Patents

Literature

130results about How to "Reduce cutting errors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

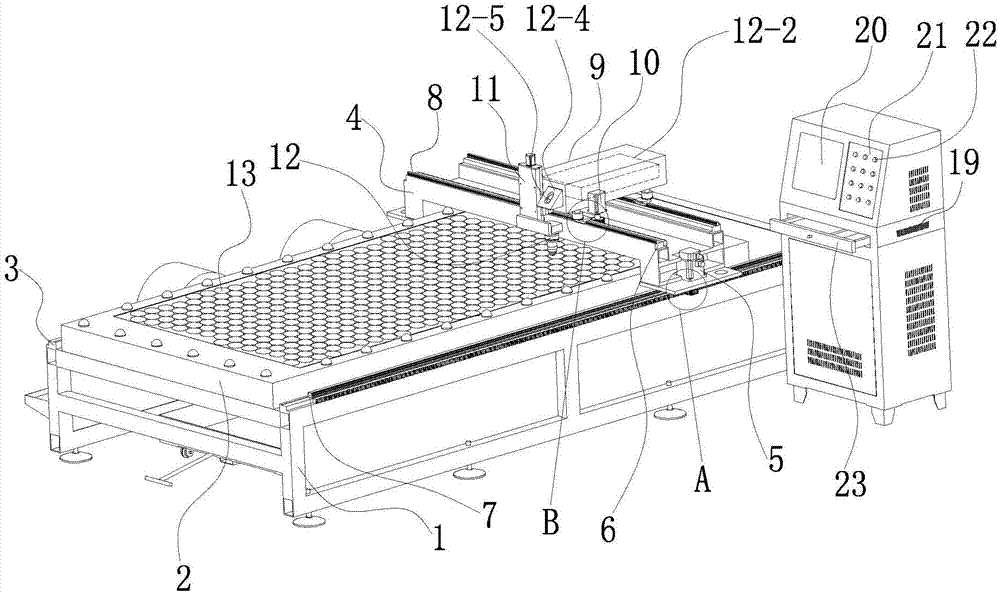

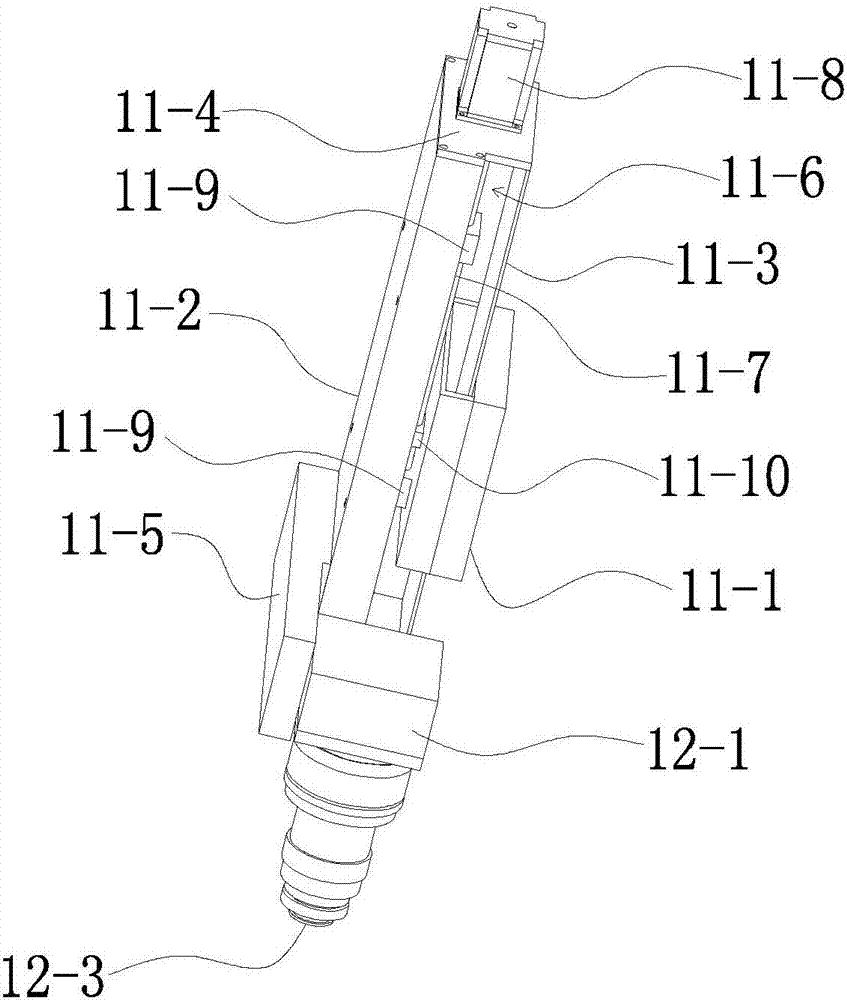

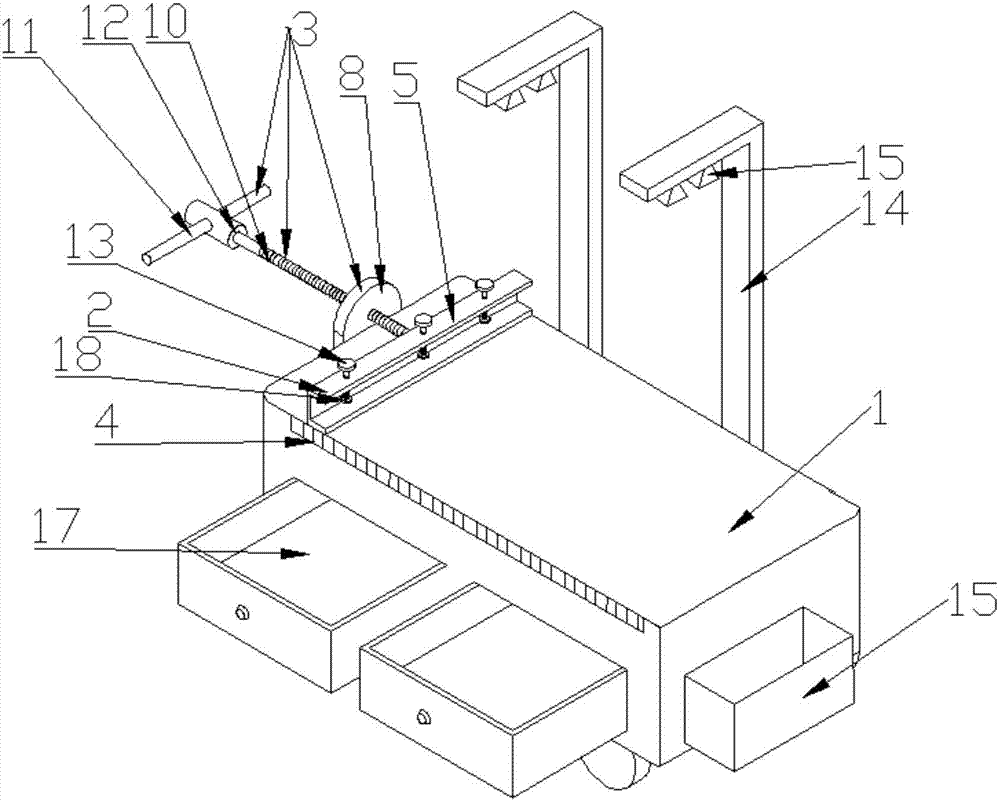

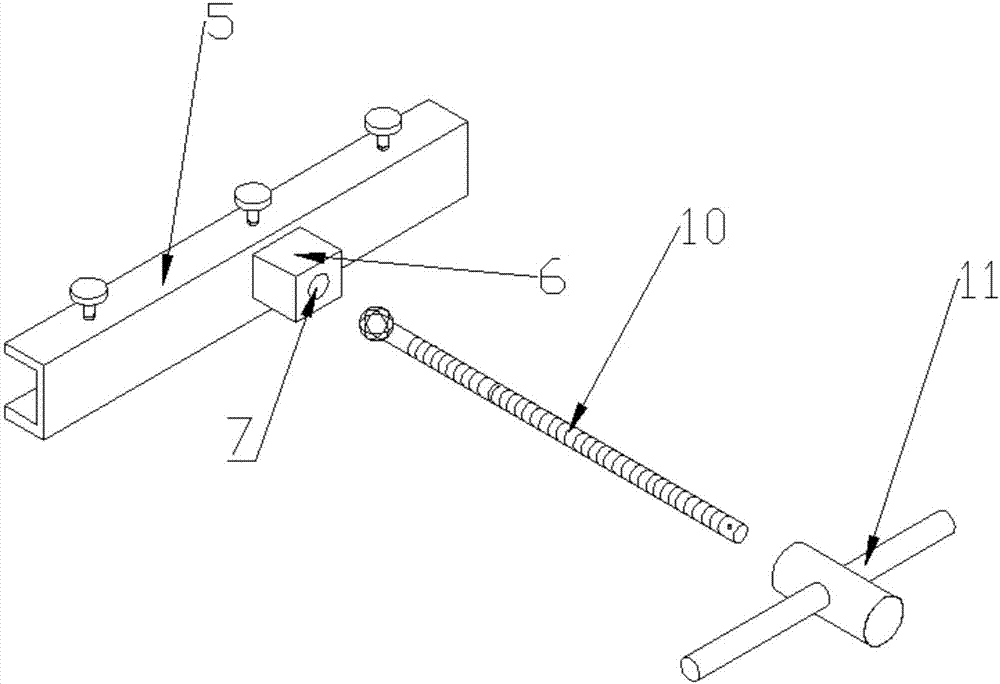

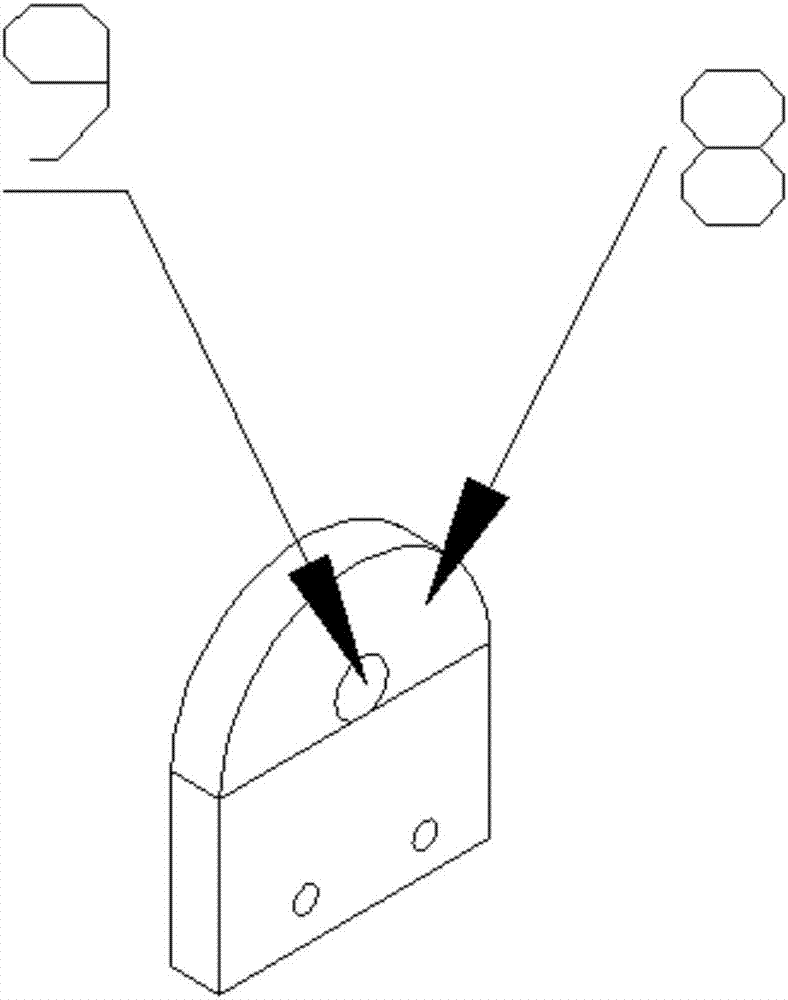

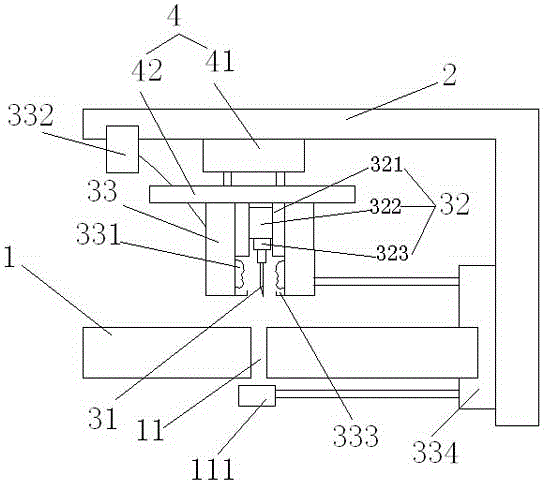

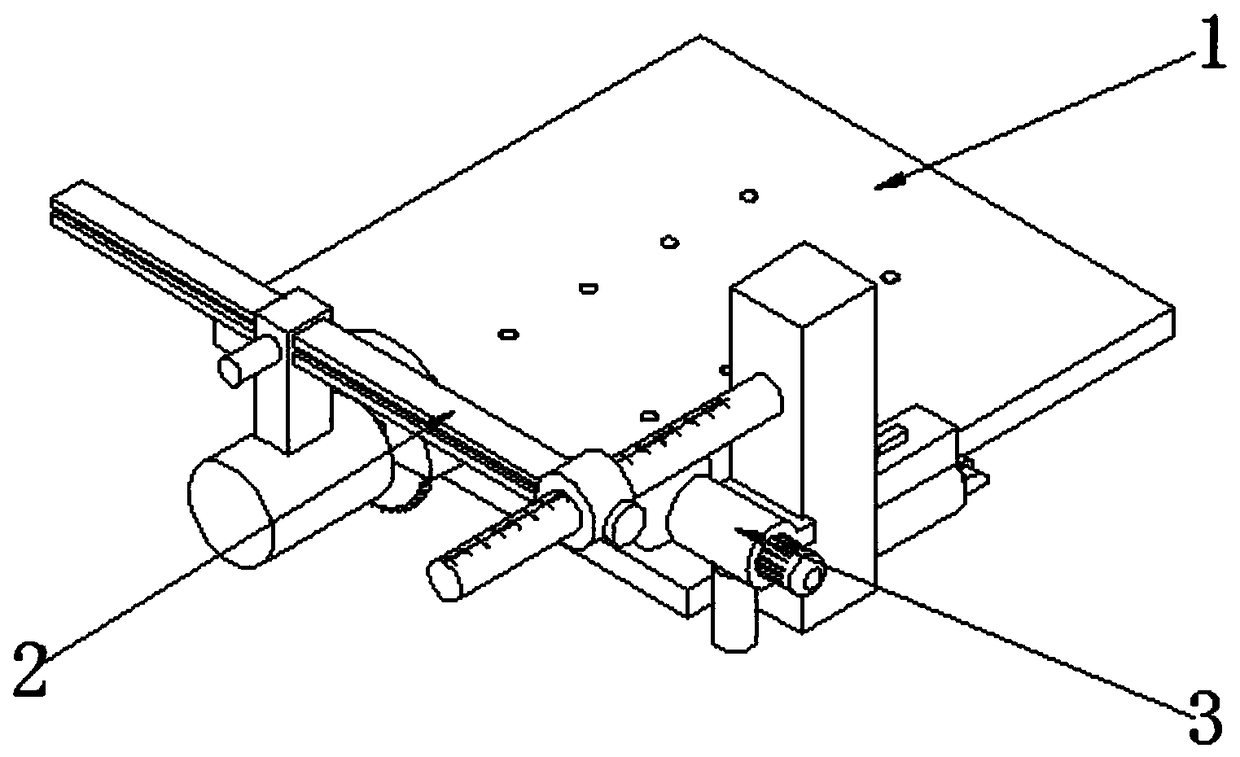

Laser cutting device for cloth

The invention relates to a perforating device for cloth. A laser cutting device for the cloth comprises a base, a working platform and a cross beam; two first linear guide rails arranged in the length direction of the base are arranged on the base; two first slides are fixedly arranged on the two first linear guide rails; two ends of the cross beam are glidingly connected onto the two first slides; first driving devices for driving the cross beam to move in the length direction of the two first slides are arranged at the two ends of the cross beam; two second linear guide rails arranged in the length direction of the cross beam are arranged on the cross beam; two second slides are fixedly arranged on the two second linear guide rails; a square box is arranged on the two second slides; the front end of the square box is glidingly connected with a moving seat device; and a laser cutting mechanism is arranged on the moving seat device and is corresponding to the position of the working platform. The laser cutting device is simple in structure, convenient and quick to use, high in automation degree and capable of realizing quick feeding of a laser cutting head and improving the production efficiency.

