Patents

Literature

251 results about "Cement factory" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wet type air purification apparatus utilizing a centrifugal impeller

InactiveUS20070051245A1Quality improvementHuman health protectionCombination devicesFresh airInternal combustion engine

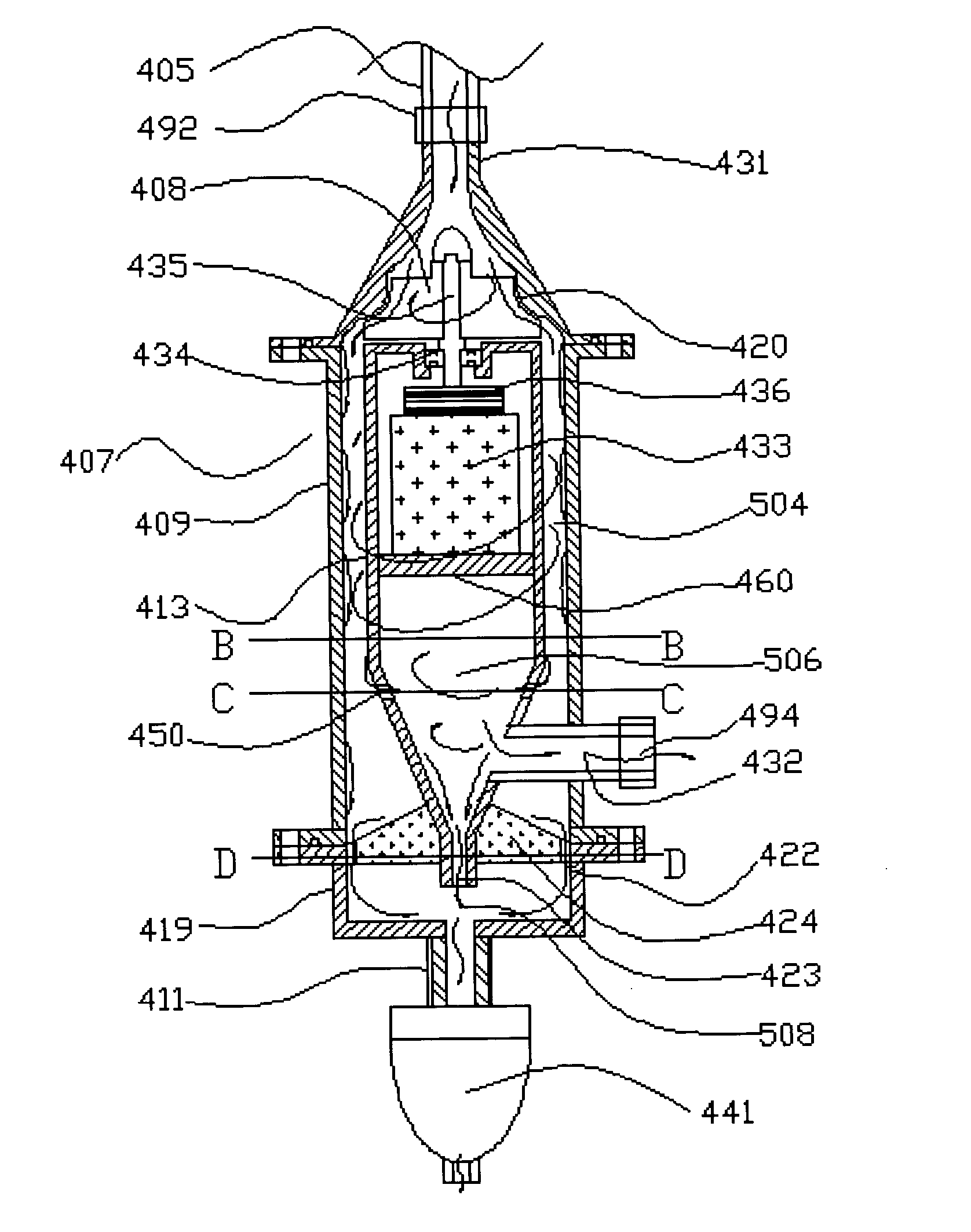

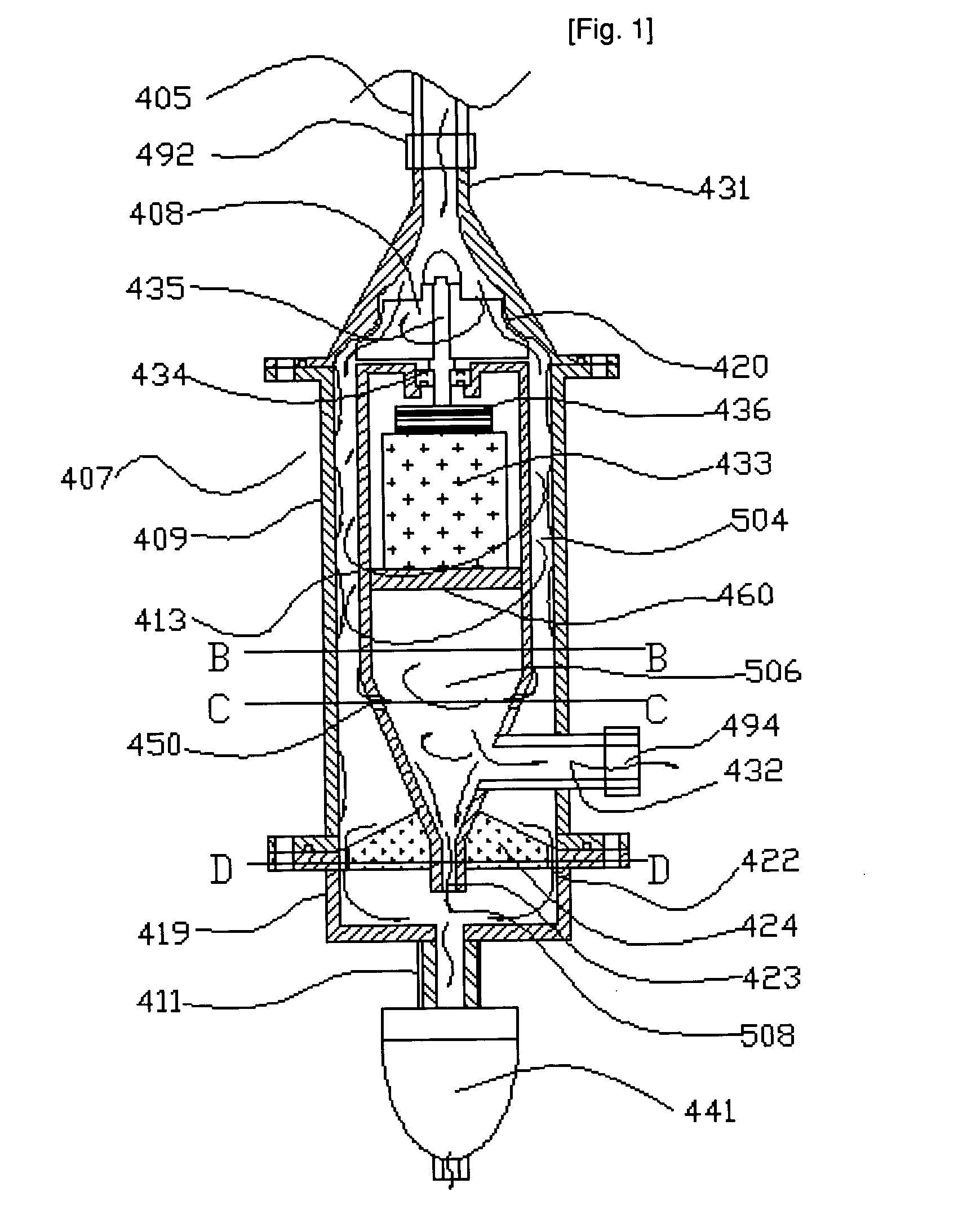

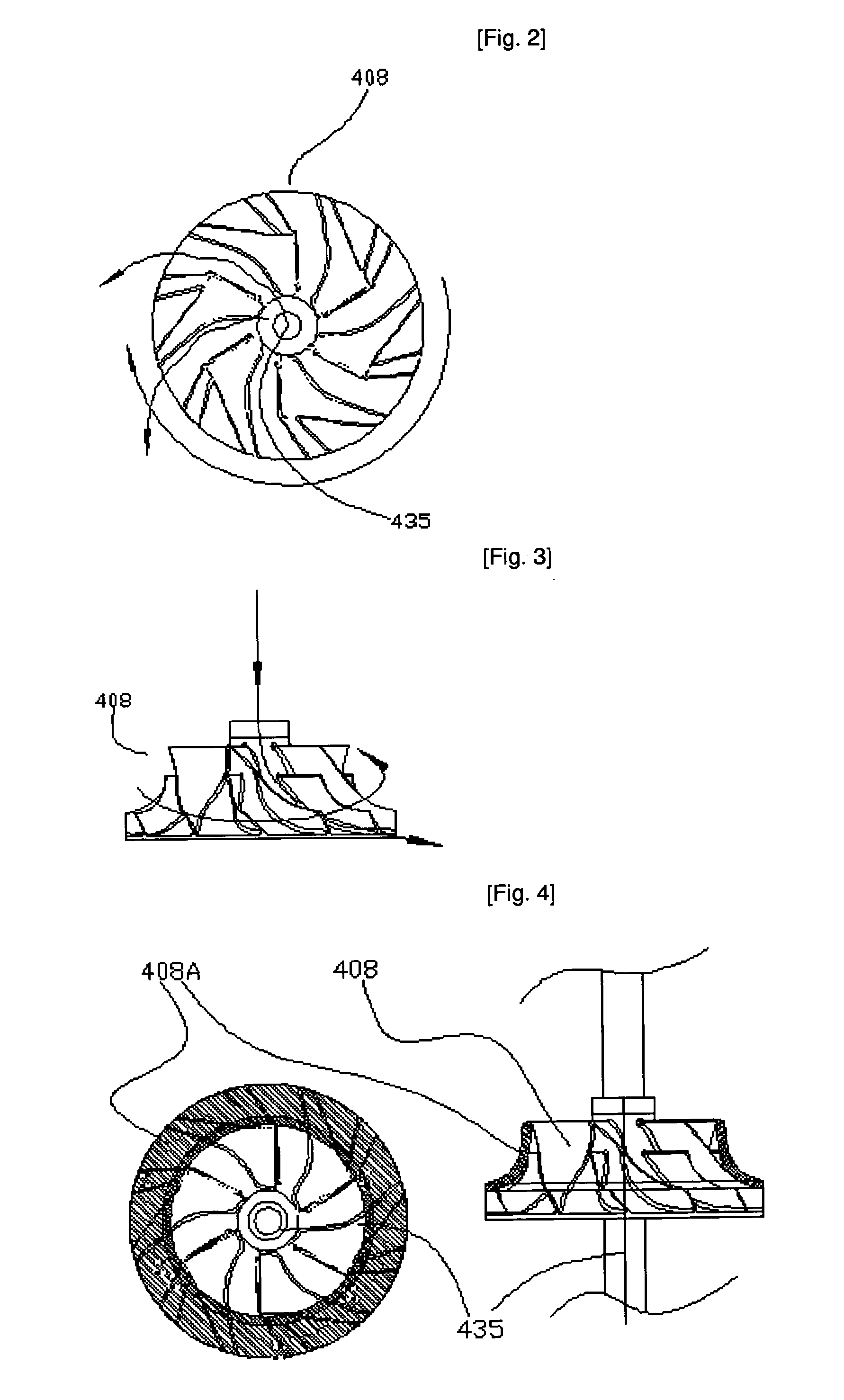

This invention relates to a wet type air cleaner utilizing a centrifugal impeller with an electric motor instead of using filters, thus the separation of particular dust, mist can be absolutely eliminated from air with the difference of specific gravity between gas and pollution liquid under centrifugal force. An wet type air cleaner utilizing a centrifugal impeller comprising: protection grill (400) and water tank (401) located on an inlet pipe (405), an electric motor (433) with a centrifugal impeller (408) and a bearing (434) located inside of centrifugal cleaner (407), a drain trap (441) and humidity controller (442) installed on an exit pipe (432) etc. Therefore centrifugal wet type air cleaner make fresh air efficiently to be carried out by centrifugal force without using filters in the field of home, office, passenger car, dust place like cement factory, machine center, exhaust gas cleaner for an industrial burner and an internal combustion engine.

Owner:YUN JANGSHIK

Dedicated pouring material for cement kiln outlet and jetting coal pipe and preparation method thereof

InactiveCN101445379AImprove thermal shock performanceGood alkali resistanceCarbide siliconCement factory

The invention discloses a dedicated pouring material for a cement kiln outlet and a jetting coal pipe, which comprises the following components by the weight percentage: 20 to 30 percent of sintered plate-shaped corundum, 20 to 30 percent of sintered and synthesized mullite, 10 to 15 percent of chrome corundum, 5 to 10 percent of silicon carbide, 3 to 5 percent of silicon carbide superfine powder, 3 to 5 percent of magnesia alumina spinel, 5 to 8 percent of zircon sand, 2 to 5 percent of activated Al2O3 micro powder, 2 to 5 percent of silicon micro powder, 3 to 5 percent of pure calcium aluminate cement, 1 to 2 percent of stainless steel fiber, 5 to 10 percent of synthesized zirconium mullite grinding powder, 0.1 to 0.15 percent of composite additives and 0.01 to 0.1 percent of explosion proof fiber. The invention further discloses a method for preparing the pouring material. The pouring material is applicable to the dry-process cement kiln outlets and the jetting coal pipes in large-scale cement plants and has the advantages of high wear resistance, good anti-stripping resistance and long service life.

Owner:JIANGSU GUOHAO REFRACTORY TECH

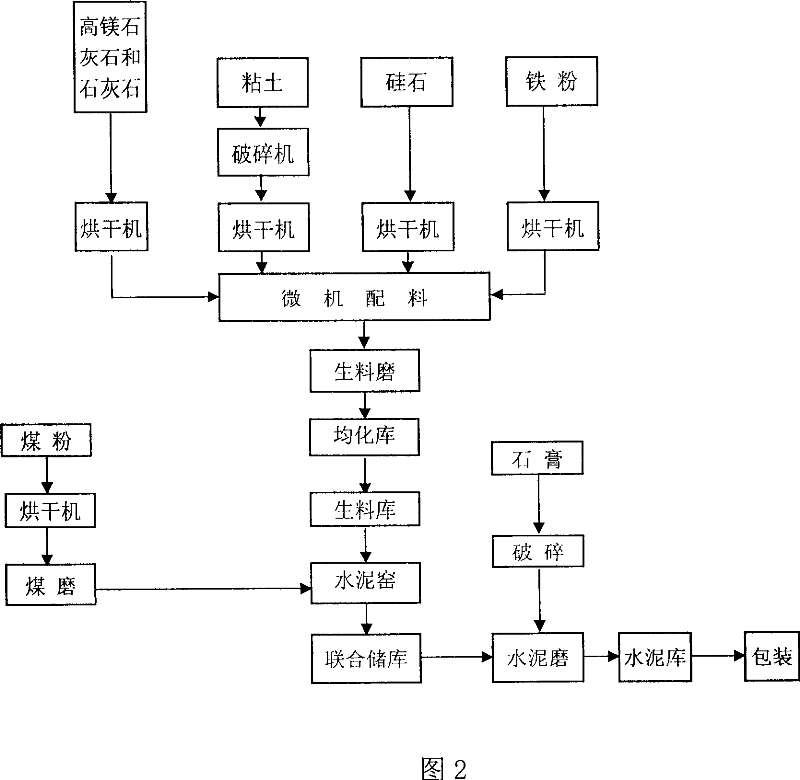

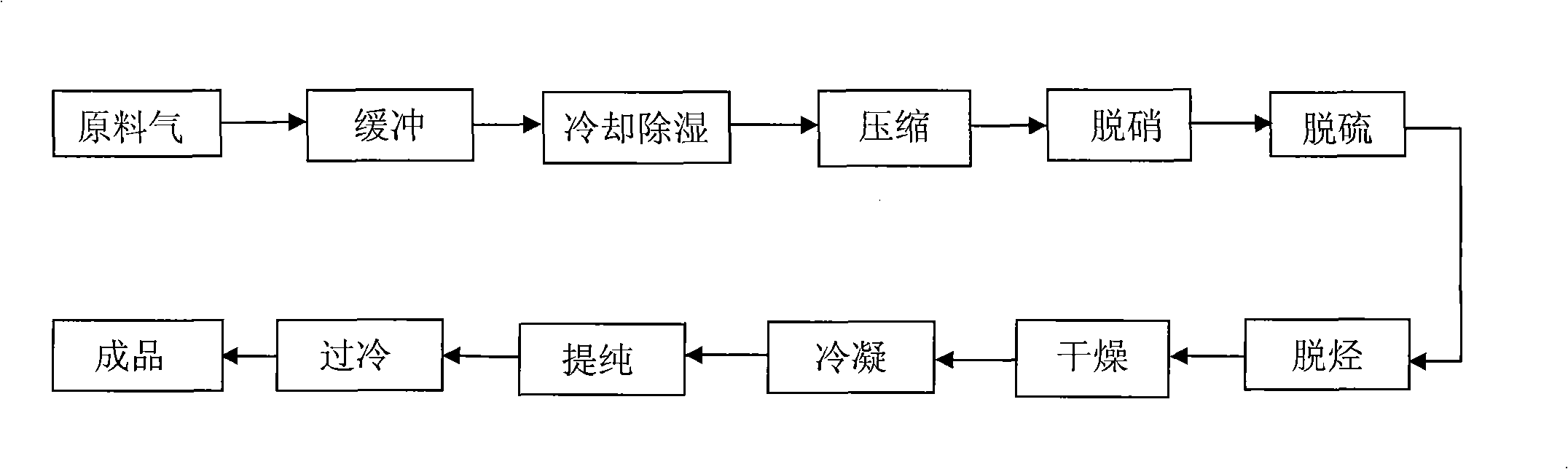

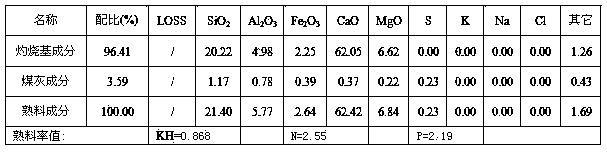

High-magnesium low-heat portland cement clinker aggregate and preparation method thereof

InactiveCN101041560AImprove crack resistanceLow heat of hydrationClinker productionHigh magnesiumPortland cement

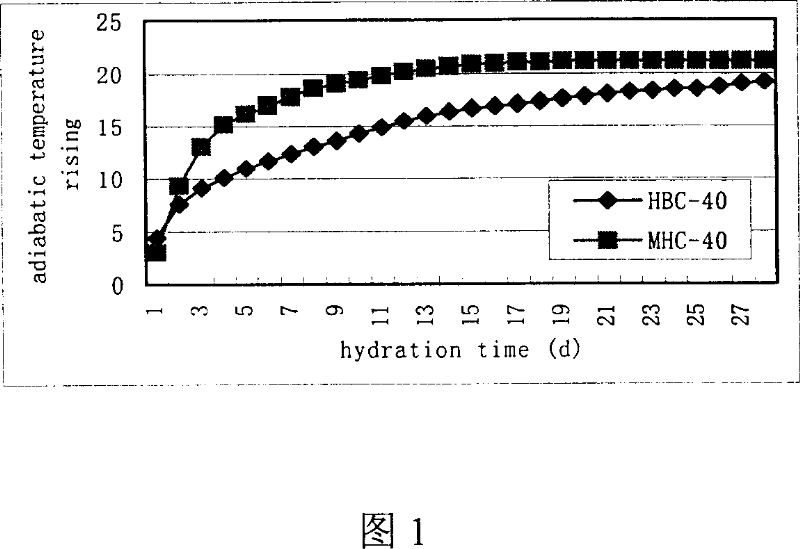

The invention discloses a high-magnesium lower thermal silicate cement clinker, making mineralogical composition at (mass percent): 40 -65% C2S, 15-40% C3S, 1-8% C3A, 10-25% C4AF and content of MgO at 2.0-6.0%. The invention also discloses a preparing method of high-magnesium lower thermal silicate cement clinker, including indispensable steps of producing cement clinker with raw materials and controlling content of MgO of cement clinker at 2.0-6.0%.

