Patents

Literature

33results about How to "Improve the quality of flue-cured tobacco" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bacillus pumilus and application thereof

ActiveCN101824391AImprove the quality of flue-cured tobaccoImprove usabilityBacteriaTobacco treatmentMicroorganismBacillus pumilus

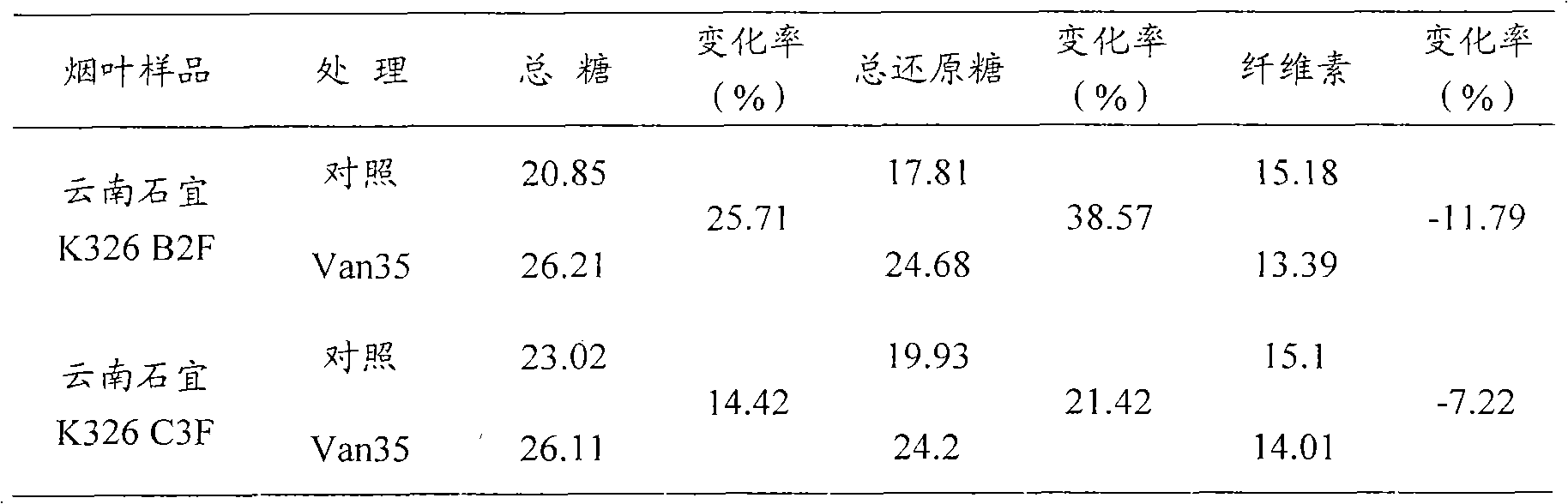

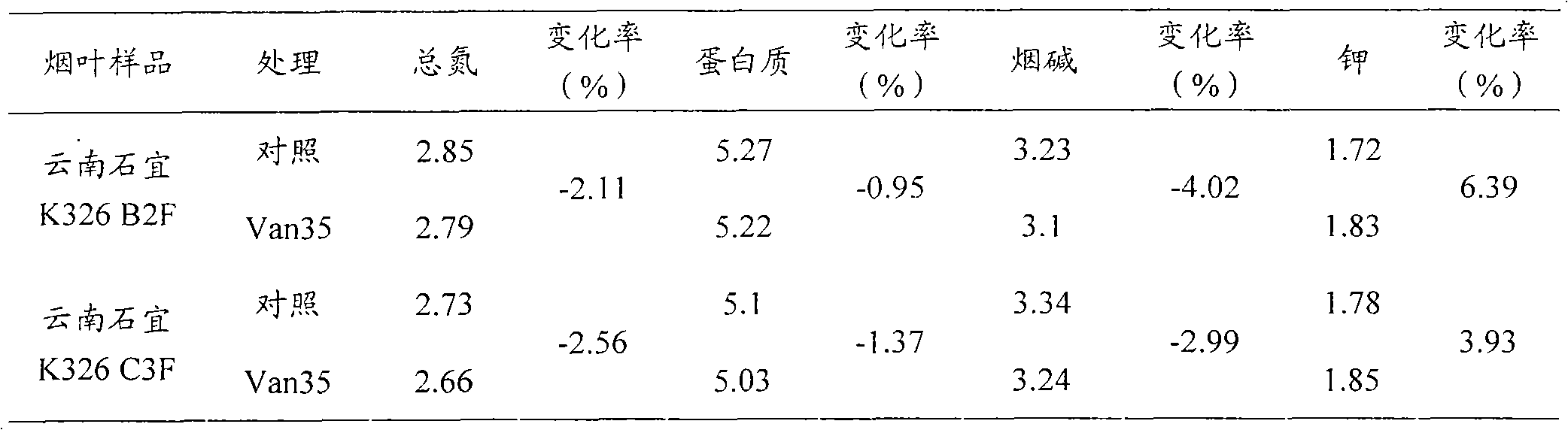

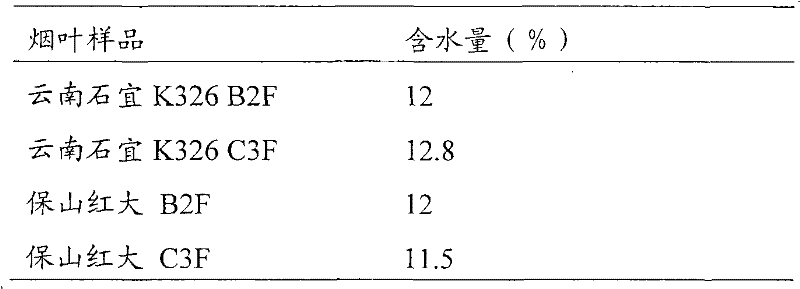

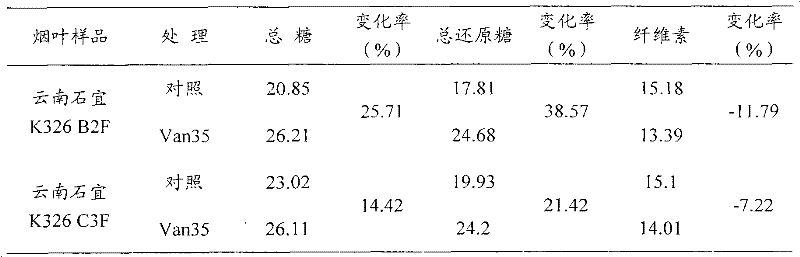

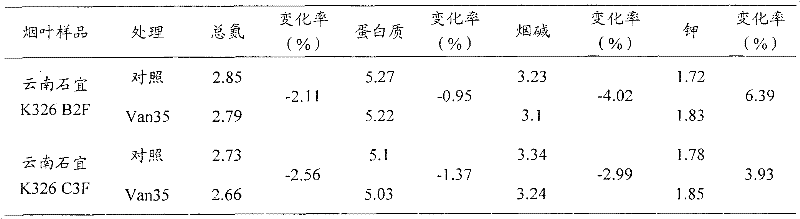

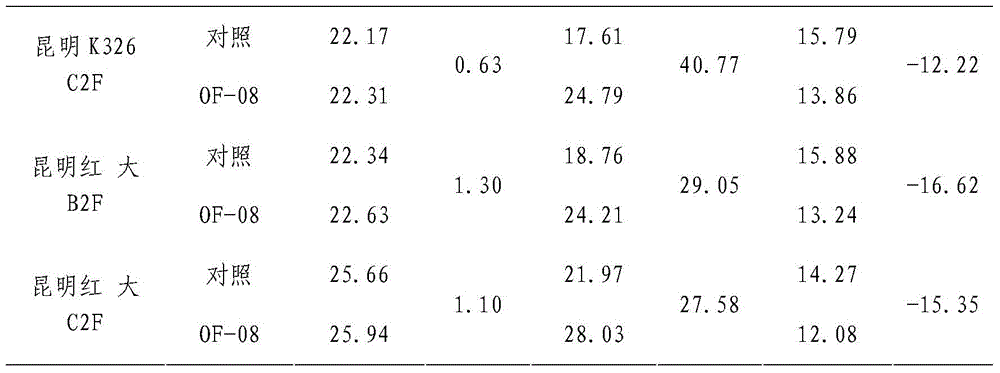

The invention discloses bacillus pumilus and application thereof, which belong to the technical field of microbes. The produced strain of the invention is named Bacillus pumilus Van35 according to classification, and the preservation number of the strain is CGMCC No.3411. When the strain preparation is spayed, the soluble total sugar content and the reducing sugar content of tobaccos can be increased, while protein, total nitrogen and nicotine content are reduced. Therefore, specific values of the ratio of dextrose to nitrogen, the ratio of total sugar to betaine and the ratio of total nitrogen to total alkaloid tend to rise, the quality of chemicals is high and the quality of the smoke panel test is improved.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

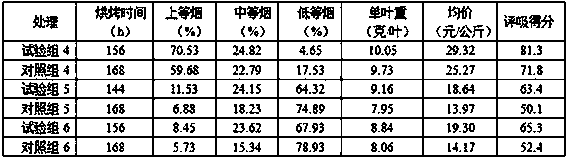

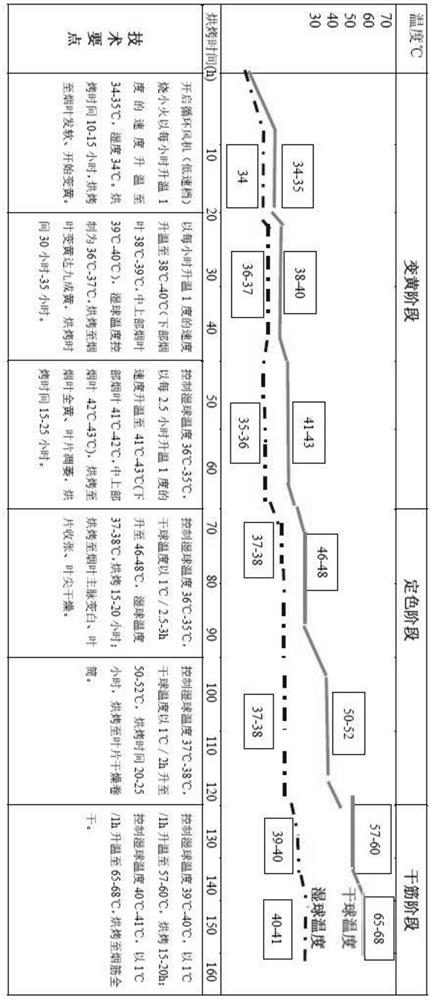

A curing method for improving protein degradation rate of tobacco leaves

The invention discloses a curing method for improving the protein degradation rate of tobacco leaves. The curing method comprises the following steps: A. harvesting; B, weaving a rod and charging thatfurnace; C, flue-curing: the flue-cured tobacco leaves are flue-cured after the oven is charged, and the flue-cured tobacco leaves can be obtained through the yellowing period, the color fixing period and the dry rib period. The method of the invention has extremely great significance for ensuring the high-quality raw material supply of the cigarette industry by regulating the curing time, optimizing the curing process, improving the protein degradation rate of the tobacco leaves, regulating the protein content, and improving the quality of the bulk curing tobacco leaves.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

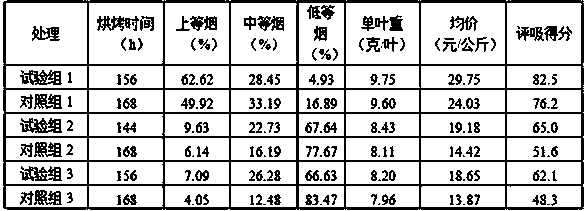

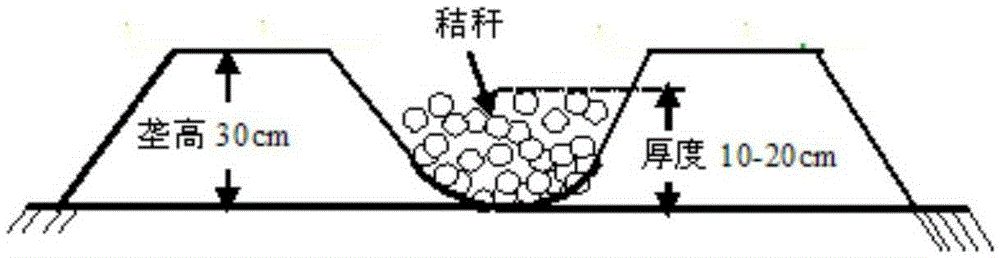

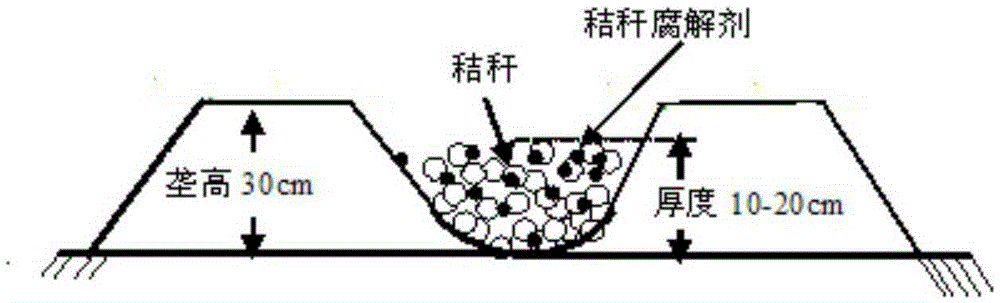

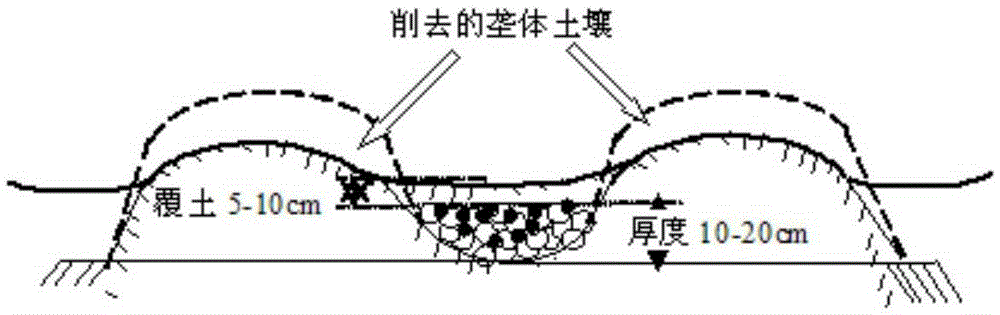

Farming method for returning straw to field locally in corn and flue-cured tobacco rotating system

ActiveCN105145003AImprove soil improvement effectReduce laborCrop conditionersMowersCropping systemTillage

The invention discloses a farming method for returning straw to the field locally in a corn and flue-cured tobacco rotating system. The method is applied to flue-cured tobacco and corn rotation plough land in a single cropping system and comprises the steps that firstly, corn is ridged to be cultivated, two rows of corn are planted per ridge, the height of each ridge is 30+ / -2 cm, the corn wide row spacing between every two adjacent ridges is 70+ / -5 cm, the narrow row spacing between two rows of corn on each ridge is 50+ / -5 cm, and the distance between plants is 25-30 cm; after the corn is harvested, ploughing is needless, original ridges and furrows are used, and the cut-off straw is directly spread over the furrows to be returned to the field; secondly, microorganism fertilizer is scattered on the straw, and soil on the ridges falls to the furrows for earthing and burying of the straw; in the next year, flue-cured tobacco base fertilizer is scattered in the furrows where the corn straw is buried 10-15 days before the flue-cured tobaccos are transplanted, the flue-cured tobaccos are planted in a single-row-ridge mode, the row spacing is 120+ / -5 cm, and the distance between plants is 50-60 cm; no-tillage ridge gathering is conducted towards the insides of the furrows along the two sides of each furrow, and ridges are formed for cultivating the flue-cured tobaccos. According to the farming method, the corn straw and the flue-cured tobacco straw are directly applied to the tobacco field locally, and therefore sustainable development of a tobacco region is effectively realized.

