Patents

Literature

40results about How to "Improve hydrophobicity and lipophilicity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of collagen-based porous oil-absorbing material

InactiveCN104971702AEasy constructionIncrease the areaOther chemical processesAlkali metal oxides/hydroxidesFiberCollagen fiber

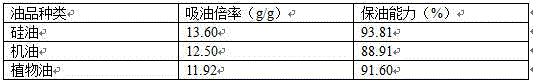

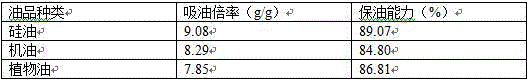

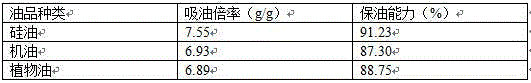

The invention relates to a preparation method of a collagen-based porous oil-absorbing material, and relates to the technical field of biomass resource recycling and environment-friendly oil-absorbing materials. A collagen-based porous oil-absorbing material preparation method provided by the invention comprises the steps that: (1) lime-expanded pelt scraps before tanning are cut into small pieces; pretreatments such as deliming, degreasing and dehydration are carried out, such that hide powder fiber is obtained; (2) the prepared hide powder fiber is dispersed in a buffering solution containing an epoxysilane coupling agent or polydimethylsiloxane for modification, such that hydrophobic lipophilic hide powder fiber is obtained; and (3) the modified hide powder fiber obtained in the step (2) is dispersed in water; and forming and drying ae carried out, such that the collagen-based porous oil-absorbing material is obtained. The method provided by the invention has the advantages of simple operation and low cost. The prepared oil-absorbing material has hydrophobic lipophilic properties and a porous structure. The material also has biodegradability and relatively high oil-absorbing capacity. Therefore, a novel application approach is developed for the high-value conversion and utilization of hide collagen fiber solid wastes.