Owner:CHINA BUILDING MATERIALS ACAD

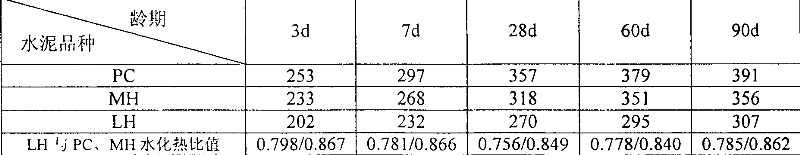

Zinc hydrometallurgy production process

InactiveCN102876888AReduce lossesHigh recovery rateProcess efficiency improvementCement factoryIndium

The invention relates to a zinc hydrometallurgy production process. According to the zinc hydrometallurgy production process provided by the invention, reduction leached supernate is subjected to preneutralization, then zinc dust is added for replacing indium, after the indium is separately removed, oxygen with the concentration being not lower than 98 percent is filled into liquid obtained after the indium is deposited, controlling the temperature in the range of 160 to 200 DEG C and controlling the pressure in the range of 1,000 to 2,000kPa, so that iron precipitates in the liquid obtained after the indium is deposited enter slags. The iron removed liquid obtained by the zinc hydrometallurgy production process has the iron content being lower than 1.2g / l, the iron removed liquid can be directly returned to be subjected to neutral leaching, and the system has stable production working conditions and is beneficial to stable production; in the iron slags obtained by the zinc hydrometallurgy production process, the zinc content is lower than 1 percent, the zinc loss is low and the zinc recovery rate is high; the iron slags can be directly sold to a cement plant and an iron and steel plant to be used as the raw materials without being stacked in a slag field, so that the zinc hydrometallurgy production process is beneficial to environmental-protection and the comprehensive utilization of resources and mineral resources are saved.

Owner:广西华锡集团股份有限公司 +1

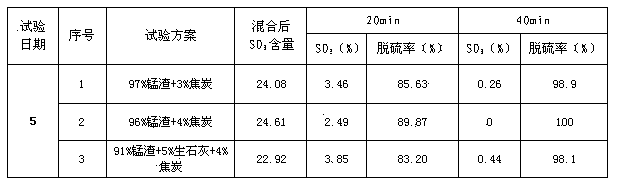

Method for extracting ammonium and modifying electrolytic manganese residue

ActiveCN104529196ARealize cascade utilizationAchieving mass utilizationSolid waste managementSolid waste disposalPretreatment methodElectrolysis

The invention relates to a method for extracting ammonium and modifying electrolytic manganese residue, and belongs to the field of environmental protection. The method comprises the steps: mixing the electrolytic manganese residue with one or more of quick lime, slake lime, carbide slag, steel slag, red mud or other alkaline slag, and heating and calcining the mixture under the condition of 200 to 500 DEG C. By adopting the method, the disadvantage that pollutants are formed in the heating process of the electrolytic manganese residue containing two volatile gases such as nitrogen and sulfur can be ingeniously avoided, the cementitious activity of the heated modified electrolytic manganese residue can be remarkably improved, and the modified electrolytic manganese residue can be used in cement factories, brick factories, concrete mixing plants and the like; more favorable advantages are as follows: the nitrogen element in the electrolytic manganese residue forms ammonia gas which is prepared into ammonia water to be recycled, and the sulfur element is cured in the residue in a form of calcium sulfate to be used as a beneficial cement excitant or retarder component. By adopting the process, the economical performance and environmental friendliness of an electrolytic manganese residue pretreatment method can be improved, an important significance for the recycling of the electrolytic manganese residue in China can be realized, the application prospect is wide, and the market value is vast.

Owner:UNIV OF SCI & TECH BEIJING

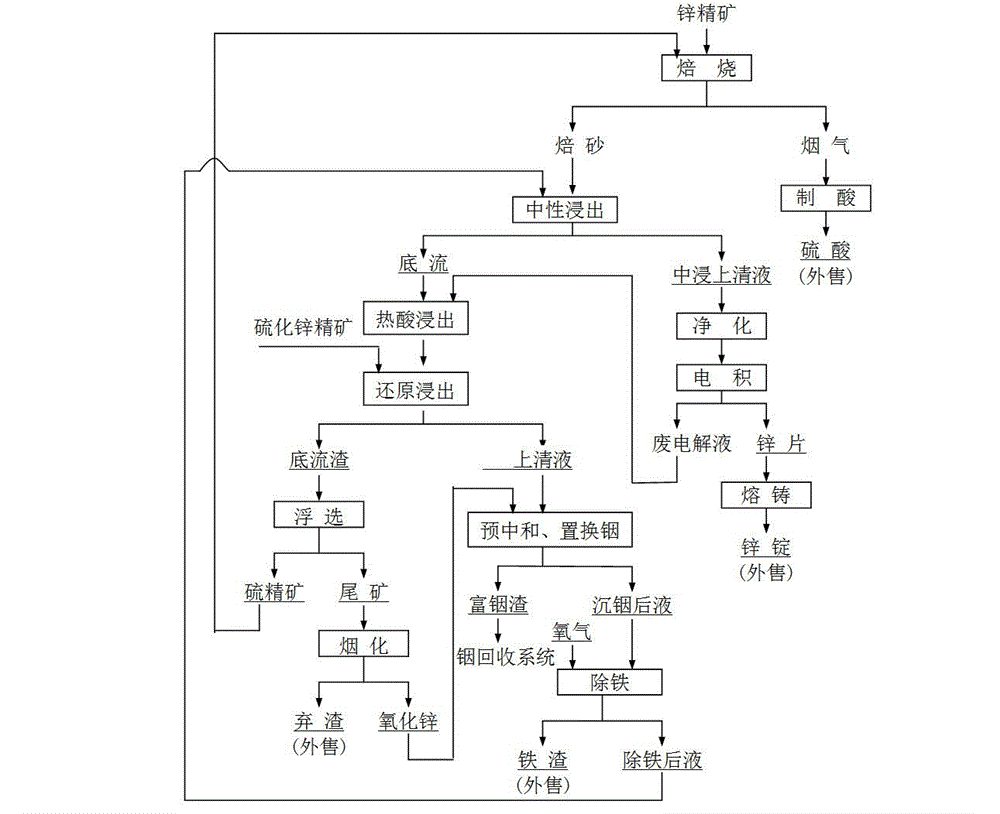

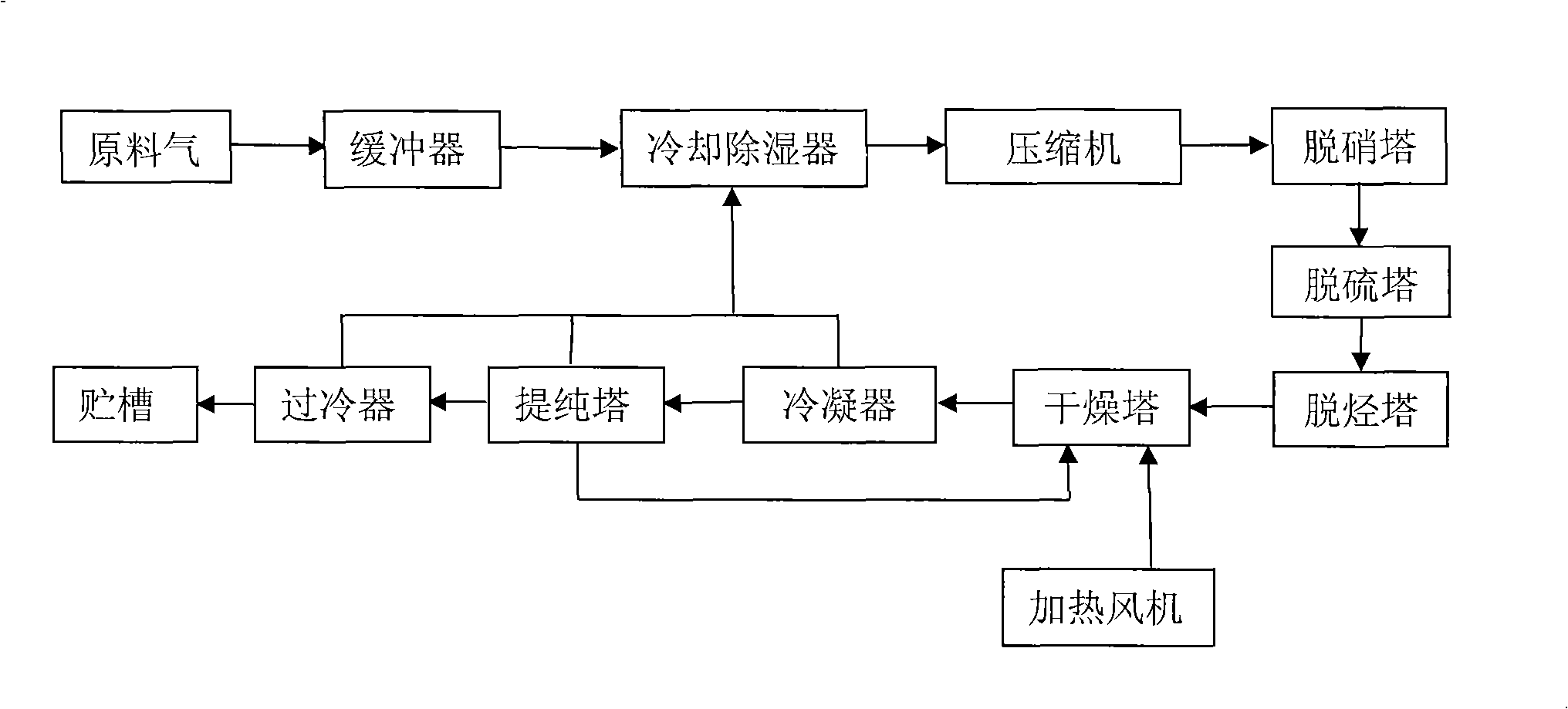

Method and apparatus for preparing food level liquid carbon dioxide with flue gas

The invention discloses a method of using flue gas to prepare food-grade liquid carbon dioxide, comprising steps that the carbon dioxide is collected and recovered as raw material to be treated by cooling, drying, compression, denitration, desulfurization and de-hydrocarbon, and is further treated by drying, purification and cooling to obtain the food-grade liquid carbon dioxide; a device to be adopted comprises a cooling dehumidifier, a compressor, a denitration tower, a desulfurization tower, a de-hydrocarbon tower, a drying tower, a condenser, a purification tower, a subcooler and a storage tank, etc., which are all connected by pipelines; the food-grade liquid carbon dioxide prepared by using the method and the device has advantages of high purity, small power consumption and low cost, etc.; the method can be widely used in the occasions of making use of the flue gas which is emitted from coal-fired power plants, cement factories, lime plants and coal-fired boilers and then collected and recovered to prepare food-grade liquid carbon dioxide.

Owner:杭州快凯高效节能新技术有限公司

Cement with high water-retaining property

ActiveCN104193202AThere is no decomposition failure problemSimple processCement productionCalcium hydroxideCement factory

The invention discloses cement with high water-retaining property. The cement with high water-retaining property consists of silicate cement clinker, a dechlorination caustic sludge mixture, a mixed material, gypsum and other auxiliaries. The water-retaining component dechlorination caustic sludge mixture of the cement is an inorganic material, so that the decomposition failure problem of organic materials is unavailable and the water-retaining rate of the cement is not lower than 90%; the cement can be produced by equipment in the existing cement plants so that the process is easy to realize; and the large solid waste such as caustic sludge and returned sand and rocks of the soda plants can be digested at the same time, and soda ash can be produced by using part of the calcium hydroxide.

Owner:SOUTH CHINA UNIV OF TECH

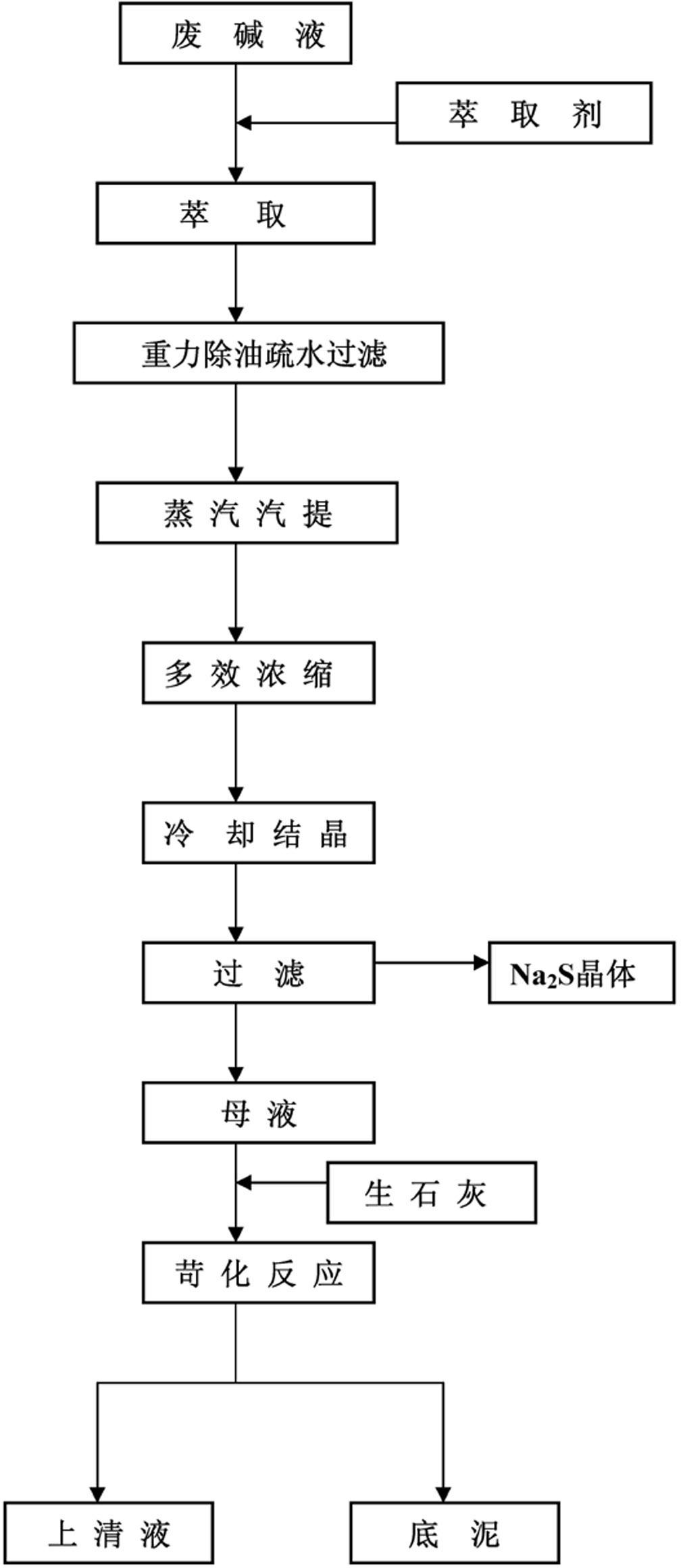

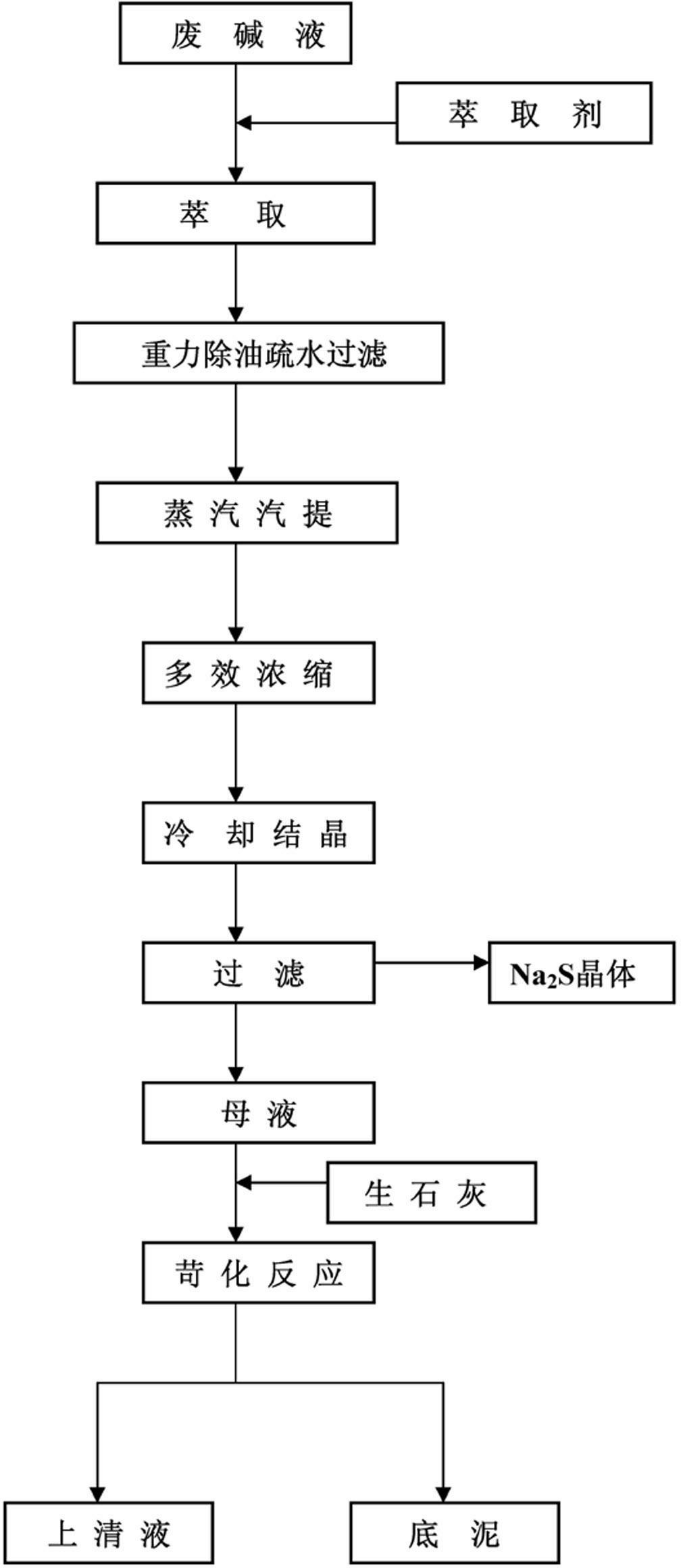

Circular and comprehensive utilization method for ethylene alkali waste liquid

ActiveCN102424498AEfficient use ofAchieving zero emissionsMultistage water/sewage treatmentWater/sewage treatment by heatingCement factoryEnvironmental engineering

The invention relates to a circular and comprehensive utilization method for ethylene alkali waste liquid. The method is characterized in that oil in waste alkali is extracted by an extractant firstly, a hydrophobic type filtering gravity oil removal tank is used for removing a oil-containing suspended substance in alkali waste liquid, hydrocarbons substances dissolved in the alkali waste liquid can be steamed by selecting an indirect steam heating stripping method, then the alkali waste liquid is evaporated and concentrated so that the Na2S concentration in the alkali liquid can reach more than 15%, and the Na2S is precipitated through cooling and crystallizing, crystals can be filtered to obtain mother liquor, the mother liquor is carried out causticizing reaction by adding quicklime, precipitated to obtain a supernatant and bottom mud, the supernatant is returned for ethylene circular and comprehensive utilization, the obtained bottom mud can be used as a raw material for cement mill. The method of the invention solves four problems of oil substances (comprising suspended substances) removal, residual alkali comprehensive disposal, sulfide treatment and dissolved organic matterdegradation in circular and comprehensive utilization of the ethylene alkali waste liquid, the ethylene alkali waste liquid treatment realizes sewage zero-discharge, saves resource and energy, and accords with circular economy idea.

