Patents

Literature

102results about How to "Overcome inertia" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

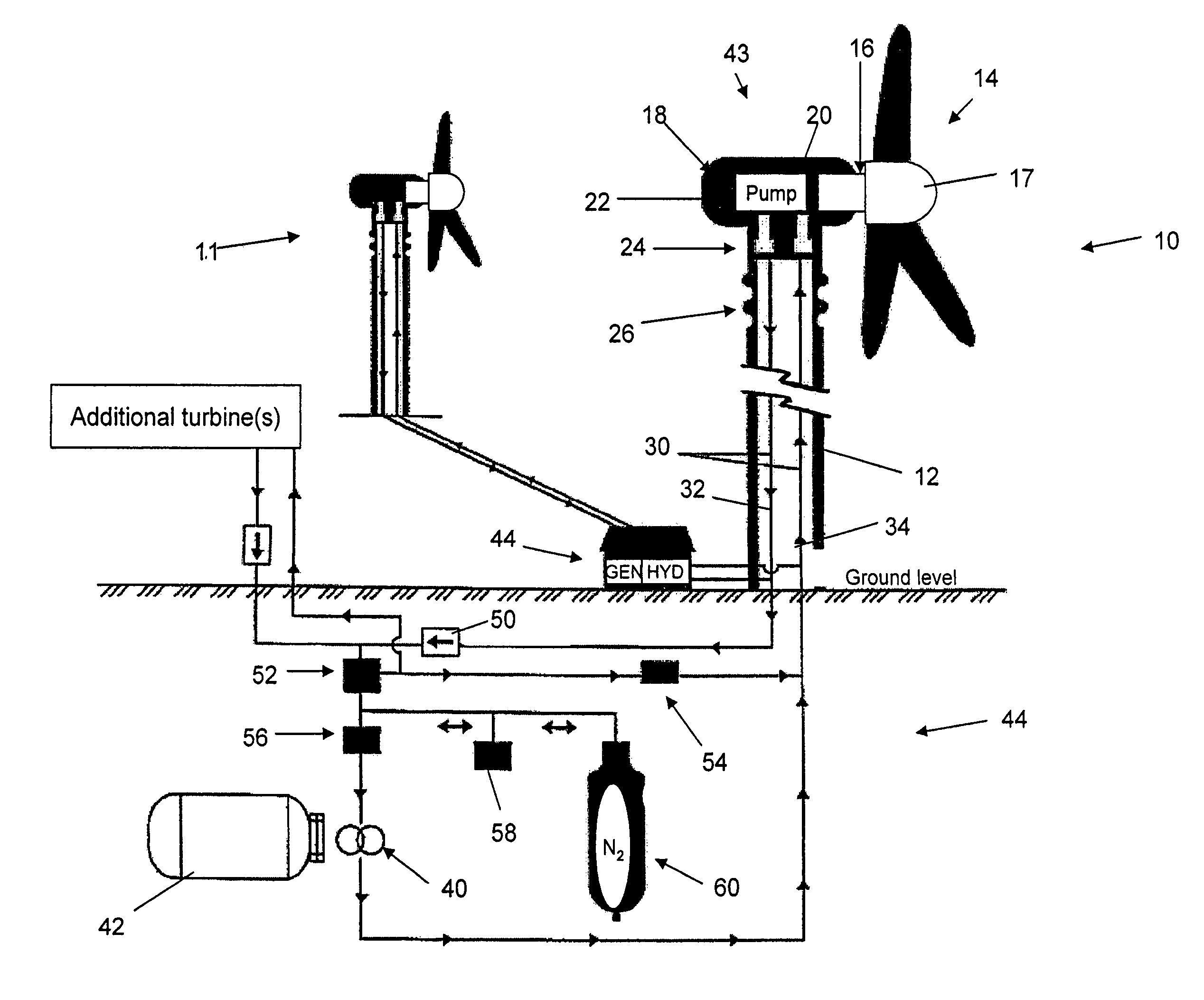

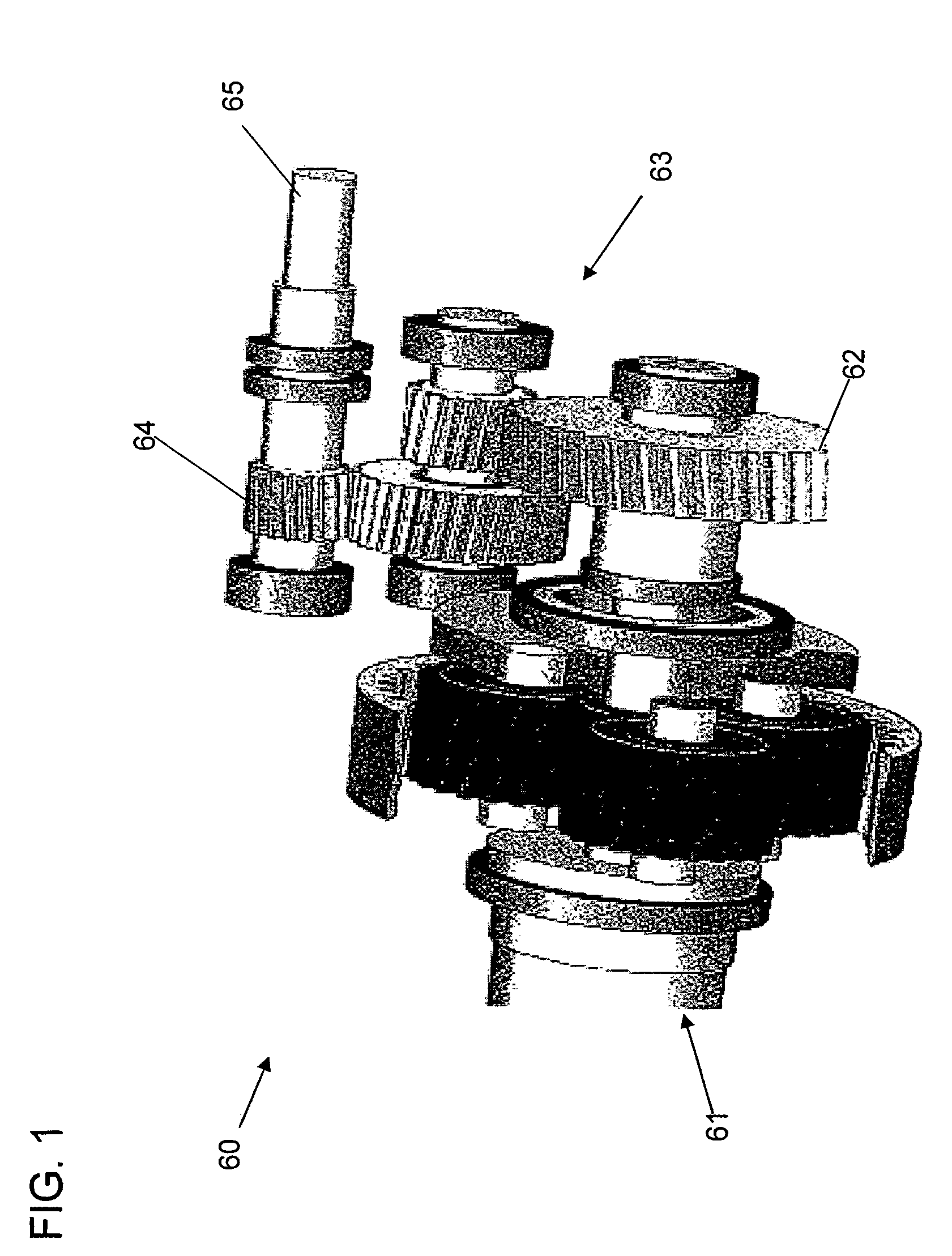

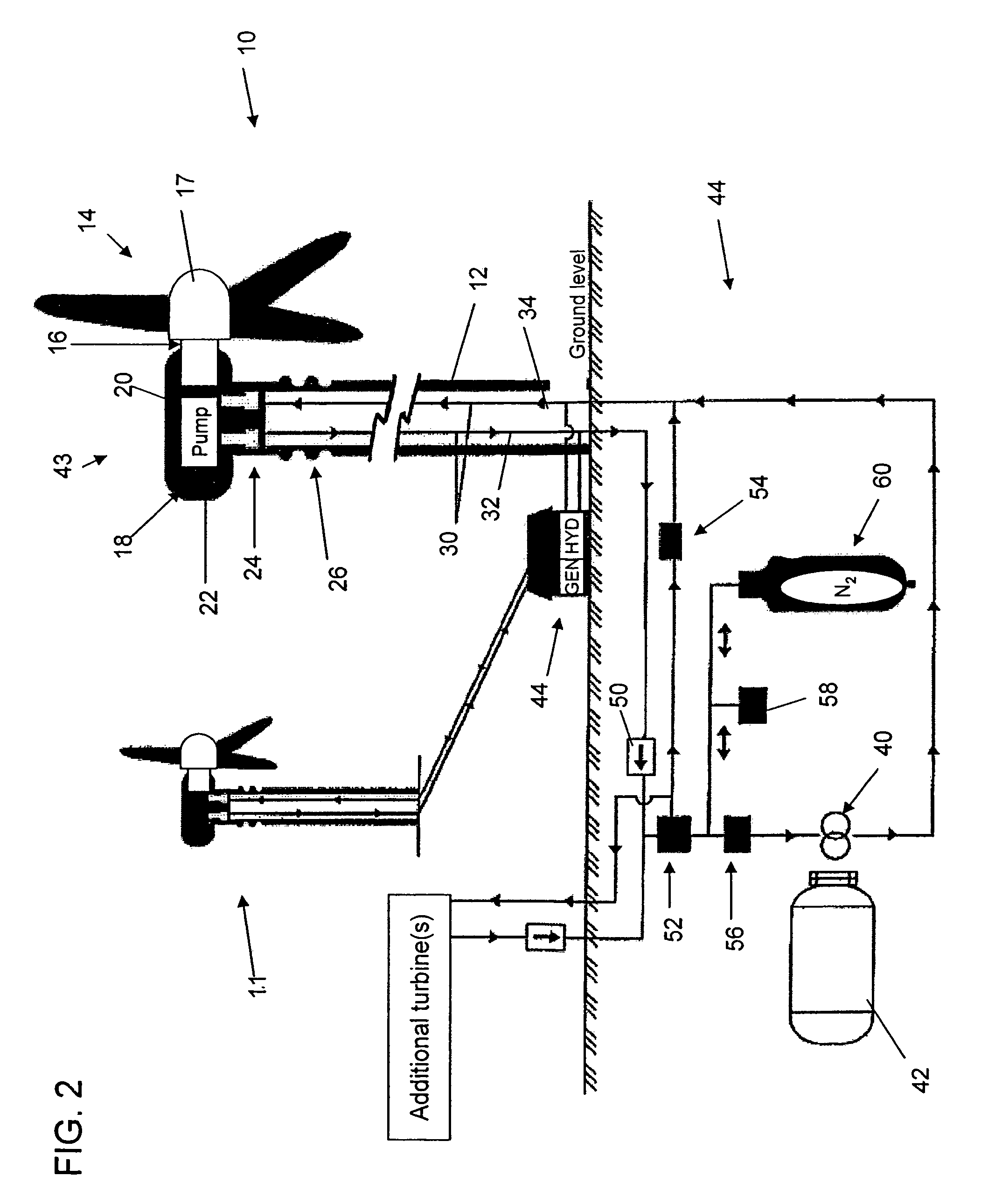

Hydro-wind power generating turbine system and retrofitting method

InactiveUS7656055B2Reduce wind speedProducing more kilowatt-hoursEngine fuctionsWind motor supports/mountsMechanical energyHydraulic pump

An electrical power producing wind turbine eliminates the possibility of being struck by lightning, reduces the complexity of gear trains and simplifies maintenance at heights. The wind turbine is electrically isolated from ground to reduce the possibility of being struck by lightning and the generator is located at ground level to simplify maintenance. The turbine blade shaft is directly attached to a hydraulic pump. The hydraulic fluid is transmitted to ground level through dielectric tubing and acts both as an electrical isolating medium and a transmitter of mechanical energy to the generator located at ground level. The wind turbine blade, shaft and hydraulic pump are electrically isolated from the support structure at the upper end.

Owner:PERRY ROBERT NELSON

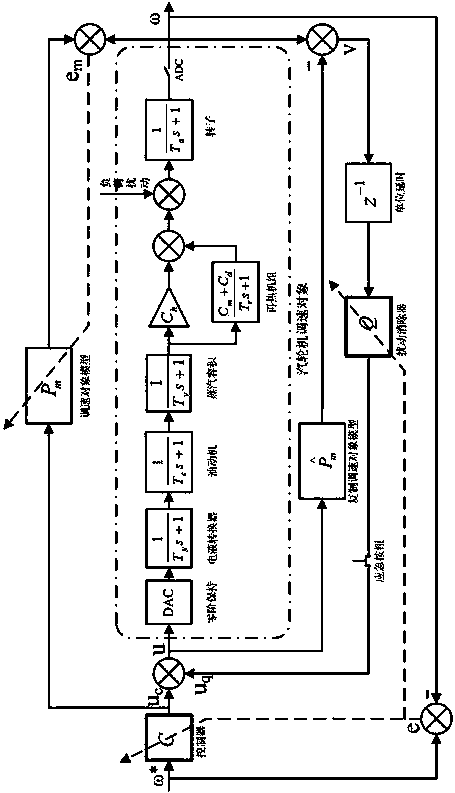

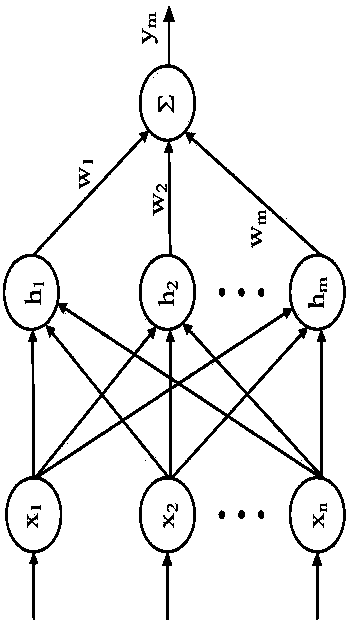

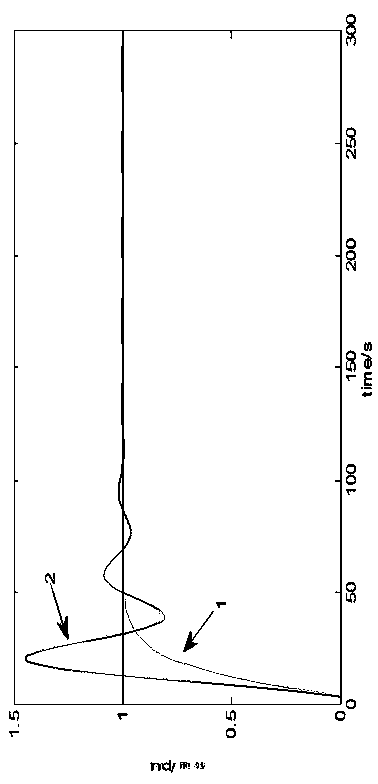

Method for controlling rotating speed of steam turbine on basis of self-adaptive inverse control

InactiveCN103557037AImprove control qualityOvercome inertiaMachines/enginesSafety/regulatory devicesTime lagOptimal control

The invention discloses a method for controlling the rotating speed of a steam turbine on the basis of self-adaptive inverse control, which aims at the characteristics of time lag, nonlinearity and obvious variation of dynamic characteristics along with the working conditions, difficulty in accurately modeling and the like of a steam turbine speed regulating system, adopts a self-adaptive inverse control theory and combines a neural network technology. According to the scheme, an object model, an inverse model and a disturbance canceling controller are obtained by utilizing RBF (Radial Basis Function) neural network on-line identification, a given rotating speed signal and external disturbance are respectively controlled to simultaneously achieve the optimal control effect and compromise does not need to be carried out between the given rotating speed signal and the external disturbance; compared with a steam turbine rotating speed PID (Proportion Integration Differentiation) cascade control method in the prior art, the self-adaptive inverse control method provided by the invention can well adapt to variation of the characteristics of a steam turbine speed regulation object, effectively overcomes the inertness and nonlinearity of the object, effectively inhibits the external disturbance and can obviously improve control quality of the steam turbine speed regulating system.

Owner:HENAN UNIV OF URBAN CONSTR

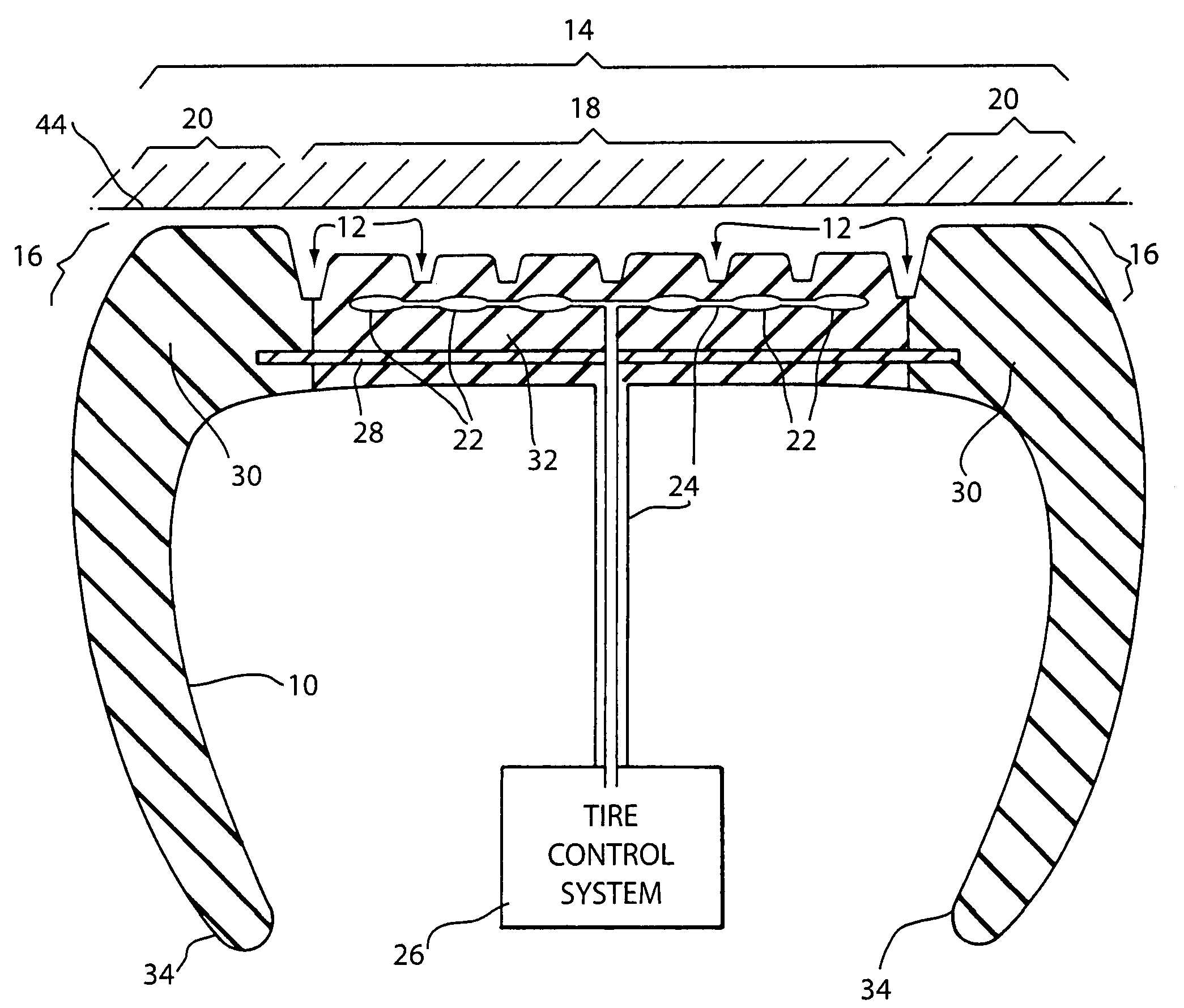

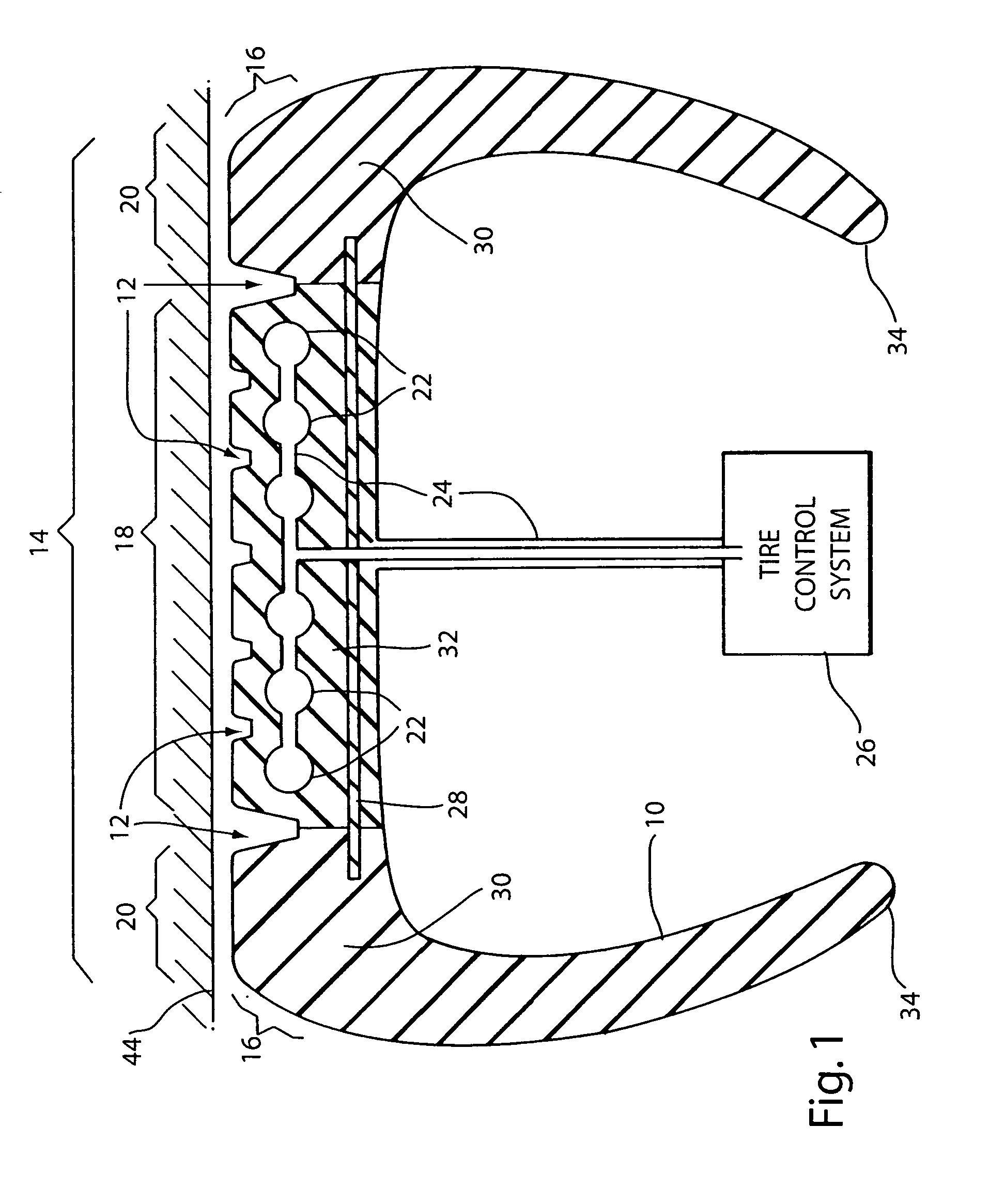

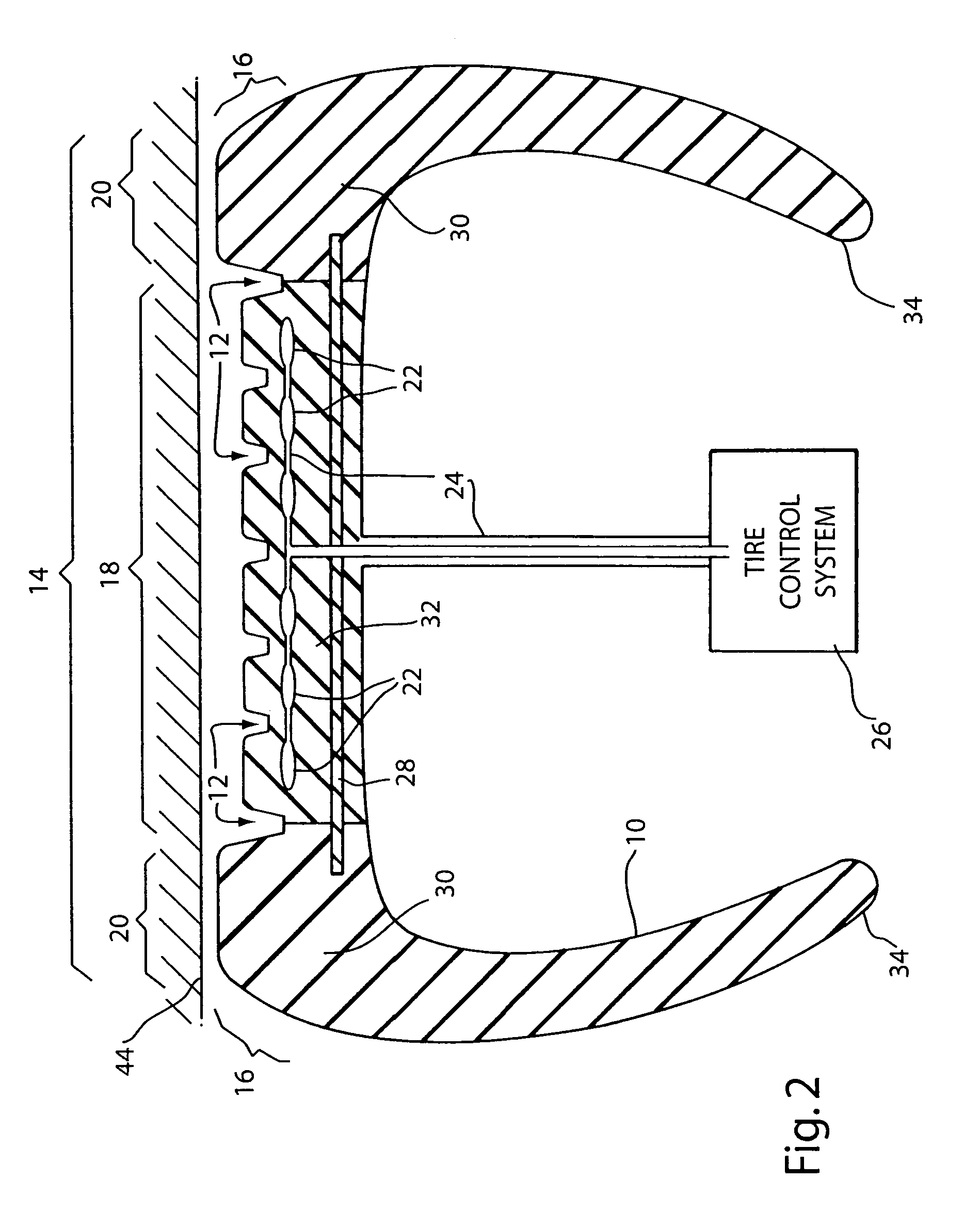

Fuel efficient vehicle tire having a variable footprint and low rolling resistance

InactiveUS7066226B1Low gas consumptionEffective dry tractionSpecial tyresTyre tread bands/patternsGround contactMicrocomputer

A tire for vehicles offering low rolling resistance wherein the ground-contact surface area is variable as a portion of the tread part can be retracted and / or extended using pneumatic, mechanical or hydraulic force to withdraw from, or come into contact with the road surface before, during or after operation permitting more efficient operation wherein the material used within the tread part that retains contact with the road may generally have a smaller internal friction loss than the material used in conventional tires and the rolling resistance is thereby reduced when the retractable portion of the tread is selectively withdrawn from contact with the road surface furthermore achieving a smaller ground-contact patch footprint. The achieved object of a tire with a lower rolling resistance yields improved fuel consumption efficiency. Improvements in exterior and interior noise levels and a reduced tendency to exhibit hydroplaning action are also attained with a variable groove volume to tread surface-contact ratio. Within one embodiment of the present invention, an automated microcomputer-based tire control system is disclosed useable to command the motion of the moveable tread portion of the said tire in response to various operational scenarios.

