Patents

Literature

39results about "Titanium and titanyl sulfates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

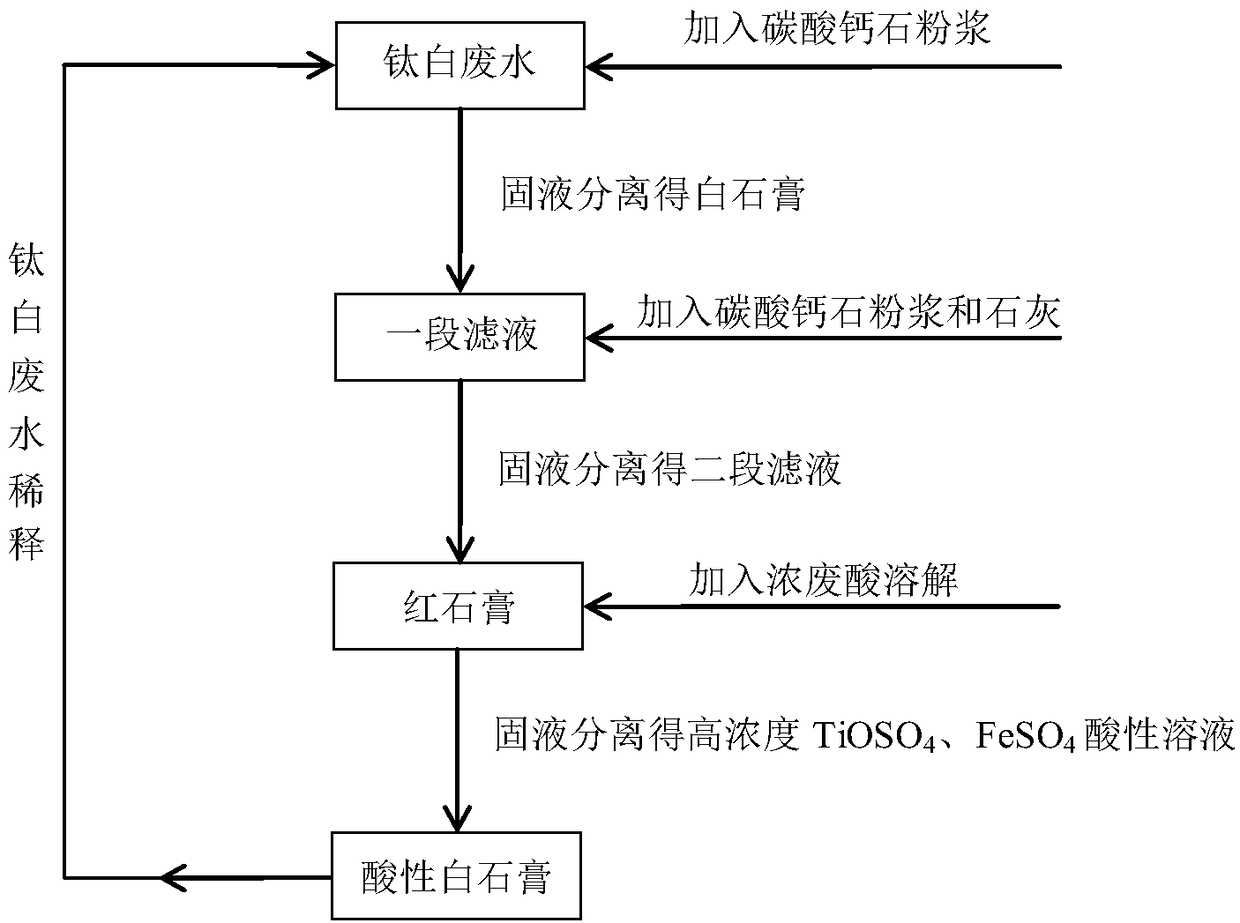

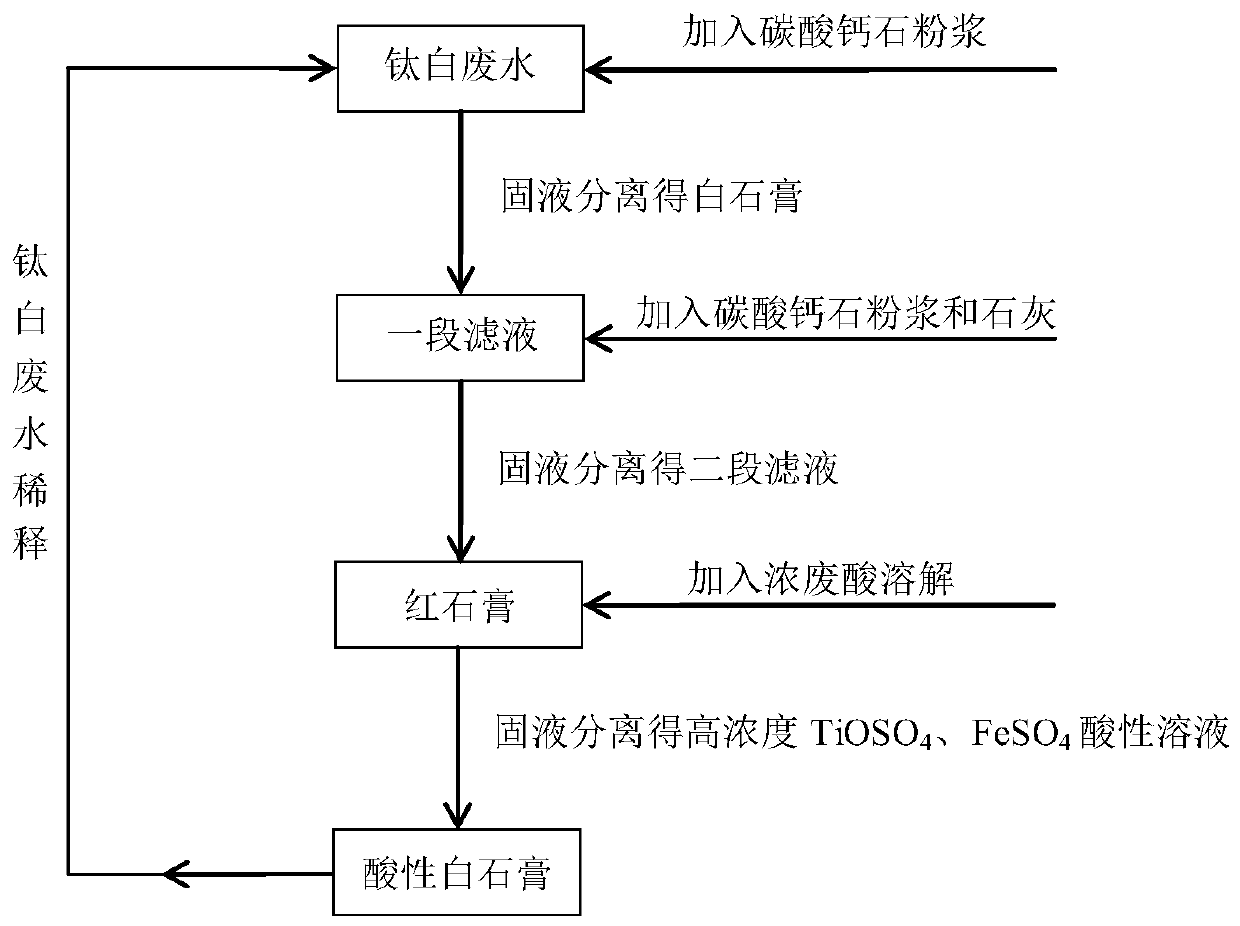

Method for converting titanium dioxide red gypsum into white gypsum and enriching titanium and iron

ActiveCN108264251AIncrease added valueSimple processTitanium and titanyl sulfatesTreatment involving filtrationHigh concentrationTreatment effect

The invention belongs to the technical field of wastewater treatment, and particularly relates to a method for converting titanium dioxide red gypsum into white gypsum and enriching titanium and iron.The method comprises the following steps: preparing white gypsum, preparing the red gypsum, converting the red gypsum into acid white gypsum, and converting the acid white gypsum into the white gypsum; through control of a process and an end point of the reaction, the produced white gypsum can be directly used for a cement factory, and can be deeply processed into building material gypsum with higher added value; through dissolution of the red gypsum by a waste concentrated acid, the red gypsum is converted into the acid white gypsum, and a TiOSO4 and FeSO4 acidic solution with a high concentration is obtained, wherein the recovery utilization rate is 95% or more; and the acid white gypsum is diluted by using titanium dioxide wastewater, and after primary neutralization is performed, thewhite gypsum is obtained. The method provided by the invention has a simple technological process, a stable treatment effect, less equipment investment, no secondary pollution, low treatment costs, considerable economic benefits and broad market prospects.

Owner:CNMC GUANGXI PGMA

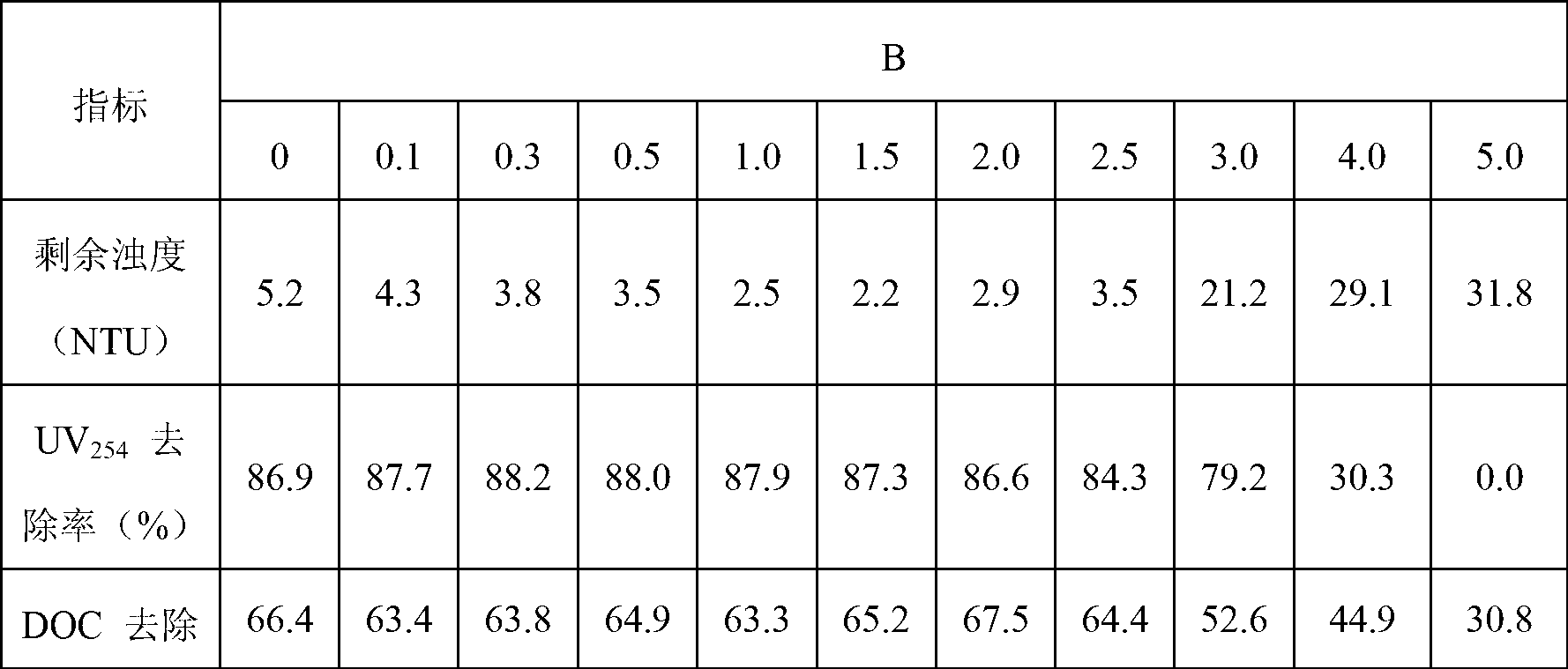

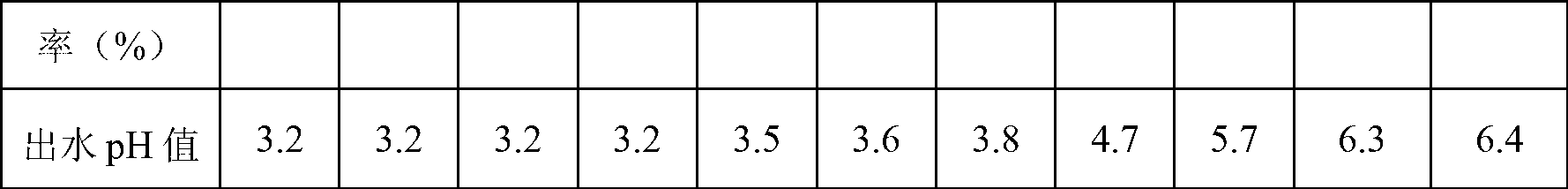

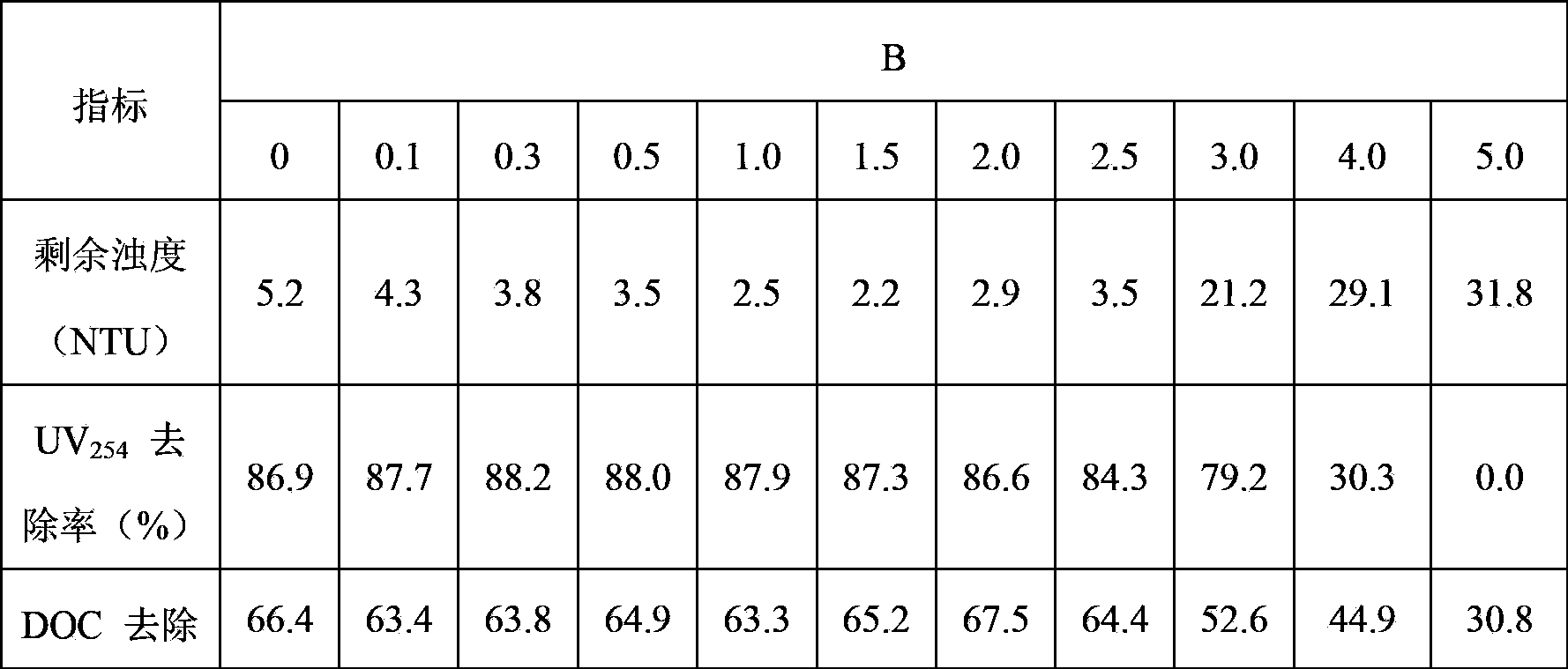

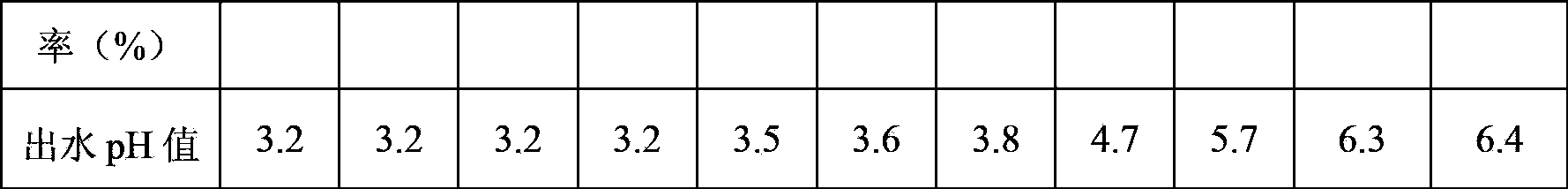

Polymeric titanium sulfate inorganic polymeric flocculant, and preparation method and application of flocculant

ActiveCN103011358AGood flocculation effectSimple production processTitanium and titanyl sulfatesSulfur compoundsTextile printerChemical industry

The invention relates to a polymeric titanium sulfate (PTS) inorganic polymeric flocculant, and a preparation method and an application of the flocculant. The PTS inorganic polymeric flocculant is prepared by taking a titanium sulfate solution and sodium hydroxide as raw materials and dropping sodium hydroxide into the titanium sulfate solution; a preset alkalization degree is 0.1-5.0; after the dropping is finished, the titanium sulfate solution and sodium hydroxide are stirred for 1.5-5h. The flocculant has the advantages of good product stability, strong adsorption bridging ability for colloidal substances, good flocculation effect, wide application range, small generated sludge quantity and the like, can be widely applied to the fields of water supply, waste water treatment, papermaking, textile printing and dyeing, daily-use chemical industry and the like, and has a good water treatment effect. The method has the characteristic that a production technique is simple, economical and rapid.

