a robot base welding and forming fixing tool clamp which comprises a base, a supporting frame, a workbench and a clamping and limiting mechanism. In the clamping and limiting mechanism, a winding motor is started to drive a winding roller to rotate, so that the winding roller drives a clamping rack to move through a traction rope; and then the clamping block is driven to enter a rectangular groove in the lower portion of the robot base, and therefore the robot base is limited and fixed through the clamping branch chains. In the supporting branch chains, an electric sliding block pushes a supporting plate to be opened through an adjusting block, a rotating lead screw drives the supporting plate to move in the opposite direction, and therefore the supporting plate can support the vertical section of the robot base, and the situation that the welding precision of the robot base is affected due to the fact that the robot base shakes in the welding process is avoided.

Owner:江苏博发机器人智能装备有限公司

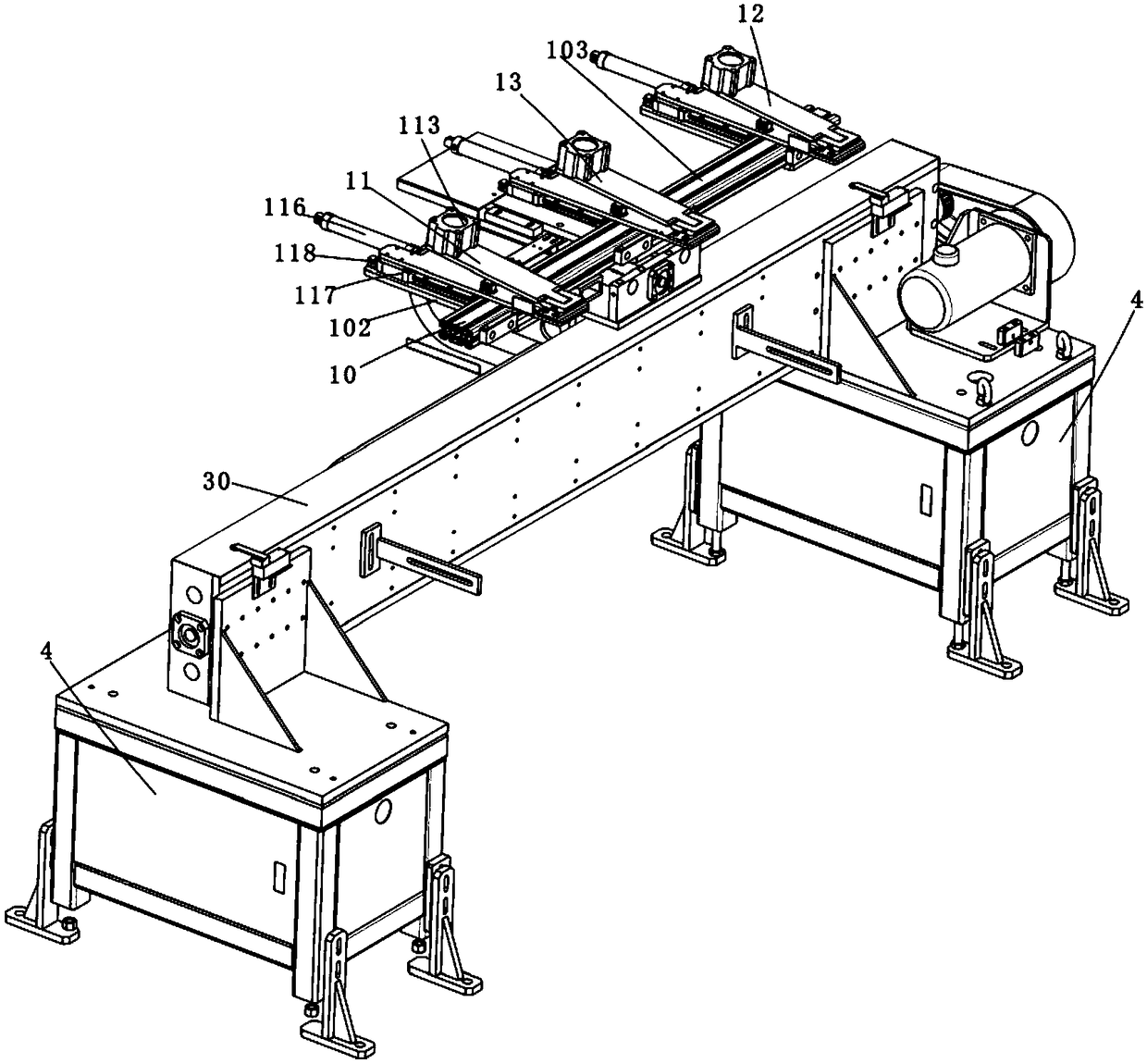

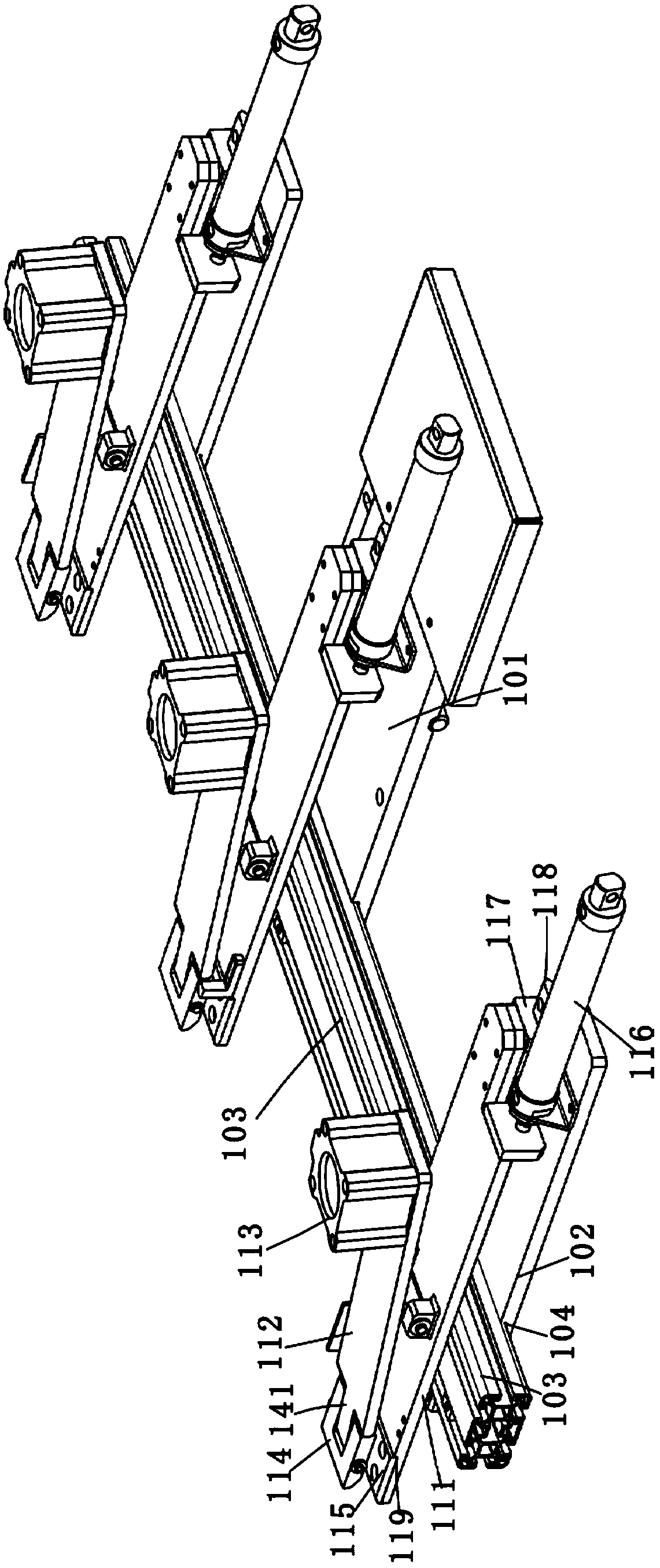

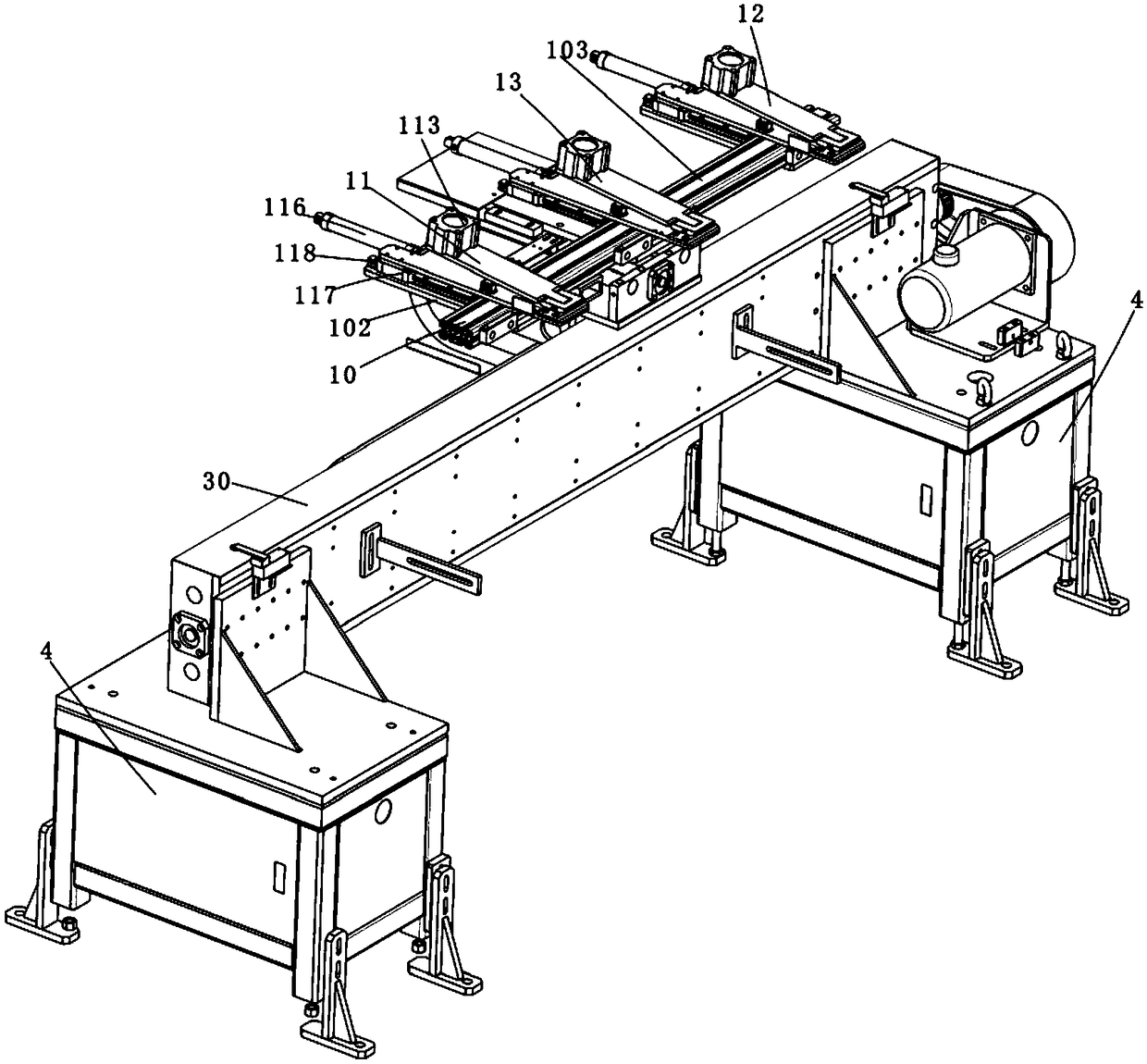

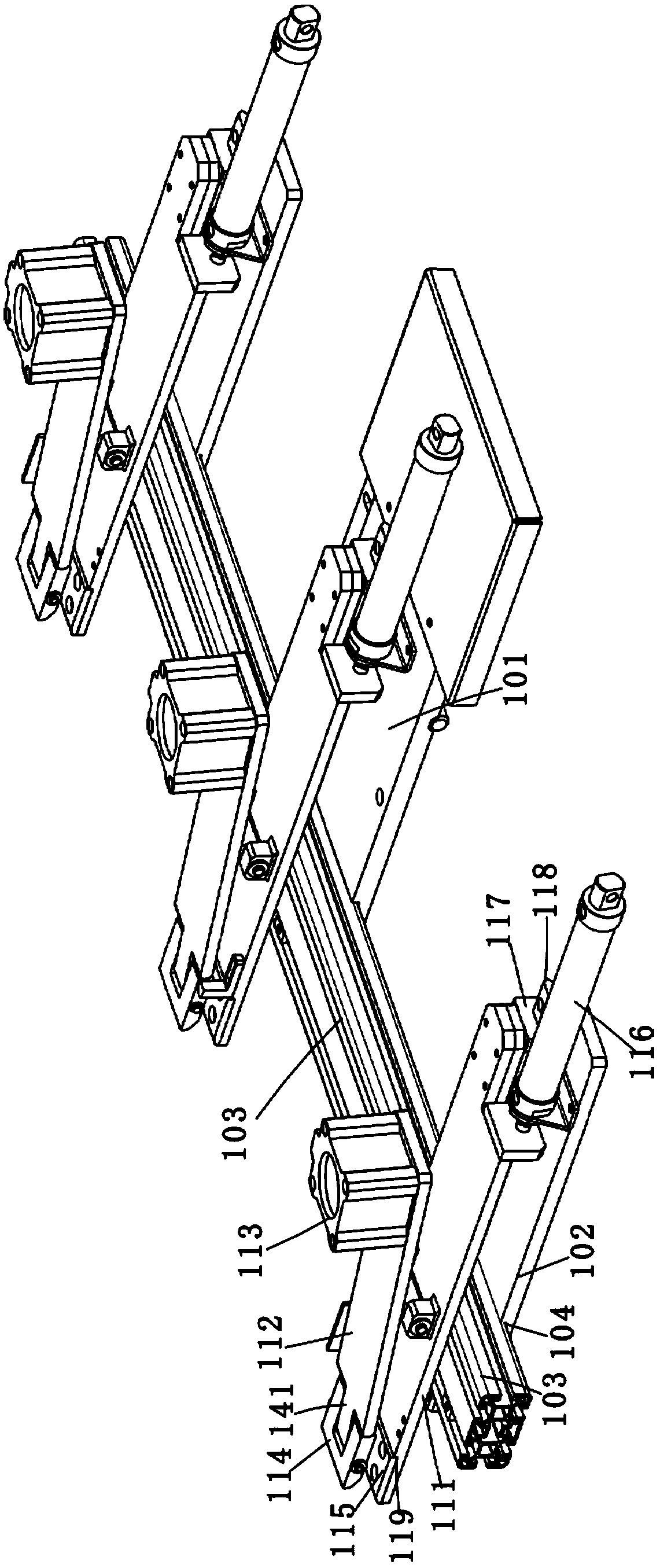

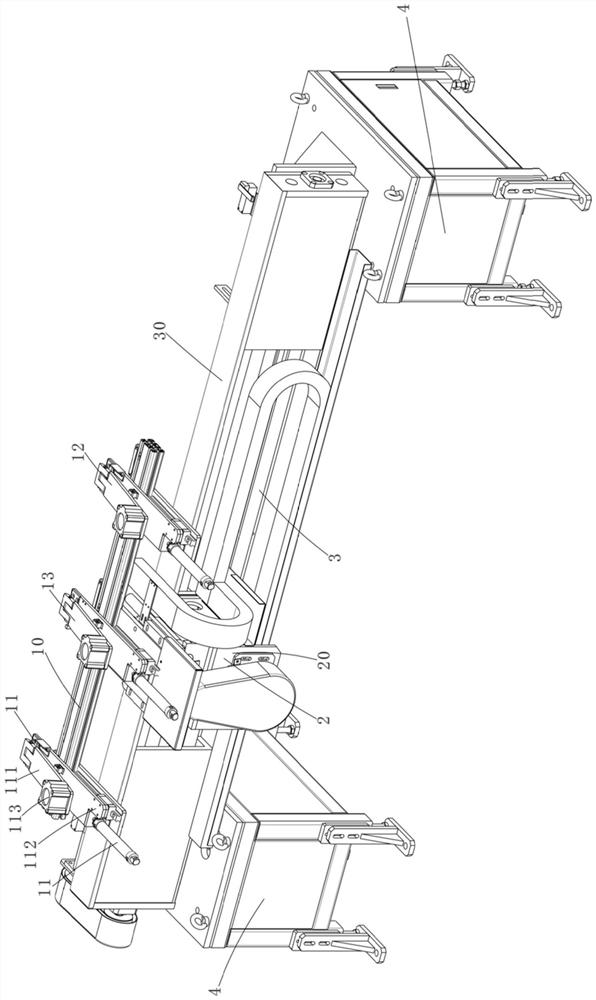

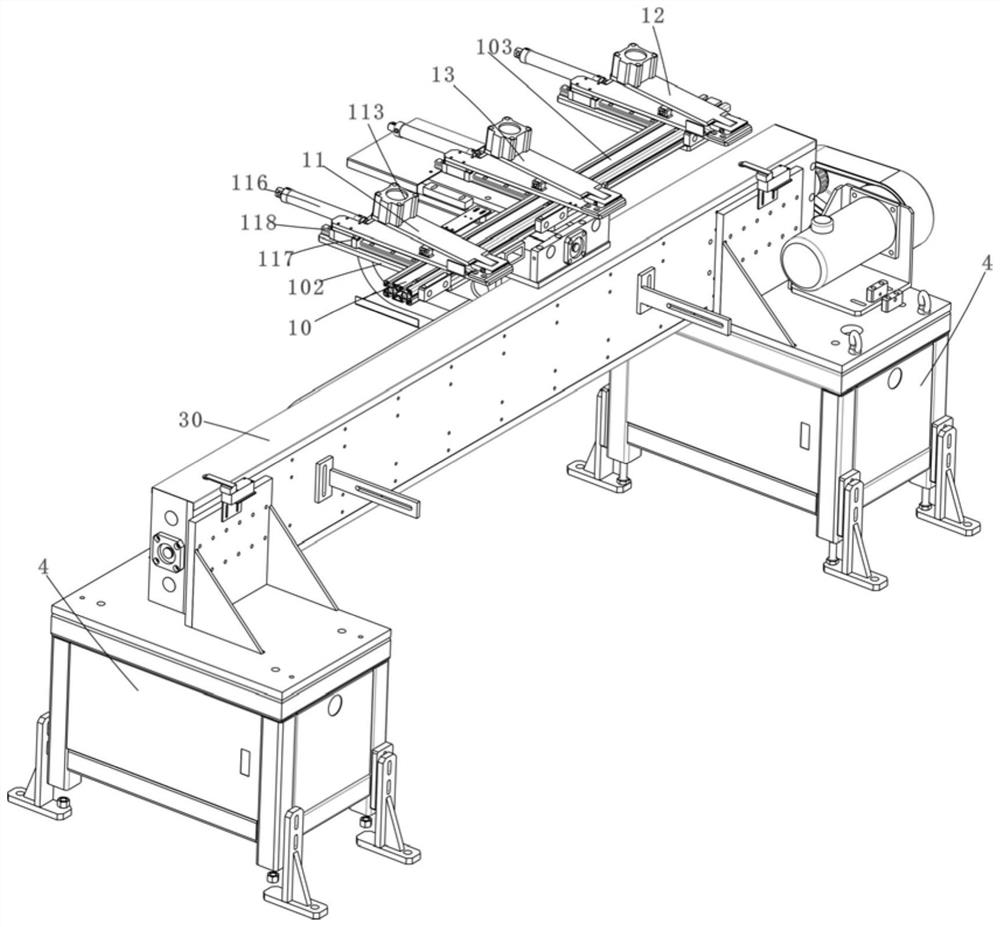

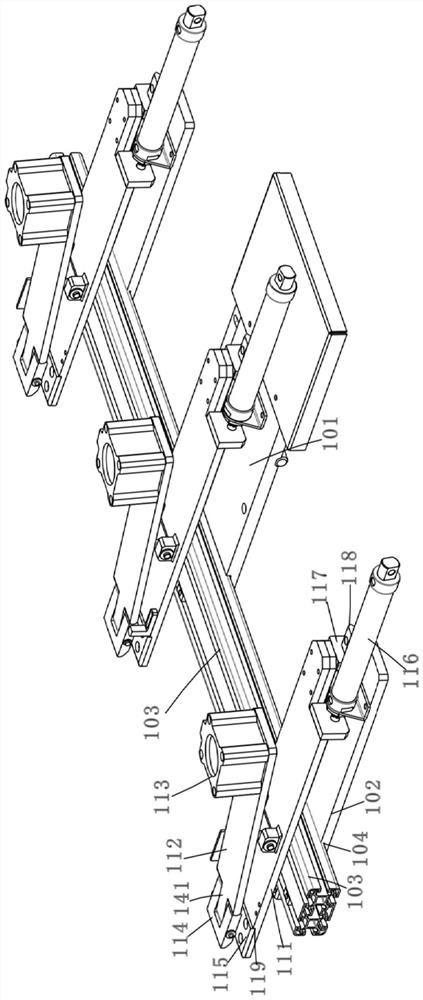

Feeding equipment used for conveying and clamping short strips

InactiveCN109290463AAvoid wastingIncrease profitMetal-working feeding devicesNon-rotating vibration suppressionPunch pressEngineering

The invention discloses feeding equipment used for conveying and clamping short strips. The feeding equipment comprises a first rack body, a first material clamping device for clamping one end of a material, a second material clamping device which is matched with the first material clamping device for clamping the other end of the material, and a third material clamping device which is arranged between the first material clamping device and the second material clamping device for clamping the middle part of the material, wherein when the third material clamping device clamps the middle part ofthe material, the first or second material clamping device loosens the material and moves backwards. The feeding equipment increases the utilization rate of the whole material, reduces material wasteamount, reduces the production cost under the same yield, realizes full and automatic feeding, prevents the material from being manually moved or turned over in a stamping process, reduces labour intensity and labour cost of a worker, improves stamping efficiency, on the material, of a stamping machine, and improves production efficiency.