Owner:FIORE ROBERT ANGELO

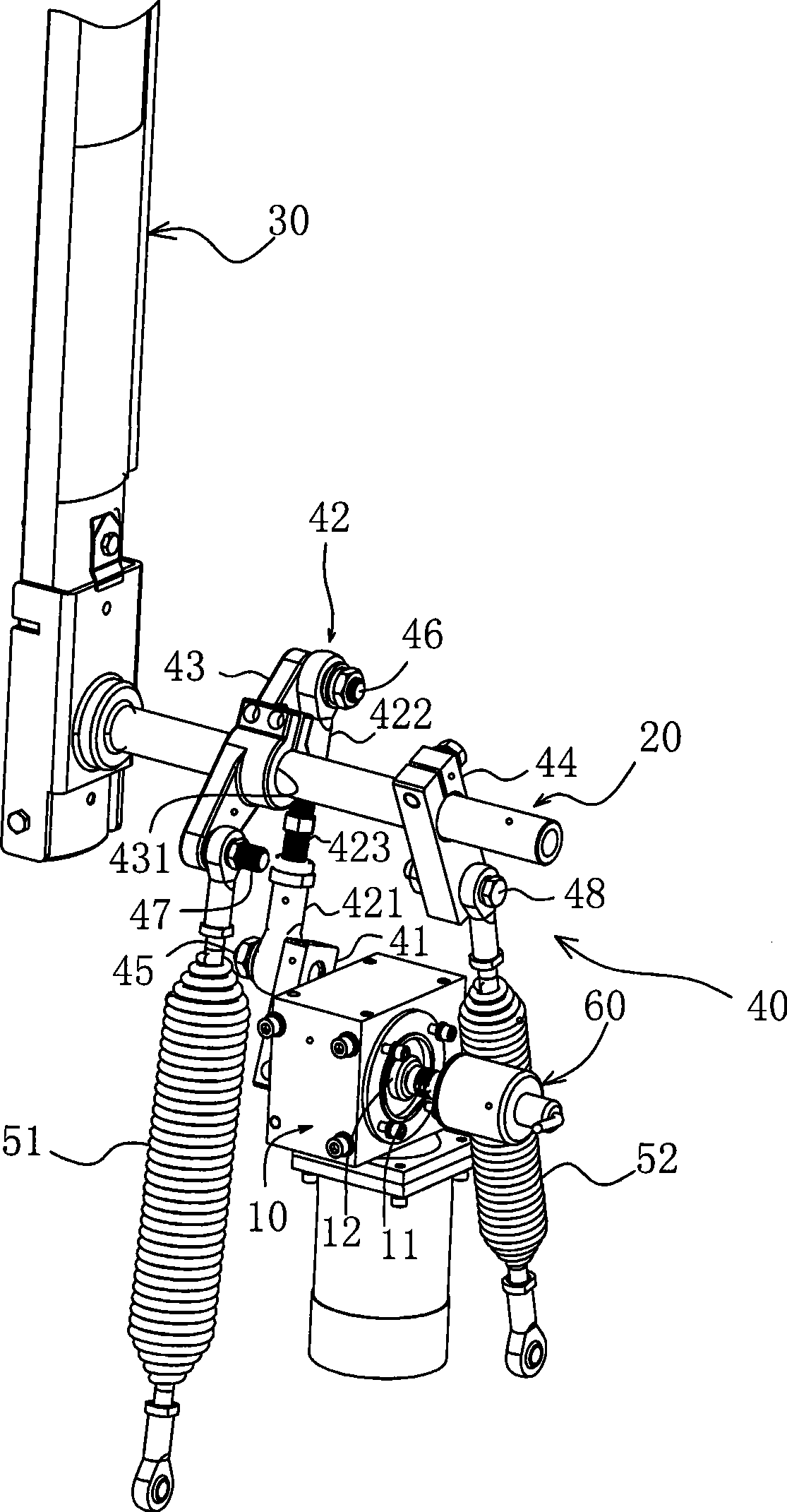

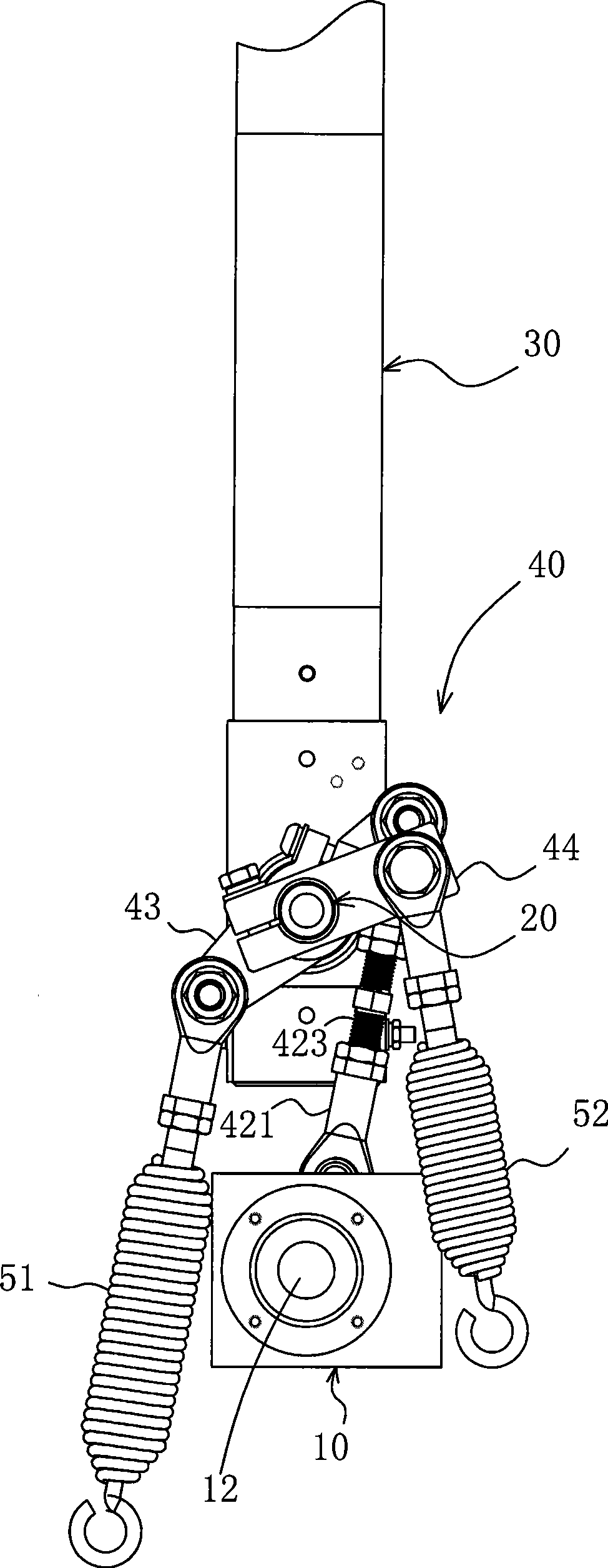

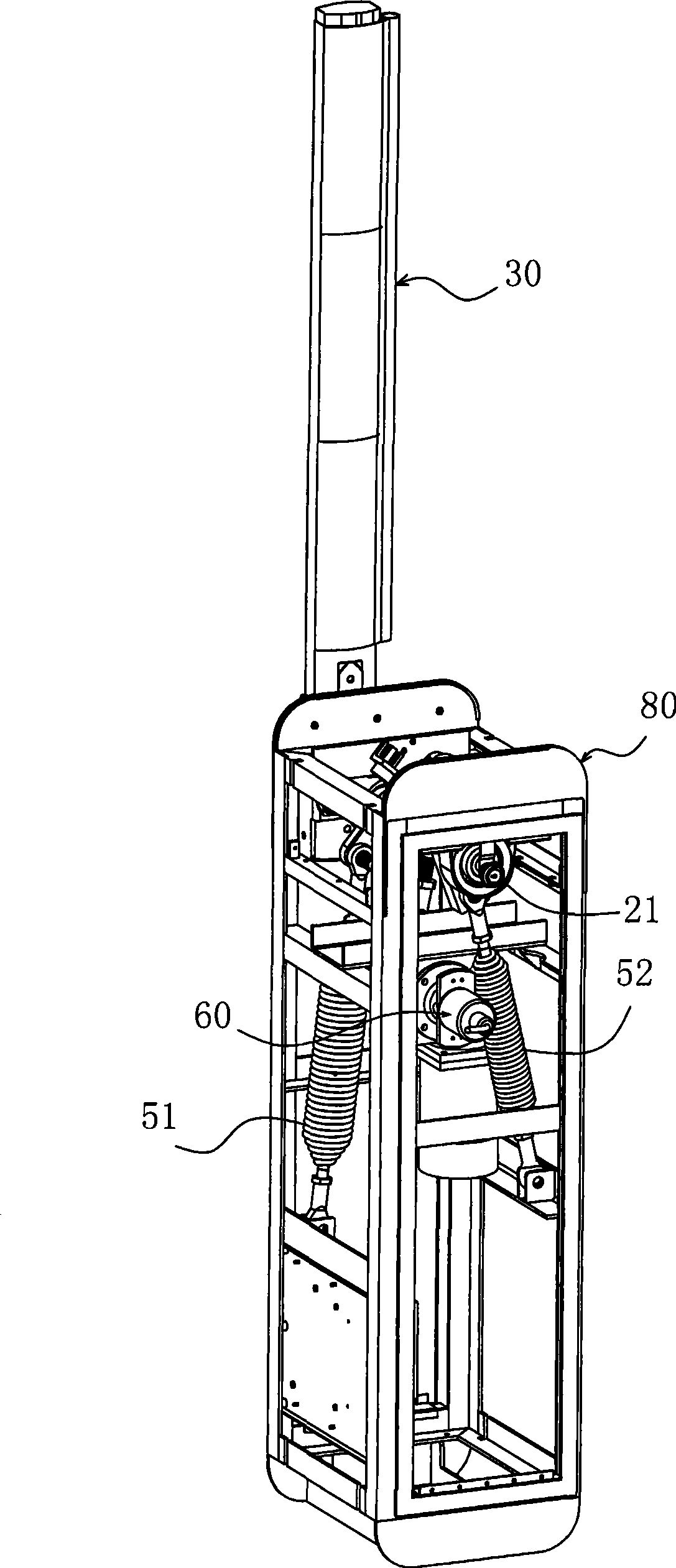

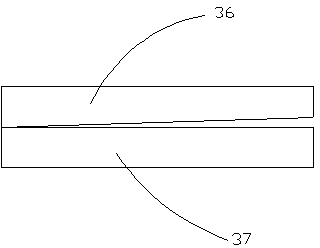

Encoding controlled bidirectional balance road gate

InactiveCN101440609ASolve the adjustmentSolve control problemsAC motor controlTraffic restrictionsFrequency changerFrequency conversion

The invention discloses a coding controllable two-way balance banister. The banister comprises a counter rotating motor, a speed reducer component, an output shaft, and a braking lever and a chassis which are arranged on the output shaft. The banister is characterized in that the motor and the speed reducer are connected with the output shaft through a crank link mechanism; the crank link mechanism is connected with a first spring and a second spring which play a role of two-way balance; the motor and a speed reducer rotary shaft of the speed reducer component are provided with a coder which performs accurate positioning on the positions moved by the braking lever; and the banister also comprises a transducer which is matched with the coder to adjust the speed of the motor. The banister can perform accurate positioning on positions moved by the braking lever and perform frequency conversion control on the speed of the motor, so as to ensure smooth operation of the braking lever and effectively save energy.

Owner:深圳市车安科技发展有限公司

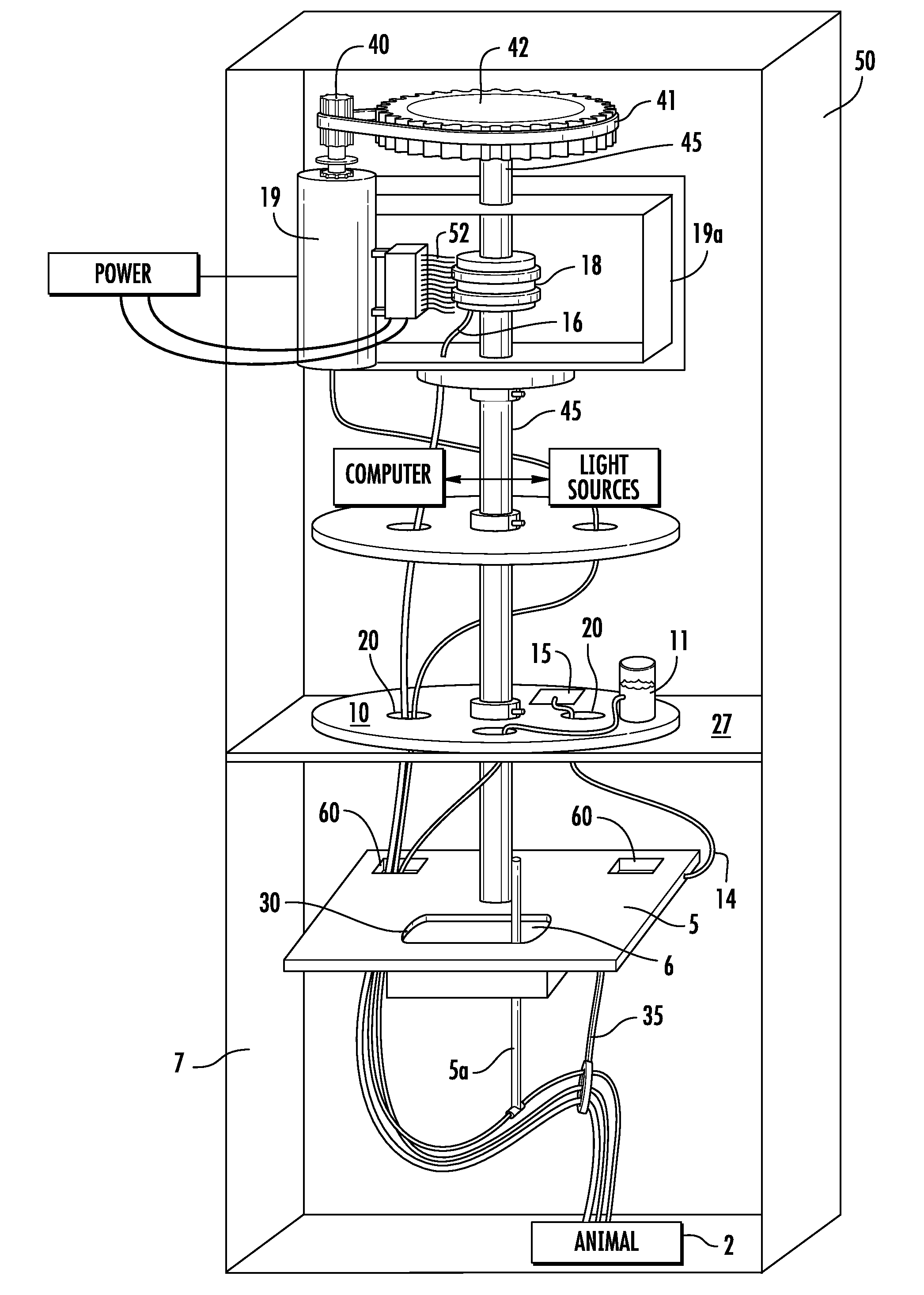

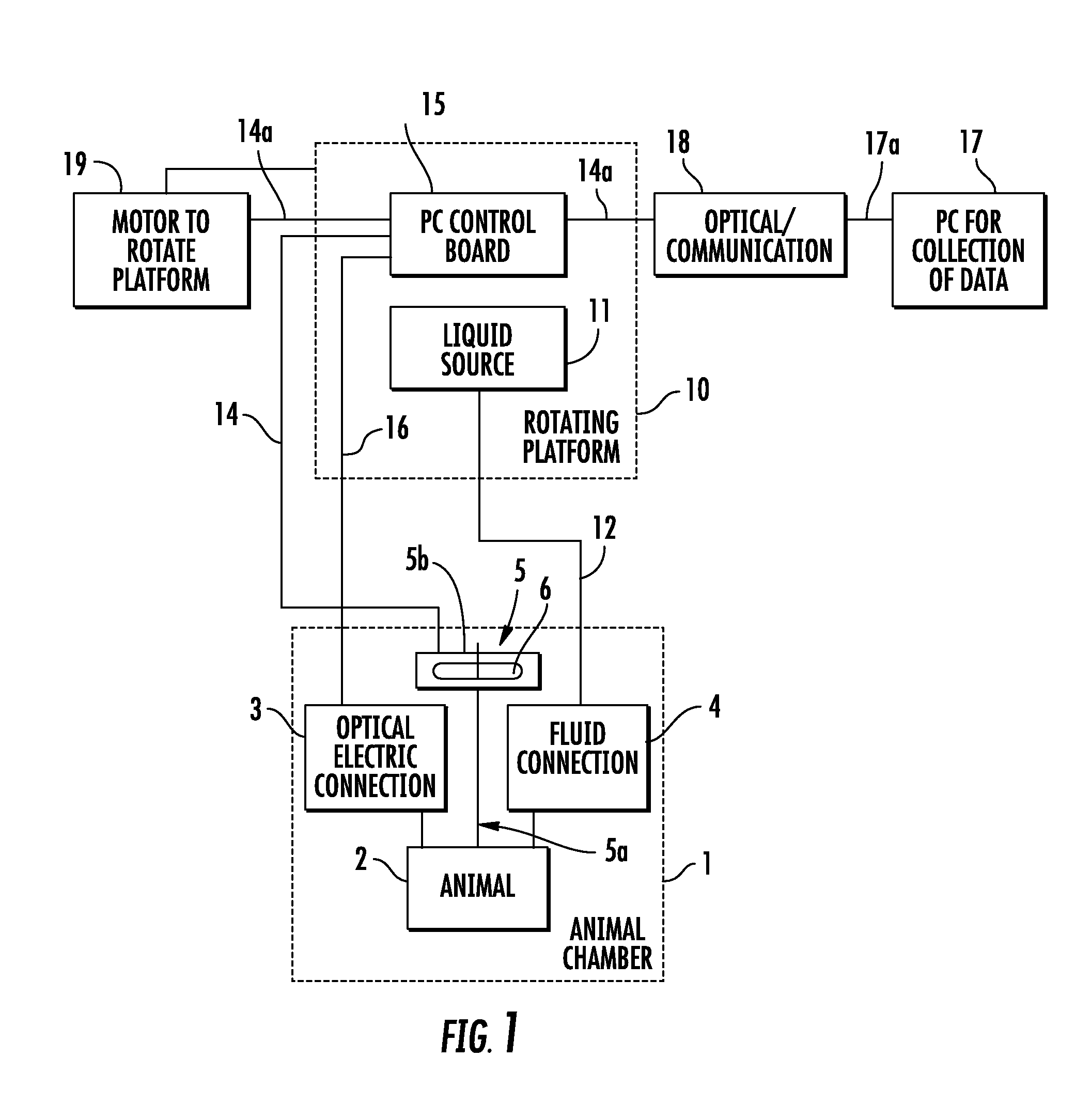

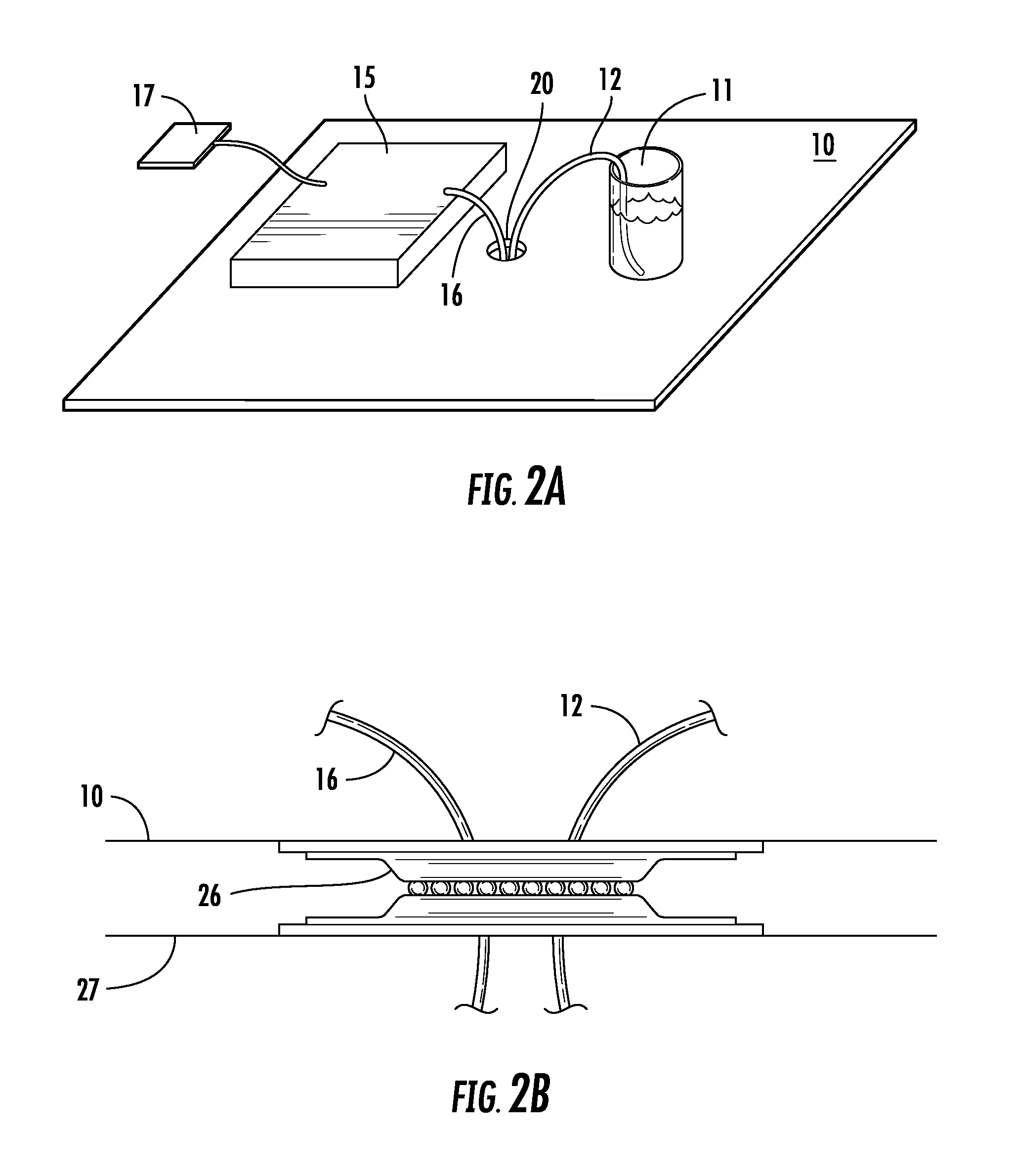

System for development of therapeutic drugs and procedures

The present invention relates to a device and method for delivering drugs or sending or receiving information to or from a lab test animal over a long period of time without having the cords attached to the animal tangle as it moves around in its enclosure.

Owner:NEUROBIOLOGY LLC

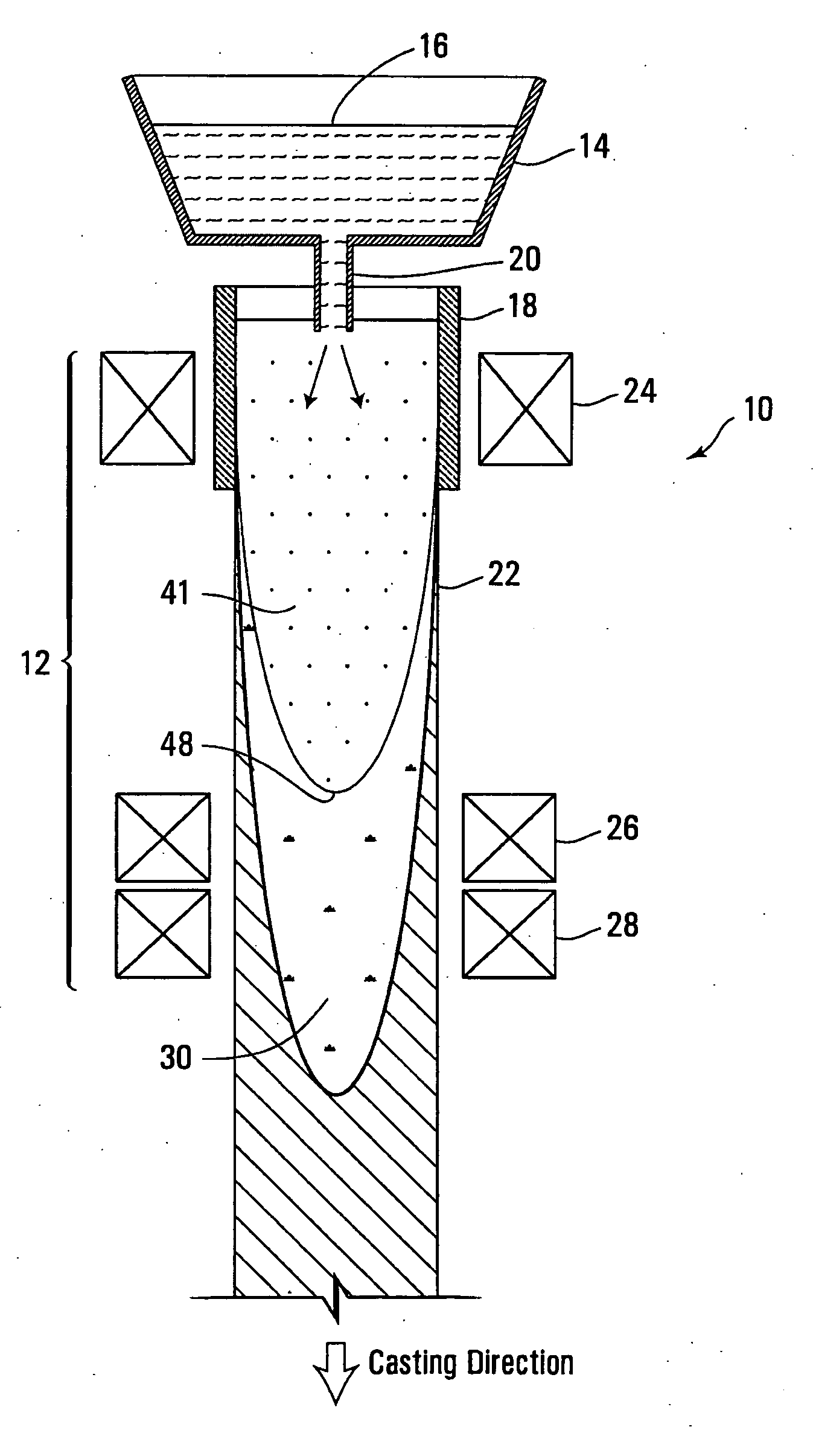

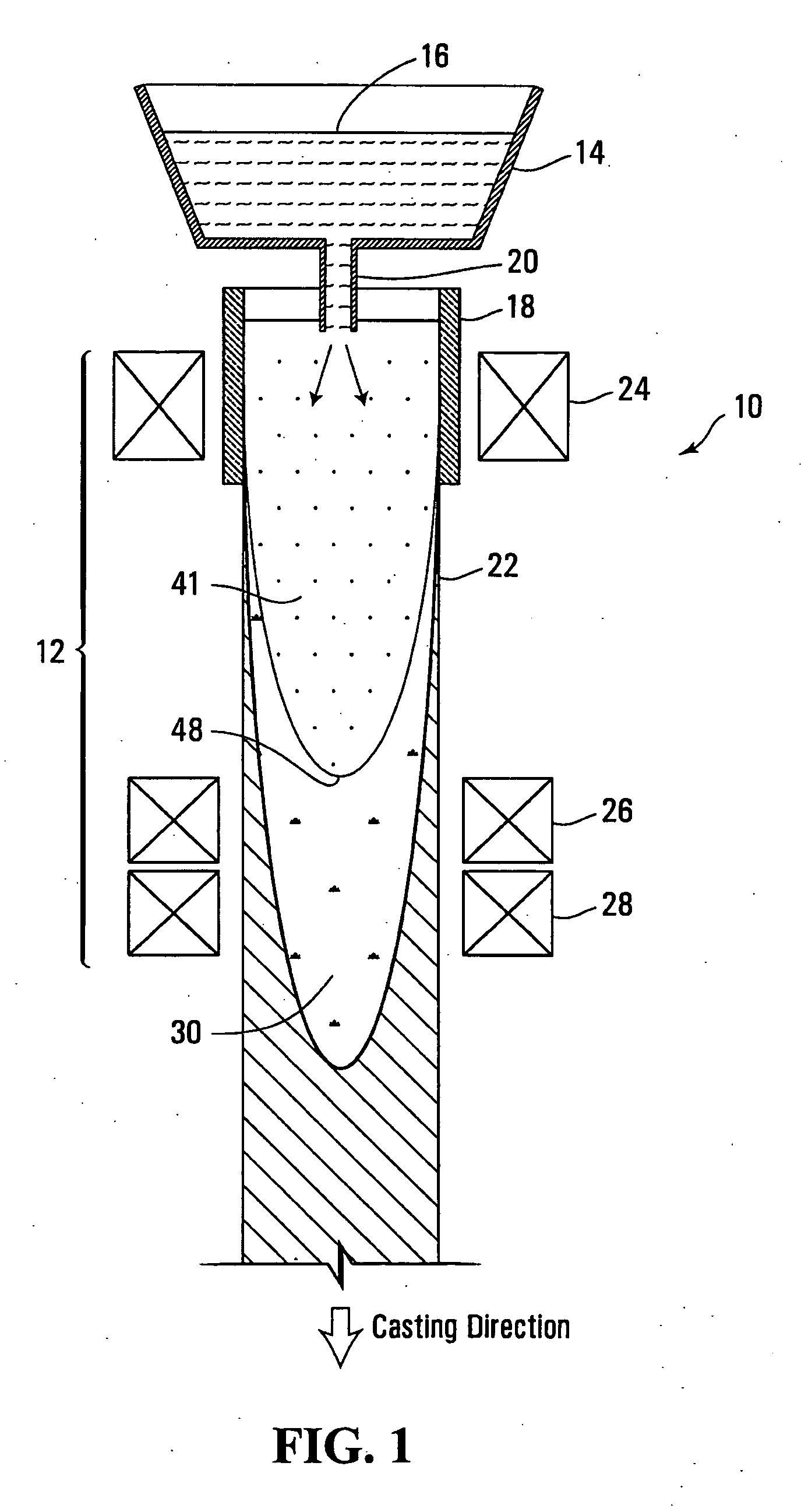

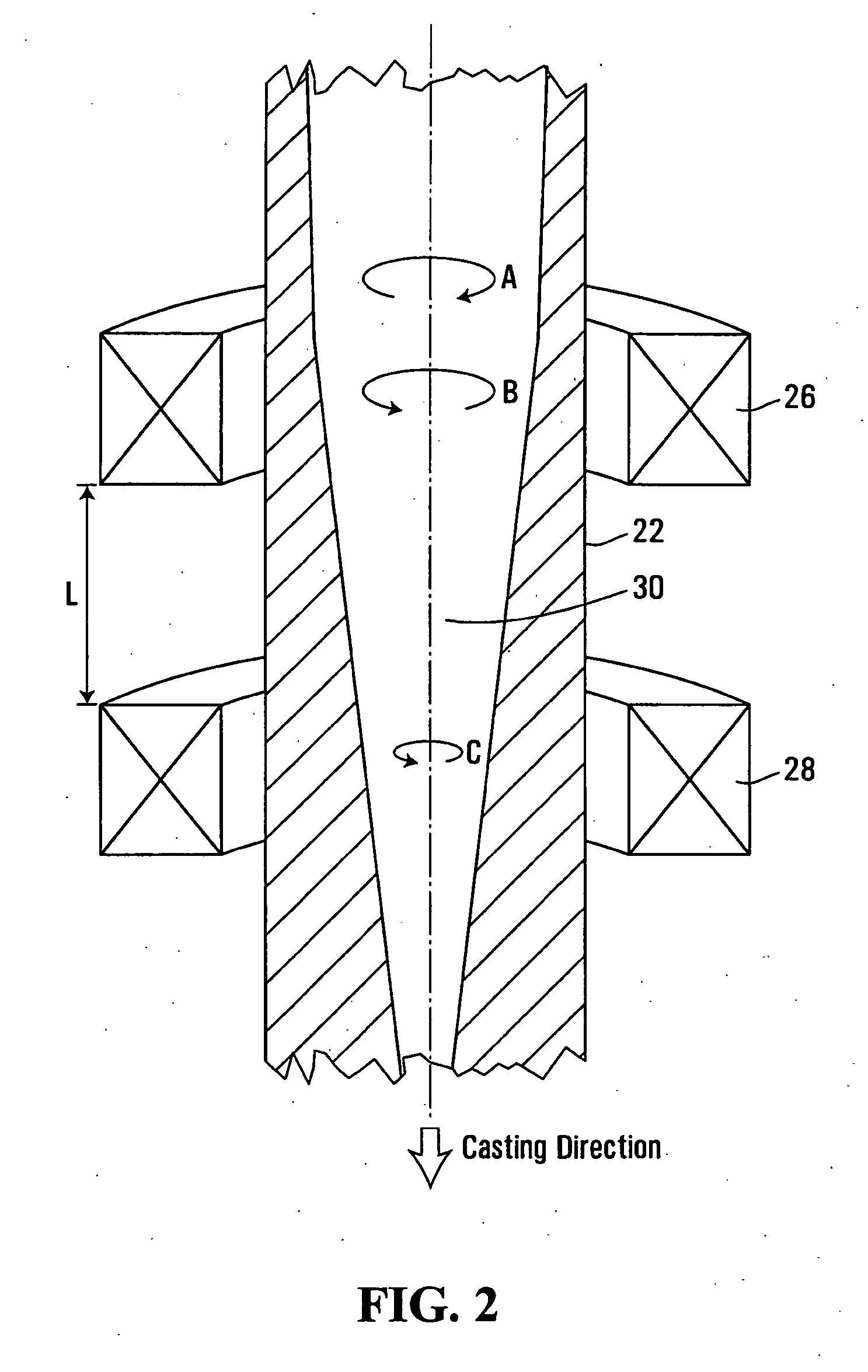

Modulated electromagnetic stirring of metals at advanced stage of solidification

InactiveUS20090242165A1Overcome inertiaTransportation and packagingMixersElectromagnetic stirringAdvanced stage

A method and apparatus for electromagnetic stirring of molten metals at an advanced stage of solidification, as may be used in continuous casting of steel billets and blooms, are disclosed. At least first and second stirrers are provided for generating first and second rotating magnetic fields of a differing frequency about an axis of solidifying molten metal. The stirrers are arranged about the molten metal in sufficiently close proximity to each other so that their respective magnetic fields superpose to produce a modulated magnetic field. The magnetic fields of the respective stirrers may either have common or opposing rotational directions. The modulated stirring produced by the magnetic fields results in oscillating primary and secondary flows and hence turbulence within the melt bulk in the region wherein temperature of the melt on its central axis is below the liquidus level and at least 10% of substantially solidified material is formed. Turbulent flow created by this stirring method disrupts formation of crystalline structures in the melt bulk and mixes solute enriched melt of the central region with the bulk volume which subsequently results in improvements of the solidification structure and overall internal quality of the cast products.