Owner:SHANDONG UNIV

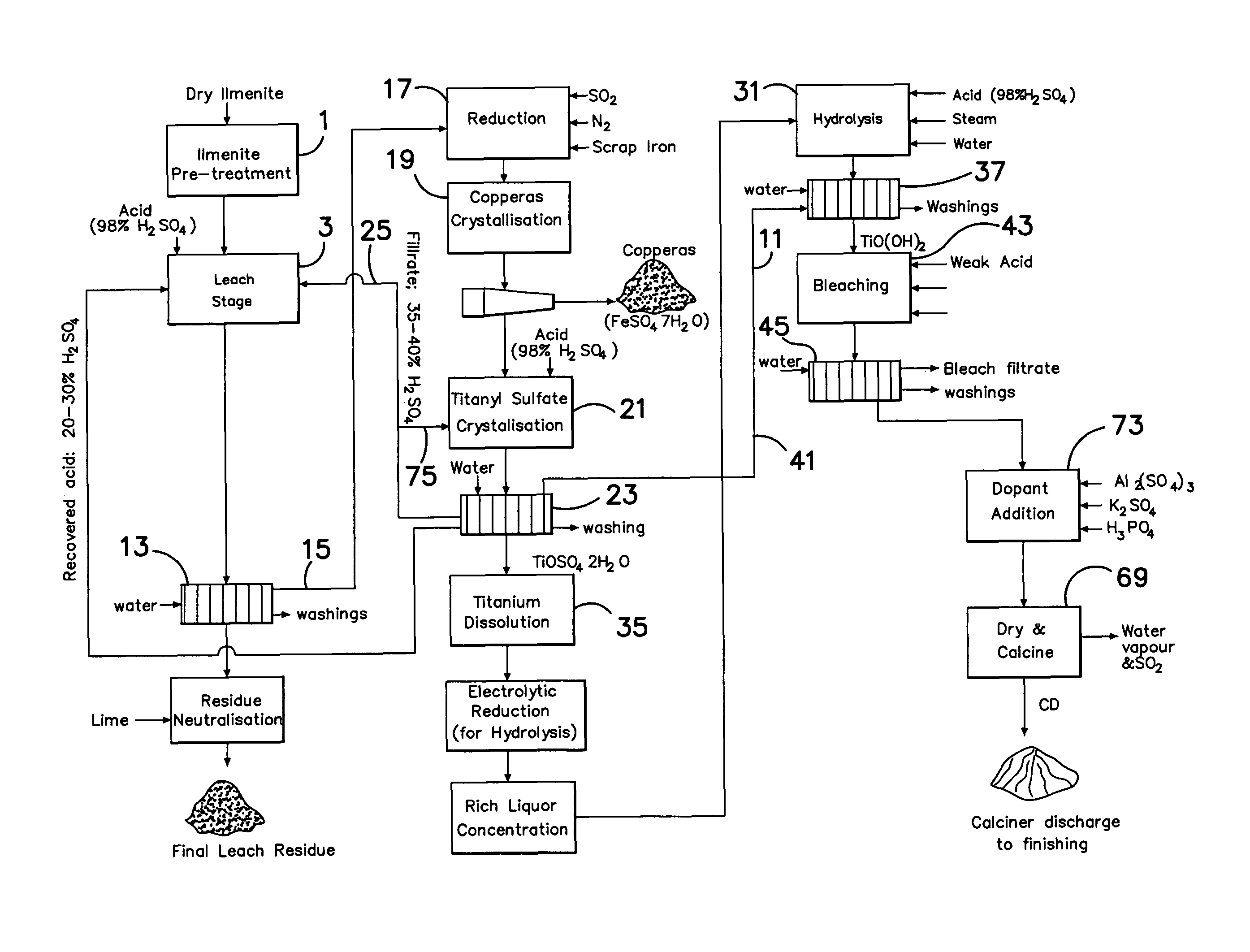

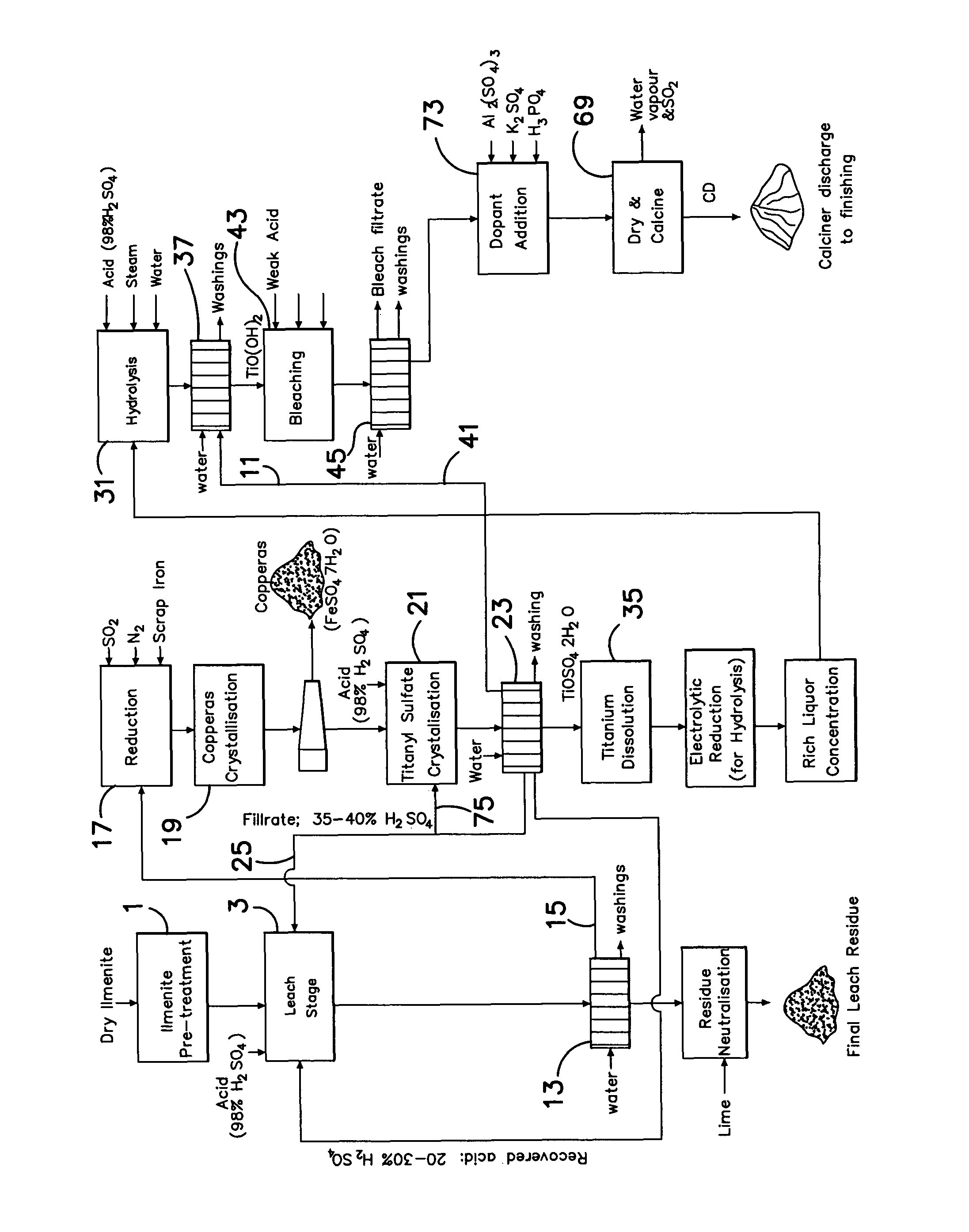

Sulfate process

A sulfate process for producing titania from a titaniferous material (as herein defined) including a step of leaching said titaniferous material with a leachant to form a process solution that includes an acidic solution of titanyl sulfate and iron sulfate, wherein said sulfate process further includes a filtration step comprising filtering said leachant to at least substantially remove titanyl sulfate particles from said leachant prior to supplying said leachant to said leach step.

Owner:BHP BILLITON INNOVATION PTY LTD

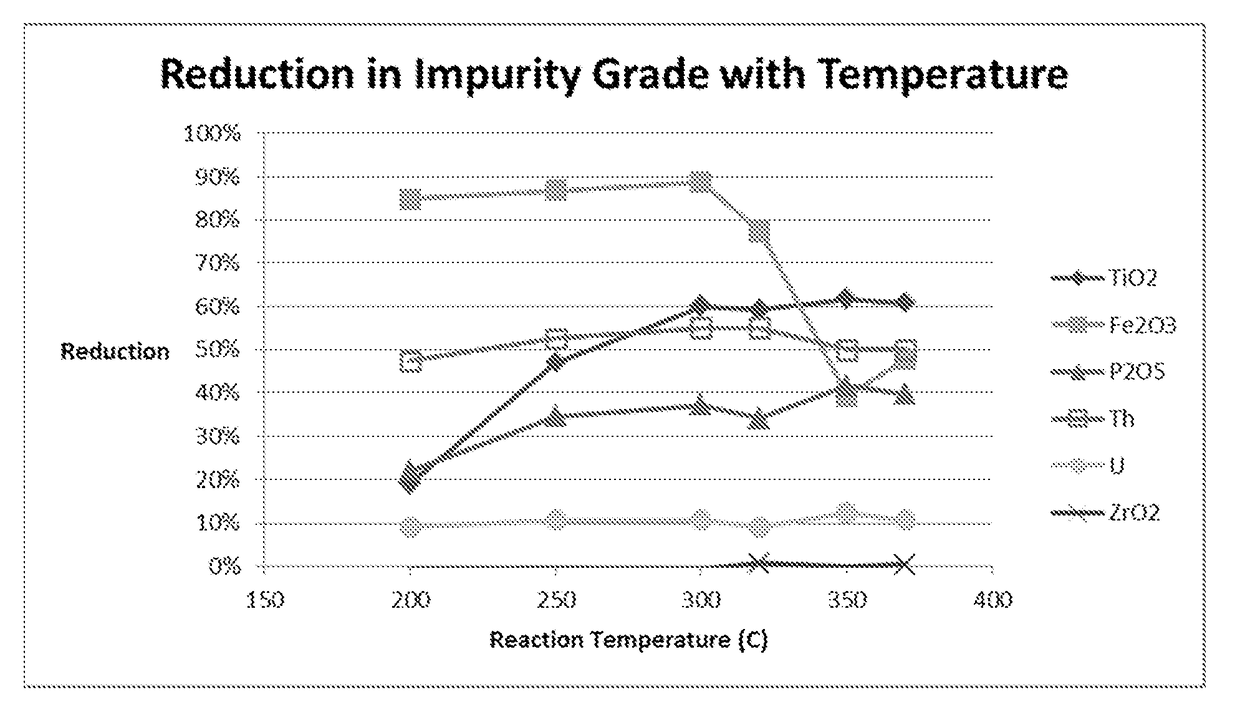

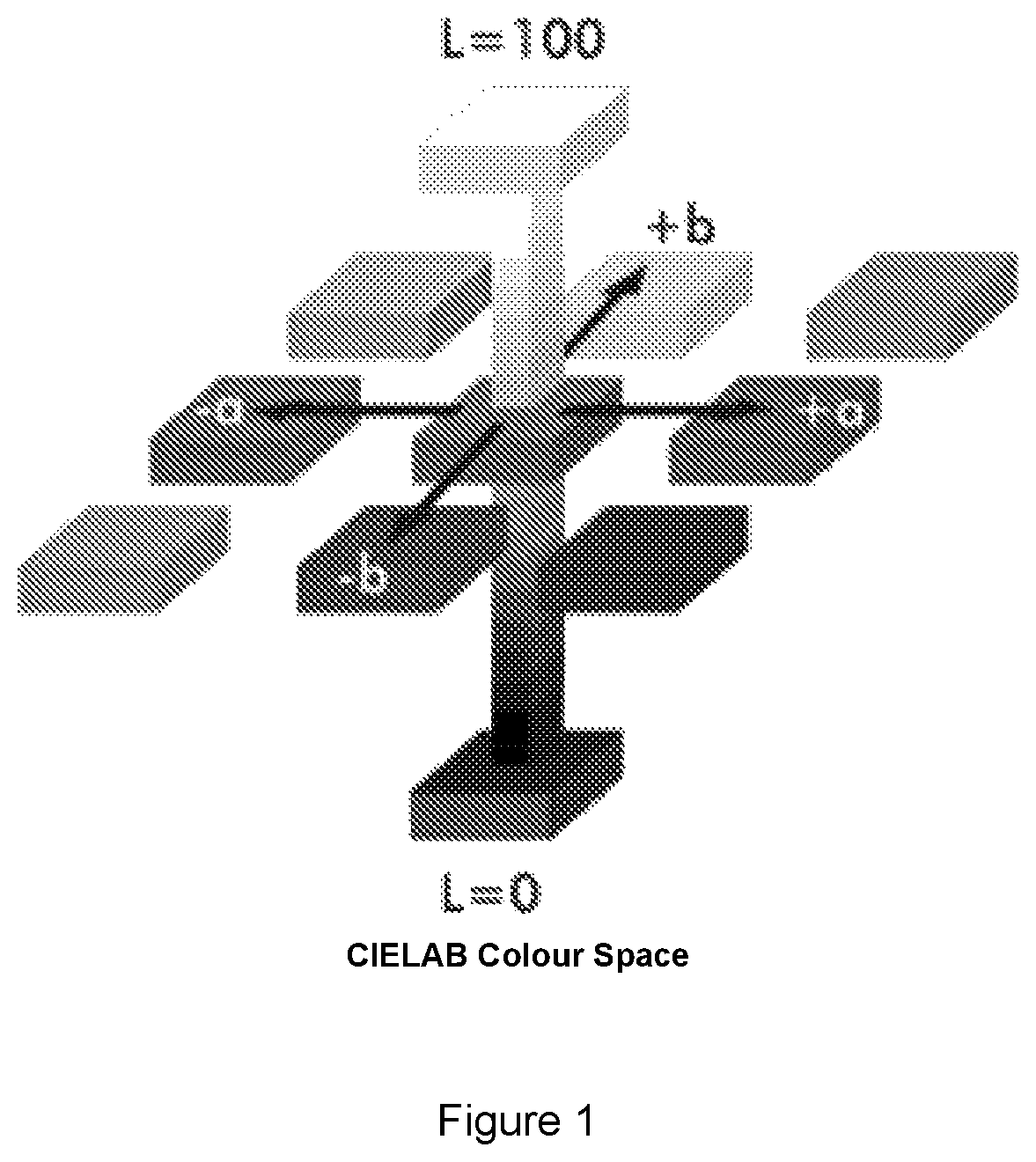

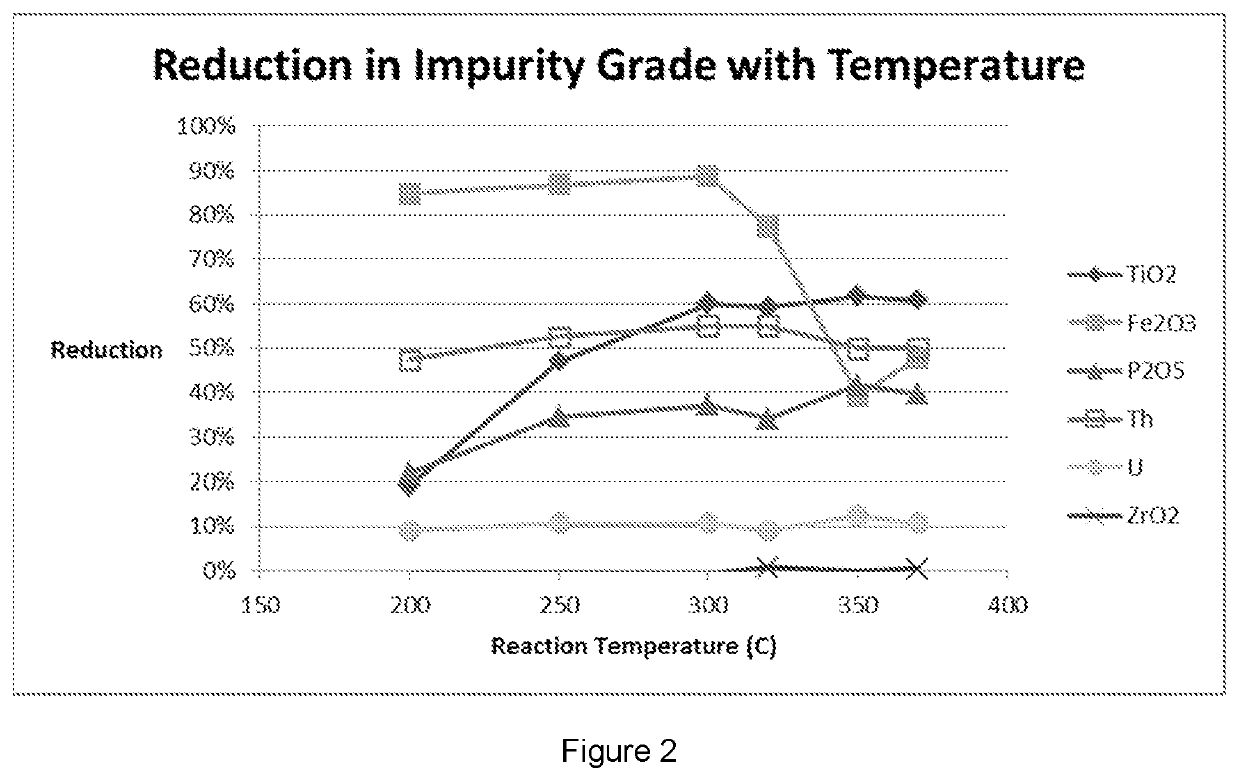

Process for Improving the Grade and Optical Quality of Zircons

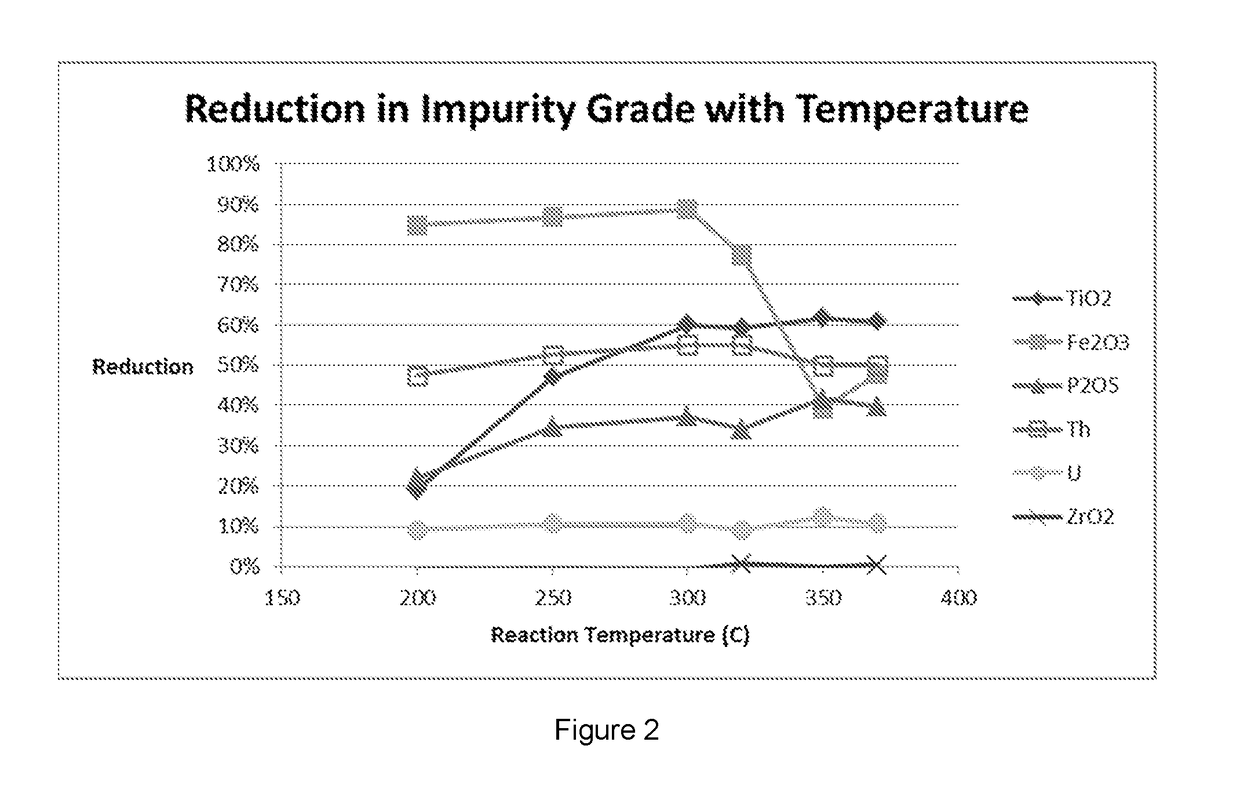

ActiveUS20180023170A1Improve Grading QualityImprove optical qualityTitanium and titanyl sulfatesIron sulfatesPregnant leach solutionSulfate

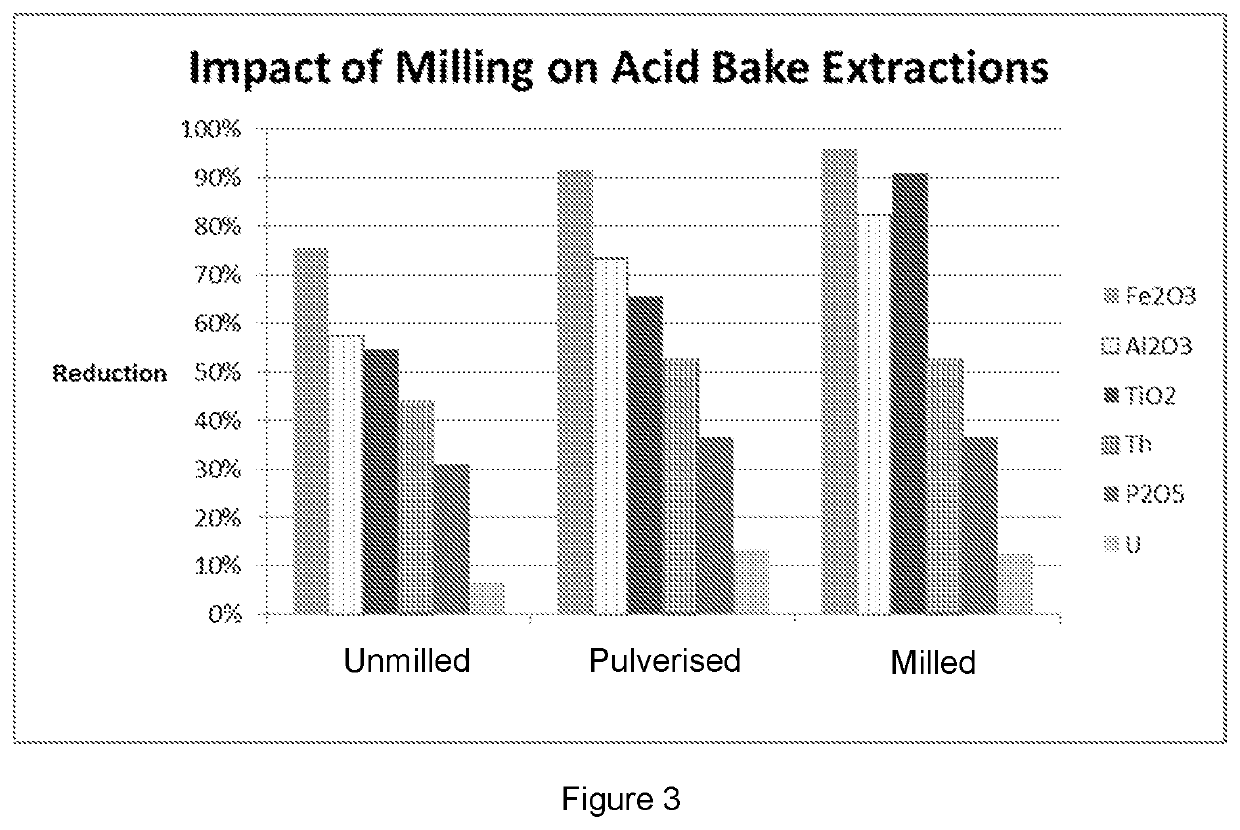

A process for improving the grade and optical quality of zircon, comprising: baking a mixture of a zircon feed and concentrated sulphuric acid at a baking temperature in the range of from 200 up to 400° C., and for a time to form water leachable sulphates with impurities therein including at least iron and titanium; leaching the baked mixture to dissolve the leachable sulphates; and separating the zircon from the leachate containing the leached sulphates, which separated zircon is thereby of improved grade and optical quality.