Owner:HANGZHOU KINGNET ELECTROMECHANICAL

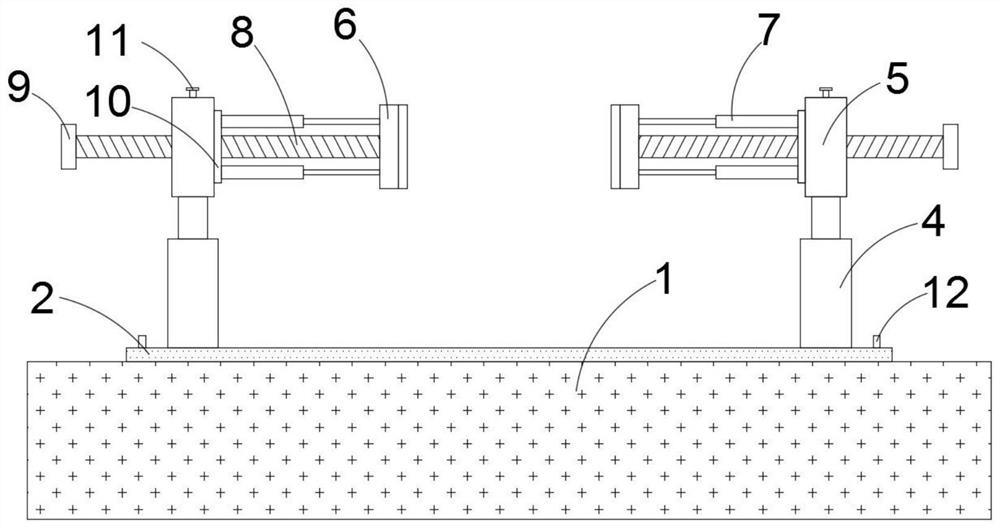

Optical fiber cable high precision wire clamping buckle

ActiveCN110394746AEasy to moveEasy to adjustOptical fibre/cable installationWork holdersMechanical engineeringOptical fiber cable

The invention discloses an optical fiber cable high precision wire clamping buckle. The optical fiber cable high precision wire clamping buckle comprises a bottom plate and a top plate, wherein a first wire clamping piece is arranged between the bottom plate and the top plate, an upper abutting piece is fixedly installed on the upper surface of the bottom plate, a lower abutting piece is further fixedly installed on the upper surface of the bottom plate, a second wire clamping piece is arranged between the bottom plate and the top plate, one end of a connection pillar is clamped through four first clamping plates, and all the first clamping plates are convenient to move, and can clamp and fix optical fiber cables different in size. By using a first lead screw and a second lead screw for controlling all the first clamping plates, accuracy is high and clamping effect is good. The optical fiber cable high precision wire clamping buckle can adapt to different installation environments, andis strong in applicability; facilitates dismounting and installing by rotating the first clamping plates and second clamping plates, and can satisfy the installing of the optical fiber cables different in specification; and is ingenious in design due to the fact that the second wire clamping piece and the first wire clamping piece are convenient to install and dismount, and is suitable for clamping of the optical fiber cables in different directions.

Owner:NINGBO ZHENGYU FASTENERS

Feeder for conveying short steel bars for stamping

InactiveCN109201920AGuaranteed stabilityAvoid wastingMetal-working feeding devicesPositioning devicesSteel barEngineering

The invention discloses a feeder for conveying short steel bars for stamping. The feeder comprises a first frame body, a first clamping device, a second clamping device, a third clamping device, a first driving device, a second driving device and a supporting device; the first clamping device is used for clamping one end of a material; the second clamping device cooperates with the first clampingdevice so as to clamp the other end of the material; the third clamping device is disposed between the first clamping device and the second clamping device and is used for clamping the middle of the material; when the third clamping device clamps the middle of the material, the first or second clamping device releases the material and moves backwards; the first driving device is used for driving the first, second and third clamping device to move forwards and backwards synchronously; the second driving device is used for driving the first driving device to move leftwards and rightwards so as to drive the first, second and third clamping device to move leftwards and rightwards synchronously; and the supporting device is used for supporting the second driving device so as to raise the first,second and third clamping device to a predetermined height and can store parts.

Owner:HANGZHOU KINGNET ELECTROMECHANICAL

Workpiece clamping device for manufacturing of mechanized agricultural equipment

InactiveCN113579802AAffect the clamping effectGood removal effectCleaning using toolsPositioning apparatusAgricultural engineeringSupport plane

