Patents

Literature

108results about How to "Increase the degree of clamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Monitoring treatment device for riverway construction fracture surface bottom mud and construction method of monitoring treatment device

ActiveCN106592673AHigh outputAvoid cloggingMechanical machines/dredgersStream regulationSludgeTreatment pond

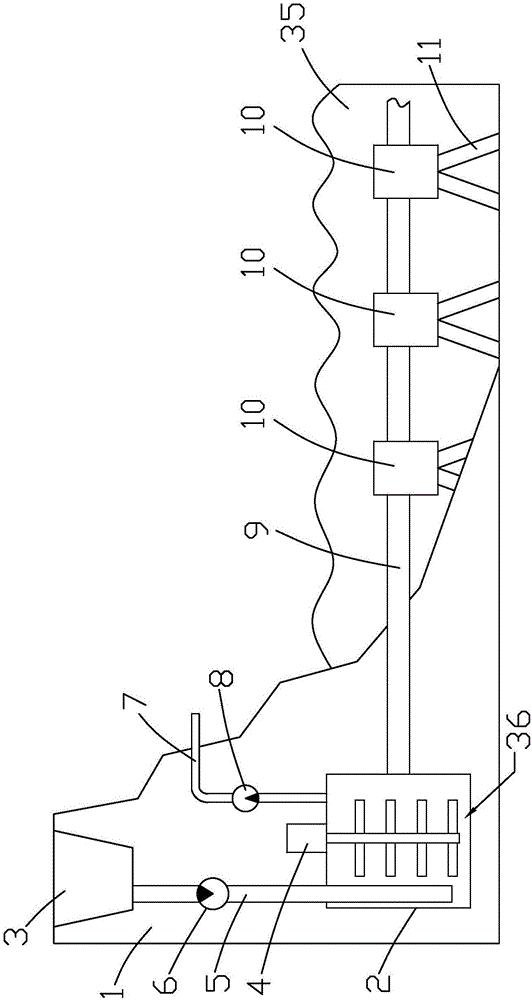

The invention discloses a monitoring treatment device for riverway construction fracture surface bottom mud and a construction method of the monitoring treatment device. The monitoring treatment device comprises bottom mud monitoring boxes, a bottom mud treatment pond and a bottom mud recycling pond; the bottom mud treatment pond is connected with the bottom mud recycling pond through a sludge output pipe which is provided with a mud pumping pump; a water inlet pipe is arranged on the top face of the bottom mud treatment pond and is communicated into water of a riverway; a stirring mechanism is arranged in the bottom mud treatment pond; the bottom mud monitoring boxes are connected with the bottom mud treatment pond through conveying pipes; and every two adjacent bottom mud monitoring boxes are connected through the corresponding conveying pipe. The construction method of the monitoring treatment device includes staking out in survey, foundation pit excavation, bottom mud treatment pond construction, bottom mud recycling pond construction, bottom mud monitoring box arrangement and bottom mud monitoring pilot running. The monitoring treatment device is simple in structure and remarkable in effect of riverway construction fracture surface bottom mud monitoring and clearing, the riverway construction fracture surface strength is improved, the bottom mud high in pollutant content can be conveniently treated, and secondary pollution formed by release of pollutants in bottom mud is prevented.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

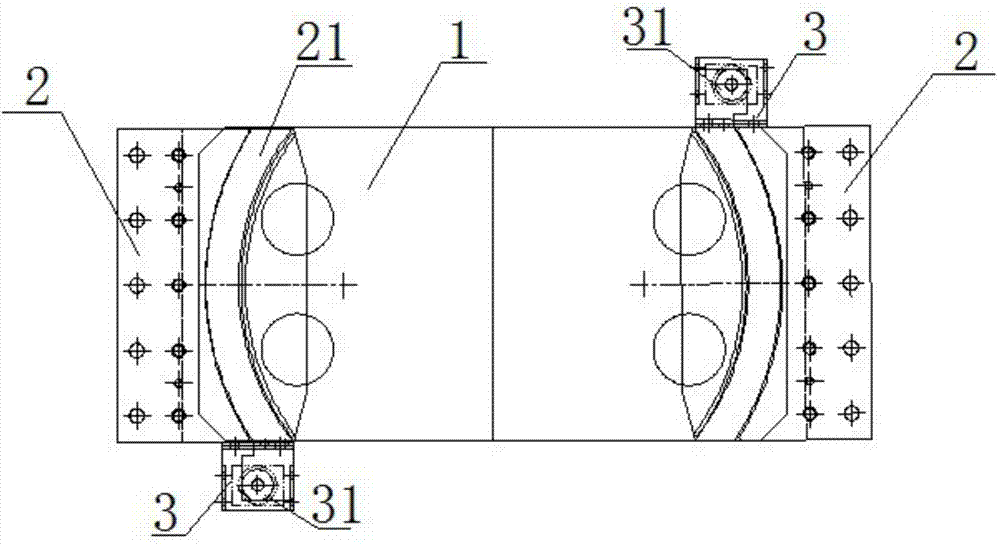

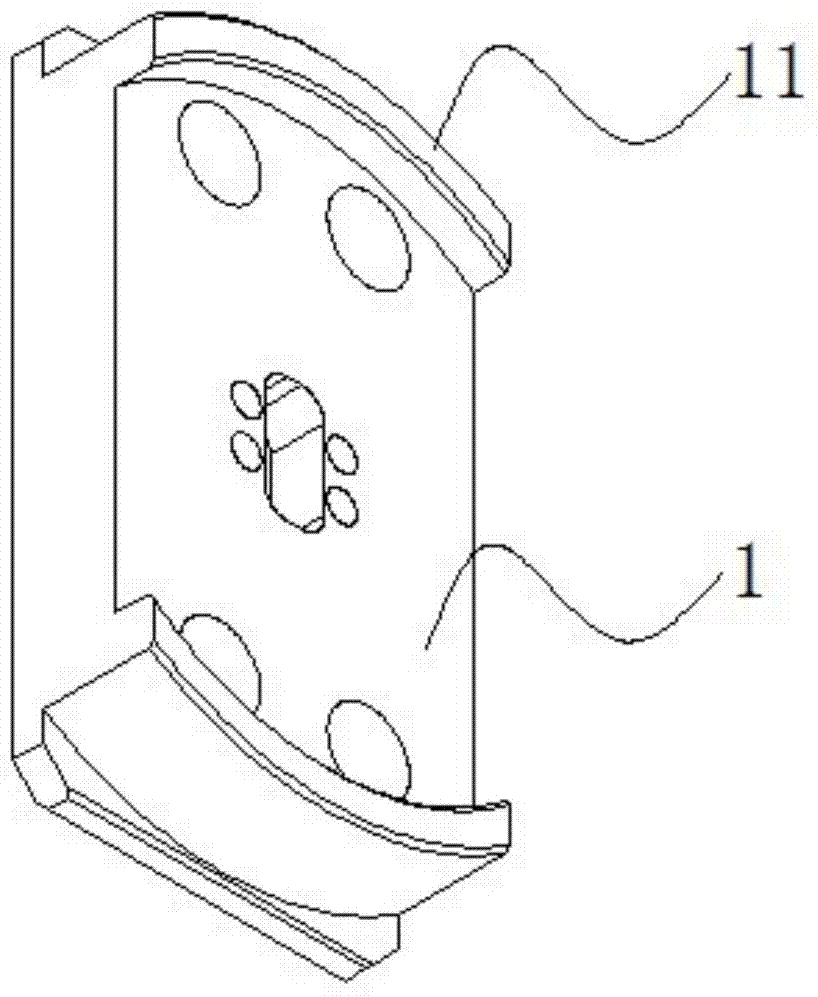

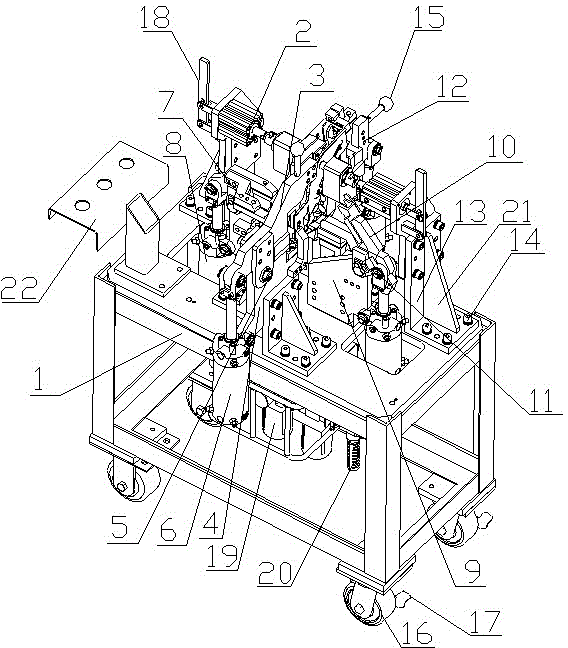

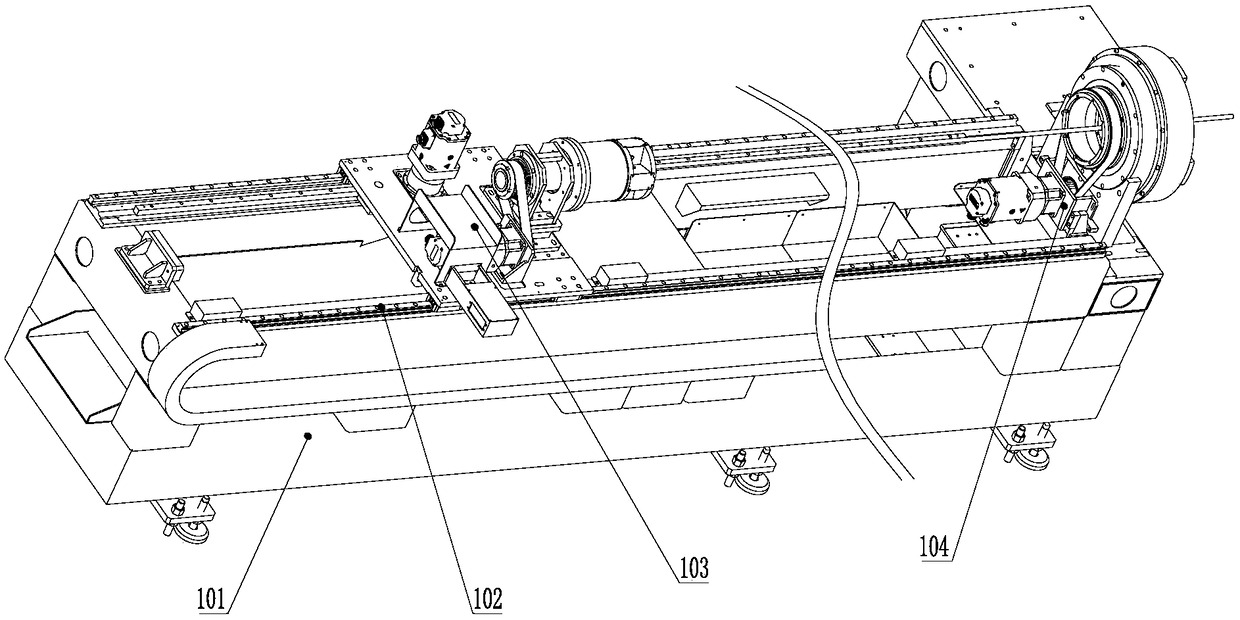

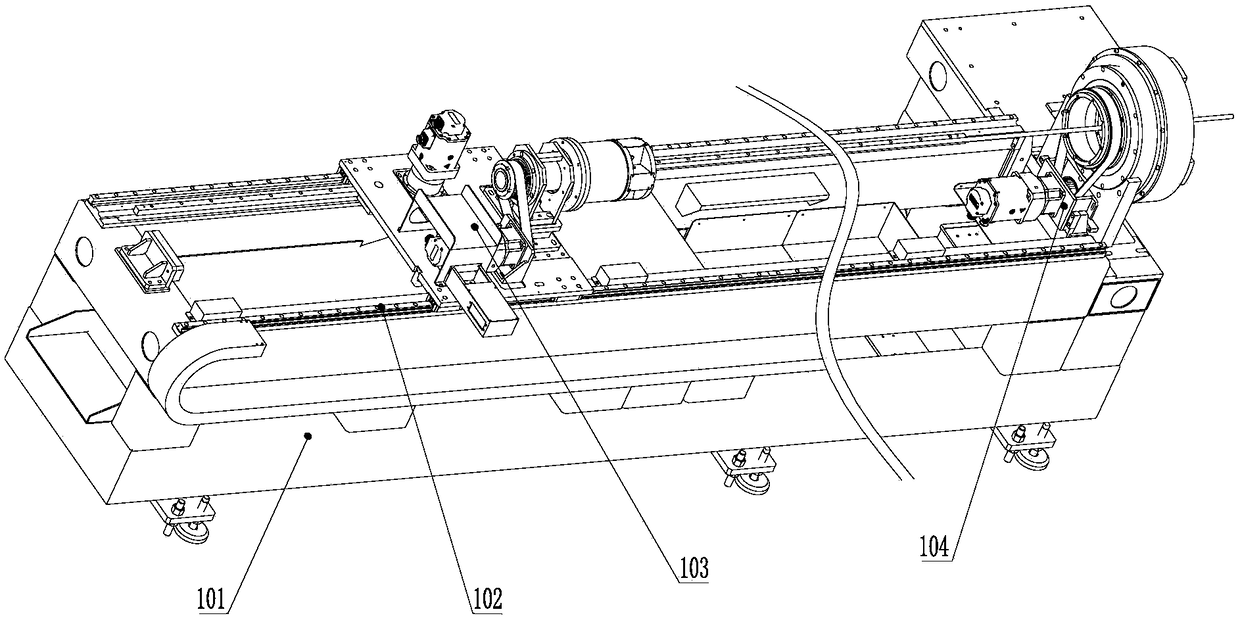

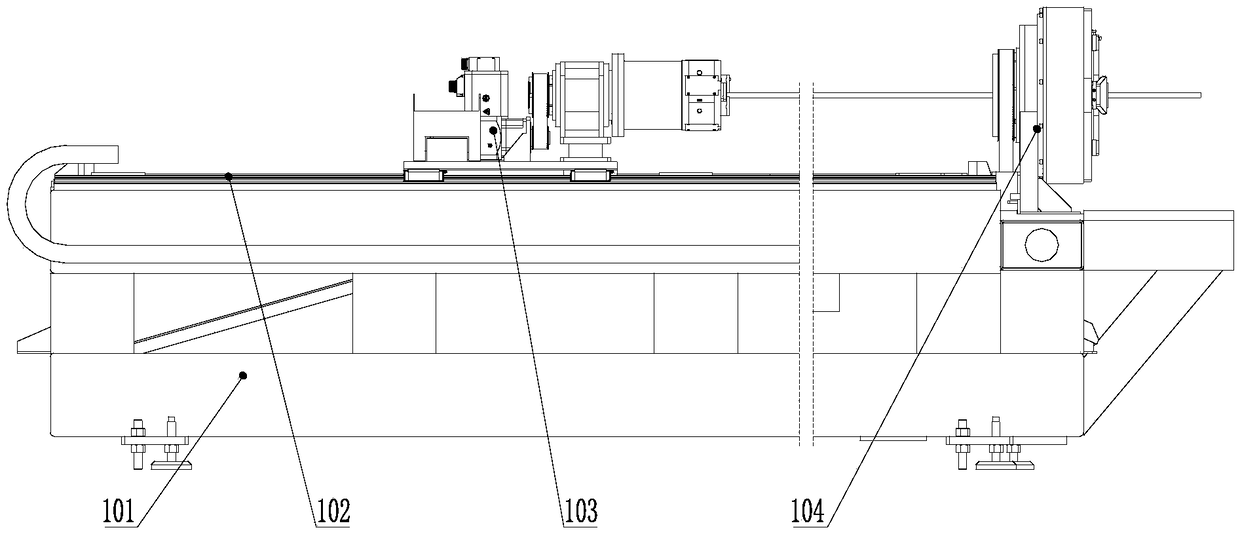

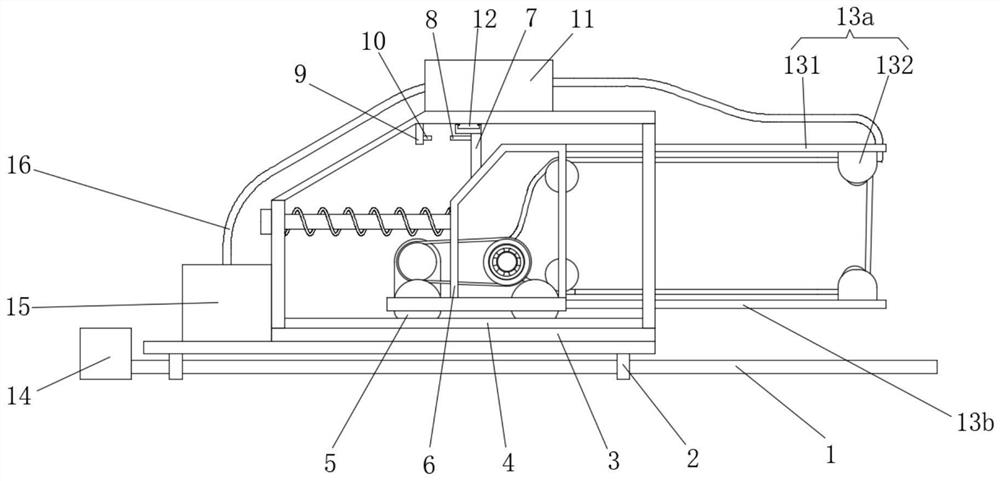

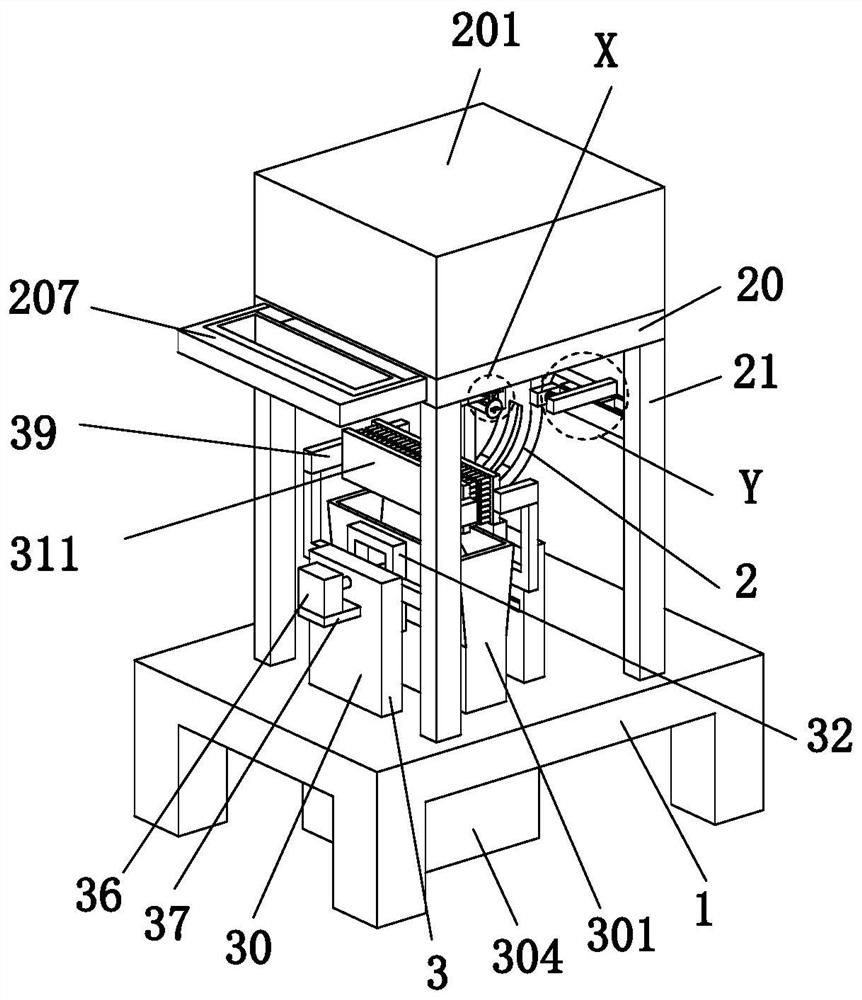

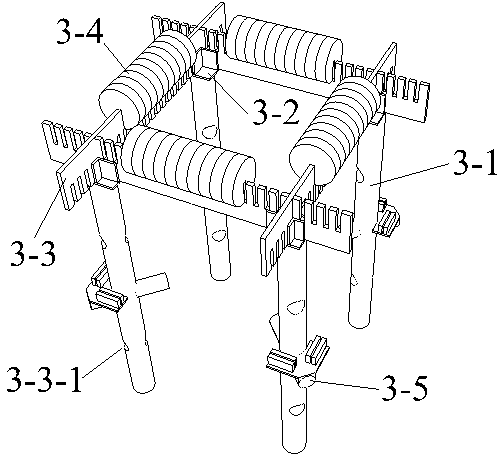

Double-worktable exchanging mechanism of machining center

ActiveCN104723123AMake sure it's locked in placeReliable lockingLarge fixed membersNumerical controlEngineering

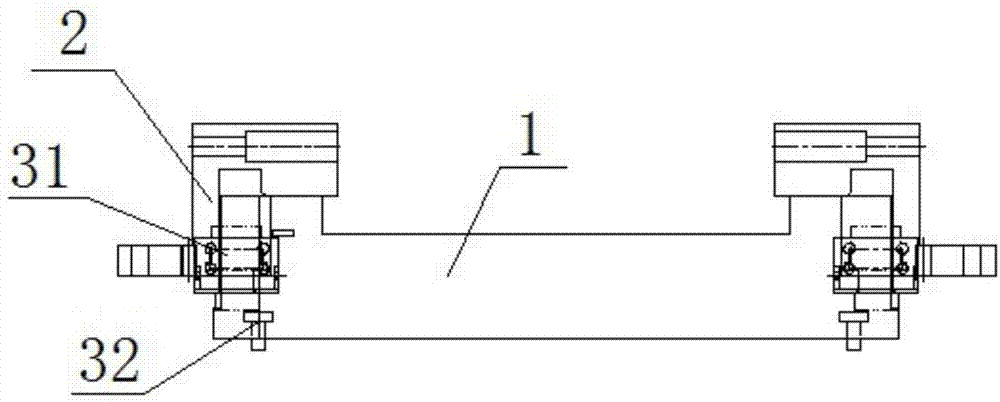

The invention relates to a double-worktable numerical-control machining center, in particular to a double-worktable exchanging mechanism of a machining center. The double-worktable exchanging mechanism of the machining center comprises a liftable base and two worktable support devices. The two worktable support devices are positioned on the upper side of the base; wireless positioning devices are further arranged on the exchanging mechanism and comprise wireless positioning switches and positioning screws, each wireless positioning switch is fixedly mounted on a side of the corresponding worktable support device, and the positioning screws are arranged on the base and are correspondingly positioned below the wireless positioning switches. The double-worktable exchanging mechanism has the advantages that shortcomings and worry due to mechanical positioning in the prior art can be overcome by wireless positioning mechanisms, the geometric precision of matching between the worktable support devices and the base can be guaranteed after worktables are exchanged, workpieces can be firmly clamped, and accordingly personal casualties or equipment damage due to separation of the two worktable support devices and the base when the two worktable support devices rotate in the air at high speeds can be prevented; the positioning speeds further can be increased, accordingly, the machining efficiency can be greatly improved, and the precision of components can be guaranteed.

