Patents

Literature

122 results about "Gelatin sponge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gelatin sponge. A spongy protein derived from animal collagen. It can be used to arrest local bleeding intraoperatively, to embolize blood vessels, or to form a protective coating around recently manipulated tissues.

Gelatin sponge and preparation method thereof

InactiveCN101574539AImprove performancePromote absorptionSurgeryAbsorbent padsGelatin spongeIrradiation

The invention provides gelatin sponge, gelatin aqueous solution is irradiated to crosslink to form gelatin hydrogel, and then the gelatin hydrogel is swollen, frozen and dried to obtain the gelatin sponge. The invention also provides a preparation method of the gelatin sponge by an irradiation crosslinking way, the whole process flow is finished in a pure water system, the irradiation and crosslinking processes have sterilizing function and good controllability, the obtained product has better structural uniformity compared with a chemical crosslinking method, and the gelatin sponge has unique advantages as biomedical materials.

Owner:厦门凝赋生物科技有限公司

Preparation of agarose coated, solid agarose-collagen beads containing secretory cells

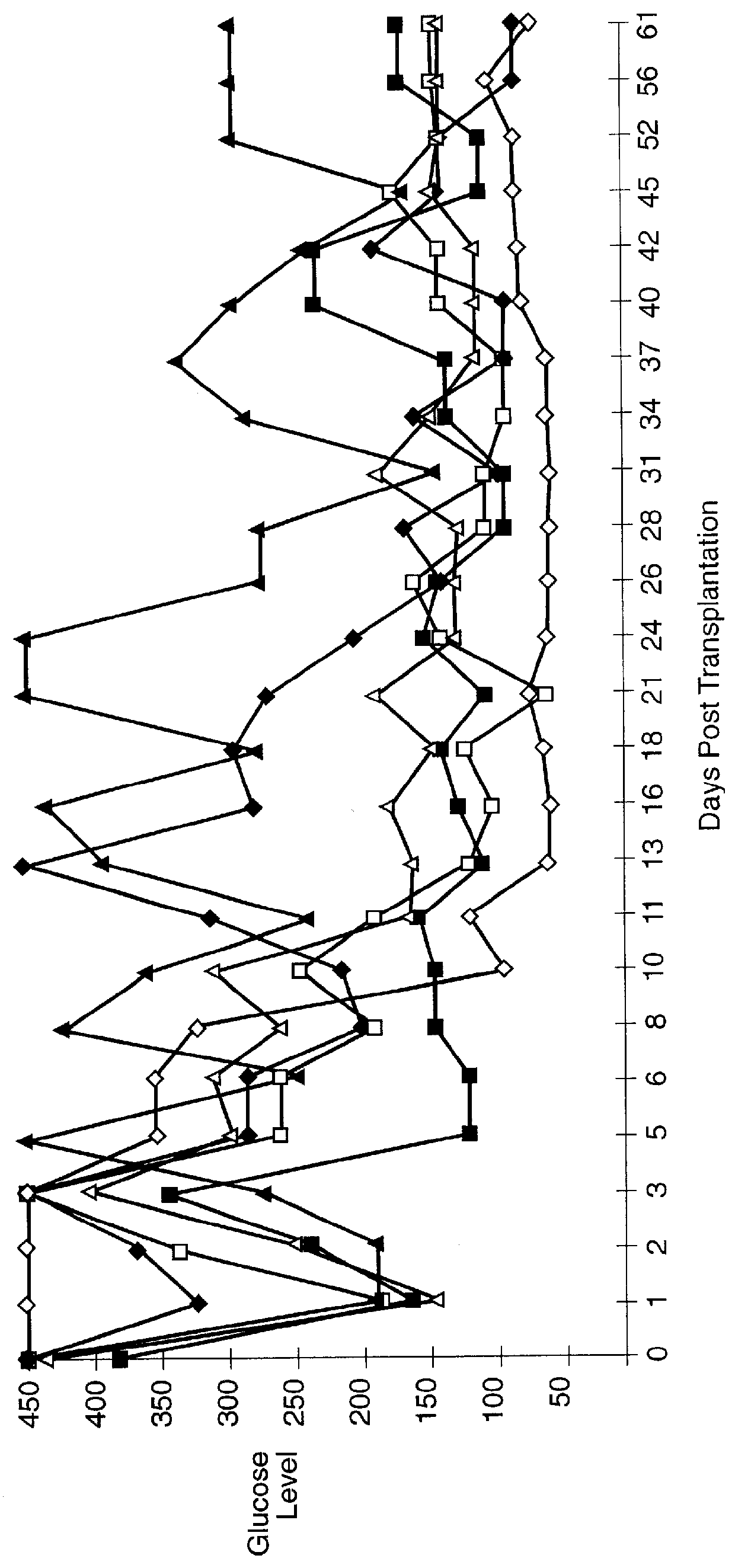

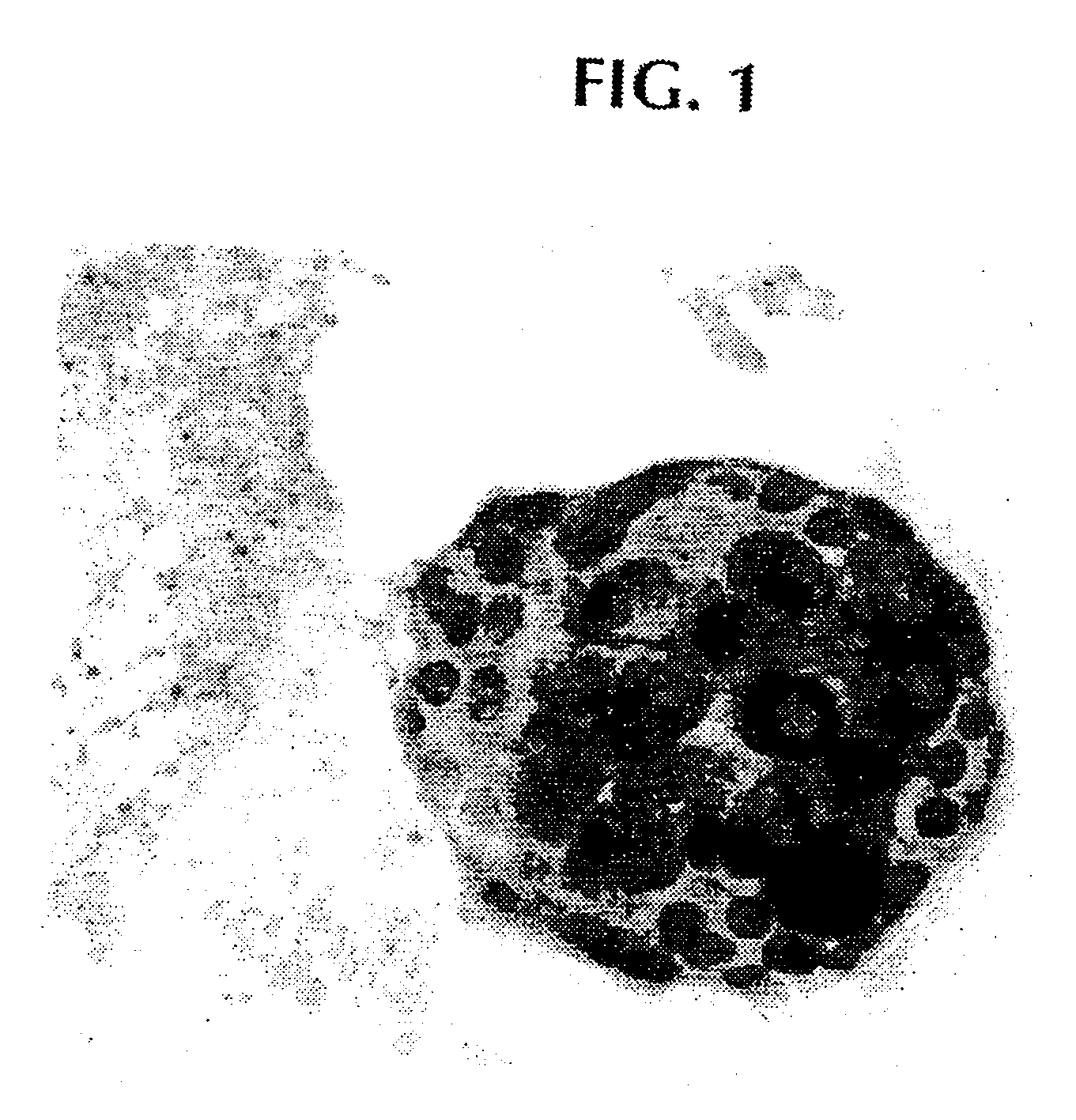

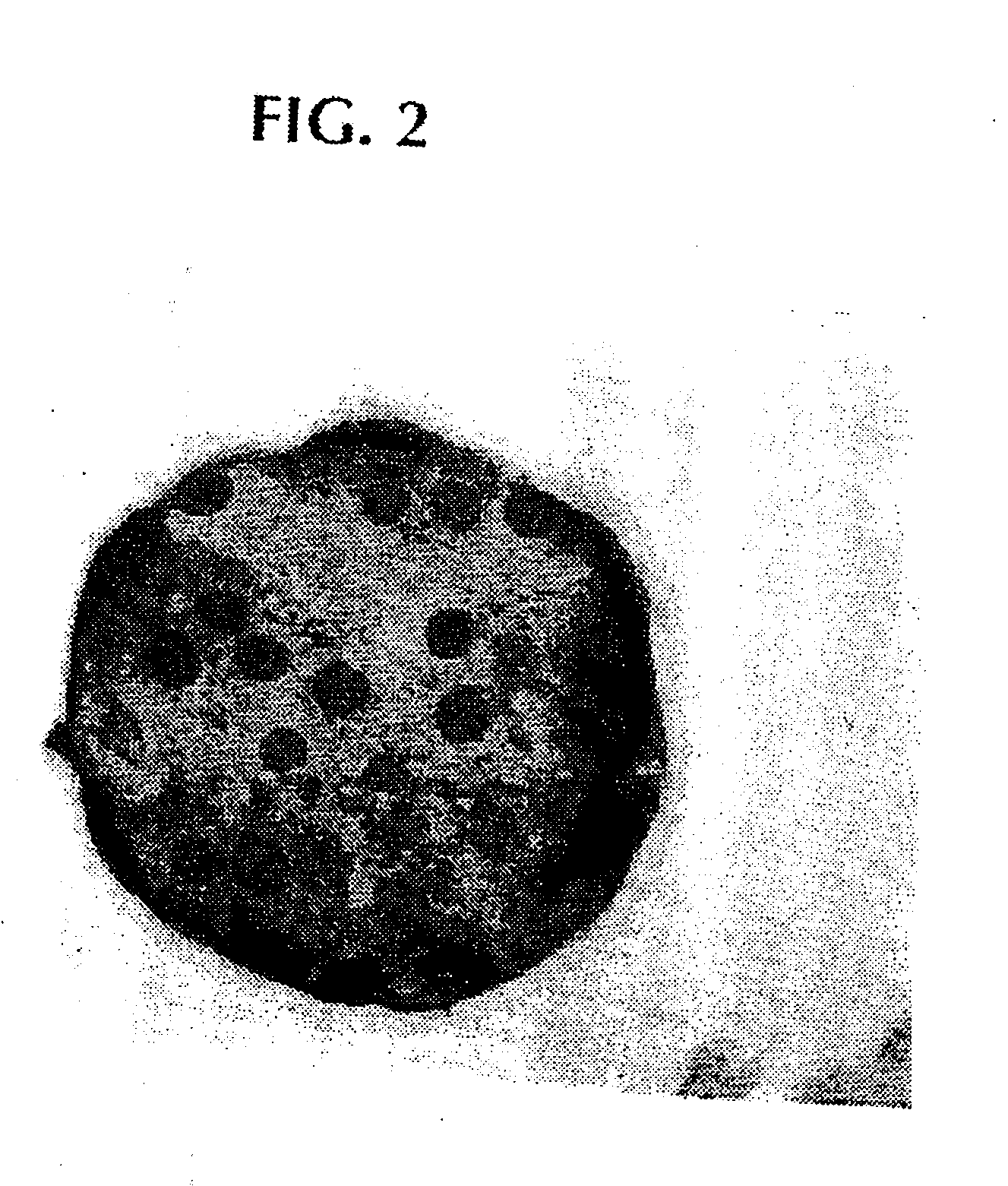

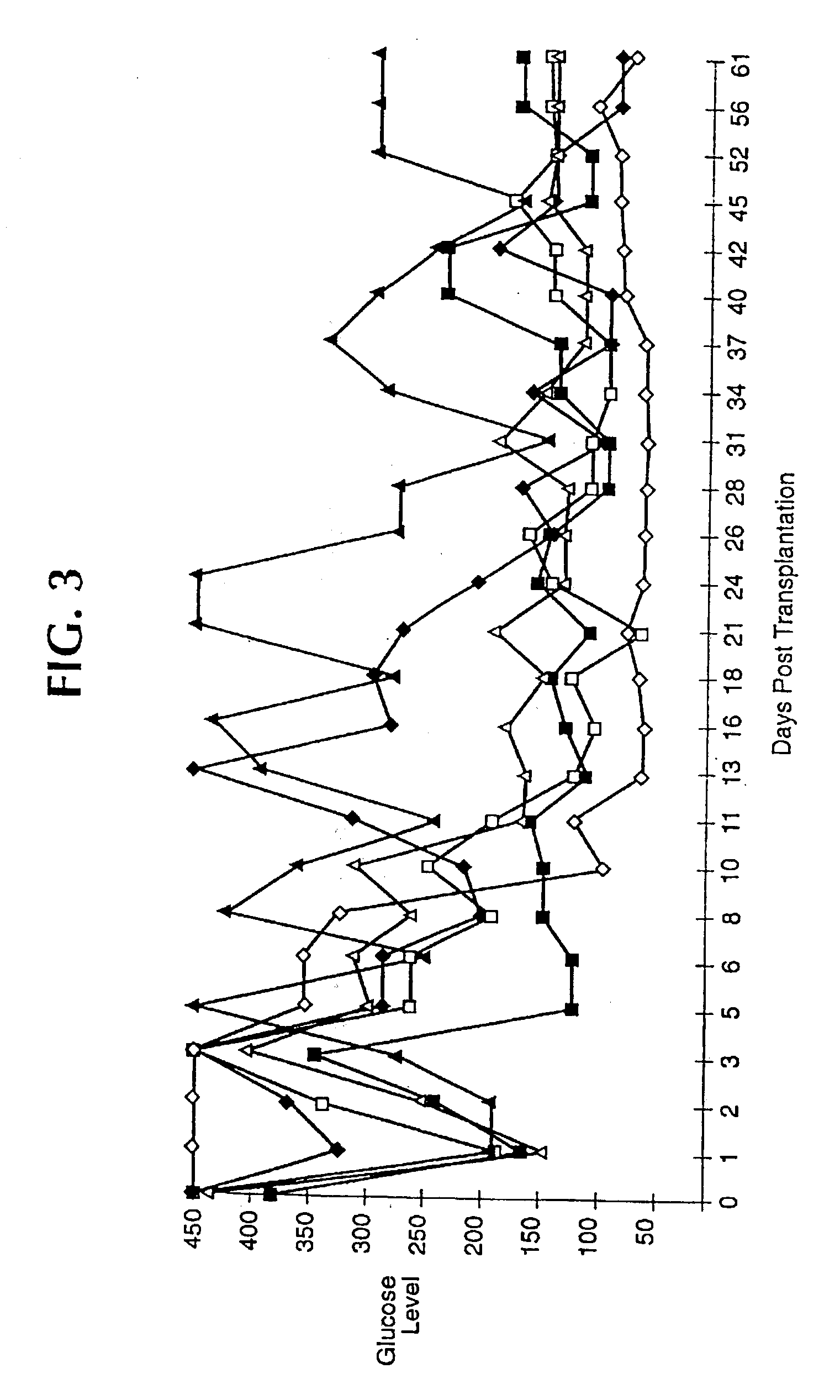

Biological agents such as secretory cells are encapsulated in a hydrophilic gel made of agarose or collagen-agarose and gelatin sponge-agarose combinations. In a preferred embodiment, semi-solid beads are formed from a suspension containing collagen, agarose and secretory cells such as pancreatic islets, the collagen is polymerized to form solid, agarose-collagen beads and the solid beads are coated with agarose. Coating is preferably by rolling the solid beads in about 5-10% agarose, contacting the rolled beads with mineral oil and washing oil from the beads. Beads containing secretory cells can be transplanted into a mammal to treat a condition caused by impaired secretory cell function.

Owner:THE ROGOSIN INST

Gelatin Sponge Comprising an Active Ingredient, Its Preparation and Use

ActiveUS20110045034A1Assist cessationImprove performancePeptide/protein ingredientsAbsorbent padsCross-linkGelatin sponge

The invention relates to an improved dry cross-linked gelatin sponge comprising a layer of an active ingredient, to methods of its preparation and uses thereof.

