Pipe fitting cutting clamping tool with cam

A technology for clamping tooling and cams, applied in the direction of clamping, positioning devices, manufacturing tools, etc., can solve the problems of large cutting errors of pipe fittings, vibration of pipe fittings, low production efficiency, etc., to reduce cutting errors, facilitate positioning, and save time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the drawings and embodiments:

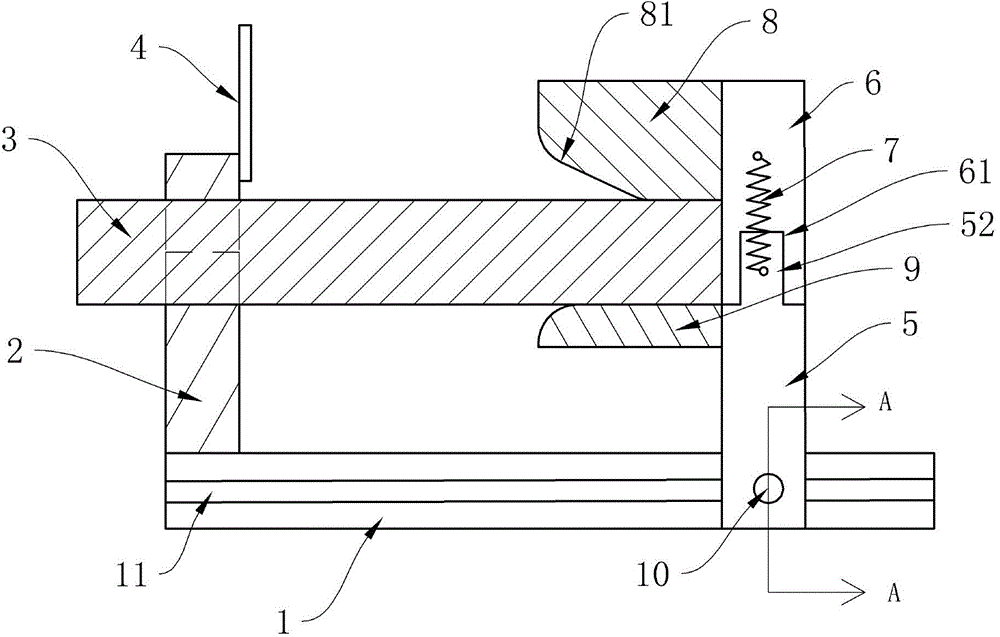

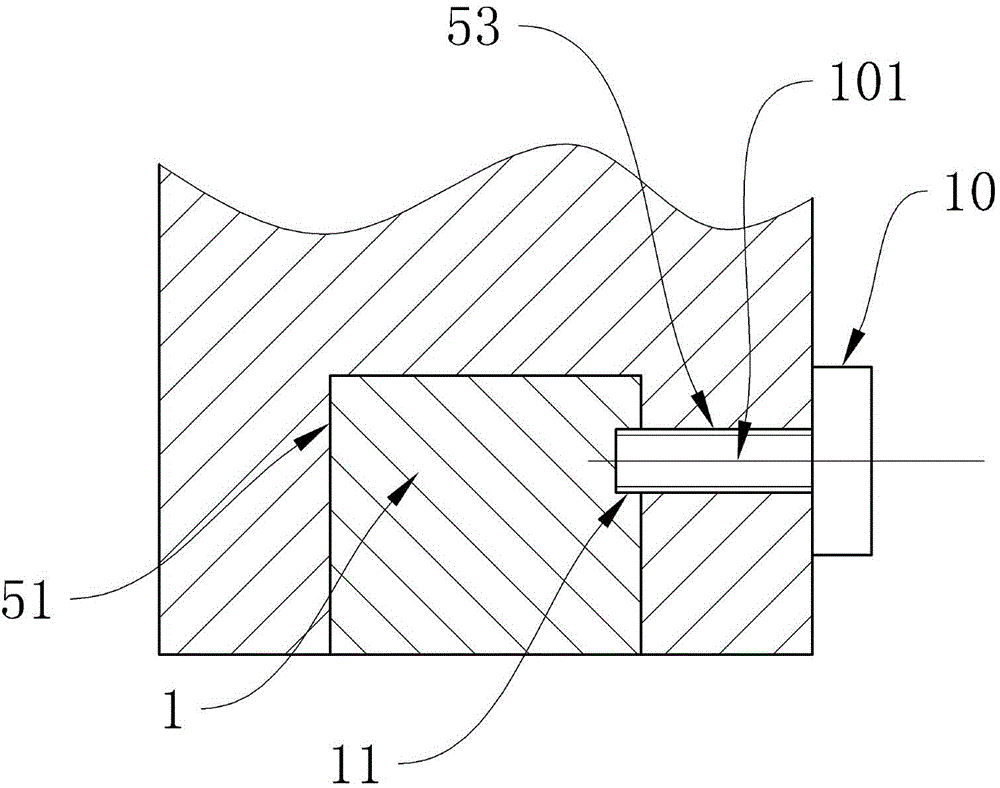

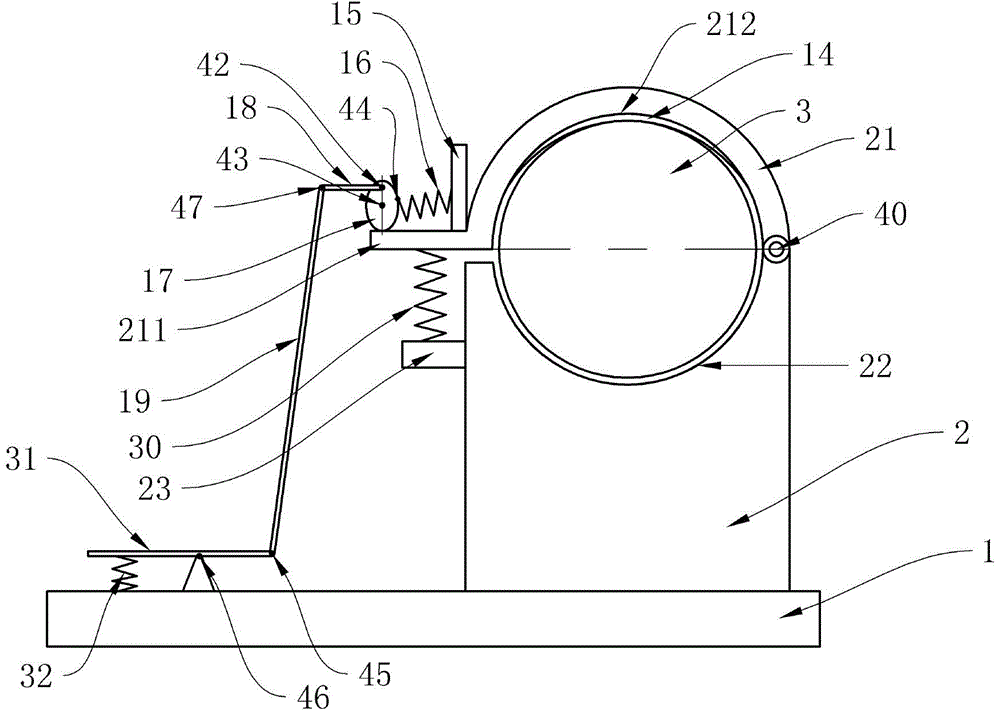

[0013] Such as Figure 1 to Figure 3 As shown, a tube cutting and clamping tool with a cam includes a limiting component and a supporting and clamping component 2. The limiting component includes a first limiting plate 5, and the bottom of the first limiting plate 5 is The end is provided with a sliding groove 51, and the sliding groove 51 is matched with the sliding rail 1; a threaded hole 53 is provided on one side of the sliding groove 51, and the bolt 10 is screwed into the threaded hole 53 and the sliding rail 1 is tightened to To make the bolt 10 better tighten the slide rail 1, a clamping groove 11 can be provided in the contact part of the slide rail 1 and the bolt 10, so that the bolt 10 can be directly clamped in the clamping groove 11;

[0014] The top of the first limiting plate 5 is provided with a stopper 9, and the stopper 9 is provided with a matching pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com