Owner:珠海横琴恒生源环保科技有限公司

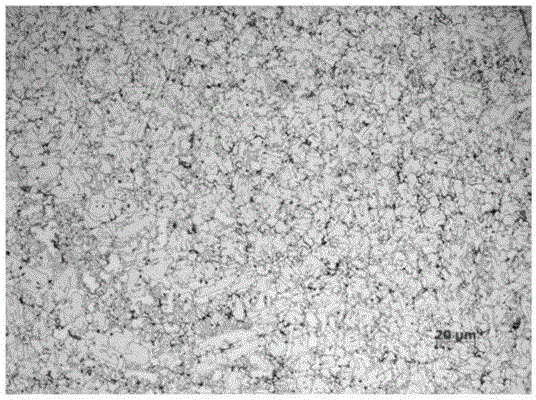

Self-shielded flux-cored wire for extrusion roller remanufacturing

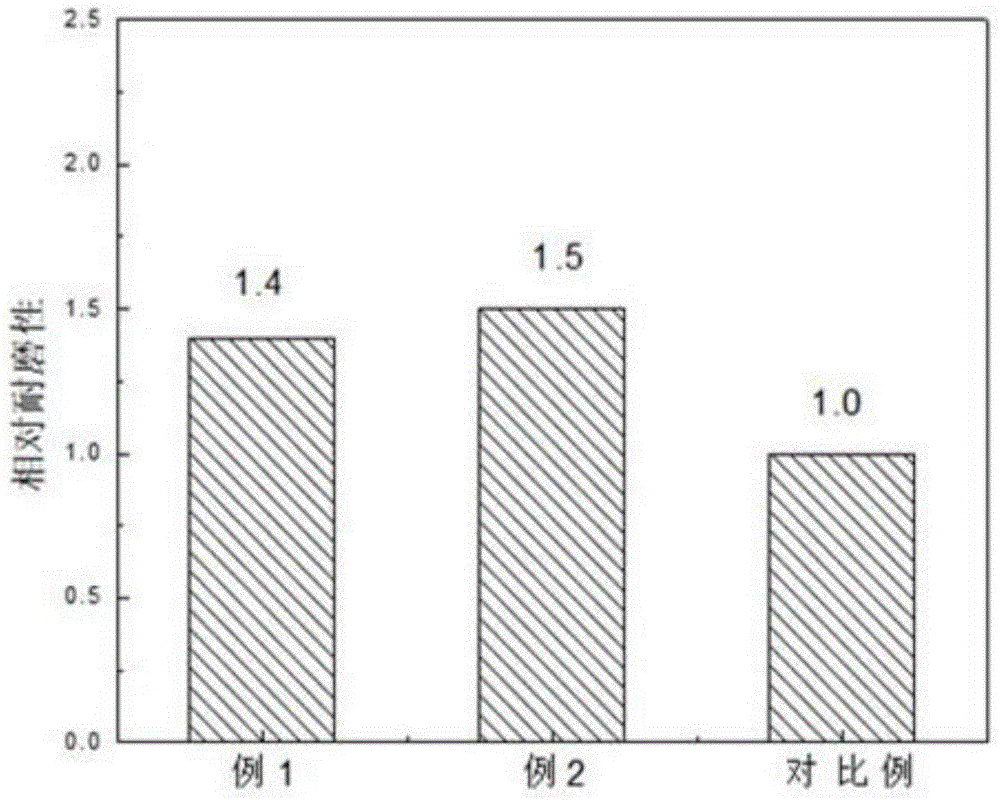

InactiveCN104959746AImprove bindingImprove toughnessWelding/cutting media/materialsSoldering mediaFerrosiliconManganese

The invention discloses a self-shielded flux-cored wire for extrusion roller remanufacturing. A mild-carbon steel strip is employed as the skin of the self-shielded flux-cored wire. The component of the flux comprises, by mass, 20%-40% of high carbon ferrochrome, 20%-40% of chromium carbide, 5%-20% of ferromolybdenum, 1%-10% of ferrovanadium, 1%-5% of ferroniobium, 1%-5% of graphite, 1%-5% of aluminum-magnesium, 1%-4% of electrolytic manganese, 1%-4% of ferrosilicon and 1%-4% of ferroboron, and the weight ratio is 44%-52%. The hardness of the surfacing alloy manufactured by the use of the self-shielded flux-cored wire can reach HRC60, and the surfacing alloy is fine and uniform in crack, is high in wear resistance, is high in shock resistance, and is suitable for being employed as a working layer in an extrusion roller remanufacturing process in a cement plant.

Owner:盐城市成功机械制造有限公司

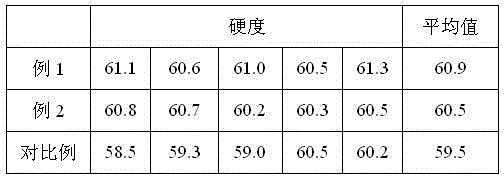

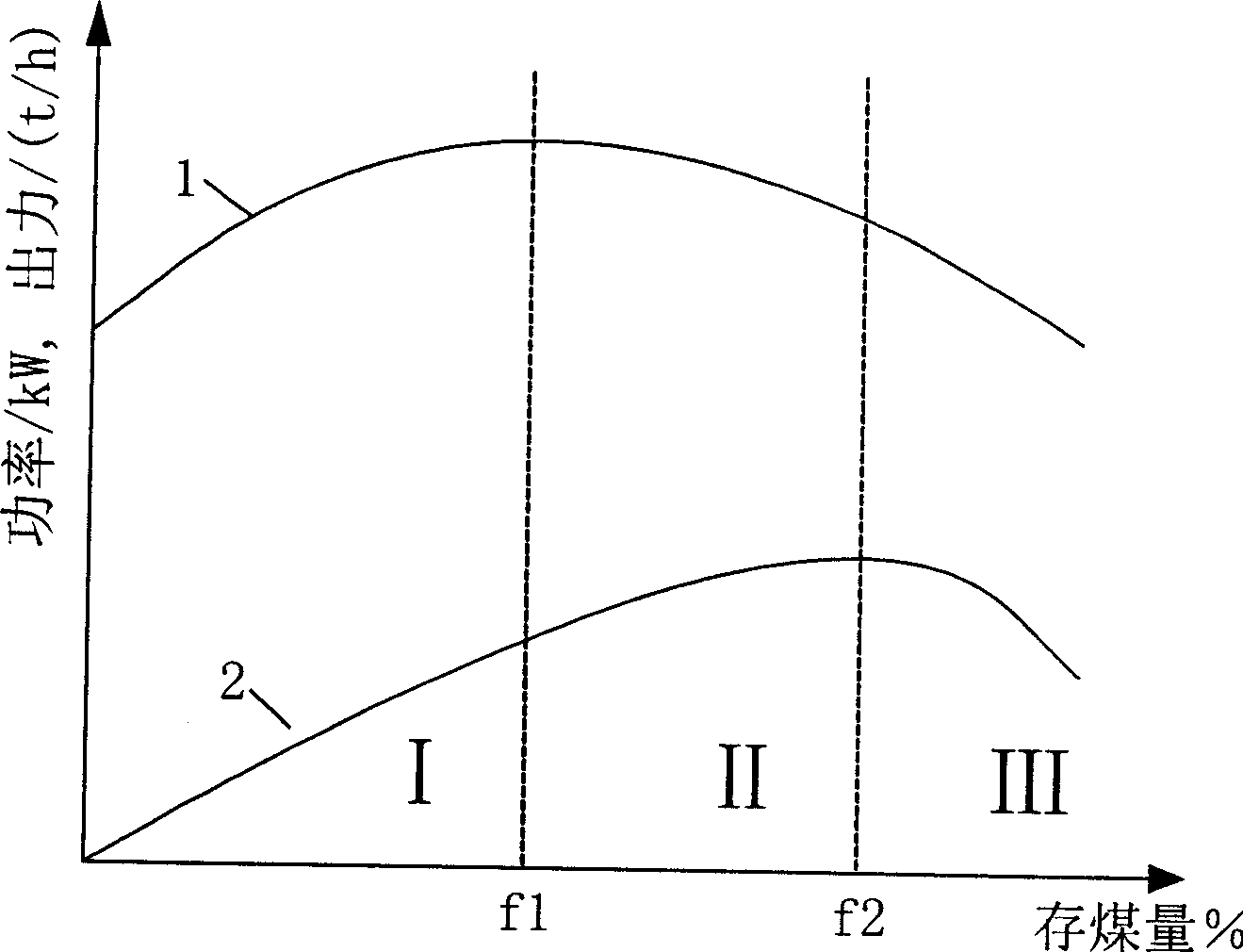

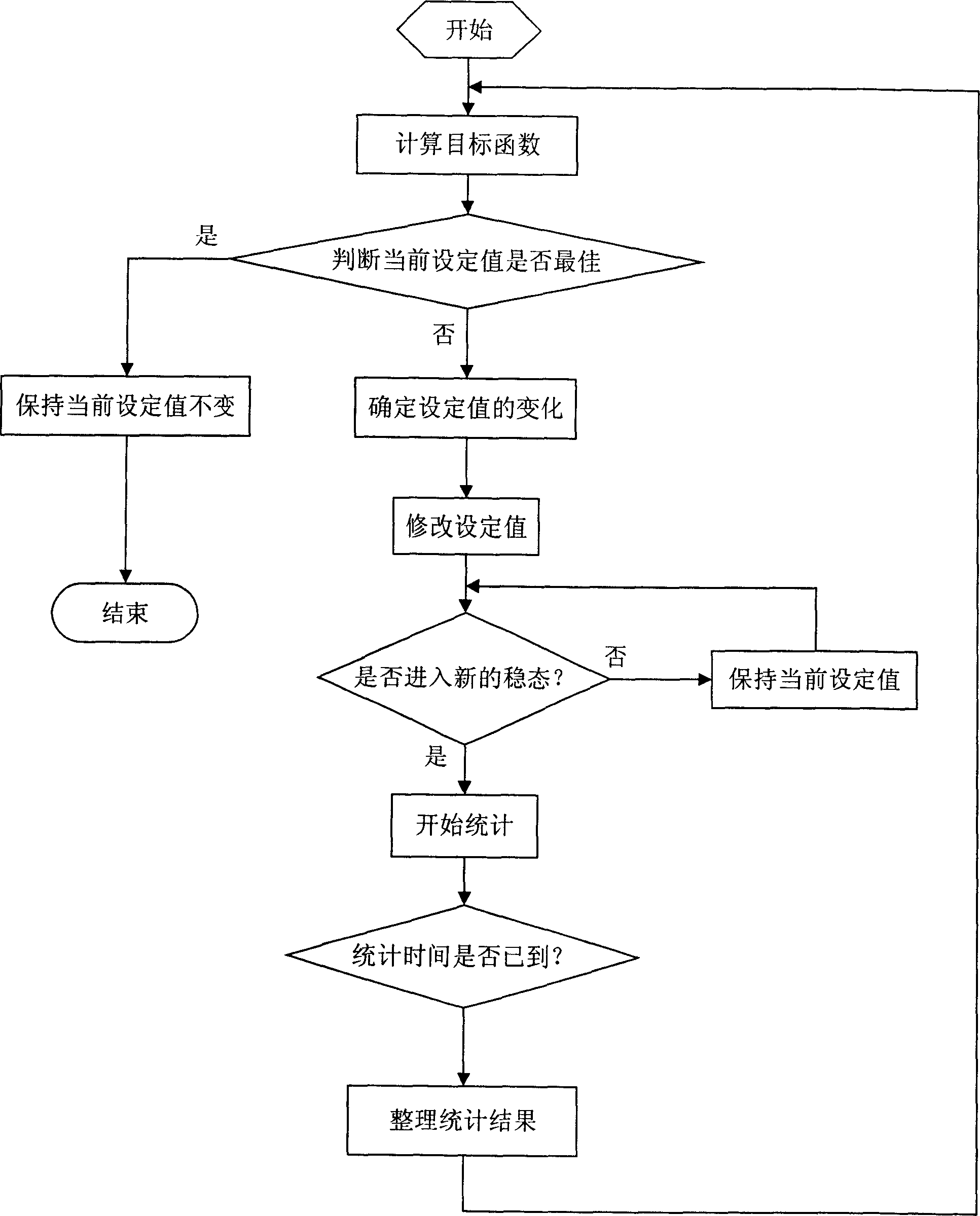

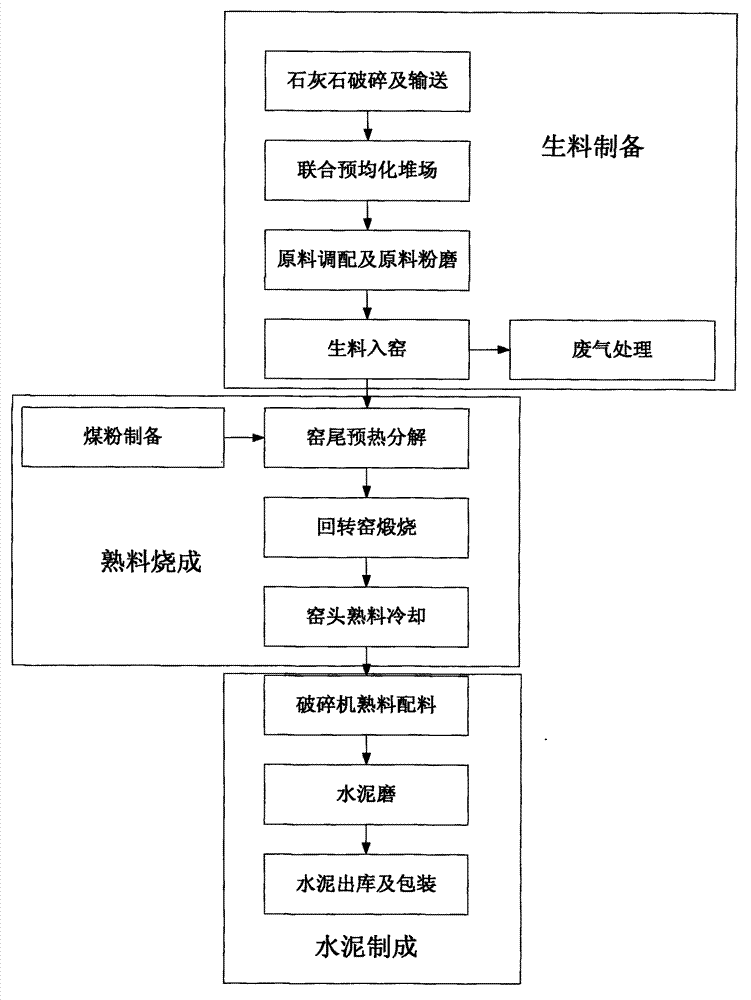

Pulverizing loop ball mill load control method for cement factory

The load control method for ball mill in powdering loop cement plant adopts a double-layer control structure, including an upper layer of self optimizing algorithm and a lower layer of multidimensional fuzzy control algorithm. The self optimizing algorithm finds out the optimal inside material storage quantity inside the ball mill as the controlling set value; and the multidimensional fuzzy control algorithm controls the material compounding links to realize the automatic regulation of the material feed quantity, so as to reach the required components in the cement production, lower the raw material amount and the cement screen residue, raise grinding fineness, ensure cement quality, increase output of ball mill and lower production cost.

Owner:XI AN JIAOTONG UNIV +1

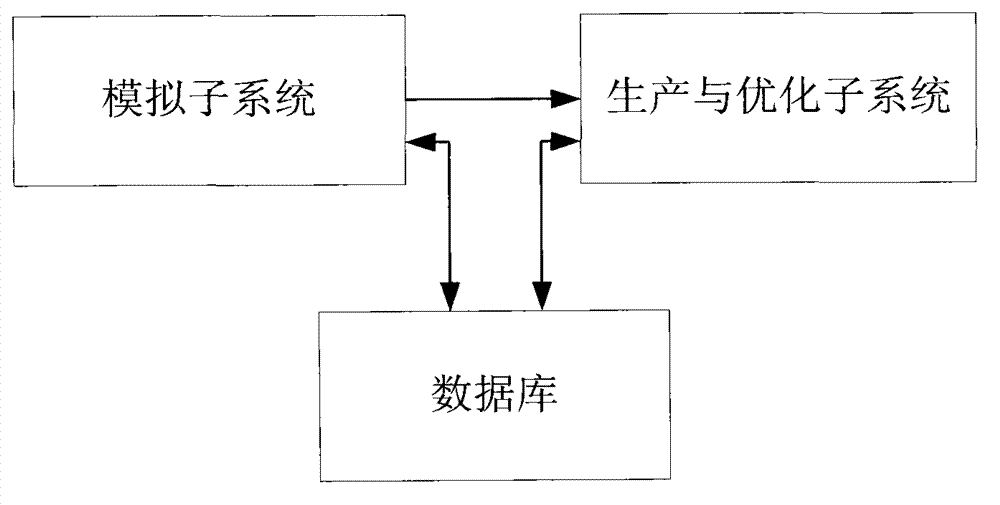

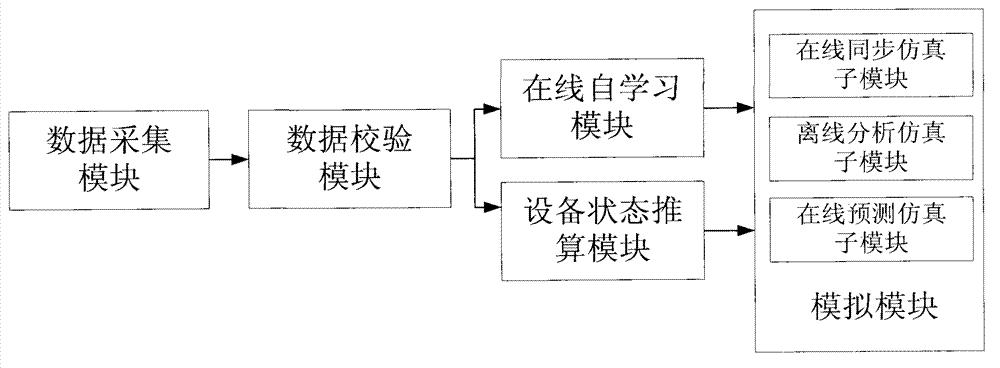

Cement digital management and control system

ActiveCN103092171ASignificantly directSignificant comprehensive benefitsEnergy industryTotal factory controlCement factoryCurrent time

The invention discloses a cement digital management and control system which comprises a simulate sub system, a production and optimization sub system and a data base. The simulate sub system is connected with the production and optimization sub system. The data base is respectively connected with the simulate sub system and the production and optimization sub system. The simulate sub system is used for performing simulating calculation to cement production. The production and optimization sub system is used for analyzing and judging whether current operating parameters and operation of cement production devices are normal, forecasting whether the operation parameters are normal after current time and controlling the cement production in an optimized mode. The data base is used for storing historic operation parameters and the current operation parameters, the range of the operation parameters and corresponding relationship between the operation parameters and state of the devices. Online simulated analysis technology, historic data analysis technology and an advanced diagnosing and optimizing method are adopted as methods of a digital management and control system so that economical and safe operation of a cement factory is achieved.