Owner:ILUKA RESOURCES

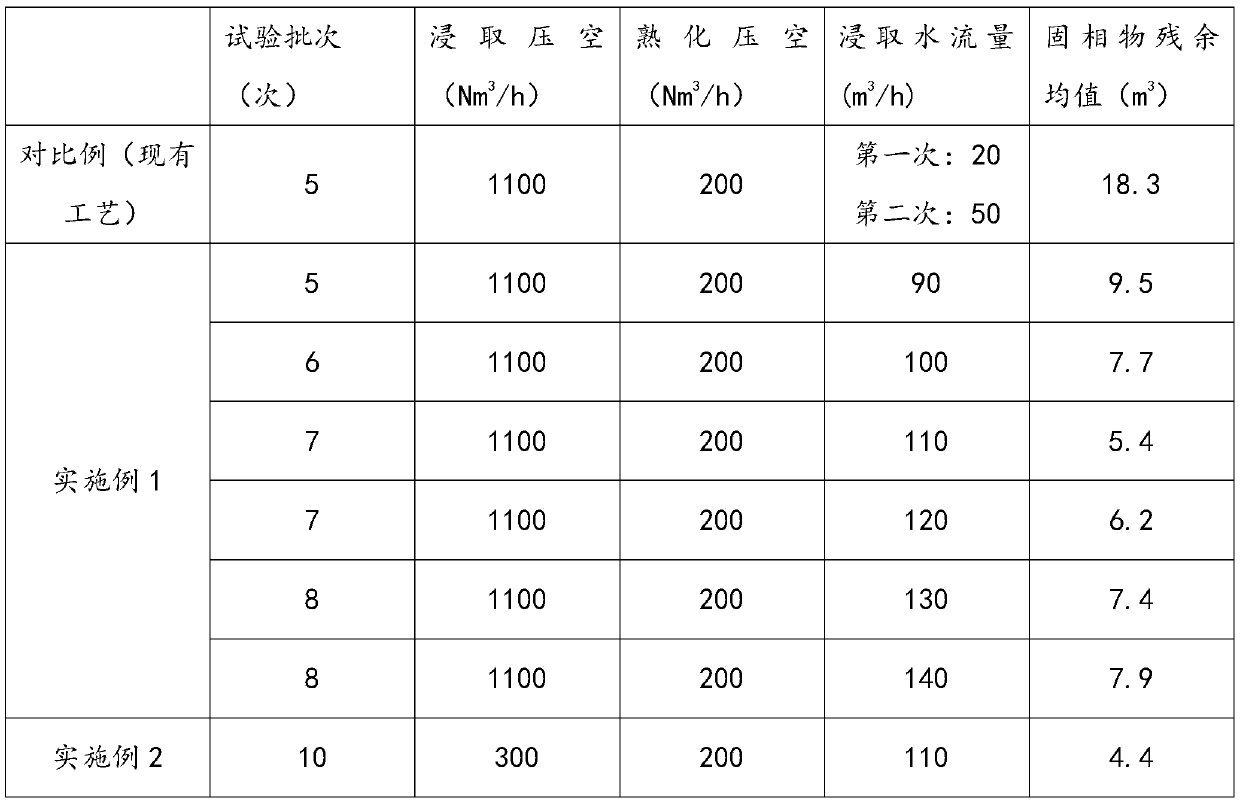

Method for reducing acidolysis solid matters in titanium dioxide production process

InactiveCN110668495AReduce riskDissolve fastTitanium and titanyl sulfatesTitanium dioxideIlmeniteWater flow

The invention belongs to the technical field of titanium dioxide production, particularly relates to a method for reducing acidolysis solid matters in the titanium dioxide production process, and aimsat the problem that in the existing ilmenite acidolysis leaching process, many solid-phase substances remain in an acidolysis tank to cause the situation that compressed air stirring is not uniform so as to cause the problem of pot overflowing due to untimely heat dissipation of the main reaction. According to the method, through comparative research on the acidolysis leaching water flow rate, leaching solid phase temperature, leaching empty flow rate, solid phase dissolving square quantity and acidolysis titanium liquid quality, the residual solid phase square quantity in the acidolysis tankis successfully reduced, the phenomenon of titaniferous solution early hydrolysis possibly caused by high temperature is avoided, and the potential safety hazard of acidolysis main reaction overflowing is reduced. The method is undoubtedly capable of reducing the overall production cost of titanium dioxide and improving the economic benefit for enterprises, and for the whole titanium dioxide industry, the new technology can relieve the dilemma that the production cost is sharply increased and promote the overall development of the titanium dioxide industry.