Owner:OMRIX BIOPHARM

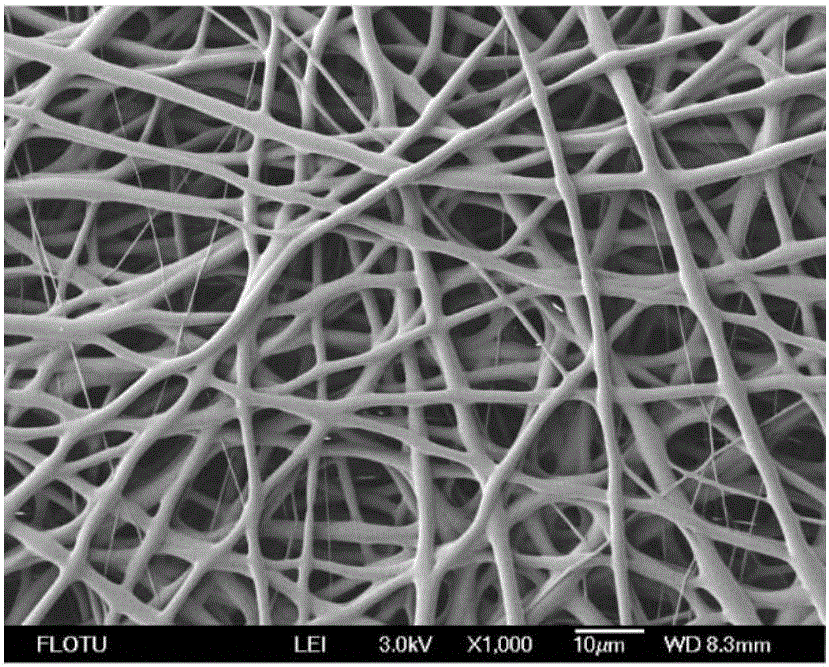

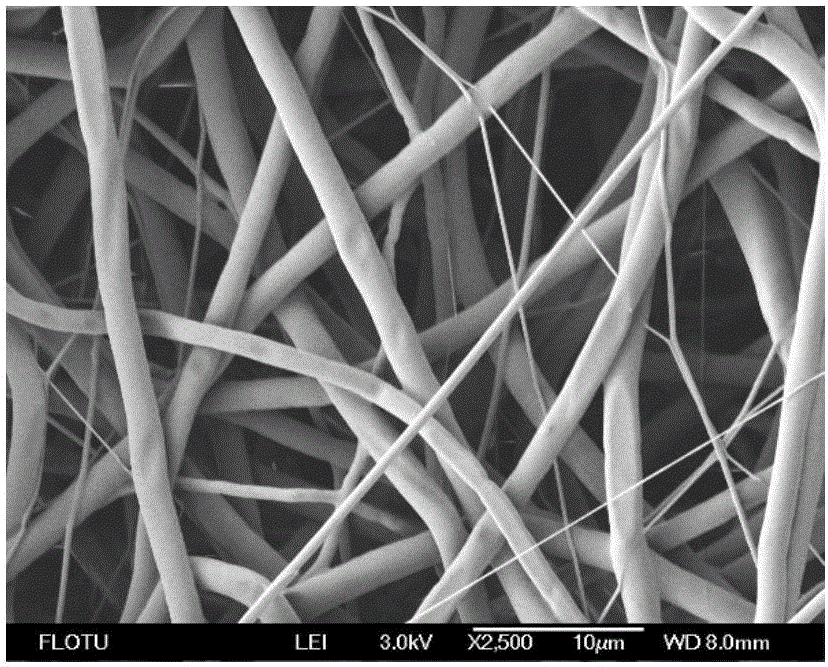

Antibacterial-hemostatic material with non-woven fabric fiber fabric structure and production method of antibacterial-hemostatic material

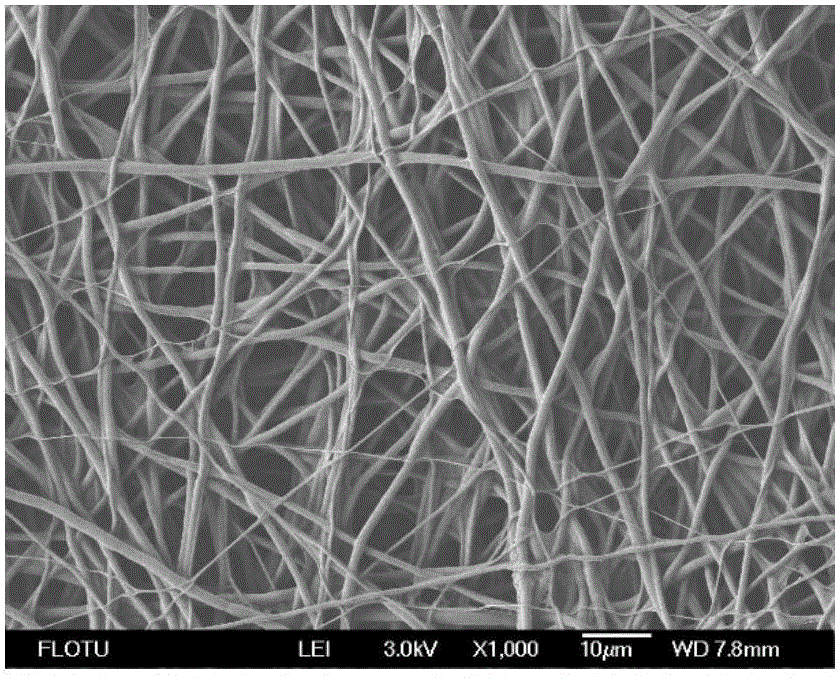

InactiveCN105012991AReduce dosageGood storage stabilityBiochemical fibre treatmentFibre typesPolyesterPorosity

The invention relates to antibacterial-hemostatic material with a non-woven fabric fiber fabric structure and a production method of the antibacterial-hemostatic material and belongs to the technical field of biomedical materials. The antibacterial-hemostatic material is characterized in that aliphatic polyester is dissolved into solvent, an electrospun fibrous membrane is produced through static spinning, chitosan is loaded on the surface of the electrospun fibrous membrane, thrombin is further loaded on the surface of the electrospun fibrous membrane, and the antibacterial-hemostatic material is produced. The material features of the aliphatic polyester and the chitosan are utilized, the structure features such as high porosity and high specific surface area of the formed electrospun fibrous membrane are utilized, stable loading of the thrombin is performed by the crosslinking action of the chitosan and glutaraldehyde, and the antibacterial-hemostatic material with the non-woven fabric fiber fabric structure is formed. The antibacterial-hemostatic material has the advantages that the material is good in antibacterial and hemostatic effects, the antibacterial and hemostatic effects of the material are obviously better than those of commercially available gelatin sponge, the material is good in mechanical performance, easy to store and convenient to remove after being used, the production method of the material is simple to operate and capable of reducing raw material use amount, and the material is applicable to fields such as surgery and trauma first-aid.

Owner:TSINGHUA UNIV

A technique for preparing absorbable gelatin sponge particle suppository with glutin as raw material

The present invention provides a technique for preparing the gelfoam particle suppository which uses the glutin as the raw material, and the invention comprises the steps of: dissolving the glutin to the water, stirring to uniform at the water-bath condition when the formaldehyde solution is added, and the white porous spongy product is produced after freezing; defreezing the white porous spongy product, removing the water and formaldehyde after washing, and the gelfoam is obtained; crushing the gelfoam after freezing and the gelfoam particle is obtained; defreezing the gelfoam particle and placing the gelfoam particle to the water to do sifting after dewatering, and drying after sifting; disinfecting the dried gelfoam particle after sifting and the gelfoam particle suppository is obtained. The cost of the method in the invention is low and the invention easily causes that the residual quantity of the formaldehyde reaches the clinical using standard.

Owner:郑隆泗

Preparation of agarose coated, solid agarose-collagen beads containing secretory cells

Biological agents such as secretory cells are encapsulated in a hydrophilic gel made of agarose or collagen-agarose and gelatin sponge-agarose combinations. In a preferred embodiment, semi-solid beads are formed from a suspension containing collagen, agarose and secretory cells such as pancreatic islets, the collagen is polymerized to form solid, agarose-collagen beads and the solid beads are coated with agarose. Coating is preferably by rolling the solid beads in about 5-10% agarose, contacting the rolled beads with mineral oil and washing oil from the beads. Beads containing secretory cells can be transplanted into a mammal to treat a condition caused by impaired secretory cell function.

Owner:THE ROGOSIN INST

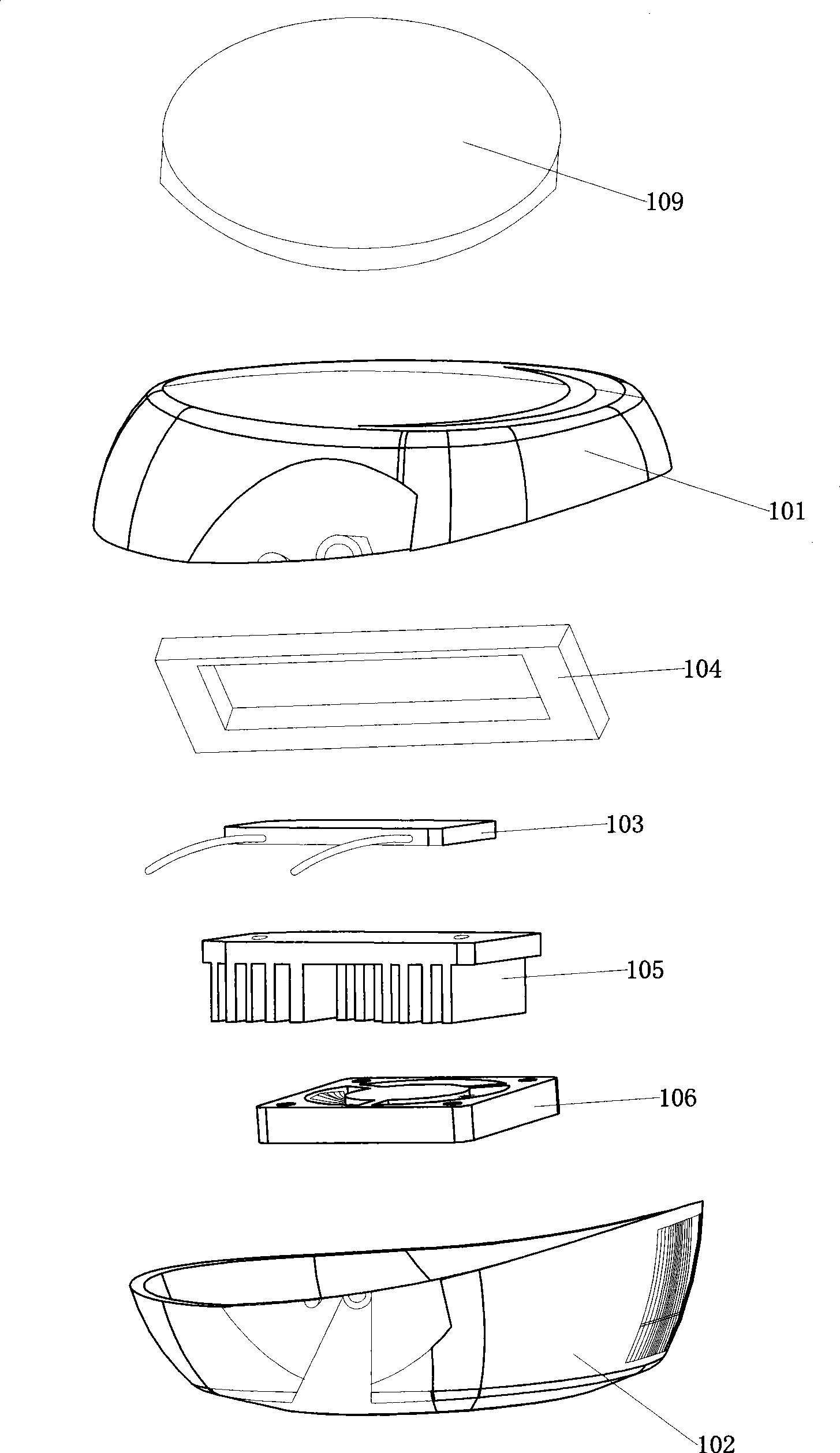

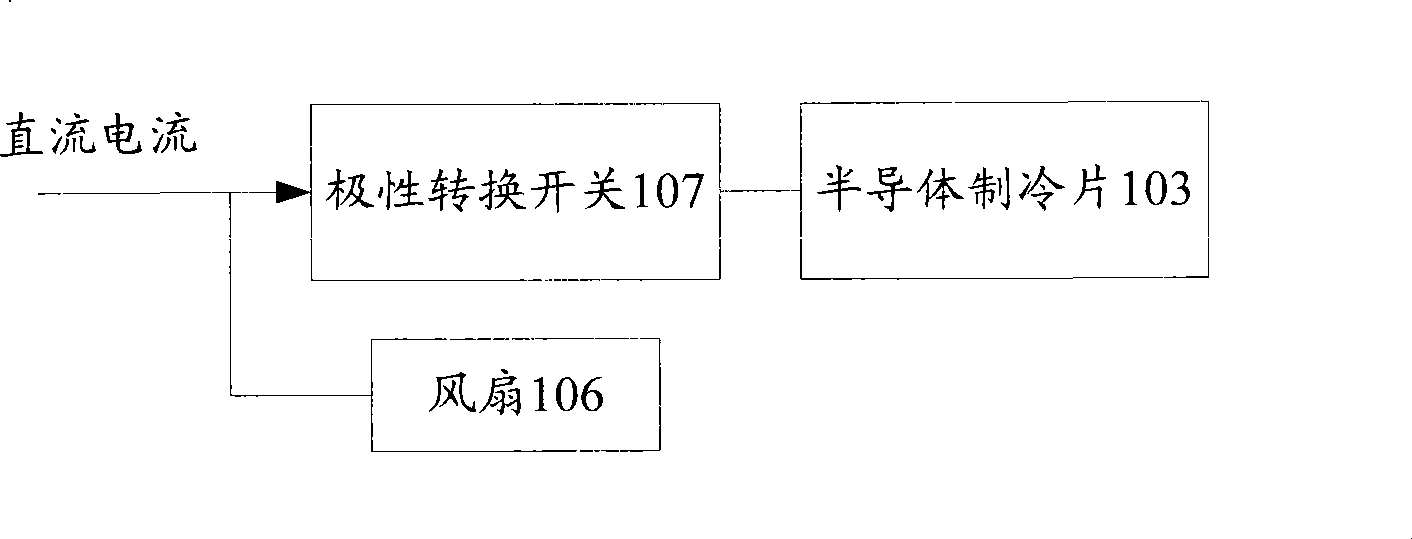

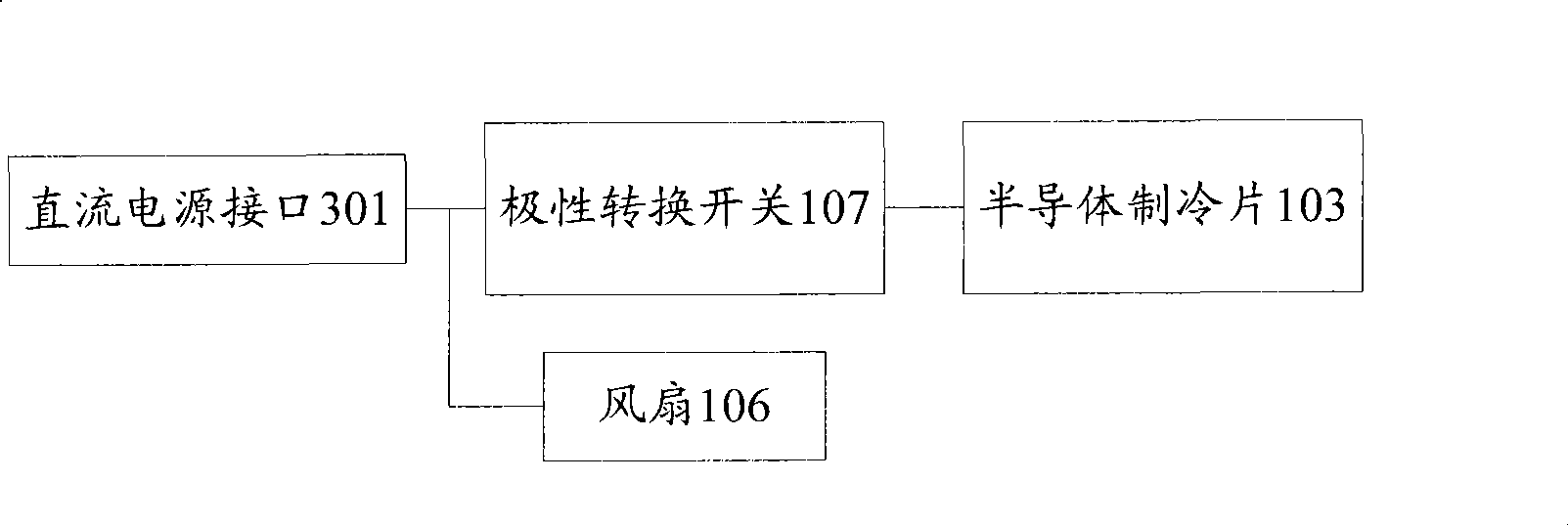

Healthcare device for cold-hot compress

InactiveCN101444447AConvenient to go out and carryRapid coolingTherapeutic coolingTherapeutic heatingElectricityHeat conducting

The invention relates to the electricity field, and discloses a healthcare device for cold-hot compress. The healthcare device comprises an upper cover and a lower cover which are fixedly connected, space formed by the upper cover and the lower cover is internally provided with a semiconductor refrigeration piece, gelatin sponge, a radiating fin, a fan and a polarity-reversing switch; a DC power socket is arranged on the upper cover or the lower cover, the DC power socket is electrically connected with an input terminal of the polarity-reversing switch, and an output terminal of the polarity-reversing switch is respectively electrically connected with the semiconductor refrigeration piece and the fan; the semiconductor refrigeration piece is arranged in the center through hole of the gelatin sponge; aluminum heat conducting fin is fixed on the upside of the semiconductor refrigeration piece by radiating glue, and the aluminum heat conducting fin is embedded at an opening of the top surface of the upper cover; and the radiating fin is fixed on the underside of the semiconductor refrigeration piece by the radiating glue, the fan is fixed on the underside of the radiating fin, and an air hole is arranged on the lower cover. The healthcare device for cold-hot compress can be more conveniently used.

Owner:陈齐武

Biodegradable quick hemostyptic dressing, and its preparing method

InactiveCN101002957AImprove adhesionLower immune responseAbsorbent padsBandagesHigh resistanceDamages tissue

A biodegradable dressing for fast haemostasis is prepared from collagen and hyaluronic acid. It has high resistance to edema, high power to recover the damaged tissue, and high safety.

