Patents

Literature

37results about How to "Cutting saves time and effort" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

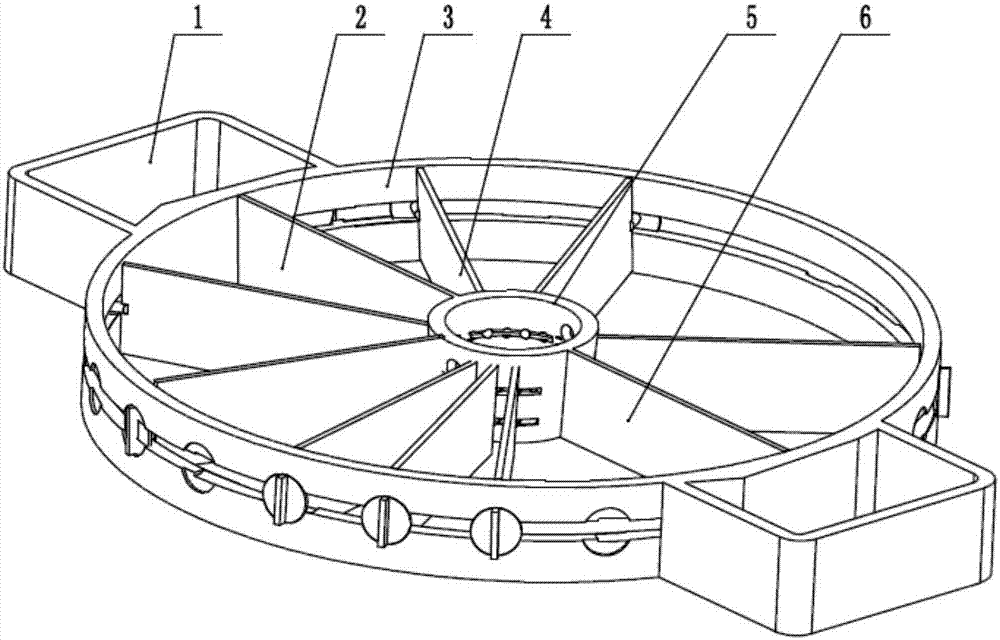

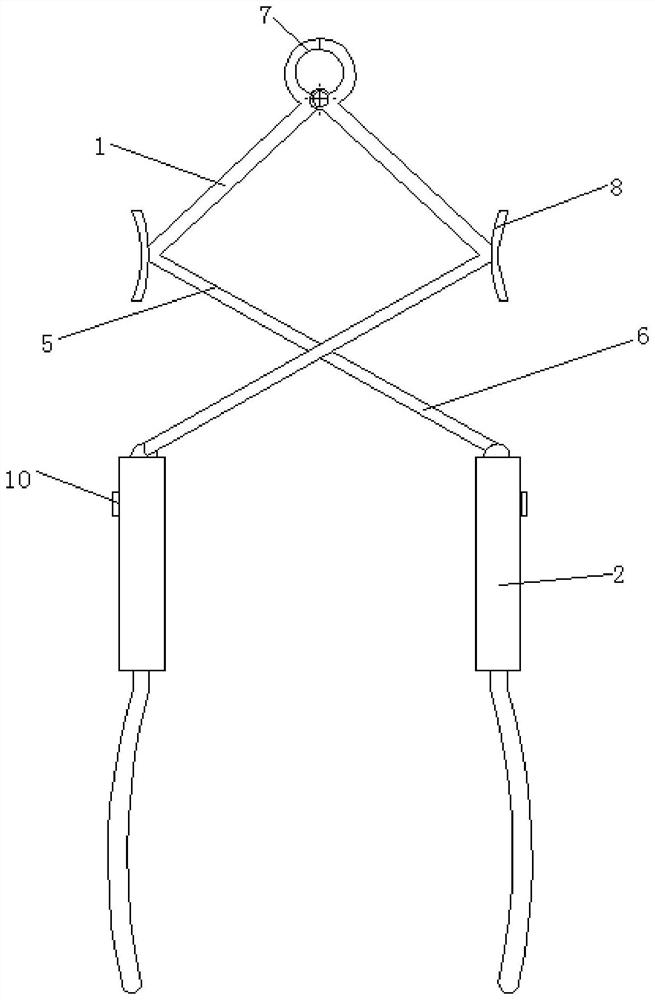

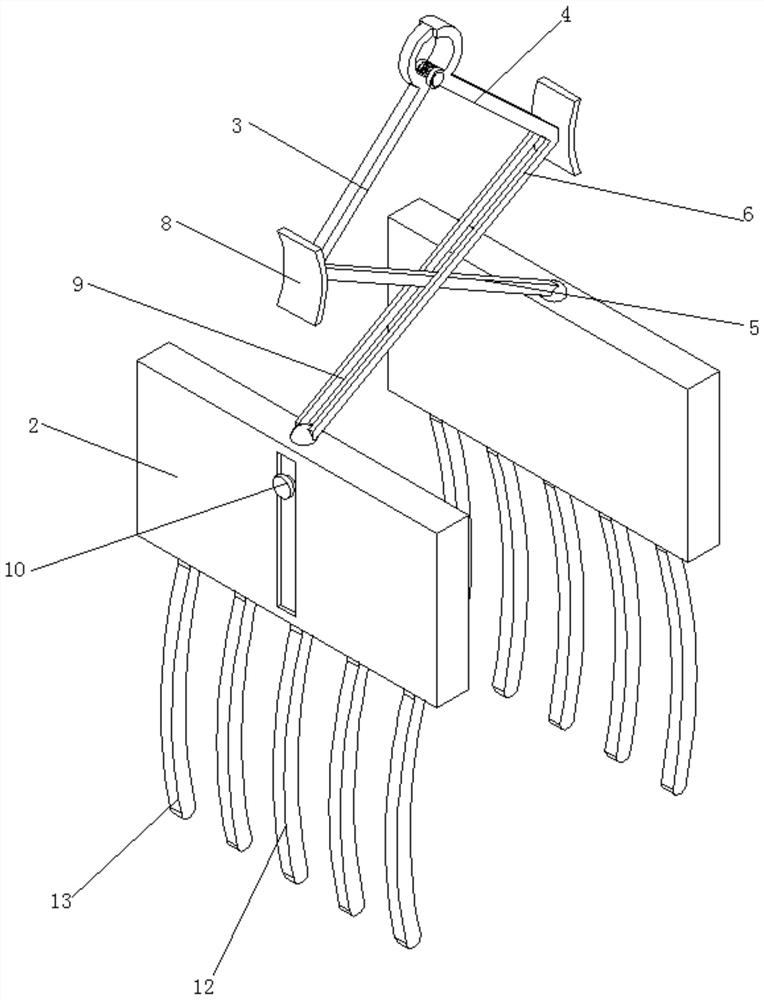

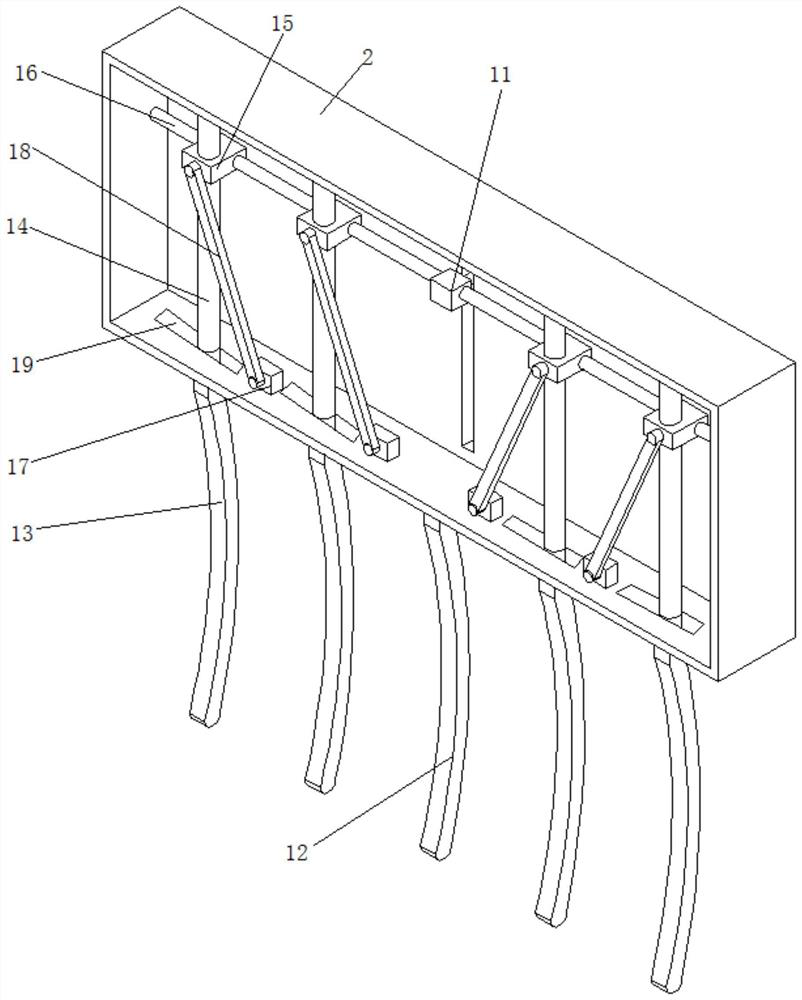

Watermelon cutting device

ActiveCN106426358ACutting saves time and effortSolve the hand-held suffering, cutting accidental injuryMetal working apparatusHabitEngineering

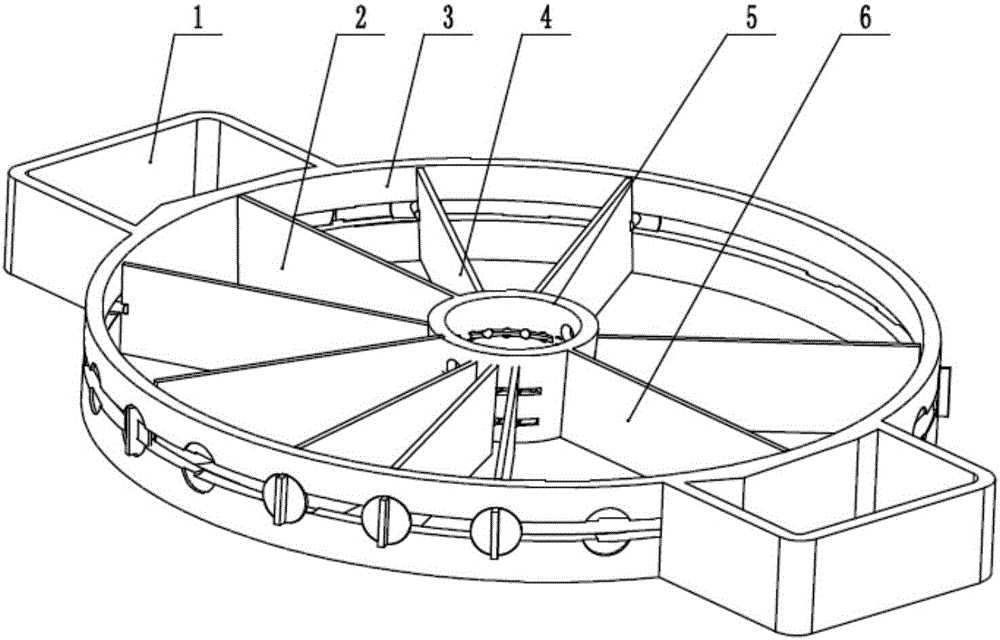

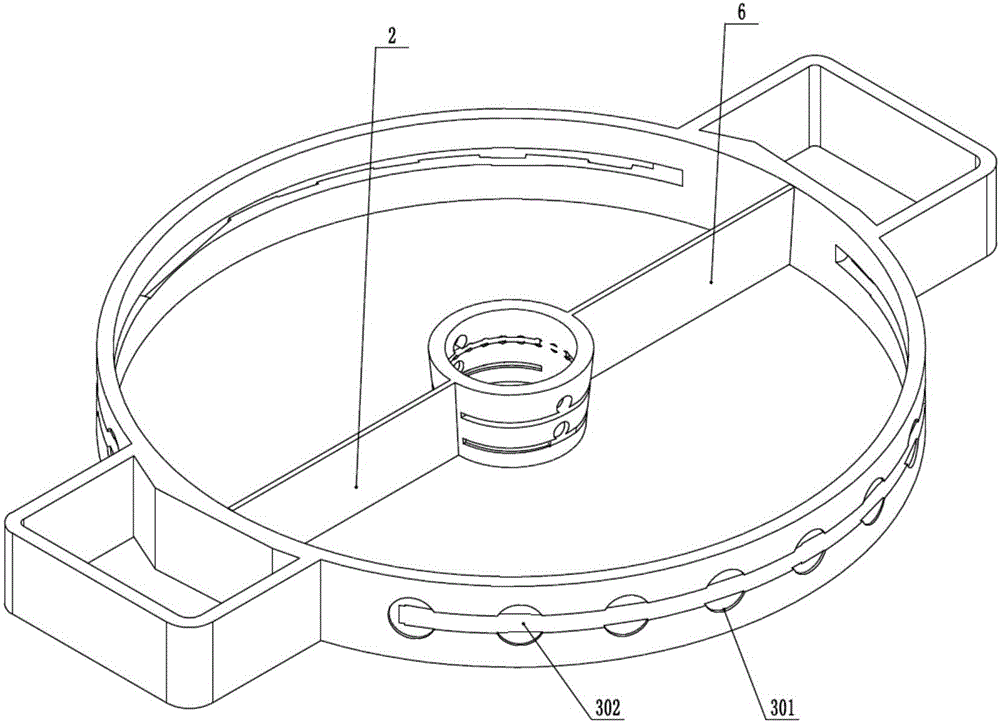

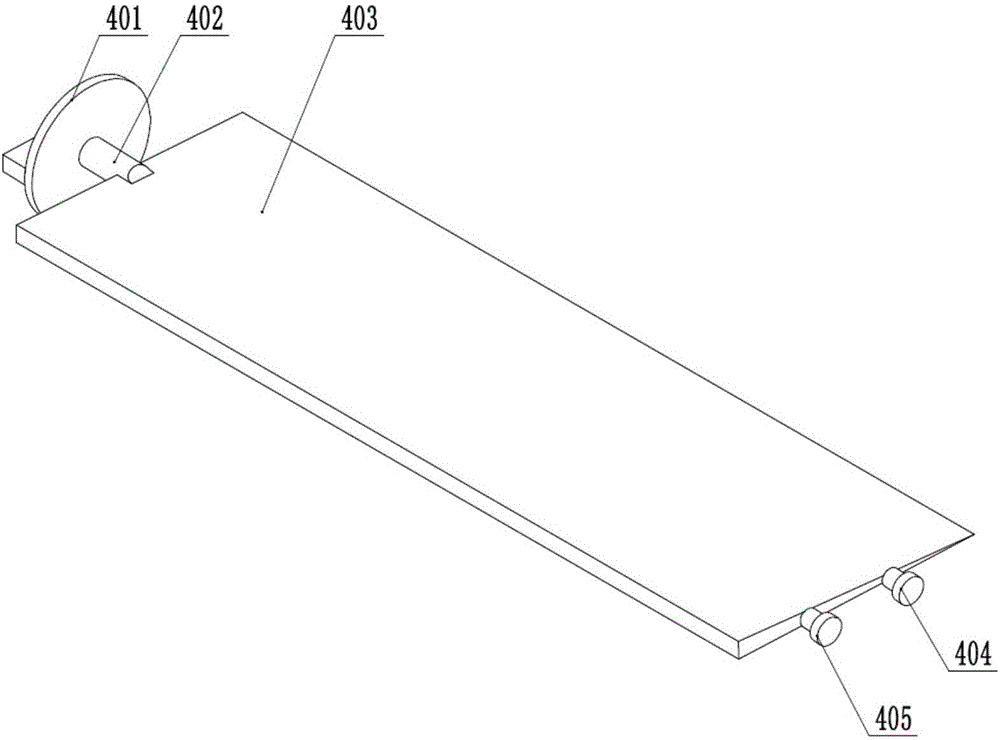

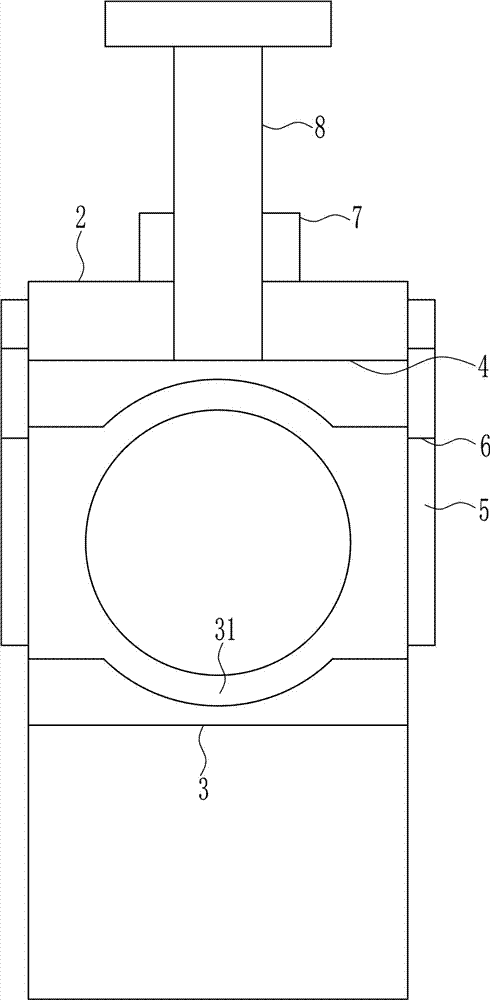

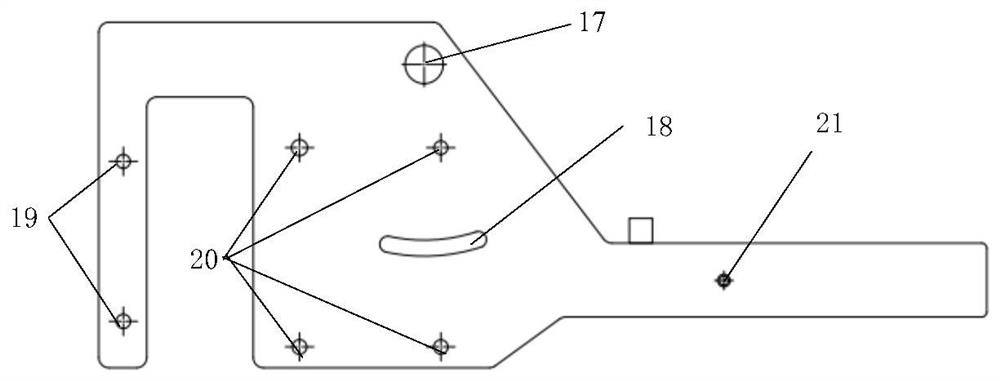

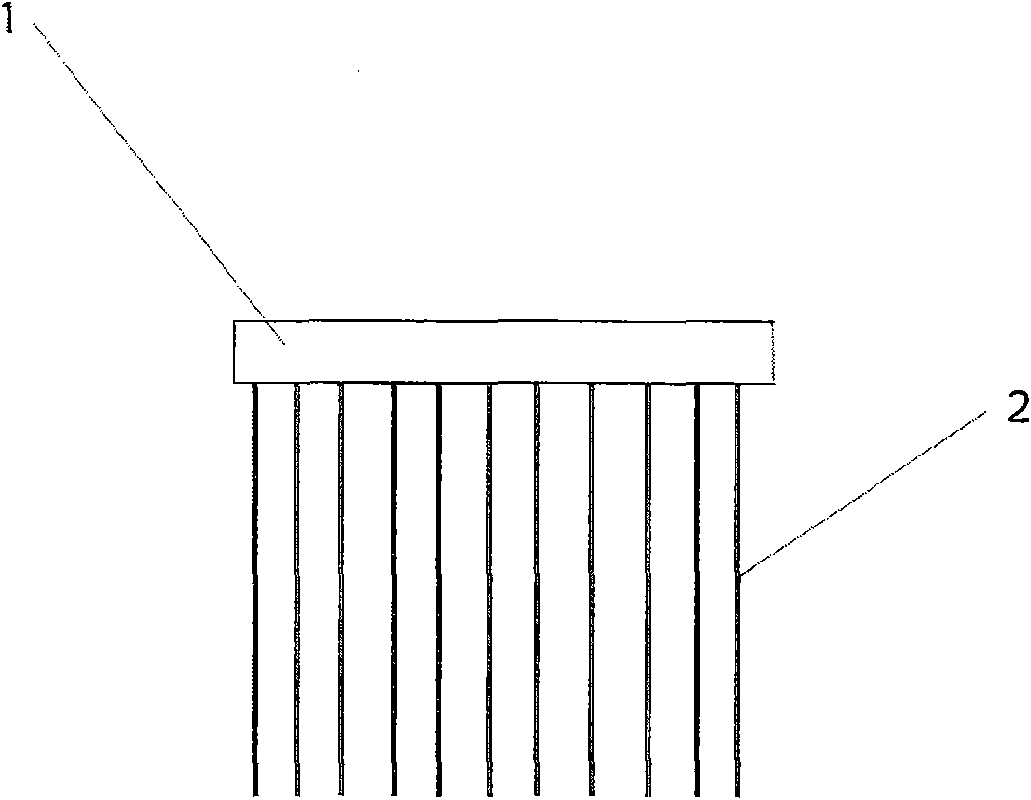

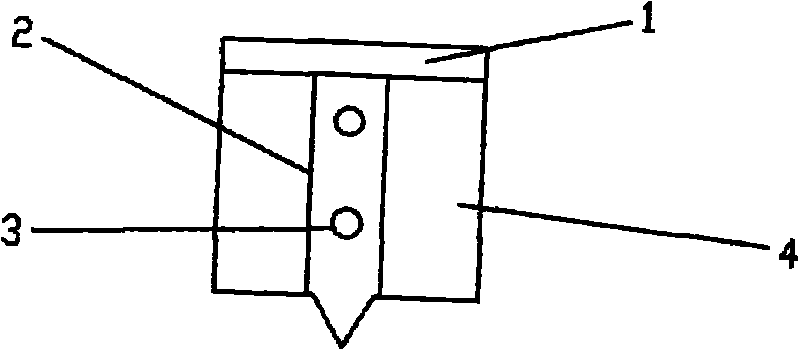

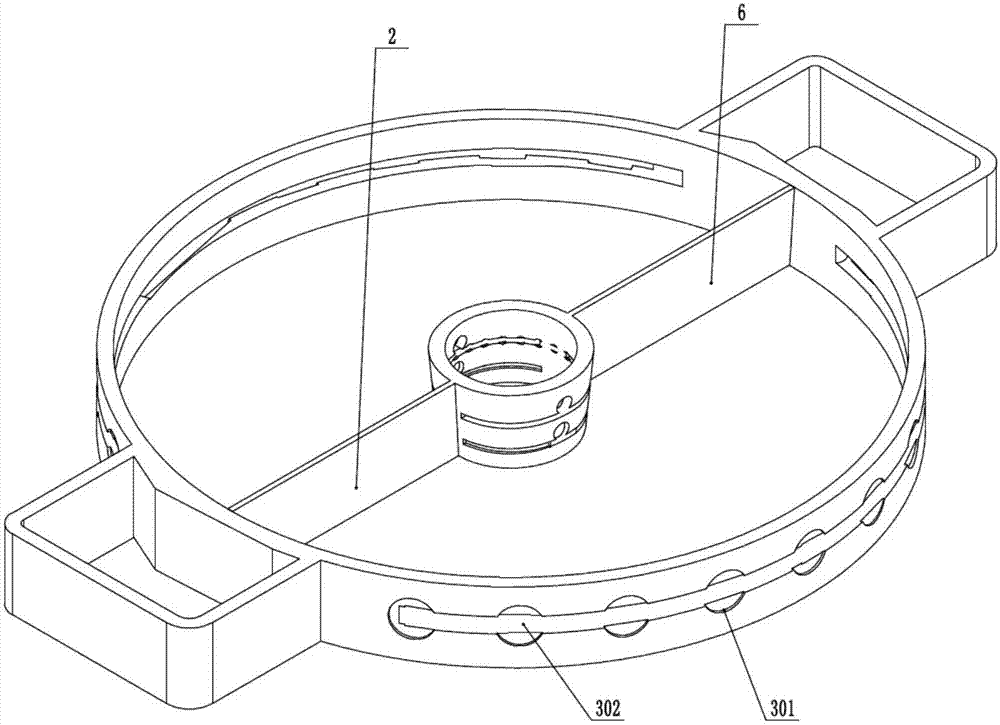

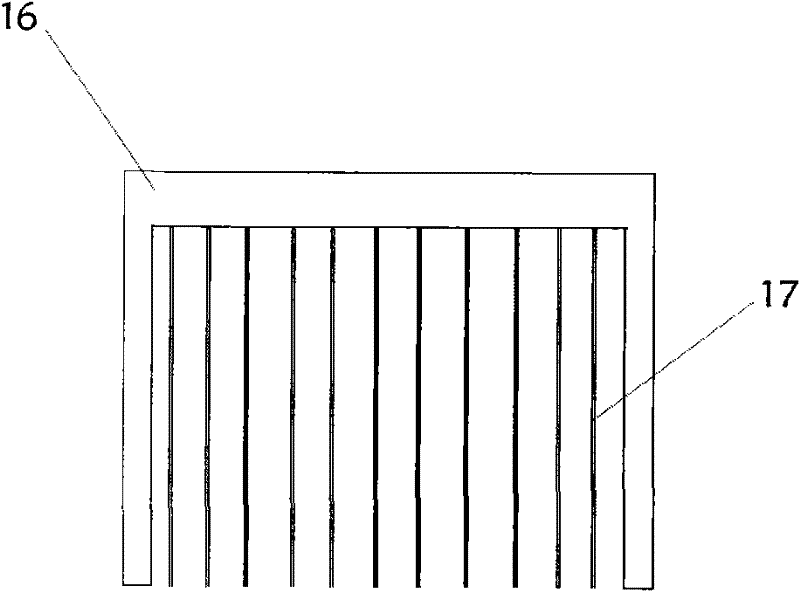

A watermelon cutting device belongs to the field of kitchen and bathroom supplies and is composed of two handles, fixed blade I, an outer contour, a plurality of moving blades, a matching core and fixed blade II; the two handles are mounted symmetrically on two sides of the outer contour, one end of the fixed blade I is fixed to the outer side of the matching core, the other end of the fixed blade I is fixed to the inner side of the outer contour, one end of the fixed blade II is fixed to the outer side of the matching core, the other end of the fixed blade II is fixed to the inner side of the outer contour, the fixed blade I and the fixed blade II are opposite to each other, and the moving blades are mounted at one end to the matching core and mounted at the other end to the outer contour. The positions of the moving blades are adjustable, watermelon strips cut after adjusting may meet the eating habit needs of different people; the quantity of the moving blades may also be adjusted through the cooperation of the moving blades, matching core and outer contour to adapt to watermelons of different diameters, and cutting the watermelons is timesaving and laborsaving.