Owner:XIANGYANG LOMON TITANIUM IND CO LTD

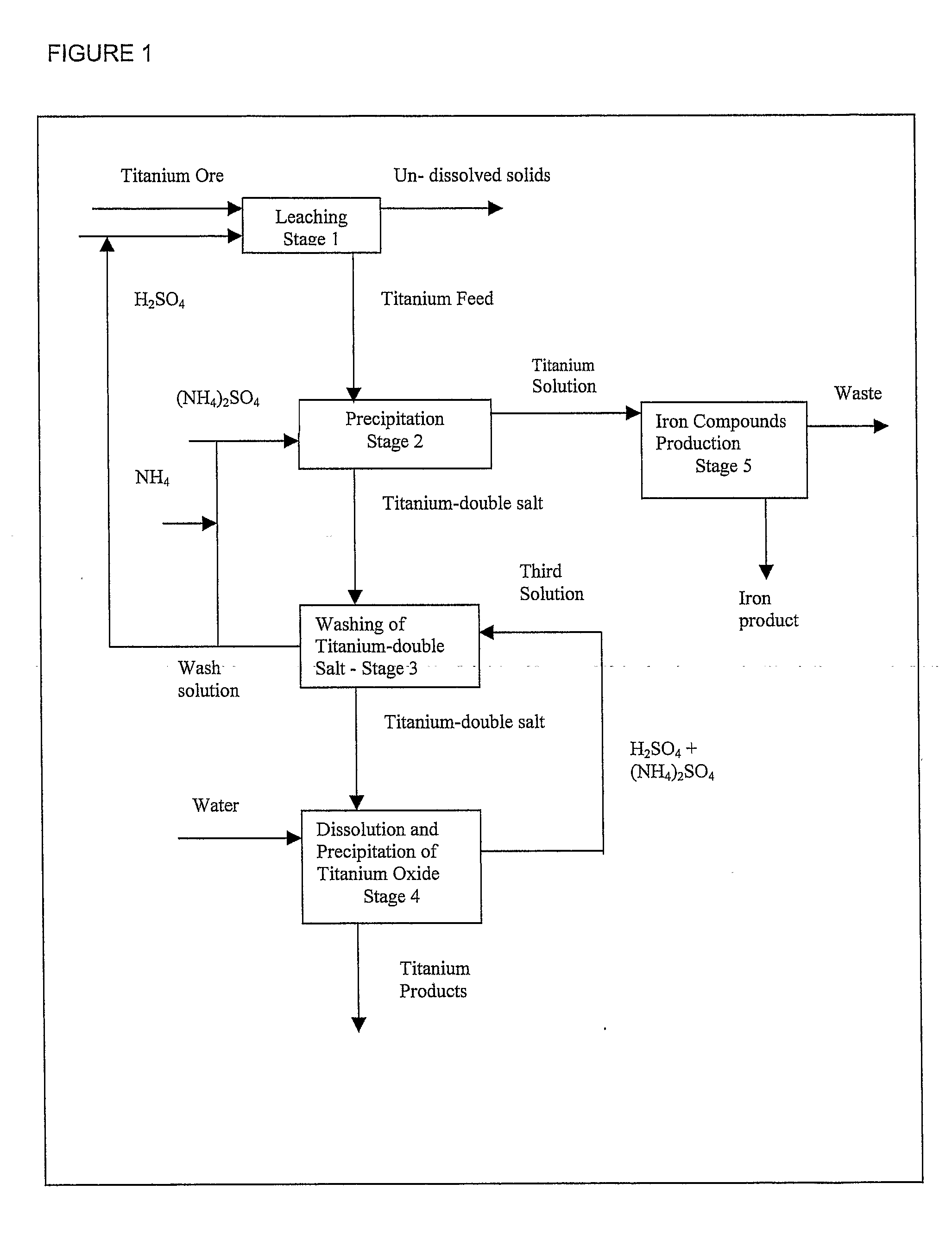

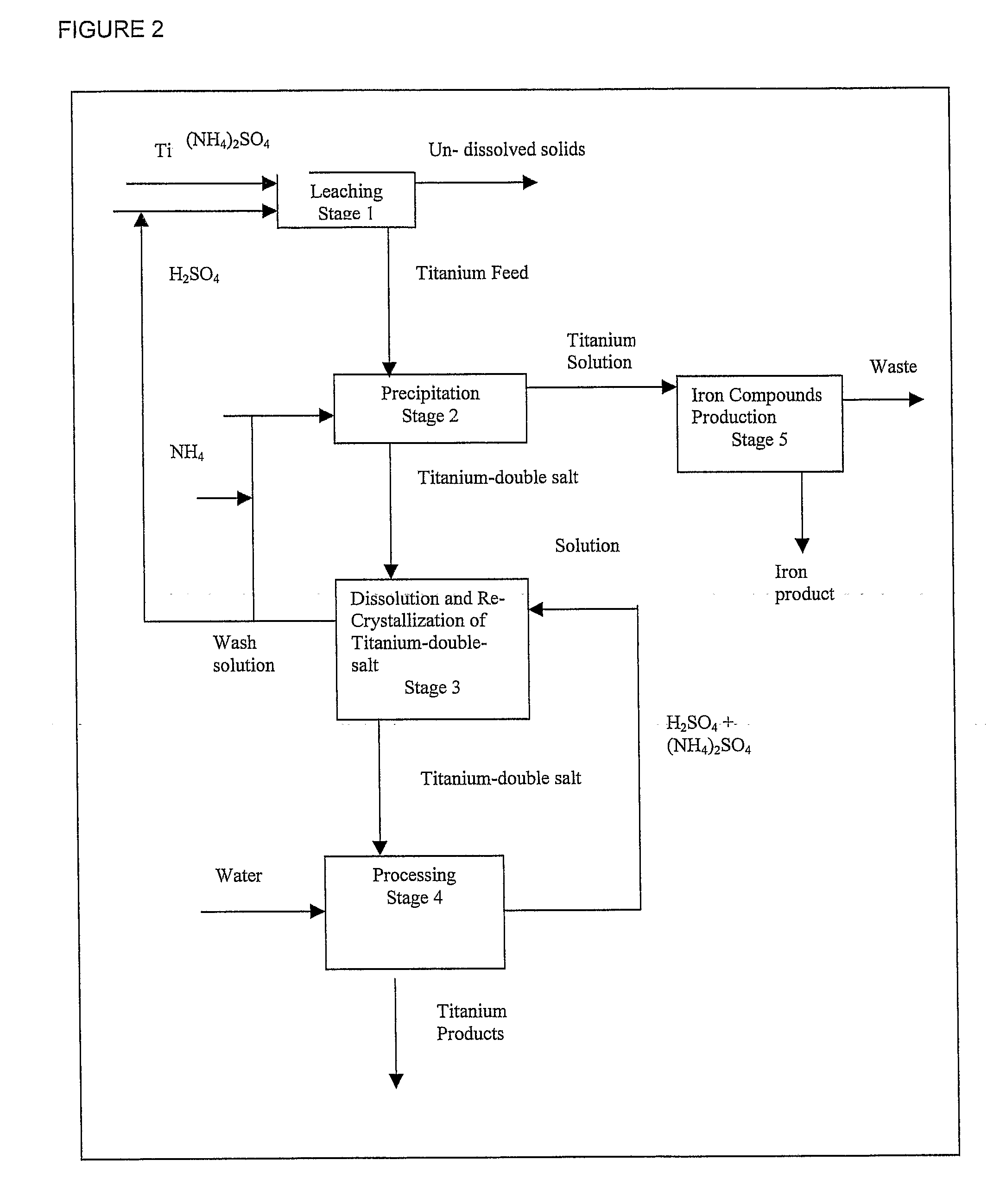

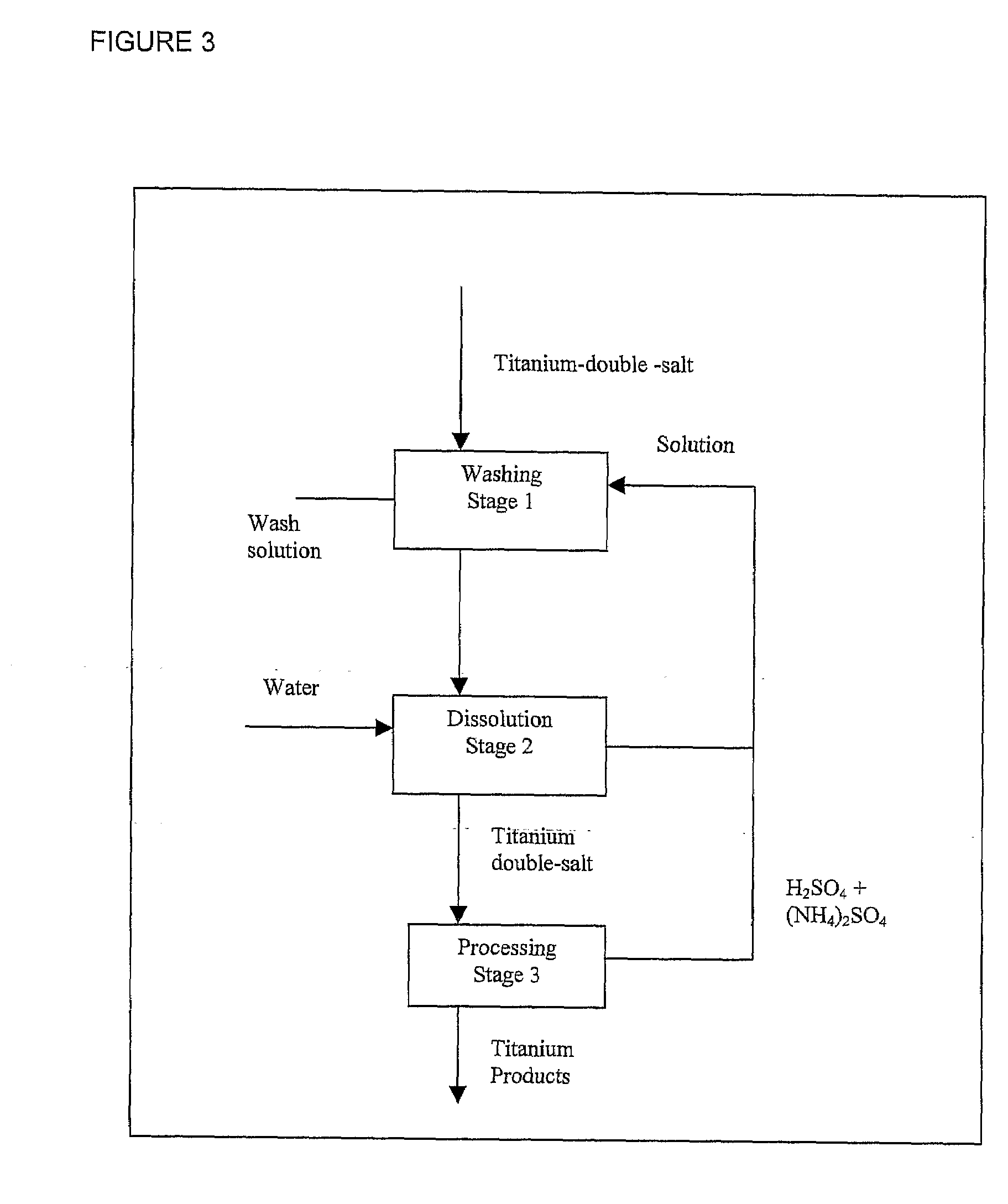

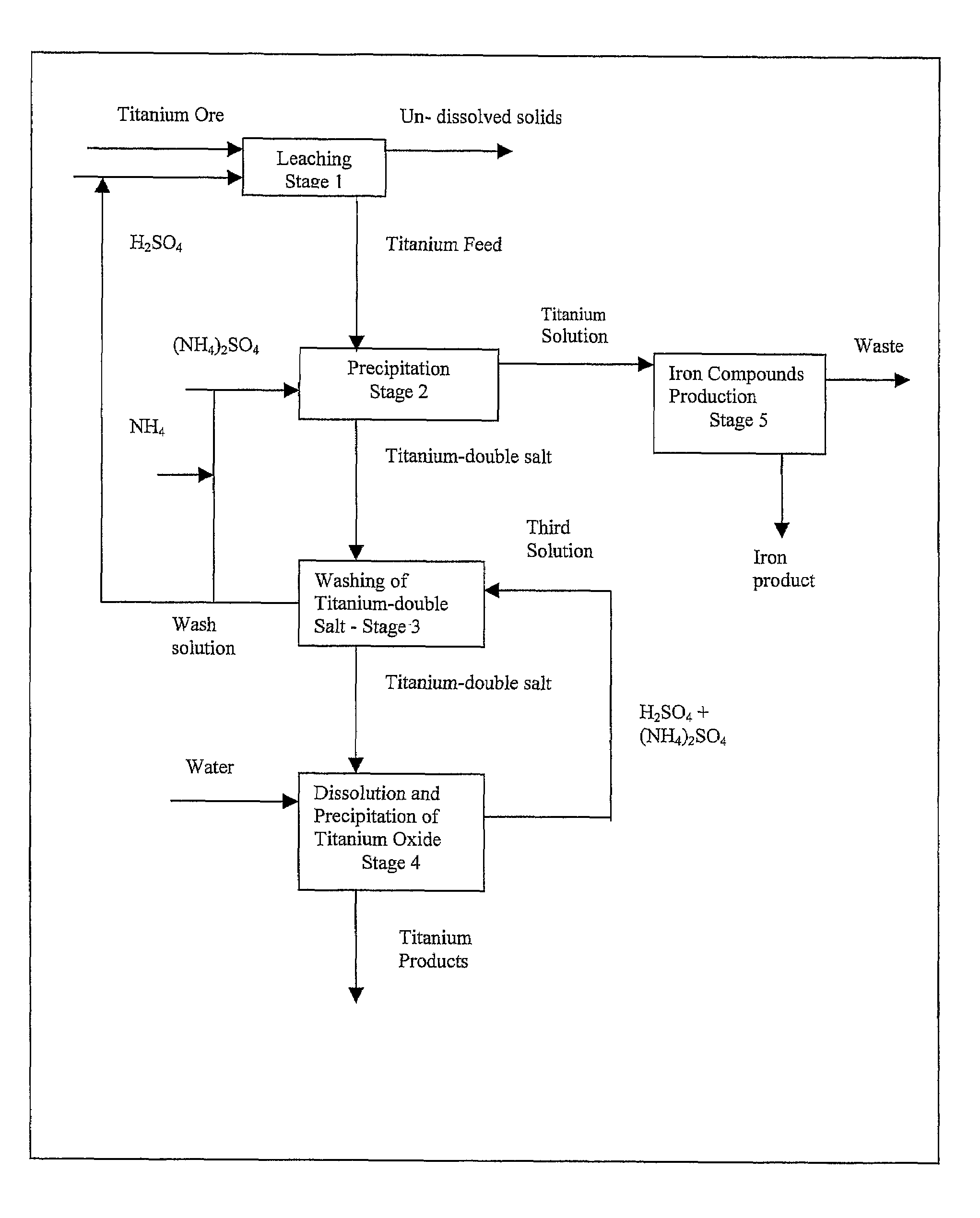

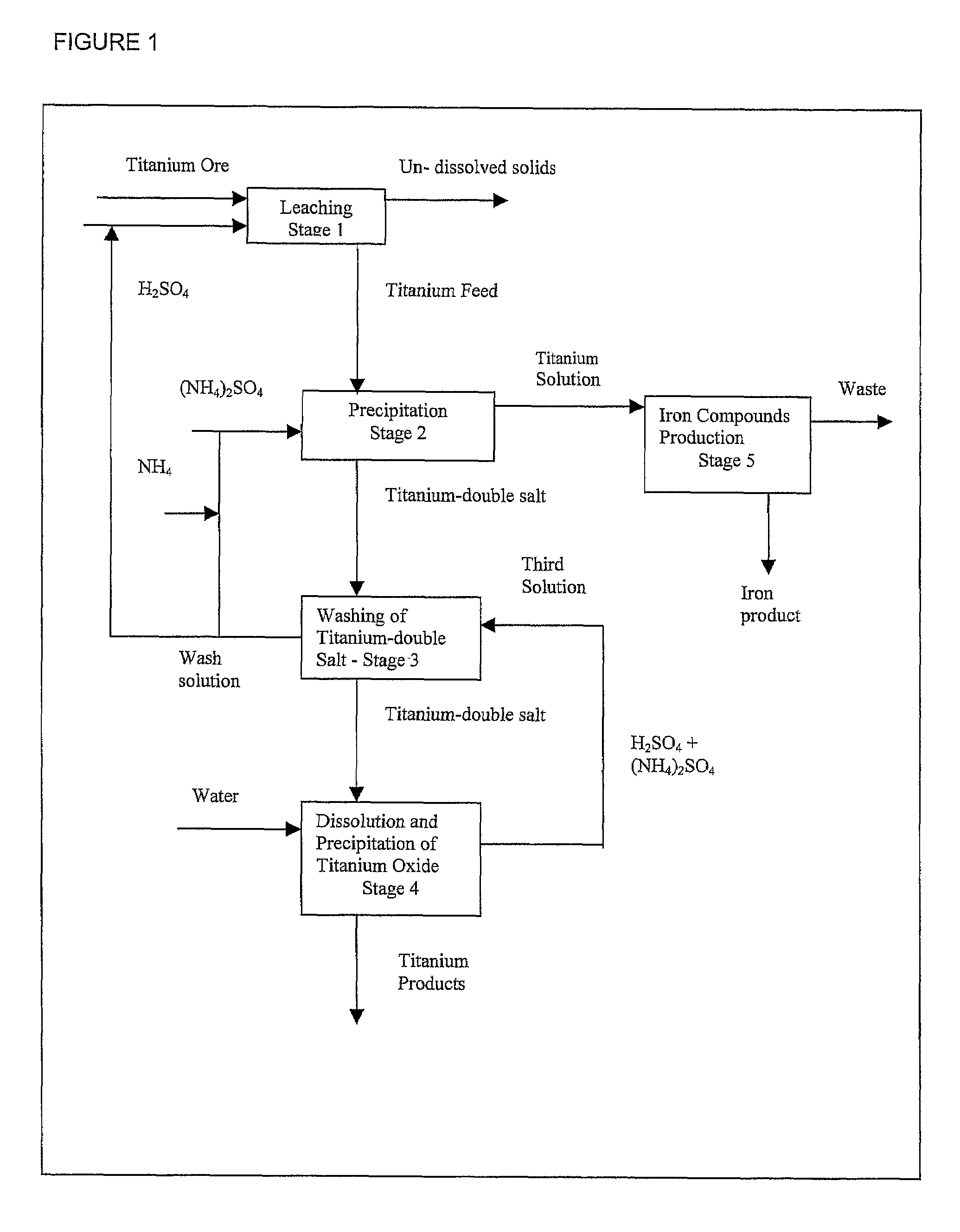

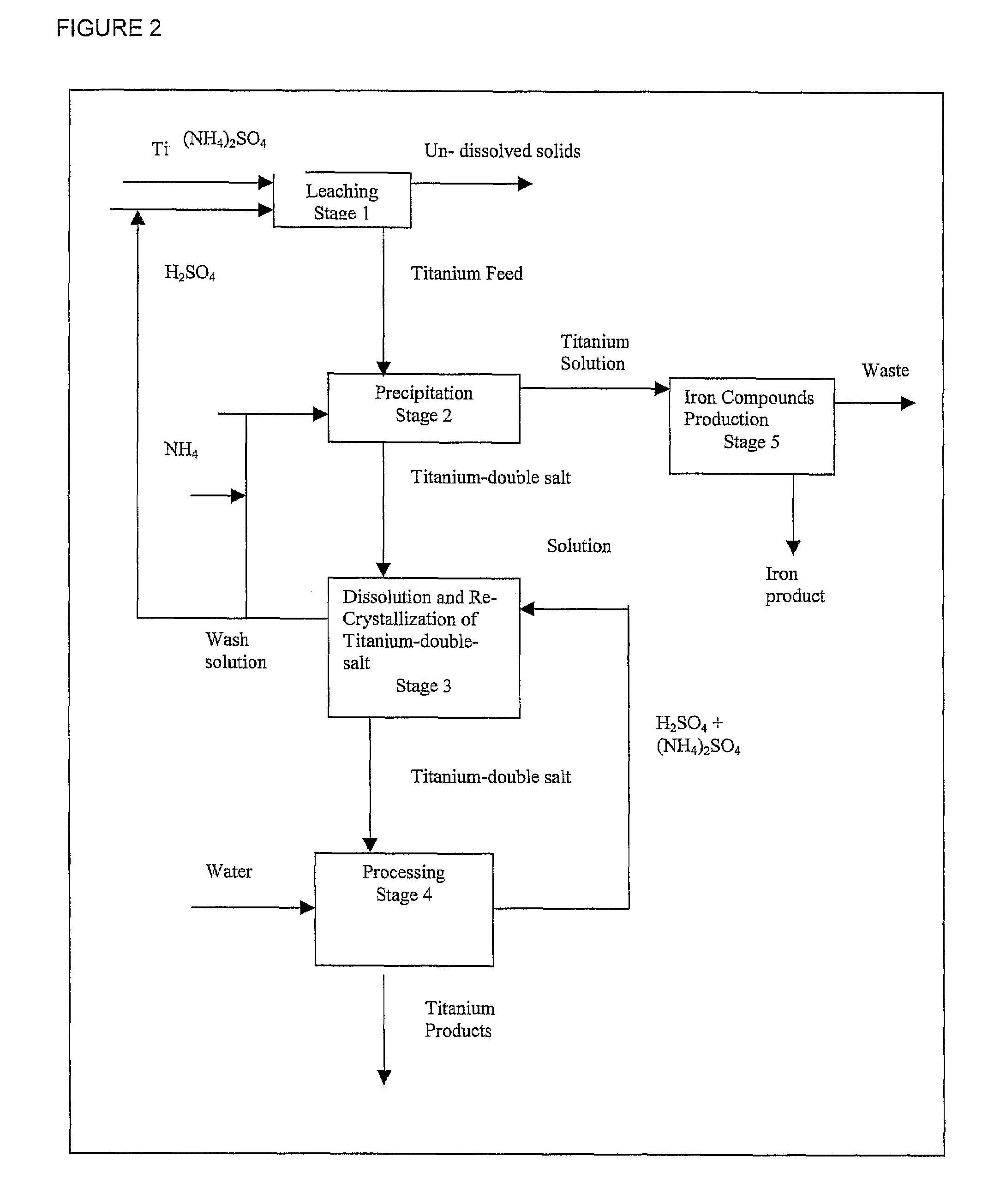

Process for the Production of Titanium Products

ActiveUS20090158895A1Efficient processingMaterial nanotechnologyTitanium and titanyl sulfatesTitanium ionDouble salt

The invention provides a method for the Industrial purification of a titanium feed stream of purity P1, by the formation of a titanium-double-salt precipitate of purity P2 and a titanium solution with purity P3, wherein P2>P1>P3, the method comprising the steps of: i. forming, from the feed, a medium comprising water, titanium ion, a cation selected from the group consisting of ammonium, cations of alkali metals, protons and a combination thereof, and an anion selected from the group consisting of OH, SO4, HSO4, halides and a combination thereof, which formed medium is further characterized by the presence of (a) a double-salt precipitate comprising titanium ion, at least one of the cations and at least one of the anions; and (b) a titanium solution; and wherein the concentration of the anion in the titanium solution is higher than 15% and the ratio between the concentrations of the cation and the anion in the titanium solution is higher than 0.2 and lower than 1.6; and ii. separating at least a portion of the precipitate from the solution.