Owner:HUNAN AGRICULTURAL UNIV

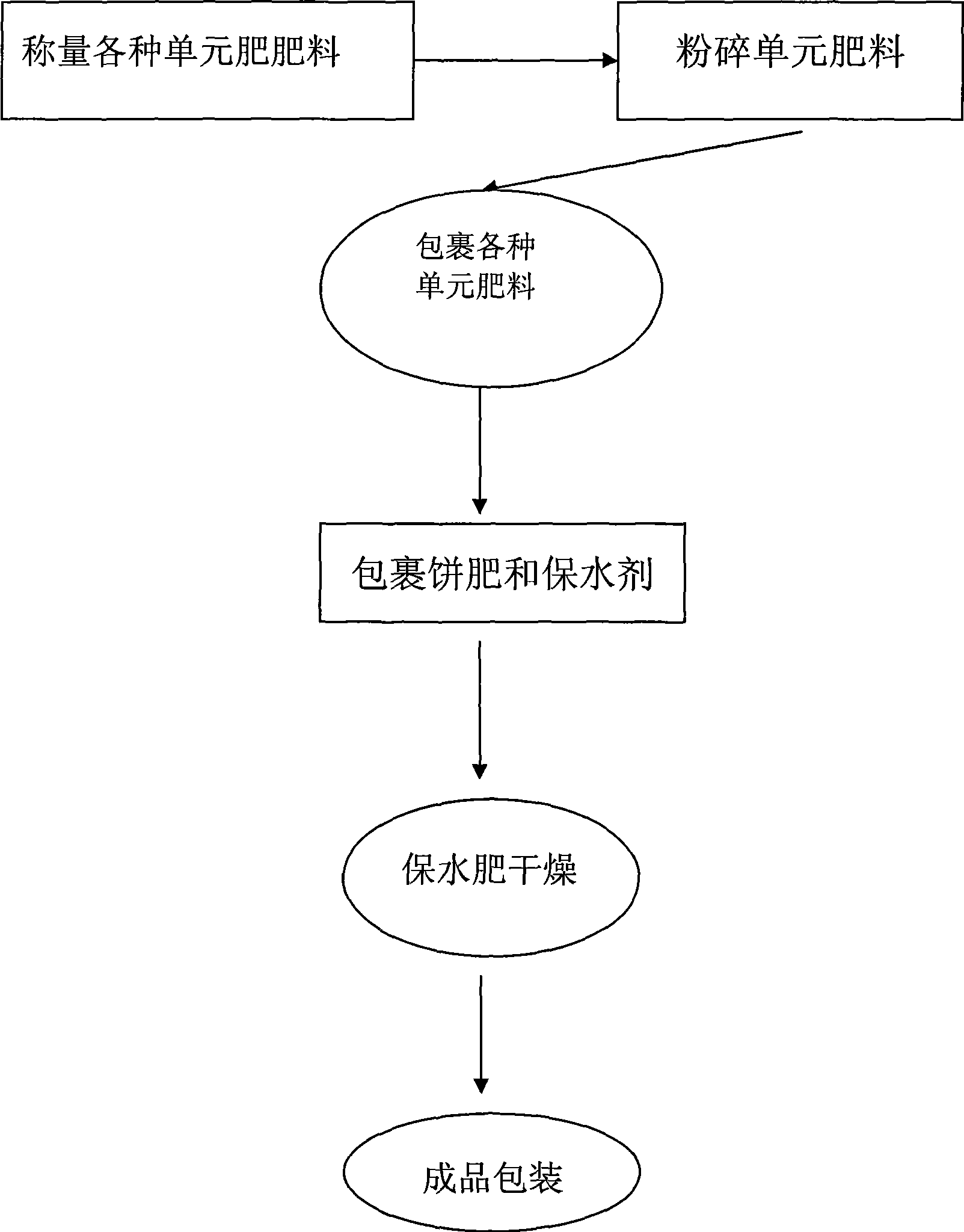

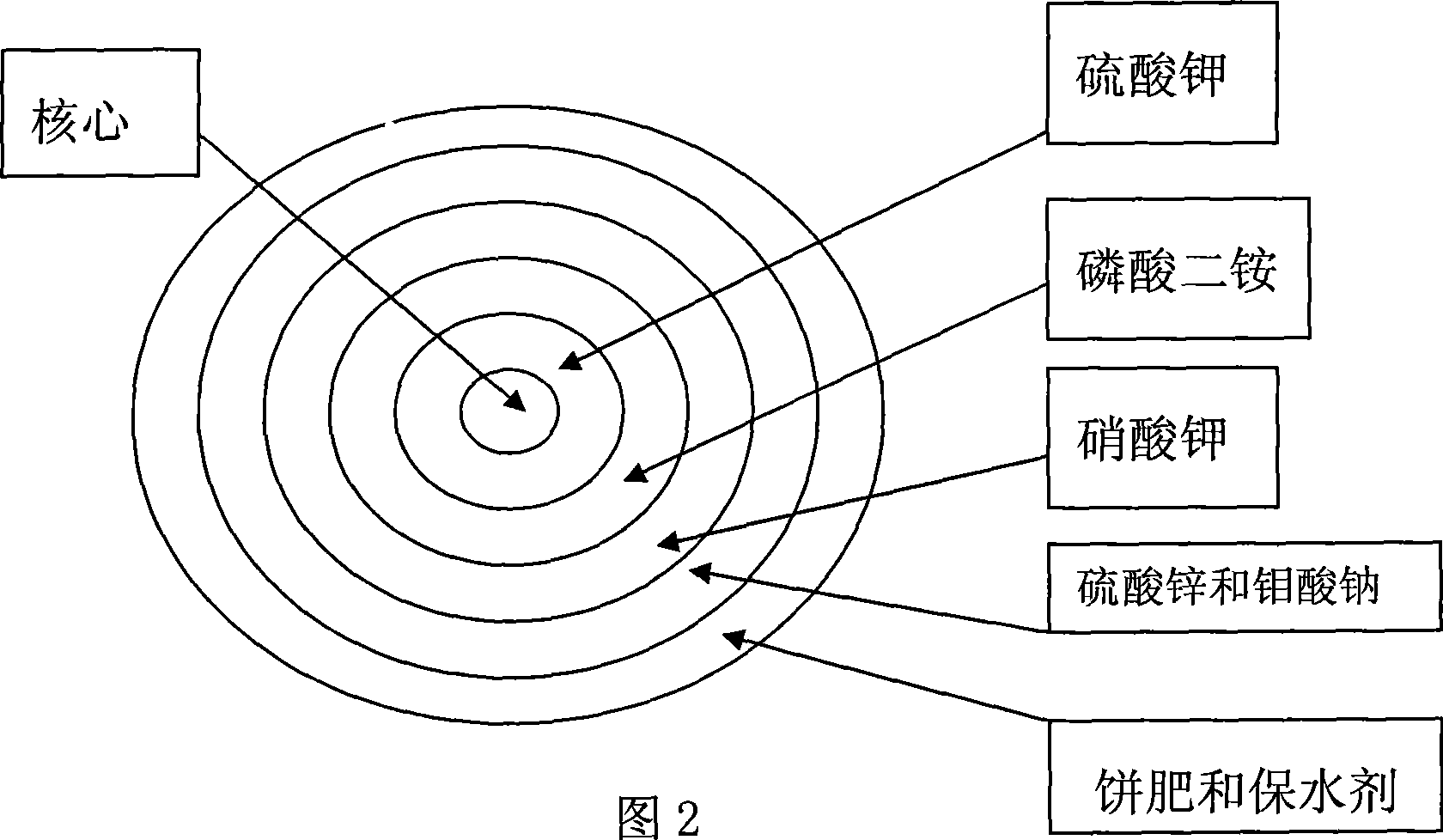

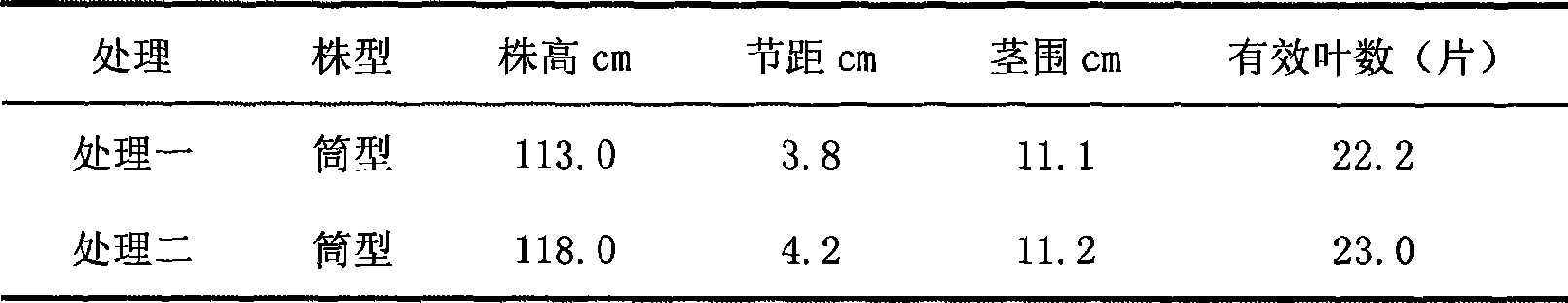

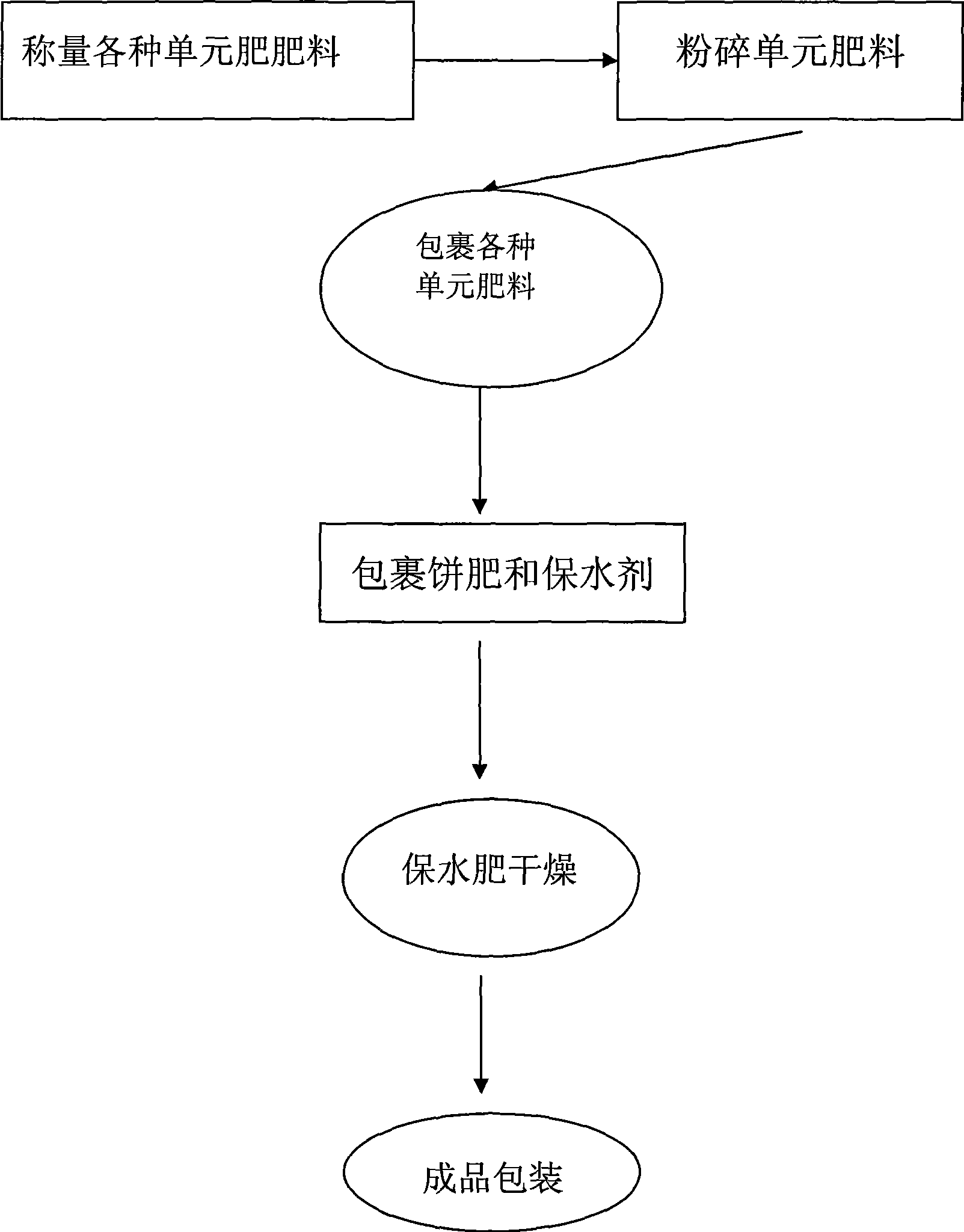

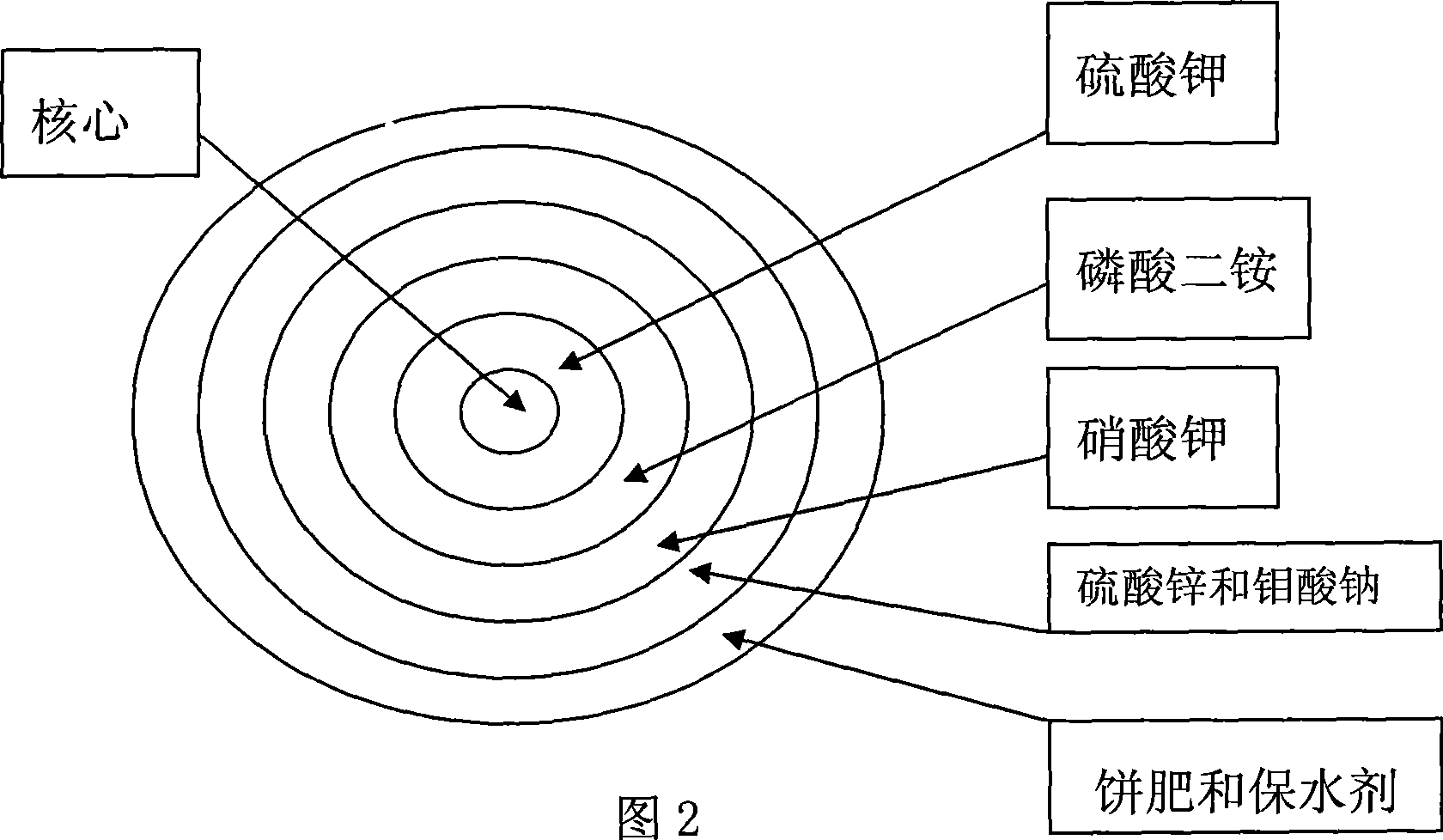

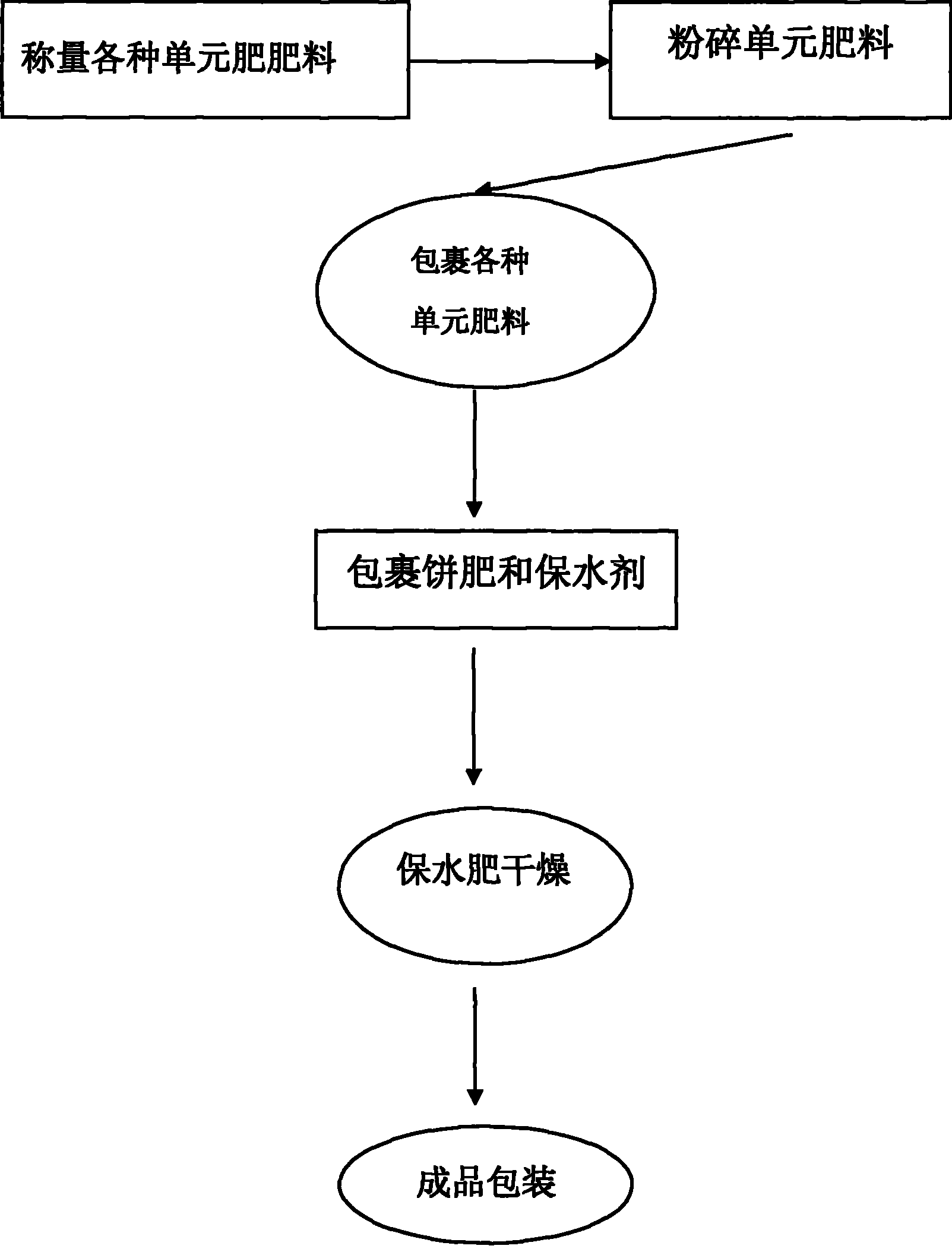

Water holding controlled release fertilizer special for tobacco and method for producing the same

InactiveCN101367686AConsistent particlesUniform particle sizeAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersAdhesiveDissolution

A water-holding controlled release fertilizer for tobacco exclusively and a preparation method thereof are provided. The water-holding controlled release fertilizer includes the following materials by the weight percentage: 2 percent to 4 percent of sand grains, 10 percent to 14 percent of lemery, 10 percent to 14 percent of potassium nitrate, 10 percent to 14 percent of diammonium phosphate, 22 percent to 26 percent of cake fertilizer, 0 percent to 4 percent of zinc sulfate, 0 percent to 0.4 percent of sodium molybdate, 20 percent to 24 percent of adhesive A, 10 percent to 14 percent of adhesive B and 1 percent to 3 percent of water retention agent. The invention adopts the method that the water retention agent is at the outmost layer so that the water retention layer absorbs water at first. The water retention layer does not contact chemical fertilizer directly. The influence of the chemical fertilizer on the absorbing effect of the water retention agent is reduced. At the same time, according to the balanced fertilization principle of cured tobacco, the kind and the quantity of the deficient element of tobacco soil is supplemented. Hereby, the compound fertilizer especially for cured tobacco of the invention is designed and manufactured. By fixing the grain diameter of a core, nutrition dissolution property is changed by fertilizer enwrapping method in order to control the release of potash fertilizer effectively. Moreover, the water retention agent absorbs water, which consequently realizes the dynamic equilibrium of fertilizer release and plant absorption.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

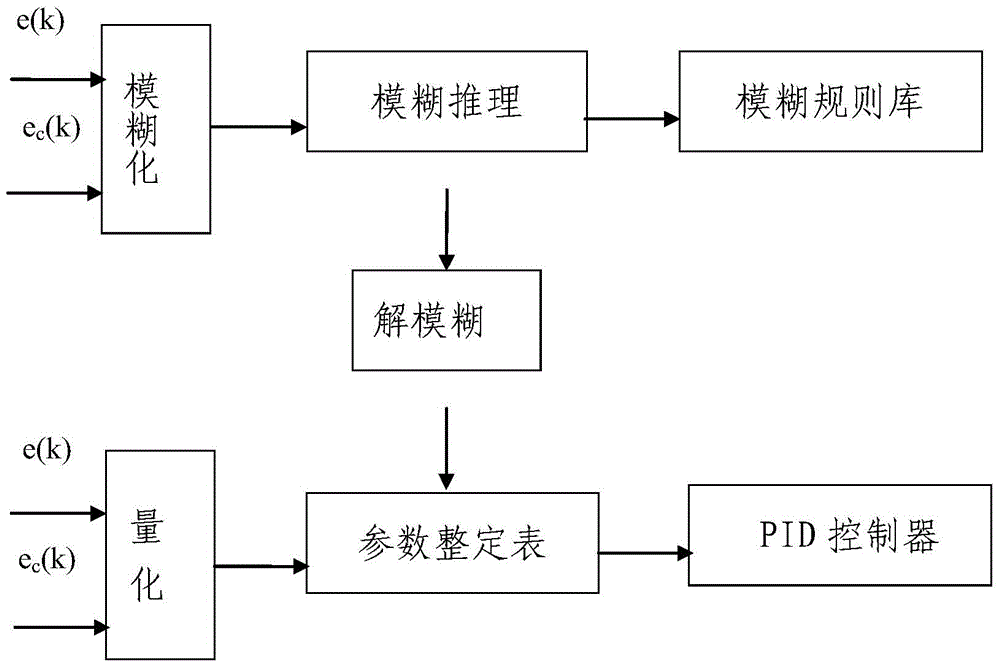