Owner:SICHUAN UNIV

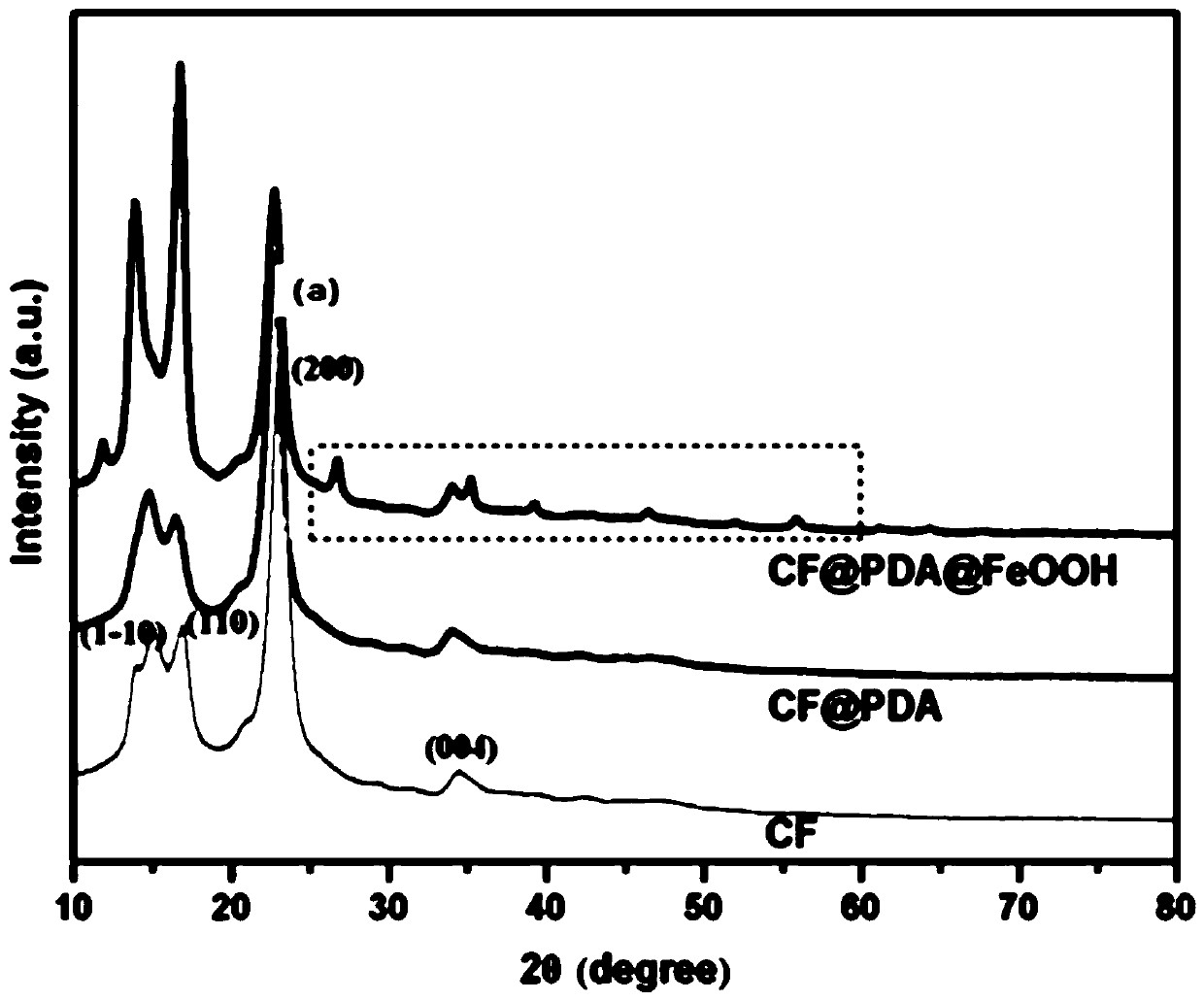

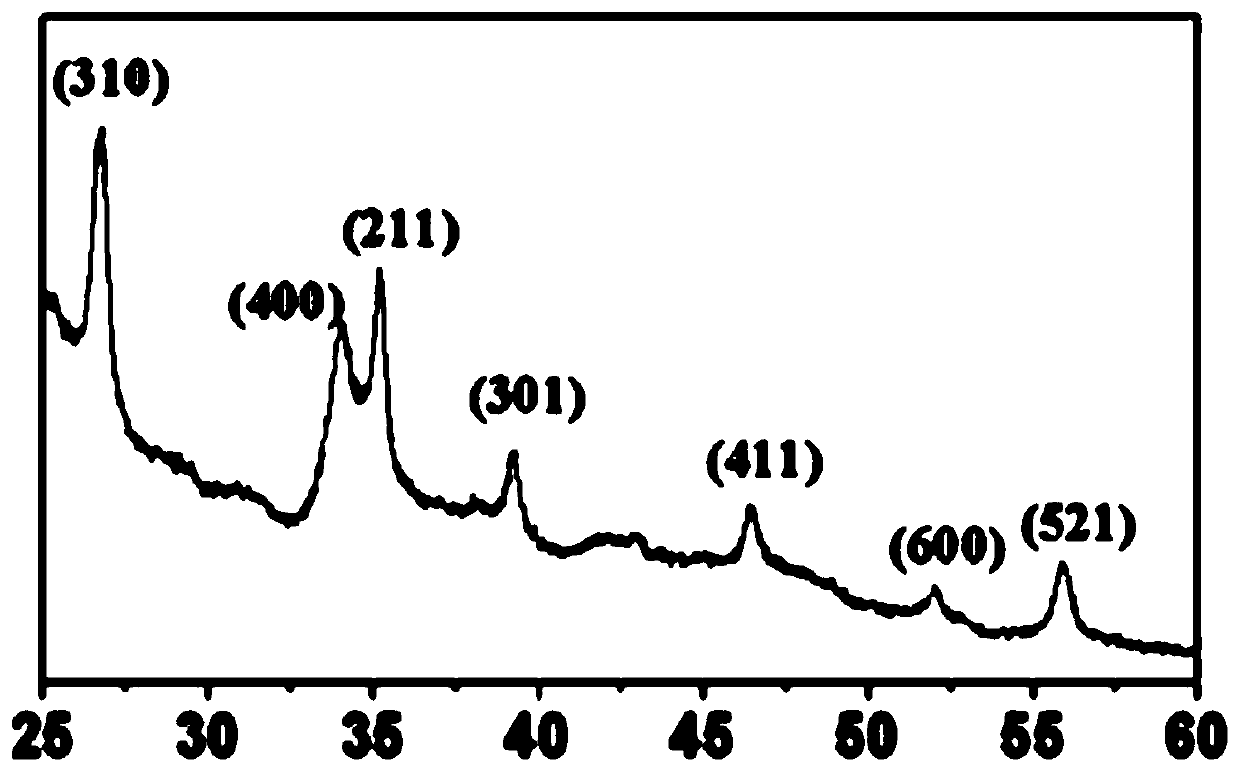

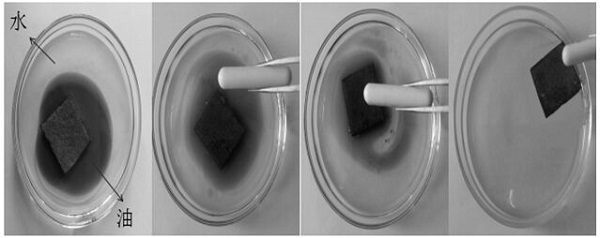

Washable photo-catalytic super-hydrophobic cotton fabric, and preparation and application thereof

