Carbon composite gelatin sponge and preparation method thereof

A gelatin sponge and carbon composite technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of poor water-oil selectivity, long cross-linking time, restricted application, etc., and achieve good oil adsorption and cross-linking time. Short, low production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

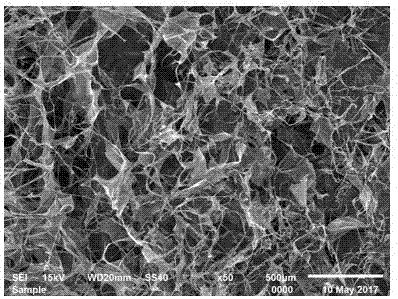

[0025] A carbon composite gelatin sponge and a preparation method thereof. The specific steps of the preparation method described in this embodiment are:

[0026] Step 1. Mix gelatin and deionized water at a solid-to-liquid ratio of 2.5 to 20kg / m 3 Mix and stir at 30-60°C for 20-40 minutes to obtain a gelatin solution.

[0027] Step 2, according to the mass ratio of the gelatin solution: metal salt: nano-carbon material being 100: (0.1~1): (10-20), adding metal salt and nano-carbon material to the gelatin solution, stirring evenly, to obtain a mixture.

[0028] Step 3: According to the volume ratio of the mixed solution: formaldehyde solution being 100: (0.3-1), add the formaldehyde solution to the mixed solution, stir for 0.5-1 hour, and obtain the hydrogel.

[0029] Step 4, freezing the hydrogel at -40~-20°C for 6~10 hours, and then drying in a freeze dryer for 42~52 hours to obtain a carbon-composite gelatin sponge.

[0030] The metal salt described in this implementati...

Embodiment 2

[0034] A carbon composite gelatin sponge and a preparation method thereof. This embodiment is the same as Embodiment 1 except metal salt and nano-carbon material.

[0035] The metal salt described in this implementation is cobalt acetate.

[0036] The nano-carbon material in this implementation is graphene.

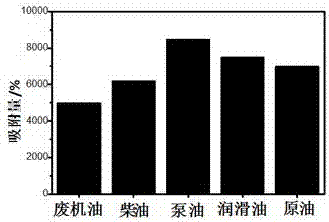

[0037] The carbon-composite gelatin sponge prepared in this example has uniform pore size distribution, good hydrophobicity and lipophilicity, high strength and good adsorption to oil.

Embodiment 3

[0039] A carbon composite gelatin sponge and a preparation method thereof. This embodiment is the same as Embodiment 1 except metal salt and nano-carbon material.

[0040] The metal salt is nickel acetate.

[0041] The nano carbon material is fullerene.

[0042] The carbon-composite gelatin sponge prepared in this example has uniform pore size distribution, good hydrophobicity and lipophilicity, high strength and good adsorption to oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com