Owner:JOMA INT +1

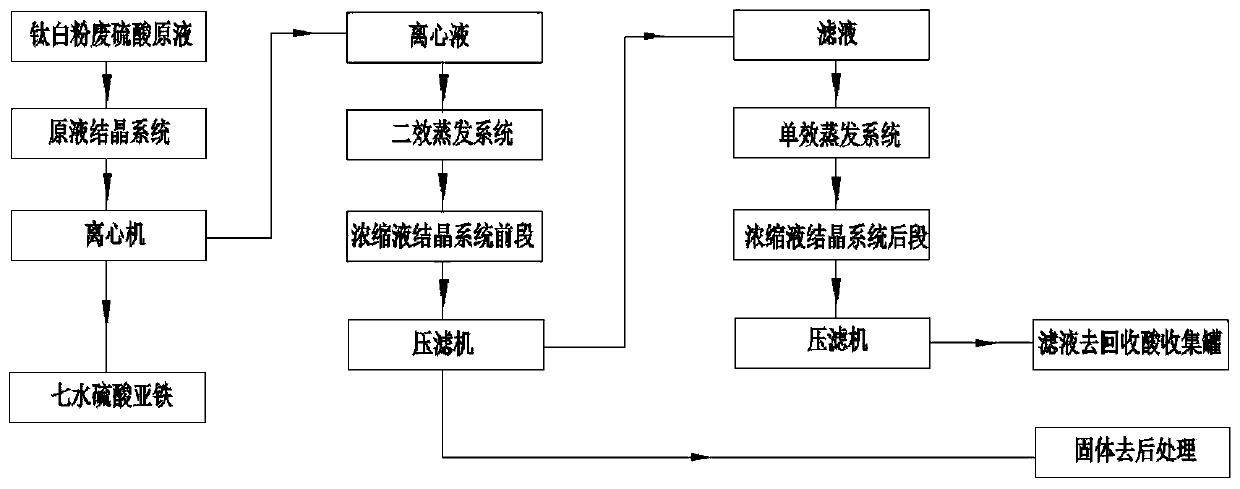

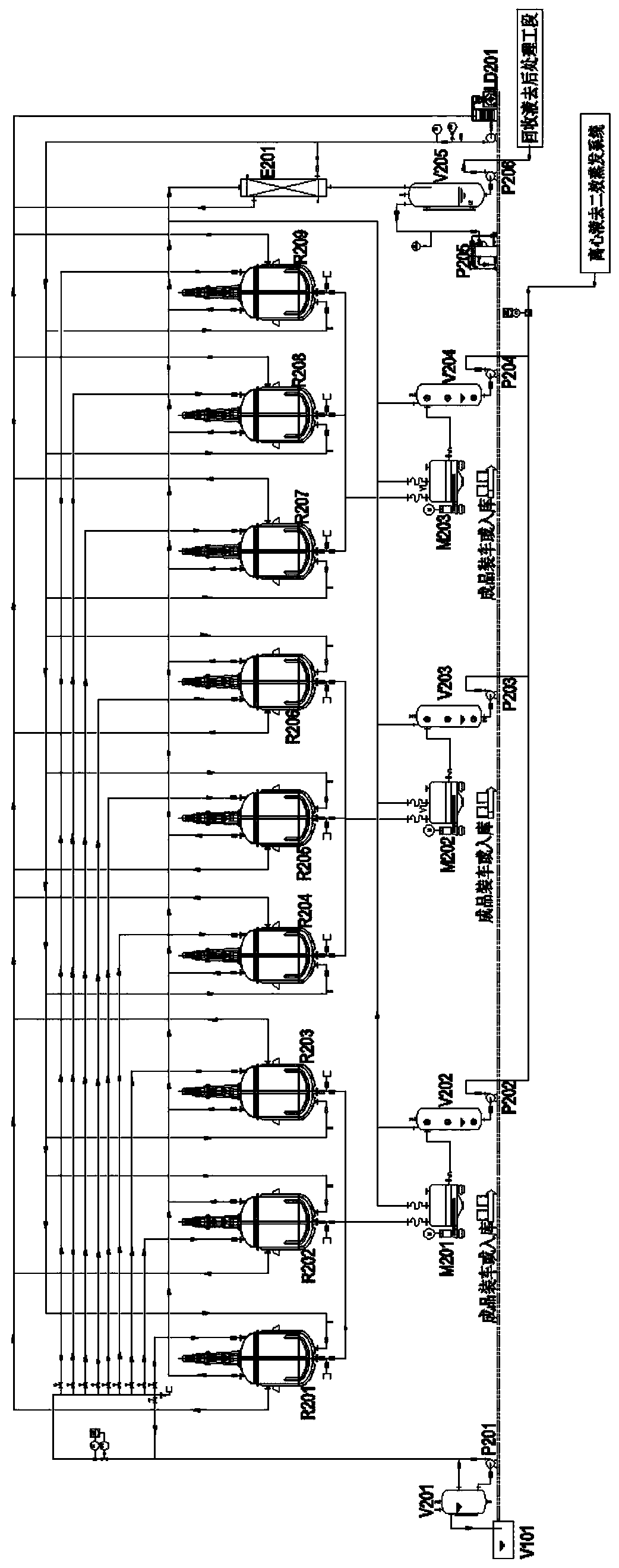

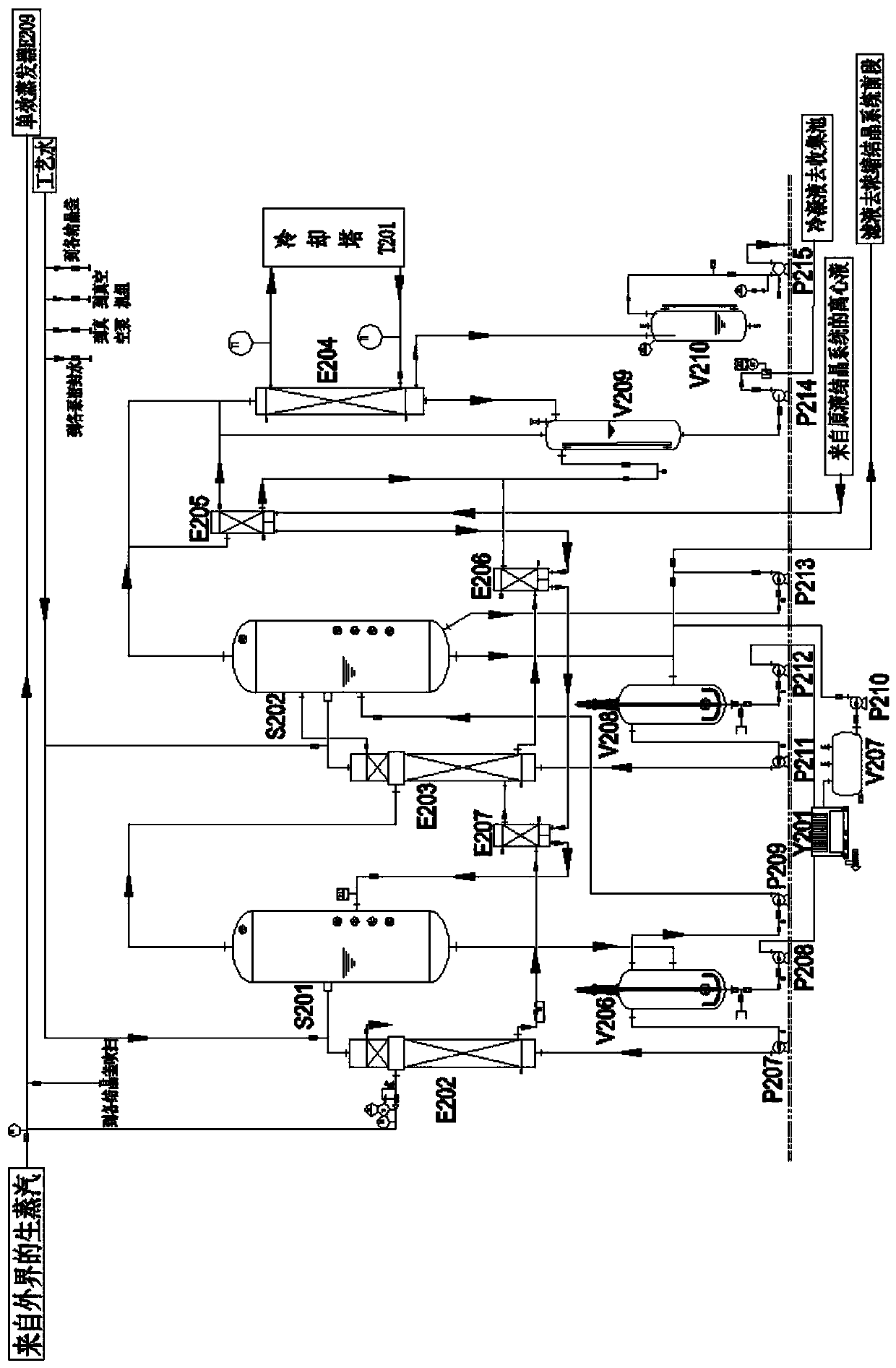

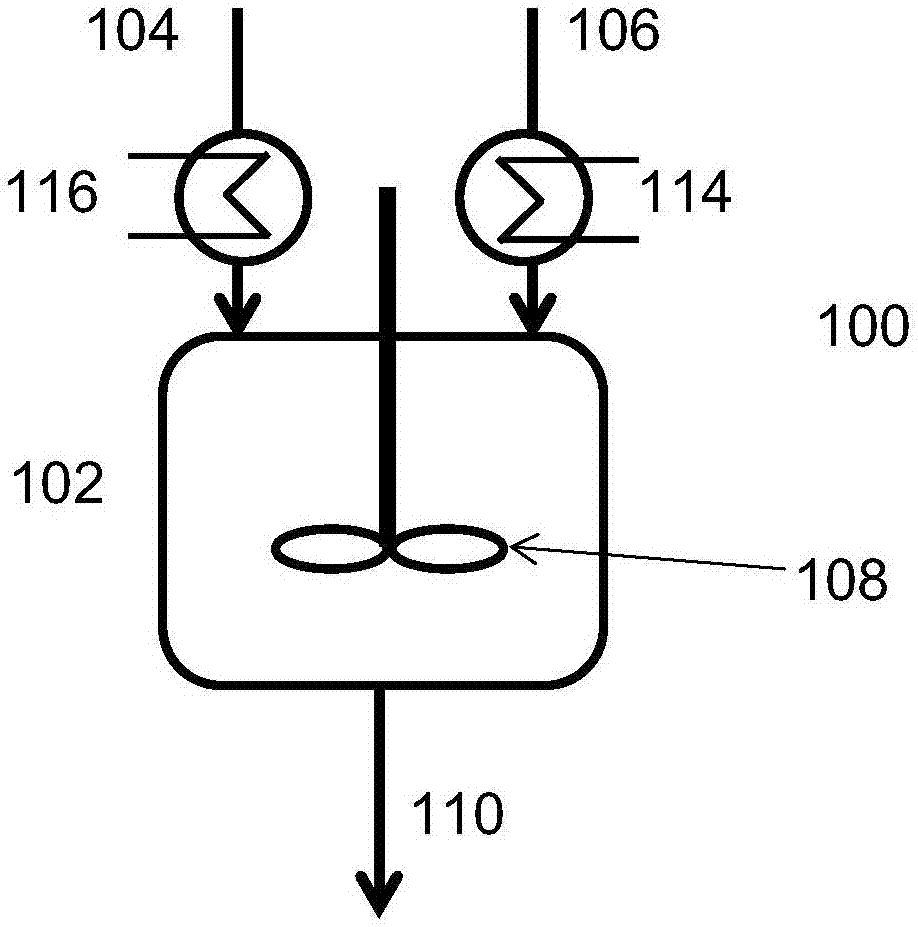

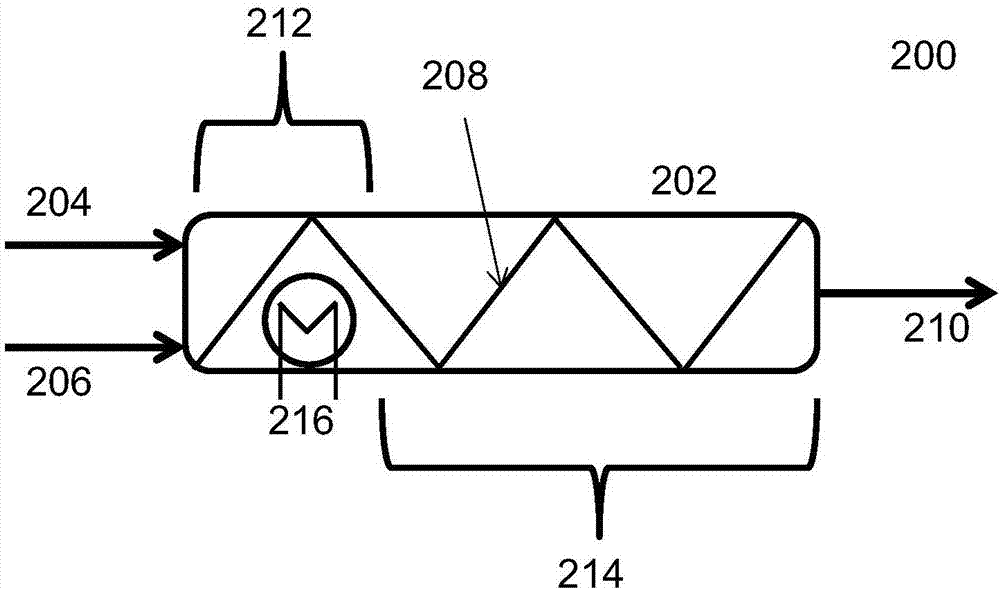

Three-stage negative pressure evaporation crystallization treatment process and device for titanium dioxide waste sulfuric acid

PendingCN111517397AHigh recovery ratePut an end to crystallizationWater/sewage treatment by centrifugal separationTitanium and titanyl sulfatesFerrous sulfate ironPhysical chemistry

The invention discloses a three-stage negative pressure evaporation crystallization treatment process and a device for titanium dioxide waste sulfuric acid. The process comprises the following steps:crystallizing and separating of ferrous sulfate in a titanium dioxide waste sulfuric acid stock solution by using a stock solution crystallization system is carried out, and centrifugally separating are carried out to obtain a ferrous sulfate heptahydrate solid and mother liquor; through the cooperative cooperation of a double-effect evaporation system, a single-effect evaporation system and a concentration and crystallization system, the possibility of crystallization and blockage of materials in the evaporator is eliminated, and the stable operation of the device is ensured; centrifugate from the stock solution crystallization system is evaporated and concentrated in the double-effect evaporation system to improve acidity and then is introduced into a front section of the concentration and crystallization system; cooling, crystallizing and filter pressing are carried out to obtain a large amount of sulfate solids; wherein the mass concentration of sulfuric acid in filtrate reaches 50%, the filtrate is continuously introduced into the single-effect evaporation system for forced circulation, the concentration of waste sulfuric acid is increased to the maximum extent, the concentrated waste sulfuric acid solution is introduced into the rear section of the concentration and crystallization system, cooling crystallization is performed, a large amount of sulfate solids are obtained through filter pressing, and a regenerated sulfuric acid solution with the mass concentration larger than or equal to 70% is obtained.

Owner:江苏泰特联合环保科技有限公司

Method for removing iron from low-concentration industrial titanium liquid and method for preparing high-purity titanium dioxide

ActiveCN114804193AHigh removal rateSimple processTitanium and titanyl sulfatesTitanium dioxidePhysical chemistryFerrous

The invention relates to a method for removing iron from low-concentration industrial titanium liquid, and belongs to the field of titanium dioxide preparation. The method specifically comprises the following steps: adding citric acid into a low-concentration industrial titanium solution, uniformly stirring to obtain a purified solution 1, adding aminomethylated polyacrylamide into the purified solution 1, uniformly stirring to obtain a purified solution 2, freezing and crystallizing the purified solution 2 at 0-10 DEG C, and filtering to obtain the purified solution which can be used for preparing high-purity titanium dioxide. According to the method, the removal rate of impurity ferrous ions in the low-concentration industrial titanium liquid is high, high-purity titanium dioxide can be prepared after the titanium liquid is subjected to the procedures of hydrolysis, washing, calcination and the like, and the method can be used in the application field of electronic titanium dioxide and the like.

Owner:PANZHIHUA UNIV

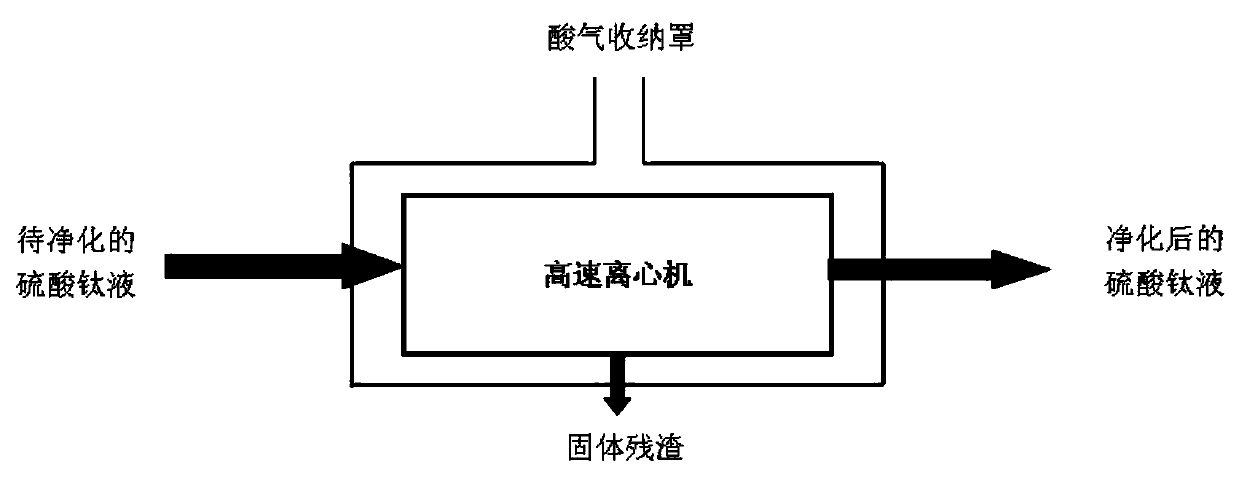

Method for efficiently purifying titanous sulfate liquid

The invention discloses a method for efficiently purifying a titanous sulfate liquid and belongs to the field of separation and purification. The technical problem to be solved by the invention is toprovide the method for efficiently purifying the titanous sulfate liquid with convenience in operation and high purifying efficiency. The method for efficiently purifying the titanous sulfate liquid comprises the step of adopting a high-speed centrifugation technique for separating the titanous sulfate liquid, thereby acquiring a deeply purified titanous sulfate liquid. The purifying process of the titanous sulfate liquid according to the method disclosed by the invention is simple and easy to be controlled, the operation is simple and convenient, the continuous running can be realized, the draining acid gas can be effectively controlled, the environmental condition of the titanium liquid purification process is improved, the green production is easily realized and the efficiency of the titanium liquid purification process is increased.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Polymeric titanium sulfate inorganic polymeric flocculant, and preparation method and application of flocculant

ActiveCN103011358BGood flocculation effectSimple production processTitanium and titanyl sulfatesSulfur compoundsTextile printerChemical industry

A preparation method of polymeric titanium sulfate (PTS) inorganic polymeric flocculant. The PTS inorganic polymeric flocculant is prepared by taking a titanium sulfate solution and a sodium hydroxide solution as raw materials and dropping the sodium hydroxide solution into the titanium sulfate solution; a preset alkalization degree is 0.1-5.0; after the dropping is finished, the titanium sulfate solution and the sodium hydroxide solution are stirred for 1.5-5h; The flocculant prepared in the method has the advantages of good product stability, strong adsorption bridging ability for colloidal substances, good flocculation effect, wide application range, small generated sludge quantity and the like, can be widely applied to the fields of water supply, waste water treatment, papermaking, textile printing and dyeing, daily-use chemical industry and the like, and has a good water treatment effect. The preparation method is simple, economical and rapid.

Owner:SHANDONG UNIV

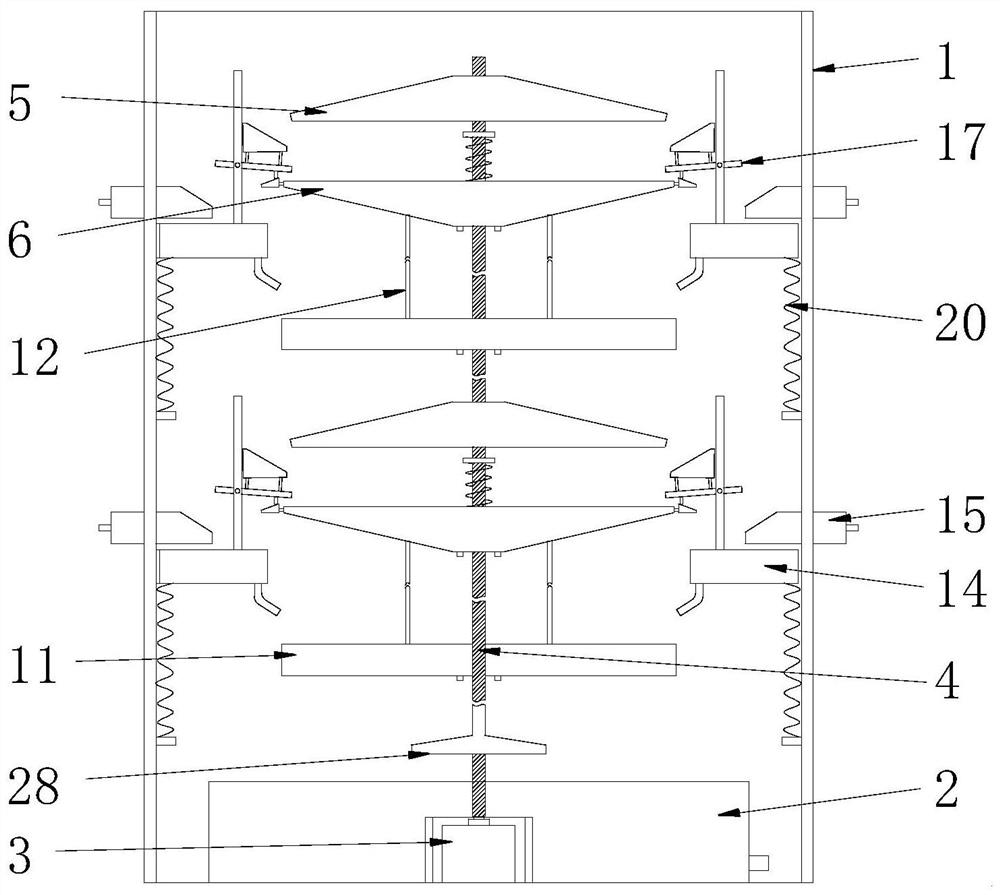

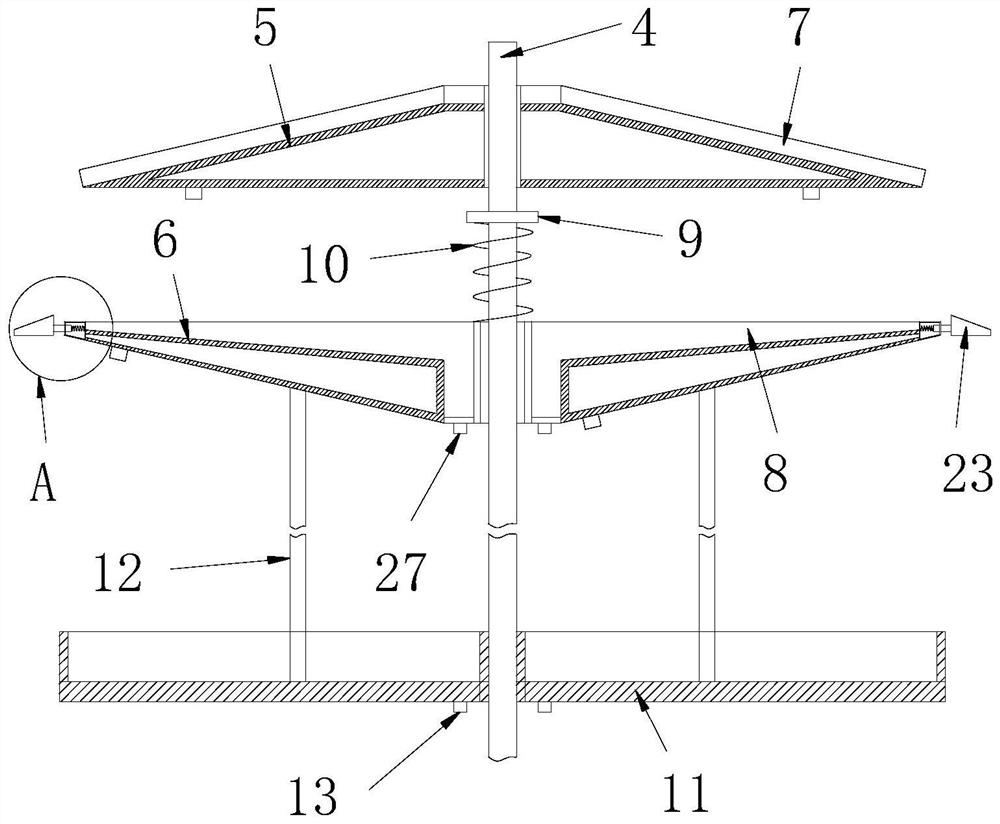

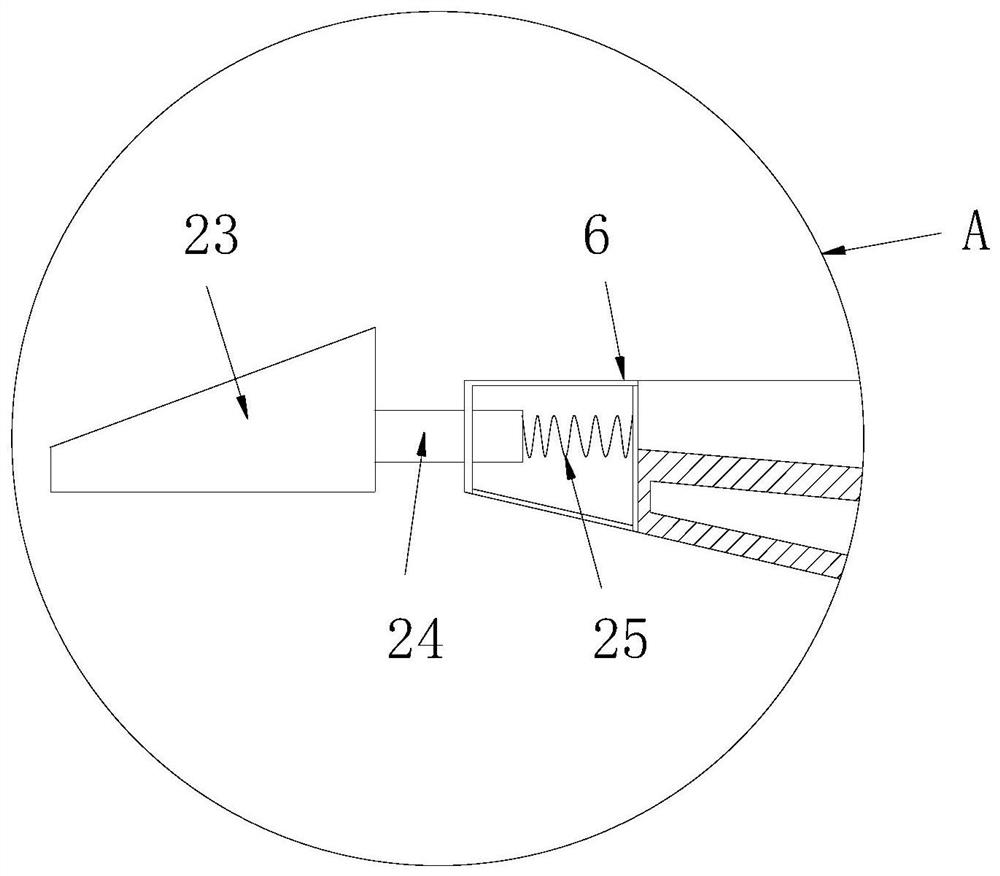

Production process for increasing whiteness of titanium dioxide

ActiveCN113044880AParticle size has little effectLittle effect of granularityTitanium and titanyl sulfatesSolution crystallizationThermodynamicsLiquid storage tank

The invention relates to the technical field of titanium dioxide processing, and discloses a production process for increasing the whiteness of titanium dioxide. Equipment used in the process comprises a shell and a liquid storage tank, wherein the shell is cylindrical, the liquid storage tank is located on the lower side of the shell, a circulating pump is arranged in the liquid storage tank, and a liquid outlet pipe is arranged at the upper end of the liquid storage tank. According to the invention, a first treatment disc and a second treatment disc are arranged on the upper side of the liquid storage tank, a solution in the liquid storage tank can be conveyed to a high position through the circulating pump, then the solution sequentially flows through the first treatment disc and the second treatment disc, and the first treatment disc and the second treatment disc both communicate with circulating cooling water, so the solution flowing through the treatment discs can be cooled. According to a technical scheme in the invention, the solution is cooled in a circulating flow mode; and compared with traditional stirring cooling, cooling efficiency is high, the influence on the particle size of crystals is small, later filtering becomes more convenient, and the processing quality of products is effectively improved.