Owner:何成敏

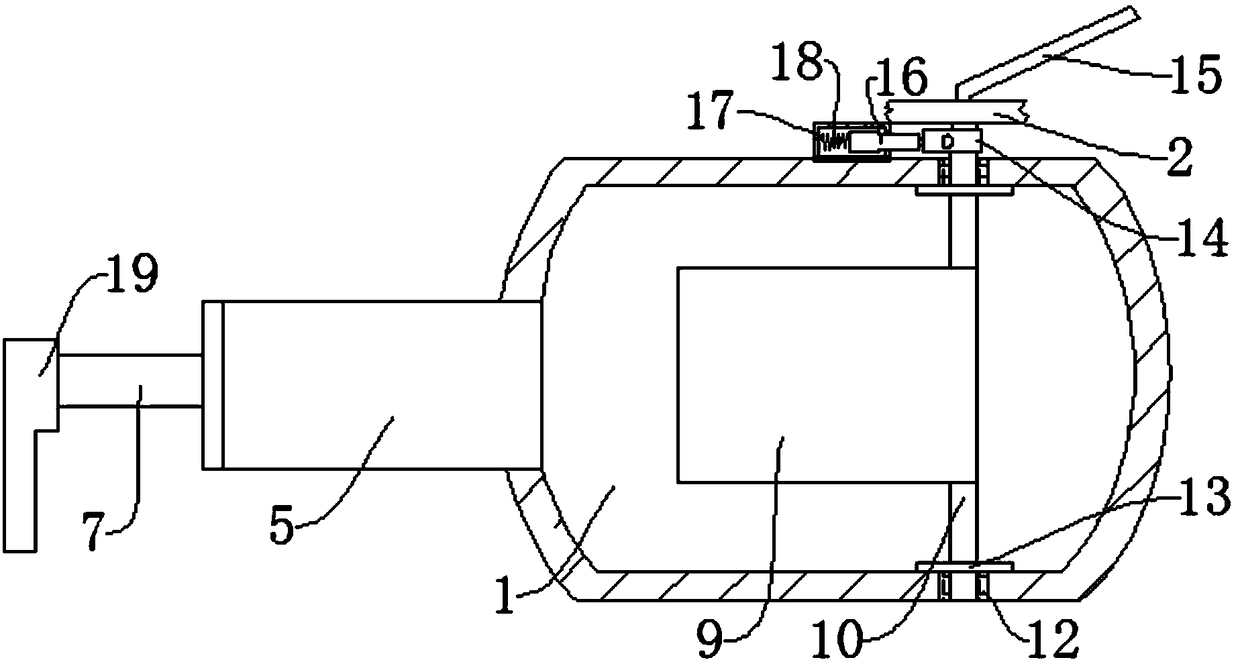

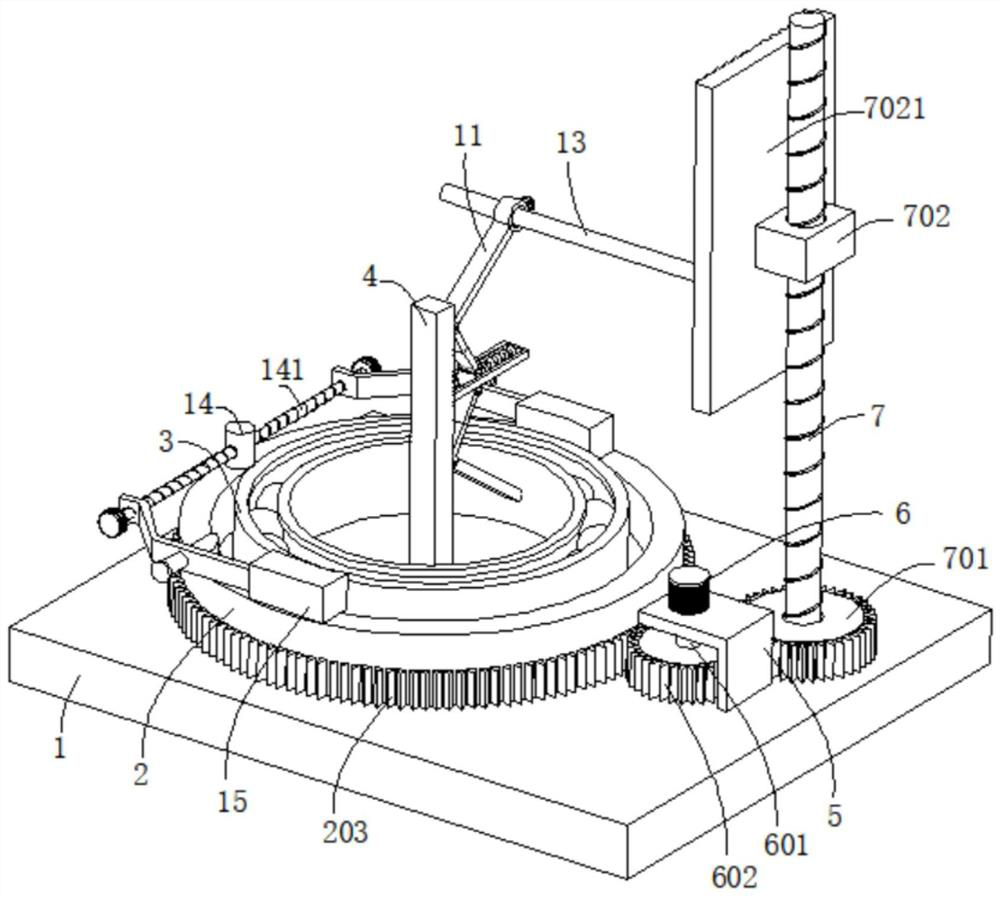

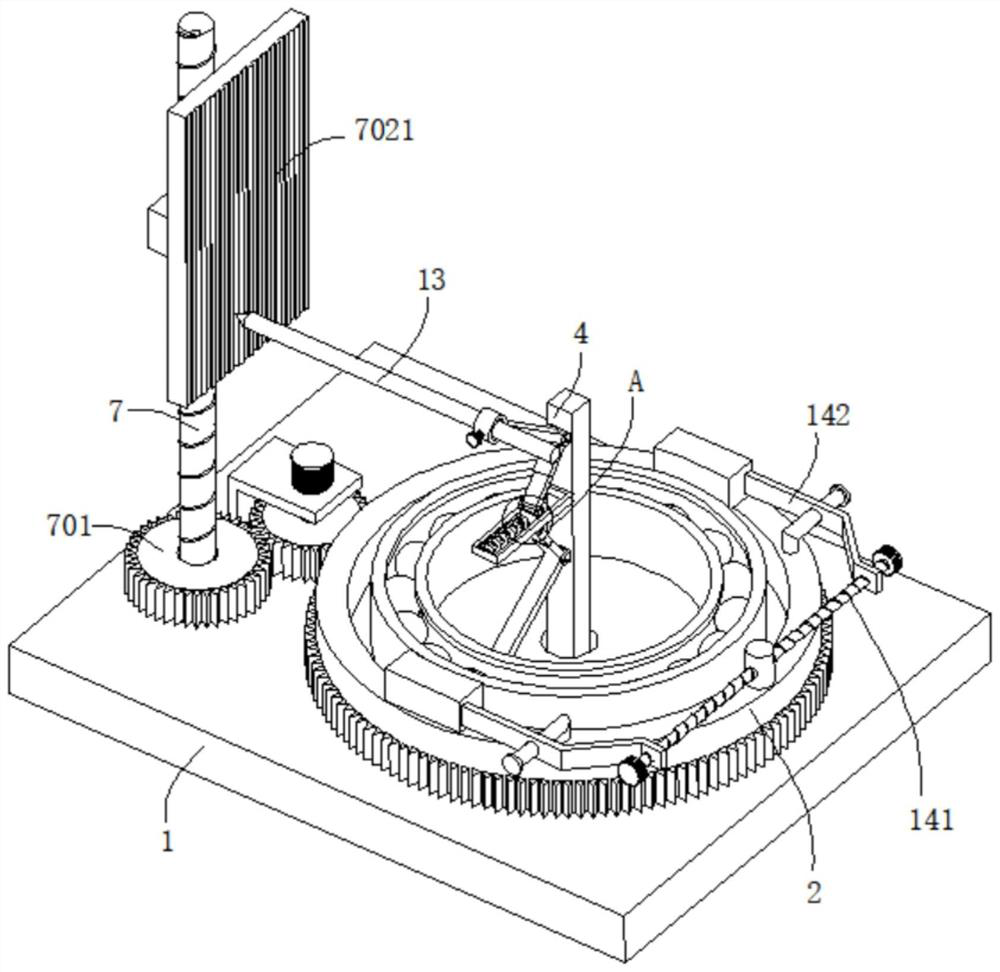

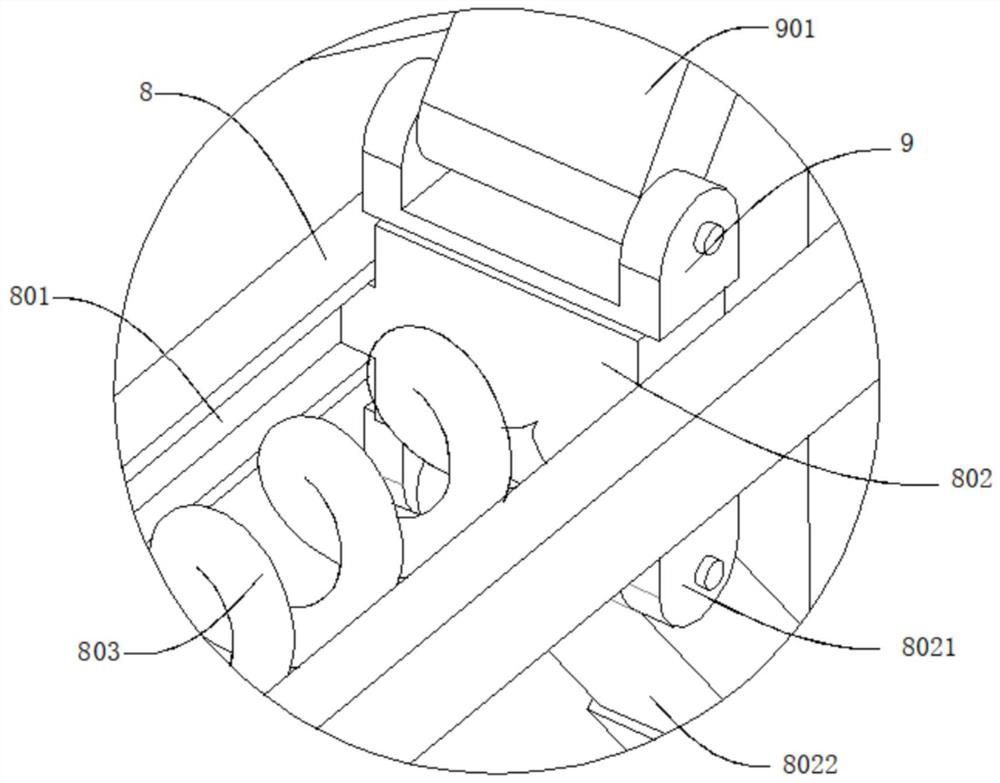

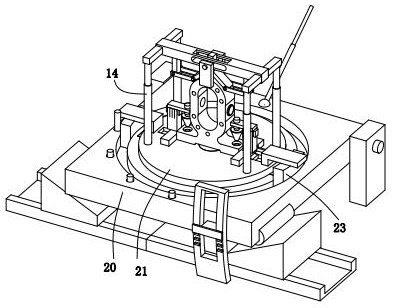

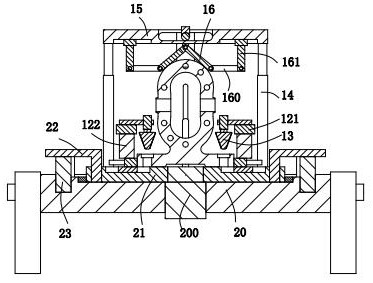

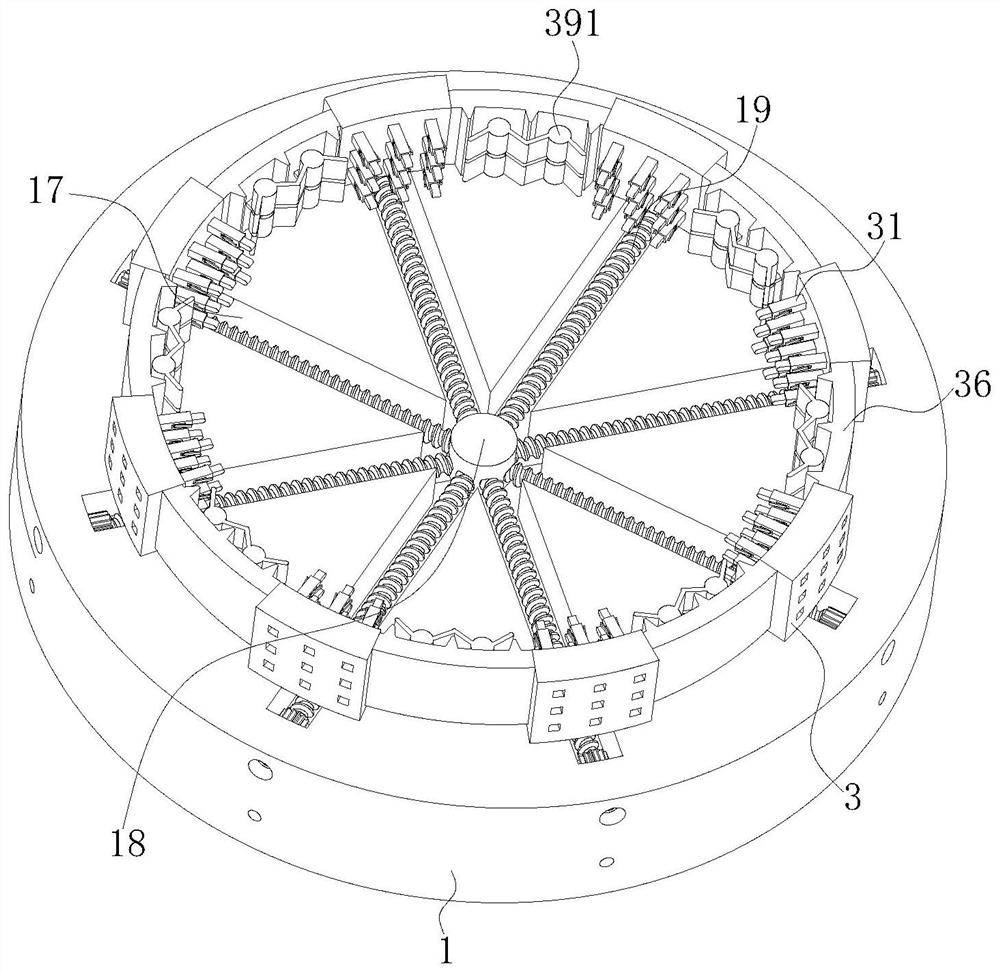

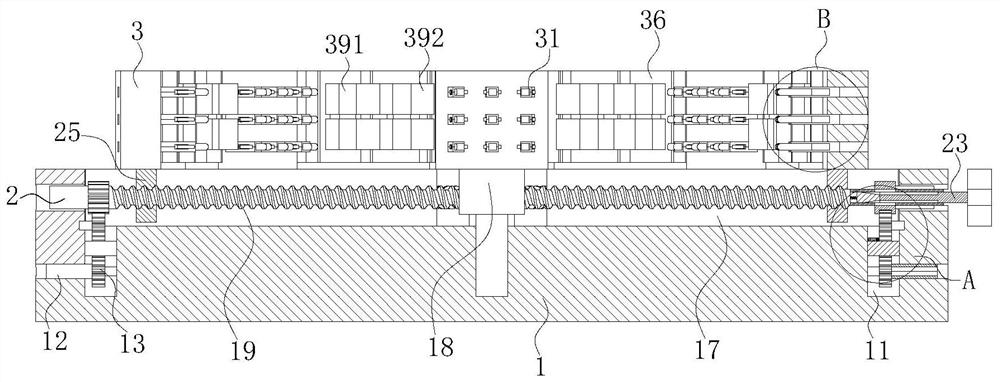

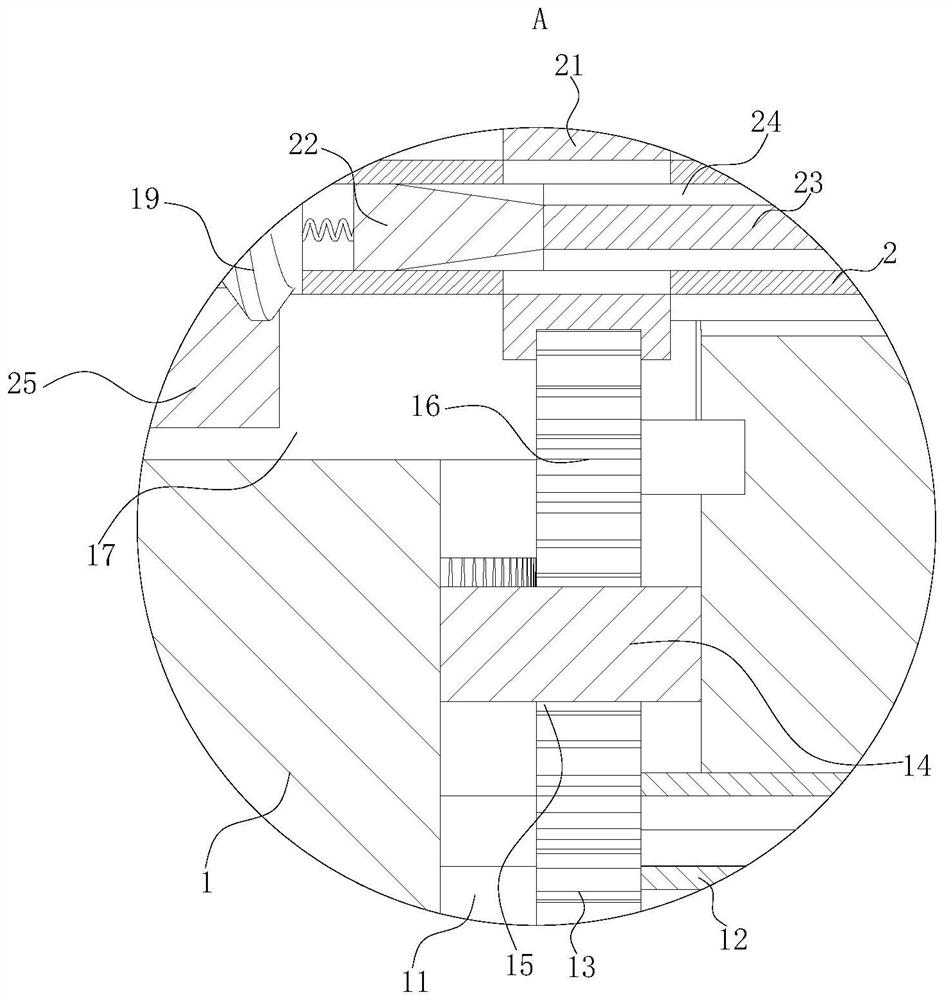

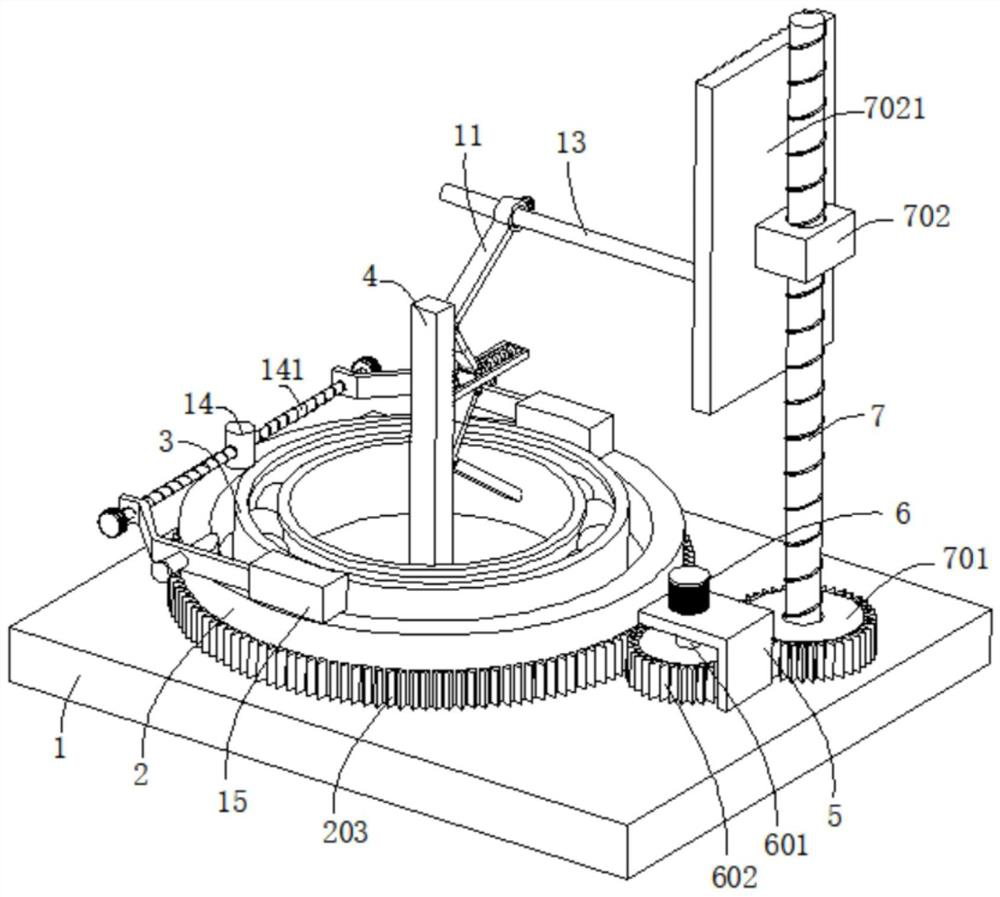

A pump body processing rotary table with clamping function

ActiveCN114603368BExpand the scope of operationReduce labor intensityLarge fixed membersPositioning apparatusMechanical engineeringPhysics

The invention relates to the field of pump body processing, in particular to a pump body processing rotary worktable with clamping function, comprising a clamping part and a rotating part, the rotary worktable has two different rotation centers, which can make the pump The body and the clamping part can be rotated both vertically and horizontally, so that the operator can expand the operating range and increase the number of operable points without frequent