Lead framework production system

A production system and lead frame technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of high labor intensity, plating layer wear, low production efficiency, etc., to improve the automation process, reduce labor intensity, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

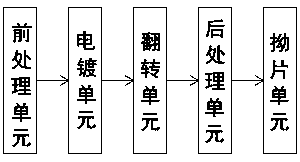

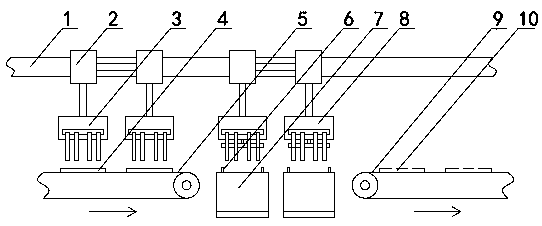

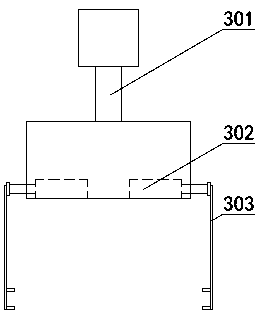

[0049] Such as figure 1 As shown, a lead frame production system includes a pre-processing unit, an electroplating unit, a flipping unit, a post-processing unit, and an angler unit arranged in sequence, combined with figure 2 , the frame 4 to be electroplated enters the electroplating unit for electroplating after going through the pretreatment procedures such as feeding, oil removal, acid neutralization, pre-copper plating, and anti-displacement in the pre-processing unit, and then the frame semi-finished product 10 is obtained after the electroplating is completed. 10 When it is exported from the electroplating unit, its electroplating layer 17 (see Figure 5 ) is in contact with the surface of the electroplating output conveyor belt 9, and the frame semi-finished product 10 is sent to the overturning unit through the electroplating output conveyor belt 9. After being overturned by the overturning unit, the electroplating layer 17 is no longer in contact with the subsequen...

Embodiment 2

[0089] In this embodiment, the angle sensor and the angle lever provided at the angle input conveyor belt 23 adopt the same technical scheme as the electroplating sensor 11 and the electroplating lever 12 at the five places on the electroplating input conveyor belt, which can realize two-piece For the shielding of the frame semi-finished products 10, two angle sliders 22 and the suction cups 24 at the bottom thereof are respectively provided with two, and the two frame semi-finished products 10 are transferred at the same time. 10 carry out the bending operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com