Owner:武安市新峰水泥有限责任公司

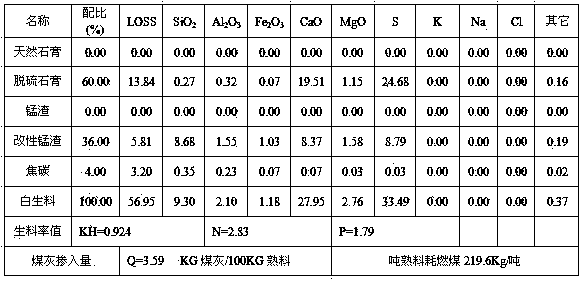

Method for producing sulfuric acid from electrolytic manganese residues

InactiveCN103613079AReduce utilizationRelieve pressureSulfur compoundsCement factoryPhysical chemistry

The invention provides a method for producing sulfuric acid from electrolytic manganese residues, and relates to a method for producing sulfuric acid from electrolytic manganese residues which are generated in the process of producing metal manganese through electrolysis. The method is characterized by comprising the following production process steps of: (1) performing drying treatment on the electrolytic manganese residues; (2) adding coke and lime to prepare a raw batch; (3) fine grinding; (4) preheating the raw batch; (5) calcining the raw batch; and (6) making the acid from the calcining smoke. The method for producing the sulfuric acid from the electrolytic manganese residues provided by the invention has the advantages that the electrolytic manganese residues are taken as the raw materials, the sulfuric acid is made from SO2 gas generated at the tail of a kiln after calcination at a high temperature, the residues after the calcination are used as raw materials for a cement active mixed material and used for cement production in a cement plant, and the sulfuric acid is used for producing electrolytic metal manganese or applied to other fields. Consequently, the influence of the stockpiling of the manganese residues on the surrounding environment is solved, and the manganese residues are recycled to be changed into things of value.

Owner:NINGXIA TIANYUAN MANGANESE LIMITED

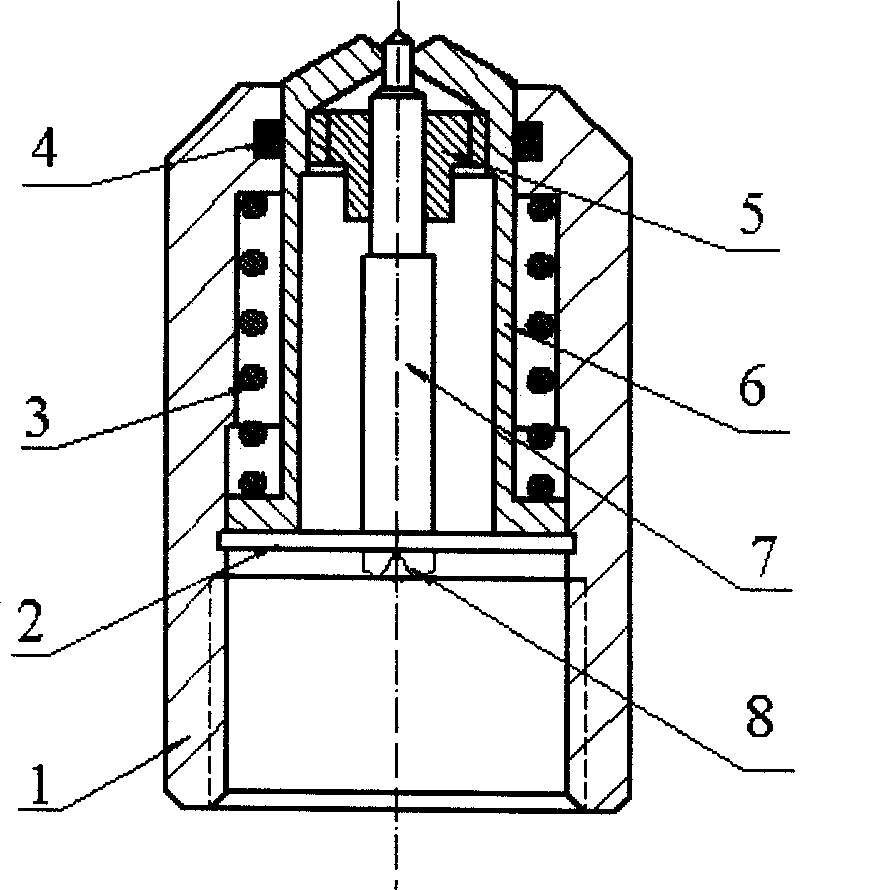

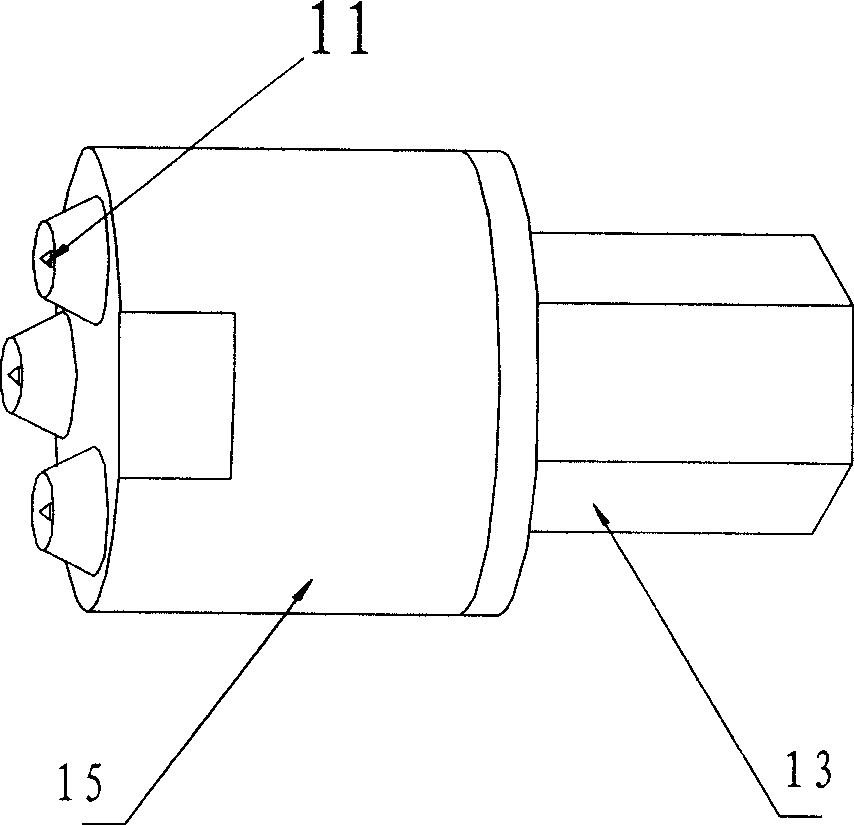

Design method for anti-blocking sprayer

InactiveCN101428255AAvoid pollutionGuarantee unimpededUsing liquid separation agentSpray nozzlesSprayerSpray nozzle

The invention relates to a nozzle component in atomizing equipment, in particular to an anti-blocking nozzle used for dust elimination and prevention in situations with a plurality of dust containing relatively complicated dust compositions, such as coal mining, ore mining, cement plants, and power plants. The anti-blocking spraying can be realized by adopting a design method of arranging one or more casings (1) or a multi-nozzle casing (15) at the top of the casing (1). The anti-blocking nozzle automatically clean a spray nozzle when in use, thereby ensuring the smoothness of the spray nozzle and preventing the spray nozzle from being polluted by the external environment; and the anti-blocking nozzle has the advantages of reasonable structure and long service life.

Owner:马文龙

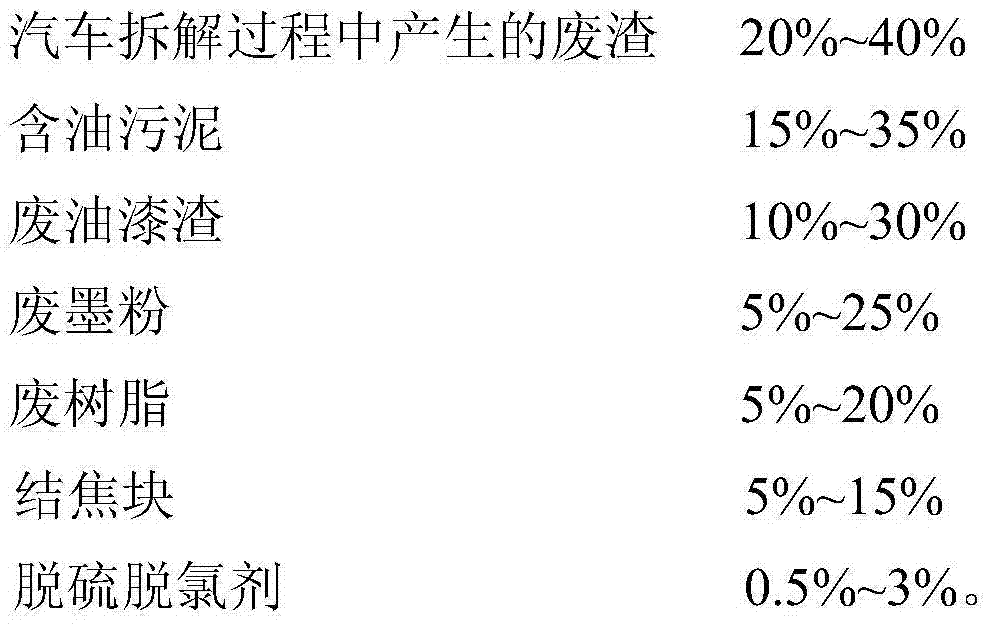

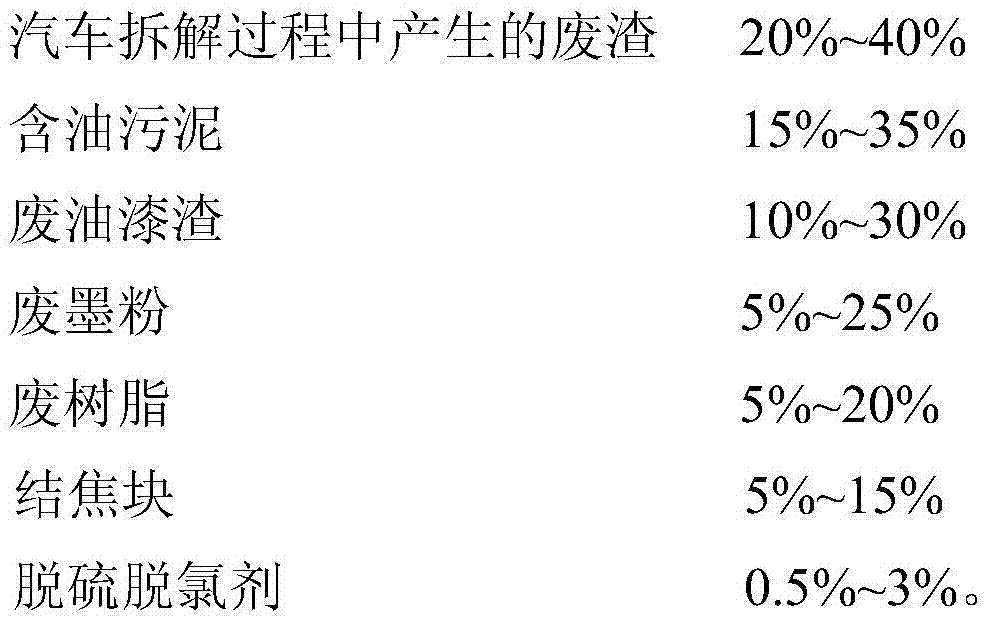

Generative fuel produced by using industrial solid waste and preparation method thereof

ActiveCN103756750AImprove adhesionBonding EfficientSolid fuelsWaste based fuelAlternative fuelsCombustion

The invention discloses a generative fuel produced by using an industrial solid waste and a preparation method thereof. The method comprises the following steps: taking industrial solid wastes such as waste residues, oily sludge, waste paint slags, waste powdered ink, waste resin, coking blocks and the like generated in a car dismantling process as calorific value components; adding a desulfurization and dechlorination agent as an auxiliary component; evenly mixing, pressing and molding, and drying, so as to obtain the generative fuel. The heat value of the generative fuel disclosed by the invention is over 4,000kcal / kg, the generative fuel can be used as an alternative fuel for a cement plant and a power plant, and is good in inflammability, and free of any combustion improver; the burnt ash content is below 20%, the fire coal substitution rate can be up to 80%, the sulfur fixation efficiency is 69.4-80.3%, the chlorine fixation efficiency is 70.4-81.1%, the content of hazardous substances (based on S and Cl) in the combustion tail gas is reduced by 70-80%. The generative fuel and the preparation method thereof provided by the invention have outstanding environmental benefits.

Owner:DALIAN DONGTAI INDAL WASTE TREATMENT

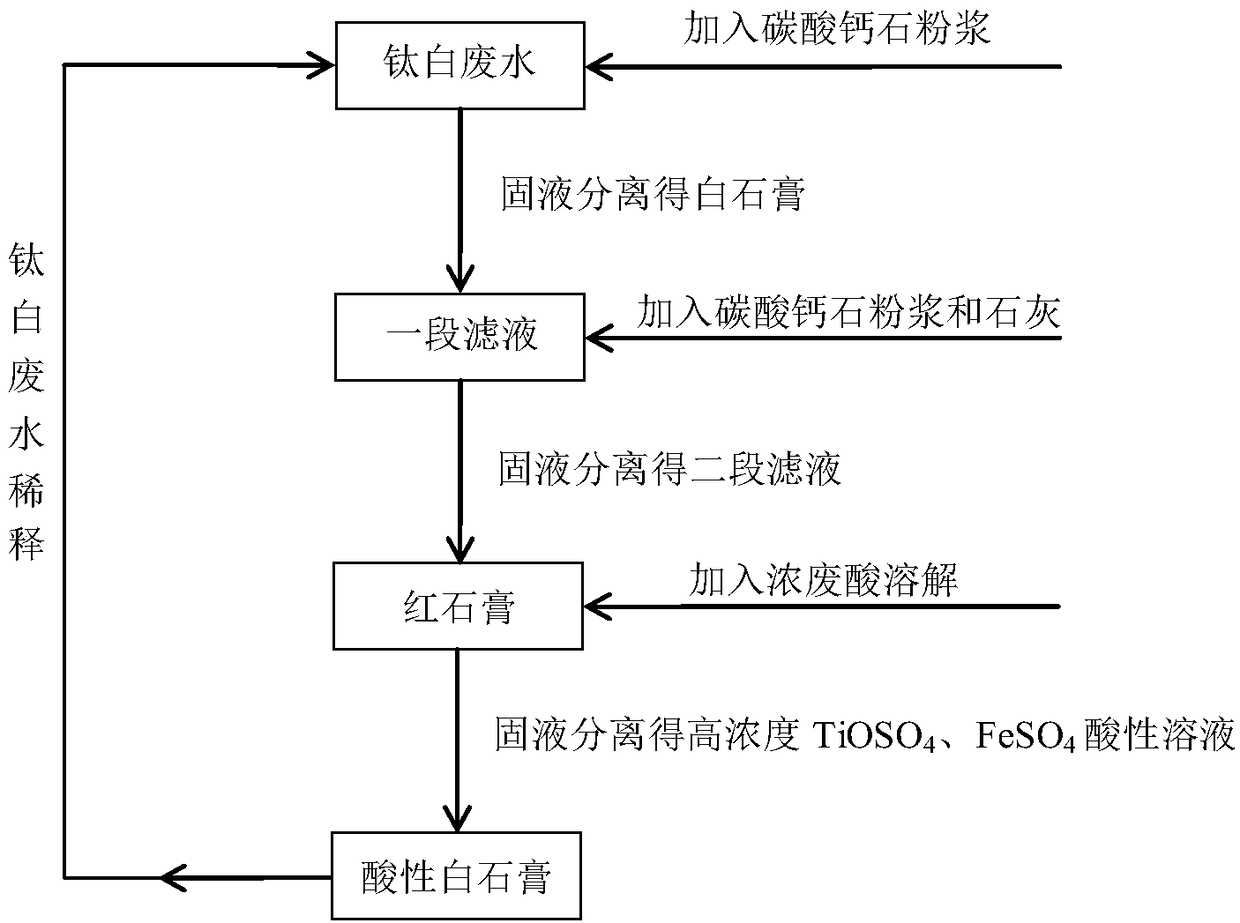

Method for converting titanium dioxide red gypsum into white gypsum and enriching titanium and iron

ActiveCN108264251AIncrease added valueSimple processTitanium and titanyl sulfatesTreatment involving filtrationHigh concentrationTreatment effect

The invention belongs to the technical field of wastewater treatment, and particularly relates to a method for converting titanium dioxide red gypsum into white gypsum and enriching titanium and iron.The method comprises the following steps: preparing white gypsum, preparing the red gypsum, converting the red gypsum into acid white gypsum, and converting the acid white gypsum into the white gypsum; through control of a process and an end point of the reaction, the produced white gypsum can be directly used for a cement factory, and can be deeply processed into building material gypsum with higher added value; through dissolution of the red gypsum by a waste concentrated acid, the red gypsum is converted into the acid white gypsum, and a TiOSO4 and FeSO4 acidic solution with a high concentration is obtained, wherein the recovery utilization rate is 95% or more; and the acid white gypsum is diluted by using titanium dioxide wastewater, and after primary neutralization is performed, thewhite gypsum is obtained. The method provided by the invention has a simple technological process, a stable treatment effect, less equipment investment, no secondary pollution, low treatment costs, considerable economic benefits and broad market prospects.

