Mold-pressed sponge sealing rubber strip

A technology for sealing rubber strips and sponges, which is applied in the field of rubber production and processing, can solve the problems of poor hand feeling of sealing rubber strips, waste materials in processing, increase pollution products, etc., and achieve the effects of good sealing performance, reduction of processing costs, and improvement of sensory quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

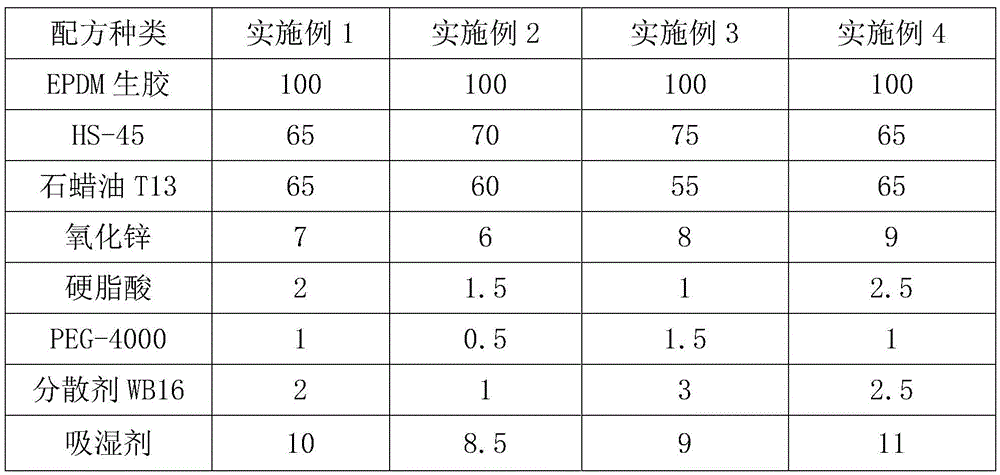

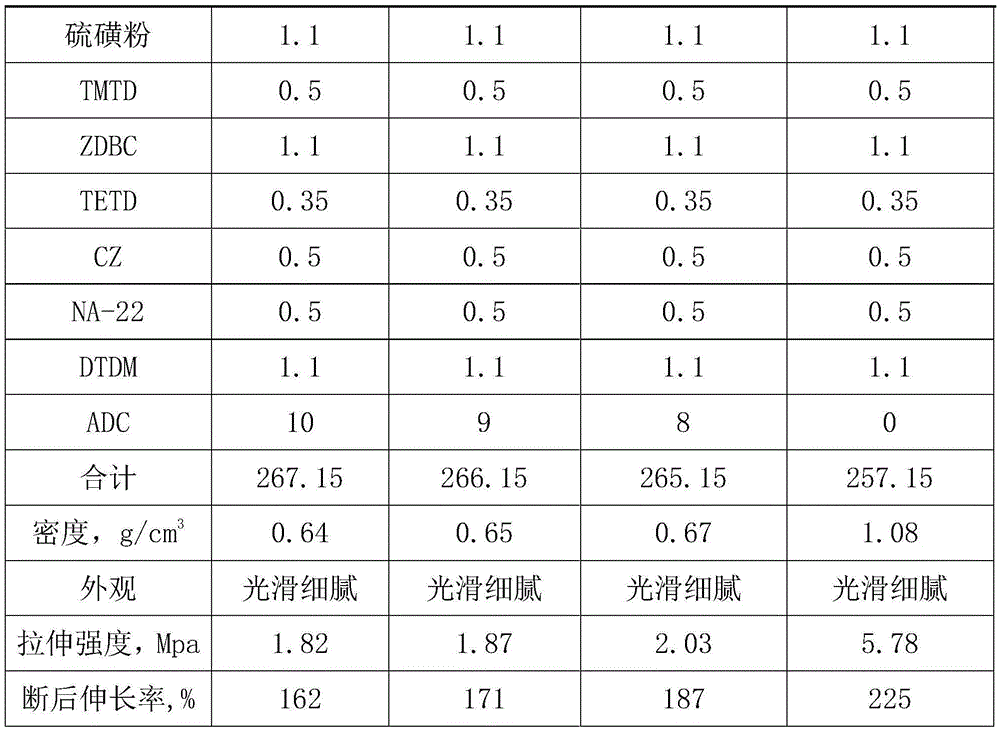

[0013] A molded sponge sealing strip disclosed by the invention comprises the following raw materials in parts by mass: 100 parts of EPDM raw rubber, 55-80 parts of reinforcing agent carbon black HS-45, 55-80 parts of paraffin oil, oxidized 5-10 parts of zinc, 1-3 parts of stearic acid, 0.5-1.5 parts of surfactant PEG-4000, 1-4 parts of dispersant WB16, 8-12 parts of hygroscopic agent, and 1.1 parts of sulfur powder 1.1 parts of accelerator ZDBC, 1.1 parts of vulcanizing agent DTDM, and 0-15 parts of foaming agent ADC. Preferably also include 0.5 parts of accelerator TMTD, 0.5 parts of accelerator TMTD, 0.5 parts of accelerator CZ, and 0.5 parts of accelerator NA-22.

[0014] Of course, the mass fraction range of some raw materials can also be appropriately narrowed, that is, the following mass fractions of raw materials are included: 100 parts of EPDM raw rubber, 60-70 parts of reinforcing agent carbon black HS-45, and 60-70 parts of paraffin oil parts, 6-9 parts of zinc oxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com