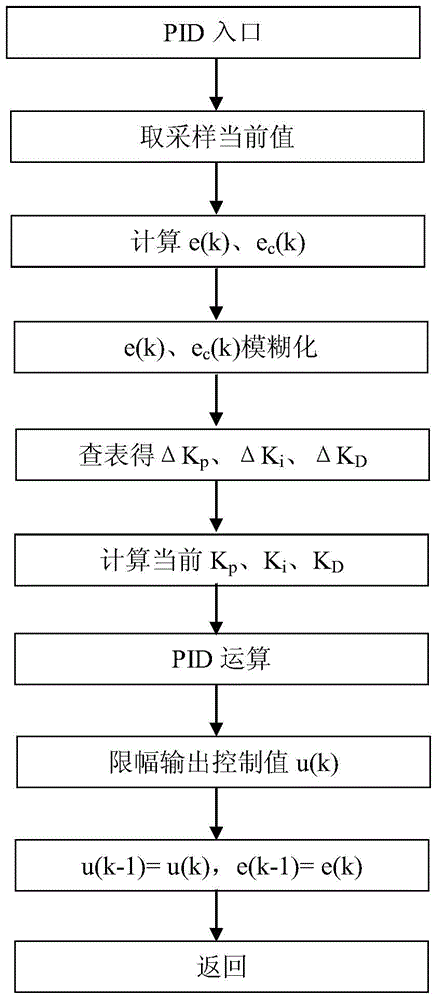

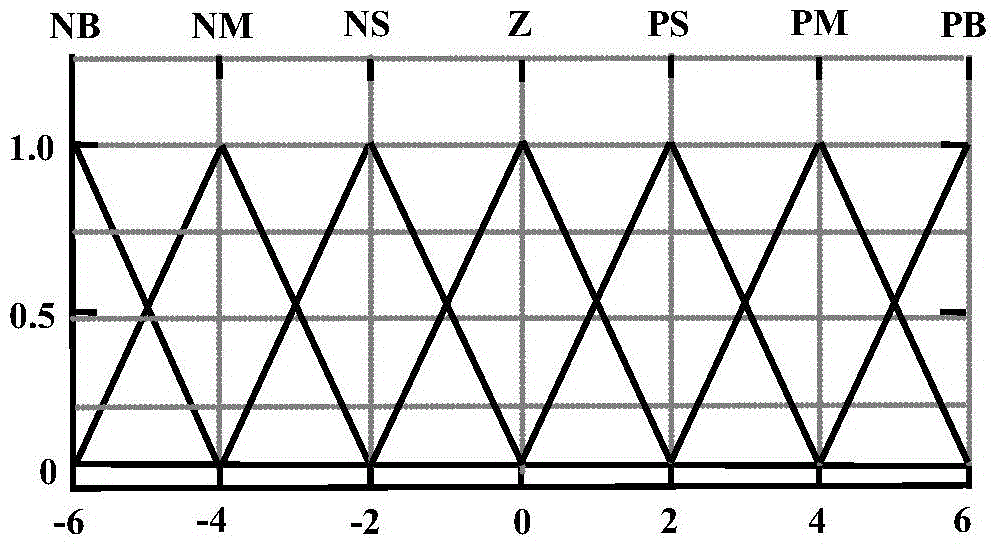

Temperature and humidity control algorithm for intensive curing barn controller

InactiveCN104375415AImprove the baking effectExtended opening timeSimultaneous control of multiple variablesAdaptive controlProportion integration differentiationOptimal control

The invention discloses a temperature and humidity control algorithm for an intensive curing barn controller and relates to the technical field of environmental control in facility agriculture. Optimized PID (proportion integration differentiation) algorithm is used, and accurate control of temperature and humidity is realized by a controller. The controller comprises a PID controller, a relay link and a fuzzy controller for calibrating PID parameters; the PID controller completes control algorithm and calculates the control amount of output; initial parameters of the PID controller are achieved through the relay link; the fuzzy controller conducts online and real-time adjustments of the PID parameters of KP, Ki and KD according to deviation e and deviation rate of change ec so that the PID controller has adaptive capacity, and the system is always in an optimal control state. The temperature and humidity control algorithm for the intensive curing barn controller has the advantages of calculating parameters and variation amount of various environmental conditions in a curing barn, realizing accurate control of the temperature and humidity of the curing barn, and the like. Furthermore, the temperature and humidity control algorithm for the intensive curing barn controller can be used as a temperature and humidity controller in an intensive curing barn in domestic regions of any different latitude to conduct algorithm.

Owner:长沙瑞和数码科技有限公司

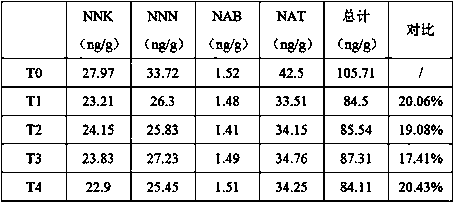

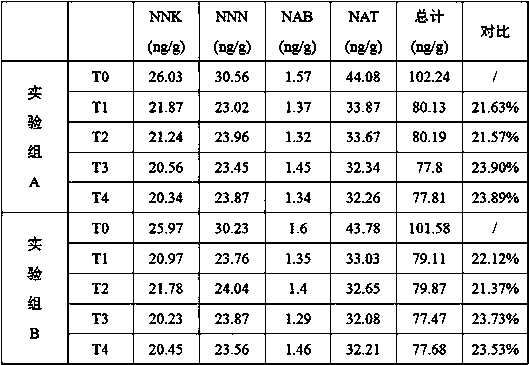

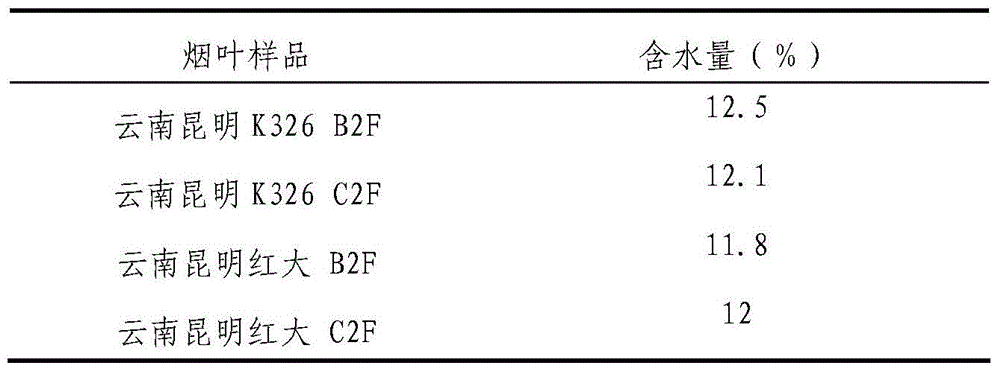

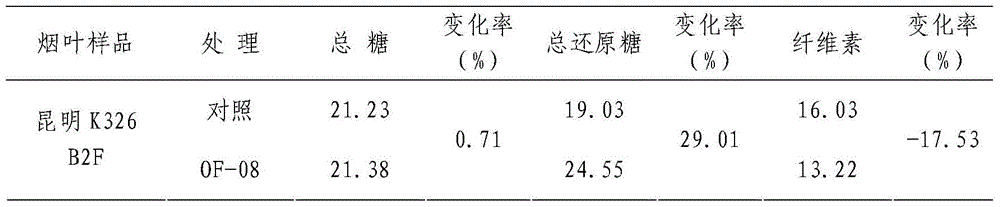

Curing method for reducing TSNAs in different varieties of flue-cured tobaccos by utilizing strains

ActiveCN110786532AProve uniquenessReduce the content of TSNAsTobacco preparationTobacco treatmentBiotechnologyNicotiana tabacum