Owner:ABB INC

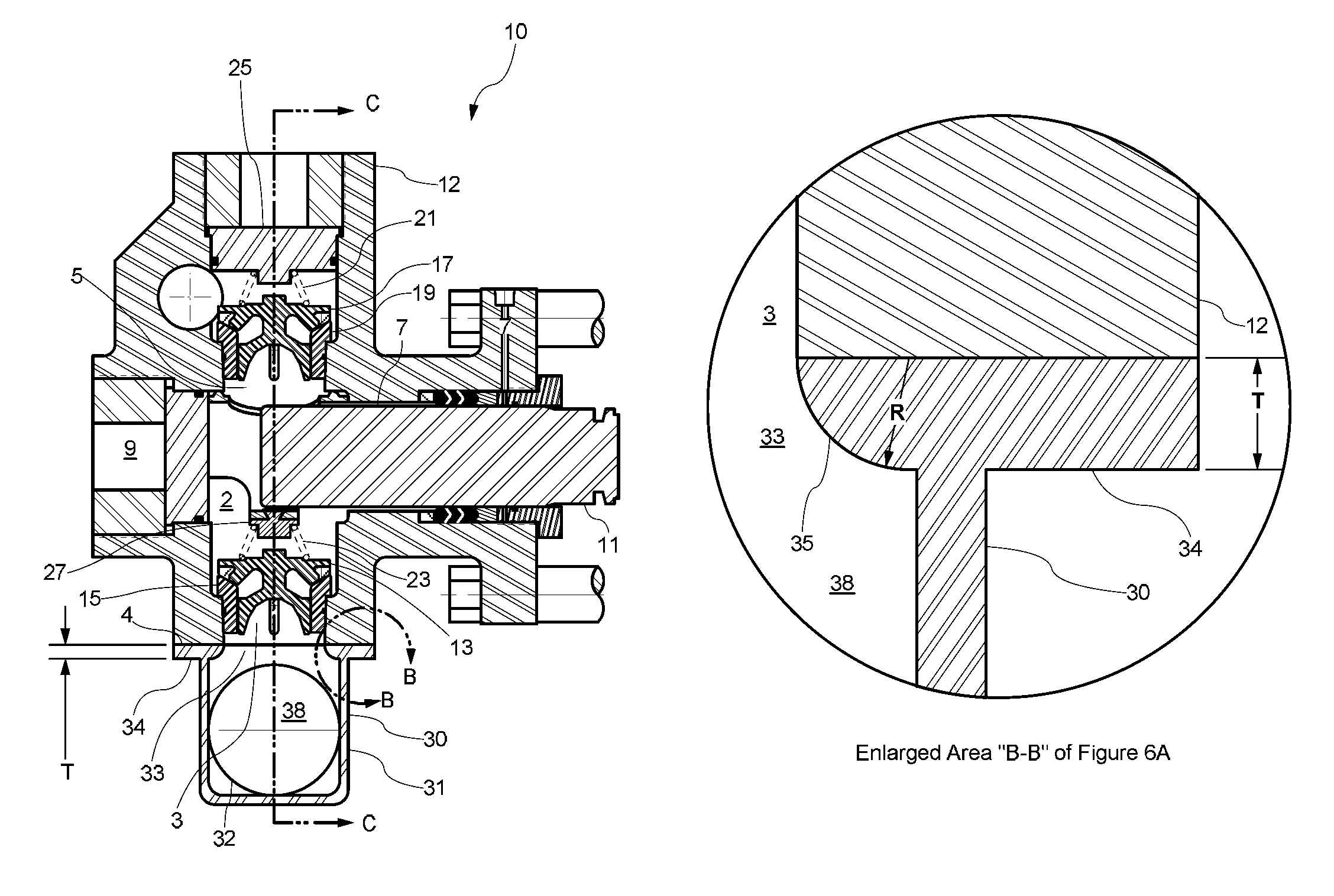

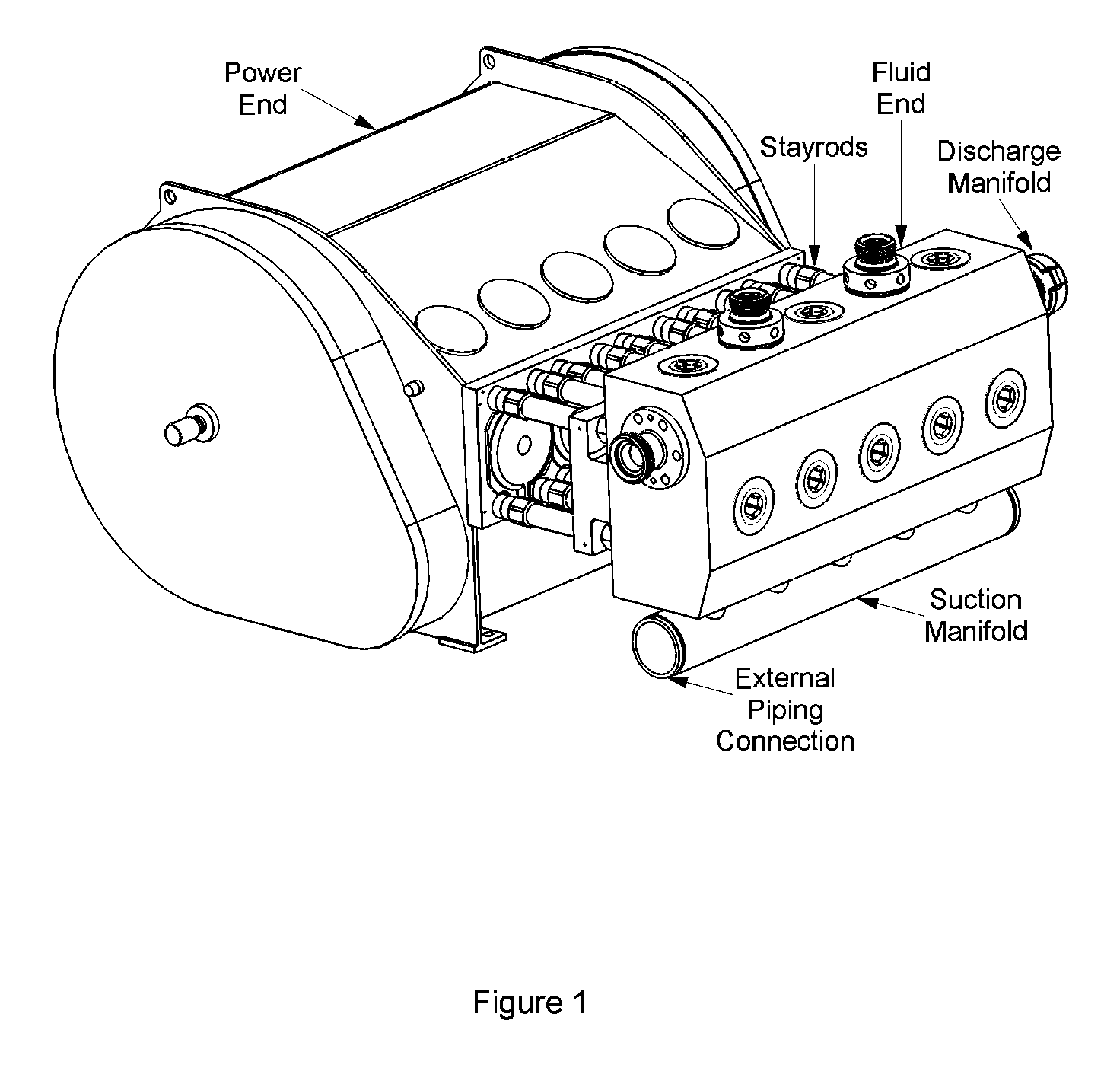

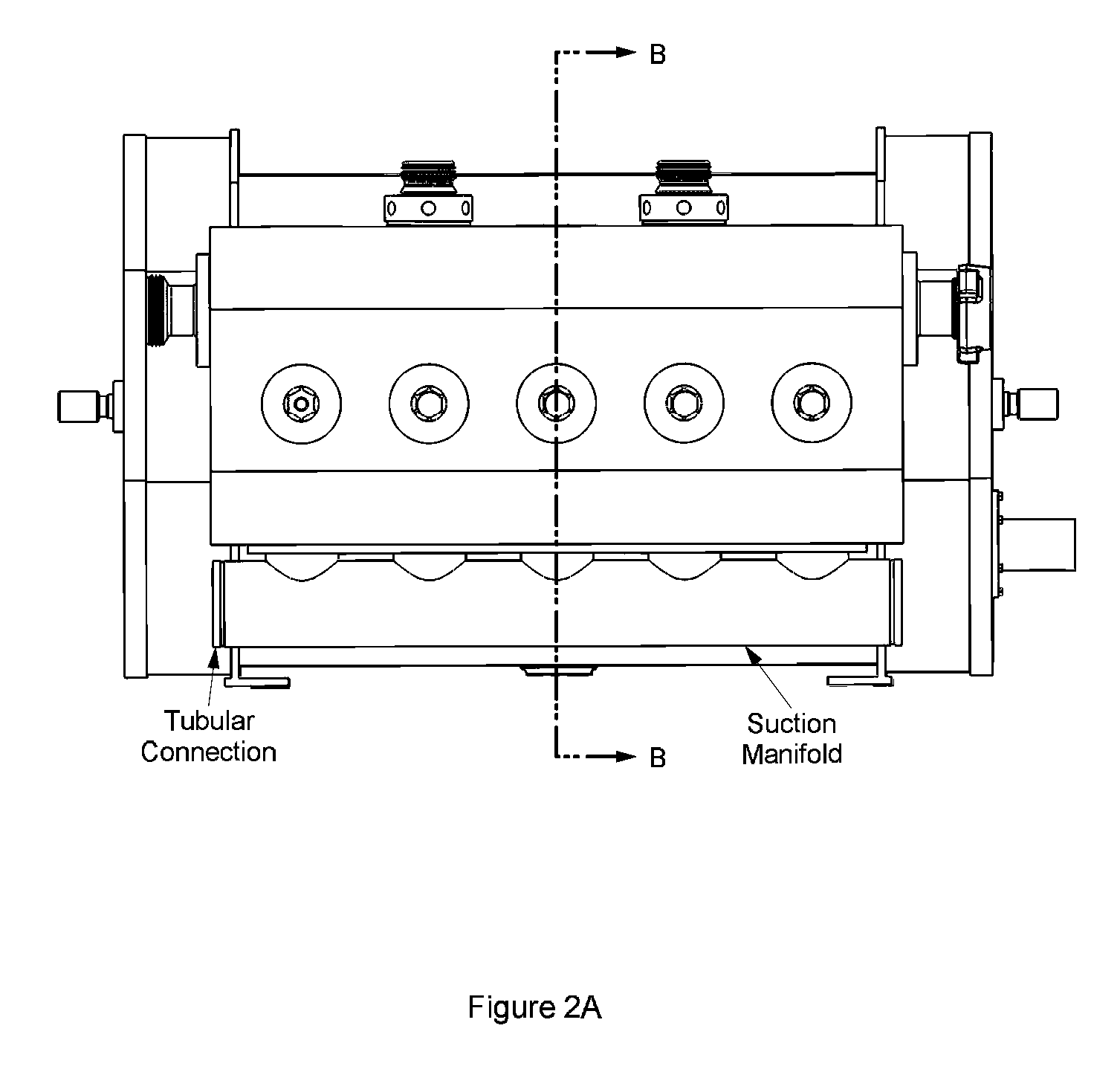

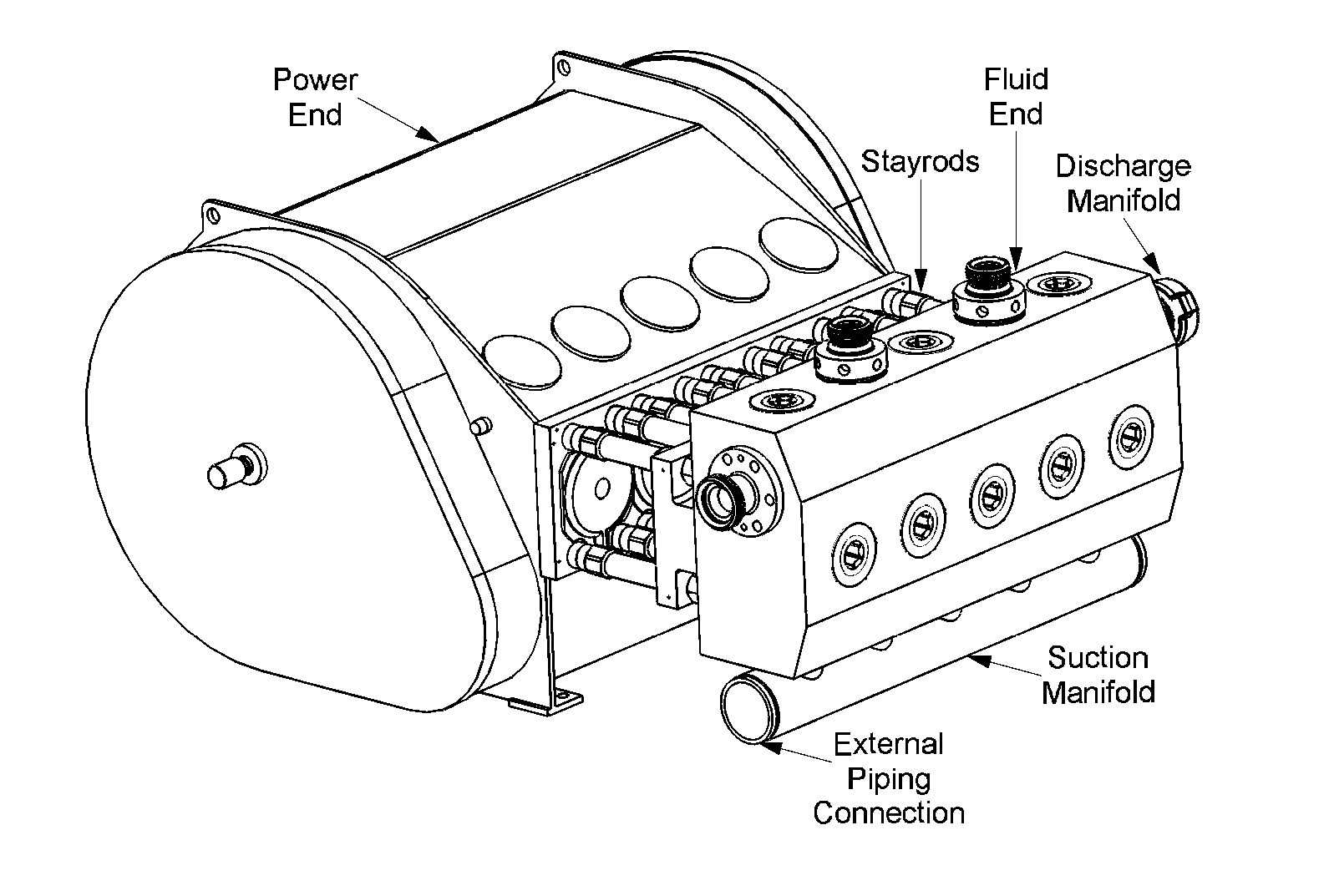

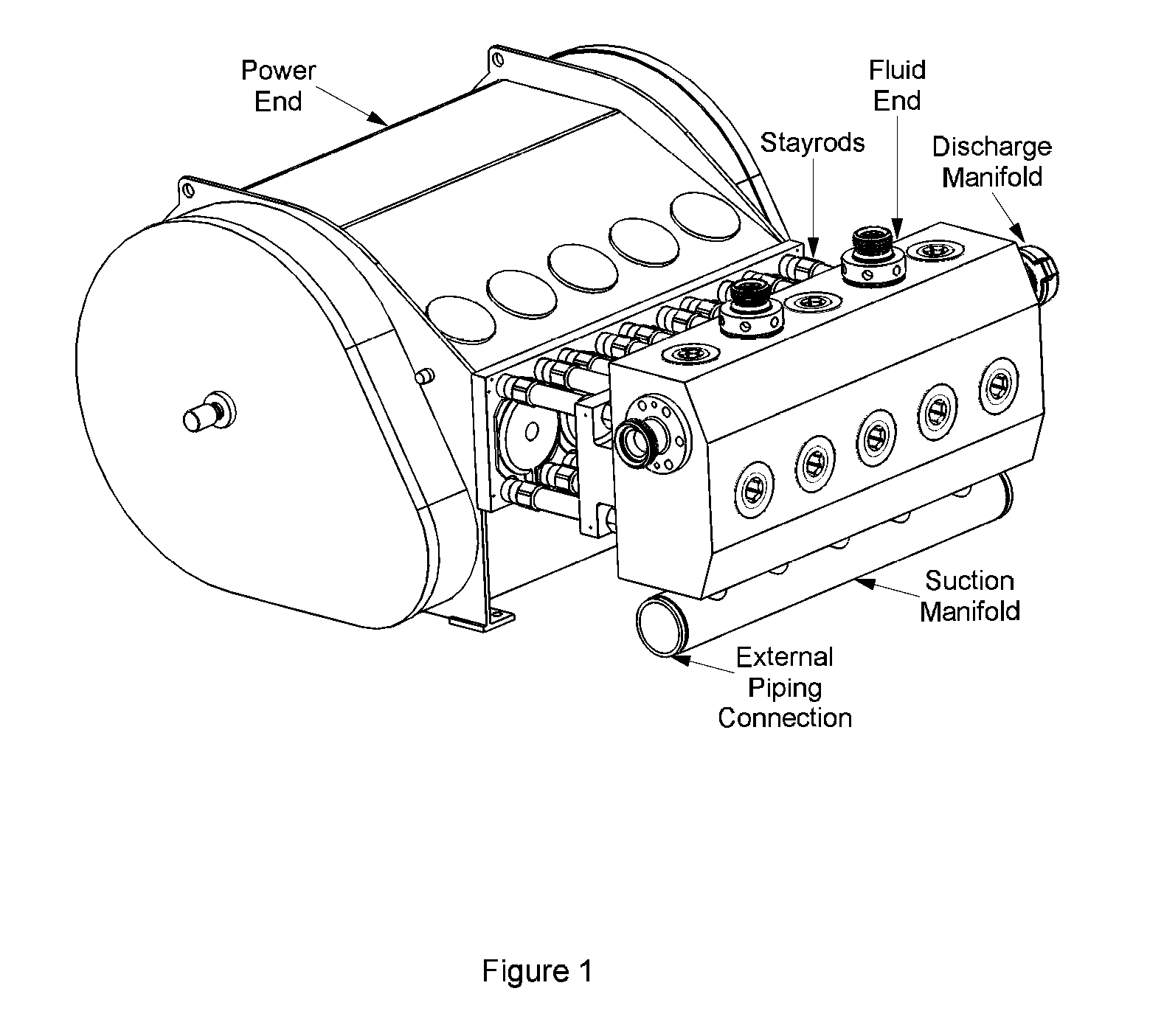

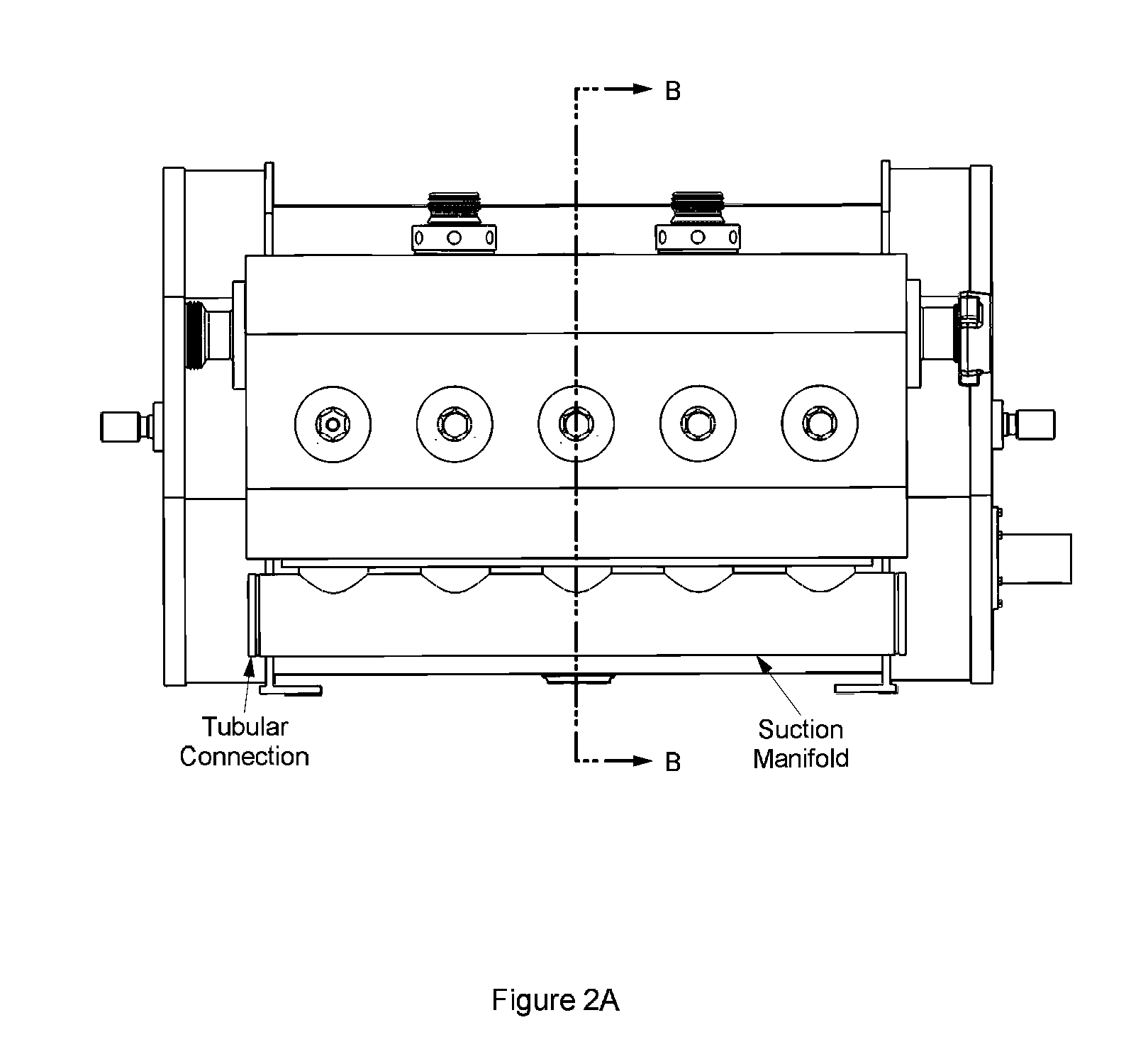

Integrated design fluid end suction manifold

InactiveUS9500195B2Reduce frictionReduce turbulencePositive displacement pump componentsPiston pumpsIntegrated designCatheter

A fluid end assembly comprising a housing, valve bodies, seals, seats, springs, and other associated parts, paired with a suction manifold that facilitates bi-directional fluid flow. The suction manifold of this invention is designed to preserve fluid energy that will ensure complete filling of the cylinder in extreme pumping conditions. The suction manifold utilizes a chamber design positioned immediately below the suction valves, eliminating all connecting ducts. Alternate embodiments of this invention include a suction manifold with an integral fluid dampeners or stabilizers.

Owner:ALTIS INVESTMENTS LLC

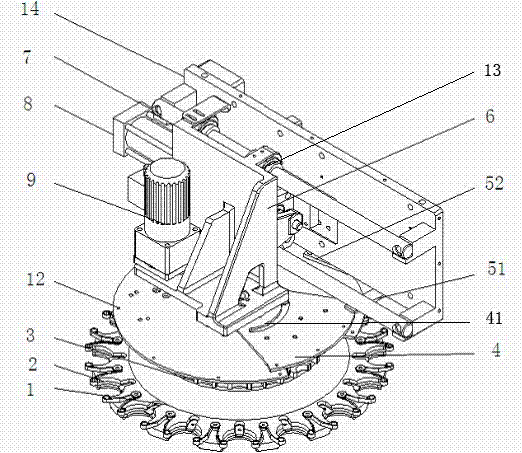

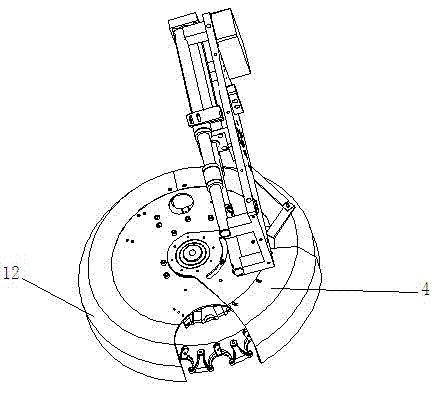

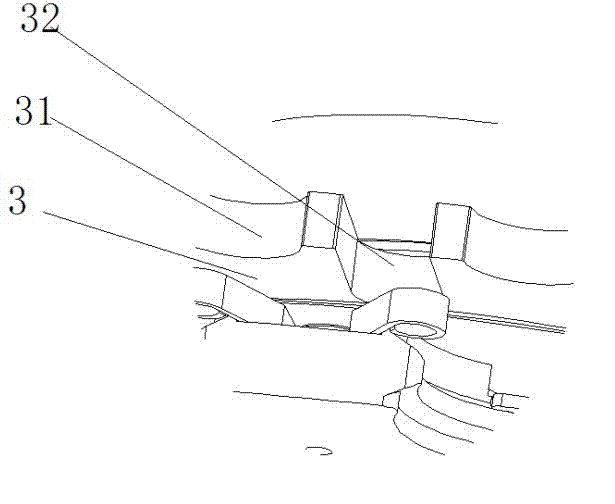

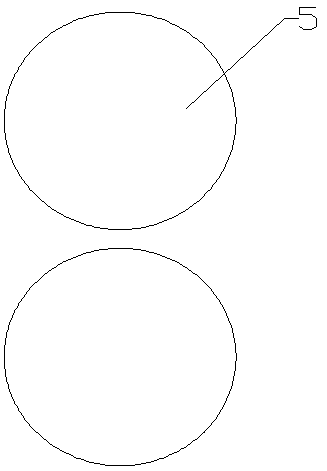

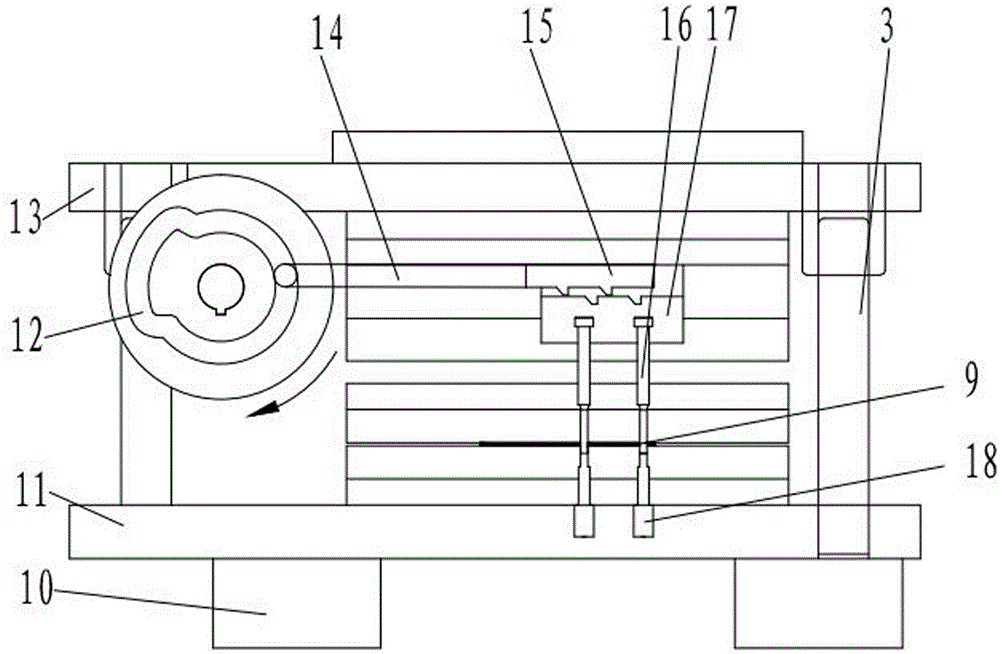

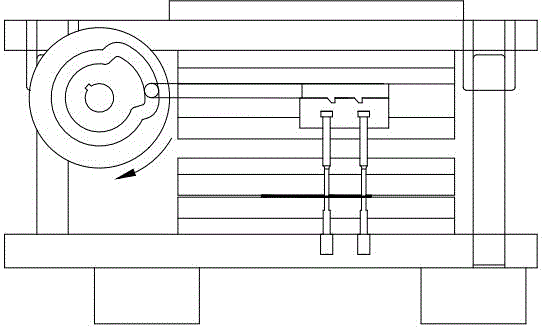

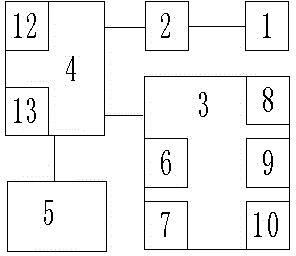

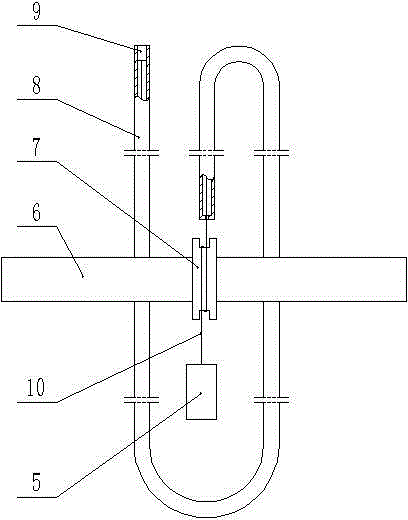

Bamboo hat tool magazine

ActiveCN102773748AOvercome inertiaDirect control positionPositioning apparatusMaintainance and safety accessoriesInertiaCircular disc

The invention discloses a bamboo hat tool magazine which comprises a circular cutter head. A plurality of cutting tool clamping parts are uniformly distributed on the circumference of the cutter head; the cutter head is fixedly connected with a transmission disc; a plurality of curved surface grooves and radial grooves are distributed on the transmission disc in an indexing staggering way; a notch circular disc is formed above the transmission disc; a notch cylindrical pin is installed on the lower surface of the notch circular disc in a centering way; the circumference of the notch circular pin is matched with the curved surface grooves on the transmission disc; an eccentric cylindrical pin is also eccentrically installed on the notch circular disc; the eccentric cylindrical pin can slide in the radial grooves; the notch circular disc is connected on a power device; the power device is connected on a bracket; and the transmission disc is connected on the bracket through a transmission shaft. The power device drives the notch circular disc to rotate; when the eccentric cylindrical pin sides in the radial grooves, the transmission disc is driven to rotate so as to drive the cutter head to rotate; when the eccentric cylindrical pin slips off a radial groove, the notch cylindrical pin enters a curved surface groove to lock the transmission disc, so that the cutter head can not rotate; and the bamboo hat tool magazine overcomes the inertia of the circular motion, and ensures that the movement of a cutting tool on the cutter head is relatively accurate, so that the clamping is convenient.

