Method for converting titanium dioxide red gypsum into white gypsum and enriching titanium and iron

A white gypsum and red gypsum technology, applied in chemical instruments and methods, titanium and titanyl sulfate, ferric sulfate, etc., can solve the problems of inability to use building materials product development, low wastewater treatment efficiency, etc., and achieve considerable economic benefits, The effect of stable treatment effect and low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

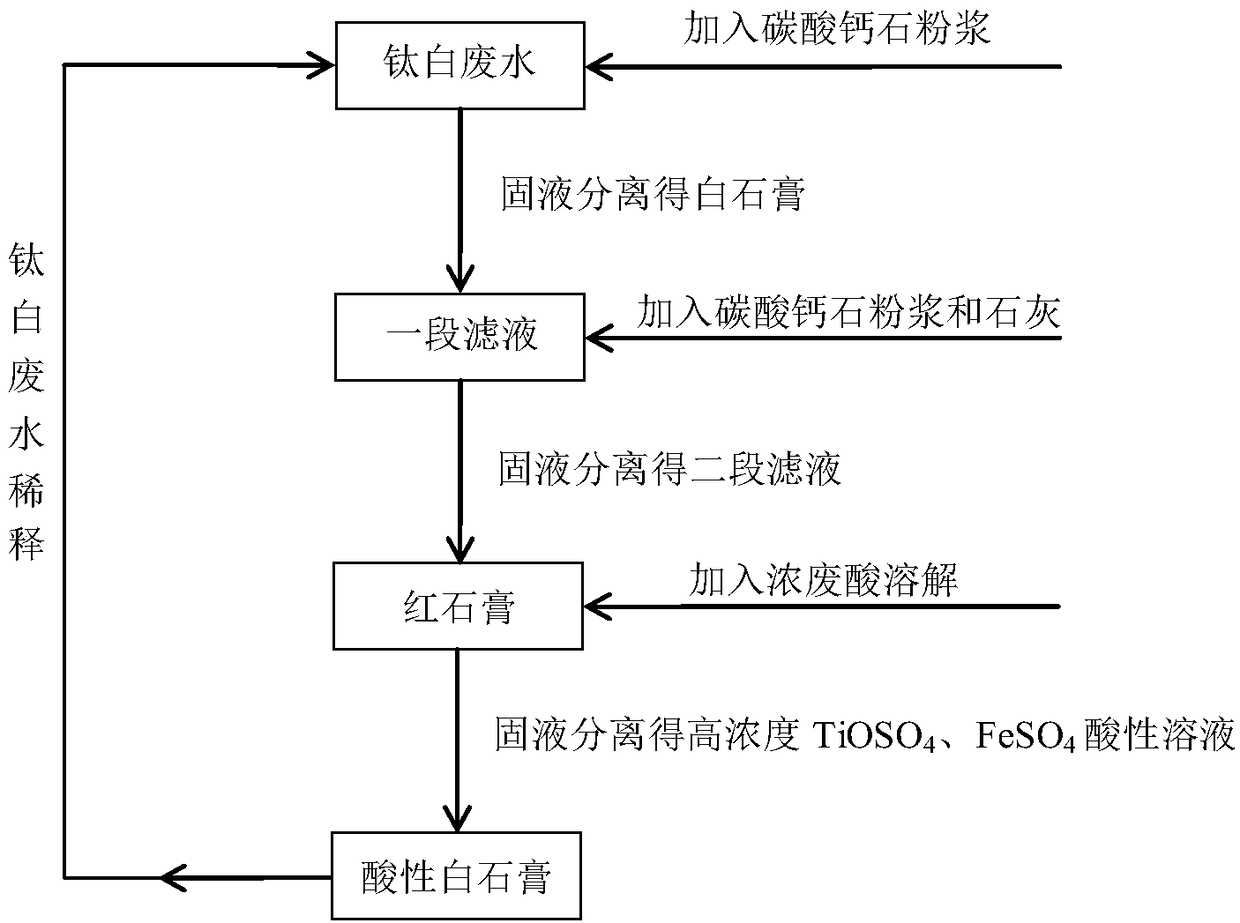

[0026] A method for converting titanium white red gypsum into white gypsum and enriching titanium and iron, comprising the following steps:

[0027] (1) Preparation of white gypsum: While blowing air, turn on the mechanical agitation, pump the titanium dioxide wastewater into the reaction tank, add calcium carbonate stone slurry at the same time, adjust to pH=1.52, stop stirring, and pass the solid-liquid mixture through the diaphragm filter press Separation, that is, white gypsum and a filtrate, titanium dioxide wastewater index: H 2 SO 4 =70.32g / l, TiOSO 4 =2.32g / l, FeSO 4 =40.05g / l; One-stage filtrate indicator: H 2 SO 4 = 18.06g / l, TiOSO 4 =2.14g / l, FeSO 4 = 36.64g / l; white gypsum index: moisture = 24.80%, SO 3 =43.92%, pH=6.52.

[0028] (2) Preparation of red gypsum: After a section of filtrate is pumped into the reaction tank, while blowing air, turn on the mechanical agitation, first add calcium carbonate stone powder slurry, adjust to pH=4.7, then add milk of l...

Embodiment 2

[0032] A method for converting titanium white red gypsum into white gypsum and enriching titanium and iron, comprising the following steps:

[0033] (1) Preparation of white gypsum: While blowing air, turn on the mechanical agitation, pump the titanium dioxide wastewater into the reaction tank, add calcium carbonate stone slurry at the same time, adjust to pH=1.55, stop stirring, and pass the solid-liquid mixture through the diaphragm filter press. Separate to obtain white gypsum and a section of filtrate. Titanium dioxide wastewater index: H 2 SO 4 = 69.12g / l, TiOSO 4 =2.95g / l, FeSO 4 =39.10g / l; One-stage filtrate indicator: H 2 SO 4 = 17.78g / l, TiOSO 4 =2.81g / l, FeSO 4 =36.13g / l; white gypsum index: moisture = 25.40%, SO 3 =43.73%, pH=6.46.

[0034] (2) Preparation of red gypsum: After a section of filtrate is pumped into the reaction tank, while blowing air, start the mechanical agitation, first add calcium carbonate stone powder slurry, adjust to pH=4.8, then add ...

Embodiment 3

[0038] A method for converting titanium white red gypsum into white gypsum and enriching titanium and iron, comprising the following steps:

[0039] (1) Preparation of white gypsum: While blowing air, turn on the mechanical agitation, pump the titanium dioxide wastewater into the reaction tank, add calcium carbonate stone slurry at the same time, adjust to pH=1.57, stop stirring, and pass the solid-liquid mixture through the diaphragm filter press. Separate to obtain white gypsum and a section of filtrate. Titanium dioxide wastewater index: H 2 SO 4 = 64.37g / l; TiOSO 4 = 2.63g / l; FeSO 4 =35.29g / l; One-stage filtrate indicator: H 2 SO 4 = 16.63 g / l, TiOSO 4 =2.52g / l, FeSO 4 = 33.18g / l; white gypsum index: moisture = 25.34%, SO 3 =44.28%, pH=6.43.

[0040] (2) Preparation of red gypsum: After a section of filtrate is pumped into the reaction tank, while blowing air, start the mechanical agitation, first add calcium carbonate stone powder slurry, adjust to pH=4.6, then a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com