Owner:PINGHU XING TIANYOUNG CLOTHING TECH CO LTD

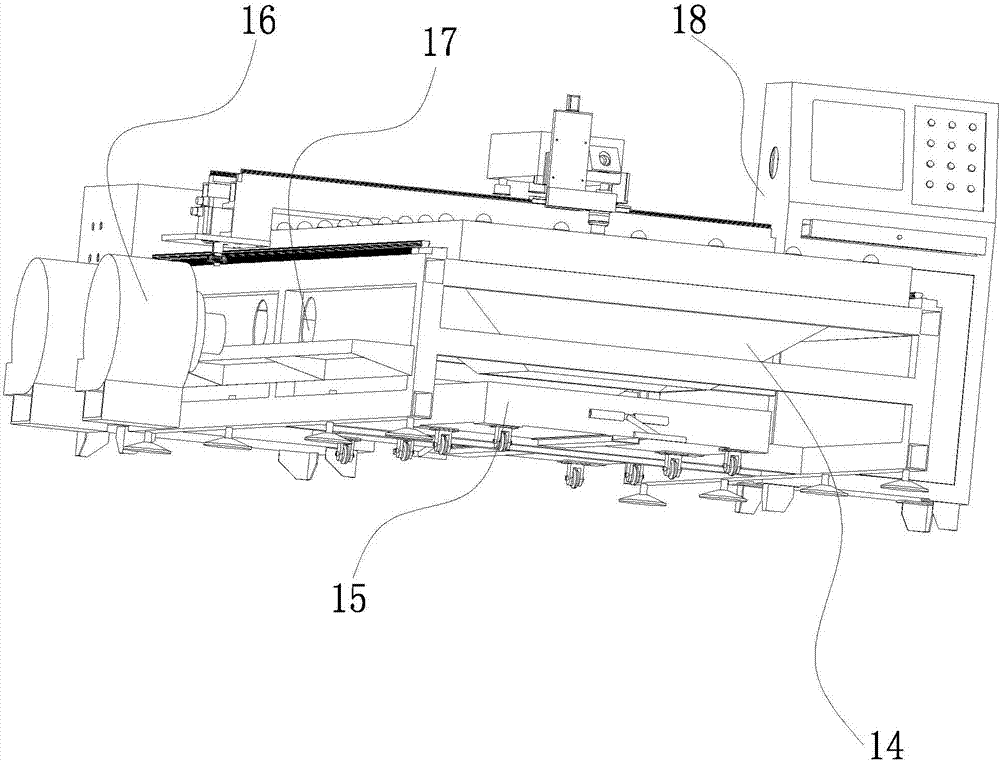

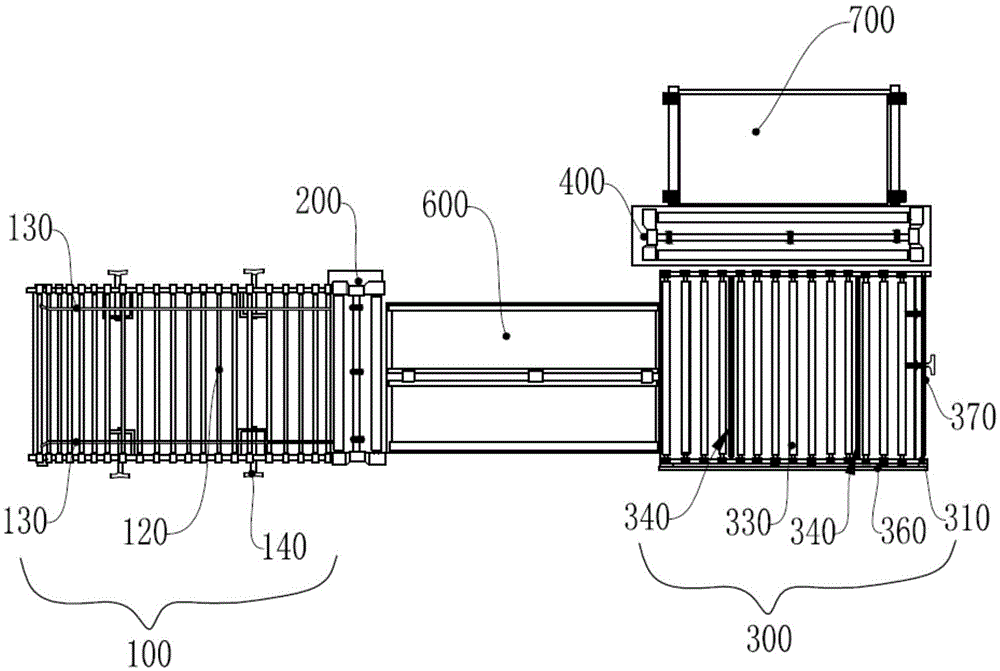

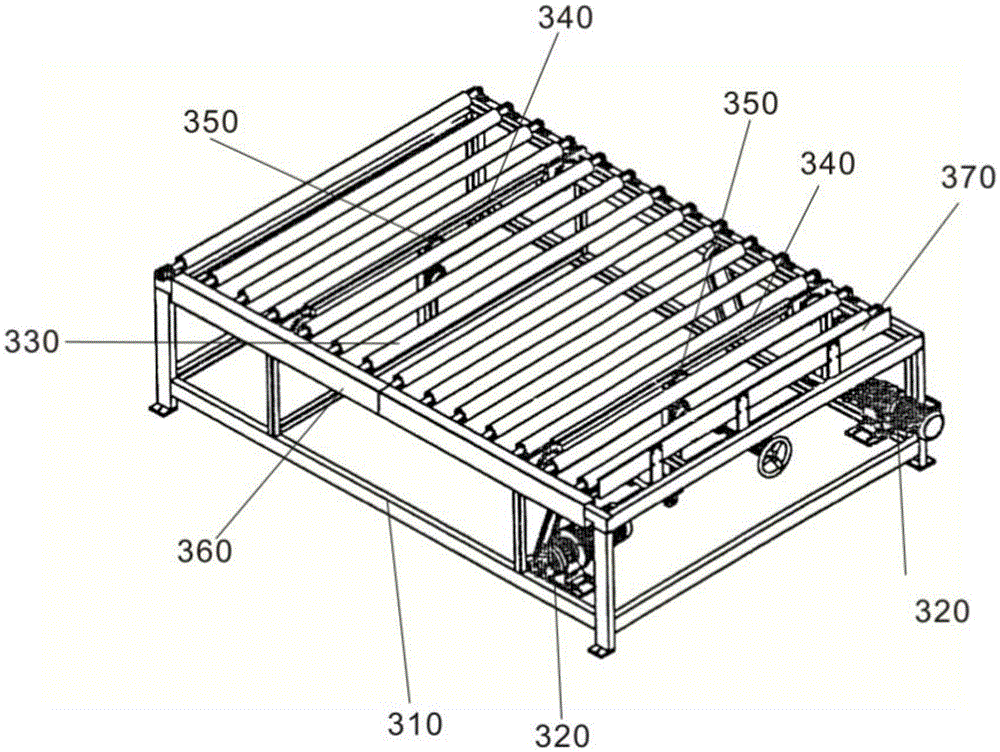

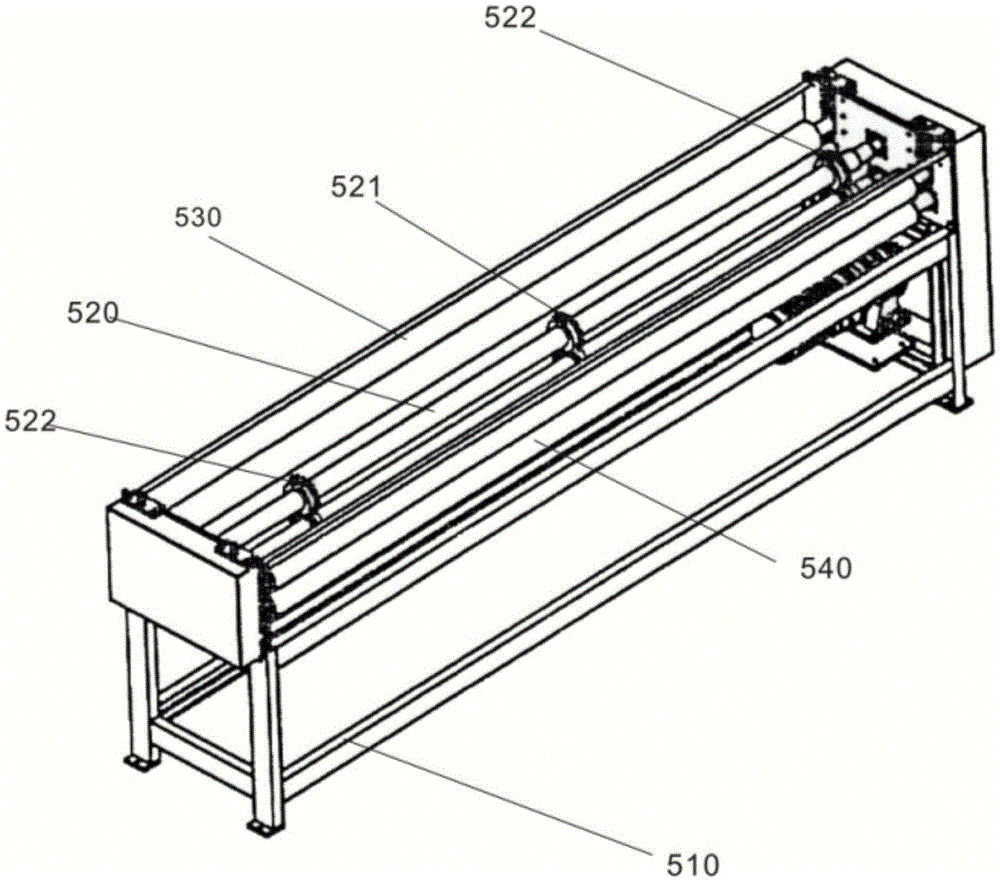

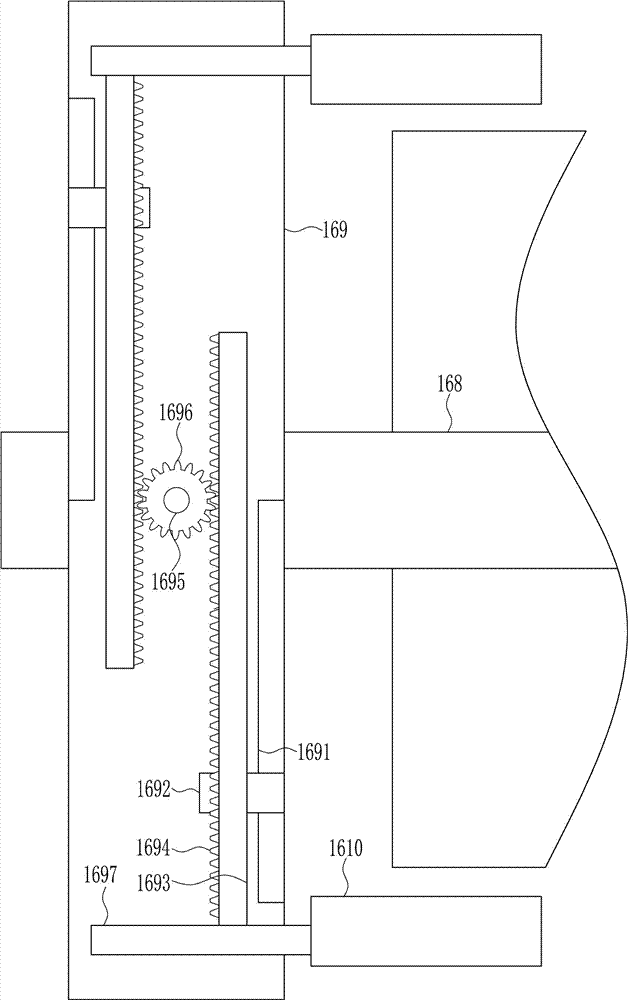

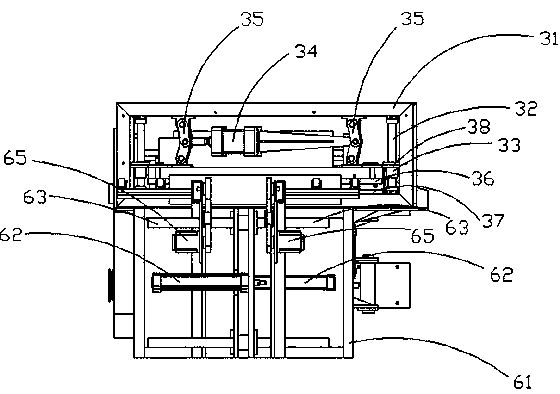

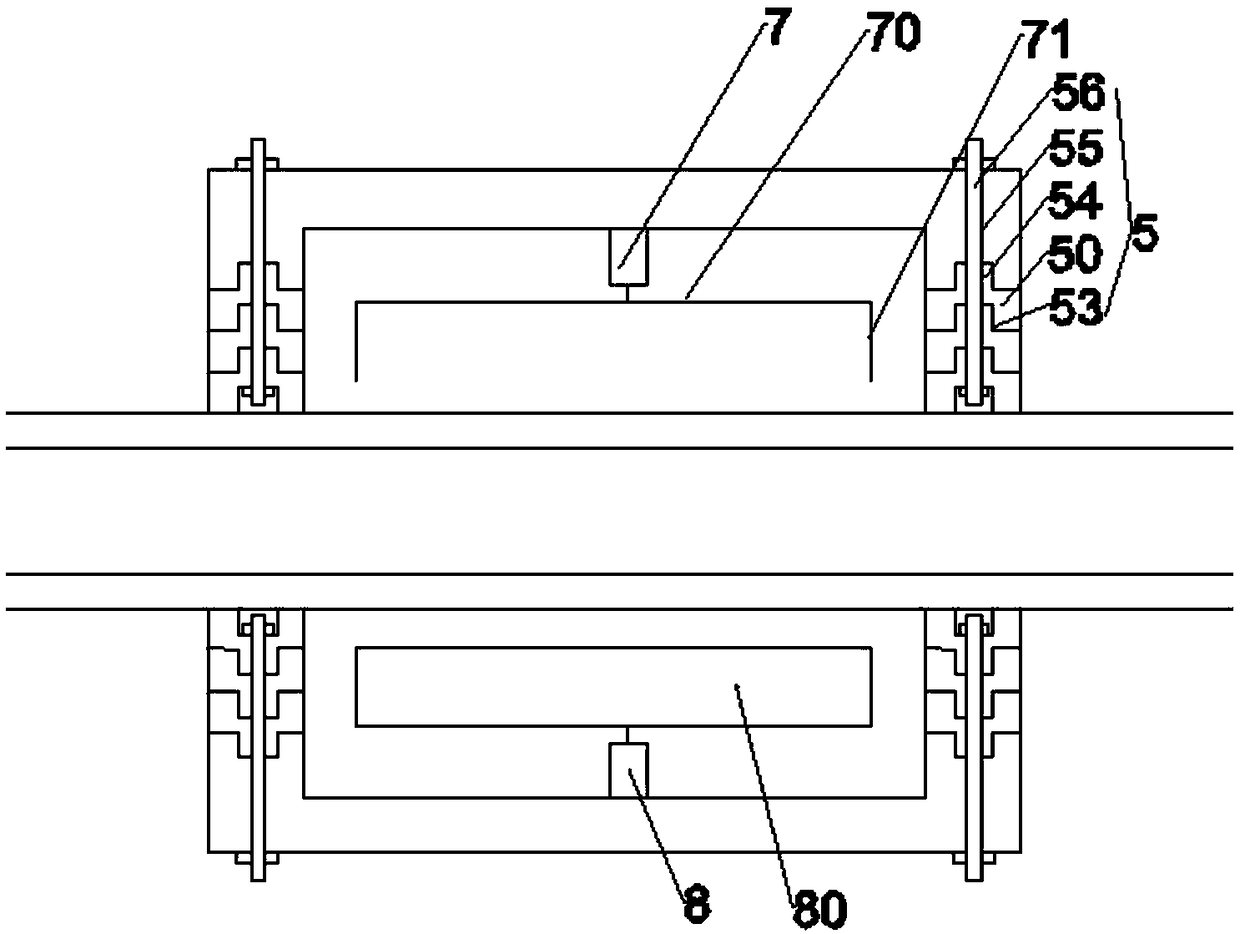

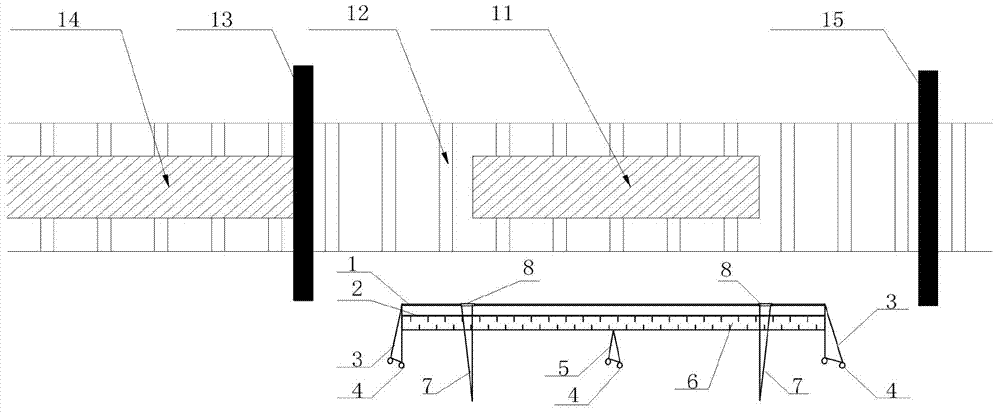

Splitting machine with transverse and longitudinal two-way cutting function

The invention relates to the field of board cutting mechanical equipment, in particular to a splitting machine with the transverse and longitudinal two-way cutting function. The splitting machine comprises a transverse transporting device, a transverse cutting machine, a steering transporting device and a longitudinal cutting machine. A transverse conveying mechanism and a longitudinal board pushing mechanism are arranged on a conveying platform of the steering transporting device. The conveying direction of the transverse conveying mechanism is perpendicular to the board pushing direction of the longitudinal board pushing mechanism. A feeding port of the transverse cutting machine is in butt joint with the discharging end of the transverse transporting device. A discharging port of the transverse cutting machine is in butt joint with the feeding end of the steering transporting device. The discharging end of the steering transporting device is in butt joint with a feeding port of the longitudinal cutting machine. The transporting devices and the cutting machines in the splitting machine all automatically and orderly work under the control of a programmable controller, the high-intelligent two-way cutting work can be achieved through the splitting machine, personnel operation is reduced, splitting efficiency is improved, and cutting errors are reduced.

Owner:GUANGDONG WALKKIND SPECIAL FIBERBOARD TECH

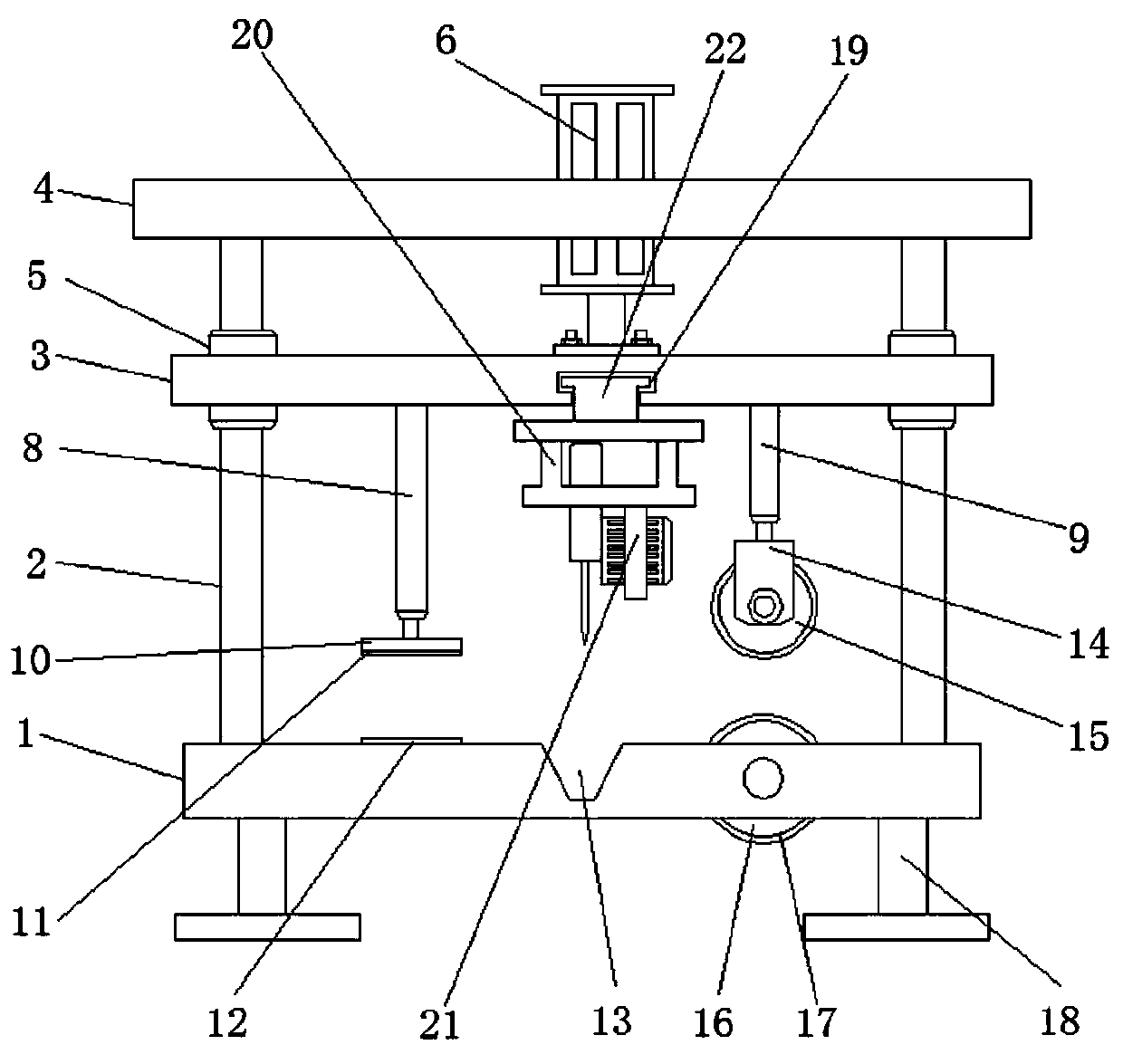

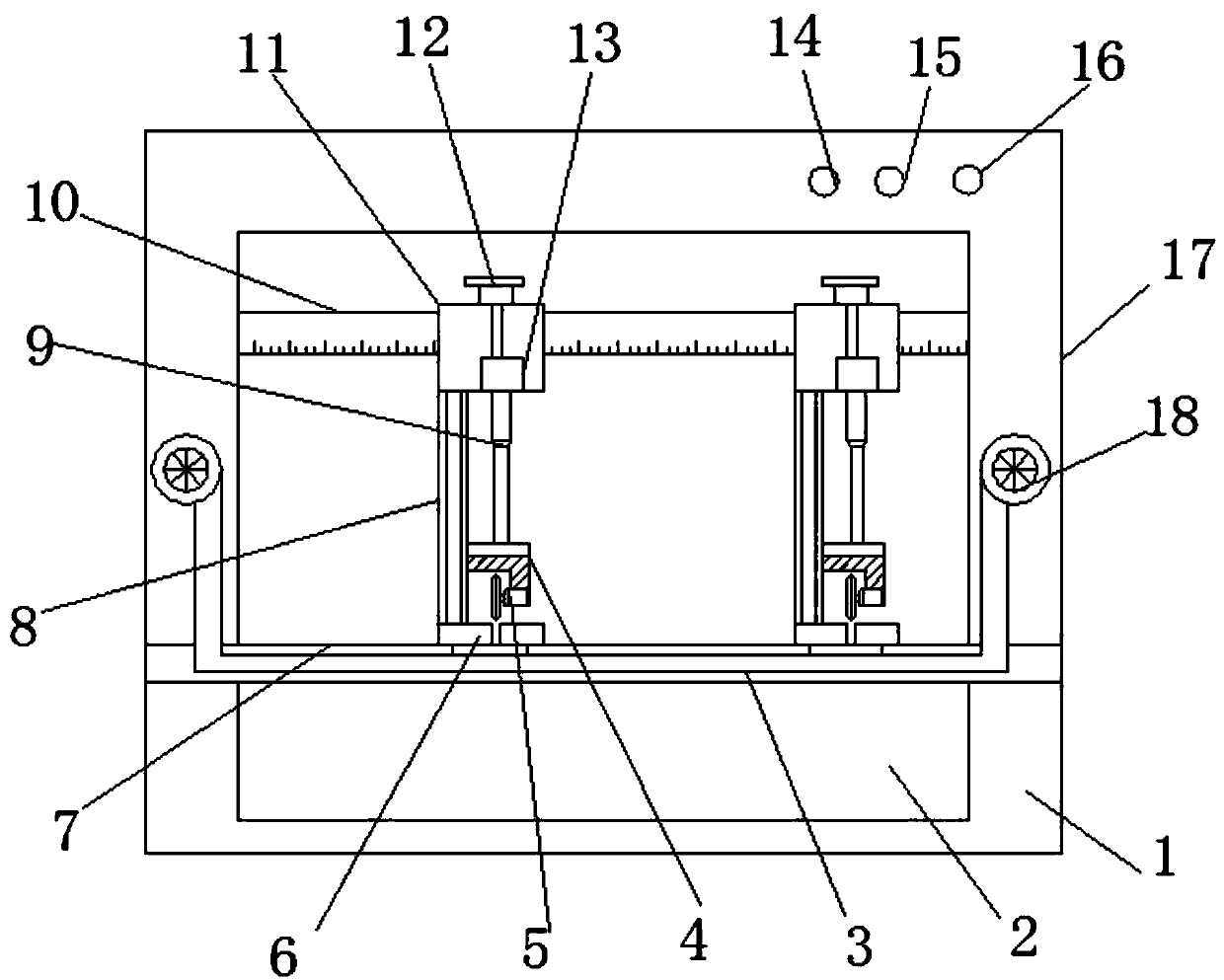

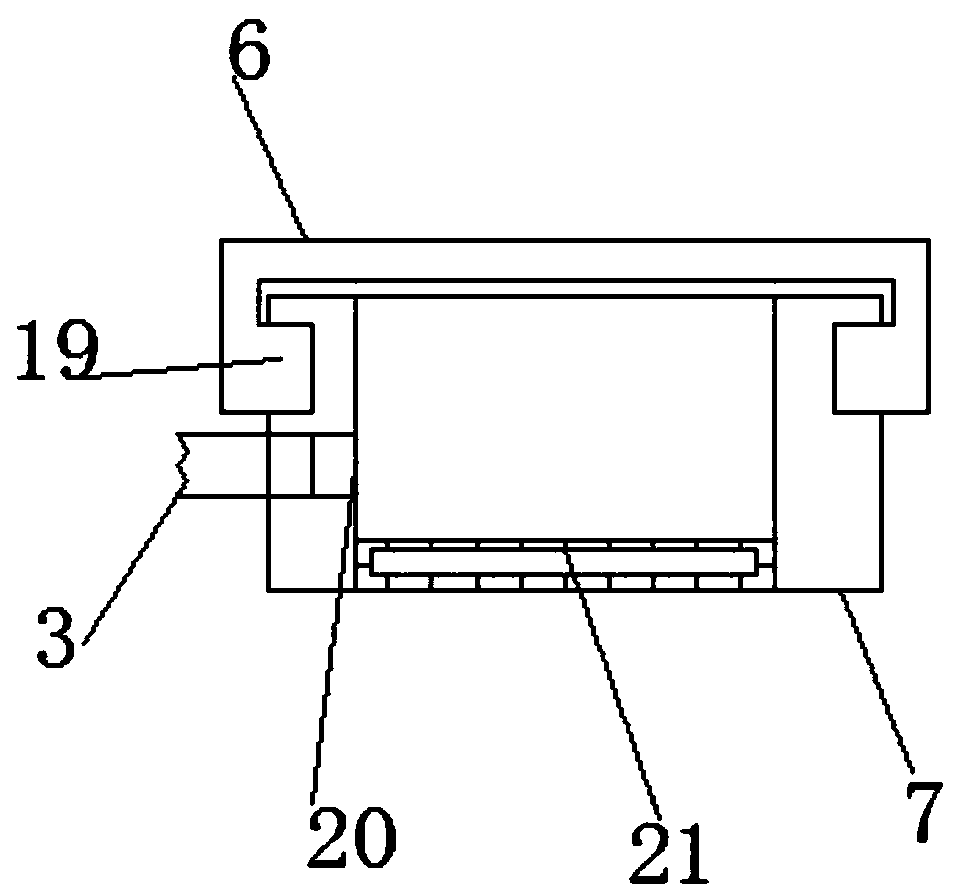

Hardware cutting machine with clamping function

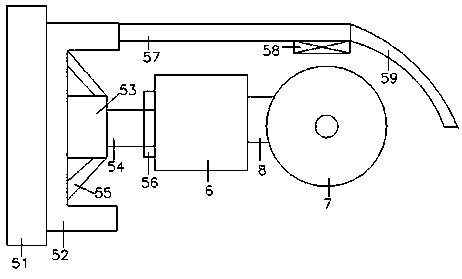

InactiveCN105855635AWith clamping functionEffective clampingPositioning apparatusMetal-working holdersDrive wheelPulp and paper industry

The invention discloses a hardware cutting machine with clamping function, comprising a cutting machine body, a cutting blade wheel is disposed inside the cutting machine body, a driven wheel is fixedly connected to a spindle of the cutting blade wheel, a motor is disposed on one side of the cutting machine body, the bottom of the motor is provided with a support plate, a driving wheel is fixedly connected to a spindle of the motor, a driving wheel on the motor is in transmission connection with the driven wheel on the cutting blade wheel through a belt, the top of the cutting machine body is provided with a handle, the bottom of the cutting machine body is fixedly connected with a fixing rod, and one side of the fixing rod is fixedly connected with one end of the support plate. The hardware cutting machine with clamping function is good in clamping effect, hardware rarely moves during cutting, cutting error is small, cutting efficiency is high, sliding of hardware is avoided, fixing effect is good, efficient processing of the hardware is guaranteed, manpower and material sources are saved, and the hardware cutting machine is simple to operate and good in application effect.

