Patents

Literature

43results about How to "Improve Grading Quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

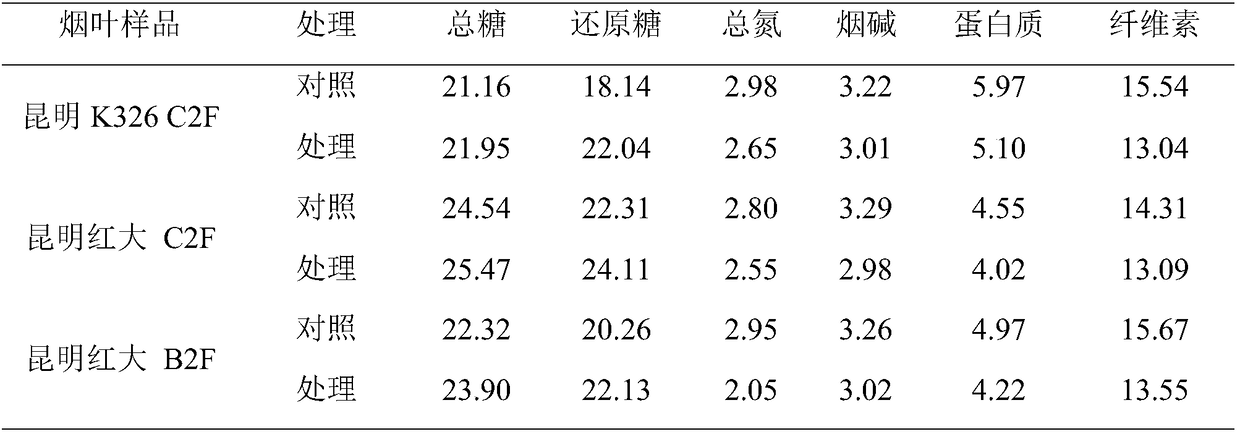

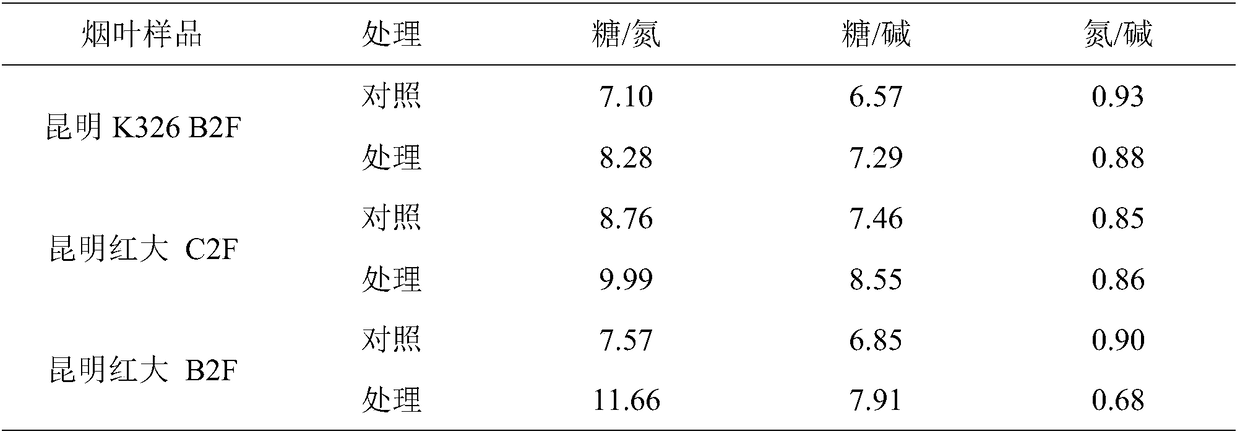

Bacillus pumilus and application thereof

ActiveCN101824391AImprove the quality of flue-cured tobaccoImprove usabilityBacteriaTobacco treatmentMicroorganismBacillus pumilus