Owner:昆山北钜机械有限公司

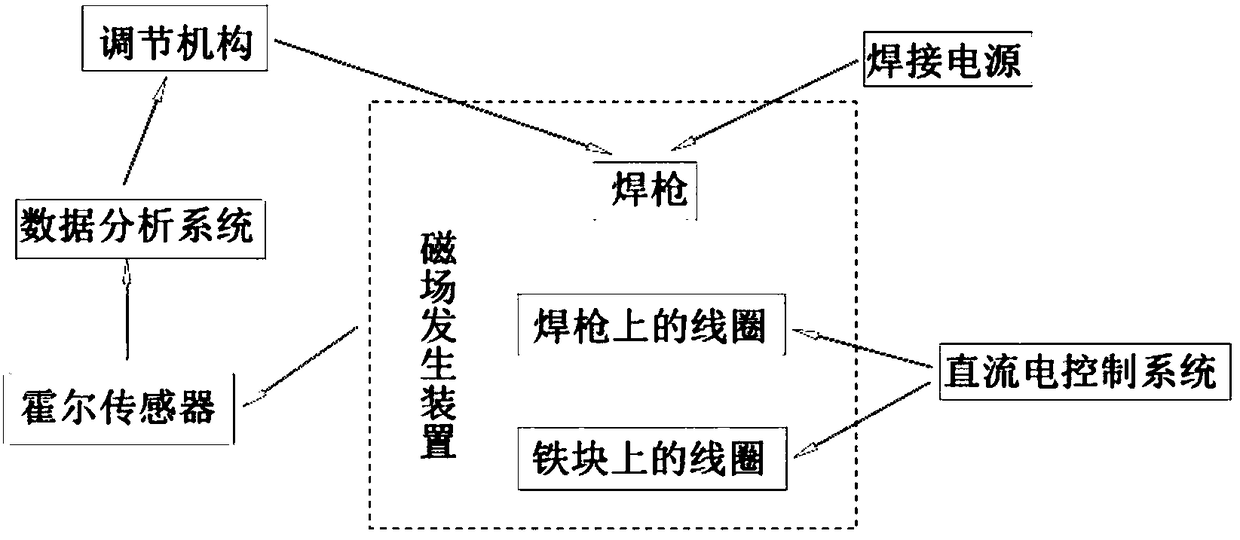

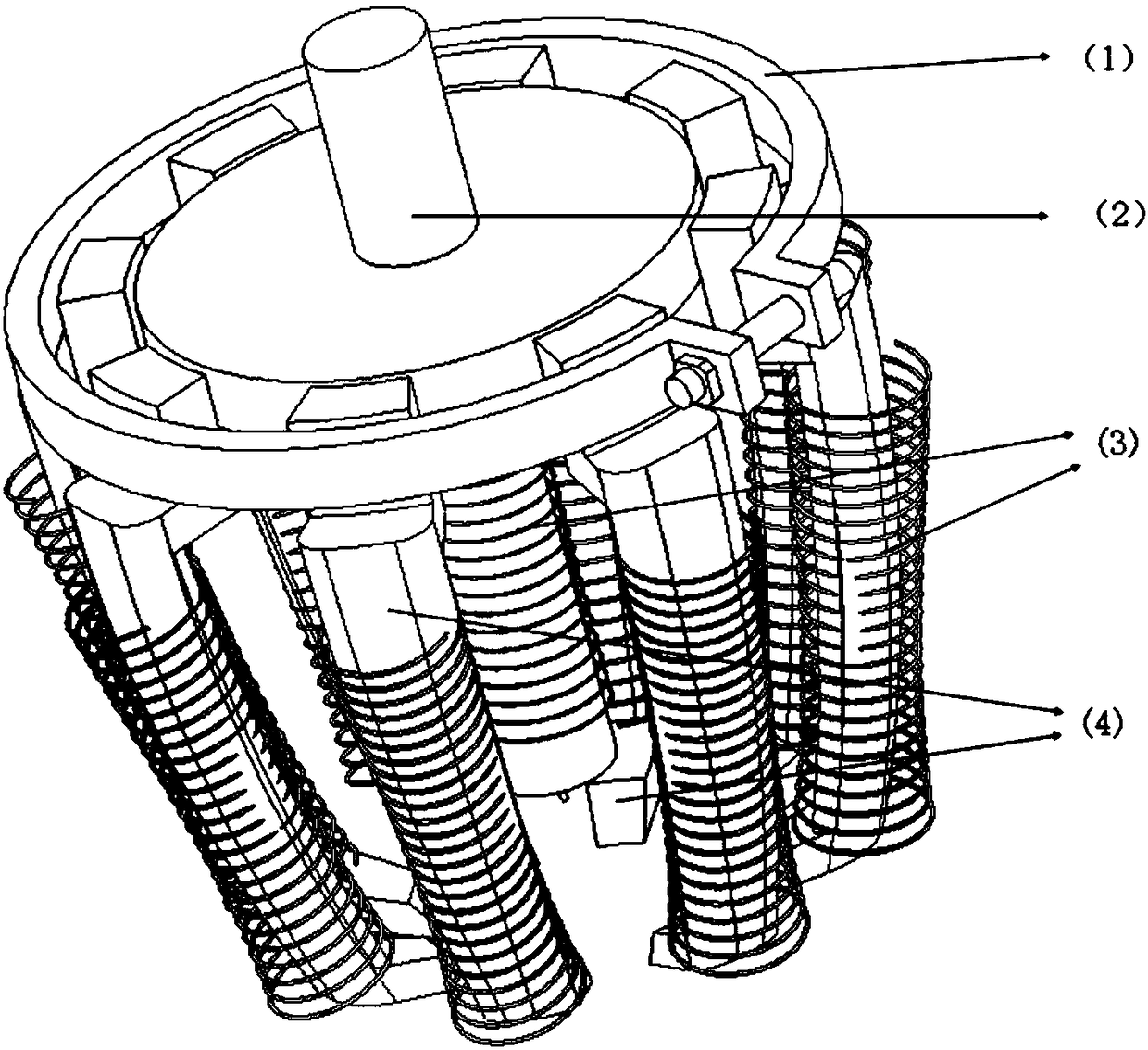

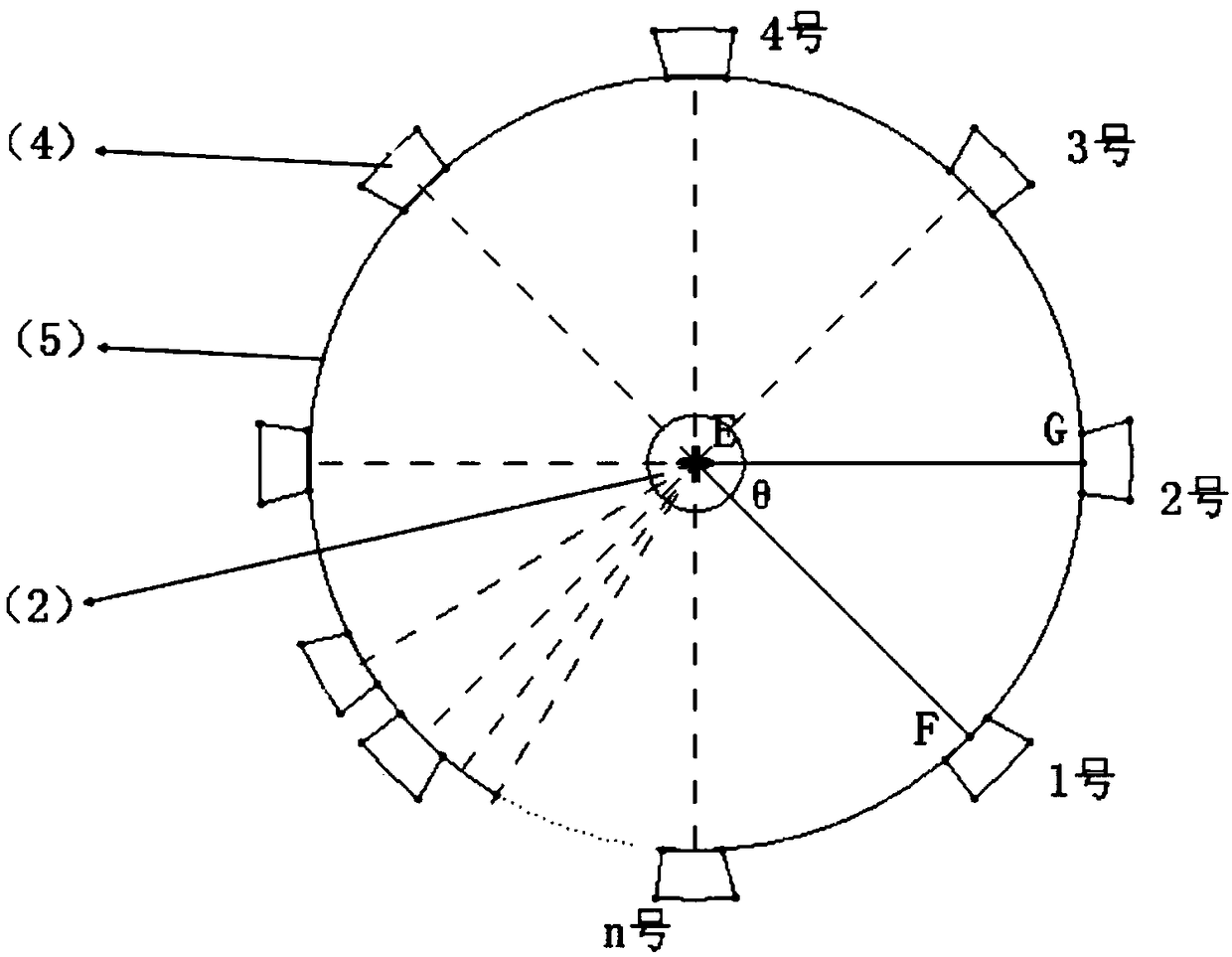

Method for controlling magnetic monopole through DC to rotate to conduct segmented arc control

ActiveCN108213650AOvercome inertiaReduce adverse effectsArc welding apparatusInstabilityMagnetic monopole

The invention provides a method for controlling a magnetic monopole through DC to rotate to conduct segmented arc control. The method is mainly used for solving the technical problems that a magneticfield is controlled unstably through exciting current, the requirement for a magnetic material is high, the electric arc behavior is difficult to control to make the swinging track of the electric arcindefinite, the scanning range is small and tracking is inaccurate due to the fact that little effective information of weld joints is acquired in the prior art are solved. According to the technicalscheme, the method is characterized in that the monopole of the magnetic field is controlled through DC to conduct segmented rotating around a welding gun shaft; an expected track of circumferentialswinging of the electric arc is equally divided into multiple segments of small-radian intervals. Within each small-radian interval, a longitudinal magnetic field with a declination angle with the welding gun shaft is manufactured through DC to make the electric arc rotate and deviate from the axis, and then the electric arc is pulled to conduct small-radian swinging through the magnetic field. Movements of the electric arc within all the intervals are combined to achieve circumferential swinging. Weld joint information is acquired to achieve automatic tracking on the weld joints by measuringchange of welding current when the electric arc swings circumferentially in different positions.

Owner:XIANGTAN UNIV

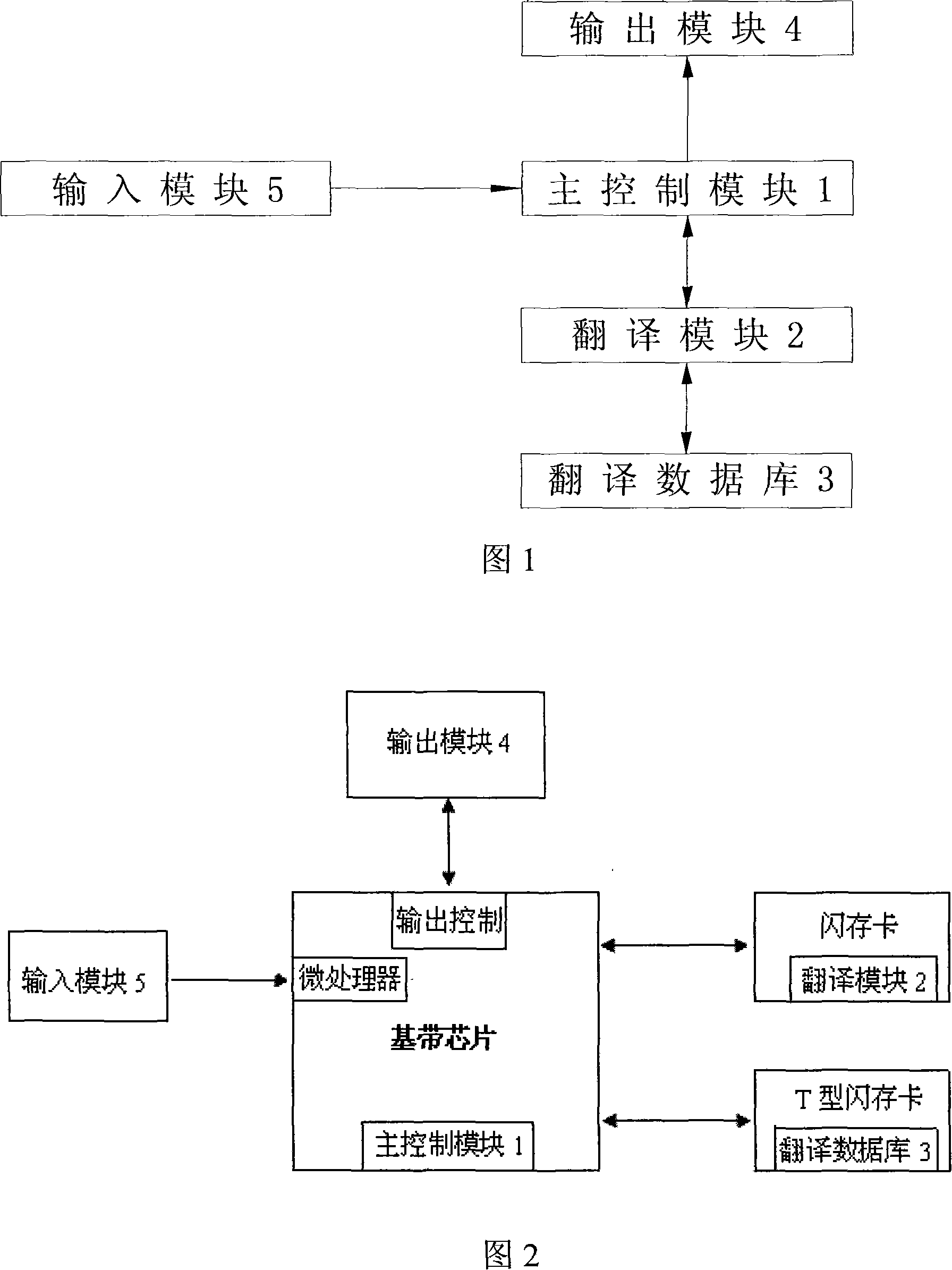

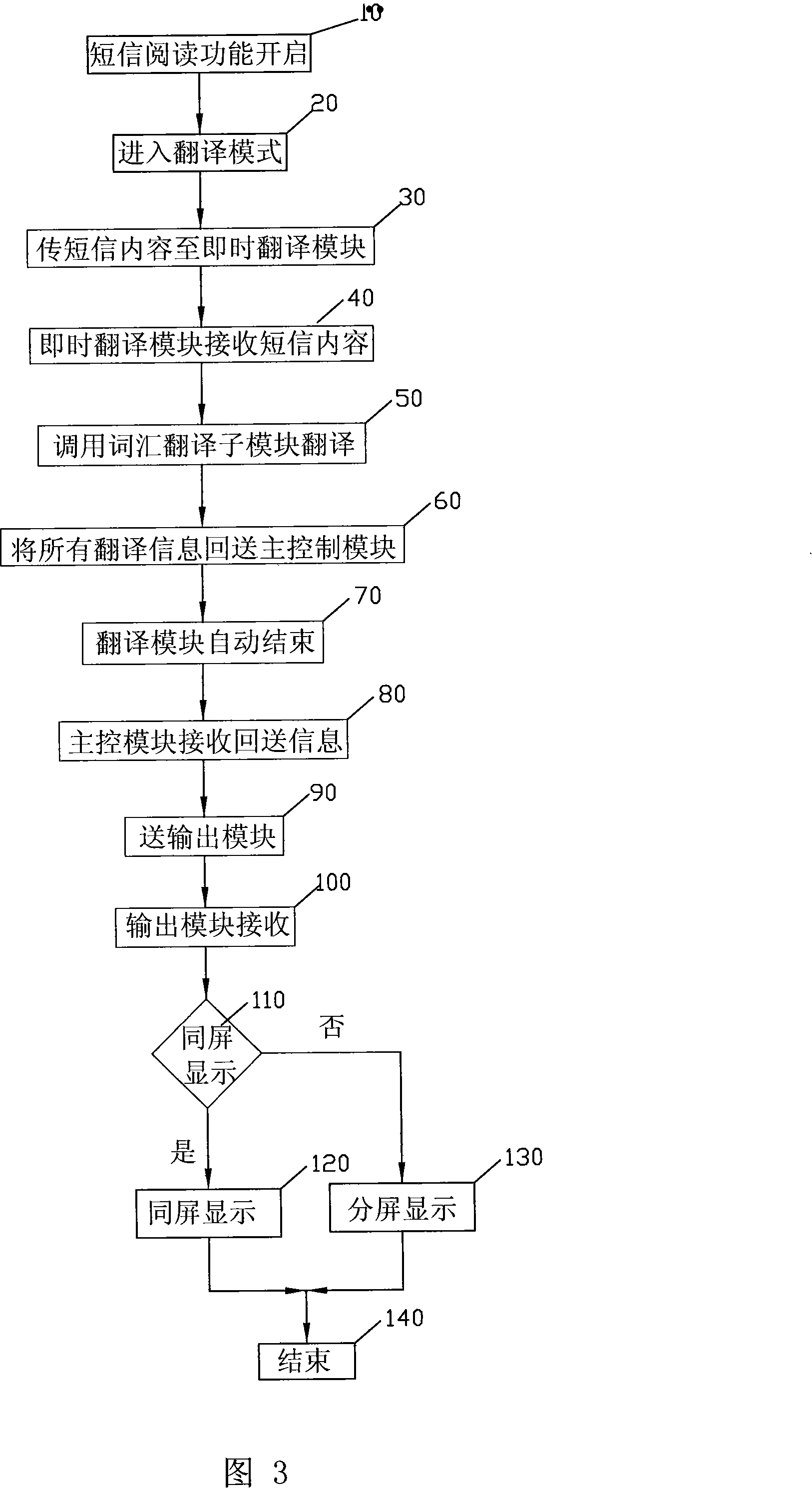

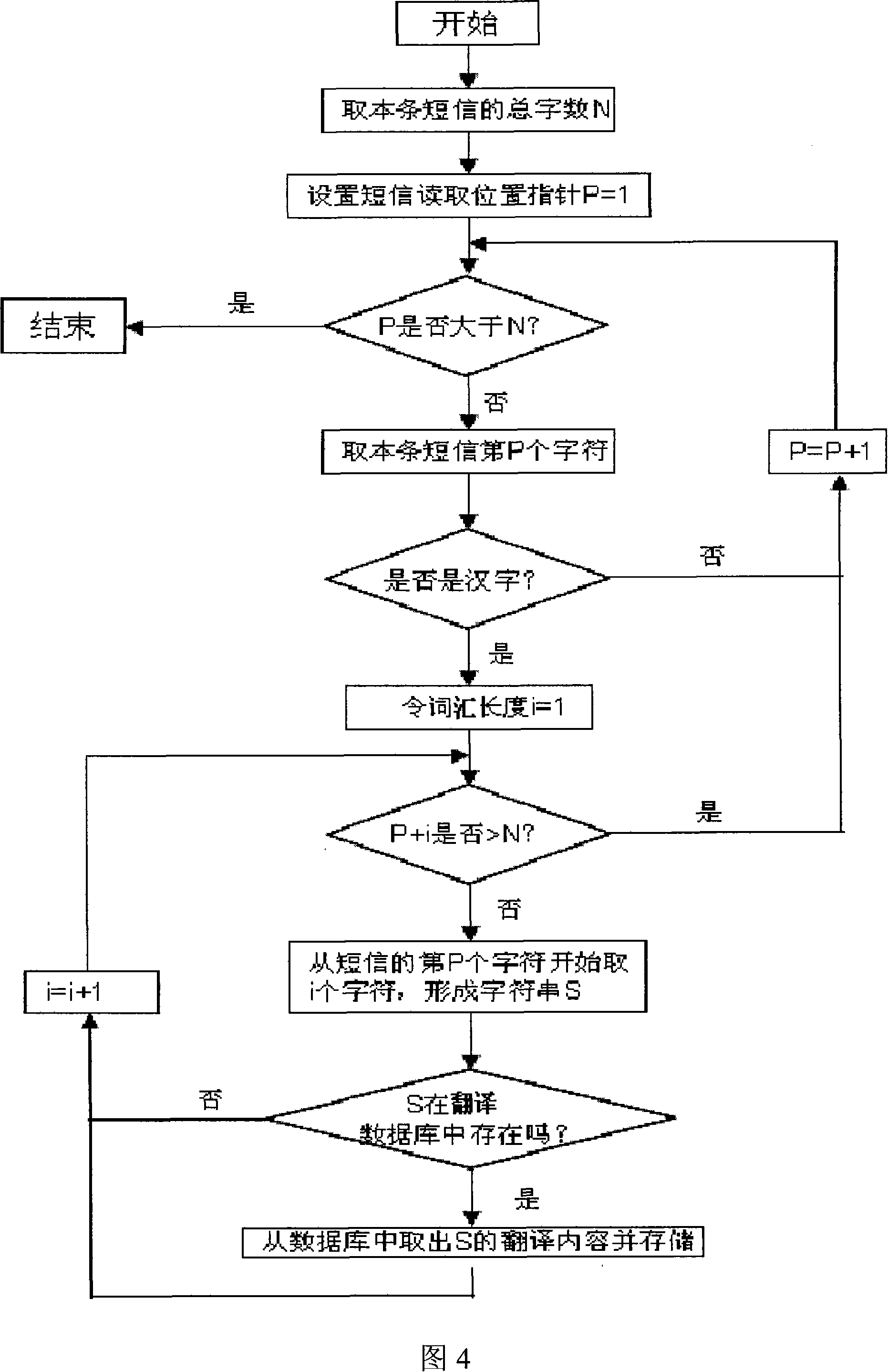

Mobile phone for learning foreign language by short message and method thereof

InactiveCN101175277AOvercome inertiaMake up for the lack of learning function designRadio/inductive link selection arrangementsSubstation equipmentPart of speechMobile phone

The invention relates to a mobile phone and a method for learning foreign languages by directly utilizing the translation results of mobile phone short messages. It solves the technical problem that the existing learning methods of mobile phones cannot realize passive learning of foreign languages anytime and anywhere. Turn on the text message reading function to automatically enter the translation mode, and the instant translation module searches the translation result of the text message content from the translation database by calling the corresponding translation sub-module and outputs the result. The operator can see the corresponding translation results, such as vocabulary, word meaning, part of speech, phonetic symbols, example sentences, common phrases, etc., while viewing the mobile phone text messages, and can also hear the pronunciation of the translation results. The device makes full use of the characteristics that the mobile phone is carried around and used to send and receive a large number of short messages, and realizes passive learning anytime and anywhere, and the learning effect is very remarkable.

Owner:BEIJING HI TECH WEALTH INVESTMENT DEV

Integrated Design Fluid End Suction Manifold

InactiveUS20140137963A1Easy to placeReduce frictionPositive displacement pump componentsPressure pumpsEngineeringIntegrated design

A fluid end assembly comprising a housing, valve bodies, seals, seats, springs, and other associated parts, paired with a suction manifold that facilitates bi-directional fluid flow. The suction manifold of this invention is designed to preserve fluid energy that will ensure complete filling of the cylinder in extreme pumping conditions. The suction manifold utilizes a chamber design positioned immediately below the suction valves, eliminating all connecting ducts. Alternate embodiments of this invention include a suction manifold with an integral fluid dampeners or stabilizers.

Owner:ALTIS INVESTMENTS LLC

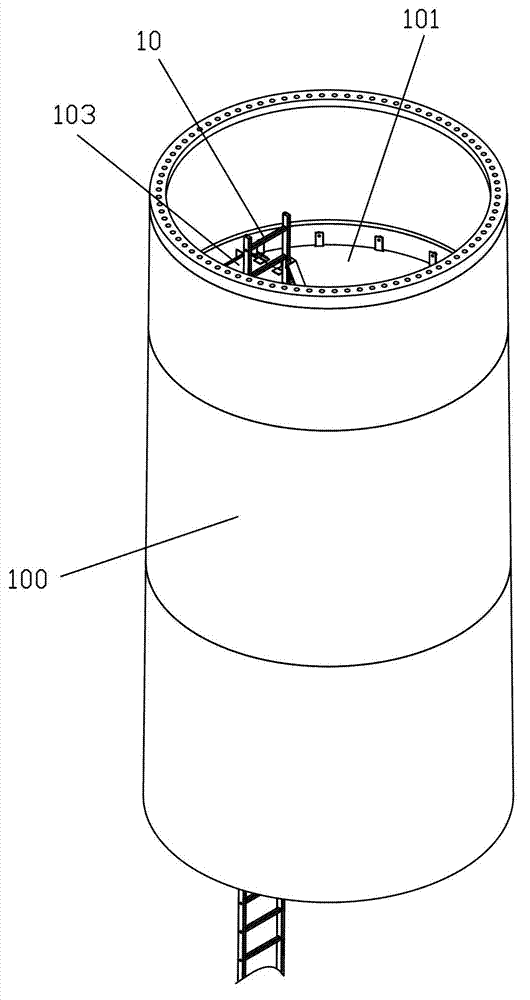

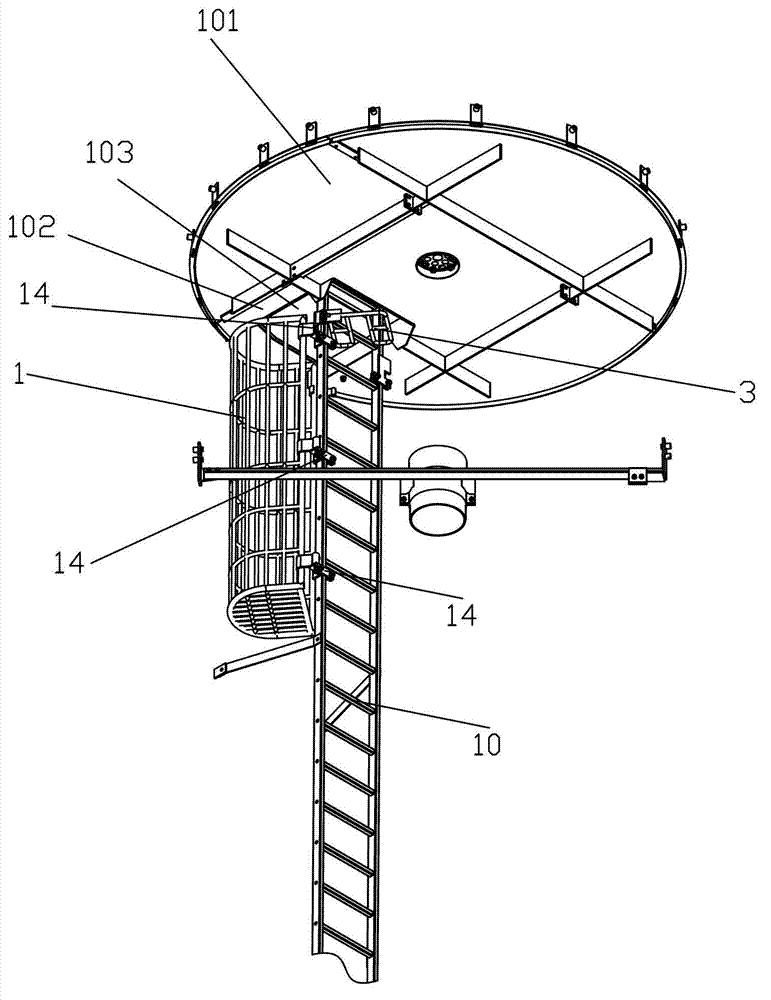

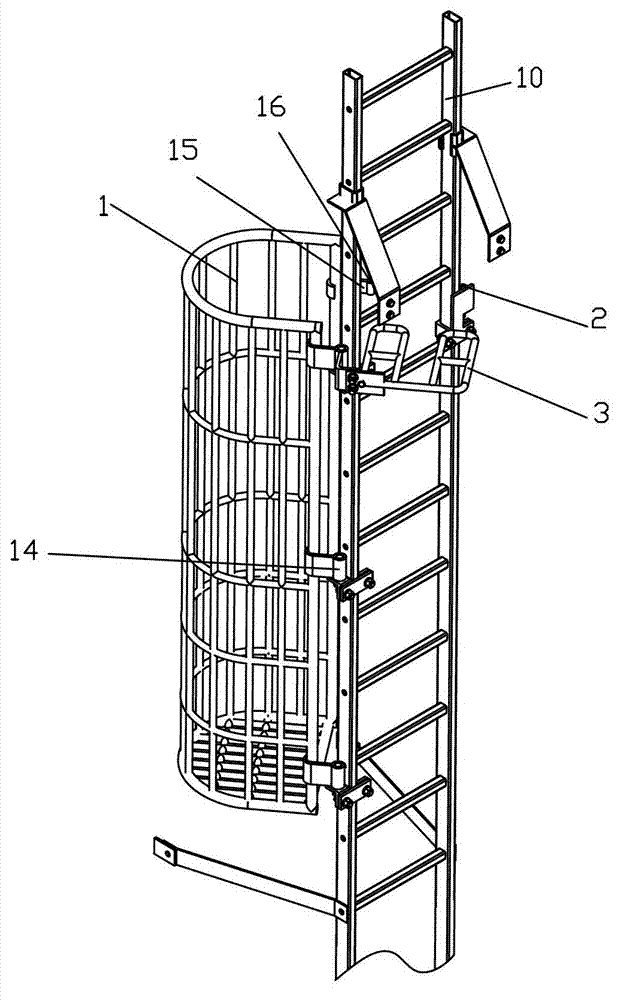

Ladder stand safety protection device on top of tower of wind driven generator

ActiveCN102889052AOvercoming Negligence and LazinessAvoid slipping or fallingWind energy generationWind motor componentsWind drivenWind force

The invention discloses a ladder stand safety protection device on the top of a tower of a wind driven generator. The ladder stand safety protection device is arranged beside the upper part of a ladder stand in the top of the tower of the wind driven generator and is characterized by comprising a protection cage hinged to one of side beams of the ladder stand; the lower part of the protection cage is sealed, and the upper part of the protection cage is open; the protection cage comprises a base frame; a guardrail is arranged on the base frame; an opening is formed in one side of the guardrail; and one side, which is open, of the guardrail is fixed on the side beam of the ladder stand through a hinge. The safety protection device is arranged on the side beam, which is about 2m away from the lower part of a yaw platform, of the ladder stand, so that negligence and inertness of people are overcome, protection measures are forcibly taken when working personnel climb up and down a manhole door of the yaw platform on the top of the tower, and a phenomenon that the working personnel accidentally drop is avoided; and the safety protection device is simple in structure, convenient to mount and use and safe.