The invention discloses a curing method for reducing TSNAs in different varieties of flue-cured tobaccos by utilizing strains. The method comprises the following steps of harvesting fresh tobacco leaves, with the proper maturity, of the flue-cured tobaccos; classifying the harvested fresh tobacco leaves and then braiding the tobacco leaves into rods; preparing a bacterial solution with the OD600 value being 1 by using at least one strain in 05-101, J45 and J54, and then uniformly spraying the bacterial solution to the surface of the tobacco leaves which have been braided into the rods; loadingthe inoculated tobacco leaves which have been braided into the rods into a bulk curing barn; and curing the tobacco leaves which are loaded in a furnace, and obtaining the tobacco leaves with the lowTSNAs content through a yellowing stage, a color fixing stage and a stem drying stage. The special bacterial solution is inoculated to the fresh tobacco leaves which are about to be loaded in the furnace, and the stage changes of the environmental temperature and humidity in a drying chamber of the curing barn in the curing process are controlled according to the varieties of the tobacco leaves,so that the degradation of the TSNAs in the flue-cured tobaccos is promoted, the purpose of controlling the TSNAs content of the tobacco leaves to improve the quality of the flue-cured tobaccos is achieved, and the great significance is achieved for reducing the harm of the TSNAs in the tobaccos to the human health and the living environment.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

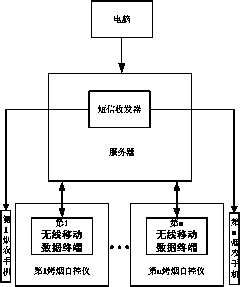

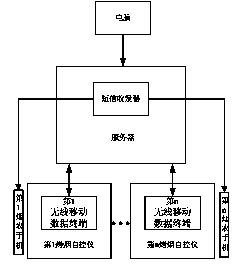

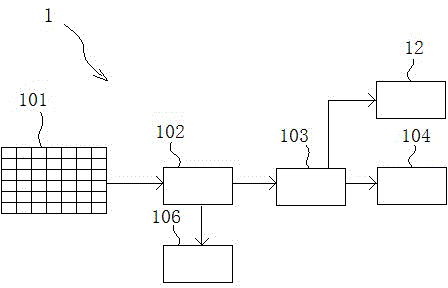

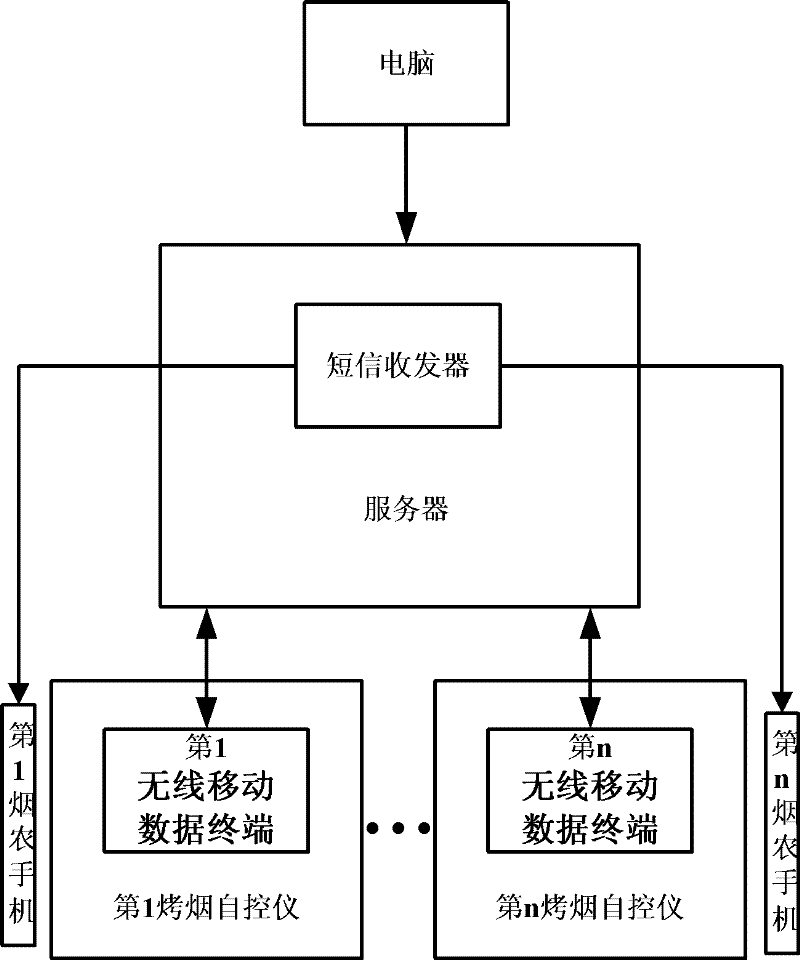

Wireless remote monitoring system for tobacco leaf roasting

InactiveCN101822416ACutting costsIncrease productionTobacco preparationProgramme total factory controlMobile data terminalTransceiver

The invention provides a wireless remote monitoring system for tobacco leaf roasting, which is characterized by comprising a computer, a server and a plurality of tobacco roasting automatic control instruments, wherein the computer is in communication connection with the server through Internet; each tobacco roasting automatic control instrument is provided with a wireless mobile data terminal; and the wireless mobile data terminal is connected with the server based on a TCP communication protocol. The server is provided with a short message transceiver, and the short message transceiver is in wireless communication connection with multiple mobile phones of tobacco growers. The computer is a 3G palm computer. The wireless remote monitoring system for tobacco leaf roasting can save the cost, and improve the tobacco roasting quality and production efficiency.

Owner:HENGYANG NORMAL UNIV

Cultivation method of rice stubble flue-cured tobacco

InactiveCN106489498AIncreasing the thicknessStay moist and plumpFertilising methodsPlant cultivationAgricultural scienceNitrogen fertilizer

The invention provides a cultivation method of rice stubble flue-cured tobacco. By improving the planting density of the rice stubble flue-cured tobacco and reducing the nitrogen fertilizer consumption, especially, increasing the topdressing fertilizer nitrogen ratio, reducing the nitrogen fertilizer consumption at the early stage, increasing the topdressing fertilizer application frequency, applying topdressing fertilizer nitrogen and water and other measures and other group regulation and control cultivation techniques, not only the high quality and reasonable yield of the rice stubble flue-cured tobacco can be guaranteed, but also the nitrogen fertilizer utilization efficiency of the flue-cured tobacco can be significantly improved, and a green, nitrogen-reducing, high-yield synergy effect can be achieved.