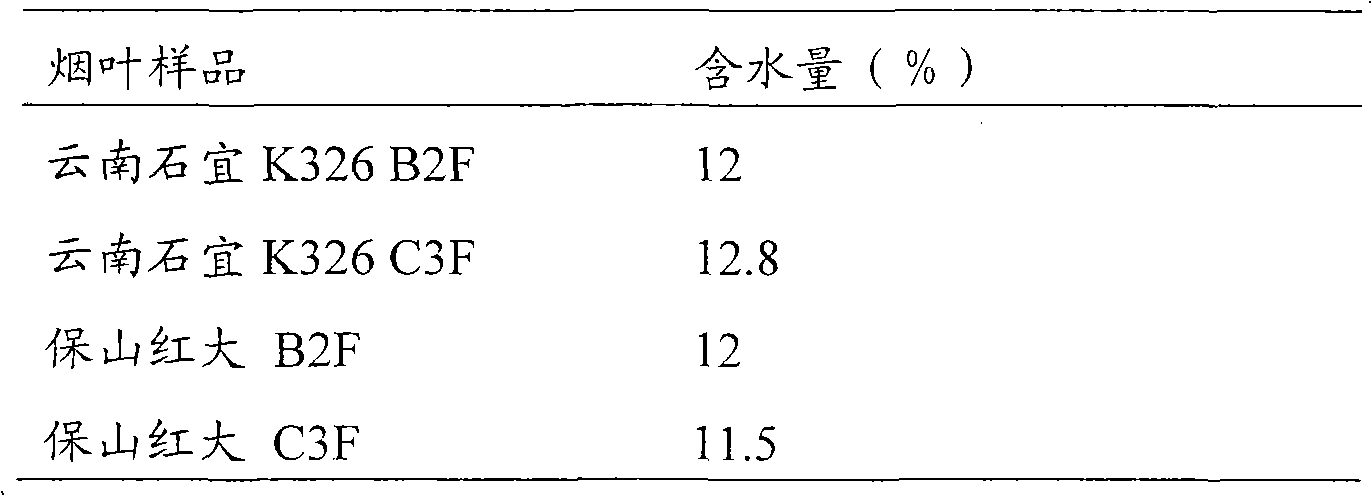

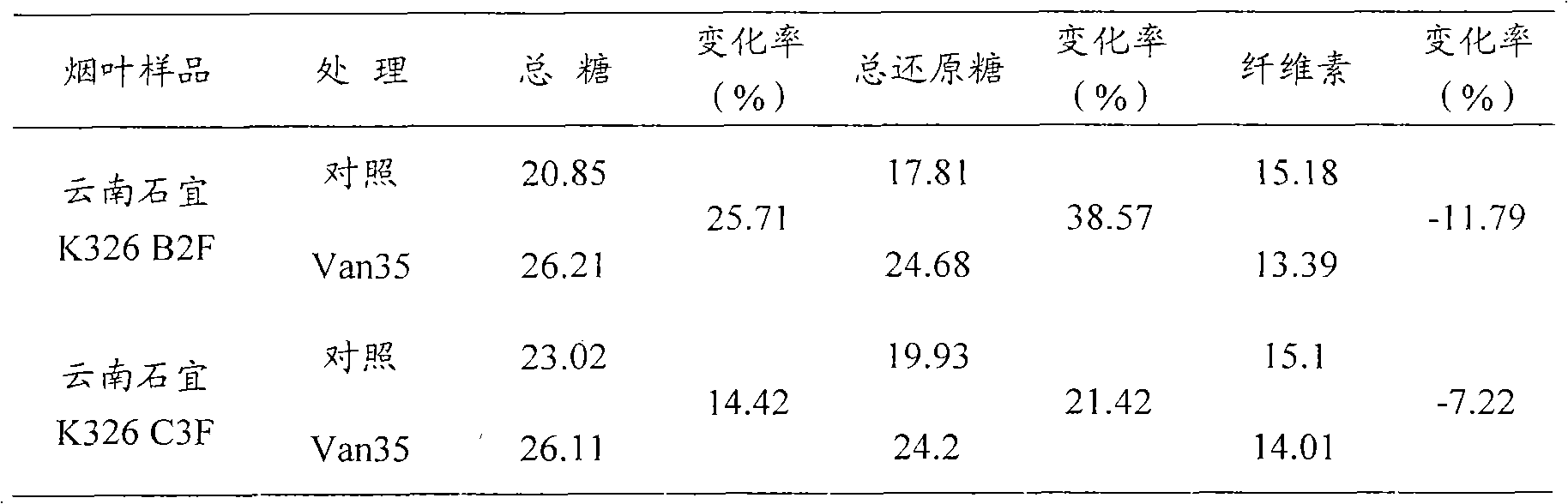

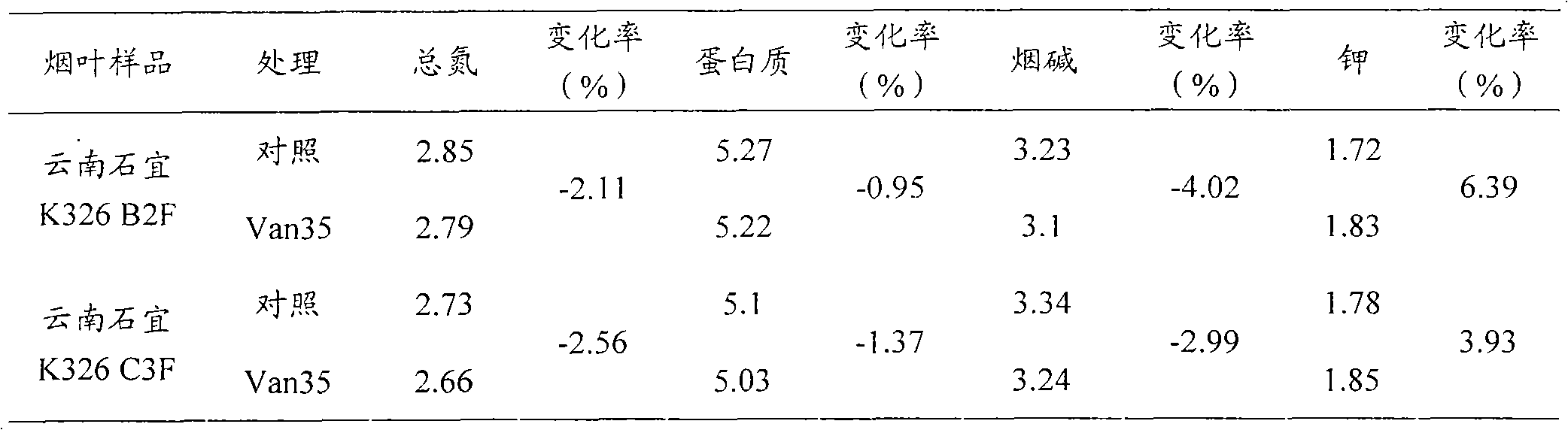

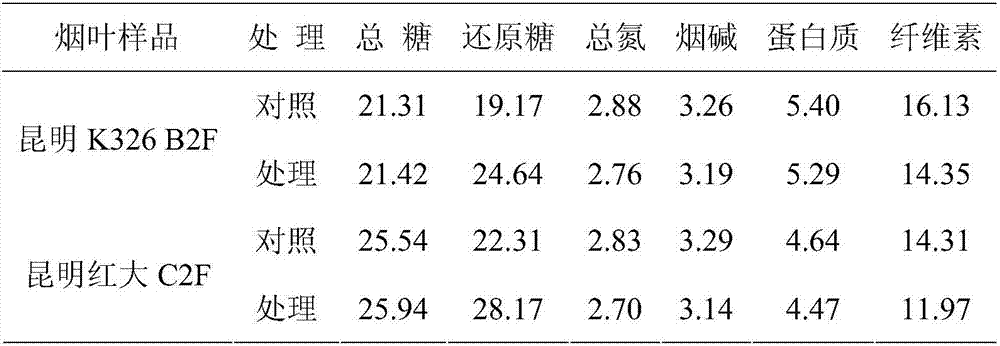

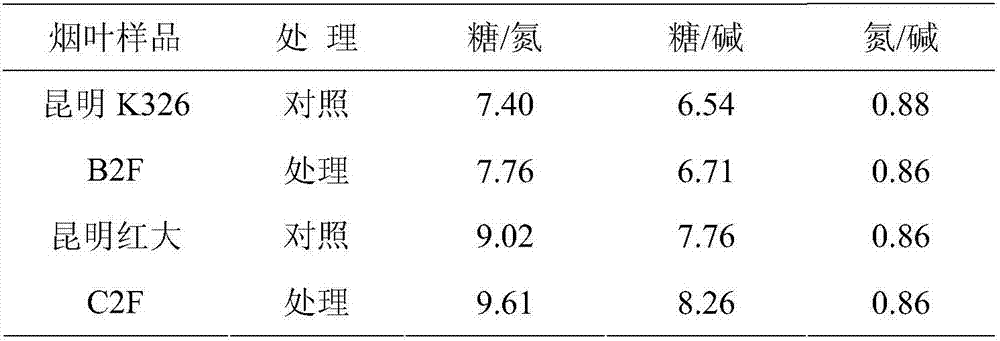

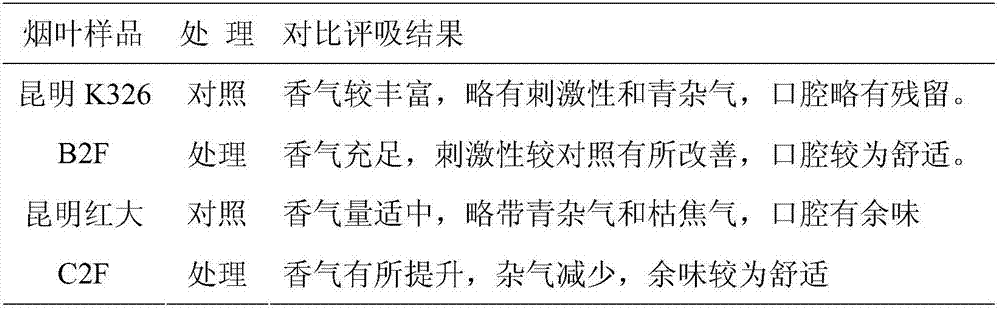

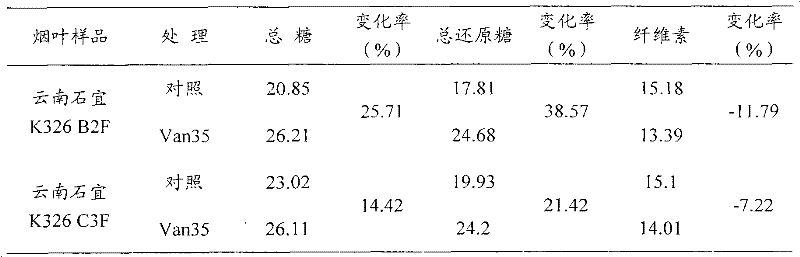

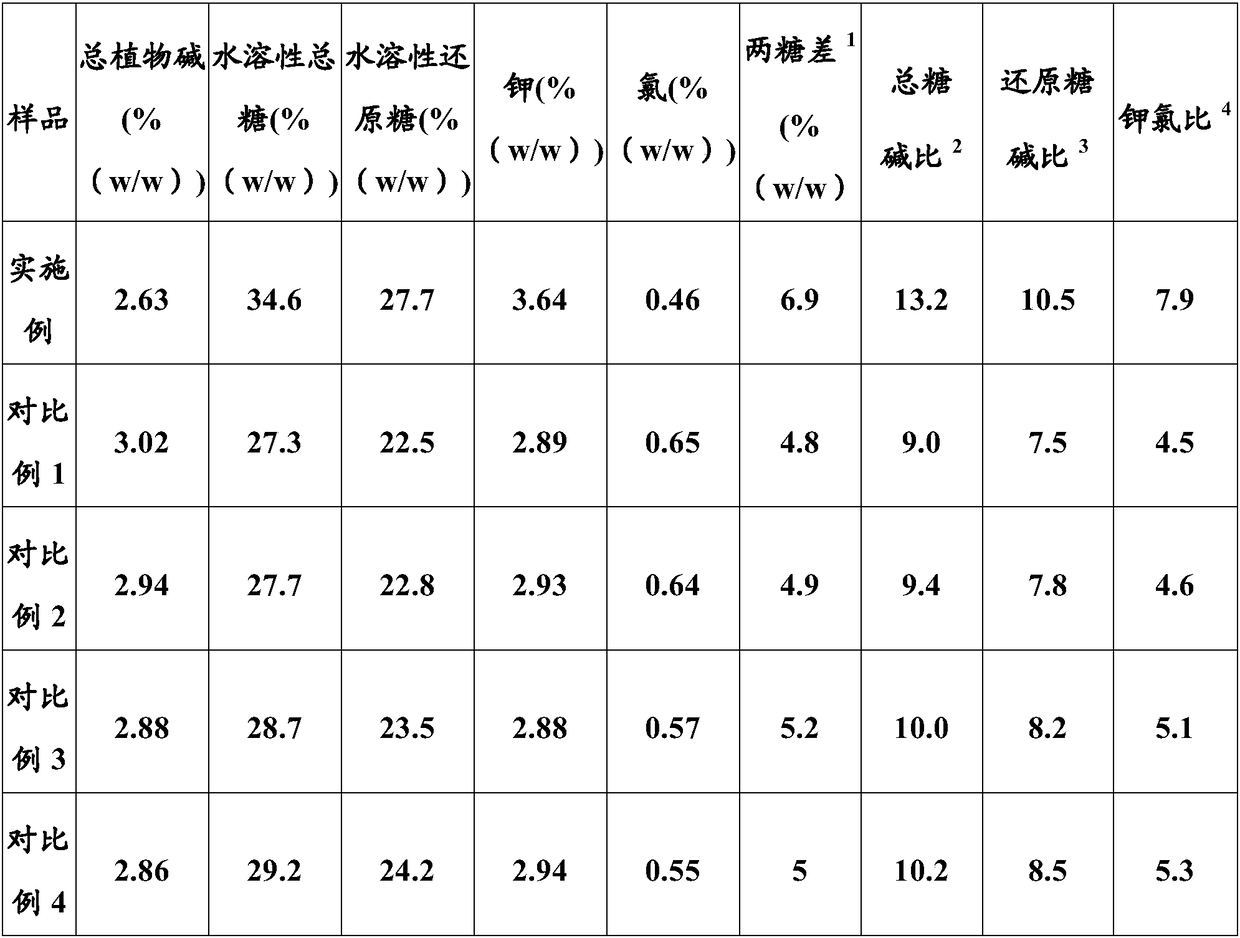

The invention discloses bacillus pumilus and application thereof, which belong to the technical field of microbes. The produced strain of the invention is named Bacillus pumilus Van35 according to classification, and the preservation number of the strain is CGMCC No.3411. When the strain preparation is spayed, the soluble total sugar content and the reducing sugar content of tobaccos can be increased, while protein, total nitrogen and nicotine content are reduced. Therefore, specific values of the ratio of dextrose to nitrogen, the ratio of total sugar to betaine and the ratio of total nitrogen to total alkaloid tend to rise, the quality of chemicals is high and the quality of the smoke panel test is improved.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Gradient separation and comprehensive recovery method for multiple metallic elements in gold concentrate

ActiveCN109351465ATo achieve the purpose of economical and environmental protectionRealize eating dry and squeezing cleanFlotationProcess efficiency improvementRecovery methodBiological activation

The invention relates to a gradient separation and comprehensive recovery method for multiple metallic elements in gold concentrate. According to the process, the first-grade technology is utilizing an efficient mixed activator and a flotation reagent for carrying out pre-flotation on the low-sulfur gold concentrate, the second-grade technology is carrying out alkali leaching cyanide gold extraction on high-sulfur concentrate, the third-grade technology is leaching gold and silver out of low-sulfur tailings through an environment-friendly medicament and a wet method, the fourth-grade technology is giving priority to lead and zinc concentrating for high-sulfur gold concentrate cyanide tailings namely first low-gold high-sulfur concentrate, the fifth-grade technology is selecting copper fromlead and zinc tailings in an activation manner, the sixth-grade technology is roasting acid making and enriching gold, silver and iron to produce iron ore concentrate through copper tailings namely second low-gold high-sulfur concentrate, and the seventh-grade technology is leaching gold and silver out of the iron ore concentrate through an environment-friendly medicament and a wet method. According to the process, the chain for comprehensively utilizing a low-sulfur gold concentrate resource is prolonged, the comprehensive recovery value of the resource and the grade quality of the productsare improved, the complete utilizing of the gold concentrate resource is achieved, and relatively high economic benefits, environment benefits and social benefits are achieved.