Owner:GUANGDONG MINGYANG WIND POWER IND GRP CO LTD

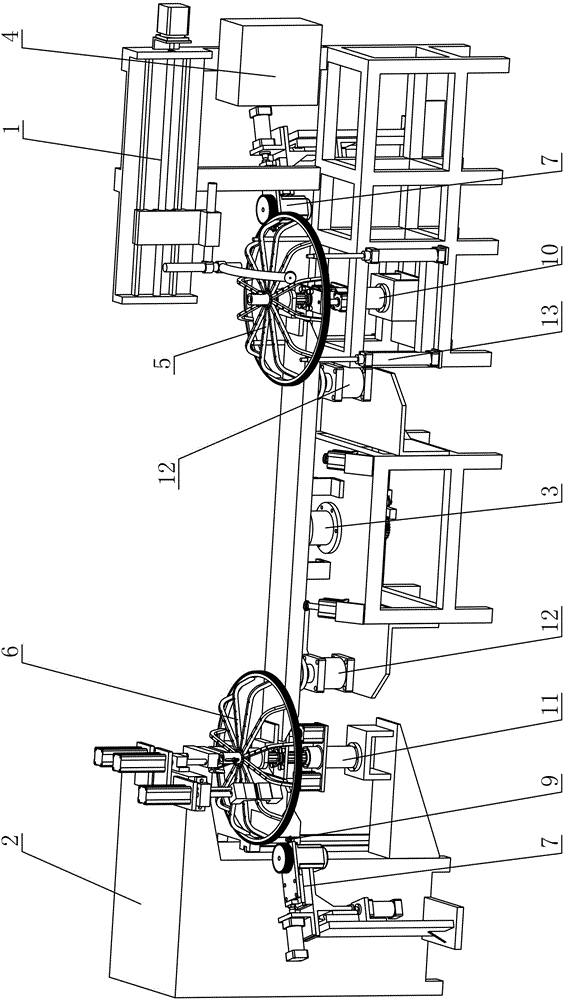

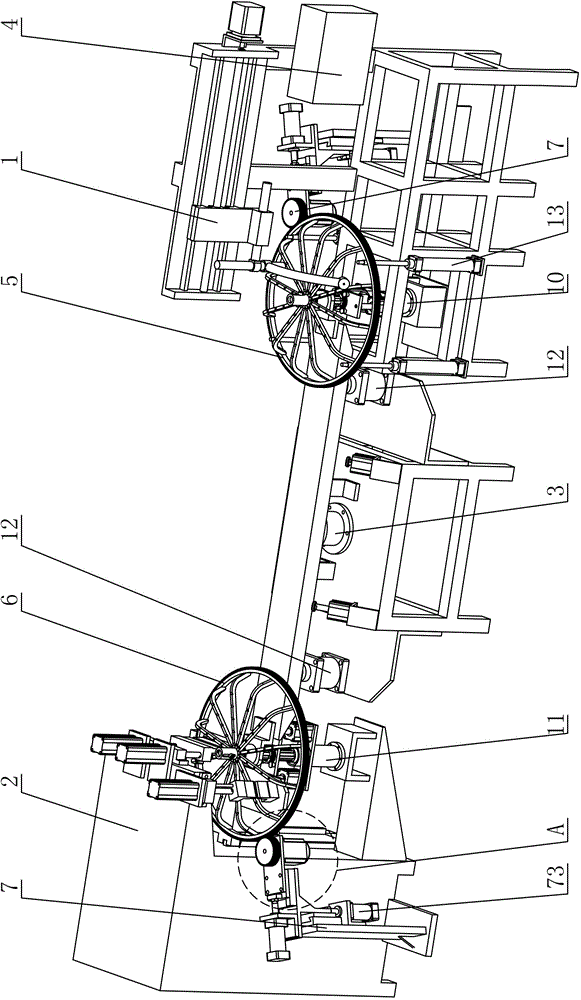

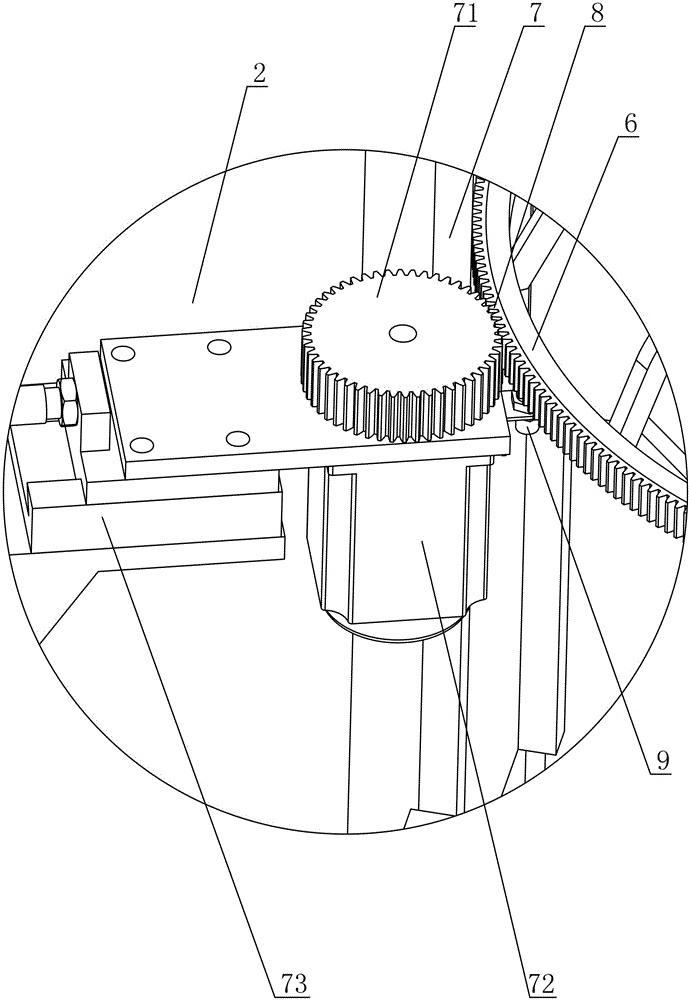

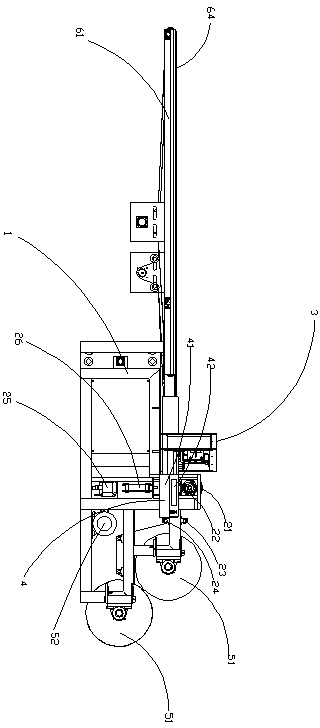

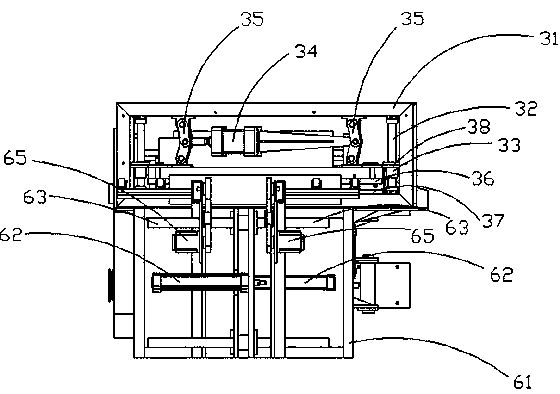

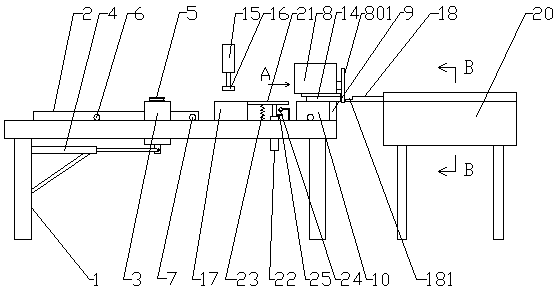

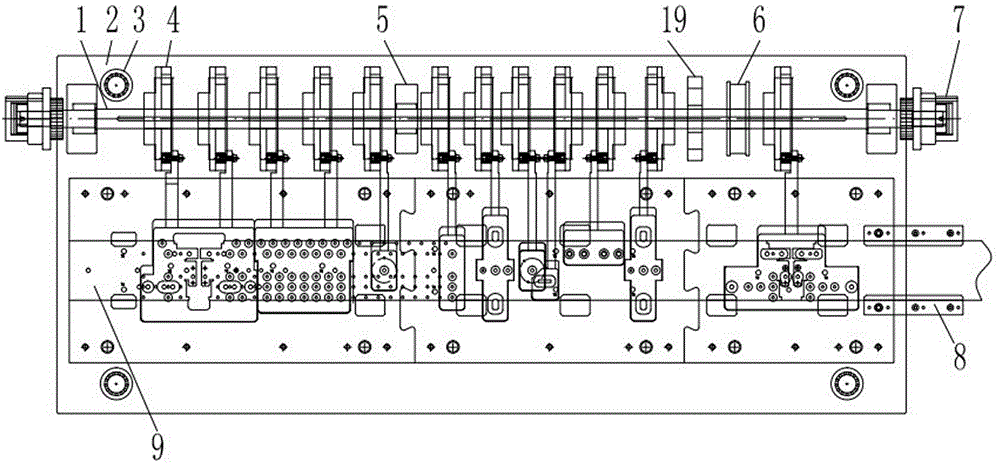

High-precision automatic fan cover production equipment

InactiveCN104308052AOvercome inertiaAvoid shakingWire articlesMetal working apparatusEngineeringAutomation

The invention discloses high-precision automatic fan cover production equipment. A winding part and a welding part are respectively provided with an external engagement driving part additionally, so that push gears of external engagement driving parts are respectively meshed with teeth on outer edges of a first processing module and a second processing module, push motors of the external engagement driving parts drive the push gears to rotate so as to drive the first and second processing modules to rotate, the original center positioning rotation driving structure is replaced, the equipment overcomes inertia, prevents waggle, and is accurate in positioning and high in running stability, automation and efficiency, and the yield and the quality of products are improved.

Owner:吴兆超

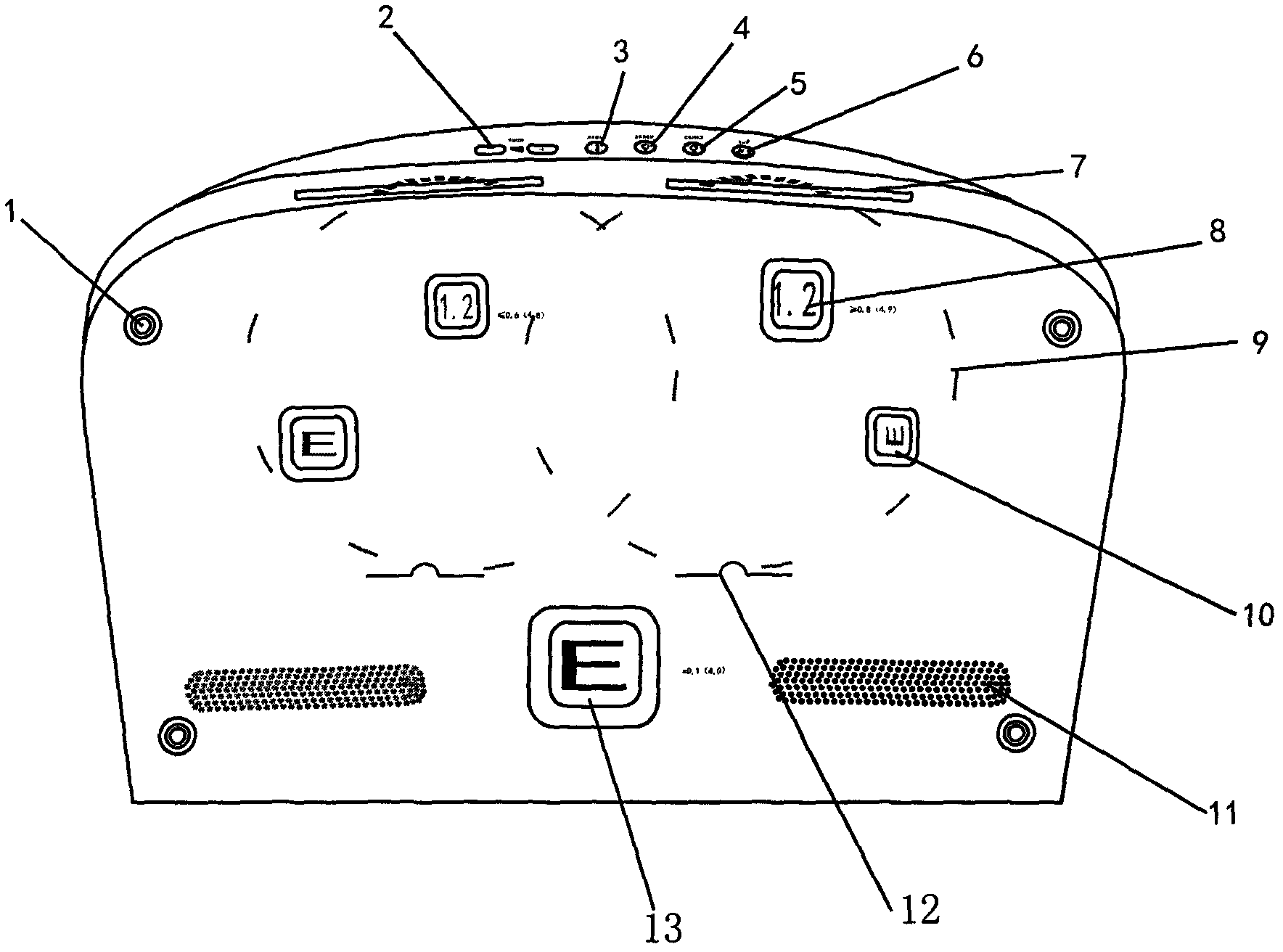

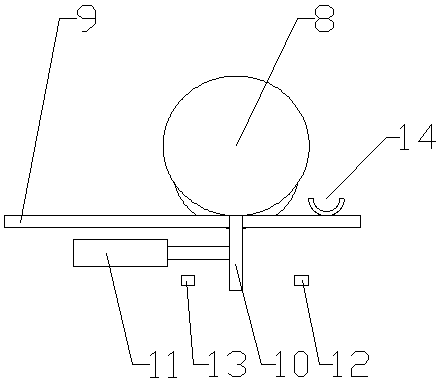

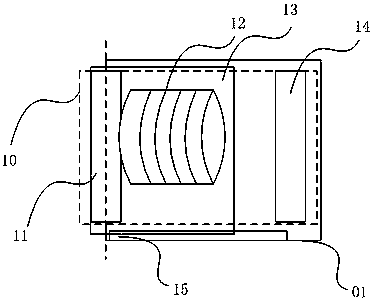

Instrument for detecting distant vision and training eye muscles

ActiveCN102151119AReduce labor burdenReduce strainEye exercisersEye diagnosticsComputer scienceVisual acuity

The invention provides an instrument for detecting distant vision and training eye muscles. At least one disc-shaped sighting target turntable (9) is arranged in a shell; a circle of sighting target values and a circle of sighting targets are arranged on the front of the sighting target turntable (9) respectively; the sighting target values correspond to the sighting targets one to one; and a sighting target value display window (8) for displaying a single sighting target value on the sighting target turntable (9) and a sighting target display window (10) for displaying a single sighting target on the sighting target turntable (9) are formed on a front panel. As one sighting target is displayed every time and the regularity of the displayed sighting targets cannot be forecast, a detected person cannot determine the direction of the sighting target by memory or regularity; therefore, the accuracy of a detection result is guaranteed.

Owner:蒋泉涛

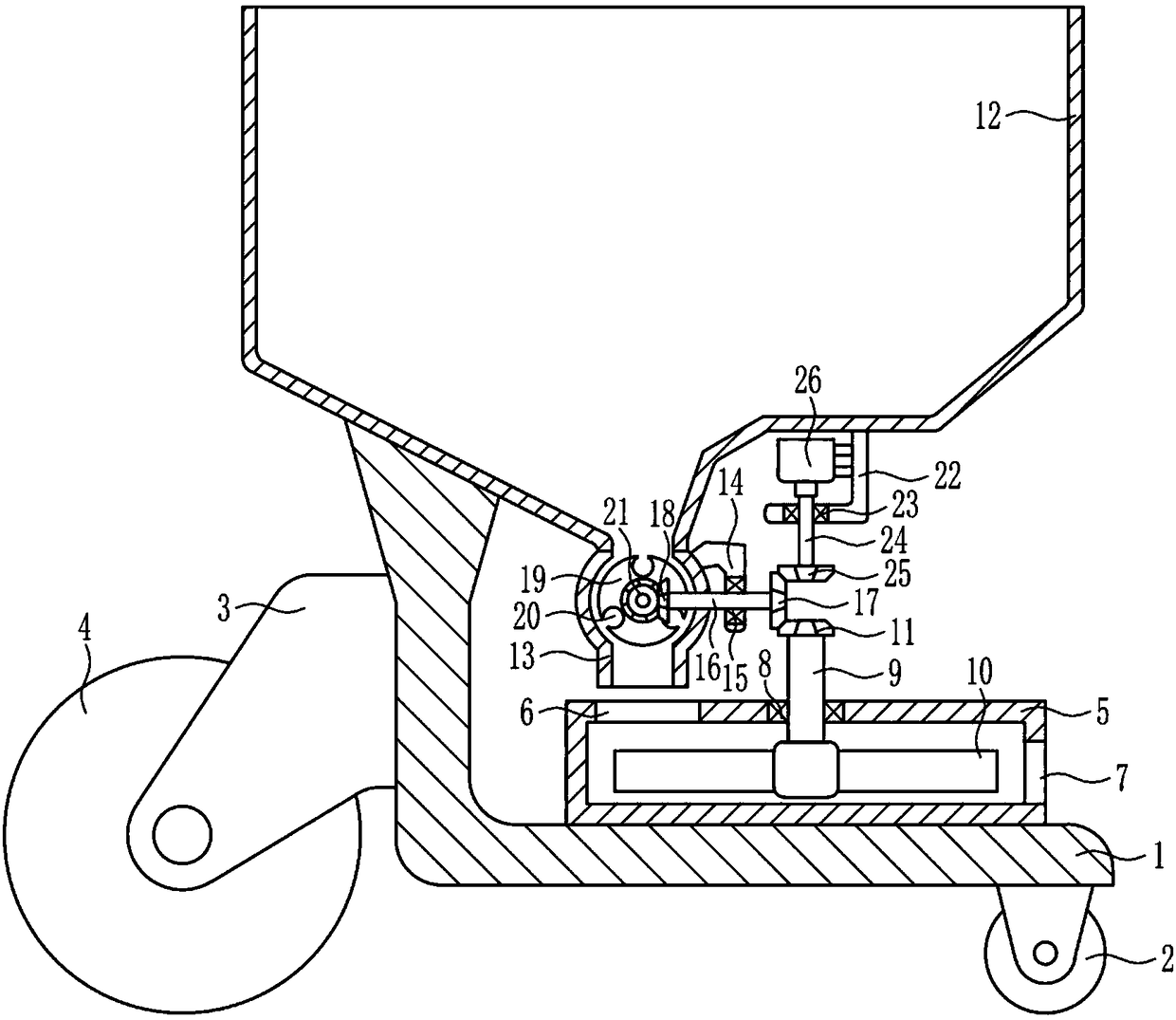

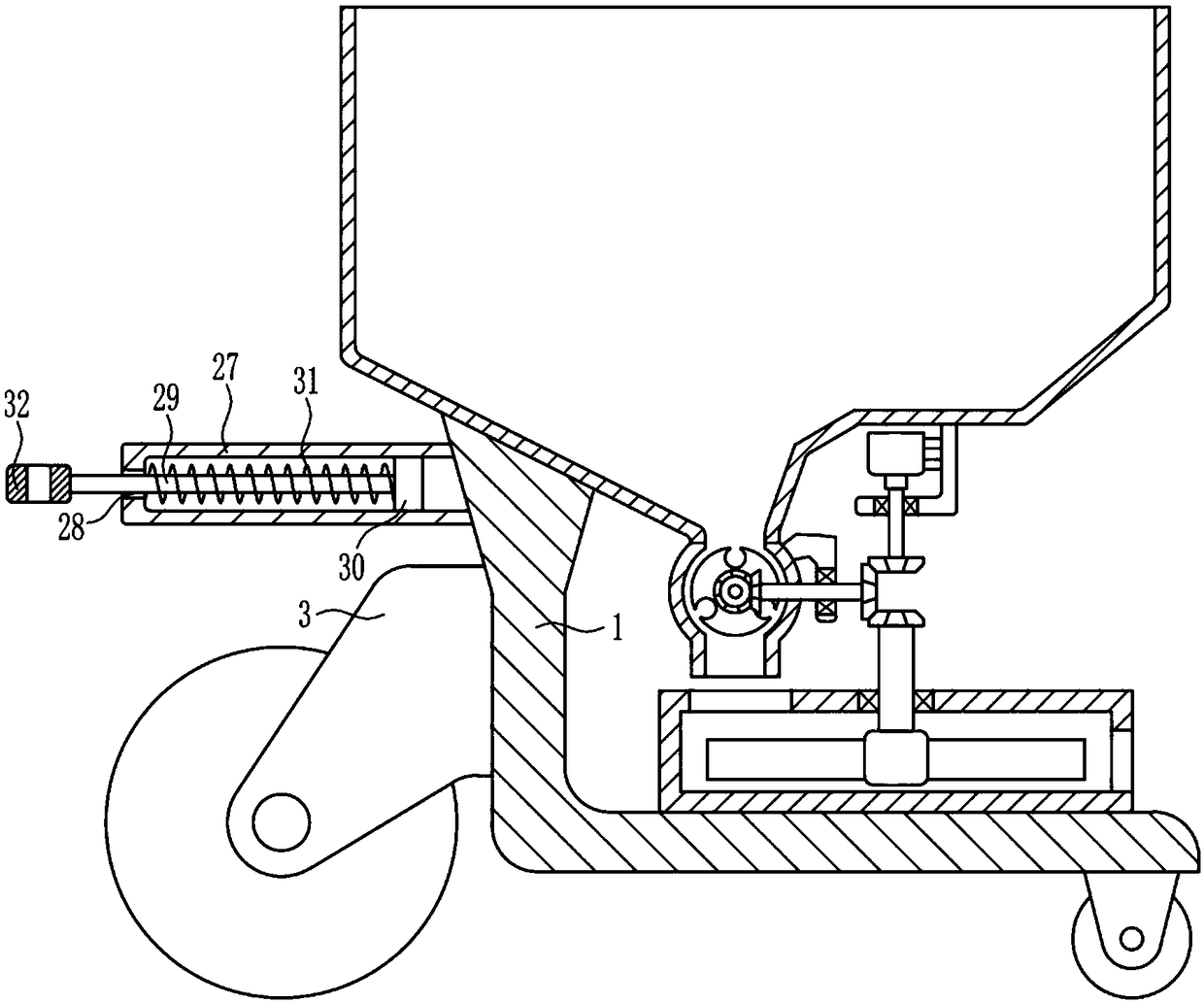

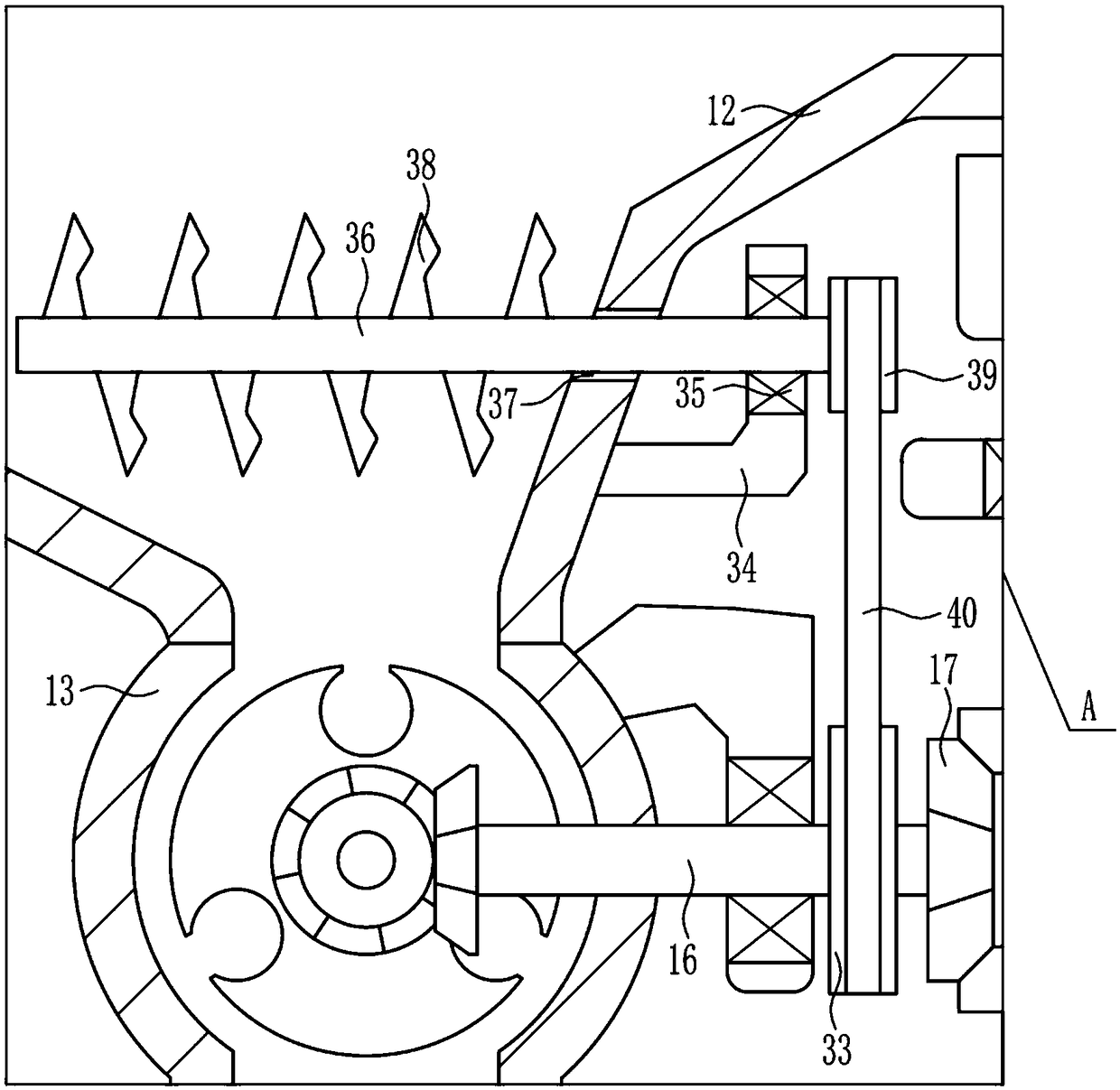

Granular fertilizer spraying equipment for pasture

InactiveCN108811650ASpray to achieveRealize intermittent feedingTransportation and packagingRotary stirring mixersAgricultural engineeringFan blade

The invention relates to granular fertilizer spraying equipment, in particular to the granular fertilizer spraying equipment for a pasture, and the granular fertilizer spraying equipment for the pasture is characterized by being capable of regulating the spraying distance and the spraying uniformity. The granular fertilizer spraying equipment for the pasture is characterized by comprising an L-shaped support, a first rolling wheel, a first installation seat, a second rolling wheel, a fertilizer outlet tank, a first bearing seat, a first rotating shaft, fan blades, a first bevel gear and the like, wherein the first rolling wheel is arranged at the right side of the bottom part of the L-shaped support; the left side surface of the L-shaped support is connected with the first installation seat; the first installation seat is provided with the second rolling wheel; the bottom part of the inner part of the L-shaped support is connected with the fertilizer outlet tank. According to the granular fertilizer spraying equipment provided by the invention, fertilizer falling into the fertilizer outlet tank can be thrown out through a second opening under high-speed rotation of the fan blades,so that spraying of the fertilizer can be realized; a spring has a buffer function, so that inertia generated during sudden stop and movement of other equipment can be prevented.

