Honeycomb-coal stone for tobacco leaf condensed roasting room and operation method thereof

A dense curing room and honeycomb technology, applied in application, tobacco, tobacco preparation, etc., can solve the problems of high curing cost, high use cost and high cost, overcome inertia and inertia, reduce labor intensity, and improve the quality of flue-cured tobacco Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

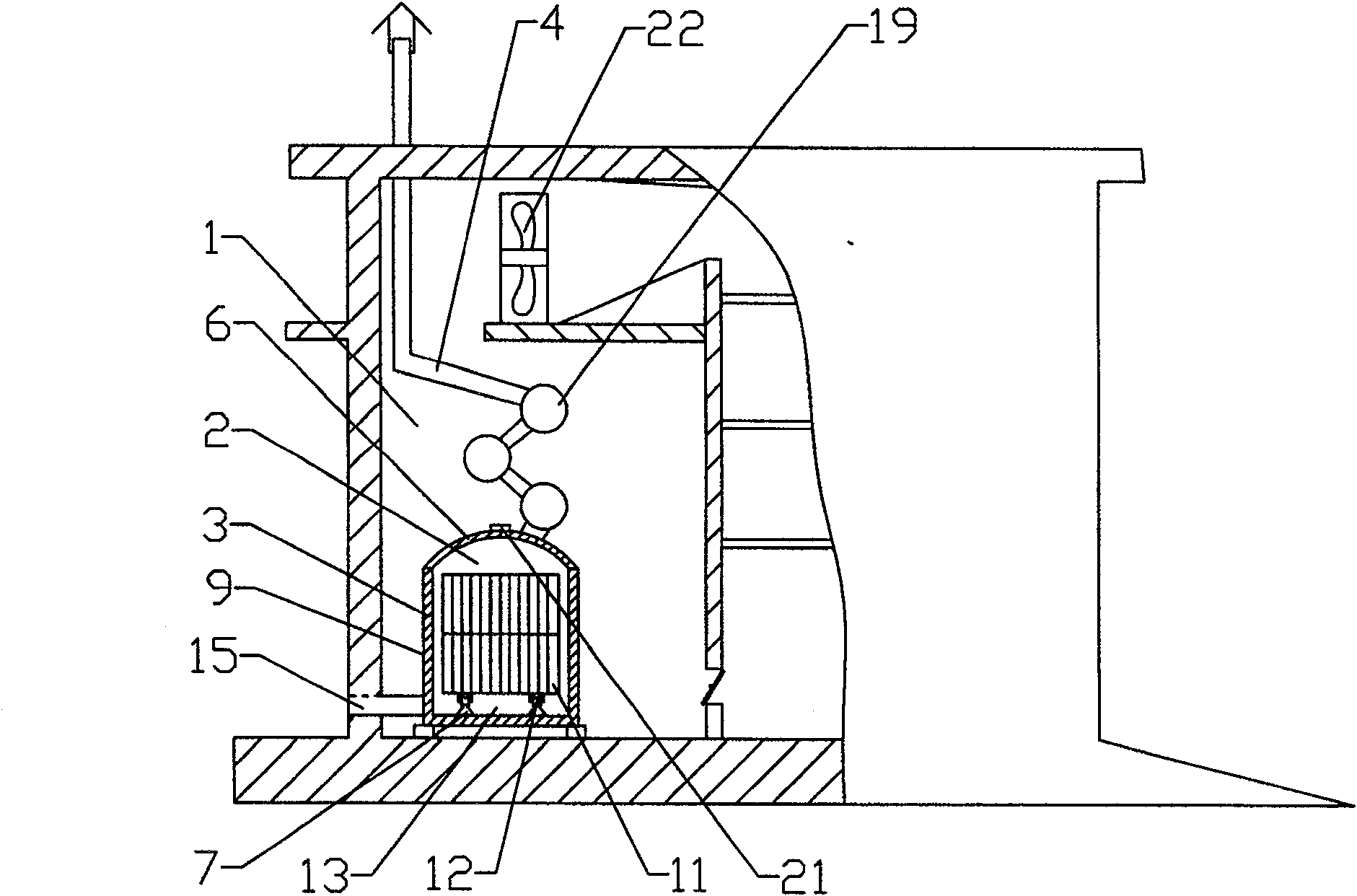

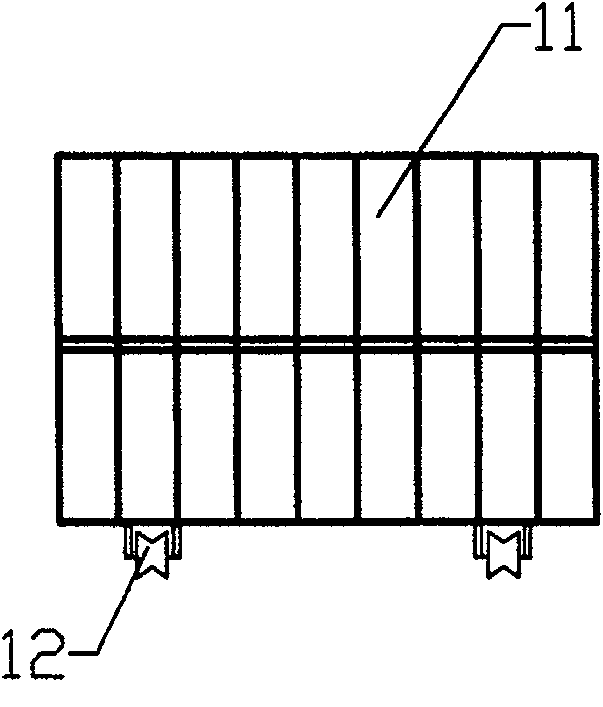

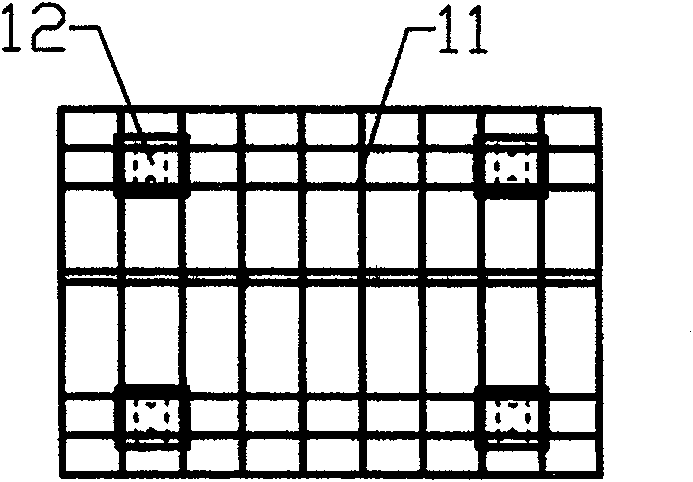

[0032] Example 1, such as figure 1 , Figure 4 As shown, a honeycomb coal furnace for a dense tobacco barn, one side of the barn is provided with a heating chamber 1, the wall of the heating room 1 is provided with two ventilation and combustion-supporting holes 15, and the ventilation and combustion-supporting holes 15 are provided with a blocking member 16, Blocking member 16 can block ventilation and combustion-supporting hole 15, and can adjust the size of ventilation and combustion-supporting hole 15 air inlets, honeycomb coal furnace 2 is arranged in heating chamber 1, and honeycomb coal furnace 2 is rectangular whole body combustion chamber, comprises furnace body 3, furnace body 3 has a length of 2.6m, a width of 0.75m, and a height of 0.6m. The chimney 4 has three cylindrical heat exchangers 19 arranged in a triangle. The diameter of the cylindrical heat exchanger 19 is 0.32m and the length is 2.5m. m, the two ends of the furnace body 3 are provided with furnace door...

Embodiment 2

[0033] Example 2, such as figure 1 , Figure 5 As shown, a kind of briquette coal furnace for tobacco leaves intensive barn, one side of the barn is provided with a heating chamber 1, and two ventilation and combustion-supporting holes 15 are arranged on the wall of the heating room 1, and the ventilation and combustion-supporting holes 15 are externally connected with a blower 17, and the power of the blower is It is 80W, the blower 17 has an adjustable damper, the blower 17 is electrically connected to the automatic baking controller 18, the briquette furnace 2 is arranged in the heating chamber 1, and the briquette furnace 2 is a rectangular whole-body combustion chamber, including a furnace body 3 and a furnace body 3 The length of the chimney is 2.3m, the width is 0.7m, and the height is 0.6m. The chimney 4 has three cylindrical heat exchangers 19 arranged in a triangle. The diameter of the cylindrical heat exchanger 19 is 0.30m and the length is 2m. Both ends of the fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com