Owner:CHANGZHOU TRANSCEND CNC MACHINE TOOL

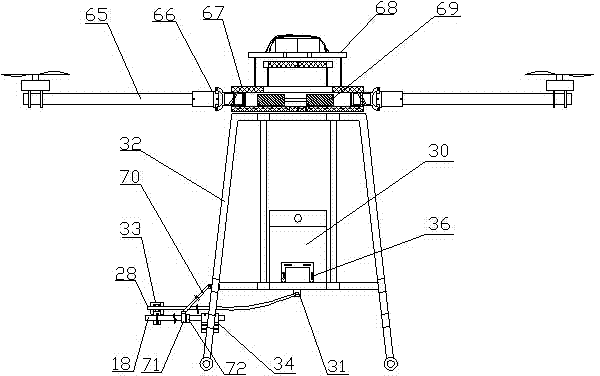

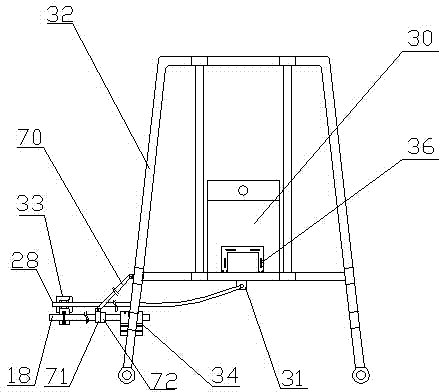

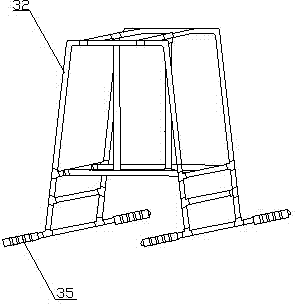

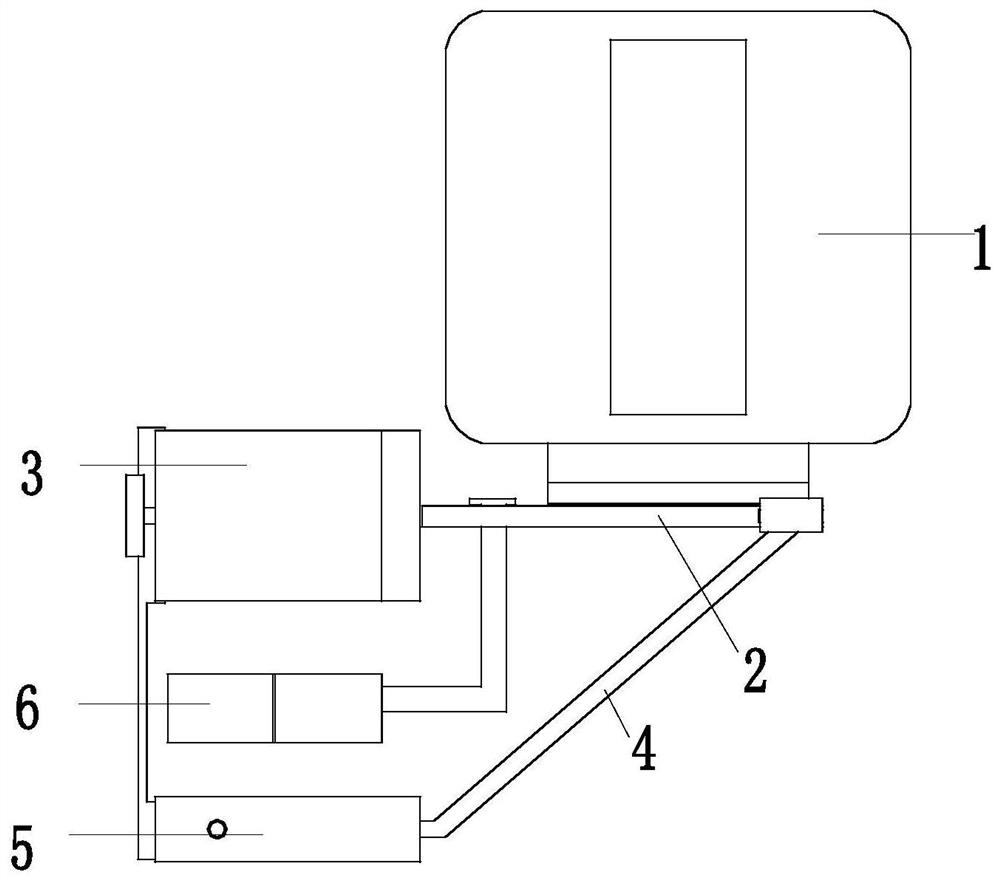

Agricultural multi-rotor aircraft

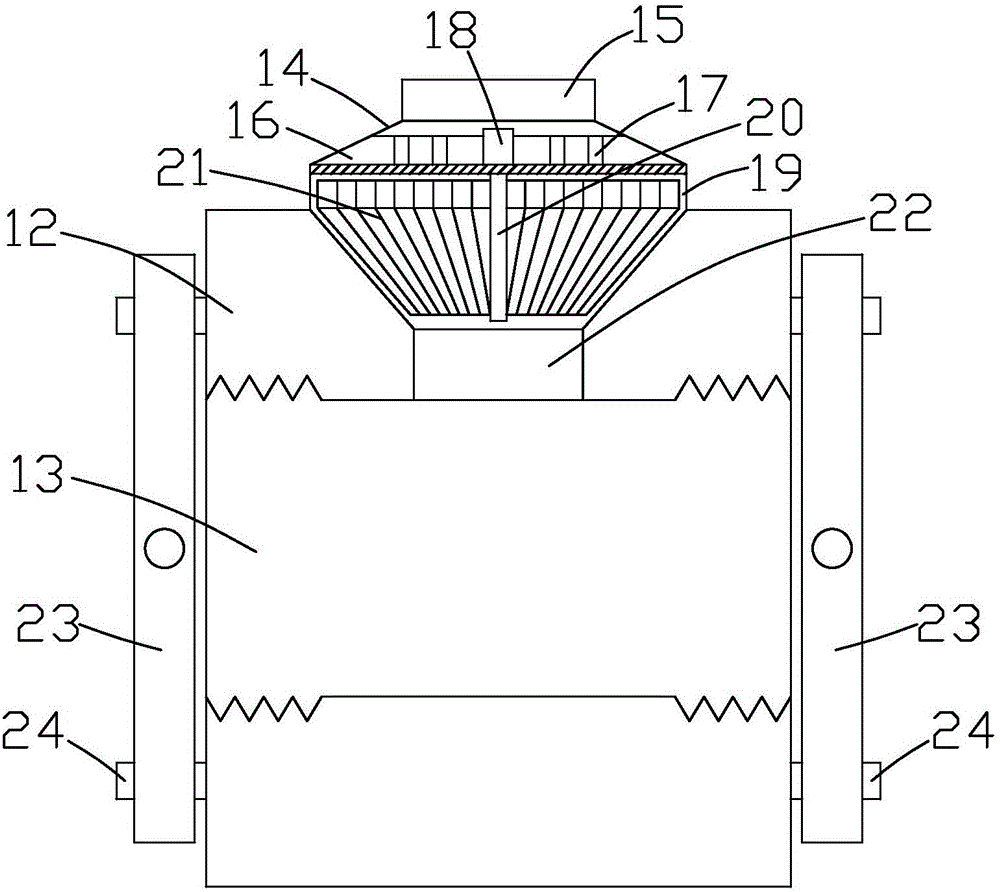

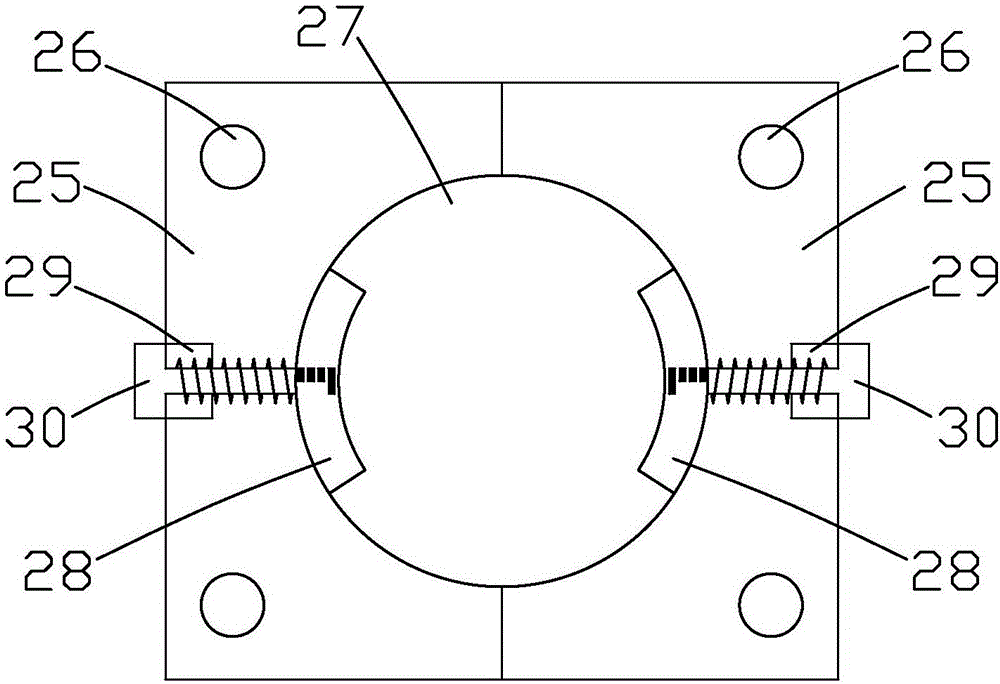

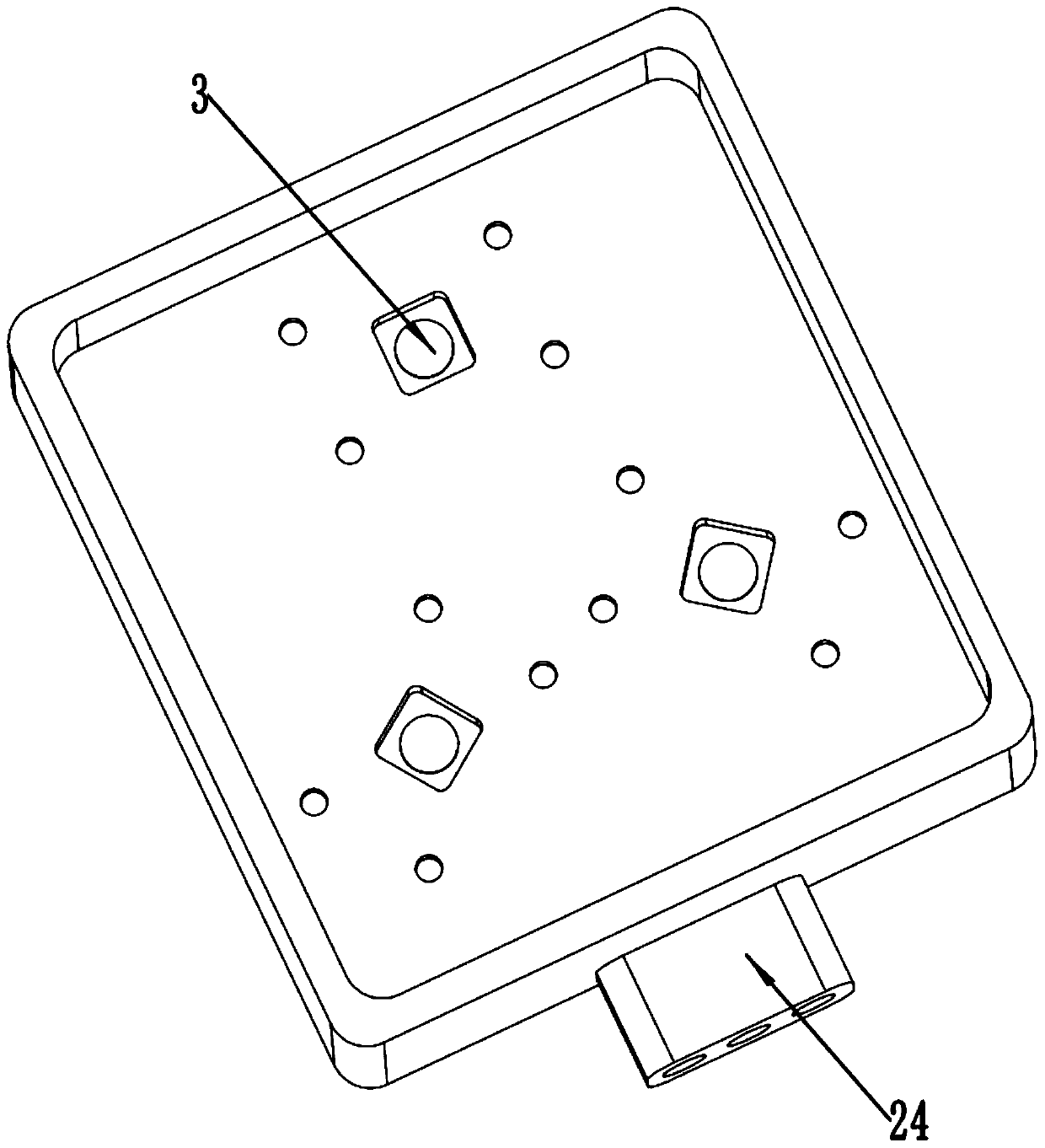

InactiveCN104743120AIncrease the degree of clampingEasy to disassembleAircraft componentsEnergy efficient board measuresFlight vehicleAgricultural engineering

The invention belongs to the technical field of agricultural machines, and particularly discloses an agricultural multi-rotor aircraft. The agricultural multi-rotor aircraft comprises a flight system and an aircraft spray system. The flight system comprises a center plate, a cell panel is arranged on the center plate, the center plate is connected with rotors through rotatable rotor connecting devices fixedly arranged on the side end faces of the center plate, and a control device is arranged in the center plate. The aircraft spray system comprises a support, an aircraft spray structure is arranged in the support and comprises a spray fixing structure and a spray rod, a pesticide box and a pesticide pump are connected to the spray fixing structure, a spray head is fixed to the spray rod, and a pesticide pipe is connected with the pesticide box, the pesticide pump and the spray head in sequence. The agricultural multi-rotor aircraft is simple in structure, convenient to disassemble and good in use effect.

Owner:张伟

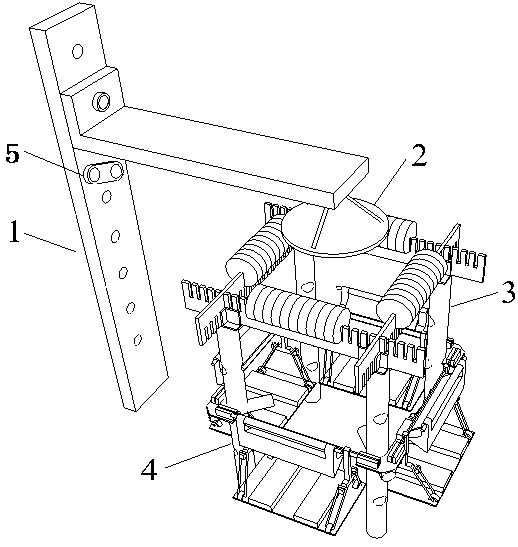

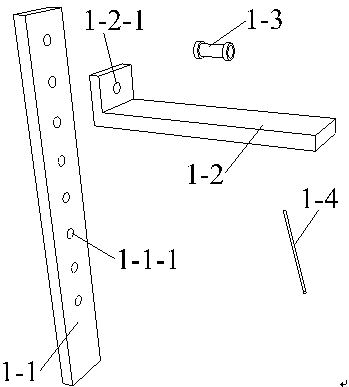

Clutch pedal welding clamp

ActiveCN104476074AIncrease the degree of clampingGuaranteed hole concentricityWelding/cutting auxillary devicesAuxillary welding devicesClutchTreadle

The invention provides a clutch pedal welding clamp which comprises a base. Clamping cylinders are arranged on the base and located on the left side and the right side of the base, a main clamp is arranged in the middle of the base, a fixed plate is arranged on the lower portion of the main clamp, the main clamp is connected onto the fixed plate through a rotating screw, the clutch pedal is clamped through the main clamp and the clamping cylinders on the left side and the right side, the clamping degree of the clutch pedal is improved, and clutch pedals with poor welding performance are avoided.

Owner:WUHU POWER TECH

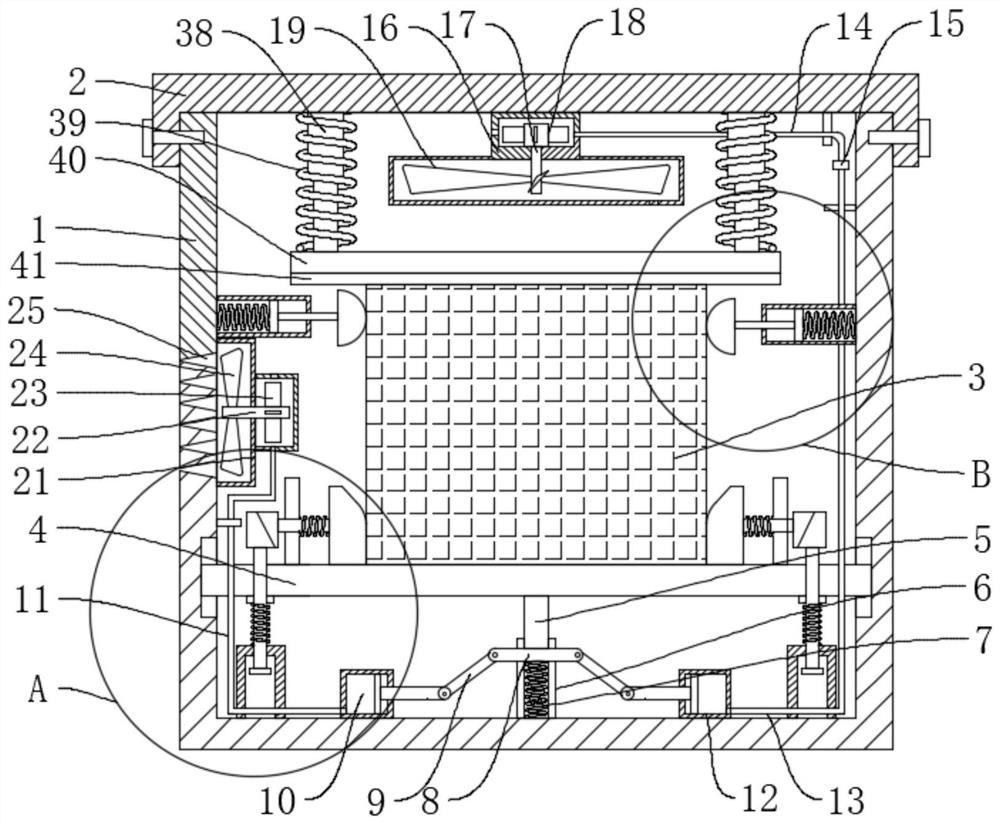

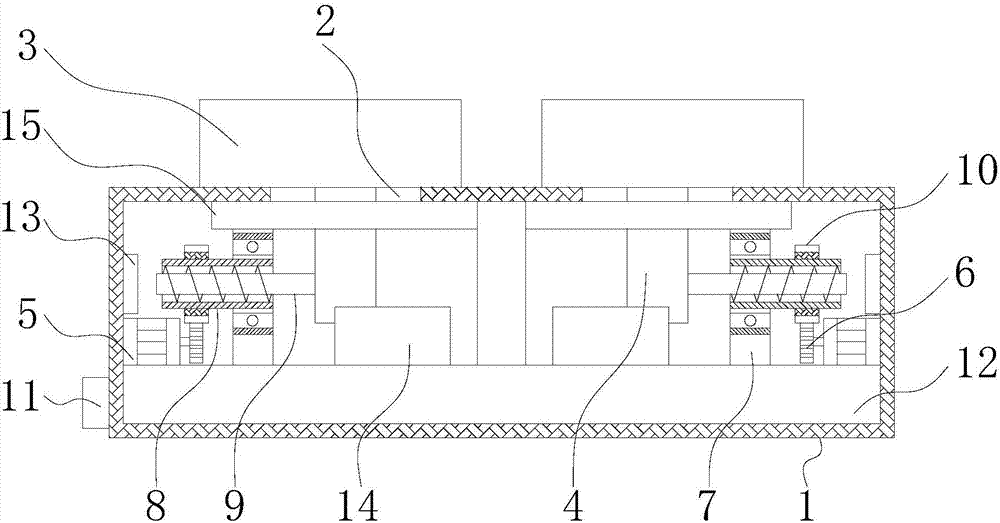

New energy automobile battery box with shock absorption function

InactiveCN112332001AWith shock absorption functionReduce shakingSecondary cellsCell component detailsNew energyEngineering

The invention discloses a new energy automobile battery box with a damping function, and belongs to the field of new energy automobiles. A new energy automobile battery box with a damping function comprises a box body, a box cover and a storage battery, a supporting plate is slidably connected into the box body, the storage battery is placed on the supporting plate, a first sliding rod is fixedlyconnected to the supporting plate, and a sliding sleeve, a first air cylinder and a second air cylinder are fixedly connected to the box body. The sliding block is rotationally connected with a firstair cylinder and a second air cylinder, a first convex frame is fixedly connected to the box cover, and a cooling fan is rotationally connected into the first convex frame. The battery box is easy touse and good in damping effect, wherein the damping effect of the storage battery is improved, and protection on the storage battery is improved; therefore, the storage battery is prevented from beingdamaged, meanwhile, the cooling fan is driven to cool the storage battery while damping is conducted, heat is discharged through the exhaust fan, cooling of the battery is facilitated, and thereforethe service life of the battery is prolonged.

Owner:王华玉

Bending processing technology of metal plate

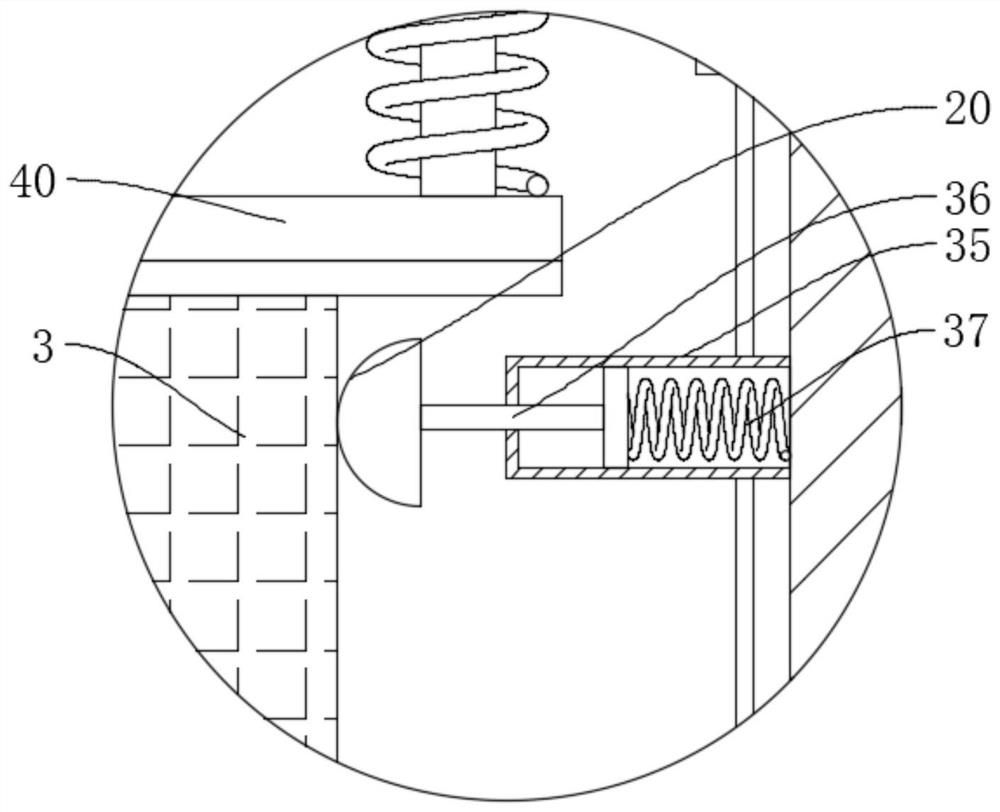

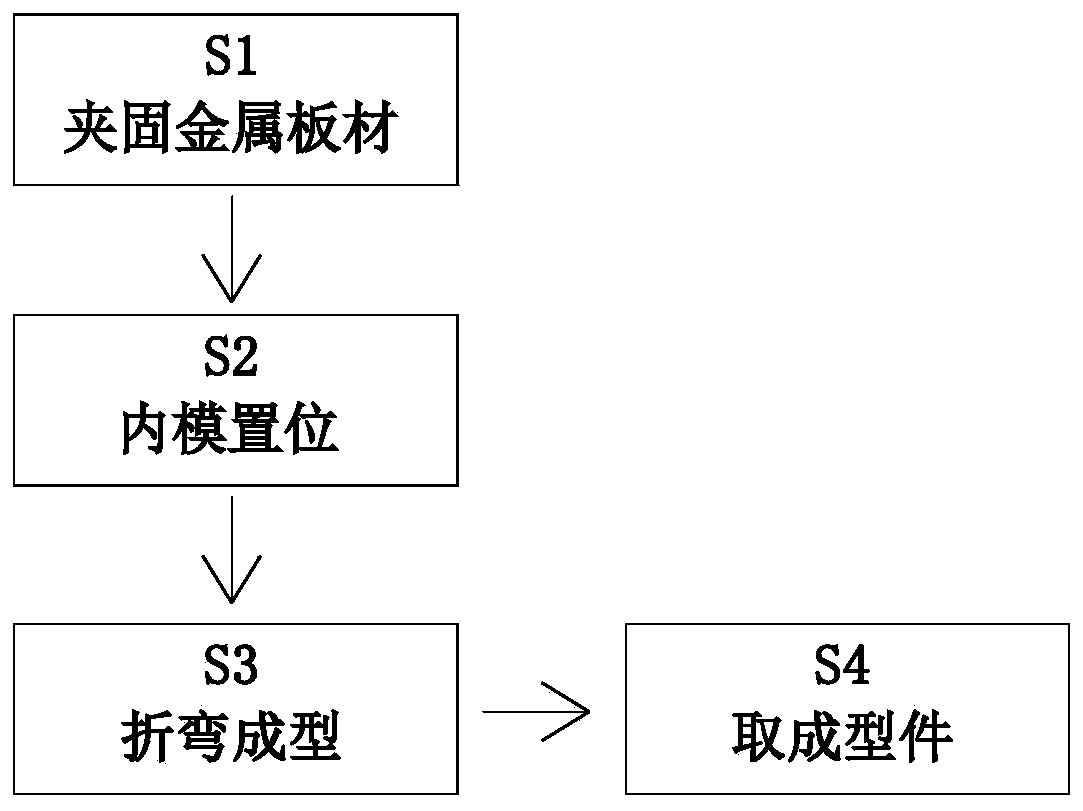

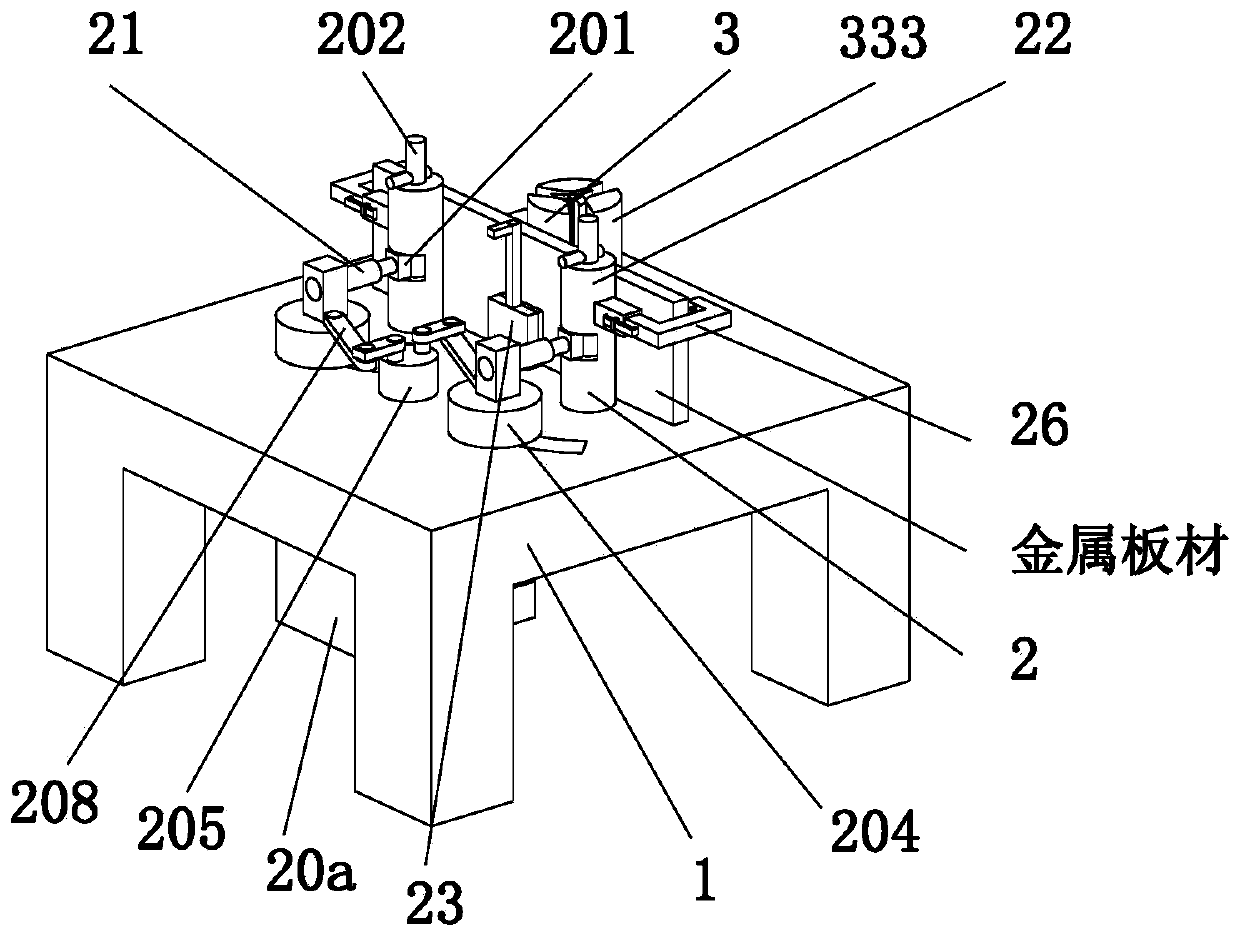

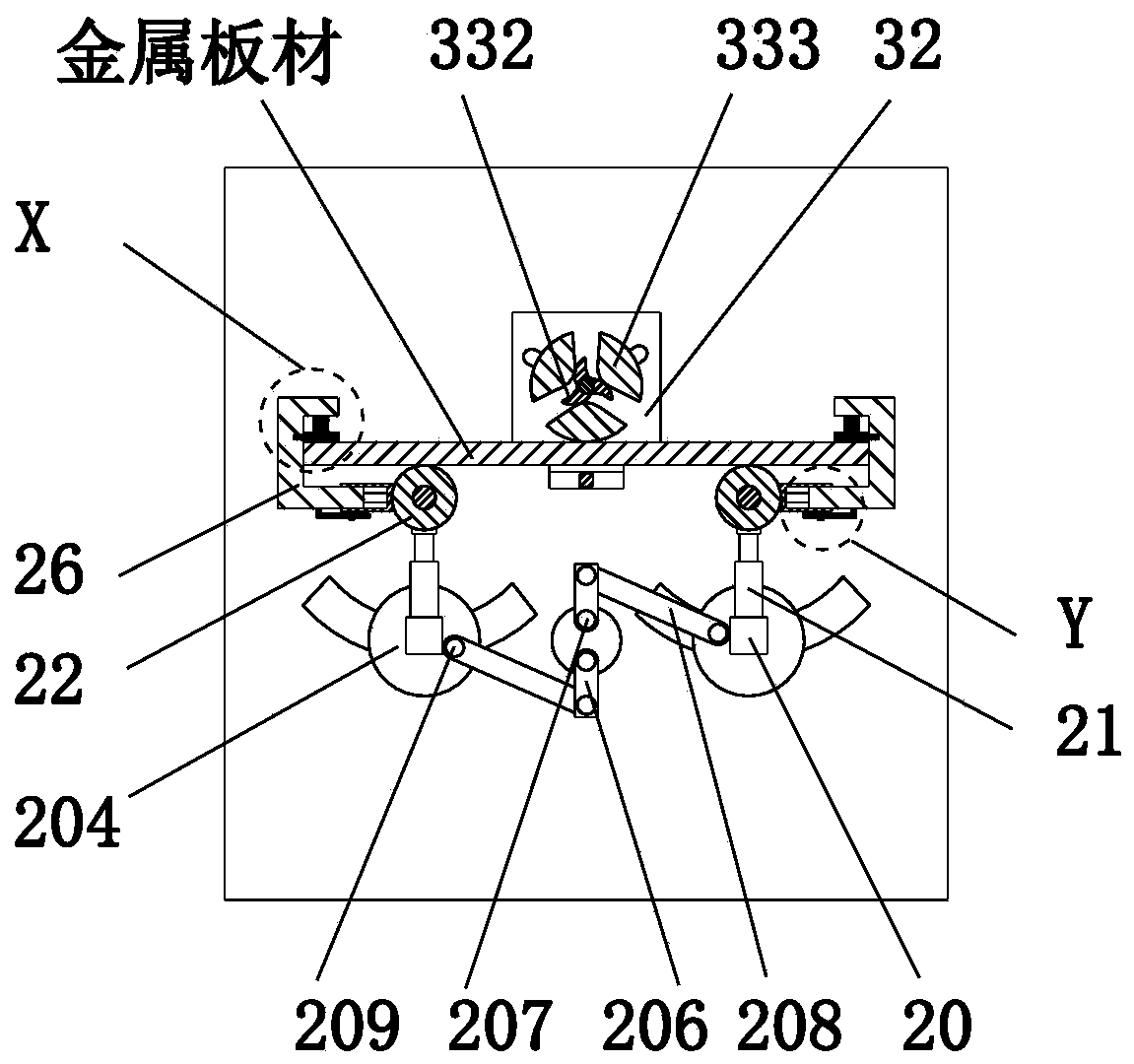

ActiveCN111530983AImprove bending qualityImprove bending accuracyShaping toolsMetal-working feeding devicesBilateral symmetryMachining process

The invention relates to a bending processing technology of a metal plate. The bending processing technology of the metal plate adopts a bending processing device of the metal plate, and comprises a working table, a clamp bending mechanism and an internal bending unit, wherein the clamp bending mechanism is arranged at the front end of the upper end of the working table in a bilateral symmetry manner, the internal bending unit is mounted at the rear end of the upper end of the working table in a sliding fit manner, and the internal bending unit is located on the rear middle side of the clamp bending mechanism. According to the technology, bending processing of the metal plate is performed by adopting design concept of a multi-aspect adjustable structure, on the basis of capacity of bendingin a longitudinal direction, the overall device is additionally provided with a structure with the effect of controlling a bending angle and width of a formed part, then the applicable range of the overall device is greatly expanded, and meanwhile, the bending quality and accuracy of the metal plate are improved with adoption of multiple structures with limiting and guiding effects.