Owner:CHANGZHOU XINBO REDUCTION GEAR CO LTD

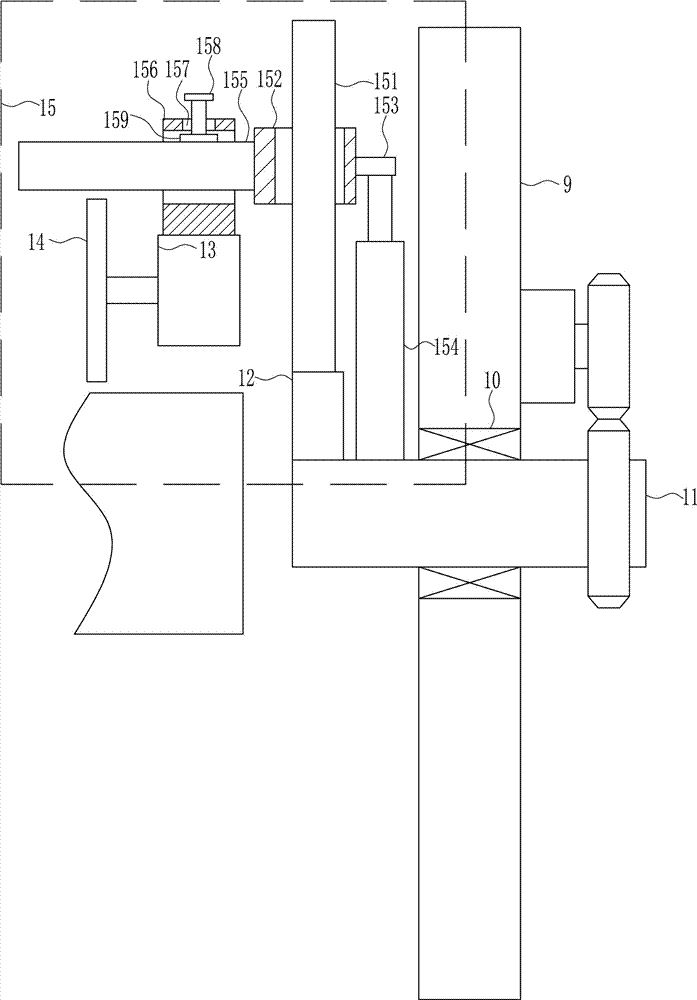

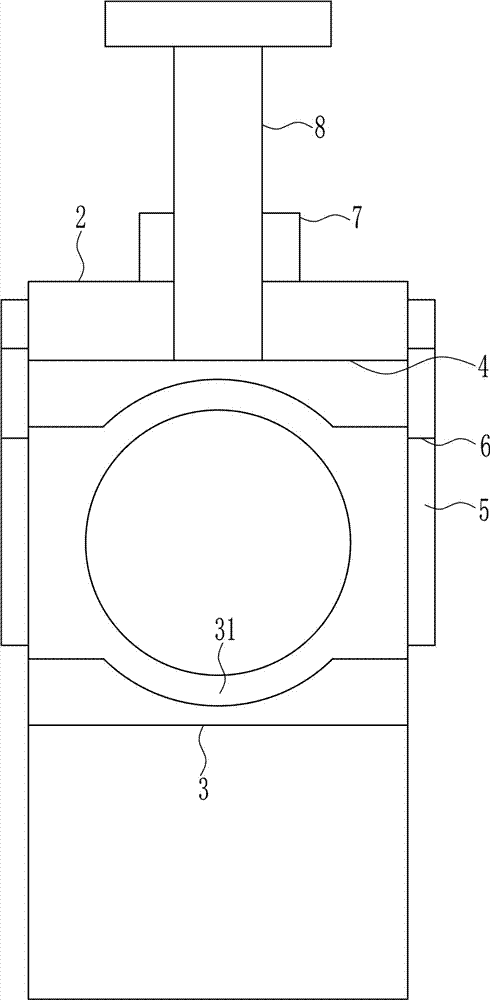

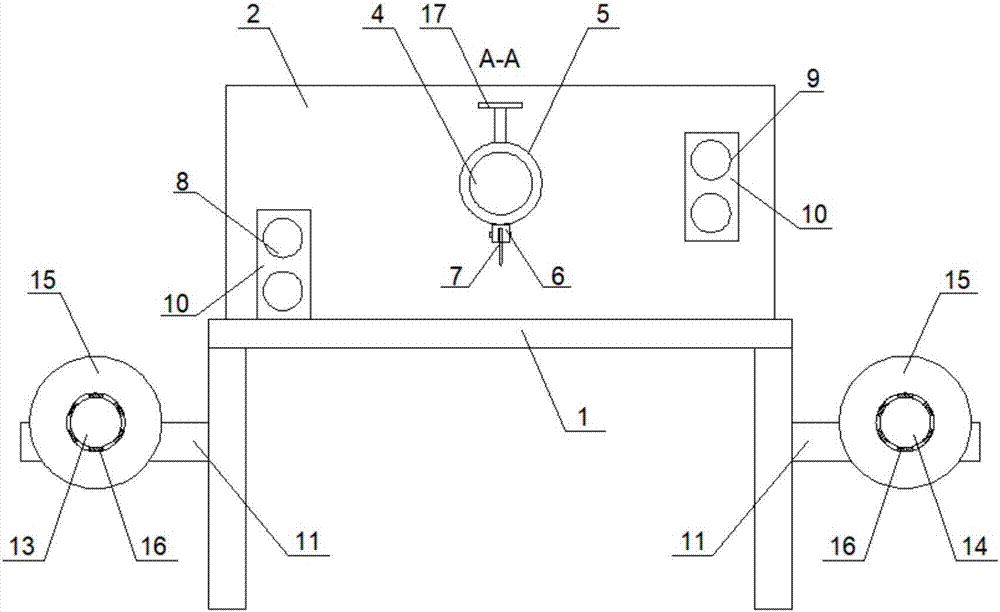

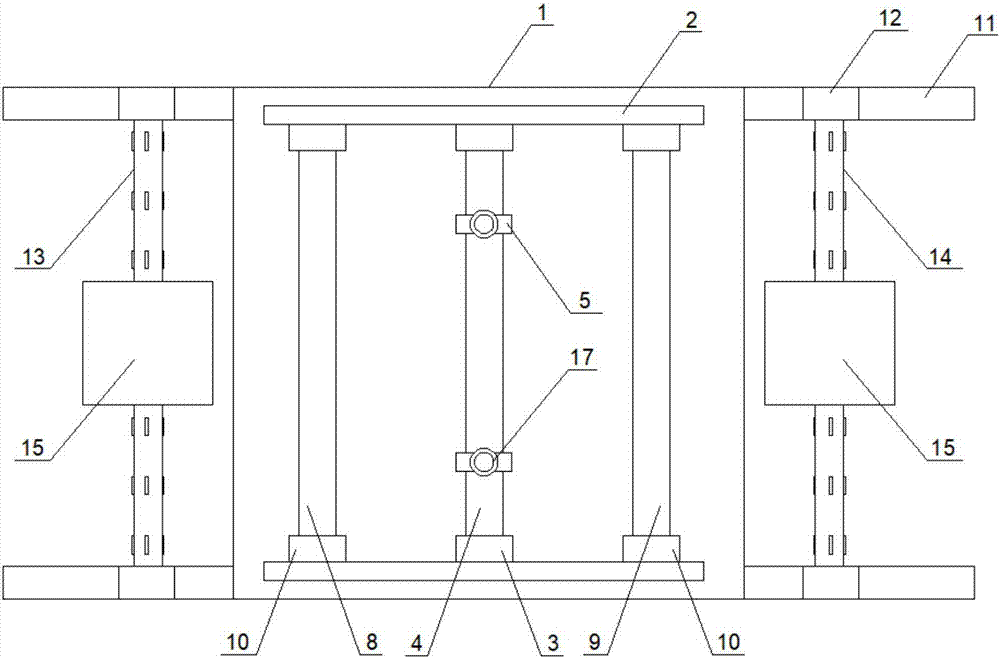

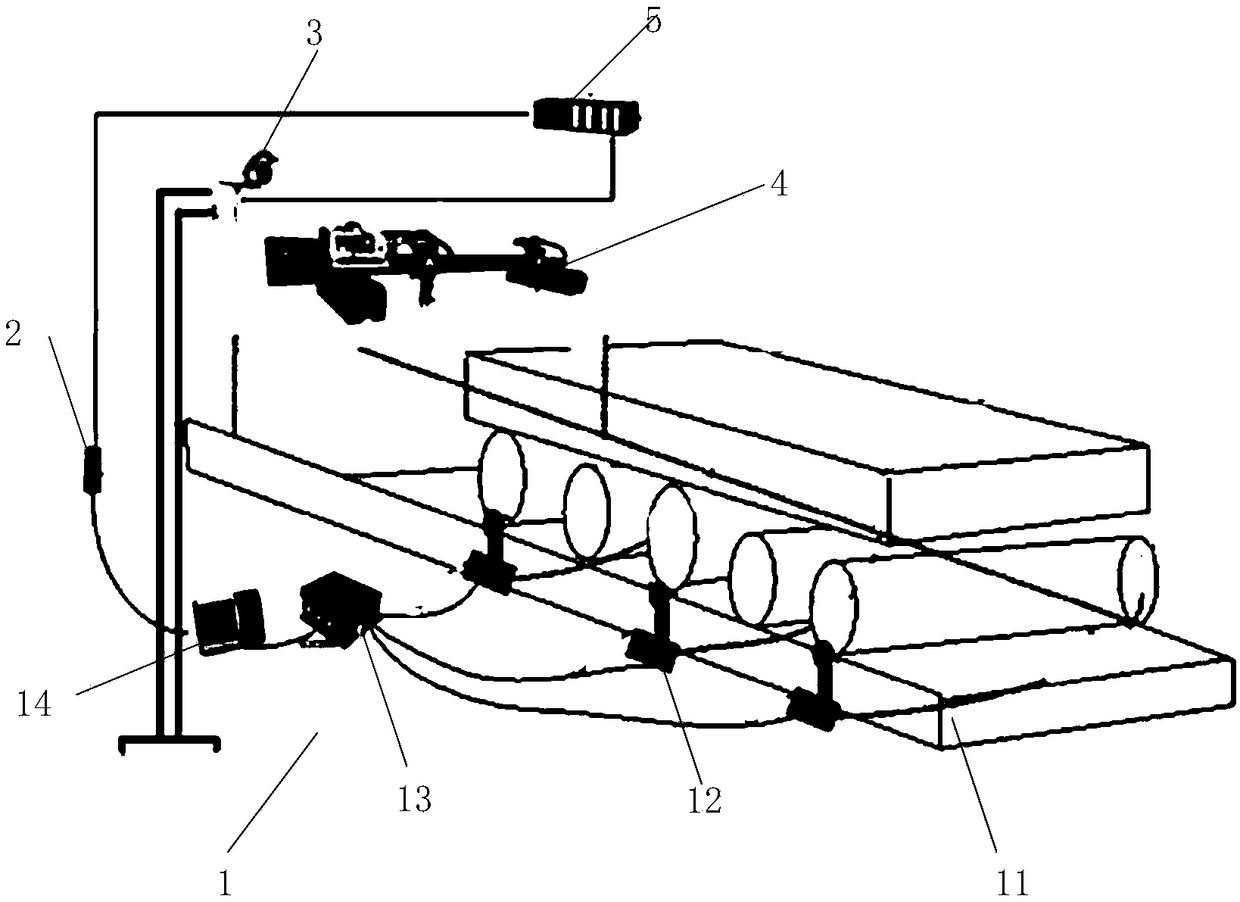

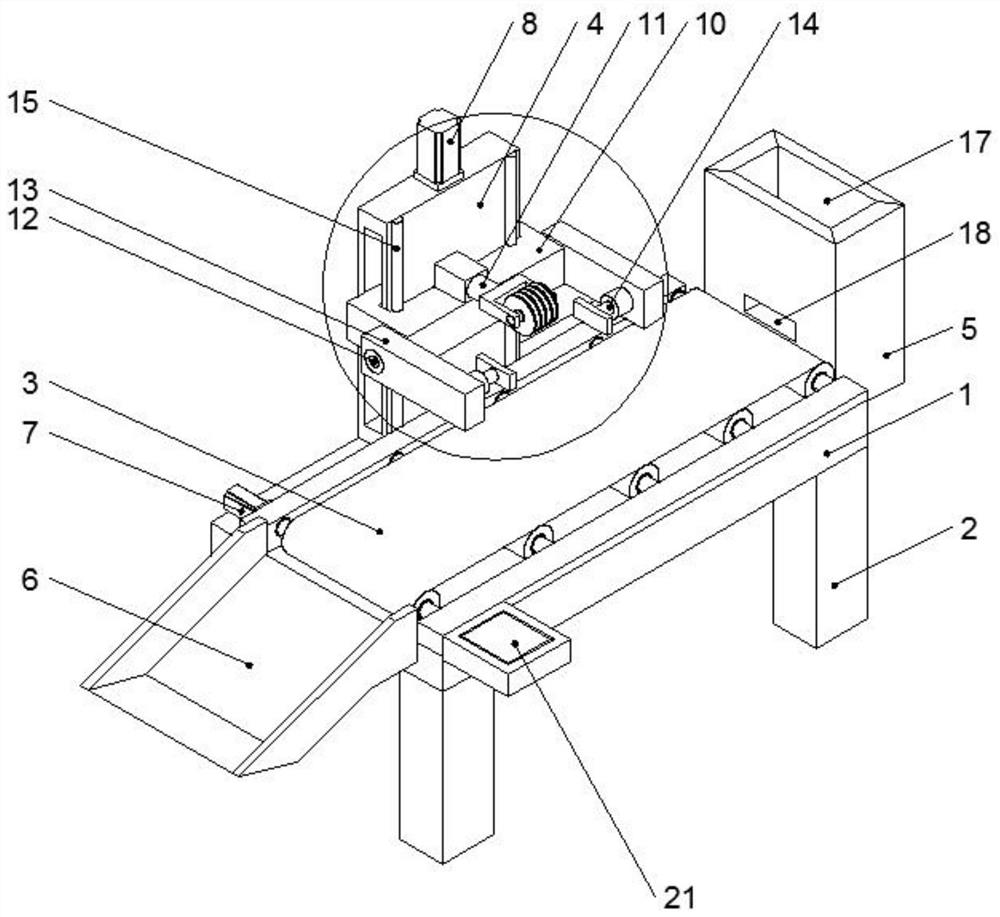

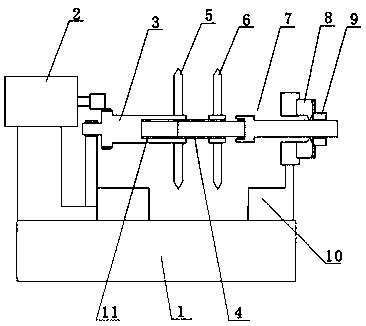

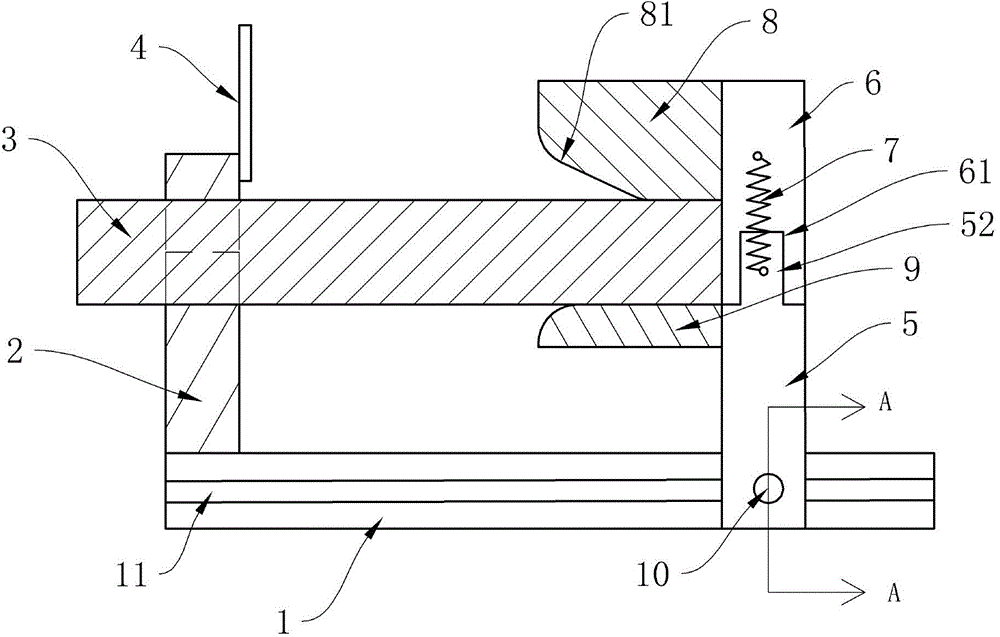

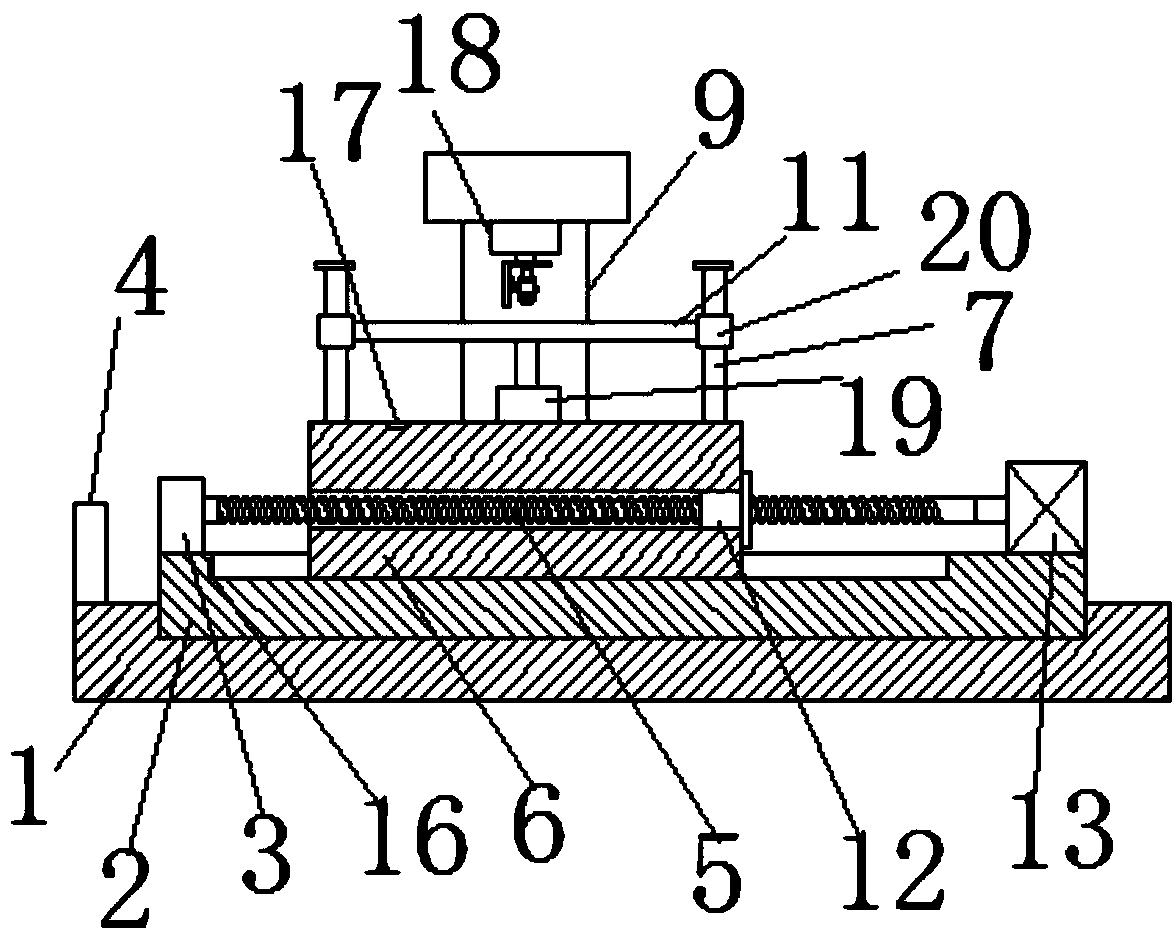

Large diameter steel pipe cutting equipment for industry

ActiveCN107042331AReduce cutting errorsCutting saves time and effortTube shearing machinesShearing machine accessoriesCivil engineering

The invention relates to steel pipe cutting equipment, in particular to large diameter steel pipe cutting equipment for industry. According to the large diameter steel pipe cutting equipment for the industry, the cutting error is small, the cutting process saves time and labor, and the cutting process is simple and rapid. The large diameter steel pipe cutting equipment for the industry comprises a bottom plate, a fixing table, a placing plate, a pressing plate, a first sliding rail, a first sliding block, a first nut, a first screw rod, a supporting plate, a first bearing seat, a rotary rod and the like; the fixing table is mounted on the left side of the bottom plate in a welding mode; and the placing plate is mounted on the lower portion inside the fixing table in a welding mode. According to the large diameter steel pipe cutting equipment, the effects that the cutting error is small, the cutting process saves time and labor, and the cutting process is simple and rapid are achieved, through the mode that annular cutting is conducted on the upper portion of the steel pipe, a small cutting knife can be used to cut the steel pipe to save cost, and the cutting quality can be guaranteed.

Owner:WUXI HUADI MACHINERY EQUIP

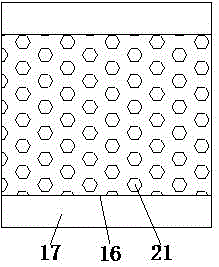

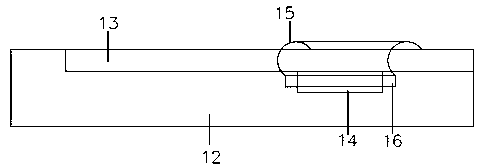

Special polyester film slitting device for bus duct

InactiveCN107498628AAvoid hidden dangersEasy to adjustMetal working apparatusWebs handlingPolyesterKnife blades

The invention discloses a special polyester film cutting device for bus duct. A cutting shaft is arranged directly above the middle position of the cutting table, and two sliding sleeve blocks are slidably mounted on the cutting shaft. The distance between the sliding sleeves is set, and the bottom end of the sliding sleeves is fixedly connected with a U-shaped cutter seat, and the cutting blades are clamped and fixed on the cutter base, and the two sides of the sliding sleeves are located on the two sides of the sliding sleeves. The distance between the cutting blades is the width of cutting the polyester film. The left and right sides of the slitting shaft are respectively provided with an upper and lower extruding shaft for feeding film and an upper and lower extruding shaft for receiving film. The slope height is set between the upper and lower extrusion axes of the film. With this technical solution, by adjusting the distance between the sliding sleeves on both sides of the slitting shaft, the distance between the cutting blades on the cutter seat fixed to the bottom of the sliding sleeve can be adjusted to meet the requirements of different product widths. Cutting, fast and convenient adjustment, which is conducive to improving the cutting efficiency.