Owner:安徽凌老伯食品有限公司

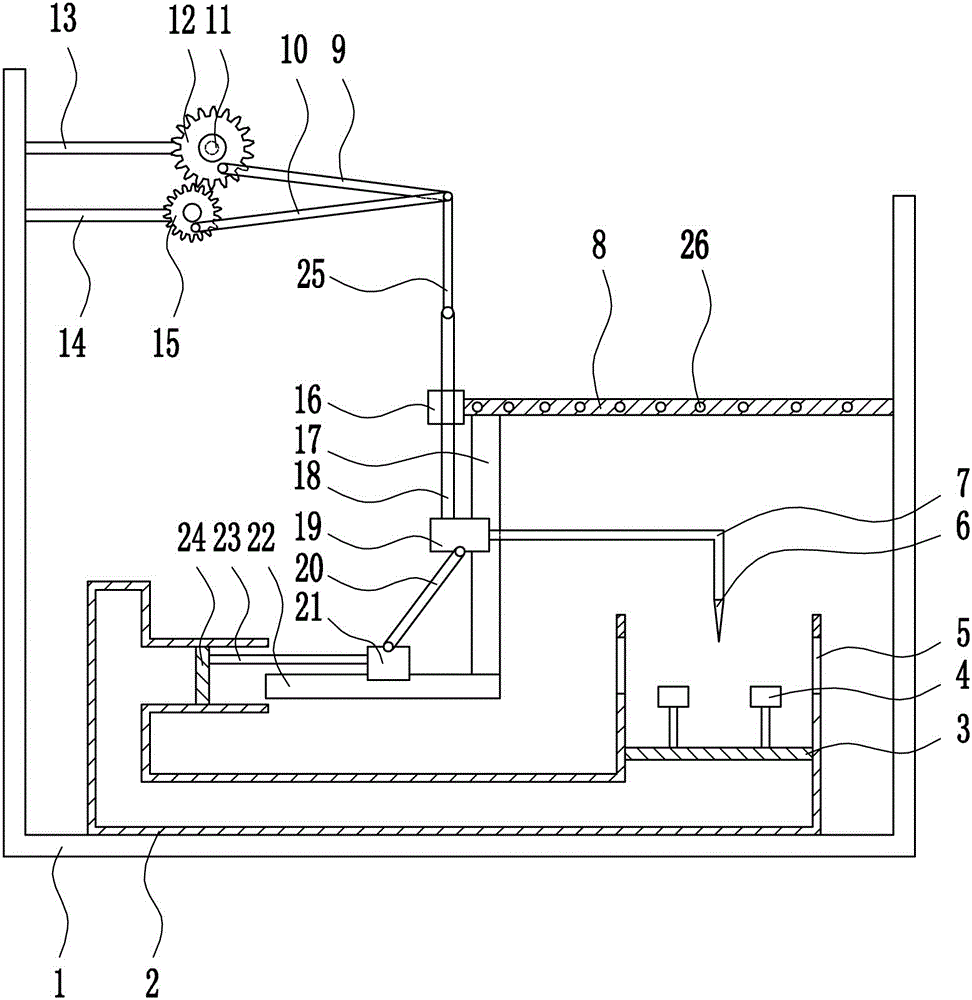

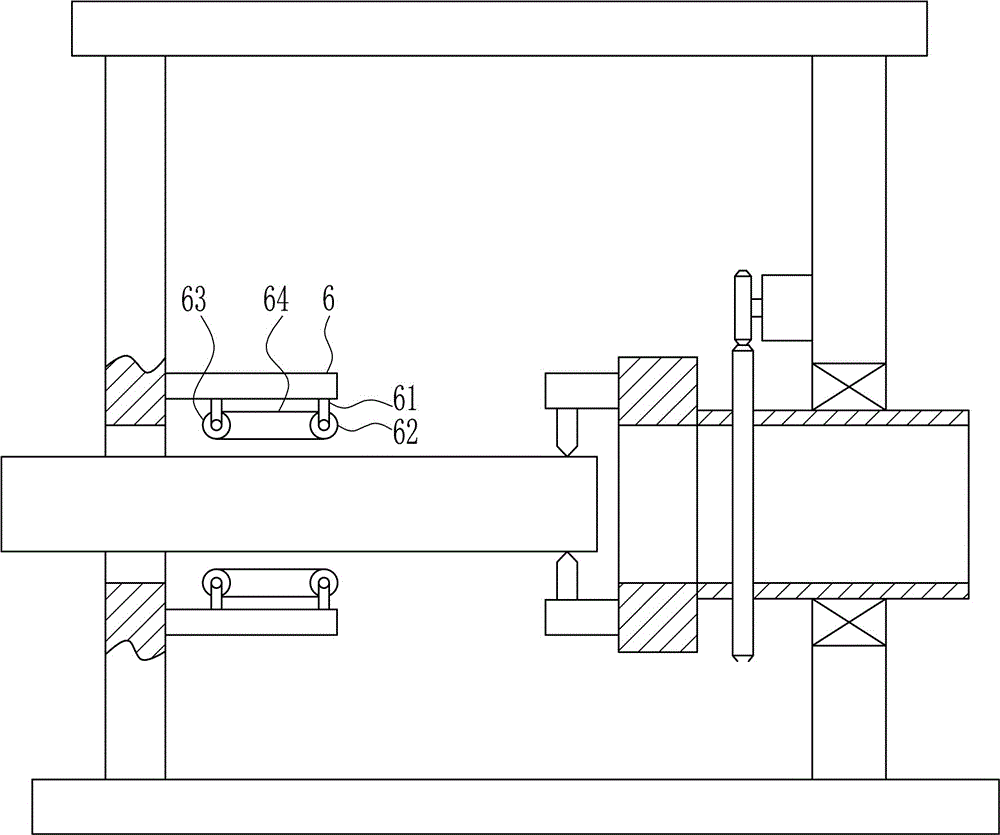

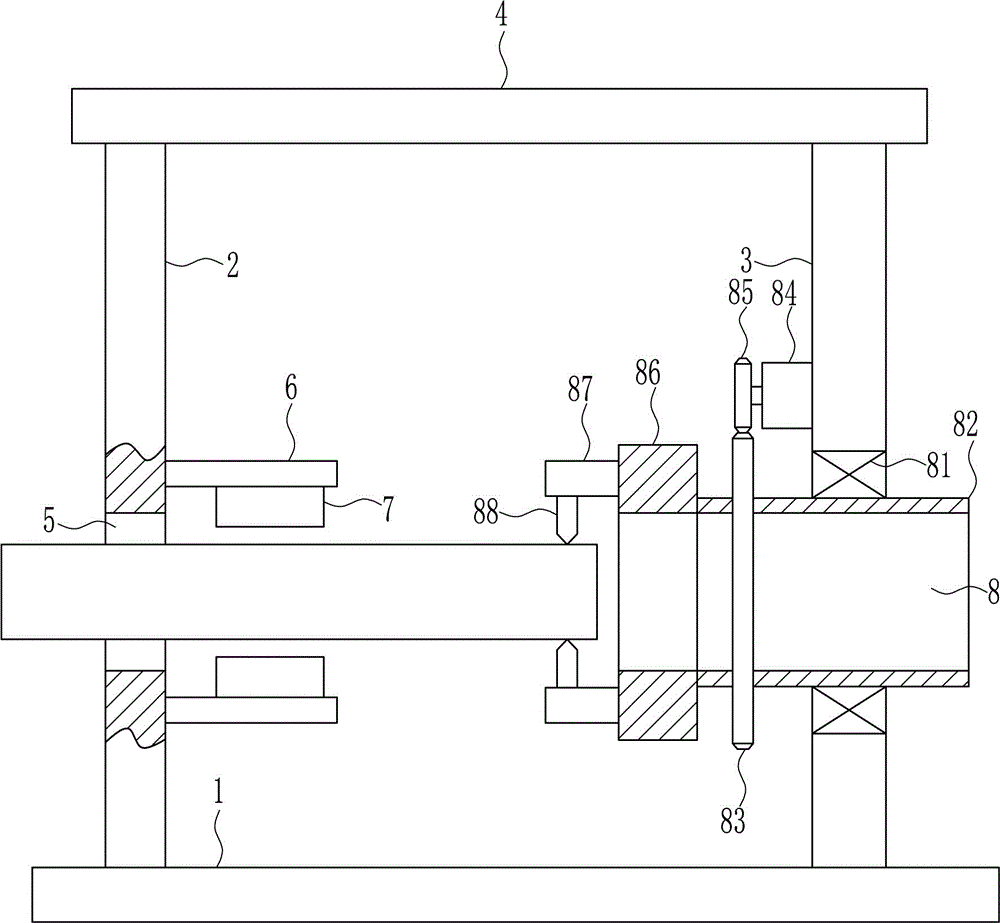

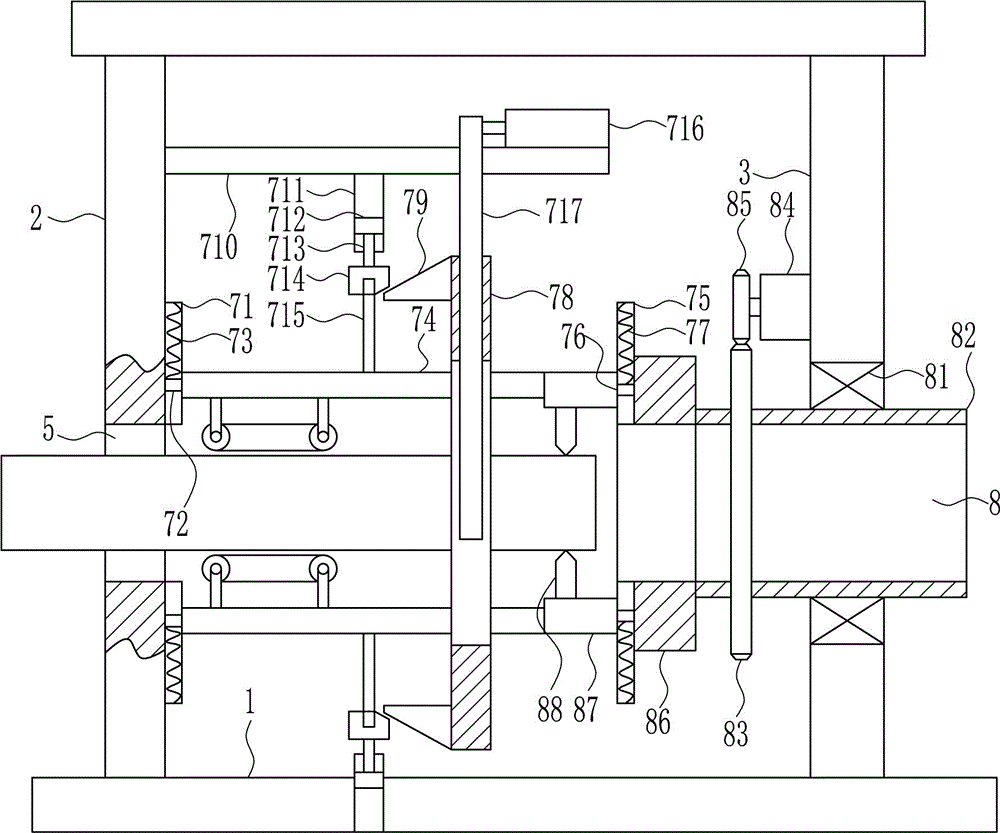

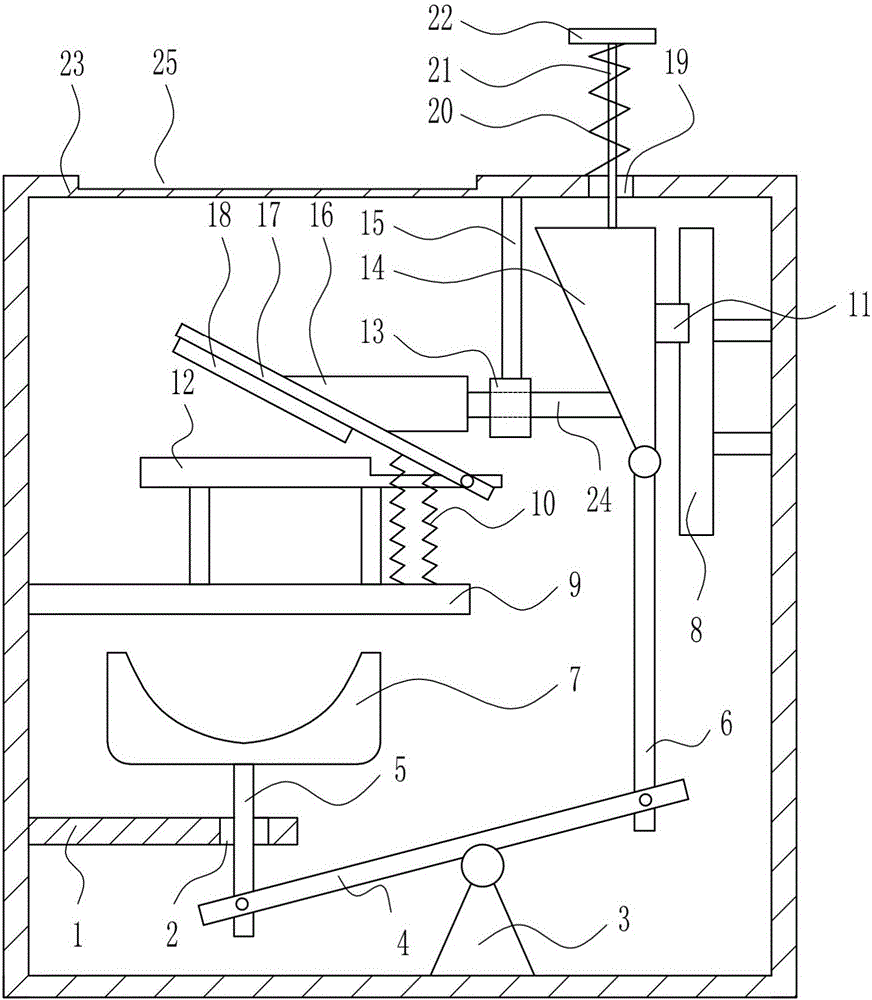

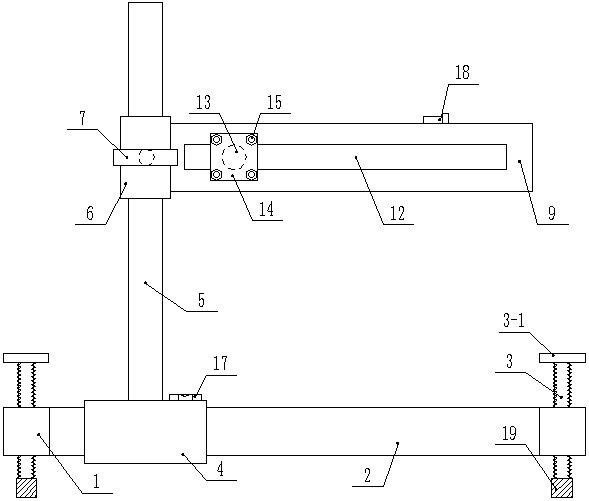

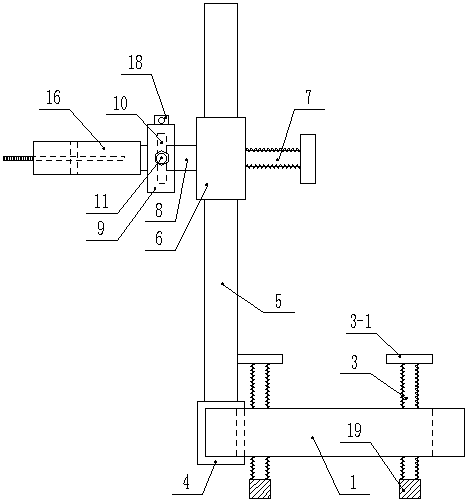

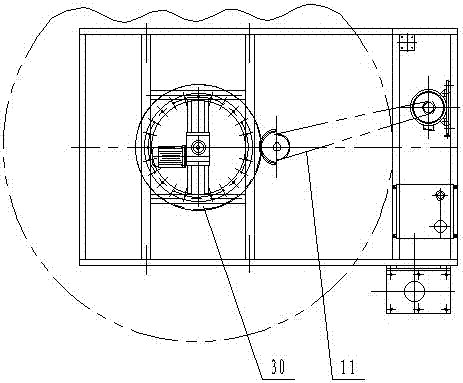

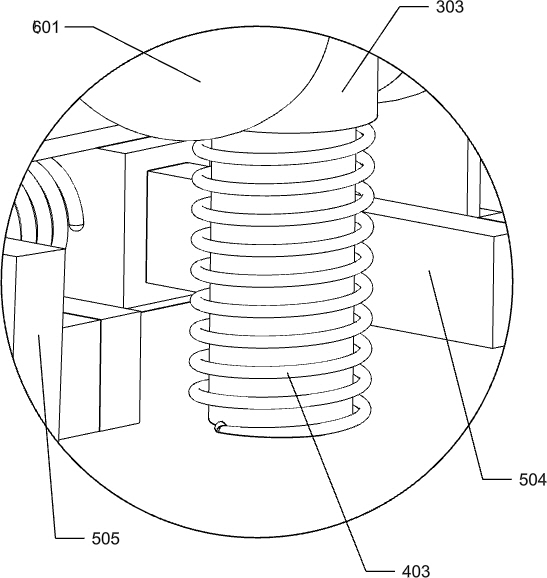

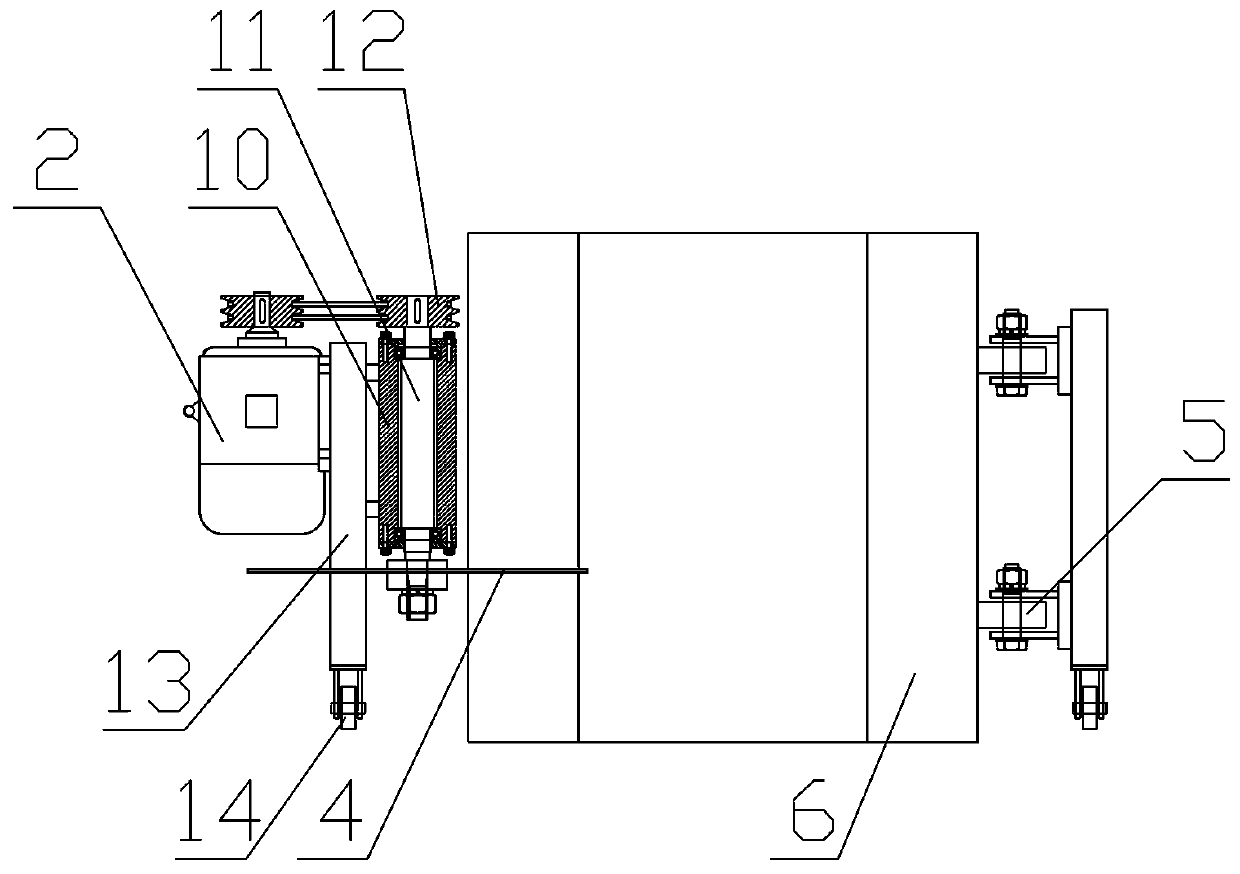

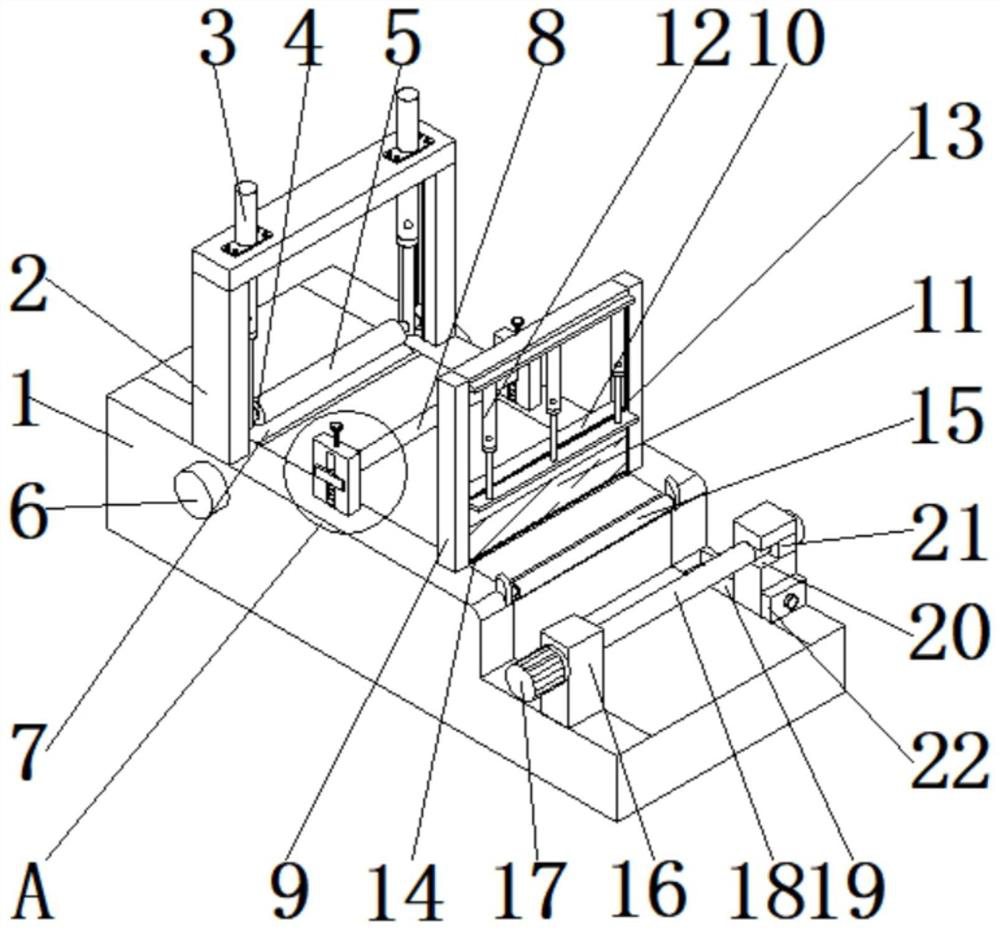

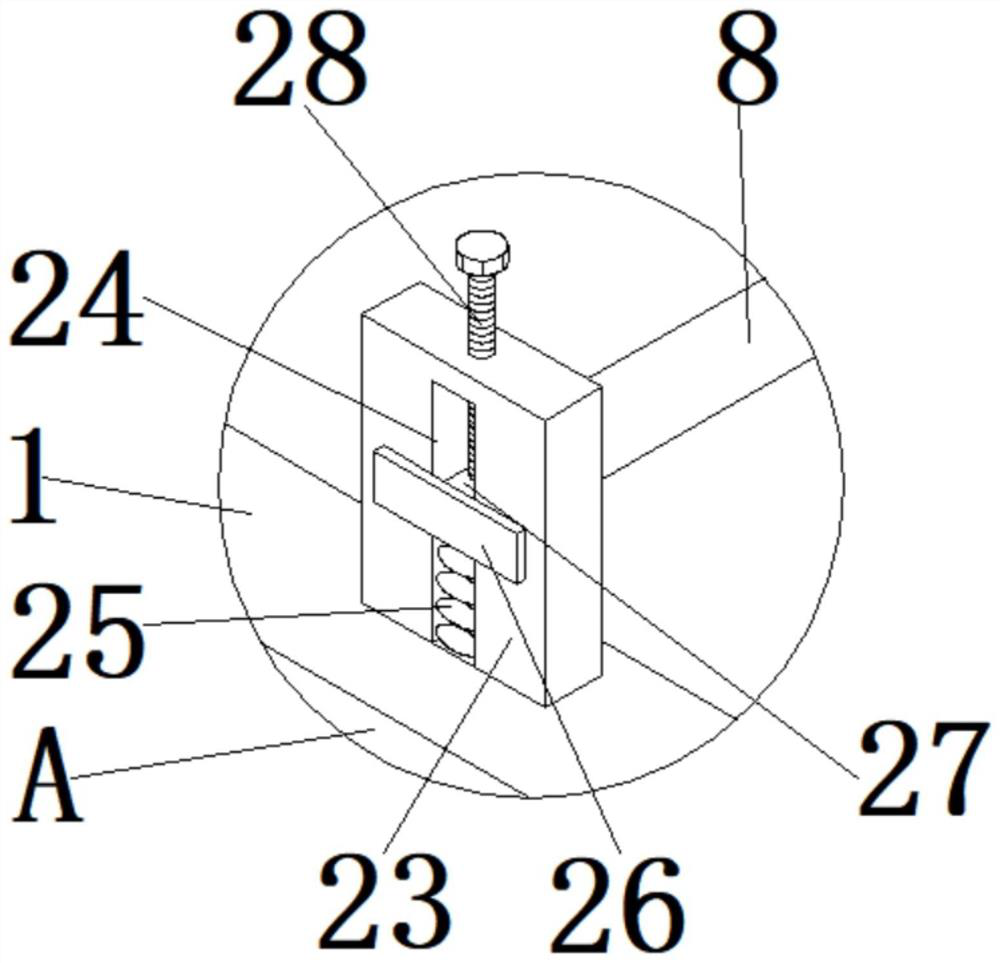

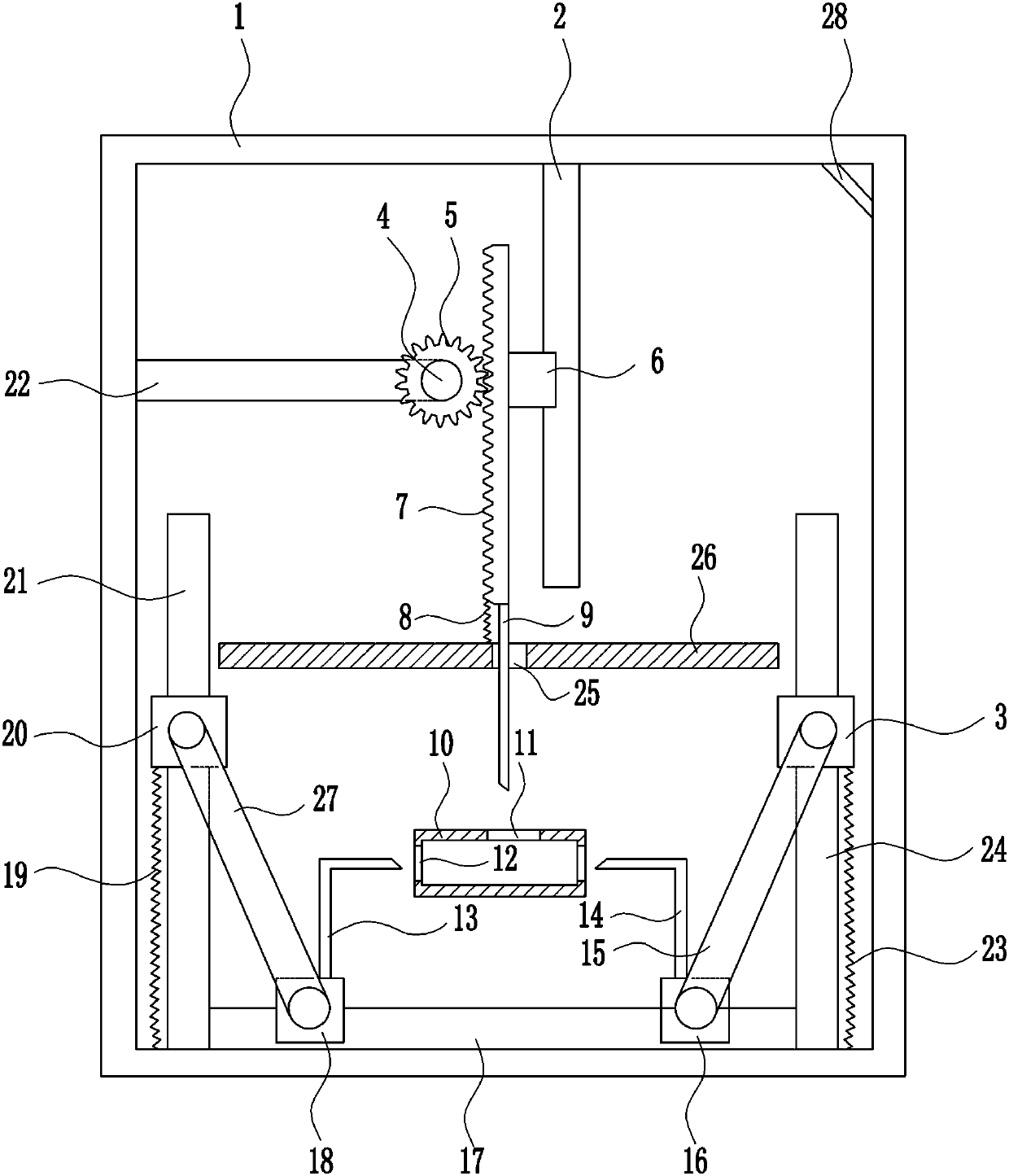

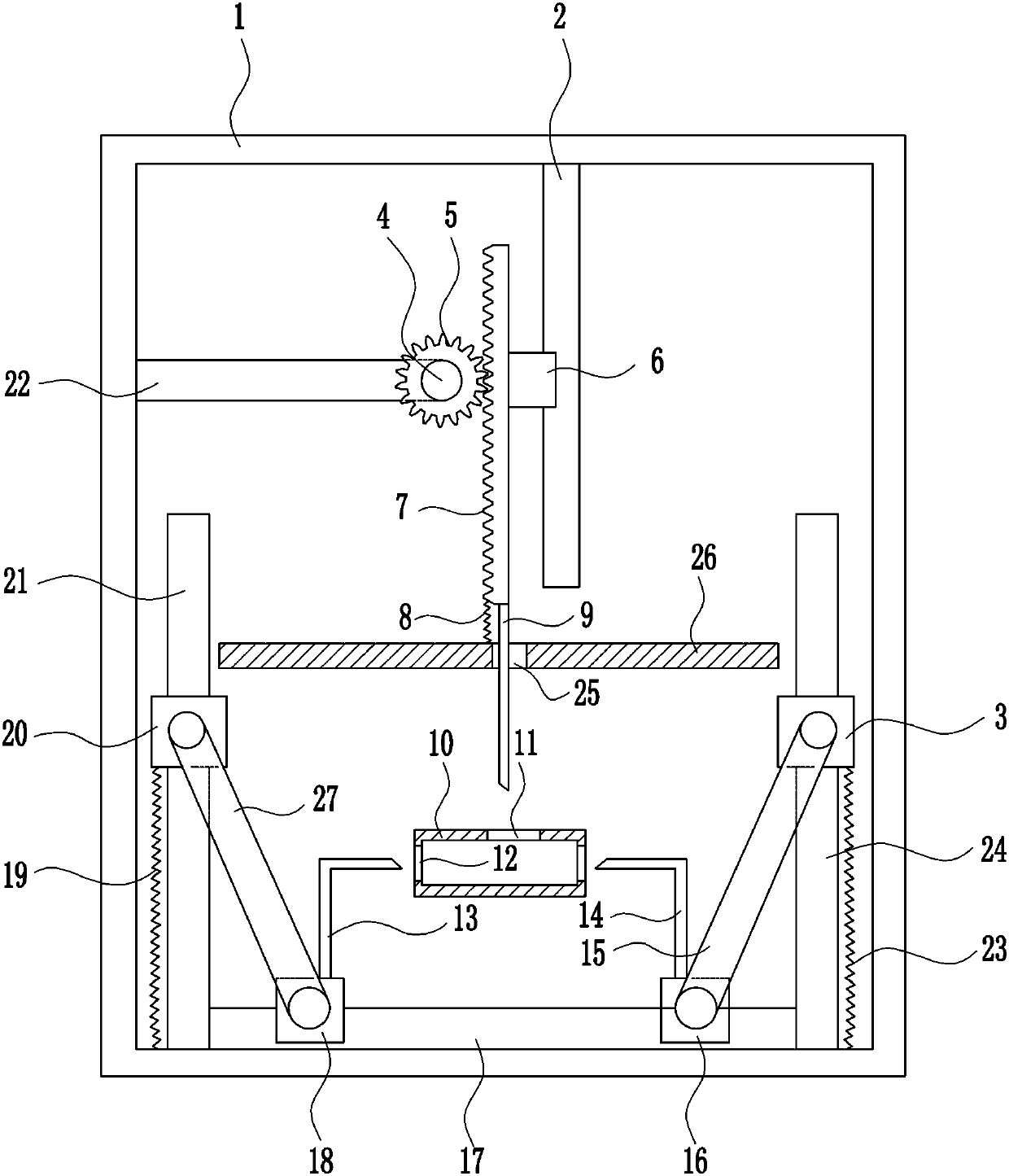

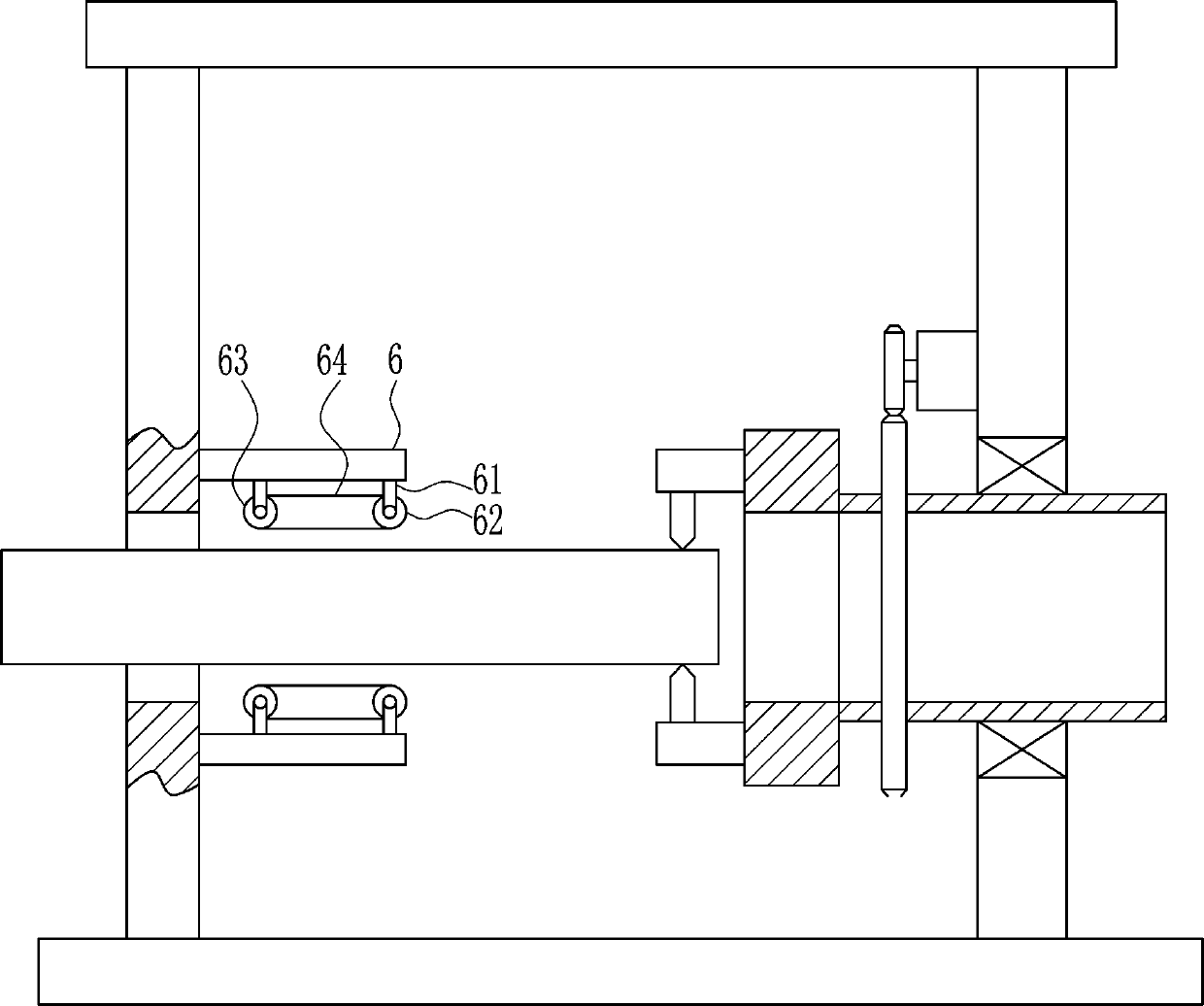

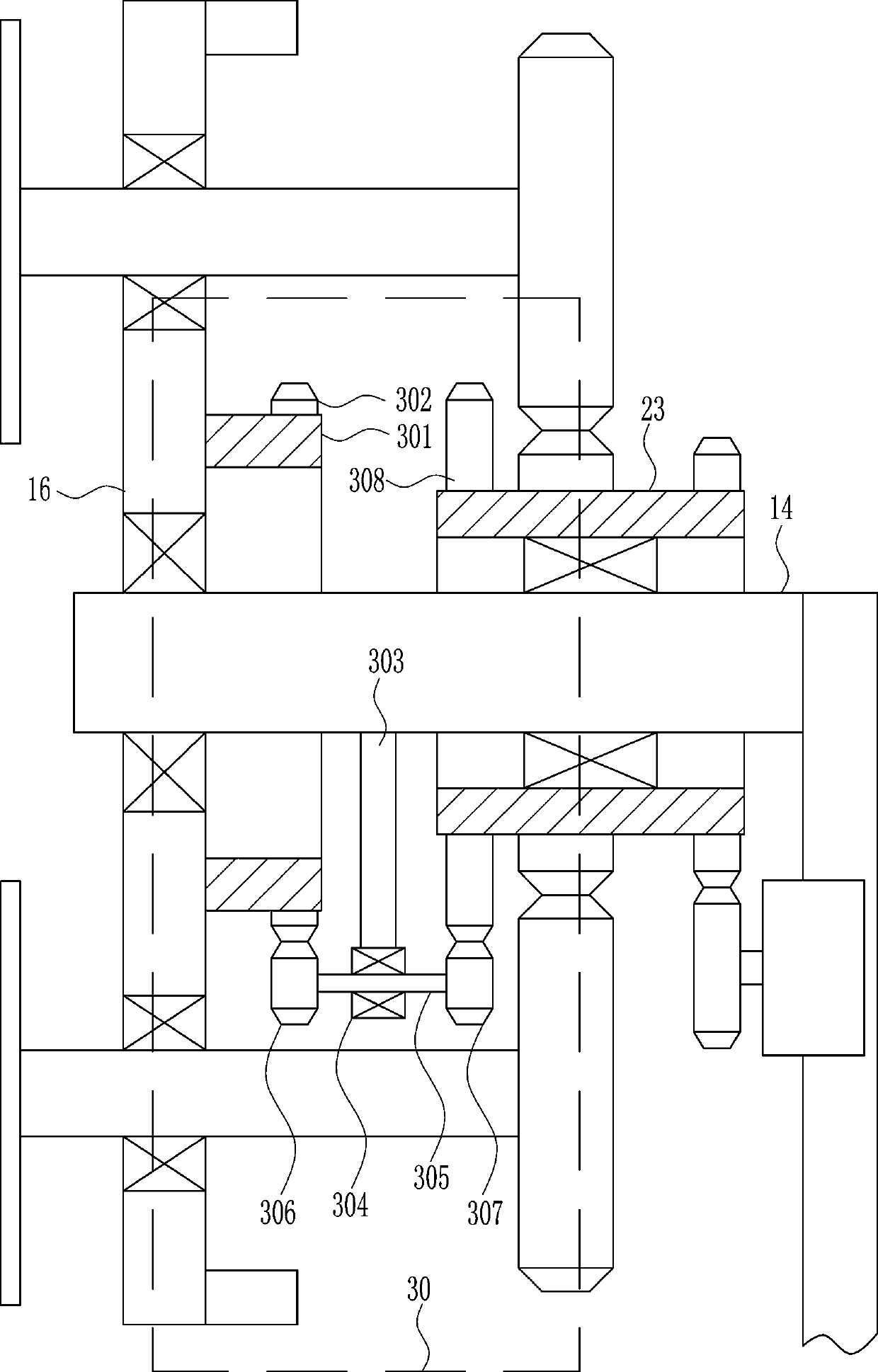

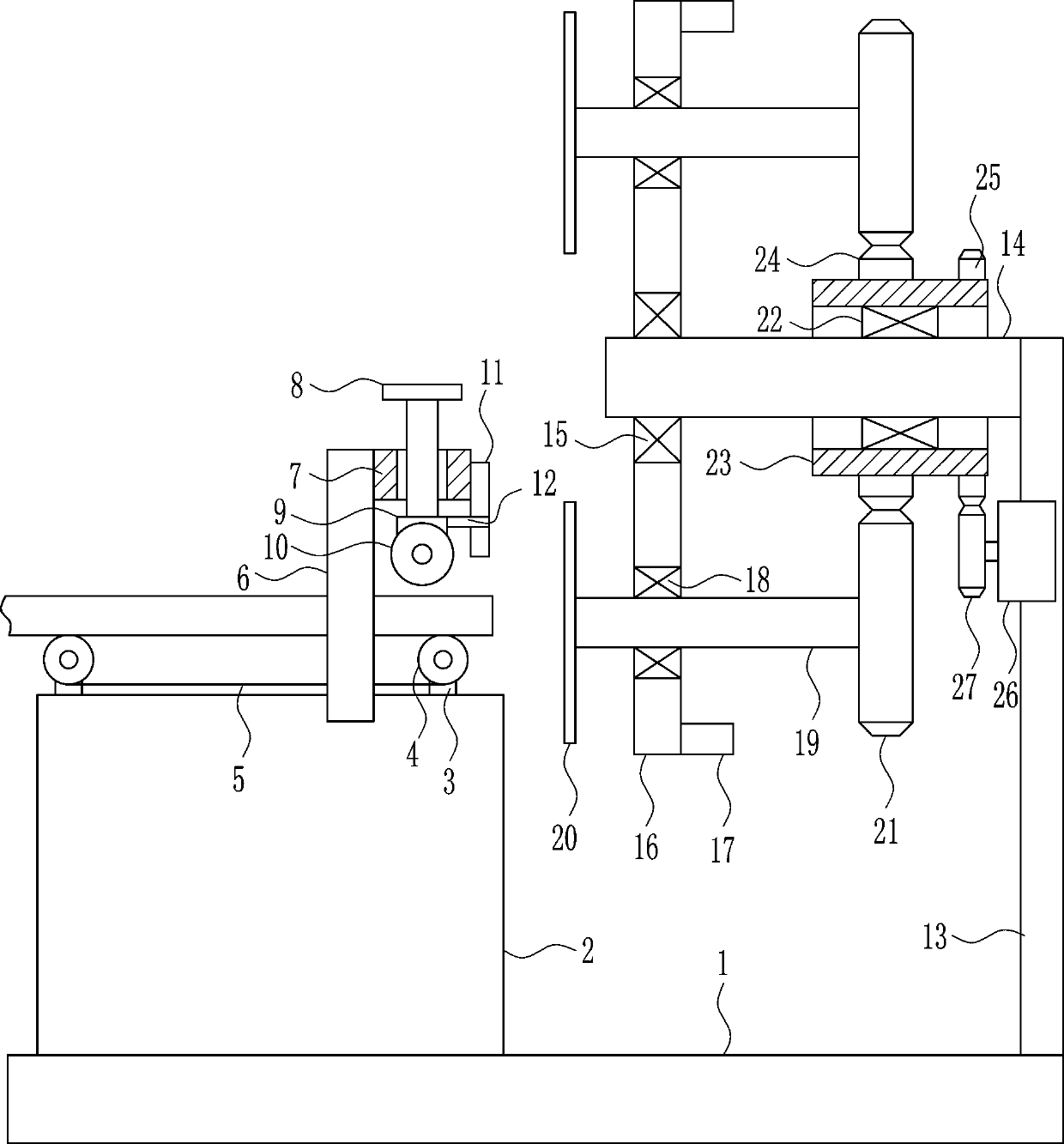

Large diameter steel pipe cutting equipment for industry

ActiveCN107042331AReduce cutting errorsCutting saves time and effortTube shearing machinesShearing machine accessoriesCivil engineering

The invention relates to steel pipe cutting equipment, in particular to large diameter steel pipe cutting equipment for industry. According to the large diameter steel pipe cutting equipment for the industry, the cutting error is small, the cutting process saves time and labor, and the cutting process is simple and rapid. The large diameter steel pipe cutting equipment for the industry comprises a bottom plate, a fixing table, a placing plate, a pressing plate, a first sliding rail, a first sliding block, a first nut, a first screw rod, a supporting plate, a first bearing seat, a rotary rod and the like; the fixing table is mounted on the left side of the bottom plate in a welding mode; and the placing plate is mounted on the lower portion inside the fixing table in a welding mode. According to the large diameter steel pipe cutting equipment, the effects that the cutting error is small, the cutting process saves time and labor, and the cutting process is simple and rapid are achieved, through the mode that annular cutting is conducted on the upper portion of the steel pipe, a small cutting knife can be used to cut the steel pipe to save cost, and the cutting quality can be guaranteed.

Owner:WUXI HUADI MACHINERY EQUIP

Efficient cable cutting device for industry

InactiveCN106077372AReduce weightImprove stabilityCleaning using gasesEngineeringMechanical engineering

The invention relates to a cutting device, in particular to an efficient cable cutting device for the industry and aims at achieving the technical purpose of providing the efficient cable cutting device for the industry, wherein the efficient cable cutting device for the industry is high in cutting efficiency. To achieve the above technical purpose, the efficient cable cutting device for the industry is provided and comprises a support, a cylinder, a first piston, thumb air cylinders, a cutting knife, a fifth connecting rod, a third connecting rod, a first connecting rod, a second connecting rod, a rotation motor and the like; the first piston and a second piston are arranged in the cylinder, the first piston is located on the left side of the second piston, and the first piston and the second piston are both matched with the inner wall of the cylinder; and through holes are formed in the left wall and the right wall on the right side of the cylinder, and the thumb air cylinders are symmetrically arranged on the left side and the right side of the top of the first piston. The efficient cable cutting device has the beneficial effect that the problems that during manual cable cutting, time and labor are wasted, efficiency is low, cutting is not smooth, and potential safety hazards exist are solved.

Owner:鄂星峄

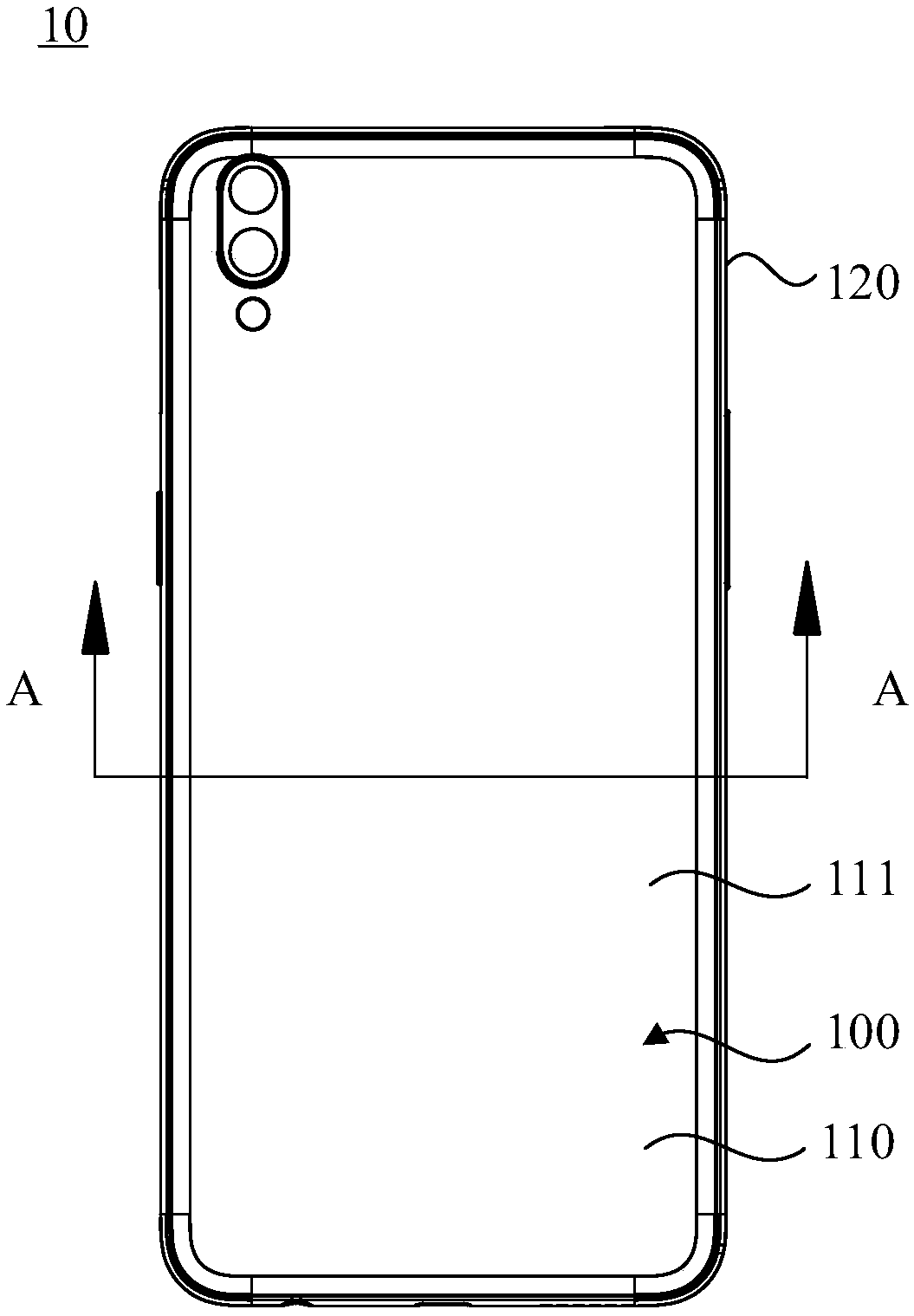

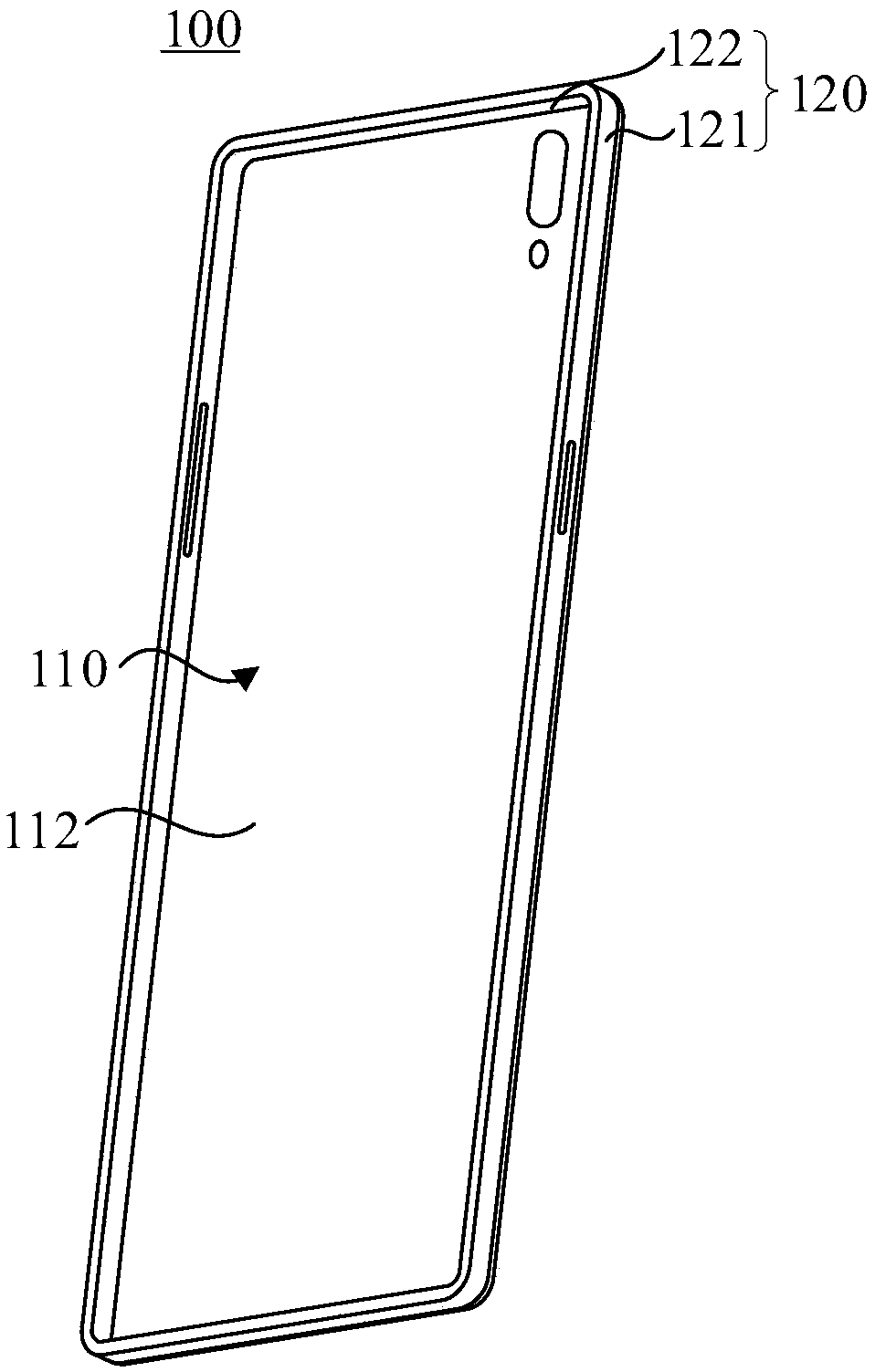

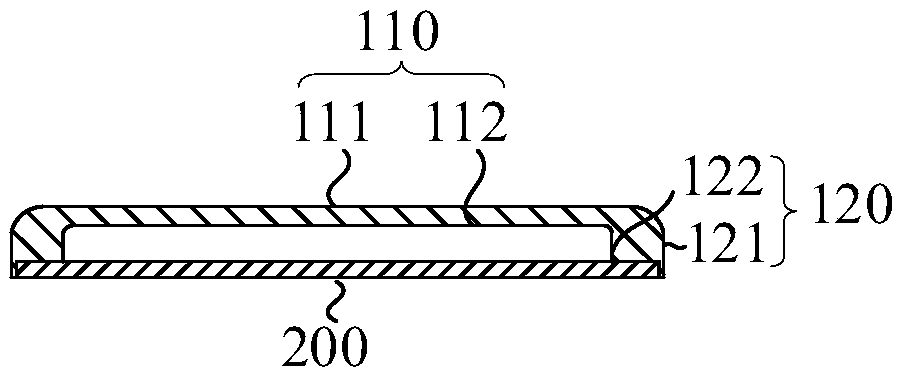

Shell, electronic device and manufacture method of shell

InactiveCN108712531AReduce manufacturing difficultyReduce manufacturing costGlass reforming apparatusTelephone set constructionsEngineeringMotherboard

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Novel industrial glass pipe cutting device

ActiveCN106746566AAchieve reductionHighly corrosiveGlass severing apparatusEngineeringBolt connection