Owner:华港电气有限公司

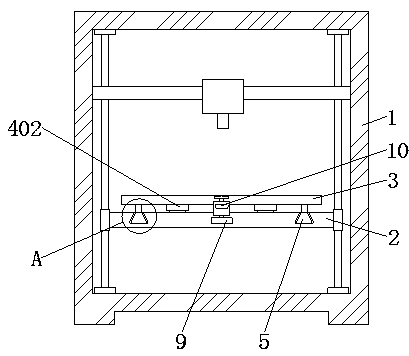

Wafer wet method etching system

ActiveCN108682639ARealize batch etchingImprove utilization efficiencySemiconductor/solid-state device manufacturingConveyor partsComputer moduleEngineering

The invention belongs to the technical field of wet method etching and specifically relates to a wafer wet method etching system comprising a mobile module, a grabbing module, a number one reaction tank, a number two reaction tank, a number three reaction tank and a material storage cylinder; the number one reaction tank, the number two reaction tank and the number three reaction tank are fixedlymounted on a bottom surface of an inner wall of the reaction bin; the mobile module is fixedly mounted on a top part of a side surface of the inner wall of the reaction bin, the grabbing module is mounted on the mobile module, the material storage cylinder is used for storing wafers, the grabbing module is used for grabbing the material storage cylinder, and the material storage cylinder is transmitted into the reaction bin from a material inlet door; wafers in the material storage cylinder are orderly placed into the number three reaction tank, the number two reaction tank and the number onereaction tank to be etched via cooperation with the grabbing module; finally the wafers in the material storage cylinder are taken out via the material outlet door; the wafer wet method etching systemis mainly used for etching the wafers and capable of improving usage efficiency of an etching liquid, the wafers can be etched in batch, and etching efficiency is improved.

Owner:NANTONG MINICHIP MICRO ELECTRONICS

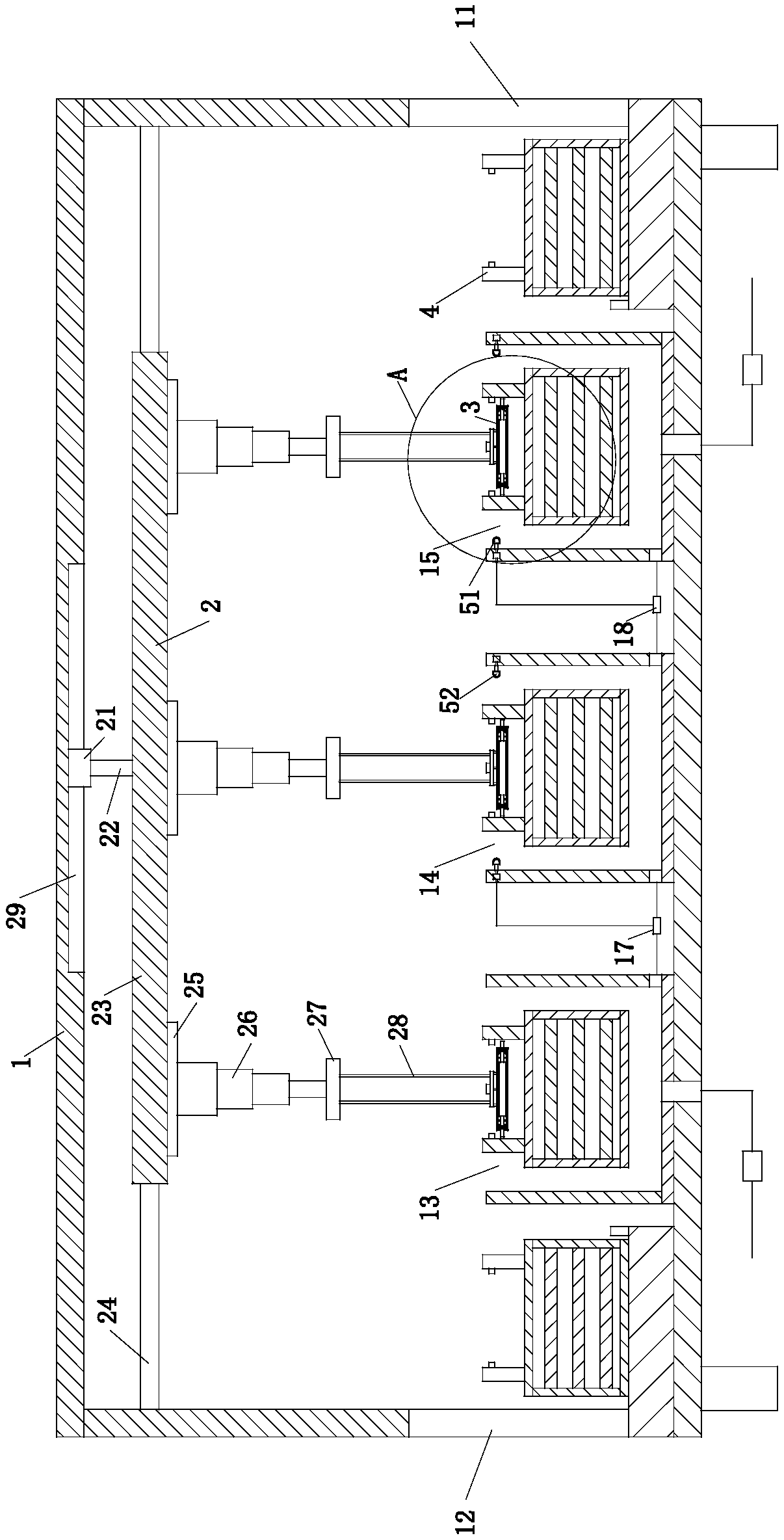

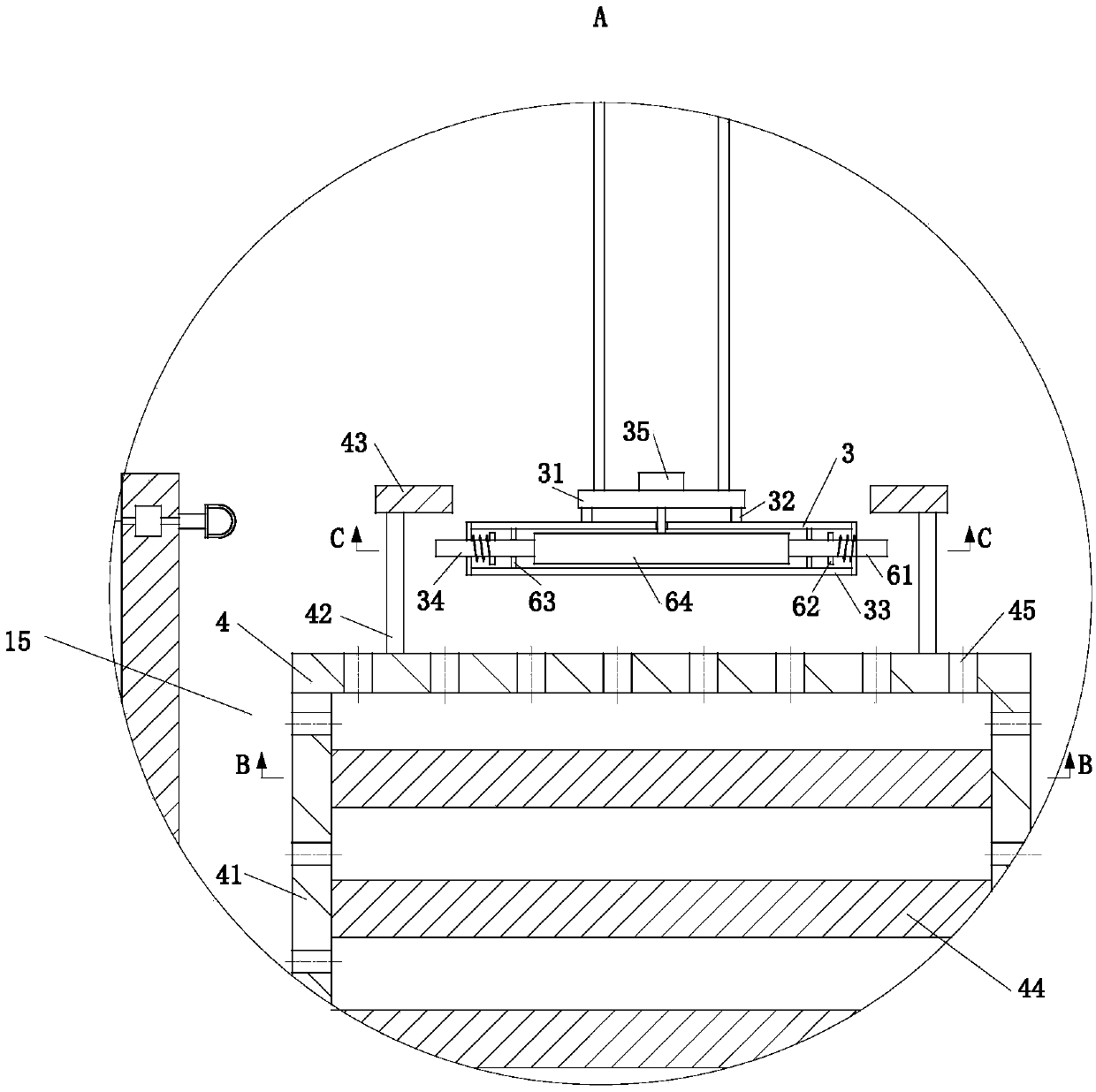

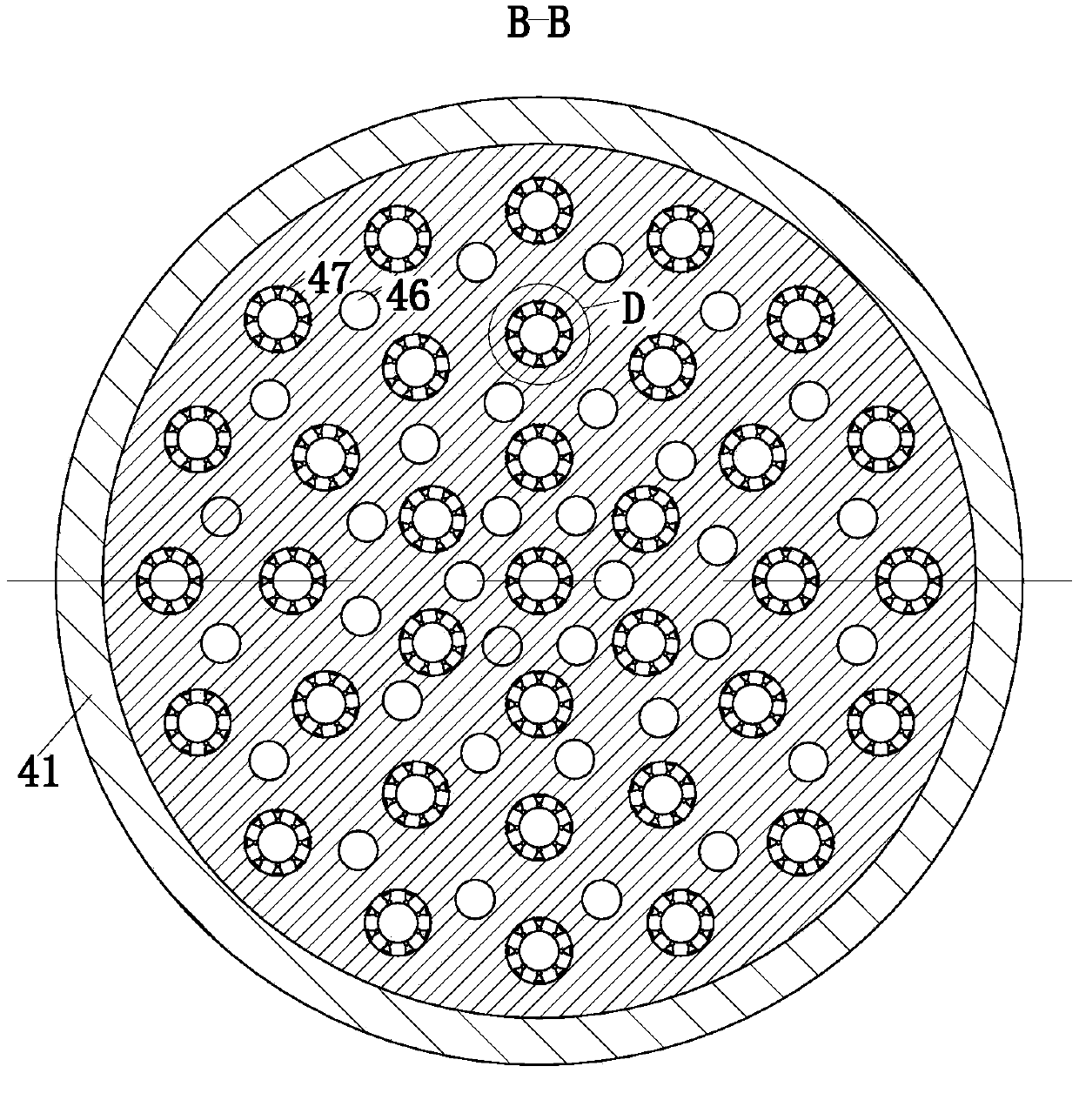

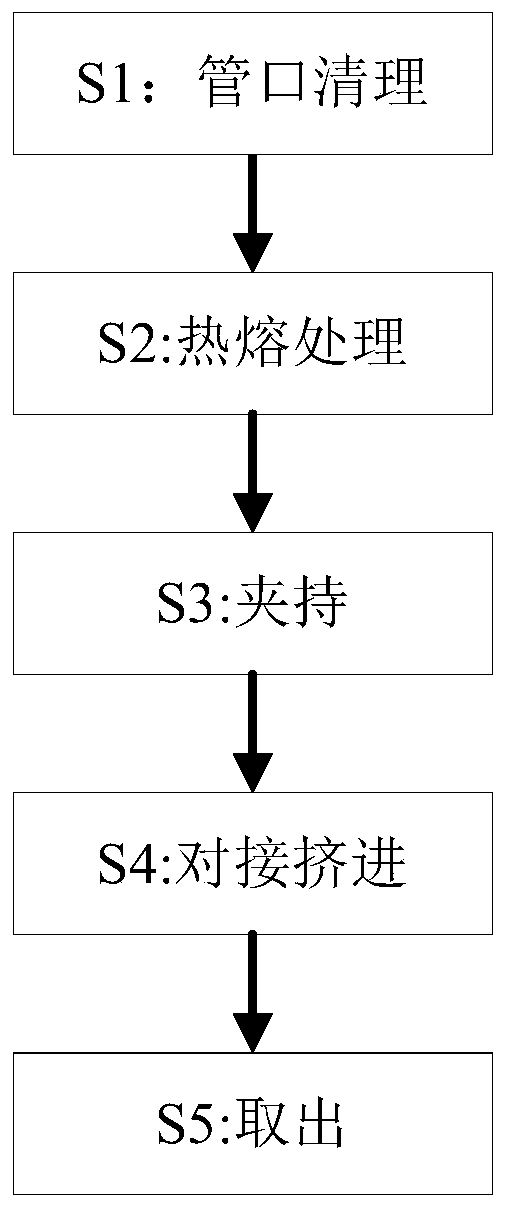

PPR pipe butt-joint hot melting connection process

InactiveCN111037928AReduces the possibility of crackingImprove stabilityTubular articlesWater leakageButt joint

The invention provides a PPR pipe butt-joint hot melting connection process which is carried out by cooperation of a bottom frame, a driving device, two embedded frames, two extrusion units and a measuring device. By means of the PPR pipe butt-joint hot melting connection process, the problems that a manual butt joint mode is usually adopted, due to the fact that pipe openings are in transition fit during butt joint and the force of a person is small, smooth butt joint is difficult, in order to reduce the difficulty of butt joint, the person can hardly avoid rotary butt joint during butt joint, while rotary butt joint usually leads to the reduction of the tightness of a butt joint, consequently, the conditions of water leakage, air leakage and the like are caused, besides, when the butt joint is carried out, the insertion depth of the pipe openings cannot be seen, and when the depth is too shallow, the butt joint openings of two PPR pipes after the butt joint can be cracked in use.