Owner:江苏昊昱科技咨询有限公司

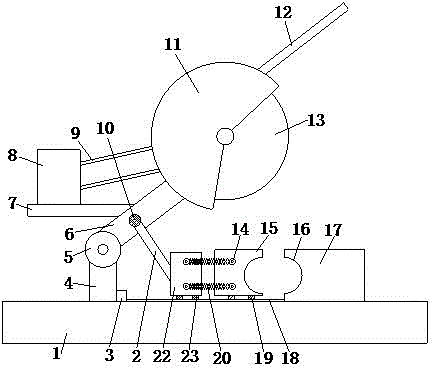

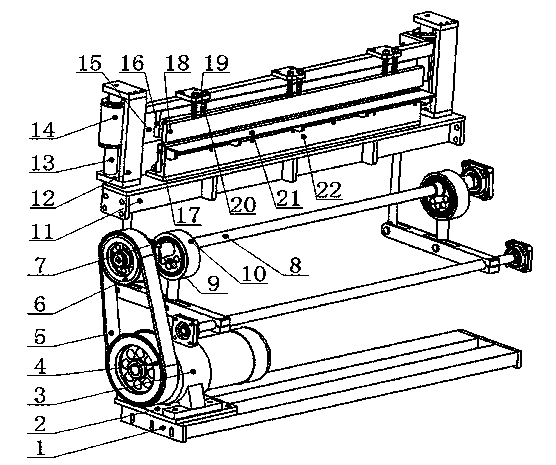

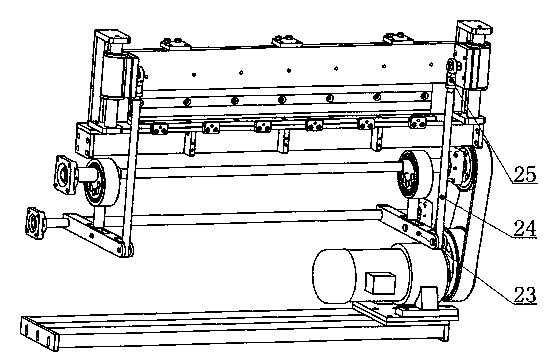

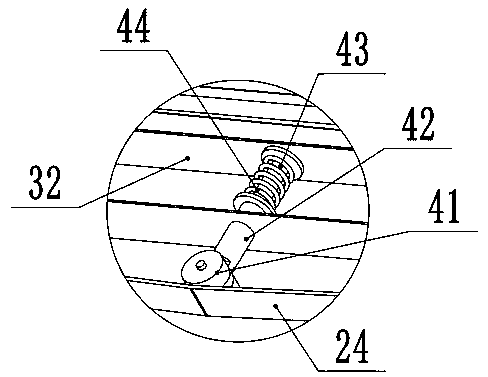

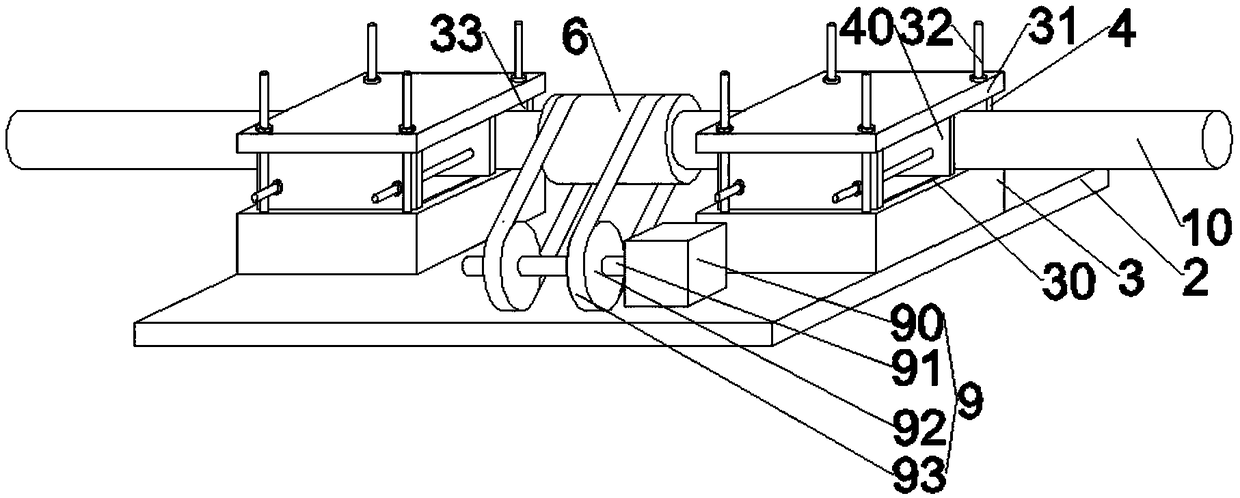

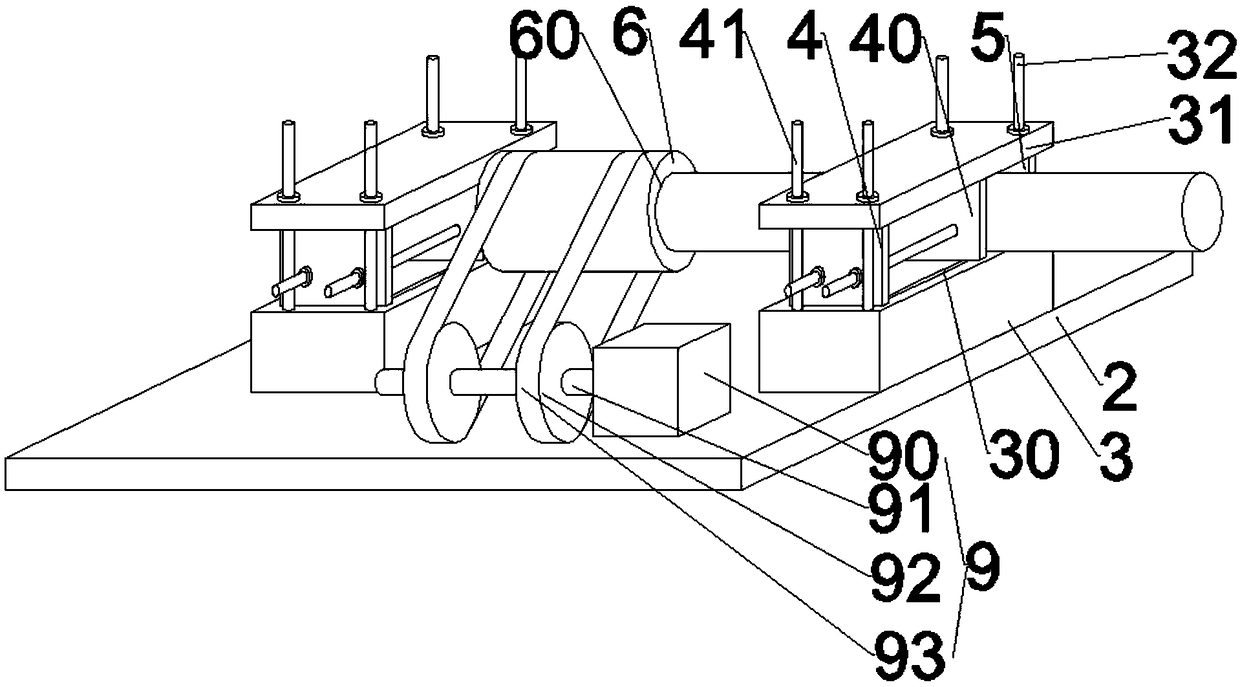

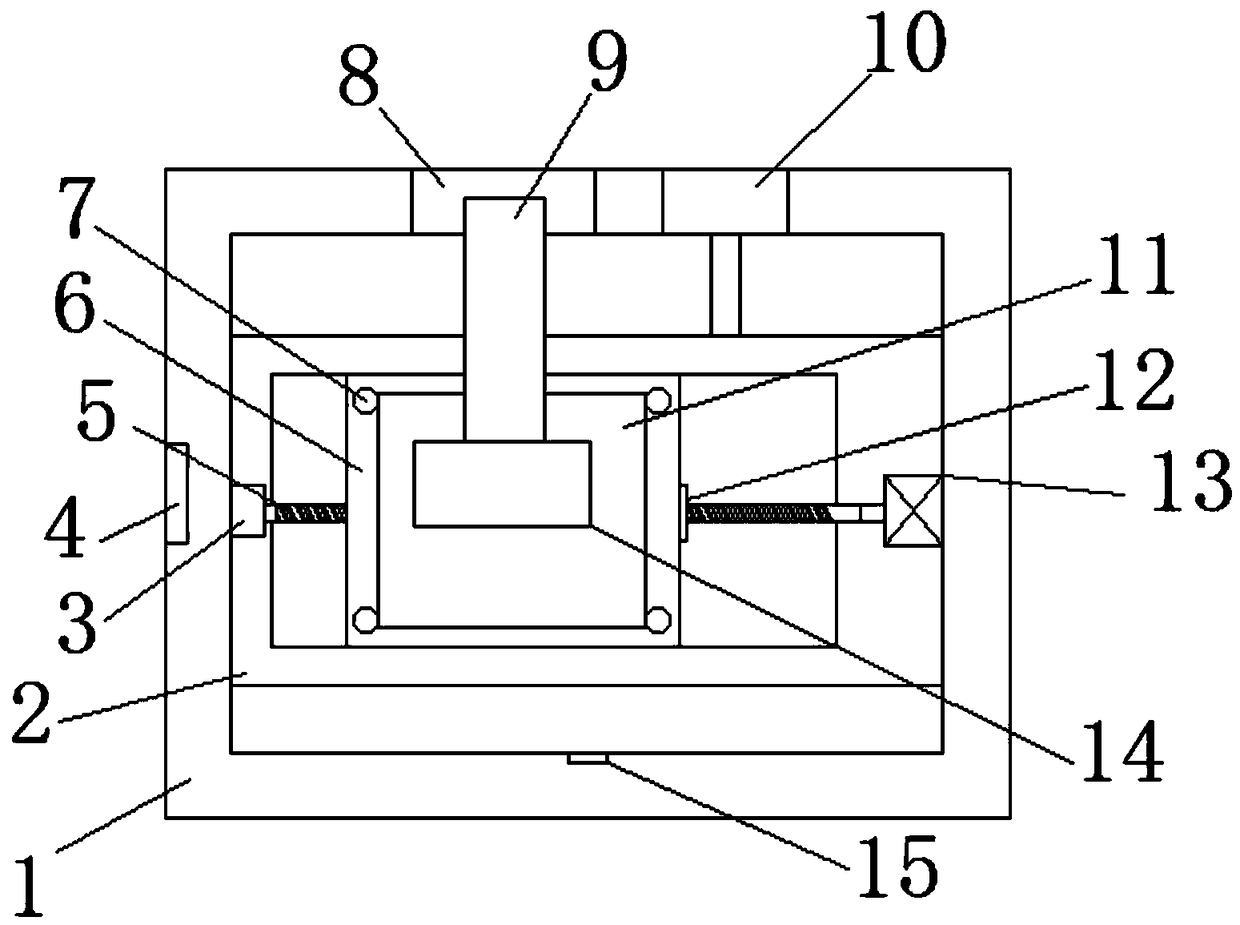

Ethylene vinyl-acetate (EVA) cutting mechanism

ActiveCN103846950ASave labor costsReduce cutting errorMetal working apparatusPerspirationEngineering

The invention discloses an ethylene vinyl-acetate (EVA) cutting mechanism. A motor mounting seat is connected with a motor mounting plate; a motor is arranged on the motor mounting plate; a driving wheel is arranged on the left side of the motor; the driving wheel is connected with a driven wheel through a synchronous belt; the driven wheel is arranged at the left end of a main shaft; an eccentric wheel is arranged on the right side of the driven wheel on the main shaft; a bearing with a seat is arranged between the driven wheel and the eccentric wheel; the eccentric wheel is arranged on the bearing with the bearing seat; the bearing with the bearing seat is connected with a connecting rod seat. According to the technical scheme of mechanical cutting, labor cost is saved, cutting errors are small, and materials and cost can be directly saved; the probability of secondary pollution is small, and the probability of contacting with hand perspiration and dirty staff and the like in manual cutting is reduced; static electricity can be eliminated, so that the influence of static electricity on materials is avoided, and multiple problems existing in manual operation are solved in mechanical operation; the cutting mechanism is simple in mechanical operation and convenient to use.

Owner:SUZHOU HORDA NEW ENERGY EQUIP

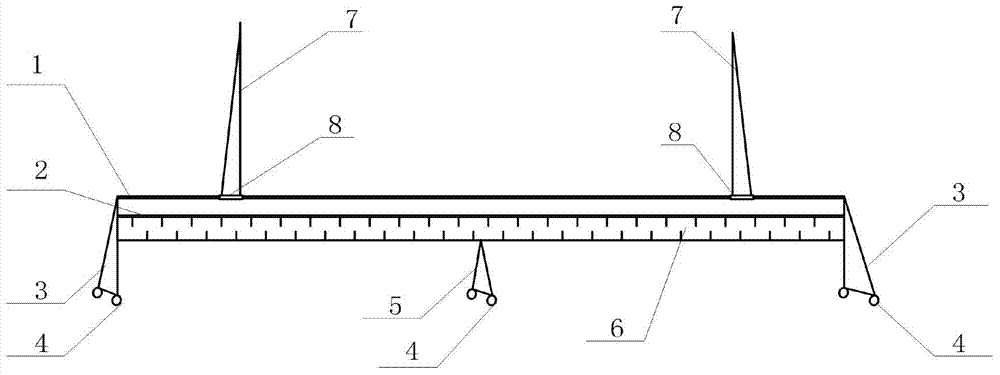

Cutting device for processing multi-axial warp-knitted fabric

InactiveCN110485142AReduce cutting errorsFast cutting speedSevering textilesMetal working apparatusEngineeringMechanical engineering

The invention discloses a cutting device for processing a multi-axial warp-knitted fabric. The cutting device comprises a support seat, wherein the top end of the support seat is fixedly connected with four vertically arranged support rods, horizontally arranged fixing plates are fixedly connected among the top ends of the four support rods, horizontally arranged lifting plates are arranged between the support seat and the fixing plates, servo air cylinders are fixedly connected to the fixing plates, and output shafts of the servo air cylinders extend to the positions below the fixing platesand are fixedly connected with the top end of the support seat; a first mounting frame is slidingly mounted at the middle position of each lifting plate, and a cutting machine is fixedly mounted on each first mounting frame. The cutting device has the advantages of being ingenious in structure, convenient to use and capable of automatically cutting the multi-axial warp-knitted fabric; compared with manual cutting, cutting errors are small, the cutting speed is high, the multi-axial warp-knitted fabric is kept in a tightened state all the time in the cutting process, the cutting quality can beeffectively improved, and the situation is prevented that a cut is uneven due to tightening of the multi-axial warp-knitted fabric.

Owner:安徽金九鼎复合材料有限公司

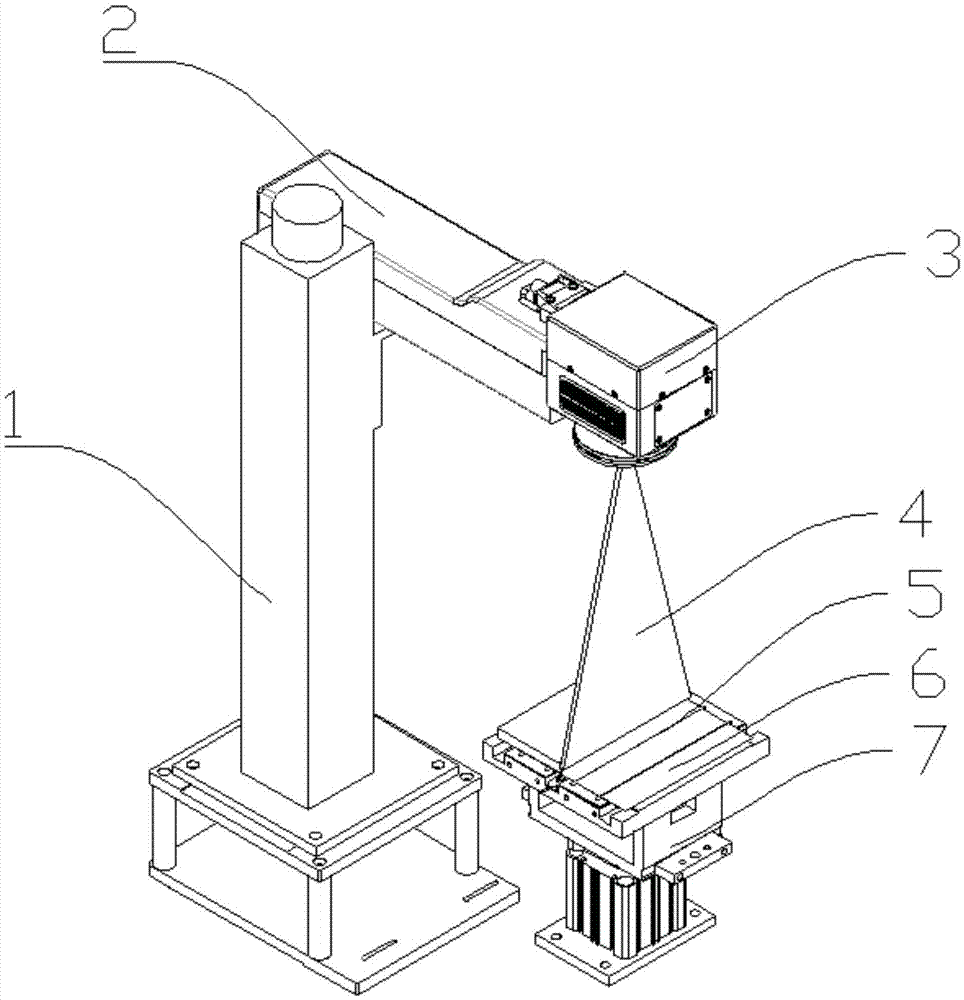

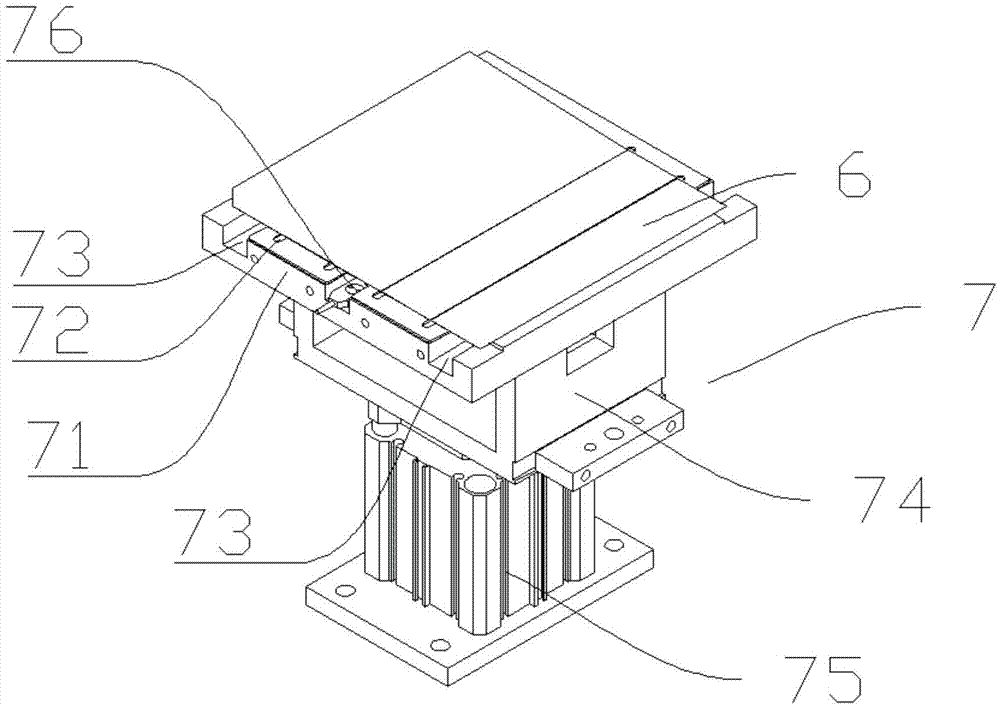

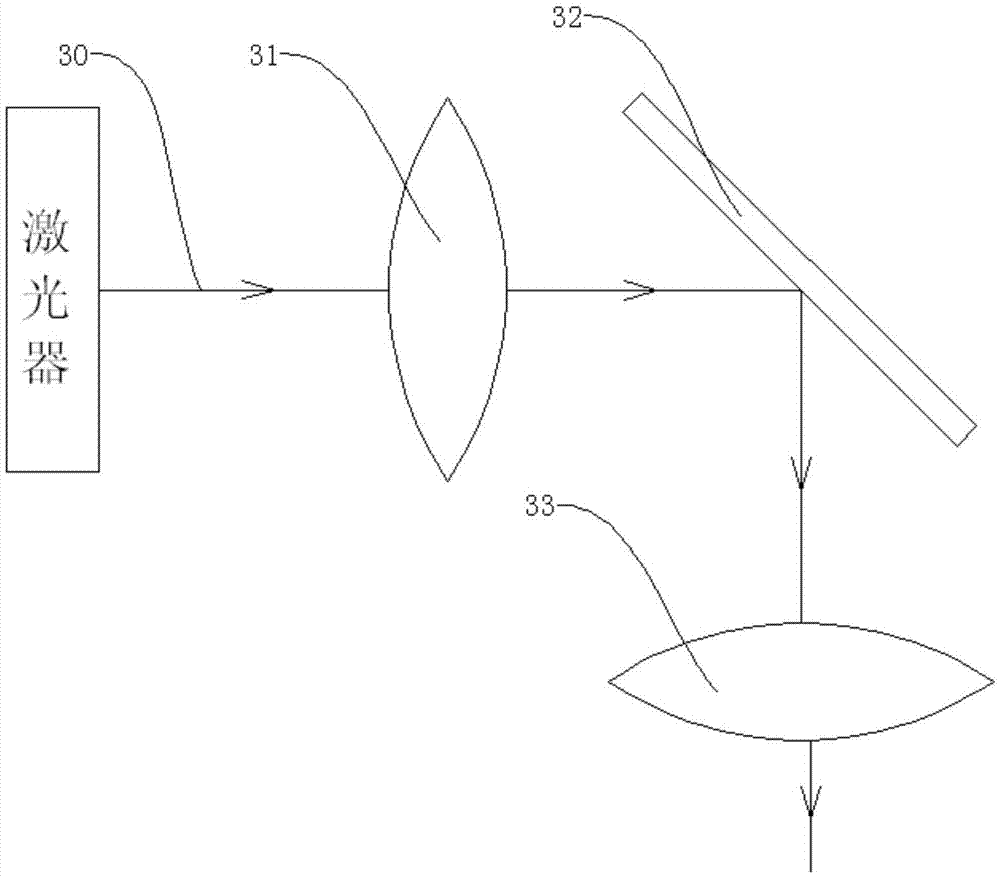

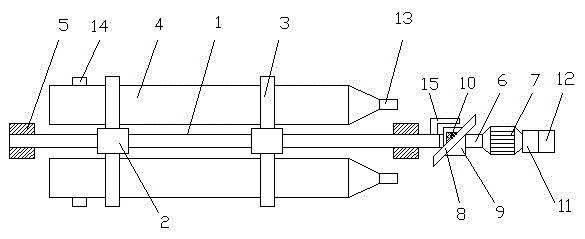

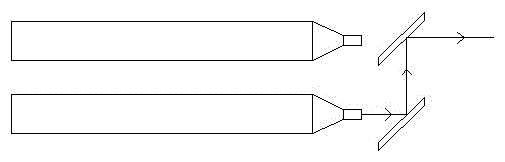

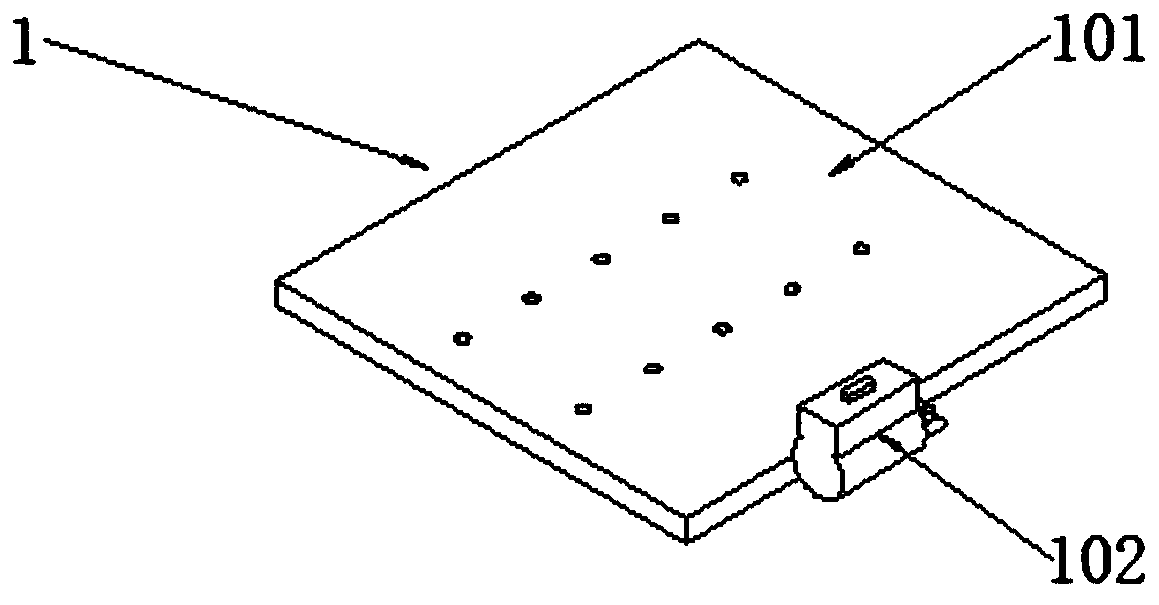

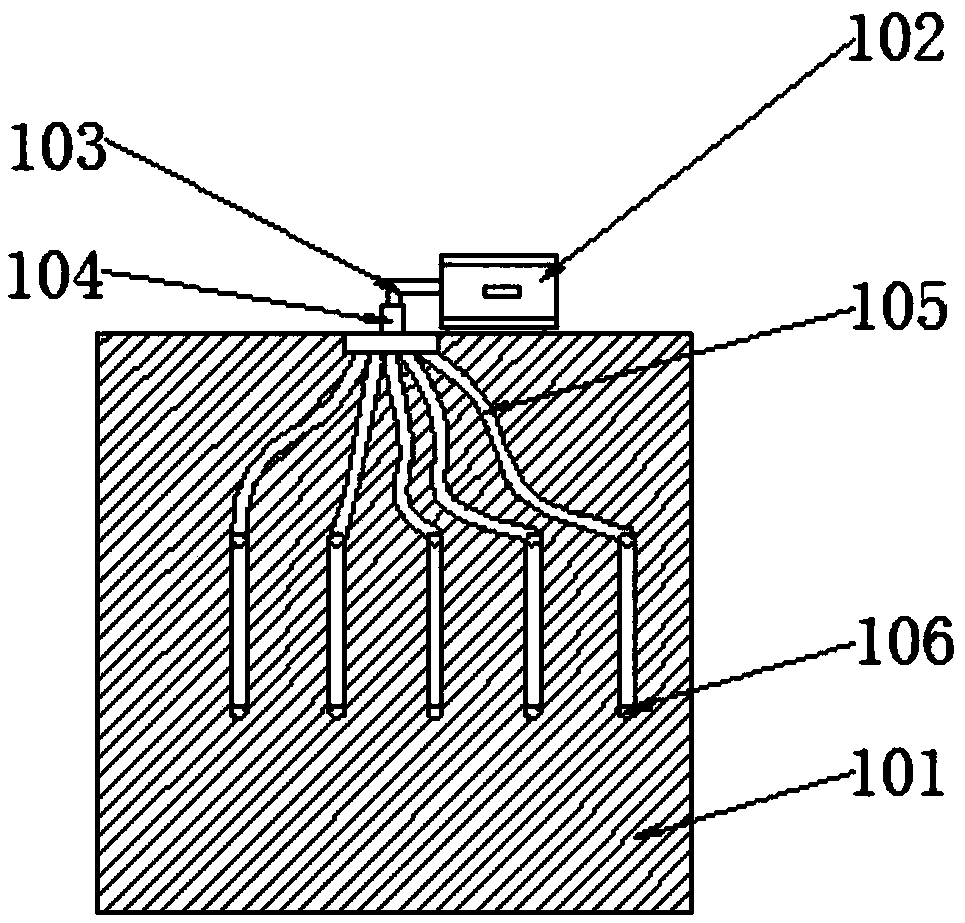

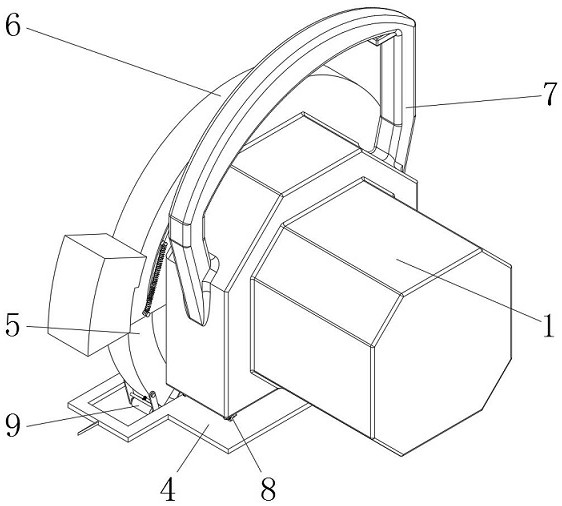

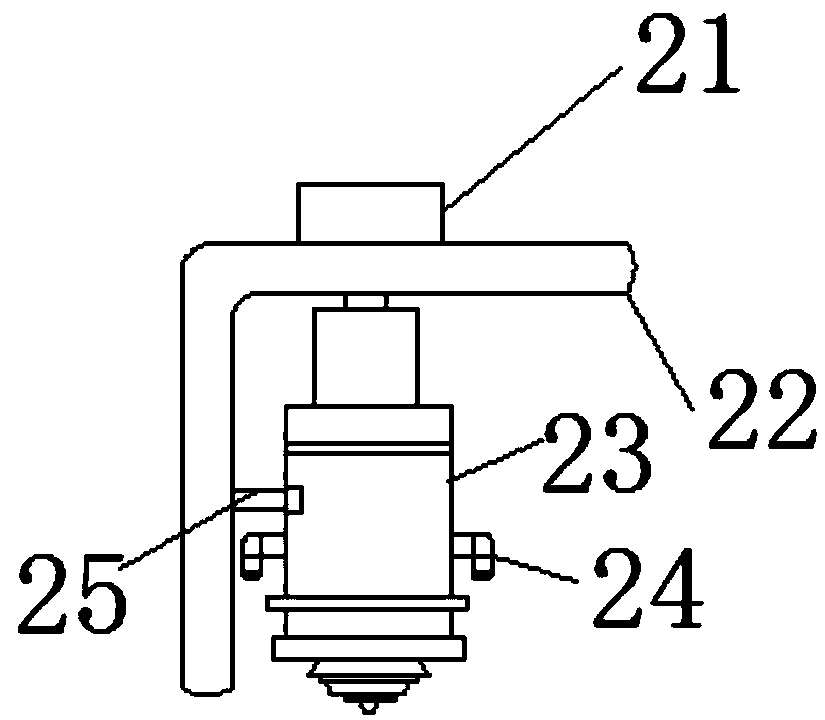

Cutting device for solar cell piece

InactiveCN107030390AOvercome slowOvercome precisionWelding/cutting auxillary devicesAuxillary welding devicesBeam expanderGalvanometer

The invention discloses a cutting device for a solar cell piece. The cutting device comprises a laser device adjusting platform, a laser device, a light spot generator and a positioning adsorption device; the laser device adjusting platform is used for adjusting the installation position of the laser device; the laser device is connected with the laser device adjusting platform and used for emitting lasers; the light spot generator is connected with the laser device and comprises a beam expander, a scanning galvanometer and a scanning field lens which are sequentially arranged, wherein the lasers sequentially pass through the beam expander, the scanning galvanometer and the scanning field lens, the beam expander is used for amplifying the diameter of the lasers to obtain laser beams with high collimation degree, and the scanning field lens is used for converging the laser beams into light spots; and the positioning adsorption device is arranged below the scanning field lens and is used for fixing the solar cell piece. The cutting device has the beneficial effects that by adopting the scanning galvanometer, a laser cutting head and work-pieces to be processed do not need to move, the cutting speed is increased, the positioning accuracy is high, the defects that the speed of mechanical movement is small and the positioning precision of mechanical movement is limited are greatly overcome, moving back and forth is not needed in the cutting process, the cutting efficiency is improved, the cutting precision is high, and the production cost of an enterprise is saved.