The invention relates to a glass cutting device, in particular to a novel industrial glass pipe cutting device. The invention aims to solve the technical problem so as to provide the novel industrial glass pipe cutting device, which has less possibilities on damaging glass pipes and hurting workers or equipment when being used for cutting the glass pipes, and is time and labor saving during a cutting process. In order to solve the technical problem, the invention provides the novel industrial glass pipe cutting device, which comprises a bottom plate and the like, wherein a left support plate is arranged at the left side above the bottom plate in a welding way; a right support plate is arranged at the right side above the bottom plate in a welding way; a top plate is arranged on the upper ends of the left support plate and the right support plate through a welding way; a through hole is formed in the lower side of the left support plate; fixing plates are symmetrically arranged at the right side of the left support plate through a bolt connection way. The novel industrial glass pipe cutting device provided by the invention achieves the effects that the possibilities on damaging the glass pipes and hurting the workers or the equipment when being used for cutting the glass pipes are less, and the time and the labor are saved during the cutting process.

Owner:临泉县蓝天钢化玻璃有限公司

Elaborate picture clipping device for home furnishing

Owner:平邑经发科技服务有限公司

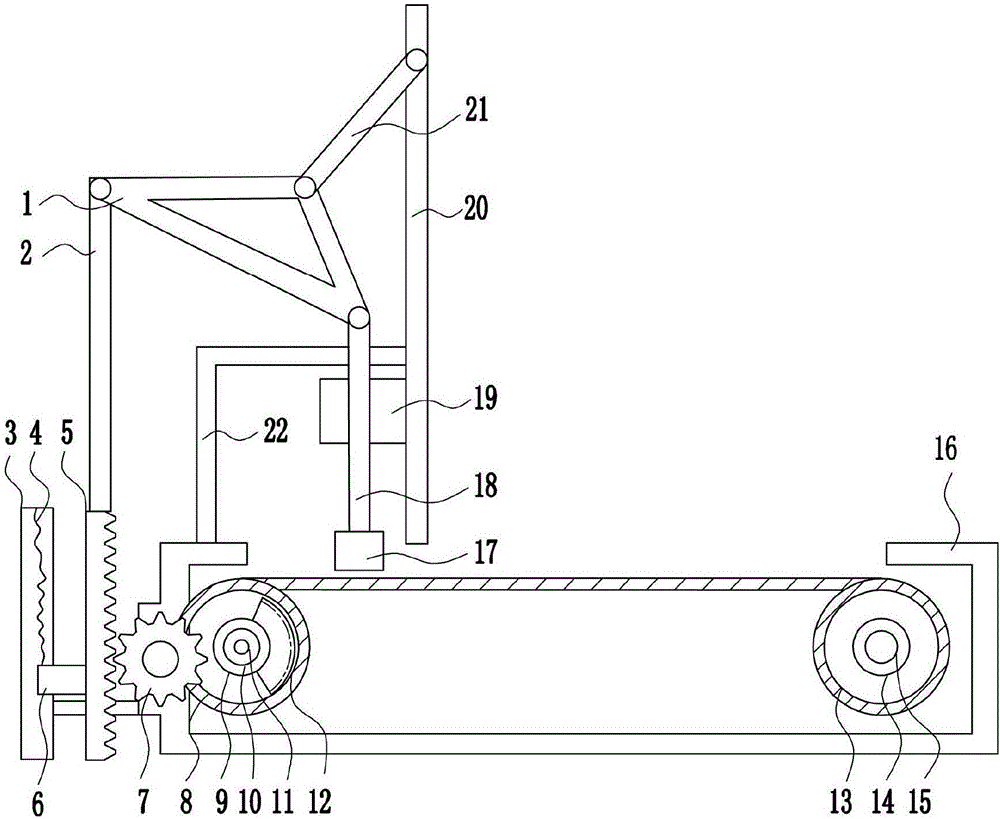

Aluminum foil fixed width cutting device for pharmaceutical packaging

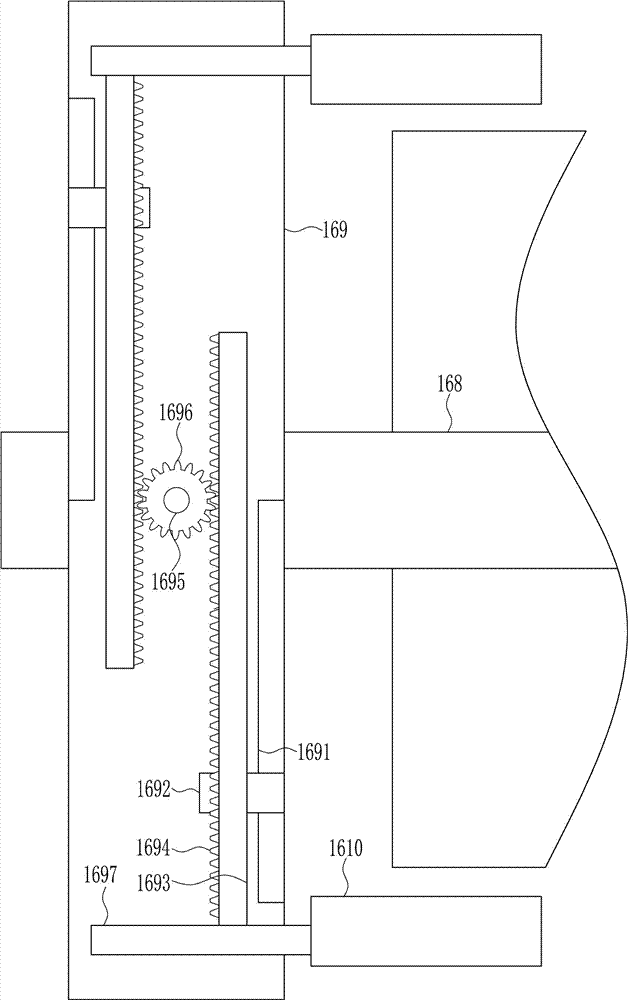

InactiveCN106584546APlay the role of reinforcementImprove securityMetal working apparatusInterference fitCoupling

The invention relates to a cutting device, in particular to an aluminum foil fixed width cutting device for pharmaceutical packaging. The technical problem to be solved is to provide an aluminum foil fixed width cutting device which is used for pharmaceutical packaging and is capable of controlling the cutting width conveniently and small in cutting friction. To solve the technical problem, the aluminum foil fixed width cutting device for pharmaceutical packaging comprises a tripod, a first connecting rod, a sliding rail, a first spring, a rack, a sliding block, a first gear, a sector gear, a gear motor, a first rotary rod, a first roller and the like. An output shaft of the gear motor is connected with the first rotary rod through a coupling, the first rotary rod is in interference fit connection with the sector gear and the first roller sequentially from front to rear. The aluminum foil fixed width cutting device achieves the effects that the cutting precision is high, the cutting width can be controlled flexibly and the time and labor are saved during cutting when the aluminum foil fixed width cutting work is conducted

Owner:广州市必盈体育有限责任公司 +1

Branch cutting device for gardens

InactiveCN106879387AHighly corrosiveStrong acid resistanceCuttersMotor driven pruning sawsCouplingEngineering

The invention relates to garden equipment, in particular to a branch cutting device for gardens. The branch cutting device for gardens achieves the technical purposes that during cutting, risks are small, time and labor are saved in the cutting process, and branches can be cut comprehensively. In order to achieve the technical purposes, the branch cutting device for gardens comprises a base plate, a guide rail, a guide sleeve, a first motor, a first gear, a first rack, a lifting rod and the like. The guide rail is installed on the upper side of the base plate in a welding mode, the guide sleeve is connected to the guide rail in a sliding mode, the first motor is installed on the right side inside the guide sleeve in a bolt connection mode, and a first motor output shaft of the front side of the first motor is connected with a first gear through a coupler. The branch cutting device achieves the effects that during cutting, risks are small, time and labor are saved in the cutting process, and the branches can be comprehensively cut.