Owner:陈昌江

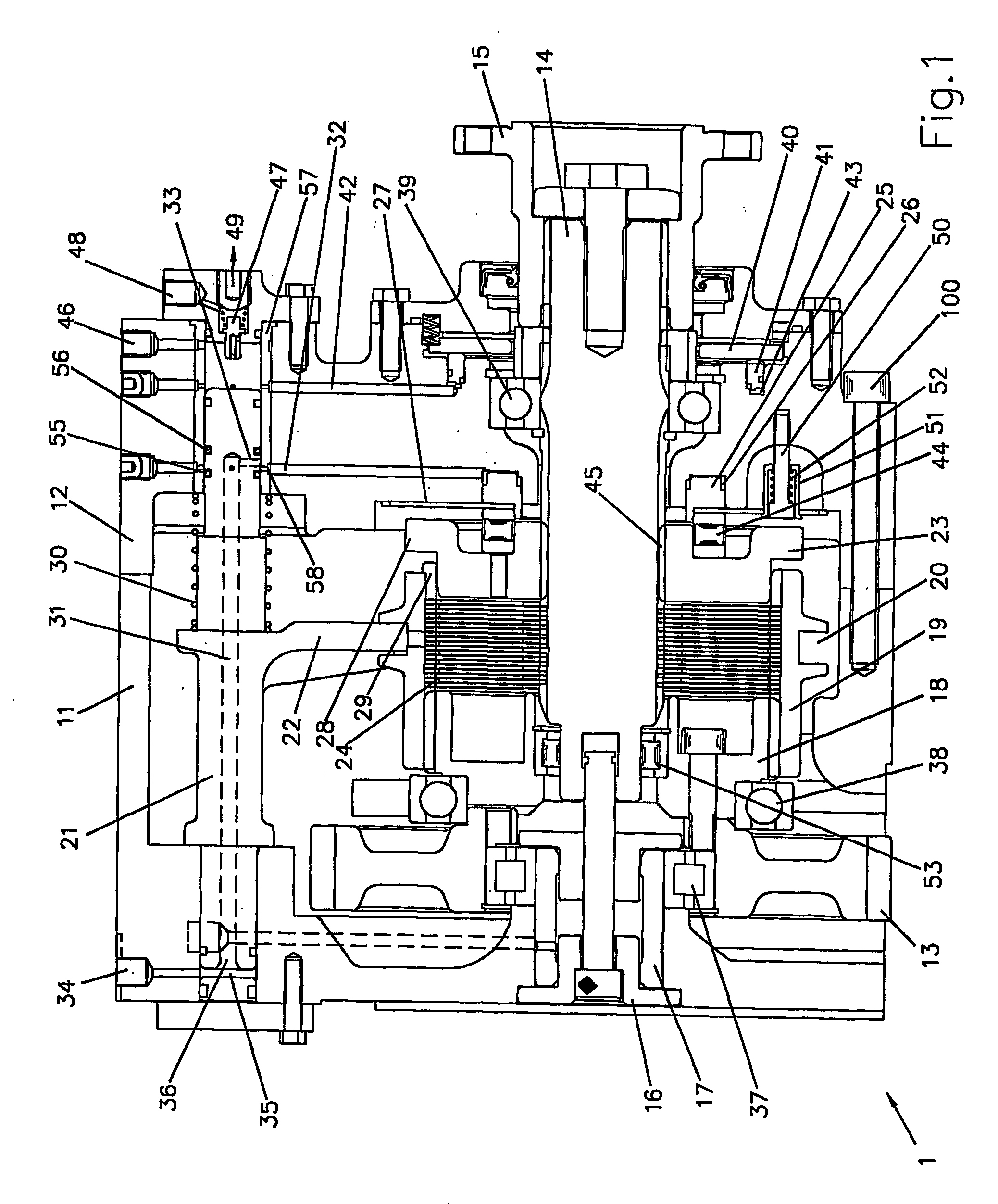

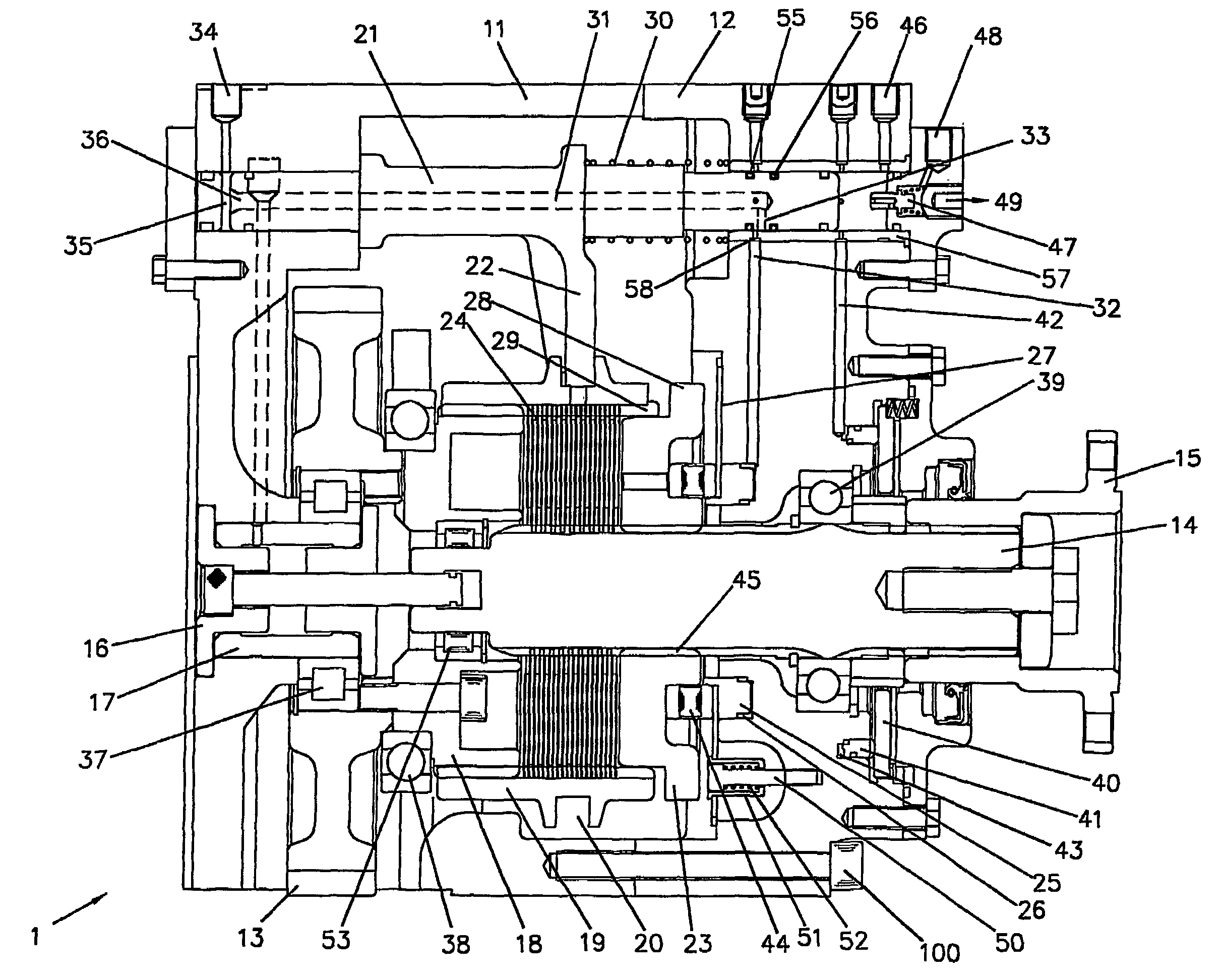

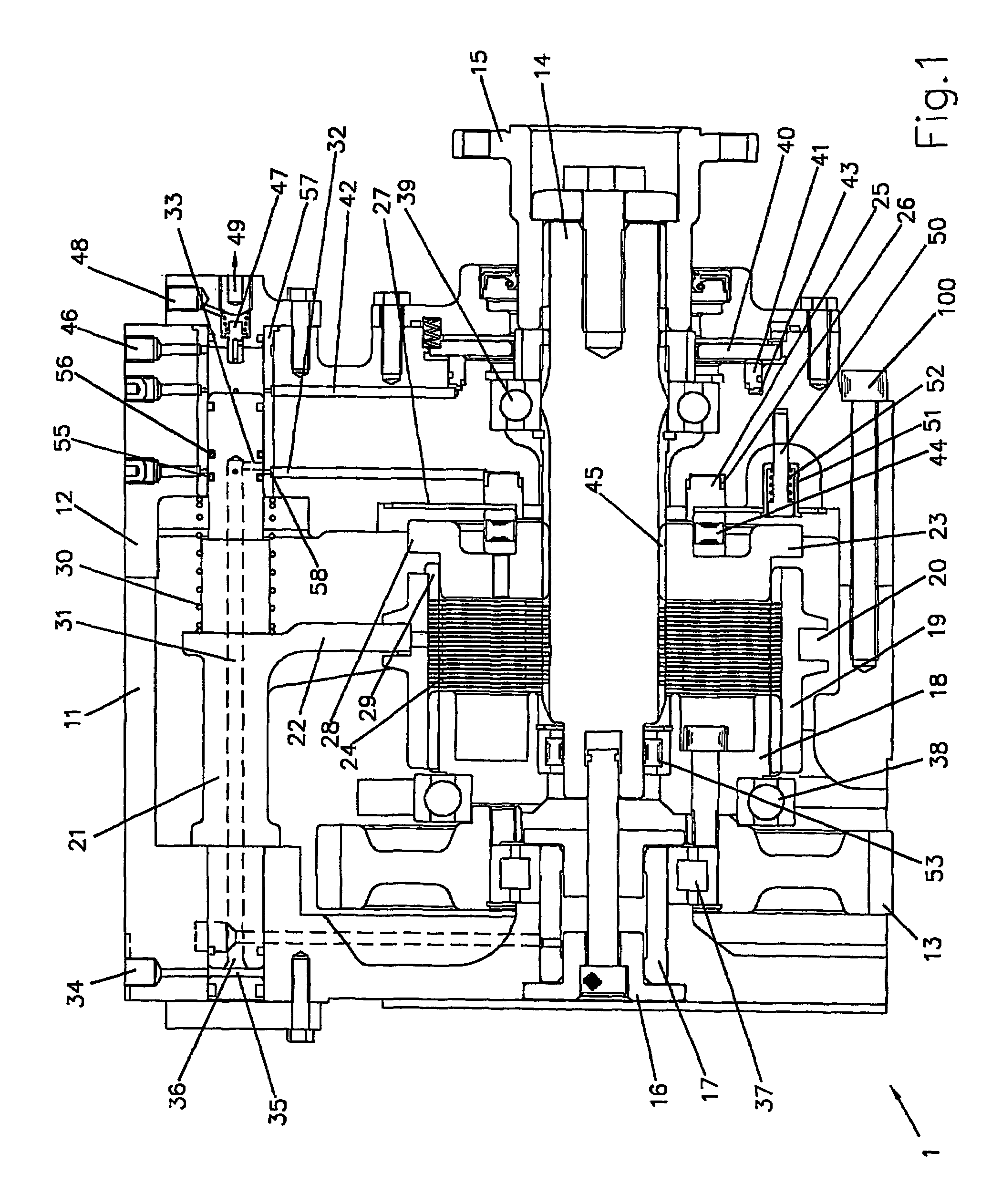

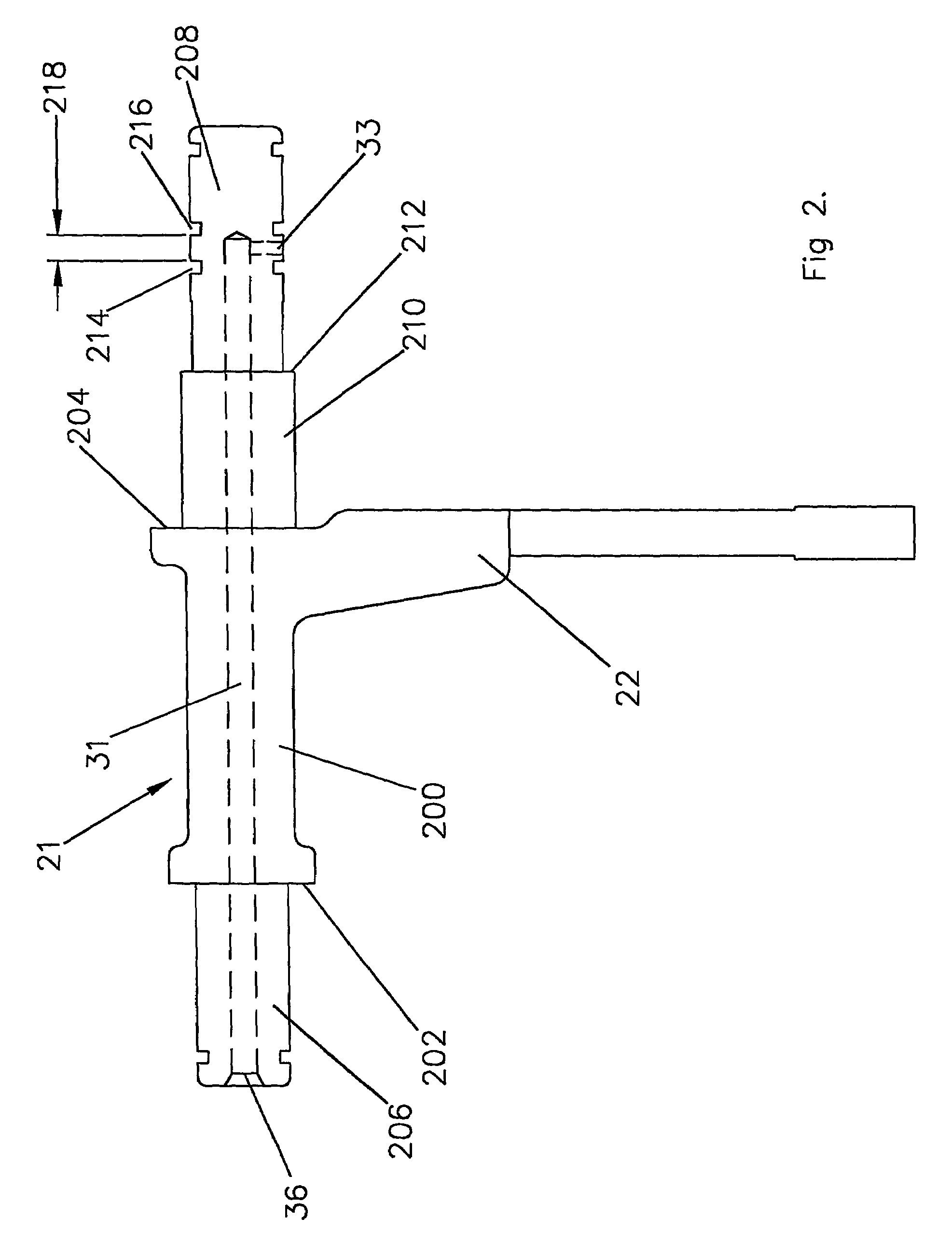

Drive engagement apparatus

InactiveUS20060169560A1Overcome inertiaIncrease the areaFluid actuated clutchesFriction clutchesPistonFriction drive

A drive arrangement (1) is disclosed where a driving gear (13) is engageable with a shaft (14) by engaging an axially movable sleeve (19) with a dog (23). One of the sleeve (19) or dog (23) is drivably connected to the gear (13) and the other to the shaft (14). A piston (21) is engaged via fork (22) with the sleeve (19); axial movement of the piston (21) causes axial movement of the sleeve (19). A delay device is included which prevent engagement between the sleeve (19) and dog (23) until the rotational speeds of those elements is equalised. The delay device include a friction plates (24) which create a friction drive between the driving force (e.g. gear (13)) and the element to be driven. The friction drive is actuated by actuator (25) under the same compressed air supply that acts on piston (21). Torque acting between the friction plates (24) and sleeve (19) prevent the sleeve (19) from moving into engagement with the dog (23) before the speeds of the sleeve (19) and dog (23) have equalised.

Owner:ARTHUR KNOWLES

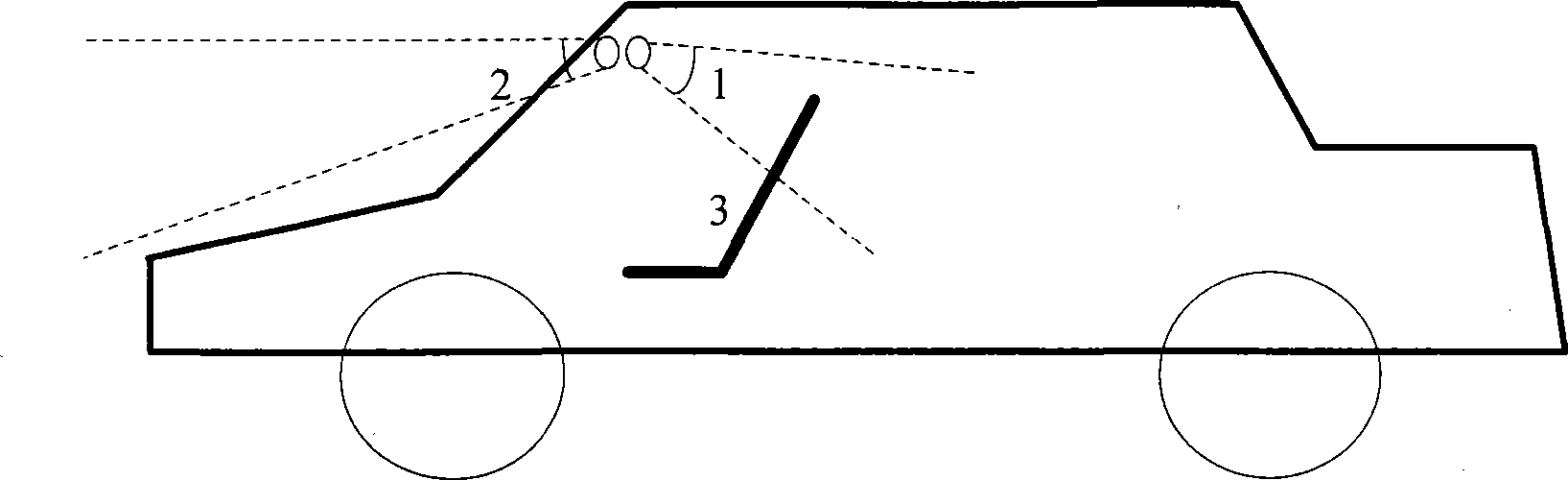

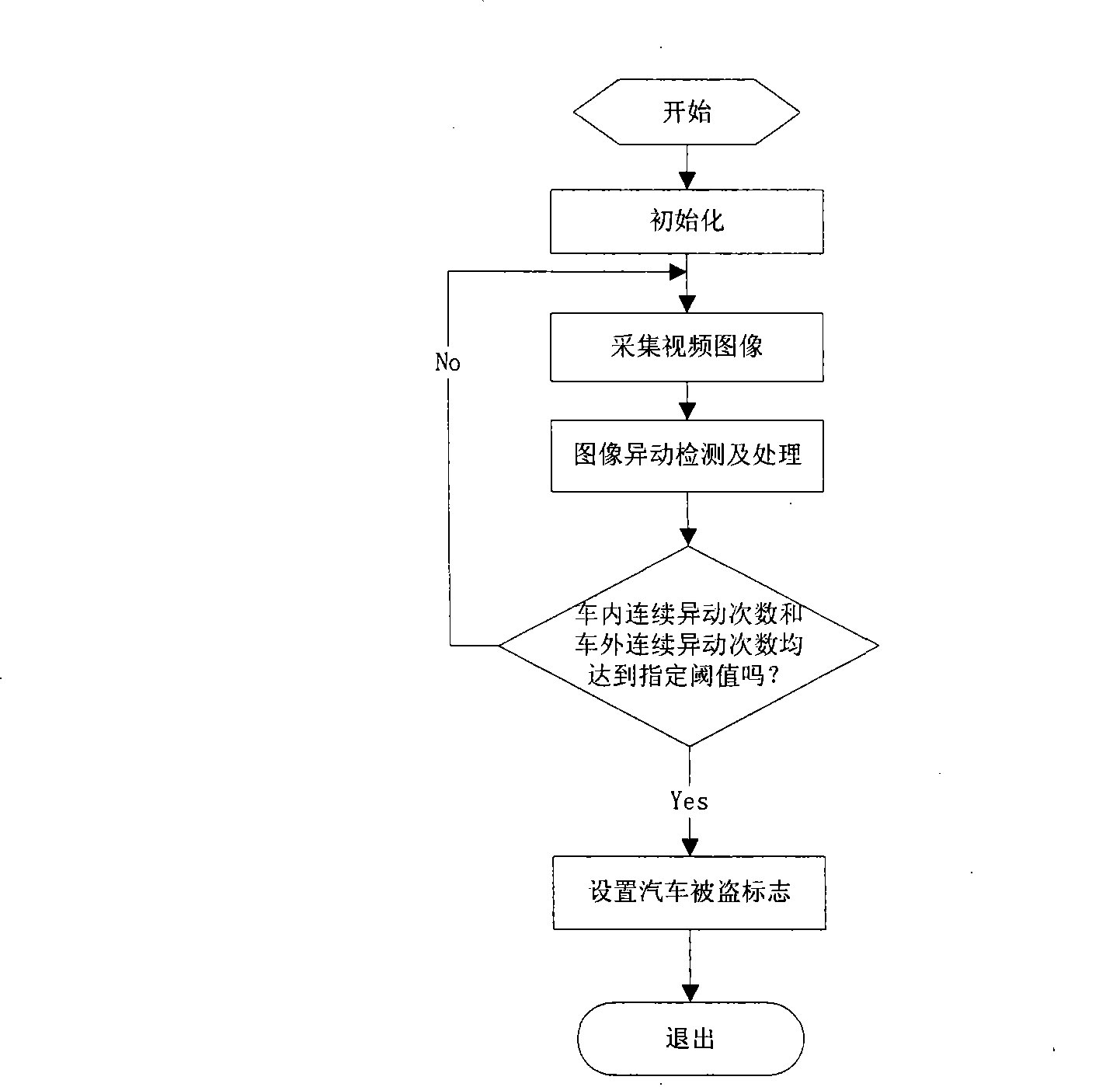

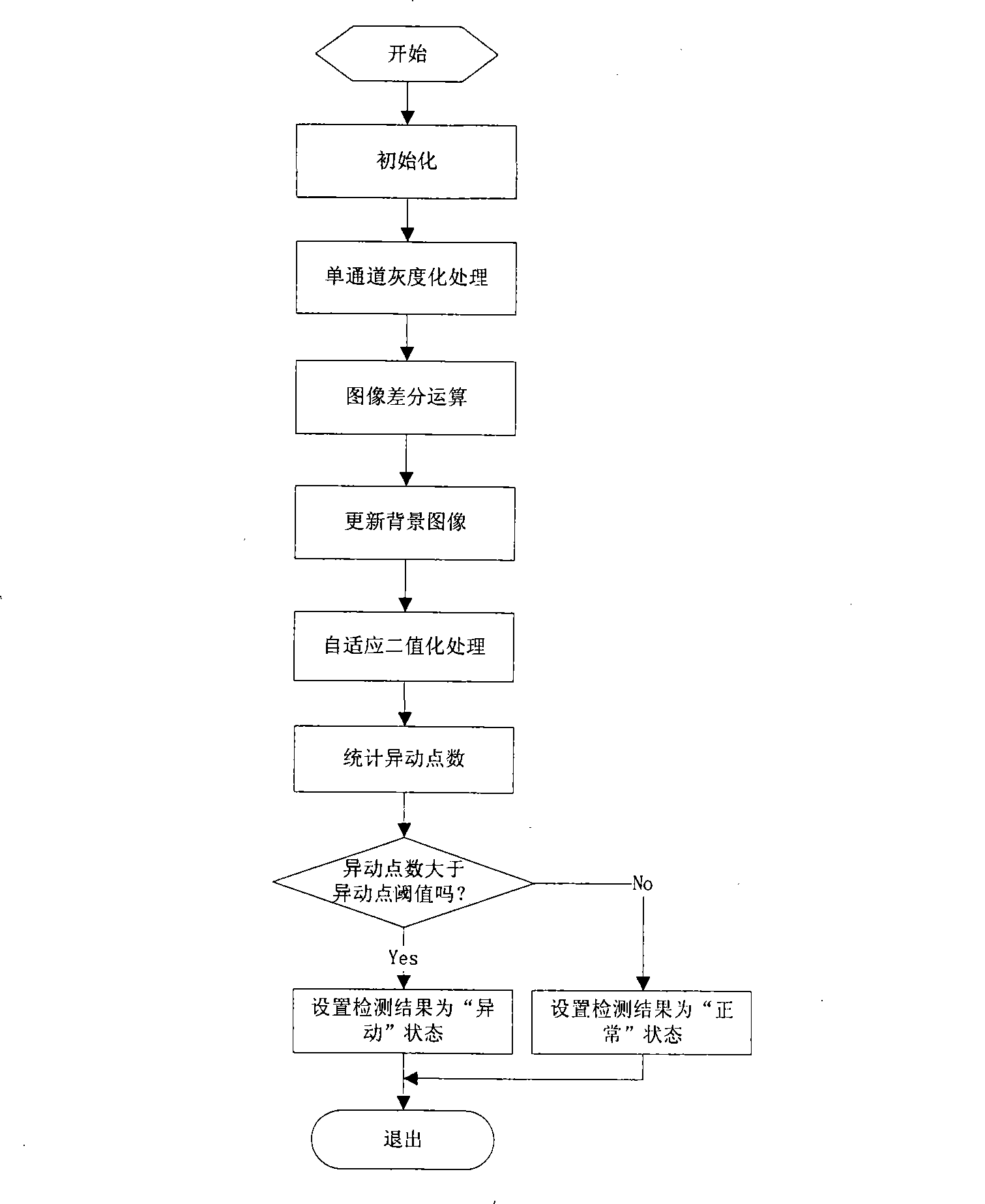

Two-stage image abnormal movement detection method used for automobile anti-theft

InactiveCN101477620AIncrease security risksAvoid the problem of evading insurance claimsAnti-theft devicesCharacter and pattern recognitionVideo imageSelf adaptive

The invention relates to a method for detecting the abnormal changes of secondary images used for car security, and belongs to the technical field of computer application. The method comprises the following steps: firstly, the image collection on a real-time basis is performed on videos inside and outside the car; then, abnormal change detection is respectively performed on the images collected inside and outside the car on the real-time basis by adopting self-adapting difference detection algorithm for video image, so as to obtain two detection results of normal image and abnormal changing images; the quantity of images with abnormal changes serves as the frequency of continuously abnormal changes; and when both the frequencies of continuously abnormal changes inside and outside the car reach a pre-established threshold value respectively, a judgment that the car is stolen is made. In the invention, only the video image collecting device is used, and no additional sensor is used except a camera, therefore, the invention has the advantages of simplicity, practicability, safety and reliability.