transposition. And it can help reduce the labor intensity of the operator and improve the work efficiency. The clamping part used in the present invention can clamp the pump body in multiple directions and at multiple points without hindering the assembly of the pump body, so as to ensure the pump body. Stability and uniform force on the pump body, at the same time, the clamping part can also implement guidance and limit processing during the pump body in place, so as to avoid the position deviation of the pump body and affect the clamping effect.

Owner:XUZHOU XINDALONG CHEM PUMP MFG CO LTD

Charcoal strip clamping device for art painting and fixing method

The invention discloses a charcoal strip clamping device for art painting and a fixing method, and belongs to the field of art tools. A sliding rod is in sliding fit with a spiral groove and a limiting groove II. A length control device is fixedly connected to the side face of a shell body. A control circular ring is connected to the outer side of the shell body through a bearing. A magnet II is in sliding fit with an arc-shaped groove I, and when a magnet II is close to the magnet I, the magnet II and the magnet I repel each other. A rectangular cylinder II is in interference fit with a rectangular cylinder I. A charcoal strip is fixed through the shell body and a clamping device body, no spring is arranged, and the situation that the service life is shortened due to long-time compression of the spring, and then the clamping effect of the clamping device body is affected is avoided; and in addition, the length of the portion, extending out of a shell, of the charcoal strip can be adjusted according to habits of a user, the situation that the extending length of the charcoal strip is too long or too short, the user needs to adjust the length with hands, fingers of the user are polluted, time is wasted is avoided, and the charcoal strips of different sizes can be clamped.

Owner:HEIHE UNIV

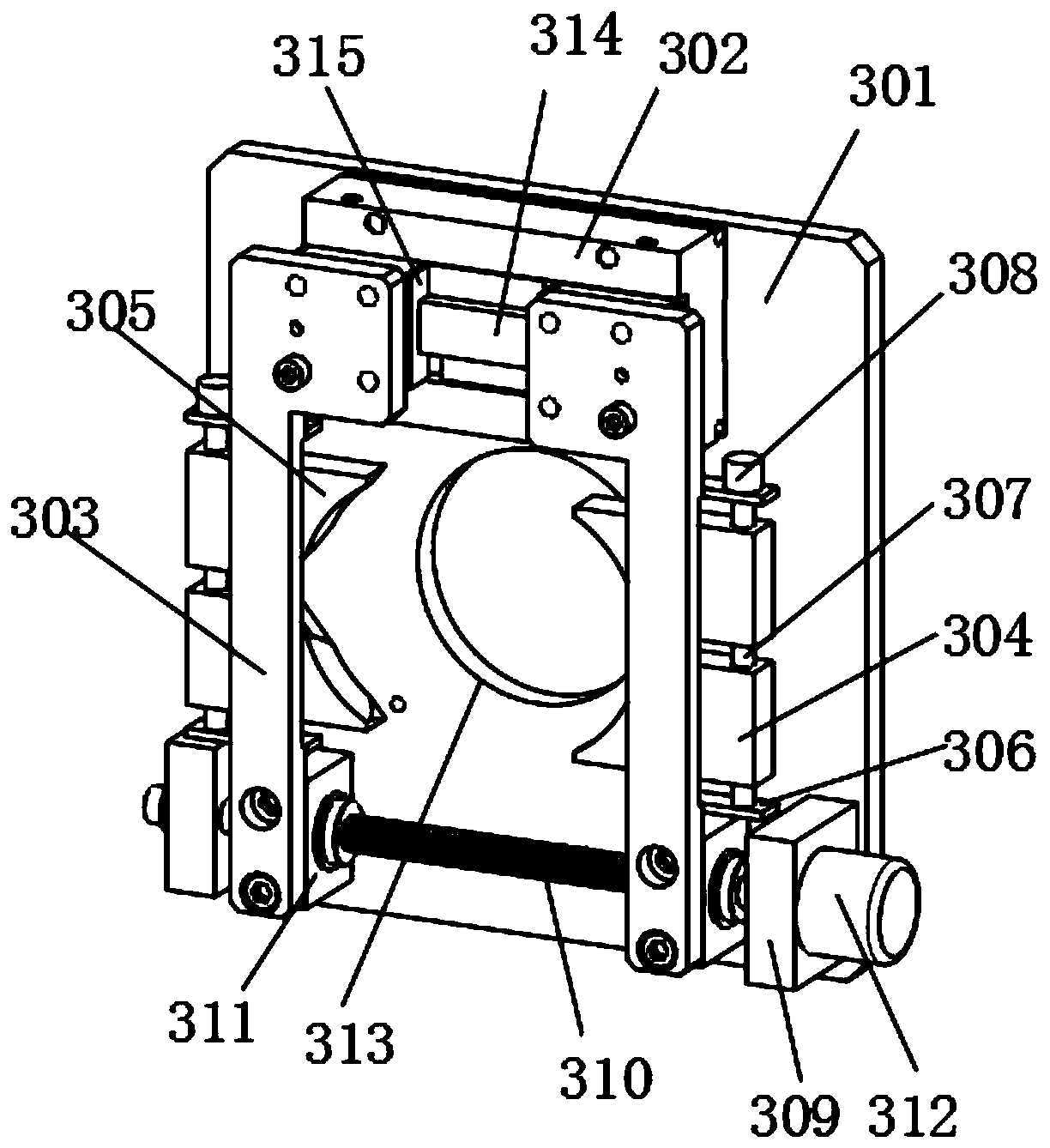

A processing and clamping mechanism for a turning plate boring machine

ActiveCN108818048BEasy to processAffect machining accuracyMetal working apparatusPositioning apparatusEngineeringMachine