Owner:CNMC GUANGXI PGMA

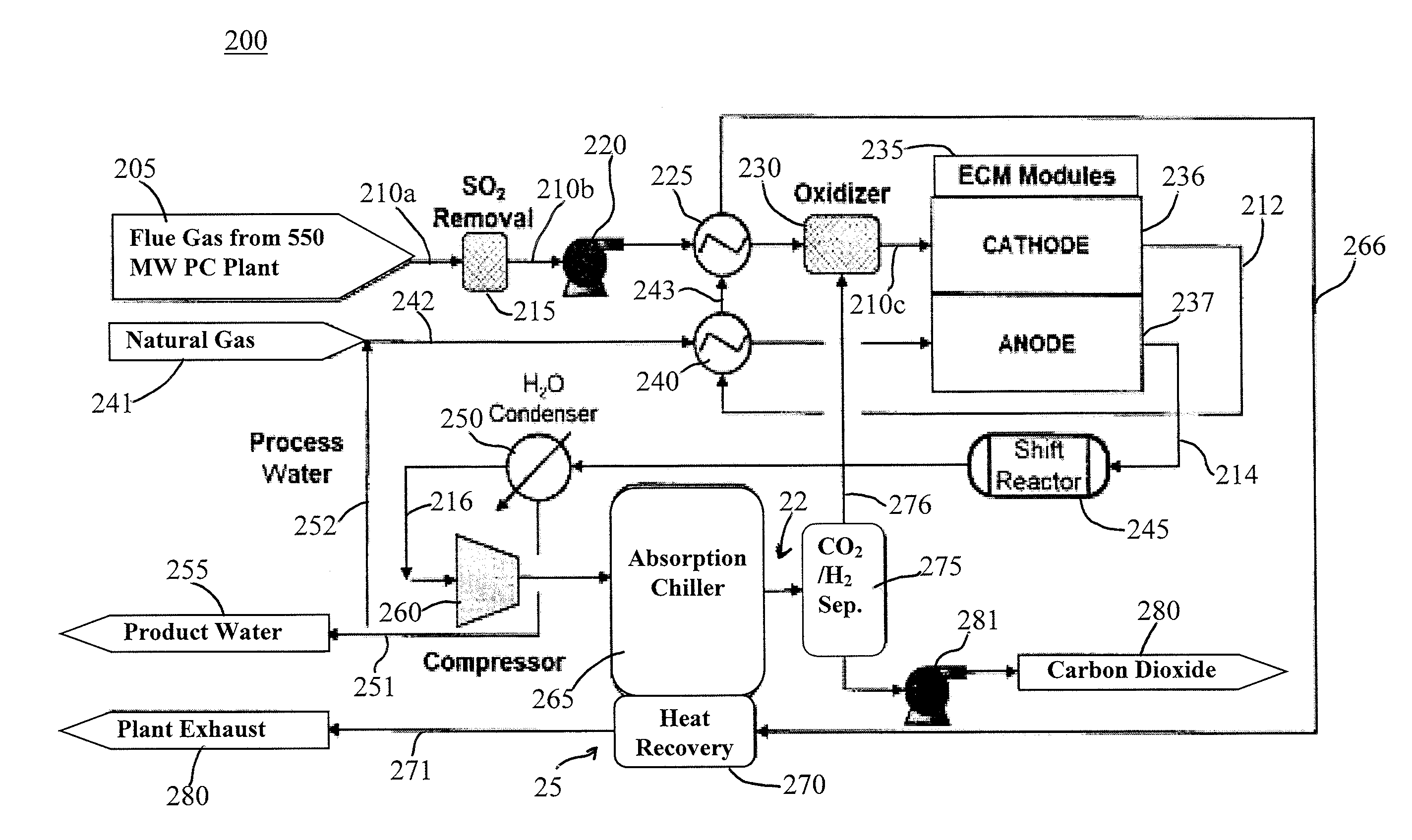

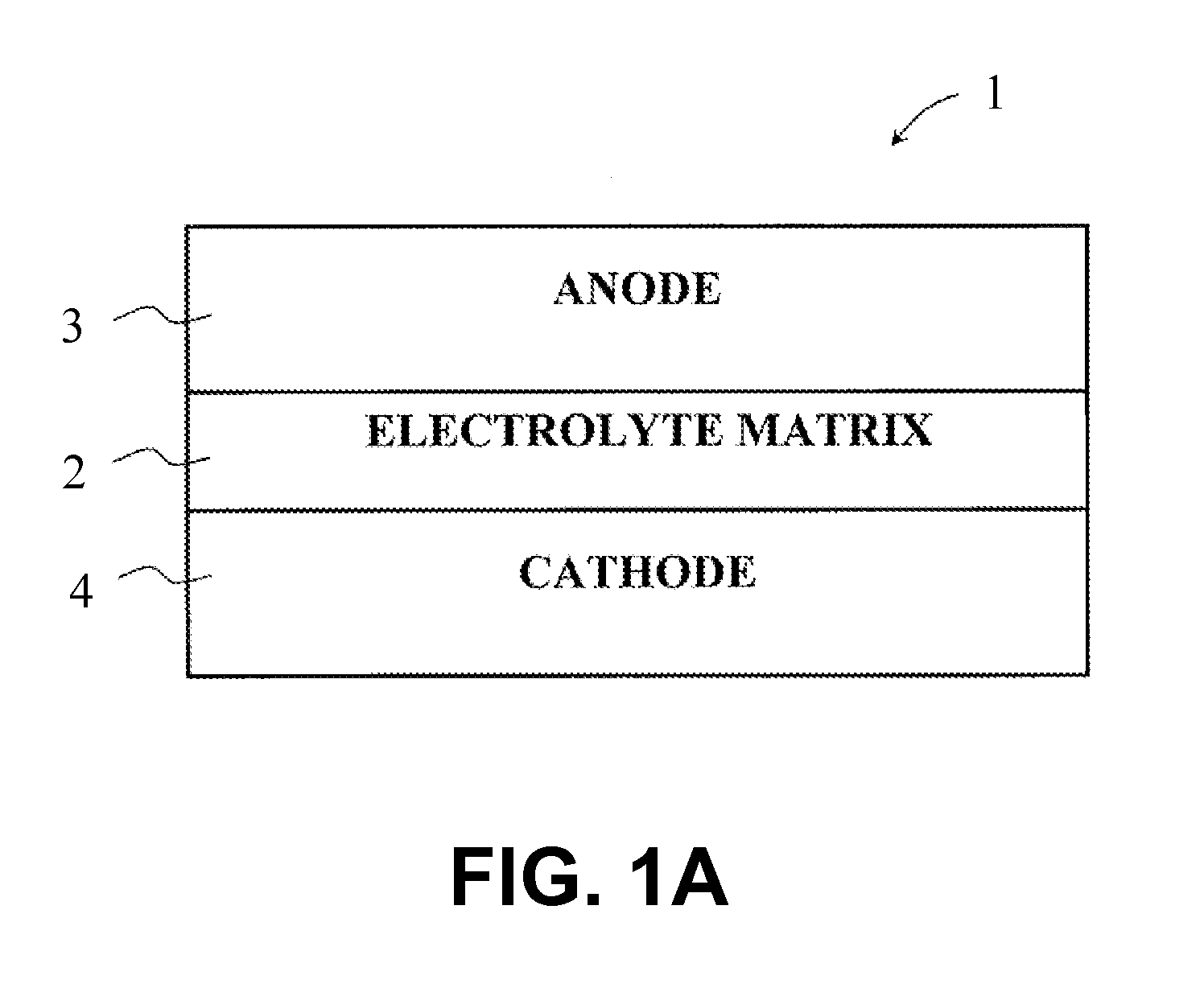

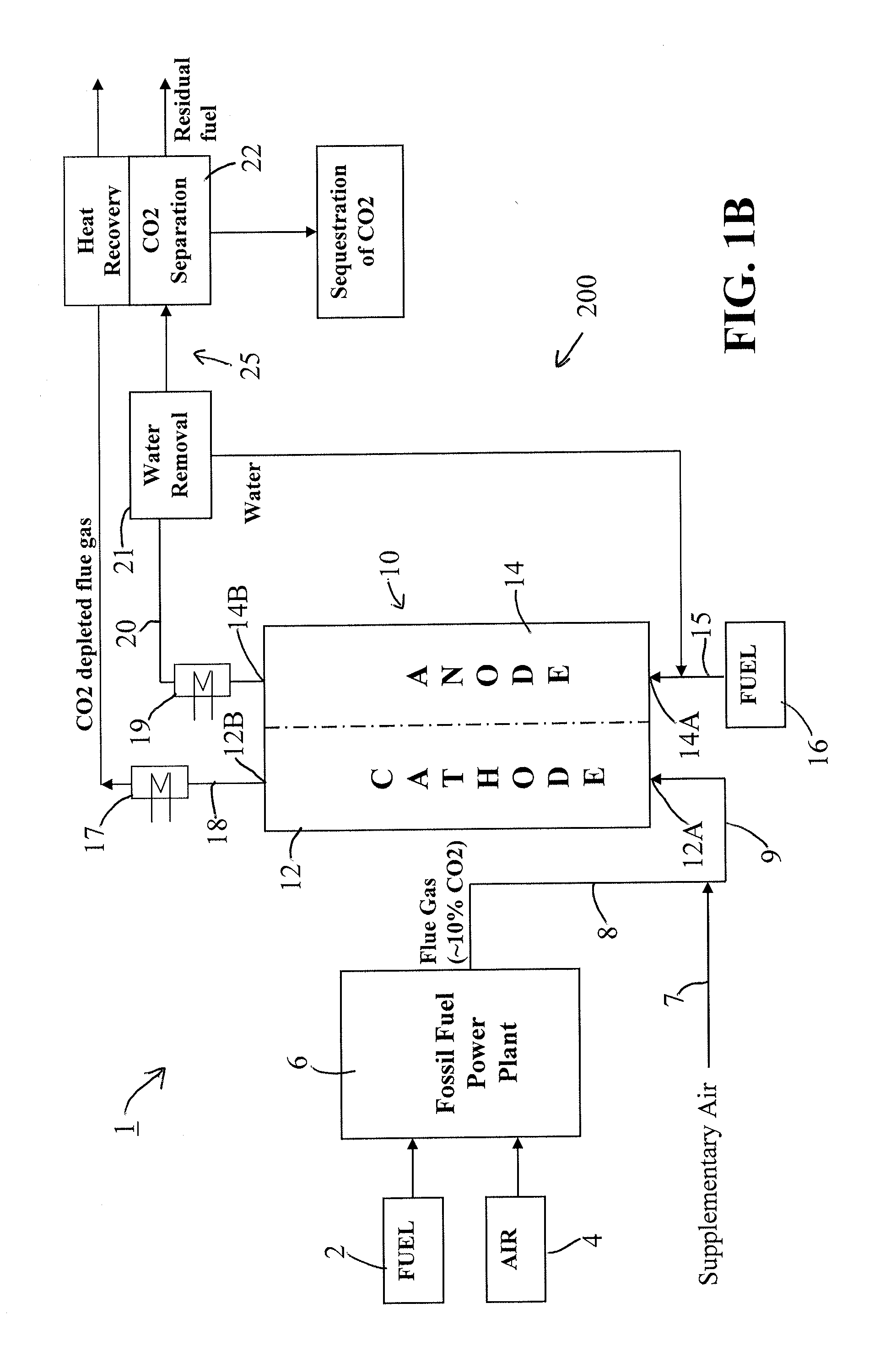

Power producing gas separation system and method

ActiveUS20160248110A1Efficient gas separationFuel cell combinationsFuel cell heat exchangeEngineeringOxygen

A power producing system adapted to be integrated with a flue gas generating assembly, the flue gas generating assembly including one or more of a fossil fueled installation, a fossil fueled facility, a fossil fueled device, a fossil fueled power plant, a boiler, a combustor, a furnace and a kiln in a cement factory, and the power producing system utilizing flue gas containing carbon dioxide and oxygen output by the flue gas generating assembly and comprising: a fuel cell comprising an anode section and a cathode section, wherein inlet oxidant gas to the cathode section of the fuel cell contains the flue gas output from the flue gas generating assembly; and a gas separation assembly receiving anode exhaust output from the anode section of the fuel cell and including a chiller assembly for cooling the anode exhaust to a predetermined temperature so as to liquefy carbon dioxide in the anode exhaust, wherein waste heat produced by the fuel cell is utilized to drive the chiller assembly.

Owner:FUELCELL ENERGY INC

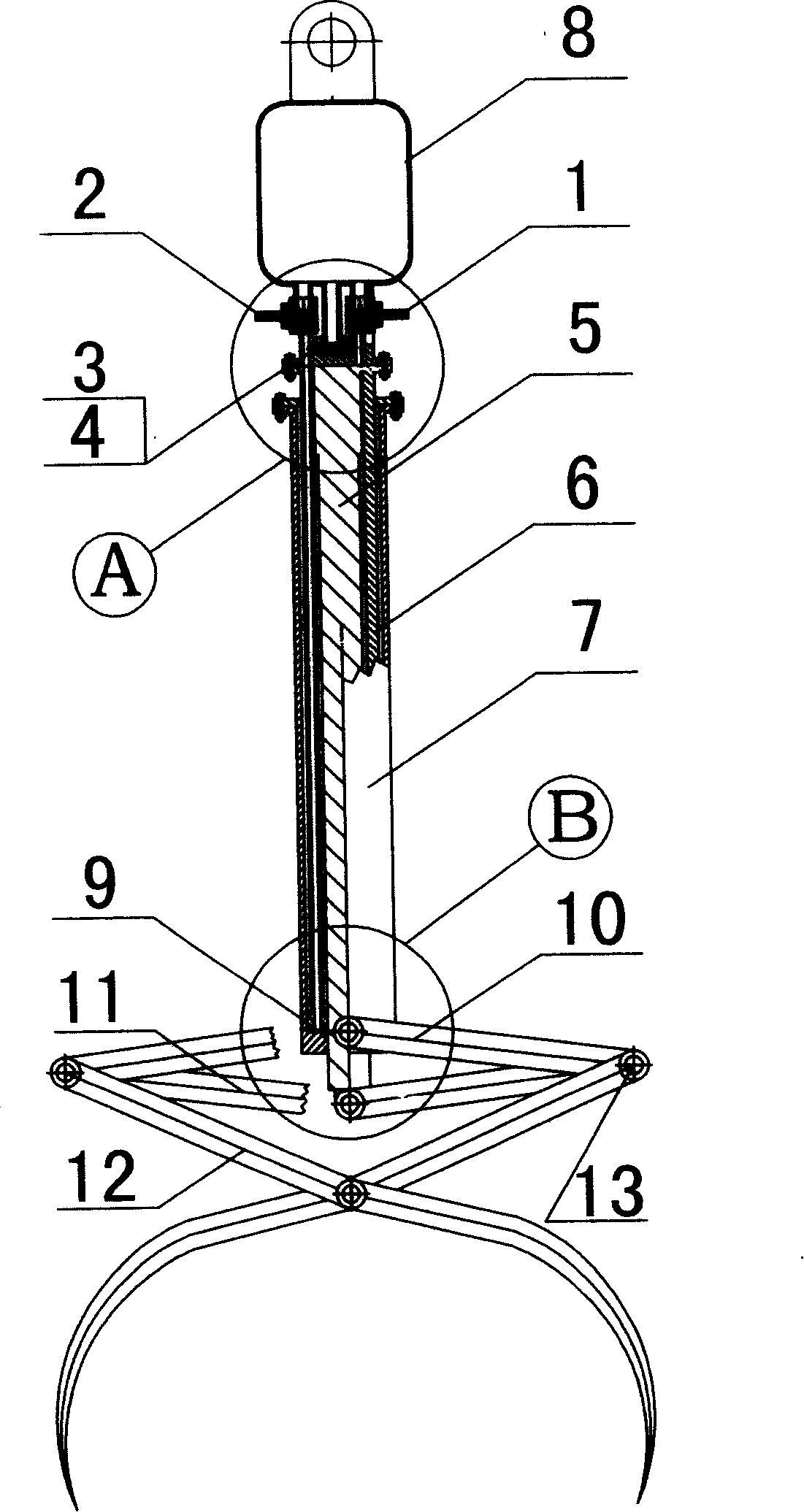

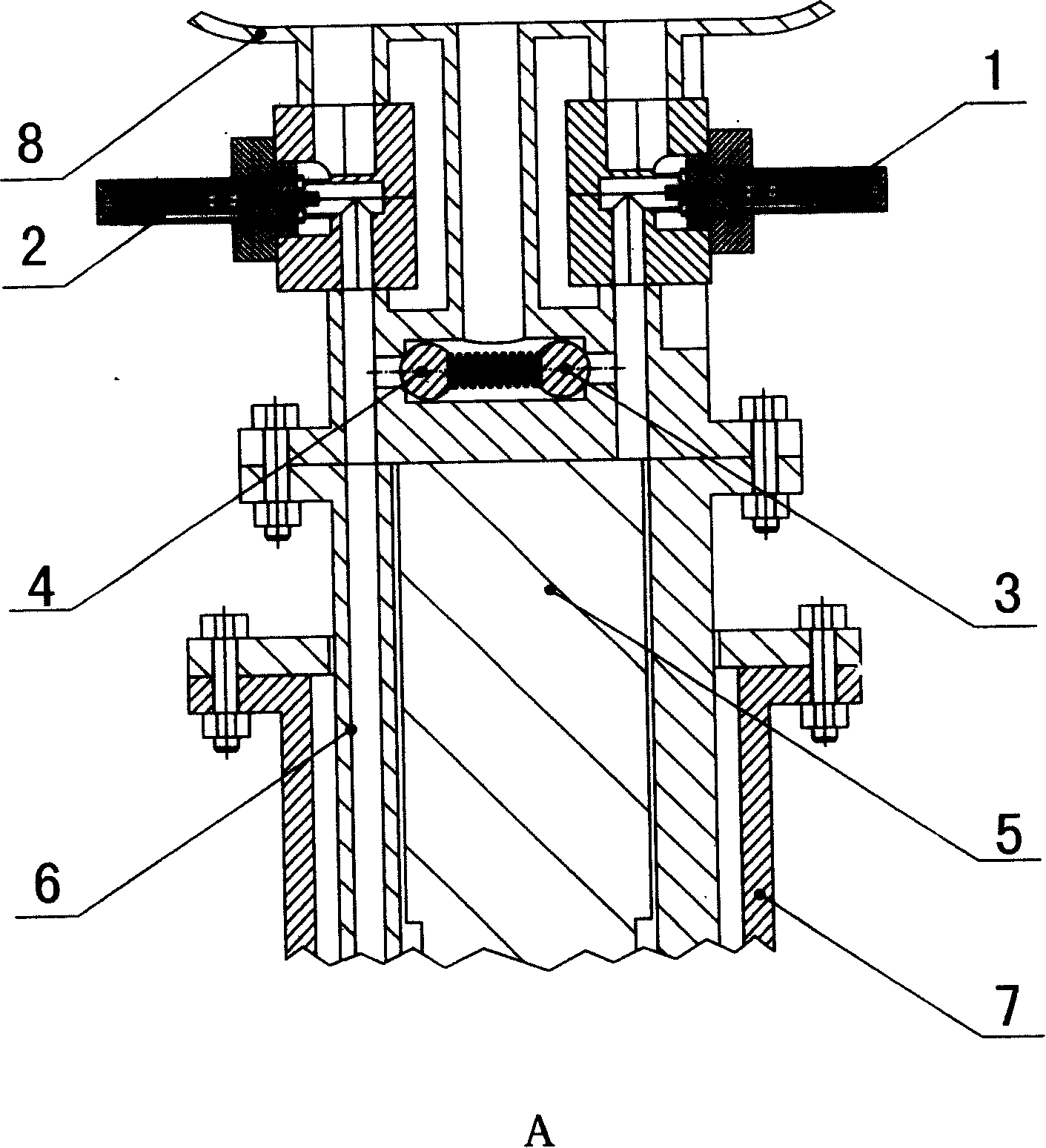

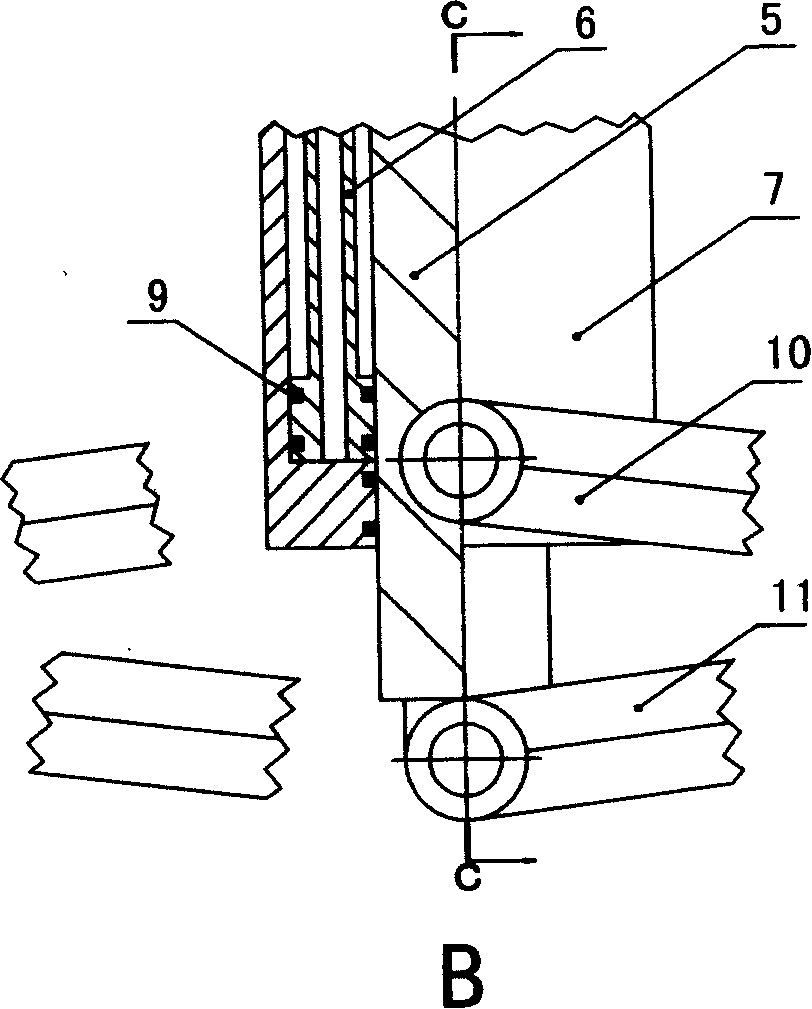

Hydraulic pressure grabhook

The invention relates to a hydraulic catch cam, which belongs to a mechanical hand. The mechanical hand comprises solenoid valves (1), (2), one-way back valves (3), (4), a piston (5), an inner cylinder body (6), an outer cylinder body (7), a hydraulic oil tank (8), a seal ring (9), an upper connecting link (10), a lower connecting link (11), a gripping claw (12) and a connecting axle pin (13). The invention has the advantages that the structure is simple, the control is automatic, the stretching is convenient and flexible, and the grabbing action, the releasing action and the reset action are finished by utilizing dead weight. The invention can be manufactured into specifications and models with different sizes to be suitable for different purposes, the invention not only can be manufactured the hand of a mobile robot, but also can be manufactured the fittings of a field working machinery which is used for substances in traveling, craning, fishing, deep pit grabbing, deep well, deep sea and a floating substance and a blocking substance in front of a fishing and grabbing cement factory and a hydropower station trash rack.

