Preparation equipment mobile monitoring system and method based on internet of things and industrial cloud

A mineral processing equipment and mobile monitoring technology, applied in the general control system, control/regulation system, network topology, etc., can solve the labor intensity of inspection personnel without inspection measures, maintenance experience support without formation of maintenance knowledge base, and maintenance without inspection measures. Involving equipment video surveillance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

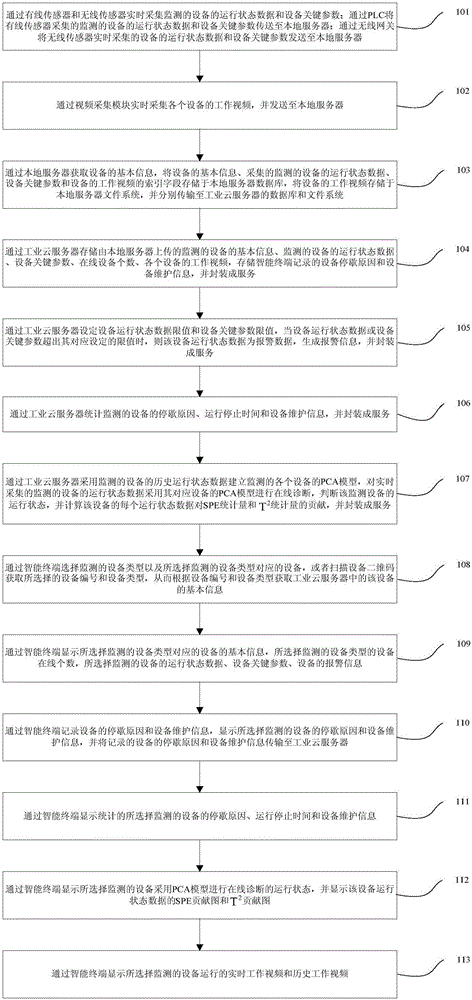

[0062] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

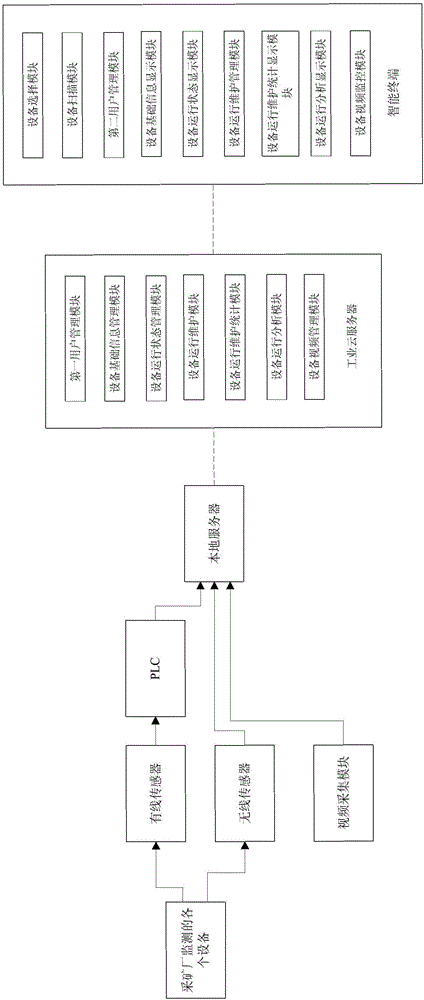

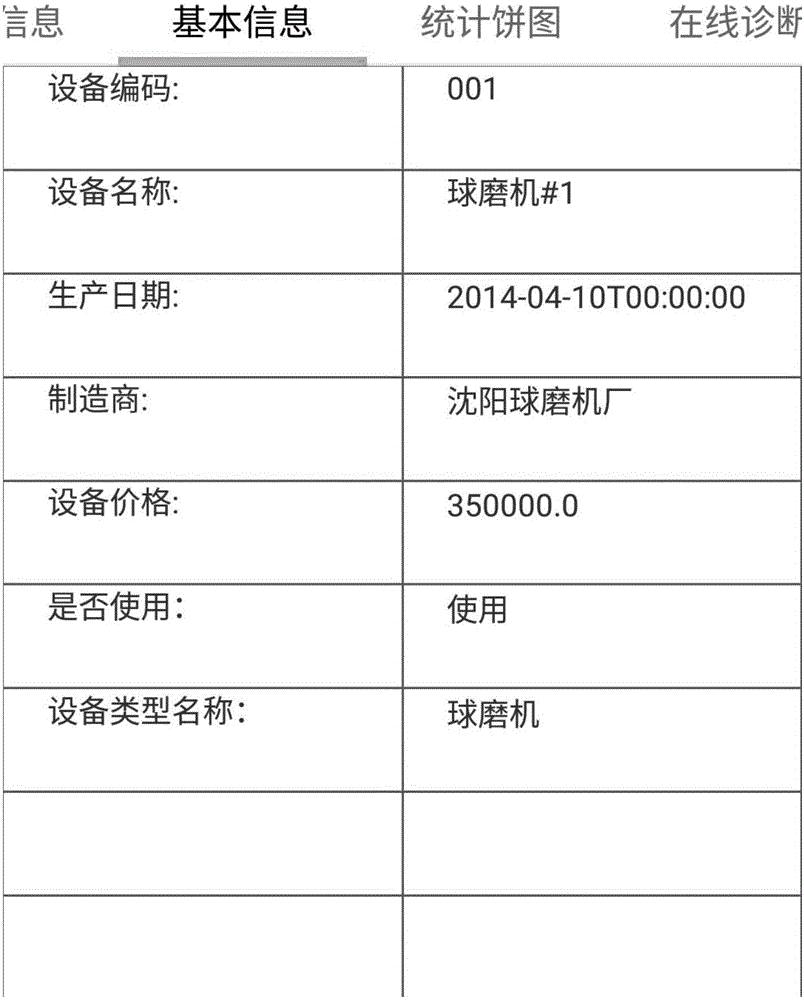

[0063] A mobile monitoring system for mineral processing equipment based on the Internet of Things and industrial cloud, such as figure 1 As shown, it includes industrial cloud server, intelligent terminal, data acquisition unit of mineral processing equipment and local server.

[0064] The data acquisition unit of mineral processing equipment includes PLC, data acquisition sensors and video acquisition modules; data acquisition sensors include wired sensors and wireless sensors.

[0065] The input end of the wired sensor and the input end of the wireless sensor are connected to various equipment monitored by the mining plant, the output end of the wired sensor is connected to the input end of the PLC, the wireless sensor is connected to the local server through the wireless gateway, the output end of the PLC and the output of the video ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com