Owner:XIANGYANG YUQING TRANSMISSION TECH

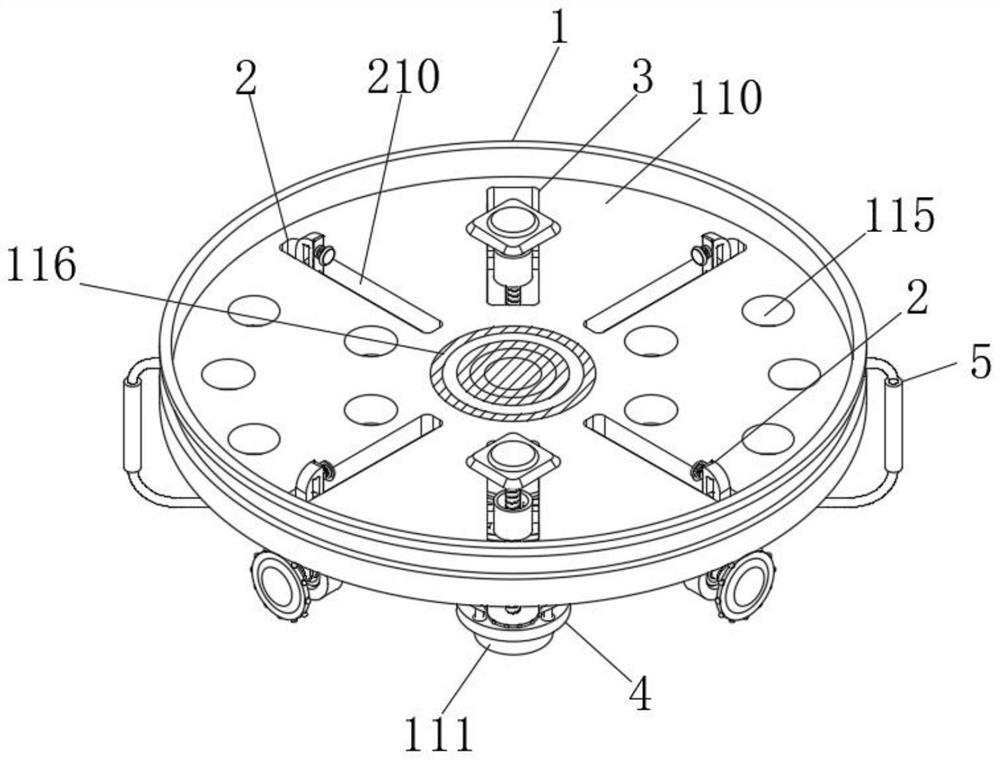

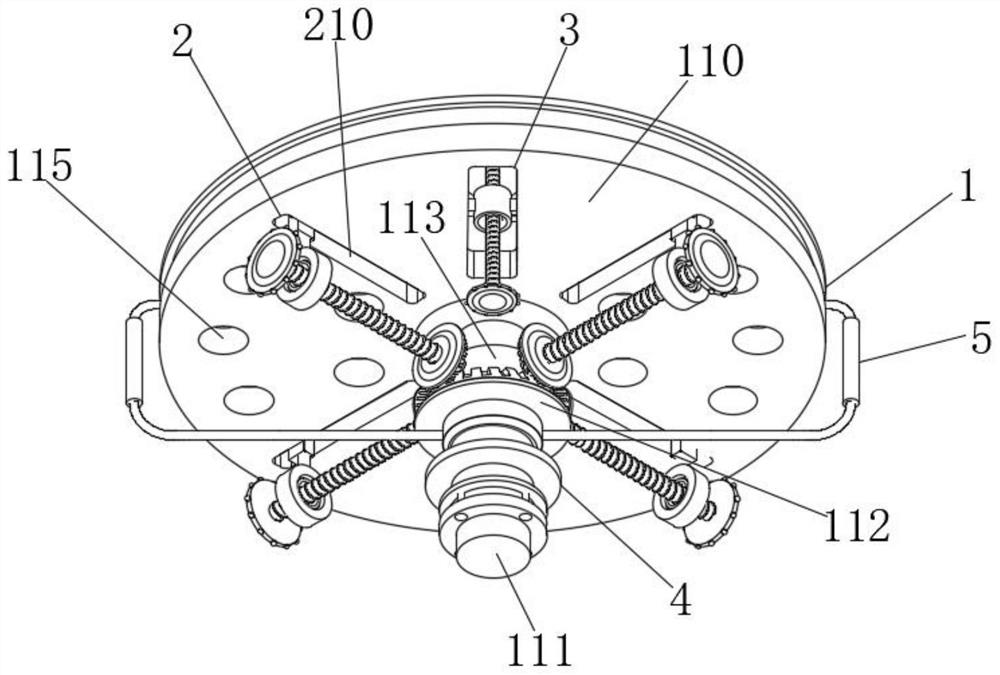

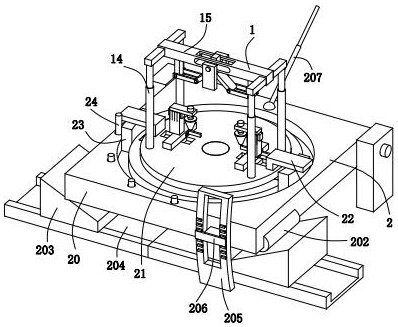

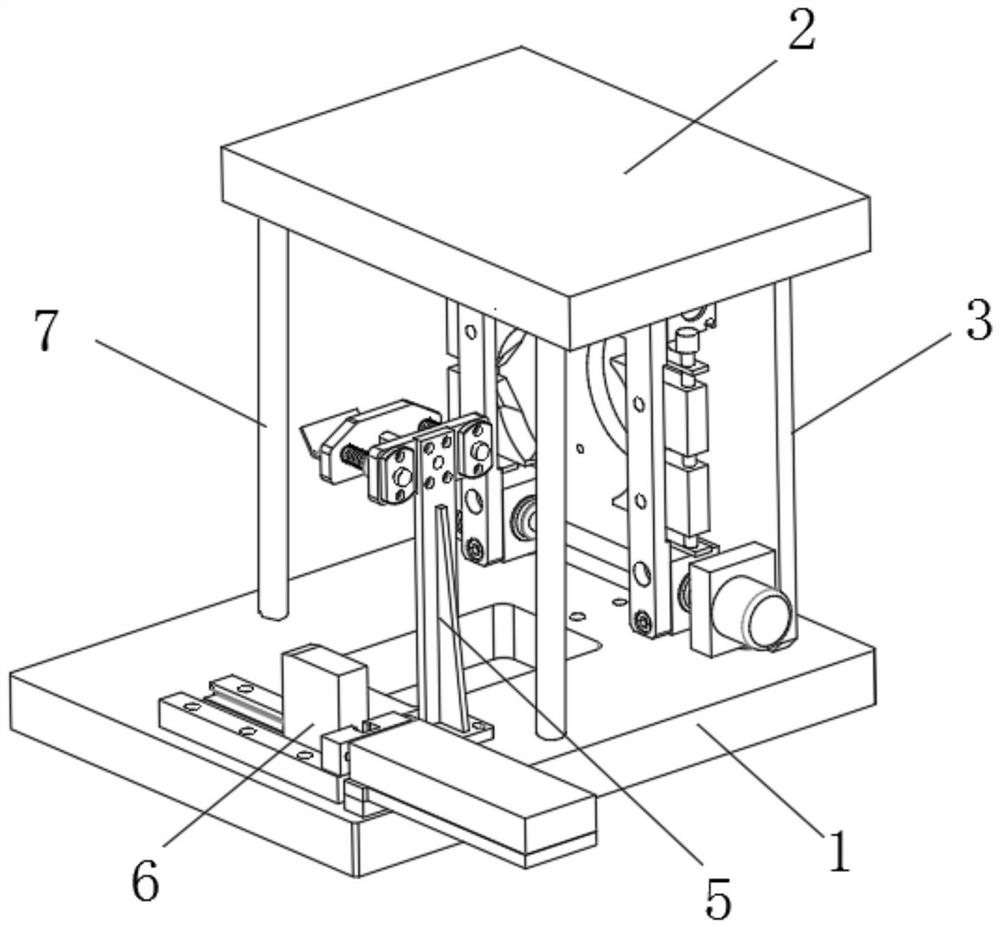

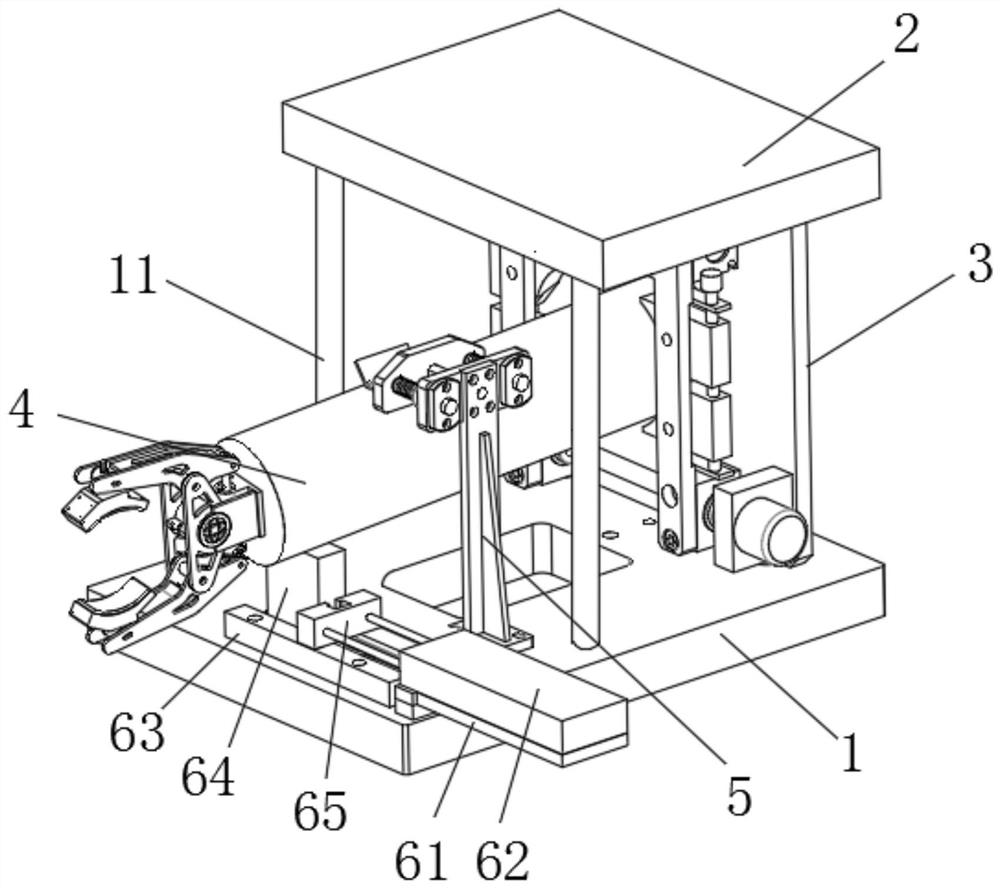

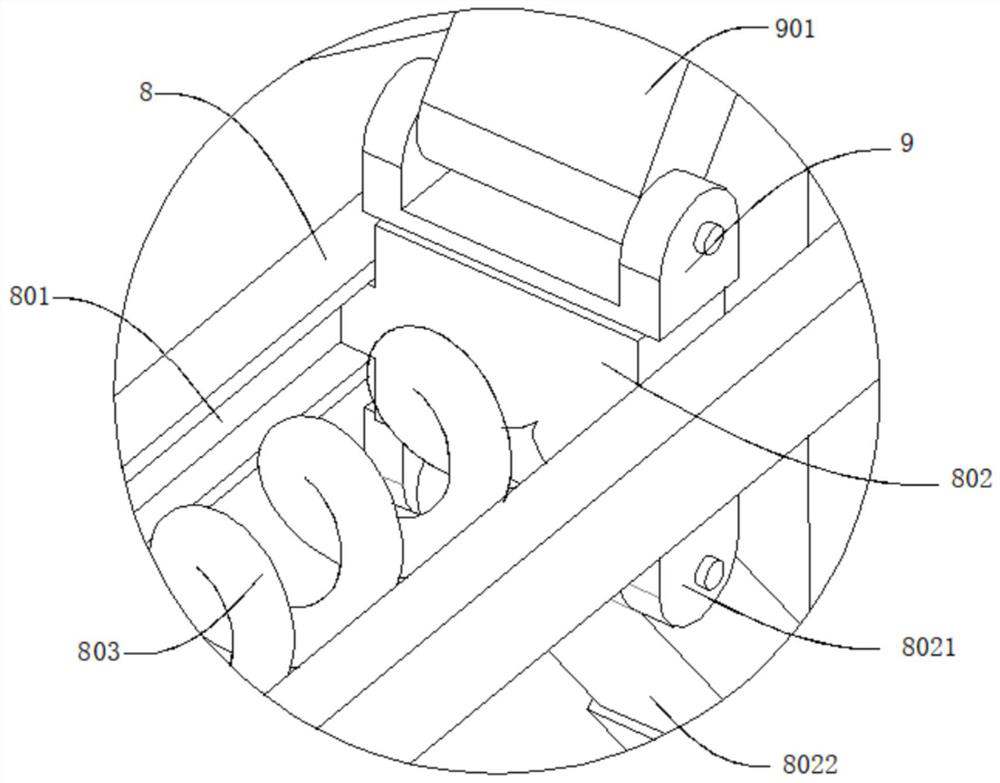

A processing and clamping mechanism for a rotary turning plate boring machine

ActiveCN108907800BAffect machining accuracyAchieve rotationLarge fixed membersPositioning apparatusRotary stageMachine

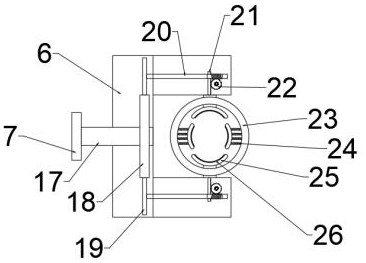

The invention relates to the technical field of machining, in particular to a clamping mechanism for processing of a rotary turning plate boring machine. The clamping mechanism can solve the problem that the processing precision is affected in the machining field as an irregular special-shaped part is hard to clamp firmly if being processed. The technical key point is as follows: the clamping mechanism comprises a worktable and a supporting assembly, wherein a rotary table top face is arranged at the bottom of the worktable, a V-shaped plate opened toward the worktable top face is movably arranged above the worktable, and the supporting assembly is used for supporting the V-shaped plate. By adopting the technical scheme, when a workpiece is processed, the workpiece can be clamped in a clamping cavity between the V-shaped plate and the end face of the worktable; and the workpiece is then processed by means of boring equipment or other equipment. Compared with a common clamp, the V-shaped plate can clamp the workpiece in the clamping cavity relatively firmly, and in particular can prevent the irregular special-shaped workpiece from rotating in the clamping cavity better to affect theprocessing precision of the workpiece.

Owner:XIANGYANG YUQING TRANSMISSION TECH

Steel structure machining platform for industrial design machining

InactiveCN112171548APoint of contact improvedIncrease the degree of clampingWork holdersGear wheelMachining process

The invention belongs to the technical field of industrial design steel structure machining platforms, and specifically relates to a steel structure machining platform for industrial design machining.The steel structure machining platform comprises a machining table; a first annular groove is formed in the inner wall of the machining table; first through grooves are evenly formed in the side, opposite to the first annular groove, of the inner wall of the machining table; a first through pipe is rotatably connected into each first through groove; each first through pipe partially extends intothe first annular groove; and the outer surface of the side, extending into the first annular groove, of each first through pipe is fixedly connected with a first gear disc. The steel structure machining platform is mainly used for solving the problems that most existing industrial design machining platforms can only clamp workpieces with fixed shapes and specifications, other clamps need to be replaced when other types of workpieces need to be clamped, and when irregular workpieces need to be clamped, due to point contact between a workbench and the workpieces, the workpieces are not firmly clamped, and therefore the machining process of the workpieces is influenced.