Owner:唐嗣林

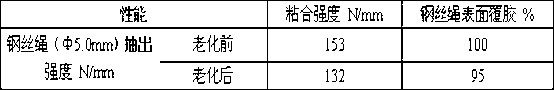

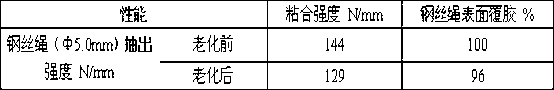

High-temperature resistant steel wire rope core conveying belt core glue and preparation method thereof

InactiveCN103102598AMeet high temperature requirementsReduce adhesionConveyorsCement factoryVulcanization

The invention relates to a preparation method of high-temperature resistant steel wire rope core conveying belt core glue. The core glue comprises the following raw material components in parts by weight: 100 parts of ethylene propylene rubber, 70-110 parts of reinforcing filler, 3-5 parts of vulcanizing agent, 5-11.5 parts of vulcanizing activator, 20-30 parts of plasticizer, 2-4 parts of anti-aging agent and 3.8-4.2 parts of adhesive, wherein the components are subjected to first-section mixing and second-section mixing to obtain high-temperature resistant steel wire rope core conveying belt core glue. According to the invention, the formula system of the high-temperature resistant steel wire rope core conveying belt core glue can realize a good effect; and after use, the high-temperature resistant steel wire rope core conveying belt core glue meets the requirement on high-temperature resistance of material conveying in a cement plant and a steel plant, prevents sharp fall of the adhesive force between the core glue and the steel wire rope caused by early aging of the core glue, greatly prolongs the service life of the conveying belt, and creates great economic benefits.

Owner:WUXI BOTON TECH CO LTD

Dedicated pouring material for cement kiln outlet and jetting coal pipe and preparation method thereof

InactiveCN101445379BImprove thermal shock performanceGood alkali resistanceCarbide siliconCement factory

The invention discloses a dedicated pouring material for a cement kiln outlet and a jetting coal pipe, which comprises the following components by the weight percentage: 20 to 30 percent of sintered plate-shaped corundum, 20 to 30 percent of sintered and synthesized mullite, 10 to 15 percent of chrome corundum, 5 to 10 percent of silicon carbide, 3 to 5 percent of silicon carbide superfine powder, 3 to 5 percent of magnesia alumina spinel, 5 to 8 percent of zircon sand, 2 to 5 percent of activated Al2O3 micro powder, 2 to 5 percent of silicon micro powder, 3 to 5 percent of pure calcium aluminate cement, 1 to 2 percent of stainless steel fiber, 5 to 10 percent of synthesized zirconium mullite grinding powder, 0.1 to 0.15 percent of composite additives and 0.01 to 0.1 percent of explosion proof fiber. The invention further discloses a method for preparing the pouring material. The pouring material is applicable to the dry-process cement kiln outlets and the jetting coal pipes in large-scale cement plants and has the advantages of high wear resistance, good anti-stripping resistance and long service life.

Owner:JIANGSU GUOHAO REFRACTORY TECH

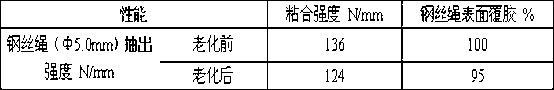

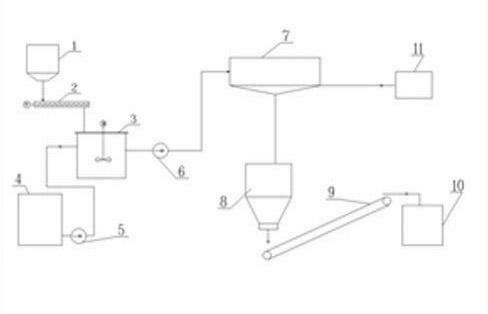

Sludge conditioning and dewatering treatment system and method

InactiveCN102674644ASavings in infrastructure costs and high-quality energyReduce drying costsSludge treatment by de-watering/drying/thickeningClinker productionTreatment costsSewage treatment

The invention discloses a sludge conditioning and dewatering treatment system. By the system, conditioner is added into sludge discharged by a sewage treatment plant, the conditioned sludge is sent to a high-pressure filtering device and is treated, and a produced mud cake is sent to a cement plant and is co-combusted for manufacturing cement. The system comprises a wet sludge storage bin, a sludge conveying pump, a slurry supply pump, a dry sludge storage bin, and dry sludge conveying equipment; the sludge conveying pump is connected with the wet sludge storage bin and a sludge conditioning tank respectively; the slurry supply pump is connected with the sludge conditioning tank and sludge dewatering equipment respectively; wastewater produced by the sludge dewatering equipment enters a wastewater treatment system and then is treated, and the treated wastewater which meets the standard is discharged; the dry sludge storage bin is connected with the sludge dewatering equipment to receive the separated dry sludge; and the dry sludge conveying equipment is connected with the dry sludge storage bin and is used for conveying the dry sludge into a loading system of the cement plant. By the sludge conditioning and dewatering treatment system, the sludge treatment cost can be effectively reduced, a large amount of high-quality energy sources can be saved, and treatment of wastes with processes of wastes against one another is realized. The invention also discloses a sludge conditioning and dewatering treatment method.

Owner:国能朗新明环保科技有限公司

Method for removing nitrogen oxide in flue gas, and nano flue gas denitration system

The invention relates to a method for removing nitrogen oxide in flue gas. The method comprises the following steps of (1) carrying pretreatment on the flue gas containing nitrogen oxide in a pretreatment container, removing solid particles with the diameters larger than 10 microns in the flue gas in the pretreatment process, and oxidizing NO into NO2; (2) enabling the pretreated flue gas to enter a denitration container, and reacting nitrogen oxide with an oxidizing agent to generate nitric acid; and (3) after purification, discharging the gas outside the denitration container. The invention also provides a nano flue gas denitration system which is characterized by comprising a pretreatment bin and a denitration bin, wherein the output end of the pretreatment bin is connected with the input end of the denitration bin. The method and the nano flue gas denitration system have the advantages that nitrogen oxide is effectively converted into nitric acid, so that the recycling benefit is far higher than the operating cost of equipment, and a user can obtain more profit. The method and the nano flue gas denitration system are suitable for other industrial markets such as a cement plant, an iron and steel plant, a municipal government waste burning plant, a medical waste burning plant, a chlorine manufacturer, and a pulp and paper manufacturing plant.

Owner:林小晓 +1

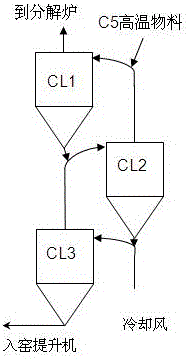

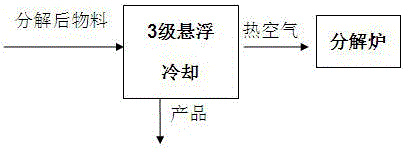

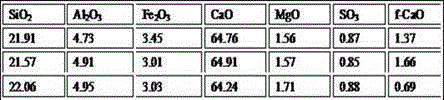

Predecomposition kiln internal circulating flue gas desulfurization technology

Relating to a removal technology of SO2 generated by production of fuel from cement, the invention provides a predecomposition kiln internal circulating flue gas desulfurization technology. Part of a class 5 cyclone high temperature material is cooled by a class 3 suspension cooling system, then the material is fed into a C1 cyclone by a kiln feeding zipper elevator to react with SO2 in flue gas so as to form CaSO3, thus realizing flue gas desulphurization. The high temperature air at a CL1 outlet converges with C5 outlet, the desulfurizer accounts for about 3% of the kiln feed raw material, and no additional desulfurizer is needed. The technology provided by the invention is used for cement plant flue gas desulfurization.

