Charcoal strip clamping device for art painting and fixing method

A gripper and painting technology, applied in the field of art tools, can solve problems such as the weakening of the gripping effect and the fixed length of the carbon fine strips.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

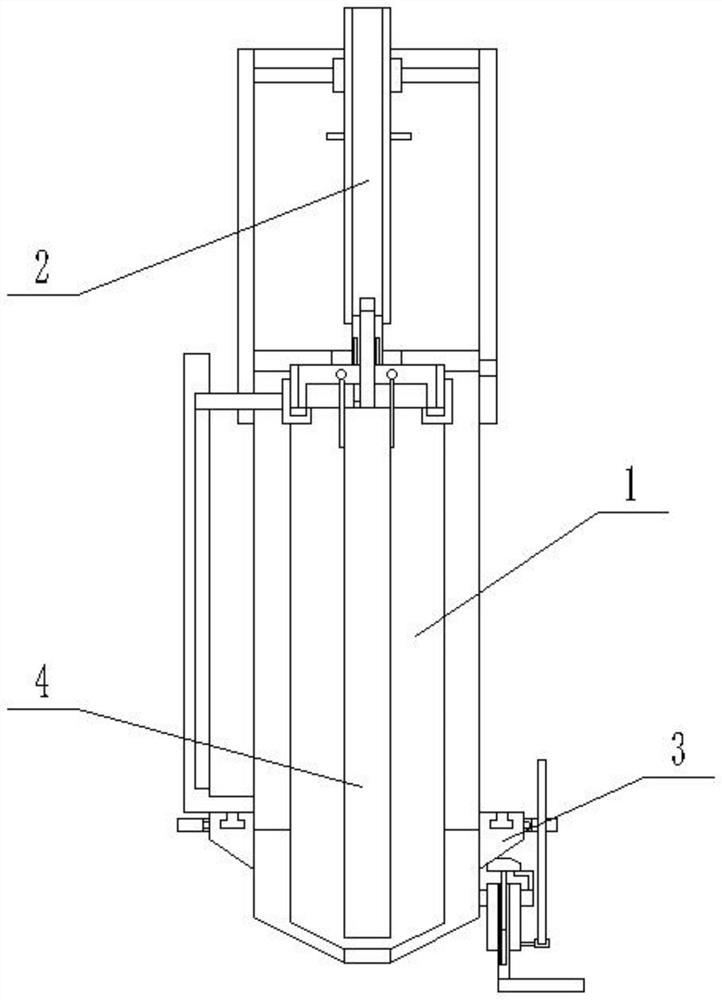

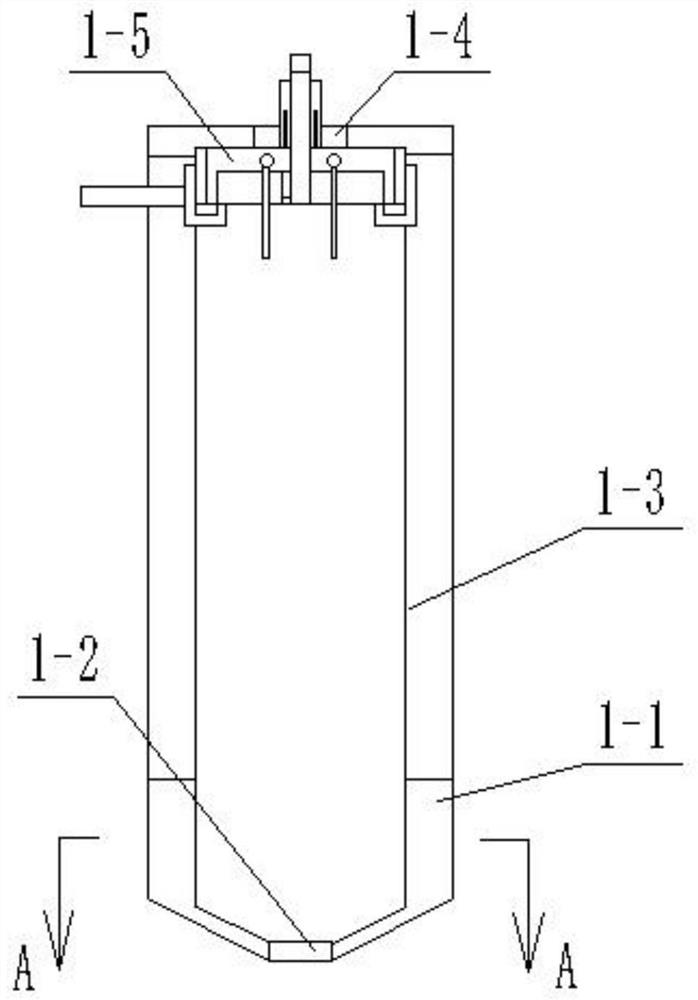

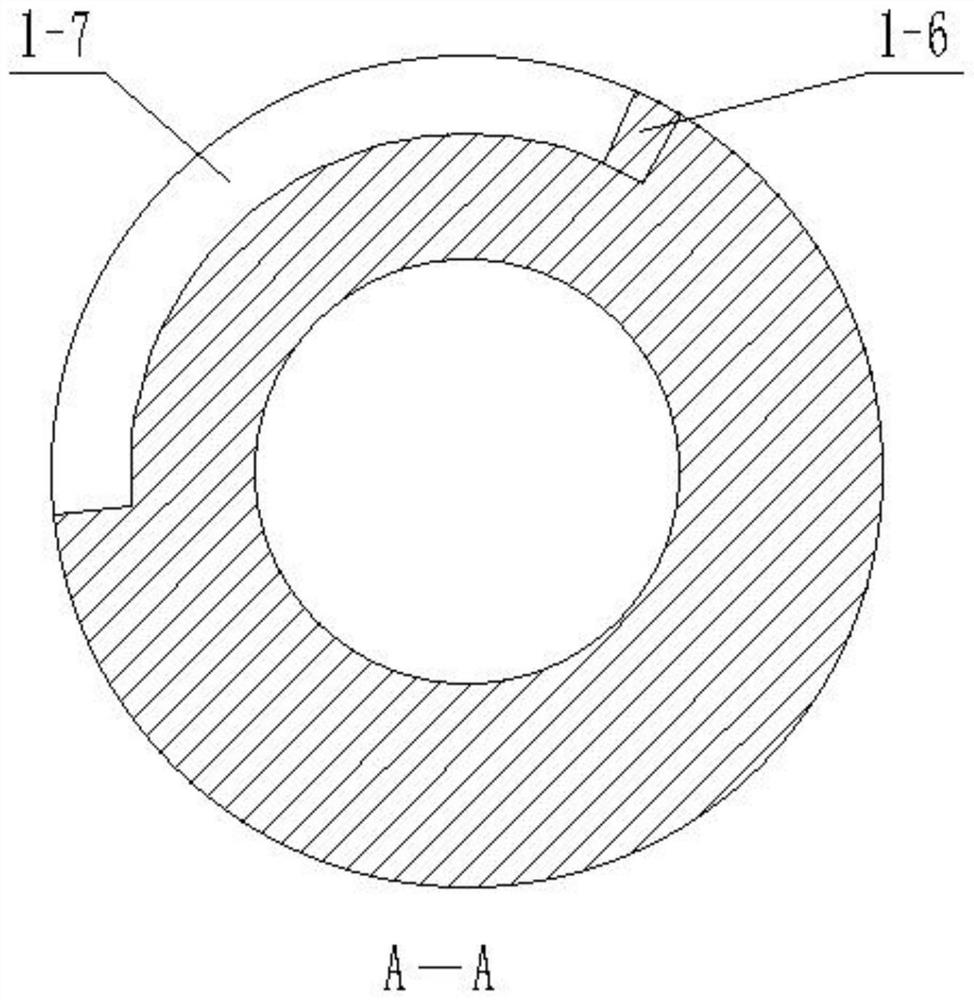

[0033] Specific implementation mode one: as Figure 1-13 As shown, this embodiment describes a carbon strip holder for fine art painting, including a housing 1, a restricting device I2 and a restricting device II3; the housing 1 includes a housing main body 1-1, a clamping device 1-5 and Magnet I1-6; the top of the housing main body 1-1 is provided with a through hole I1-4, the bottom end of the housing main body 1-1 is provided with a through hole II1-2, and the side wall of the housing main body 1-1 is axially provided with Two slideways I1-3; the clamping device 1-5 is arranged inside the housing main body 1-1, and the clamping device 1-5 is slidingly matched with the slideway I1-3; the outer wall of the housing main body 1-1 An arc-shaped groove I1-7 coaxial with the housing main body 1-1 is provided near the bottom end; the magnet I1-6 is fixedly connected to one end of the arc-shaped groove I1-7;