Owner:TSINGHUA UNIV

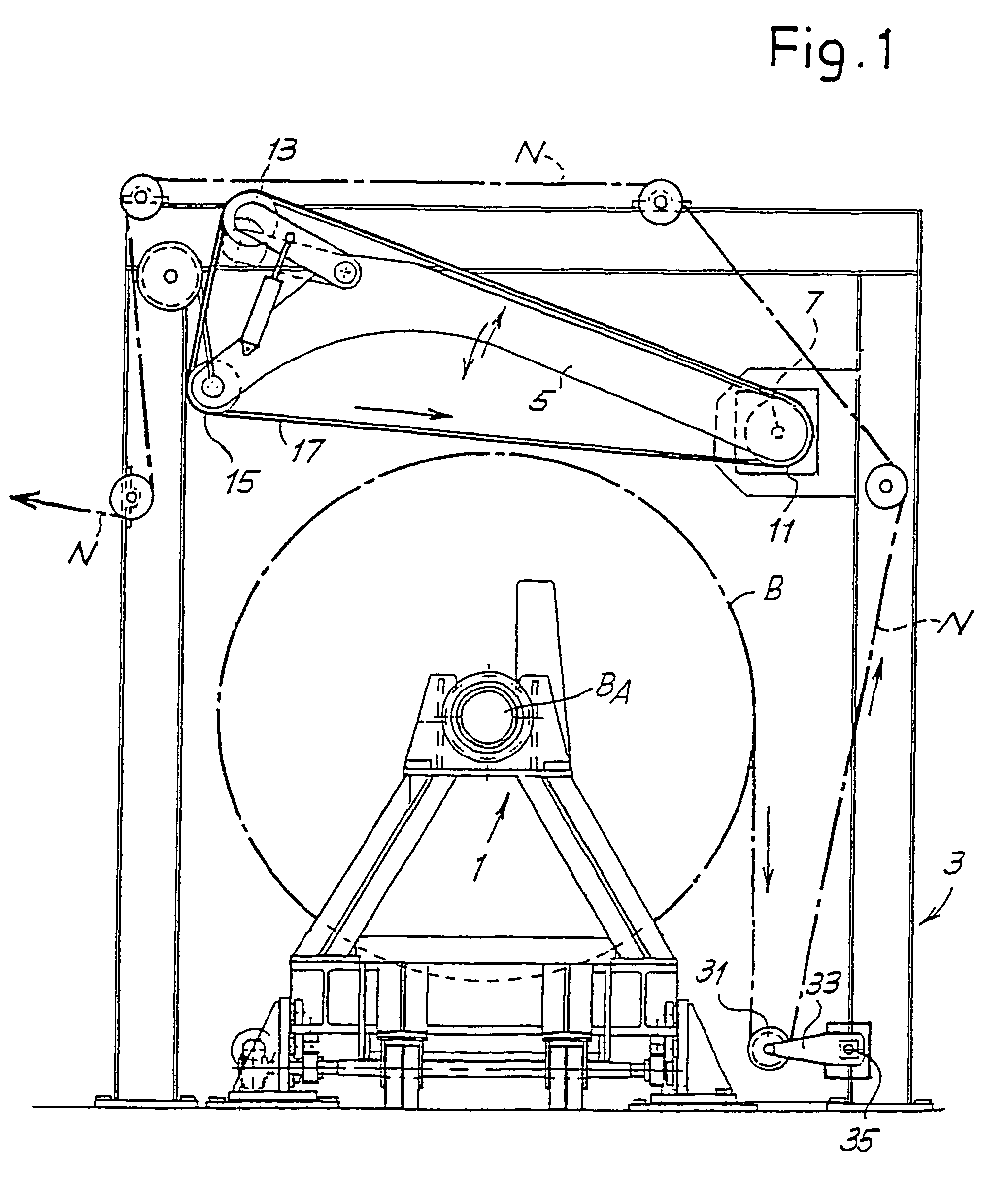

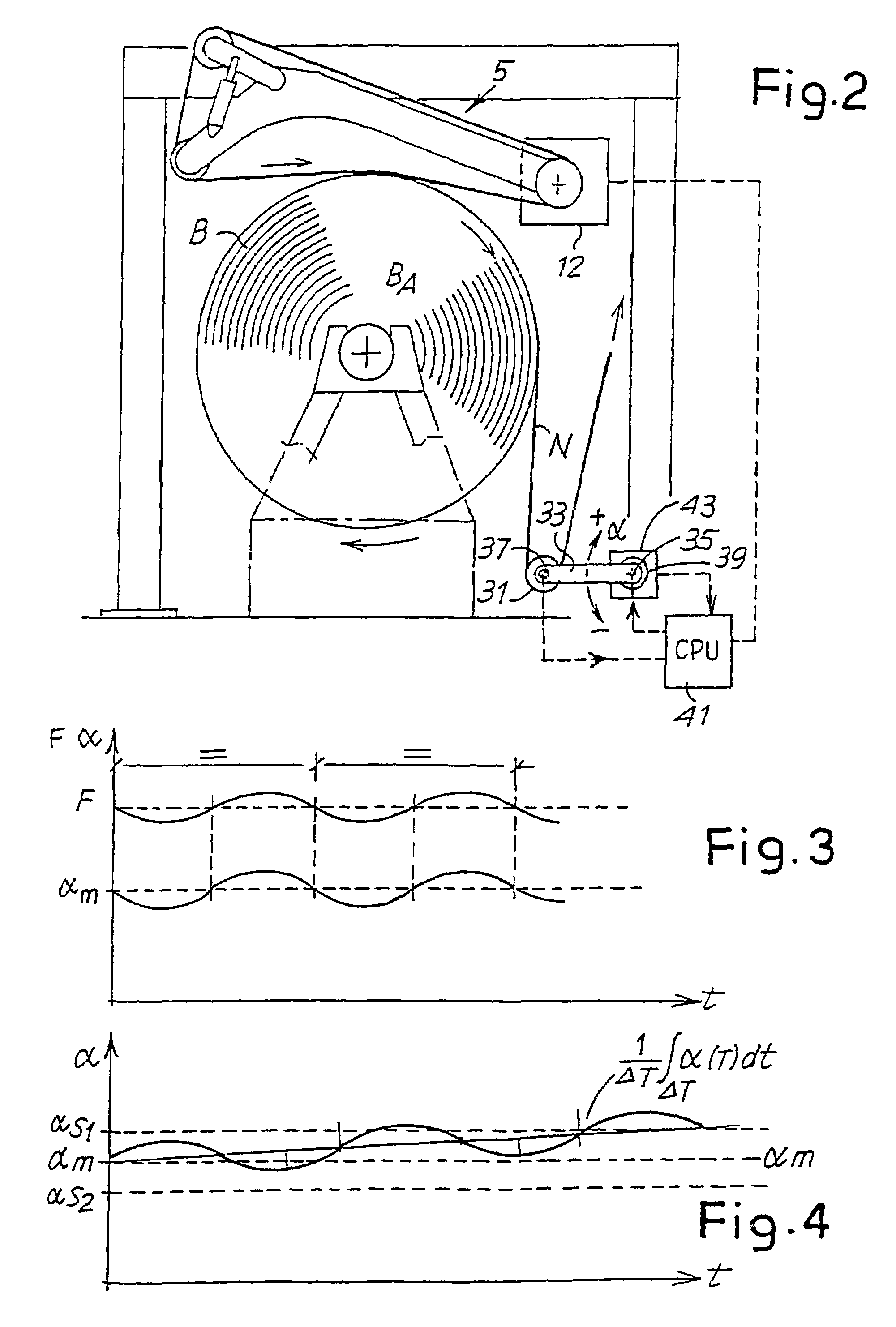

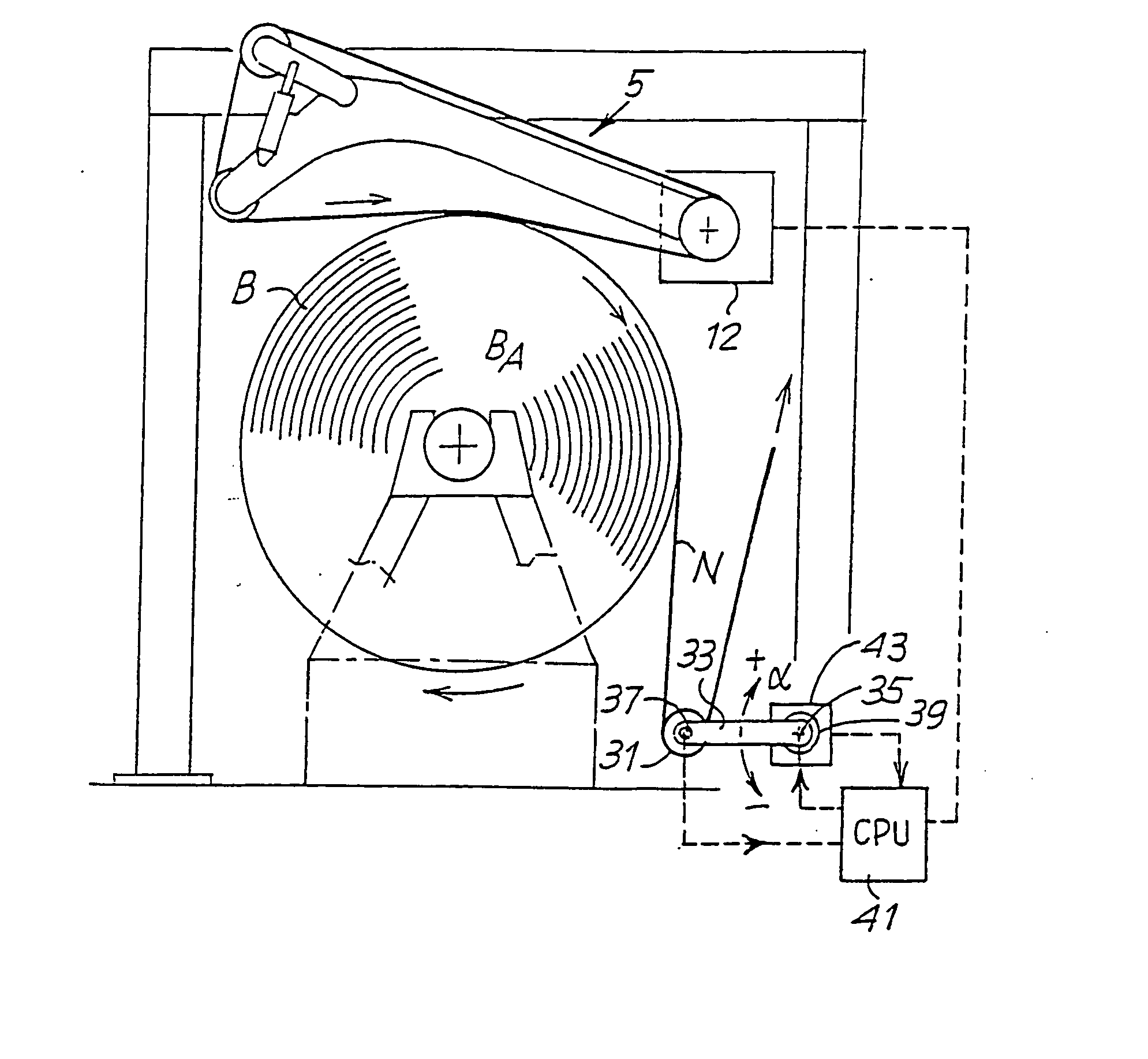

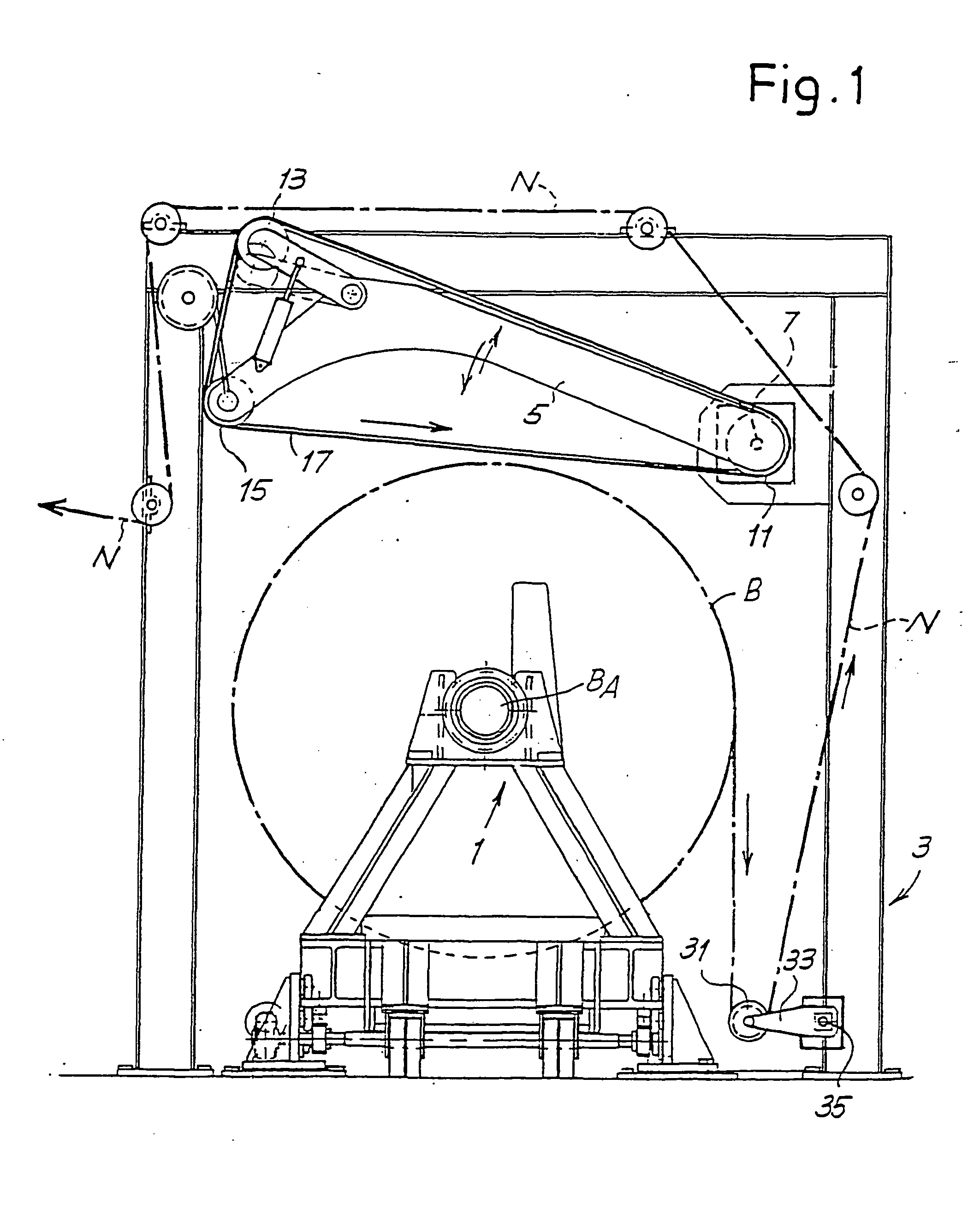

Device and method for controlling the tension of a weblike material

InactiveUS7413139B2Effective controlPrecise tension controlFilament handlingFunction indicatorsTransducerActuator

Owner:FABIO PERINI SPA

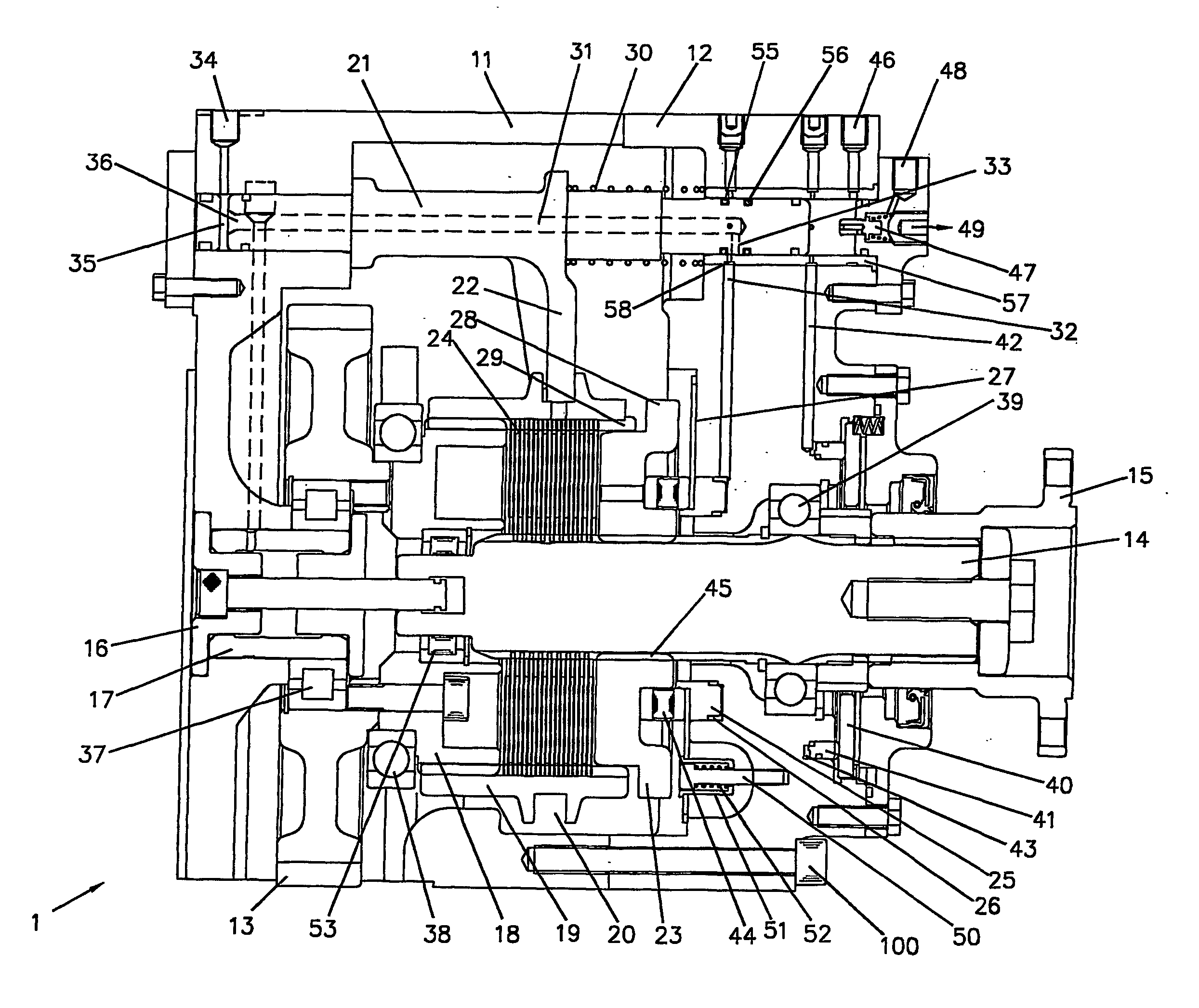

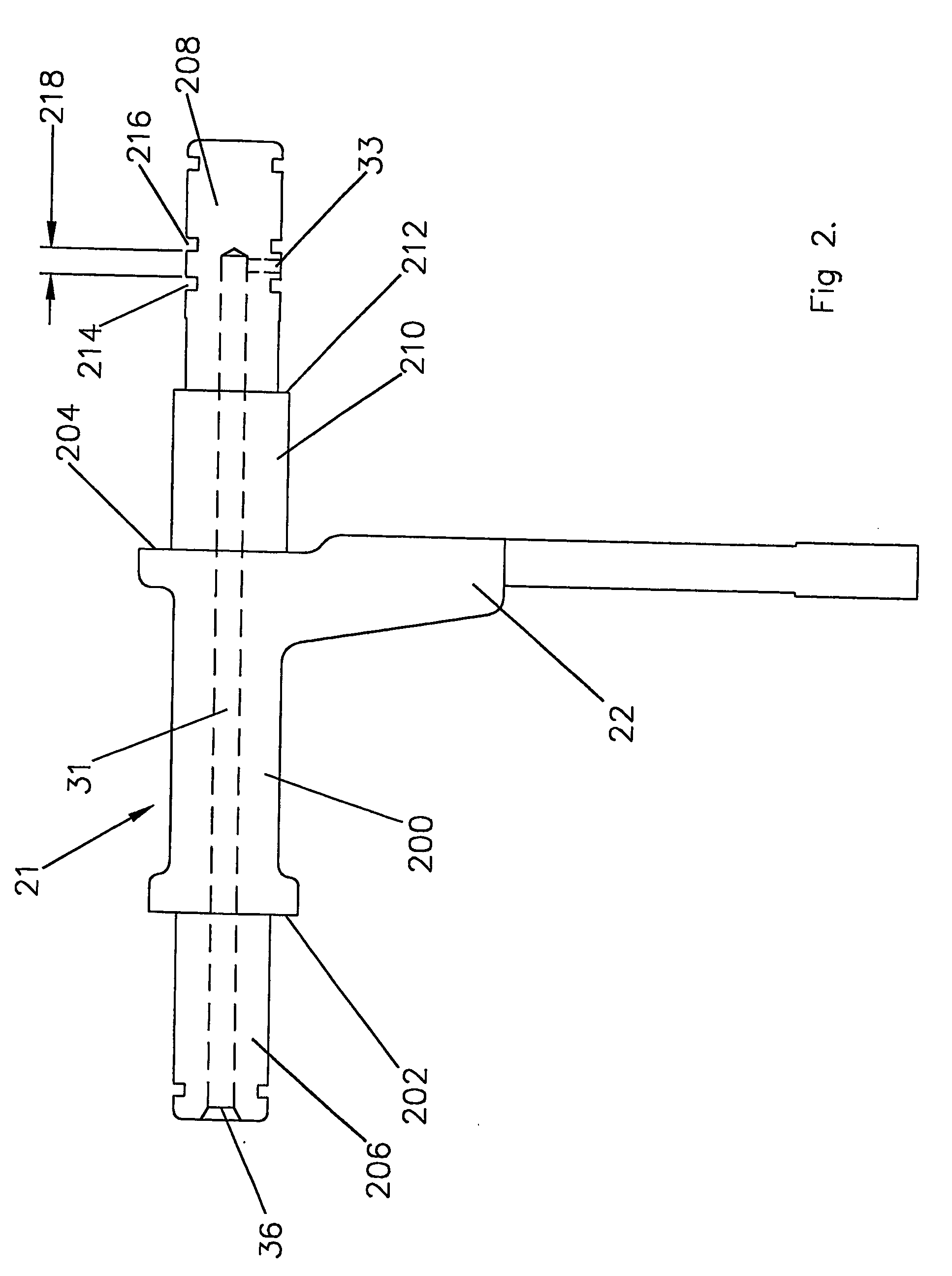

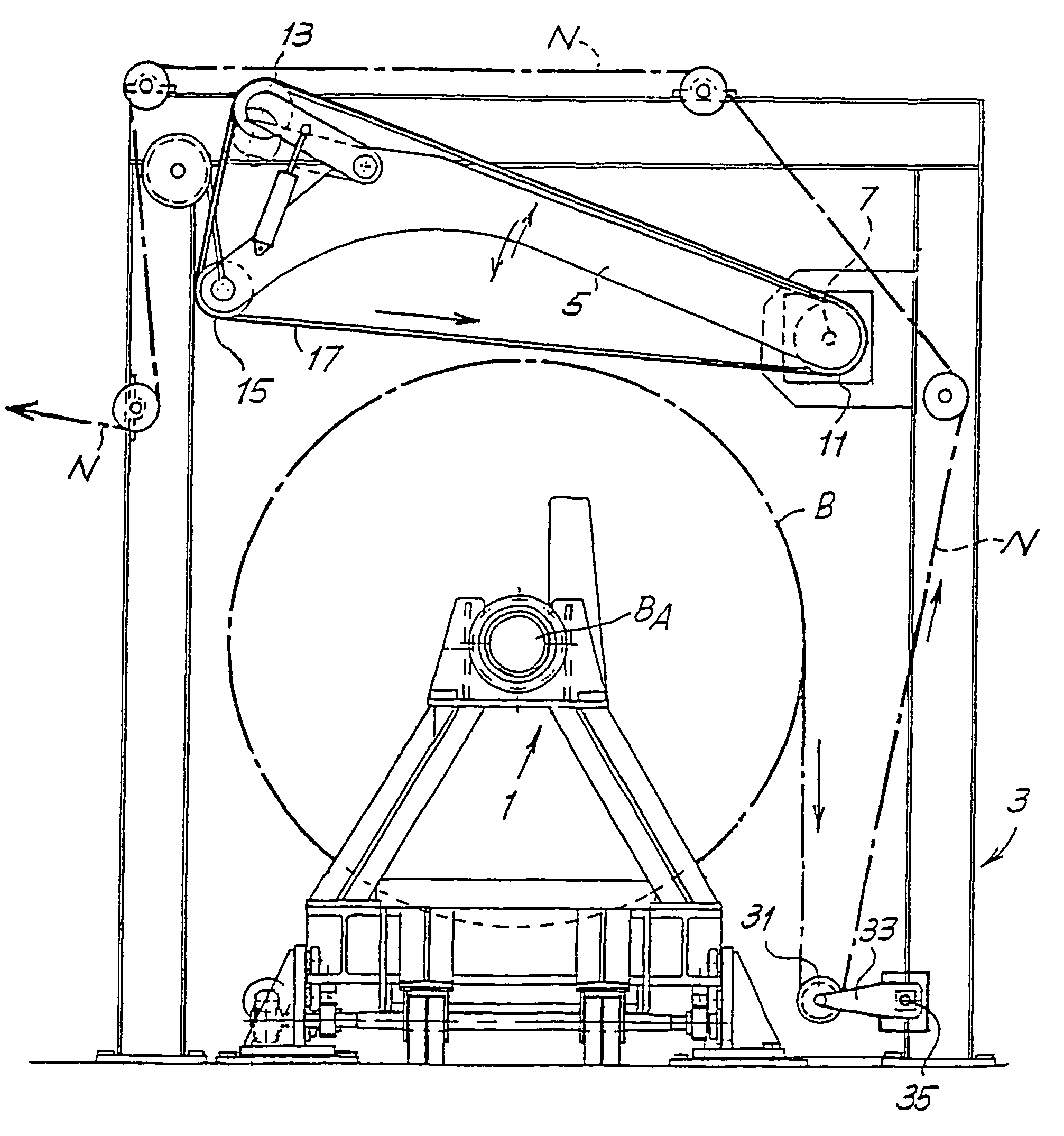

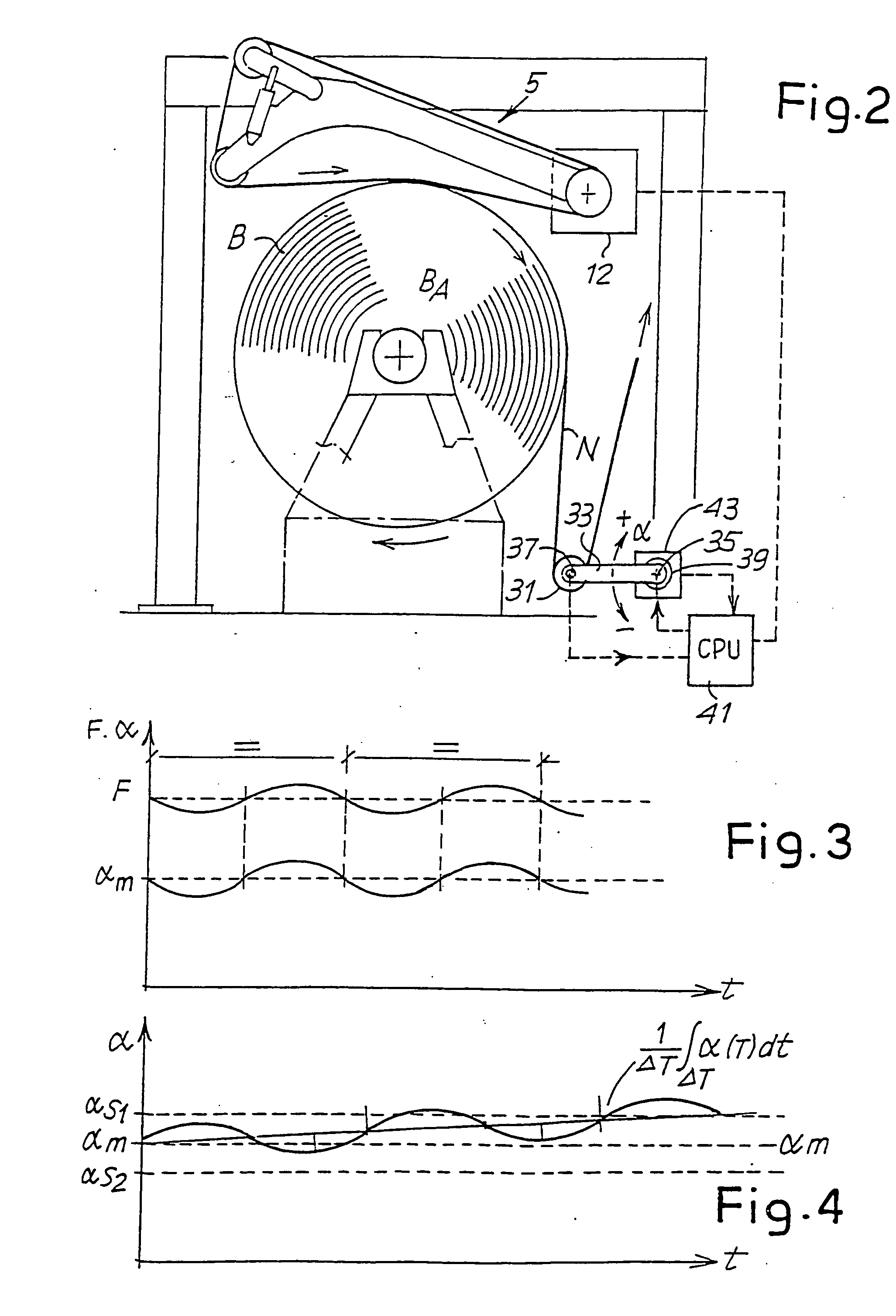

Device and method for controlling the tension of a weblike material

InactiveUS20050253013A1Effective controlPrecise tension controlFilament handlingFunction indicatorsTransducerActuator

The control device comprises: at least one member (12; 12X) for regulating the speed of advance on the weblike material; a central control unit (41); a guiding roller (31) with mobile axis, over which the weblike material is run; and a position transducer (39) for detecting the position of the guiding roller (31) and for generating a position signal for controlling the speed of said weblike material. The guiding roller (31) is supported in a controlled position, and associated thereto is at least one sensor (37) for detecting a load (F) applied by the weblike material (N) on the guiding roller (31). In addition, an actuator (43) controls a displacement of the guiding roller according to a feedback signal generated by the sensor (37). The actuator is controlled so as to make up for variations of the load of the weblike material by moving the axis of the guiding roller, and the member for regulating the speed of advance of the weblike material (5) is controlled by said central control unit (41), according to the position signal, so as to maintain the axis of the guiding roller (31) in a position that is on average constant.

Owner:FABIO PERINI SPA

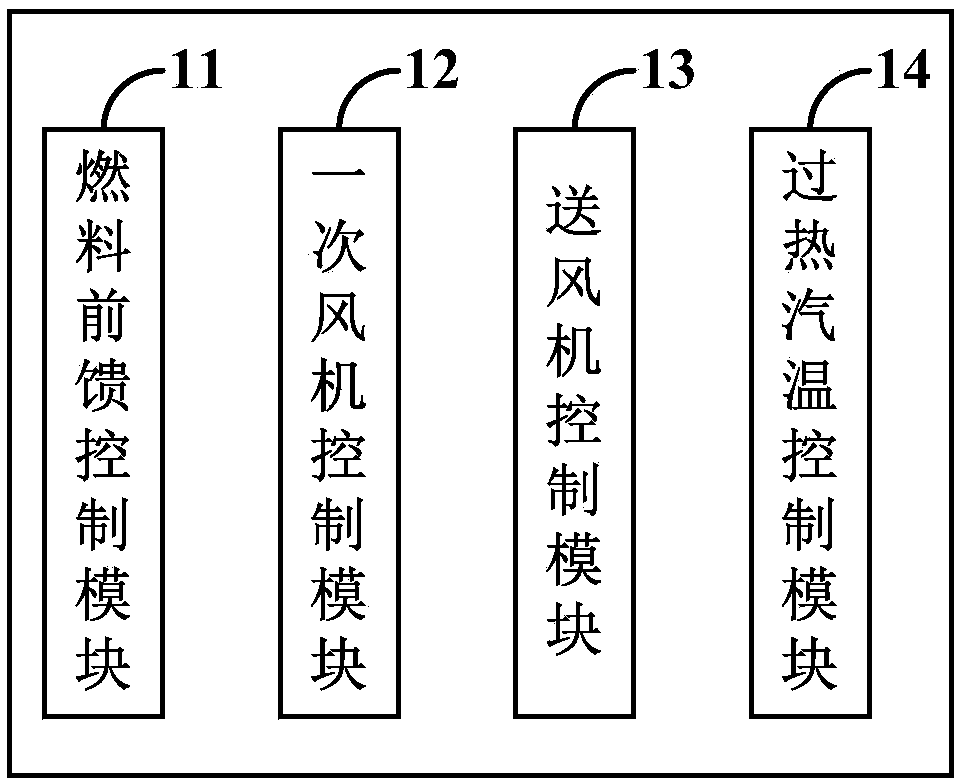

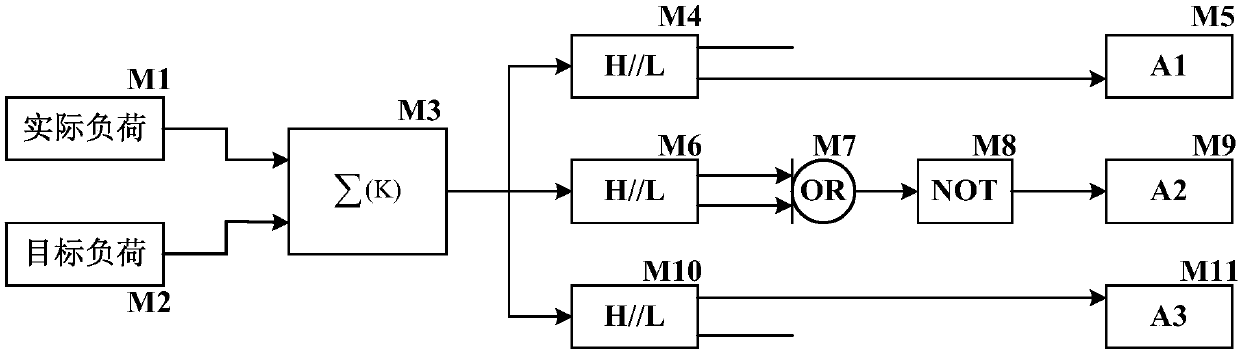

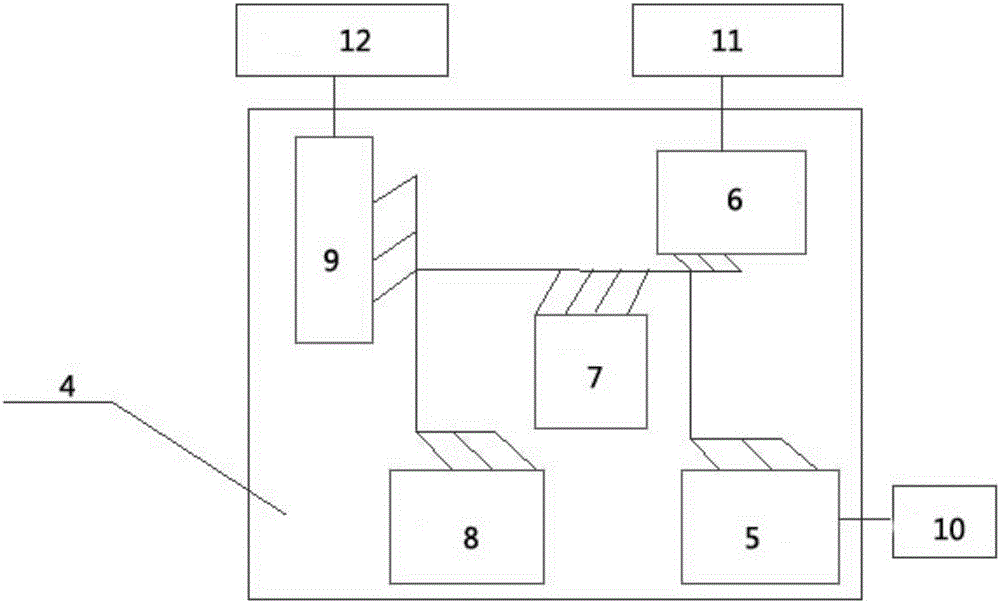

Intelligent control system of thermal power unit

ActiveCN107906499AAdjust Control BiasAccurate control offsetFuel supply regulationBoiler controlPower equipmentEngineering

The invention relates to the field of intelligent control on power equipment, provides an intelligent control system of a thermal power unit, and aims to solve the technical problem about the way to control the thermal power unit to quickly and stably track an AGC response. A fuel feed-forward control module of the control system can adjust the fuel control offset according to the load state and can correct the fuel control target value according to the adjusted fuel control offset. A primary fan control module can adjust the primary fan opening degree offset according to the fuel quantity state. An air supply fan control module can adjust the air supply fan opening degree offset according to the fuel quantity state. A superheated steam temperature control module can adjust the de-superheating water regulating valve opening degree according to the temperature information of the thermal power unit. According to the technical scheme, the fuel feed-forward control module, the primary fancontrol module, the air supply fan control module and the superheated steam temperature control module have the synergistic effect, the combustion inertia of the thermal power unit can be overcome, the load can be increased and decreased quickly, the load changing rate can be effectively controlled, and load overcorrection can be prevented.

