Feed equipment for conveying and clamping short strips

A feeding equipment and material clamping technology, applied in mechanical equipment, metal processing equipment, feeding devices, etc., can solve problems affecting the normal operation of equipment, equipment damage, parts falling off, etc., to reduce labor intensity and labor costs, reduce Vibration, the effect of improving stamping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

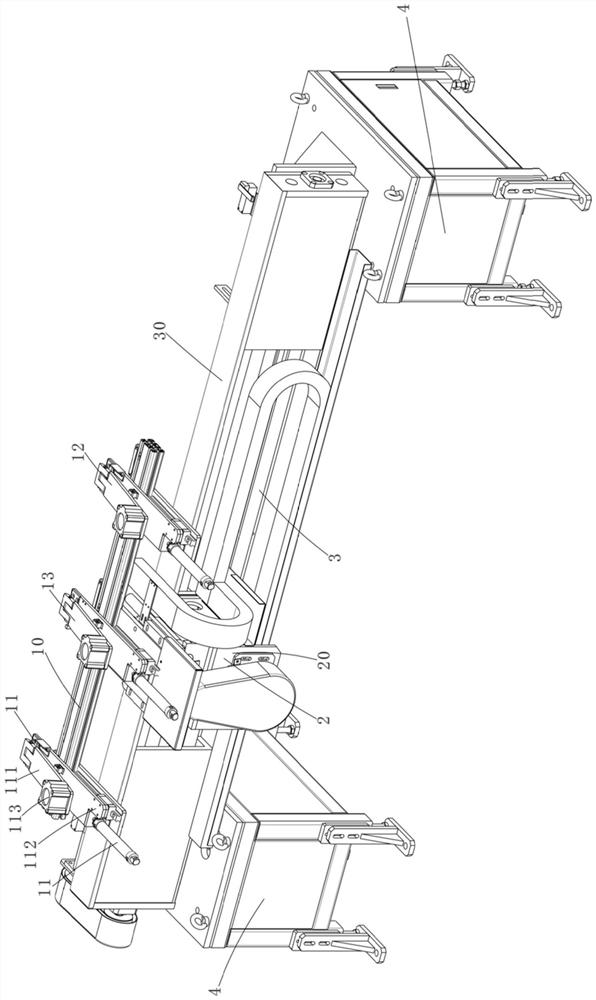

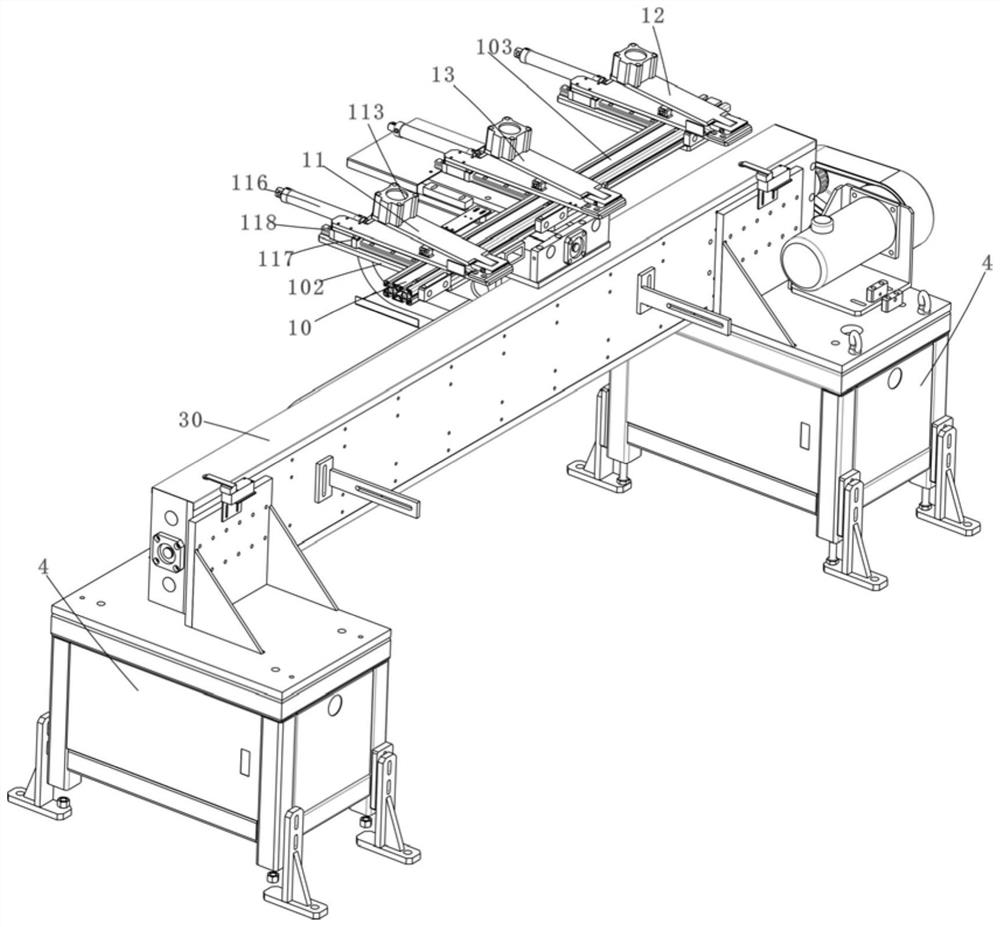

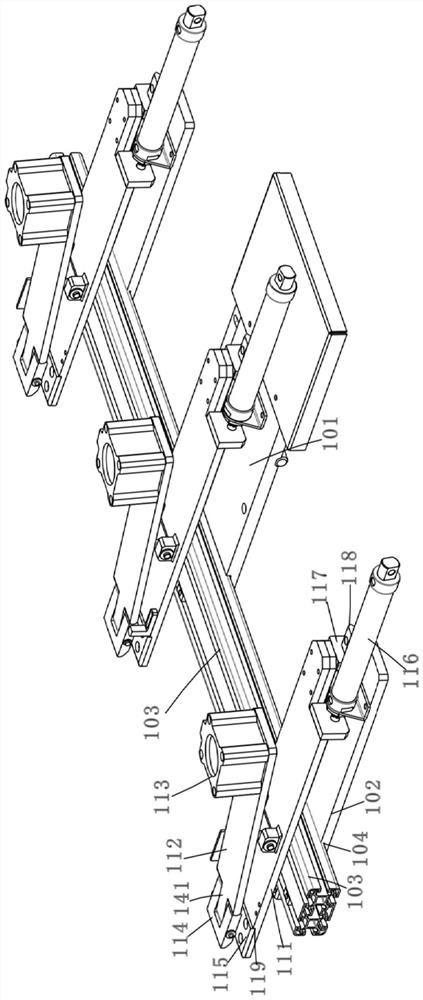

[0041] Such as Figure 1-13As shown, a feeding device for conveying and clamping short strips includes a first frame body 10, a first clamping device 11, a second clamping device 12, a third clamping device 13, and a first driving device 2 and the second driving device 3, wherein the above-mentioned first frame body 10 includes a first support plate 101 arranged horizontally, two second support plates 102 arranged horizontally and a support profile vertically connected to the first and second support plates 103, wherein the above-mentioned first and second support plates are metal plates, and the length of the first and second support plates is the same, the difference is that the width of the first support plate 101 is wider than the width of the above-mentioned second support plate 102; the above-mentioned The first support plate 101 is located in the middle of the two second support plates 102, and a groove 104 is provided at the front ends of the first and second support p...

Embodiment 2

[0053] Such as Figure 14-17As shown, the difference between this embodiment and Embodiment 1 is that this embodiment discloses a shock absorbing device 5 for absorbing vibrations on the second driving device, specifically: the shock absorbing device 5 includes a cylinder body 51, a cavity 52. Hydraulic oil and damping piston 53, the cylinder 51 is a metal cylinder, the cavity 52 is a cylindrical cavity formed on the cylinder 51, and the hydraulic oil is filled in the cavity 52; The damping piston 53 includes a rod body 531 and an elastic sealing block 532. The rod body 531 is a metal column, and the elastic sealing block 532 is a cylindrical rubber block. There are two positioning rings on the side wall of the elastic sealing block 532. Concave ring 533, a sealing ring 534 is sleeved in each ring of positioning concave ring 533, and the sealing ring 534 is a rubber ring. When the damping piston 53 is inserted into the cavity 52, the sealing ring 534 is in close contact with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com