Owner:江苏勃仑化学有限公司

New sulfate process titanium dioxide acidolysis method

ActiveCN109467122AReduce lossReduce potential hazardsTitanium and titanyl sulfatesTitanium dioxideSulfateTitanium

The invention discloses a new sulfate process titanium dioxide acidolysis method. Sulfuric acid with mass fraction being 98% is utilized to be subjected to a reaction with titanium ore powder, and themain reaction is performed safely by controlling flow of compressed air and frequency of an exhaust draught fan; the method has technical effects as follows: raw material cost is saved, the risk of overflowing in the main reaction is reduced, and the acidolysis rate of ore is increased.

Owner:SHANDONG DAWN TITANIUM IND

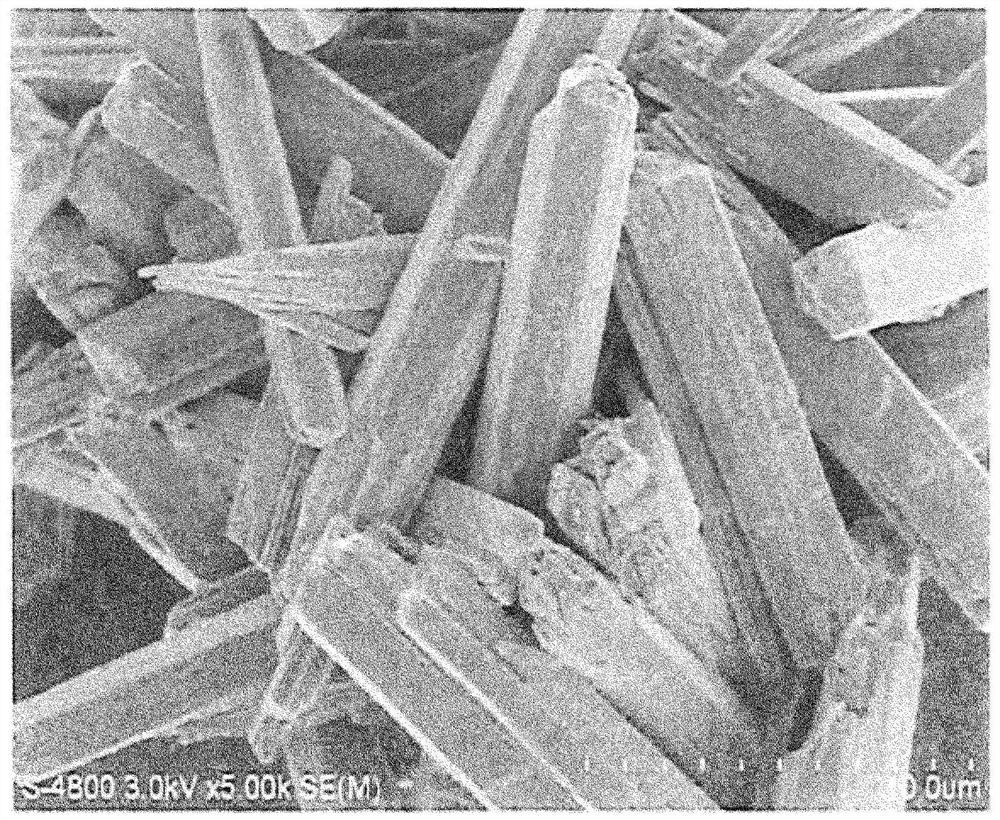

Method for preparing high-purity titanyl sulfate crystals

The invention relates to a method for preparing high-purity titanyl sulfate crystals. The method includes the following steps that 1, ilmenite concentrate is subjected to acidolysis and sedimentationaccording to an acidolysis flow of a sulfuric acid method for preparing titanium dioxide, and after unreacted acidolysis dregs are separated, an acidolysis liquid is obtained; 2, the acidolysis liquidobtained in step 1 is maintained at 100-180 DDG C, sulfuric acid and titanyl sulfate seed crystals are added for crystallization, and after the crystallization is conducted completely, separation iscarried out when the temperature is still high to obtain acicular crystals; 3, the acicular crystals obtained in step 2 is scrubbed in dilute sulfuric acid to obtain the titanyl sulfate crystals. According to the method, the acidolysis liquid of the ilmenite concentrate is adopted as the raw material, a high-temperature crystallization mode is utilized to seed out the titanyl sulfate crystals, andthen thorough scrubbing is conducted to obtain the high-purity titanyl sulfate crystals.

Owner:SICHUAN LOMON TITANIUM IND CO LTD

Purification method for titanium sulfate solution

InactiveCN109319831ARealize deep purificationSimple processTitanium and titanyl sulfatesPurification methodsSulfate

The invention provides a purification method for a titanium sulfate solution which comprises the step of performing centrifugal separation and membrane separation on the titanium sulfate solution to obtain a purified titanium solution. The purification method for the titanium solution disclosed by the invention has a simple technology, can achieve continuous operation, has smaller equipment volume, can effectively control acid gas to be exhausted out, can improve the environment condition of a titanium solution purification procedure and achieves green production. As equipment used by the purification method disclosed by the invention is simple, the purification method is easy to implement and has a good application prospect.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Preparation method of raw material for producing titanium dioxide of decorative base paper

ActiveCN107500346AUnchanged stabilityImprove acid hydrolysis rateTitanium and titanyl sulfatesIron powderSulfate

The invention provides a preparation method of a raw material for producing titanium dioxide of decorative base paper, and belongs to the technical field of titanium dioxide of decorative base paper. The method comprises the following steps: A, selecting titanium ore of which the residue on sieve is 10.0-20.0% under 325 meshes and the residue on sieve is 0 under 200 meshes, the water content is not greater than 0.5%, TiO2 is not less than 45%, Fe2O3 is not greater than 8%, and the temperature is not greater than 40 DEG C; selecting sulfuric acid on the concentration of 30-55% and under the temperature of being not greater than 40 DEG C; mixing sulfuric acid and titanium ore; cooling to obtain a titanium ore pre-mixed material; B, feeding the titanium ore pre-mixed material into a reaction tank; stirring; adding sulfuric acid on the concentration of 98%; reacting; then curing; C, cooling the cured material; adding dilute sulphuric acid; then adding sand filtering water to dissolve; D, adding zero-valent iron powder to the dissolved liquid to react; E, precipitating the liquid obtained in the reaction in step D; collecting supernate; filtering to obtain titanous sulfate containing not greater than 30mg / L of filtrate solid content. The method is stable to operate, high in acidolysis rate, stable in quality index, and stable in quality of titanium dioxide prepared by the sulfuric acid method.

Owner:HEBEI MILSON TITANIUM DIOXIDE

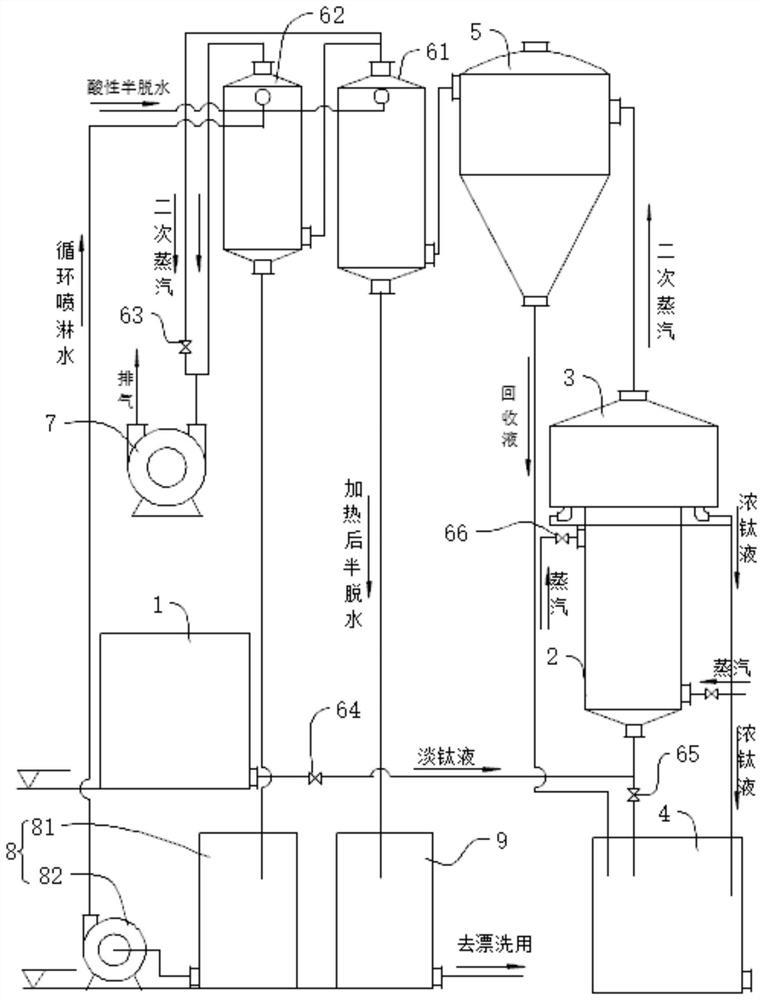

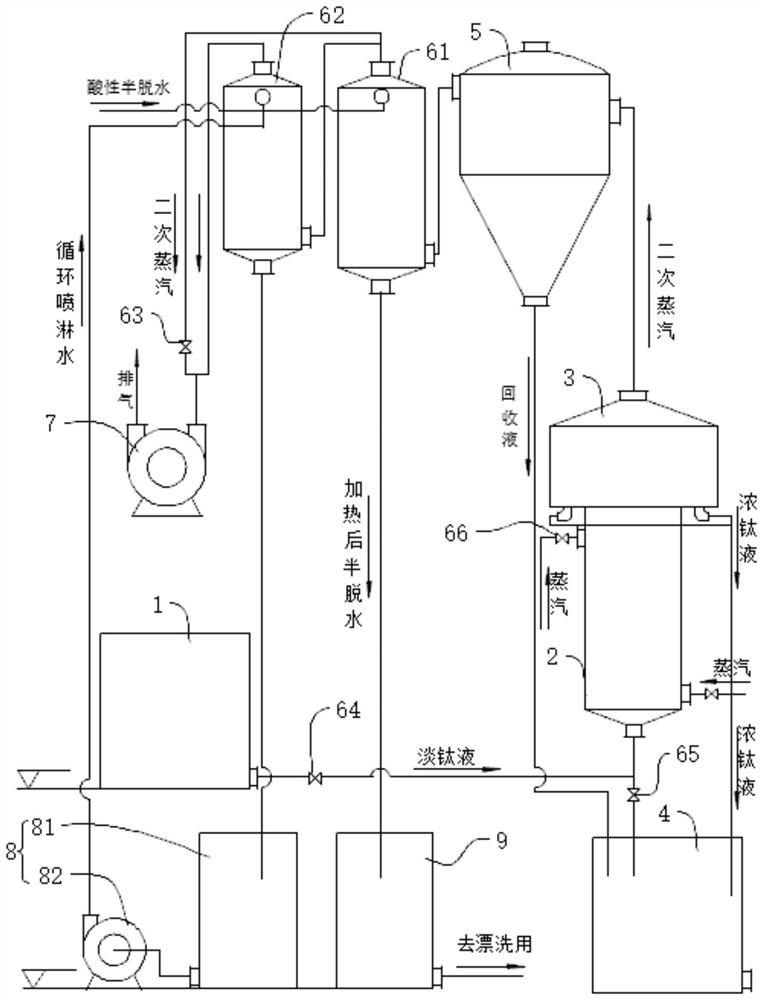

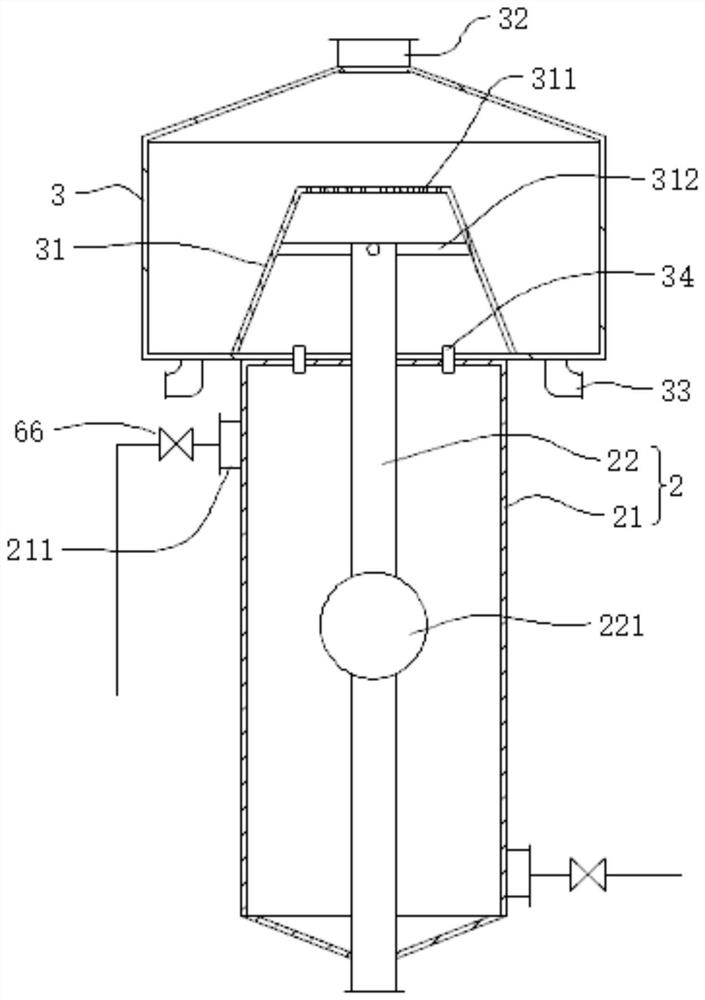

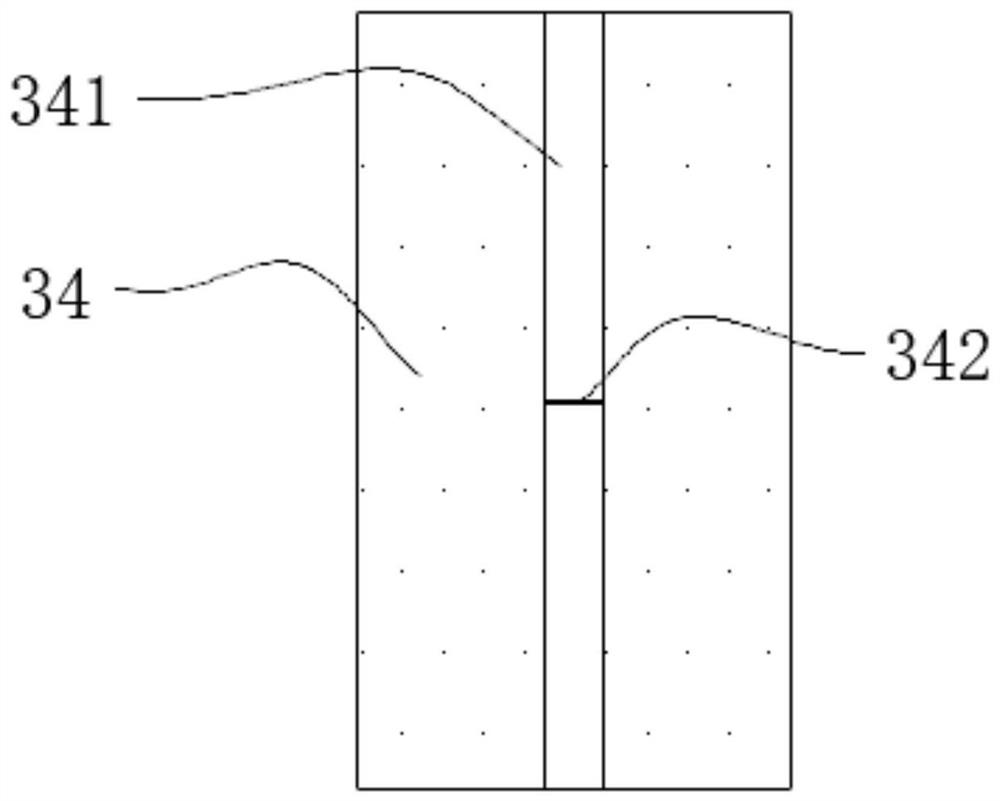

Titanium dioxide concentration process

ActiveCN113144644AReduce corrosionNo corrosive damageTitanium and titanyl sulfatesEvaporator accessoriesSteam condensationEngineering

The invention relates to the field of titanium dioxide production, and discloses a titanium dioxide concentration system and a titanium dioxide concentration process, the titanium dioxide concentration system comprises an evaporation module for concentrating light titanium liquid, a condensation module and a heat recovery module; the evaporation module comprises a dilute titanium tank, a heat exchanger, an evaporation chamber, a concentrated titanium tank, a cyclone separator, a primary steam condenser, a secondary steam condenser and a vacuum pump; the dilute titanium tank is connected with the heat exchanger which is connected with the evaporation chamber; the heat exchanger is connected with steam and is connected with the evaporation chamber; the evaporation chamber is connected with the concentrated titanium tank, and the evaporation chamber is connected with the cyclone separator; the cyclone separator is connected with the concentrated titanium tank, the cyclone separator is connected with the primary steam condenser, and the primary steam condenser is connected with the vacuum pump; and the secondary steam condenser is connected with the primary steam condenser, and the secondary steam condenser is connected with the vacuum pump. The method has the effect of relieving the problem that concentration system equipment is corroded by acidic semi-dehydration.

Owner:广西顺风钛业有限公司

Beneficiation of titanium bearing materials

InactiveCN107531507AIncrease concentrationEfficient recyclingTitanium and titanyl sulfatesTitanium dioxideRutileMaterials science

This invention relates to the beneficiation of titanium bearing materials having a substantial component of anatase and / or rutile and / or pseudorutile structure. Such materials include anatase ores andminerals and other sources of anatase, as well as blends or mixtures that include traditional sources of titanium and titanium dioxide such as ilmenite and titanium slag. The invention is of particular, though not exclusive, interest in the processing of anatase materials to titanium dioxide of pigment quality. The process is additionally effective in processing materials having a substantial component of anatase or rutile, e.g. leucoxene.