Owner:李吉宁 +1

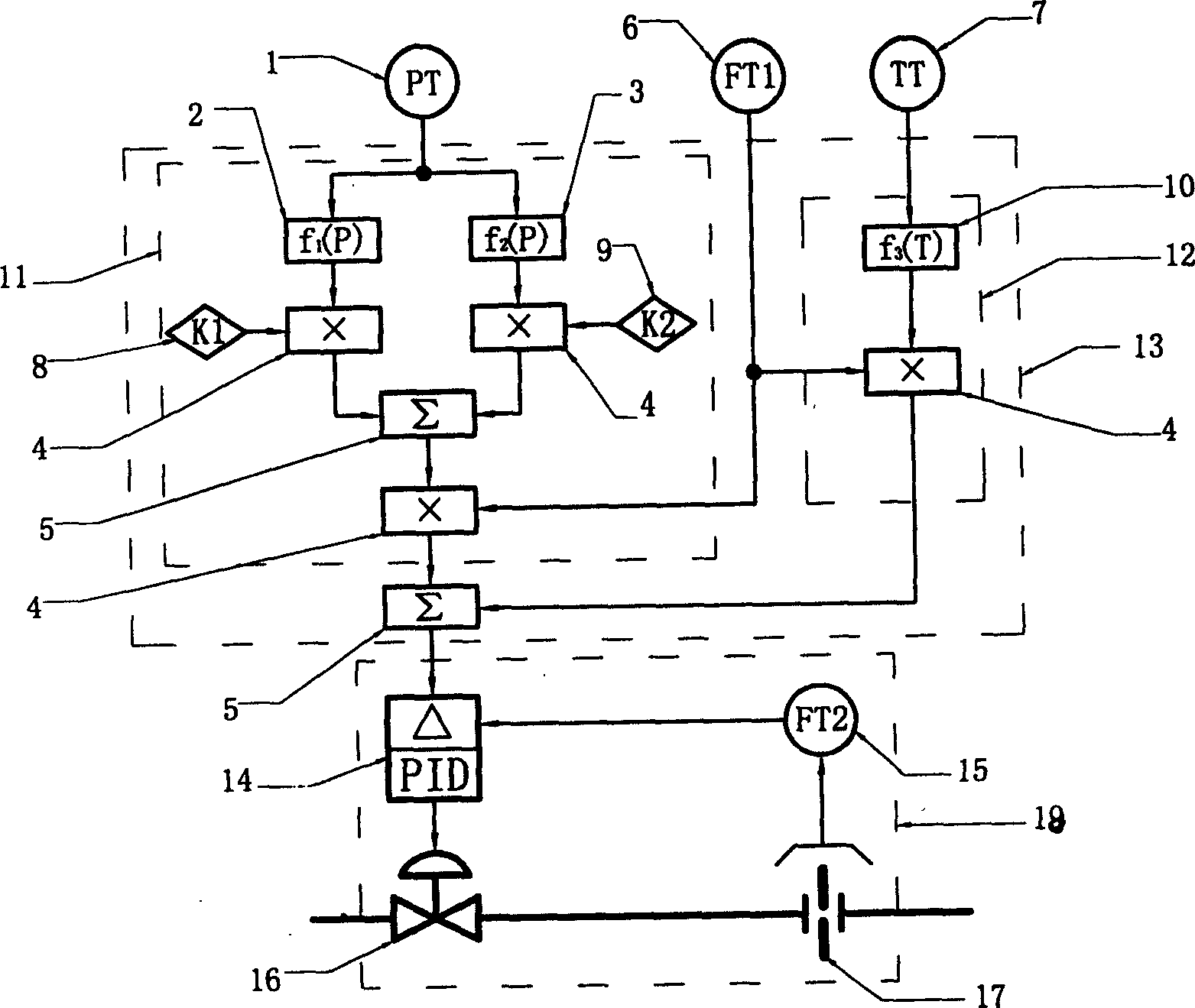

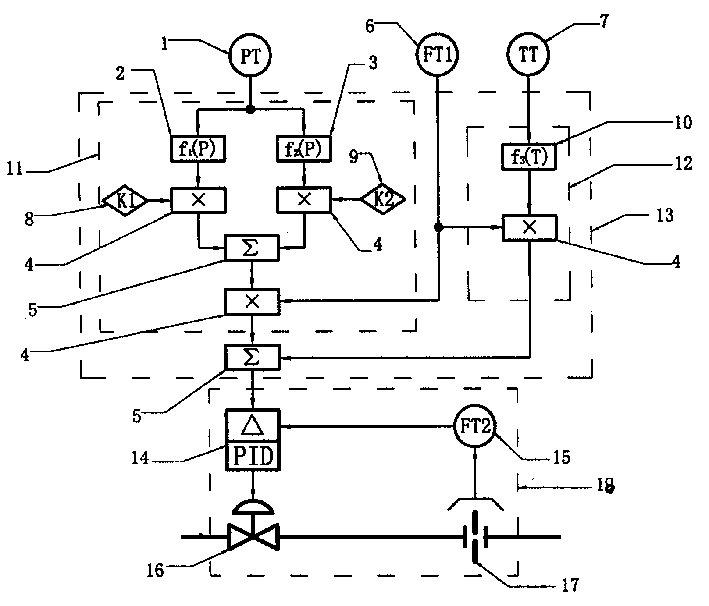

Automatic regulating and controlling method of wet steam boiler dryness

InactiveCN1442628ARealize automatic controlOvercome inertiaBoiler controlAuto regulationControl system

An automatic regulation and control method for the dryness of wet steam boiler features that on the basis of the principle that there is a special correlation between the enthalpy and dryness of wet steam, the consumed fuel is controlled for regulating the enthalpy of wet steam and in turn its dryness. Its advantages are high automation level, simple structure and operation, and high safety.

Owner:李金叶

Intelligent control type material cutting device

ActiveCN103832868AQuality improvementHigh degree of automationArticle deliveryWebs handlingElectricityEngineering

The invention discloses an intelligent control type material cutting device which comprises a machine frame, a material placing mechanism connected with the machine frame, a material feeding mechanism arranged on the material placing mechanism and then connected with the machine frame, a cutting mechanism arranged on the material feeding mechanism and then connected with the machine frame, a material collecting mechanism arranged on the cutting mechanism and then connected with the machine frame, and an intelligent electric control system arranged on the machine frame and electrically connected with the material feeding mechanism, the cutting mechanism and the material collecting mechanism. Compared with traditional manual operation, the intelligent control type material cutting device has the advantages that the automation degree is high, working efficiency is improved, accuracy control capacity is improved, the number of cutting errors caused by mis-operation is reduced, and cutting quality is improved. Furthermore, the device can conduct quick setting by means of a numerical control system according to the requirements of the manufacturing technique, for example, the material cutting sizes can be set quickly by setting the number of rotating circles of the material feeding mechanism.

Owner:SUZHOU IND ROBOT TECH

Cable cutting machine

The invention relates to the field of power supply facilities, and particularly discloses a cable cutting machine. The cable cutting machine comprises a rack and a PLC control system. A conveying system, a cutting system and a discharging system are arranged on the rack. The conveying system comprises a conveying cylinder. A sliding block is arranged at the output end of the conveying cylinder. Two ratchet wheels are arranged on the sliding block. The sliding block is located on a sliding rail. Two travel switches are mounted on the sliding rail. A conveying trough is located in front of the sliding rail. A pressing cylinder is arranged between the sliding rail and the conveying trough and is provided with a pressing plate. The discharging system comprises a discharging pipe and a discharging hopper. According to the cable cutting machine, the two ratchet wheels are arranged and can rotate in only one direction, so that when an output shaft of the conveying cylinder is output, the tworatchet wheels are used as clamps to drive a cable to advance; and when the output shaft is retreated, the ratchet wheels rotate while the cable does not move under the combined action of the pressingcylinder, and the cylinder can stop instantly, so that the advancing inertia of the cable is prevented, and the defect that the cable is arched forwards when a motor is used is overcome.

Owner:CHENGWU POWER SUPPLY CO STATE GRID SHANDONG ELECTRIC POWER CO LTD

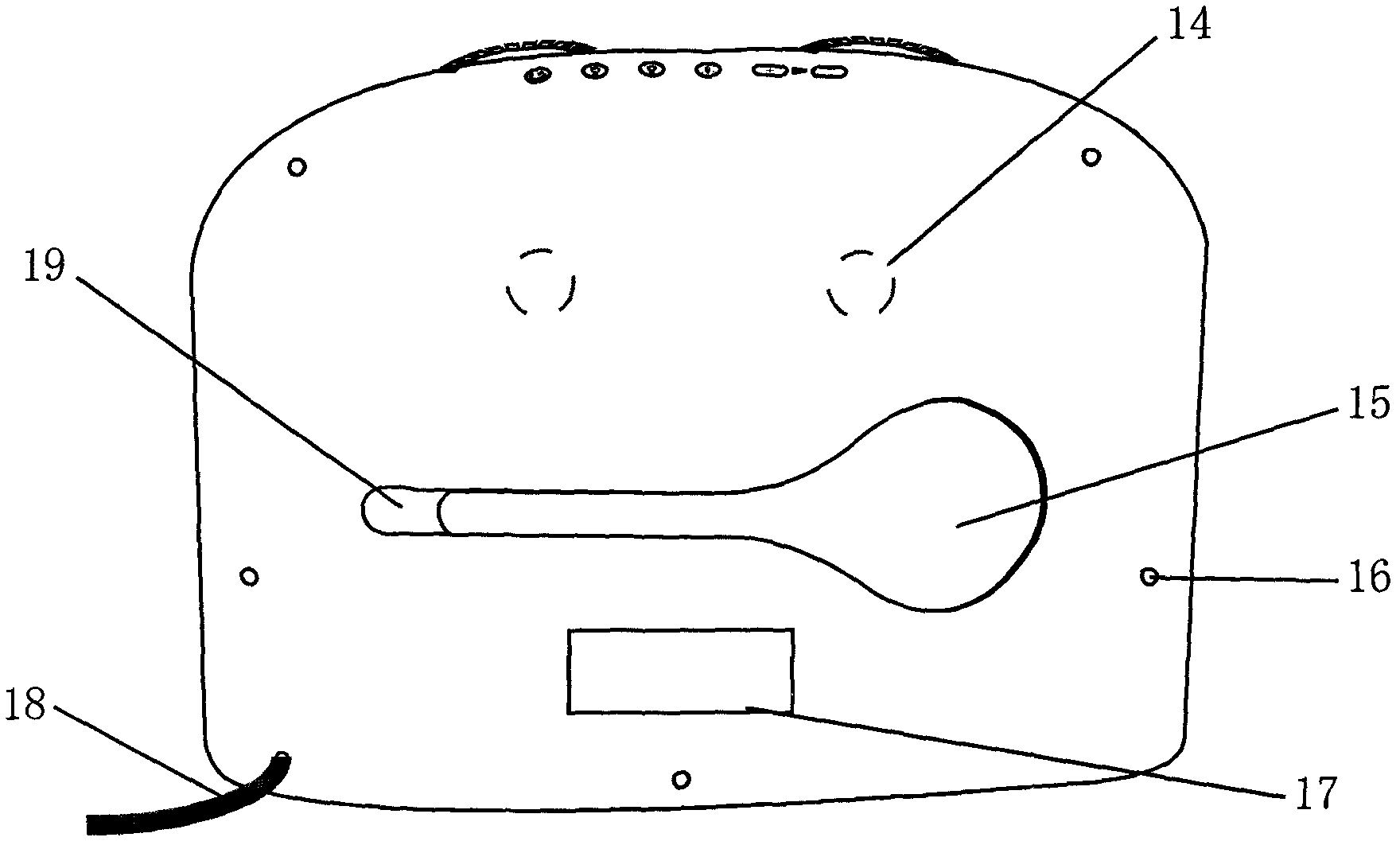

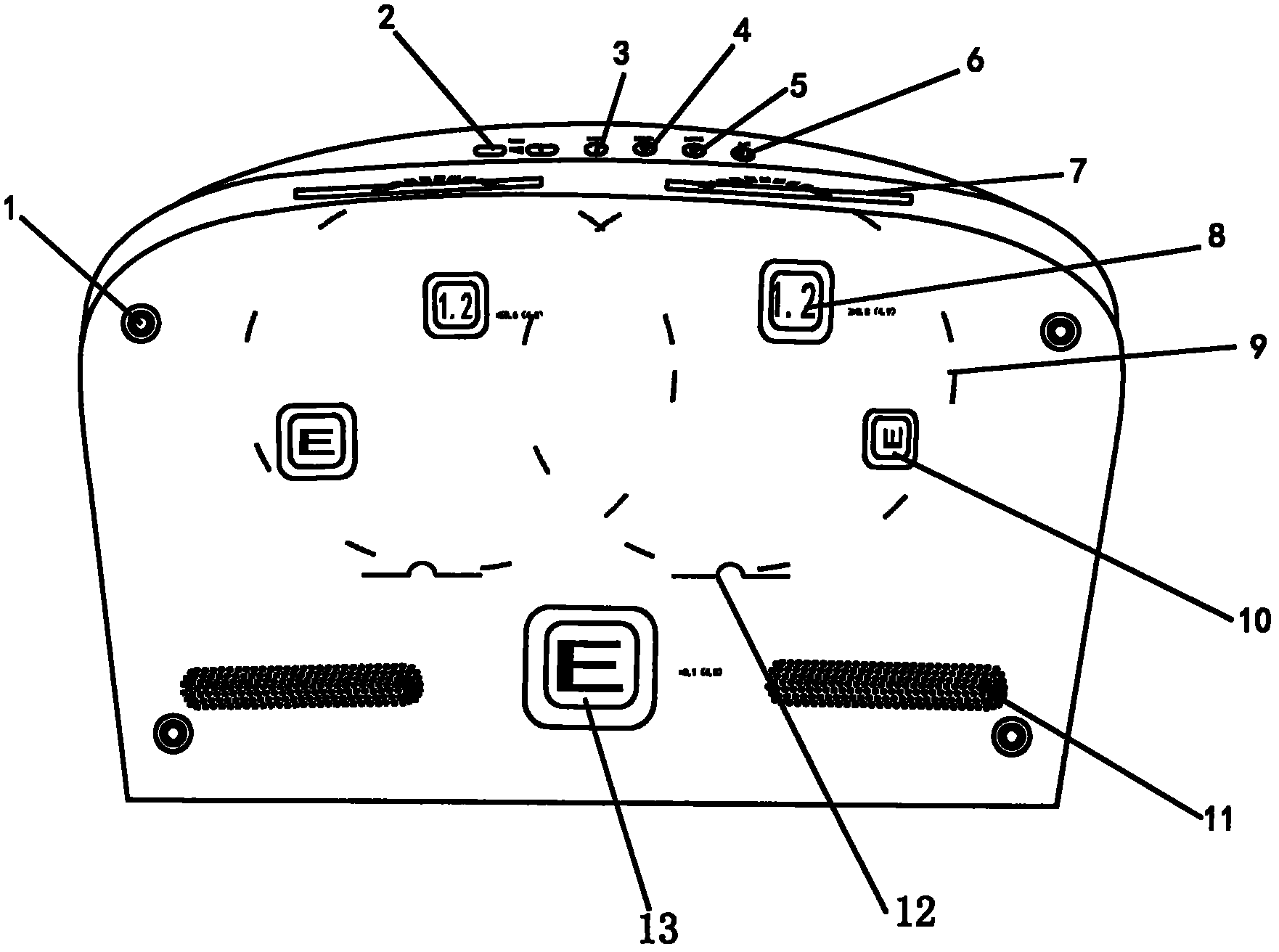

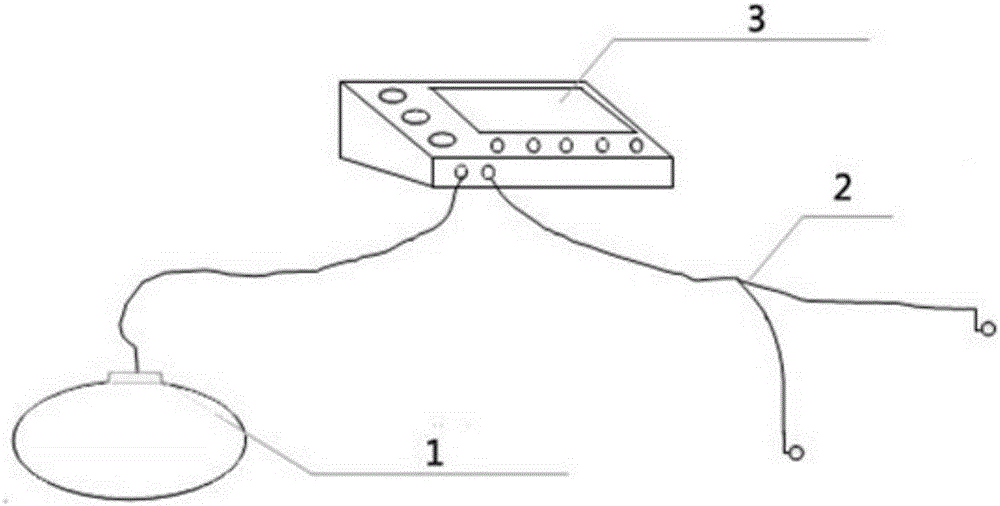

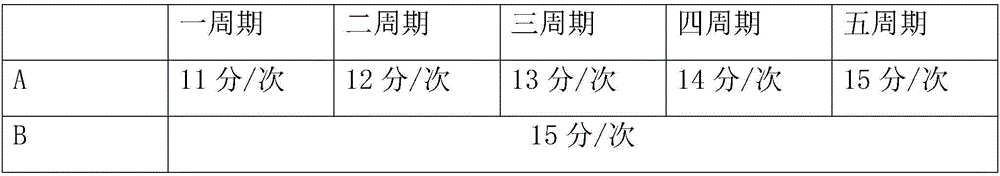

Dynamic respiration guidance instrument and working method thereof

InactiveCN106178428AStrong adjuvant effectAvoid discomfortGymnastic exercisingRespiratory organ evaluationRadiologyWorking set

The invention discloses a dynamic respiration guidance instrument and a working method thereof. The problems that in the prior art, a respiration guide technology is not matched with a current physical condition, and adjustment measures are not reasonable are solved. The dynamic respiration guidance instrument comprises a guidance instrument host, a respiration sensing mechanism and a respiration guidance mechanism; the respiration sensing mechanism obtains a guidance strategy according to received data and controls the respiration guidance mechanism to give out a respiration prompt. According to the dynamic respiration guidance instrument and the working method thereof, in-depth study is conducted on traditional medical expiration and inspiration movements such as a martial art and body building practice, a prevention and treatment integrated traditional concept is developed, passiveness is changed into activeness, a respiration guidance mechanism is built, real-time detection is combined, dynamic regulation of the respiratory rate is achieved, regular life movement characteristics are formed, and the purposes of maintenance and prevention are achieved.

Owner:张伟

PCB (printed circuit board) self circulation re-washing cylinder

ActiveCN104640363AOvercome inertiaEfficient removalConductive pattern polishing/cleaningPrinted circuit boardMechanical engineering

The invention discloses a PCB (printed circuit board) self circulation re-washing cylinder, which comprises a cylinder body, a heating device, an ultrasonic wave device, a swinging device, a filtering device and a pump, wherein the cylinder body is used for containing a PCB and medicine liquid taking reaction with ink, the heating device is built in the cylinder body and is used for heating the medicine liquid, the ultrasonic wave device is built in the cylinder body and is used for giving out ultrasonic waves for enabling the PCB to vibrate so that the ink in a PCB hole can be removed, the swinging device is built in the cylinder body and is used for driving the medicine liquid to oscillate and swing in the cylinder body, the filtering device is used for filtering the medicine liquid after the reaction with the ink, the pump is used for pressurizing the medicine liquid for flushing the PCB, and the bottom of the cylinder body is sequentially connected with the filtering device and the pump by pipelines and is then connected into the top of the cylinder body. The PCB self circulation re-washing cylinder has the advantages that the PCB can be circularly cleaned, and the ink in the PCB, particularly in the hole can be effectively removed.

Owner:SHENZHEN XINGDA PCB

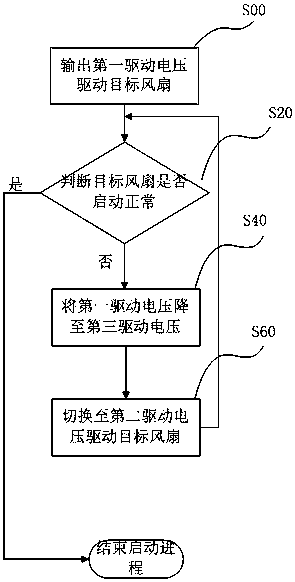

Target fan starting method

ActiveCN108105119AOvercome inertiaIncrease the probability of successful startupPump componentsDigital data processing detailsVoltageComputer engineering

The invention discloses a target fan starting method. The method includes the steps that a first driving voltage is output to drive a target fan; whether the target fan is started normally or not is judged; if it is judged that starting is normal, the starting process is ended; if it is judged that starting is abnormal, the first driving voltage is dropped to a third driving voltage; and the voltage is switched to a second driving voltage to drive the target fan, whether the target fan is started normally or not is judged continuously, and the second driving voltage is higher than the first driving voltage.

Owner:QINGDAO HISENSE LASER DISPLAY CO LTD

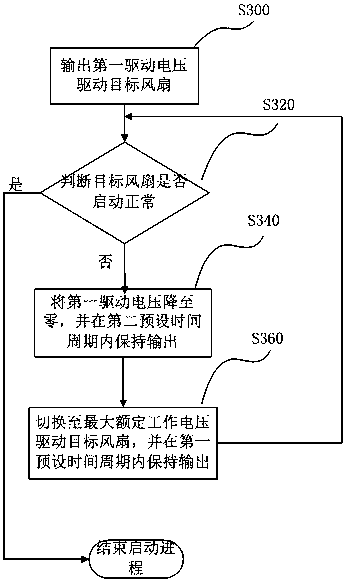

Multi-variety-shared cam-type distribution punching progressive die

The invention belongs to the field of machining and discloses a multi-variety-shared cam-type distribution punching progressive die which comprises a die platform, a driving shaft and more than one set of cam mechanisms. The cam mechanisms are arranged on the die platform and arranged in a coaxially driving manner through the driving shaft, one end of the driving shaft is connected with a driving device while the other end of the same is provided with an adjusting device, an upper die and a lower die are arranged on one sides of the cam mechanisms, the lower die is arranged on the die platform, the upper die is arranged correspondingly to the lower die and connected with the die platform through a guide member at the edge of the upper die, and sheet metal parts are arranged between the upper die and the lower die. By the multi-variety-shared cam-type distribution punching progressive die, production of the sheet metal parts of various types can be realized; quick production of similar products different in length is realized by replacing a cam without demounting the progressive die from equipment so as to improve processing efficiency.

Owner:CANGZHOU ORBON ELECTRICAL & MECHANICAL PROD MAKING

Vehicle emergency braking device

ActiveCN104986149AGuaranteed normal brakingSuccessful brakingBraking element arrangementsPedestrian/occupant safety arrangementShortest distanceShort distance

The invention provides a vehicle emergency braking device, belongs to the technical field of automotive safety protection and achieves the effect that a vehicle is stopped at a short distance by using additional braking force. The vehicle emergency braking device is technically characterized by comprising a braking buffer part, a braking control unit and a braking part. The braking buffer part comprises a braking shaft, a pulley, a slotted steel tube, a sliding block and a wire rope. The braking shaft is horizontally fixed to a crossbeam of the vehicle and located at the position of the center of gravity of the vehicle, the pulley is installed at the middle of the braking shaft, the slotted steel tube is arranged at the crossbeam of a vehicle chassis, the sliding block is installed in one end of the slotted steel tube in a sleeving manner, the other end of the slotted steel tube is provided with a round hole and is close to the pulley, one end of the wire rope is connected to the sliding block, the wire rope is arranged along the slotted steel tube, and the other end of the wire rope penetrates out of the round hole, is wound on the pulley and is then connected to the braking part. The vehicle emergency braking device is particularly suitable for emergency braking of the vehicle and the vehicle can be stopped at a short distance.

Owner:崔东元

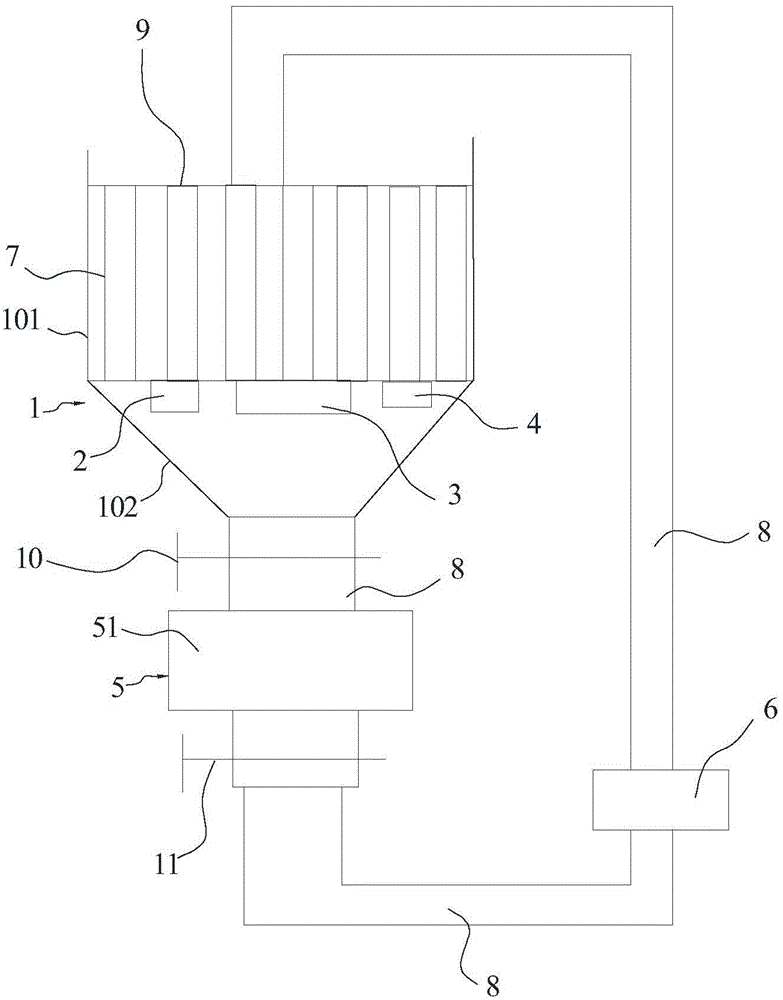

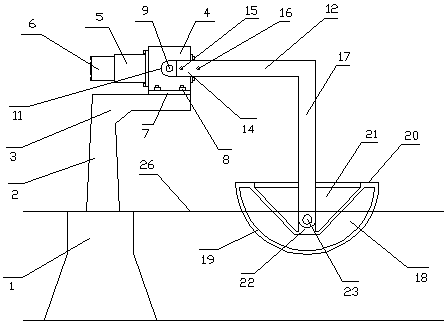

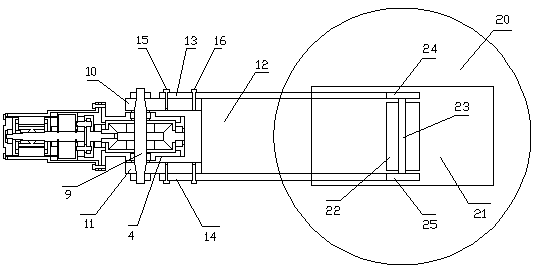

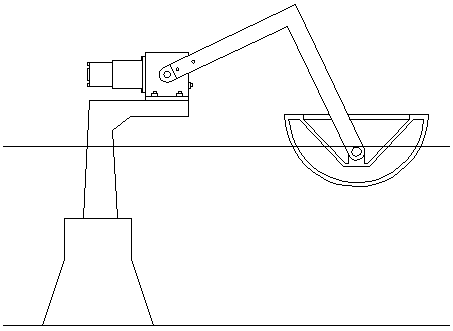

Reef wave power generation device

ActiveCN109185024AOvercome inertiaStable speedHydro energy generationMachines/enginesSeparated stateFreewheel

A reef wave power generation device does not occupy the space resource of a coast sand beach, a semispherical buoy moves up and down along with waves all the time during rising tide or falling tide ofsea water, a lower swing rod, an upper swing rod, a left connection arm and a right connection arm are driven to swing up and down, a drive shaft is driven to rotate alternately in the forward direction and the reverse direction, when the drive shaft rotates in the forward direction, a right overturn clutch is in a coupling state, a right cone gear is driven to rotate in the forward direction, the right cone gear drives a rear cone gear to rotate in the forward direction, at the moment, a left overturn clutch is in a disengaged state, a left cone gear idles in the reverse direction, forward rotation and reverse rotation of the drive shaft share the same principle, the rear cone gear keeps rotating in the forward direction all the time, the left cone gear and the right cone gear drive a front cone gear and the rear cone gear to accelerate for drive, balanced drive is achieved, three planetary gears drive an accelerating shaft to drive a flywheel and a columnar rotor to rotate at a highspeed through two-stage acceleration, inertia of the flywheel overcomes the pause phenomenon caused by alternation of the forward rotation and the reverse rotation of drive, the columnar rotor is made to be stable in rotation speed, and power generation is stable.

Owner:诚航新能源车辆有限公司

Drive engagement apparatus

InactiveUS7497311B2Overcome inertiaIncrease the areaFluid actuated clutchesFriction clutchesActuatorControl theory

Owner:ARTHUR KNOWLES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com