InactiveCN111335038AStrong adhesionImprove photocatalytic performanceOrganic-compounds/hydrides/coordination-complexes catalystsLiquid repellent fibresPhoto catalyticAqueous droplet

The invention discloses a washable photo-catalytic super-hydrophobic cotton fabric, wherein a dopamine modified cotton fabric, the surface of which is loaded with beta-FeOOH nano-particles, is used asa carrier; and the surface of the carrier is modified with dodecanethiol. The invention discloses a preparation method of the washable photo-catalytic super-hydrophobic cotton fabric. Dopamine modification processing on the purified cotton fabric is carried out; by taking ferric salt as a precursor, the beta-FeOOH nano-particles grow on the surface of the dopamine fabric in situ; then, a low-surface-energy matter, namely dodecanethiol, is modified on the surface of the rough fabric; and thus, the super-hydrophobic cotton fabric having water resistance and photo-catalytic performance is obtained. The fabric in the invention can completely degrade methylene blue solution within 180 min in visible light; furthermore, the water resistance is good; after circulation for five times, both the stability and the reliability of degrading the methylene blue solution can reach 90%; furthermore, the surface droplet static contact angle of the cotton fabric is greater than 150 DEG C; and, after oilwater separation through different oil, the separation rate is greater than 98%.

Owner:安徽省农业科学院棉花研究所

Preparation method of nanoscale organobentonite

ActiveCN104760968AGuarantee product qualityShorten the production cycleMaterial nanotechnologySilicon compoundsSodium BentoniteMass ratio

The invention discloses a preparation method of nanoscale organobentonite, which comprises the following six steps: (1) bentonite raw ore processing, (2) sodium modification, (3) centrifugation purification, (4) inorganic acid modification, (5) organic coating reaction, and (6) a post treatment stage. The preparation method has the characteristics that through substep purification, a mass ratio of a sodium agent to suspending liquid is kept at 0.3%; in an inorganic acid modification process, improvements are performed by adjustment of a PH value to subacid and a charging mode in the organic coating reaction stage; the bentonite is subjected to delaminating dispersion, centrifugation purification and superfine grading to prepare pure montmorillonite with the content greater than 95%; then, double octadecyl dimethyl ammonium chloride is used for performing the organic coating reaction; finally crushing to a nanoscale particle size is performed, that is, the average lamellar thickness is less than 25 nanometers; and the preparation method ensures the product quality, shortens the production cycle greatly, lowers the production cost, and is suitable for large-scale popularization and application.