Owner:台州蓝锐机电科技有限公司

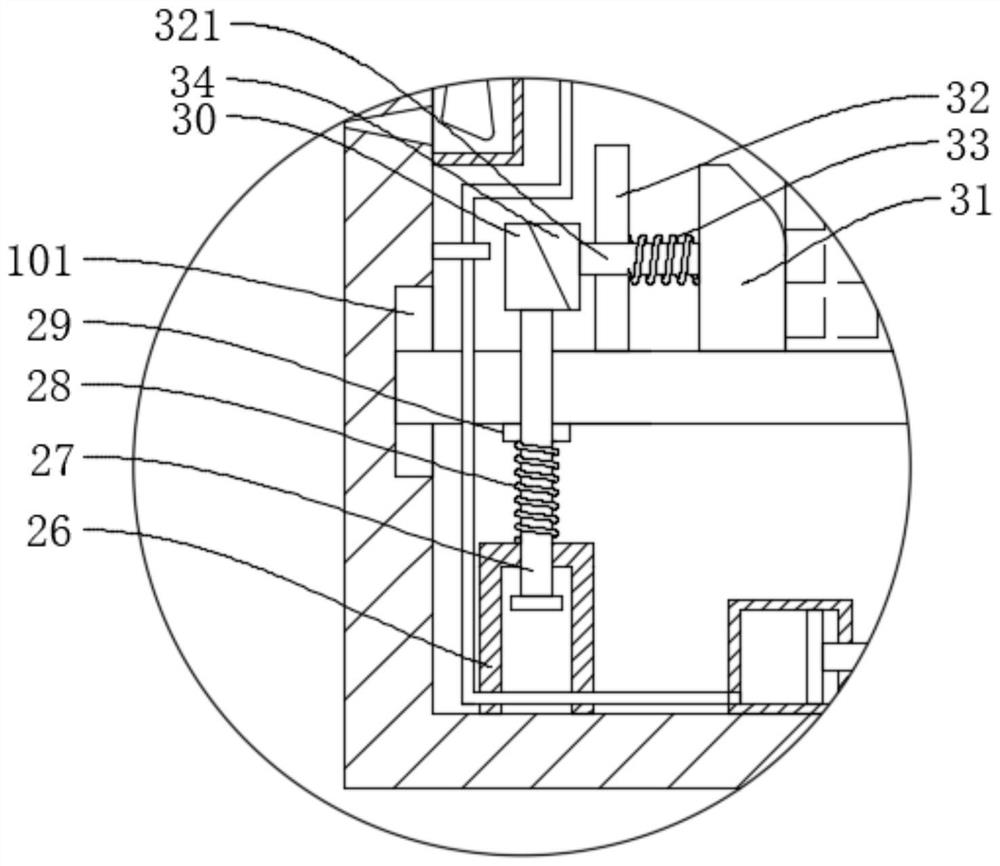

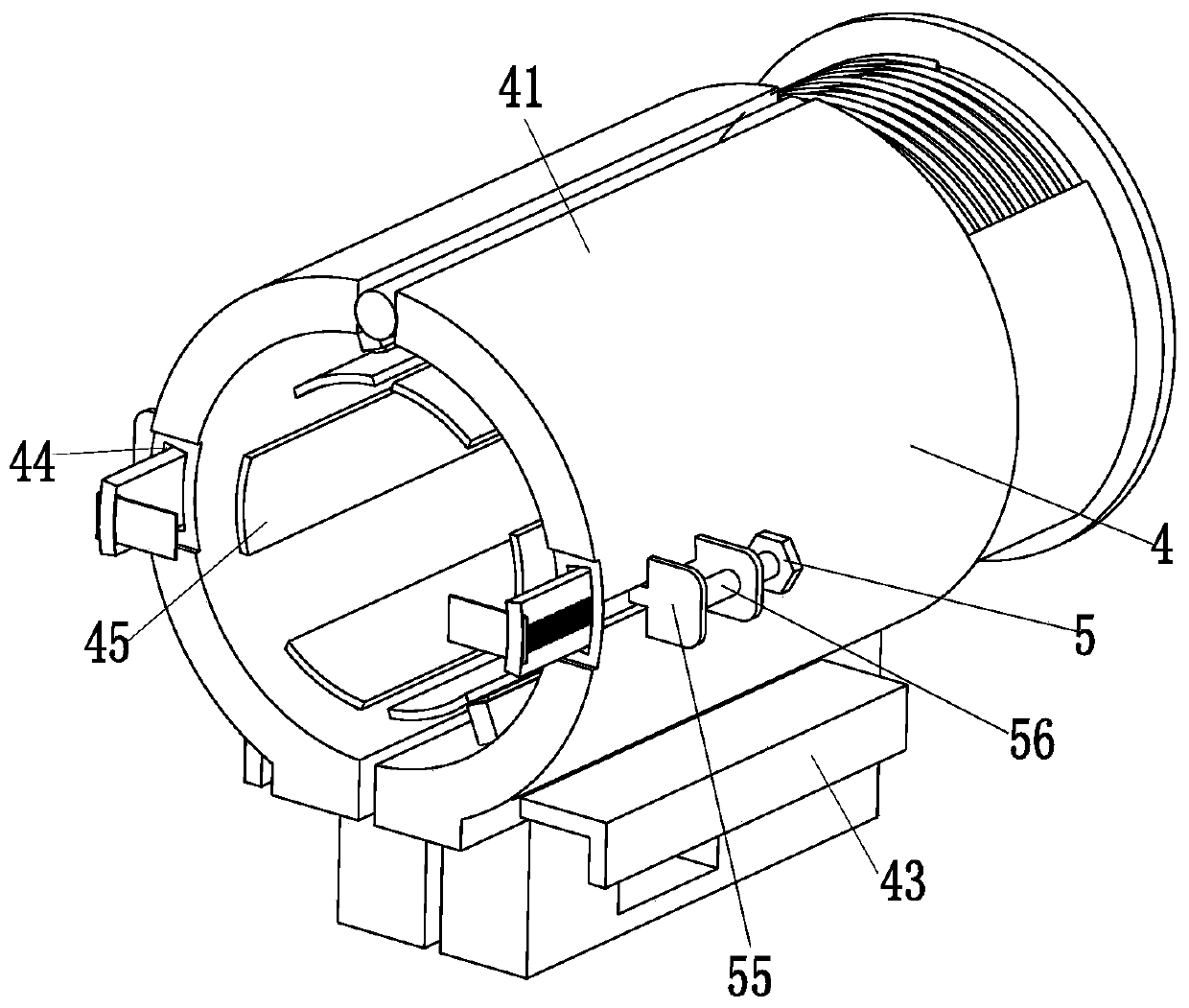

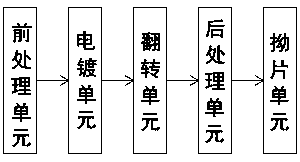

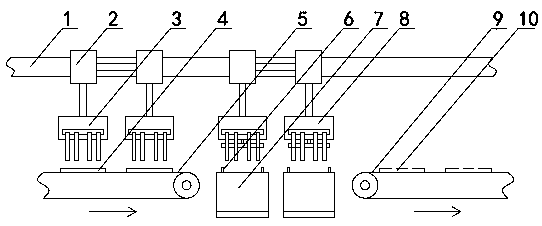

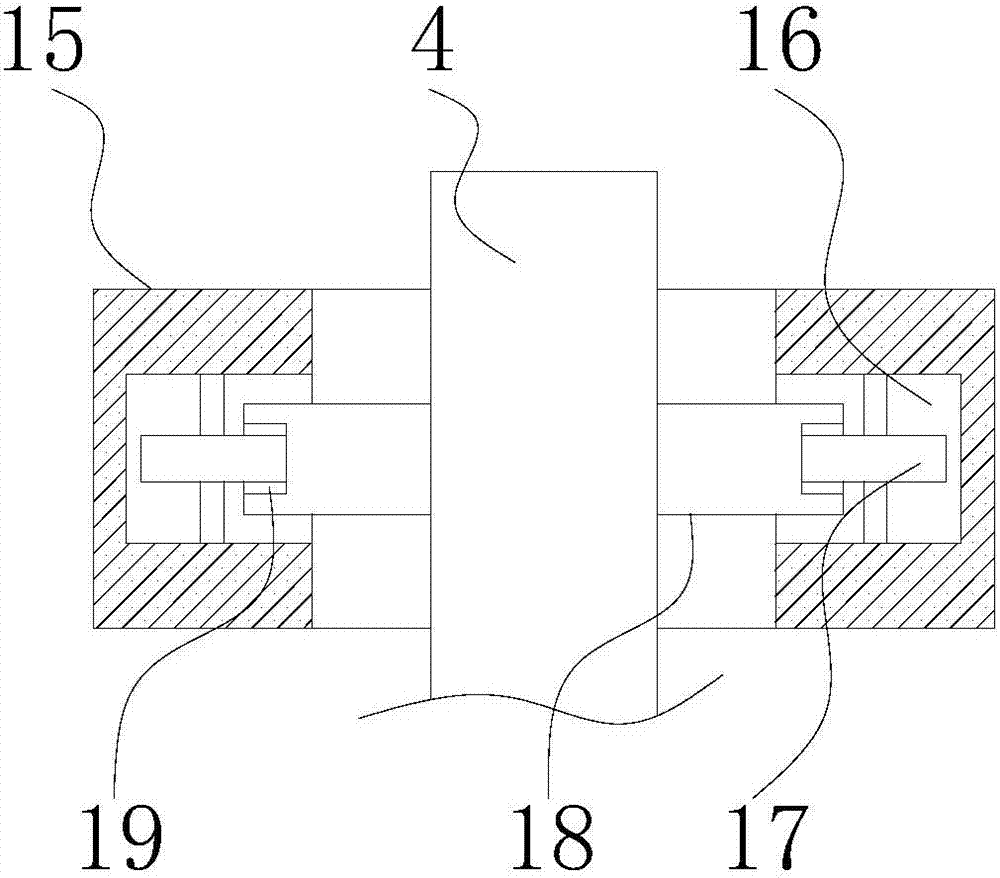

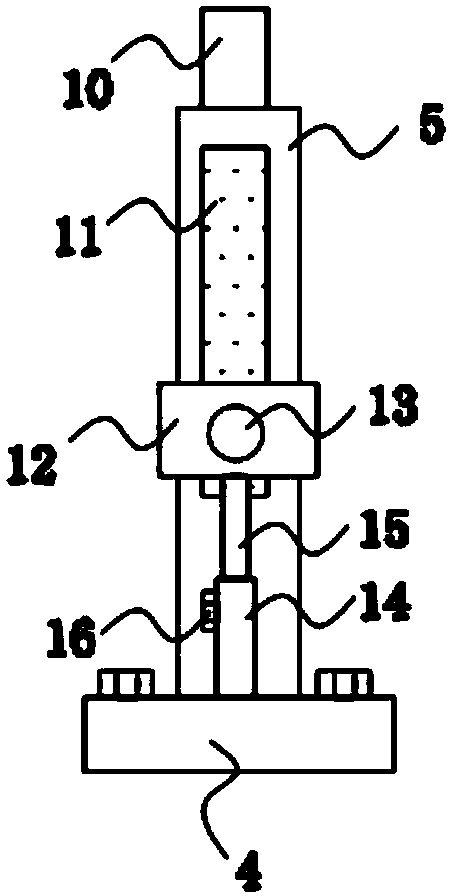

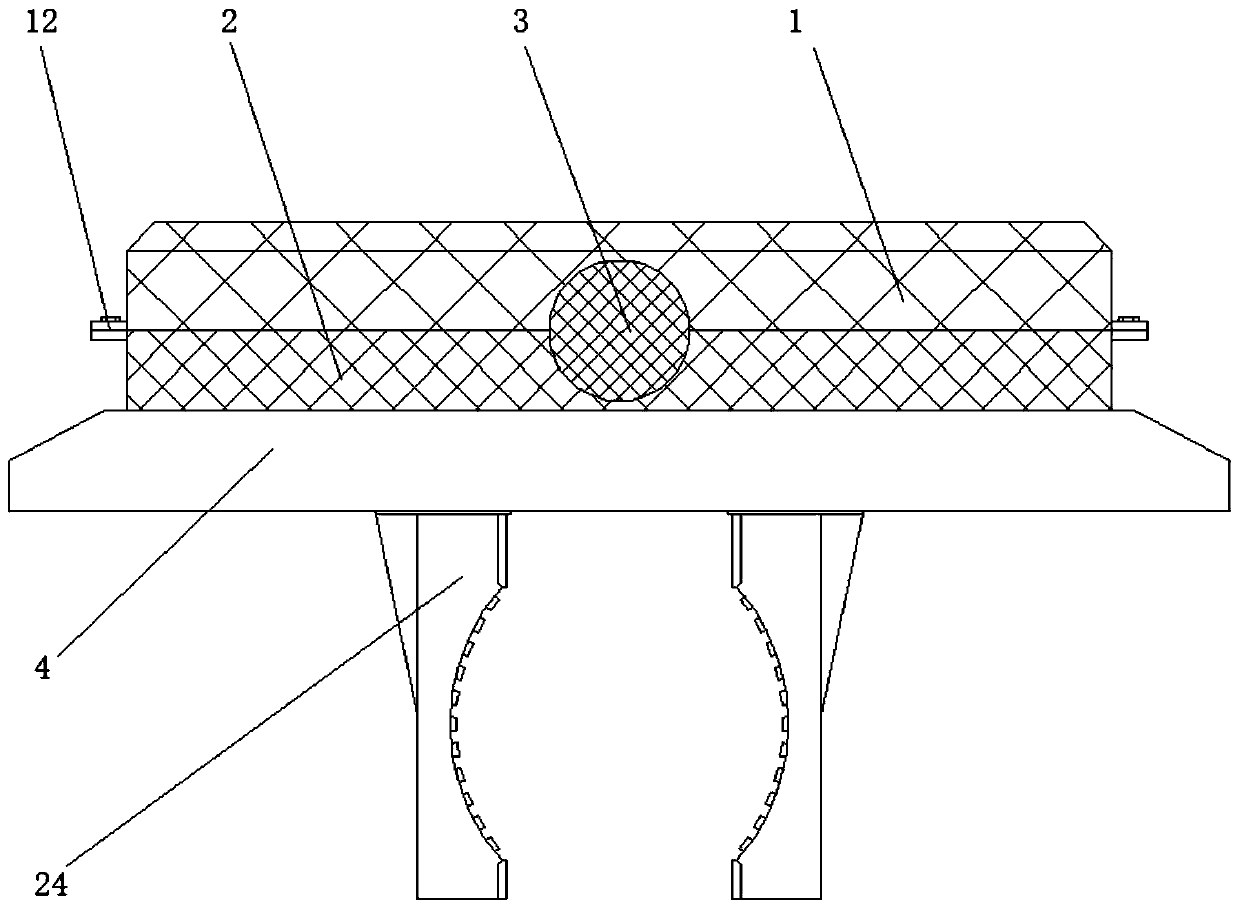

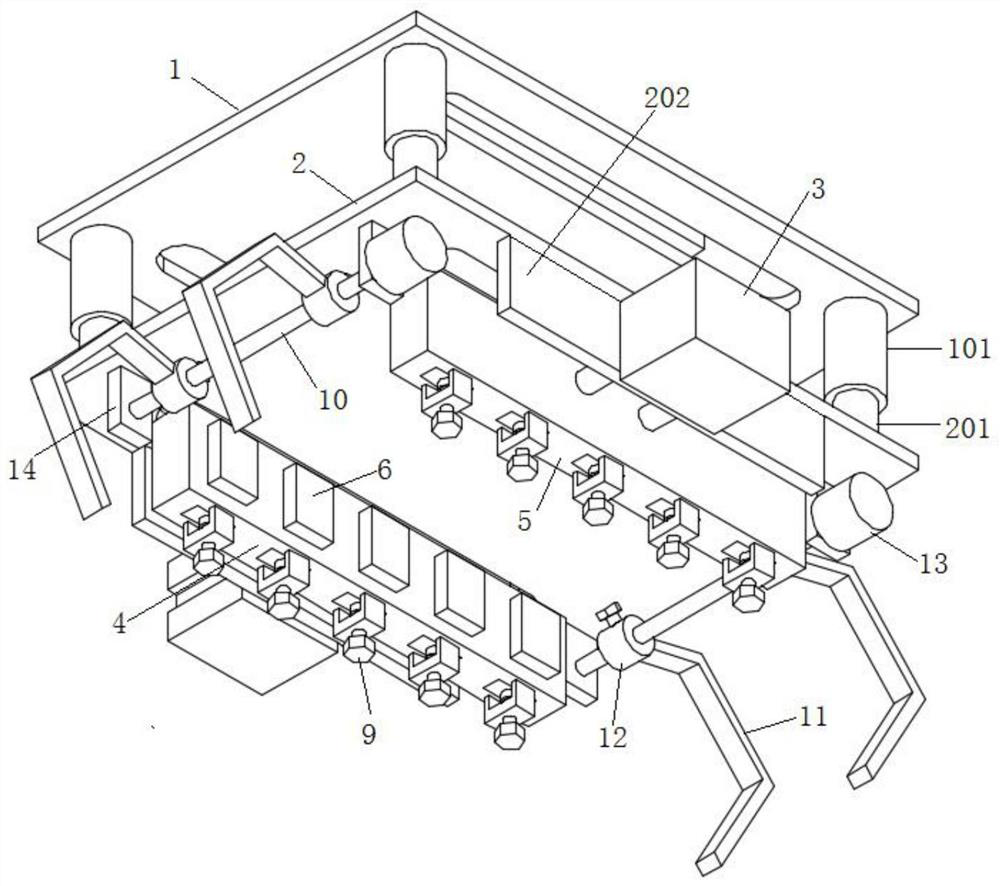

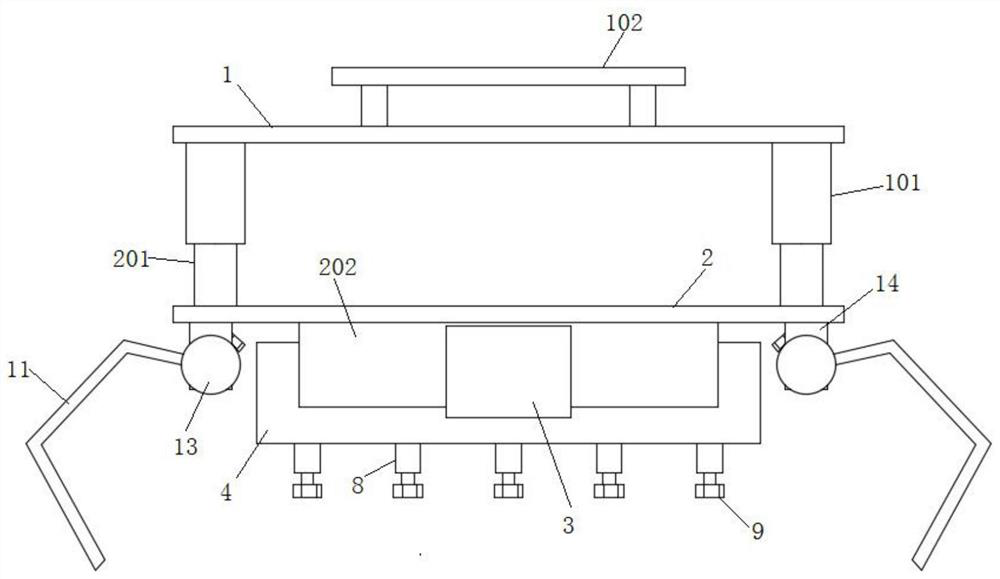

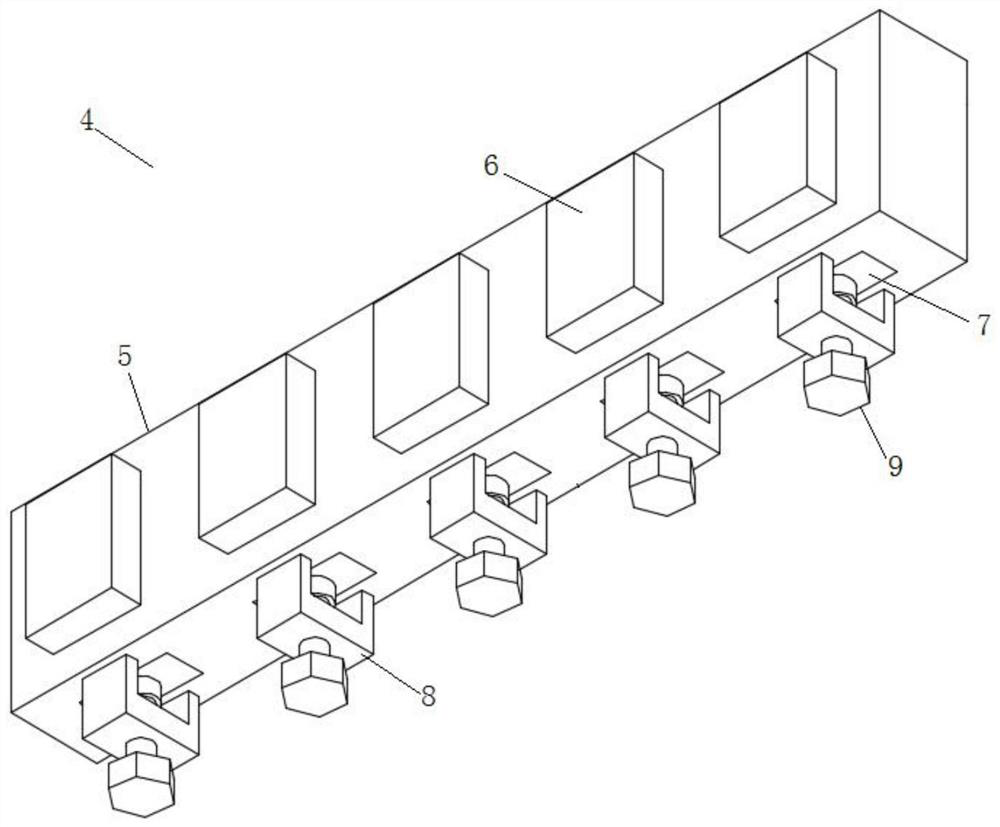

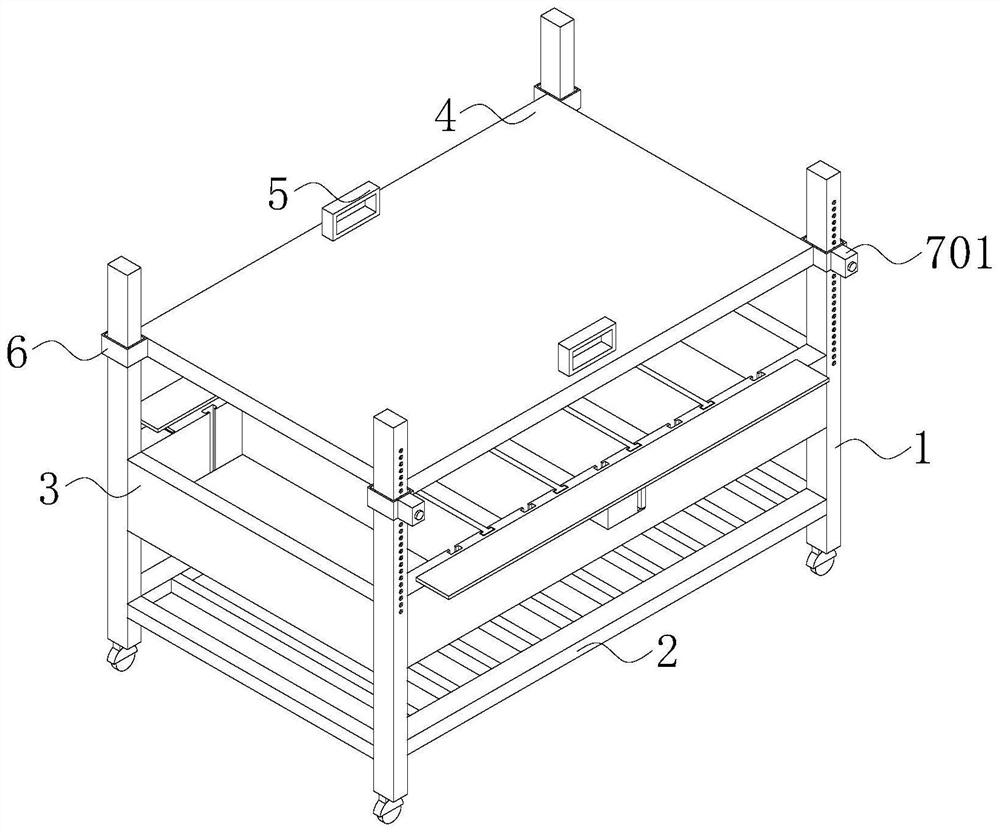

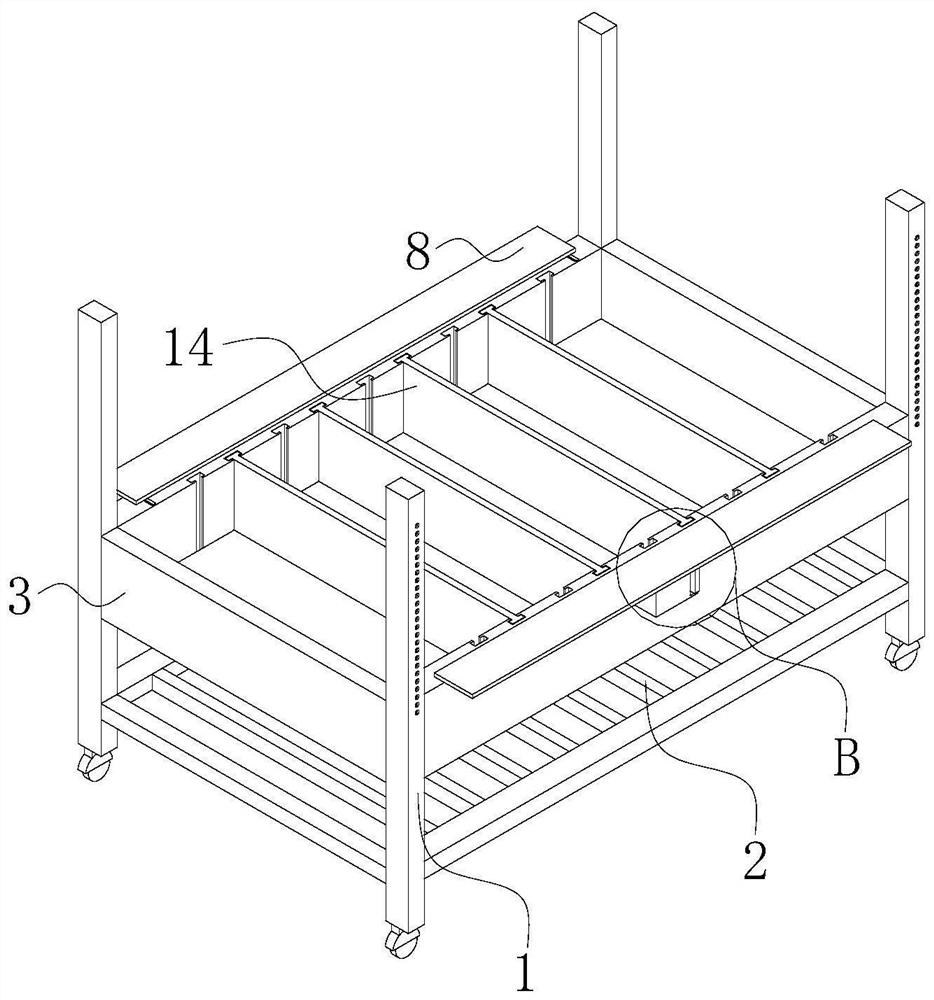

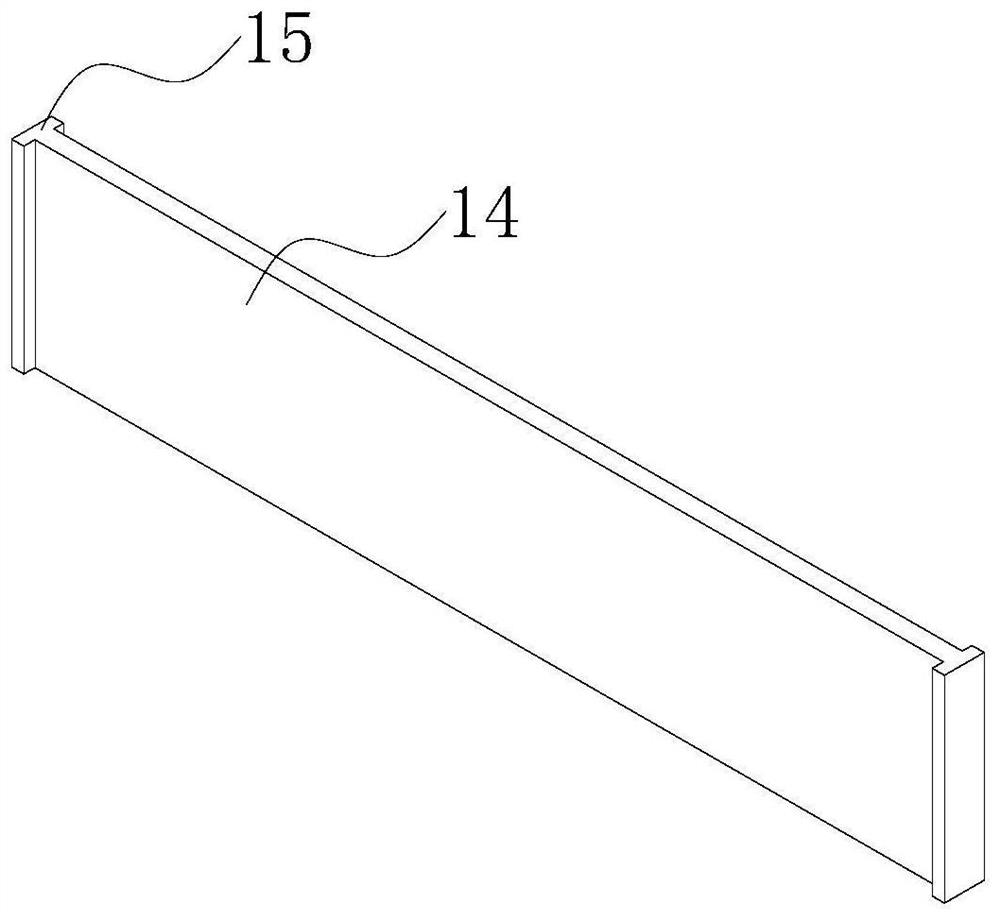

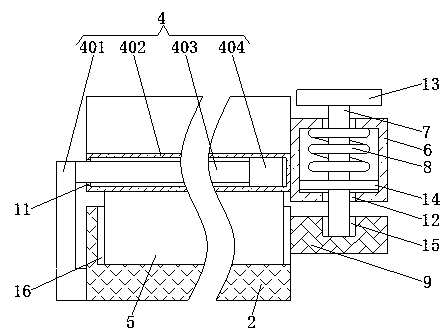

Lead framework production system

ActiveCN110190000AFacilitate the automation processAvoid wear and tearSemiconductor/solid-state device manufacturingTransfer procedureEngineering

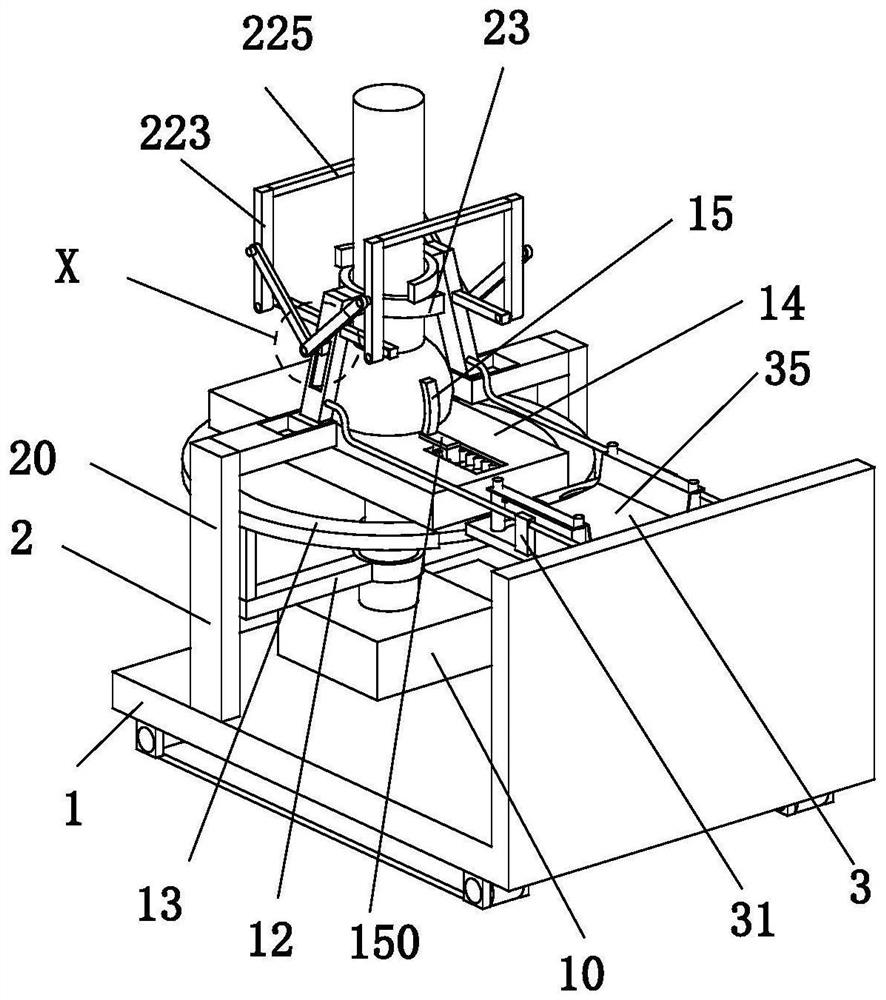

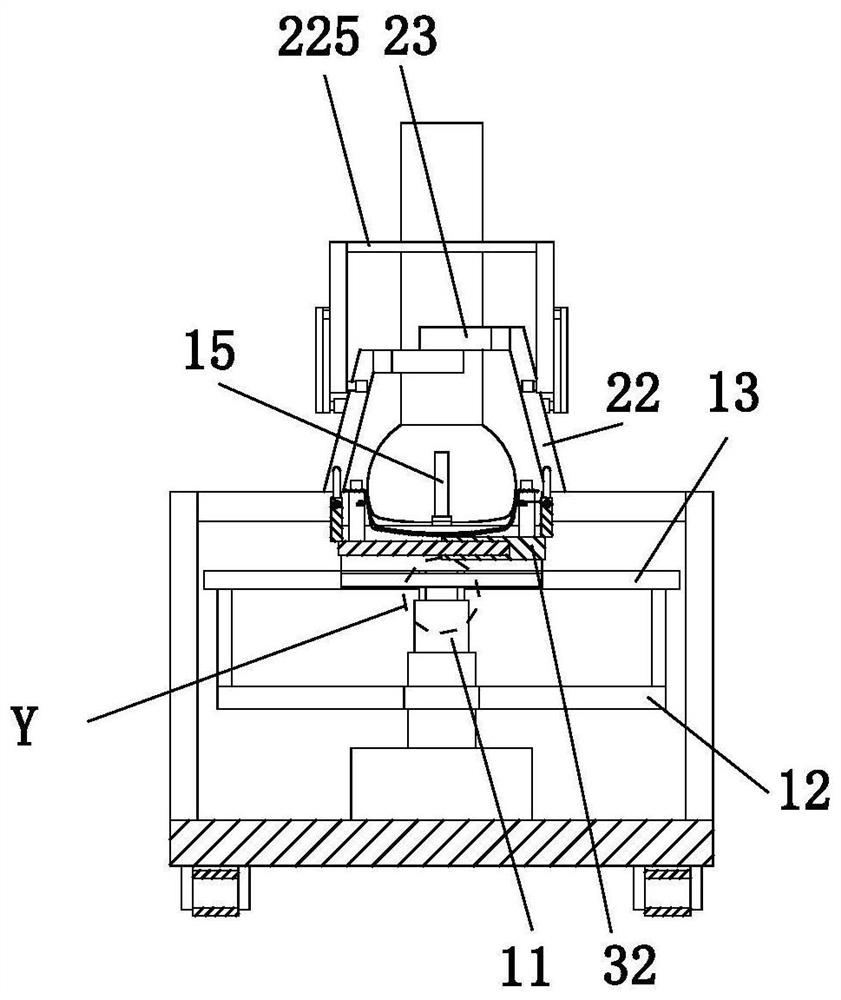

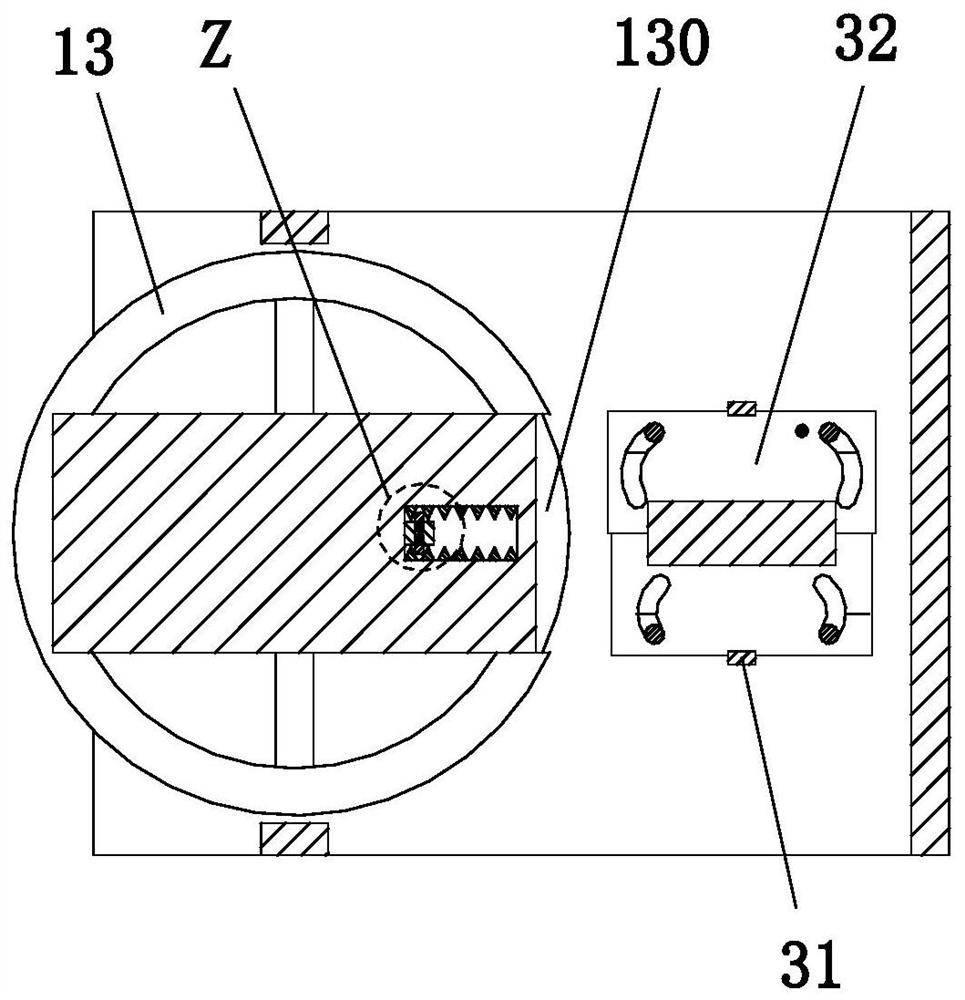

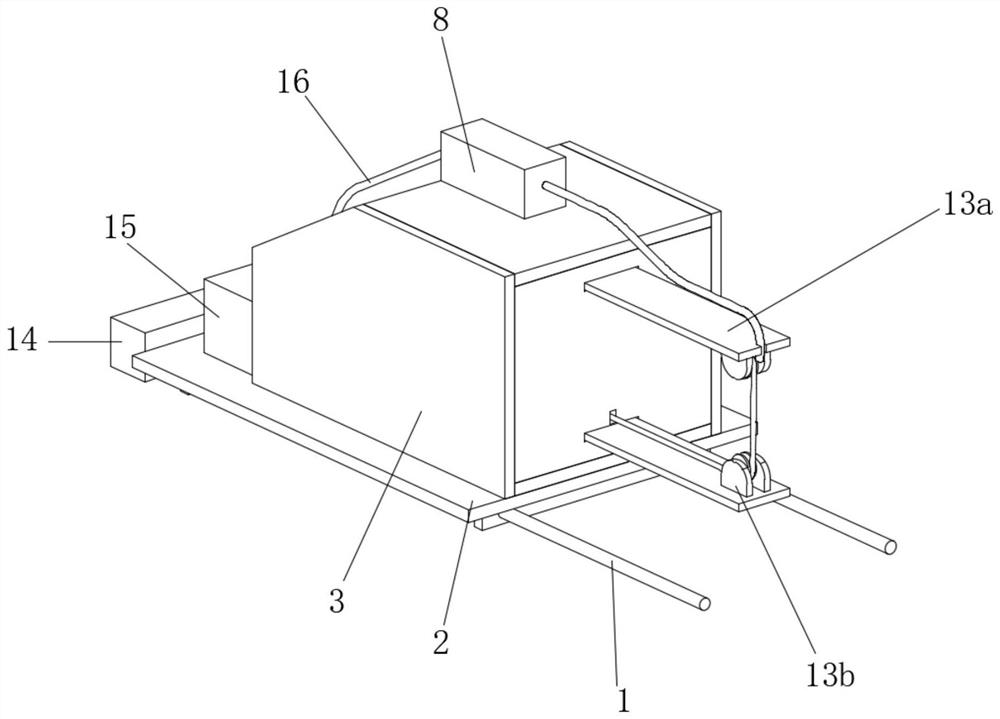

The invention relates to a lead framework production system and belongs to the technical field of semiconductor production. The lead framework production system includes an electroplating unit, an overturning unit and a bending unit that are sequentially disposed. After a to-be-electroplated framework (4) is electroplated in the electroplating unit, a framework semi-finished product (10) is obtained and then enters the overturning unit, after the framework semi-finished product (10) is overturned by an overturning bin (13), front and back sides are reversed with each other, the framework semi-finished product (10) is placed on a surface of an overturning output conveyor (15) and conveyed by the overturning output conveyor (15) to a bending input conveyor(23) of the bending unit, separationof a framework single unit (35) and a framework frame (37) in the framework semi-finished product (10) is carried out in the bending unit, and the framework single unit (35) is transferred to a finished product zone (28). The lead framework production system is advantaged in that processes such as electroplating, overturning and bending in the lead framework production process are completed, automation of the lead framework is improved, and wear of the lead framework during transport is avoided.