Owner:SUZHOU AUTOWAY SYST

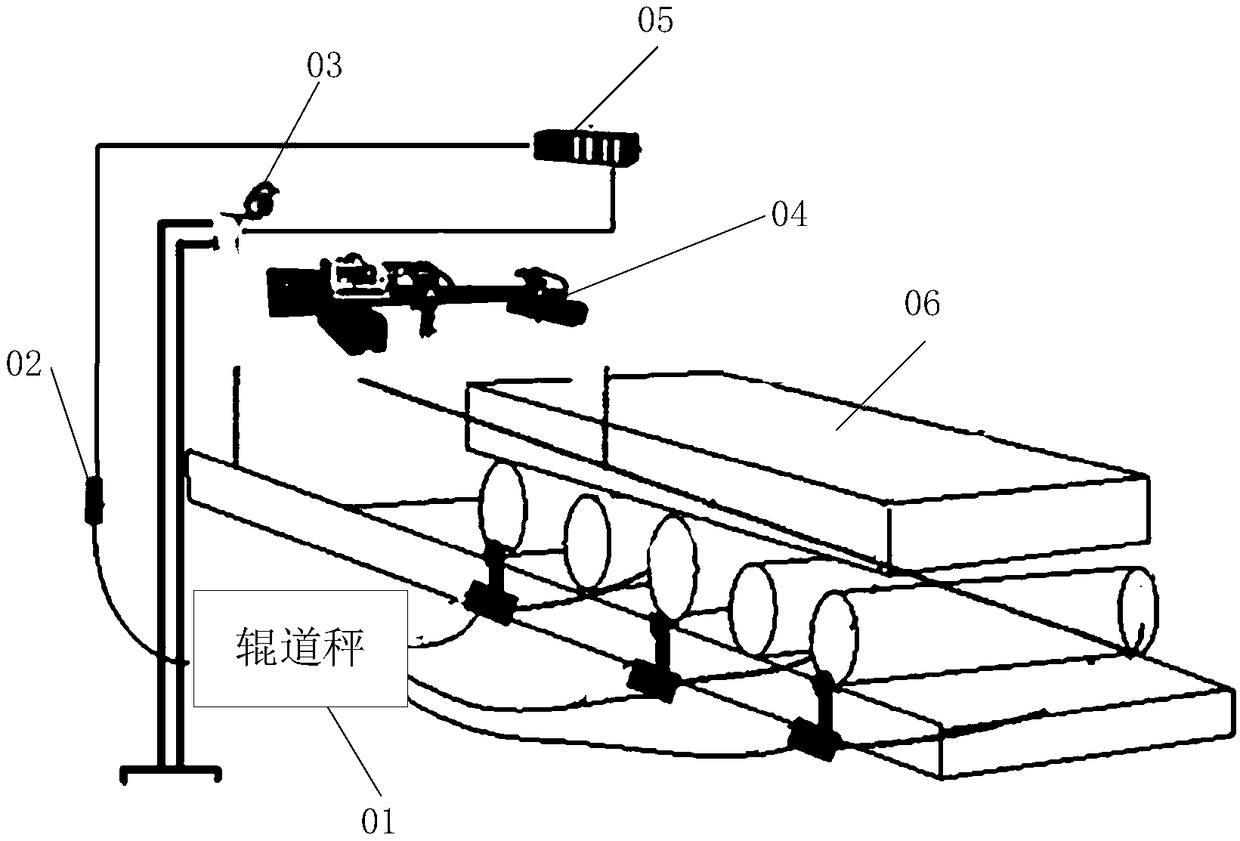

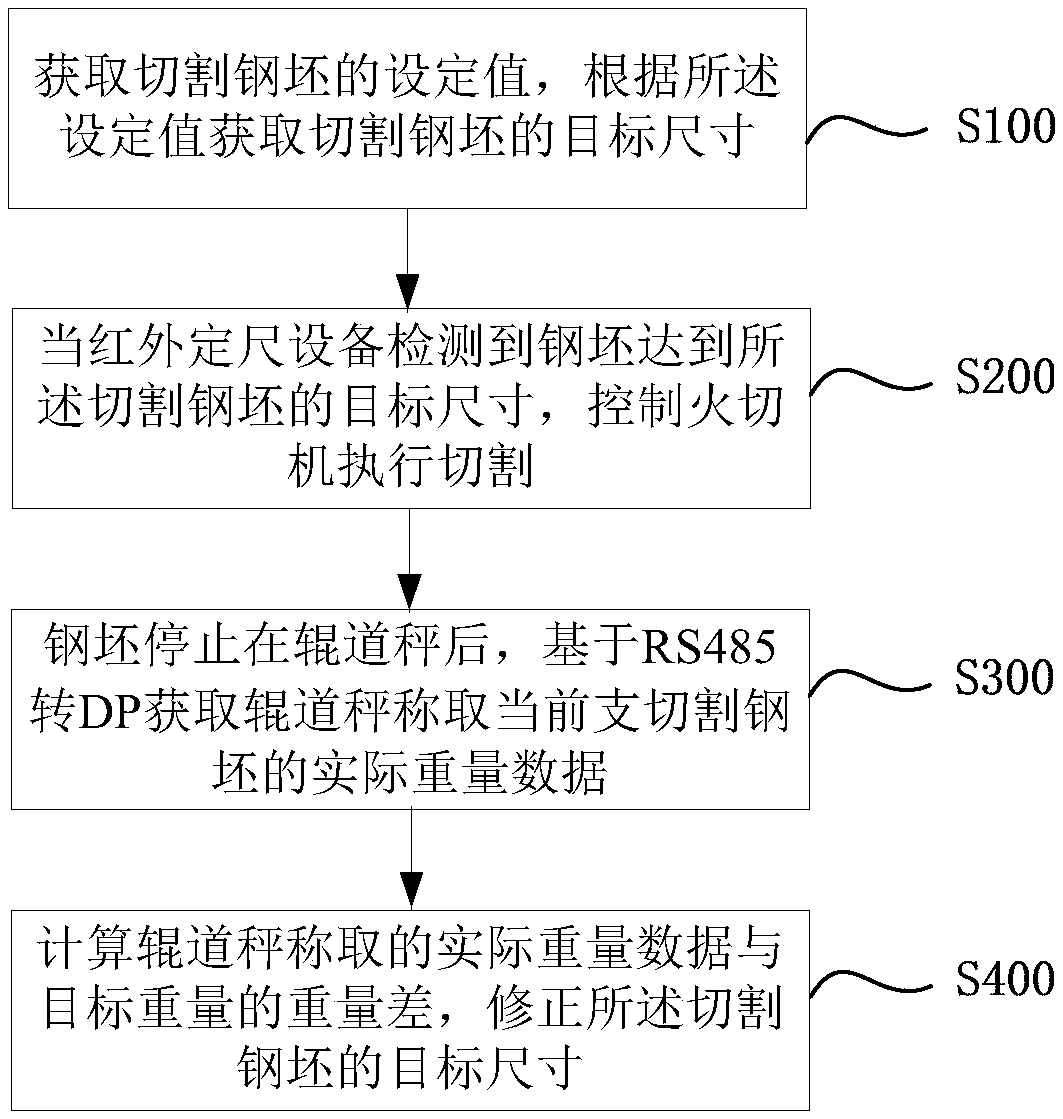

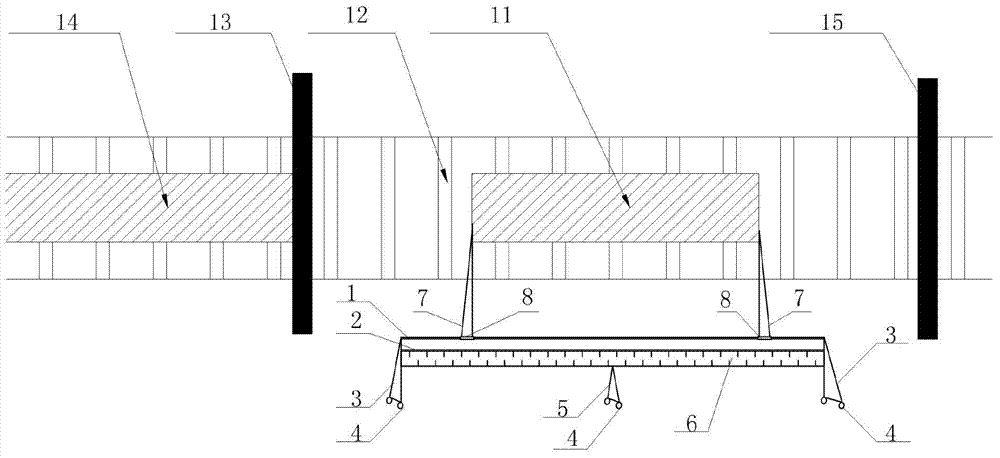

Continuous casting billet cutting control method and system, and application

InactiveCN108845542AHigh precisionGuaranteed accuracyProgramme controlComputer controlControl systemTarget weight

The invention provides a continuous casting billet cutting control method and system, and an application. The method comprises steps that a set value of a cut billet is obtained, and the target size of the cut billet is obtained according to the set value; when that the billet reaches the target size of the cut billet is detected by an infrared sizing device, a fire cutting machine is controlled for performing cutting; after the billet stops at a roller scale, actual weight data of the current cut billet weighed by the roller scale based on RS485 to DP is obtained; weight difference between the actual weight data weighed by the roller scale and the target weight is calculated, and the target size of the cut billet is corrected. The method is advantaged in that accuracy of the difference between the actual weight data of the current cut billet and the target weight can be effectively ensured, effectiveness of target size correction of the cut billet is ensured, the cutting error is reduced, and cutting accuracy is improved.

Owner:SHANDONG IRON & STEEL CO LTD

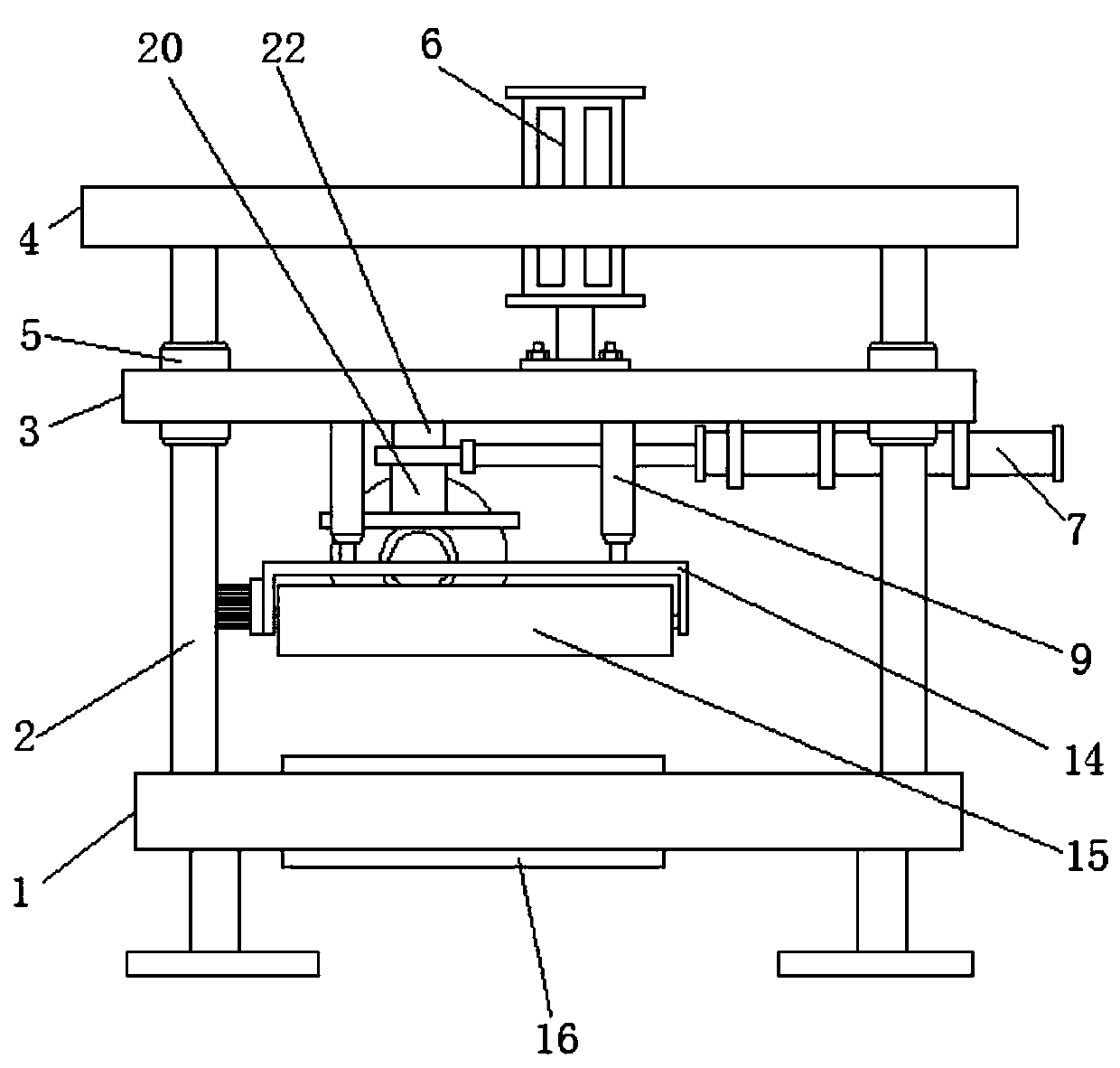

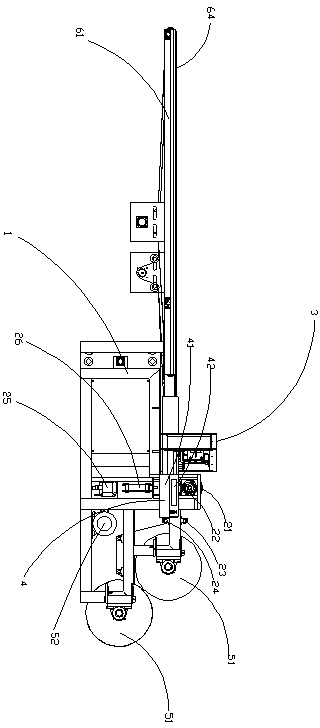

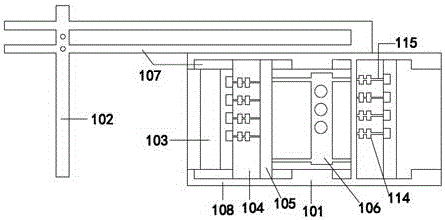

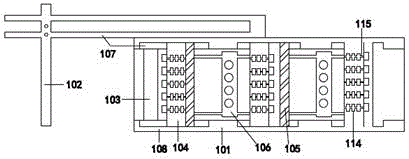

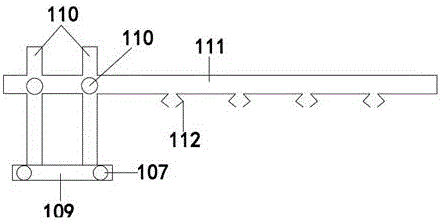

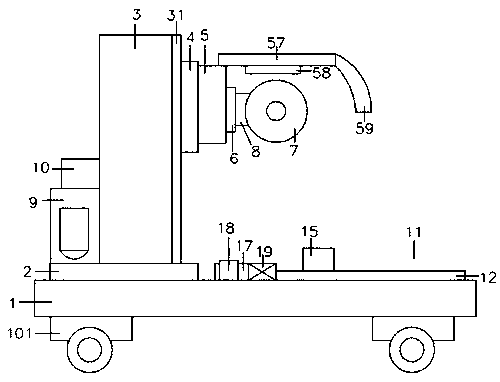

Multi-size automatic steel pipe cutting machine

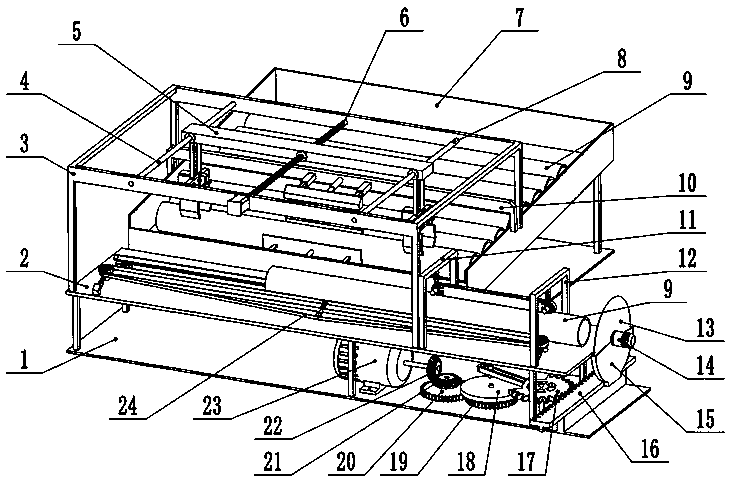

ActiveCN111203586AWith snap back featurePrecise feedingMetal sawing devicesMachiningIndustrial engineering

The invention provides a multi-size automatic steel pipe cutting machine. The multi-size automatic steel pipe cutting machine comprises a bottom plate, an upper plate, a conveying support, a first unthreaded shaft, a lead screw sliding table, a lead screw, a storage bin, a second unthreaded shaft, a pipe blocking support, a first feeding support, a second feeding support, a swing cutting unit, a feeding unit, a third servo motor, a first feeding supporting plate, a second conveying belt, a second feeding supporting plate, a feeding unit, a grabbing unit and the like; the grabbing unit is usedfor rapidly and accurately taking and feeding, the feeding units are uniformly distributed on the circumference of the steel pipe to accurately position the steel pipe, and the swing cutting unit cancontinuously and efficiently cut the steel pipe. The multi-size automatic steel pipe cutting machine greatly improves the machining efficiency of material machining, and liberates the labor force.

Owner:美泰(常州)控制系统有限公司

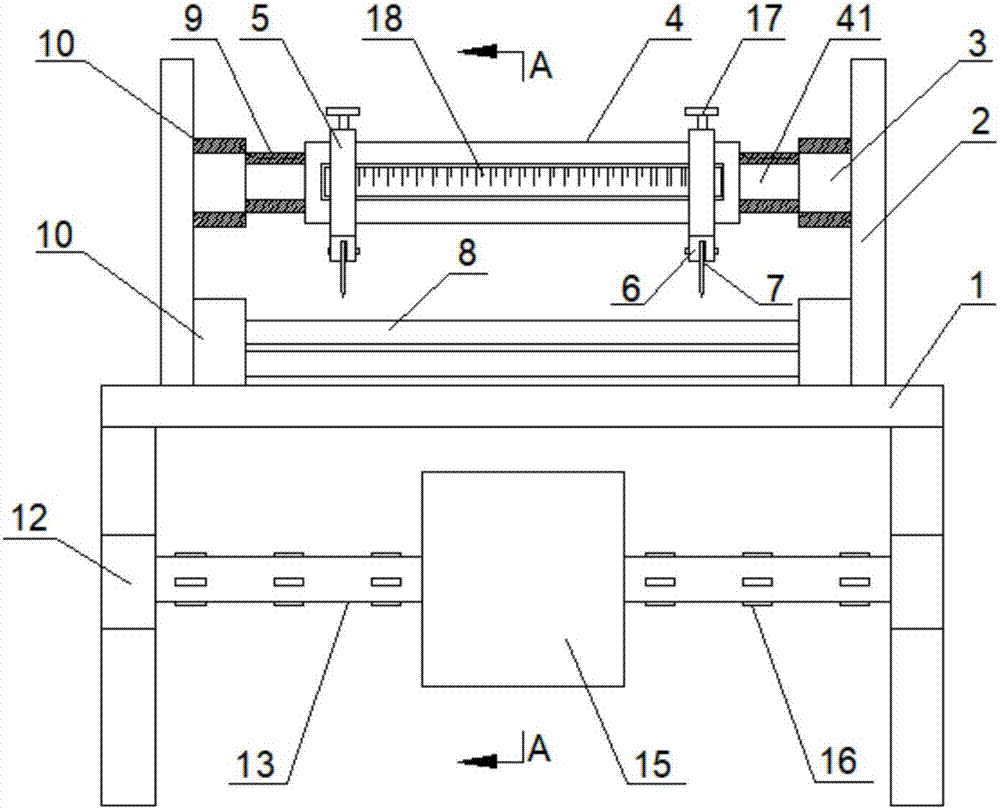

Equal-length cutting device for steel plate

InactiveCN107457448ANot easy to get tiredImprove efficiencyMetal working apparatusMaintainance and safety accessoriesSheet steelRebar

The invention discloses an equal-length cutting device for a steel plate, and relates to the field of building material processing. The equal-length cutting device comprises a horizontal workbench, a clamping part arranged on the horizontal workbench and capable of moving left and right, and a drive part used for driving the clamping part to move left and right on the horizontal workbench, wherein a graduated scale is arranged at one end close to the top of the horizontal workbench, of the side surface of the horizontal workbench. The equal-length cutting device disclosed by the invention solves the following three problems: (1) the positions of steel bars are gradually moved in a cutting process, so that cutting accuracy is low; (2) flexible scale measurement has a large error and costs much time in the case of each measurement; and (3) operating personnel are extremely easily fatigued in the case of direct estimation without measurement, so that the cutting error is increased.