Owner:刘宇航

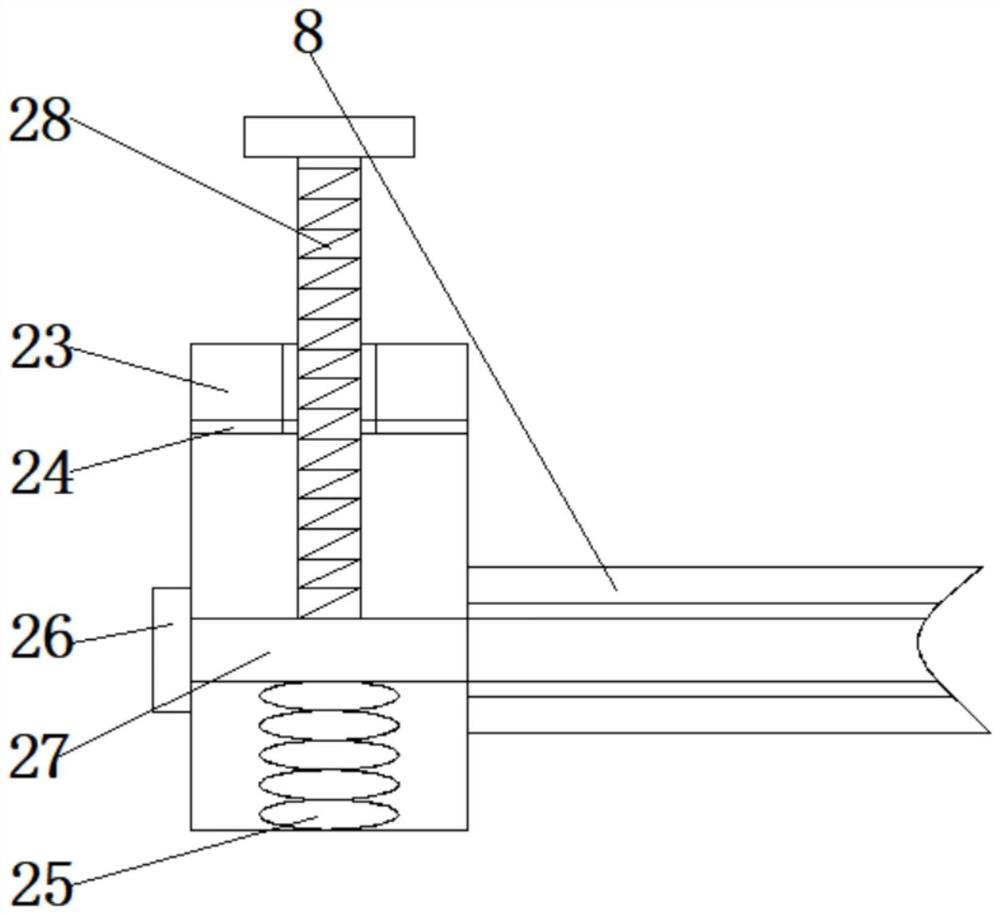

Water-electricity grooving machine auxiliary device

The invention discloses an auxiliary device for a hydroelectric slotting machine, comprising vertical rods, horizontal rods are fixed between the vertical rods, threaded rods are threaded on the vertical rods, handles are fixed on the upper ends of the threaded rods, fixed blocks are fixed on the lower ends, and the horizontal rods There is a sleeve A on the upper sleeve, a support rod is fixed on the sleeve A, and a sleeve B is sleeved on the support rod. Connecting rod, the disc is fixed on the connecting rod, there is a horizontal plate on the disc, the disc is connected in rotation in the horizontal plate, the side end of the horizontal plate is threaded with the bolt B, the horizontal plate is provided with a through groove, and inserted into the through groove There is a slide bar, one end of the slide bar is fixed with a baffle plate, and the other end is fixed with a hydroelectric slotting machine, the baffle plate is threadedly connected with a bolt C, a level measuring device is installed on the sleeve A, and a laser transmitter is installed on the horizontal plate. The device can perform horizontal cutting, vertical cutting and oblique cutting, which is convenient and fast, saves time and effort, and at the same time plays the role of support and reinforcement.

Owner:南京苏格信息技术有限公司

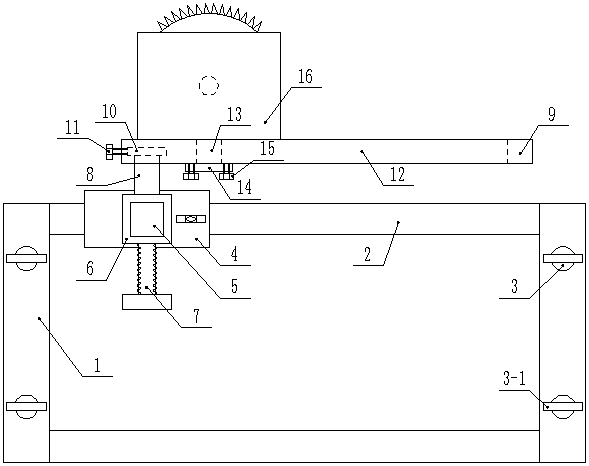

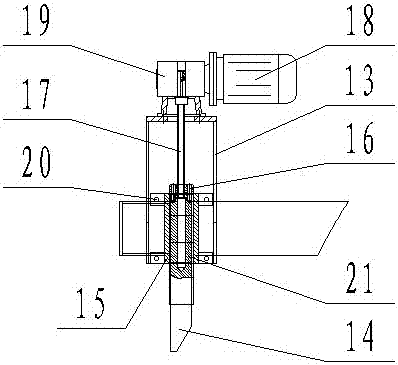

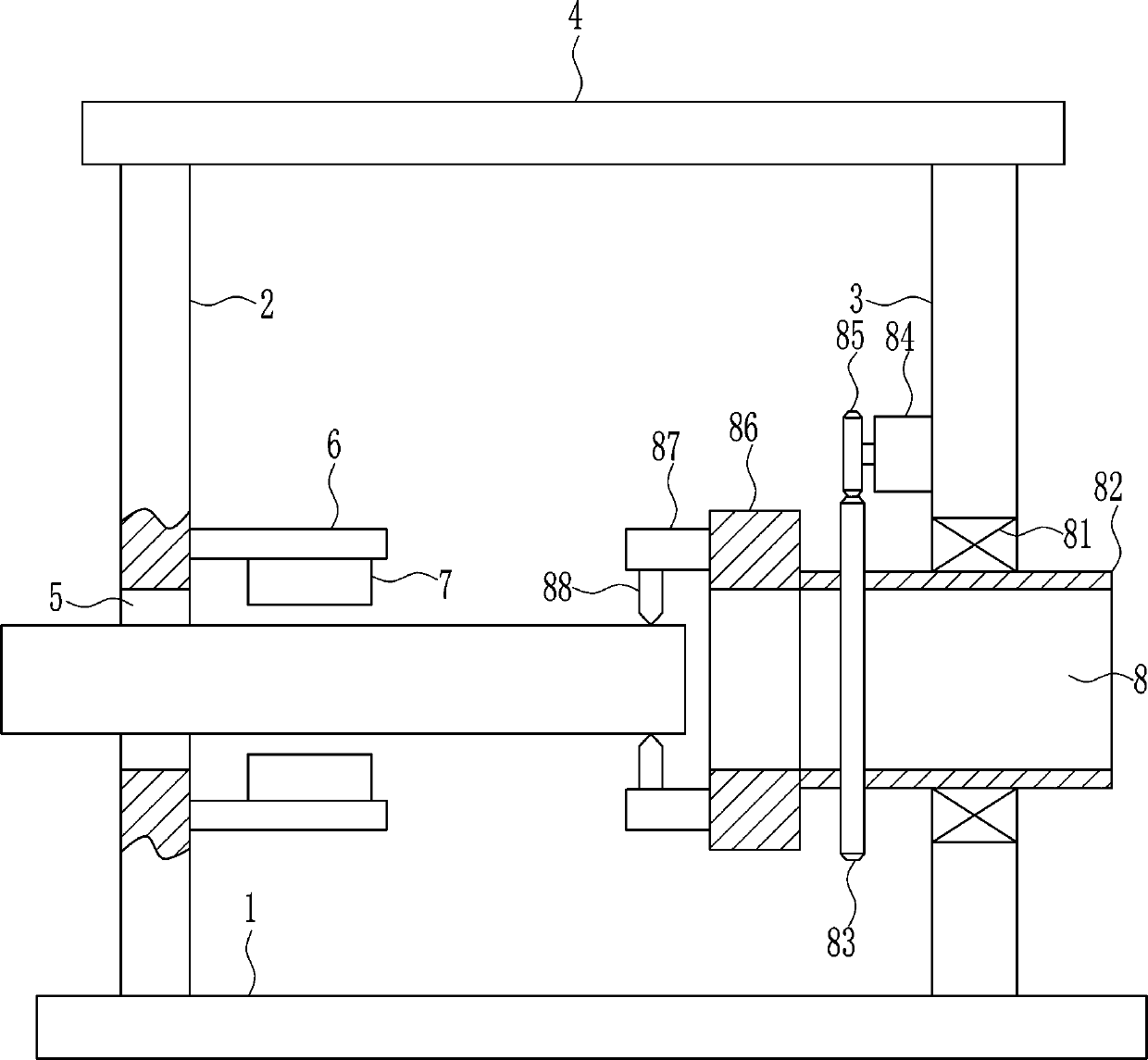

Engineering tire sidewall cutting machine

PendingCN108000753AReasonable designEasy to usePlastic recyclingMetal working apparatusEngineeringAutomation

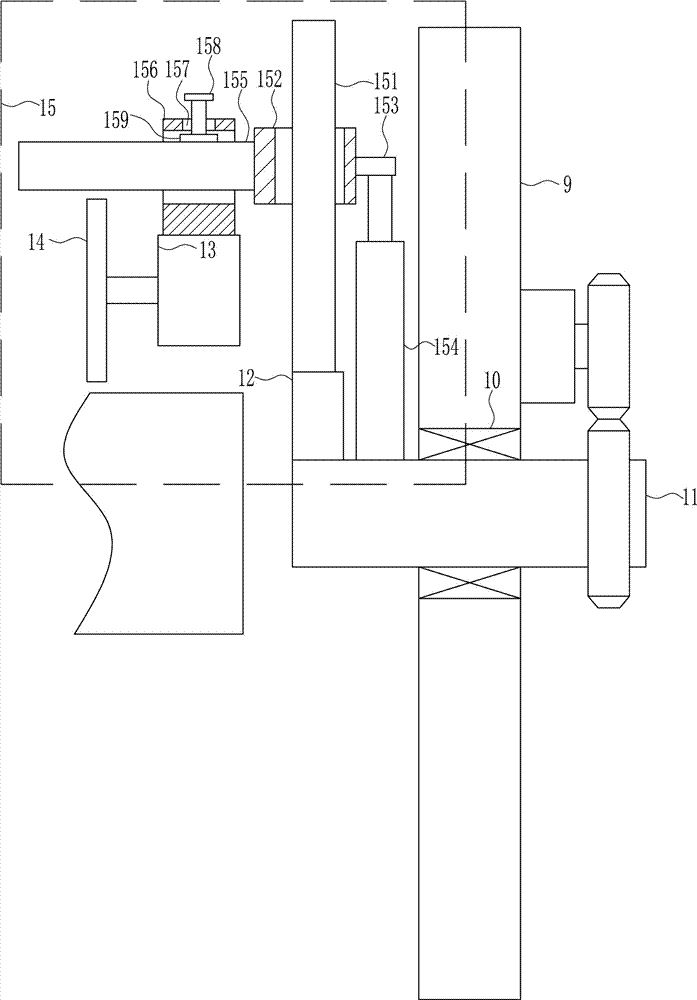

The invention discloses an engineering tire sidewall cutting machine which comprises a base, an inner upright column, an outer upright column, a horizontal connecting arm and a tire cutting mechanism;the tire cutting mechanism comprises a vertical cutting tool mechanism, a rotating platform, a rotary support, a rotary support power system, a tensioning mechanism and a tensioning mechanism power system; the vertical cutting tool mechanism is connected with the horizontal connecting arm; one seat ring of the rotary support is connected with the rotating platform; the rotary support power systemdrives the seat ring to rotate; the other seat ring of the rotary support is fixedly connected with the base through a strut; the tensioning mechanism is arranged on the upper surface of the rotatingplatform; the tensioning mechanism power system drives the tensioning mechanism to support an inner ring of an engineering tire; and the vertical cutting tool mechanism is arranged at the end of thehorizontal connecting arm. The engineering tire sidewall cutting machine is reasonable in design, convenient in use, and high in automation degree, time and labor are saved during cutting, and the cutting efficiency is improved.

Owner:新乡市新宇田橡塑机械有限公司

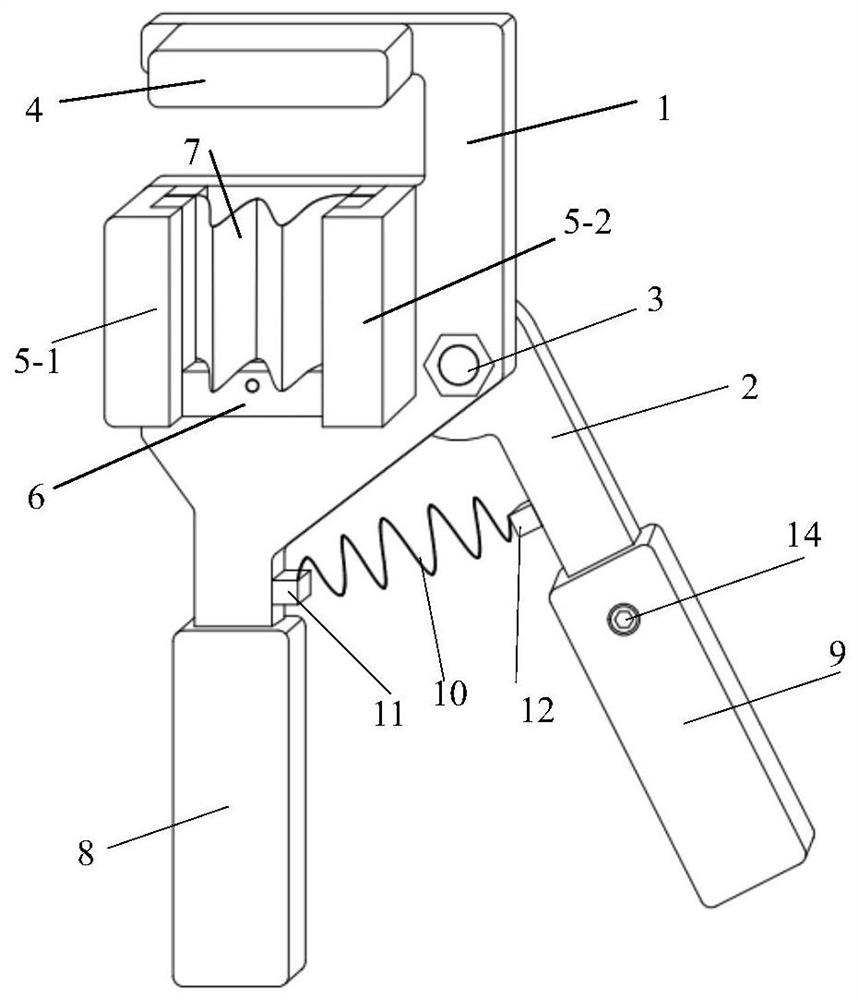

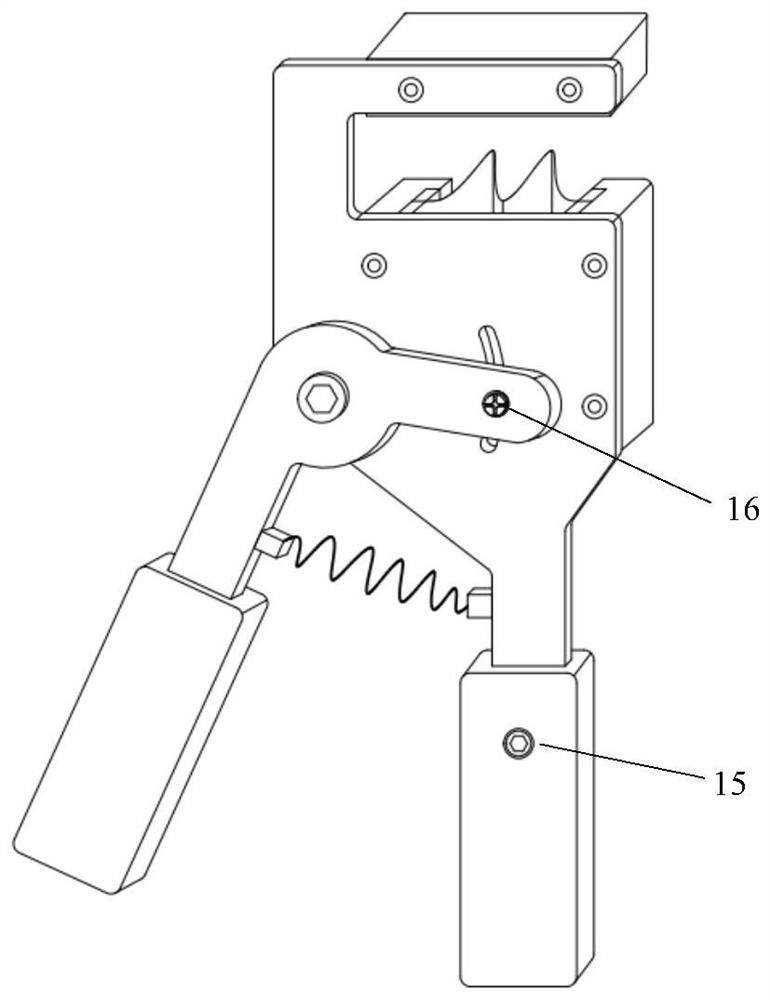

Fruit tree grafting method

The invention discloses a fruit tree grafting method. The method comprises the steps of scion collection, rootstock preparation, grafting cutting and management after grafting, and a grafting device is used for grafting cutting. Grafting cutting comprises the following steps that a first working arm of the grafting device is close to a rootstock, a notch at the front end of the first working arm stretches into a to-be-cut point of the rootstock, the first working arm and a second working arm which are hinged to each other are rotated, the second working arm drives an M-shaped grafting knife onthe first working arm to move forwards, the M-shaped grafting knife makes contact with a cushion table at the front end of the first working arm and is clamped, and therefore the rootstock is cut into an M-shaped knife edge; and a scion branch is cut into scion branch sections with inverted M-shaped knife edges by the same method. By means of the method, the thickness range of rootstock and scionselection can be effectively increased, and the scion supply amount of a single stock plant is increased; and in addition, the purpose of greatly improving the grafting survival rate can be achievedby improving the fitness between the stock and the scion.

Owner:苏州永乐种源科技有限公司

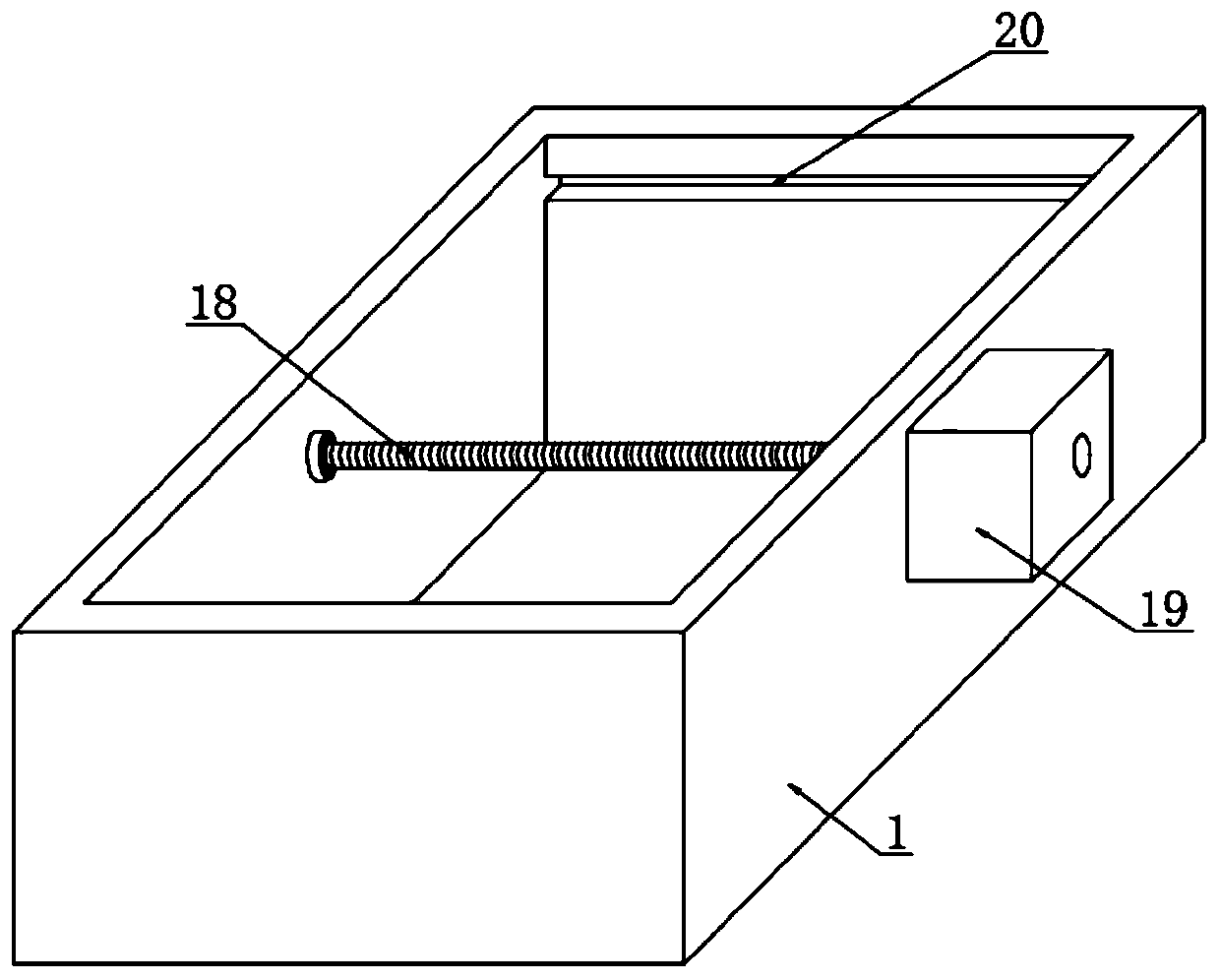

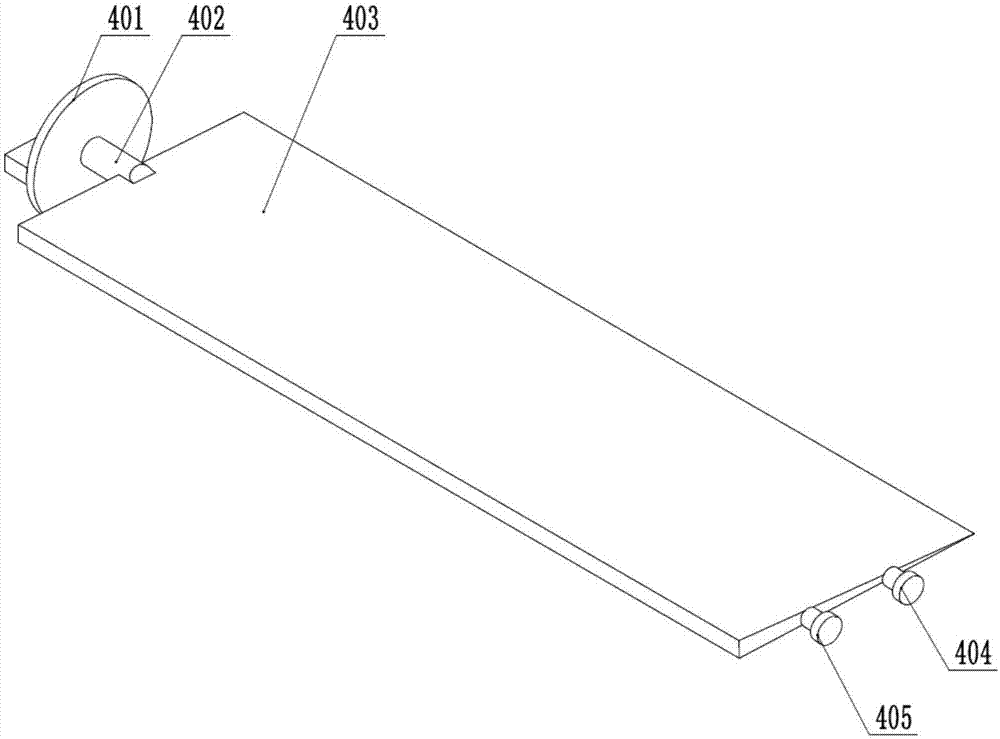

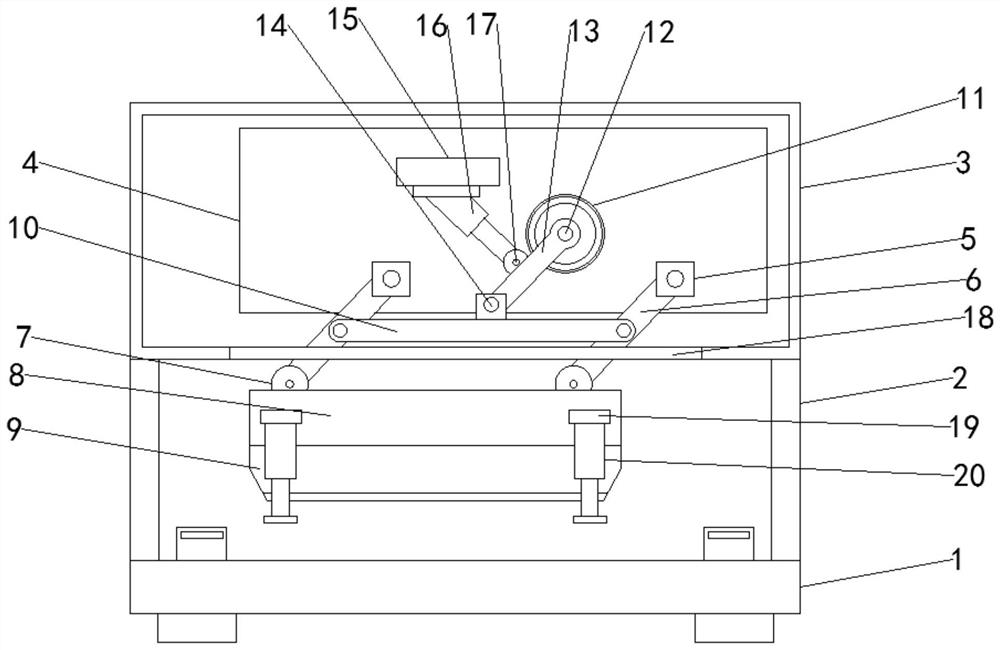

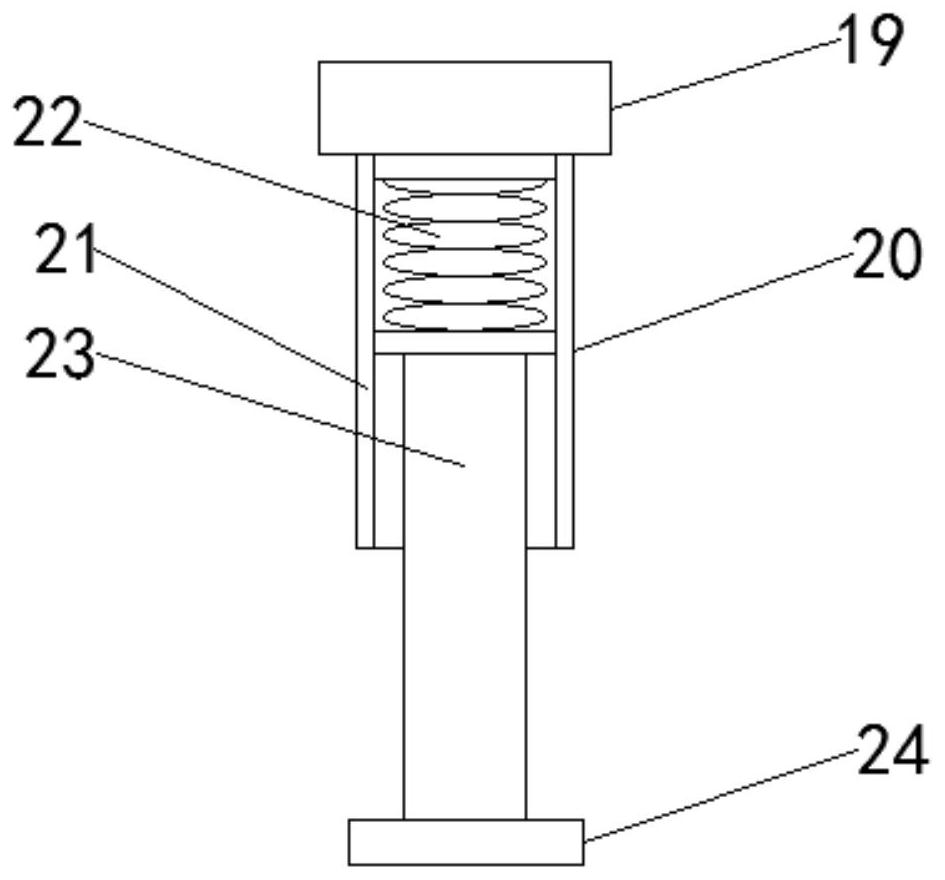

Gold foil dicing device

InactiveCN111993485ACutting saves time and effortImprove cutting efficiencyMetal working apparatusEngineeringKnife blades

The invention relates to a dicing device, in particular to a gold foil dicing device. According to the gold foil dicing device, workers do not need to frequently change gold foil cutting positions, one piece of gold foil can be cut into a plurality of square blocks through one-time reciprocating, and the workers do not need to manually clean redundant gold foil corners, so that the gold foil dicing efficiency is improved. According to the technical scheme, the gold foil dicing device comprises mounting frames, a placing plate and the like, wherein the placing plate is connected between the tops of the mounting frames. A buffer mechanism moves up and down through a swing mechanism to cut a gold foil on a sponge containing block body into blocks, so that time and labor are saved. A blade moves downwards to make contact with the gold foil through the buffer mechanism, so that the gold foil dicing efficiency is improved. Leftover materials on the sponge placing block body can be rapidly shifted outwards through a shifting mechanism, so that workers can clean the leftover materials conveniently.