Owner:ANHUI YINUOQINGCHUN IND DESIGN CO LTD

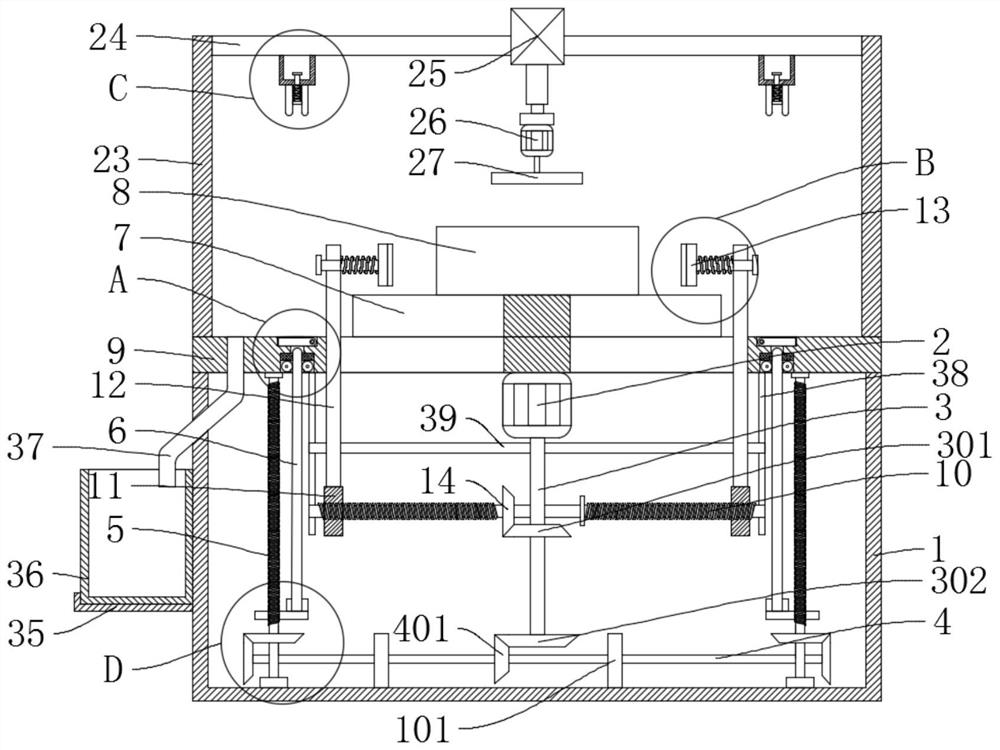

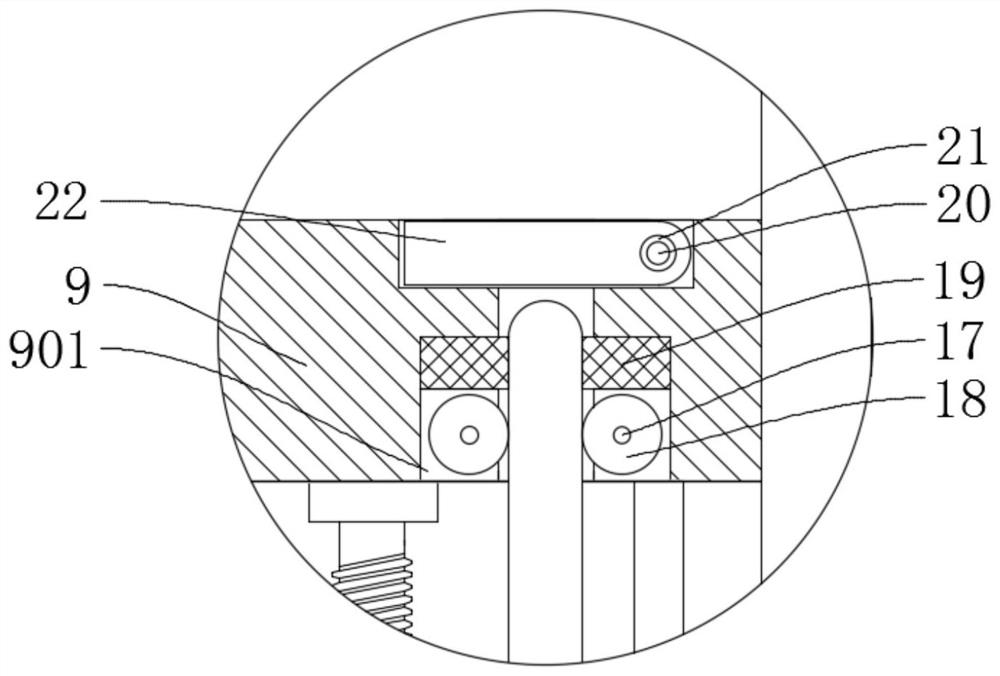

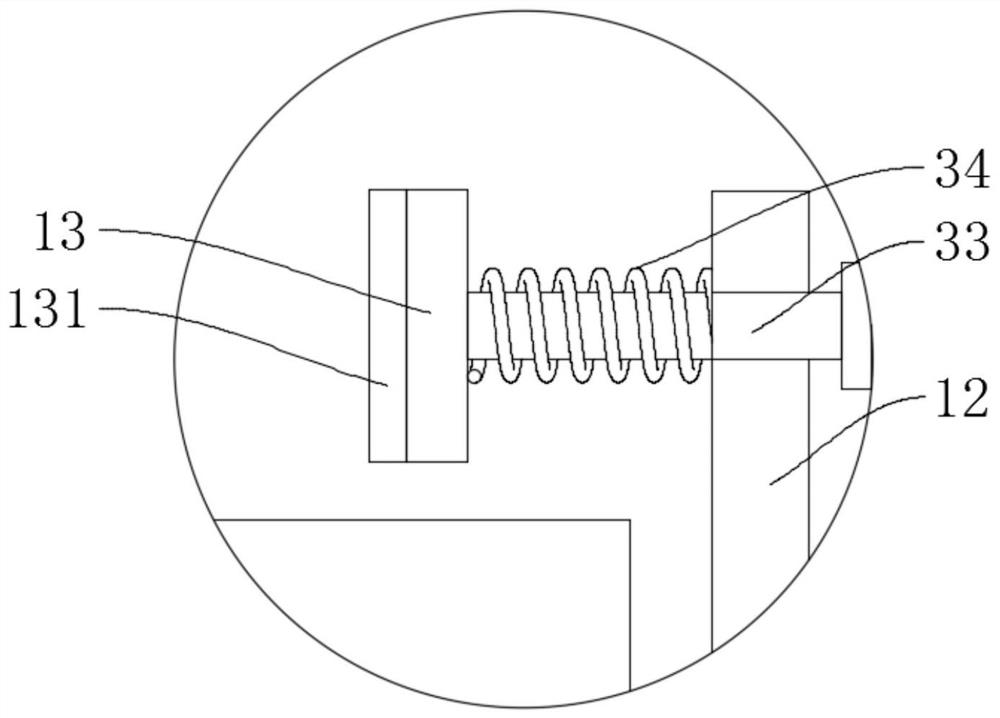

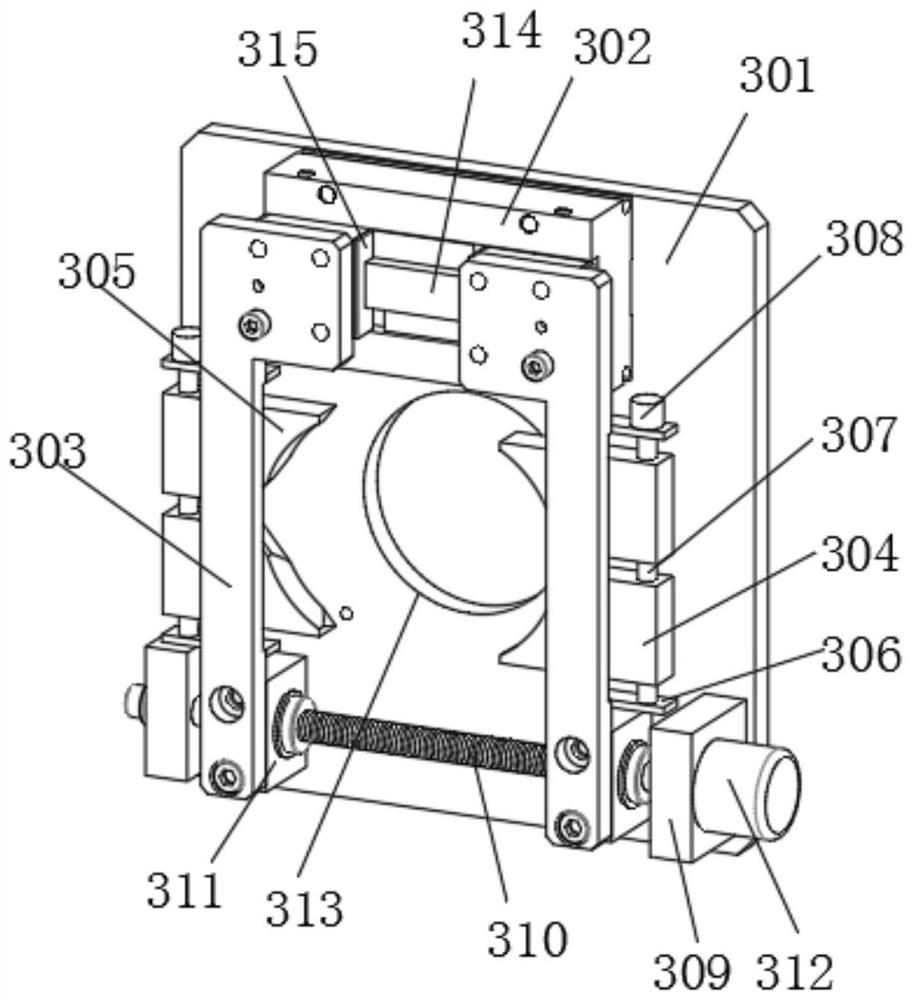

A machining clamp locking device

The invention discloses a machining fixture locking device. The machining fixture locking device comprises a base plate; two extension cylinders are symmetrically and fixedly mounted on the base plate; piston rods are arranged on the two extension cylinders, and are fixedly connected with tooth plates; buffer cavities are formed in the piston rods; piston blocks are slidingly connected into the buffer cavities; moving rods are fixedly connected to one sides of the piston blocks; the ends, far from the piston blocks, of the moving rods are fixedly connected with clamping plates; the other sidesof the piston blocks are fixedly connected with second springs; and the ends, far from the piston blocks, of the second springs are fixedly connected to the side walls of the buffer cavities. Tooth blocks adaptively slide up, and meanwhile, drive first springs to compress; and under the elastic effect of the first springs, the tooth blocks are engaged with the tooth plates again, and meanwhile, end surfaces B abut against the tooth plates to prevent retreating of the tooth plates, so that the locking effect on the piston rods is achieved, and the influence on the clamping effect of the pistonrods by instable air pressure of the extension cylinders is prevented.

Owner:浙江零捷网络科技有限公司

A clamping mechanism for processing special-shaped parts

ActiveCN108994638BEasy to processAffect machining accuracyLarge fixed membersPositioning apparatusAbnormal shapedMachining

The invention relates to the technical field of machining, in particular to a special-shaped part machining clamping mechanism. The problem that in the field of machining, when a special-shaped part without a regular shape is machined, the special-shaped part cannot be firmly clamped easily, and the machining precision is affected is solved. According to the technical scheme, the special-shaped part machining clamping mechanism is characterized in that the special-shaped part machining clamping mechanism comprises a workbench; a V-shaped plate with an opening facing upwards and a supporting assembly for supporting the V-shaped plate are movably arranged on the upper portion of the workbench; and the height of the supporting assembly is adjustable. By adopting the technical scheme, when a workpiece is machined, the workpiece can be clamped in a clamping cavity between the V-shaped plate and the end surface of the workbench, and then the workpiece can be machined through hole boring or other equipment. Compared with common clamps, the workpiece can be firmly clamped in the clamping cavity through the V-shaped plate, especially the special-shaped part without a regular shape, and thesituation that the workpiece rotates in the clamping cavity, and the machineing accuracy of the workpiece is affected can be well avoided.

Owner:XIANGYANG YUQING TRANSMISSION TECH

A robot base welding forming fixing fixture

ActiveCN114273849BAffect welding accuracyImprove applicabilityWelding/cutting auxillary devicesAuxillary welding devicesControl engineeringElectric machinery

The invention relates to the field of robot assembly and forming, in particular to a welding and forming fixing tooling fixture for a robot base, which includes a base, a support frame, a worktable and a clamping and limiting mechanism. In the clamping and limiting mechanism designed by the present invention, a winding motor starts Drive the winding roller to rotate, so that the winding roller drives the clamping frame to move through the traction rope, and then drives the clamping block into the rectangular groove under the robot base, so as to limit and fix the robot base through the clamping chain; In the support chain, the electric slider pushes the support plate to open through the adjustment block, and the rotating lead screw drives the support plate to move towards each other, so that the support plate can support the vertical section of the robot base and prevent the robot base from shaking during the welding process. Affects the welding accuracy of the robot base.

Owner:江苏博发机器人智能装备有限公司

Optical fiber cable high-precision clip buckle

ActiveCN110394746BEasy to moveEasy to adjustOptical fibre/cable installationWork holdersMechanical engineeringOptical fiber cable

The invention discloses a high-precision clamping buckle for an optical fiber cable. There is a second clamping piece between the bottom plate and the top plate, and one end of the connecting column is clamped by four first clamping plates; each first clamping plate is easy to move, and can clamp and fix optical fiber cables of different sizes , each first clamping plate is controlled by the first lead screw and the second lead screw, with high precision and good clamping effect; the clamping buckle can meet different installation environments and has strong applicability; rotate the first clamping plate The second clamping plate and the second clamping plate are easy to disassemble and can meet the installation of optical fiber cables of different specifications; the second clamping part and the first clamping part are more convenient to install and disassemble, and the design is ingenious. The clamping buckle can be applied to For the clamping of fiber optic cables in different directions.

Owner:NINGBO ZHENGYU FASTENERS

A kind of bearing inner diameter automatic detection equipment

ActiveCN112414350BImprove detection efficiencyImprove detection accuracyMechanical measuring arrangementsGear wheelElectric machinery

The invention discloses an automatic detection device for the inner diameter of a bearing, which belongs to the technical field of bearing detection. An automatic detection device for the inner diameter of a bearing, comprising a workbench, the top of the workbench is rotatably connected with a storage platform, the outer wall of the storage platform is dug with a placement groove, the inner wall of the placement groove is connected with a bearing main body, the outer wall of the workbench is connected with a fixing seat, and the inner wall of the placement groove is dug There is a concave hole matched with the fixed seat, the central axis of the fixed seat and the placement groove are in the same line, the outer wall of the fixed seat is connected with the detection mechanism and the recording mechanism, the top of the workbench is connected with the support seat, and the top of the support seat is connected with the drive motor , the output end of the driving motor is connected with a rotating shaft, and the end of the rotating shaft away from the driving motor passes through the support seat and is connected with the first gear; the present invention detects the bearing main body through the detection mechanism, improves detection efficiency and detection accuracy, and records The mechanism can convert the situation of the inner diameter detection into a wave image, which is convenient for intuitive understanding and observation.

Owner:宁波川原精工机械有限公司

Feed equipment for conveying and clamping short strips

InactiveCN109290463BAvoid wastingIncrease profitMetal-working feeding devicesNon-rotating vibration suppressionPunchingProcess engineering

The invention discloses a feeding device for conveying and clamping short strips, which comprises a first frame body; a first material clamping device for clamping one end of the material; a second material clamping device and the first clamping device The material device cooperates to clamp the other end of the material; the third material clamping device is arranged between the first and second material clamping devices, and is used to clamp the middle part of the material, when the third material clamping device clamps the material In the middle, the first or second clamping device releases the material and moves backward. The invention improves the utilization rate of the whole material, reduces the amount of material waste, and reduces the production cost under the same output; realizes fully automatic material feeding, avoids manual movement or flipping of materials during the stamping process, and reduces workers' labor. Reduce labor intensity and labor cost, improve the stamping efficiency of the punch press on the material, that is, increase the production efficiency.

Owner:HANGZHOU KINGNET ELECTROMECHANICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com