Owner:成都捷科菲友信息技术有限公司

Chemical plastic plate equidistant cutting device

InactiveCN112277037ASame push timeImprove cutting efficiencyMetal working apparatusBall screwElectric machinery

The invention discloses a chemical plastic plate equidistant cutting device. The chemical plastic plate equidistant cutting device comprises a workbench, supporting legs are fixedly connected to the four corners of the bottom end of the workbench, a conveying belt is fixedly arranged in the middle of the top end of the telescopic workbench, a lifting plate frame is fixedly arranged at the position, located on one side of the conveying belt, of the top end of the workbench, a plate hopper is fixedly arranged on one side of the workbench. the tail end of a rotating shaft of a transmission wheelat one end of the conveying belt is fixedly connected with a first steppeing motor, a second stepping motor is fixedly arranged in the middle of the top end of the lifting plate frame, a ball screw isarranged in the lifting plate frame along the central axis, the top end of the ball screw penetrates through the top end of the lifting plate frame and is fixedly connected to the tail end of a rotating shaft of the second stepping motor, the outer wall of the ball screw is in threaded connection with a lifting table, fixing shafts are fixedly arranged in the middles of the two ends of the lifting table, and clamp bases are fixedly connected to the tail ends of the fixing shafts. The chemical plastic plate equidistant cutting device is simple and reasonable in structure and novel in design, and has high equidistant cutting efficiency in the aspect of plastic plate equidistant cutting.

Owner:鹤山市顺鑫实业有限公司

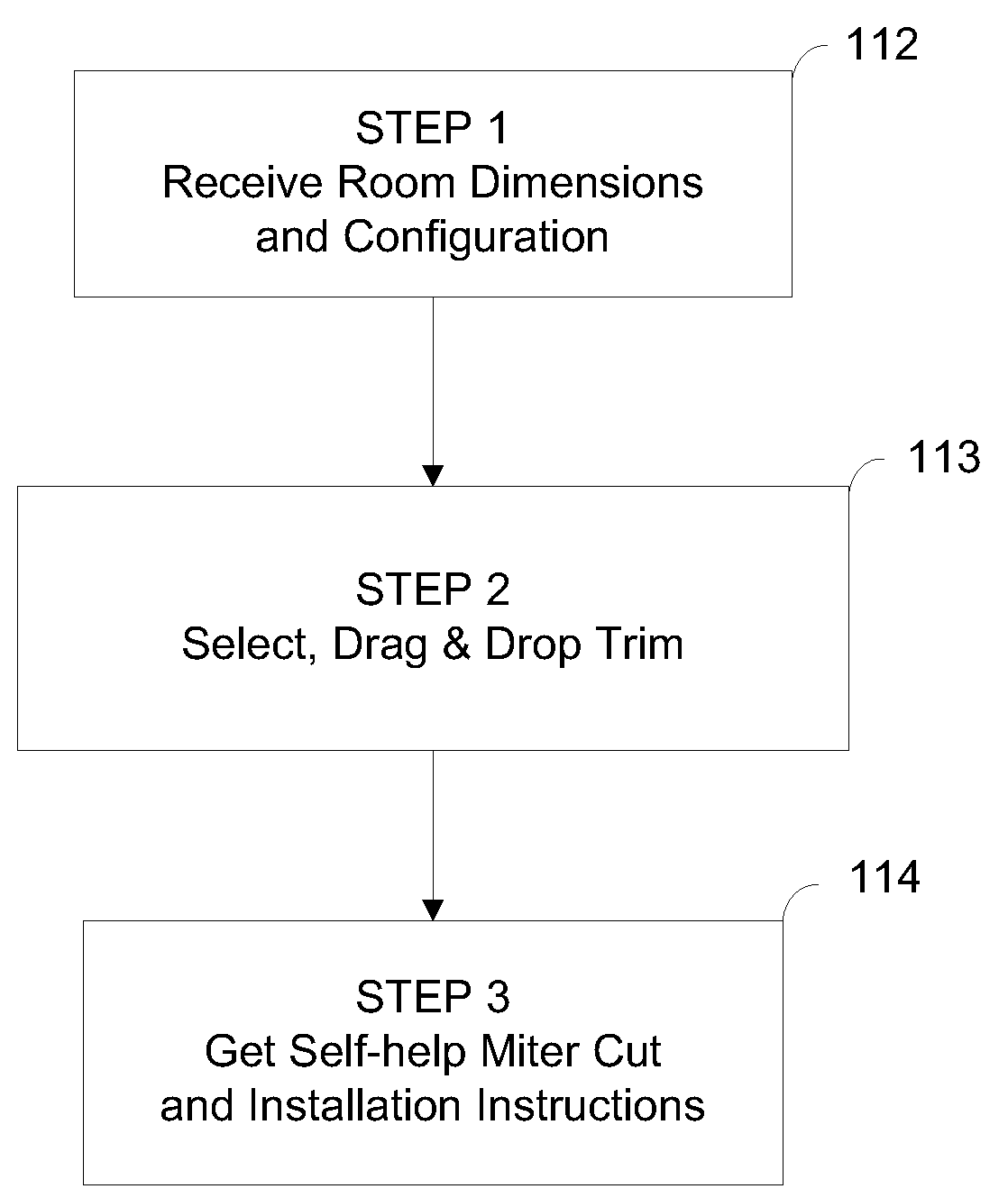

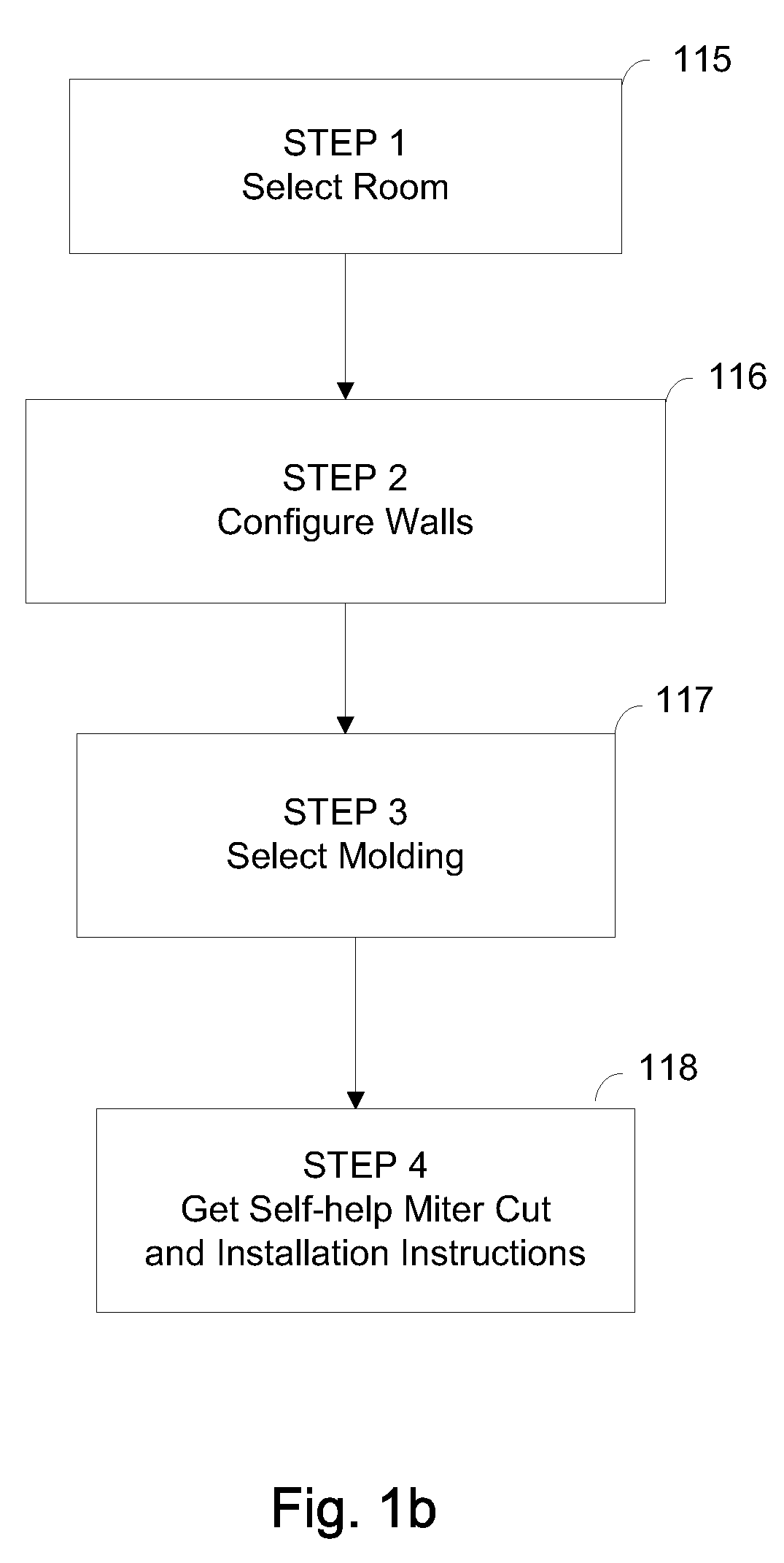

System and method for generating self-help cutting instructions of decorative trim

InactiveUS20090144175A1Simple processShorten the timeForecastingCommerceEngineeringMaterial requirements

The present invention relates to a technique for efficient interior and decorative designs and more particularly to a system and process to determine a plurality of self-help cutting instructions of decorative trim, and to a method that simplifies the process of planning, cutting, installing, and estimating material requirements and costs related to decorative trim.

Owner:PENAFLOR RONALDO G

Adjustable combined cutting wheel

InactiveCN110355414AReasonable structural designNot easy to damageShearing machinesShearing machine accessoriesDrive shaftAgricultural engineering

The invention discloses an adjustable combined cutting wheel comprising a worktable and two cutting wheels. The worktable is provided with a bracket, the bracket is provided with a motor, the motor isconnected with a transmission shaft, the transmission shaft is provided with the first cutting wheel, the tail end of the transmission shaft is connected with a rotating shaft, the rotating shaft isprovided with the second cutting wheel, the tail end of the rotating shaft is provided with a mounting seat, the rotating shaft is connected to the mounting seat through a bearing, the worktable is provided with a clamping device, and the clamping device is arranged below the first cutting wheel and the second cutting wheel. The adjustable combined cutting wheel is reasonable in structural design,not prone to being damaged and high in working efficiency. The two cutting wheels are arranged on the transmission shaft and the rotating shaft, the transmission shaft and the rotating shaft are inserted, the distance can be adjusted, equal-distance battens can be directly cut, the cutting error is small, and efficiency is high.

Owner:卢梅芳

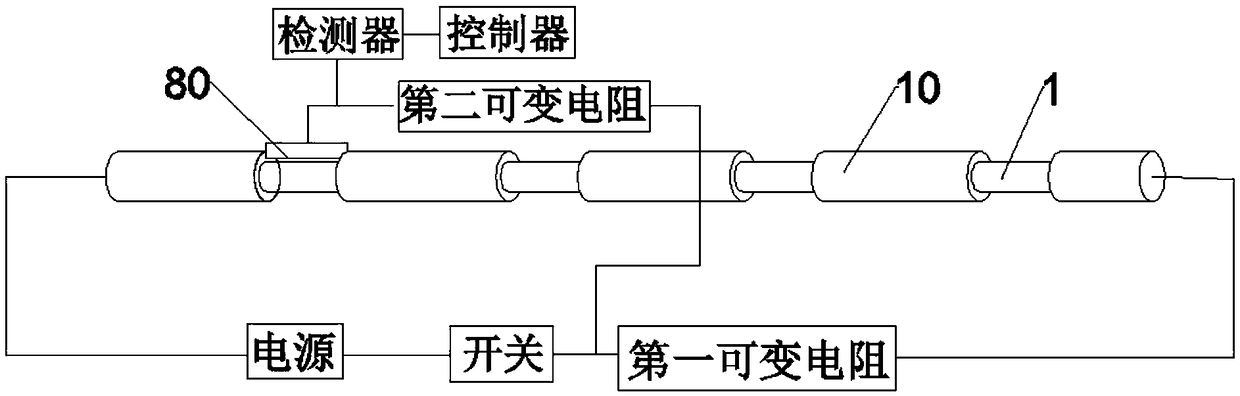

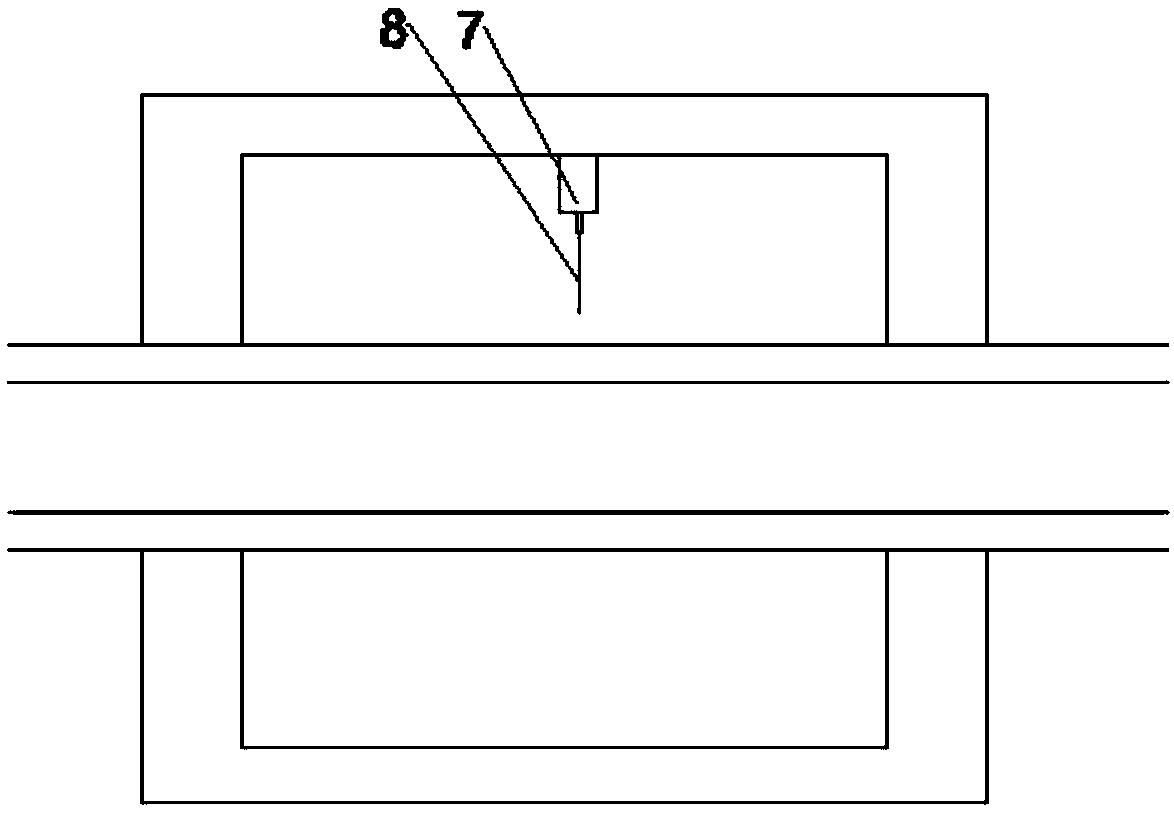

Intelligent control type material cutting device

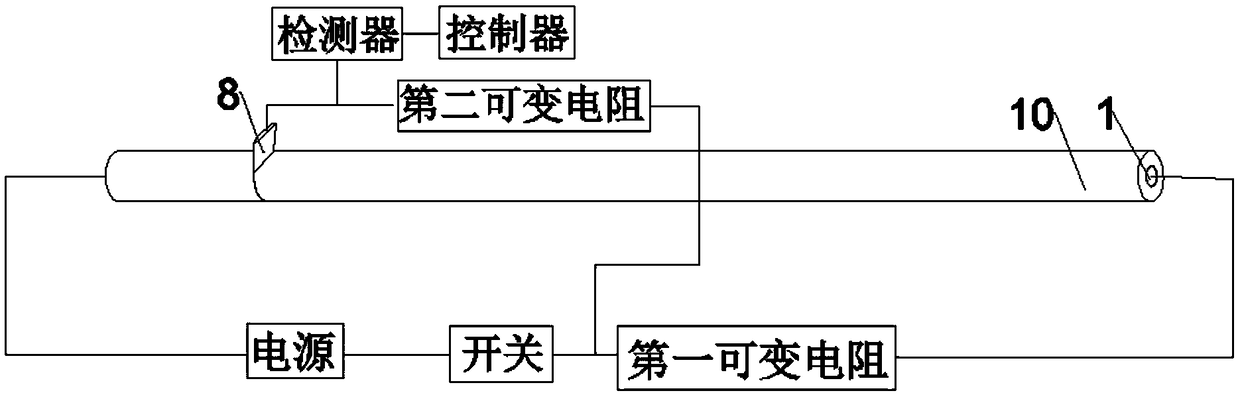

ActiveCN103832868AQuality improvementHigh degree of automationArticle deliveryWebs handlingElectricityEngineering

The invention discloses an intelligent control type material cutting device which comprises a machine frame, a material placing mechanism connected with the machine frame, a material feeding mechanism arranged on the material placing mechanism and then connected with the machine frame, a cutting mechanism arranged on the material feeding mechanism and then connected with the machine frame, a material collecting mechanism arranged on the cutting mechanism and then connected with the machine frame, and an intelligent electric control system arranged on the machine frame and electrically connected with the material feeding mechanism, the cutting mechanism and the material collecting mechanism. Compared with traditional manual operation, the intelligent control type material cutting device has the advantages that the automation degree is high, working efficiency is improved, accuracy control capacity is improved, the number of cutting errors caused by mis-operation is reduced, and cutting quality is improved. Furthermore, the device can conduct quick setting by means of a numerical control system according to the requirements of the manufacturing technique, for example, the material cutting sizes can be set quickly by setting the number of rotating circles of the material feeding mechanism.

Owner:SUZHOU IND ROBOT TECH

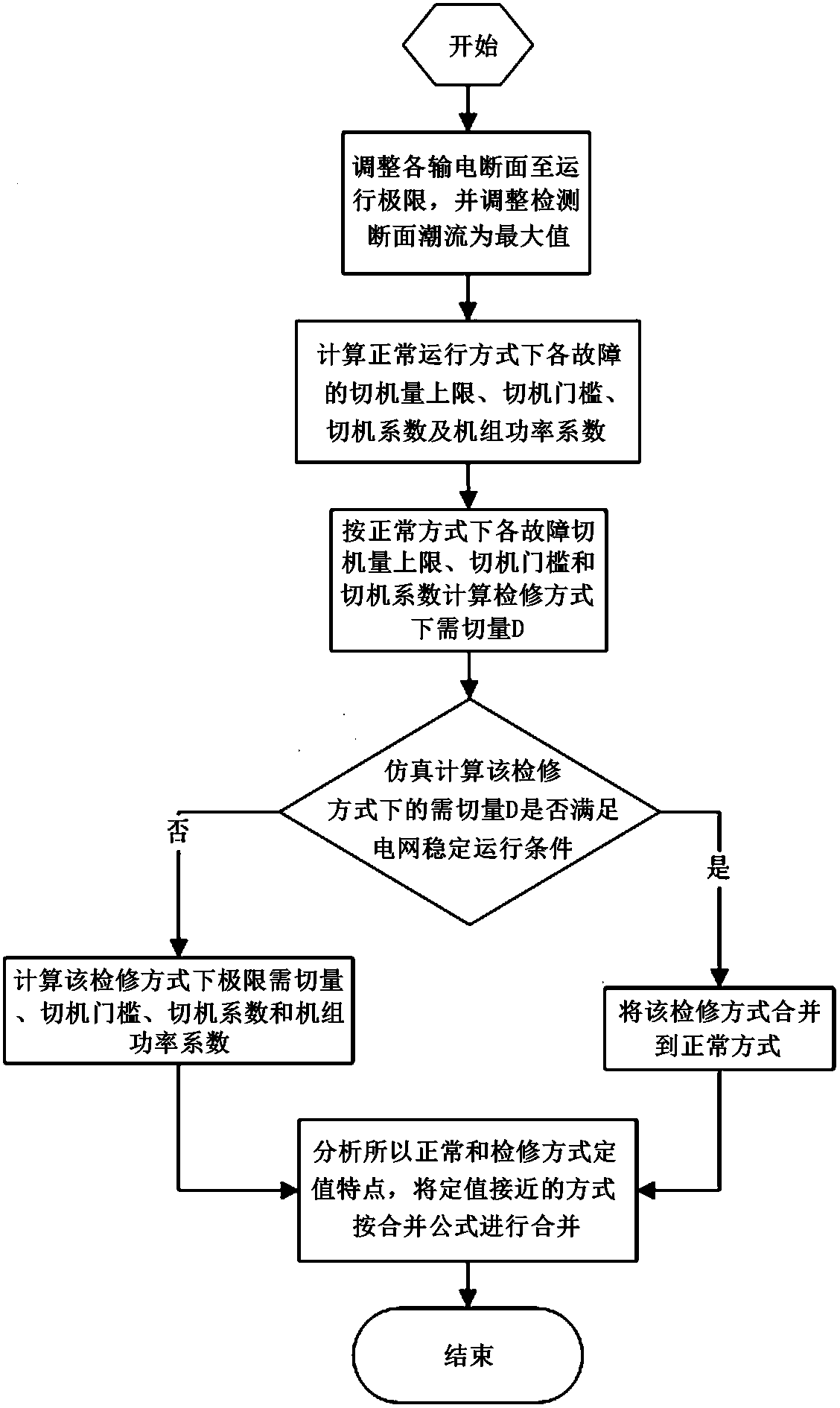

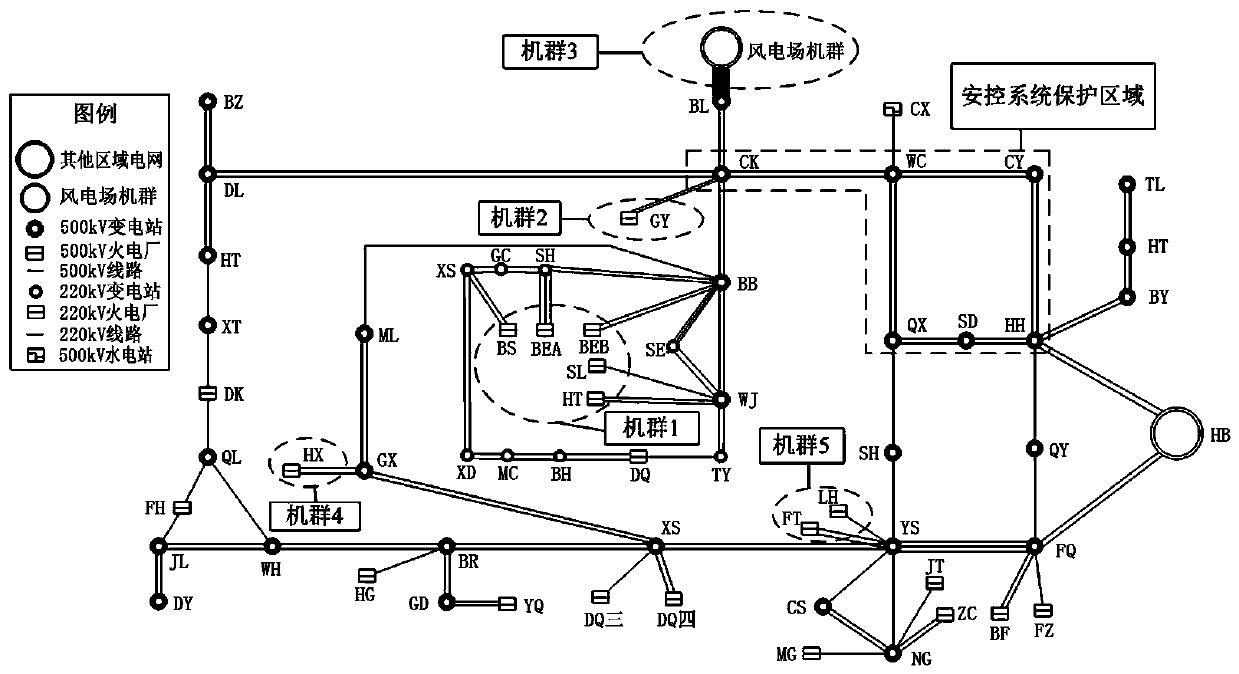

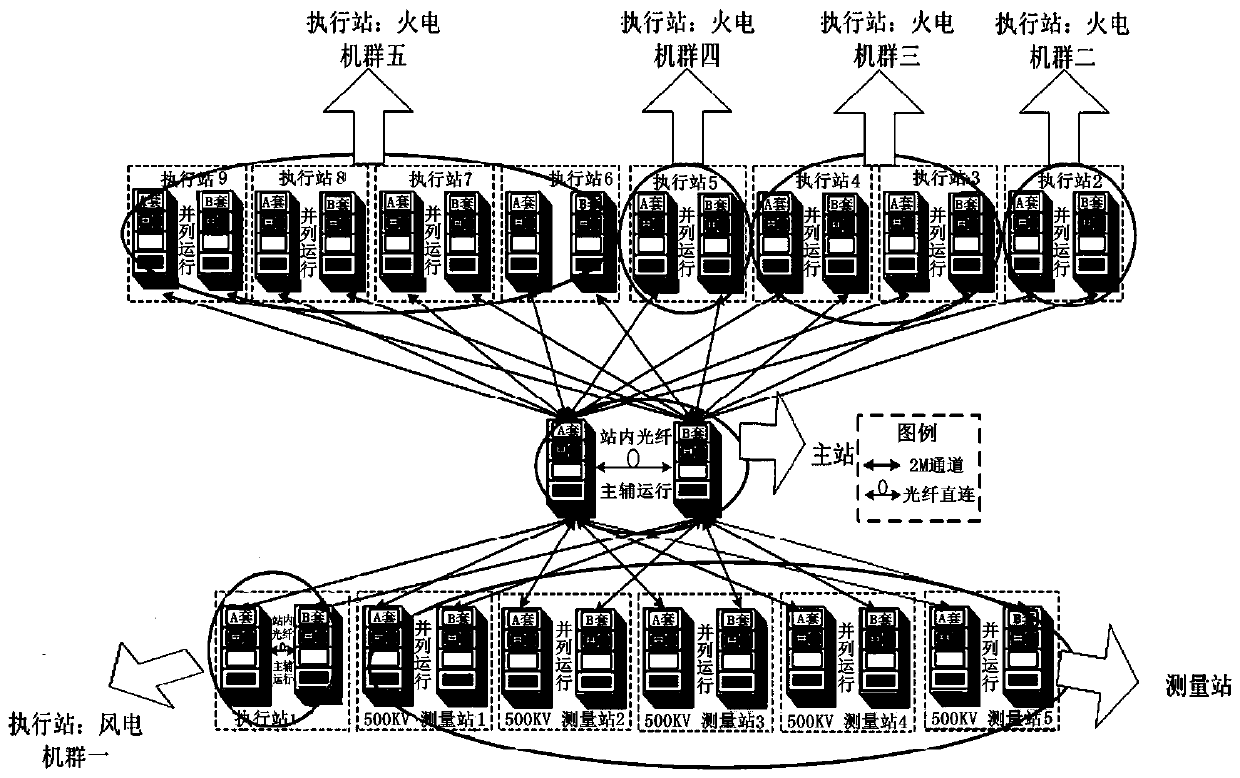

Safety and stability control system strategy making method considering cluster power coefficient

ActiveCN111585286ASolve the problem of large overcutReduce economic lossPower network operation systems integrationAc network voltage adjustmentControl systemControl engineering

The invention belongs to the technical field of power system safety and stability control. The invention discloses a safety and stability control system strategy making method considering a cluster power coefficient. The method comprises the steps that firstly, the generator tripping amount upper limit, the generator tripping threshold, the generator tripping coefficient and the unit power coefficient are calculated respectively, then the obtained relation among the generator tripping amount upper limit, the generator tripping threshold, the generator tripping coefficient and the unit power coefficient is analyzed; multiple sets of strategy constant values are combined in a special mode; and a safe and stable control strategy is simplified. The method is used for realizing minimum accurategenerator tripping when a power system has a serious fault; different generator tripping characteristic differences of different generator groups are considered; the influence of the difference on safety control strategy making is qualitatively and quantitatively analyzed; the problems of large overcut amount and large generator tripping error caused by determining the generator tripping amount by a unit with the worst generator tripping effect in an existing safety control strategy setting method are fundamentally solved; and making of a constant value strategy can be effectively simplifiedthrough a provided special mode combination method.