[0034] The clamping device 1-5 includes a cover 1-5-1, a threaded cylind...

specific Embodiment approach 2

[0042] Specific implementation mode two: as Figure 1-13 As shown, this embodiment is a further description of Embodiment 1. When the screw rod 1-5-10 cooperates with the thread on the inner wall of the rectangular cylinder I1-5-9, the insert at the lower end of the rectangular cylinder I1-5-9 Groove breaks away from limit bar 1-5-11. When the rectangular cylinder I1-5-9 rotates with the rectangular cylinder II2-4, it does not drive the limit rod 1-5-11 to rotate, and then does not drive the cover 1-5-1 to rotate, so as to avoid affecting the clamping of the clamping device 1-5. hold the effect.

specific Embodiment approach 3

[0043] Specific implementation mode three: as Figure 1-13 As shown, this embodiment is a further description of Embodiment 1, and the arc center angle corresponding to the arc-shaped groove I1-7 is less than or equal to 30°. Ensure the distance between the magnet Ⅰ1-6 and the magnet Ⅱ3-5, avoid the length of the arc groove Ⅰ1-7 being too long, when the magnet Ⅰ1-6 and the magnet Ⅱ3-5 repel, the magnet Ⅱ3-5 collides with the arc groove Ⅰ1-7 The edge reduces the risk of the magnet II 3-5 falling and affects the service life of the magnet II 3-5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com