Owner:HUNAN AGRICULTURAL UNIV

Flue-cured tobacco flue-curing barn control system and control method thereof

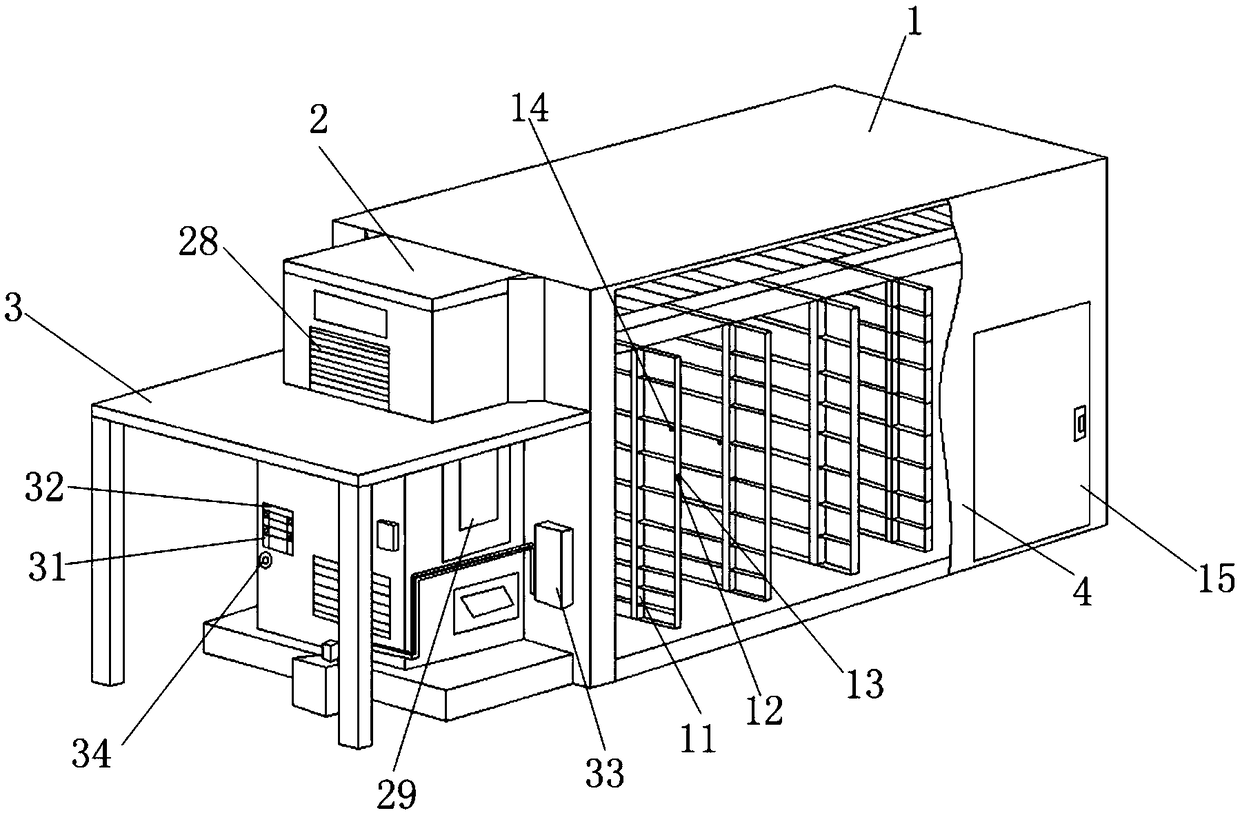

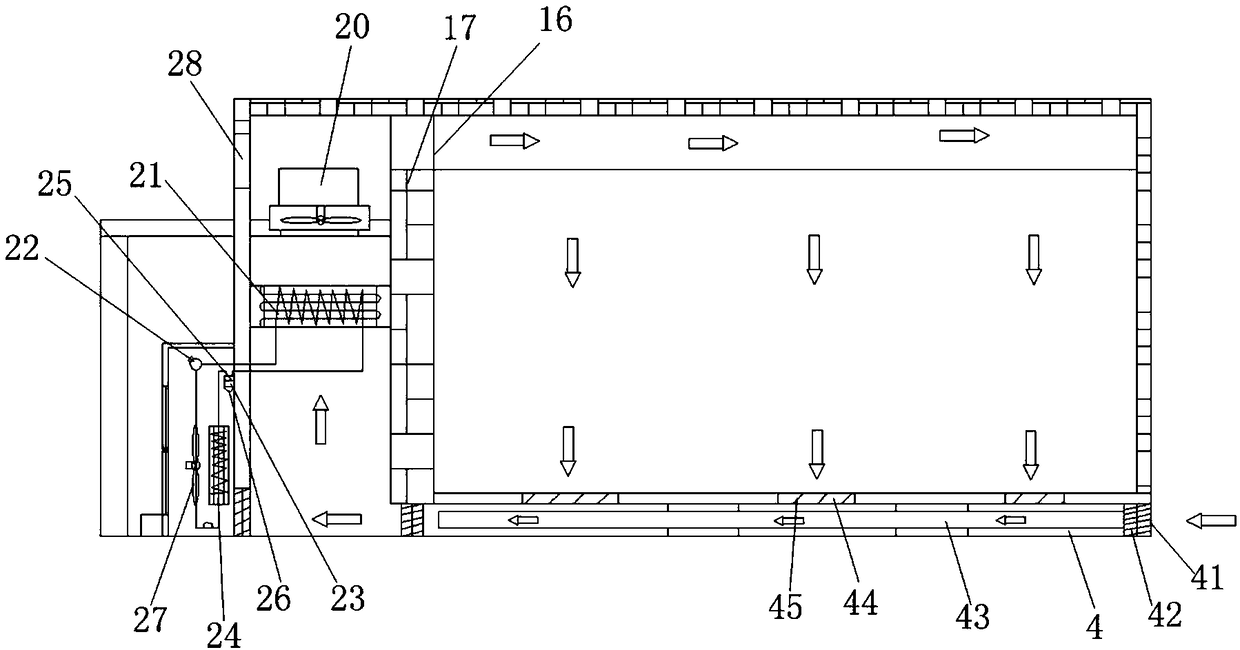

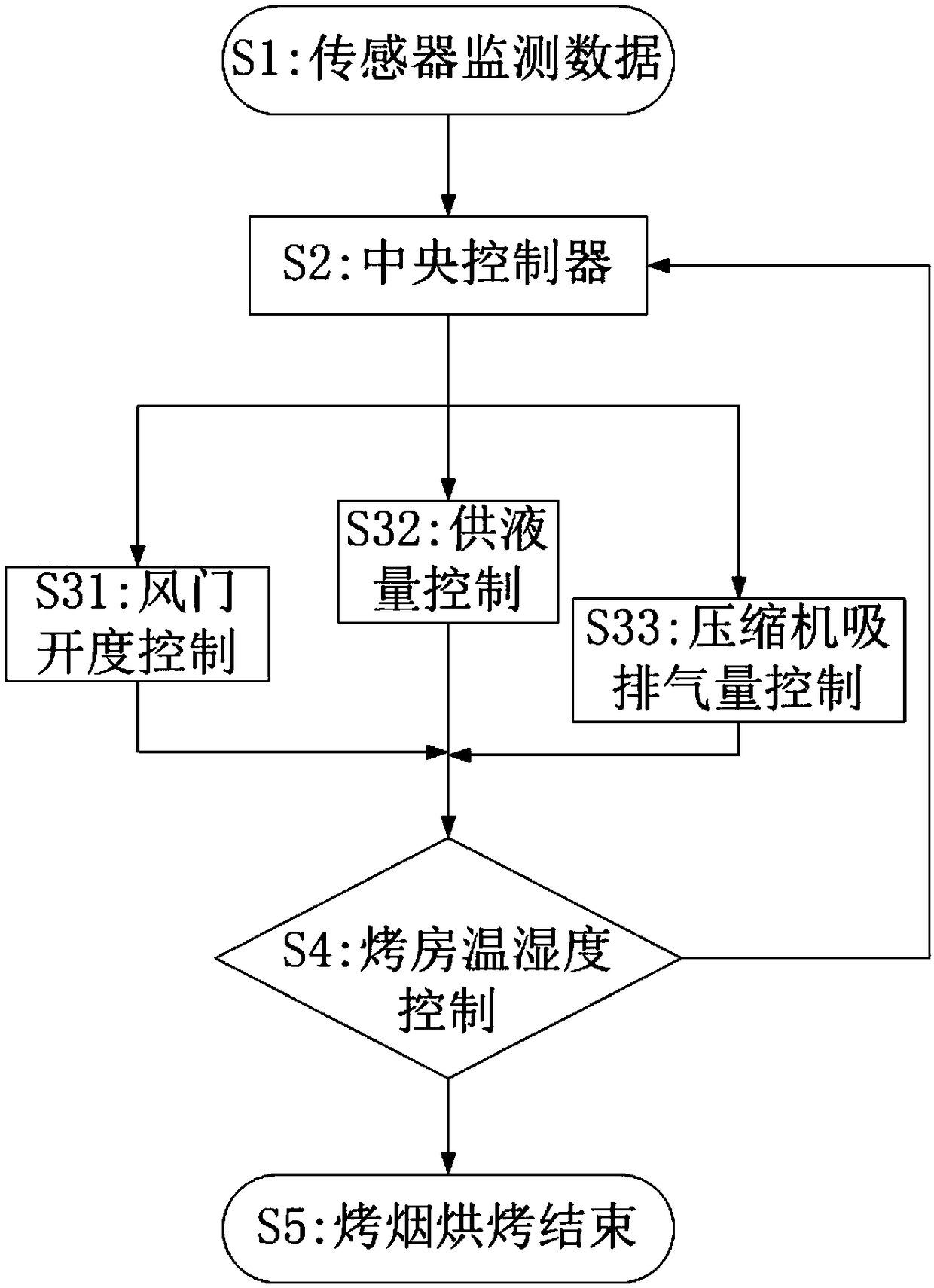

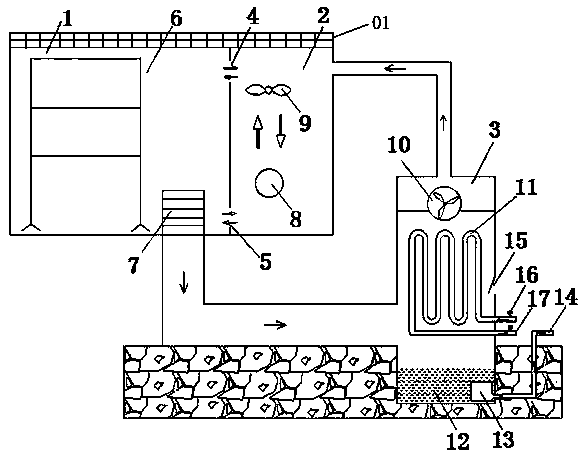

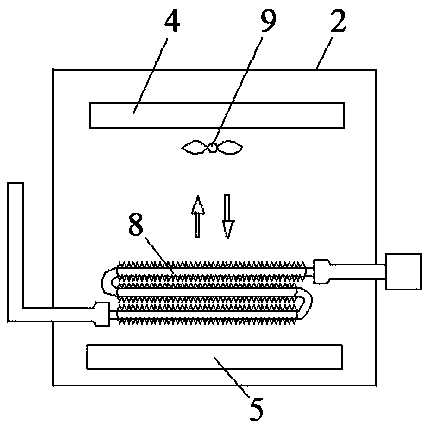

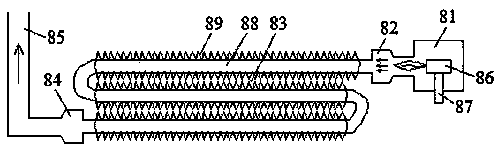

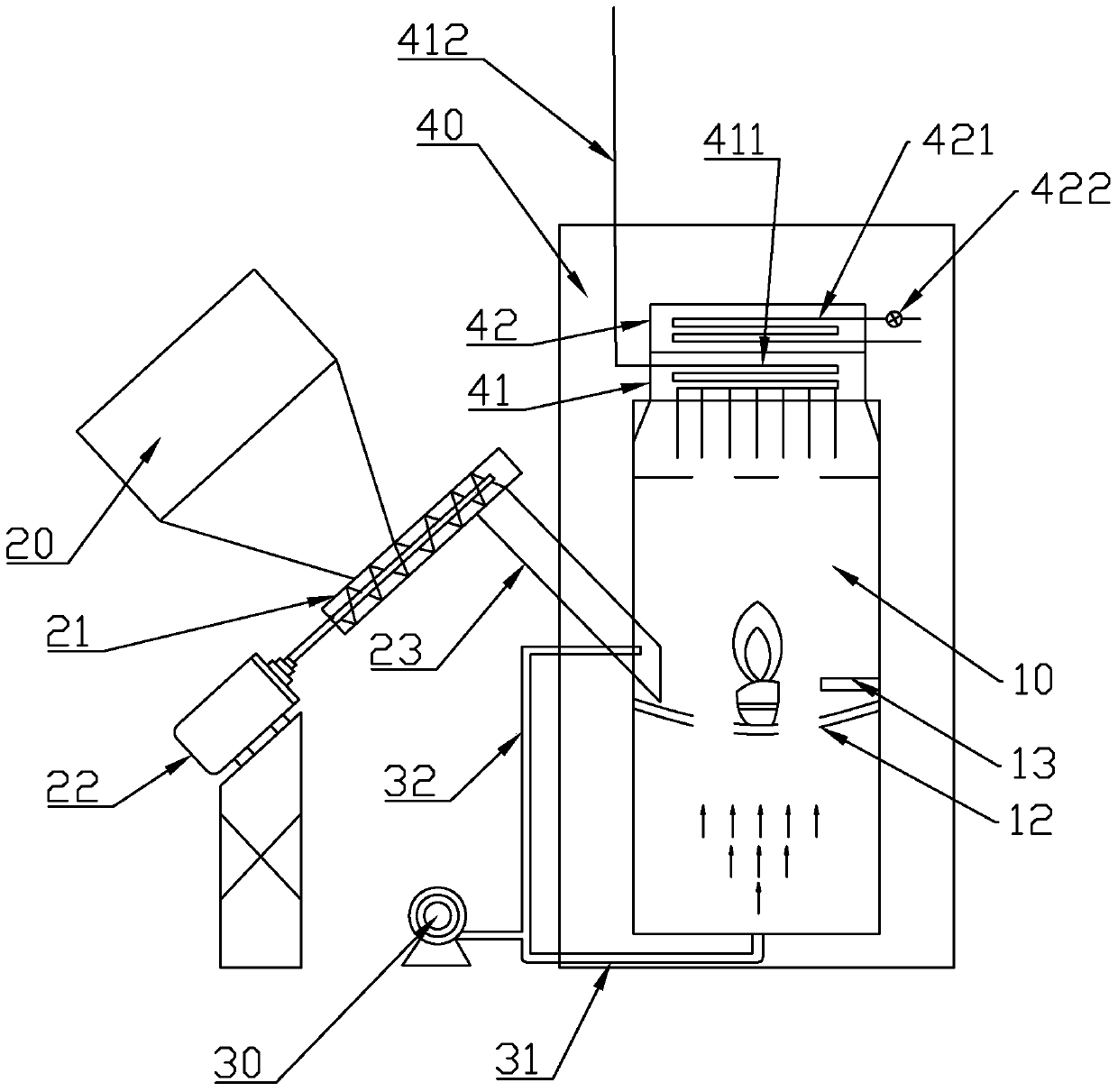

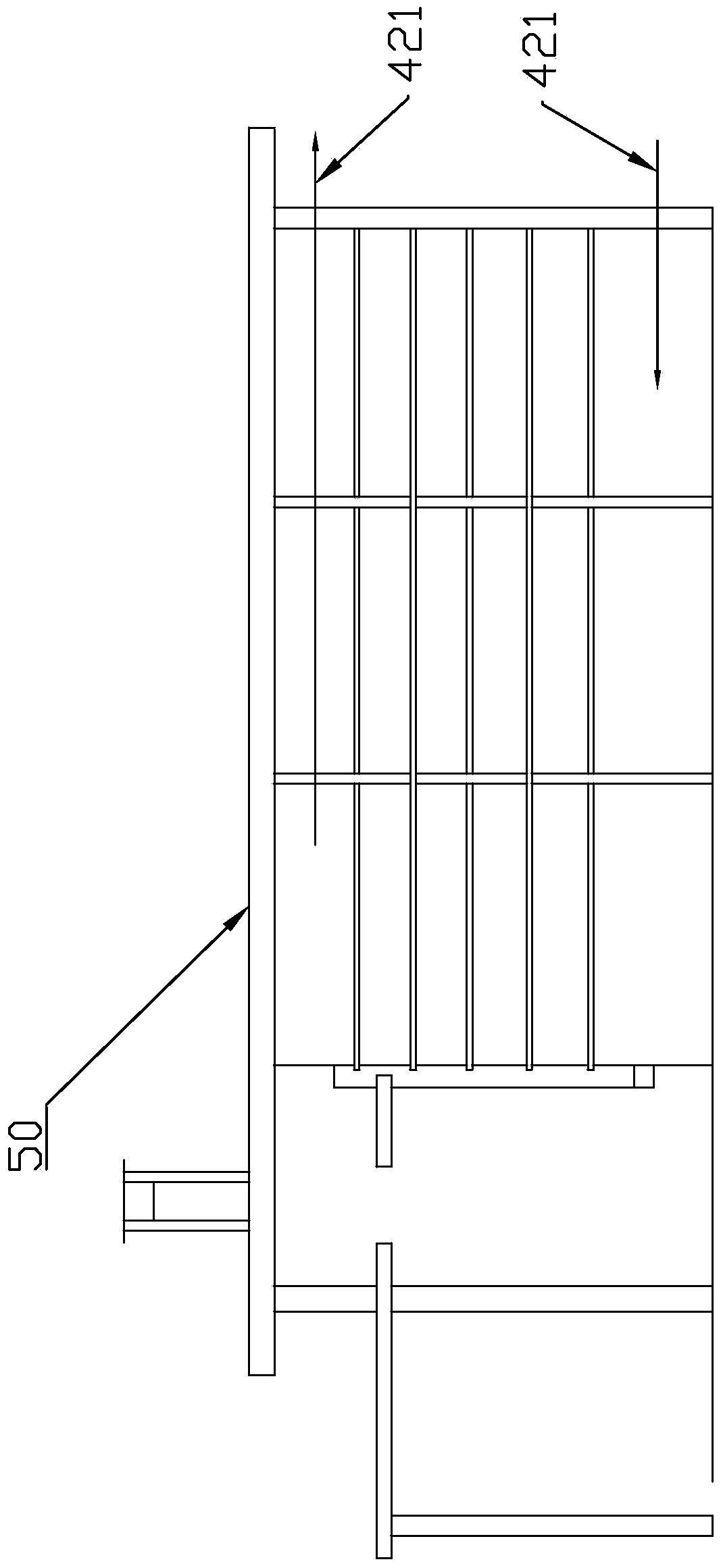

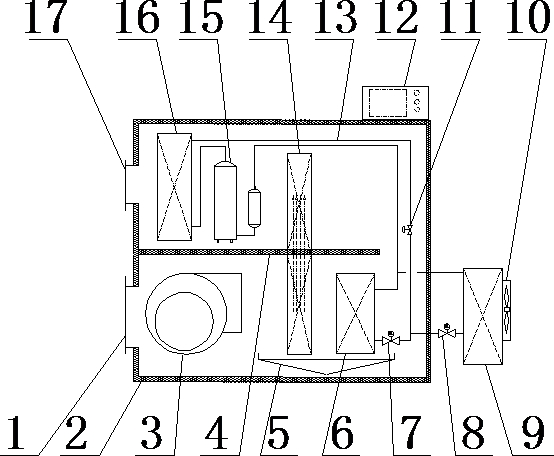

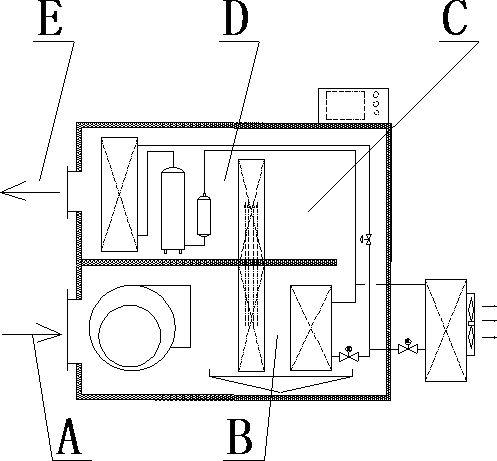

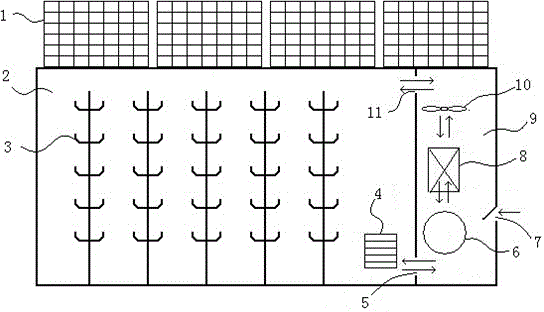

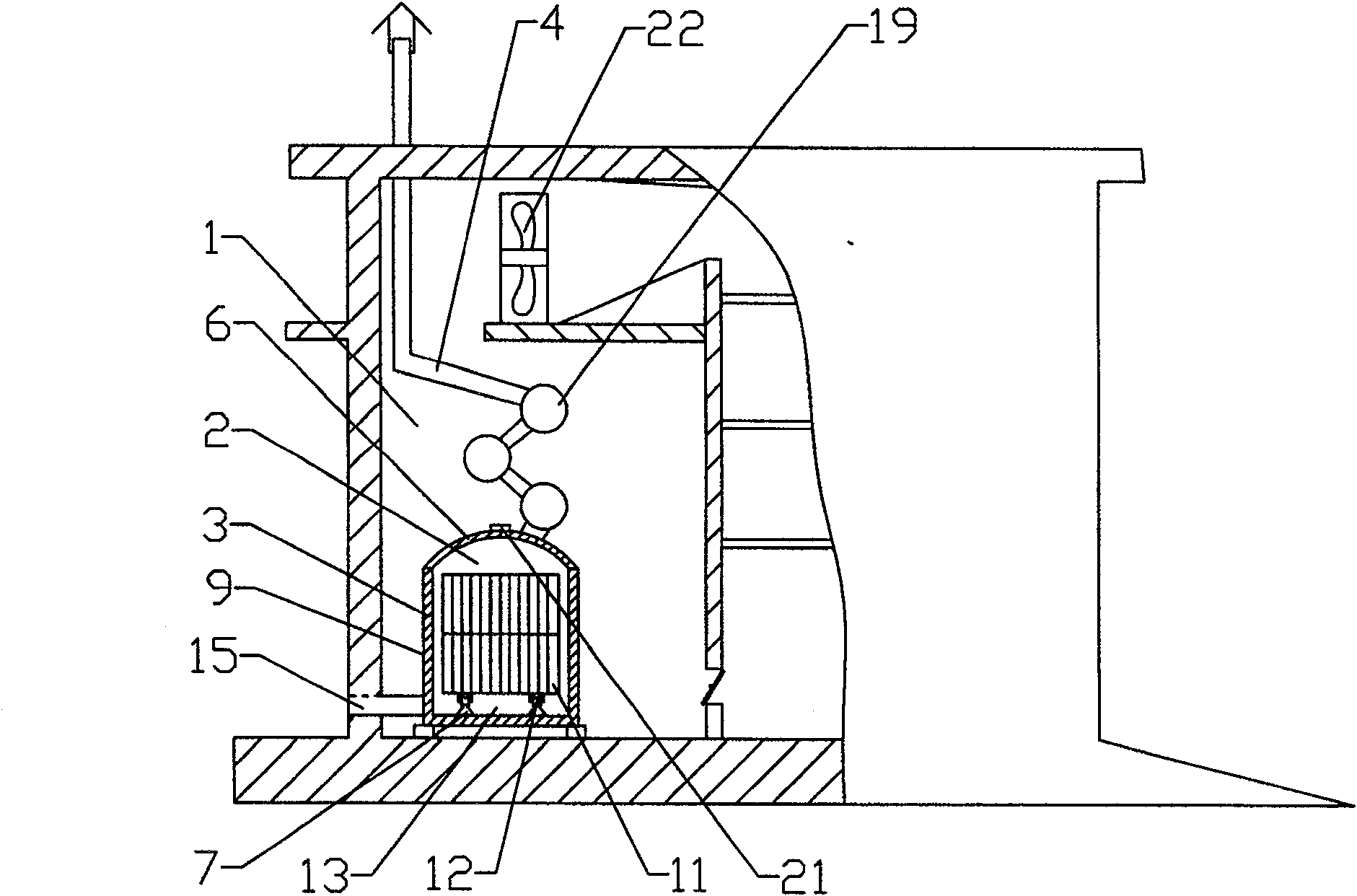

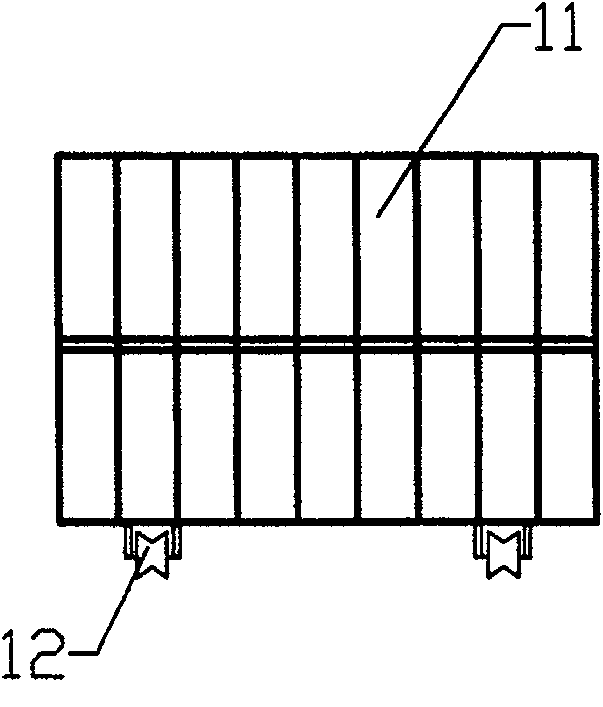

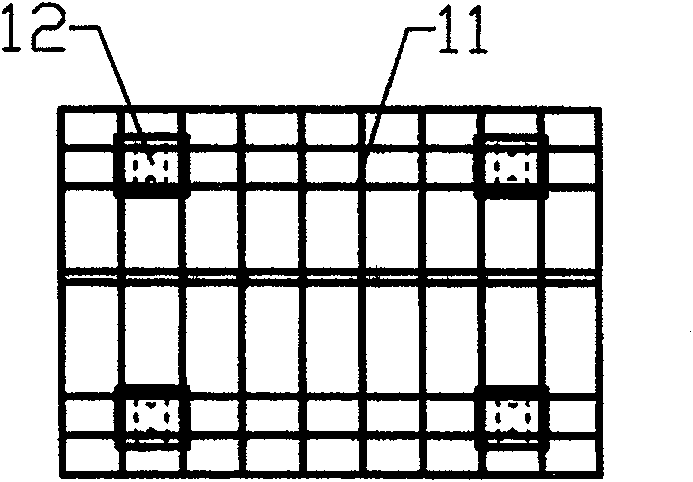

PendingCN109007949ASolve pollutionSolve efficiency problemsTobacco preparationMeasurement devicesControl systemThree stage

The invention provides a flue-cured tobacco flue-curing barn control system and a control method thereof, and relates to the technical field of flue-curing of flue-cured tobacco. The flue-cured tobacco flue-curing barn control system comprises a flue-curing chamber (1), a heat pump unit chamber (2), a retaining wall (3), and a moisture exhaust passage (4). The moisture exhaust passage (4) is disposed below the flue-curing chamber (1). The flue-curing chamber (1) is adjacent to the heat pump unit chamber (2). The retaining wall (3) is horizontally arranged. The flue-curing barn is convenient toset up and install, has a long service life, and can greatly improve the utilization rate of heat energy by the use of the heat pump unit chamber, thereby reducing the labor cost. The control methodof the flue-cured tobacco flue-curing barn control system accurately controls the temperature and humidity of the flue-curing barn by controlling the return air, and guarantees the quality of the flue-cured tobacco strictly according to the requirements of the three-stage flue-curing process.