Owner:SHANDONG GUODA GOLD

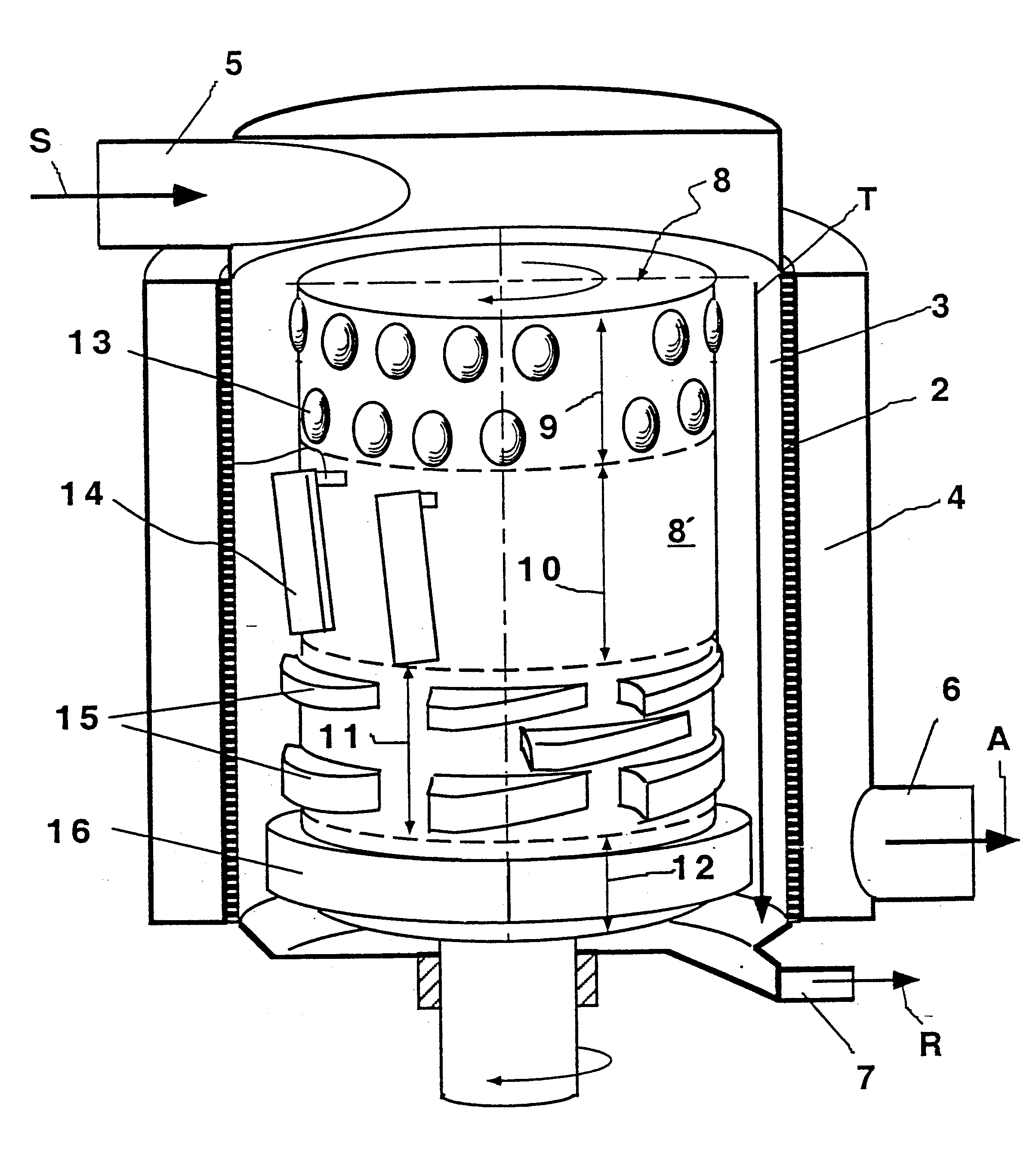

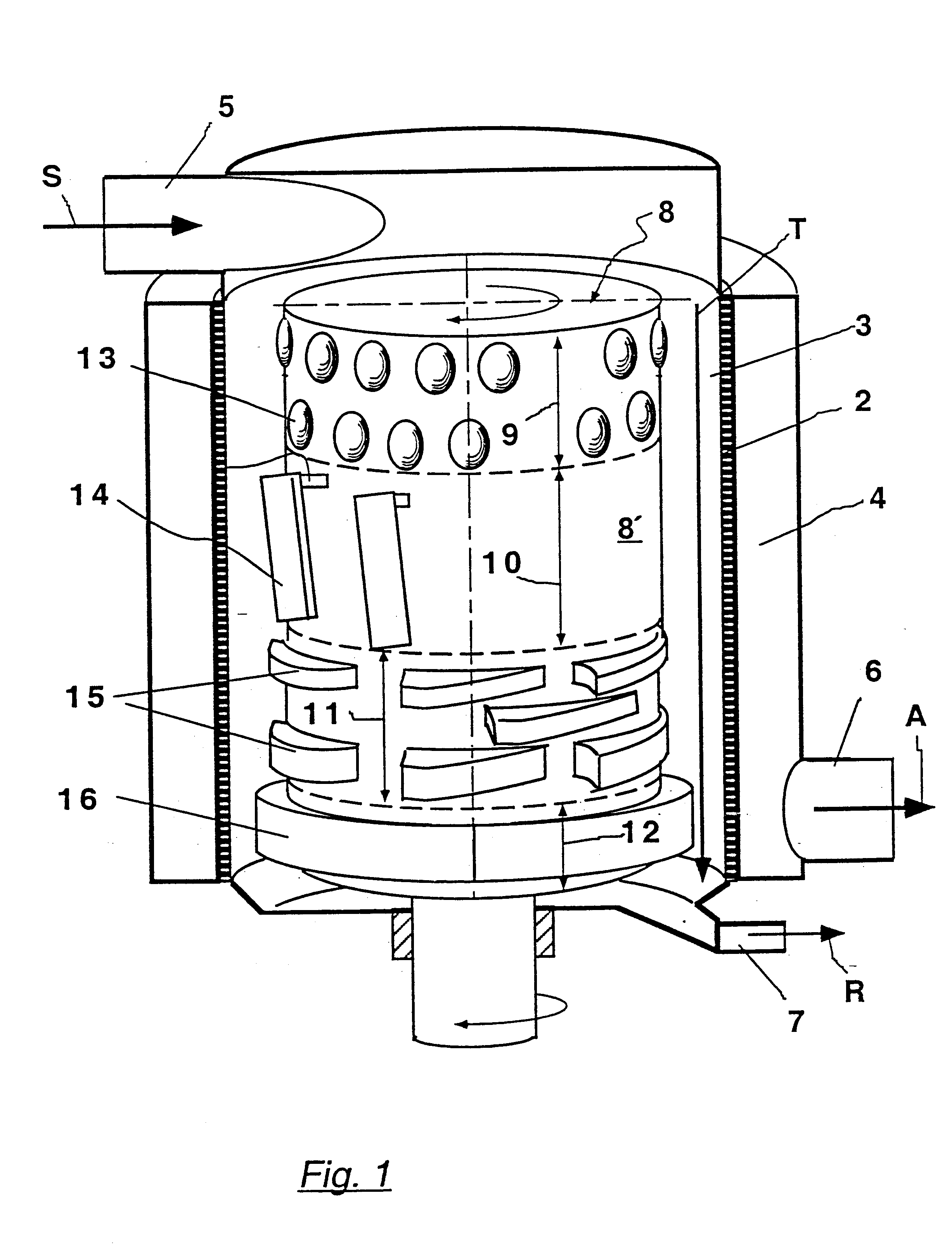

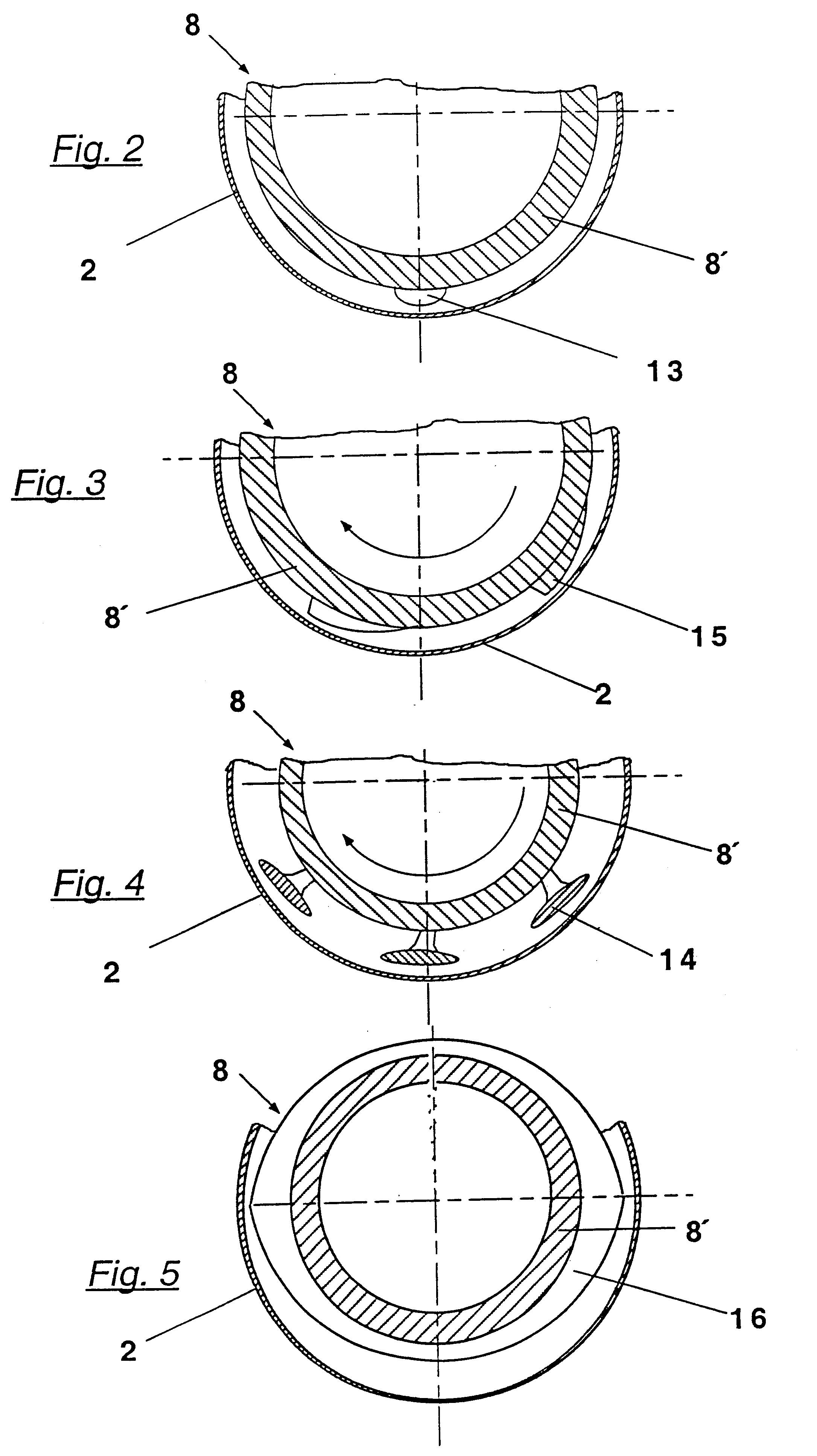

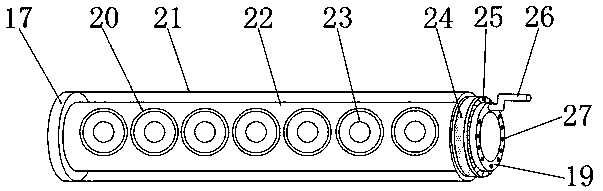

Pressure screening apparatus for screening a paper stock suspension and screen clearer for such a screening apparatus

InactiveUS6311850B1Increase productivityScreen clearing effect in different clearing zones is increasedSievingFats/resins/pitch/waxes removal in pulpEngineeringMechanical engineering

A pressure screening apparatus for screening a stock suspension and screen clearer for a pressure screening apparatus. The pressure screening apparatus includes an inflow chamber, a suspension inflow connected to one end of the inflow chamber, a reject outflow connected to another end of the inflow chamber, an accepted stock chamber, an acceptance stock pipe connected to the accepted stock chamber, at least one screen element disposed between the inflow chamber and the accepted stock chamber, a screen clearer adapted to move with respect to the at least one screen element for preventing clogging of the at least one screen element, the screen clearer comprising at least a first clearing zone and at least a second clearing zone, the first clearing zone having a plurality of clearing elements and the second clearing zone having a plurality of clearing elements which are different from those of the first clearing zone, wherein the stock suspension flows into the pressure screening apparatus via the suspension inflow such that a portion of the stock suspension flows through the clearing zones and exits the pressure screening apparatus through the reject outflow. The screen clearer includes a substantially cylindrical body having a cylindrical outer surface. The cylindrical outer surface includes at least a first clearing zone and at least a second clearing zone. The first clearing zone has a plurality of clearing elements. The second clearing zone has a plurality of clearing elements which are different from those of the first clearing zone. The cylindrical body is rotatably mountable.

Owner:VOITH SULZER PAPIERTECHN PATENT

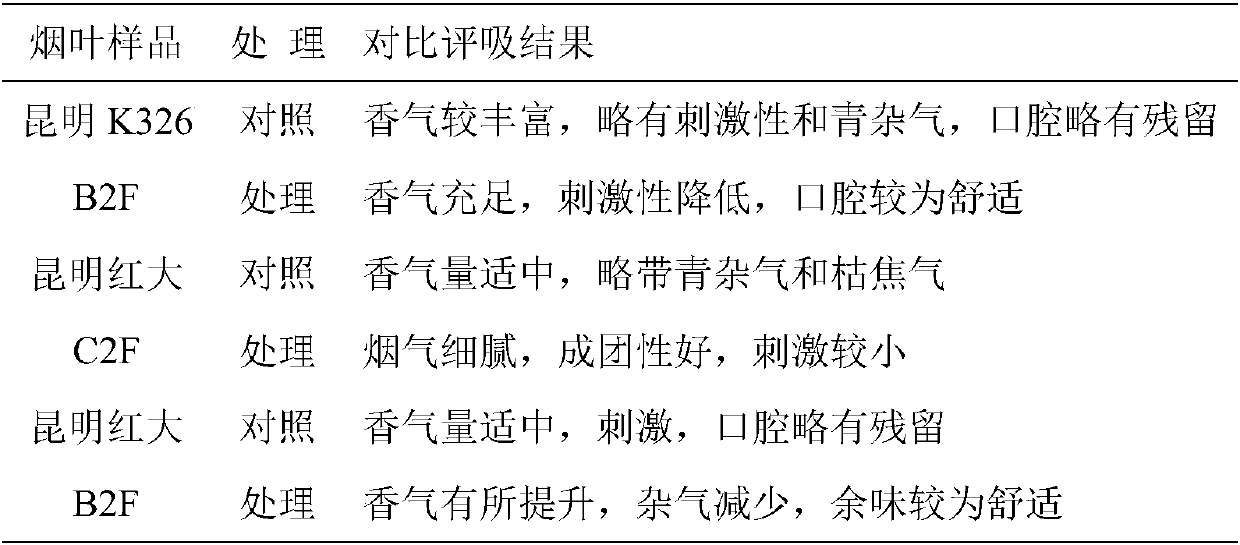

Tobacco flue-curing and amending agent

InactiveCN1370474AIncrease the amount of aromaIncrease aromaTobacco preparationPotassium nitratePhosphate

The present invention belongs to tobacco flue-curing and amending technology. The tobacco flue-curing and amending agent consists of licorice, potassium gluconate, potassium citrate, potassium nitrate, ammonium dibasic phosphate, fructose, sugar and water. It can raise the quality of treated tobacco in the process of tobacco flue-curing and amending. The said product can be formed into solid, liquid, aerosol or other forms.

Owner:吴昊

Multi-grade gold-solver-copper-zinc enriching and comprehensive recovering method for cyanide gold refining waste residues

ActiveCN107217135AEliminate pollution hazardsTo achieve the purpose of economical and environmental protectionProcess efficiency improvementPregnant leach solutionCyanide

The invention relates to a multi-grade gold-solver-copper-zinc enriching and comprehensive recovering method for cyanide gold refining waste residues. The multi-grade gold-solver-copper-zinc enriching and comprehensive recovering method for the cyanide gold refining waste residues comprises the following steps that the first grade is a technology that decyanation is conducted after mixing cyanide gold refining waste residues, high-temperature hot residues generated by roasting acid-making and purifying warm dilute acid slurry mixing; the second grade is a gold-solver-sulfur-concentrate floating-selecting and enriching technology by using high efficiency mixing activator and floating agents; the third grade is a technology for iron ore concentrate generated through floating-selecting tailing magnetic-separation; the fourth grade is a technology for producing the iron ore concentrate by floating-selecting gold-solver-sulfur-concentrate, high-temperature roasting acid-making and enriching gold-solver-iron; the fifth grade is a wet-process gold-silver leaching technology for the iron ore concentrate by using environmental protection agents; the sixth grade is a precipitating enriching technology for gold and silver in leaching liquid; and the seventh grade is a comprehensive precipitating recovering recycling technology for copper and zinc in the leaching liquid after gold-silver extraction. According to the multi-grade gold-solver-copper-zinc enriching and comprehensive recovering method for the cyanide gold refining waste residues, the pollution and damages of the cyanide gold refining waste residues on surround environment are removed, through the multi-grade enriching technology, gold, solver, copper and zinc in the cyanide gold refining waste residues can be recovered comprehensively and integratedly, and the objectives of comprehensive processing and recovering, cyclic utilization and economic and environmental protection can be achieved.

