Intelligent control type material cutting device

An intelligent control and cutting technology, applied in thin material handling, transportation and packaging, winding strips, etc., can solve the problems of cutting equipment shutdown, inaccurate cutting position, affecting work efficiency, etc., and achieve precision control. Improve, improve work efficiency, reduce the effect of cutting errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

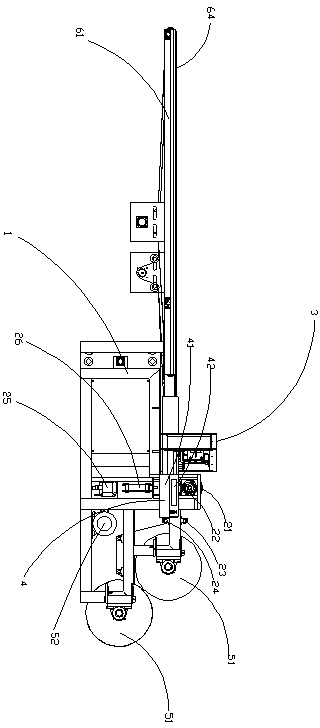

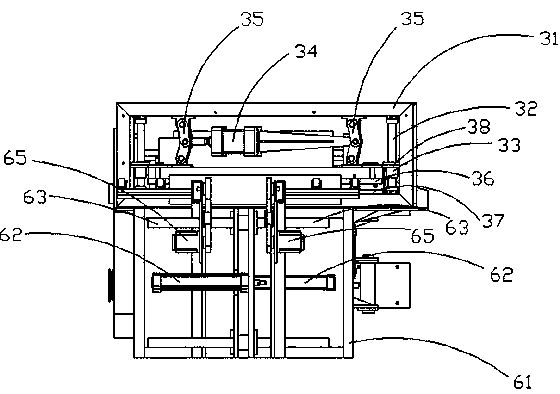

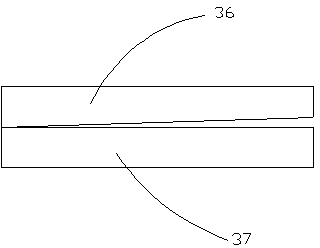

Embodiment 1

[0041] like Figure 1-4 As shown, an intelligently controlled cutting device in this embodiment includes: a frame 1; The two inflatable shafts 51 are erected on the frame 1 and are electrically connected to the drive motor 52. The drive motor 52 drives the two inflatable shafts 51 to rotate at the same time. The inflatable shaft 51 can also be set to one or more than two. The root can be adjusted according to the process requirements; the feeding mechanism, which is arranged after the above-mentioned discharging mechanism and is connected with the above-mentioned frame 1, the feeding mechanism includes a driving roller 21, a first driven roller 22, a second driven roller 22, and a second driven roller. The roller 23, the third driven roller 24 and a servo motor 25, the driving roller 21 and each driven roller are respectively erected on the frame 1 in turn, wherein the first driven roller 22 is erected under the driving roller 21, The second driven roller 23 and the third dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com