Owner:GUIZHOU TOBACCO CORP QIANXINAN CORP

Method for improving quality of flue-cured tobacco in red soil

InactiveCN104232098AImprove qualityPromote growthOrganic fertilisersSoil conditioning compositionsPotassiumTotal nitrogen

The invention discloses a method for improving quality of a flue-cured tobacco in red soil. An oxygen fertilizer and silicon, calcium, magnesium, phosphorus and potassium fertilizers are fertilized into a tobacco field of which soil is red soil; the application amount of the oxygen fertilizer is 1.0-2.0g per plant; the application amount of the silicon, calcium, magnesium, phosphorus and potassium fertilizers is 50-100kg per mu; the application method comprises the following steps: 1) sampling soil, and testing a pH value; and 2) determining to fertilize different amounts of oxygen fertilizer, and silicon, calcium, magnesium, phosphorus and potassium fertilizers according to different pH values. According to the method for improving the quality of the flue-cured tobacco in the red soil, the ventilation condition of the soil is improved, the moisture and fertilizer preservation capacities of the soil are enhanced, meanwhile, the rhizosphere soil reducing substances can be reduced, the effects of increasing temperature, increasing oxygen and promoting rooting of tobacco seedlings are achieved, the total nitrogen content of the tobacco leaves can be increased, the harmony of chemical components of the tobacco leaf is improved, especially reduction of nicotine is facilitated, the yield and the quality of the tobacco leaves are improved, and the method is especially suitable for large-area popularization and application on the tobacco field with the red soil.

Owner:INST OF SOIL FERTILIZER & RESOURCE ENVIRONMENT JIANGXI ACAD OF AGRI SCI

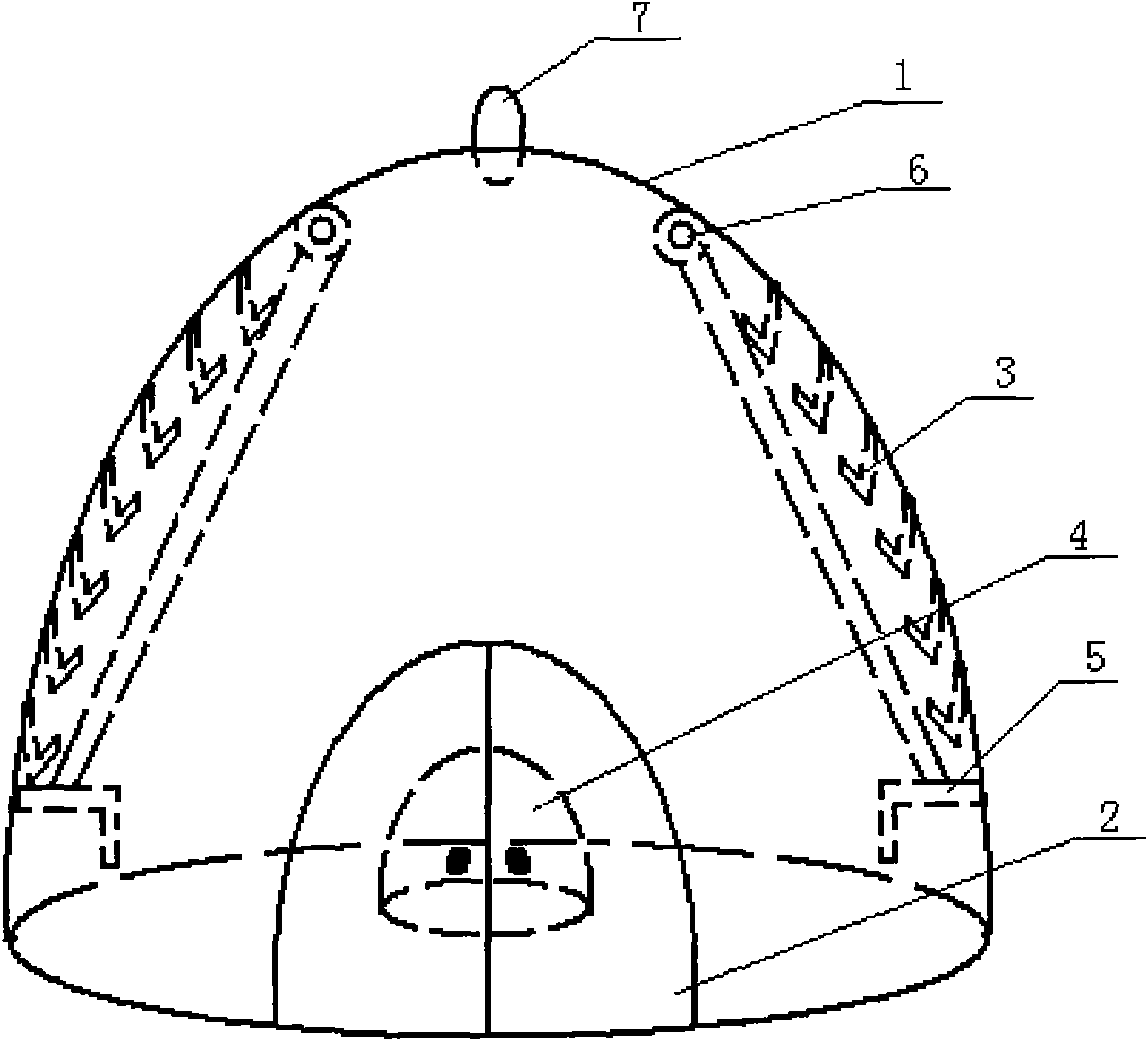

Cyclically solar-heated tobacco curing barn

InactiveCN105361232AClean and hygienicEasy to buy raw materialsTobacco preparationAir volumeSolar power

The invention relates to the technical field of tobacco curing equipment, in particular to a cyclically solar-heated tobacco curing barn. In the cyclically solar-heated tobacco curing barn, an upper air vent and a lower air vent are provided between a curing chamber and a heating chamber, a tobacco hanger for hanging tobacco is disposed in the curing chamber, and the wall of the curing chamber is provided with a louver moisture exhaust; a methanol combustion heater and a cyclic fan are disposed in the heating chamber, and the methanol combustion heater is disposed below the cyclic fan; the lower portion of a dewatering chamber is communicated with the louver moisture exhaust of the curing chamber, the upper portion of the dewatering chamber is communicated with an upper end of the heating chamber, and a dewatering device, a water drainer and an air intake auto-adjusting port are arranged in the dewatering chamber, the water drainer is disposed below the dewatering device, and the air intake auto-adjusting port is arranged in a wall of the dewatering chamber. A roof of the tobacco curing bar is also provided with a solar generator. The methanol is used as a clean energy source to cure the tobacco at a low cost without emission of smoke dust and sulfur dioxide, so that the requirement on energy conservation and environment protection is met.

Owner:GUANGDONG BRANCH OF CHINA TOBACCO GENERAL +1

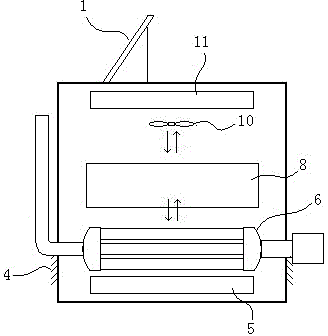

Biomass pellet burner for flue-cured tobacco

InactiveCN104613641BImprove baking qualityLow running costTobacco preparationFinal product manufactureCooling coilEngineering

The invention provides a biomass particle combustion furnace for flue-cured tobaccos. The furnace comprises a biomass particle combustion furnace body and a heat exchange chamber. The biomass particle combustion furnace body comprises a main furnace body and a feeding device, a fire grate is arranged in a hearth of the main furnace body, a basin-shaped depression is formed in the central position of the fire grate, and the heat exchange chamber is arranged on the hearth. The feeding device comprises a bin, a spiral feeding device, a variable frequency motor and a conveying pipe, the lower end of the conveying pipe is obliquely communicated with the position above the fire grate, the heat exchange chamber is divided into a smoke chamber and a hot air chamber which are sealed and conduct heat to each other, a cooling coil is arranged in the smoke chamber, smoke generated in the biomass particle combustion furnace body flows through the cooling coil to be discharged out of a chimney, and a circulating pipeline connected with a flue-cured tobacco chamber is arranged in the hot air chamber and connected with a circulating fan.

Owner:广西节得乐生物质能源科技有限公司

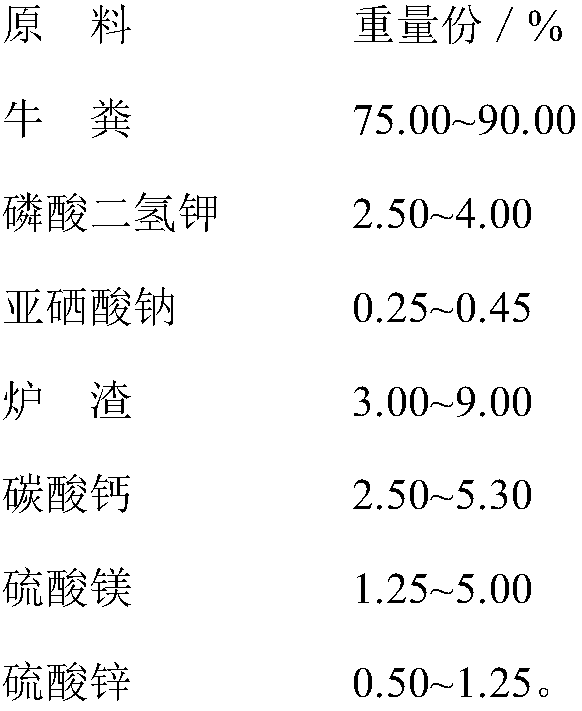

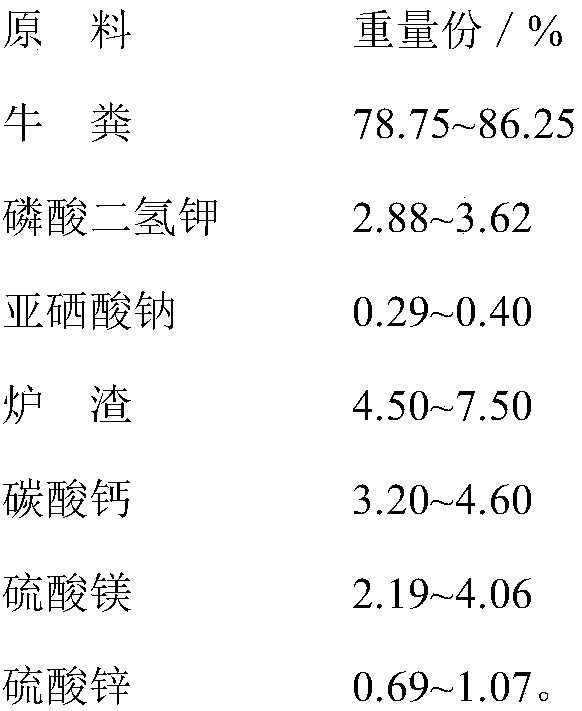

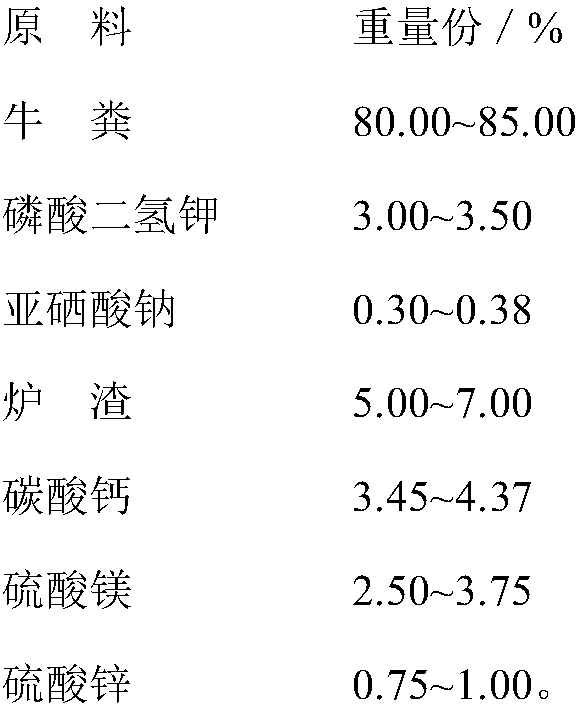

Flue-cured tobacco cadmium-reducing organic fertilizer based on cow dung and preparation method and application thereof

InactiveCN108373391AReduce contentSolve fertilization technologyCalcareous fertilisersMagnesium fertilisersDecompositionPhosphate

The invention discloses flue-cured tobacco cadmium-reducing organic fertilizer based on cow dung and a preparation method and application thereof. The flue-cured tobacco cadmium-reducing organic fertilizer comprises cow dung, potassium dihydrogen phosphate, sodium selenite, furnace slag, calcium carbonate, magnesium sulfate and sulfuric acid according to a certain ratio. The preparation method comprises A, stack retting decomposition of cow dung, potassium dihydrogen phosphate and sodium selenite, B, furnace slag preparation, and C, preparation of enough amounts of other three commodity raw materials and furnace slag raw materials prepared through the step B based on the mass of the cow dung matrix in step A, and uniform stirring of the raw materials and a stack retting decomposition raw material prepared through the step A so that the flue-cured tobacco cadmium-reducing organic fertilizer is obtained. The flue-cured tobacco cadmium-reducing organic fertilizer has a simple formula. Thepreparation method is easy and is easy to operate. The product satisfies the national organic fertilizer standards, significantly passivates the soil cadmium activity, reduces flue-cured tobacco cadmium accumulation, reduces the soil active cadmium by 28.8-44.9% and flue-cured tobacco cadmium content by 18.8-50.3%, especially reduces the cadmium in the upper leaves by 42.9-50.3% and has a large promotion and application value in the heavy metal-polluted tobacco areas such as cadmium-polluted tobacco areas.

