Ethylene vinyl-acetate (EVA) cutting mechanism

A technology of cutting knife and bottom cutting knife, which is applied in metal processing and other directions, can solve the problems of large cutting error and high chance of secondary pollution, etc., and achieve the effect of small cutting error, small chance of pollution and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below with reference to the accompanying drawings and examples.

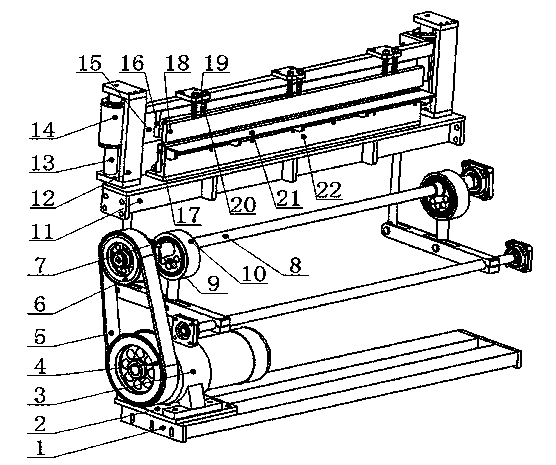

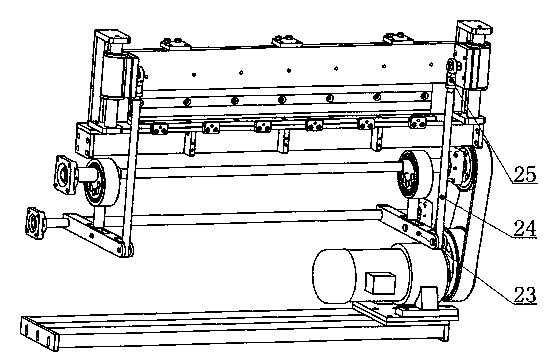

[0016] The invention proposes an EVA cutting mechanism. refer to figure 1 As shown, a kind of EVA cutting mechanism, motor mounting seat 1 and motor mounting plate 2 are connected, and motor 3 is installed on described motor mounting plate 2, and driving wheel 4 is installed on the left side of described motor 3, and described driving wheel 4 Connect with driven wheel 6 by synchronous belt 5, described driven wheel 6 is installed on the left end of main shaft 8, and eccentric wheel 9 is installed on described main shaft 8 and described driven wheel 6 right side, described driven wheel 6 and A bearing with a seat 7 is installed between the eccentric wheels 9, and the eccentric wheel 9 is installed on the bearing with the bearing seat 10, and the bearing with the bearing seat 10 is connected with the connecting rod seat 23, and the connecting rod seat 23 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com