Owner:SANSEN BIOTECH XIAN

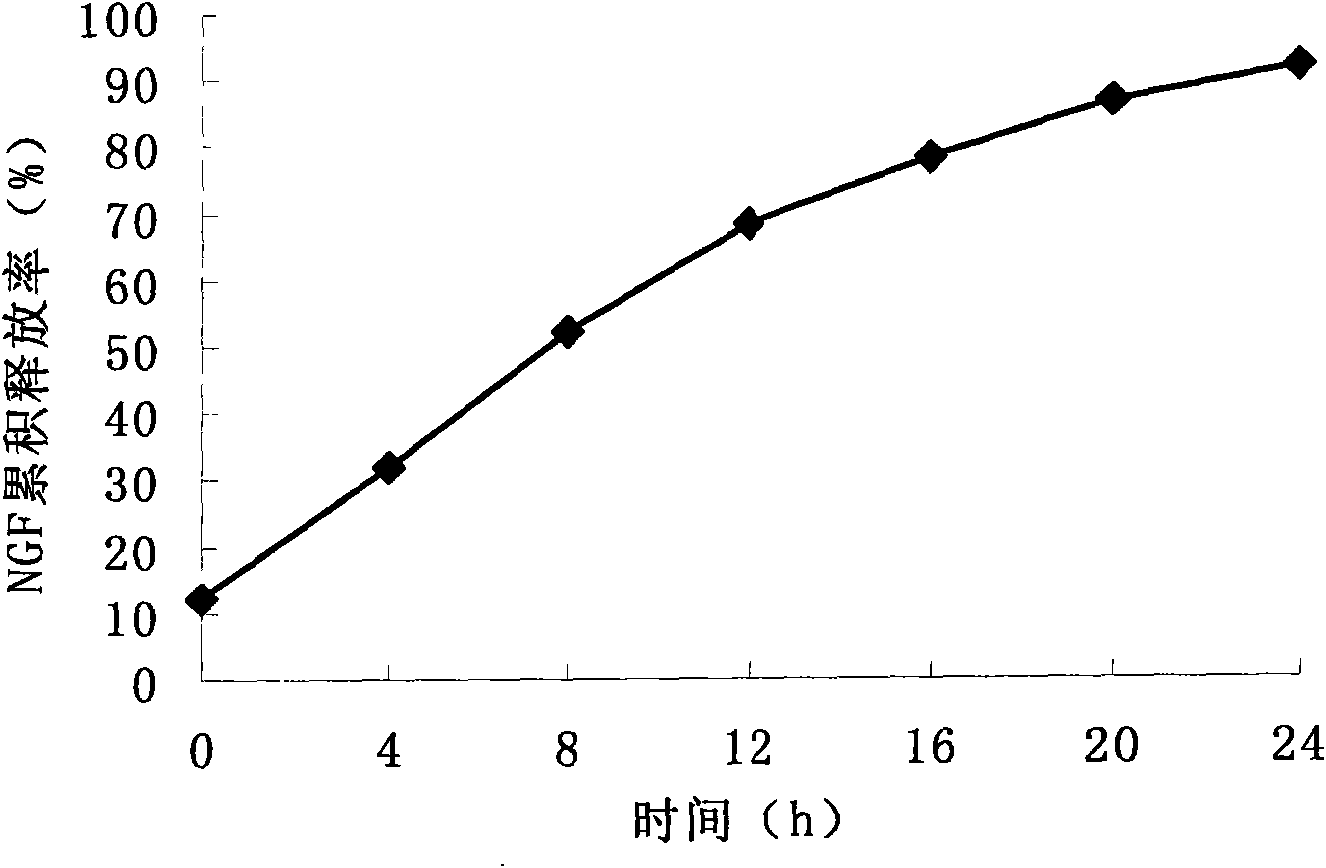

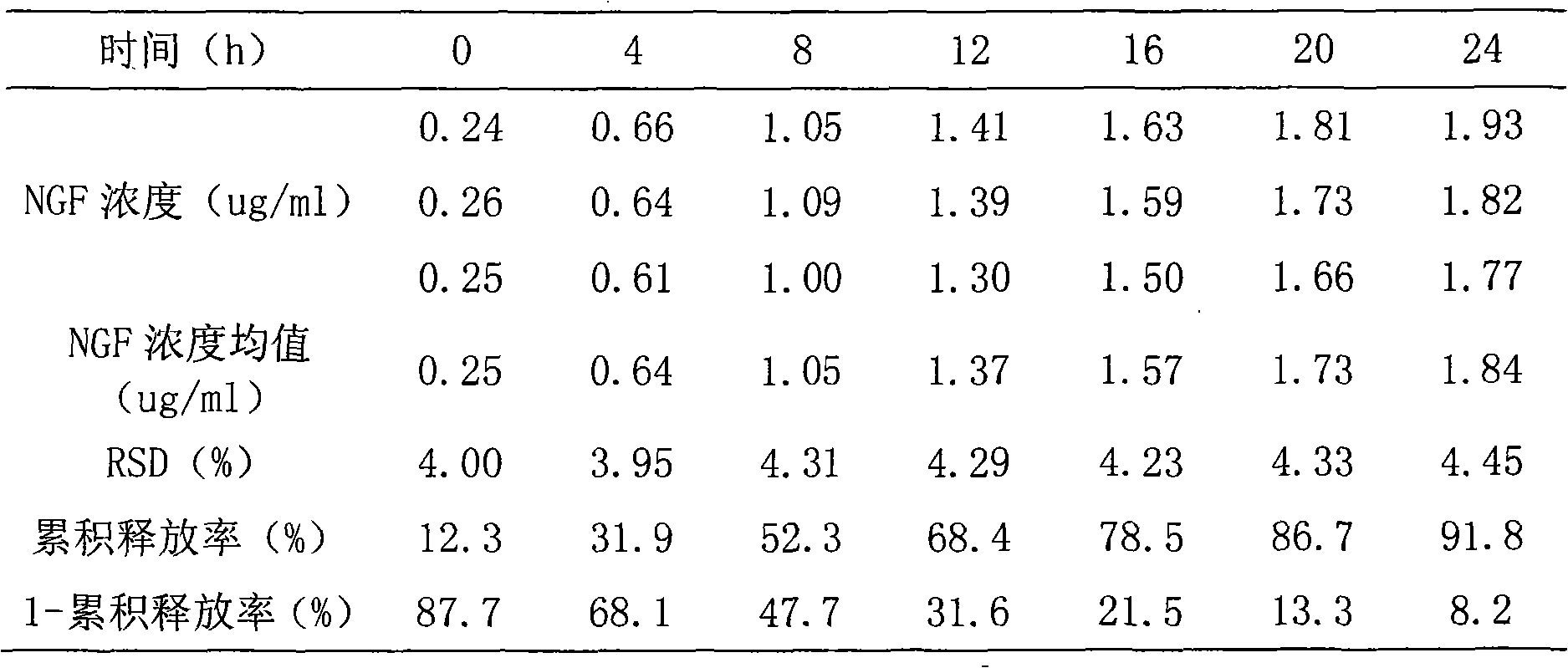

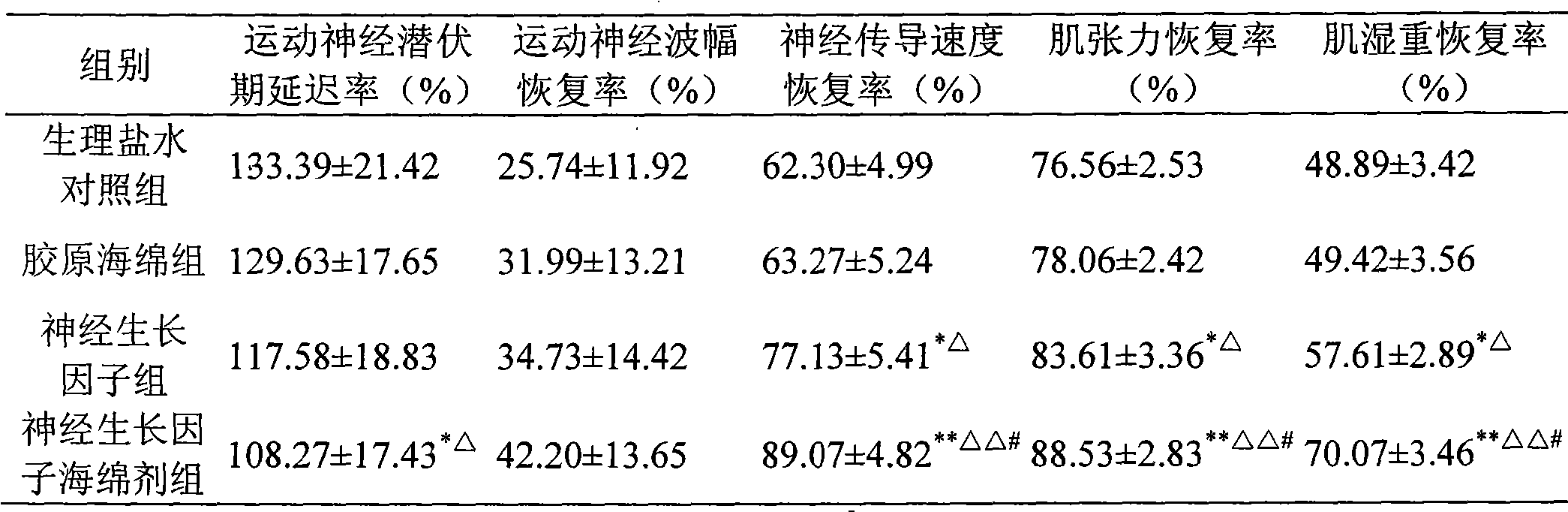

Nerve growth factor sponginum and preparation method thereof

InactiveCN101612113AIncrease concentrationRelieve painConnective tissue peptidesNervous disorderGelatin spongeNerve pathology

The invention relates to a nerve growth factor sponginum and a preparation method thereof, belonging to the technical field of medicine. The sponginum comprises nerve growth factor with weight percent content being 0.01-2% and collagen sponge or gelatin sponge matrix, the nerve growth factor is fixed on the collagen sponge or gelatin sponge matrix in a crosslinking way by an aldehydes crosslinker. The sponginum can cause the nerve growth factor to be released to the nerve pathology or wound tissue partial position continuously for a long time in effective dose, and play a role in effectively curing nerve tissue damage.