Owner:SHANDONG GUODA GOLD

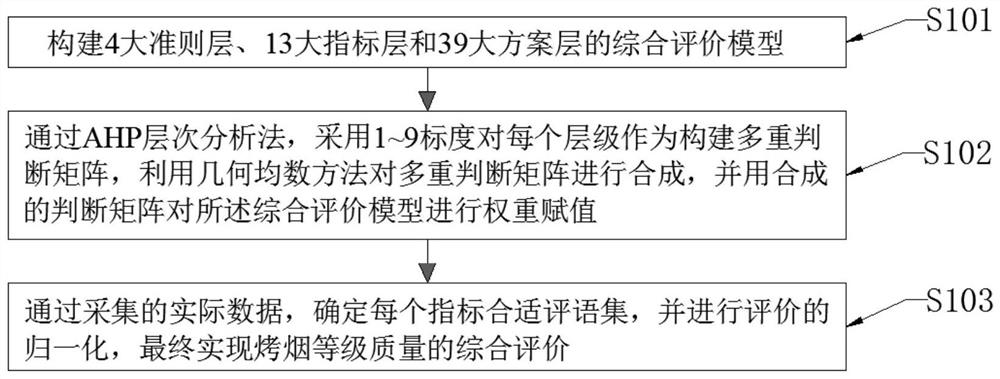

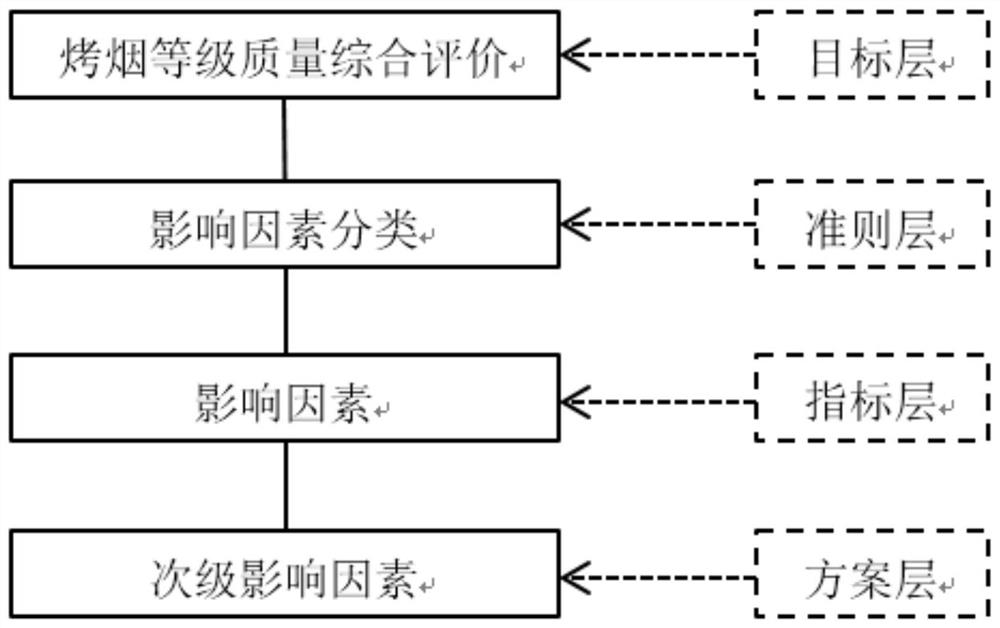

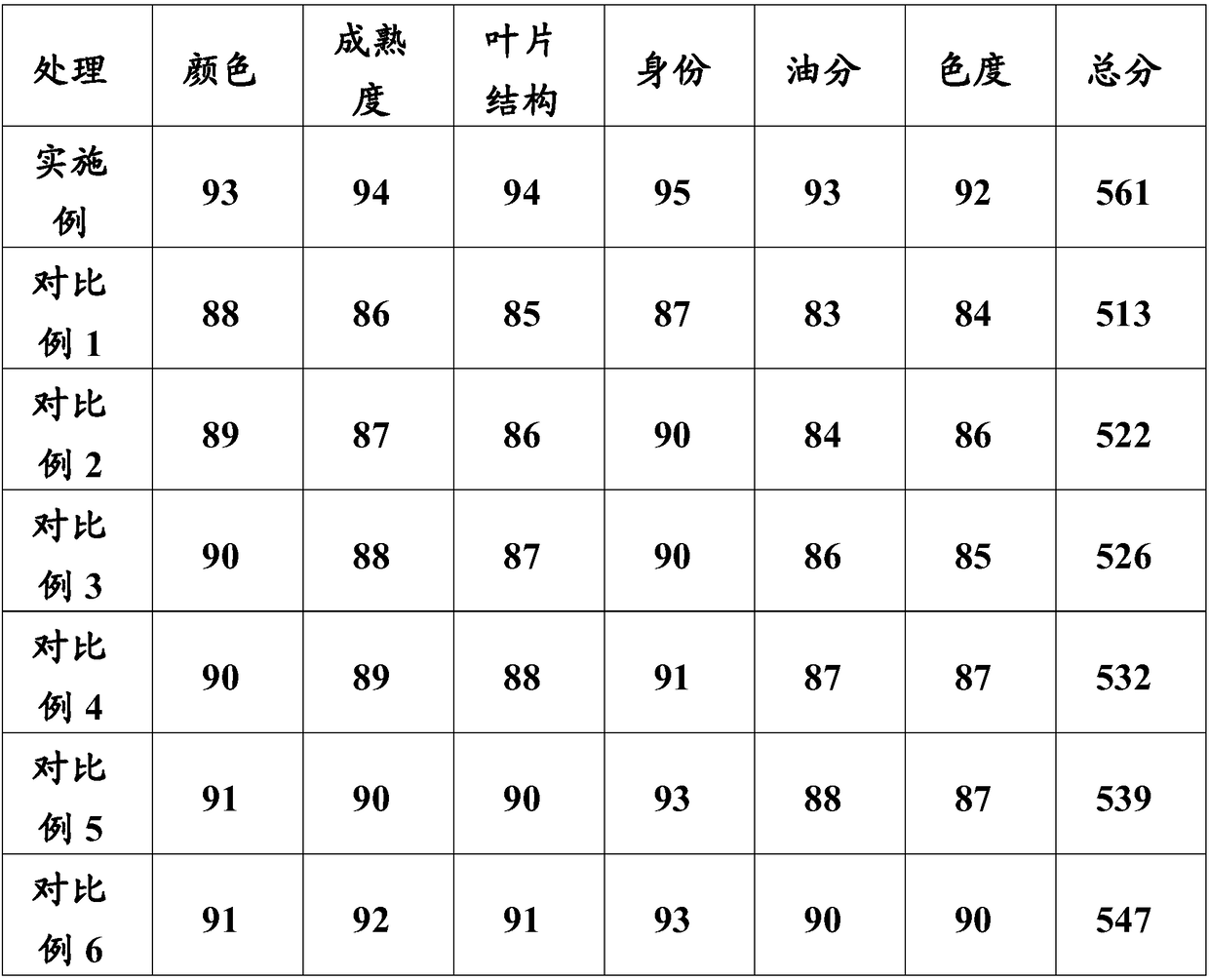

Comprehensive evaluation method of flue-cured tobacco grade quality evaluation index system

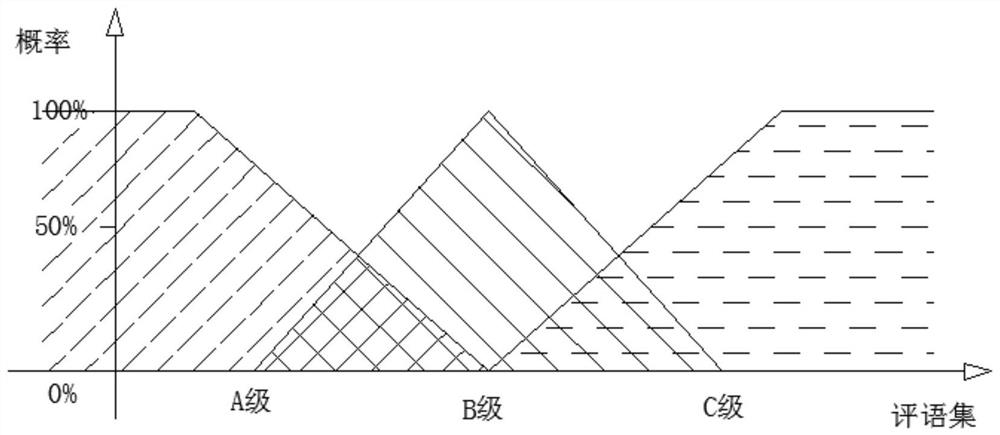

PendingCN111815149AQuality improvementImprove the status quo of grade qualityResourcesManufacturing computing systemsQuality controlProcess engineering

The invention discloses a comprehensive evaluation method of a flue-cured tobacco grade quality evaluation index system. The comprehensive evaluation method comprises the following steps: constructinga comprehensive evaluation model of four criterion layers, thirteen index layers and 39 scheme layers; through an AHP analytic hierarchy process, constructing a judgment matrix by multiple persons based on 1-9 scales, and synthesizing the judgment matrix of the multiple persons by adopting an appropriate method, so that weight assignment is carried out on the comprehensive evaluation model; and determining an appropriate comment set of each index according to the acquired actual data, and normalizing the evaluation to finally realize comprehensive evaluation of the flue-cured tobacco grade quality. The method has the advantages that the current situation that the tobacco grade quality of the production area is evaluated by means of subjective impression at present can be improved, quantitative and modular numerical evaluation is provided for tobacco quality of different areas, and a theoretical basis is provided for further improving the tobacco grade quality of the production area and improving the flue-cured tobacco production, operation and quality control level.

Owner:YUNNAN TOBACCO QUALITY SUPERVISION MONITORING STATION

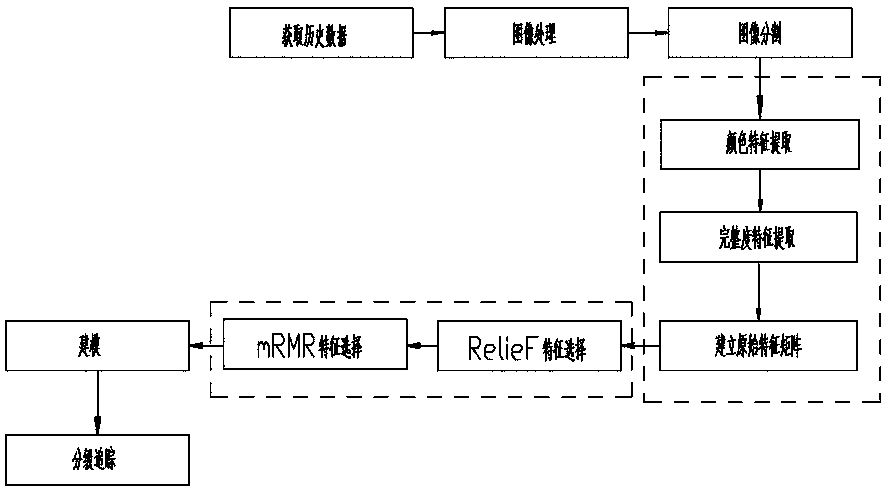

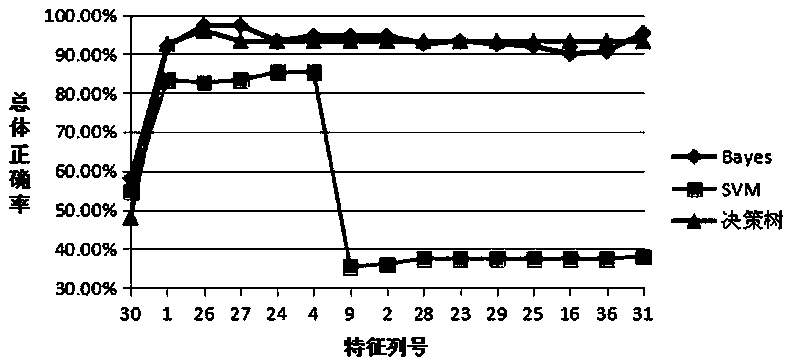

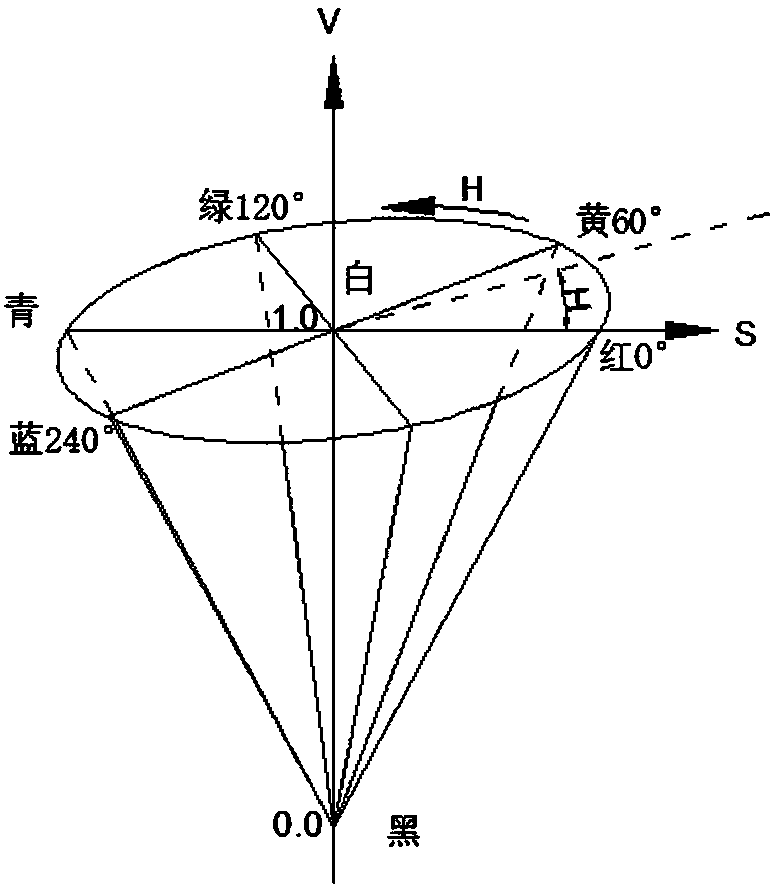

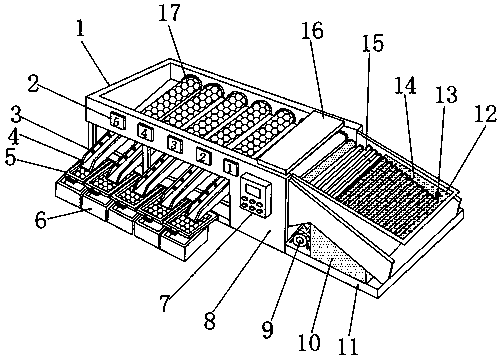

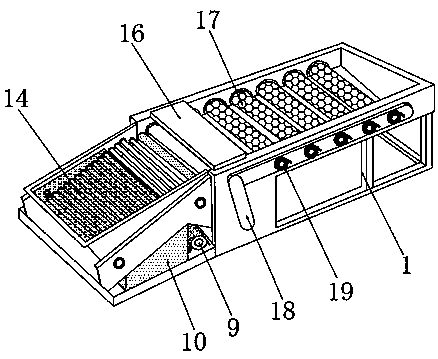

Walnut kernel grading method and walnut kernel grading device based on machine vision

ActiveCN108855988AHierarchical implementationRealize automatic gradingCharacter and pattern recognitionSortingWalnut NutMachine vision

The invention relates to the technical field of grading and tracking based on machine vision, in particular to a walnut kernel grading method and walnut kernel grading device based on the machine vision. The walnut kernel grading method based on the machine vision sequentially comprises the following steps that historical sample data are obtained, images are processed, the images are segmented, anoriginal characteristic matrix is established, characteristics are selected, a model is founded, and grading and tracking are carried out. According to the walnut kernel grading method and walnut kernel grading device based on the machine vision, the structure is reasonable and compact, and use is convenient. After walnut kernel images are collected through the machine vision, tracking and grading are carried out on the walnut kernels by a PC host, after the walnut kernels reach a grading position, and the walnut kernels are blown into a grading discharge groove in a method of air-blowing, sothat grading of the walnut kernels is realized. The characteristics of bin19, K1 and bin15 are adopted, and a naive bayesian classification method with the best classification effect is utilized as agrading model of the walnut kernels. The grading processing is high in speed, automatic grading of dynamic walnut kernels can be realized on a conveying platform, manual grading is replaced, and labor is saved.