Owner:GUIZHOU TOBACCO SCI RES INST +1

A kind of Bacillus pumilus and its use

ActiveCN101824391BImprove the quality of flue-cured tobaccoImprove usabilityBacteriaTobacco treatmentMicroorganismChemical quality

The invention discloses a bacillus pumilus and its application, belonging to the technical field of microorganisms. The production strain of the present invention is classified and named as Bacillus pumilus Van35; the preservation number is CGMCC No.3411. Spraying the strain preparation can increase the content of soluble total sugar and reducing sugar in tobacco leaves, and decrease the content of protein, total nitrogen and nicotine. Therefore, the ratios of sugar-to-nitrogen ratio, sugar-to-alkaline ratio and nitrogen-to-alkaline ratio tend to increase, which makes the chemical quality more harmonious and improves the smoking quality of tobacco leaves.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Water holding controlled release fertilizer special for tobacco and method for producing the same

InactiveCN101367686BConsistent particlesUniform particle sizeAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersAdhesiveDissolution

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

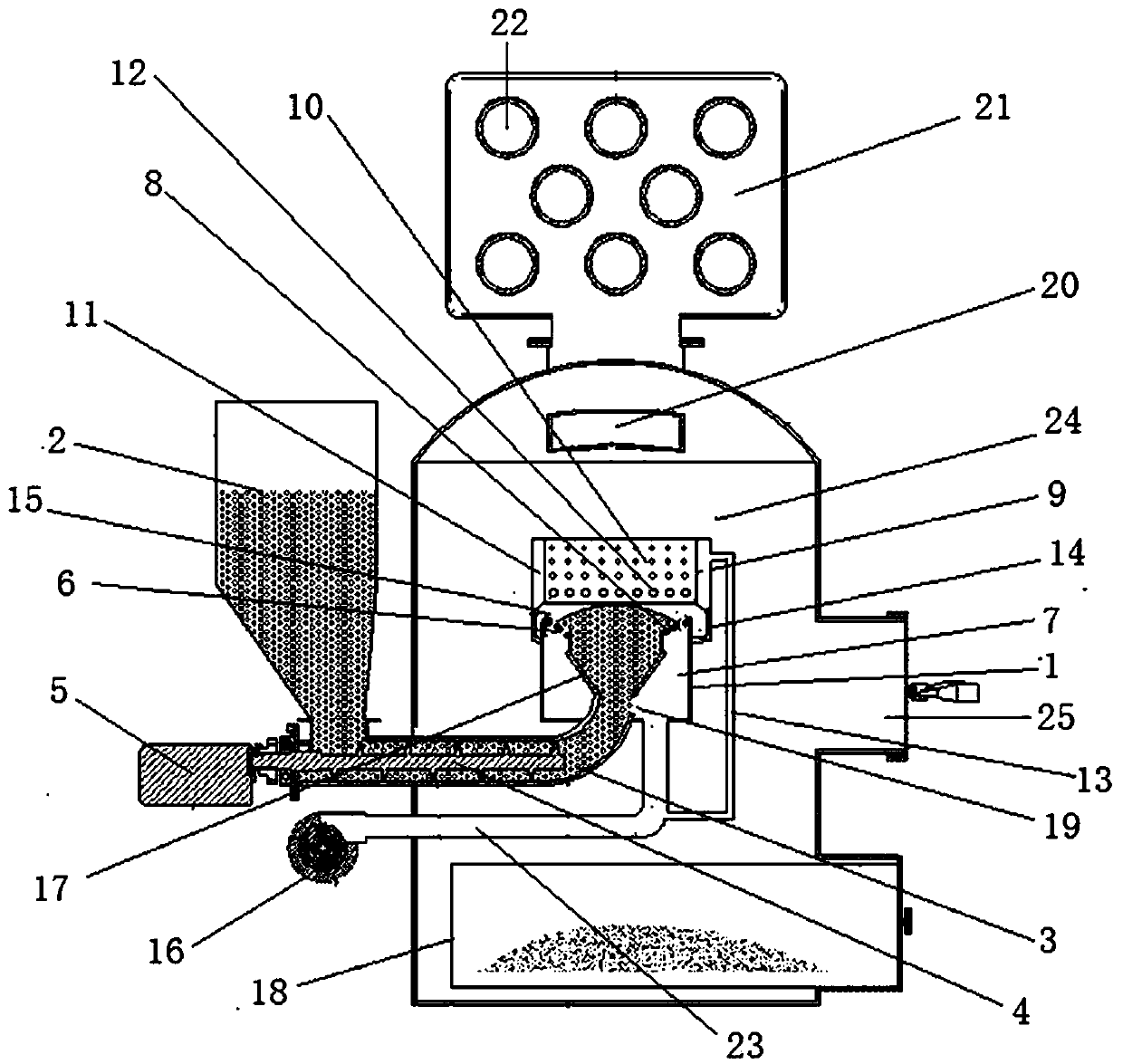

Gasification combustion device for tobacco flue-curing

PendingCN107830726AAvoid gatheringEfficient and stable cooling effectTobacco preparationTobacco dryingCombustion chamberCombustor

The invention provides a gasification combustion device for tobacco flue-curing. The gasification combustion device comprises a combustor (1), a feeding hopper (2), a feeding pipe (3) and a feeding screw conveyer (4), wherein the combustor (1) is arranged in a combustion chamber (24); the combustion chamber (24) communicates with a heat-dissipating device (21) arranged in a tobacco flue-curing room; a secondary oxygen distributor (9) is arranged above the combustor (1); the secondary oxygen distributor (9) comprises a gasification combustion chamber (10) and an oxygen distribution chamber (11); oxygen distribution holes (12) are formed between the oxygen distribution chamber (11) and the gasification combustion chamber (10); the oxygen distribution chamber (11) communicates with an oxygensupply fan (16) through an oxygen distribution pipe (13); and the secondary oxygen distributor (9) is mounted on the combustor (1) trough supporting legs (14). By adoption of the gasification combustion device provided by the invention, fuel gas generated from fuel gasification and tar in the fuel gas can be completely combusted, the tar can be prevented from entering a heat-dissipating pipe of the tobacco flue-curing room and gathering on the wall of the heat-dissipating pipe, the efficient and smooth heat-dissipating effect can be guaranteed, and the flue-cured tobacco quality can be improved.

Owner:ZHANGJIAGANG COMPANY HUNAN PROVINCIAL TOBACCO

A heat pipe type automatic flue-curing machine

ActiveCN107212453BImprove recycling efficiencyReduce electric powerTobacco preparationLighting and heating apparatusThermodynamicsProcess engineering

Owner:SHANGHAI DONGJIAN PURIFYING EQUIPS

A kind of long sporogenous yeast and its application

ActiveCN104164372BIncrease aromaImprove the quality of flue-cured tobaccoFungiTobacco treatmentSporeMicroorganism

Owner:CHINA TOBACCO YUNNAN IND

A kind of spring peanut-spring tobacco ecological high-yield planting method

ActiveCN111264327BIncrease productionImprove qualityFabaceae cultivationTobacco cultivationEnvironmental resource managementIntercropping

The invention relates to an ecologically high-yield planting method of spring peanut-spring tobacco, which belongs to the technical field of crop planting. Changing the planting time of peanuts while adjusting the planting density can change the yield of flue-cured tobacco and peanuts, thereby affecting the total income. The object of the present invention is to provide an ecological high-yield planting method of spring peanut-spring tobacco. Spring Peanut‖Chunyan 2: 2 intercropping-intercropping mode (1 ridge and 2 rows intercropping-intercropping of peanuts and 2 ridges of tobacco intercropping-intercropping), this mode ensures high yield and high quality of flue-cured tobacco, and at the same time achieves an increase in peanut income of 120kg / mu. Peanut yield increased by 110 kg per mu of pods, improved the quality of flue-cured tobacco, and increased the comprehensive output value by 22%; reduced soil-borne diseases, improved the soil ecological environment, and effectively solved the problems of tobacco field soil micro-ecological imbalance and serious tobacco field soil-borne diseases. Coordinated development of land cultivation and land use.

Owner:VEGETABLE RES INST OF SHANDONG ACADEMY OF AGRI SCI

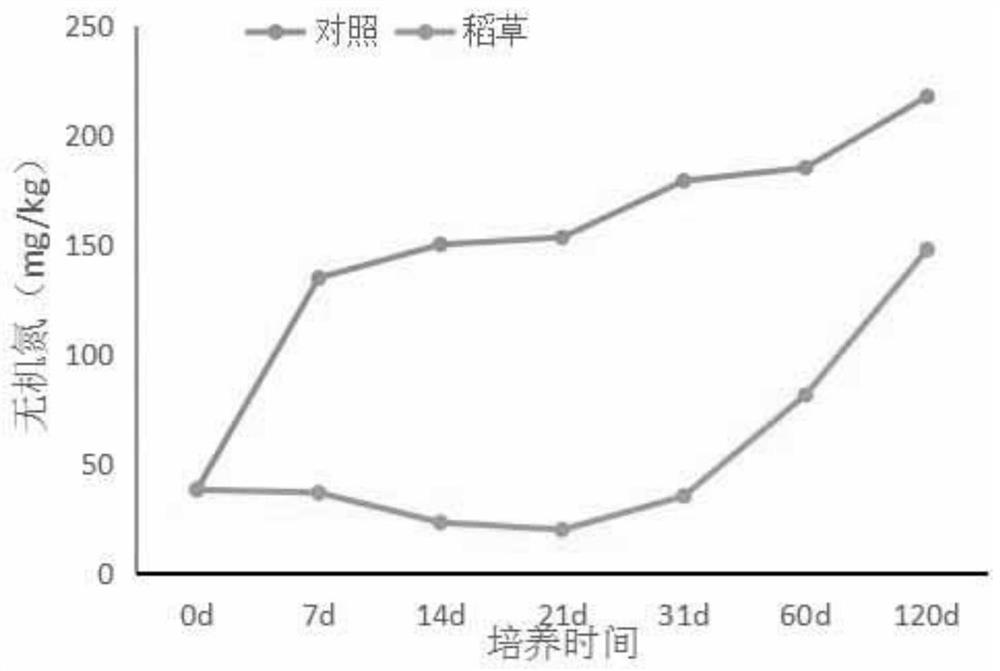

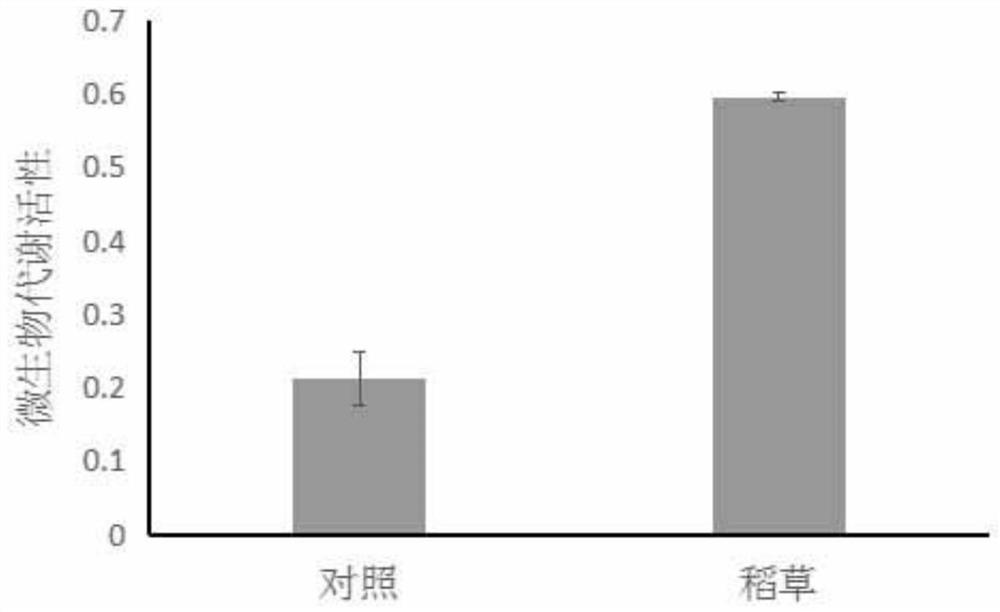

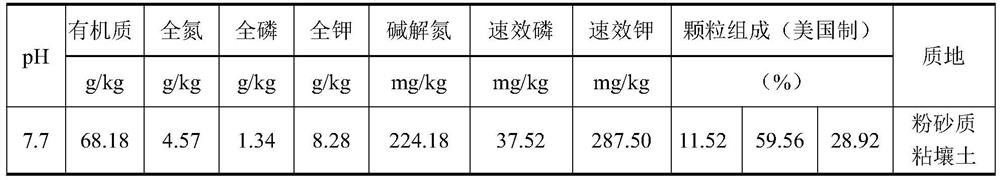

A method for controlling nitrogen and increasing quality of flue-cured tobacco in high organic matter tobacco field soil

ActiveCN109328957BMake up for the phenomenon of fatteningDelay rapid decay timeTobacco cultivationSoil-working methodsOrganic matterCuring of tobacco

The invention discloses a high organic matter tobacco field soil flue-cured tobacco nitrogen controlling and quality improving method, and relates to the technical field of flue-cured tobacco planting. The method particularly comprises the following steps of 1, tobacco planting field preparation, wherein a tobacco field is selected, organic matter returns to the field, time for returning to the field is determined, and a mode of returning to the field is determined; 2, fertilization before planting; 3, tobacco seedling field planting; 4, fertilization after planting; 5, management after planting. The method has the advantages of being capable of enhancing the soil biological activity, controlling the soil nitrogen mineralization capacity, improving the tobacco quality and the like, the method is suitable for planting flue-cured tobacco in a high organic matter tobacco field of a rice-tobacco crop rotation area.

Owner:湖南省烟草公司永州市公司 +2

Planting method for ecological high yield of spring peanut-spring tobacco

ActiveCN111264327AIncrease productionImprove qualityFabaceae cultivationTobacco cultivationEnvironmental resource managementEcological environment

The invention relates to a planting method for ecological high yield of spring peanut-spring tobacco and belongs to the technical field of crop planting. The planting time of peanuts can be changed while planting densities are adjusted, the yield of flue-cured tobacco and peanuts can be changed, and furthermore, the total benefit can be affected. The invention aims to provide a spring peanut-spring tobacco ecological high-yield planting method. A spring peanut-spring tobacco 2:2 relay intercropping-intercropping mode (two rows of peanuts in one ridge and two ridges of tobacco are in relay intercropping-intercropping) is adopted, and by adopting the mode, the yield of peanuts can be increased by 120kg / mu while high yield and high quality of the flue-cured tobacco is ensured. The yield per mu of peanuts can be increased by 110kg, the quality of the flue-cured tobacco can be improved, and the comprehensive output value is increased by 22%; soil-borne diseases can be reduced, ecological environments of soil can be improved, problems of ecological unbalance of soil in tobacco fields, serious soil-borne diseases of the tobacco fields, and the like, can be effectively solved, and harmonious development of land maintenance and use is achieved.

Owner:VEGETABLE RES INST OF SHANDONG ACADEMY OF AGRI SCI

Honeycomb-coal stone for tobacco leaf condensed roasting room and operation method thereof

InactiveCN100569122CReduce investmentAverage price increaseTobacco preparationInsulation layerHoneycomb

The invention discloses a honeycomb coal furnace for a dense tobacco barn. One side of the barn is provided with a heating chamber. The honeycomb furnace is in the heating room. The honeycomb furnace includes a furnace body and a chimney. The outer casing, the upper part of the furnace body is provided with a furnace cover, and the two ends of the furnace body are provided with furnace doors. The outer casing, furnace cover and furnace door are provided with an insulating layer made of refractory materials, and the side of the furnace body is provided with air intake and combustion-supporting holes. There is a track on the bottom surface of the hearth in the furnace body, and a coal-burning basket is set in the furnace body. The bottom of the coal-burning basket is provided with a pulley corresponding to the track. An air inlet chamber is formed between the bottom of the coal-burning basket and the bottom surface of the hearth in the furnace body. The air chamber is connected with the air intake and combustion-supporting hole, and the heights correspond to each other, so that the periodic law of coal combustion: small, medium, large, medium and small processes occur in the same combustion furnace, the baking temperature is more stable, and the baking quality is improved. Improvement, can burn a furnace of smoke after one ignition, easy to operate and reduce labor intensity.