Owner:WUHAN HITECK BIOLOGICAL PHARMA

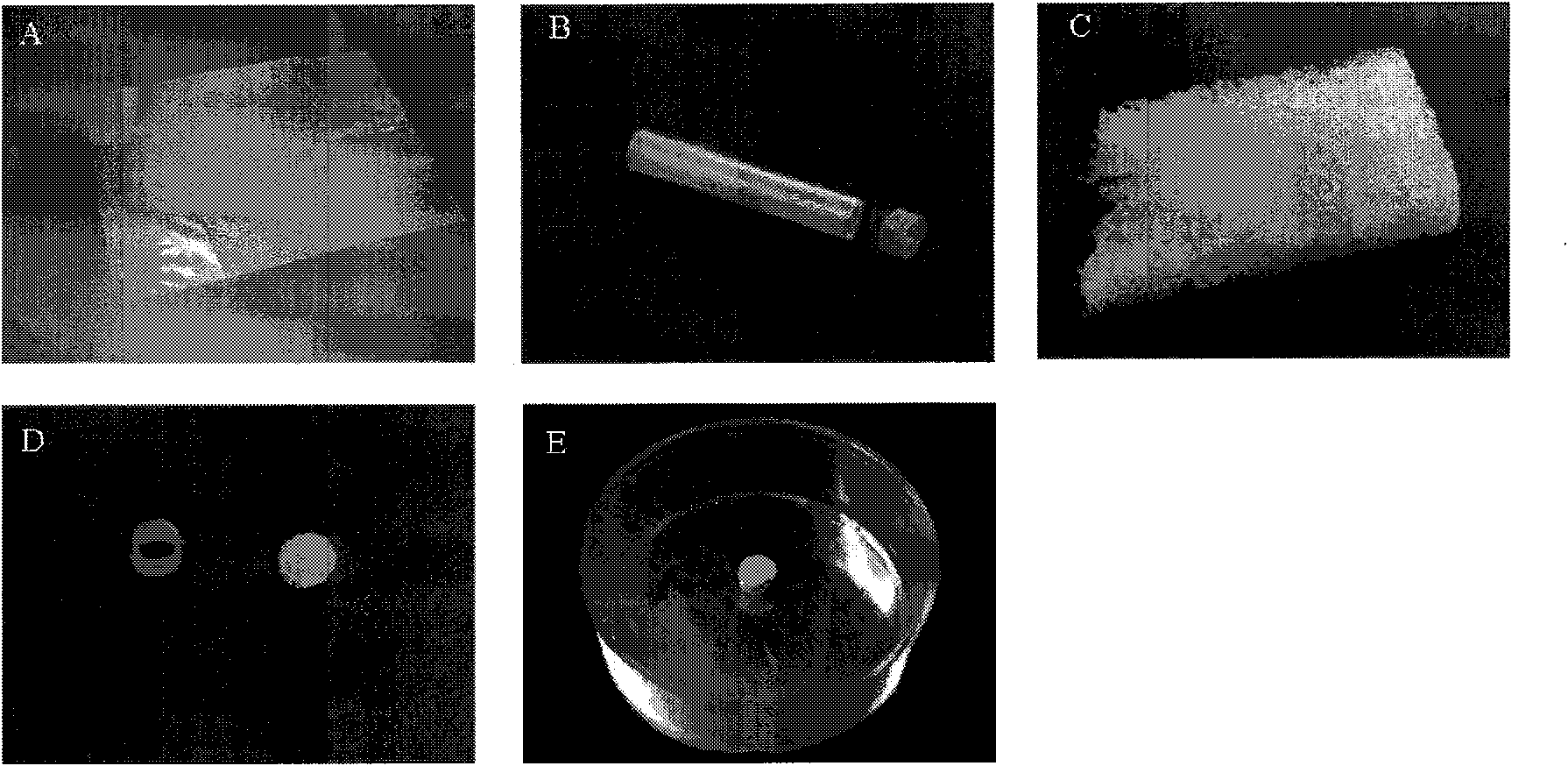

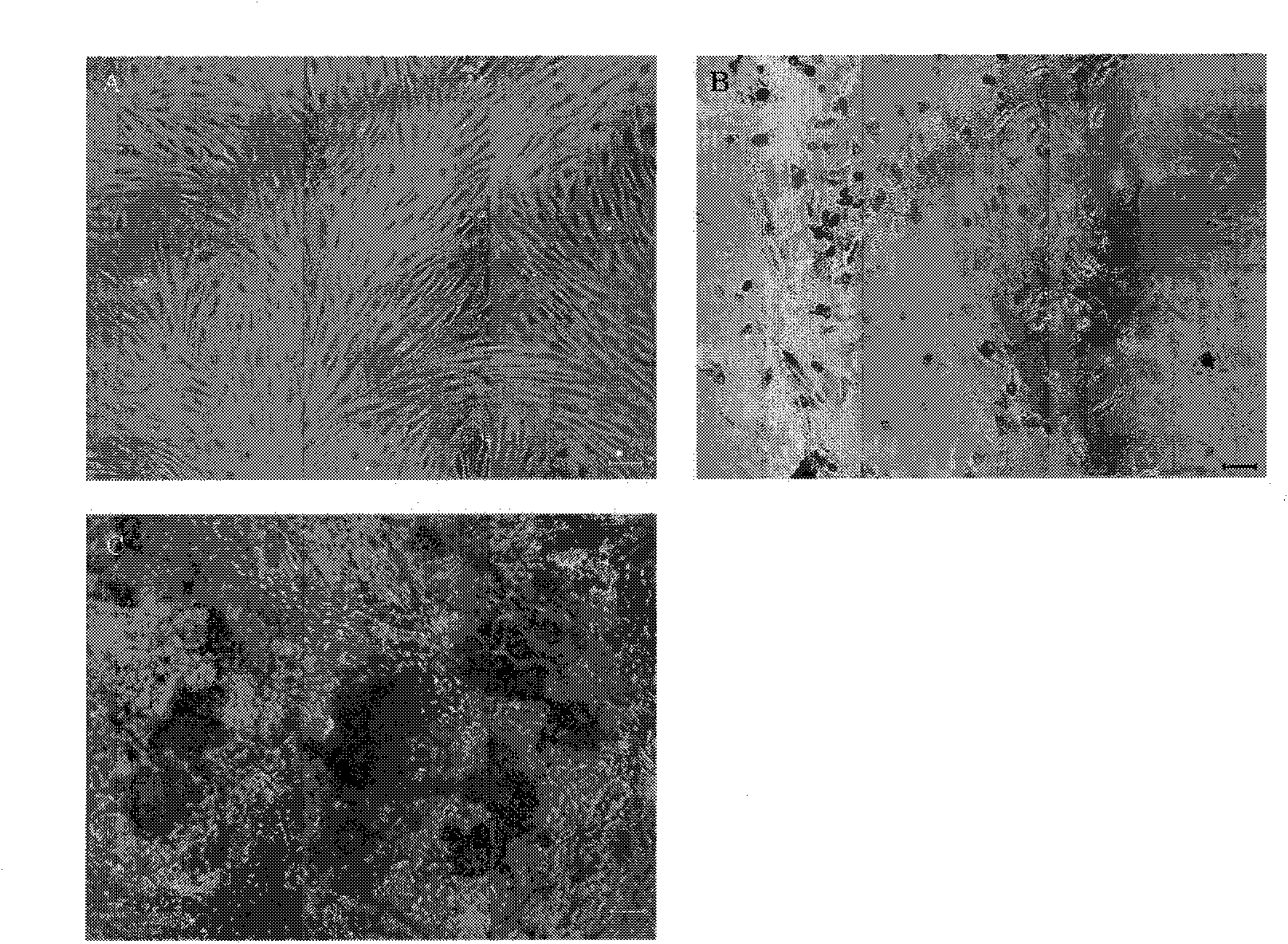

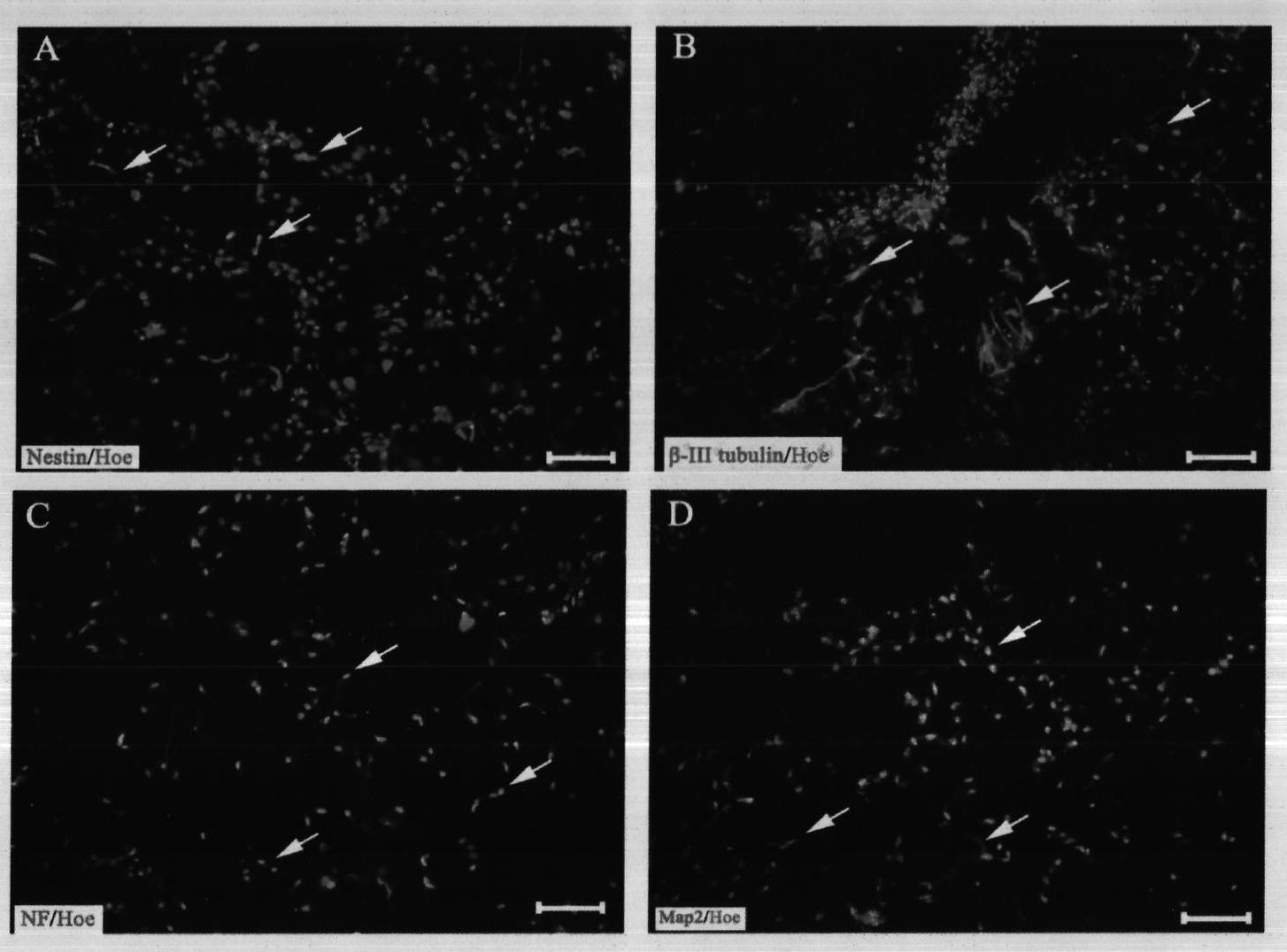

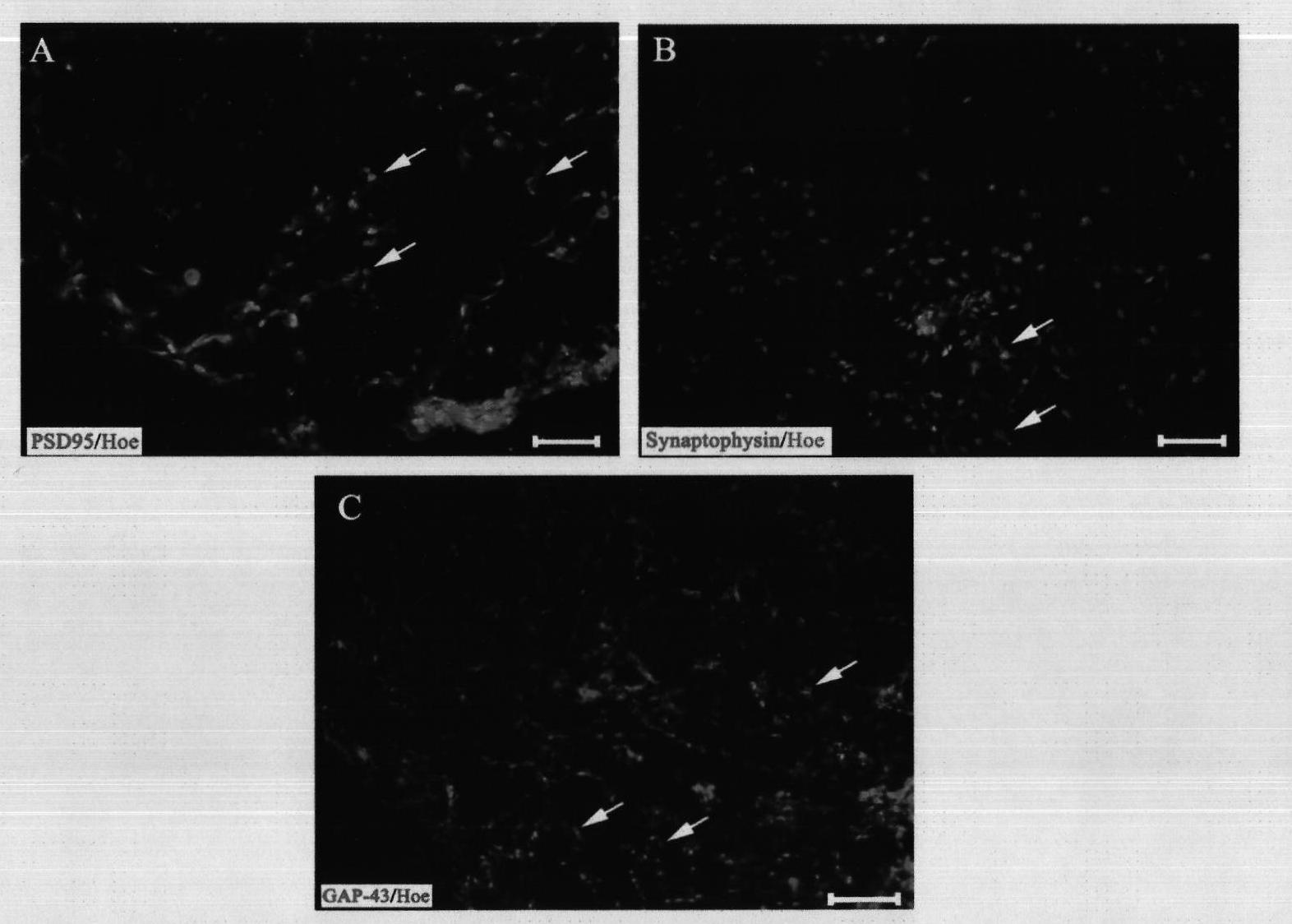

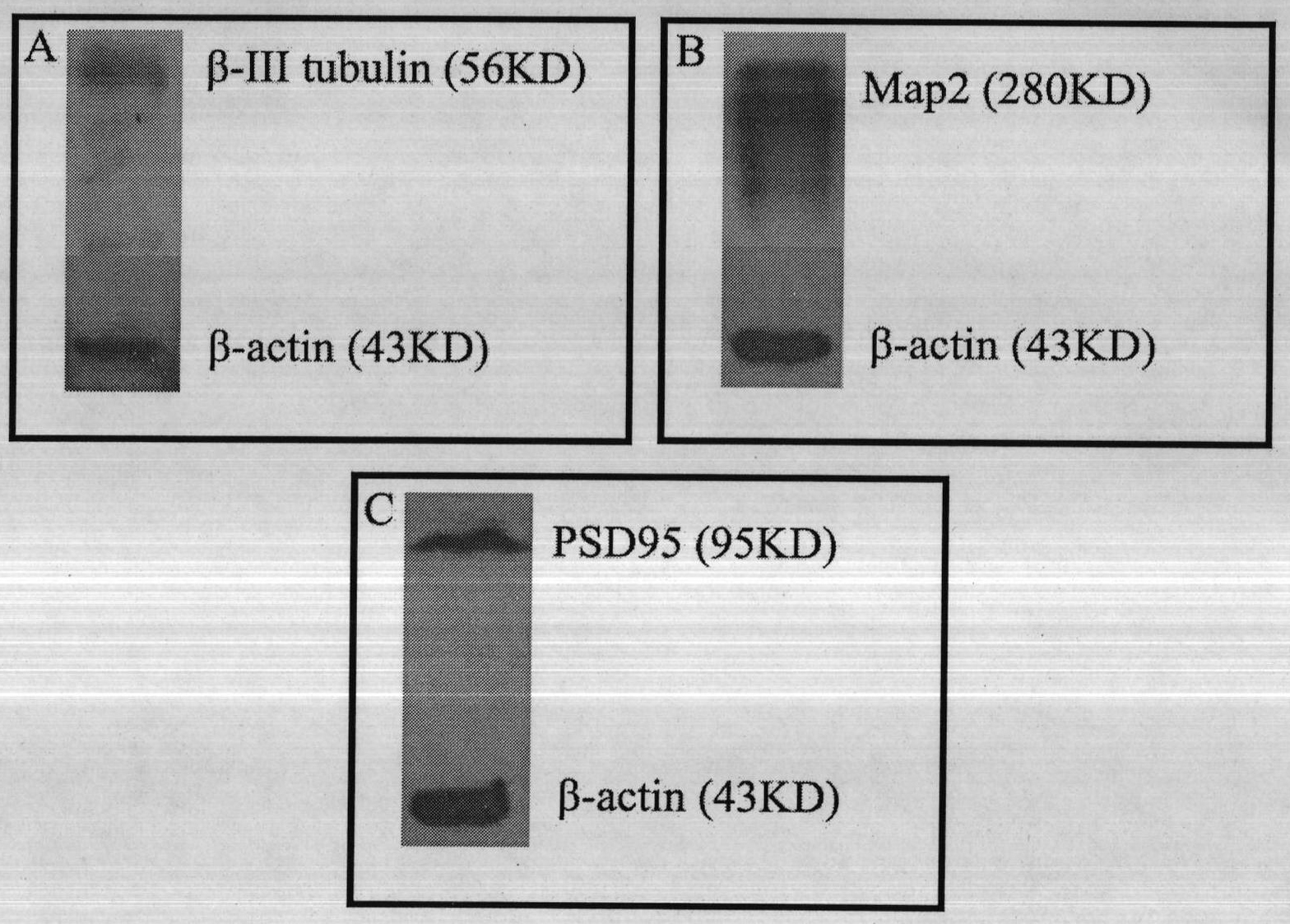

Construction of gelatin sponge cylinder bracket used for repairing nerve injury

ActiveCN101653366APromote regenerationImprove the quality of lifeSurgeryCatheterGelatin spongeSpinal cord

The invention relates to a construction method of a porous gelatin sponge cylinder bracket material used for repairing nerve injury, in particular to a construction method of a stem cell-containing porous gelatin sponge cylinder bracket and an application thereof. When in use, the porous gelatin sponge cylinder bracket planted with stem cells and noblecellsor thereof / and schwann cells is transplanted to the injury part of complete transaction or hemitransection spinal cord, which can better promote injured nervus centralis regeneration and function reparation. The invention has important significance in strengthening injured neuron protection after spinal cord trauma in biological tissue engineering level, promoting axonal regeneration of injured neuron, improving quality of life of the sick and injured, reducing the heavy burdens of society and families, and promoting socioeconomic development of China.

Owner:SUN YAT SEN UNIV

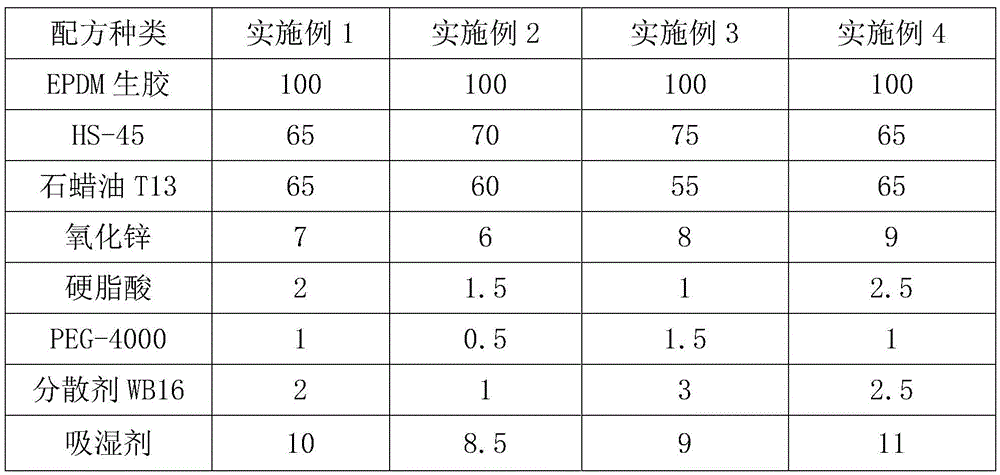

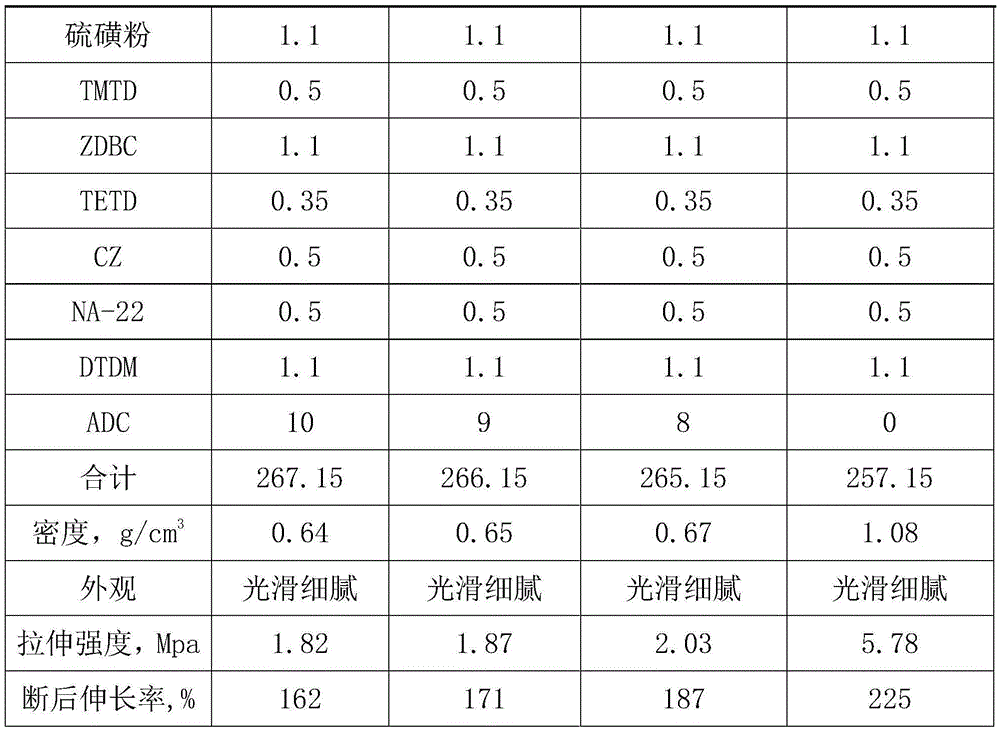

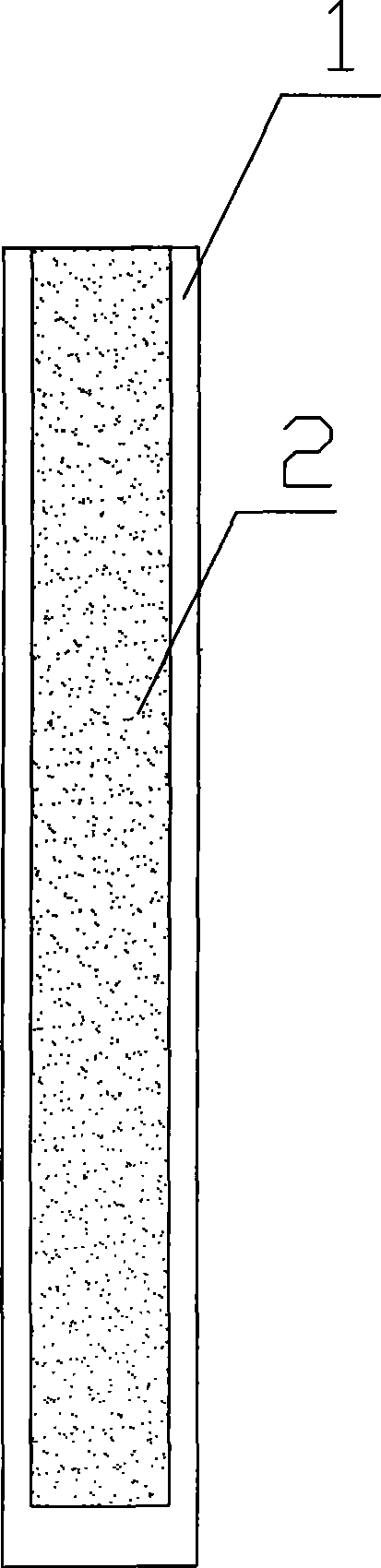

Mold-pressed sponge sealing rubber strip

The invention relates to the technical field of production and processing of rubber, particularly a mold-pressed sponge sealing rubber strip. The mold-pressed sponge sealing rubber strip comprises the following raw materials in parts by mass: 100 parts of EPDM (ethylene-propylene-diene monomer) unvulcanized rubber, 55-80 parts of reinforcing agent carbon black HS-45, 55-80 parts of paraffin oil, 5-10 parts of zinc oxide, 1-3 parts of stearic acid, 0.5-1.5 parts of surfactant PEG-4000, 1-4 parts of dispersing agent WB16, 8-12 parts of moisture absorber, 1.1 parts of sulfur powder, 1.1 parts of accelerator ZDBC, 1.1 parts of vulcanizing agent DTDM and 0-15 parts of foaming agent ADC. By using the ultralow-mooney-viscosity unvulcanized rubber and abundant chemical foaming agent, the rubber at the mold-pressed the sealing strip corner part of the sealing strip can be foamed in the mold to become gelatin sponge, so that the vertical bar position and the corner position of the sealing strip have close density of rubber, similar hand feeling and consistent door closing force, thereby enhancing the esthetic quality of the sealing strip, lowering the pollution product quantity to some extent, ensuring the excellent sealing property of the product in the use process, enhancing the hand feeling and lowering the processing cost of the manufacturer.

Owner:ZHEJIANG XIANTONG RUBBER & PLASTIC CO LTD

Hemostatic suppository for blocking organ puncture path

The invention discloses a styptic blocked plug for a viscera puncture path, which comprises a shell and an interior core, wherein the shell is provided with an opening and is made of a hydrophilic and resolvable organism degradable material, and the interior core is arranged in the shell and is mainly made of gelatin sponge. The styptic blocked plug for the viscera puncture path of the invention can not only ensure that the gelatin sponge takes the effect of hemostasia immediately, but also prevent the gelatin sponge from absorbing water prematurely to bulge. Therefore, the gelatin sponge is easily pushed to the deep part of the puncture path and cannot be dashed out easily by blood, all gelatin sponge grains are released to take the durative effect of hemostasia after the shell thaws. The styptic blocked plug has accurate, reliable, good and thorough effects of blocking and hemostasia, which is capable of curing maniple hemorrhage of the puncture path effectively and reducing or getting rid of the risk of secondary hemorrhage and massive haemorrhage; the styptic blocked plug also has a better styptic effect on the massive haemorrhage of the puncture path; and the styptic blocked plug has the advantages of wide material resource, low cost, simple preparation, convenient use, no any toxic and side effect and wide application prospect.