Owner:XINJIANG AGRI UNIV

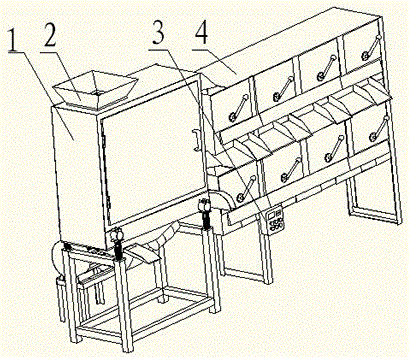

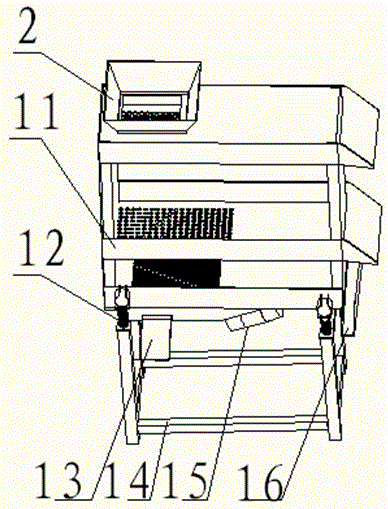

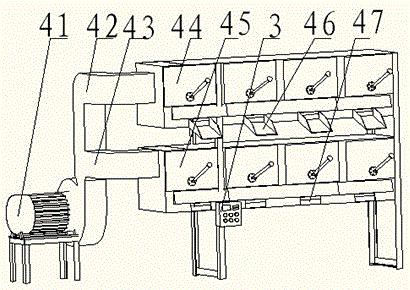

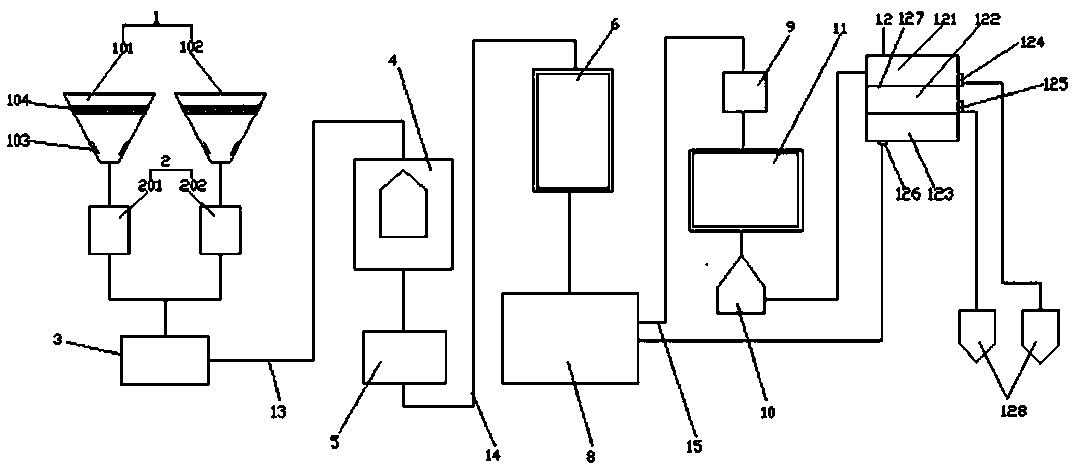

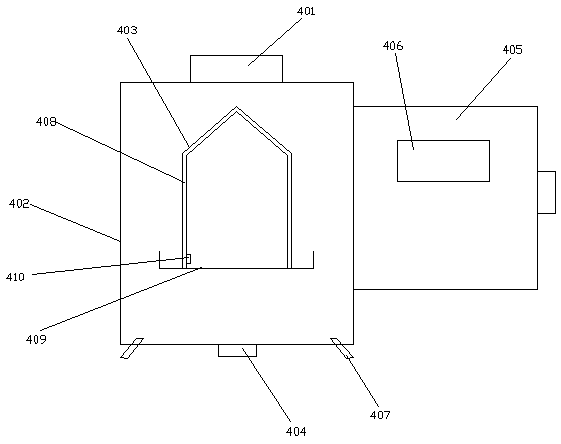

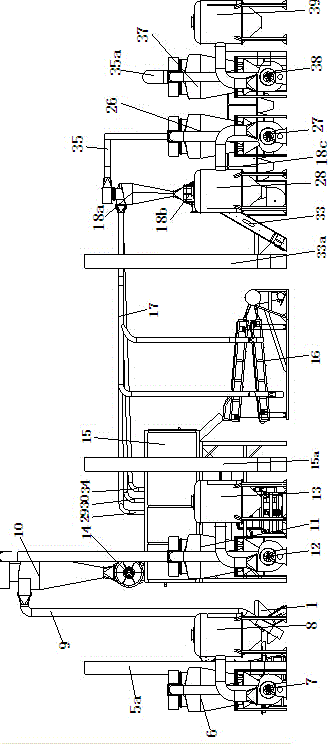

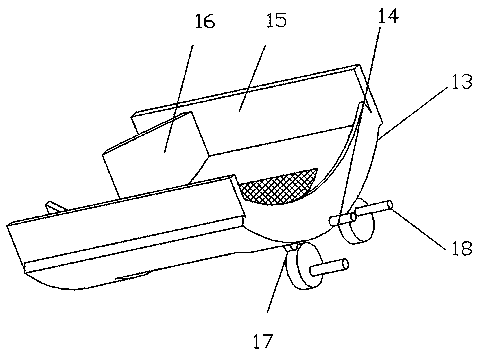

Multi-stage sorting device for mechanically picking fresh tea leaves

InactiveCN105710037ACompact structurePracticalSievingPre-extraction tea treatmentElectrical controlBiology

The utility model relates to a multistage sorting device for mechanically picked fresh tea leaves, which relates to the technical field of tea processing machinery. It includes fresh tea leaves winnowing parts, fresh tea leaves vibrating screening parts, feed hopper, electrical control box, and is characterized in that: tea fresh leaves vibrating screening parts include vibrating motor, vibrating sieve box, bracket assembly, said vibrating sieve box It is composed of upper and lower three-layer screens and sieve boxes arranged from coarse to fine; the air selection components for fresh tea leaves include fans and bellows components. The first group of bellows and the second group of bellows are respectively connected with two sets of air ducts; the feed hopper is connected to the first layer of coarse screen box; the second layer of medium and fine screen box is located under the first layer of coarse screen box; the third layer The fine sieve box is located below the middle and fine sieve box on the second layer, and the lower part of the third layer of fine sieve box is provided with a chamber, the left side of the chamber is provided with a debris outlet, and the right side of the chamber is provided with a fine leaf outlet. The invention has the positive effects of improving the grade quality of tea leaves and increasing the output of high-quality tea leaves.

Owner:丁仕波

Granulated feed producing and processing equipment and method

PendingCN109480319AMessy layoutHigh energy consumptionFeeding-stuffProcess equipmentProcess engineering

The invention relates to granulated feed producing and processing equipment and method. The granulated feed producing and processing equipment comprises a raw material receiving system, a crushing system, a mixing machine, a granulating system and a quantitative packaging system, wherein the raw material receiving system comprises a feeding device, a dosing device, a stirring barrel, an impurity removing device and a dust removing device; the crushing system comprises a crusher and an ozone generating device; the granulating system comprises a conditioning device, a granulator and a cooler; and the quantitative packaging system comprises a sorting machine and a quantitative packaging mechanism. Through adoption of the granulated feed producing and processing equipment disclosed by the invention, the defects that in the prior art, a set of perfect feed producing and processing equipment does not exist, most conventional equipment has single equipment working procedure, the equipment layout is in disorder, the energy consumption is high, the production process is complex, the production efficiency is low, and the product quality cannot be guaranteed, are solved; and the granulated feed producing and processing equipment disclosed by the invention is high in automation degree, simple in structure, high in production efficiency and low in cost, and can produce multi-grade products,and the grade quality is high.

Owner:韶关正邦农牧科技有限公司

Fruit grading machine

The invention discloses a fruit grading machine. The fruit grading machine comprises a grading machine body, the front end of the grading machine body is fixedly provided with a feeding groove, and abase is fixedly arranged at the position, under the feeding groove, of the front end of the grading machine body; and a screening roller is rotationally arranged on the inner side of the grading machine body, and a dehumidification plate is fixedly arranged at the upper end of the grading machine body. According to the fruit grading machine, an inner cover is added to the inner side of the screening roller, the diameters of leakage holes of an outer cover is changed through arranging leakage holes with different diameters in the inner cover, and thus the application range of the grading machine is expanded; falling force generated by falling of fruits can be relieved through a net bag and a buffering net bag on a pulling plate, and thus the falling force generated by falling can not causedamage to the outer surface of the fruits; and the fruits needing to be graded can be cleaned conveniently through a cleaning groove, the cleaned fruits can be wiped conveniently through cooperation with the dehumidification plate, and thus water drops on the surfaces of the fruits can be conveniently removed, and the cleanness of the surfaces of the fruits can be kept.

Owner:丽水市莲都区祥和电子产品厂

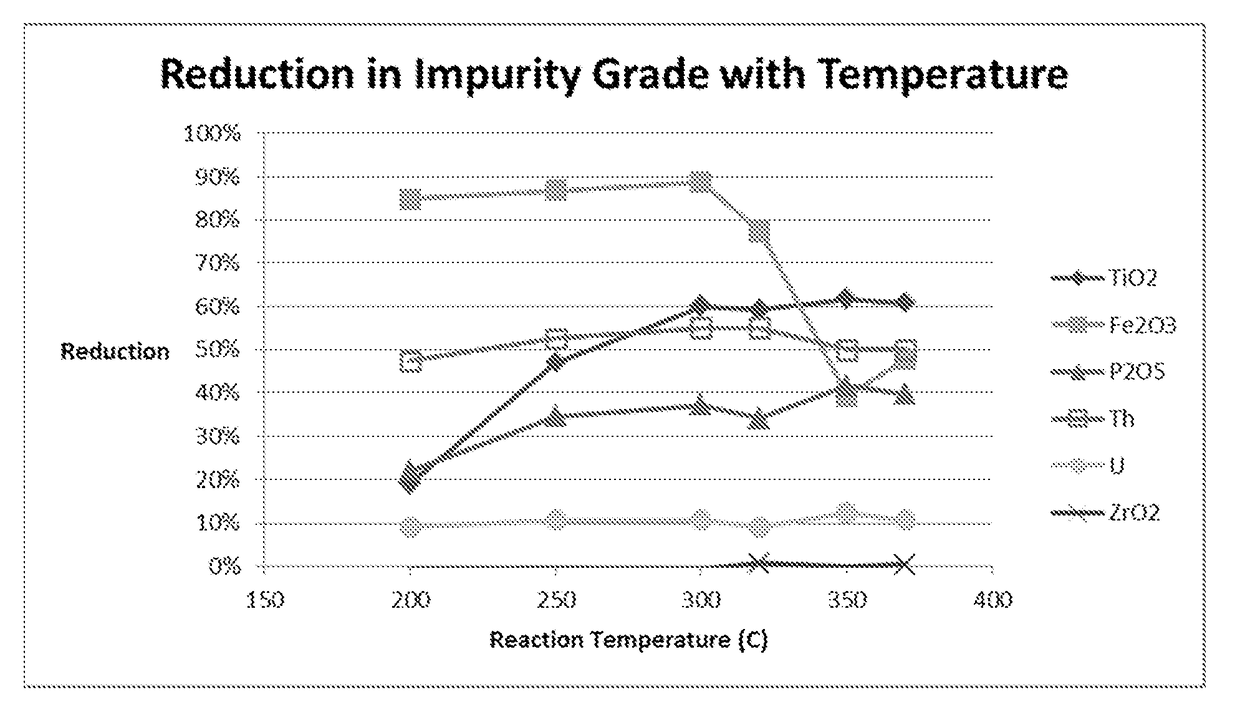

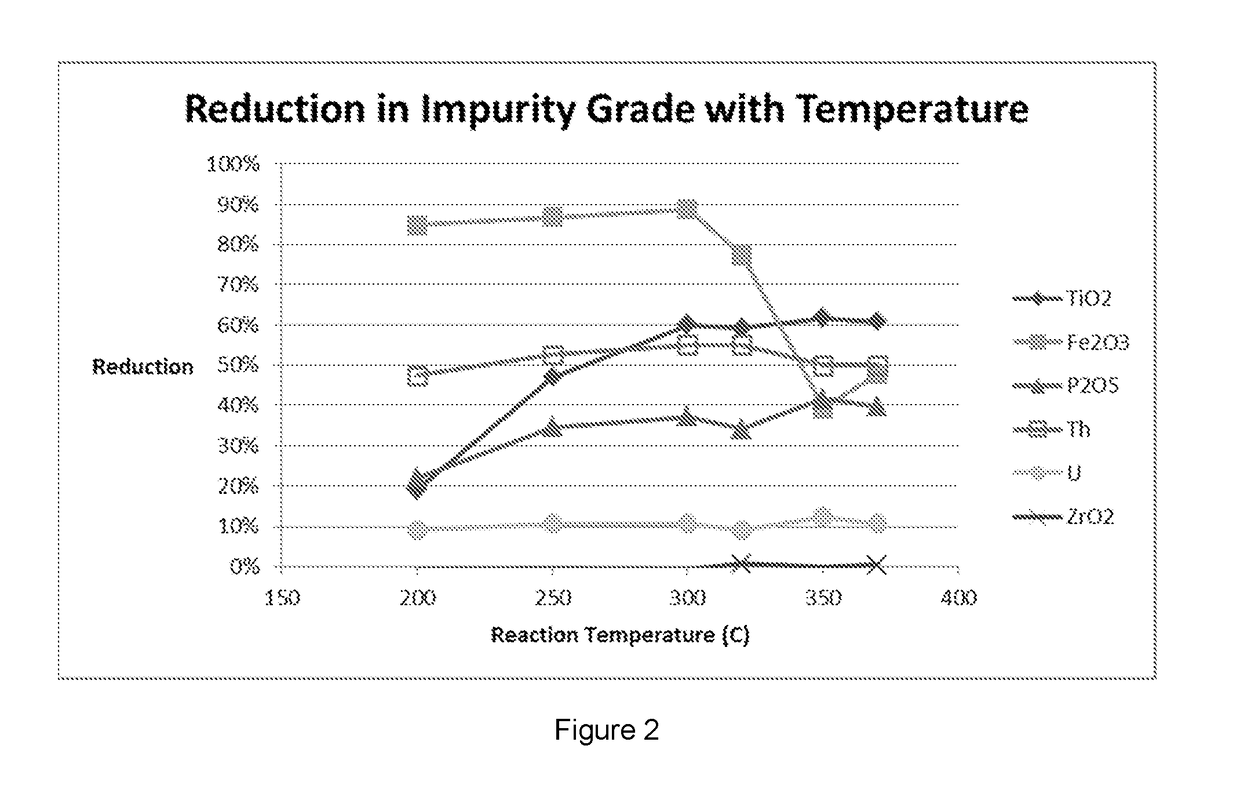

Process for Improving the Grade and Optical Quality of Zircons

ActiveUS20180023170A1Improve Grading QualityImprove optical qualityTitanium and titanyl sulfatesIron sulfatesPregnant leach solutionSulfate

A process for improving the grade and optical quality of zircon, comprising: baking a mixture of a zircon feed and concentrated sulphuric acid at a baking temperature in the range of from 200 up to 400° C., and for a time to form water leachable sulphates with impurities therein including at least iron and titanium; leaching the baked mixture to dissolve the leachable sulphates; and separating the zircon from the leachate containing the leached sulphates, which separated zircon is thereby of improved grade and optical quality.