Owner:INNER MONGOLIA POWER GRP

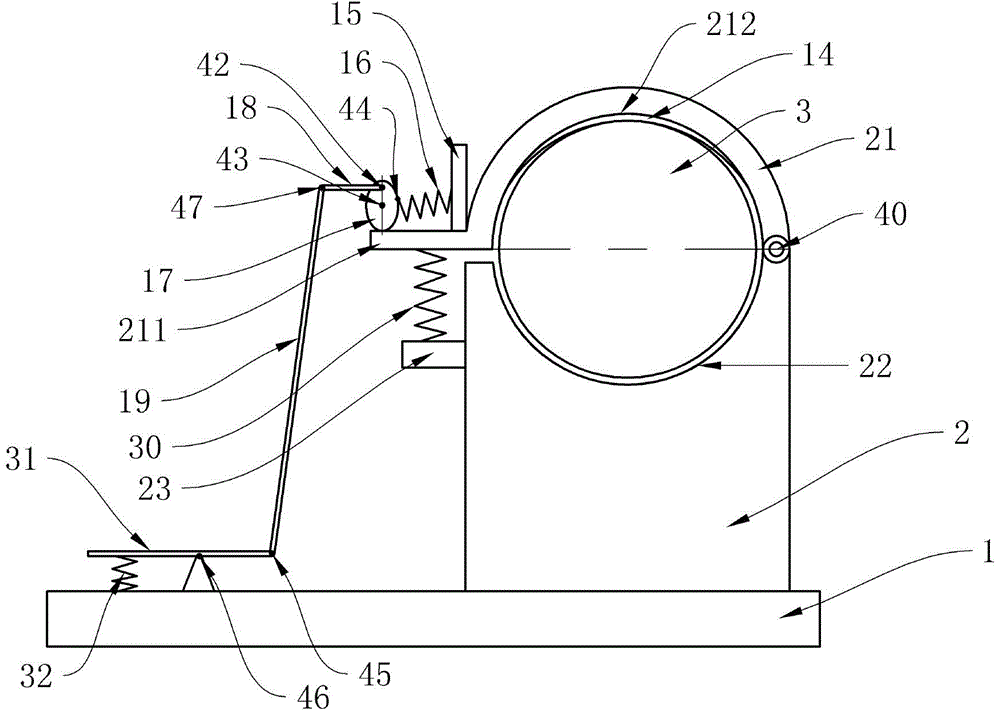

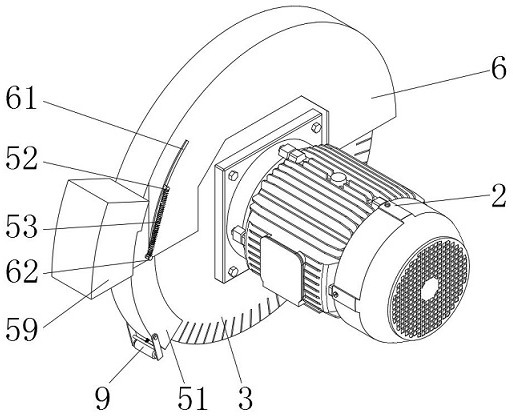

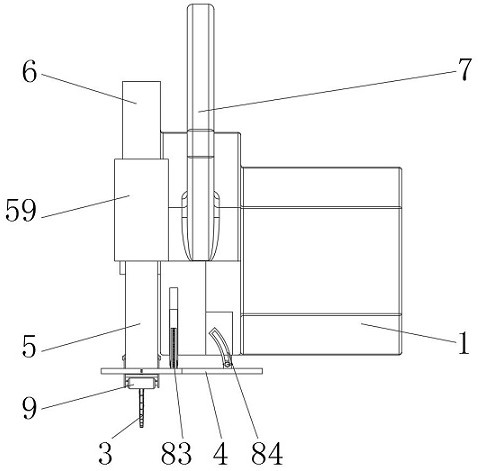

Serpentine spring cutting device

PendingCN107552687AEasy to removeAvoid cutting errorsGas current separationWire springsIron powderEngineering

The invention discloses a serpentine spring cutting device. The serpentine spring cutting device comprises a base and a frame; an iron powder collecting box is arranged in the centre of the base; a spring fixing groove is formed in the upper part of the base; the bottom of the frame is fixedly connected with the left end and the right end of the top of the base; a switch button is arranged at thetop of the front side of the frame; an air blower switch is arranged on the right of the switch button; a control switch is arranged on the right of the air blower switch; and a fixed transverse rod is arranged on the inner side of the frame. According to the serpentine spring cutting device, a filtering net is arranged at the bottom end in the spring fixing groove, and an air blowing opening is formed in the left side of the spring fixing groove, so that the air which is blown out from the air blowing opening cleans chippings produced by cutting through the filtering net after the serpentinespring is cut; a graduated scale is arranged at the bottom of the front side of the fixed transverse rod, and a graduated scale positioning groove is formed in the front side of the moving box, so that the distance, required to be cut, of the serpentine spring is conveniently determined by a user before cutting; and the serpentine spring cutting device is practical, and is suitable to be widely popularized and used.

Owner:NANJING LISHUI LIHUA SPRING FACTORY

Reflecting laser generation device for cutting machine

ActiveCN105057886APrevent rotationThe problem of implementing alternate workLaser beam welding apparatusOptoelectronicsInductor

The invention discloses a reflecting laser generation device for a cutting machine. The reflecting laser generation device for the cutting machine comprises a first center shaft, glass laser devices, a second center shaft, a small motor, a reflector, a laser inductor, a pole change device and a control chip. The glass laser devices are arranged on the outer side of the first center shaft. One end of each glass laser device is provided with a laser emitter. At least two glass laser devices are arranged parallel to the first center shaft and provided with laser switches. Two supporting seats are arranged on the lower side of the first center shaft and arranged triangularly. The second center shaft is arranged on one side of the first center shaft. One side of the second center shaft is fixedly connected with the small motor and can rotate. A reflector seat is arranged on the second center shaft. The reflector is arranged and can rotate on a guide rail, so that the laser devices work alternately; and meanwhile, the glass laser devices can be automatically started and stopped through the laser inductor.

Owner:JINAN G WEIKE SCI & TECH

Efficient cutting device for sofa leather

ActiveCN104263860BAbsorb in timeTimely processingLeather clicking/perforating/clickingMetal working apparatusEngineeringMechanical engineering

The invention belongs to the field of sofa processing and relates to an efficient cutting device for sofa leather. The cutting device comprises a cutting table, a cutting structure arranged above the cutting table, and a mounting frame used for mounting the cutting structure, wherein a cutting joint strip is arranged on the cutting table; the cutting structure comprises a cutting knife arranged over the cutting joint strip, a control structure used for controlling the cutting knife to move up and down, and pressure heads which are arranged on the two sides of the cutting knife and used for stabilizing the leather; the cutting structure is mounted on the mounting frame through a drive structure; the drive structure is used for controlling the cutting structure to move up and down. The cutting device is simple in structure, easy to operate, high in cutting efficiency, small in cutting error, little in environmental pollution and relatively environment-friendly; generated dust can be absorbed and processed in time.

Owner:ZHEJIANG ANJI HUIYE FURNITURE

Tile cutting machine used for indoor and outdoor decoration engineering

InactiveCN108858827AGuaranteed accuracyEasy to operateWorking accessoriesStone-like material working toolsWorking environmentEngineering

The invention discloses a tile cutting machine used for indoor and outdoor decoration engineering. The tile cutting machine includes a fixing mechanism, a cutting mechanism and a dust suction mechanism. The cutting mechanism is installed on one side of the fixing mechanism, and the dust suction mechanism is installed on one side of the cutting mechanism. By changing the air pressure, tiles different in size are fixedly sucked onto a worktable through the fixing mechanism, it is ensured that the positions of the tiles are fixed during cutting, and convenience is provided for operation; meanwhile, during cutting, a sliding rod can be directly measured by the cutting mechanism according to scales and a cutting size, a cutting blade linearly moving along a supporting slide rail can ensure theaccuracy of cutting at the same time, cutting errors are reduced, and materials are saved. During cutting, a lot of dust is generated on incisions, and the dust suction mechanism is used for sucking and filtering the dust to ensure a great working environment and safe operation.

Owner:李壮

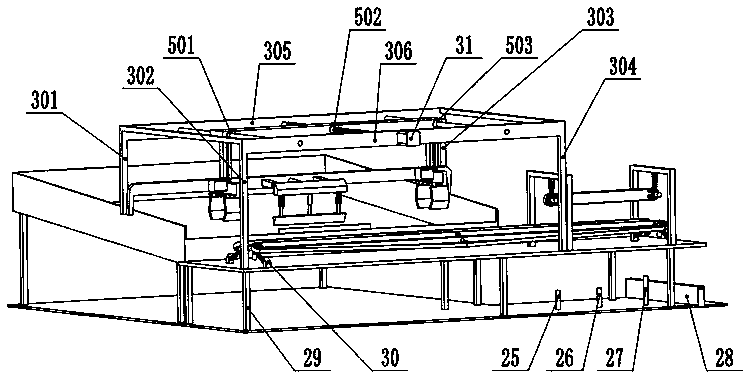

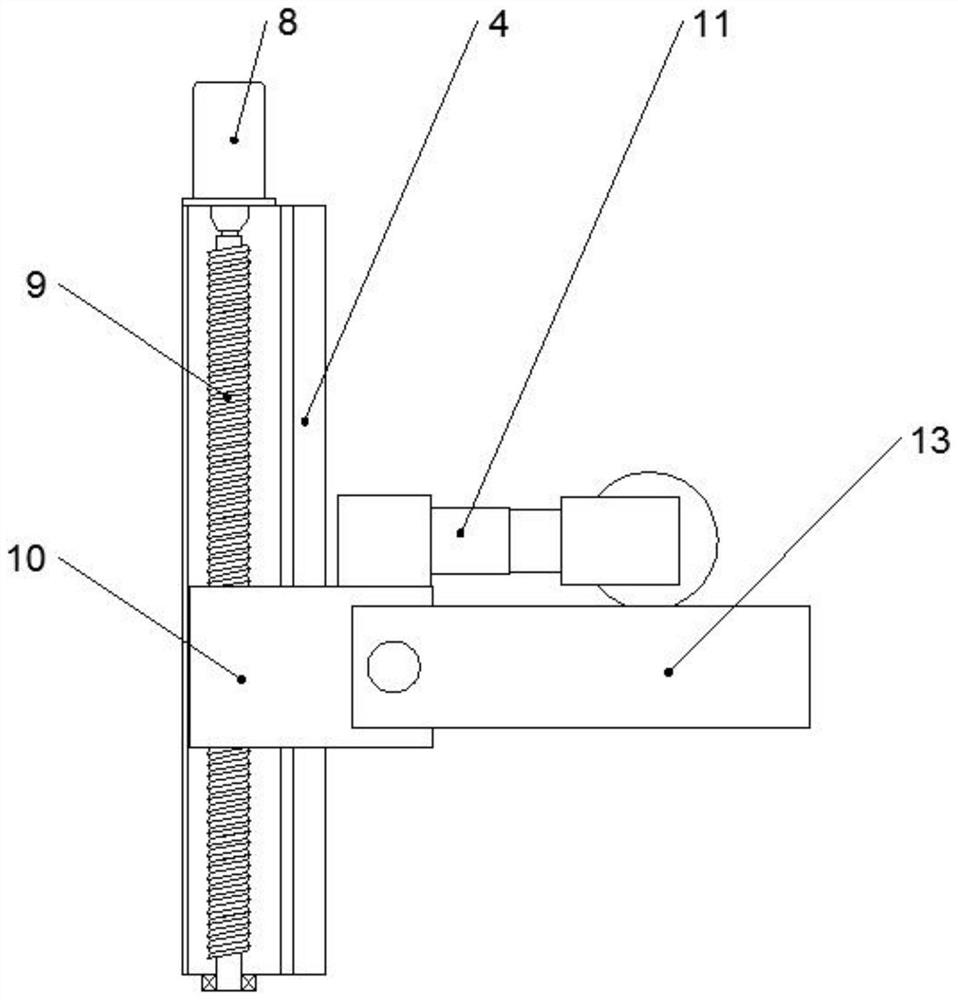

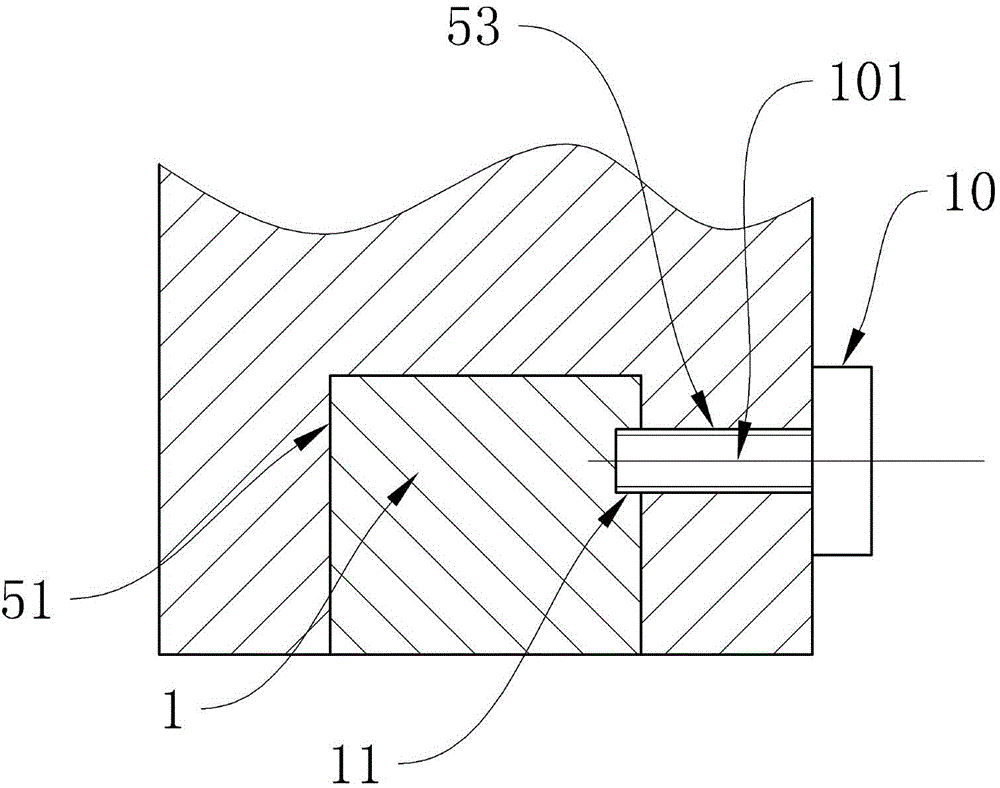

Pipe fitting cutting clamping tool with cam

InactiveCN106142192AReduce cutting errorsSimple structureMetal working apparatusPositioning apparatusPipe fittingEngineering

The invention discloses a pipe fitting cutting positioning tool with a clamping function. The tool comprises a limiting part and a support clamping part. The support clamping part comprises a supporting plate fixed to a sliding rail. A semicircular mounting half groove is formed in the top of the supporting plate, and the right end of the mounting half groove is hinged to an arc-shaped gland through a first hinge. The inner side cross section of the gland is in an arc shape, and a buffer compressing block is fixed to the inner side of the gland. A pressing plate is arranged at the left end of the gland, and the lower surface of the pressing plate is connected with the top end of a stretched spring. The bottom end of the stretched spring is connected to an extending block. The center of a cam is hinged to the supporting plate through a third hinge. The top end of the cam is hinged to the right end of a first connecting rod through a fourth hinge. The left end of the first connecting rod is hinged to the top end of a second connecting rod through a fifth hinge. The bottom end of the second connecting rod is hinged to the right end of a third connecting rod through a sixth hinge. The third connecting rod is hinged to the sliding rail through a first fixed hinge. A reset spring is connected between the left end of the third connecting rod and the sliding rail.

Owner:CHONGQING YINGJIE SCI & TECH CO LTD

Electric circular saw with dust collection function

The invention relates to the technical field of electric circular saws, and discloses an electric circular saw with a dust collection function, which comprises an electric saw shell, a driving motor, a saw blade, an adjusting plate and a collection assembly, the driving motor is located on the back of the electric saw shell, the saw blade is located on an output shaft of the driving motor, and a protective cover is arranged on the outer side of the saw blade and connected with the electric saw shell. A handle is arranged on the side, close to the protective cover, of the electric saw shell, the adjusting plate is located under the saw blade and the handle and connected with the lower surface of the electric saw shell through the adjusting assembly, the adjusting assembly enables the adjusting plate to move vertically and adjust the angle, and the collecting assembly is connected with the protective cover. The distance between the installation protruding block and the installation plate is adjusted through the telescopic rod in the adjusting assembly, when the cutting depth of a cut object needs to be specified, the length, exposed out of the portion below the saw bite, of the saw blade is changed, the cutting depth can be controlled, workers can cut the object more conveniently and rapidly, and the cutting error of the cut object is smaller.

Owner:南通世纪电动工具有限公司

Stripping machine suitable for electric wires of different thicknesses

InactiveCN109286113AAvoid cutting damageImplement the peeling operationLine/current collector detailsEngineeringElectric wire

The invention discloses a stripping machine suitable for electric wires of different thicknesses. The stripping machine comprises a base, a pair of fixing mechanisms, a cutting mechanism, a rotating mechanism and a supporting mechanism, wherein the cutting mechanism comprises a hollow roller and adjusting assemblies slidably arranged at two end portions of the roller, each group of the adjusting assemblies comprises a plurality of lantern rings which are sequentially and slidably sleeved from inside to outside, each lantern ring comprises arc-shaped plates and springs which are sequentially and alternately connected in a fixed manner in an annular shape along the circumferential direction, the inner side walls of the end portions of the roller and the inner side walls of the arc-shaped plates of each lantern ring are recessed inwardly to form grooves, and the outer side walls of the arc-shaped plates of each lantern ring protrude outwards to form protrusions matched with the grooves adjacent thereto, so that the plurality of lantern rings are sequentially and slidably sleeved. The stripping machine has the beneficial effects of carrying out synchronous and rotary propulsion to cuta portion to be stripped, avoiding cutting errors caused by deformation of the electric wire due to the traditional pressed propulsion operation, and being suitable for the stripping operation of electric wires of different thicknesses.

Owner:北海市天硌打印耗材有限公司

Glass tube cutting equipment

ActiveCN106219959AEnsure safetyReduce cutting errorsGlass severing apparatusCross overGlass container

The invention discloses glass tube cutting equipment which comprises a bracket, a mechanical arm, a joining net, a rotator, a cutter and heating equipment, wherein the bracket comprises a plurality of bracket guide rails and a bracket side table; the bottom end of the mechanical arm is penetrated by the guide rails on the side face of the bracket table so as to be suspended above the bracket; two ends of the joining net are embedded in the inner side face of the bracket side table; the rotator crosses over the bracket; the cutter is tightly connected with the rotator; the heater is positioned inside the bracket. The glass tube cutting equipment is capable of simultaneously cutting a plurality of glass tube containers, and a glass container can be cut into multiple sections. In addition, according to the glass tube cutting equipment, the problem that glass tubes with the length of more than 1m cannot be cut is solved.

Owner:陈富强

Rotary intelligent end stripper

InactiveCN109462128AEasy to moveReduce distortionLine/current collector detailsElectrical testingMechanical engineering

The invention discloses a rotary intelligent end stripper, which comprises a base, a pair of fixing mechanisms, a cutting mechanism, a rotating mechanism and a supporting mechanism, wherein the cutting mechanism comprises a hollow roller; a telescopic motor is arranged on the inner side wall of the roller; a free end of an output shaft of the telescopic motor is fixedly connected to a double-cutting knife with a bottom blade and a side blade; the double-cutting knife is arranged above a to-be-stripped part; the telescopic motor stretches to drive the bottom blade of the double-cutting knife tocut the to-be-stripped part along the radial direction; a rotating motor rotates to drive the side blade of the double-cutting knife to cut the to-be-stripped part along the circumferential direction; the supporting mechanism comprises a supporting seat arranged below the roller, a roller which can be fixed above the roller along the circumferential direction in a rotary sheathed manner; and theouter side wall of the roller is detachably arranged above the supporting seat. The rotary intelligent end stripper has the following beneficial effects that the deformation degree of an insulating cover caused by clamping is relieved through four-point symmetric clamping, and meanwhile, the to-be-stripped part is cut in a synchronous rotary propulsion manner, so that the cutting error caused by wire deformation due to the traditional press-in operation is avoided.