Owner:THE FIRST AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIVERSITY OF PLA

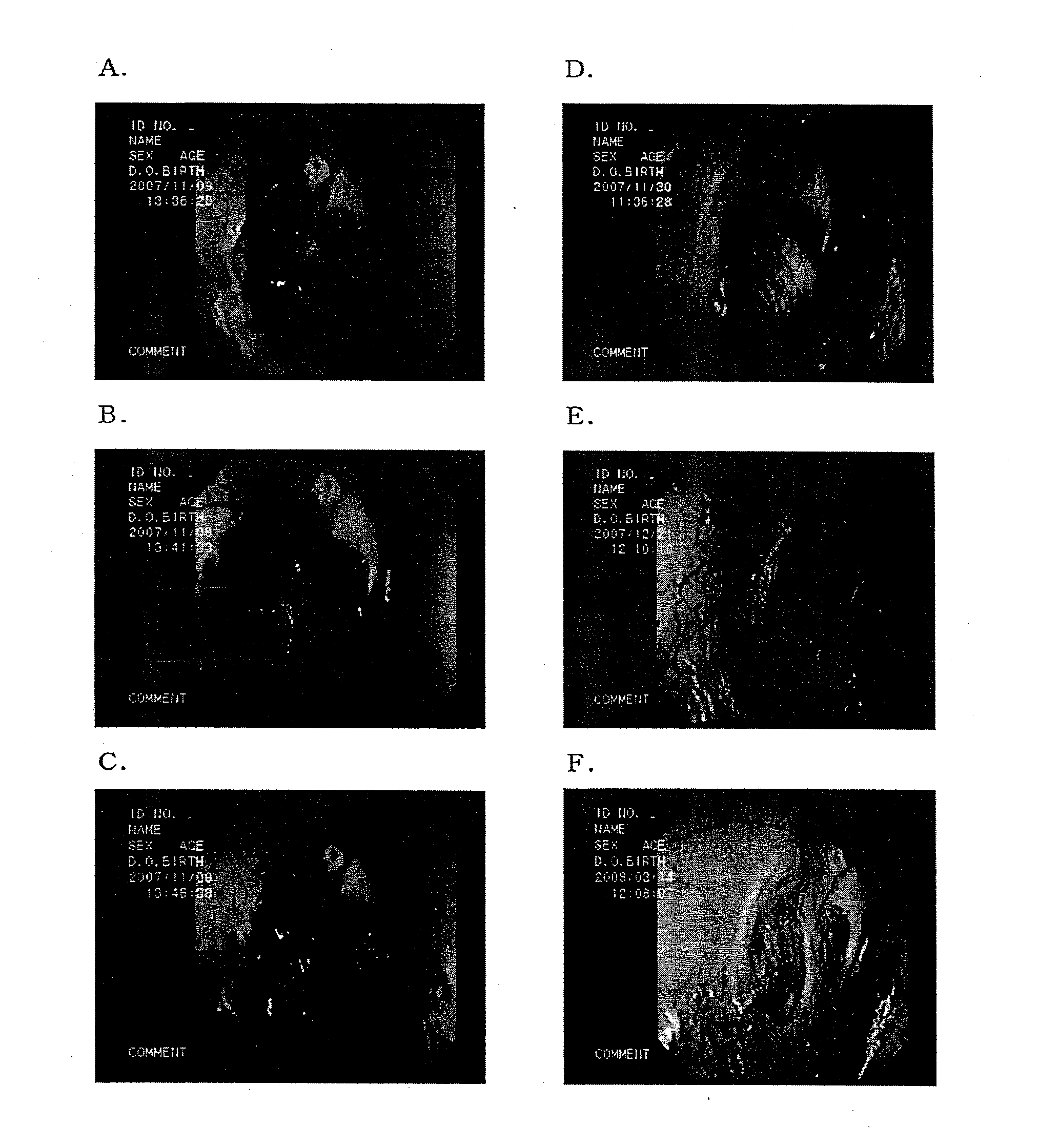

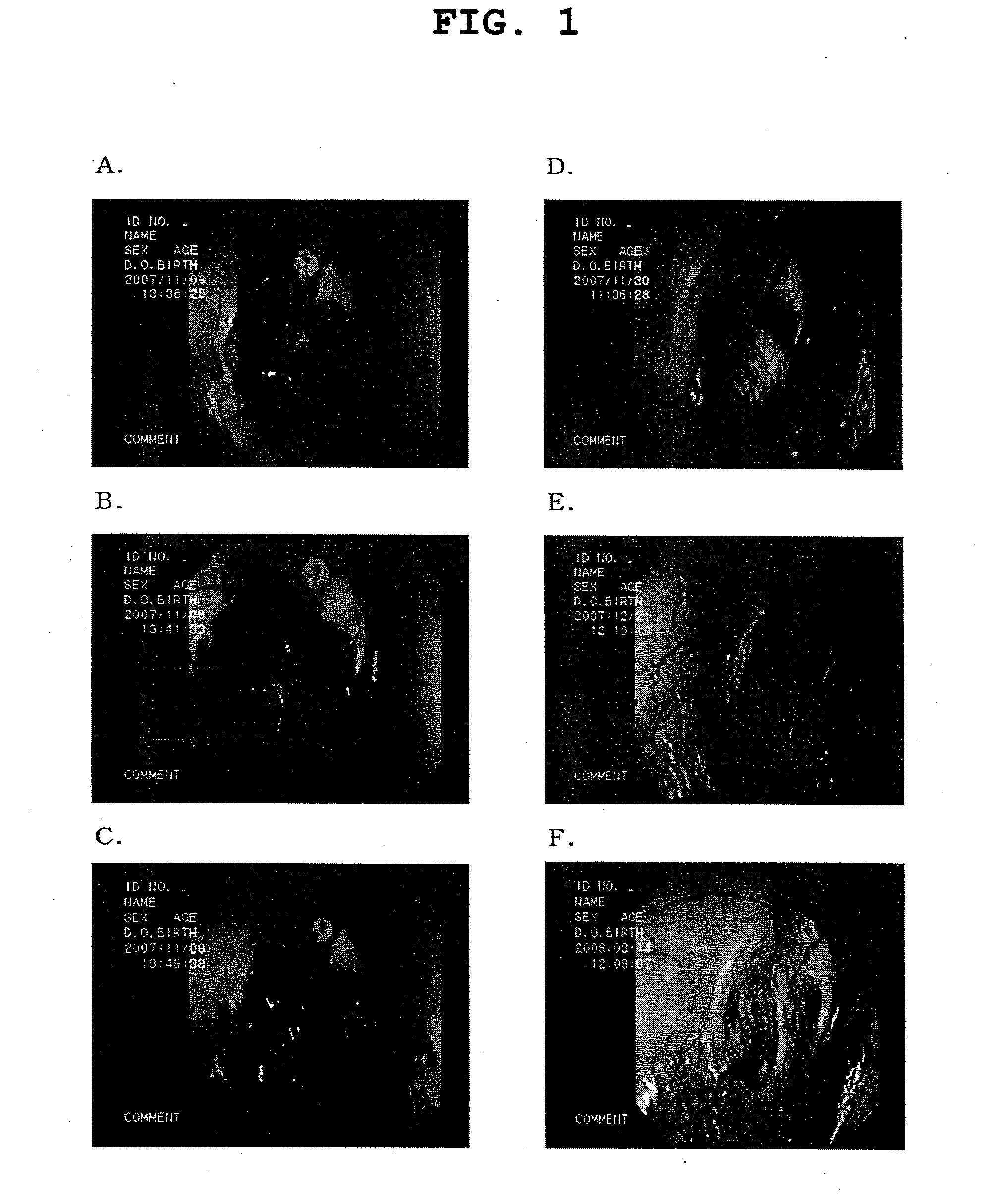

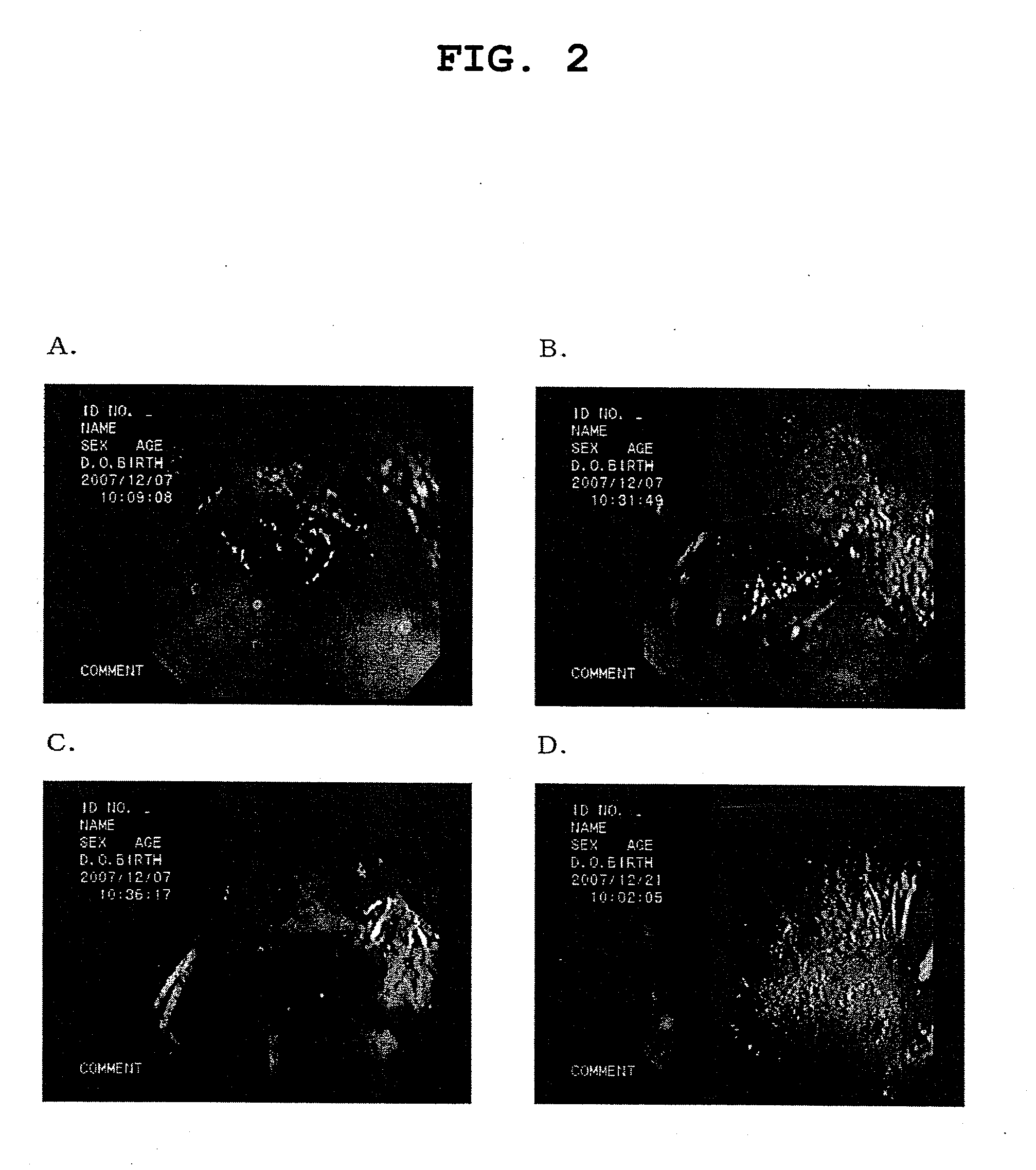

Agent for regenerating tympanic membrane or external auditory canal

ActiveUS20110110987A1Repair is possiblePrevent dryingSenses disorderPeptide/protein ingredientsExternal Auditory CanalsGelatin sponge

Provided is a tympanic membrane or ear canal regeneration agent comprising a combination of a gelatin sponge that carries basic fibroblast growth factor (bFGF) and a covering material. The covering material is used not only to fix the gelatin sponge to the affected portion, but also for the purpose of preventing drying and infections to provide a culturing environment that is favorable for regenerating tissue isolated from the outside. To promote tissue regeneration, the margin of the tympanic membrane or ear canal defect is preferably freshened in advance.

Owner:NOBELPHARMA CO LTD

Gelatin sponge and preparation method thereof

The invention provides gelatin sponge, gelatin aqueous solution is irradiated to crosslink to form gelatin hydrogel, and then the gelatin hydrogel is swollen, frozen and dried to obtain the gelatin sponge. The invention also provides a preparation method of the gelatin sponge by an irradiation crosslinking way, the whole process flow is finished in a pure water system, the irradiation and crosslinking processes have sterilizing function and good controllability, the obtained product has better structural uniformity compared with a chemical crosslinking method, and the gelatin sponge has uniqueadvantages as biomedical materials.

Owner:厦门凝赋生物科技有限公司

Porous gelatin sponge and preparation method thereof

ActiveCN108530671AIncrease internal porosityIncrease the areaPharmaceutical delivery mechanismAbsorbent padsCross-linkPorosity

The invention discloses a preparation method of porous gelatin sponge. The preparation method comprises the following steps: S1, dissolving a crosslinking agent; adding gelatin in a stirring process and carrying out crosslinking reaction; S2, transferring a cross-linked gelatin solution into a sealed reaction container; introducing gas until the pressure in the reaction container reaches one atmospheric pressure or more, and then keeping for 10min or more; S3, carrying out programmed cooling on the gelatin solution treated by step S2 to be completely cured; S4, freezing and drying the cured gelatin; S5, immersing the freeze-dried gelatin into absolute ethyl alcohol and purified water in sequence to remove the crosslinking agent; S6, carrying out secondary freeze-drying on the immersed gelatin in step S5 and sterilizing to obtain the porous gelatin sponge. According to the preparation method of the porous gelatin sponge, disclosed by the invention, gas introduction and pressurizing, andprogrammed cooling curing treatment are carried out after the gelatin is crosslinked, and the inner porosity and specific surface area of the gelatin sponge are effectively increased; the water absorption performance of the gelatin sponge is improved so that the bleeding-stopping speed of the gelatin sponge is improved and the bleeding-stopping time is shortened.

Owner:MEDPRIN REGENERATIVE MEDICAL TECH

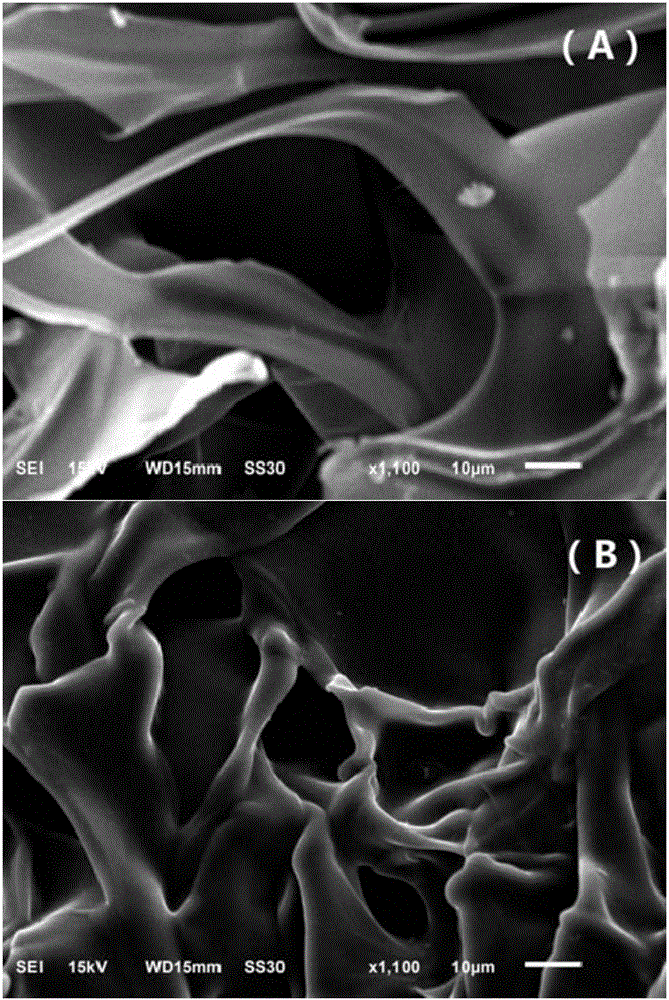

Aquatic product fish skin gelatin sponge and preparation method thereof

The invention relates to the technical field of medical instruments, and in particular relates to an aquatic product fish skin gelatin sponge and a preparation method thereof. The aquatic product fish skin gelatin is used as a main material, chitosan is used as an auxiliary material, and glutaraldehyde is used as a cross-linking agent; the raw material liquids of different proportions are subjected to freeze drying to prepare fish skin gelatin sponges with different properties; the preparation process of the sponge is simple; the sponge is low in cost and readily available; some defects of the conventional collagen sponge are overcome. The prepared fish skin gelatin sponge has a uniform porous netlike microstructure and higher mechanical strength and good moisture absorption and is a better biomedical material.