Owner:ILUKA RESOURCES

Application of kineococcus cavernae sp to tobacco quality improvement

InactiveCN107151636AImprove qualityIncrease aromaTobacco treatmentBacteriaSequence analysisBacteroides

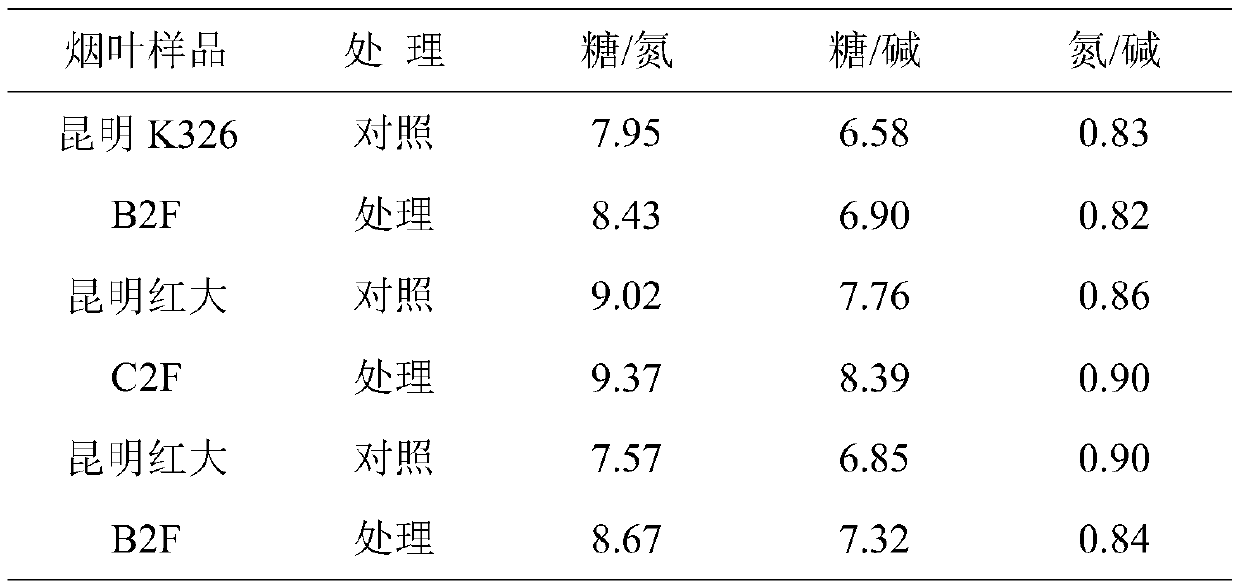

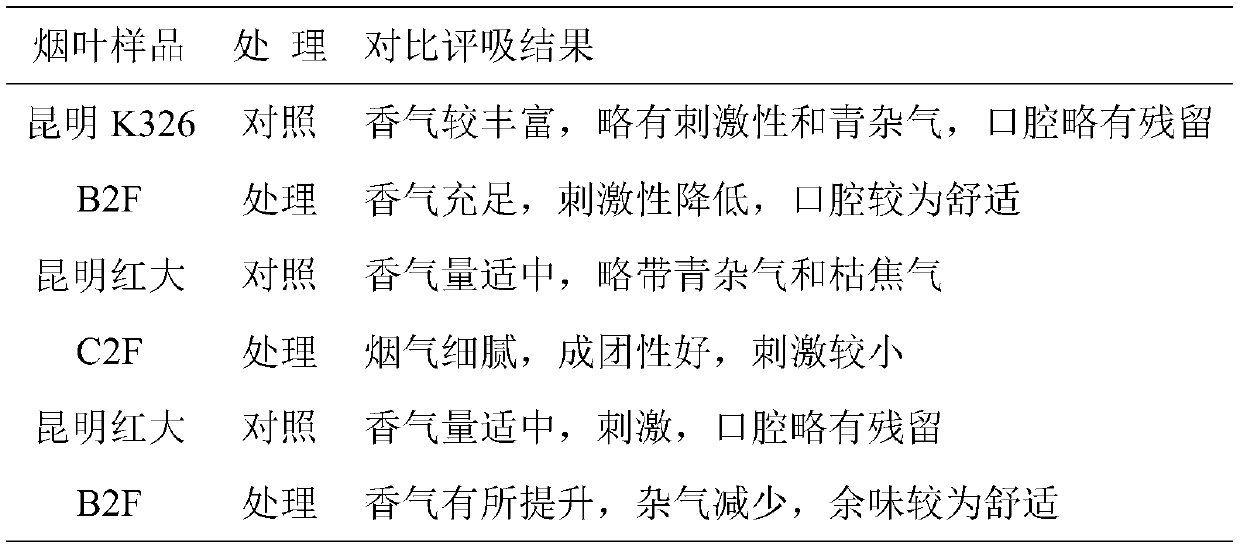

The invention discloses application of kineococcus cavernae sp to tobacco quality improvement. The strain named kineococcus cavernae sp is preserved in the China Center for Type Culture Collection on December 9, 2016, and a preservation number is M2016738. According to microbiological characteristic analysis and 16S rDNA gene sequence analysis, the strain is a novel bacterium. By spraying of an SYSUZL-1 bacterial agent to tobacco leaves prior to mellowing fermentation, tobacco aroma quality is improved, reducing sugar content is increased, contents of proteins, cellulose, total nitrogen and nicotine are decreased, and a sugar-nitrogen ratio, a sugar-nicotine ratio and a nitrogen-nicotine ratio are in increasing tendency, so that intrinsic chemical components of the tobacco leaves are harmonized, and organoleptic quality is improved evidently.