Owner:王浩然

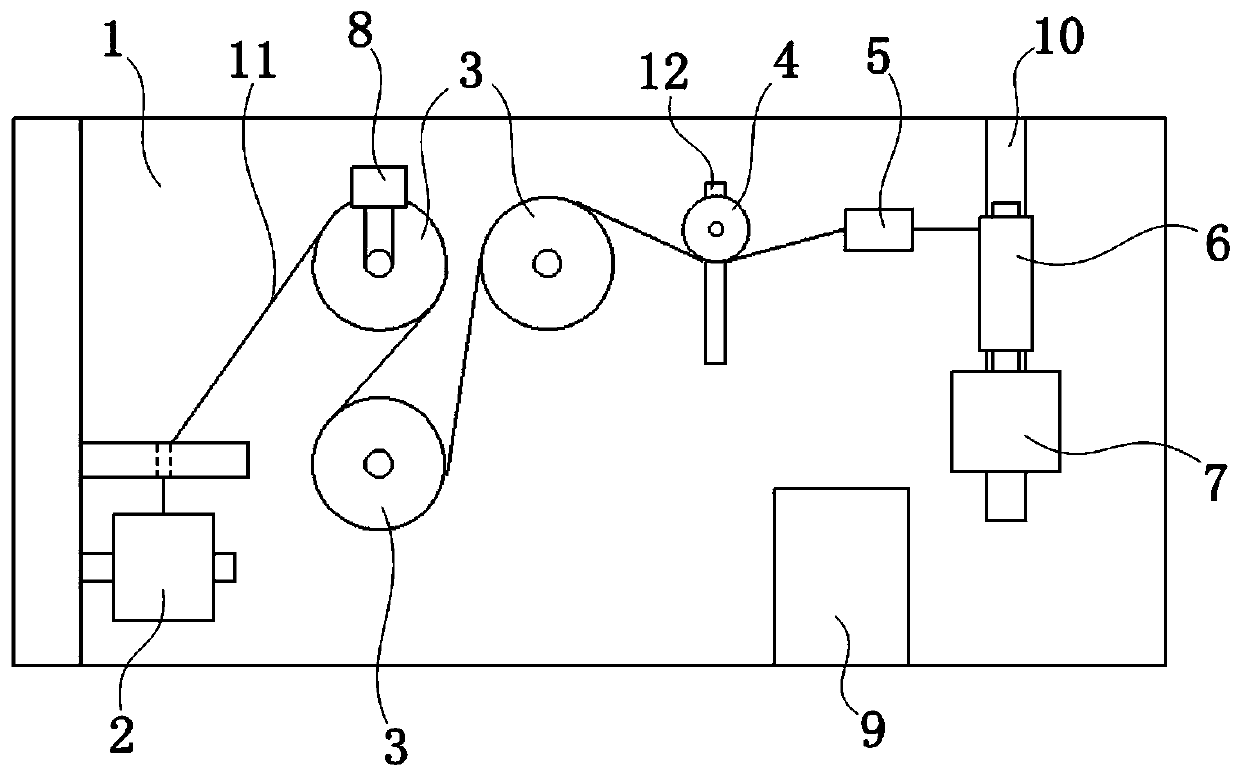

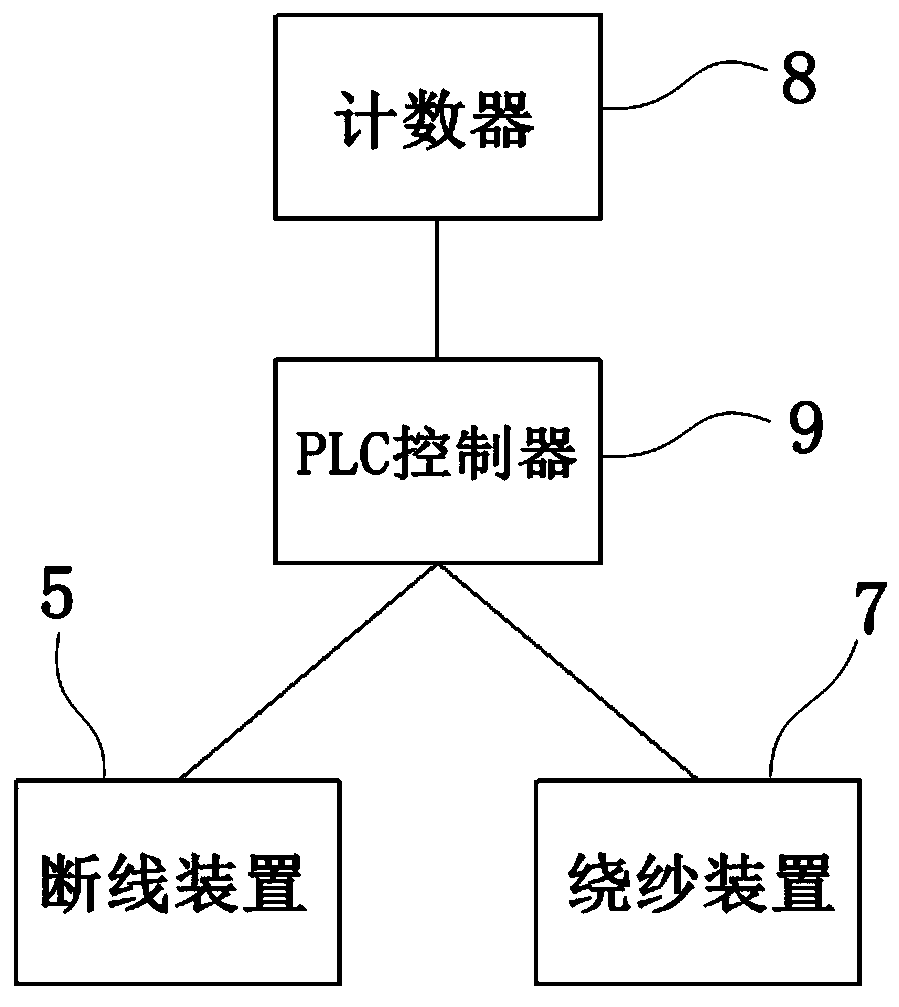

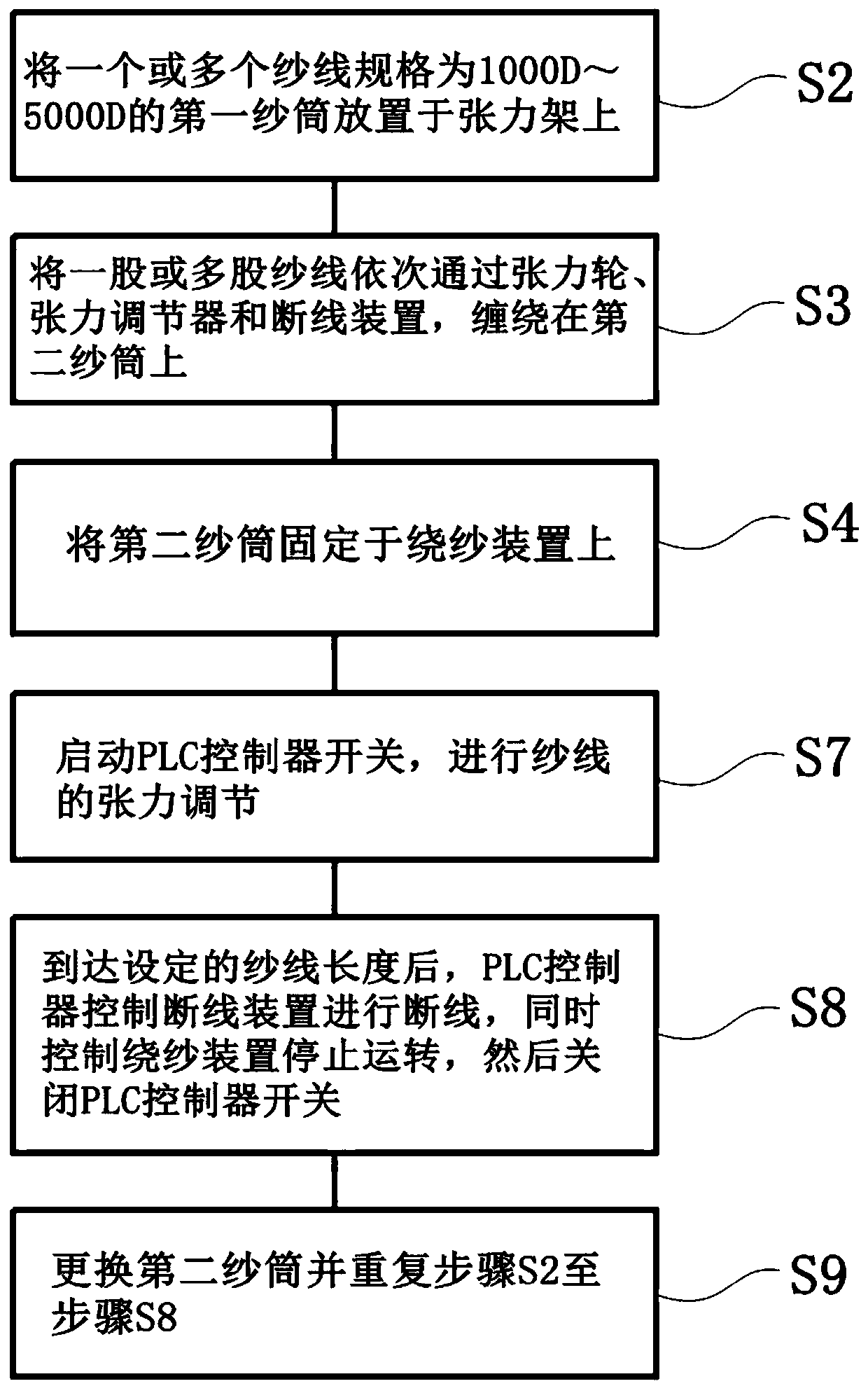

Yarn tension adjusting device and application method thereof

PendingCN110104489AEasy to operateHigh tension adjustment efficiencyWebs handlingEngineeringYarn tension

The invention provides a yarn tension adjusting device and an application method thereof. The adjusting device comprises a tension frame, a first spindle, a tension wheel, a tension adjuster, a yarn breaker and a yarn winder, wherein the tension frame is provided with an adjusting guide rail; the first spindle is arranged on the tension frame and is used for providing yarns to be treated; the tension wheel is fixed onto the tension frame through the cooperation of a shaft and a bearing and is used for balancing the tensile forces of the yarns; the tension adjuster is arranged on the adjustingguide rail and is used for adjusting a drawing force stressed on the yarns; the yarn breaker is arranged on the tension frame is used for shearing the yarns; the yarn winder is arranged on the tensionframe; and a second spindle is arranged on the yarn winder and is used for winding the yarns with the tensile forces being adjusted. The yarn tension adjusting device provided by the invention is high in automation degree, simple to operate, high in adjusting efficiency, and better adjusting effect compared with an existing tension adjusting device.

Owner:TAIAN ROPE NET PLASTIC +1

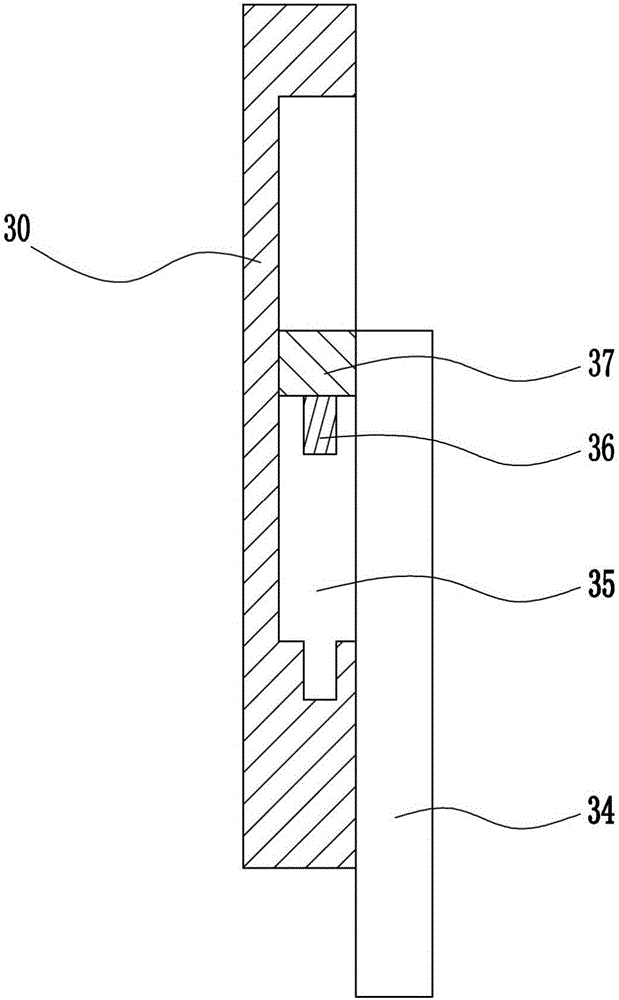

Medical cutting knife

The invention provides a medical cutting knife, which comprises a fixed body and a blade, wherein the blade is fixed on the fixed body and is extended out of the lower part of the fixed body. The medical cutting knife can reduce pollution in the process of preparing gelatin sponge particles, keep fresh of the gelatin sponge particles, shorten the oxidation time of the gelatin sponge particles in air, reduce the consumption of gelatin sponge, and save time and labor in cutting.

Owner:北京西贝利德科贸有限公司

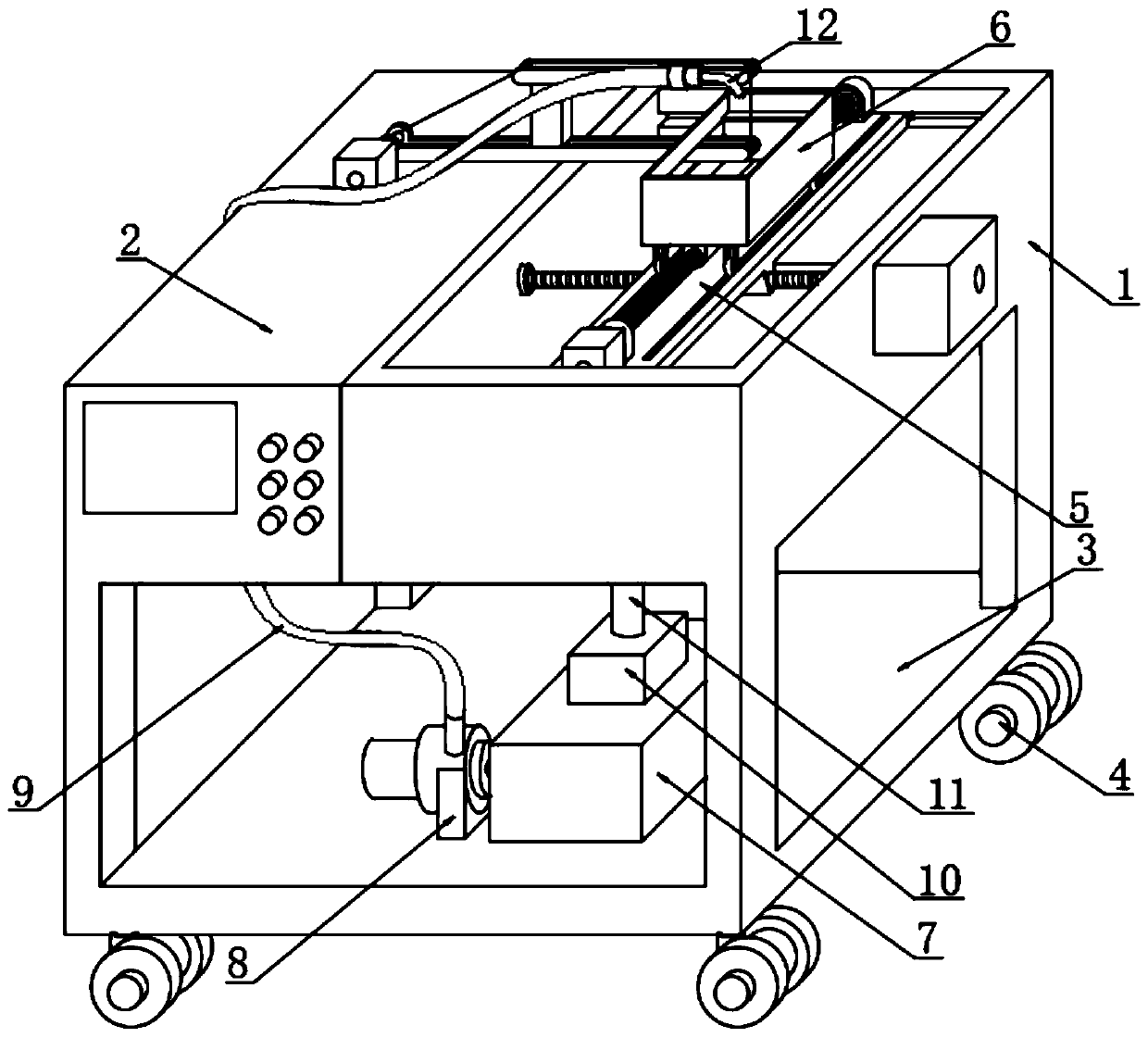

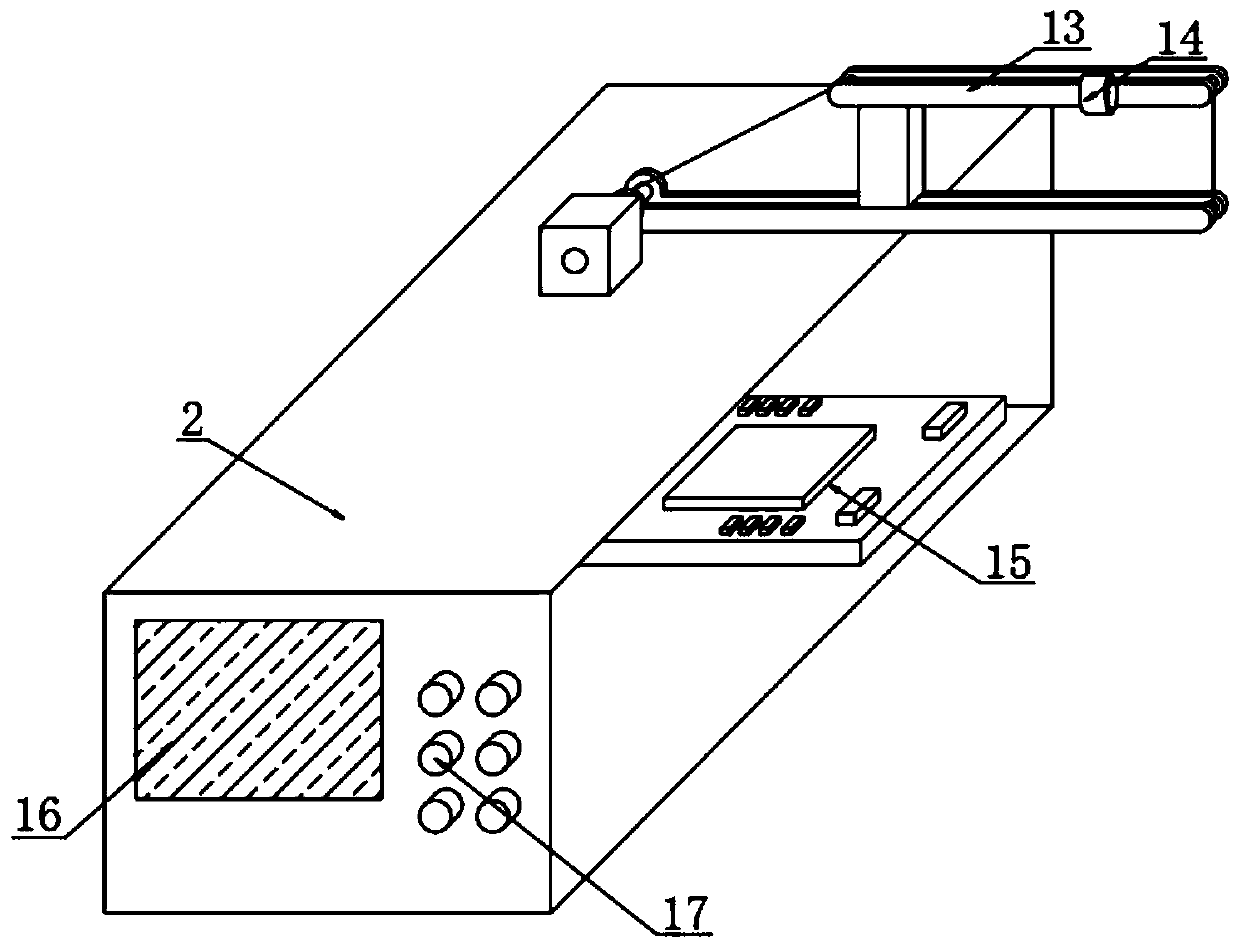

Wire cutting device based on mold processing

InactiveCN110860744AEasy to useImprove fluencyElectrical-based auxillary apparatusWire cuttingProcess engineering

The invention discloses a wire cutting device based on mold processing, and particularly relates to the technical field of mold processing. The wire cutting device includes a cutting box body, a control box body is welded to one side of the cutting box body, and a bottom plate is welded to the lower part of the cutting box body. Universal wheels are welded to one side of the lower surface of the bottom plate, a water tank is installed on one side of the upper surface of the bottom plate, a filter box is welded to the upper end of the water tank in a penetrating mode, and a waste liquid pipe iswelded to the upper surface of the filter box in a penetrating mode; and a water pump is installed on one side of the water tank in a penetrating mode, a liquid conveying pipe is connected to the upper end of the water pump in a penetrating mode, a nozzle is installed at one end of the liquid conveying pipe in a penetrating mode, a displacement assembly is slidably connected into the cutting boxbody, and a water blocking plate is slidably connected to the upper surface of the displacement assembly. The wire cutting device based on the mold processing is provided with a coolant circulating device, is electrically adjusted, is small in size, and is provided with the universal wheels, and pulleys are arranged at the sliding connection positions.