Owner:新恒汇电子股份有限公司

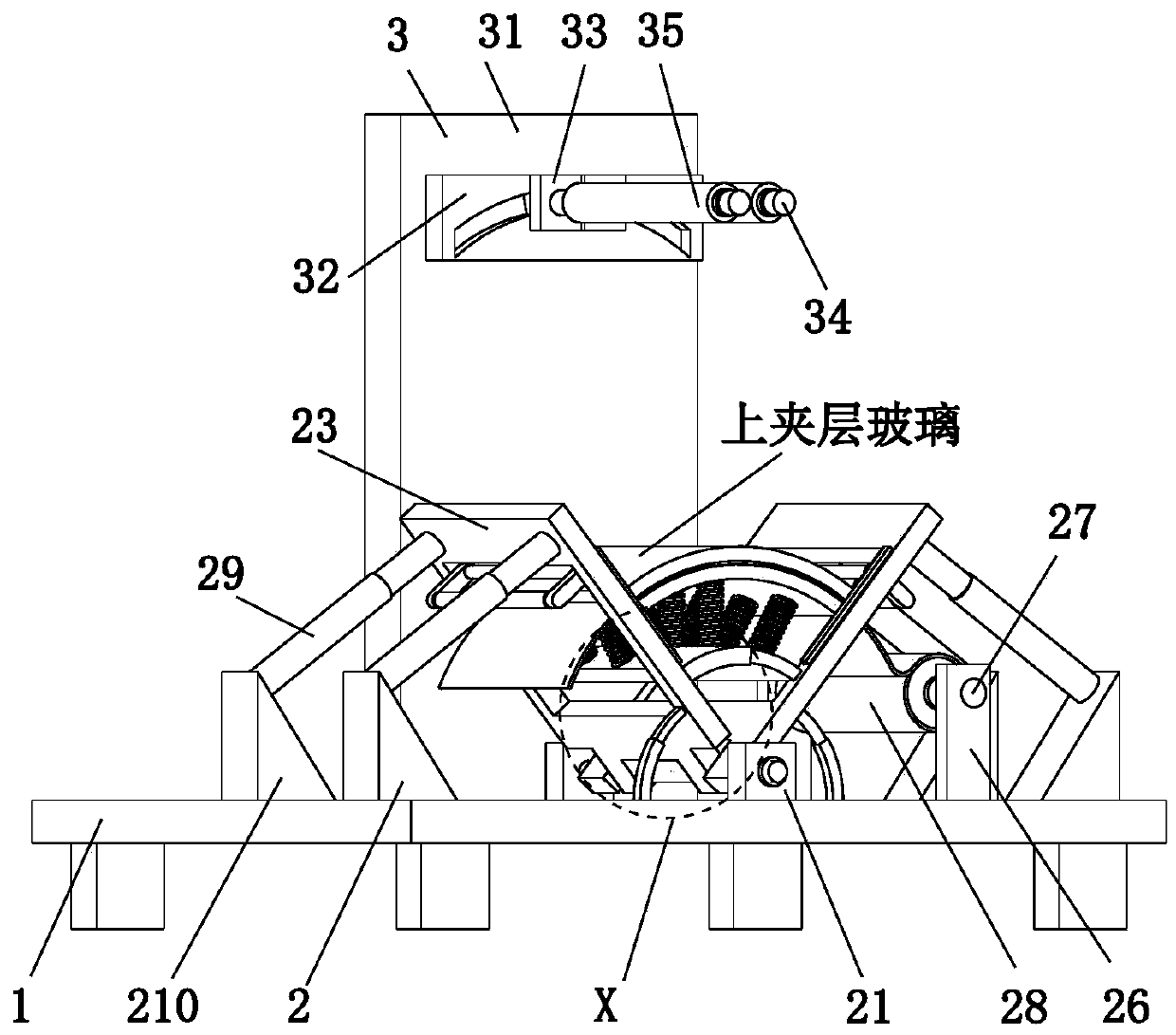

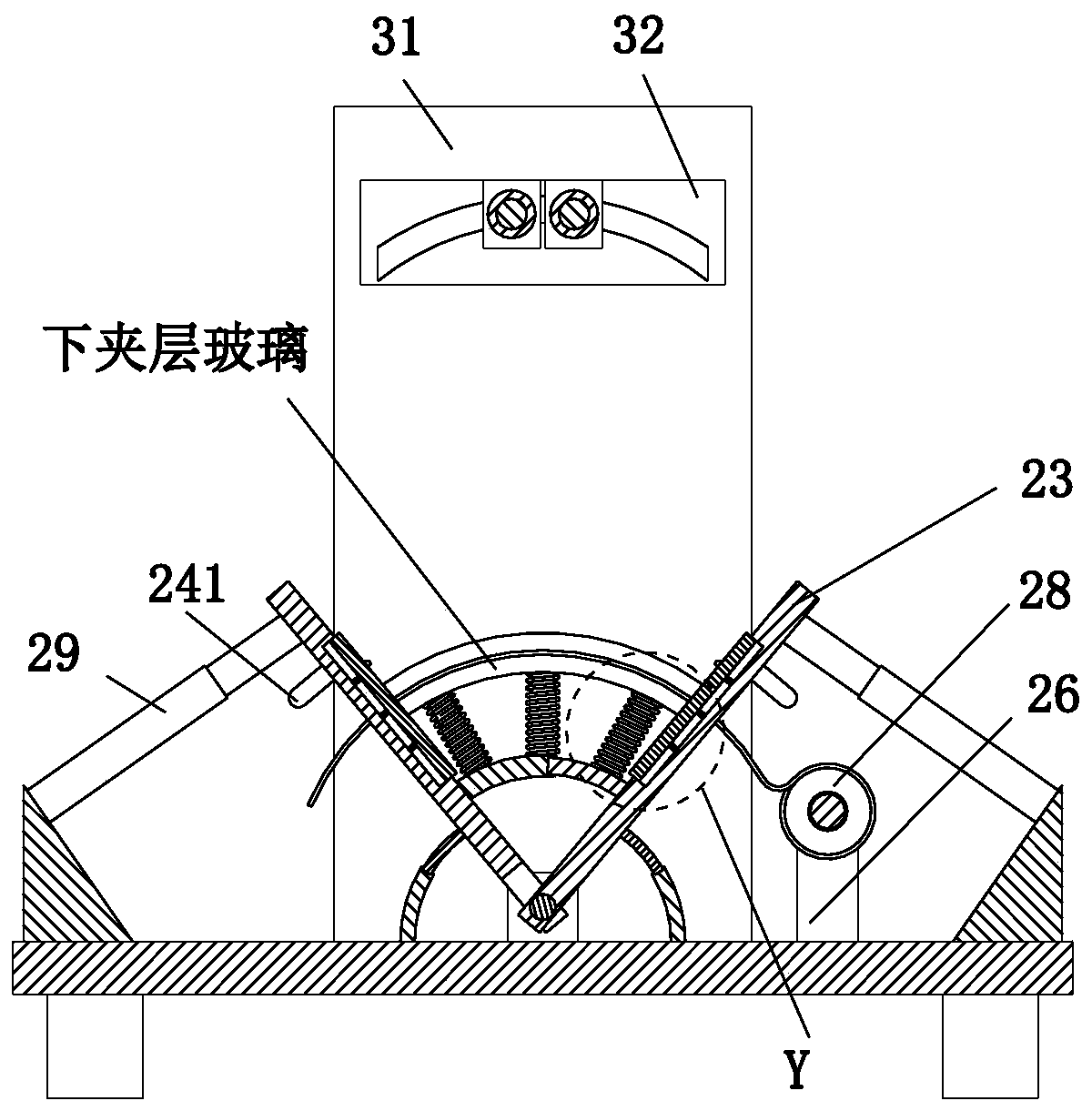

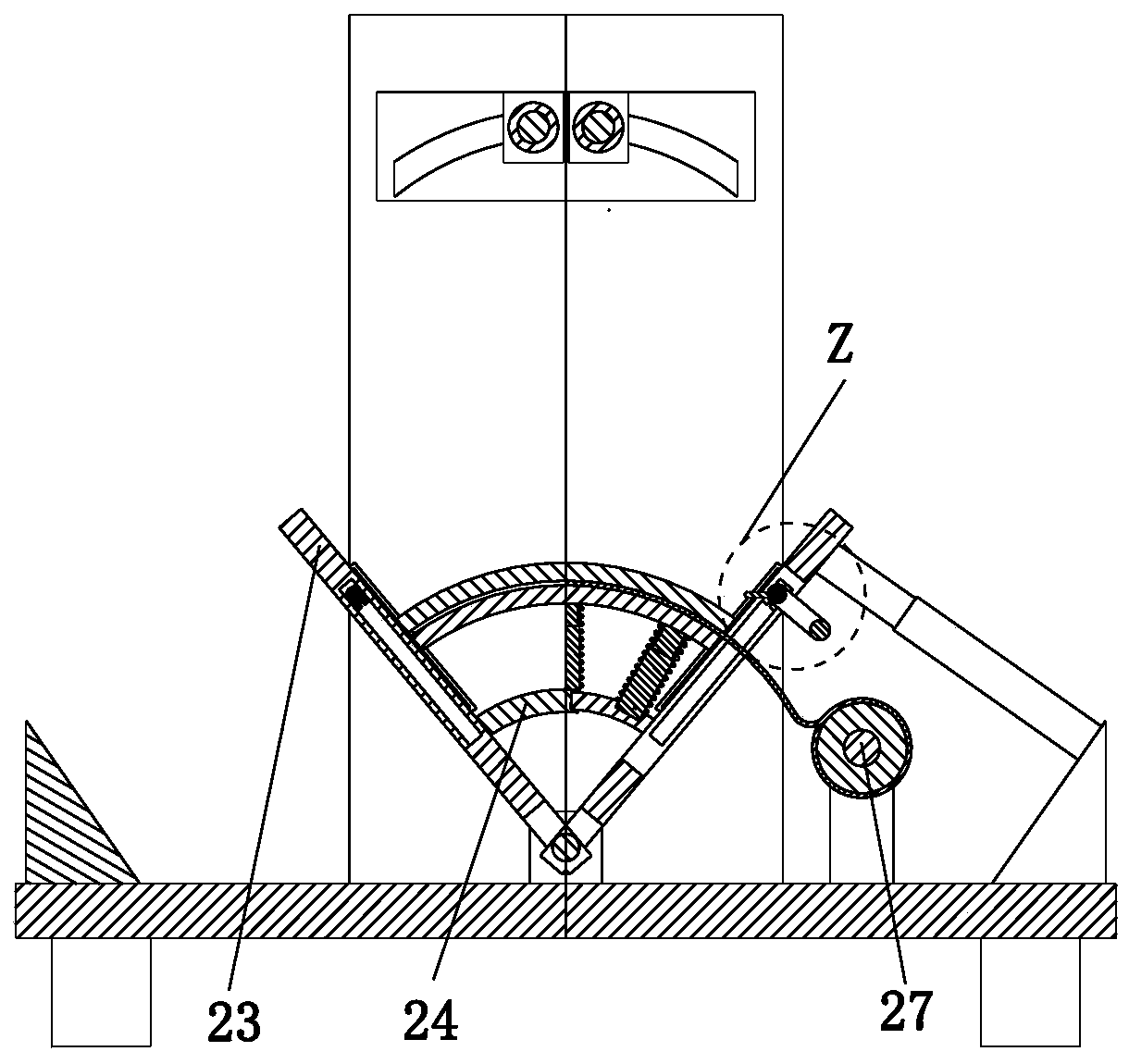

Auxiliary clamp tool for laminated glass production and processing

ActiveCN110978725AHigh forming precisionIncrease profitLaminationLamination apparatusWorkbenchIndustrial engineering

The invention relates to an auxiliary clamp tool for laminated glass production and processing. The tool comprises a workbench, a clamping and fixing device and a rolling device, the clamping and fixing device is installed on an upper end face of the workbench, the rolling device is arranged on a rear side of the clamping device, and the rolling device is installed on an upper end face of the workbench. According to the auxiliary clamp tool for laminated glass production and processing, a V-shaped adjustable design concept is adopted for processing laminated glass, a clamp is of a V-shaped structure and can adapt to clamping and fixing of curved laminated glass, meanwhile, the middle angle of the clamp can be accurately controlled, the clamp can adapt to clamping of laminated glass raw sheets of different thicknesses and sizes, the laminated glass forming precision is improved, and the equipment utilization rate is increased.

Owner:广西远大玻璃节能科技股份有限公司

Metal machining workbench for medical device

InactiveCN106976012AImprove efficiencyQuality improvementGrinding drivesGrinding work supportsThreaded pipeMedical treatment

The invention discloses a metal processing workbench for medical appliances, which comprises a base, movable holes are opened on both sides of the top of the base, blocks are movably connected to both sides of the top of the base, and The bottom is fixedly connected with a movable block, the bottom of the movable block passes through the movable hole and extends to the inner cavity of the base, both sides of the inner cavity of the base are fixedly connected with a motor, and the output shaft of the motor is fixedly connected with a first gear, A transition plate is provided in the inner cavity of the base and between the two motors, and the interior of the transition plate is movably connected with a threaded pipe through a bearing. The invention can drive the first gear and the second gear to rotate through the motor, and then can drive the threaded rod, the movable block and the clamping block to move through the threaded tube until the two clamping blocks can clamp the workpiece, and the clamping degree is higher. The efficiency of metal processing for medical appliances is improved, the quality of metal workpieces for medical appliances is improved, and the problem of causing huge economic losses to metal processing enterprises for medical appliances is avoided.

Owner:浙江高派机器人科技有限公司

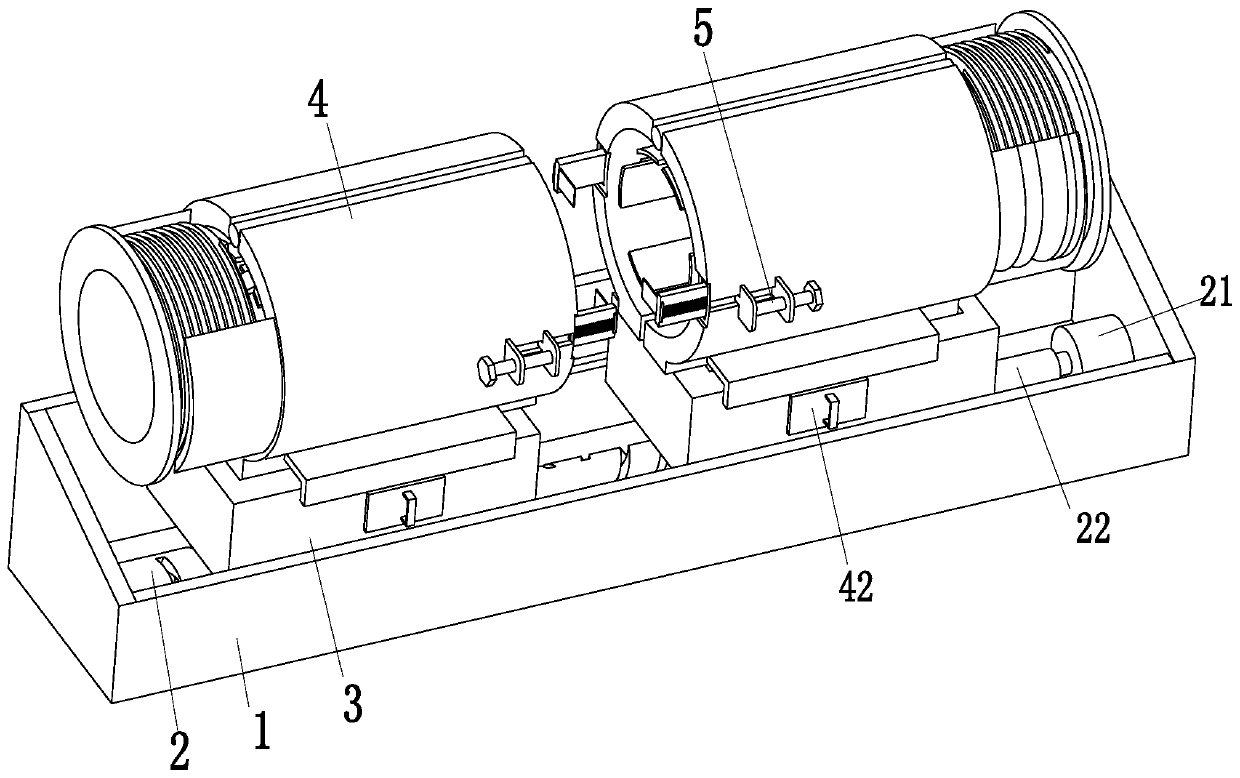

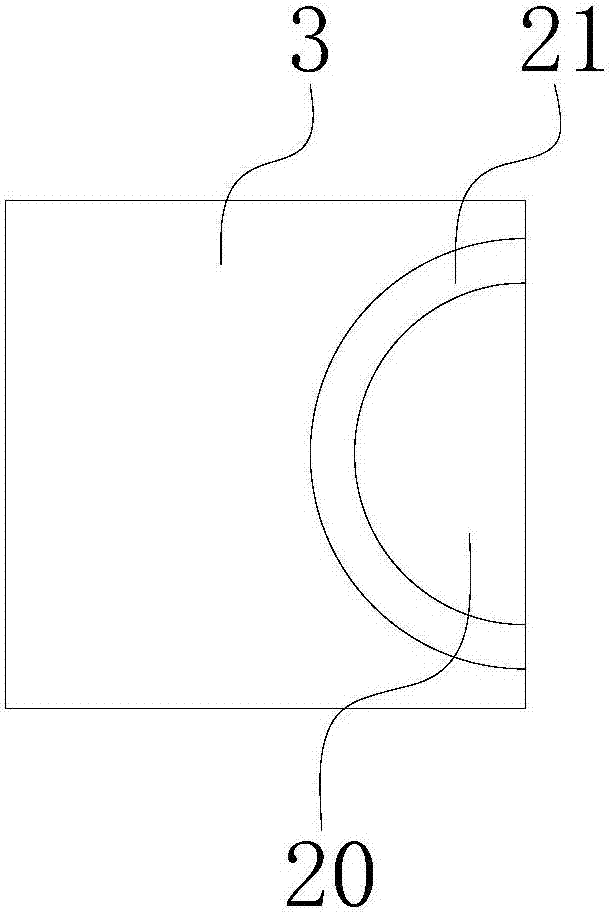

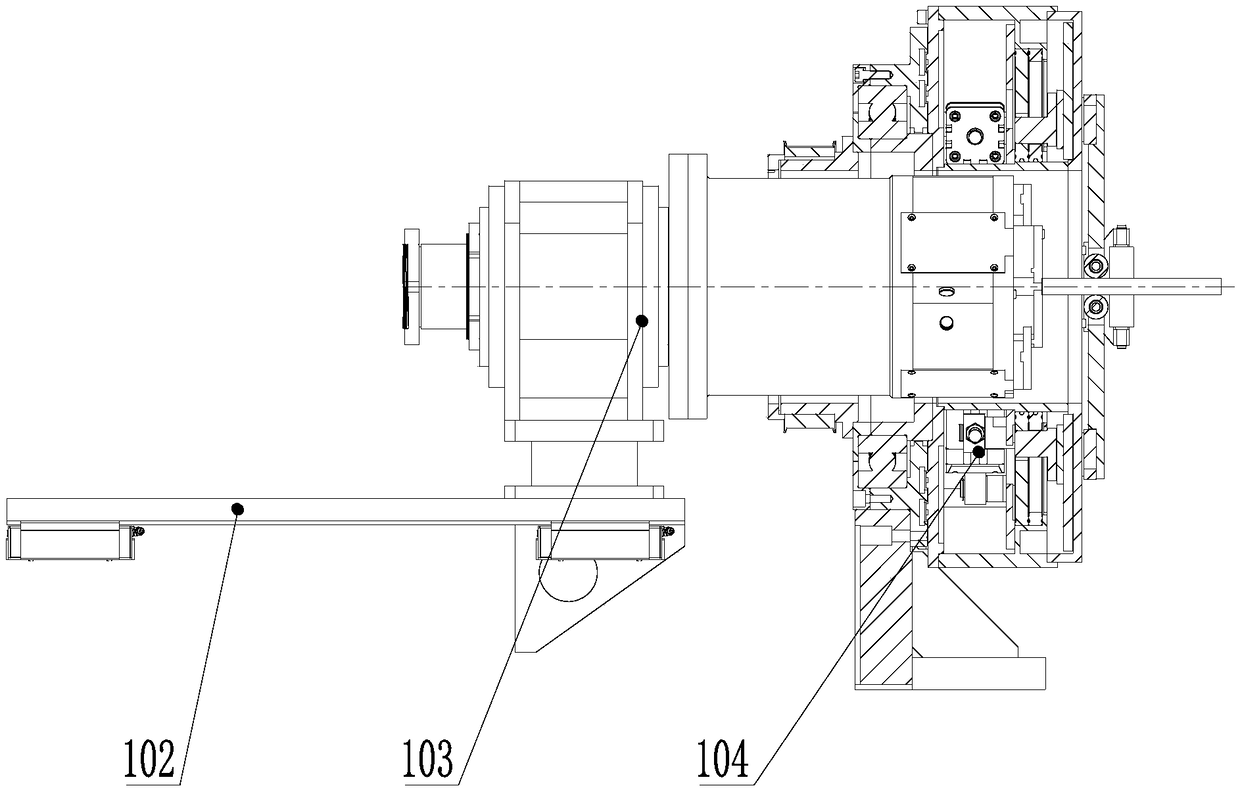

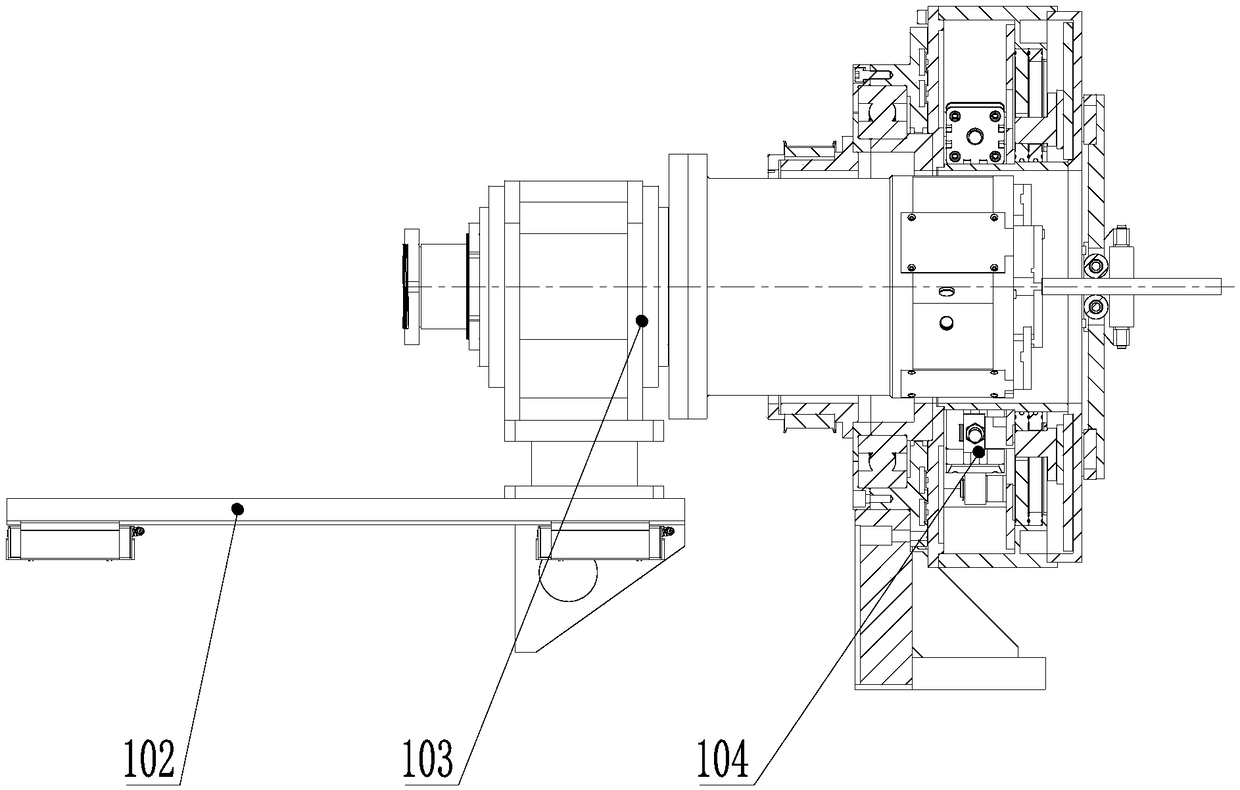

Double-insurance pneumatic clamping chuck

PendingCN108817433AReduce thicknessShorten the lengthChucksPositioning apparatusEngineeringMechanical engineering

The invention provides a double-insurance pneumatic clamping chuck. The double-insurance pneumatic clamping chuck comprises a connecting disc, a chuck outer sleeve, a chuck inner sleeve, a separationdisc, a mounting disc, a clamping device, a guide device, a conversion device and a driving device, wherein one end of the chuck outer sleeve is provided with a connecting plate, the other end of thechuck outer sleeve is provided with the mounting disc, the chuck inner sleeve coaxially arranged with the chuck outer sleeve is further arranged between the connecting disc and the mounting disc, theguide device is arranged on the mounting disc, the clamping device is arranged on one side, outside the guide device, of the guide device, the conversion device is arranged on one side inside the guide device, the driving device is arranged between the conversion device and the connecting disc, the separation disc is arranged between the conversion device and the driving device, the conversion device is used for converting axial rotation of the conversion device into radial movement of the clamping device, and the driving device comprises a first driving device and a second driving device. Thetwo driving devices are arranged, so that double driving in one clamping direction can be realized, and normal operation of the equipment when one driving device breaks down is avoided.