Owner:北海市天硌打印耗材有限公司

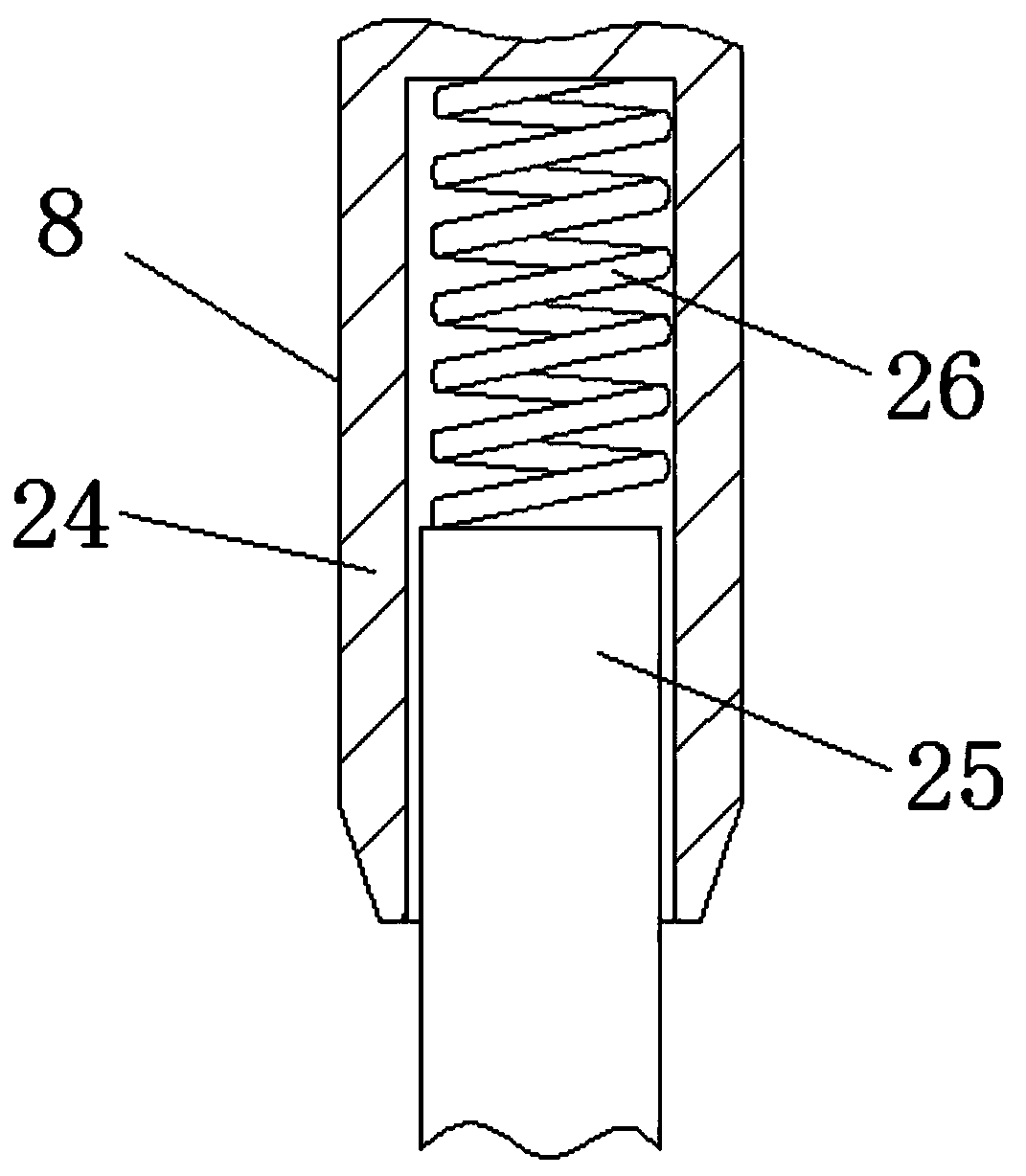

Steel pipe special cutting machine and using method thereof

ActiveCN109530783ASimple structureEasy to operateTube shearing machinesMaintainance and safety accessoriesEngineeringSteel tube

The invention relates to a steel pipe special cutting machine and a using method thereof. The steel pipe special cutting machine comprises a base, sliding wheels capable of being fixed are arranged onthe base, a damping table is arranged on the base, a supporting shaft is arranged on the damping table, a sliding rail is arranged on the supporting shaft, a ram matched with the sliding rail is arranged on the sliding rail, the ram is connected with a rotating shaft through a fixing device, one end of the rotating shaft is connected with a connector on a cutting piece, the rotating shaft is connected with a speed stabilizer on a motor, and a processing device is arranged on the base. The steel pipe special cutting machine is simple in structure, easy to operate, good in fixing effect, capable of improving the working efficiency and precision, good in cutting quality, low in cost and wide in application range.

Owner:苏州卡恩图电子科技有限公司

Mobile on-line casting blank length measuring device and measuring method thereof

ActiveCN103611906ALow implementation costFast measurement resultsCasting parameters measurement/indication devicesLength measurementMaterials science

The invention discloses a mobile on-line casting blank length measuring device which comprises an upper portion steel pipe, a lower portion steel pipe, supports, pulleys, a steel plate ruler, verniers and casing pipes. The two ends of the upper portion steel pipe and the two ends of the lower portion steel pipe are fixed on the two supports respectively. The upper portion steel pipe and the lower portion steel pipe are arranged in parallel, and the upper portion steel pipe is located on the upper portion of the lower portion steel pipe. The steel plate ruler is fixed on the lower portion of the lower portion steel pipe, and scales are arranged on the steel plate ruler. The pulleys are arranged at the bottoms of the supports. The two casing pipes are arranged on the upper portion steel pipes, and the two verniers are fixed on the two casing pipes respectively. The invention further discloses a measuring method of the mobile on-line casing blank length measuring device. According to the mobile on-line casting blank length measuring device and the measuring method of the mobile on-line casting blank length measuring device, the actual length of casting blank can be fed back in time, the precision of a cutting system is corrected according to the specific length which is fed back, the cutting errors of the on-line casting blank are reduced, the sizing qualification rate of the casting blank is ensured, and therefore the yield of the casting blank is improved.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Laser cutting machine used for machining LED light guide board and convenient to adjust

InactiveCN108838524AAchieve freedom of movementIncrease flexibilityLaser beam welding apparatusHydraulic cylinderLight guide

The invention discloses a laser cutting machine used for machining an LED light guide board and convenient to adjust. The laser cutting machine comprises a base. A first sliding groove is formed in the outer wall of the top of the base. A first moving platform is connected to the inner wall of the first sliding groove in a sliding manner. A displayer is fixed to the outer wall of the top of the base through screws. A first hydraulic cylinder is fixed to the outer wall of the top of the base through screws. A first moving platform is fixed to one end of an extending rod of the first hydraulic cylinder through screws. A first installing groove is formed in the inner wall of one side, away from the first hydraulic cylinder, of the first sliding groove. A first distance inductor is fixed to the inner wall of the first installing groove through screws. A second sliding groove is formed in the outer wall of the top of the first moving platform. A second moving platform is connected to the inner wall of the second sliding groove in a sliding manner. According to the laser cutting machine, a working table can move freely in the X direction, the Y direction and the Z direction, the flexibility of the device is improved greatly, and the cutting error and the cutting fault are reduced.

Owner:巩同庆

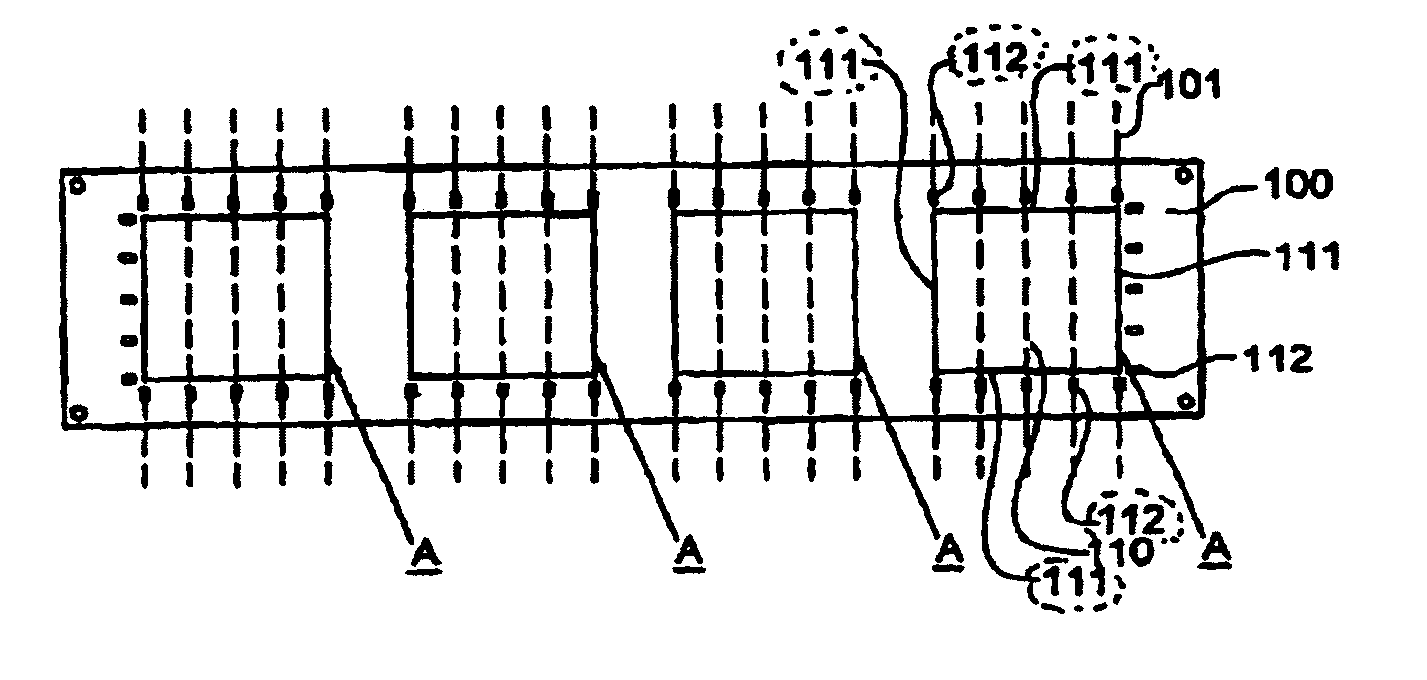

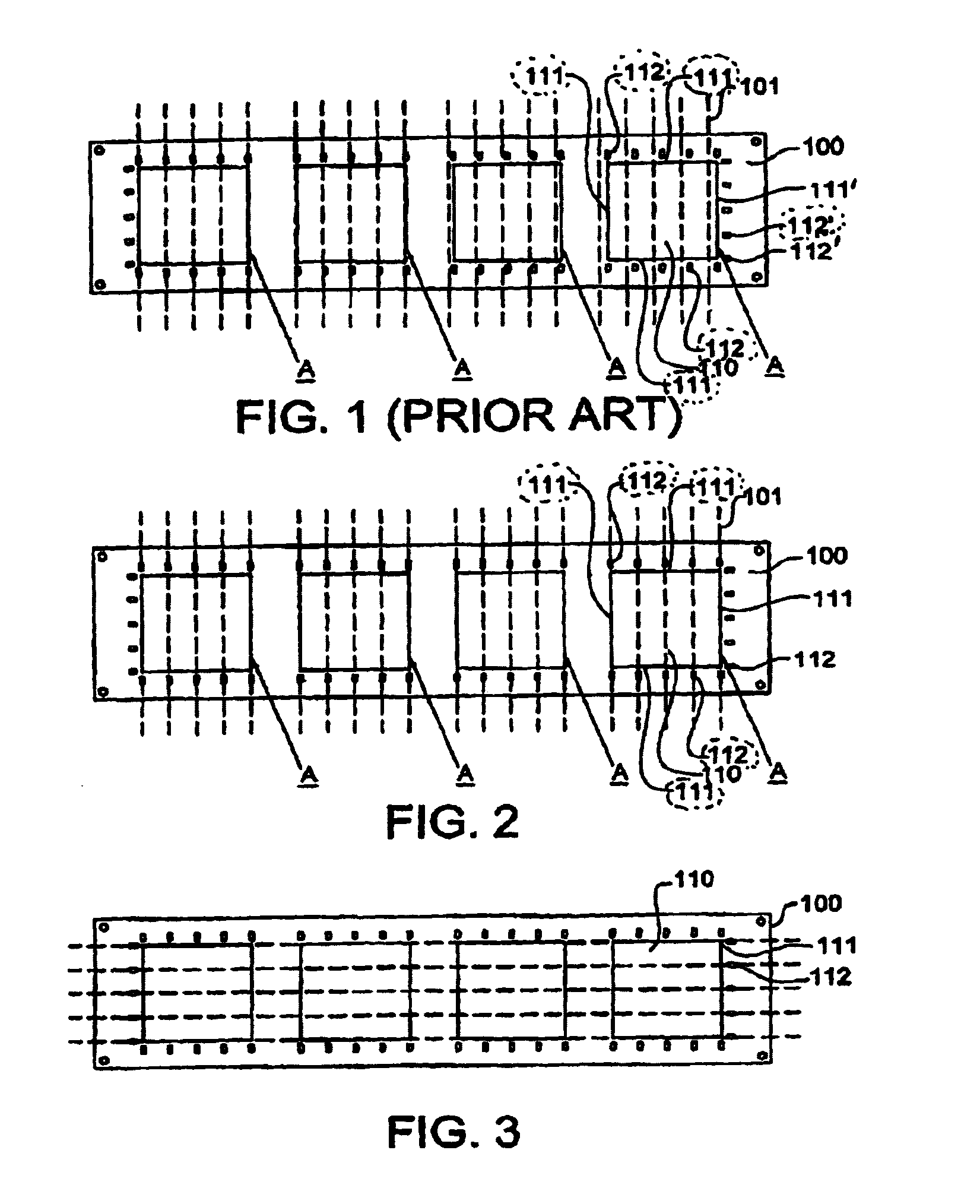

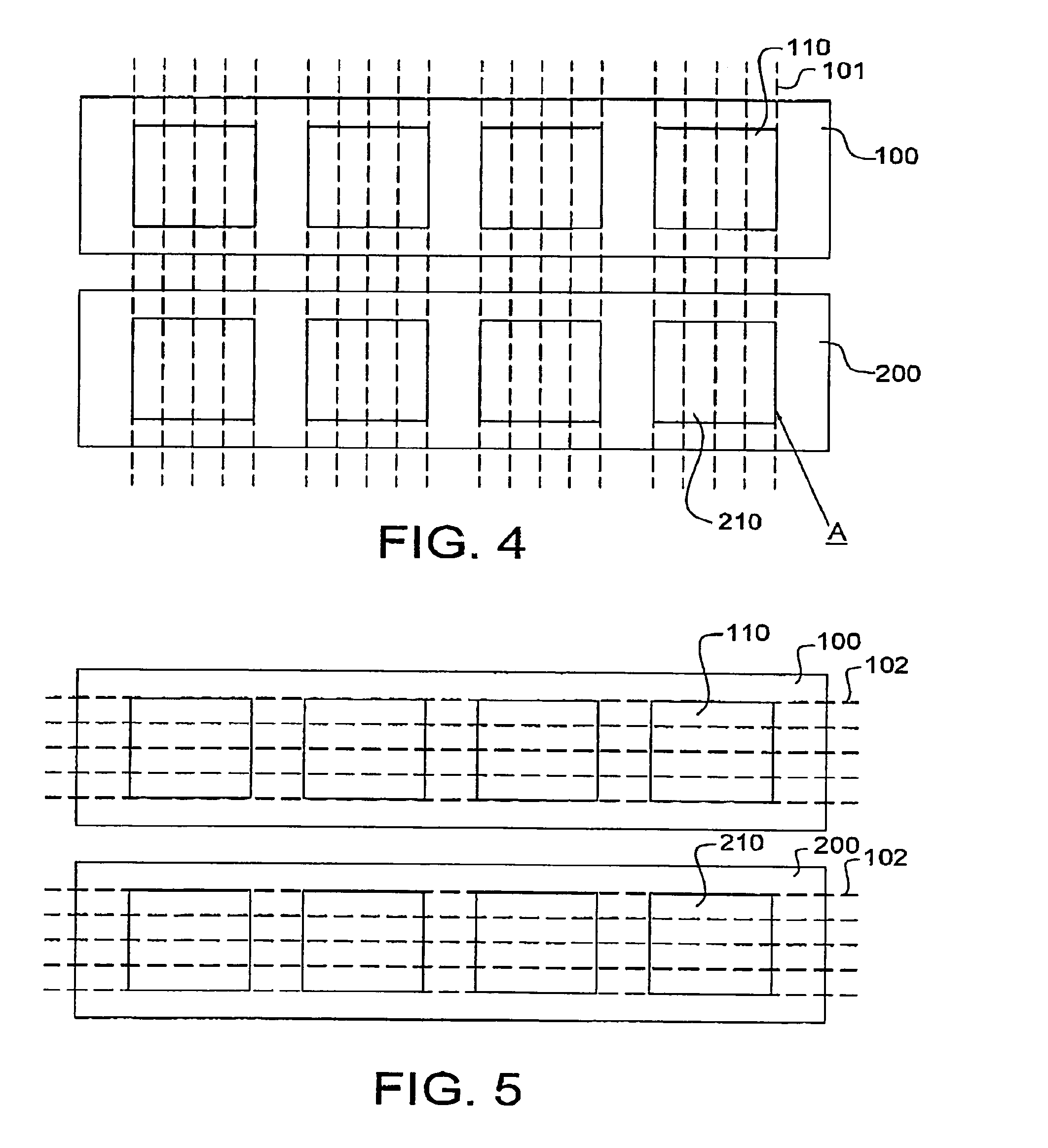

Process for sawing substrate strip

InactiveUS7168352B2Reduce cutting errorsReduce errorsMetal sawing accessoriesSemiconductor/solid-state device manufacturingElectrical and Electronics engineeringEngineering

A process for sawing a substrate strip marks corresponding to substrate areas of substrate strips which are arranged side-by-side on a plate. A saw machine is mechanically moved to the substrate areas and positioned by the alignment marks of corresponding substrate areas for cutting the substrate areas of the substrate strips in the first phase. Then the saw machine is further mechanically moved to the substrate areas again and is positioned by the alignment marks of corresponding substrate areas again for cutting the substrate areas of the substrate strips in the second phase. Therefore, an error in any of the substrate areas in the first phase and second phase will not accumulate to the subsequent substrate areas in the substrate strip.

Owner:ADVANCED SEMICON ENG INC

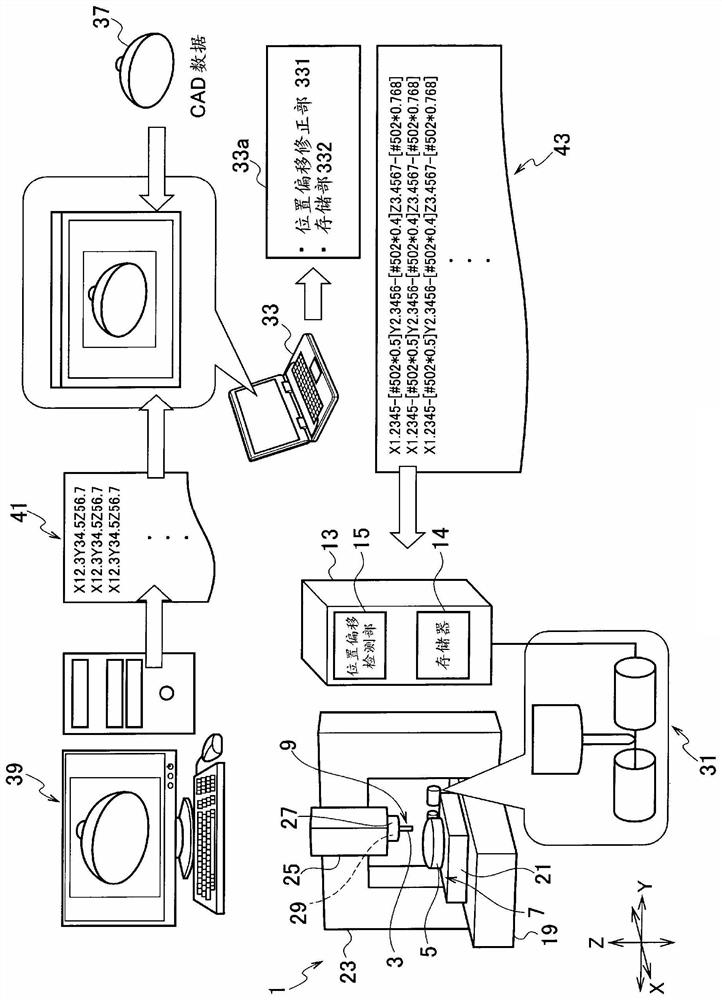

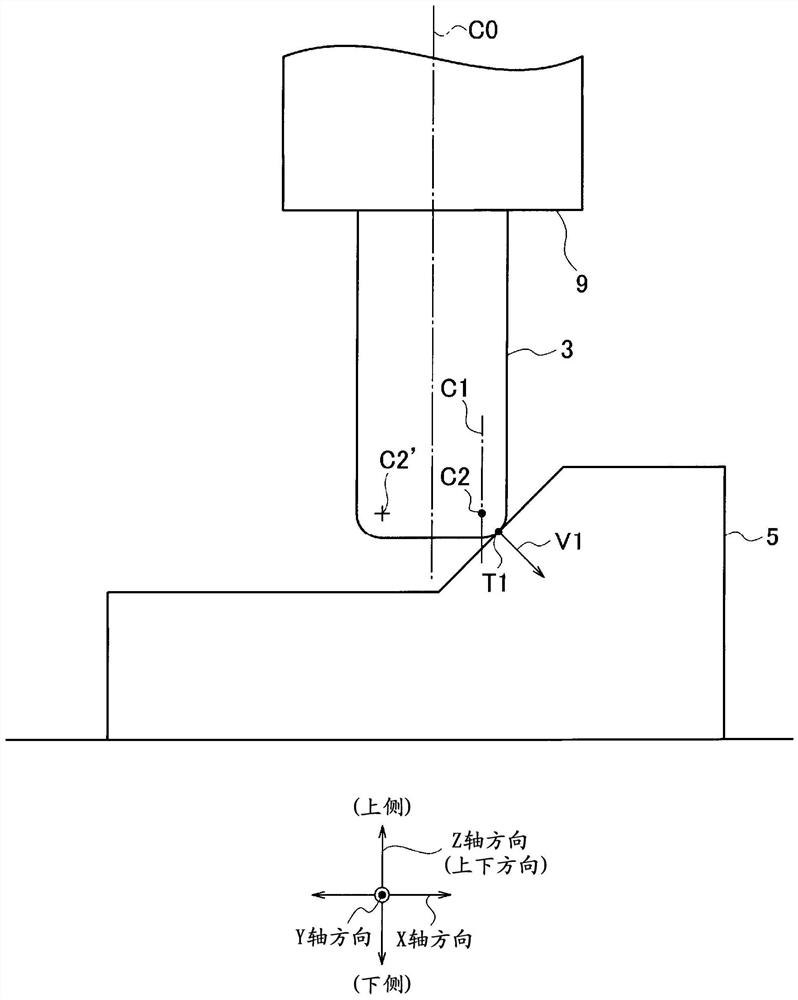

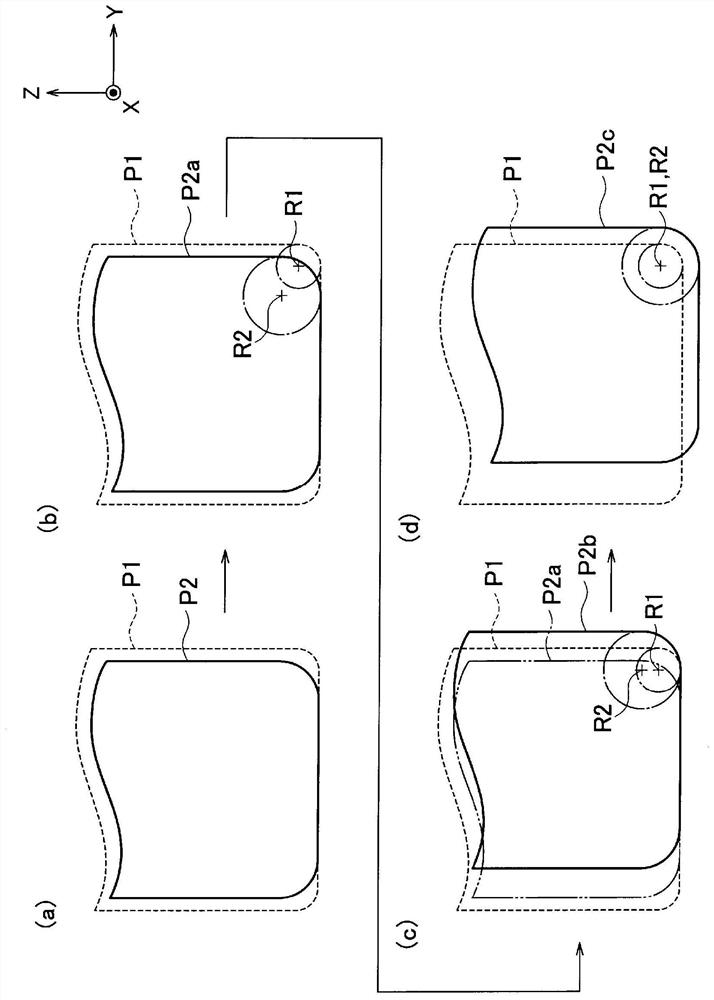

Workpiece machining method and workpiece machining device

PendingCN113710418AReduce cutting errorsProgramme controlAutomatic control devicesRotational axisMilling cutter

A workpiece machining device (1) is provided with a positional displacement correction unit (331) that detects the positional displacement between a real contour line (P2) of a radius end mill (3) and an ideal contour line (P1) and corrects the positional displacement of the radius end mill (3). The positional displacement correction unit (331) calculates a first correction value for aligning the center of a first circular-arc portion forming a circular-arc shape in a corner portion of the ideal contour line (P1) with the center of a second circular-arc portion forming a circular-arc shape in a corner portion of the real contour line (P2) in a plane orthogonal to the rotation axis, and corrects a machining point of the radius end mill (3) using the first correction value.

Owner:SHIBAURA MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com