Owner:嘉兴德衡智能装备有限公司

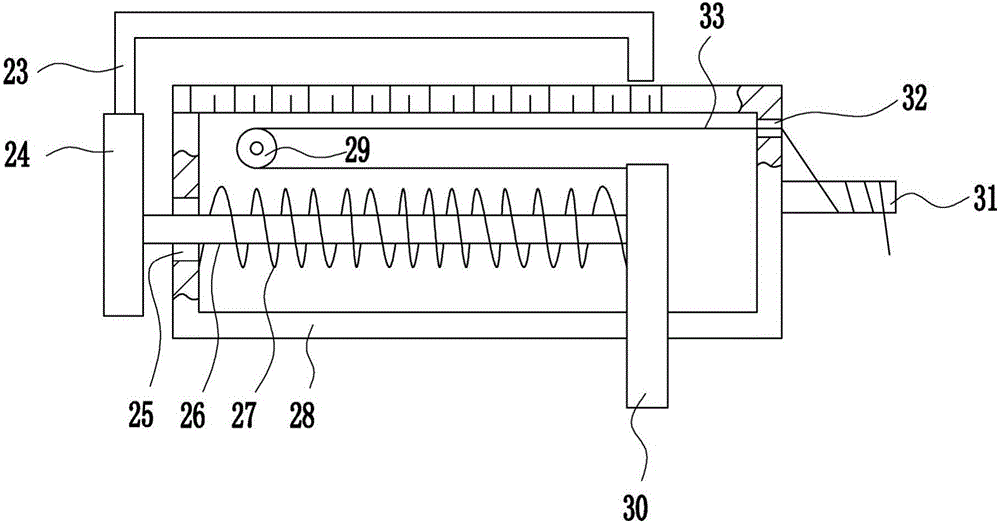

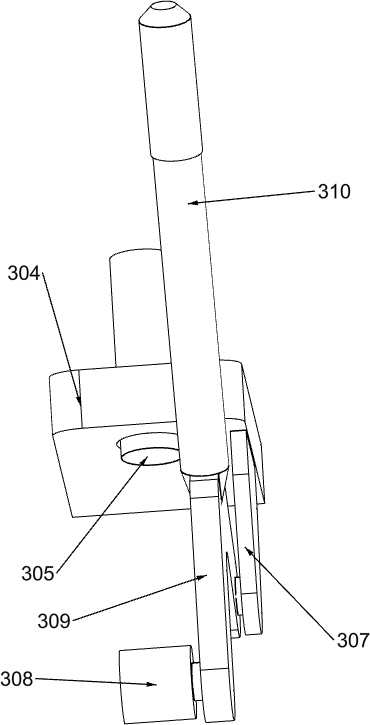

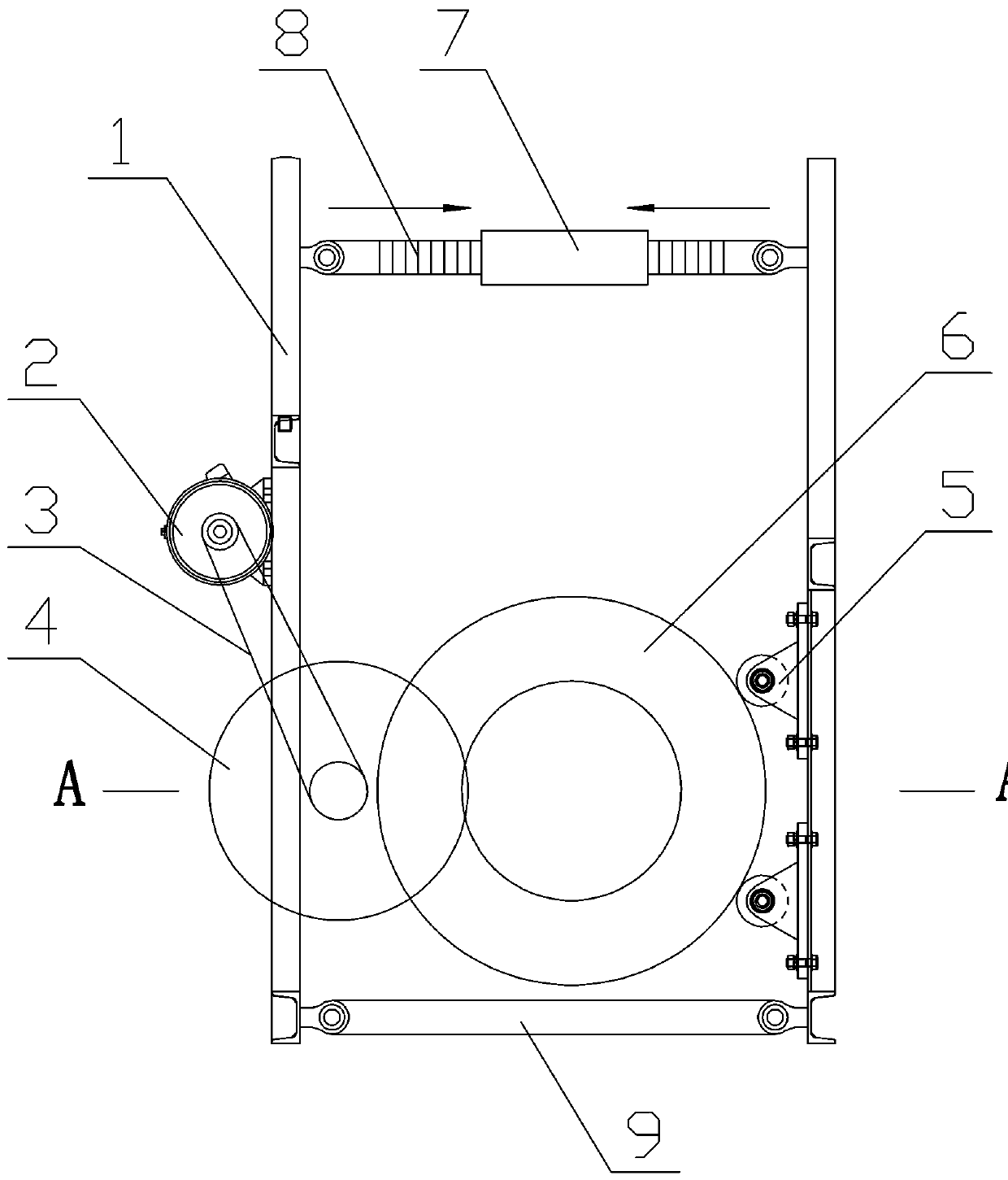

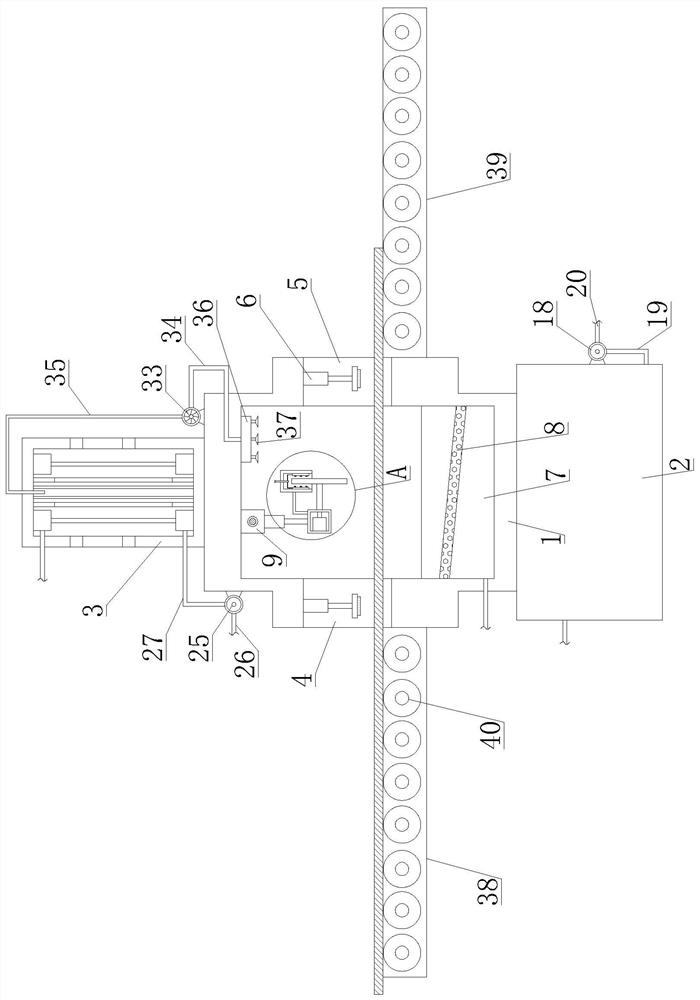

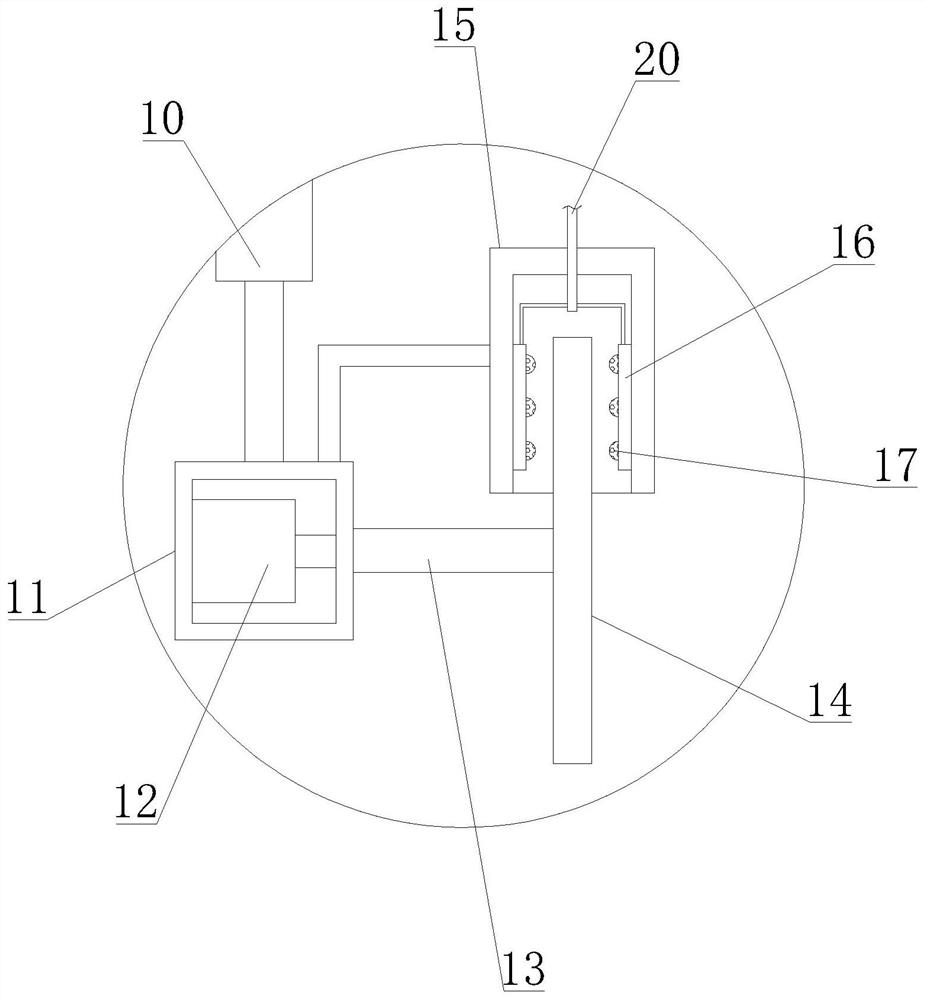

Automatic cutting device for pre-stressed high-strength concrete (PHC) tubular piles

InactiveCN111216253AEasy to adjustNovel structural designStone-like material working toolsTransmission beltClassical mechanics

The invention relates to an automatic cutting device for pre-stressed high-strength concrete (PHC) tubular piles. The automatic cutting device has a transverse connecting rod, wherein the two ends ofthe transverse connecting rod are respectively hinged with a longitudinal cutting rod, the front ends of the longitudinal cutting rods are hinged to the transverse connecting rod, the bottom of each longitudinal cutting rod is provided with two supporting legs vertically downward, and universal wheels are installed at the bottoms of the supporting legs; the supporting legs below one of the longitudinal cutting rods are provided with at least two sets of tube wall supporting rollers, and the supporting legs below the other of the two longitudinal cutting rods are provided with a cutting motor and a cutting sleeve vertically; and a cutting shaft is installed in the cutting sleeve through a bearing, the upper end of the cutting shaft is in transmission connection with the cutting motor through a belt wheel and a transmission belt, and a cutting blade is installed at the lower end of the cutting shaft. The automatic cutting device is novel and simple in structural design, convenient to operate and quite convenient to adjust for PHC tubular piles with different diameters, saves time and labor during cutting, and has high efficiency and good cutting effects.

Owner:HUANGSHI ONTIME ELECTROMECHANICAL

A watermelon cutting device

ActiveCN106426358BCutting saves time and effortSolve the problem of accidentally fallingMetal working apparatusEngineeringHabit

Owner:安徽凌老伯食品有限公司

Copper strip pressing device

InactiveCN112355655AImprove flattening effectReduce knottingOther manufacturing equipments/toolsStructural engineeringMechanical engineering

The invention discloses a copper strip pressing device. The copper strip pressing device comprises a main table body, a flattening mechanism, a cutting mechanism and a pressing mechanism, a pressing frame is fixedly connected to one end of the top end of the main table body, first electric telescopic pushing rods are fixedly connected to one side of the top end of the pressing frame, supporting plates are arranged at one end of the pressing frame, and the bottom ends of the supporting plates are fixedly connected with the top end of the main table body. The copper strip pressing device has thebeneficial effects that the cutting mechanism, second electric telescopic pushing rods, a contraction groove, a trapezoidal cutting block and a V-shaped cutting knife are arranged, when cutting is carried out, after a worker pre-estimates the size of a correspondingly wound copper strip, the V-shaped cutting knife slides downwards along the contraction groove under telescopic pushing of the second electric telescopic pushing rods, when the V-shaped cutting knife is pushed to the top end of the trapezoidal cutting block to cut a copper strip at the top end of the trapezoidal cutting block, size cutting of the copper strip is facilitated, time and labor are saved during cutting, and the labor cost is reduced.

Owner:贵溪中星铜材有限公司

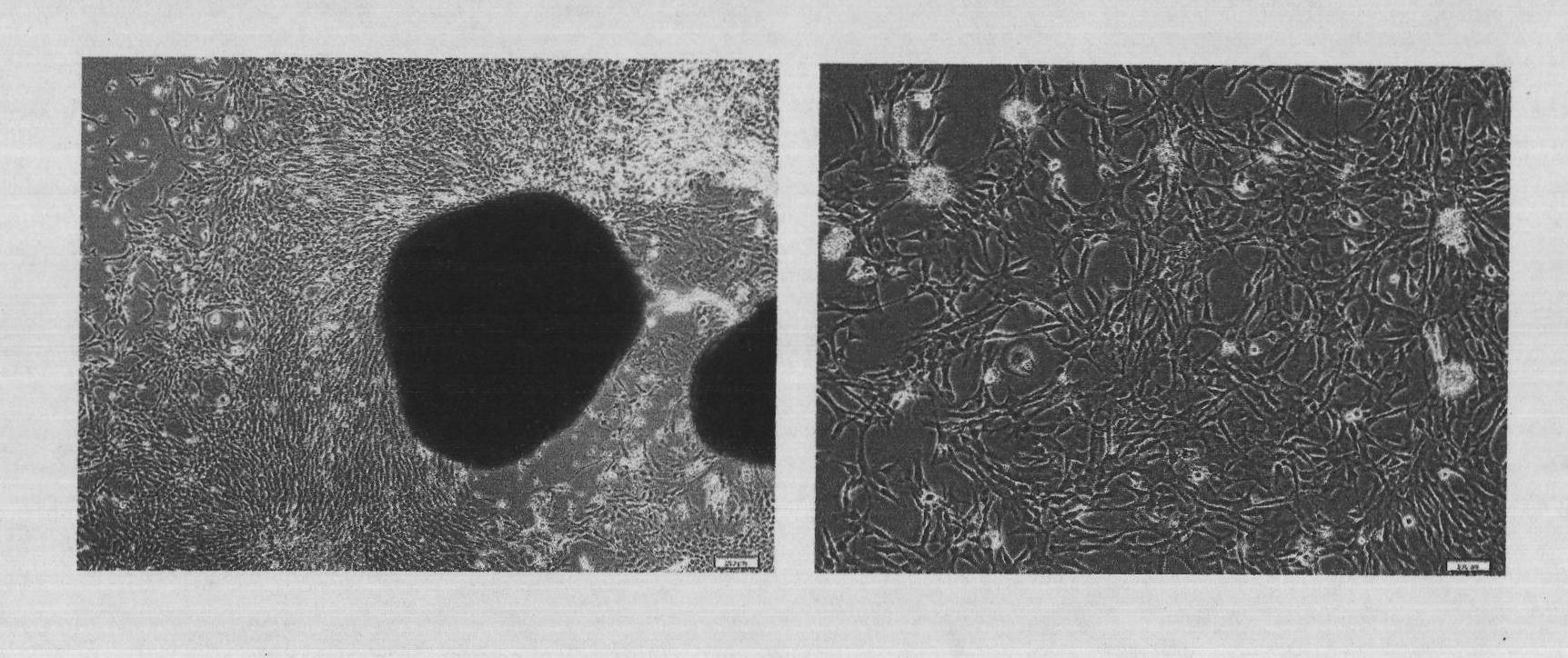

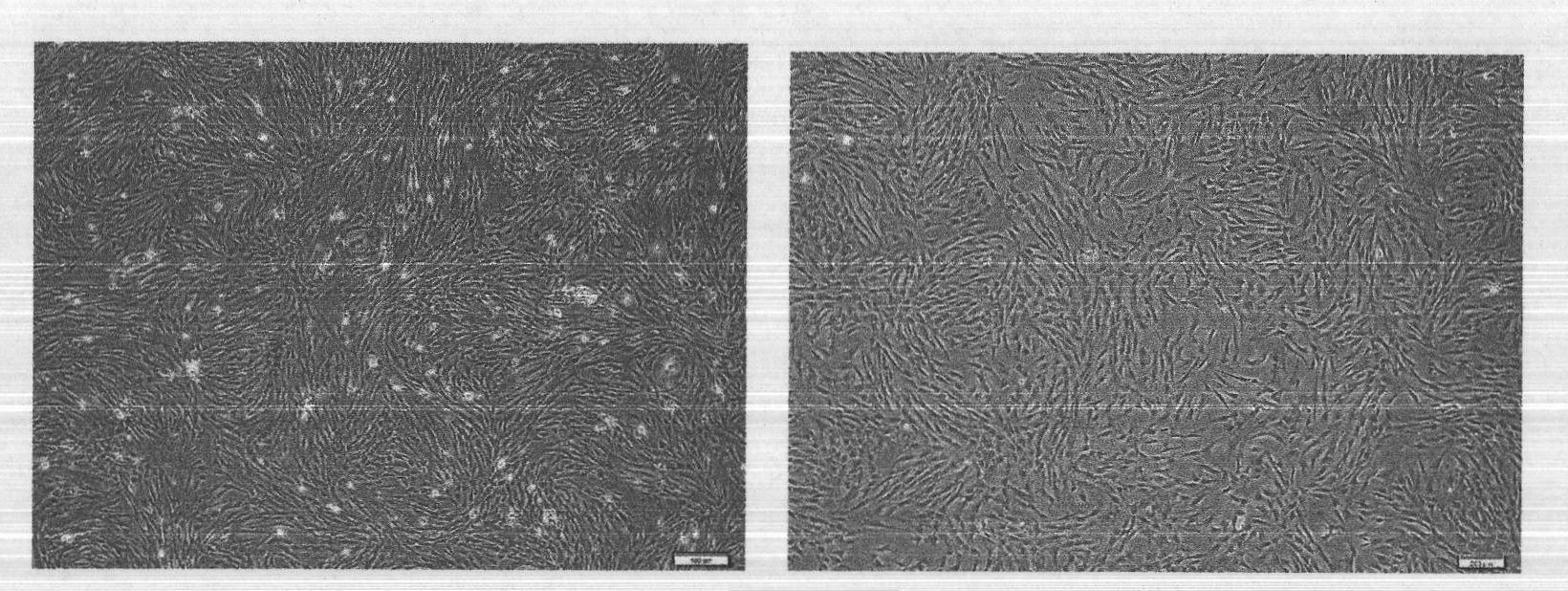

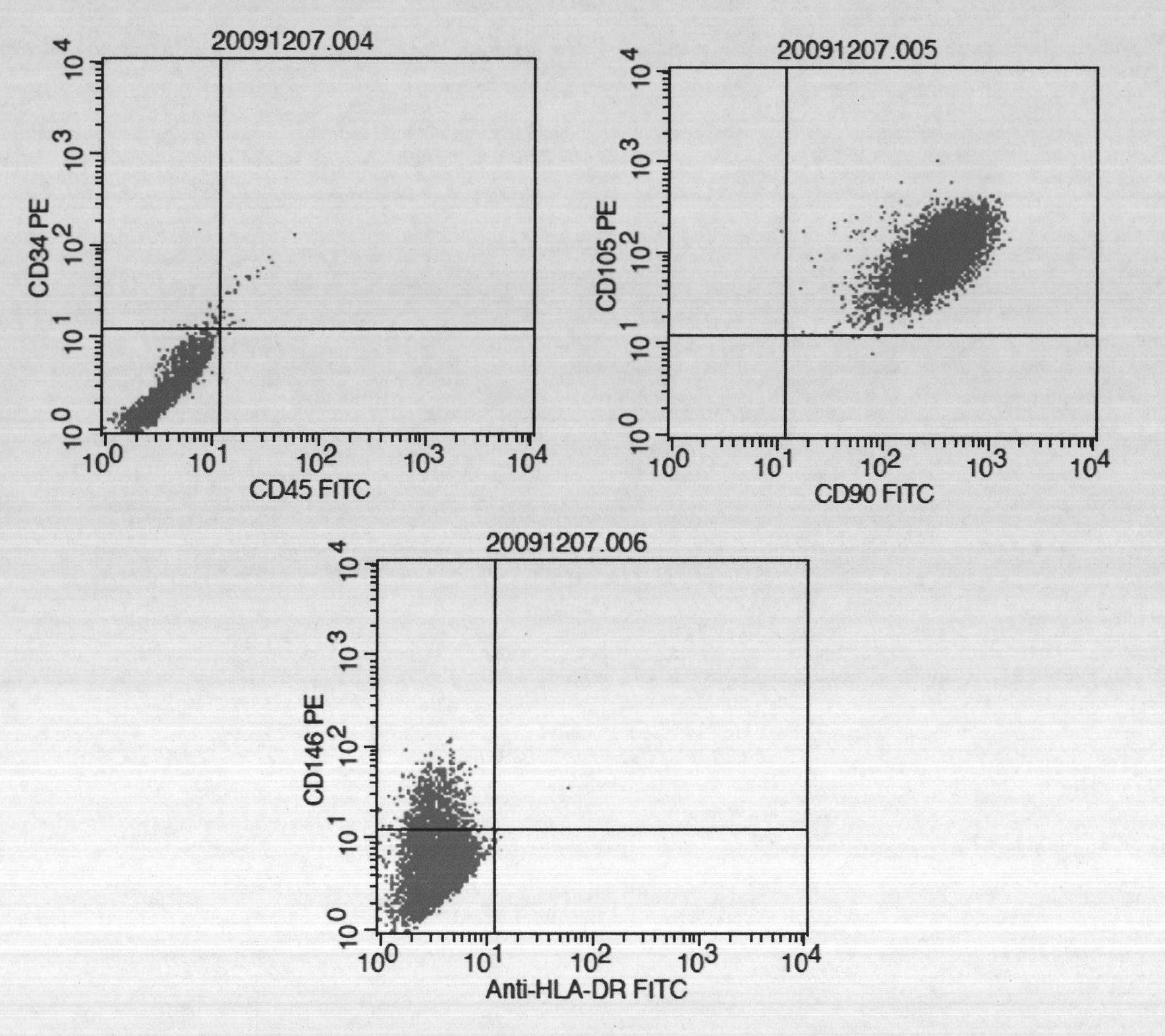

Large-scale preparation method of placenta mesenchymal stem cells

InactiveCN101921728AEasy to drawCutting saves time and effortEmbryonic cellsGerm cellsMesenchymal stem cellPollution

The invention relates to a preparation method of placenta mesenchymal stem cells. The method routinizes the preparation process, simplifies operation steps, shortens the operation time and reduces the workload, thereby preventing pollution to a great degree, reducing reagent and material required in the preparation process and increasing the yield of mesenchymal stem cells.

Owner:青岛奥克生物开发有限公司

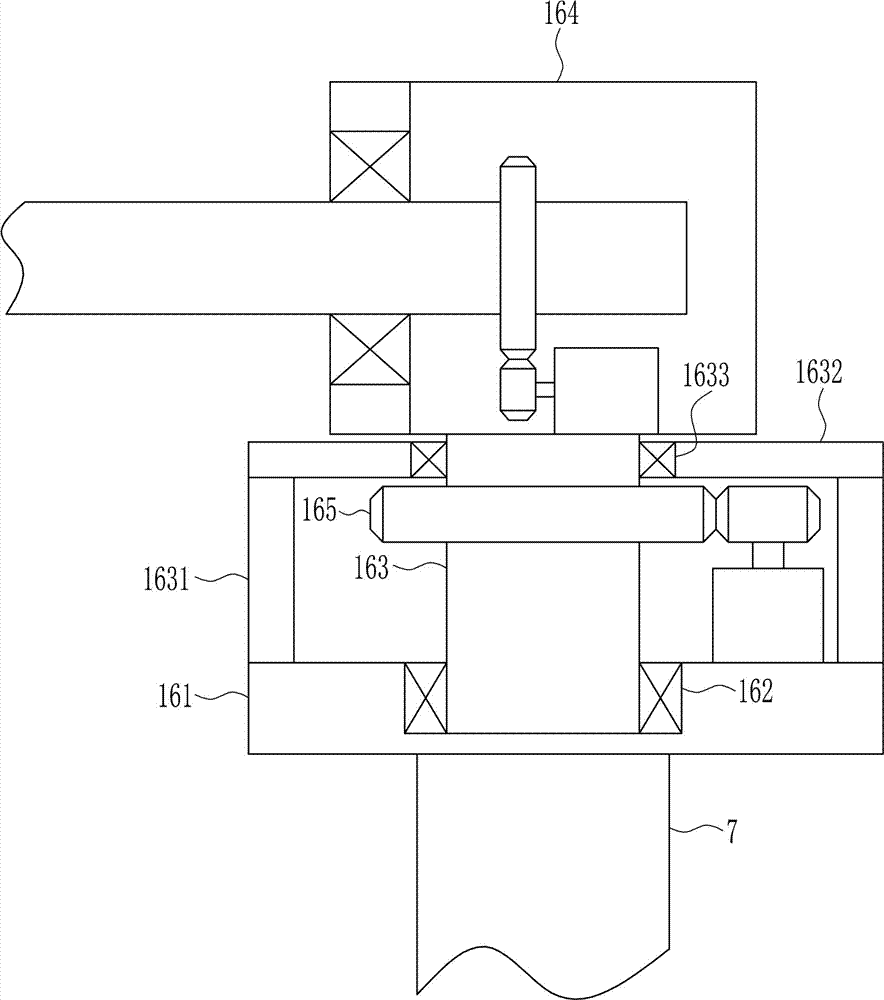

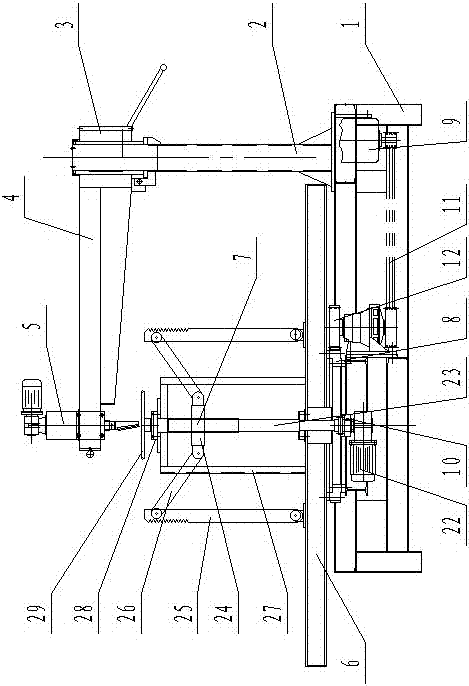

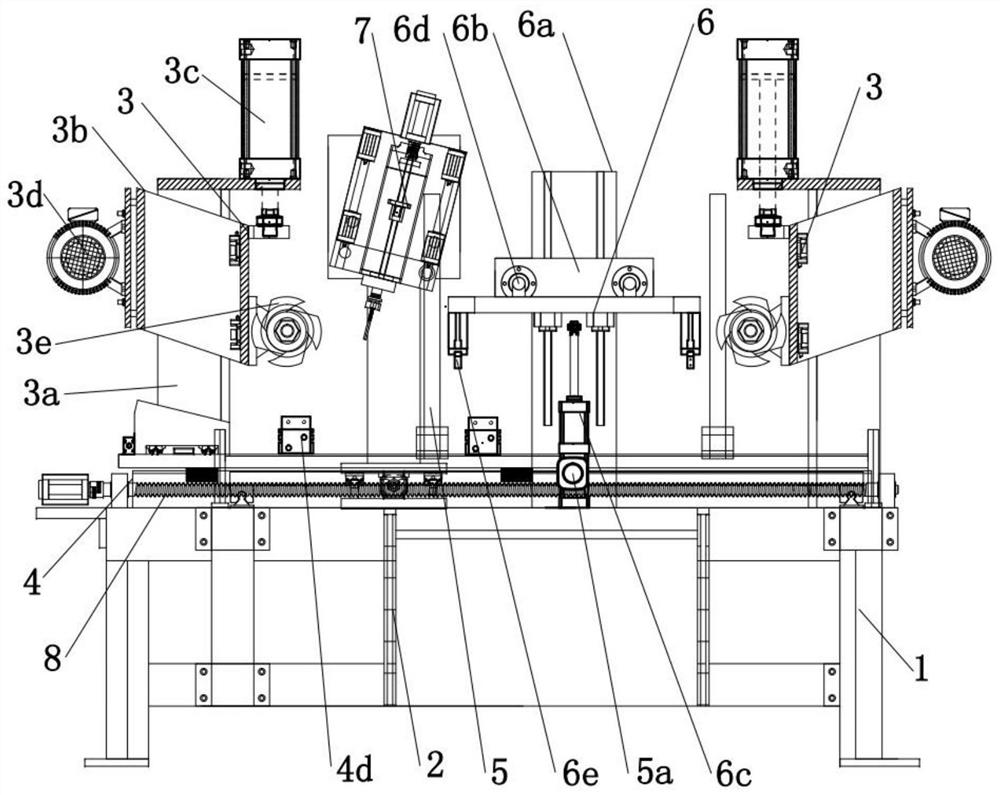

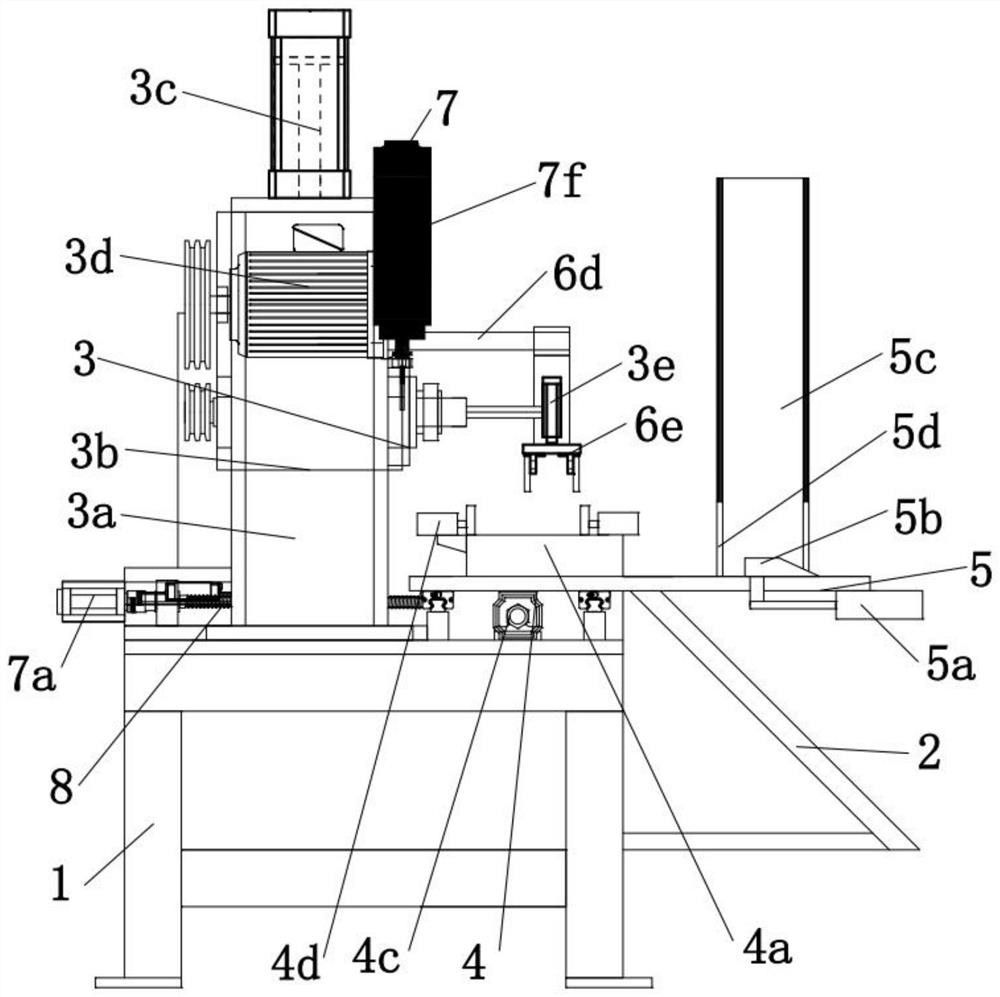

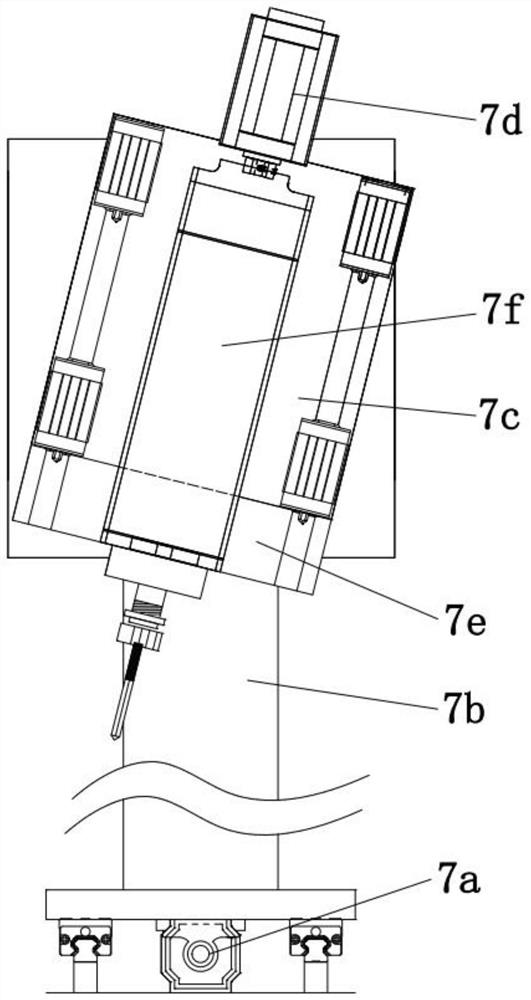

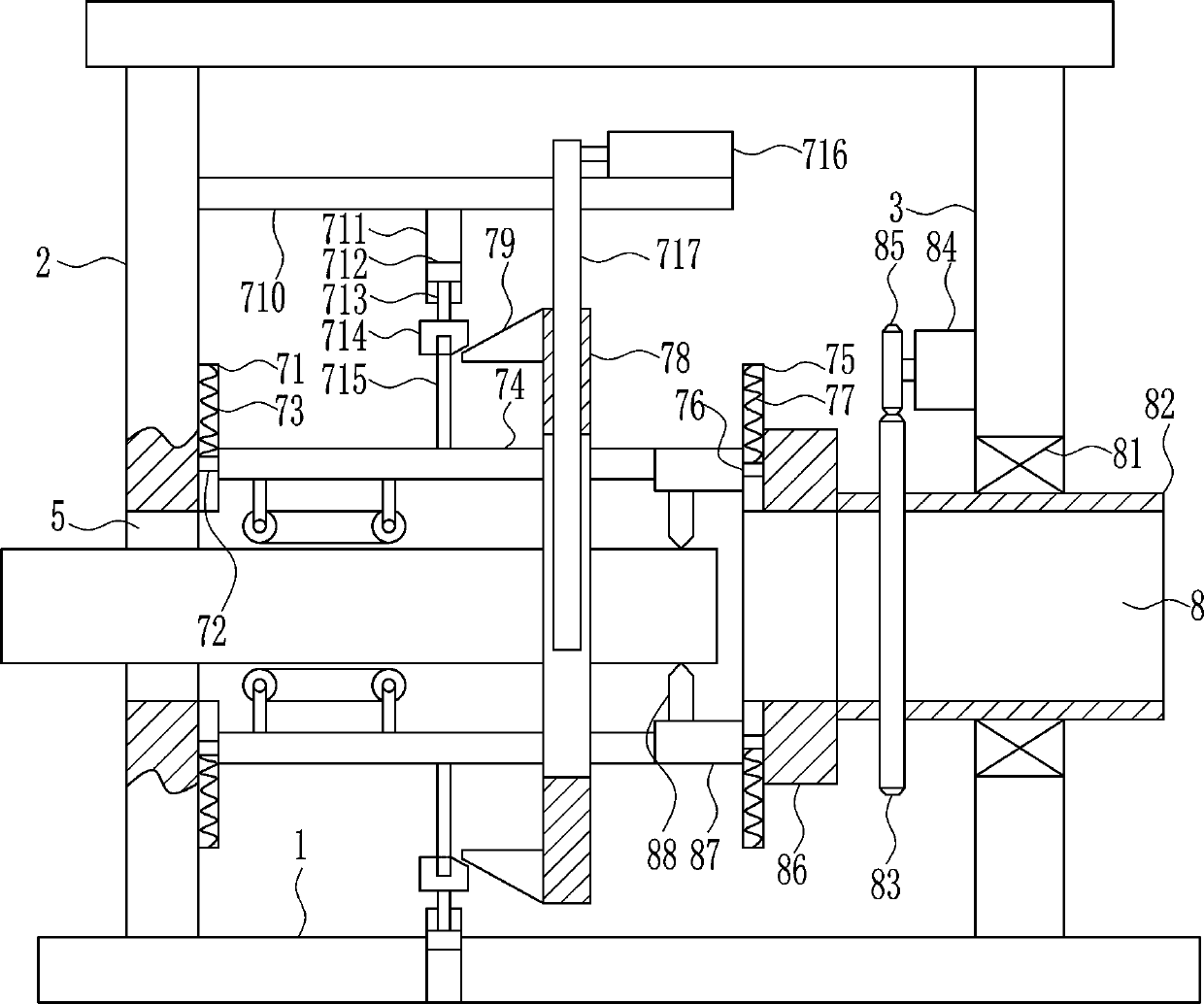

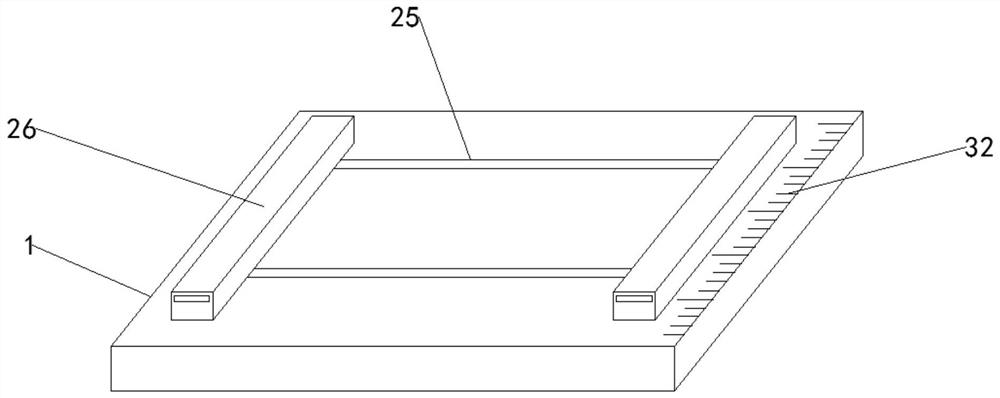

Automatic feeding type multi-dimensional processing device for electric guitar handle