Owner:SHANDONG LEIMING CNC LASER EQUIP CO LTD

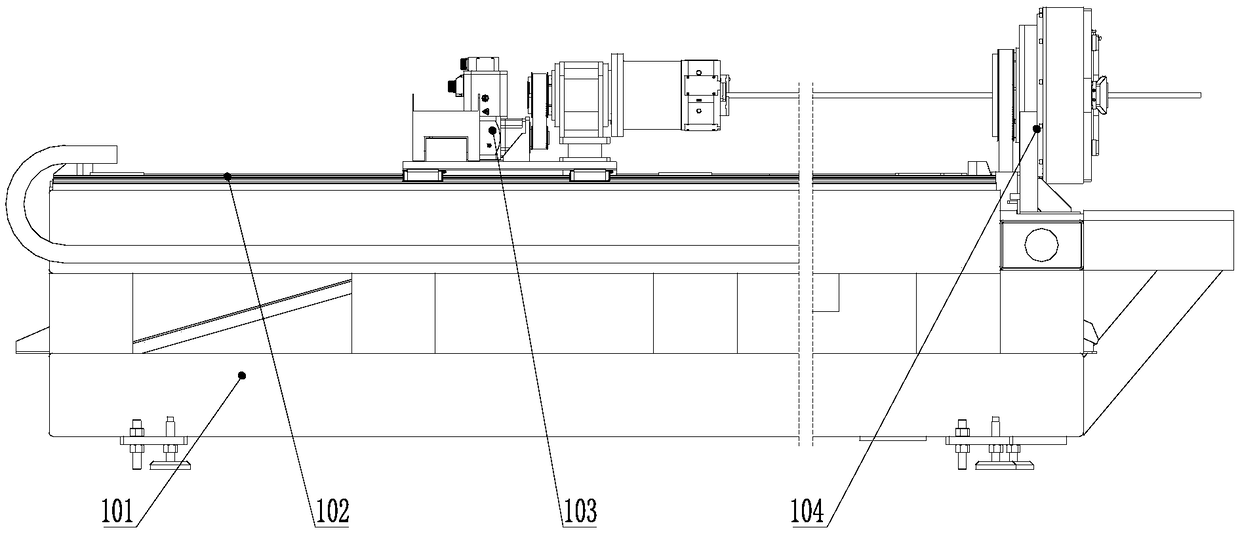

Pneumatic installing and clamping chuck

PendingCN108856775AAchieve clampingImprove versatilityAutomatic workpiece supply/removalLarge fixed membersEngineeringMechanical engineering

The invention relates to a pneumatic installing and clamping chuck, which comprises a connecting disc, a chuck outer sleeve, a chuck inner sleeve, a separation disc, an installing disc, a clamping device, a guide device, a conversion device and a driving device, wherein one end of the chuck outer sleeve is provided with the connecting disc; the other end of the chuck outer sleeve is provided withthe installing disc; the chuck inner sleeve in coaxial arrangement with the chuck outer sleeve is also arranged between the connecting disc and the installing disc; a guide device is arranged on the installing disc; the clamping device is arranged at one side of the outside of the guide device; the conversion device is arranged at one side of the inside; the driving device is arranged between theconversion device and the connecting disc; the separation disc is arranged is arranged between the conversion device and the driving device; the conversion device converts the axial rotation into theradial movement of the clamping device; the clamping device comprises a first clamping device and a second clamping device. The circumference movement of the conversion device is converted into the radial movement of the clamping device; two devices are installed, so that the clamping on workpieces with irregular cross sections can be realized; the universal performance of the pneumatic installingand clamping chuck can be improved.

Owner:SHANDONG LEIMING CNC LASER EQUIP CO LTD

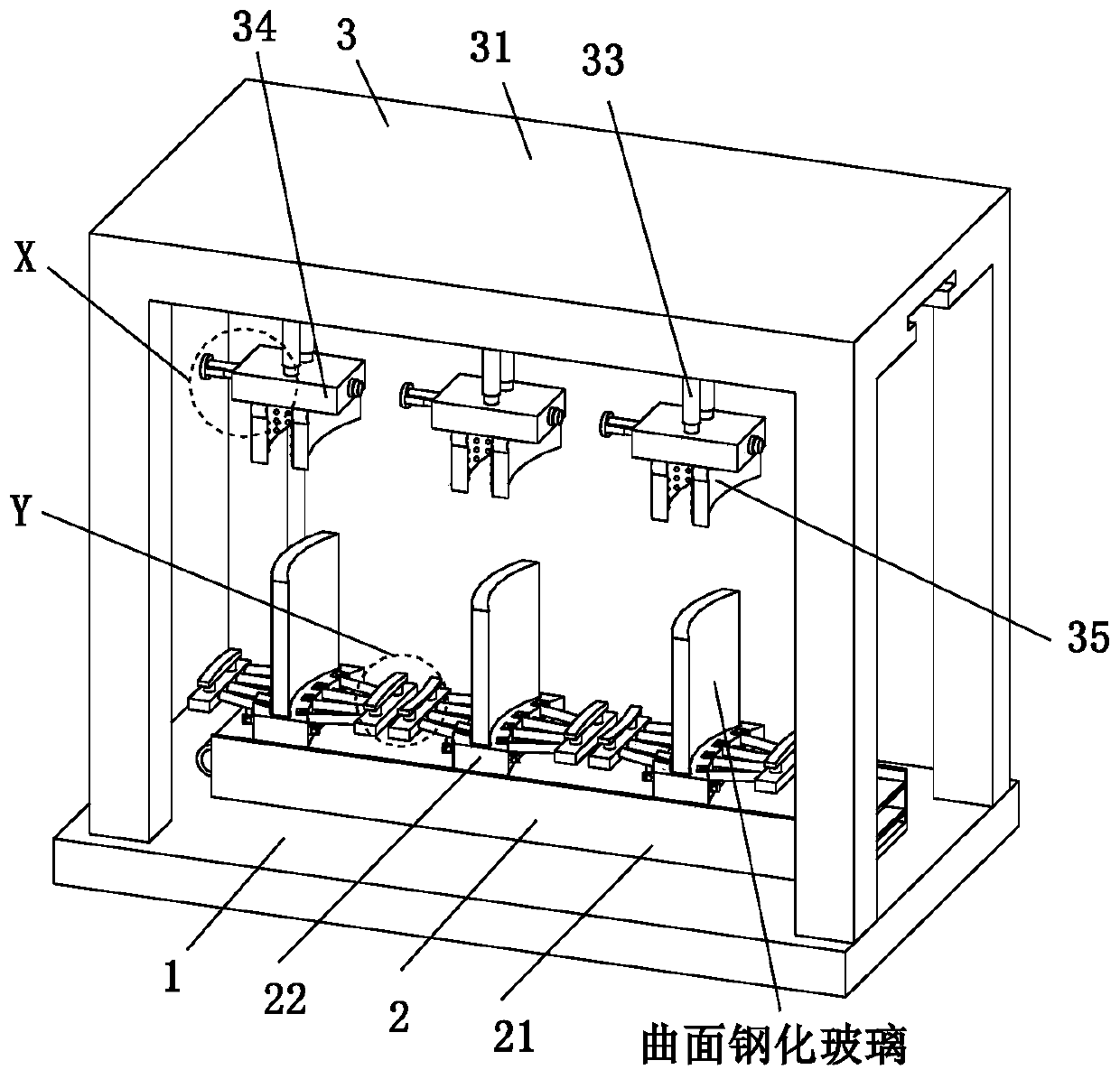

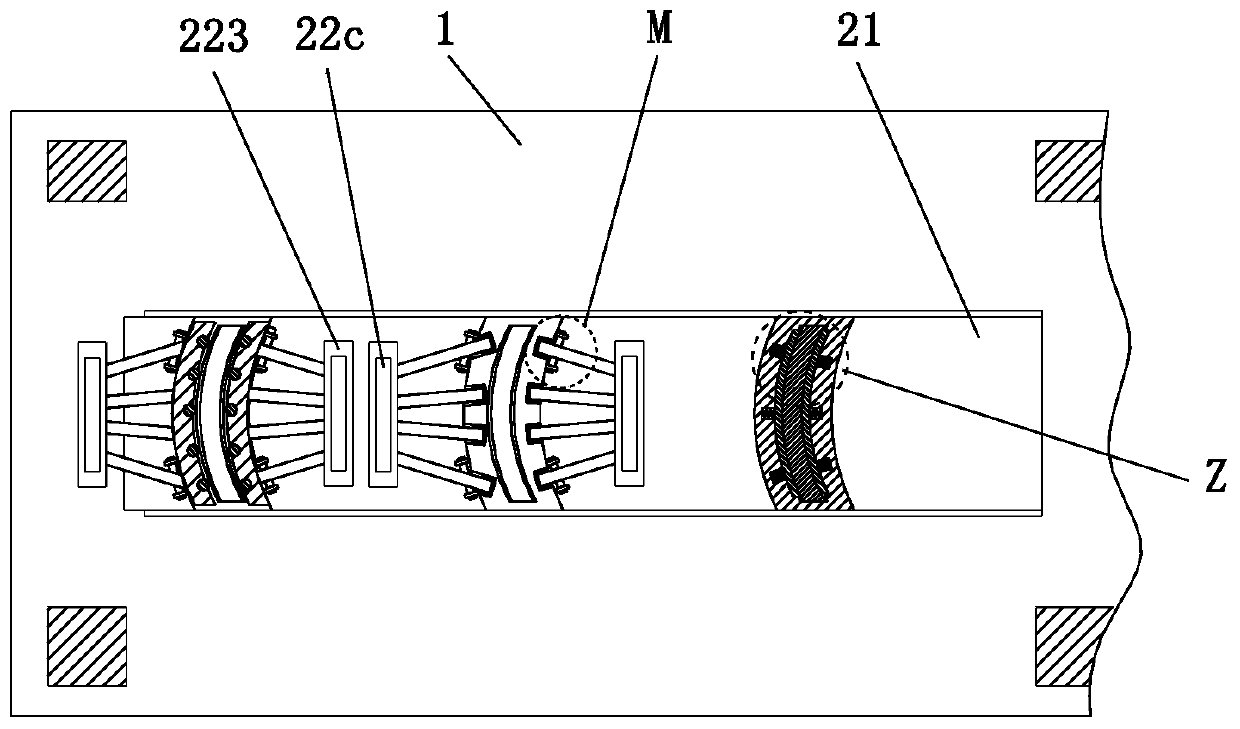

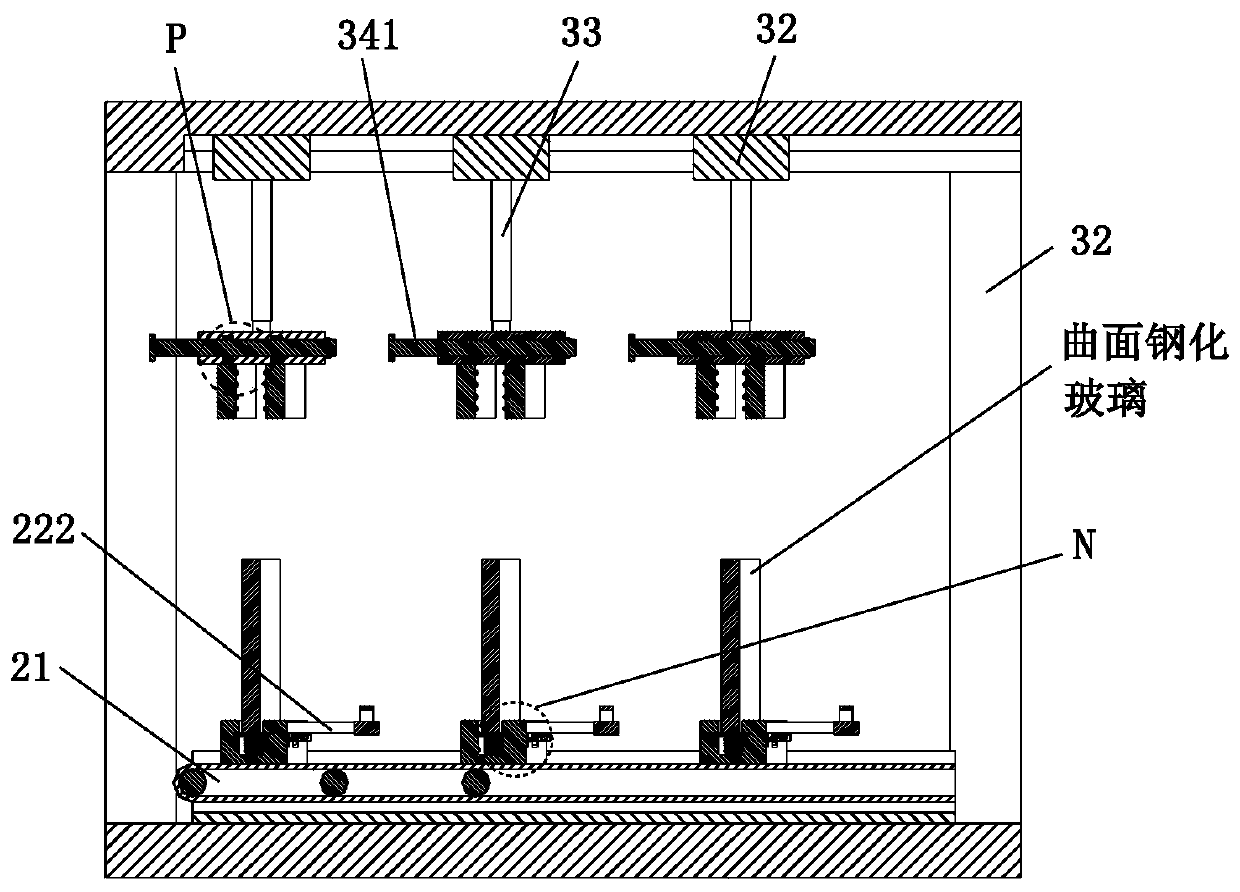

Curved tempered glass production, manufacturing and transferring device

ActiveCN110980293AImprove the stabilityIncrease profitConveyorsCharge manipulationToughened glassIndustrial engineering

The invention relates to a curved tempered glass production, manufacturing and transferring device. The device comprises a ground table, a lower clamping and fixing device and an upper clamping and fixing device; the lower clamping and fixing device is installed on the upper end face of the ground table; and the upper clamping and fixing device is mounted above the lower clamping and fixing device. According to the curved tempered glass production, manufacturing and transferring device of the invention, a design concept of multi-point fixation and adjustability is adopted to implement the transfer of curved tempered glass; the upper end and the lower end of the curved tempered glass are both clamped and fixed, so that the overall stability degree of the curved tempered glass in a placing and carrying process is improved; and an adjustable structure is adopted, so that the device of the invention can adapt to the clamping and carrying of the curved tempered glass with different thicknesses, and therefore, the overall utilization rate of the device is increased.

Owner:湖南华祎科技有限公司

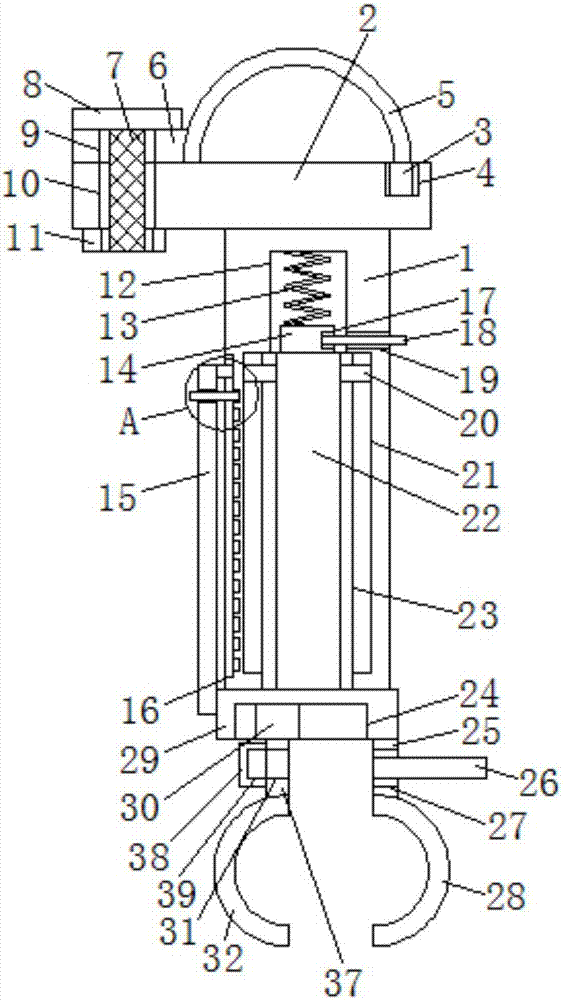

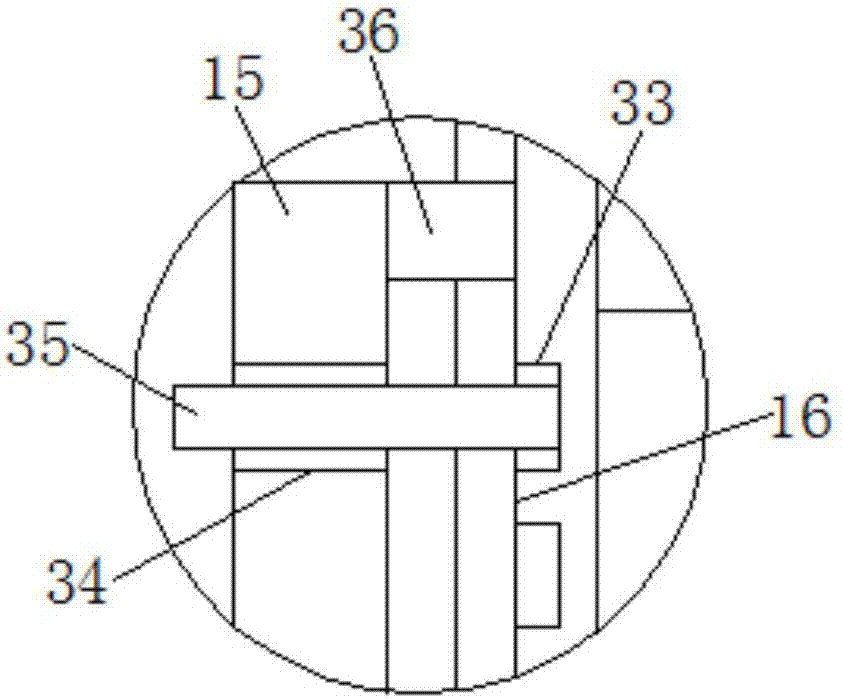

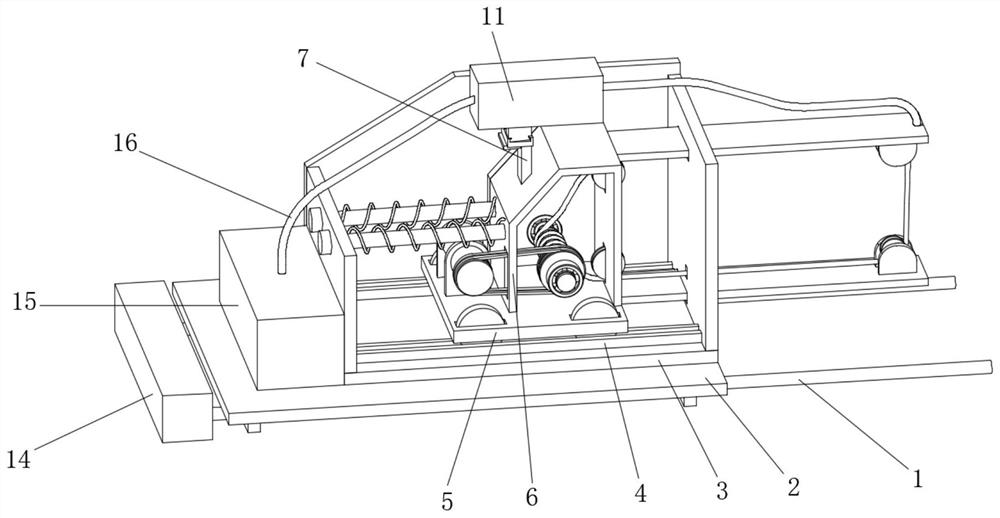

Spacing rod used for erecting high-voltage bus

PendingCN107508233AIncrease the degree of clampingImprove clamping effectMaintaining distance between parallel conductorsLap jointPower engineering

The present invention provides a spacing rod used for erecting a high-voltage bus, and relates to the electric power engineering field. The spacing rod used for erecting the high-voltage bus comprises a rod body, a top plate is fixedly connected at the top of the rod body, and a fixing plate is in lap joint with the upper surface of the top plate. An upper snap ring is fixedly connected at the right side of the fixing plate, the bottom of the upper snap ring is in lap joint with the upper surface of the top plate, and the upper surface of the fixing plate is equipped with an open hole communicated with the lower surface. A screw is in threaded connection inside the open hole, and the upper surface of the top plate is equipped with a screw hole communicated with the lower surface. According to the spacing rod used for erecting the high-voltage bus, by using the upper snap ring to drive a clamping block to be inserted in a groove, an effect of increasing the clamping degree of the upper snap ring to the high-voltage bus is realized; by the mutual cooperation of the screw, the fixing plate and the top plate, the effect that the screw fixes the fixing plate and the top plate mutually, at the same time, fixes the upper snap ring, is realized; and by sliding a sliding block rightwards, an effect that a first snap ring and a second snap ring clamp the high-voltage bus, is realized.

Owner:WETOWN ELECTRIC GRP CO LTD

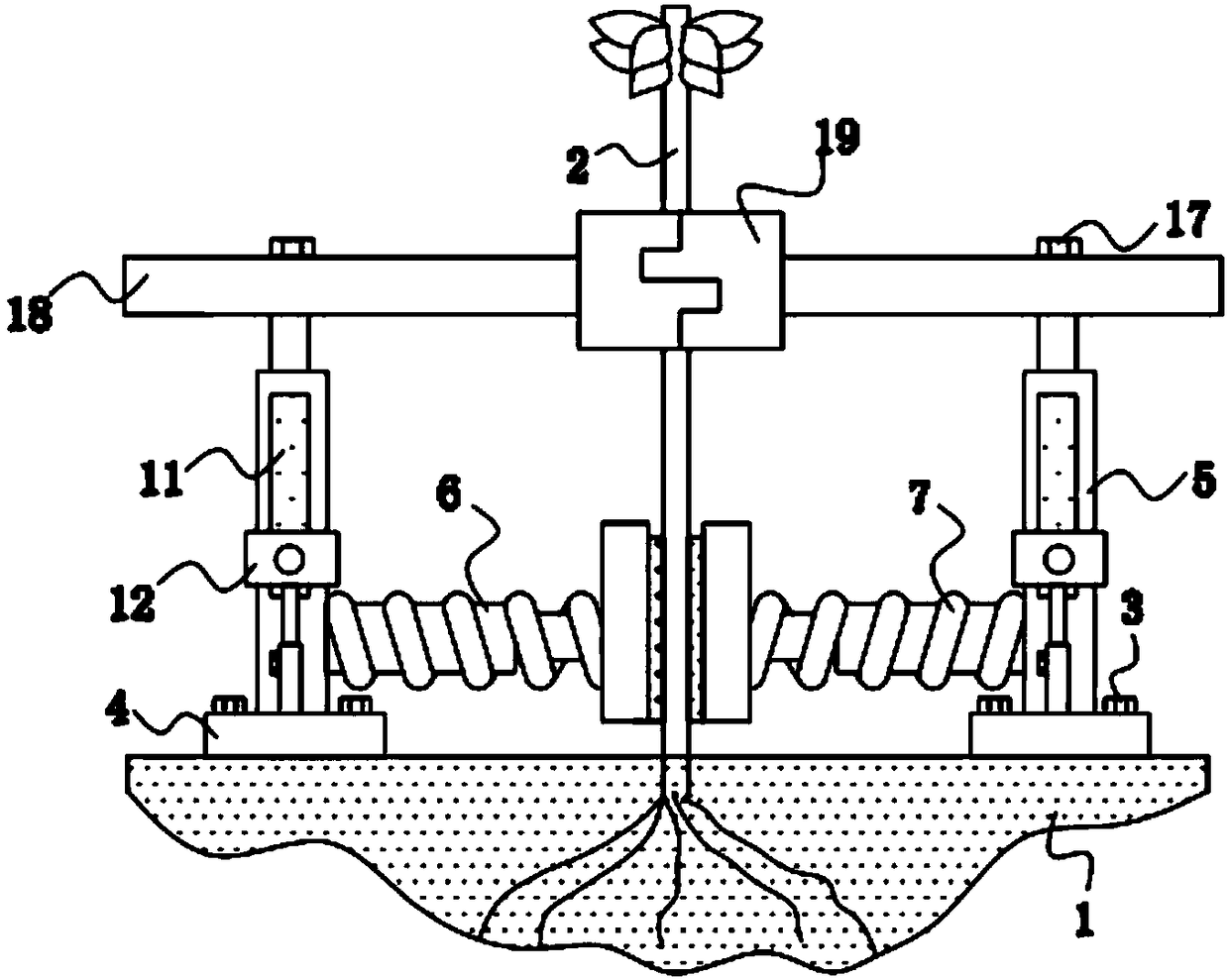

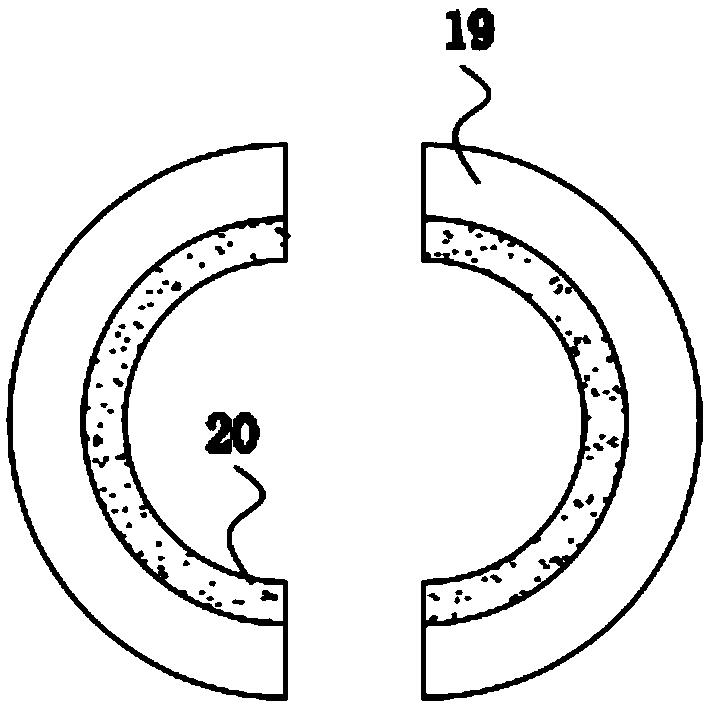

Convenient-to-adjust righting device for nursery stock planting

The invention discloses a convenient-to-adjust righting device for nursery stock planting. A soil layer and a nursery stock trunk planted on the soil layer are involved; fixed bases are connected to the left and right sides of the upper portions of the soil layer through anchor rods, guide sleeves are connected to the upper ends of the fixed bases, retractable rods are connected to the sides, close to each other, of the two guide sleeves, the outer walls of the retractable rods are sleeved with rubber springs, and abutting plates are connected to the end portions of the retractable rods. According to the convenient-to-adjust righting device for nursery stock planting, the anchor rods and the fixed bases are connected with the soil layer by means of external force (a hammer can be preferably selected for use), the stability of the fixed bases can be improved accordingly, and it is ensured that the subsequent work is smoothly carried out; the retractable rods are connected to the sides,close to each other, of the two guide sleeves, the outer walls of the retractable rods are sleeved with the rubber springs, the abutting plates are connected to the end portions of the retractable rods, a polyurethane cushion closely attached to the bottom of the outer wall of the nursery stock trunk adheres to the inner walls of the abutting plates through an adhesive, and therefore the nursery stock trunk can be abutted against from the bottom of the outer wall of the nursery stock trunk.