Owner:YANTAI INST OF COASTAL ZONE RES CHINESE ACAD OF SCI

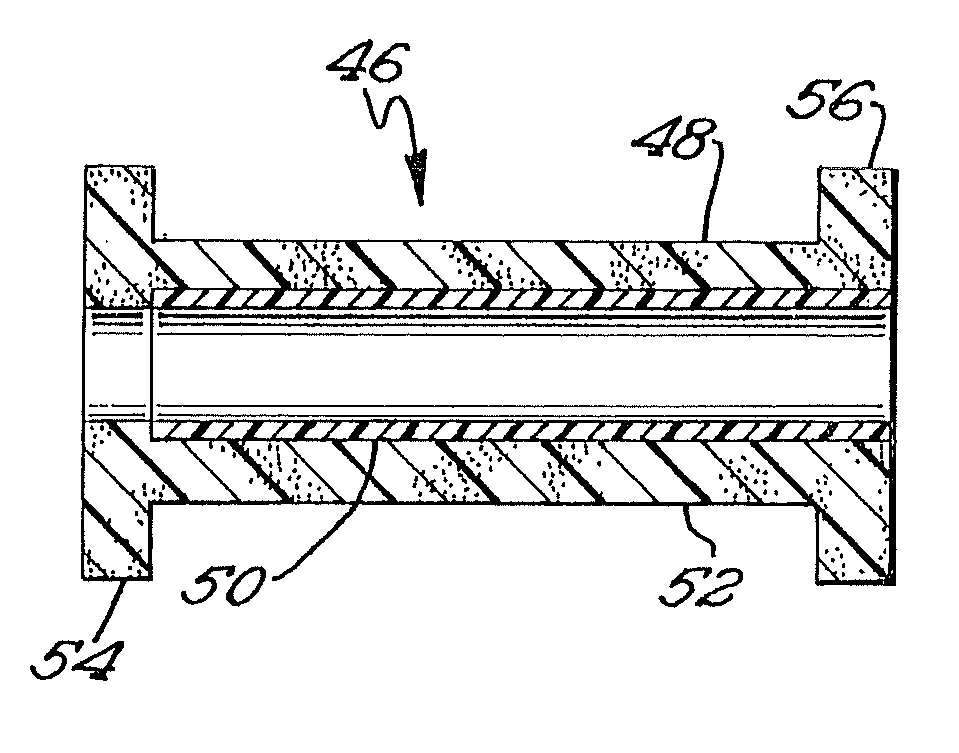

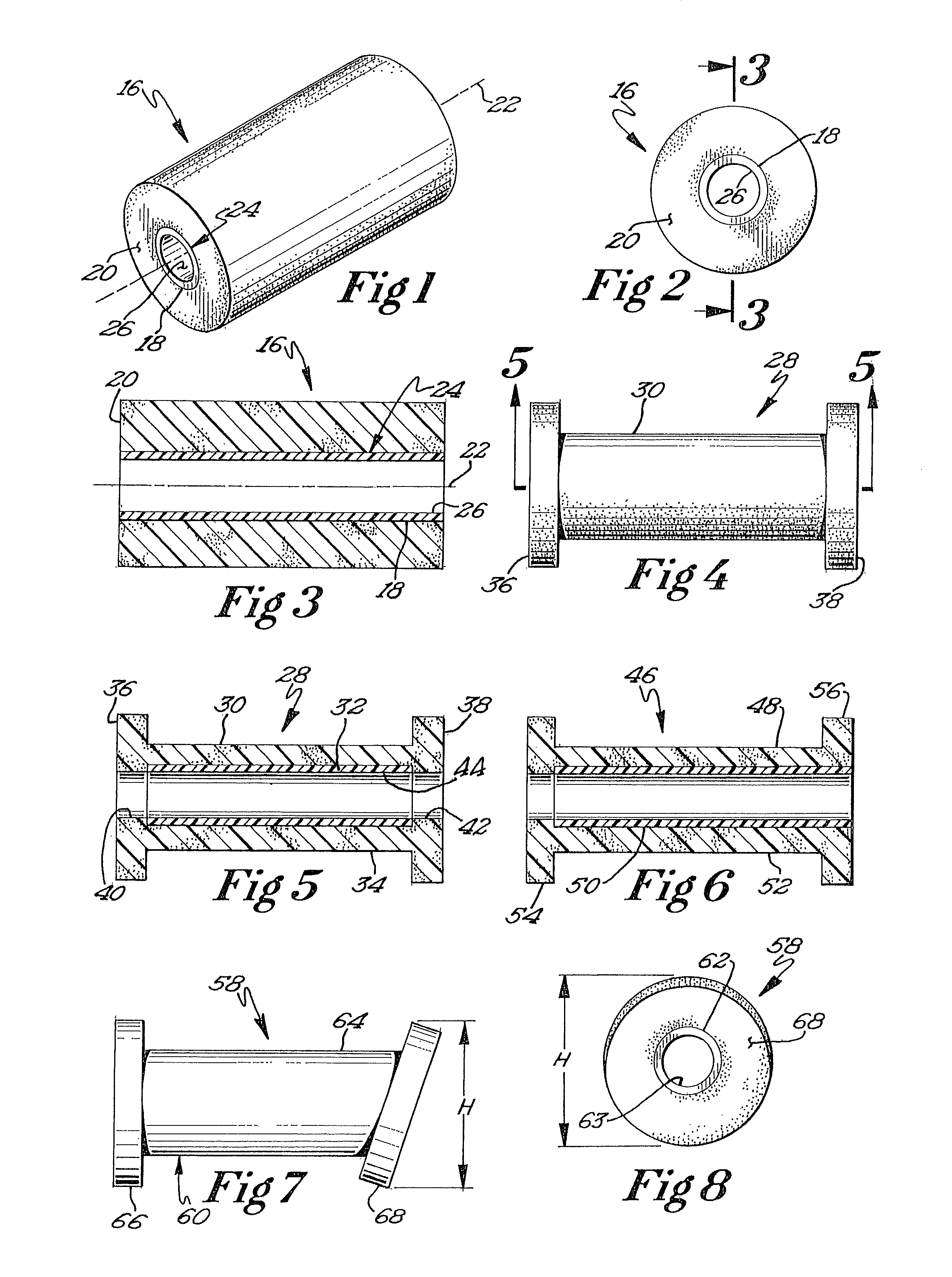

Biodegradable prosthesis

A body compatible and resorbable prosthesis has a tubular body incorporating denatured gelatin sponge material, either as a unitary gelatin sponge or as fragmented or powdered sponge material dispersed throughout a structurally self supporting medium. One version of the prosthesis uses the fragmented or powdered form of the gelatin sponge and is substantially homogeneous. An alternative prosthesis employs an inner tubular layer of gelatin film. The gelatin film layer is surrounded by an outer tubular layer, formed either of the gelatin sponge or the fragmented medium incorporating the gelatin sponge dispersion.

Owner:SKOVLUND MEDICAL PROD

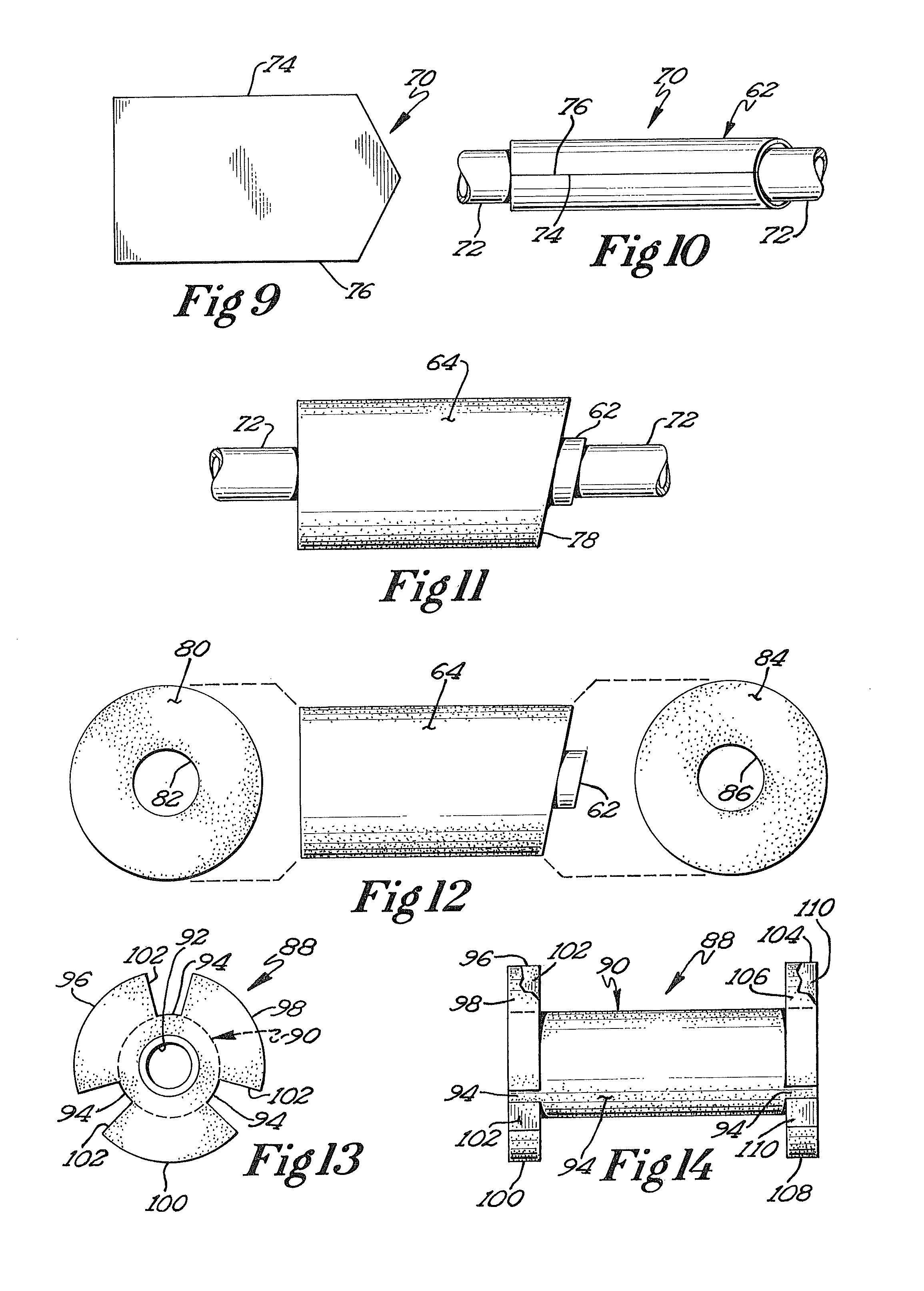

3D polypyrrole chitosan gelatin composite electric conduction material and preparation method thereof

ActiveCN107715170AHigh mechanical strengthGood biocompatibilityTissue regenerationProsthesisCross-linkPolypyrrole

The invention relates to a preparation method of a 3D polypyrrole chitosan gelatin composite electric conduction material. According to the preparation method, chitosan and pyrrole are used as raw materials, under the existence of a single electron reducing agent, namely, ferric trichloride, a polypyrrole- chitosan polymer is generated through reaction; then under the existence of a cross-linkingagent, namely, glutaraldehyde, the polypyrrole-chitosan polymer is cross-linked in pores of a gelatin sponge sheet, and thus the 3D polypyrrole chitosan gelatin composite electric conduction materialwith the porous structure is formed. The 3D polypyrrole chitosan gelatin composite electric conduction material prepared by adopting the method disclosed by the invention has relatively good mechanical strength, good biocompatibility, relatively high electric conduction property, relatively low impedance, and small voltage loss, and can accelerate transmission of Ca<2+> among myocardial cells. Anin-vitro evaluation experiment proves that the 3D polypyrrole chitosan gelatin composite electric conduction material has feasibility and effectiveness when used as a repair material in the heart of the rat to replace a whole-layer right ventricle outflow channel defect.

Owner:FIRST HOSPITAL OF SHANXI MEDICAL UNIV

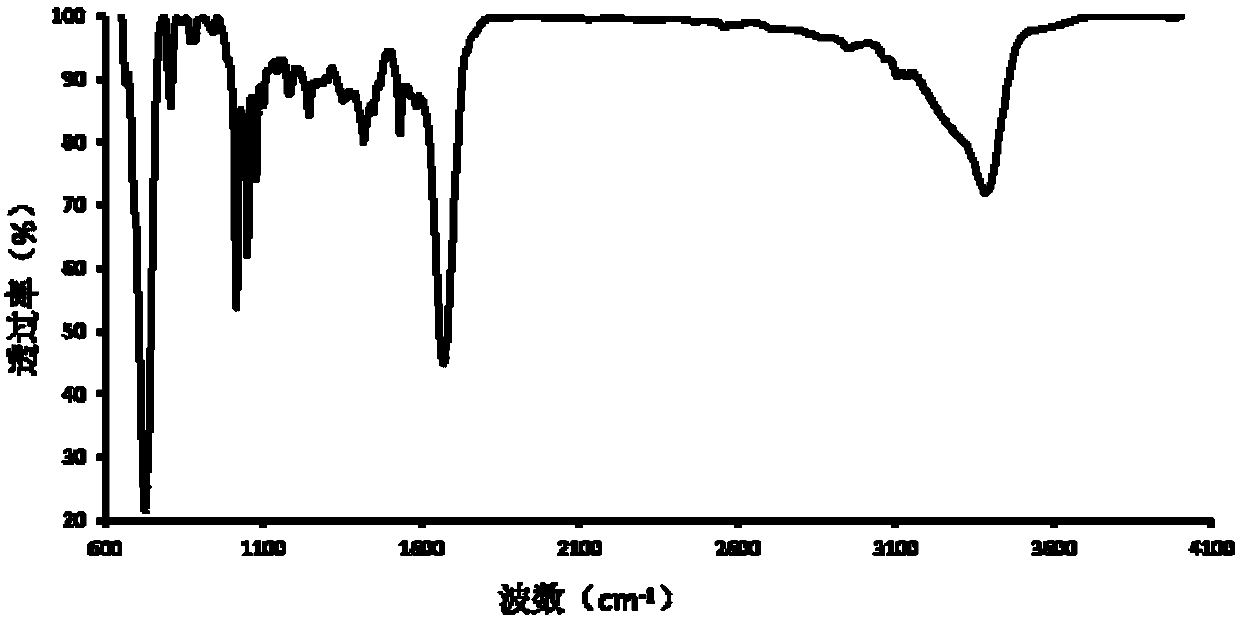

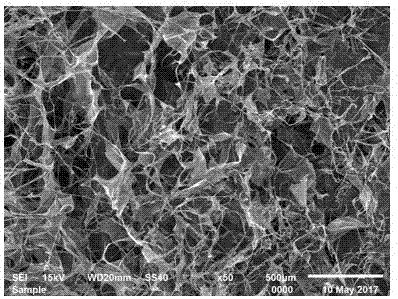

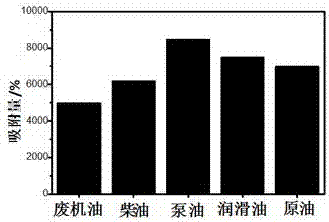

Carbon composite gelatin sponge and preparation method thereof

InactiveCN107349912AImprove bindingImprove adsorption capacityOther chemical processesCarbon compositesLiquid ratio

The invention relates to carbon composite gelatin sponge and a preparation method thereof. According to the technical scheme, gelatin and deionized water are mixed in the solid-to-liquid ratio of 2.5-80 kg / m<3> and stirred at the temperature of 30-80 DEG C, a gelatin solution is obtained; metal salt and a nano-carbon material are added to the gelatin solution in the mass ratio of the gelatin solution, the metal salt and the nano-carbon material being 100:(0.1-5):(0-30), the mixture is stirred uniformly and a mixed liquid is obtained. A formaldehyde solution is added to the mixed liquid in the volume ratio of the mixed liquid to the formaldhyde solution being 100:(0.3-3), the mixture is stirred for 0.5-1 h, and hydrogel is obtained; the hydrogel is frozen at the temperature of subzero 40 DEG C-subzero 2 DEG C for 6-10 h and dried in a freezer dryer for 42-52 h, and the carbon composite gelatin sponge is obtained. The preparation method has the characteristics of simple synthetic process, low cost, environment-friendliness, short crosslinking time and easiness in control, and the prepared carbon composite gelatin sponge is uniform in pore size distribution, good in hydrophobic and lipophilic property, good in strength and good in oil adsorption.

Owner:WUHAN UNIV OF SCI & TECH

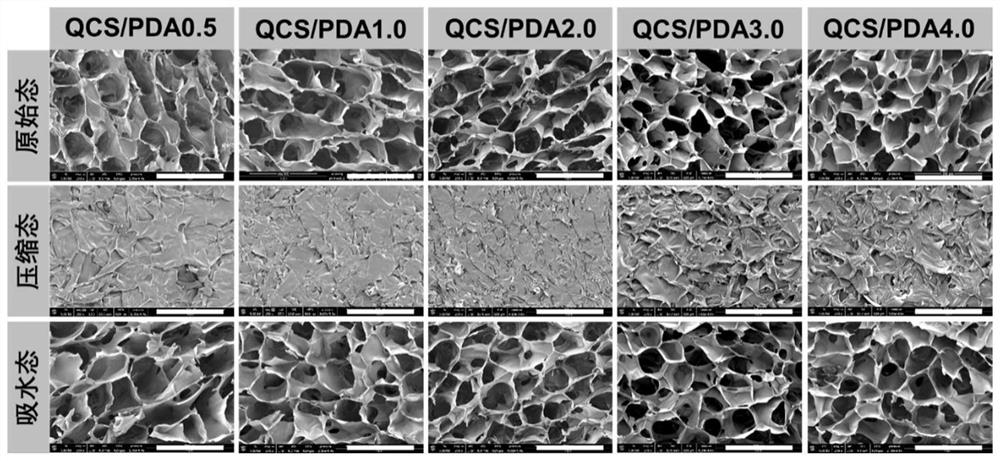

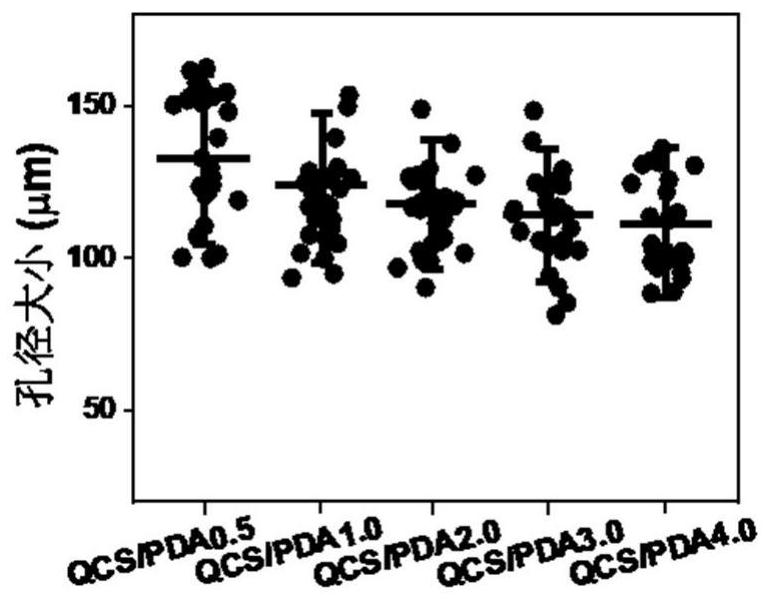

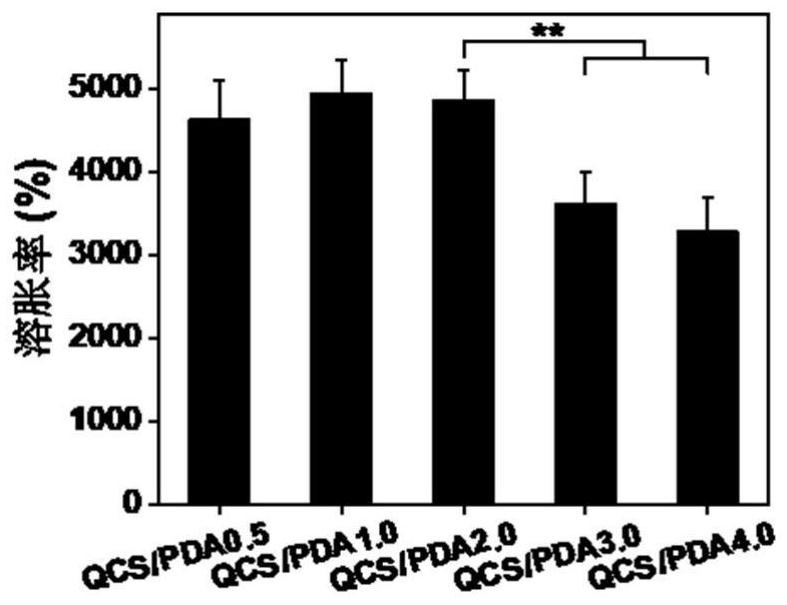

Multifunctional tissue adhesion cryogel dressing as well as preparation method and application thereof

ActiveCN111905143AImprove adhesionHigh activityAntibacterial agentsAerosol deliveryGelatin spongeBiocompatibility

The invention discloses a multifunctional tissue adhesion cryogel dressing as well as a preparation method and application thereof. The multifunctional tissue adhesion cryogel dressing is characterized in that amino-containing polysaccharide and a polysaccharide derivative with blood coagulation promoting capability are used as base materials, and polydopamine formed by dopamine oxidative polymerization is used for crosslinking the amino-containing polysaccharide and the polysaccharide derivative in a cryogel system. so that the hemostatic and wound healing promoting properties of the cryogelcan be further enhanced, and the cryogel is endowed with good oxidation resistance and good photo-thermal properties. A hemostatic adhesive tape has good biocompatibility, bacterium resistance, oxidation resistance, tissue adhesion and other properties, and has better blood cell and platelet adhesion, enrichment, activation and blood coagulation capabilities than medical gauze and gelatin sponge.The multifunctional tissue adhesion cryogel dressing is suitable for hemostasis of various different types of human wounds.