Owner:齐砚勇 +1

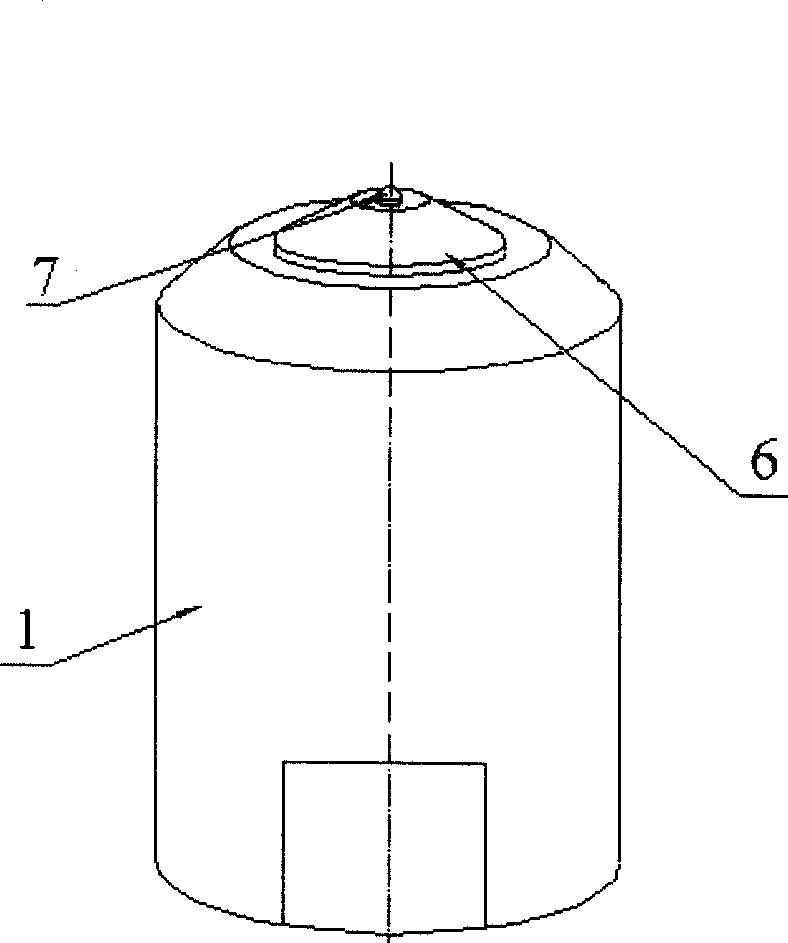

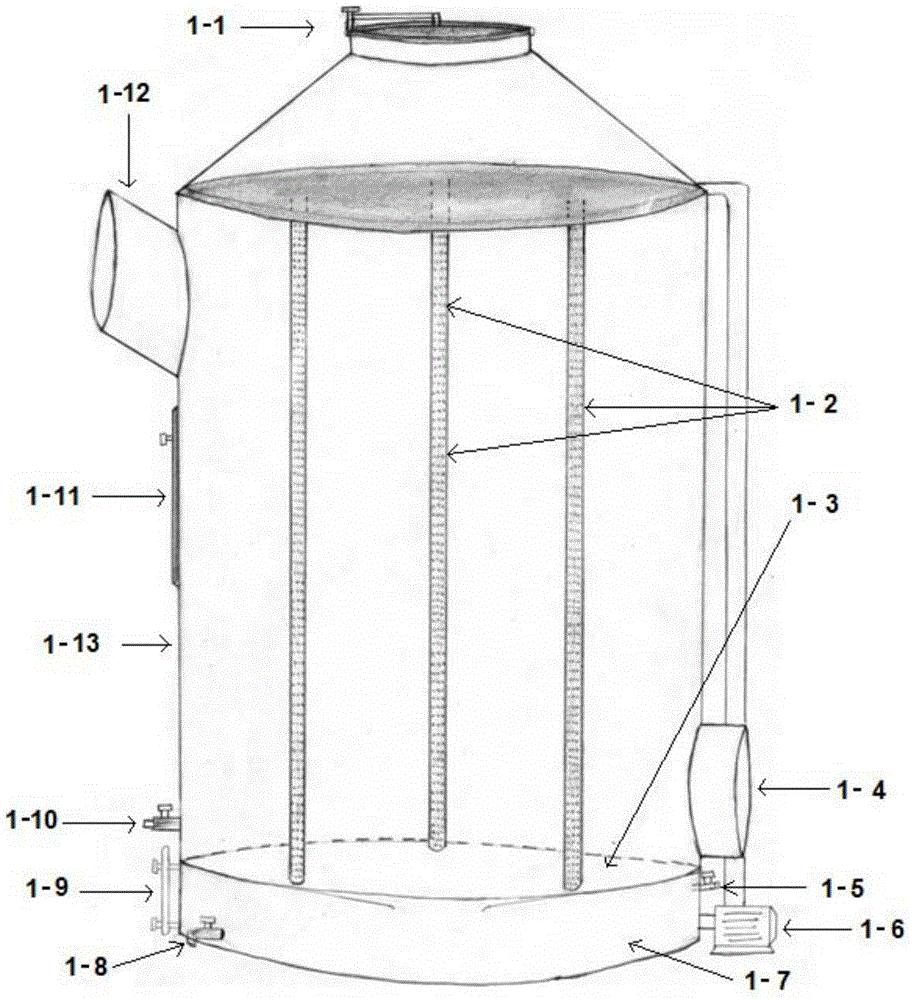

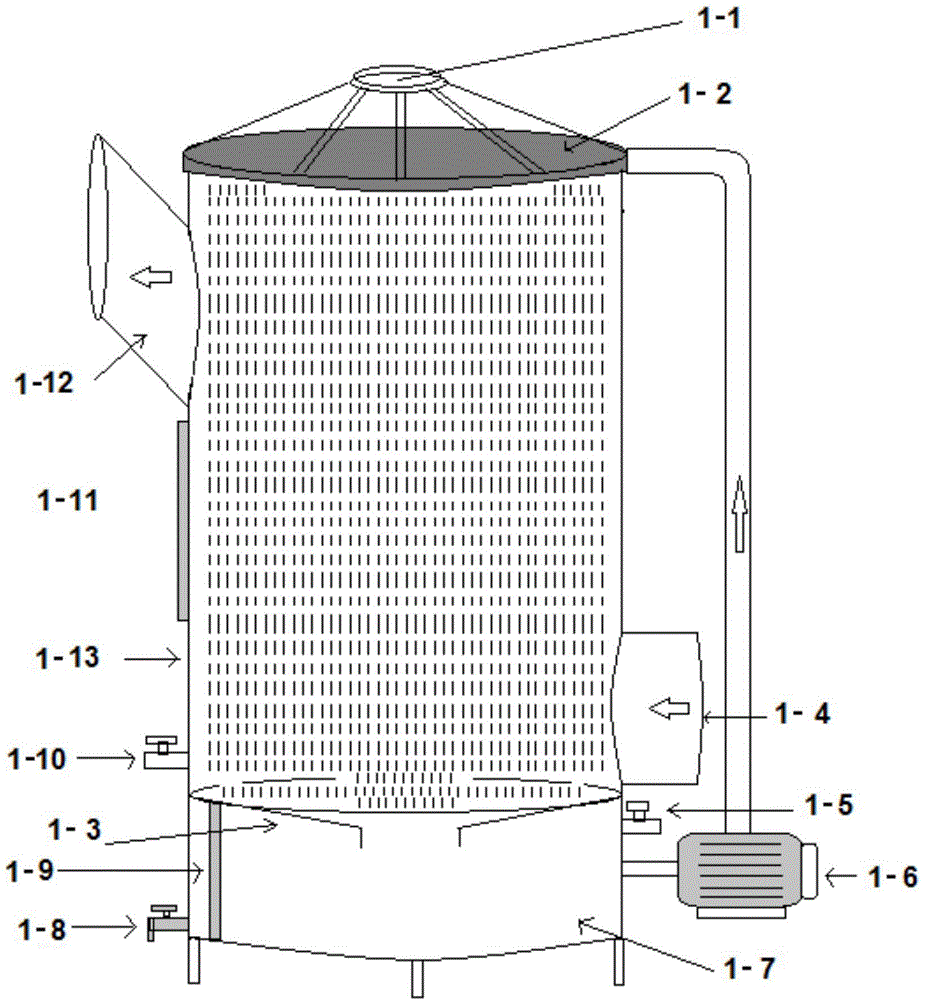

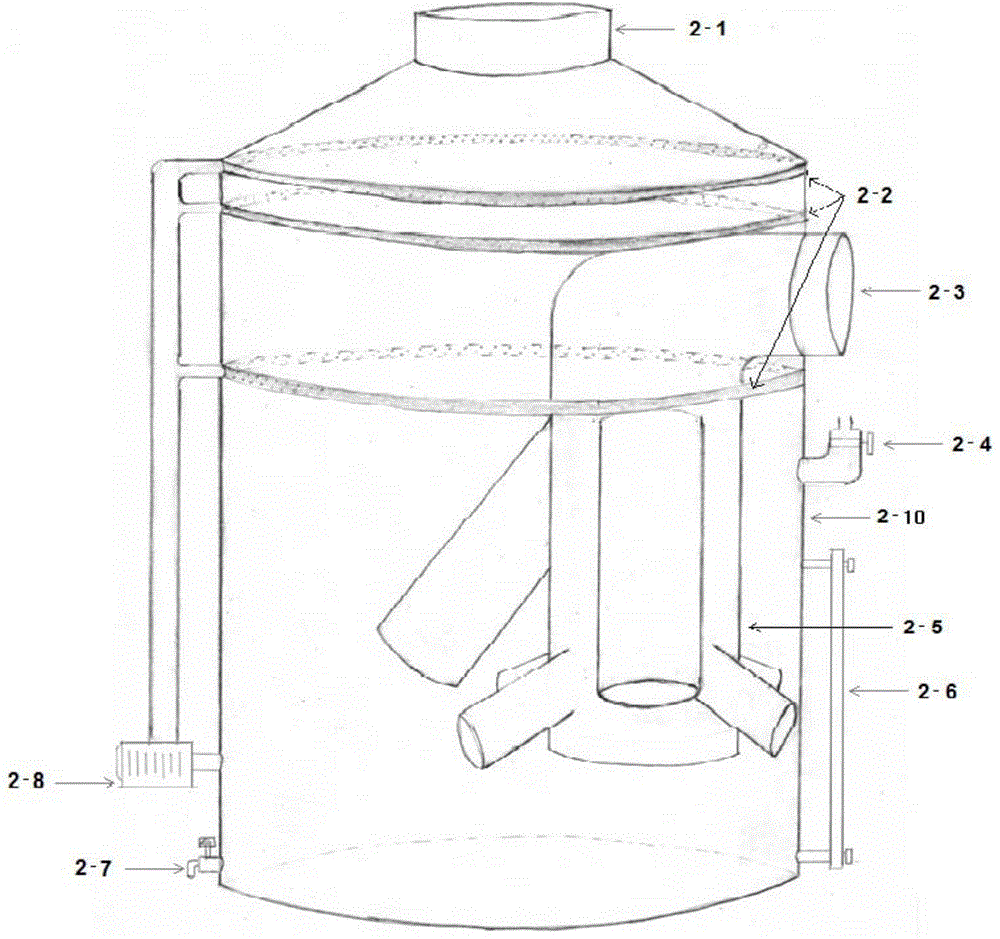

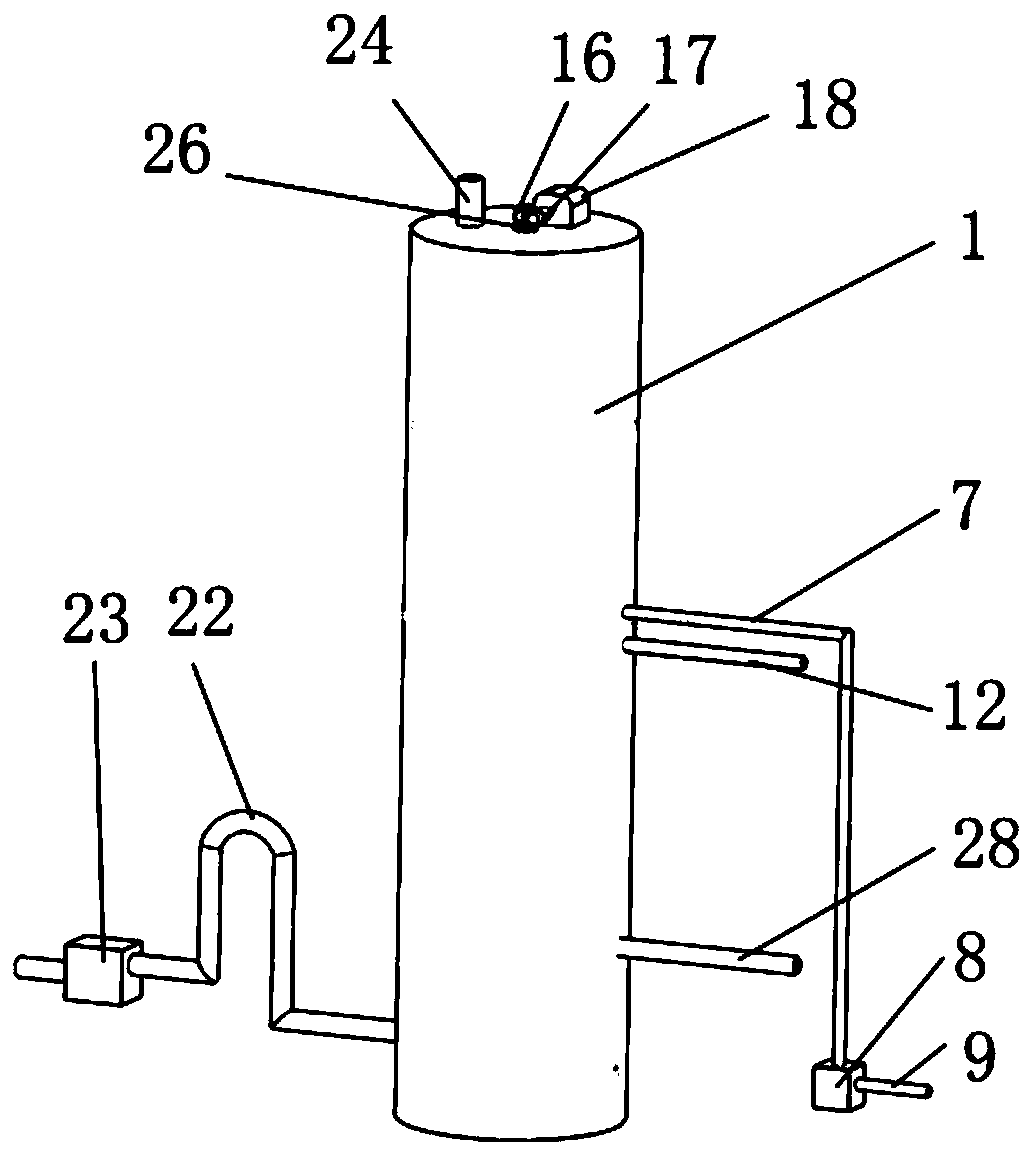

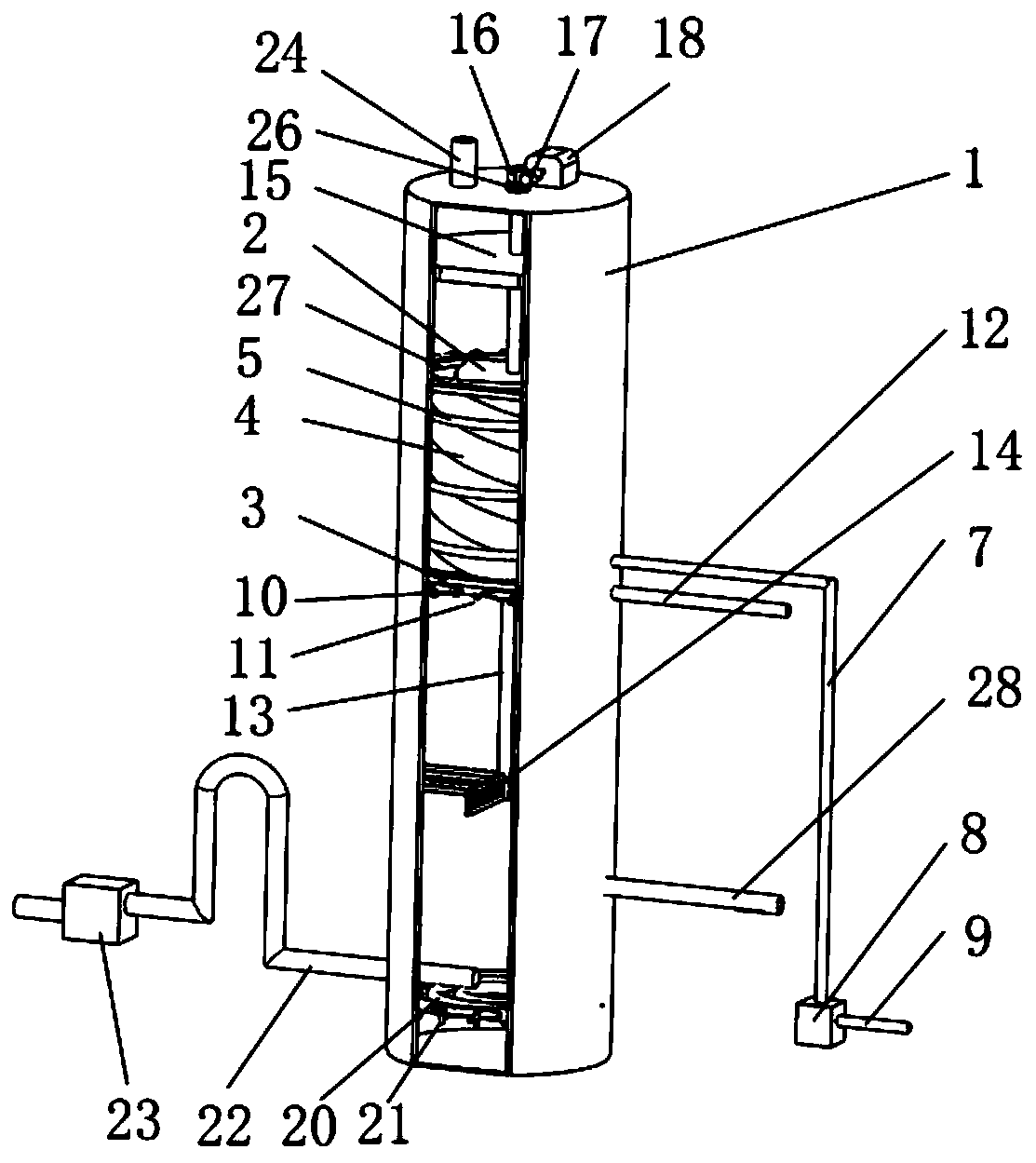

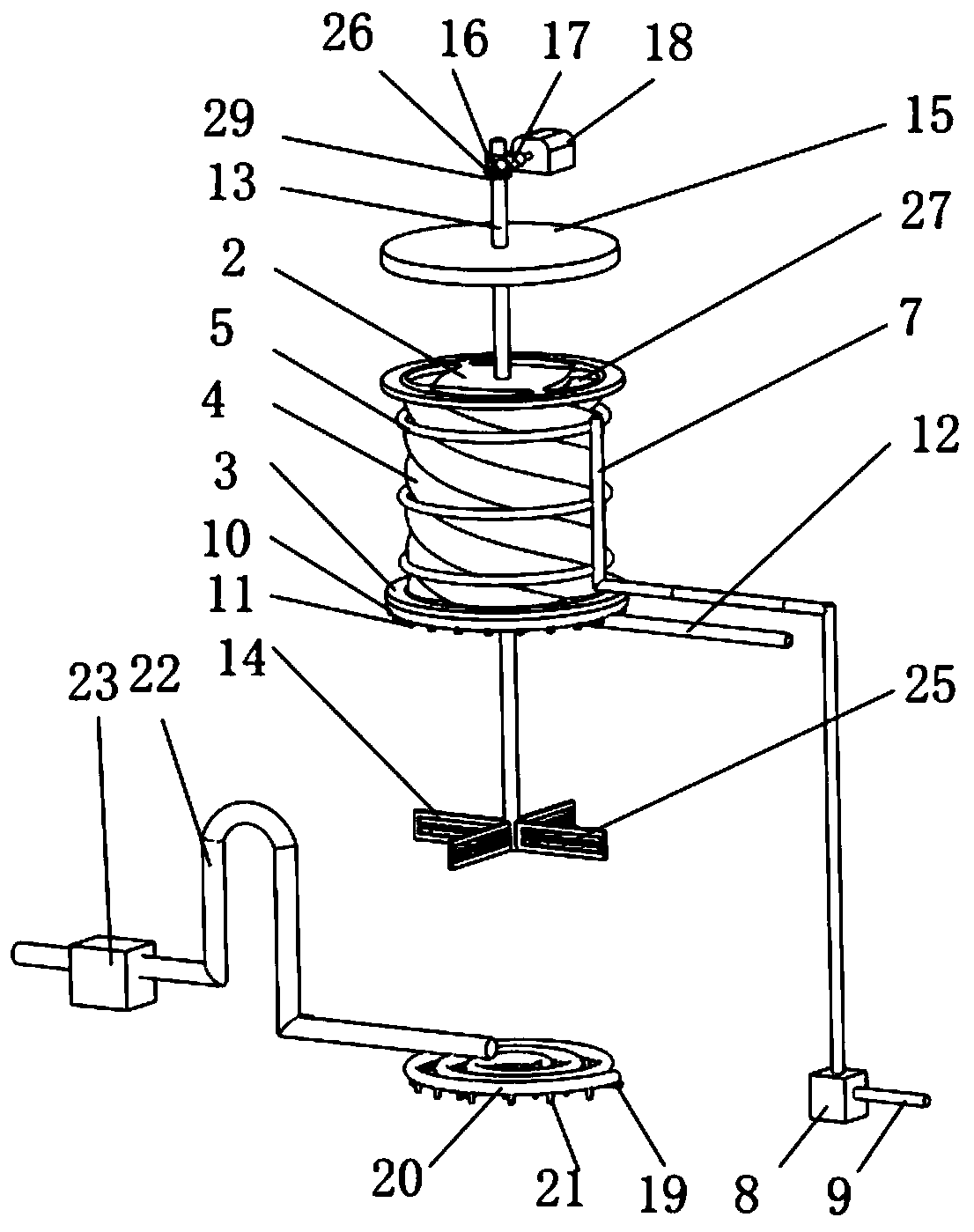

Cement plant desulfurization and denitrification waste gas treatment apparatus

PendingCN110975579AReasonable structural designCompact structureGas treatmentDispersed particle separationCement factoryProcess engineering

The present invention discloses a cement plant desulfurization and denitrification waste gas treatment apparatus, which comprises: a cylindrical body with two closed ends; a mist spraying showering part which comprises a mist spraying part and a showering part, wherein the mist spraying part is arranged on the cylinder body, and the showering part is arranged on the mist spraying part; a turbulentflow part which comprises a rotating rod, turbulent flow blades, a demister and a rotating power piece, wherein the rotating rod and the rotating power piece are both arranged on the cylinder body, and the turbulent flow blades and the demister are both arranged on the rotating rod; a preliminary desulfurization part which comprises a gas transmission fixing frame, a gas transmission pipe, a gastransmission nozzle and a waste gas input pipe, wherein the gas transmission fixing frame is arranged on the cylinder body, the gas transmission pipe is arranged on the gas transmission fixing frame,the gas transmission nozzle is arranged on the gas transmission pipe, and the waste gas input pipe is connected with the gas transmission pipe. The cement plant desulfurization and denitrification waste gas treatment apparatus is reasonable in structural design, and can perform multiple different forms of desulfurization treatment on waste gas; and the waste gas is converted into a turbulent flowstate from a laminar flow state, so that the waste gas can be uniformly distributed in the cylinder body, and the desulfurization efficiency can be effectively improved.

Owner:苏州仕净科技股份有限公司

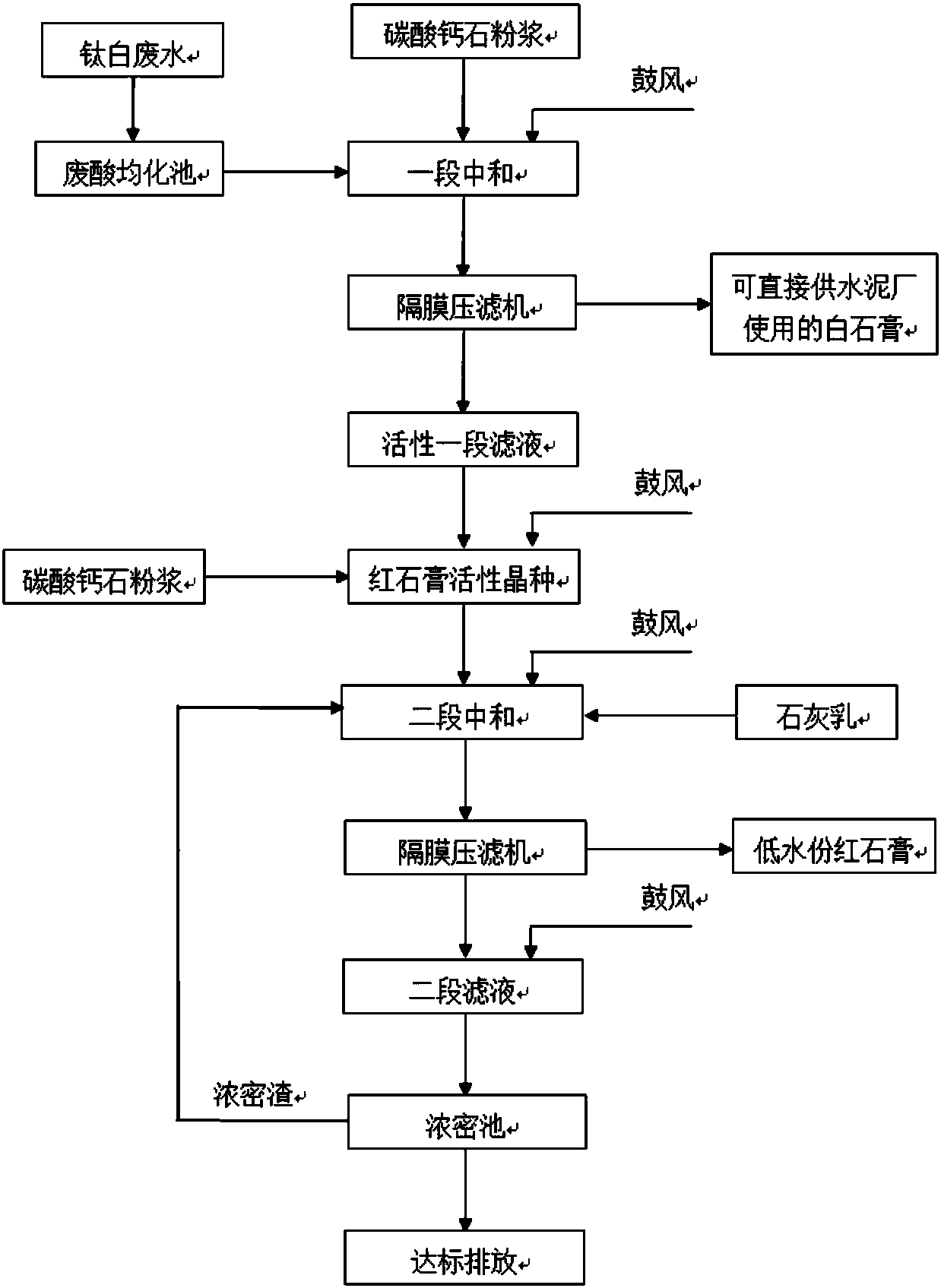

Method for treating titanium dioxide wastewater

ActiveCN108373215AReduce moistureEliminate the calcination and drying processSolid waste managementWater contaminantsCement factoryEmission standard

The invention belongs to the technical field of wastewater treatment and particularly relates to a method for treating titanium dioxide wastewater. The method includes the steps of firstly, preparingwhite gypsum; secondly, preparing red gypsum active seed crystal; thirdly, performing two-stage neutralization; fourthly, performing aeration and sedimentation. The method has the advantages that by reaction end point control, TiSO4 with the stability being not smaller than 100 in active-stage filtrate is hydrolyzed completely to finally generate TiO(OH)2 seed crystal particles which are small anduniform in size so as to obtain the red gypsum active seed crystal; by the end point control, the produced white gypsum is low in water content and can be directly used by a cement factory, red gypsum whose water content is low and SO3 content meets cement production requirements, the calcining and drying procedure of the white gypsum is omitted, the calcining and drying cost of titanium gypsum is lowered greatly, and the water content and the SO3 content of the red gypsum can meet the cement production requirements of the cement factory when the water content is 34-37% and the SO3 content is33-35%; meanwhile, discharged wastewater meets the emission standards of GB8978-1996.

Owner:CNMC GUANGXI PGMA

Process for preparing fuel derived from urban domestic garbage

The invention relates to the preparing method of the rubbish derived fuel which can make the city life rubbish be transformed with high added value. The invention adopts biological and mechanical treatment to decrease the volume, decrease the water content, reduce the weight and increase the heating power of the rubbish. The separated organic residue and stabilized organic biomass serve as the rubbish derived fuel which coexists with cement processing material burning in cement factory, electricity generating in power station and coal burning in concentrated heat supply. The invention can make the rubbish less harmful, transform the rubbish with high added value as well as decrease the bulk of the rubbish so the invention has obvious social, environmental and economic returns.

Owner:SHANGHAI UNIV

Cement admixture used for building ready-mixed dry mixed mortar and application method thereof

InactiveCN102329106AReduce equipment investmentReduce land occupationSolid waste managementCement factorySolid matter

The invention discloses a cement admixture used for building ready-mixed dry mixed mortar and an application method thereof. The cement admixture comprises the following components: 45-98% of cement, 0-40% of mineral admixture, 0-15% of lime or gypsum and 0.1-5% of additive. 10-50% of cement mixture and 50-90% of sand are mixed, water with 10-20% weight of solid matter is added, stirring to be uniform is carried out, and the cement admixture is used for building construction. Dry ready-mixed mortar is divided into two parts, one part is the cement admixture, and the other part is baked sand. The two parts are separately stored and transported, quantitative cement is added in the scene, and mixing is carried out to obtain the mortar for building. Equipment investment and floor area of a ready-mixed mortar factory are greatly reduced, even the cement admixture is produced by a cement factory without requiring the read-mixed mortar factory, and social investment can be greatly saved.