Owner:淮北达驰电气科技有限公司

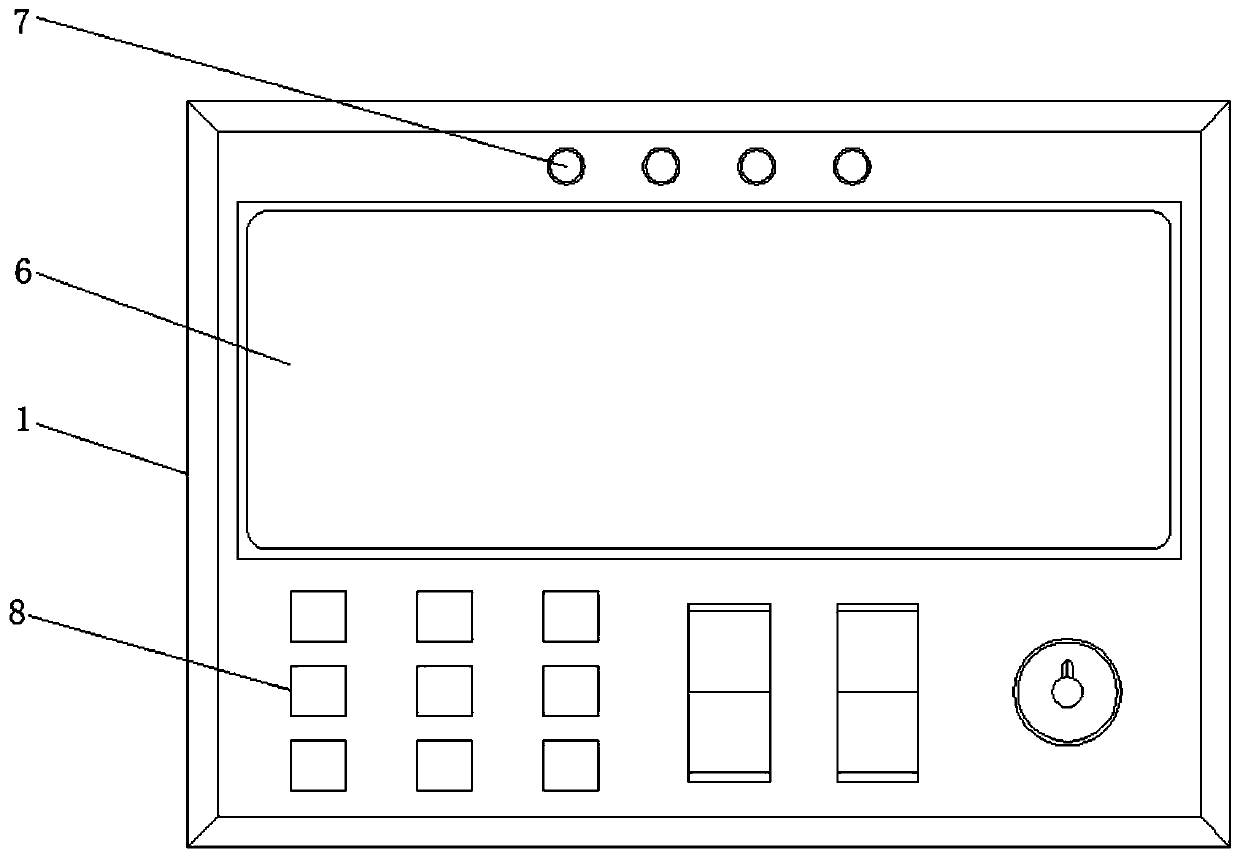

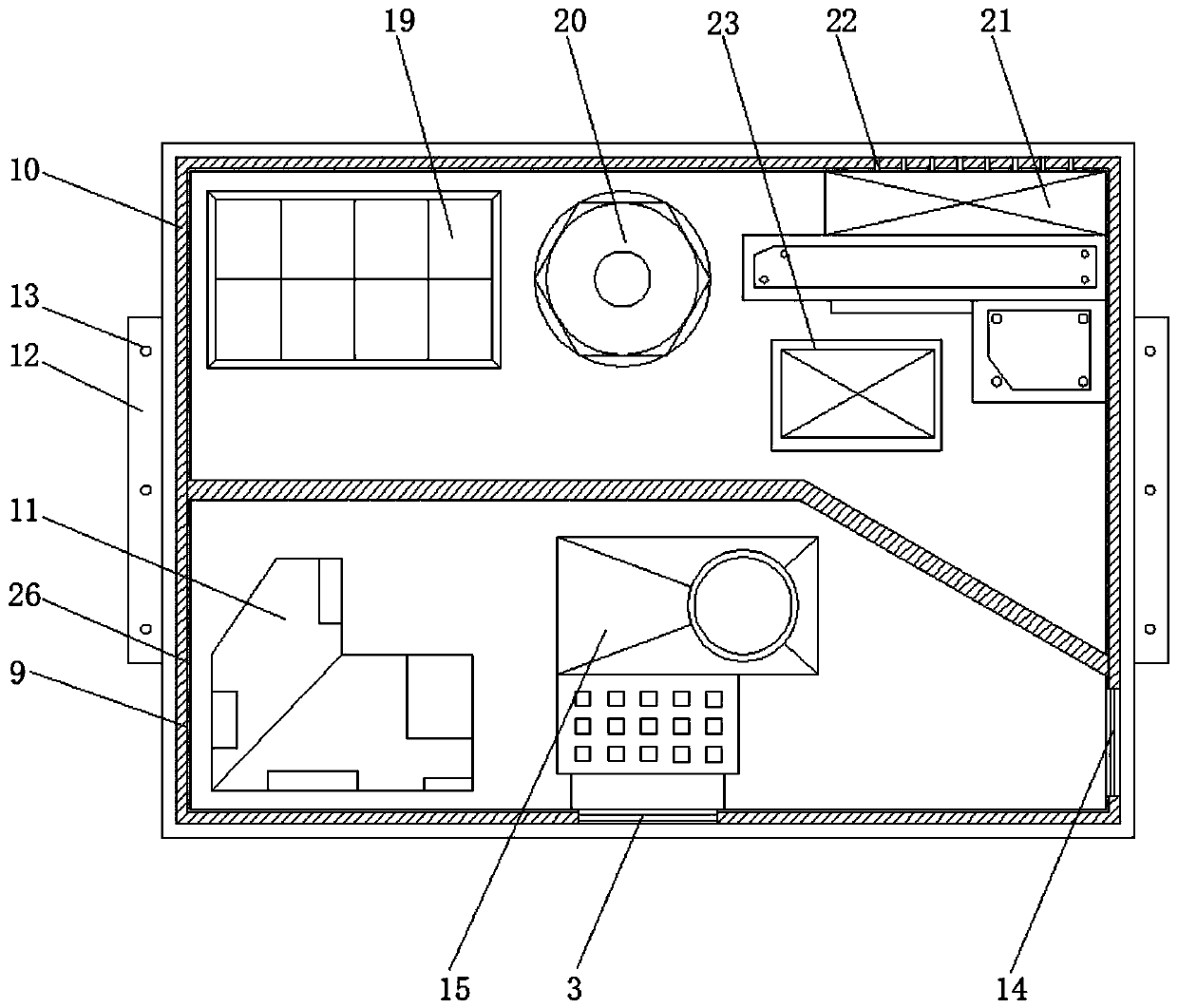

Remote alarm system for clinical ward air detection

InactiveCN111429707AEasy maintenanceAvoid inhalationAlarmsElectric transmission signalling systemsPatient's roomTerminal equipment

The invention discloses a remote alarm system for clinical ward air detection. The system comprises a first box body, a center plate and an air quality detection module. A second box body is arrangedbelow the first box body; a dust screen is arranged at a joint of front surfaces of the second box body and the first box body; the center plate is fixed below the second box body; a storage battery plate is mounted in the center plate; and a display screen is embedded in an outer wall of the first box body, indicator lights are evenly arranged above the display screen, input keys are installed below the display screen, a detection cavity is arranged in the second box body, a main control cavity is connected to an upper portion of the detection cavity, and an air quality detection module is installed on a left side in the detection cavity. Signal connection with external Internet terminal equipment can be performed through a wireless signal transmitter so that functions of remote data transmission and alarm reminding are achieved, and meanwhile, connection and fixation are performed through a clamping effect, installation is easy, and fixation is convenient.

Owner:南通市第一老年病医院

Garden big tree transplanting and binding equipment

InactiveCN112438174AImprove the stabilityImprove the efficiency of migration workAgricultural machinesForestryTree rootAgricultural engineering

The invention relates to garden big tree transplanting and binding equipment. The garden big tree transplanting and binding equipment comprises a dragging vehicle, a fixing unit and a binding mechanism, the dragging vehicle is of an L-shaped structure, the fixing unit is installed at the upper end of the left end face of the dragging vehicle, and the binding mechanism is connected between the leftend of the fixing unit and the upper right end of the dragging vehicle. According to the garden big tree transplanting and binding equipment, the design concept of combining multiple controllable clamping and fixing structures is adopted for garden big tree transplanting and binding, so that the purpose of improving the overall stability degree of trees in the root binding process is achieved; and compared with a manual binding manner, the binding manner adopted by the binding mechanism has the advantages that the binding treatment of automatic annular wrapping of tree roots with soil can berealized, so that the efficiency of tree transplanting work can be greatly improved, and the artificial inconvenience and the labor intensity of workers can also be reduced.

Owner:HANGZHOU JINGYU LANDSCAPE ENG CO LTD

Fretsaw with self-adjusting feed amount

InactiveCN112248247AReduce the chance of breakageRelief of deformationMetal sawing devicesMetal sawing accessoriesEngineeringStructural engineering

The invention relates to the technical field of material cutting, and discloses a fretsaw with the self-adjusting feed amount. When the contact area of a wire saw and a cutting material is reduced, the self elastic force of a stress spring is smaller than the acting force of the material on the wire saw at the moment, so that a balance cutting device integrally moves towards the right side in Figure 2, and the cutting speed is accelerated; the fretsaw can automatically adjust the cutting speed according to the contact area of the wire saw and the material, so that the cutting efficiency is maximized; meanwhile, the wire saw is in a stable state; the fretsaw enables the wire saw to be in the optimal work state while ensuring the cutting efficiency; the service life of the wire saw is prolonged; and the use cost of the fretsaw is reduced. In addition, a stable stroke direction is given to the balance cutting device by an outer bin shell, and meanwhile, the amplitude of vibration of the balance cutting device driven by the wire saw during cutting is also reduced, so that the processing precision and stability of the fretsaw are improved.

Owner:易忠萍

Telescopic connecting pipe screwing equipment for building construction

InactiveCN103423519AIncrease the degree of clampingPrevent looseningPipe supportsArchitectural engineeringBuilding construction

The invention relates to connecting pipe screwing equipment, belongs to the technical field of clamping equipment, and discloses telescopic connecting pipe screwing equipment for building construction. The telescopic connecting pipe screwing equipment comprises an upper clamping sleeve and a lower clamping sleeve. Upper connecting plates are mounted at two ends of the upper clamping sleeve, lower connecting plates are arranged at two ends of the lower clamping sleeve and are connected with the upper connecting plates by nuts and studs, knobs are arranged on the tops of the studs, the lower ends of the studs are nested in sleeves, and bottom plates are mounted at the bottoms of the sleeves. The telescopic connecting pipe screwing equipment for building construction has the advantages that owing to the upper clamping sleeve, the lower clamping sleeve, the studs and the sleeves, a pipeline clamping degree is high, and pipelines are prevented from being loosened; the height of an integral mechanism can be adjusted via the studs, so that the integral mechanism can be adjusted according to actual construction places, the heights of the pipelines keep consistent, the problem of different pressures due to different heights of pipelines is solved, and the service life of each pipeline is prolonged; the telescopic connecting pipe screwing equipment does not need to be maintained frequently, and accordingly the integral budget of an enterprise is reduced.

Owner:侯欣竹

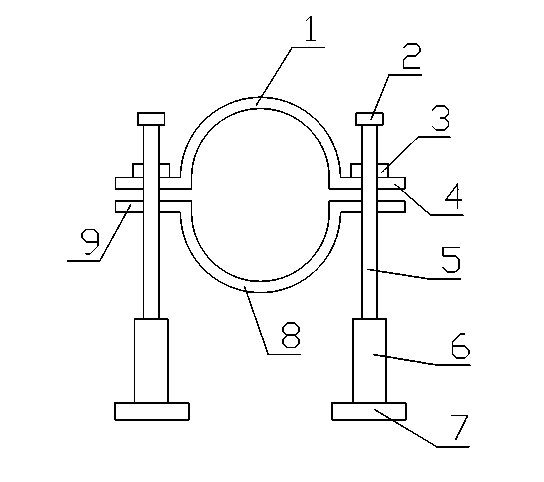

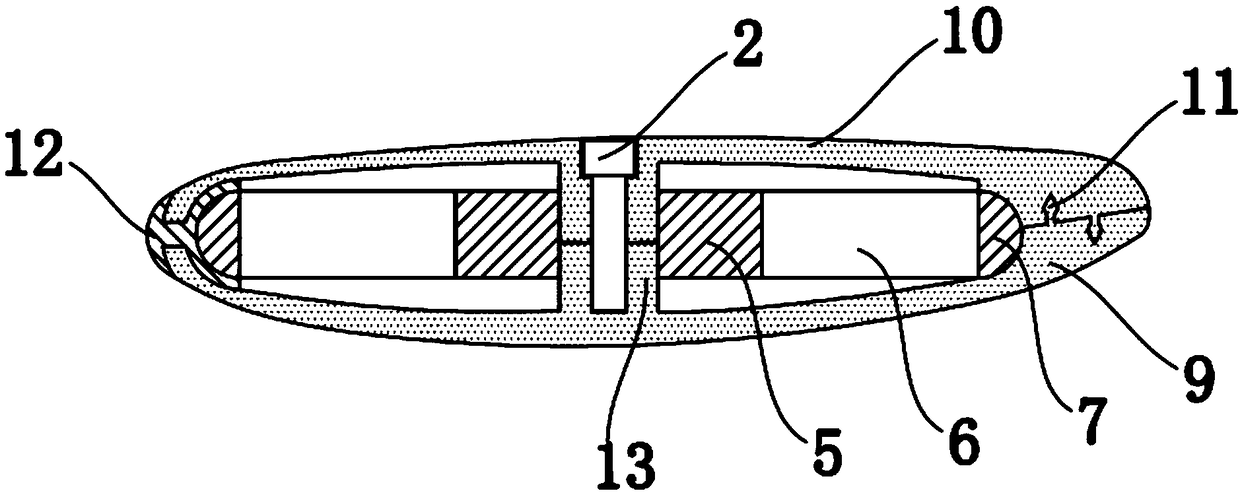

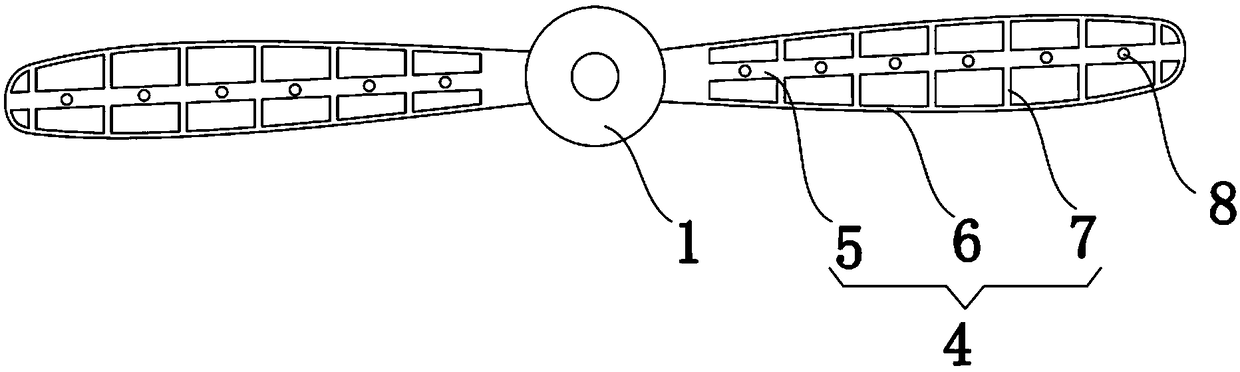

Unmanned aerial vehicle propeller and production process thereof

InactiveCN108657417AReduce weightIncrease the degree of clampingPropellersWeight reductionFiberCarbon fibers

The invention discloses an unmanned aerial vehicle propeller and a production process thereof. The propeller comprises a fixed seat and blades, wherein the blades comprise supporting frameworks, the supporting frameworks and the fixed seat are integrally arranged, upper blades and lower blades are fixedly connected to the upper and lower sides of the supporting frameworks through bolts, and reinforcing edges are fixed to the windward sides of the upper blades and lower blades. According to the unmanned aerial vehicle propeller, the joints of the windward sides of the upper blades and the lowerblades can be sealed and fixed through the reinforcing edges, the wind resistance is reduced, the windward sides of the upper blades and the lower blades are prevented from being separated when rotating, the resistance caused by the wind resistance to the reinforcing edges is greater when the rotating speed is increased, the reinforcing edges can be pushed to improve the clamping degree of the upper blades and the lower blades, the upper blades and the lower blades can be fixed to each other through fixing feet, the stability of the blades is improved, the aluminum alloy supporting frameworkswhich are machined to be empty are matched with the carbon fiber blades, the weight of the blades can be effectively reduced, and the lightweight design of the blades is facilitated.

Owner:魏浩峰 +6

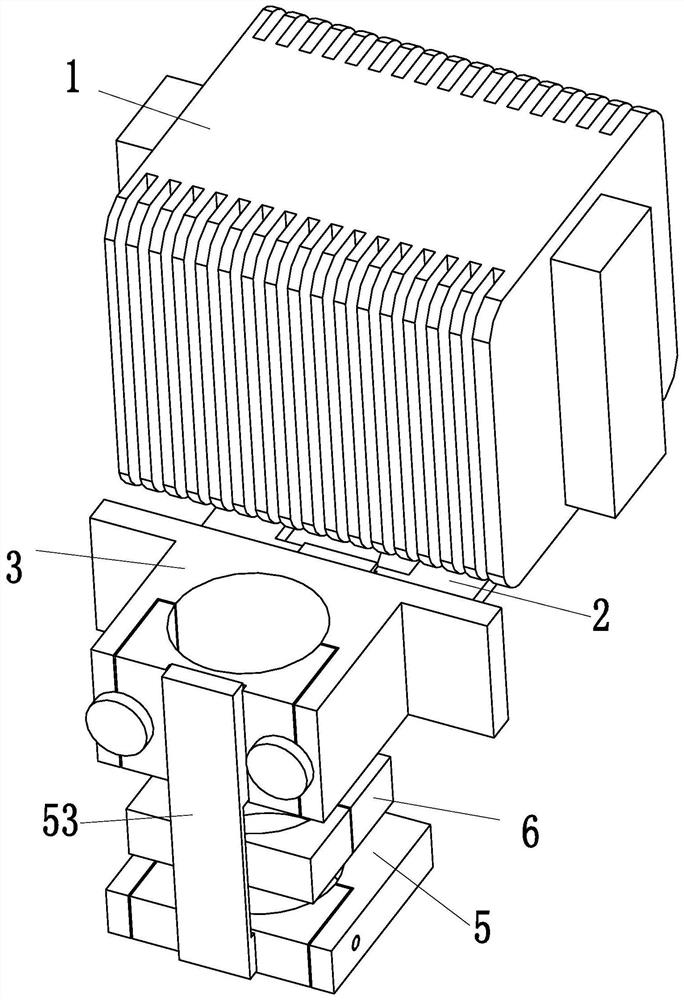

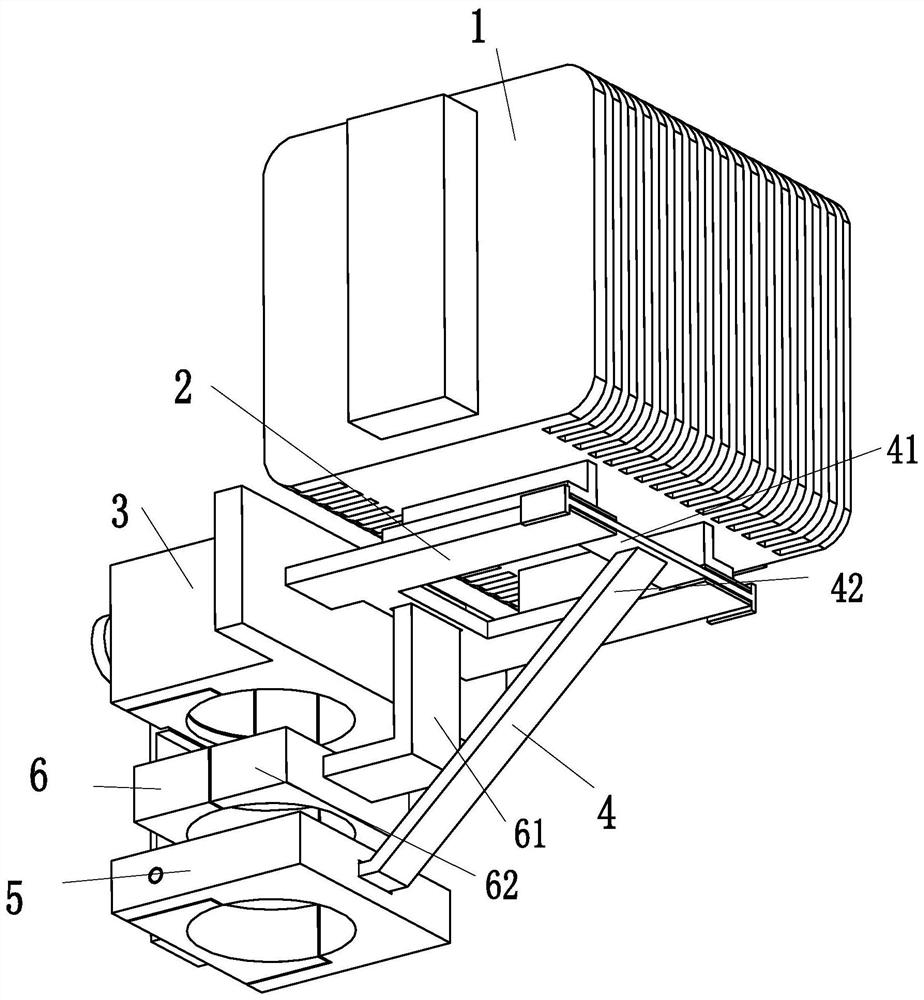

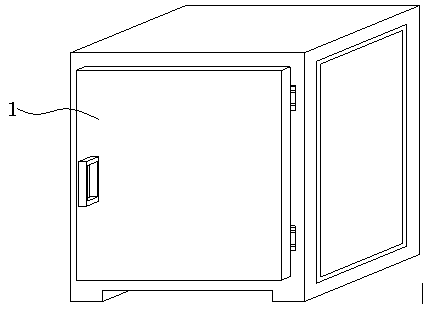

Power transformer convenient to install

InactiveCN113035509AReduce slippageSliding situation blockingTransformers/reacts mounting/support/suspensionTransformers/inductances casingsTransformerControl theory

The invention relates to a power transformer convenient to install. The power transformer comprises a transformer body, a bottom frame, a first fixing device, a support frame, a second fixing device and an emergency fixing device, wherein the bottom frame is installed at the lower end of the transformer body, the first fixing device is installed at the front end of the bottom frame, the support frame is embedded in the rear end of the bottom frame, the second fixing device is installed at the lower end of the support frame, and the emergency fixing device is installed on the bottom frame. The power transformer of the invention can overcome the problems that when a traditional power transformer is installed, the power transformer is usually installed on a rod-shaped object through a fixing frame, the fixing frame and the rod-shaped object are generally locked and clasped one time for reducing the risk of high-altitude operation of personnel during installation of the transformer, a clasping degree is low due to single-time clasping, and in severe weather, wind resistance is poor, the situation of loosening of the power transformer possibly occurs, and the transformer slides down and is damaged.

Owner:江苏悦成变压器有限公司

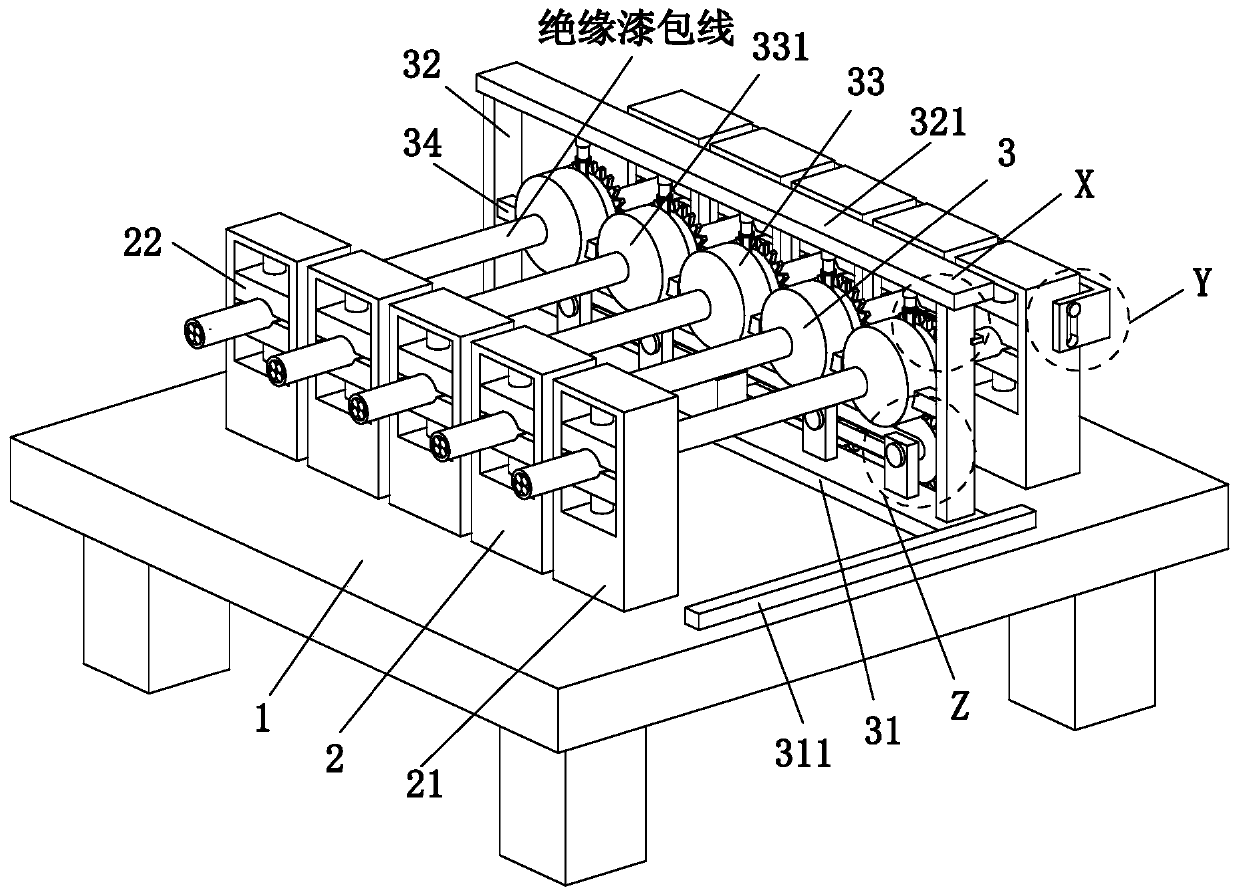

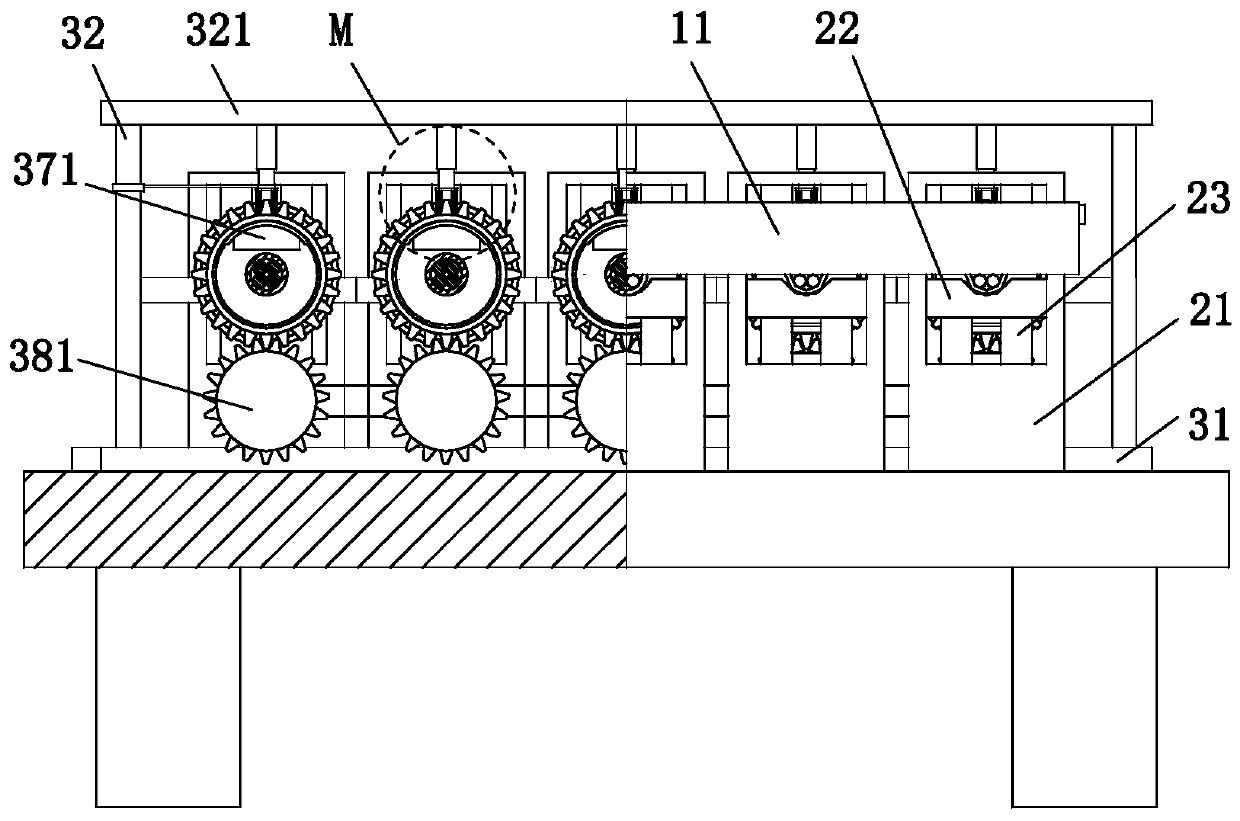

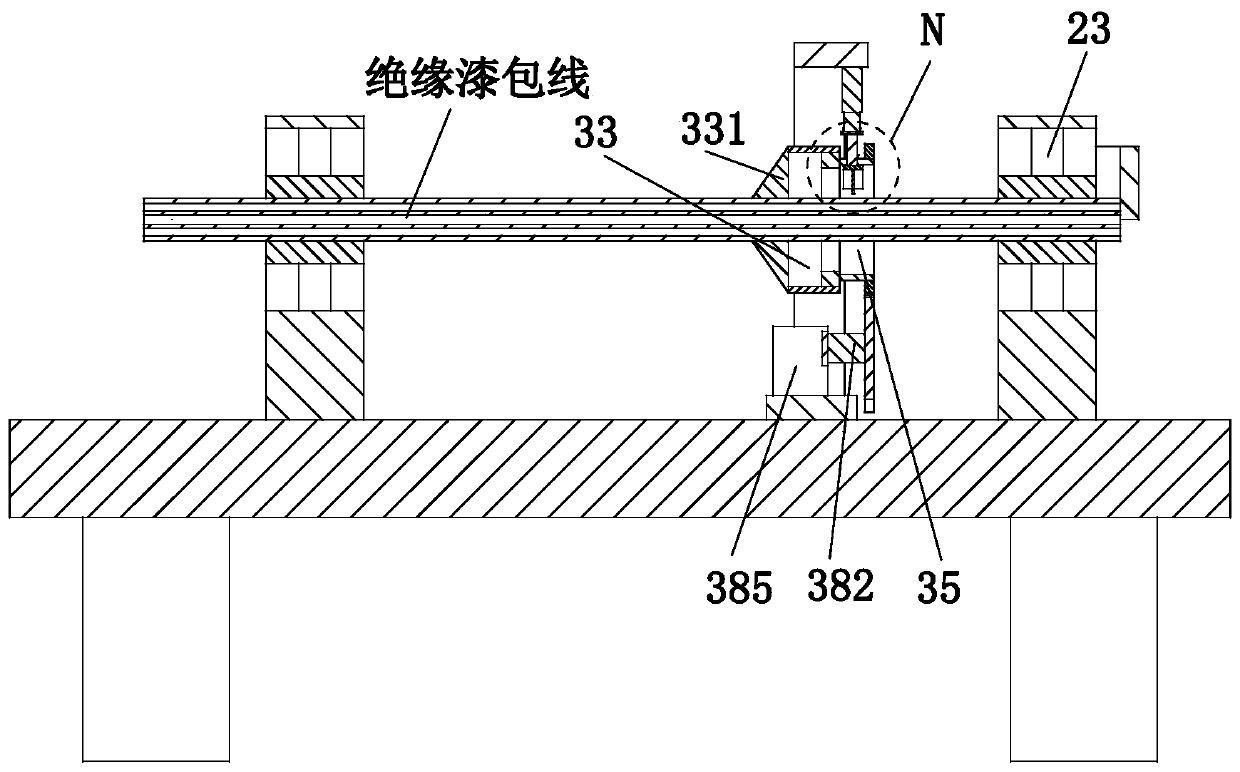

Insulated enamelled wire producing manufacturing cutting device and cutting machining method

ActiveCN110814224AHigh precisionIncrease profitApparatus for cutting/splicing cablesApparatus for removing/armouring cablesMachiningIndustrial engineering

The invention relates to an insulated enamelled wire producing manufacturing cutting device. The insulated enamelled wire producing manufacturing cutting device comprises a worktable, fastening devices and a cutting device, the fastening devices are symmetrically mounted at the front and back of the upper end face of the worktable, the cutting device is mounted on the middle part of the upper endface of the worktable in a slide fit mode, and the cutting device is located between the fastening devices. According to the insulated enamelled wire producing manufacturing cutting device and a cutting machining method, a design idea of adjustable structure is adopted to perform cutting treatment on an insulated enamelled wire, so that one equipment can adapt to the full cutting and peeling requirements of the insulated enamelled wire, the utilization rate of the equipment is improved, the cutting device plays an assisting transporting role on a cutting part of the insulated enamelled wire while the cutting effect is realized, and the labor strength of workers is reduced.