Owner:XI AN JIAOTONG UNIV

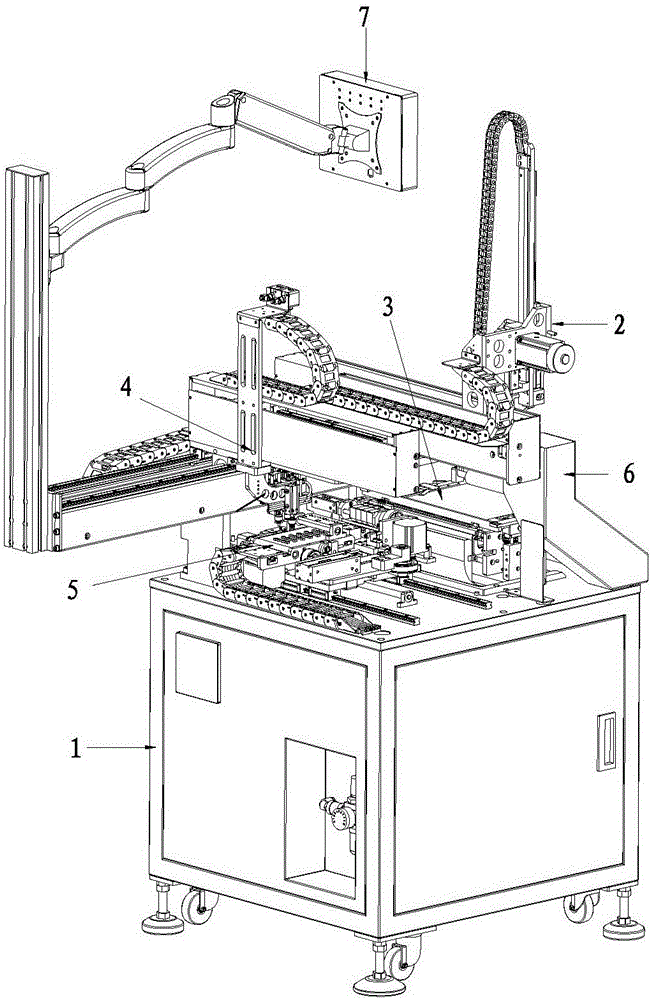

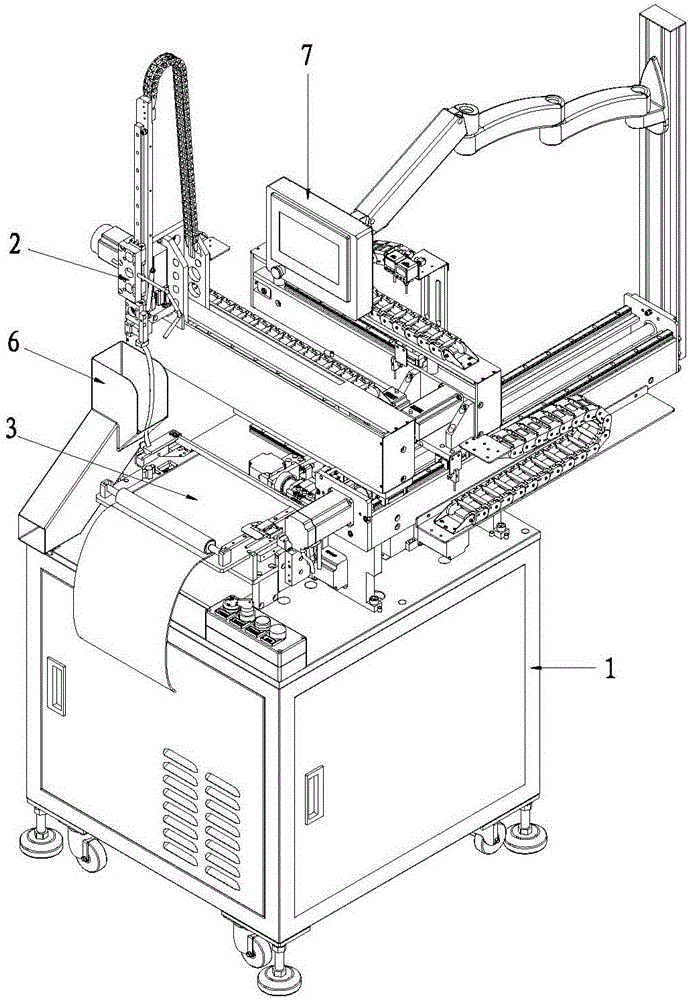

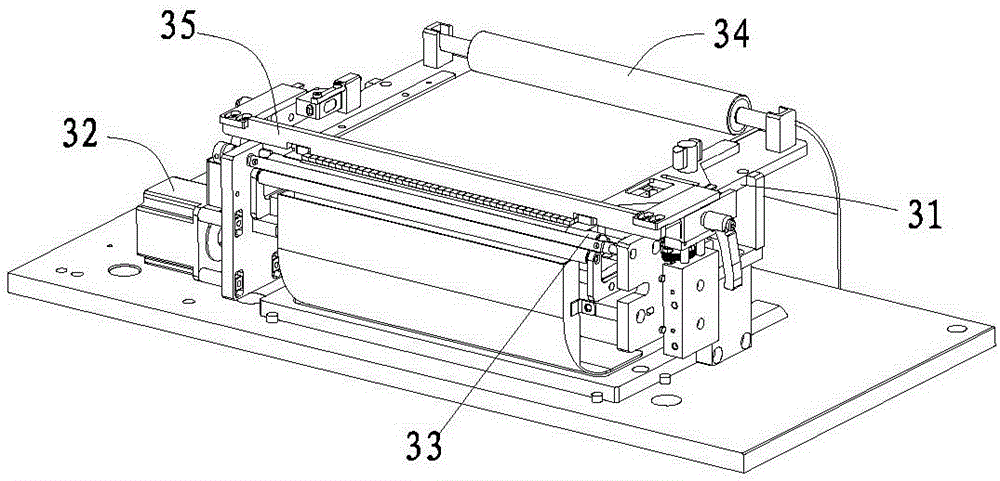

Automatic double-sided gelatin sponge pasting machine

The invention discloses an automatic double-sided gelatin sponge pasting machine which comprises a rack, a release paper waste-clearing mechanical hand, a sponge paste supply platform, a sponge pick-and-place mechanical hand, a sponge stripping and arranging mechanism and a waste discharge runner, wherein the sponge paste supply platform and the sponge stripping and arranging mechanism are sequentially arranged on the rack; the waste discharge runner is arranged at one side of the sponge paste supply platform; the release paper waste-clearing mechanical hand is arranged above the sponge paste supply platform; and the sponge pick-and-place mechanical hand is arranged above the sponge stripping and arranging mechanism. The automatic double-sided gelatin sponge pasting machine is delicate and reasonable in structural design, is simple to operate, can replace manual work to realize processes of automatically supplying, tearing off release paper, pasting and the like, so that the working efficiency is greatly improved, the labor intensity of an operator is reduced, phenomena such as deviating, missed pasting and the like are avoided, and the product quality is effectively guaranteed; besides, the automatic double-sided gelatin sponge pasting machine is compact and simple in structure, is simple to operate, can be suitable for the industries such as package, printing and electronics, is wide in scope of application, and is beneficial for being widely popularized and applied.

Owner:贝至科技(东莞)有限公司

Hemostasis bandage capable of absorbing micropore vacuum polysaccharides and manufacturing method thereof

InactiveCN104398339AEasy to useImprove adhesionNon-adhesive dressingsAdhesive dressingsGelatin spongeEngineering

The invention discloses a hemostasis bandage capable of absorbing micropore vacuum polysaccharides and a manufacturing method of the hemostasis bandage. The hemostasis bandage capable of absorbing the micropore vacuum polysaccharides comprises non-woven fabric; the edge of the non-woven fabric is provided with medical pressure-sensitive adhesives; a gelatin sponge is pasted to the surface of the non-woven fabric; the surface of the gelatin sponge is covered with release paper; grooves are formed in the surface of the gelatin sponge; hemostasis particles capable of absorbing the micropore vacuum polysaccharides are inlaid into the grooves; the hemostasis particles capable of absorbing the micropore vacuum polysaccharides come from plant starch; and the hemostasis bandage capable of absorbing the micropore vacuum polysaccharides is obtained through a series of manufacturing steps. The hemostasis bandage and the manufacturing method have the advantages that the hemostasis bandage capable of absorbing the micropore vacuum polysaccharides is convenient to use, high in stability, high in self absorbing capacity, capable of rapidly sealing wounds, free of adhesions with the surfaces of the wounds, suitable for wide hemorrhage wound surface scope and free of limitation of using environments; the hemorrhage of the surfaces of the wounds is effectively controlled; the effect of preventing infections is achieved; and the hemostasis bandage and the manufacturing method are of an important significance in rescuing lives of the wounded.

Owner:史跃

Gelatin sponge for trauma hemostasis, as well as preparation method of gelatin sponge

InactiveCN104127909ASimple manufacturing methodEasy to prepareAbsorbent padsBandagesGelatin spongeBULK ACTIVE INGREDIENT

The invention discloses a gelatin sponge for trauma hemostasis. The gelatin sponge is prepared from the following main active ingredients in parts by weight: 3-9 parts of gelatin, 0.5-2.5 parts of formaldehyde solution, and 50-150 parts of water for injection. The preparation method of the gelatin sponge for trauma hemostasis is simple, and the gelatin sponge for trauma hemostasis is low in manufacturing cost, very obvious in trauma hemostasis effect, and capable of conducting disinfection and hemostasis.

Owner:张秀华

Construction of artificial neural network sample catheter for repairing spinal cord injury

ActiveCN102008360APromote repairImprove the quality of lifeTubular organ implantsNerve networkGelatin sponge

The invention relates to a construction method of an artificial neural network sample catheter for repairing spinal cord injury, in particular to a method for constructing a functional artificial neural network sample catheter by using a porous gelatin sponge cylindrical stand and application thereof. When applied, the functional artificial neural network sample catheter is transplanted to an injured part of complete transverse or semi-transverse spinal cord so as to better promote the injured central nervous regeneration and functional repair. The method has significance for enhancing protection of injured neurons after spinal cord injury, promoting reconstruction of a neural network, improving the quality of life of the wounded and sick, lightening the social and family burden and promoting the social and economic development of China at a biological tissue engineering level.

Owner:SUN YAT SEN UNIV

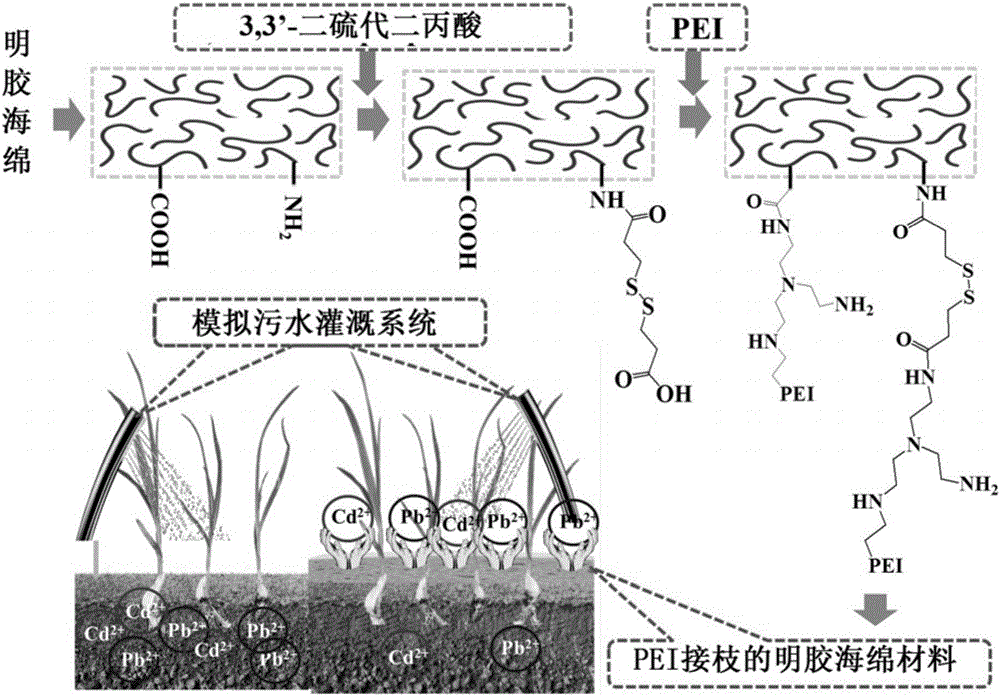

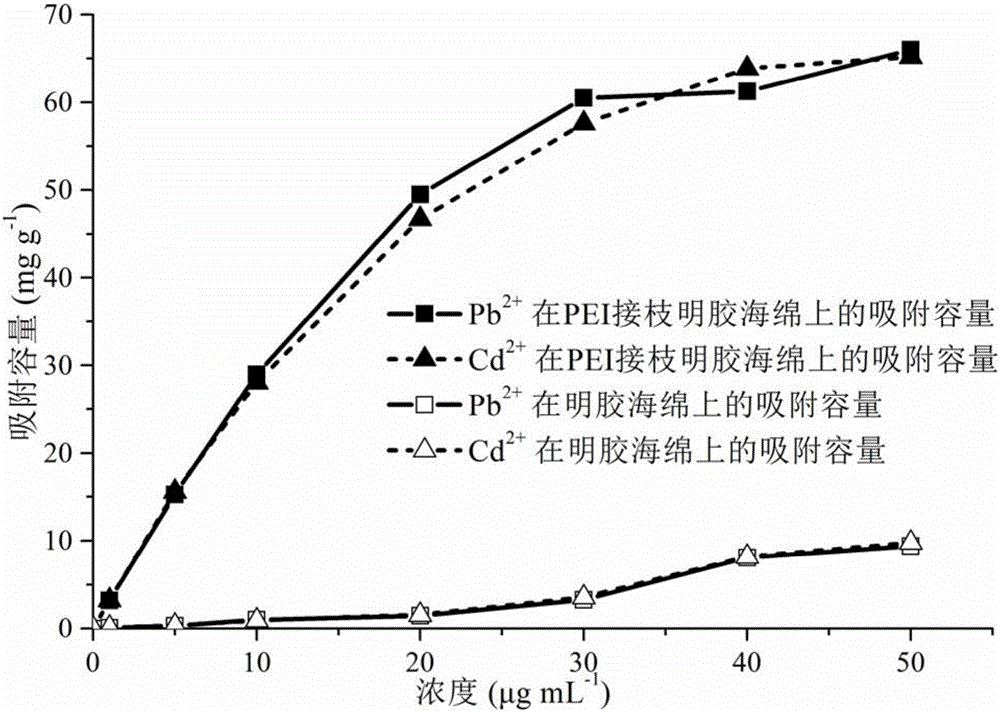

Preparation of PEI-grafted gelatin sponge and application of PEI-grafted gelatin sponge in heavy metal sewage treatment

InactiveCN105754137AStrong water absorptionPromote recoveryOther chemical processesWater contaminantsEcological environmentAbsorption capacity

The invention discloses preparation of a PEI-grafted gelatin sponge and application of the PEI-grafted gelatin sponge in heavy metal sewage treatment, and belongs to the field of ecological environment safety.The PEI-grafted gelatin sponge is prepared through the steps that carboxylation modification is performed on a gelatin sponge to completely convert amino groups on the surface of the gelatin sponge into the carboxyl groups; the gelatin sponge is modified with PEI and carboxyl groups through the acting force among ions to prepare the PEI-grafted gelatin sponge.The prepared PEI-grafted gelatin sponge can be applied to heavy metal-containing sewage treatment and also can be used for preparing a heavy metal absorbent.The adopted preparation method is mild in reaction, short in reaction time, poisonless in used material, low in preparation cost, high in safety and simple in after-treatment; the prepared PEI-grafted gelatin sponge has the advantages that the adsorption capacity on the heavy metal ions is high, the water absorption capacity of the gelatin sponge is kept, most sewage can be retained when the PEI-grafted gelatin sponge is applied to sewage irrigation, the absorption and exchange time of a sponge material and heavy metal is prolonged, and the purification effect on the heavy metal is improved.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Preparation of agarose coated, solid agarose beads containing secretory cells

Biological agents such as secretory cells are encapsulated in a hydrophilic gel made of agarose or collagen-agarose and gelatin sponge-agarose combinations. In a preferred embodiment, semi-solid beads are formed from a suspension containing collagen, agarose and secretory cells such as pancreatic islets, the collagen is polymerized to form solid, agarose-collagen beads and the solid beads are coated with agarose. Coating is preferably by rolling the solid beads in about 5-10% agarose, contacting the rolled beads with mineral oil and washing oil from the beads. Beads containing secretory cells can be transplanted into a mammal to treat a condition caused by impaired secretory cell function.

