Lifting assembly mechanism for graphite boat loading and unloading wafers

An assembly mechanism and lifting technology, which is applied in the direction of conveyor objects, transportation and packaging, electrical components, etc., can solve the problems of low assembly accuracy, short service life, low production efficiency, etc., to improve safety and increase friction , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

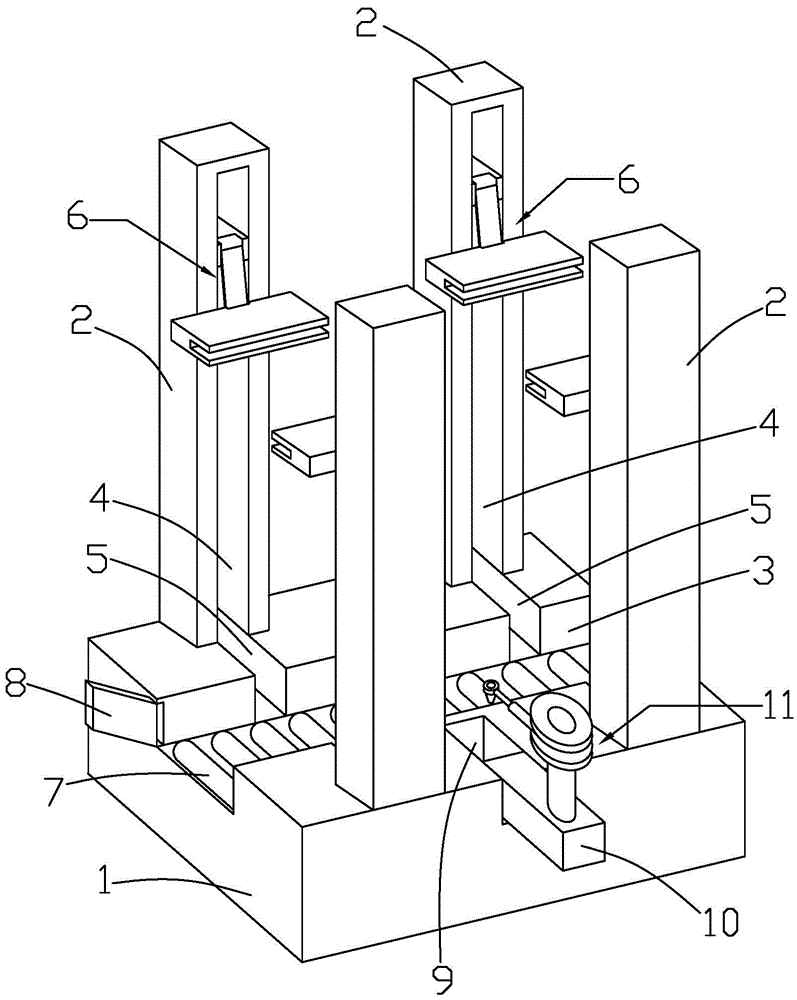

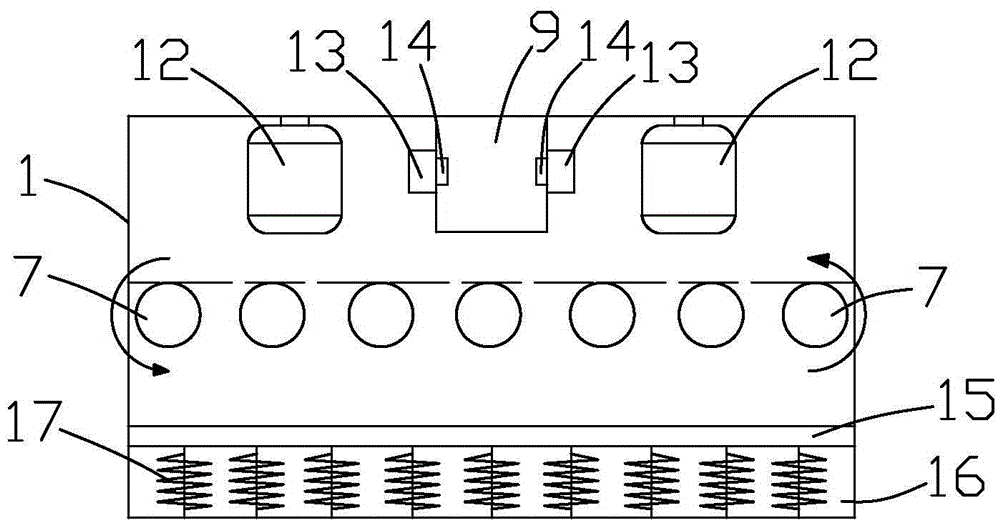

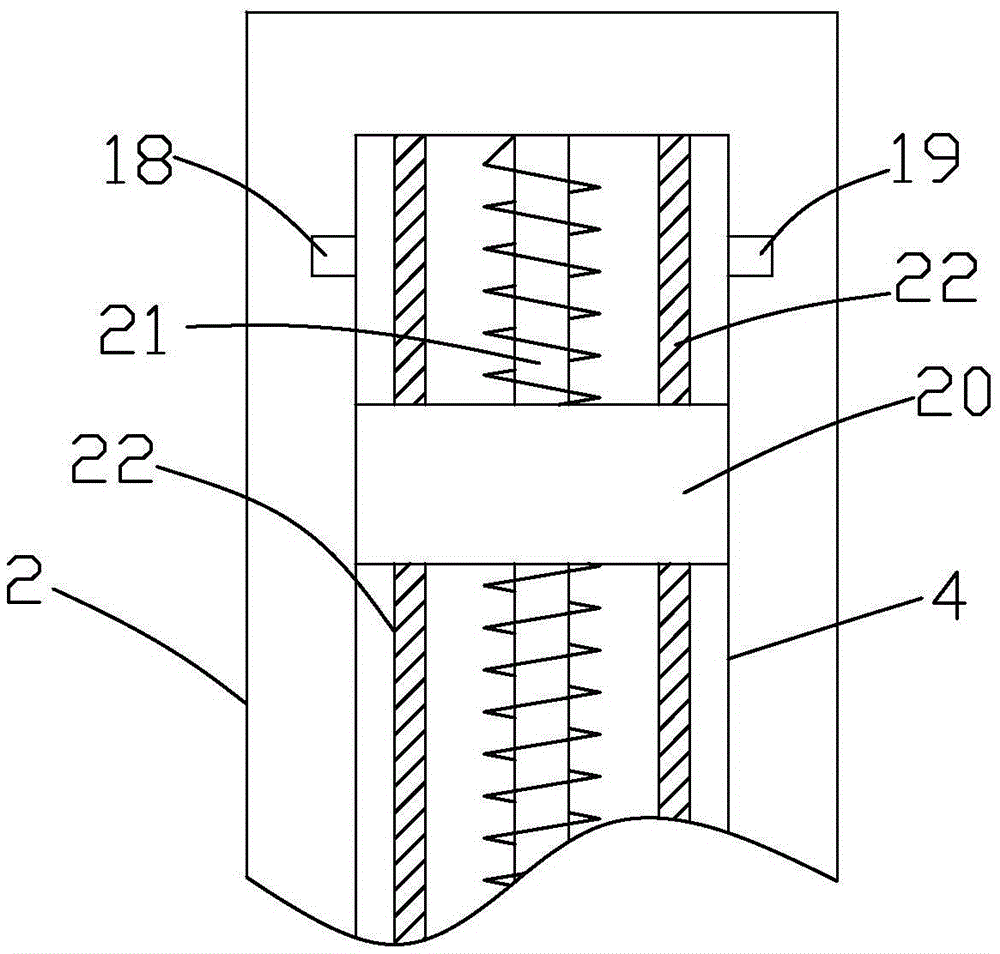

[0030] Such as Figure 1 to Figure 5As shown, it is an elevating assembly mechanism for graphite boat loading and unloading sheets according to the present invention. The elevating assembly mechanism includes a base 1, and at least four supporting columns 2 are symmetrically arranged on the top surface of the base 1, and the supporting columns 2 and the base 1 Vertically connected, the supporting column 2 is provided with a lifting guide groove 4, and the two sides of the lifting guide groove 4 are respectively provided with an infrared transmitter 18 and an infrared receiver 19, and the infrared transmitter 18 and the infrared receiver 19 are located on the same horizontal line. When the straight path between the infrared emitter 18 and the infrared receiver 19 was cut off by the lifting plate 20, the lifting plate 20 would slow down and move until it stopped. When the straight path between the infrared emitter 18 and the infrared receiver 19 was connected, The lifting plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com