PendingCN114770671AGuaranteed flatnessGuaranteed machining accuracyStringed musical instrumentsMulti-purpose machinesElectric guitarEngineering

The automatic feeding type multi-dimensional machining device for the electric guitar handle comprises a rack assembly, a workbench is arranged on the top of the rack assembly, a material storage mechanism is arranged on the edge portion of the front side of the workbench, and a material grabbing mechanism is arranged on the edge portion of the rear side of the workbench and corresponds to the material storage mechanism. A clamping and feeding mechanism is arranged on the portion, between the material storage mechanism and the material grabbing mechanism, of the workbench, the clamping and feeding mechanism is parallel to the long axis of the workbench, the two ends of the workbench are each provided with a guitar handle machining mechanism perpendicular to the long axis of the workbench, and a drilling mechanism is arranged between the guitar handle machining mechanism at any end and the material grabbing mechanism. The drilling mechanism is located on the edge portion of the rear side of the workbench, and a discharging guide groove extending downwards to the lower portion of the rack assembly is formed between the storage mechanism and the clamping and feeding mechanism. The device is compact and reasonable in structure, the flatness and the machining precision quality of the electric guitar handle are effectively guaranteed, the defective rate is greatly reduced, and the labor intensity, the danger coefficient and the production cost are reduced.

Owner:GUNAGZHOU WEIBAI MUSICAL INSTR MFGCO LTD

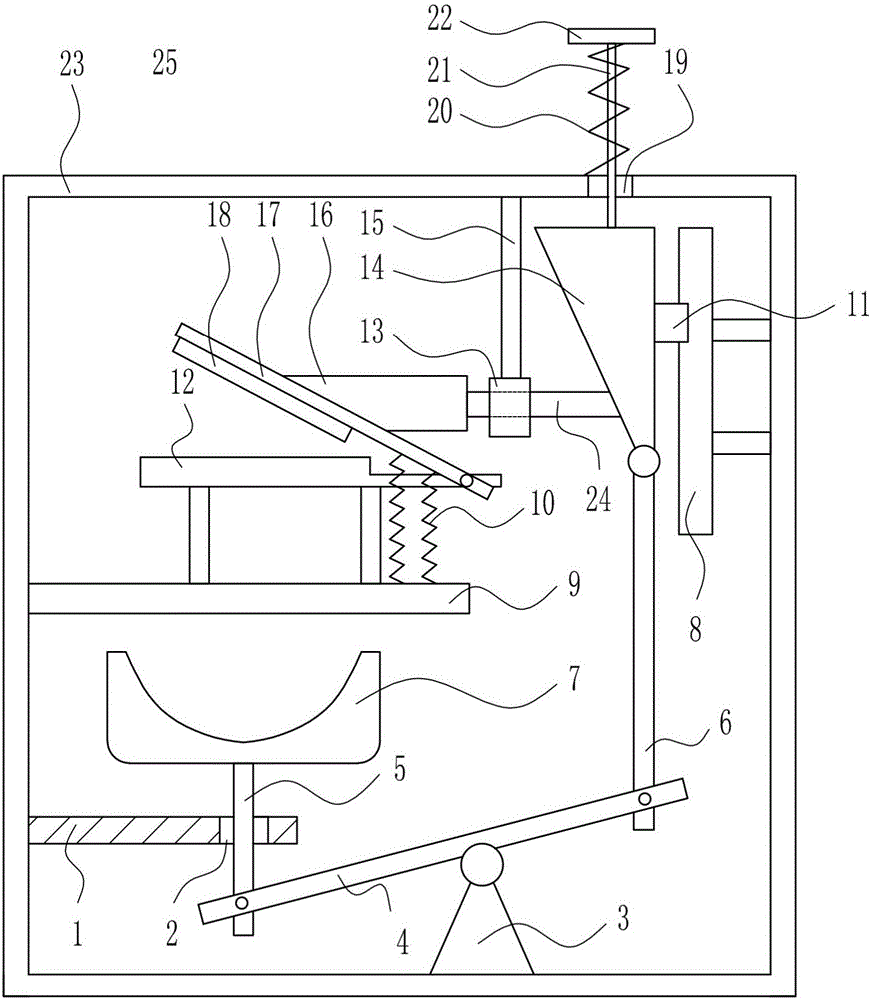

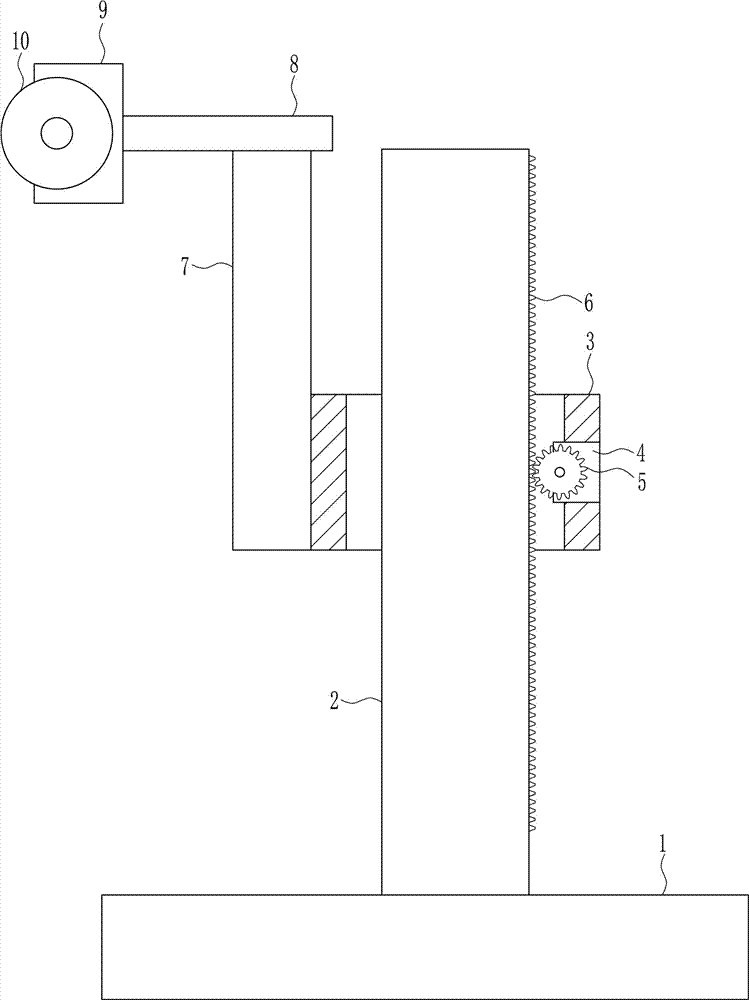

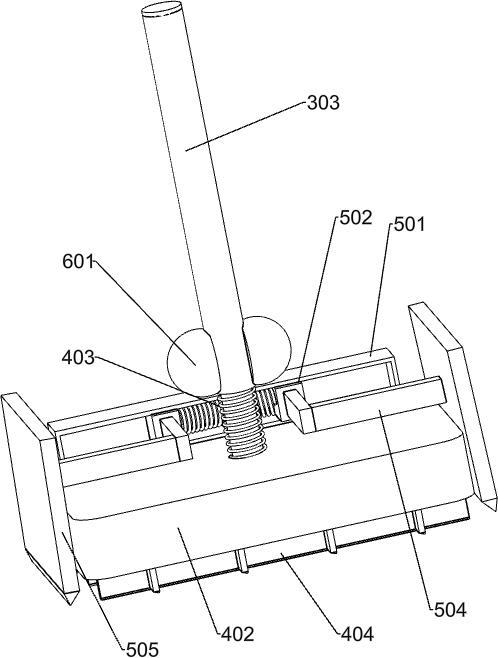

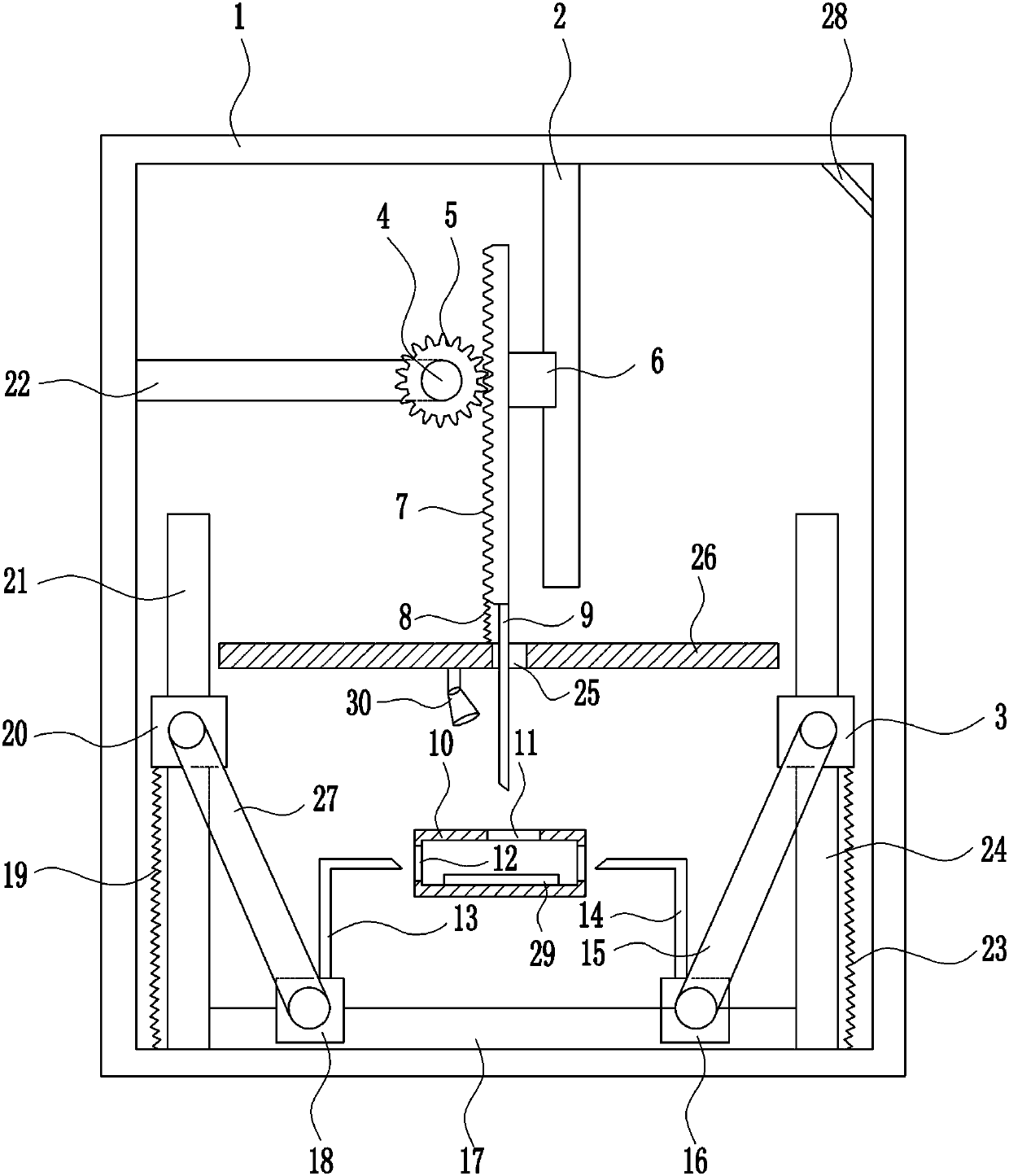

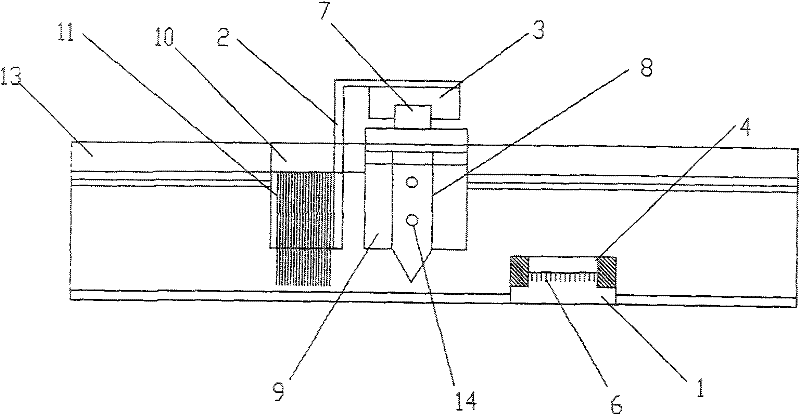

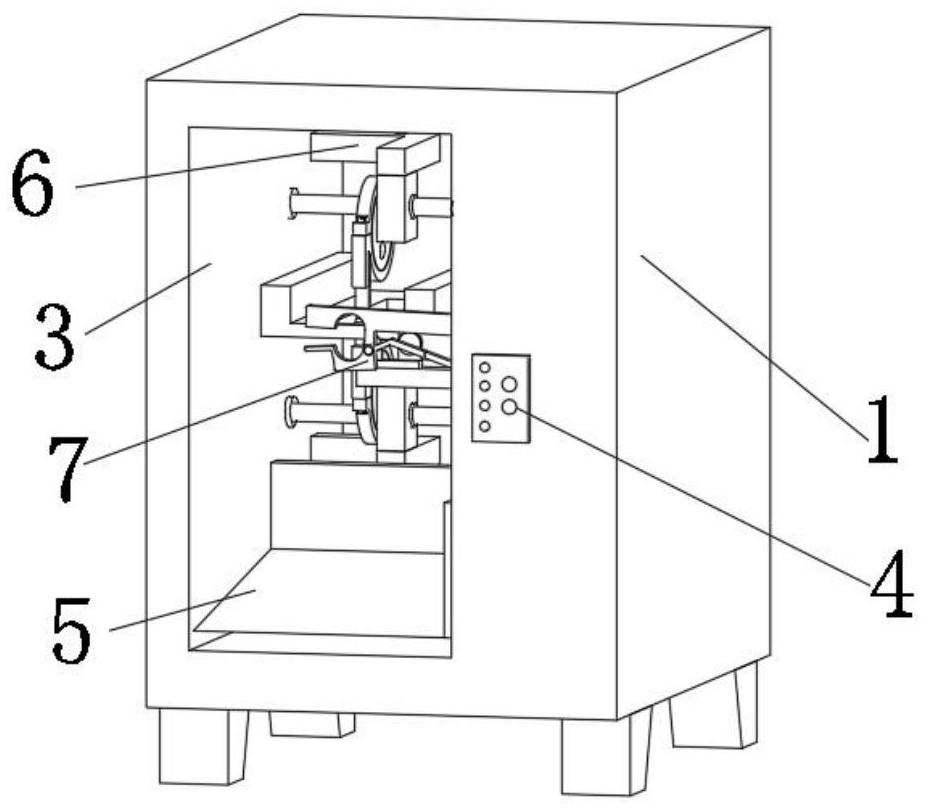

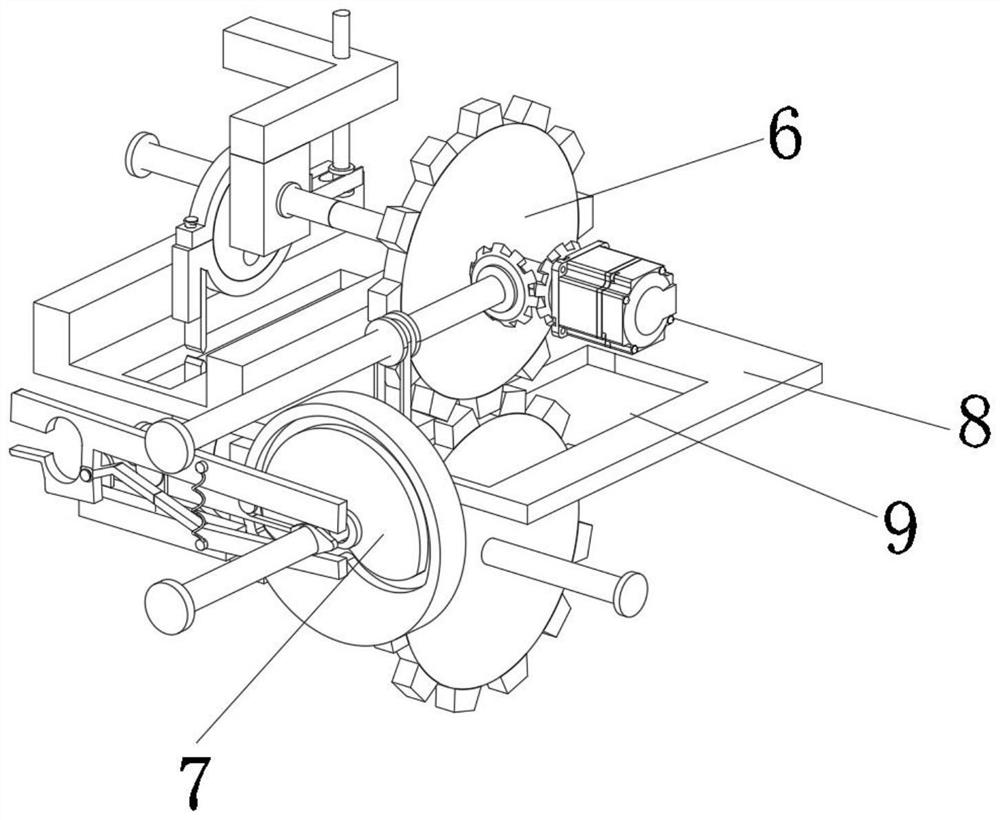

A rapid cutting device for rare earth ore

ActiveCN106584683BCutting saves time and effortEasy to operateWorking accessoriesStone-like material working toolsElectric machineGear wheel

The invention relates to a cutting device, in particular to a rare earth ore rapid cutting device. The technical problem to be solved by the present invention is to provide a rare earth ore rapid cutting device with high cutting efficiency. In order to solve the above technical problems, the present invention provides such a rapid rare earth ore cutting device, which includes a box body, a fourth slide rail, a first slide block, a rotating motor, a gear, a fifth slide block, a rack, a third elastic Components, the first cutting knife, the placement frame, the second cutting knife, the third cutting knife, the first connecting rod, the second sliding block, the second sliding rail and the third sliding block, etc.; the bottom of the box is arranged in sequence from left to right There are a second elastic element, a third slide rail, a second slide rail, a first slide rail and a first elastic element. The invention achieves the effects of time-saving and labor-saving rare earth ore cutting, simple operation, high device strength and long service life of the device, and also because of the arrangement of reinforcing ribs.

Owner:芜湖启博知识产权运营有限公司

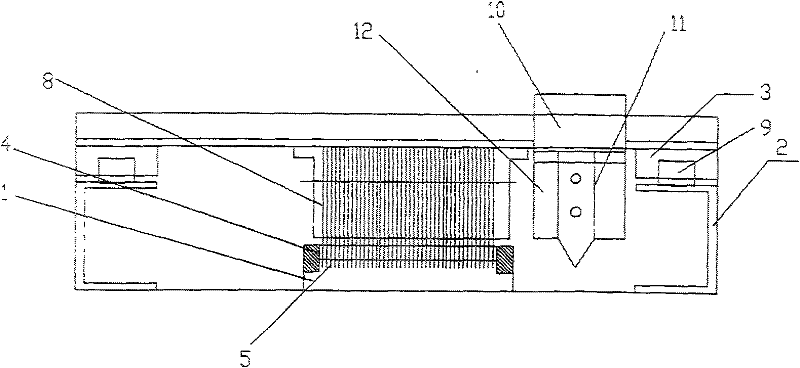

Medicinal cutter

ActiveCN101870116BReduce wear and tearReduce pollutionMetal working apparatusGelatin spongeSupport plane

The invention provides a medicinal cutter. The medicinal cutter comprises a bearing tray, a transverse cutter head, a longitudinal cutter head and a support frame, wherein the support frame is arranged on the bearing tray and is provided with a sliding rail; the cutter head is arranged on the sliding rail; and a square groove is formed on the bearing tray which is provided with a transverse cutting trough parallel with the transverse side of the groove and a longitudinal cutting trough parallel with the longitudinal side of the groove. The medicinal cutter has the advantages of reducing the pollution from the preparation process of gelatin sponge particles, maintaining the freshness of the gelatin sponge particles, reducing the oxidation time of the gelatin sponge particles in air and theconsumption of gelatin sponge and saving time and labor for cutting.

Owner:ZHONGYU BEIJING BIOLOGICAL ENG

Leather shoe fabric cutting equipment for leather shoe processing

InactiveCN112890374AConvenient fixed conveying operationReduce tiltShoemaking devicesHeelsDrive shaftStructural engineering

The invention relates to the technical field of leather shoe processing equipment, in particular to leather shoe fabric cutting equipment for leather shoe processing, which comprises an outer shell, a feeding port is formed in one side of the outer shell, a discharging port is formed in the other side of the outer shell, an operation button is arranged on the surface of the outer shell on one side of the discharging port, and a conveying plate is fixed in the outer shell. And an open groove is formed in the surface of the conveying plate, a conveying mechanism is installed in the outer shell, and the conveying mechanism comprises a servo motor. The output shaft of the servo motor drives the driving shaft and the auxiliary moving shaft to synchronously rotate, so that the outer sleeve shells arranged on the driving shaft and the auxiliary moving shaft in a sleeving mode eccentrically rotate along the movable shaft pins through the sliding grooves, and pushing pieces on the outer sleeve shells can make contact with leather shoe fabric on the conveying plate at regular time, and the leather shoe fabric is driven to advance forwards in a timed and quantitative mode, so that the cut leather shoe fabric can be fixed and conveyed conveniently, and the overall cutting accuracy can be effectively improved.

Owner:WENZHOU POLYTECHNIC

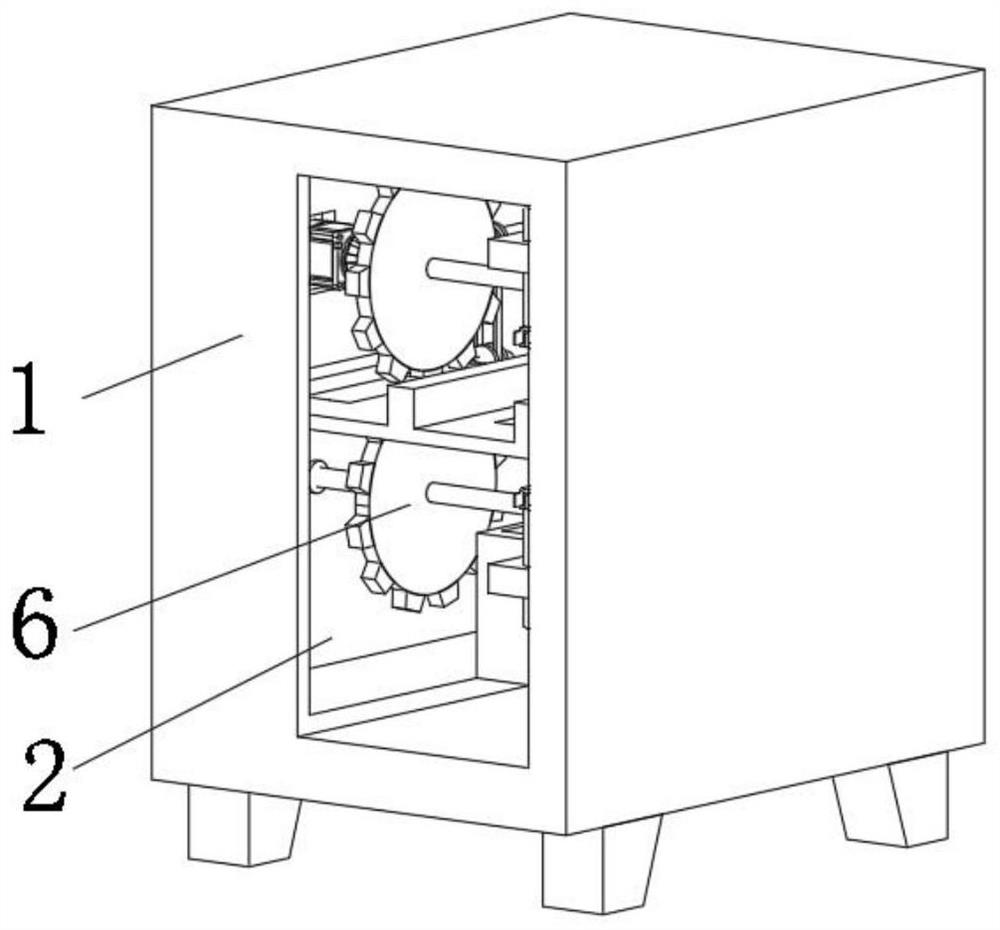

A kind of industrial glass pipe cutting equipment

ActiveCN106746566BCutting saves time and effortQuick cutGlass severing apparatusEngineeringBolt connection

The invention relates to a glass cutting device, in particular to a novel industrial glass pipe cutting device. The invention aims to solve the technical problem so as to provide the novel industrial glass pipe cutting device, which has less possibilities on damaging glass pipes and hurting workers or equipment when being used for cutting the glass pipes, and is time and labor saving during a cutting process. In order to solve the technical problem, the invention provides the novel industrial glass pipe cutting device, which comprises a bottom plate and the like, wherein a left support plate is arranged at the left side above the bottom plate in a welding way; a right support plate is arranged at the right side above the bottom plate in a welding way; a top plate is arranged on the upper ends of the left support plate and the right support plate through a welding way; a through hole is formed in the lower side of the left support plate; fixing plates are symmetrically arranged at the right side of the left support plate through a bolt connection way. The novel industrial glass pipe cutting device provided by the invention achieves the effects that the possibilities on damaging the glass pipes and hurting the workers or the equipment when being used for cutting the glass pipes are less, and the time and the labor are saved during the cutting process.

Owner:临泉县蓝天钢化玻璃有限公司

Drawing cutting device for mechanical automation specialty

PendingCN112917522AImprove croppingImprove flatnessMetal working apparatusEngineeringMechanical engineering

The invention belongs to the technical field of cutting, and particularly relates to a drawing cutting device for mechanical automation specialty. The device comprises a cutting table, wherein supporting rods are fixedly connected to the four corners of the upper end face of the cutting table, a mounting box is fixedly connected to the upper end faces of the four supporting rods, and a mounting plate is fixedly connected to the back of the inner wall of the mounting box. A cutter holder at the bottom performs the same right lower movement, so that the cutter is driven to move downwards and move rightwards at the same time, a drawing at the upper end of the cutting table is obliquely cut, an air cylinder shrinks after cutting is completed, and the cutter can be driven to retract, so that compared with vertical tangent cutting, the flatness of the cutting face is improved, more labor is saved, and the drawing cutting effect is improved; and the device solves the problems that according to an existing drawing cutting device, generally used drawing cutting devices are all in a vertically-downward straight cutting mode, and when a plurality of drawings are cut at the same time, power needed by the cutter is large, meanwhile, the cutting face is uneven, the cutting effect is poor, the drawings cannot be well fixed, and the cutting effect is affected due to displacement of the drawings in the cutting process.