Owner:ILUKA RESOURCES

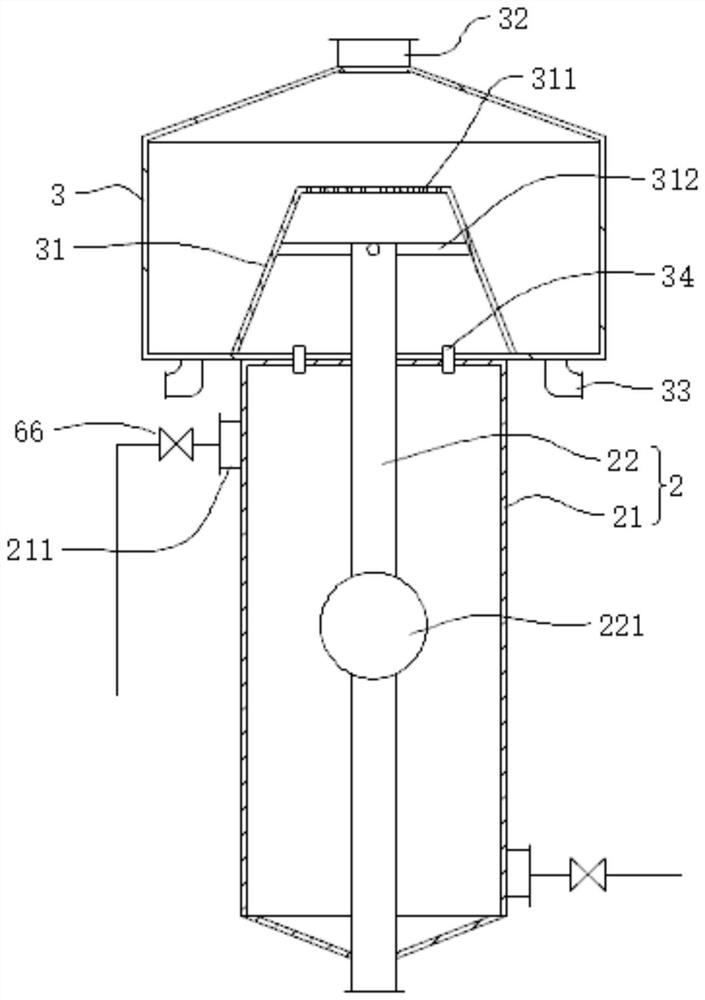

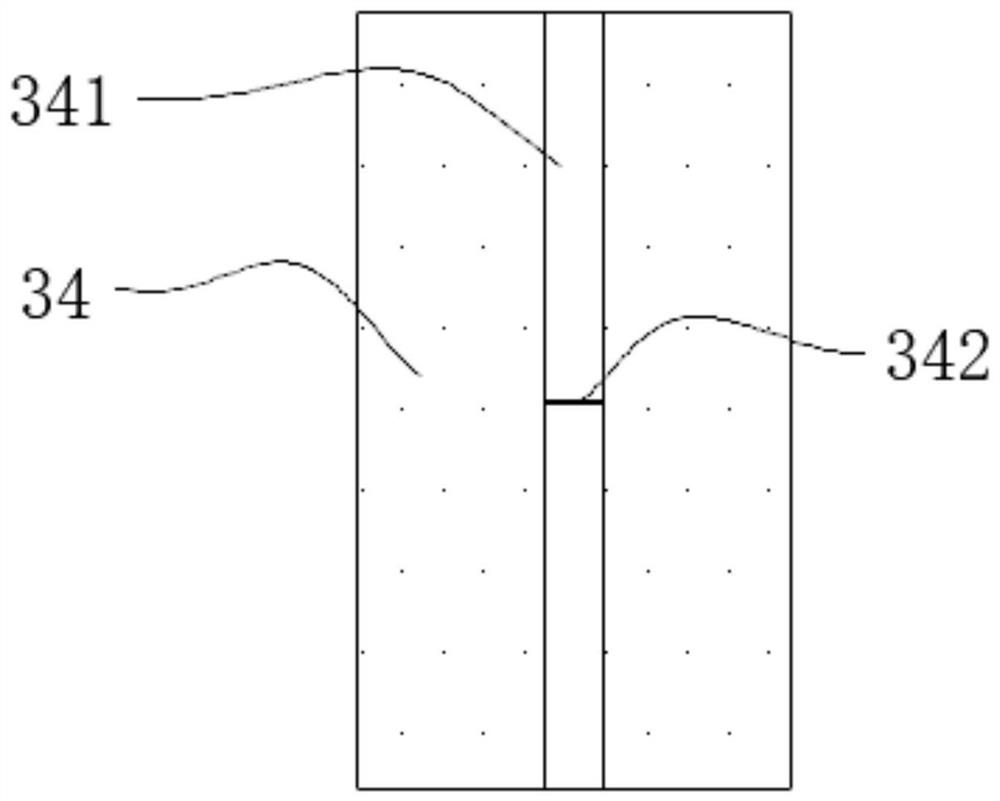

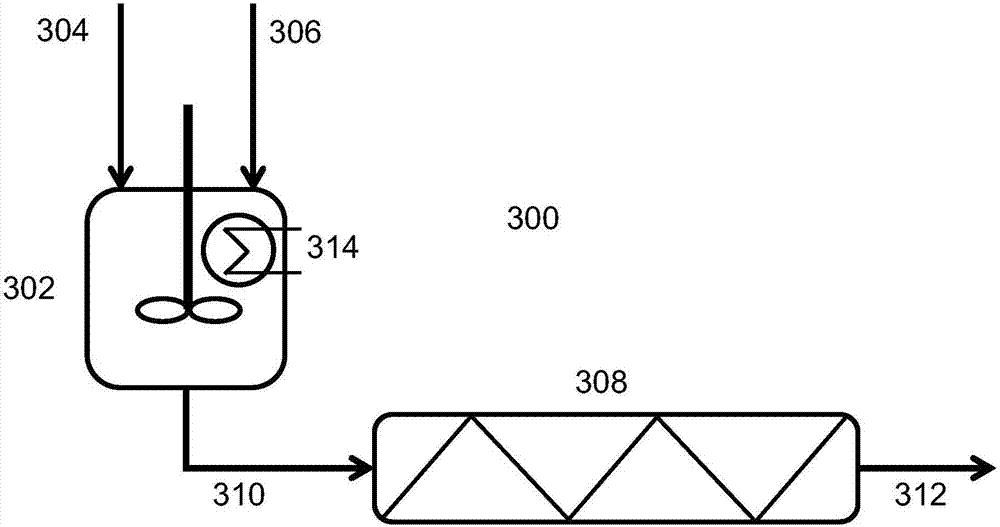

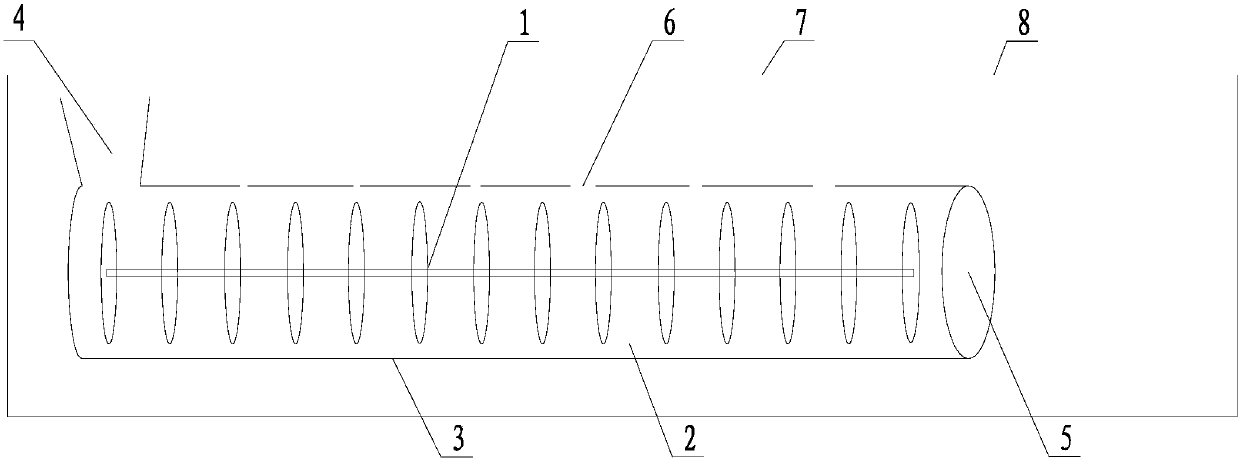

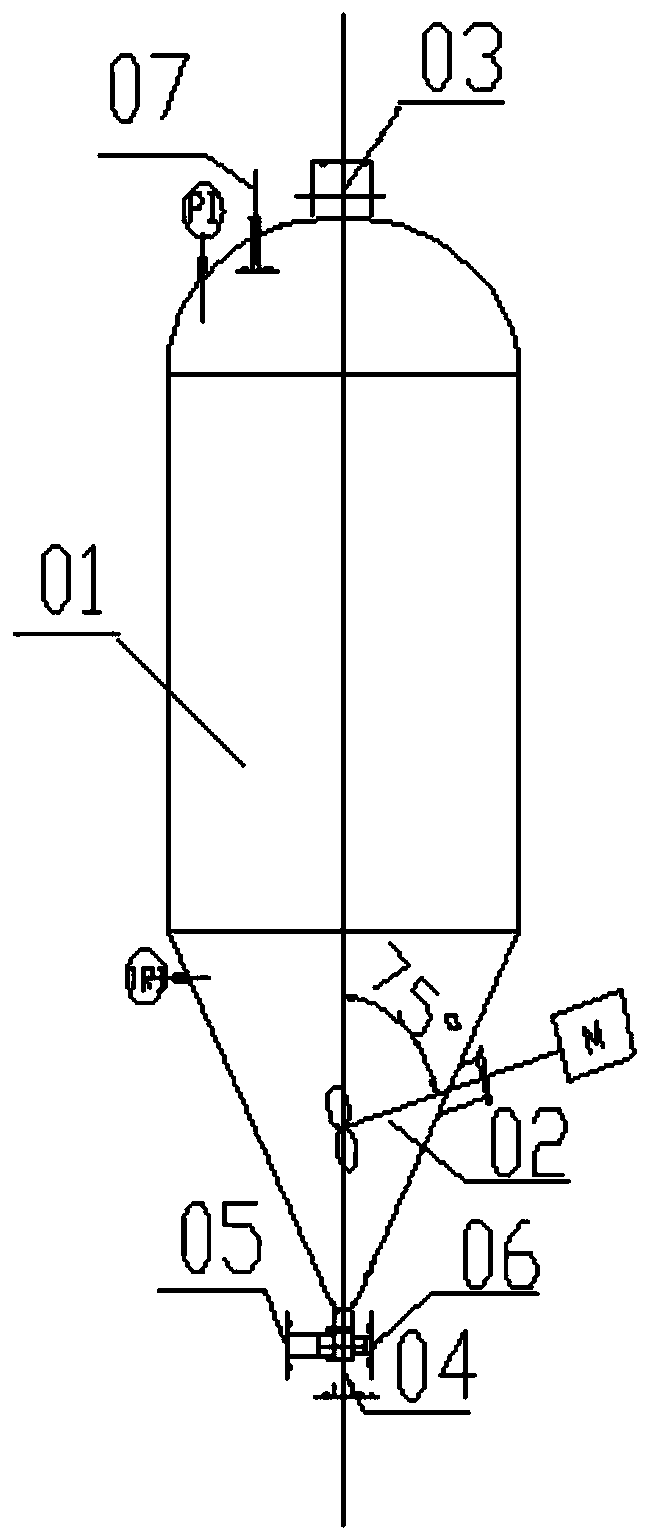

Reactor for producing titanium sulphate compound by process intensified continuous acidolysis reaction

InactiveCN107649089AReduce volumeReduce gapProcess control/regulationTitanium and titanyl sulfatesManufacturing technologyTitanium sulphate

The invention discloses a reactor, particularly discloses the reactor for producing a titanium sulphate compound by process intensified continuous acidolysis reaction, and belongs to the technical field of metallurgical production equipment design and manufacture. The invention provides the reactor for producing the titanium sulphate compound by the process intensified continuous acidolysis reaction, which can remarkably reduce a dead angle of the reaction and reduce the scarring hardening rate of a solid phase in a process. The reactor comprises a stirrer and a reactor body which contains a reaction accommodating cavity; the reaction accommodating cavity is of a cylindrical structure which is placed horizontally.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Process for improving the grade and optical quality of zircons

ActiveUS11066726B2Quality improvementSmall particle sizeTitanium and titanyl sulfatesIron sulfatesPhysical chemistryTitanium

A process for improving the grade and optical quality of zircon, comprising: baking a mixture of a zircon feed and concentrated sulphuric acid at a baking temperature in the range of from 200 up to 400° C., and for a time to form water leachable sulphates with impurities therein including at least iron and titanium; leaching the baked mixture to dissolve the leachable sulphates; and separating the zircon from the leachate containing the leached sulphates, which separated zircon is thereby of improved grade and optical quality.

Owner:ILUKA RESOURCES

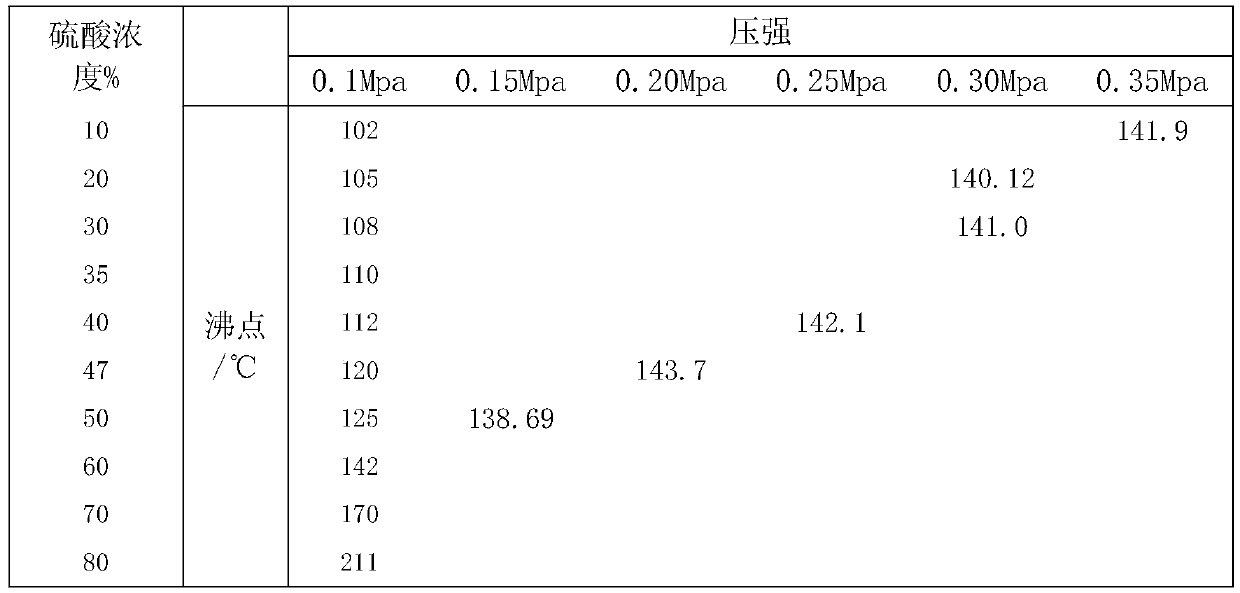

The preparation method of trivalent titanium solution

ActiveCN107814411BReduce the amount addedReduce manufacturing costTitanium and titanyl sulfatesBoiling pointTitanium

Owner:广西顺风钛业有限公司

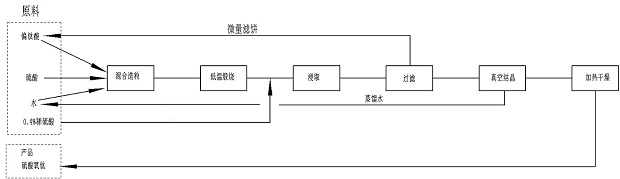

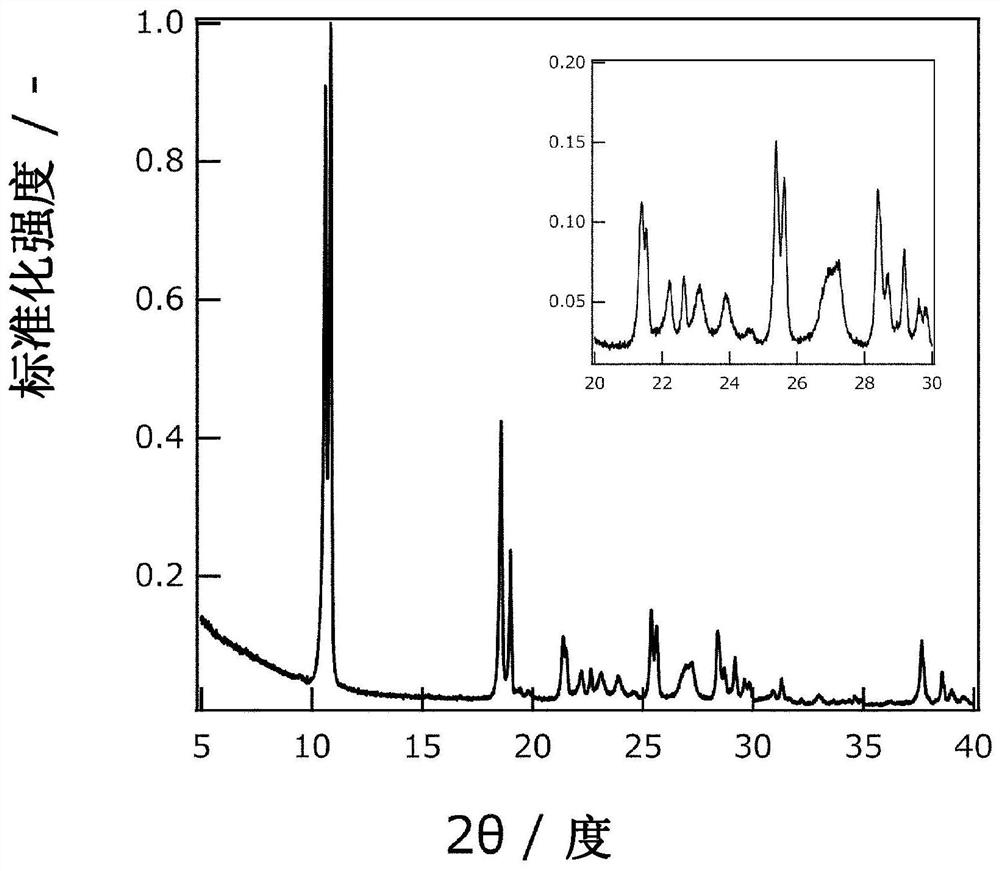

A new process for preparing fully water-soluble titanyl sulfate powder

The invention discloses a new process for preparing fully water-soluble titanyl sulfate powder. The metatitanic acid powder and sulfuric acid are mixed and granulated, and the crude product of titanyl sulfate is obtained through low-temperature calcination, and then leached and dissolved by dilute sulfuric acid, and the solution is filtered. Then the titanyl sulfate solution is vacuum concentrated, heated and dried to obtain high-quality fully water-soluble titanyl sulfate powder. This method adopts a new calcination process in the preparation of crude titanyl sulfate, and replaces the reaction kettle in the acid-dissolving section with a calciner, which reduces the residue of sulfuric acid in the system, so a new crystallization process can be adopted without adding additional titanyl sulfate seeds , filtration operations and the use of organic solvent flushing agents such as ethanol simplify the production process of titanyl sulfate.