Owner:CHINA TOBACCO YUNNAN IND

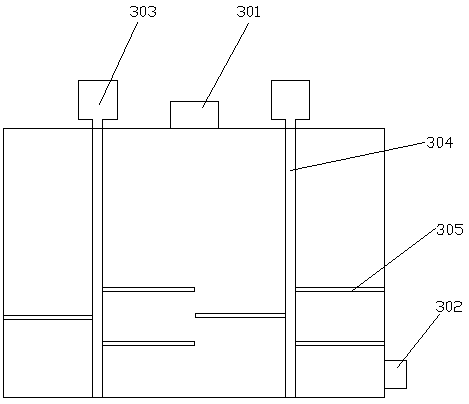

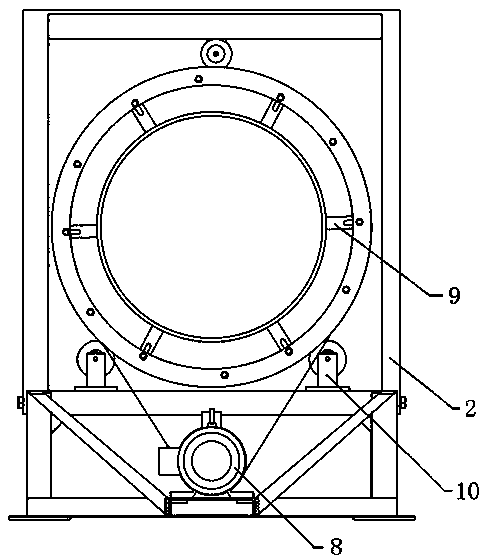

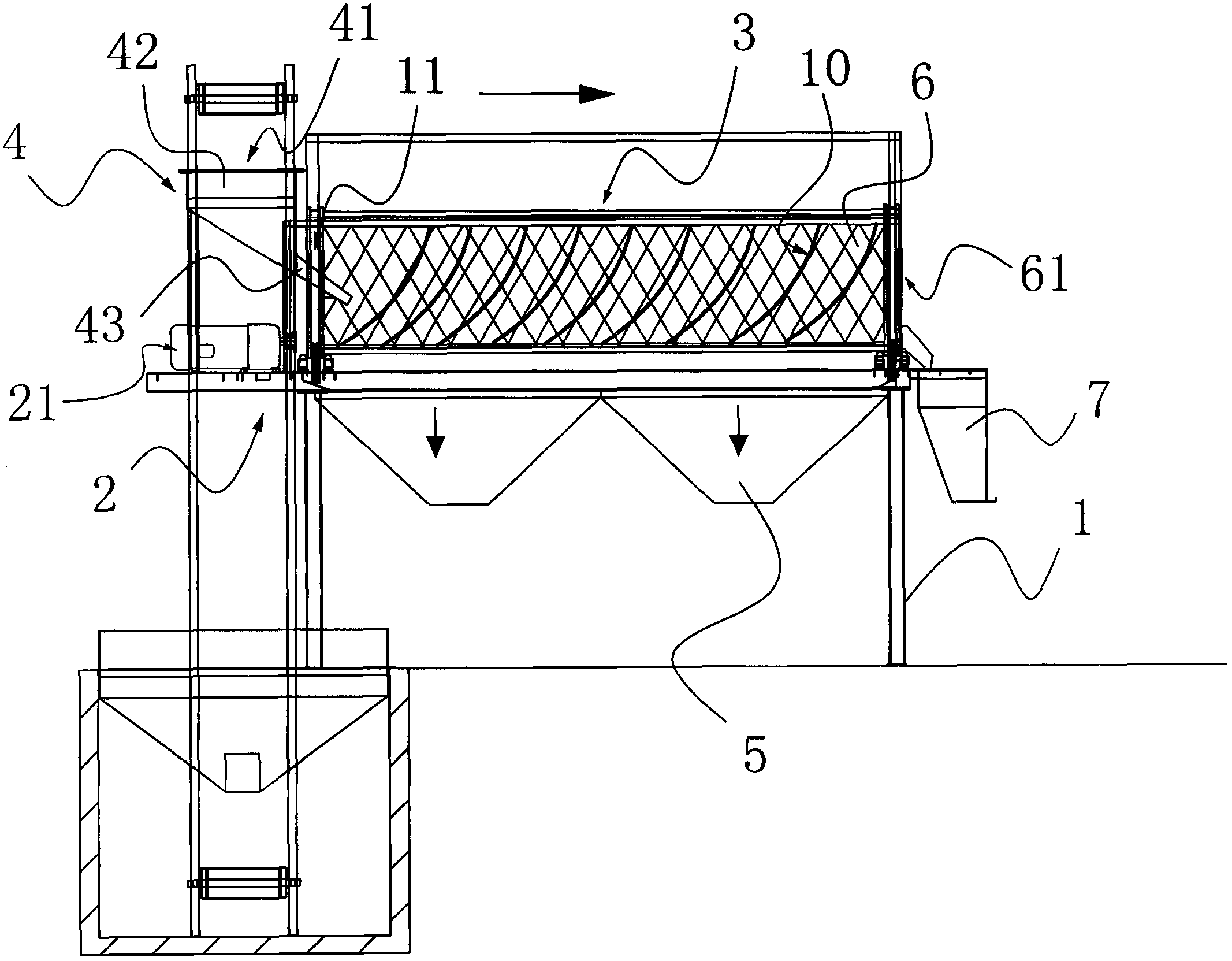

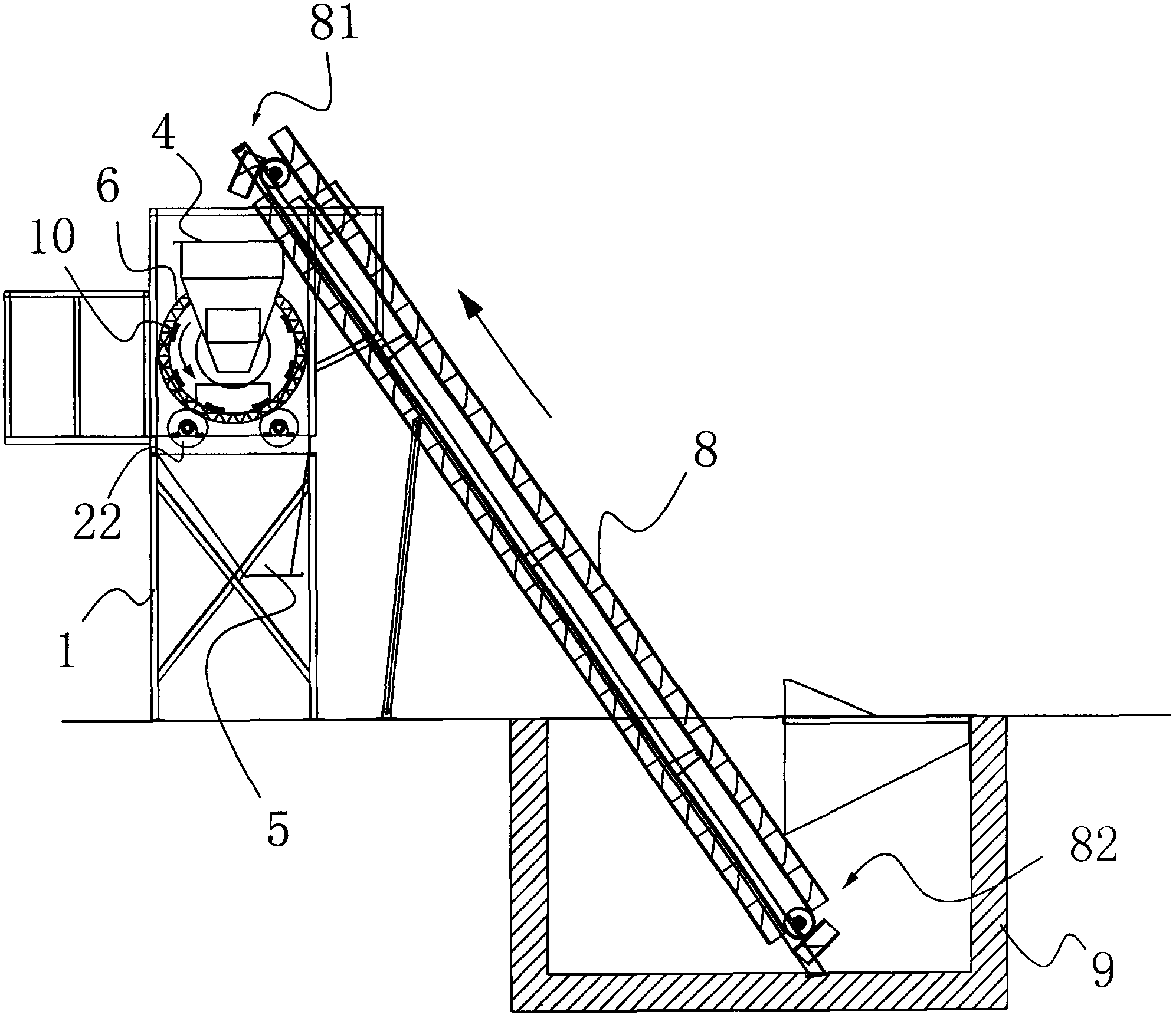

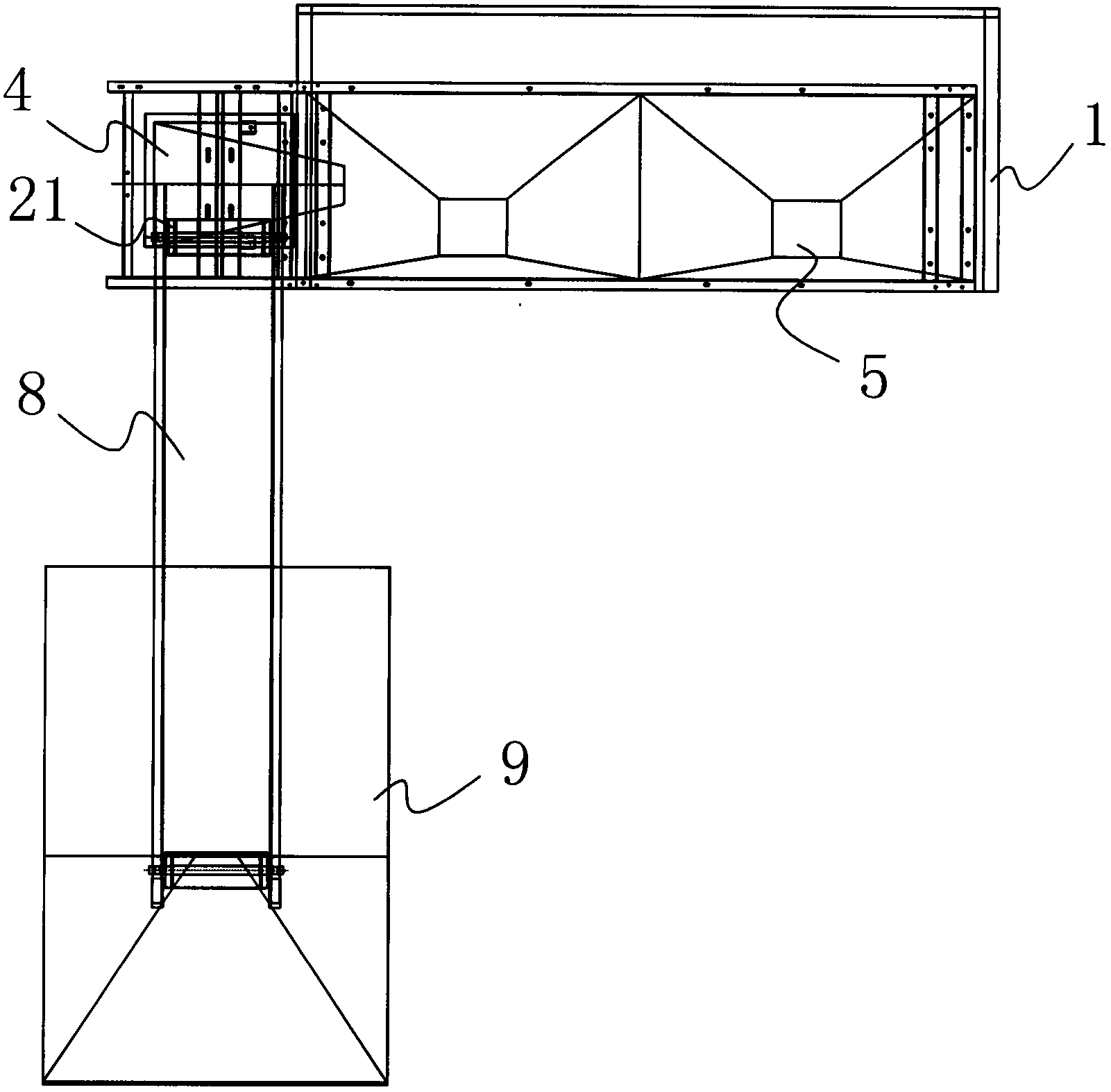

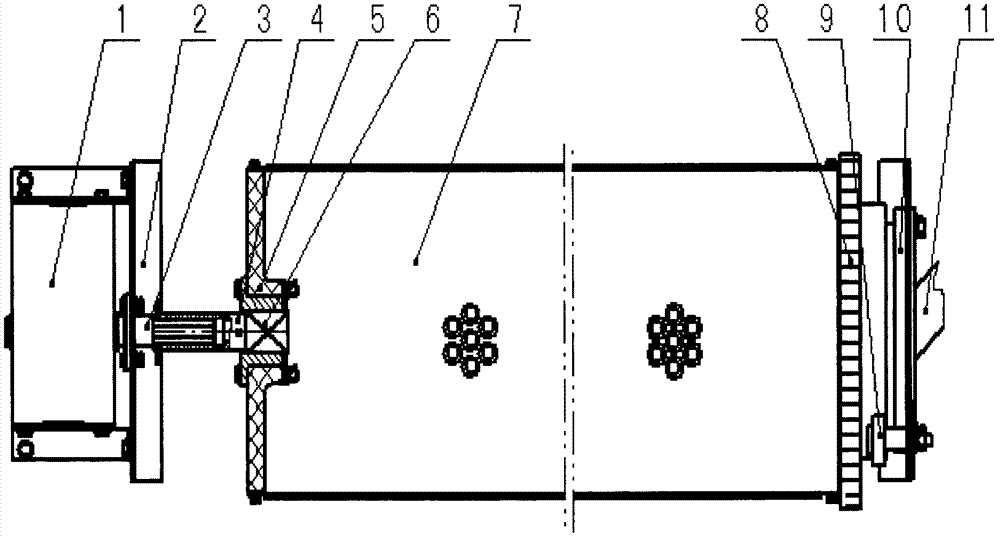

Multi-factor adjustable drum sieve and multi-factor adjustable drum sieving cleaning device

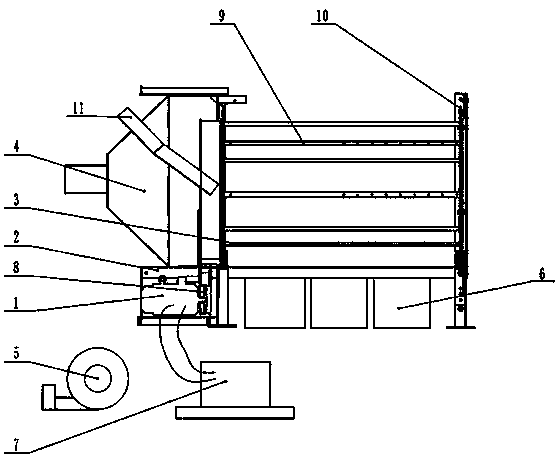

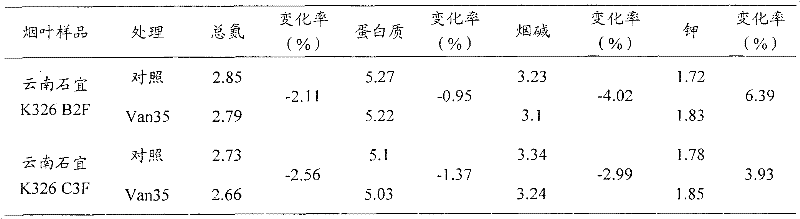

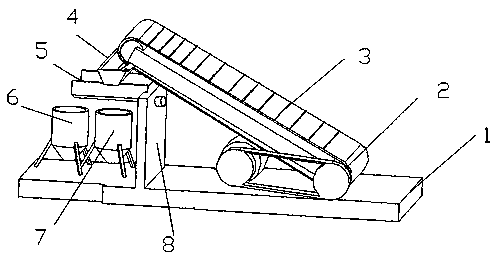

InactiveCN103920647ARaise the gradeImprove Grading QualityGas current separationEngineeringCentrifugal fan

The invention discloses a multi-factor adjustable drum sieve and a multi-factor adjustable drum sieving cleaning device. The multi-factor adjustable drum sieving cleaning device comprises a centrifugal fan (5), an air inlet cover (4), discharging boxes (6) and the drum sieve. The air inlet cover (4) is in a funnel shape, the small-opening end of the air inlet cover (4) serves as an air inlet to be connected with an air outlet of the centrifugal fan (5) through a pipe, the large-opening end of the air inlet cover (4) serves as an air outlet to surround one end of a drum sieve body (3) to form an air channel, a feeding opening (11) is formed in the upper portion of the air inlet cover (4) and provided with a feeding plate, an outlet of the feeding plate extends into the drum sieve body (3), and the discharging boxes (6) are placed below a machine frame (2). The multi-factor adjustable drum sieve and the multi-factor adjustable drum sieving cleaning device are easy and convenient to operate and good in sieving effect, the sizes of meshes of the drum sieve can be changed according to different material varieties, and the multi-factor adjustable drum sieve and the multi-factor adjustable drum sieving cleaning device are wide in application range and high in adaptability.

Owner:NANJING AGRICULTURAL UNIVERSITY

Classificator for dried fruits

InactiveCN103008225AImprove screening and grading efficiencyEasy to replaceSievingScreeningEngineeringDried fruits

The invention discloses a classificator for dried fruits. The classificator for the dried fruits comprises a stand. The stand is provided with a screen sorting mechanism mutually connected with a power drive mechanism; the screen sorting mechanism is a long tube-shaped screen which is arranged along the length direction of the stand and can rotate around the axis of the long tube-shaped screen; the inner wall of the long tube-shaped screen is provided with a plurality of material pushing ribs arranged in a thread form from the inlet direction to the outlet direction of the screen sorting mechanism; and a plurality of sorted receiving hoppers are paved at the bottom part of the long tube-shaped screen in sequence along the axis direction of the long tube-shaped screen. Through the spiral material pushing ribs arranged on the inner wall of the long tube-shaped screen and rotary screening and sorting, materials can move in time during a screening and sorting process, and therefore, the production efficiency of the screening and sorting is improved, the materials in the long tube-shaped screen can be completely sorted to the greatest extent, and the sorting quality is improved.

Owner:青岛老三东生物科技股份有限公司

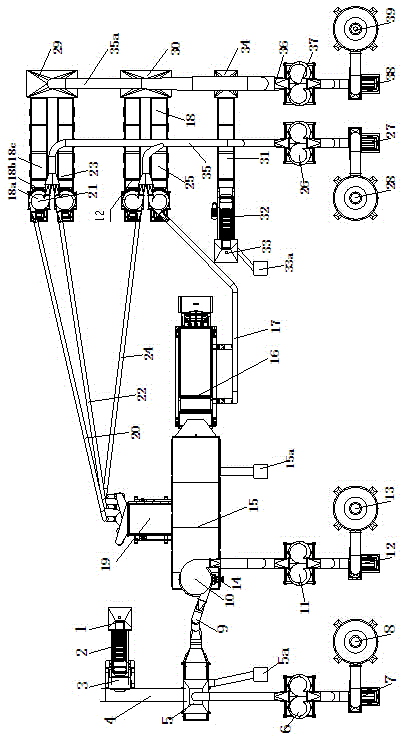

Tea leaf screening line

InactiveCN104941819AGuaranteed cleanlinessImprove cleanlinessPre-extraction tea treatmentVortex flow apparatusCycloneAgricultural engineering

The invention relates to a tea leaf screening line which comprises a feed port, wherein the left side of the feed port is connected with a first conveying belt placed transversely; a vertical tea cutting machine is mounted on the left side of the first conveying belt; the left side of the vertical tea cutting machine is connected with a second conveying belt placed longitudinally; a vibratory feeder is mounted on the front side of the second conveying belt; the lower end of the vibratory feeder is connected with a first sundry outlet; the front side of the vibratory feeder is connected with a first dedusting pipeline system; a first high pressure fan is mounted on the front side of the first dedusting pipeline system; a first pulse dust collector is mounted on the right side of the first high pressure fan; and the right side of the vibratory feeder is connected with a first cyclone feeding device by a first air pipe. The tea leaf screening line can automatically realize the functions of sorting raw tea leaves, removing impurities, dedusting, and cleaning the raw tea leaves, and has the advantages that the tea leaf screening line is easy and simple to operate, low in labor intensity and high in production efficiency, the cleanliness of the tea leaves is high, and the grading quality is high.

Owner:YIYANG SHENGXI MACHINERY EQUIP MFG

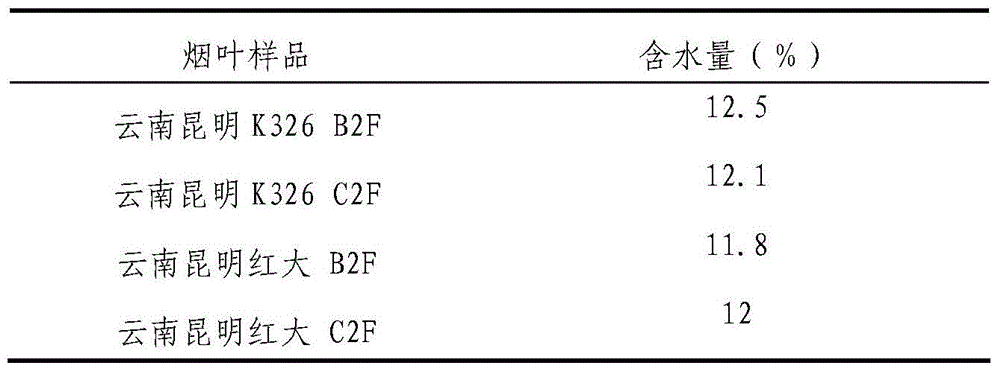

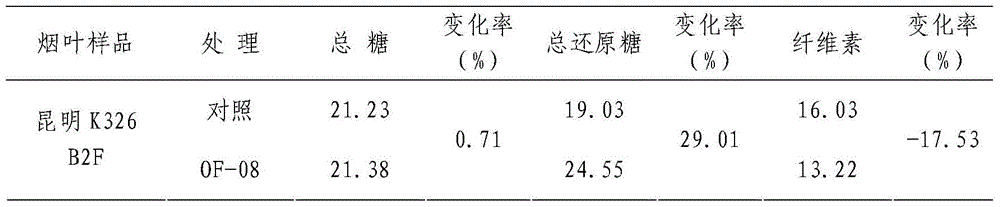

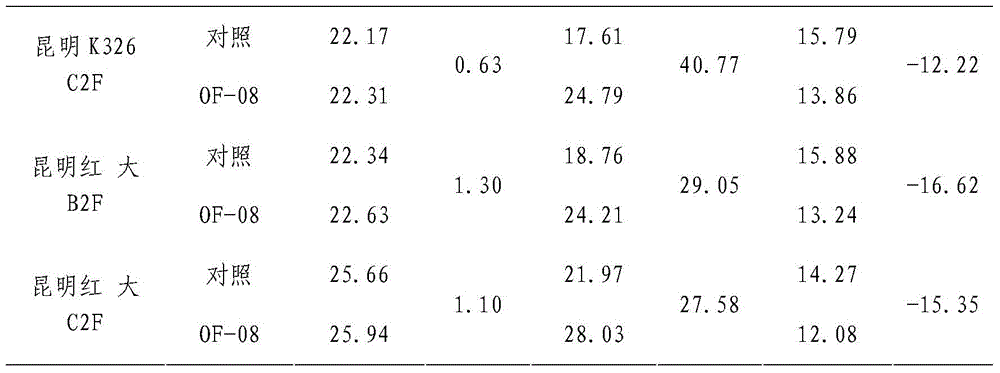

Method for improving quality of tobacco leaves by lysobacter sp

The invention discloses a method for improving the quality of tobacco leaves by lysobacter sp. The strain is classified and named as Lysobacter sp C8-1, and is preservatized at the General Microbiology Center of the China Microbial Culture Collection Management Committee on September 28, 2017, and the preservation number is CGMCC No. 1.16271. After microbiological analysis and 16S rDNA gene sequence analysis, it is indicated that the strain is a new type of bacteria. After being sprayed with C8-1 bacteria agent and fermented with alcoholization, the quality of tobacco leaves is improved, the availability of tobacco leaves is greatly improved, the fermentation of tobacco leaves is accelerated, the grade quality of tobacco leaves is improved, the aroma quality and reducing sugar content of tobacco leaves are increased, the content of protein, cellulose, total nitrogen and nicotine is decreased, and the ratio of sugar to nitrogen, the ratio of sugar to nicotine and the ratio of nitrogen to nicotine are increased, thereby making the chemical compositions in the tobacco leaves more harmonious and improving the sensory quality.