Owner:JIUQUAN VOCATIONAL & TECHN COLLEGE

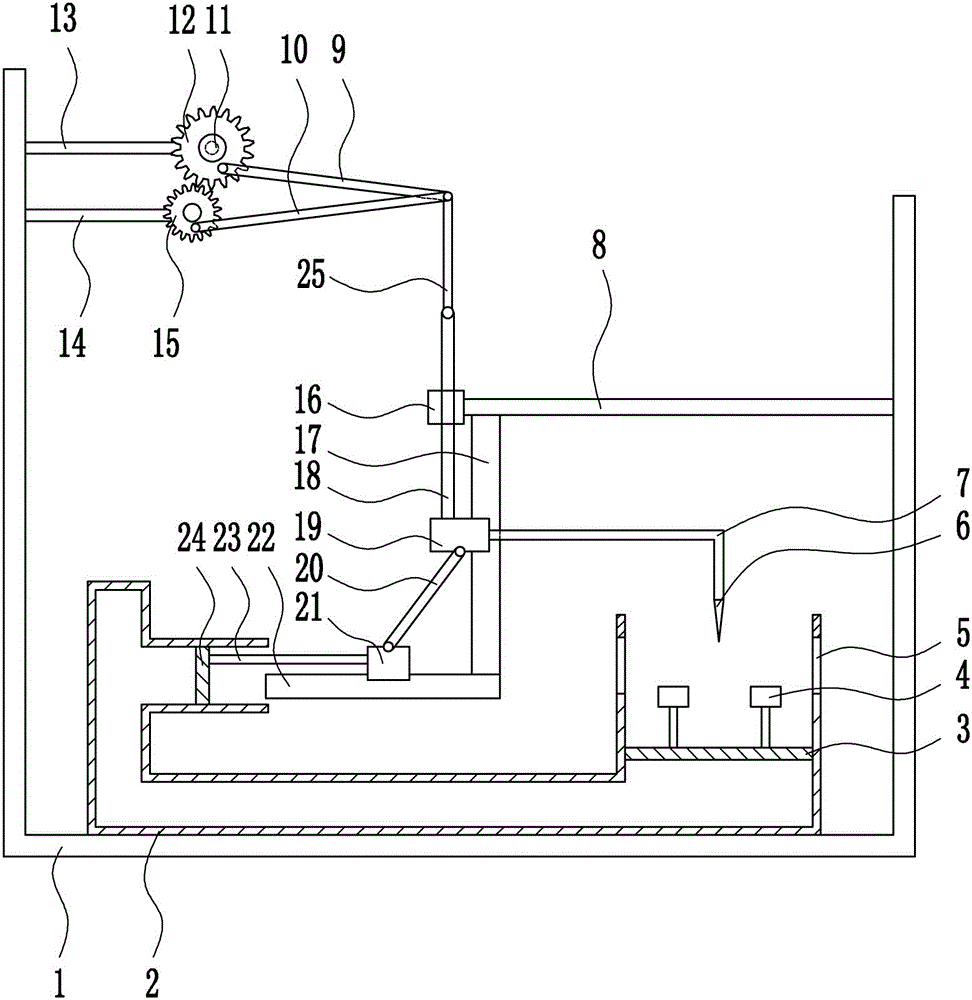

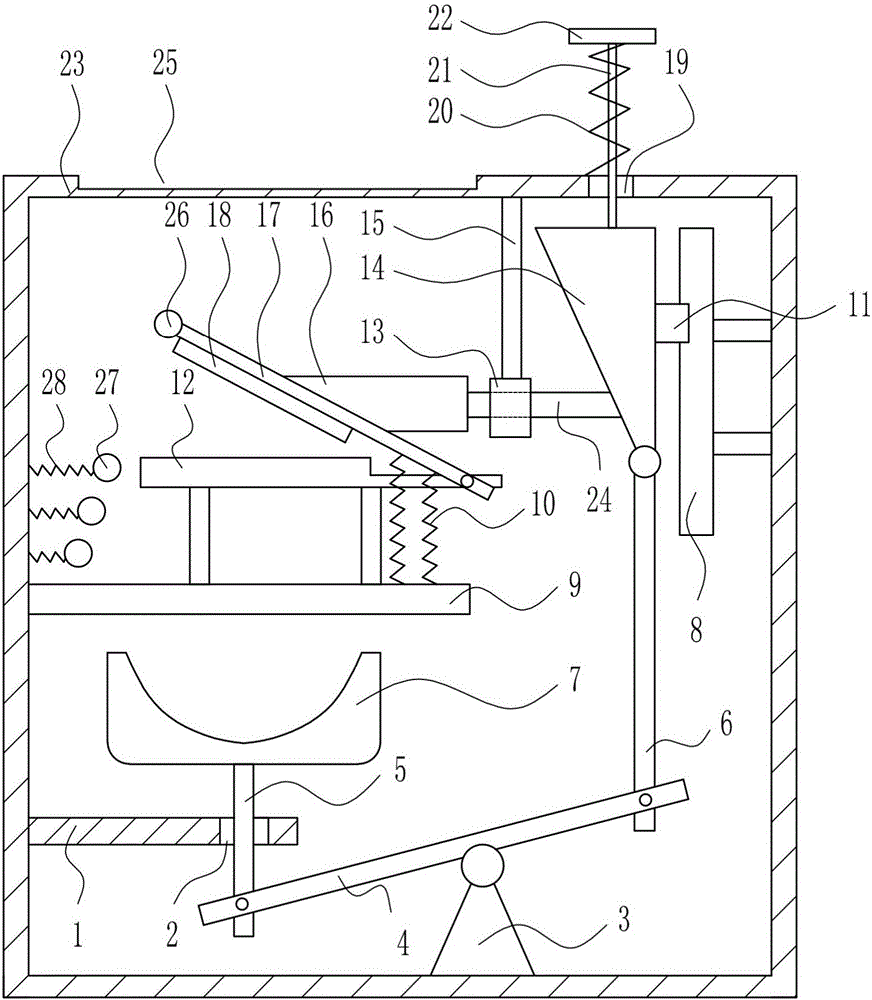

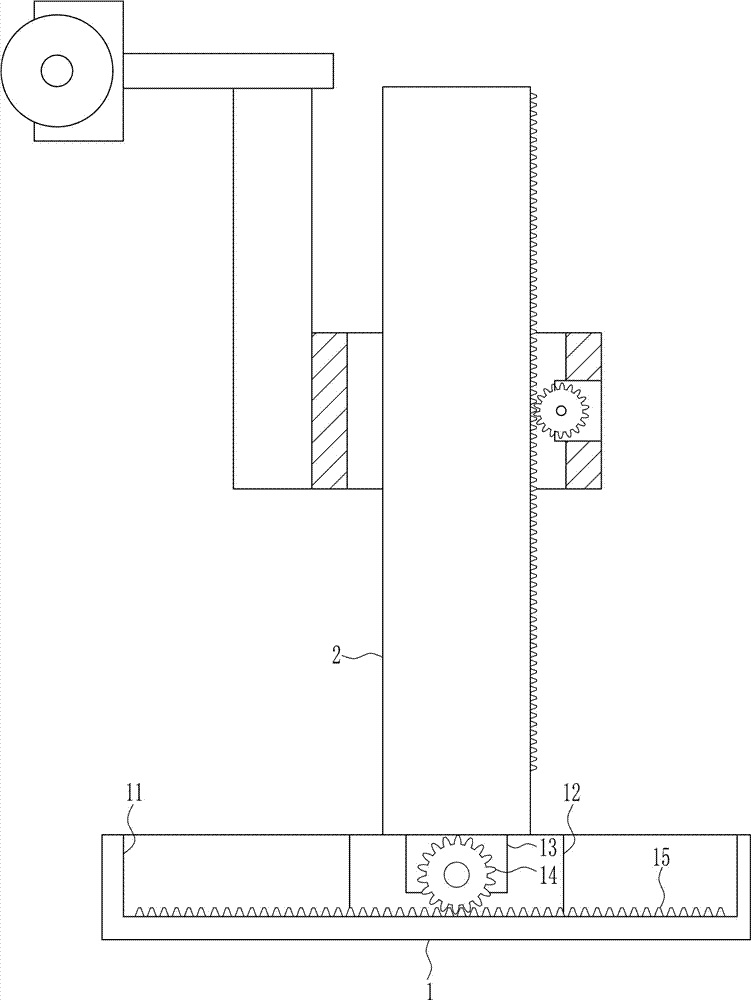

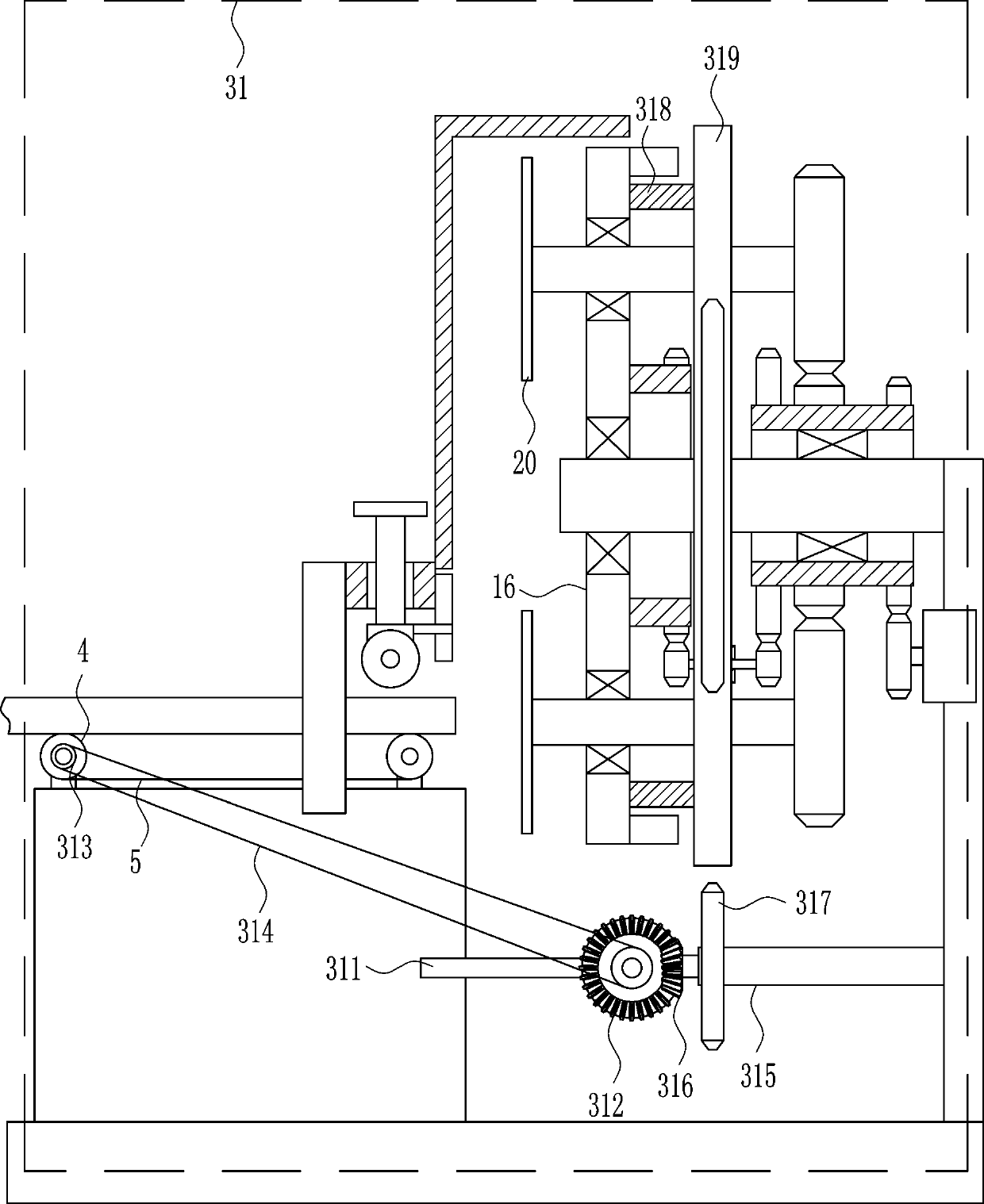

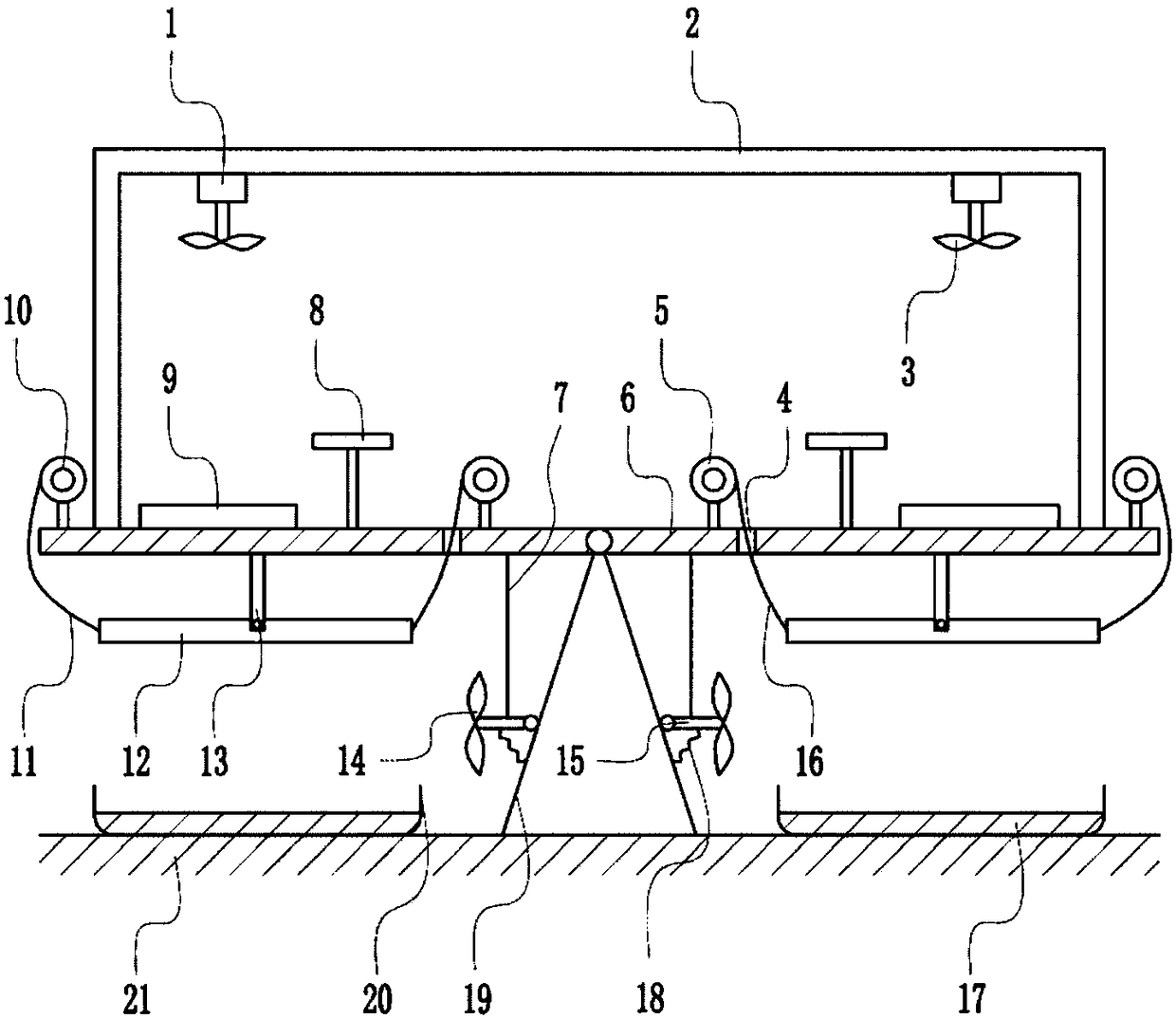

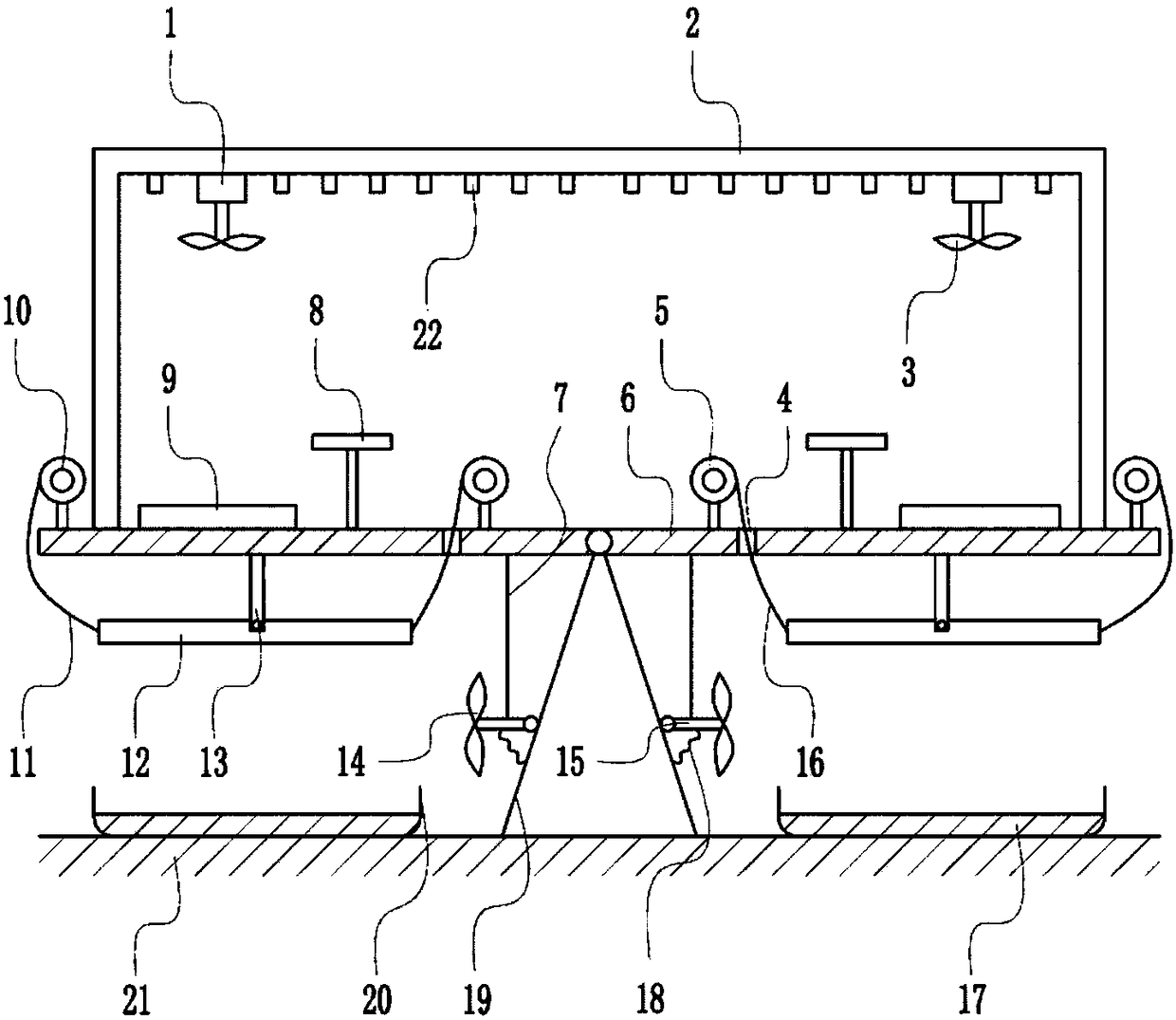

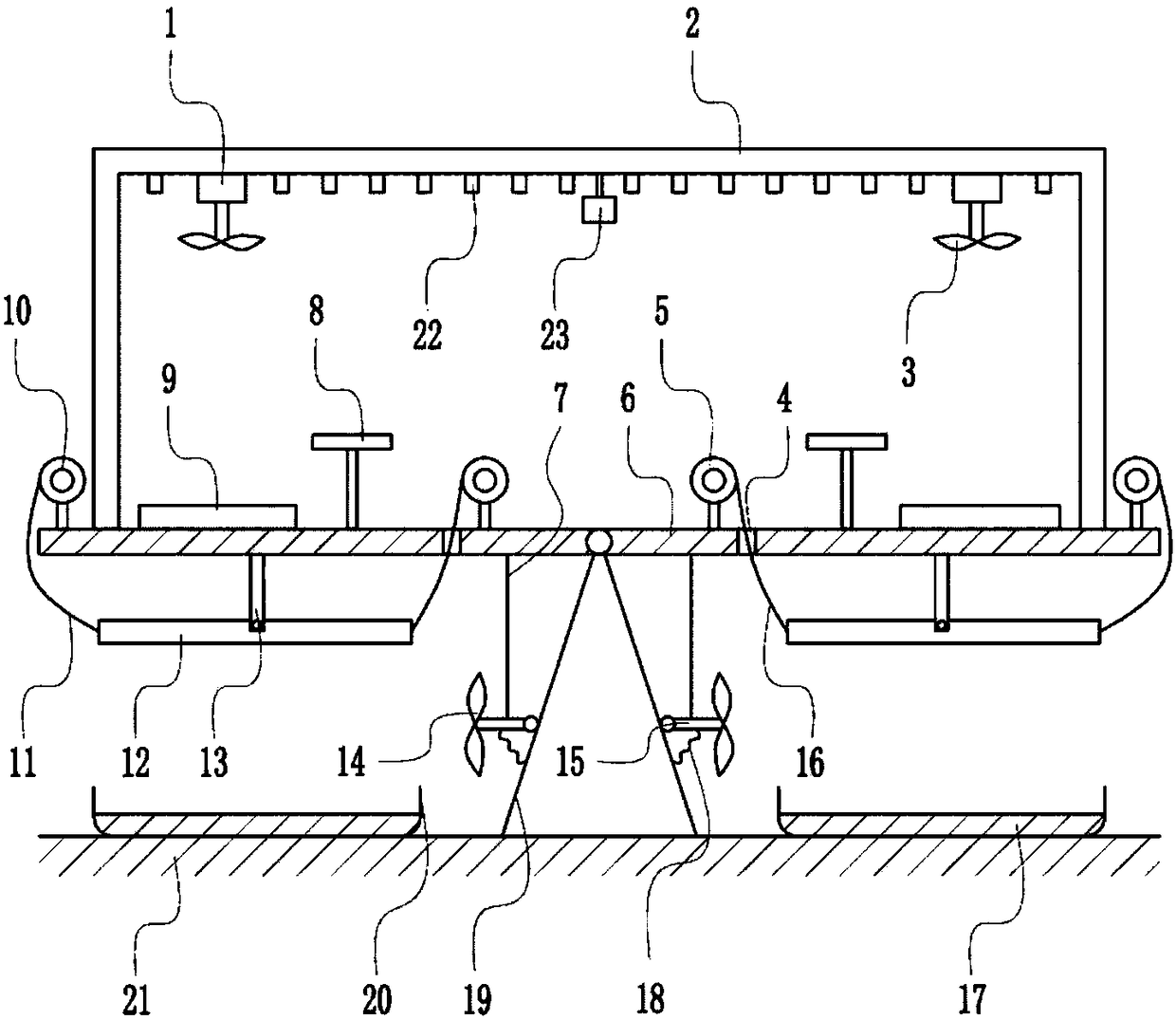

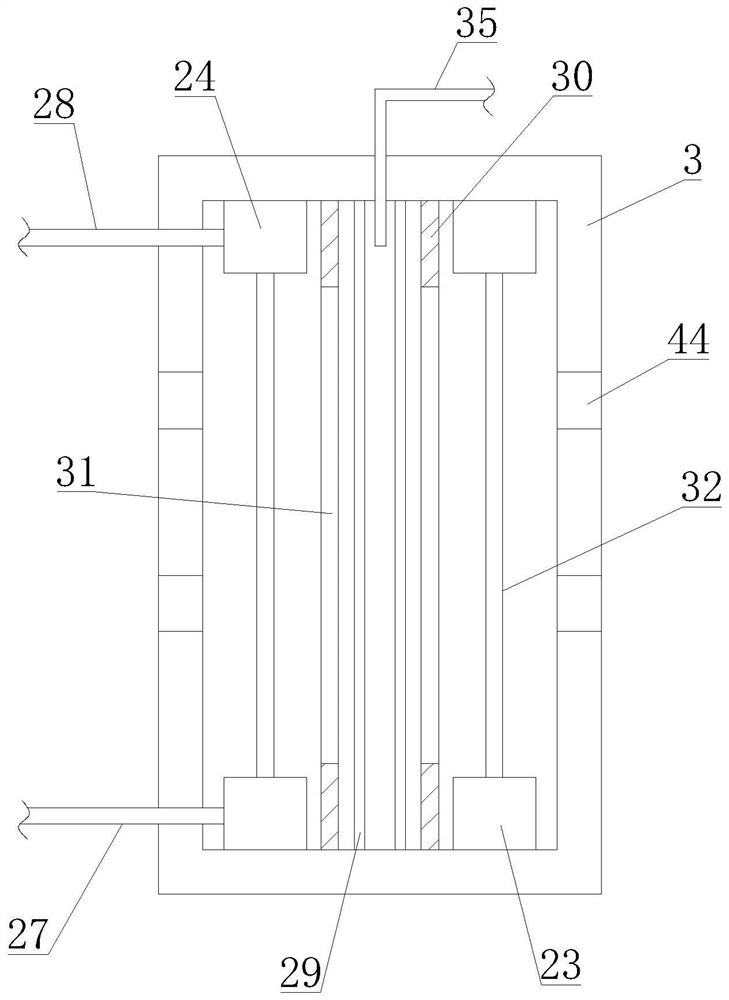

A rapid and equal-length self-propelled cutting equipment for wooden poles used in construction

ActiveCN108312249BCutting saves time and effortReduce riskProfiling/shaping machinesWood working safety devicesGear wheelArchitectural engineering

The invention relates to building timber processing equipment and in particular relates to rapid equal length self-traveling cutting equipment for wooden poles for construction. A technical problem tobe solved in the invention is to provide the rapid equal length self-traveling cutting equipment for wooden poles for construction through which the cutting process is time-saving and labor-saving and risk is low during cutting. In order to solve the technical problem, the rapid equal length self-traveling cutting equipment for wooden poles for construction provided by the invention comprises a bottom plate, a slide block and the like. A mounting table is connected to the left side of the bottom plate; first fixing blocks are connected to the left and right sides of the upper side of the mounting table; first runners are rotationally connected to the upper parts of the front sides of the first fixing blocks. According to the cutting equipment disclosed by the invention, the effects that the cutting process is time-saving and labor-saving and the risk is low during cutting are achieved; with the adoption of a manner of rotating two cutting knives and rotating by a connecting plate, inaddition to a manner of driving a conveyor belt to move to the right by virtue of a sector gear, woods can be subjected to rapid equal length cutting, and risk caused by excessive manual operations inthe cutting process can be avoided.

Owner:JIAXING LONGJUN INFORMATION TECH

Rotary turf cutting device for agriculture

InactiveCN108064638ACutting saves time and effortImprove cutting efficiencyHops/wine cultivationTurf growingMechanical engineeringAgriculture

Owner:HENAN GAOSHENG ENTERPRISE MANAGEMENT CONSULTING CO LTD

A method for physically breaking dormancy of Hovenia dulcis seeds

ActiveCN109121552BEasy to operateCutting saves time and effortSeed immunisationSeed dormancyWarm water

The invention discloses a method for physically breaking citrus trifoliata seed dormancy. The method includes the steps: a kneading a citrus trifoliate fruit with dry fruit peel; b disinfecting seedsacquired in the step a by potassium permanganate solution at the normal temperature, cleaning the disinfected seeds by clear water, soaking the cleaned seeds for 30 minutes in warm water of 40-50 DEGC, and soaking the seeds for 1-2d by clear water at normal temperature; c selecting obvious imbibition seeds, stabilizing the selected seeds by tweezers, enabling the seeds to be 0.15-0.25cm higher than the tweezers, and cutting seeds by a blade along the direction perpendicular to seed ridges downwards or horizontally cutting the seeds by the blade along the direction parallel to the seed ridgesto expose endosperm; d laying degreasing cotton on the bottom layer of a culture vessel, wetting the degreasing cotton by clear water, placing the seeds completely removed seed shells in the culture vessel, and placing the culture vessel into an illumination incubator to culture the seeds. According to the method, the germinating time of the citrus trifoliata seeds is short and about 3-4 days, effects are stable, and germination rate is stable and reaches 82.3%.

Owner:烟台市林业科学研究所

Multifunctional cutting device for steel plate processing

ActiveCN112743144BEasy inputHigh outputShearing machinesMaintainance and safety accessoriesWater storage tankStructural engineering

A multifunctional cutting device for steel plate processing, including a protective box, a water storage tank and a dust filter box; a pressing assembly is arranged in the input port and the output port; the cutting knife is connected with the connecting shaft, and the upper part of the cutting knife is located in the arc cover ;A water collecting piece is arranged in the arc-shaped cover, and a nozzle is arranged on the water collecting piece; a first water pump and a hose are arranged on the first water delivery pump, and the first water suction pipe is connected with the water storage tank, and the hose is connected with the water collecting piece Connected; the filter cartridge is set in the dust filter box; the water distribution ring and the water collection ring are also provided in the dust filter box; the heat pipe is connected to the water distribution ring and the water collection ring; The second water suction pipe is connected with the water collection tank, the water delivery pipe is connected with the water distribution ring, and the water return pipe is connected with the water collection ring and the water storage tank; the dust suction pipe extends into the protective box, and the exhaust pipe extends into the filter cartridge. The invention not only facilitates the cutting of the steel plate, but also can cool down the cutting knife and process the dust gas generated in the cutting process, has various functions and excellent use effect.

Owner:蓬莱大金海洋重工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com