Owner:盛富春

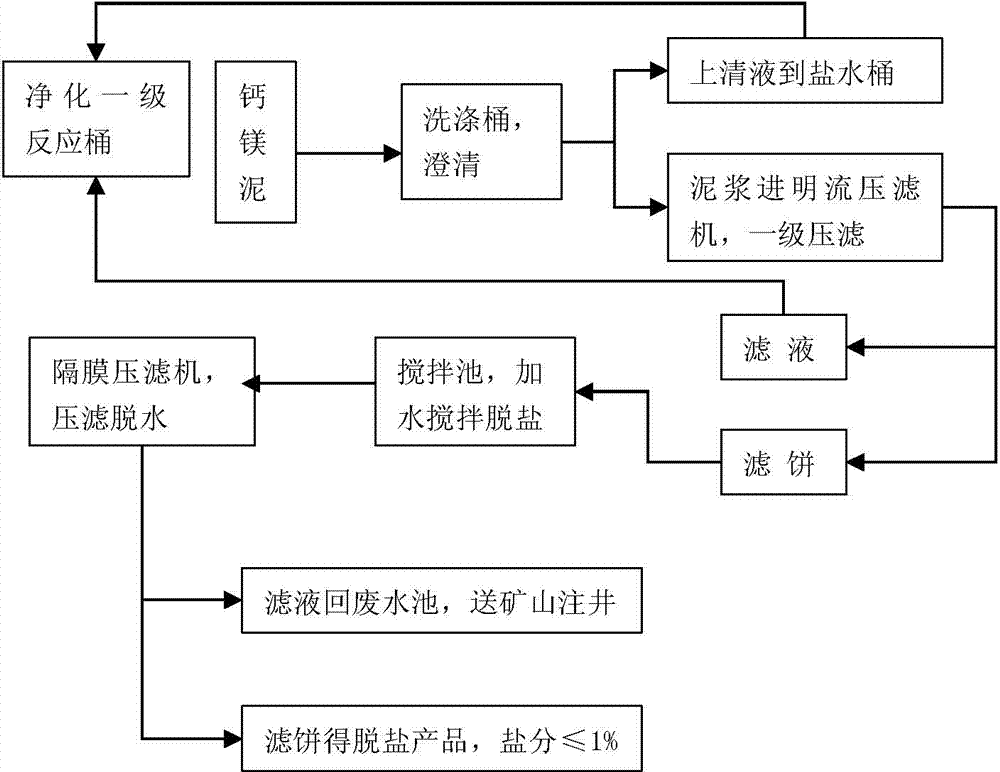

Method for desalting calcium magnesium slime by two-step process

InactiveCN102730737AIncrease moisture contentWide range of usesCalcium/strontium/barium carbonatesSludge treatmentCement factoryPhysical chemistry

The invention relates to a method for desalting calcium magnesium slime by a two-step process, which aims to solve the problem of calcium magnesium slime generated in the brine purification process. The invention adopts the two-step process, fully considers different physicochemical properties of CaSO4, Ca(OH)2, Mg(OH)2 and CaCO3, and changes high-salt-content high-water-content waste calcium magnesium slime into valuable substances by carrying out precipitation, dehydration, desalting by washing, dehydration and the like on gypsum and magnesium slime generated by brine purification first-order reaction and saliferous calcium carbonate slime generated by second-order reaction, so that the salt content of the calcium magnesium slime can be less than 0.5% or lower, and the water content is lower than 15%. The saliferous gypsum generated by first-order reaction can be sold to a cement plant as a cement retarder after desalting, and can also be used as an additive for making a brick, thereby changing waste residues into valuable substances. The CaCO3 waste residues of the second-order reaction have wider application prospects after desalting due to high content.

Owner:HENAN JINDADI CHEM IND CO LTD

Glass-fluorine complex fire resistant filter material and method for manufacturing same

InactiveCN101244353AHigh mechanical strengthImprove wear resistanceFiltration separationCardingFiltration

The invention relates to a glass-fluoride composite high temperature resistance filtering material and a corresponding manufacture method, the filtering material comprises a special high temperature resistant fiberglass woven fabric and a polytetrafluoroethylene fiber net; the manufacture method comprises a plurality of steps as followings: processing polytetrafluoroethylene short fiber to obtain the polytetrafluoroethylene fiber net through the technologies of opening, mixing, carding and web forming, folding the special high temperature resistant fiberglass woven fabric and the polytetrafluoroethylene fiber net together, further compounding the two materials with a technology of spun-laced, then finishing and setting after dew prevention at last. The filtering material has the advantages of high mechanical strength, low elongation, good oxidation resistance, better high temperature resistant ability, filtration velocity, filtering precision and service life than glass fiber membrane filter media, main application in steel factory, cement factory and chemical factory.

Owner:DONGHUA UNIV

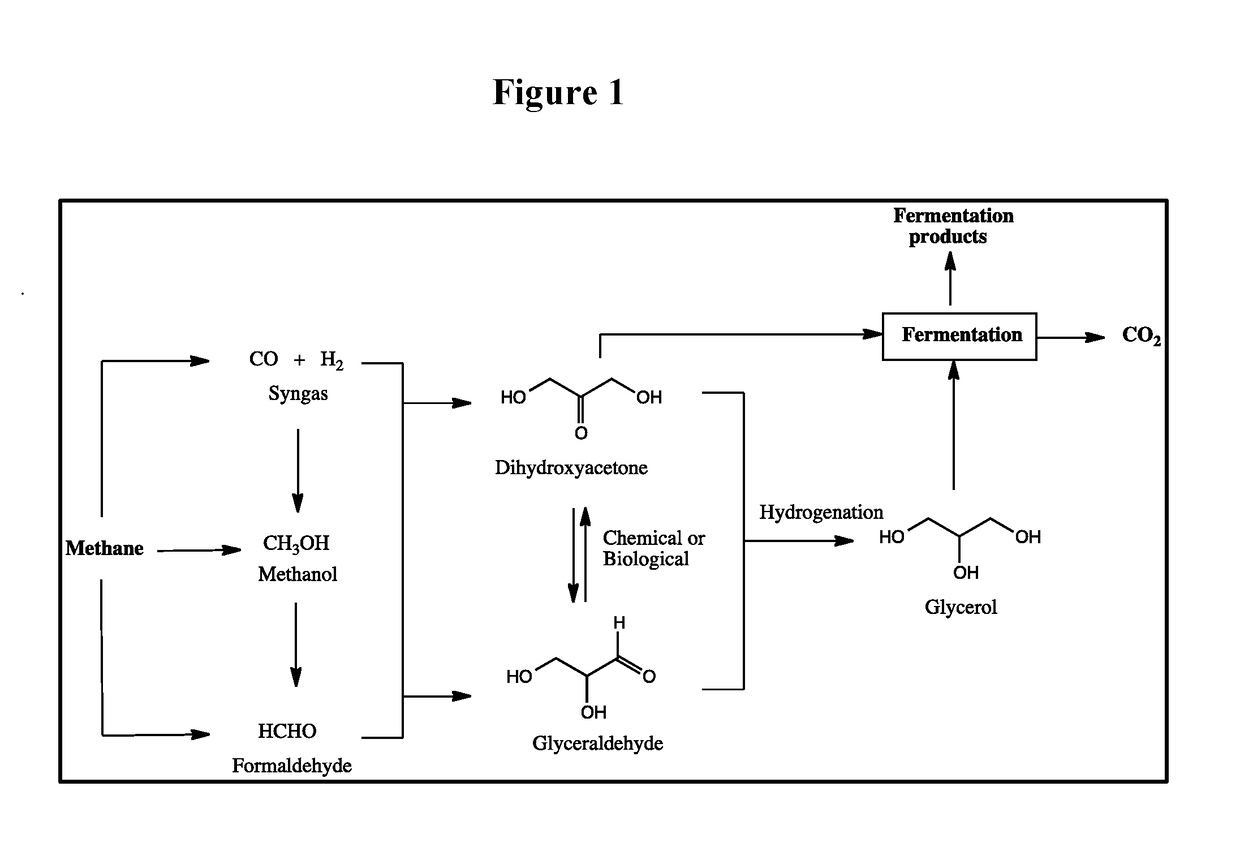

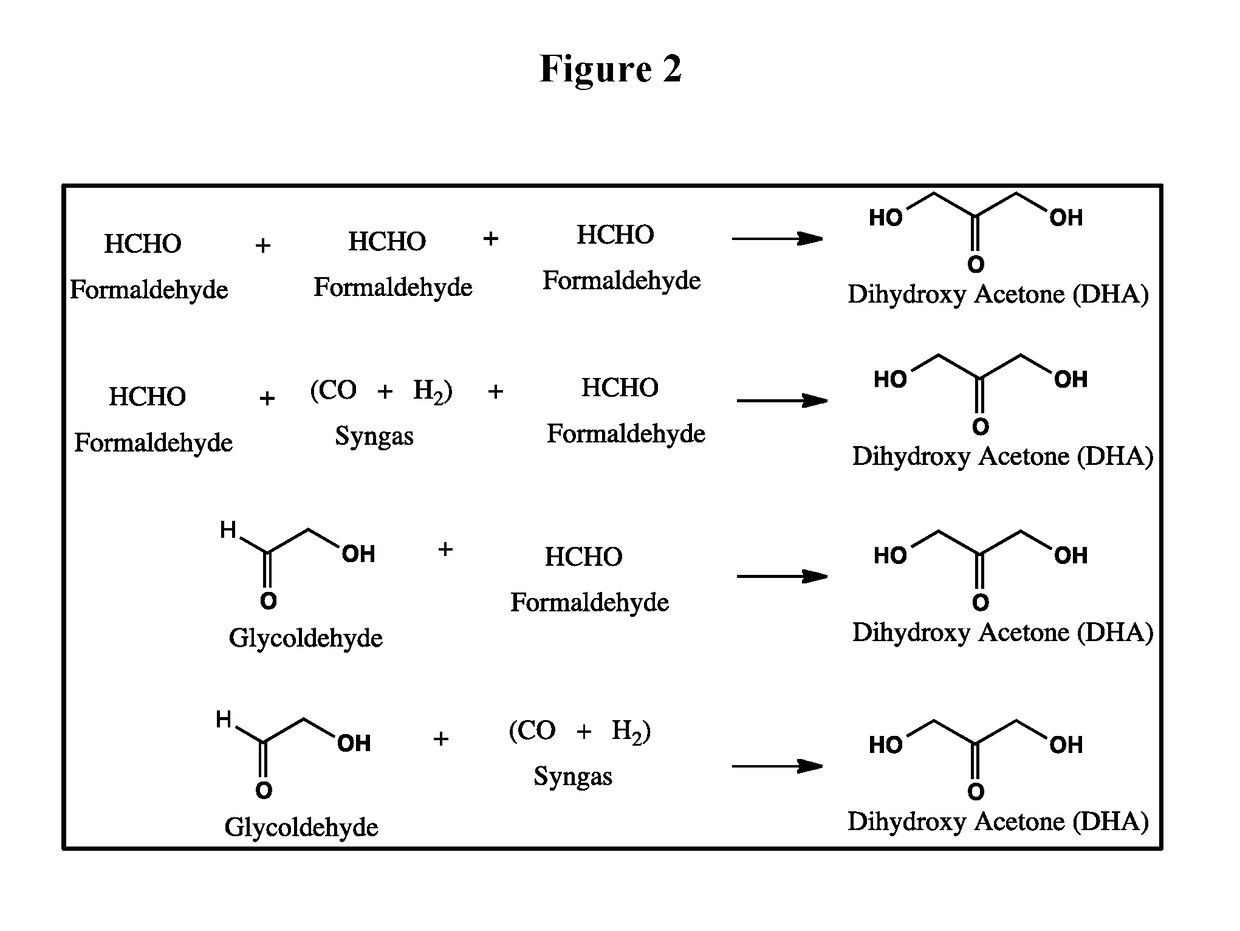

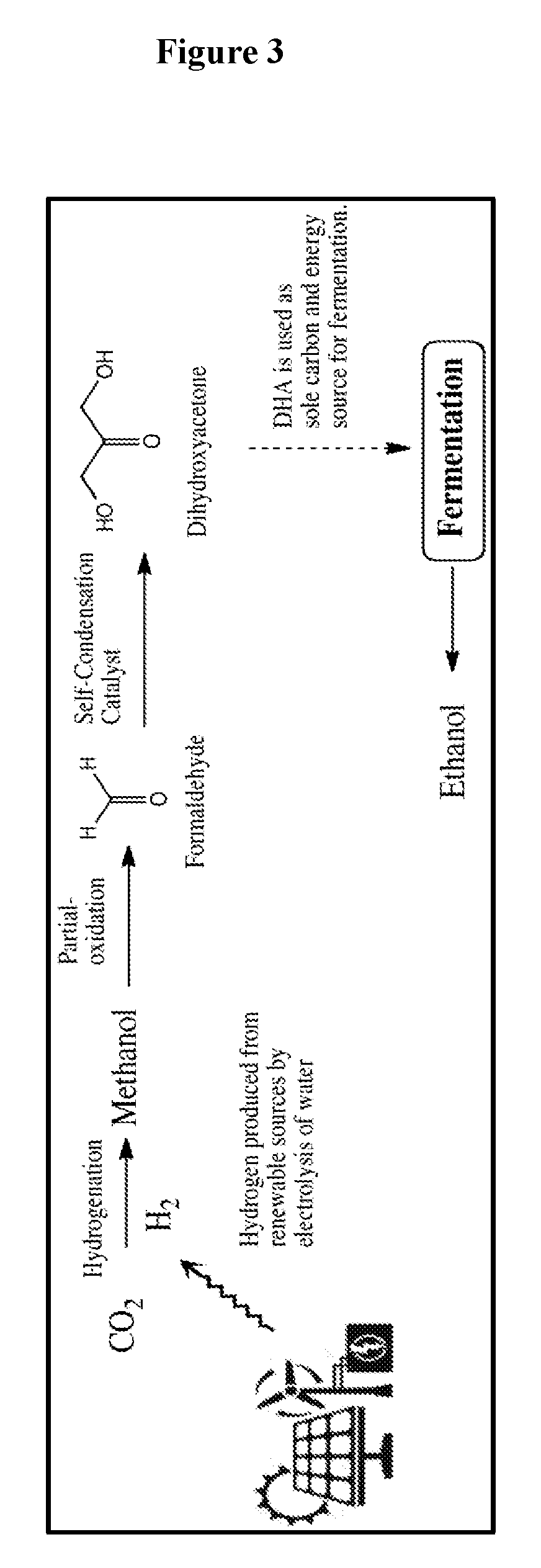

Biological fermentation using dihydroxyacetone as a source of carbon

The present invention relates to the use of hydrocarbons derived from natural gas in the fermentative production of biochemicals including biofuels. More specifically, the present invention provides the method for manufacturing dihydroxyacetone (“DHA”) from natural gas, biogas, biomass and CO2 released from industrial plants including electricity-generating plants, steel mills and cement factories and the use of DHA as a source of organic carbon in the fermentative production of biochemicals including biofuels. The present invention comprises three stages. In the first stage of the present invention, syngas and formaldehyde are produced from natural gas, biogas, biomass and CO2 released from industrial plants. In the second stage of the present invention, formaldehyde and syngas are condensed to produce DHA. In the third stage of the present invention, biochemicals including biofuels are produced from DHA using fermentation process involving wild type or genetically modified microbial biocatalysts.

Owner:KEMBIOTIX LLC

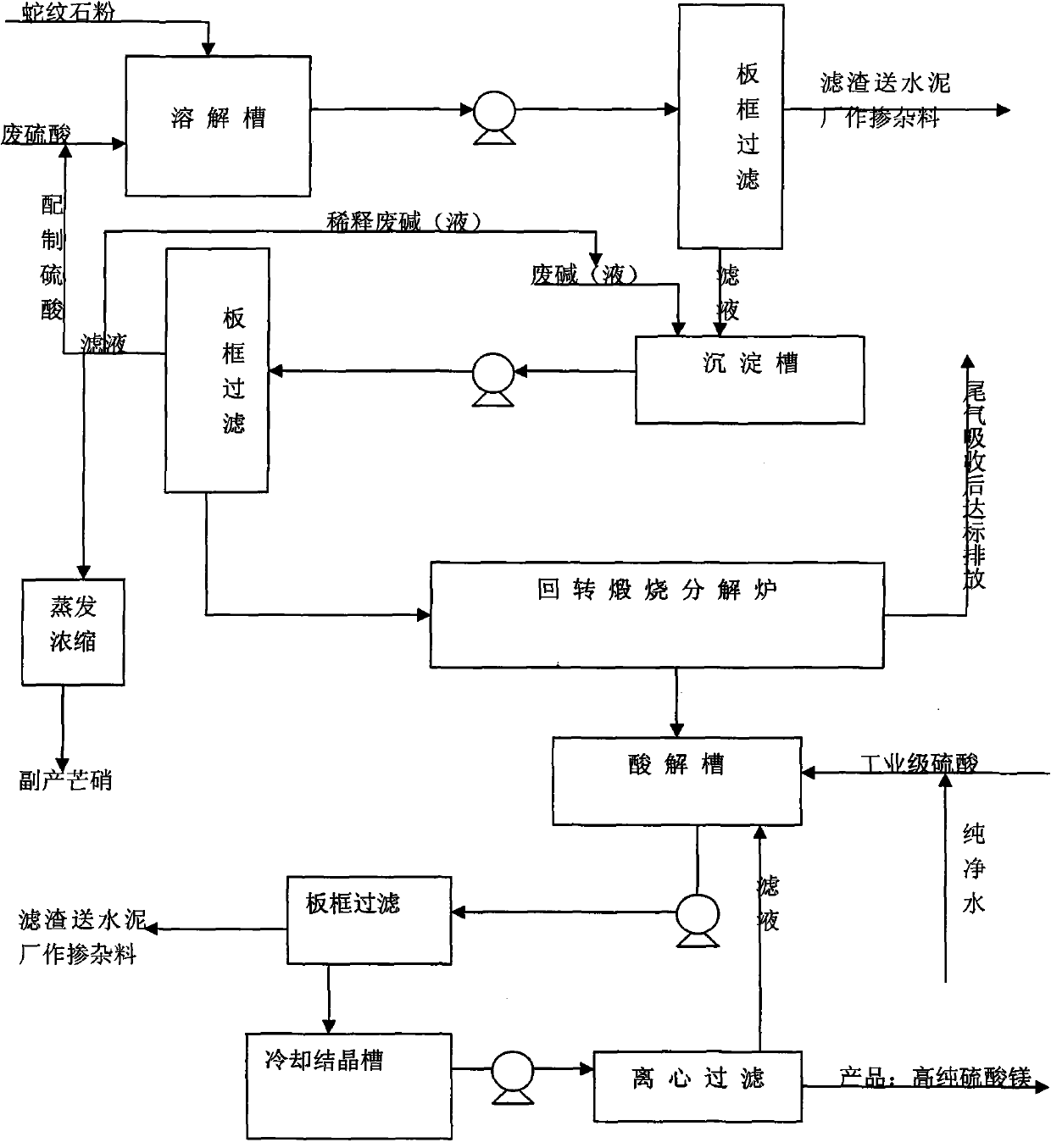

Method for comprehensively utilizing waste acid and waste alkali for producing high-purity magnesium sulfate

The invention belongs to a comprehensive utilization and treating method of recovered industrial wastes. Specifically, the method comprises technologies that: serpentine powder is dissolved by using waste sulfuric acid; a precipitate is neutralized by using waste alkali; and the material is subject to other processes such as high-temperature decomposition, such that high-purity magnesium sulfate is obtained. When the method provided by the invention is implemented, a large quantity of waste sulfuric acid and waste alkali (liquid) produced by enterprises of pesticides, medicines and hydrazine hydrates can be consumed. Organics brought by the waste can be completely decomposed and removed in a rotary decomposing furnace. Heavy metals in the waste acid and alkali can be precipitated with a pH regulation method; the precipitate is filtered, and is used as a doping material in cement factories; residual SO4<2-> in the technology is combined with Na<+>, and a by product sodium sulfate can be produced through evaporative concentration. With the method, the content of produced magnesium sulfate product is higher than 99.5%. With the method, environmental pollution of related pollutant-discharging enterprises can be solved, and wastes can be effectively utilized. The method belongs to green and environment-friendly technologies, and is suitable for large-scale productions. The method has a good application and popularization prospect.

Owner:四川金岸环保科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com