Method for automatically detecting and classifying glass defects

A technology for automatic detection of glass defects, applied in image analysis, image data processing, instruments, etc., can solve the problems of low accuracy of manual inspection, easy visual fatigue of workers, missed detection of glass defects, etc., to speed up the automation process and save labor costs , The effect of high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to understand the technical content of the present invention more clearly, the following examples are given in detail. It should be understood that the examples are only used to illustrate the present invention, not to limit the present invention.

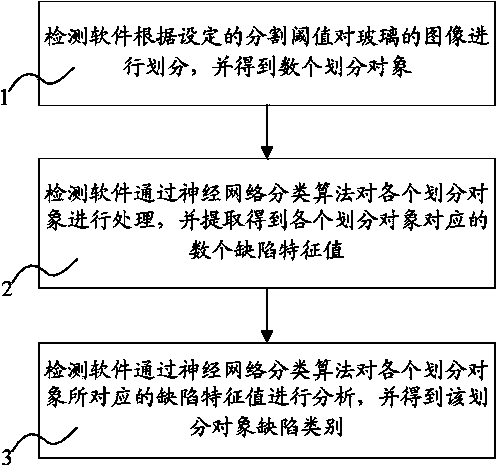

[0025] see figure 1 , in one embodiment, a kind of method for automatically detecting and classifying glass defect of the present invention comprises the following steps:

[0026] (1) The detection software divides the glass image according to the set segmentation threshold, and obtains several divided objects;

[0027] (2) The detection software processes each division object through a neural network classification algorithm, and extracts several defect feature values corresponding to each division object;

[0028] (3) The detection software analyzes the defect feature values corresponding to each division object through a neural network classification algorithm, and obtains the defect category of the divisio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com