Owner:SHANDONG JIAOTONG UNIV

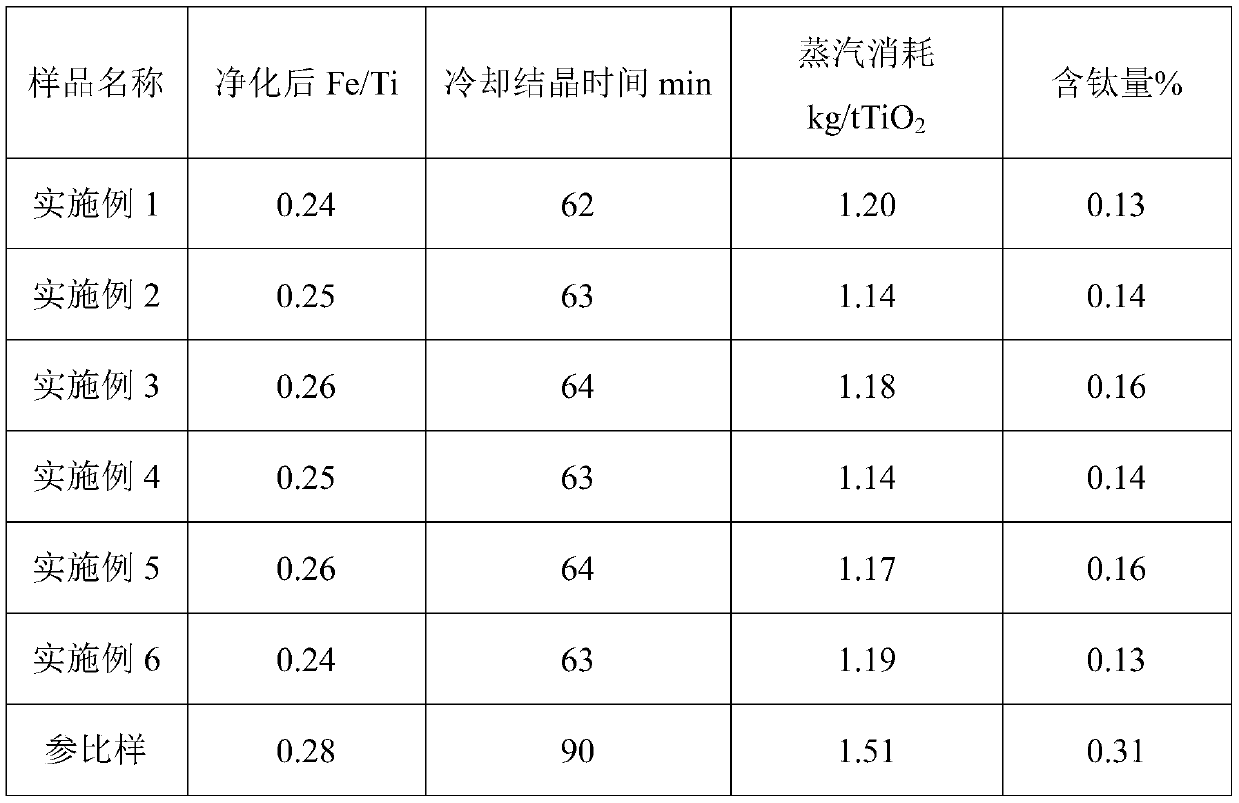

A purification method for raw materials for production of decorative base paper titanium dioxide

ActiveCN107935029BReduce consumptionReduce titanium contentTitanium and titanyl sulfatesIron sulfatesPurification methodsSulfate

The invention discloses a purification method of a decorative base paper titanium dioxide production material, and belongs to the technical field of sulfuric acid method titanium dioxide production. The method is performed in a crystallizing tank with a stirrer, and comprises the following steps: A, feeding titanium sulfate solution into the crystallizing tank, and starting the stirrer; B, controlling pressure in the crystallizing tank to cool down a material; C, leading auxiliary steam into the crystallizing tank, meanwhile leading auxiliary circulation water into the crystallizing tank, andcontrolling tank feeding temperature and tank discharging temperature of the auxiliary circulation water, pressure in the tank and material temperature in the tank; D, leading main steam into the crystallizing tank, meanwhile leading main circulation water into the crystallizing tank, and controlling tank feeding temperature and tank discharging temperature of the main circulation water, pressurein the tank and material temperature in the tank; E, stopping the leading of auxiliary steam, main steam, auxiliary circulation water and main circulation water, emptying till pressure in the tank isequal to environment pressure, and filtering. The method realizes purification of the titanium sulfate solution, and improves the crystallization efficiency of ferrous sulfate in the titanium sulfatesolution.

Owner:HEBEI MILSON TITANIUM DIOXIDE

A raw material preparation method for the production of decorative base paper titanium dioxide

ActiveCN107500346BUnchanged stabilityImprove acid hydrolysis rateTitanium and titanyl sulfatesIron powderSulfate

The invention provides a preparation method of a raw material for producing titanium dioxide of decorative base paper, and belongs to the technical field of titanium dioxide of decorative base paper. The method comprises the following steps: A, selecting titanium ore of which the residue on sieve is 10.0-20.0% under 325 meshes and the residue on sieve is 0 under 200 meshes, the water content is not greater than 0.5%, TiO2 is not less than 45%, Fe2O3 is not greater than 8%, and the temperature is not greater than 40 DEG C; selecting sulfuric acid on the concentration of 30-55% and under the temperature of being not greater than 40 DEG C; mixing sulfuric acid and titanium ore; cooling to obtain a titanium ore pre-mixed material; B, feeding the titanium ore pre-mixed material into a reaction tank; stirring; adding sulfuric acid on the concentration of 98%; reacting; then curing; C, cooling the cured material; adding dilute sulphuric acid; then adding sand filtering water to dissolve; D, adding zero-valent iron powder to the dissolved liquid to react; E, precipitating the liquid obtained in the reaction in step D; collecting supernate; filtering to obtain titanous sulfate containing not greater than 30mg / L of filtrate solid content. The method is stable to operate, high in acidolysis rate, stable in quality index, and stable in quality of titanium dioxide prepared by the sulfuric acid method.

Owner:HEBEI MILSON TITANIUM DIOXIDE

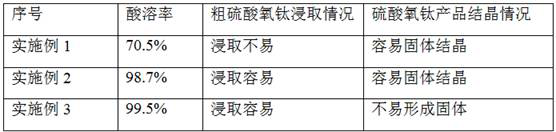

Production method of titanyl sulfate and nano titanium dioxide

PendingCN113998731AWide adaptabilityAdaptableMaterial nanotechnologyTitanium and titanyl sulfatesSulfatePhysical chemistry

The invention provides a production method of titanyl sulfate and nano titanium dioxide, which comprises the following steps: by taking ilmenite, metatitanic acid or sulfuric acid leachate of other titanium-containing materials as a raw material, adding a certain amount of concentrated sulfuric acid into the feed liquid, heating to supersaturate titanium, separating out titanyl sulfate crystals, and separating out crystallization mother liquor to obtain a commodity titanyl sulfate; and calcining titanyl sulfate to obtain an anatase type or rutile type nano titanium dioxide product, and carrying out post-treatment to obtain the commodity nano titanium dioxide. According to the technology, equipment of a traditional sulfuric acid method titanium dioxide production process can be completely utilized, additional equipment investment is not needed, and compared with an existing sulfuric acid method titanium dioxide production process, the technology has the advantages of being better in product quality, higher in crystallization speed, wide in feed liquid application range and the like.

Owner:CENT SOUTH UNIV

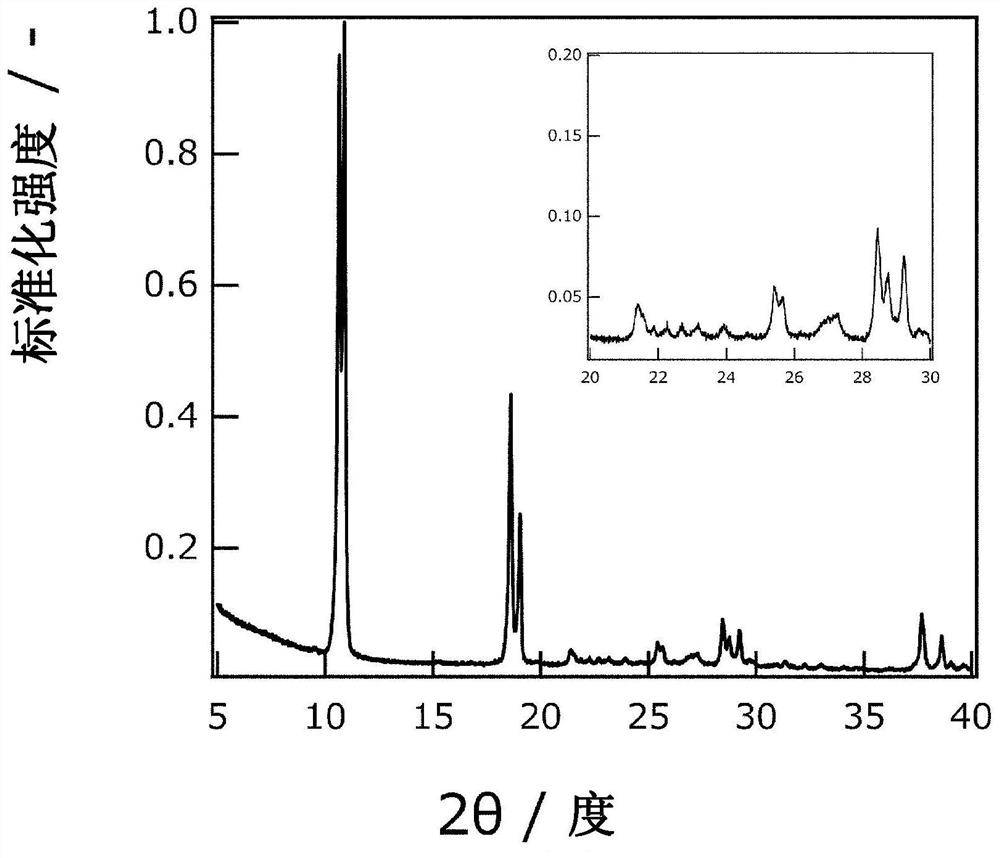

Titanyl sulfate hydrate powder, method for producing titanyl sulfate hydrate powder, method for producing aqueous titanyl sulfate solution, method of producing electrolyte solution, and method for producing redox flow battery

ActiveCN112805244AFast dissolutionEfficient preparationTitanium and titanyl sulfatesRegenerative fuel cellsElectrolytic agentPhysical chemistry

According to the present invention, a titanyl sulfate hydrate powder is characterized by containing 25-40% by mass of titanium element in terms of TiO2, 40-60% by mass of sulfur element in terms of H2SO4, and niobium element in such an amount that the molar ratio of niobium element to titanium element (Nb / Ti) is from 0.00005 to 0.012, with the molar ratio of the sulfur element content to the titanium element content (S / Ti) being from 1.1 to 1.5, and is also characterized by containing a crystal of titanyl sulfate dihydrate (TiOSO4*2H2O). Consequently, the present invention is able to provide: a titanyl sulfate hydrate powder which has high rate of dissolution into water; a method for producing this titanyl sulfate hydrate powder; and a method for producing an aqueous titanyl sulfate solution, a method for producing an electrolyte solution and a method for producing a redox flow battery, each of which uses this titanyl sulfate hydrate powder.

Owner:TAYCA CORP

Process for the production of titanium products

ActiveUS7700057B2Efficient processingMaterial nanotechnologyTitanium and titanyl sulfatesDouble saltTitanium

The invention provides a method for the Industrial purification of a titanium feed stream of purity P1, by the formation of a titanium-double-salt precipitate of purity P2 and a titanium solution with purity P3, wherein P2>P1>P3, the method comprising the steps of: i. forming, from the feed, a medium comprising water, titanium ion, a cation selected from the group consisting of ammonium, cations of alkali metals, protons and a combination thereof, and an anion selected from the group consisting of OH, SO4, HSO4, halides and a combination thereof, which formed medium is further characterized by the presence of (a) a double-salt precipitate comprising titanium ion, at least one of the cations and at least one of the anions; and (b) a titanium solution; and wherein the concentration of the anion in the titanium solution is higher than 15% and the ratio between the concentrations of the cation and the anion in the titanium solution is higher than 0.2 and lower than 1.6; and ii. separating at least a portion of the precipitate from the solution.

Owner:JOMA INT +1

A titanium dioxide concentration process

ActiveCN113144644BReduce corrosionNo corrosive damageTitanium and titanyl sulfatesEvaporator accessoriesSteam condensationEngineering

The present application relates to the field of titanium dioxide production, and discloses a titanium dioxide concentration system and process, wherein a titanium dioxide concentration system includes an evaporation module, a condensation module and a heat recovery module for concentrating thin titanium liquid; the evaporation module includes a thin Titanium tank, heat exchanger, evaporation chamber, concentrated titanium tank, cyclone separator, primary steam condenser, secondary steam condenser and vacuum pump; the thin titanium tank is connected with the heat exchanger, and the heat exchanger is connected with the evaporation chamber; The heat exchanger is connected to the steam, the heat exchanger is connected to the evaporation chamber; the evaporation chamber is connected to the concentrated titanium tank, and the evaporation chamber is connected to the cyclone separator; the cyclone separator is connected to the concentrated titanium tank, and the cyclone separator is connected to the primary steam condenser. The primary steam condenser is connected with the vacuum pump; the secondary steam condenser is connected with the primary steam condenser, and the secondary steam condenser is connected with the vacuum pump. The present application has the effect of alleviating the problem of corrosion of concentration system equipment by acid semi-dehydration.

Owner:广西顺风钛业有限公司

A new sulfuric acid process titanium dioxide acid hydrolysis method

ActiveCN109467122BReduce lossReduce potential hazardsTitanium and titanyl sulfatesTitanium dioxideAcid hydrolysisSulfate

The invention discloses a new sulfate process titanium dioxide acidolysis method. Sulfuric acid with mass fraction being 98% is utilized to be subjected to a reaction with titanium ore powder, and themain reaction is performed safely by controlling flow of compressed air and frequency of an exhaust draught fan; the method has technical effects as follows: raw material cost is saved, the risk of overflowing in the main reaction is reduced, and the acidolysis rate of ore is increased.

Owner:SHANDONG DAWN TITANIUM IND

A method for converting titanium white red gypsum into white gypsum and enriching titanium and iron

ActiveCN108264251BIncrease added valueSimple processTitanium and titanyl sulfatesTreatment involving filtrationCement factoryTitanium

The invention belongs to the technical field of wastewater treatment, and particularly relates to a method for converting titanium dioxide red gypsum into white gypsum and enriching titanium and iron.The method comprises the following steps: preparing white gypsum, preparing the red gypsum, converting the red gypsum into acid white gypsum, and converting the acid white gypsum into the white gypsum; through control of a process and an end point of the reaction, the produced white gypsum can be directly used for a cement factory, and can be deeply processed into building material gypsum with higher added value; through dissolution of the red gypsum by a waste concentrated acid, the red gypsum is converted into the acid white gypsum, and a TiOSO4 and FeSO4 acidic solution with a high concentration is obtained, wherein the recovery utilization rate is 95% or more; and the acid white gypsum is diluted by using titanium dioxide wastewater, and after primary neutralization is performed, thewhite gypsum is obtained. The method provided by the invention has a simple technological process, a stable treatment effect, less equipment investment, no secondary pollution, low treatment costs, considerable economic benefits and broad market prospects.

Owner:CNMC GUANGXI PGMA

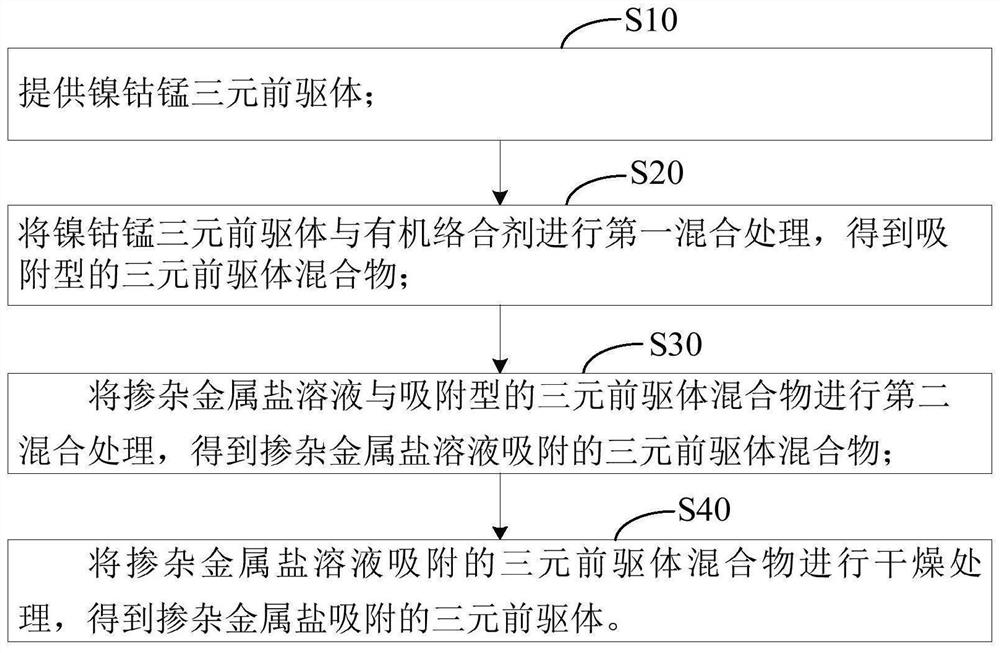

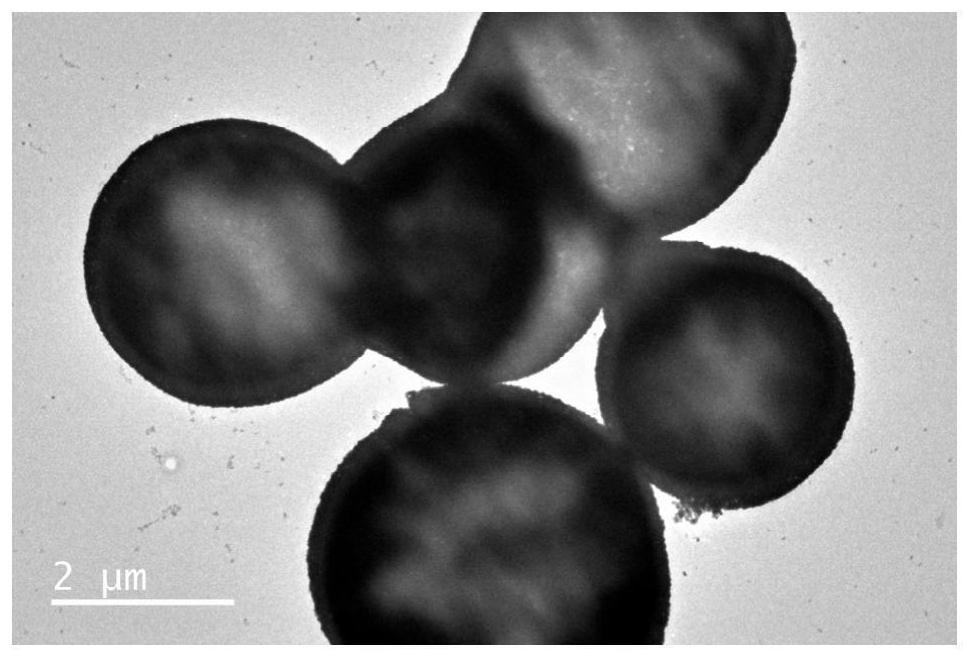

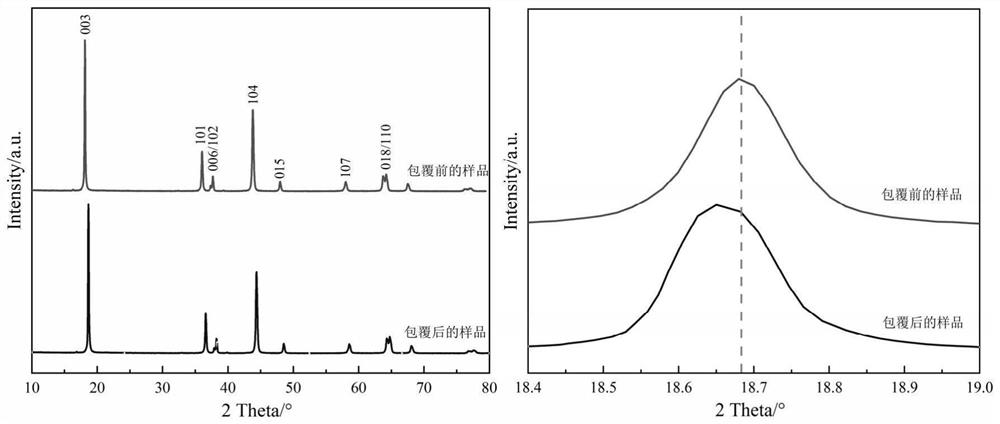

Composite ternary material as well as preparation method and application thereof

ActiveCN114057238AImprove electrical performanceImprove anti-overchargeTitanium and titanyl sulfatesAluminium oxide/hydroxide preparationCrystal structureCyclic stability

The invention relates to the technical field of lithium battery electrode materials, and provides a composite ternary material which has a core-shell structure and comprises a ternary precursor material and a doped metal salt layer coating the surface of the ternary precursor material. The composite ternary precursor provided by the invention contains the doped metal salt layer coated on the surface of the ternary precursor material, after the composite ternary precursor and a lithium source are sintered, a ternary material with uniformly distributed doped metal elements and coated with the metal oxide layer can be formed, the metal doping can effectively inhibit the conversion of the crystal structure of the surface layer of the material in the circulation process, and the coating of the metal oxide layer can avoid the direct contact with electrolyte and inhibit the side reaction, so that the circulation stability of the material can be improved.

Owner:GUANGDONG JIANA ENERGY TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com