Owner:THE ROGOSIN INST

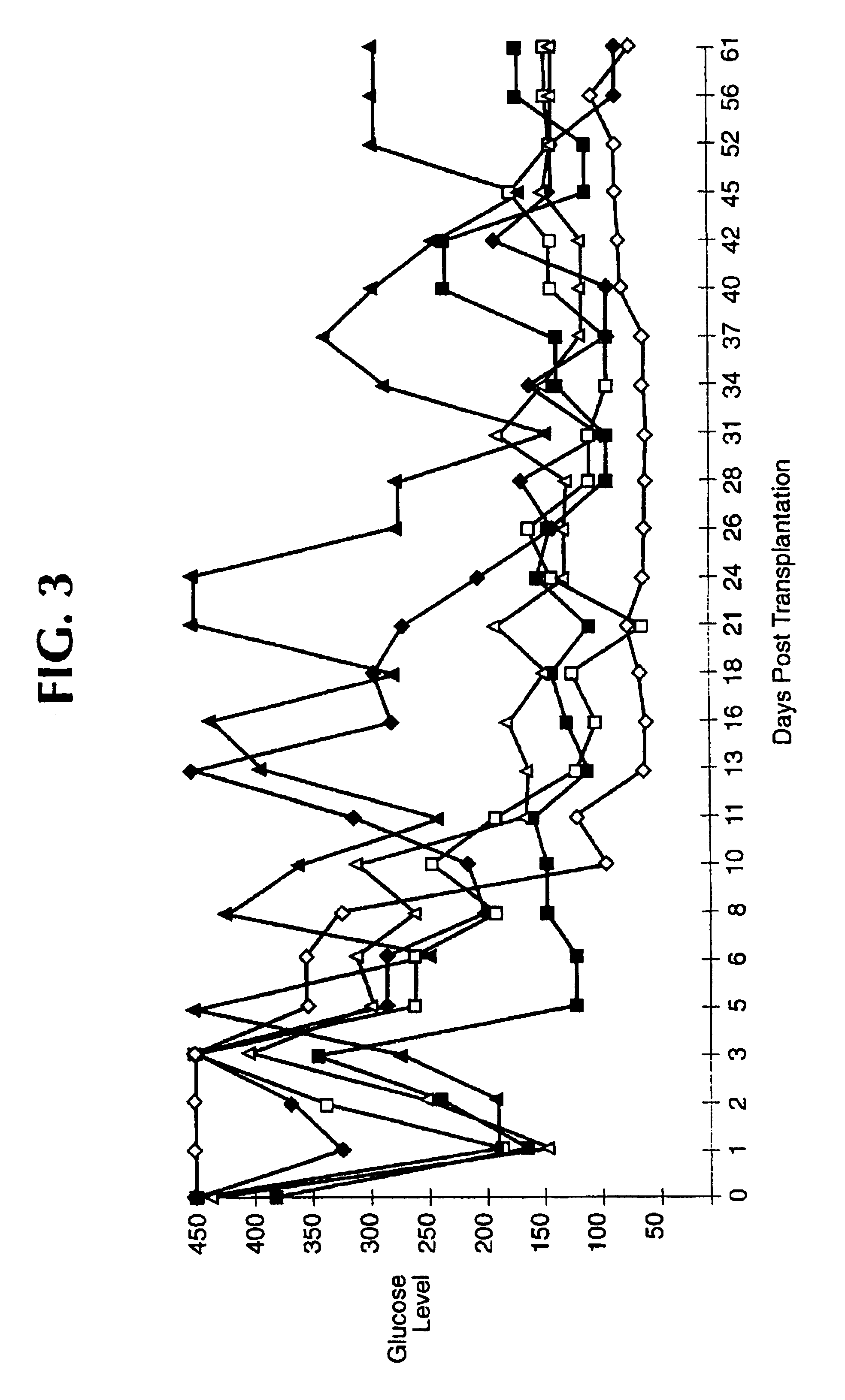

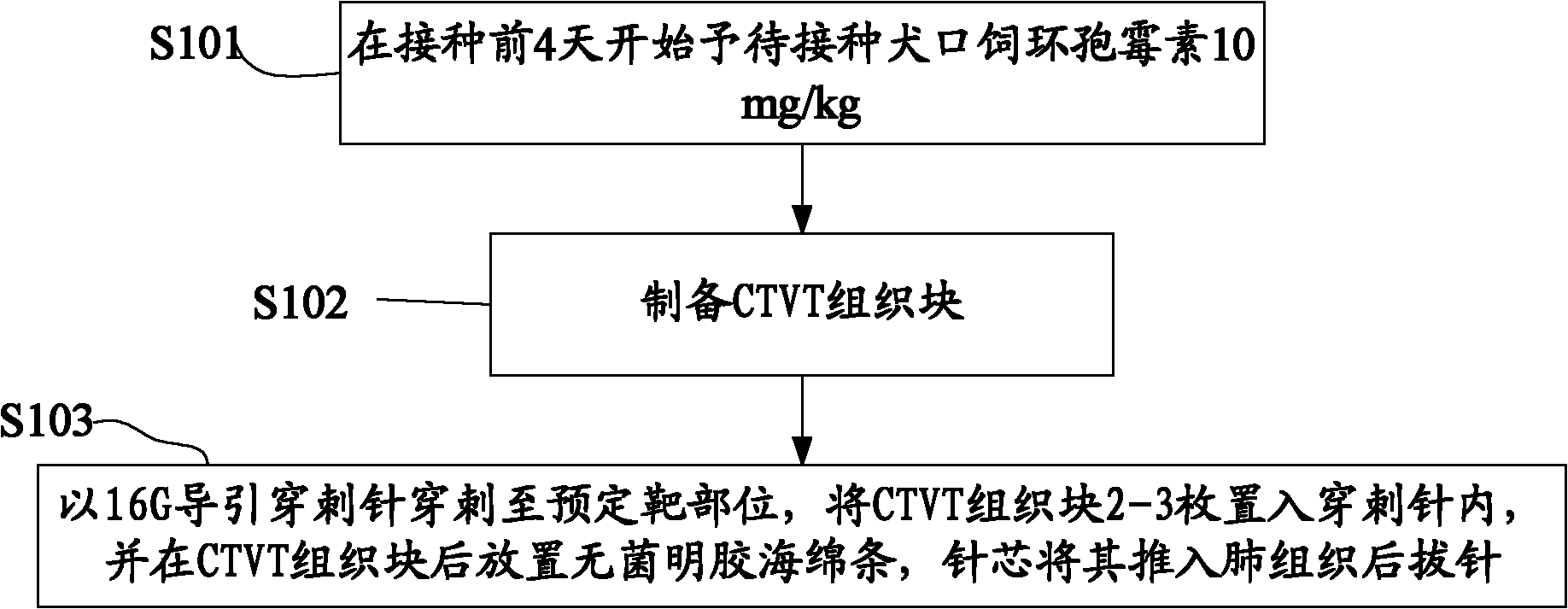

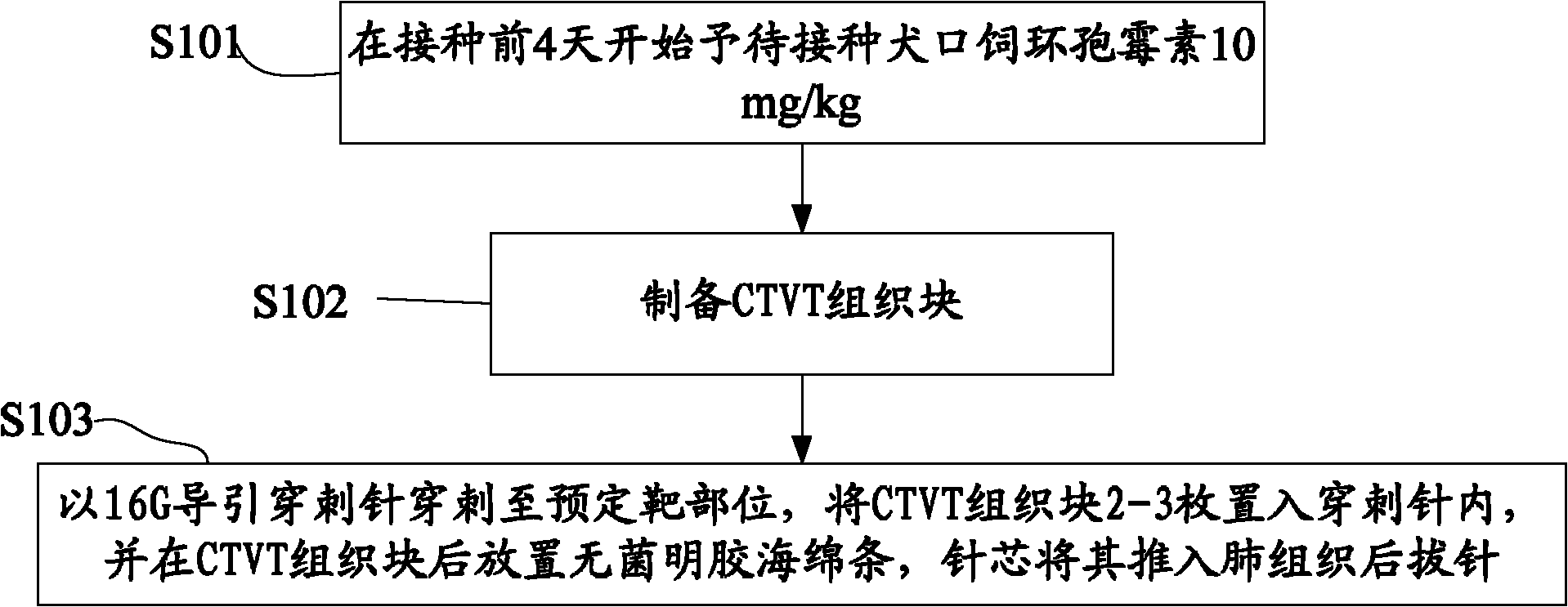

Method for constructing lung tumor experimental animal model

InactiveCN102048757AEasy to prepareImprove general conditionSurgical needlesMammal material medical ingredientsAbnormal tissue growthCyclosporins

The invention provides a method for constructing a lung tumor experimental animal model. The method comprises the following steps of: 1, feeding a dog with cyclosporin according to the weight ratio of the dog to cyclosporin of 10mg to 1kg 4 days before inoculation; 2, preparing canine transmissible venereal tumor (CTVT) tissue blocks; and 3, puncturing to a predetermined target part by using a 16G guide puncture needle, placing 2 to 3 CTVT tissue blocks into the puncture needle, arranging a sterile gelatin sponge strip behind the CTVT tissue blocks, pushing the tissue blocks into lung tissues by a needle core and pulling the needle out. In the method, CTVT cells are used as tumor strains, the tumor tissue blocks are prepared through subcutaneous tumor cell passage by using the characteristics of transplantability and genetic stability; in-lung planting is performed by a minimally invasive intervention method to establish a dog transplantable lung cancer model; and the model can be applied to related experimental researches such as growth, invasion, transfer and the like of large-sized animal lung tumors.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

Gelatin sponge embolism microspheres and preparation method thereof

The invention discloses a method for preparing gelatin sponge embolism microspheres, and the method comprises the following steps: (1) preparing a gelatin aqueous solution; (2) slowly adding the gelatin aqueous solution to an oil phase containing an emulsifier, and stirring evenly; (3) adding a cross-linking agent, reacting while stirring at 0-10 DEG C; (4) standing, pouring an oil layer out afterlayering, using a Twain 80 aqueous solution for washing microspheres until the oil phase is washed away, and using purified water to wash for a plurality of times; and (5) sieving for screening, andrespectively drying the microspheres with different particle sizes at low temperature to obtain the gelatin sponge embolism microspheres. The preparation method is simple in operation, the productioncycle is short, the cost is low, the hemolysis test meets standard requirements, and the residual amount of the cross-linking agent conforms to clinical use standards.

Owner:HAINAN JIANKE PHARMA

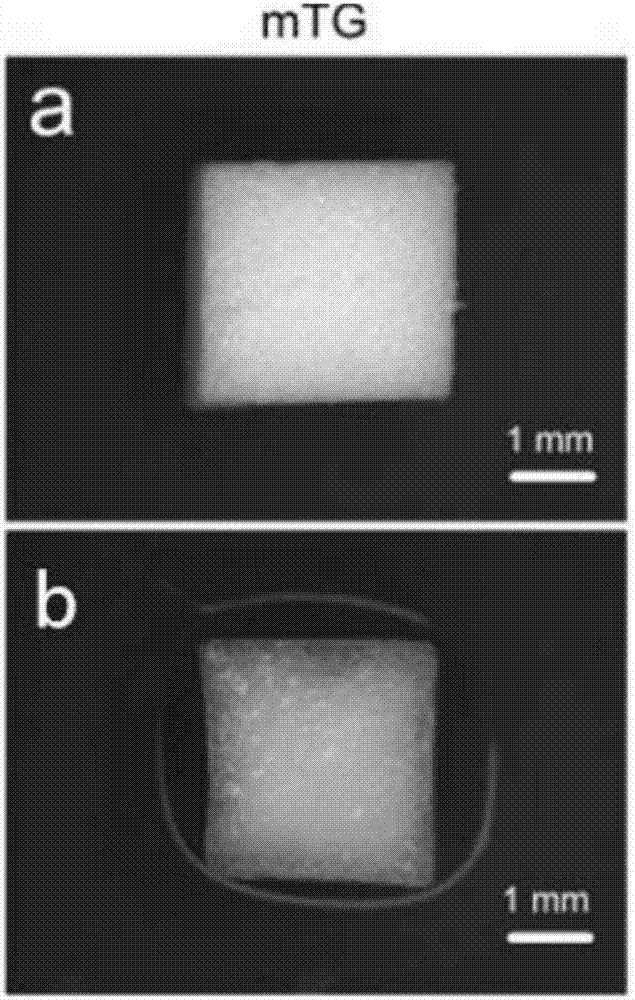

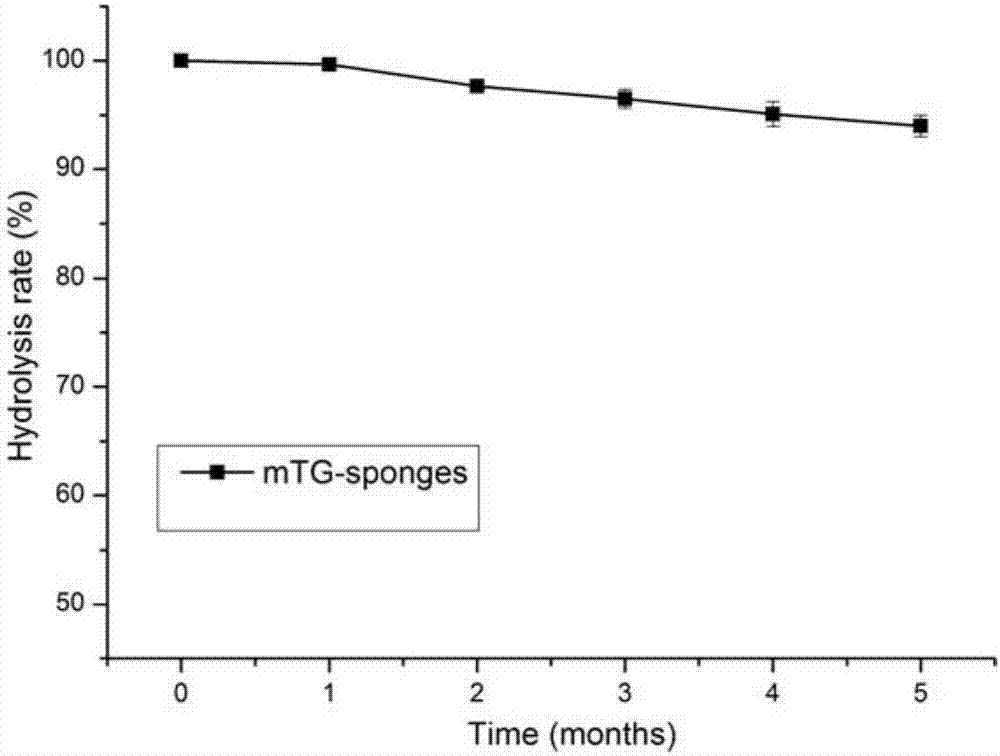

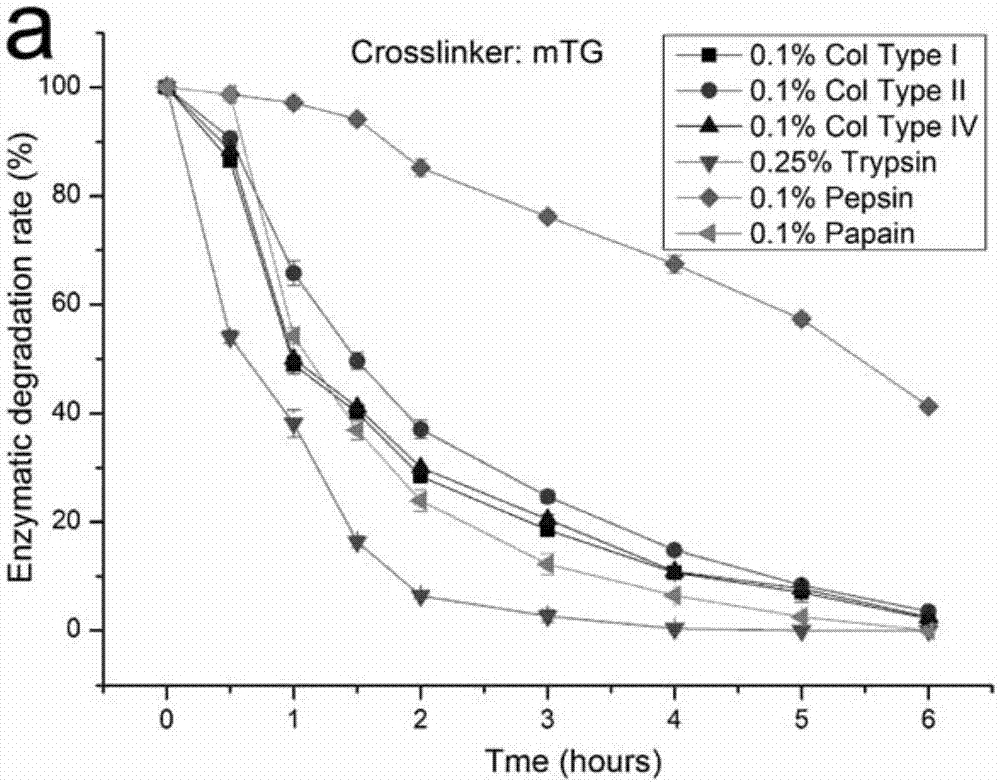

Preparation method of gelatin sponge scaffold

InactiveCN107261216AImprove physical propertiesHigh porositySurgical adhesivesPharmaceutical delivery mechanismPorosityControlled release

The invention discloses a gelatin sponge scaffold. A preparation method of the gelatin sponge scaffold comprises the following steps: (1) preparing gelatin solution; (2) preparing transglutaminase solution; and (3) mixing the gelatin solution prepared in the step (1) and the transglutaminase solution prepared in the step (2), carrying out incubating, thus forming hydrogel, carrying out refrigerating, and carrying out freeze drying, thus preparing the sponge scaffold. The sponge scaffold is free of cytotoxicity, and has excellent physical property, excellent comprehensive performance, good porosity, good compression modulus, and good degradation resistance; in addition, the biocompatibility is good, so that cells can well grow in the scaffold; the scaffold is implanted into the body, a formed material wrapping layer is thin, blood capillaries are formed on the outer wrapping layer, and thus the growth of the regenerated tissue is facilitated; the gelatin sponge scaffold can be taken as the materials such as the tissue engineering scaffold, clinical hemostatic sponge and medicine controlled-release carriers to be used for the cell and tissue engineering applications, and has the broad prospect.

Owner:SICHUAN UNIV

Peach tree planting method on hillside

ActiveCN105359913AHigh sweetnessPrevent quality degradationBio-organic fraction processingExcrement fertilisersGelatin spongeSweetness

The invention provides a peach tree planting method on a hillside. The method comprises the following steps of (1) preparing before planting, (2) planting, including planting peach tree seedlings in various cement framework groups on a hillside from the bottom to the top according to a height gradual increase order, and (3) applying fertilizer, wherein in the fertilizer applying step, one month after plantation, a plurality spherical gelatin sponge are placed around a root of each peach tree seedling; a sunward hillside with the gradient of 37 to 45 degrees is selected; peach tree seedlings are planted in various cement framework groups on a hillside from the bottom to the top according to the height gradual increase order; the peach tree seedlings are distributed in a step shape to ensure the peach tree seedlings to enjoy the sunshine to the largest extent; with thorough sunniness, peach sweetness can be enhanced; a problem of peach quality decrease due to uneven sunniness acquired by peach trees planted on a flat land and lack of sunniness to lower sides of the peach trees can be solved; and hillside stability can be improved when the peach trees are planted on the hillside.

Owner:哈威光电科技(苏州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com