Owner:CHINA TOBACCO YUNNAN IND

Preparation method of premixed raw material of ferrite magnet presintering material

InactiveCN102070331AFully mechanical flipConsistent and precise granularityImpellerWorking environment

The invention relates to a preparation method of a premixed raw material of a ferrite magnet presintering material, belonging to the production field of the raw material of manufacturing industry. The method comprises the following steps: firstly, sending coarse slurry which is prepared by mixing premixed coarse material in a tube mill, performing continuous mixing and grinding in the tube mill to prepare uniform, regular and fine premixed raw material, then sending the premixed raw material to a large capacity precisely-controlled tank, and performing homogenizing treatment to the premixed raw material through the longitudinal circular stirring of pump delivery, the transverse stirring of the agitation impeller and the edge stirring of the vertical fins on the tank wall; and secondly, detecting the components, and adjusting accurately to prepare the premixed raw material with accurate components and uniform grain size. The method of the invention adopts continuous production and does not adopt the traditional and extensive batch production method of the ball mill, thus the production efficiency can be obviously increased, the labor intensity of the operator and the production cost can be reduced, the working environment can be improved, the grain size and components of the premixed raw material slurry product can be highly consistent and accurate and a solid foundation can be laid for the improvement of the quality grades of the downstream magnetic products.

Owner:WUHAN JINGHONG MAGNETIC IND

A kind of Bacillus pumilus and its use

ActiveCN101824391BImprove the quality of flue-cured tobaccoImprove usabilityBacteriaTobacco treatmentMicroorganismChemical quality

The invention discloses a bacillus pumilus and its application, belonging to the technical field of microorganisms. The production strain of the present invention is classified and named as Bacillus pumilus Van35; the preservation number is CGMCC No.3411. Spraying the strain preparation can increase the content of soluble total sugar and reducing sugar in tobacco leaves, and decrease the content of protein, total nitrogen and nicotine. Therefore, the ratios of sugar-to-nitrogen ratio, sugar-to-alkaline ratio and nitrogen-to-alkaline ratio tend to increase, which makes the chemical quality more harmonious and improves the smoking quality of tobacco leaves.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Vertical type sand making machine graded energy-saving feeding device

The invention relates to the technical field of sand making equipment, and particularly discloses a vertical type sand making machine graded energy-saving feeding device. The vertical type sand makingmachine graded energy-saving feeding device comprises a bottom seat, a conveying belt and a screening piece, wherein one end of the conveying belt is arranged on the bottom seat, a support plate is fixedly arranged below the other end of the conveying belt and on the upper surface of the bottom seat, the screening piece is arranged on the support plate, the screening piece comprises an arc screening plate and a motor, the arc screening plate is rotatably connected onto one side wall of the support plate through a central shaft, two groups of driven belt wheels are rotatably arranged on the other side wall of the support plate, a drive belt wheel is fixedly arranged on an output shaft of the motor in a coaxial mode, the drive belt wheel is connected with a driven belt wheel through a belt,two eccentric gears are rotatably arranged on the side wall of the support plate in a stagger mode, the eccentric gears are fixedly connected with the driven belt wheel, and a first sand making machine and a second sand making machine are respectively installed on two parts, at the tail end of the arc screening plate and below the arc screening plate, of the bottom seat. The vertical type sand making machine graded energy-saving feeding device has the advantages of being simple in structure, low in work load, high in work efficiency, good in grading quality, smooth in sliding, and convenientto popularize and implement.

Owner:ZAOZHUANG SNKSAN INTELLIGENT MACHINERY CO LTD

Method for improving quality of tobacco leaves by using blastococcus cavernae sp.

ActiveCN107760618AImprove qualityIncrease aromaTobacco preparationBacteriaSequence analysisMicroorganism

The invention discloses a method for improving the quality of tobacco leaves by using blastococcus cavernae sp.. The strain is classified and named as Blastococcus cavernae sp., and is preserved in the China Center for Type Culture Collection CCTCC, and the preservation number is M2016739. Microorganism property analysis and 16S rDNA gene sequence analysis show that the strain is a novel bacterium. After an SYSUZL-2 agent is sprayed to tobacco leaves, and after alcoholization fermentation, the fragrance quality of the tobacco leaves is improved, the content of reduction sugar is increased, thecontents of proteins, cellulose, total nitrogen and nicotine are reduced, the ratios of sugar to nitrogen, sugar to nicotine and nitrogen to nicotine trend are increased, chemical components of the tobacco leaves are relatively well harmonized, and the sensory quality of the tobacco leaves is also remarkably improved.

Owner:CHINA TOBACCO YUNNAN IND

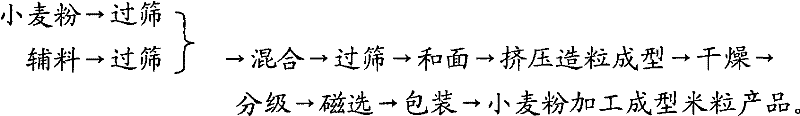

Product of rice grains formed by processing wheat flour and processing method thereof

Owner:HUBEI BAIDIAN IND

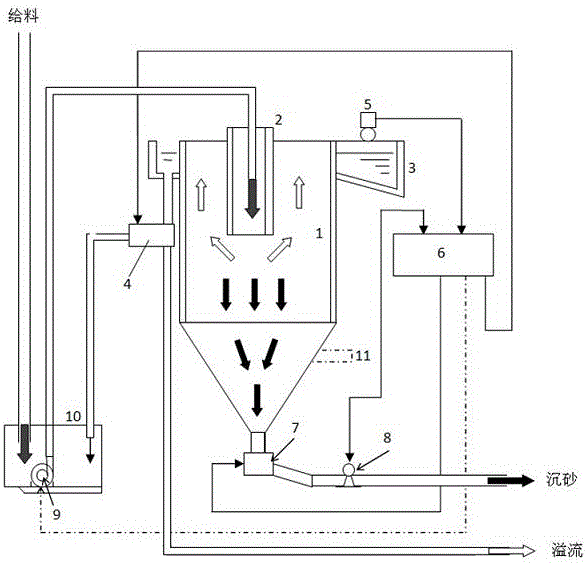

A solid-liquid classification device

ActiveCN104475230BImprove Grading QualityMeet the needs of useWet separationGranularitySolid particle

Owner:中铝国际技术发展有限公司

Transmission structure of cylindrical counter-bore classifying screen for corn seeds

The invention relates to a transmission structure of a cylindrical counter-bore classifying screen for corn seeds. The transmission structure comprises a reducer with a motor, a body, a cylindrical counter-bore screen and a feed pipe. The transmission structure is characterized in that the cylindrical counter-bore screen is arranged in the body, a feed end of the cylindrical counter-bore screen is fixed on a fixed ring on one side of the body, and a discharge end of the cylindrical counter-bore screen is fixed on a fixed disc on the other side of the body. The reducer is arranged on one side of the body. A connecting shaft is arranged on one side of the cylindrical counter-bore screen, and the connecting shaft is connected with the reducer through a reducer shaft. A fixed sleeve is arranged on the fixed disc. The fixed ring is connected with an inner guide hole through a riding wheel, and the inner guide hole is connected with the feed pipe. The transmission structure of the cylindrical counter-bore classifying screen for the corn seeds classifying is simple to operate and fine in classifying effect, and specification of cylindrical mesh size can be changed according to different material types, so that the transmission structure is wider in application and higher in applicability.

Owner:四川奥凯川龙农产品干燥设备制造有限公司

A kind of long sporogenous yeast and its application

ActiveCN104164372BIncrease aromaImprove the quality of flue-cured tobaccoFungiTobacco treatmentSporeMicroorganism

Owner:CHINA TOBACCO YUNNAN IND

Curing method of flue-cured tobacco with high content of water

The invention discloses a method for preparing flue-cured tobacco leaves with high water content, which includes (1) yellowing stage: the technical essentials are to accelerate the yellowing speed and reduce the consumption of contained substances. (2) Color fixing stage: The technical essentials are dehumidification in advance and enhanced dehumidification. (3) Dry gluten stage: the technical essentials are to control the dry bulb and limit the wet bulb. The method can reduce the risk of roasting dregs of flue-cured tobacco leaves with higher water content, improve the quality of tobacco leaves of this type, improve the grade quality after modulation, and increase the income of tobacco farmers.

Owner:CHINA TOBACCO GUANGXI IND

A method for comprehensive recovery of various metal elements in gold concentrate by step separation

ActiveCN109351465BTo achieve the purpose of economical and environmental protectionRealize eating dry and squeezing cleanFlotationProcess efficiency improvementSocial benefitsProcess engineering

The invention relates to a gradient separation and comprehensive recovery method for multiple metallic elements in gold concentrate. According to the process, the first-grade technology is utilizing an efficient mixed activator and a flotation reagent for carrying out pre-flotation on the low-sulfur gold concentrate, the second-grade technology is carrying out alkali leaching cyanide gold extraction on high-sulfur concentrate, the third-grade technology is leaching gold and silver out of low-sulfur tailings through an environment-friendly medicament and a wet method, the fourth-grade technology is giving priority to lead and zinc concentrating for high-sulfur gold concentrate cyanide tailings namely first low-gold high-sulfur concentrate, the fifth-grade technology is selecting copper fromlead and zinc tailings in an activation manner, the sixth-grade technology is roasting acid making and enriching gold, silver and iron to produce iron ore concentrate through copper tailings namely second low-gold high-sulfur concentrate, and the seventh-grade technology is leaching gold and silver out of the iron ore concentrate through an environment-friendly medicament and a wet method. According to the process, the chain for comprehensively utilizing a low-sulfur gold concentrate resource is prolonged, the comprehensive recovery value of the resource and the grade quality of the productsare improved, the complete utilizing of the gold concentrate resource is achieved, and relatively high economic benefits, environment benefits and social benefits are achieved.

Owner:SHANDONG GUODA GOLD

Preliminary flue-curing method for Honghua Dajinyuan tobacco leaves, obtained tobacco leaves and application thereof

ActiveCN108185496AImprove Grading QualityRaise the average priceTobacco preparationNicotiana tabacumChemical composition

The invention belongs to the field of tobacco curing, and particularly relates to a preliminary flue-curing method for Honghua Dajinyuan tobacco leaves. The method comprises the steps that fresh Honghua Dajinyuan tobacco leaves are subjected to six-stage flue-curing, and the six-stage flue-curing includes a yellowing earlier stage, a yellowing intermediate stage, a yellowing later stage, a fixation earlier stage, a fixation later stage and a stem drying stage, wherein the flue-curing temperature of the yellowing earlier stage is 32-33.5 DEG C, and the difference between the flue-curing temperature and the wet bulb temperature is 0.5-1 DEG C. The invention further relates to the tobacco leaves obtained through the method and application thereof in tobacco products. The preliminary flue-curing method can improve the Honghua Dajinyuan grade quality, the auxiliary set tobacco proportion is decreased, the average price of Honghua Dajinyuan flue-cured tobacco is increased, and the appearancequality, the chemical composition and sensory quality of the flue-cured tobacco are improved.

Owner:CHINA TOBACCO FUJIAN IND

Tobacco flue-curing and amending agent

InactiveCN1289013CIncrease the amount of aromaIncrease aromaTobacco preparationPotassium nitratePhosphate

The present invention belongs to tobacco flue-curing and amending technology. The tobacco flue-curing and amending agent consists of licorice, potassium gluconate, potassium citrate, potassium nitrate, ammonium dibasic phosphate, fructose, sugar and water. It can raise the quality of treated tobacco in the process of tobacco flue-curing and amending. The said product can be formed into solid, liquid, aerosol or other forms.

Owner:吴昊

Method for Improving Tobacco Leaf Quality by Utilizing Bacillus burrowing Bacillus

ActiveCN107760618BImprove qualityIncrease aromaTobacco preparationBacteriaSynechococcusSequence analysis

The invention discloses a method for improving the quality of tobacco leaves by using Bacillus burrowing bacteria. The strain used was classified as Blastococcus cavernae sp, which was preserved in the National Center for Type Culture Collection CCTCC on December 9, 2016, with the preservation number M2016739. The microbiological characteristics analysis and 16S rDNA gene sequence analysis showed that the strain was a new bacterium. Spraying SYSUZL-2 bacterial agent on tobacco leaves and then undergoing alcohol fermentation can increase the aroma quality and reducing sugar content of tobacco leaves, and reduce the content of protein, cellulose, total nitrogen and nicotine, and the ratio of sugar to nitrogen, sugar to alkali and nitrogen to alkali The ratio tends to increase, which makes the internal chemical components of tobacco leaves more harmonious, and the sensory quality is also significantly improved.

Owner:CHINA TOBACCO YUNNAN IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com