Owner:SHANDONG WEIFANG TOBACCO CO LTD +1

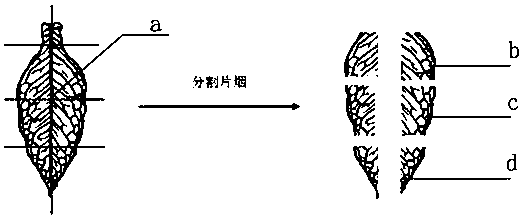

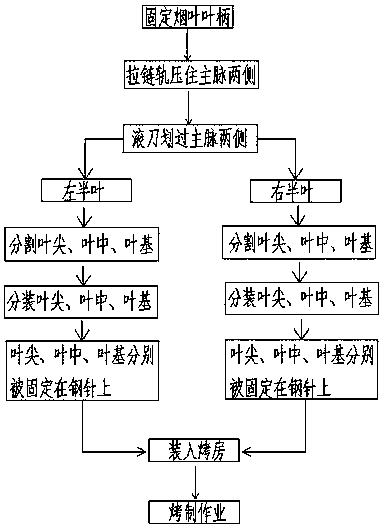

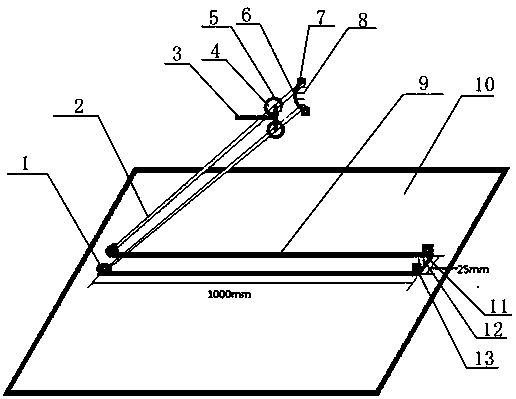

A pretreatment method and pretreatment tool for tobacco leaves before roasting

The invention provides a pretreatment method of tobacco leaves before curing. In the pretreatment method, a special main vein removing tool and a special tobacco leaf charging tool are used. The pretreatment method comprises the following operating steps: A, removing main veins of the tobacco leaves by using the main vein removing tool to obtain left half leaves and right half leaves; B, segmenting the left half leaves and the right half leaves into leaf bases, leaf middles and leaf tips by using a carving knife respectively; C, charging the leaf bases, the leaf middles and the leaf tips disorderly by using the tobacco leaf charging tool respectively; D, fixing the leaf bases, the leaf middles and the leaf tips into corresponding boxes by using long needles on the tobacco leaf charging tool respectively. The pretreatment method is simple and convenient to use; by the pretreatment method, the main veins can be quickly removed, segmentation of the leaf bases, the leaf middles and the leaf tips is facilitated, and cell damage during segmentation is avoided; in addition, a way of charging the tobacco leaves into the boxes by class is adopted, and in the curing process, the problem of collapse caused by water loss-type withering of the leaves is solved; through pretreatment before curing, the quality of flue-cured tobacco is integrally improved.

Owner:TOBACCO RES INST CHIN AGRI SCI ACAD +1

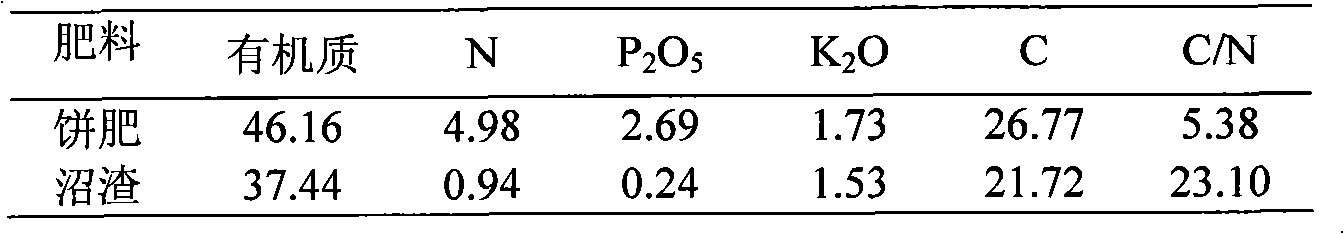

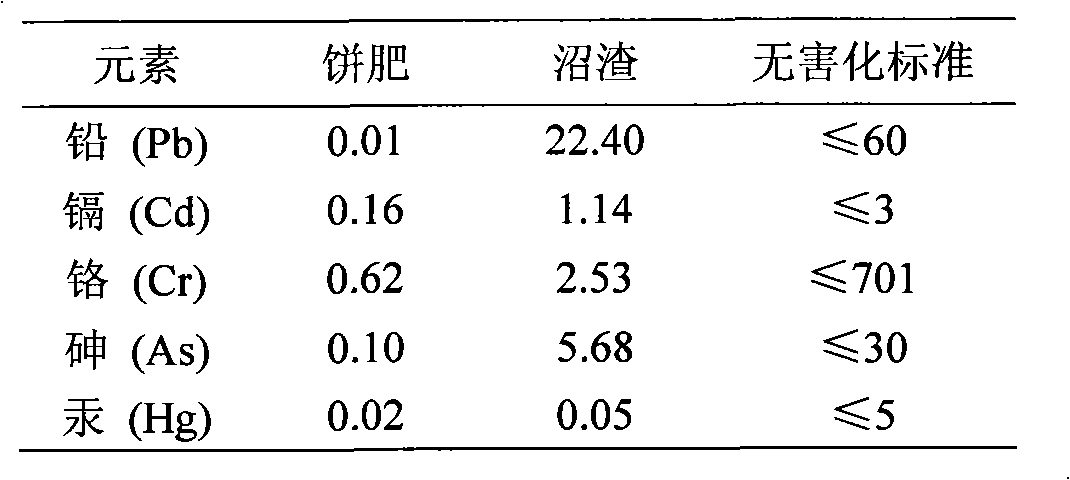

Special basal fertilizer used in ecological tobacco leaf plantation

InactiveCN102267828BRepair or protect the micro-ecological environmentRestoring or protecting the ecological environmentBio-organic fraction processingClimate change adaptationEcological environmentZINC SULFATE HEPTAHYDRATE

The invention discloses a special basal fertilizer used in ecological tobacco leaf plantation. The invention belongs to the technical field of organic fertilizers. The special basal fertilizer used in ecological tobacco leaf plantation comprises components of, by weight: 19 to 23% of fermented cake fertilizer, 43 to 47% of biogas residue, 17 to 21% of common calcium superphosphate, 2.3 to 2.7% ofpotassium nitrate, 0.27 to 0.32% of borax, 0.8 to 0.9% of zinc sulfate heptahydrate, 9.5 to 9.9% of potassium sulfate, 0.05 to 0.15% of potassium humate, and 0.64 to 0.68% of mixed microbial manure. The basal fertilizer is prepared through steps that: (1) cake fertilizer and biogas residue are dried and crushed, such that a basic mixture is obtained; (2) the mixed microbial manure is added; and (3) common calcium superphosphate, potassium nitrate, borax, zinc sulfate heptahydrate, potassium sulfate, and potassium humate are added. With the basal fertilizer provided by the invention, soil micro ecological environment can be repaired or protected, tobacco plant disease resistance can be improved, quality of fire-cured tobacco can be improved, and ecological tobacco production can be continuously and healthily developed.

Owner:HUBEI CHINA TOBACCO IND

Wireless remote monitoring system for tobacco leaf roasting

InactiveCN101822416BCutting costsIncrease productionTobacco preparationProgramme total factory controlMobile data terminalTransceiver

The invention provides a wireless remote monitoring system for tobacco leaf roasting, which is characterized by comprising a computer, a server and a plurality of tobacco roasting automatic control instruments, wherein the computer is in communication connection with the server through Internet; each tobacco roasting automatic control instrument is provided with a wireless mobile data terminal; and the wireless mobile data terminal is connected with the server based on a TCP communication protocol. The server is provided with a short message transceiver, and the short message transceiver is in wireless communication connection with multiple mobile phones of tobacco growers. The computer is a 3G palm computer. The wireless remote monitoring system for tobacco leaf roasting can save the cost, and improve the tobacco roasting quality and production efficiency.

Owner:HENGYANG NORMAL UNIV

Baking method of sun-cured tobacco filial generation

ActiveCN112471575AImprove the quality of flue-cured tobaccoAvoid hardening and yellowing and roasting blackTobacco preparationClimate change adaptationHigh humidityProcess engineering

The invention discloses a baking method of sun-cured tobacco filial generation, which improves the existing flue-cured tobacco bulk curing technology, and particularly comprises the following steps of: (1) performing baking at high temperature and humidity in a main yellowing stage, baking the tobacco to be soft, baking the tobacco to be yellow and preventing thetobacco from being green; (2) adopting a proper high temperature and a low humidity in the later period of yellowing are achieved, discharging little moisture in advance, and avoiding blackening after hard yellowing; (3) slowly heatingto proper low humidity at the initial stage of color fixing, so that brown slices can be reduced; (4) properly increasing the humidity (increased by 2 DEG C) in the middle and later periods of colorfixing to achieve orange baking; and (5) properly reducing the temperature in the later period of color fixing and the stem drying stage, and reducing aroma loss. Aiming at the flue-cured tobacco characteristics of the sun-cured tobacco filial generation, the matched curing process is designed through the improved cooperation, the flue-cured tobacco quality of the sun-cured tobacco filial generation can be effectively improved, and the technical problem that an existing flue-cured tobacco bulk curing technology is not suitable for curing the sun-cured tobacco filial generation can be effectively solved.

Owner:GUIZHOU TOBACCO SCI RES INST

Novel tobacco furnace

InactiveCN101569434AImprove the quality of flue-cured tobaccoTobacco preparationCoalCuring of tobacco

A novel tobacco furnace comprises a furnace body, a furnace door and a hook. The furnace body is provided with a fuel chamber; the inner wall of the furnace body is provided with a crank, a pulley and a hook; the pulley is connected with the crank through a rope; and the top out of the furnace body is provided with an automatic alarm. By adopting the structure, coal can be placed in the fuel chamber as fuel, tobacco leaf to be baked is sent to the hook through the crank and the pulley, and the furnace door is closed, then tobacco leaf is baked under sealing condition, thereby achieving the aim of improving the tobacco quality.

Owner:李若云

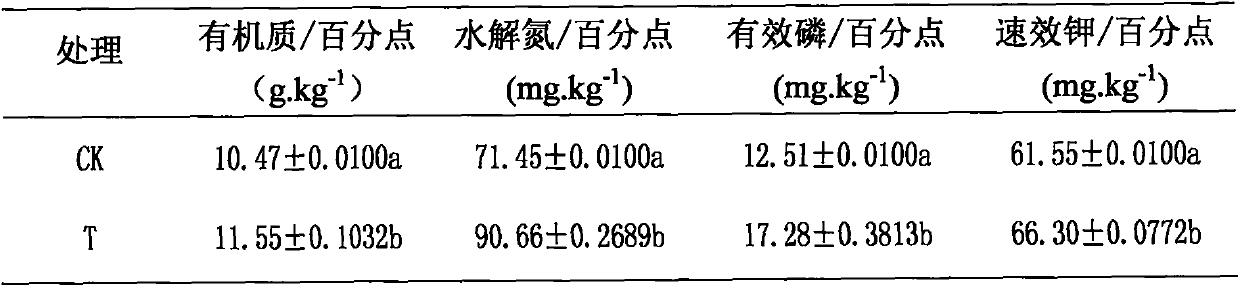

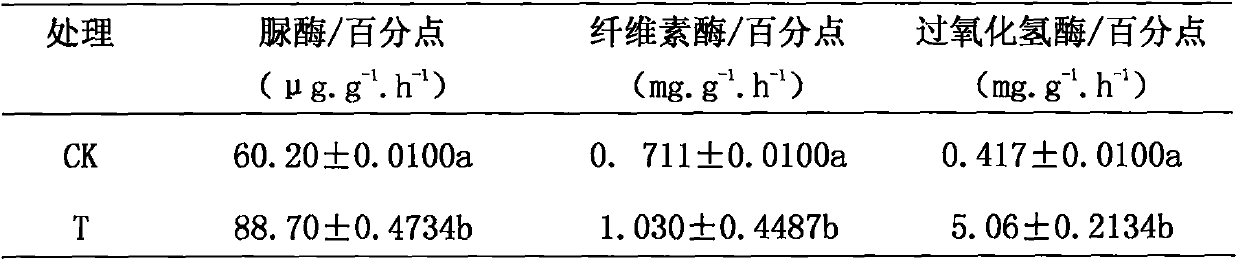

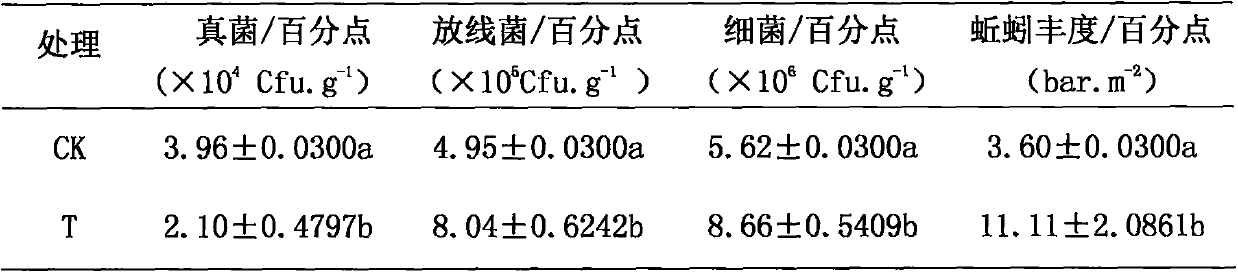

Method for ecologically regulating and controlling continuous cropping obstacles of tobaccos by interplanting coprinus comatus in tobacco field

InactiveCN110583415AEfficient ecological regulationGood biological propertiesClimate change adaptationBioloigcal waste fertilisersContinuous croppingNicotiana tabacum

Provided is a method for ecologically regulating and controlling continuous cropping obstacles of tobaccos by interplanting coprinus comatus in a tobacco field. A 'coprinus comatus-cellulase-soil organic matter-soil organism-soil urease' ecological chain is constructed. The method comprises the specific operating steps: (1) shaded soil under tobacco plants is used as a coprinus comatus cultivationbed; (2) the tobacco field is furrowed and disinfected; (3) coprinus comatus fungus blocks are prepared, wherein a coprinus comatus fungus block base material comprises wheat straw, wheat bran, cow dung, urea, gypsum and lime; after pretreatment, material stirring, pile-building fermentation, pile turning and material airing are carried out on the fungus block base material, coprinus comatus strains are sown according to 10% of the dry weight of the base material; (4) the coprinus comatus fungus blocks are put into the cultivation bed: (5) coprinus comatus fungus leftovers are directly ploughed into the soil after tobacco leaves are harvested. By adopting the method, the soil microenvironment of the tobacco field is fundamentally improved, phenolic acid type allelopathic auto-toxic substances in the rhizosphere soil of the tobaccos are continuously and stably digested, and ecological regulation and control of continuous cropping of the tobaccos are realized; the coprinus comatus cultivation leftovers are recycled, so that waste is turned into wealth, the coprinus comatus cultivation cost is reduced, the quality of flue-cured tobaccos is improved, and income of tobacco farmers is increased.

Owner:SHAOYANG POLYTECHNIC

A roasting method for increasing the protein degradation rate of tobacco leaves

ActiveCN109123745BImprove degradation rateRegulate protein contentTobacco preparationBiotechnologyProtein degradation

The invention discloses a roasting method for improving the protein degradation rate of tobacco leaves. The roasting method comprises the following steps: A. harvesting; B. weaving rods and loading into a furnace; Baking, after the yellowing period, color fixing period and gluten drying period, the roasted tobacco leaves can be obtained. The method of the present invention regulates the curing time, optimizes the curing process, increases the protein degradation rate of the tobacco leaf, regulates the protein content, and improves the quality of densely cured tobacco leaves, which is of great significance for ensuring the supply of high-quality raw materials for the cigarette industry.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com