Owner:HENGYANG NORMAL UNIV

Grabbing clamping hand structure of lead storage battery box filling machine

ActiveCN112847412AEliminate errorsIncrease the degree of clampingGripping headsStructural engineeringHand structure

The invention discloses a grabbing clamping hand structure of a lead storage battery box filling machine, and relates to the technical field of storage battery machining. The structure comprises an upper seat and a lower seat which are fixedly connected with each other; a pair of air cylinders is symmetrically and fixedly connected to the lower surface of the lower seat, clamping hand assemblies are fixedly connected to piston rods of the air cylinders, and a mounting plate for mounting the air cylinders is fixedly connected to the lower seat; each clamping hand assembly comprises a base body, the base body is of a cuboid structure, the opposite side faces of the two base bodies are each provided with a plurality of first channels in the horizontal direction, pressing blocks capable of moving left and right are connected into the first channels, second channels are formed in the lower surfaces of the base bodies, and pushing blocks capable of moving up and down are connected into the second channels; and an inclined guide groove is formed in one face of each pressing block, and a guide rod is fixedly connected to each pushing block. According to the grabbing clamping hand structure, the base bodies are connected with the pressing blocks corresponding to lead storage batteries one to one, clamping of each lead storage battery is guaranteed, and therefore the problem that the lead storage batteries fall off in the grabbing process of a clamping hand is solved.

Owner:TIANNENG BATTERY GRP ANHUI

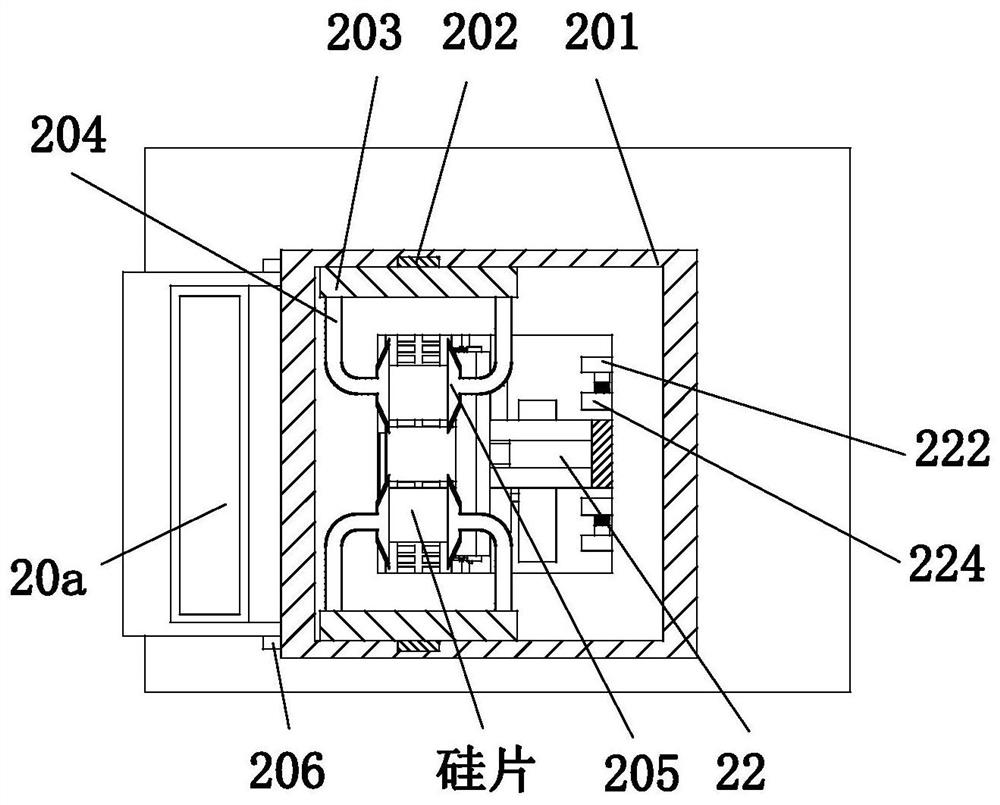

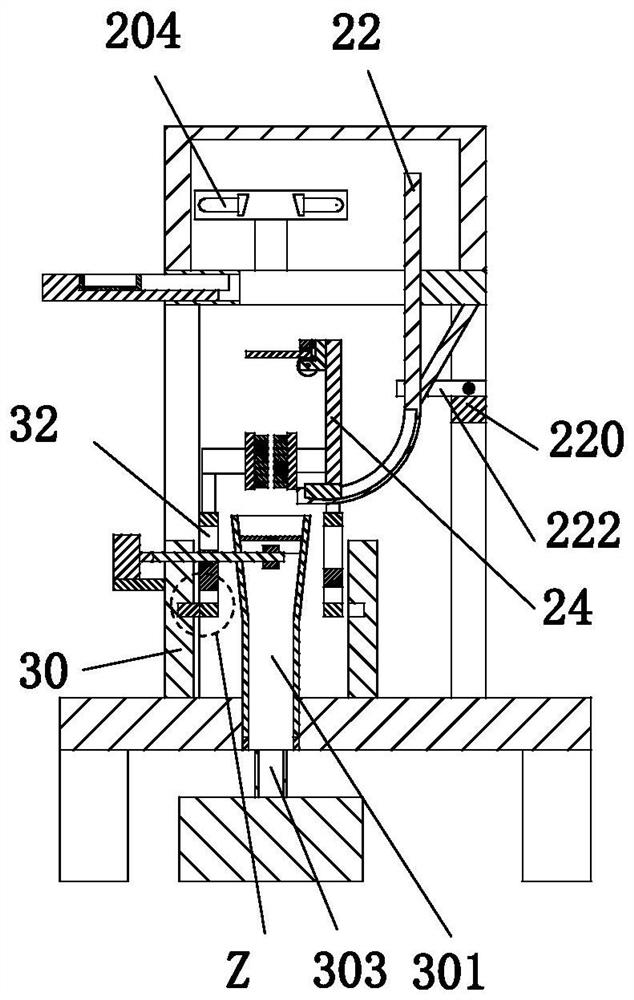

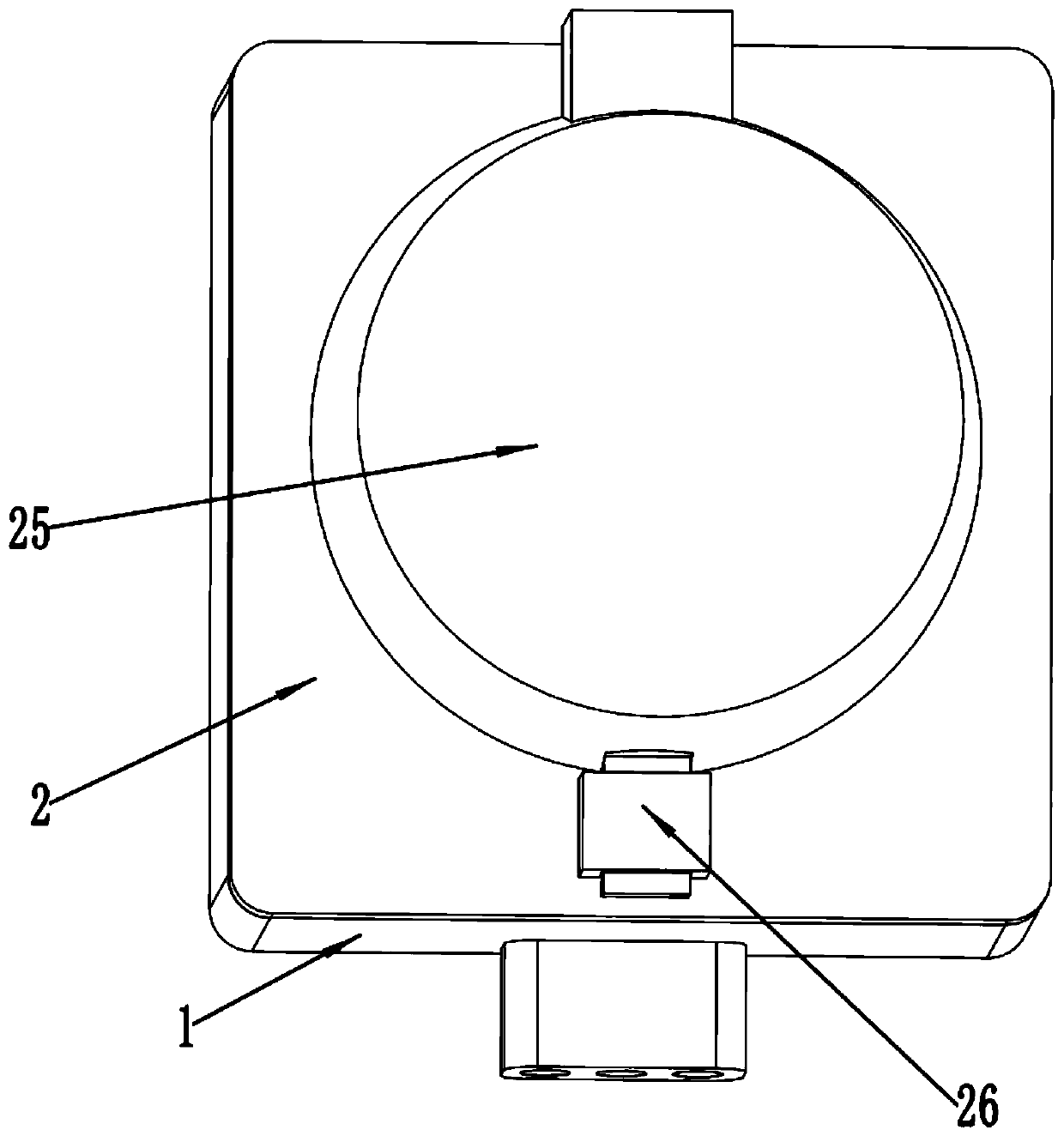

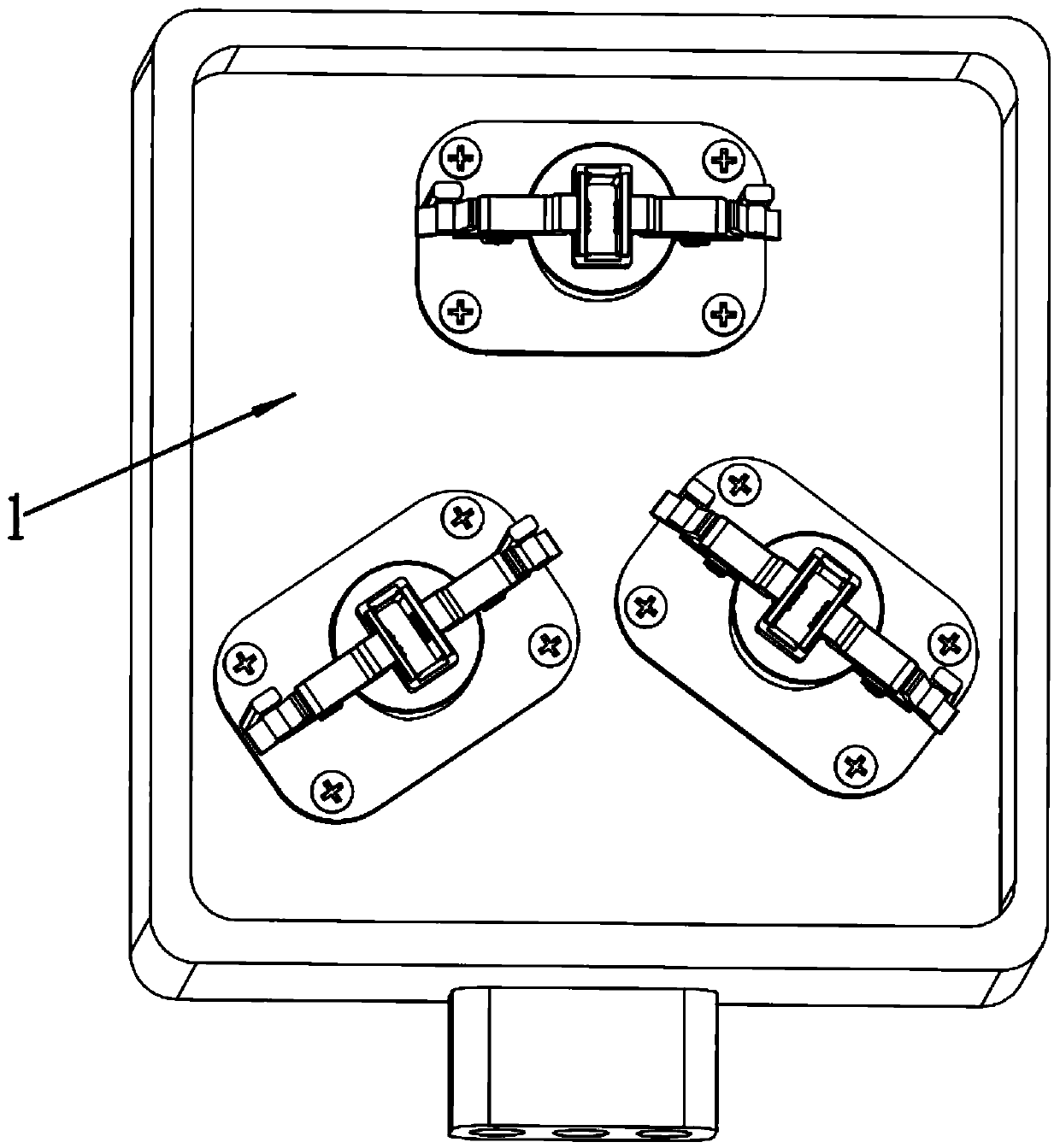

Solar silicon wafer recycling treatment device

ActiveCN111687090AImprove cleanlinessGood for shake offFinal product manufactureDirt cleaningSurface cleaningEngineering

The invention relates to a solar silicon wafer recycling treatment device. The solar silicon wafer recycling treatment device comprises a workbench, a clamping mechanism and cleaning mechanisms, wherein the clamping mechanism is mounted on the upper end face of the workbench, the cleaning mechanisms are arranged on the left side of the clamping mechanism, and the lower ends of the cleaning mechanisms are connected with the upper end face of the workbench. Solar silicon wafer recycling treatment is carried out by adopting the design concept of multiple structures with a cleaning effect, the adopted cleaning mechanisms can present a state of reciprocating in a front-back staggered mode, and thus the silicon wafer surface cleaning degree can be improved, and a concentrated treatment and collecting structure for cleared impurities is further arranged.

Owner:马鞍山华鑫财务咨询有限公司

Clamping anti-shedding mechanism and socket

ActiveCN110350364AIncrease the degree of clampingClamp tightlyCoupling device detailsEngineeringSliding contact

The invention relates to a clamping anti-shedding mechanism and a socket. The mechanism includes a sliding push rod, a semi-arc turning rod, a pressing plate, a compression spring, a jack stepped column and a clamping column, wherein the jack stepped column is connected with the compression spring, an inclined surface is arranged on a side of the jack stepped column, an inclined surface is arranged at one end of the sliding push rod, the inclined surface of the sliding push rod is slidably connected with the inclined surface of the jack stepped column, the other end of the sliding push rod isprovided a sliding push rod push bead, the sliding push rod push bead is into sliding contact with the semi-arc turning rod, the clamping column is mounted in a circular hole of the jack stepped column, when a plug is inserted, the jack stepped column is pressed through the plug to drive the inclined surface to make the sliding push rod move towards an outer side, the sliding push rod push bead ispushed by the sliding push rod to push the semi-arc turning rod to turn to push the clamping plate and a friction block to firmly fix the plug, clamping is tighter, and automatic clamping is achieved.

Owner:海宁市利得宝印染有限公司

Transportation device preventing automobile parts from shaking and dropping

PendingCN111976819AEasy to transport and placeAvoid shakingHand carts with multiple axesMotor vehicle partStructural engineering

Owner:合肥暇耐机电设备有限公司

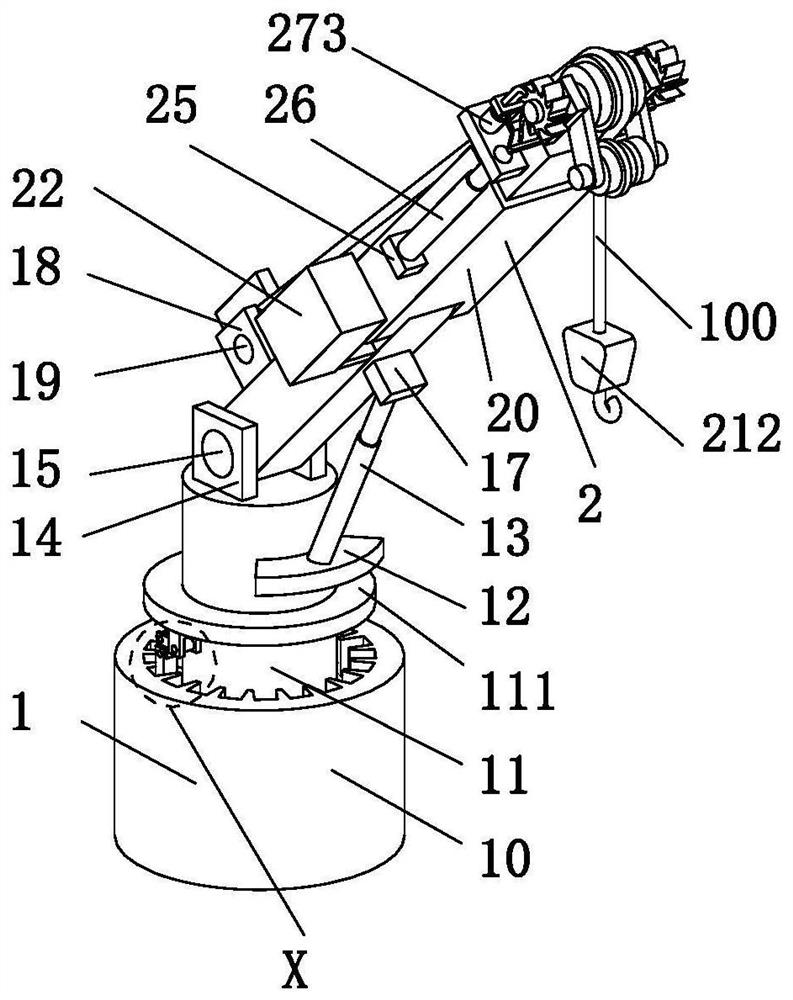

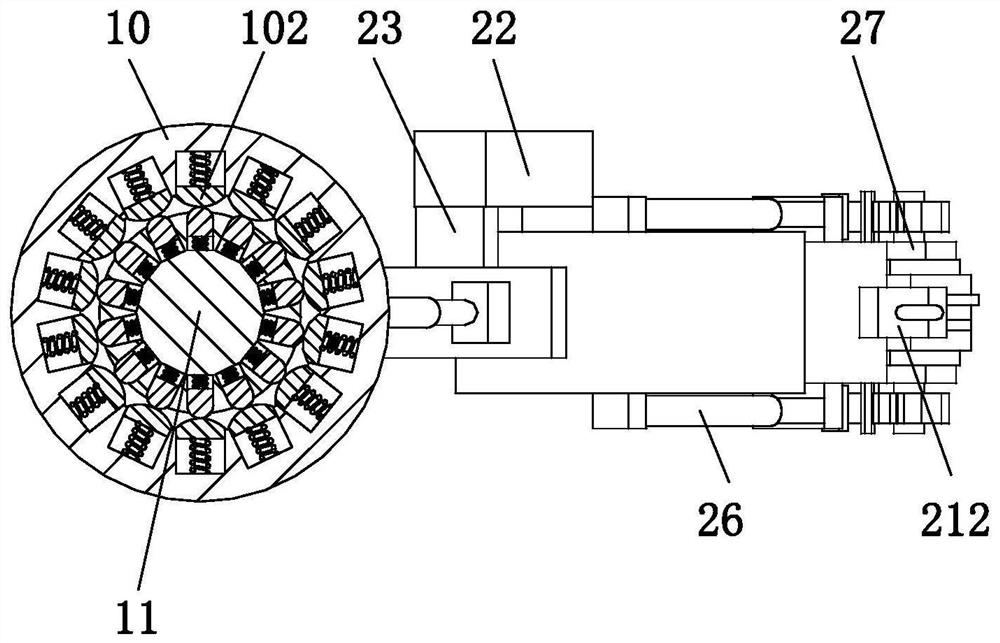

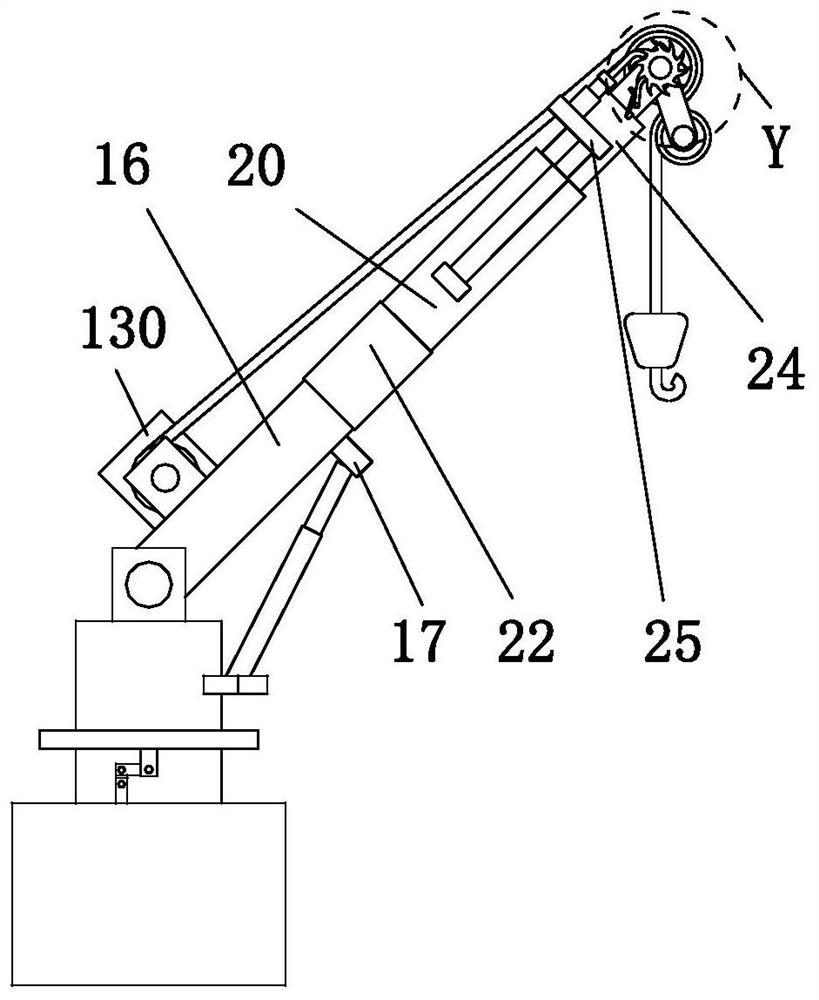

Crane telescopic arm positioning and fixing equipment for water conservancy ship

ActiveCN112062008AImprove application rateAvoid collisionCranesMarine engineeringStructural engineering

The invention relates to crane telescopic arm positioning and fixing equipment for a water conservancy ship. The crane telescopic arm positioning and fixing equipment comprises a base mechanism and amain stretching mechanism, the lower end of the base mechanism is installed on the existing working ground, and the main stretching mechanism is arranged at the right end of the base mechanism. A telescopic arm of a crane for the water conservancy ship is positioned and fixed by adopting the design concept of multiple rotatable structures. The base mechanism and the main stretching mechanism are matched to achieve multi-angle and multi-height and length size change of the whole crane telescopic arm positioning and fixing equipment, and then the adaptability of the whole crane telescopic arm positioning and fixing equipment to cargo hoisting at different positions is improved.

Owner:河南远东重工机械制造有限公司

Integrity testing device for construction film material under action of force and thermal radiation and using method

PendingCN107589143AIncreasing the thicknessSimple partsMaterial strength using tensile/compressive forcesMaterial thermal analysisEngineeringTest fixture

The invention relates to an integrity testing device for a construction film material under the action of force and thermal radiation and a using method. The method comprises the steps that a single-shaft or double-shaft film material test piece is laid on two or four groups of rib sliding blocks; the two or four drooping ends of the test piece separately and sequentially bypass triangular prism surfaces of two or four sets of self-locking clamps; the lower edges of two or four front vertical suspended beams press the surface of the test piece; the rest ends of the test piece are upturned; thetwo ends of two or four sets of front vertical suspended beams respectively penetrate the lifting eyes I of two or four lifting hooks and are embedded into two or four pairs of vertical groove IV andvertical groove V of a supporting device; mass blocks with the same weight are laid on two or four supporting plates; a lifting device, on which a thermal radiation source and video equipment are fixed, is fixed on the ground; the thermal radiation source and the video equipment are turned on; when the single-shaft or double-shaft film material test piece is broken, a test is over. The device canperform testing research on the film material test piece with different thermal radiation intensities and at different film surface stress ratio states, so as to obtain data, such as failure development processes, failure modes and integrity duration subjected to fire, of the film material test piece.

Owner:TIANJIN FIRE RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com