Owner:HUANGSHAN BAIYUE ACTIVATED CLAY

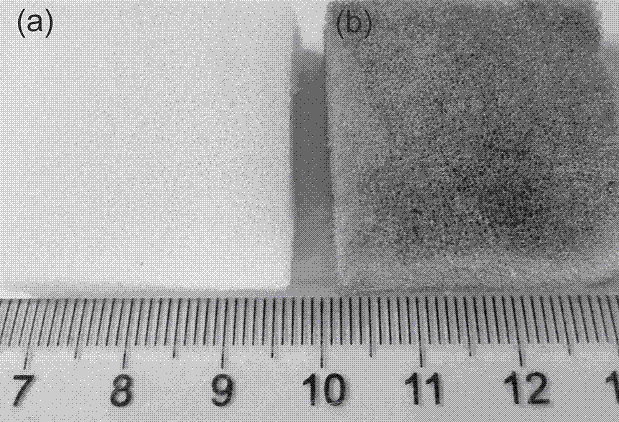

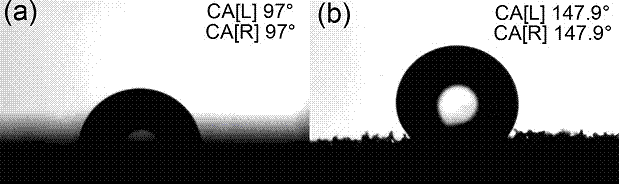

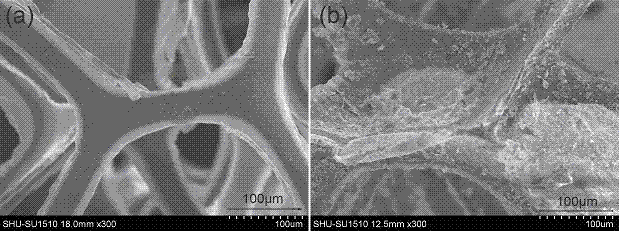

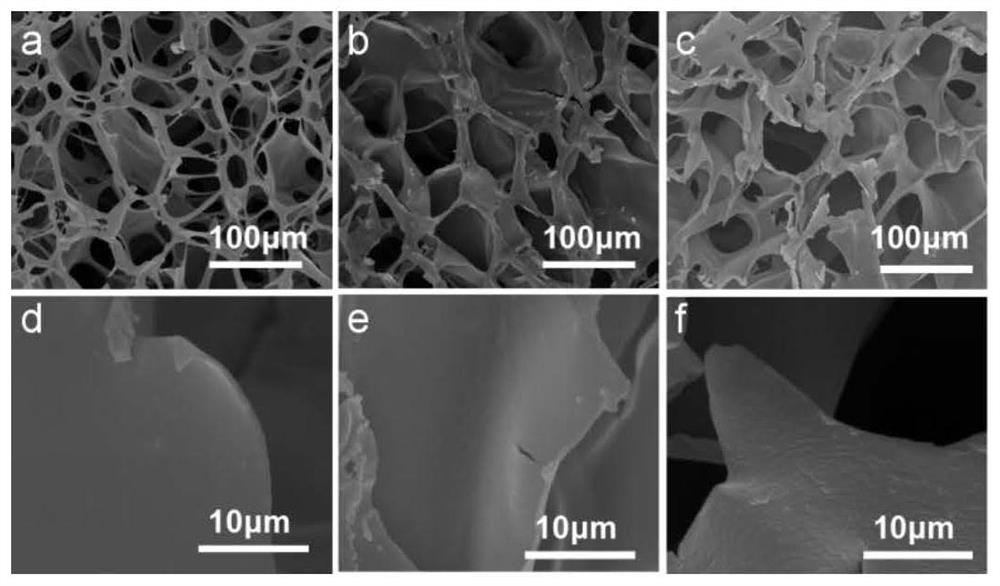

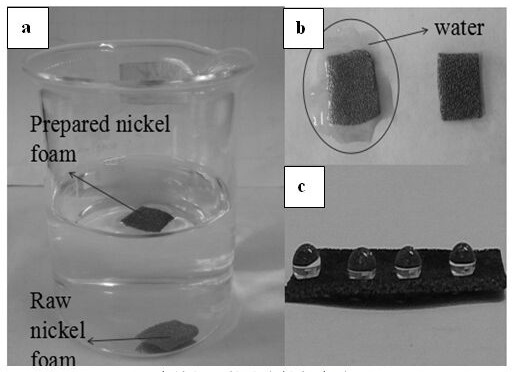

Polyurethane sponge loaded with hybridized graphene coating and preparation method of polyurethane sponge

ActiveCN104289203AImprove hydrophilic abilityImprove hydrophobicity and lipophilicityOther chemical processesZinc oxides/hydroxidesCvd grapheneGraphene coating

The invention discloses a polyurethane sponge loaded with a hybridized graphene coating and a preparation method of the polyurethane sponge. The sponge is formed by loading the micrometer zinc oxide hybridized graphene coating on a polyurethane sponge, and the thickness of the coating is 0.3-0.8mm; the mass ratio of zinc oxide to graphene is 5 percent. According to the test of the hydrophobic effect and the oil absorption ability of the loaded sponge, an experiment shows that the hydrophilia of the sponge turns into high hydrophobicity (a contact angle is 147.9 degrees), the oil adsorption ability of the sponge is obviously increased, and the saturated adsorption quantity of the sponge on diesel reaches 28.01g. Graphene which is modified with hybridized micrometer zinc oxide and graphene oxide is loaded on the sponge, so that the hydrophobic and lipophilic property of the polyurethane sponge is improved; therefore, the effective preparation method for oil polluted water body remediation is provided.

Owner:SHANGHAI UNIV

Organic bentonite for white oil-based drilling fluid and preparation method thereof

InactiveCN104031623AHigh viscosityImprove hydrophobicity and lipophilicityDrilling compositionSodium BentoniteBentonite suspension

The invention relates to organic bentonite for white oil-based drilling fluid of the petroleum industry, the natural gas industry and the like, and a preparation method of the organic bentonite. The hydrophobicity, the lipophilicity and the high-temperature resistance of the organic bentonite are improved, and the organic bentonite is good in compatibility, high in system viscosity and moderate in dynamic shearing force. According to the technical scheme, the organic bentonite comprises the following raw materials in percentage by mass: 60-80 parts of sodium bentonite as the bentonite, 10-30 parts of m-alkyl trimethyl ammonium halide as quaternary ammonium salt, 2-10 parts of sodium lauryl sulfate, sodium dodecyl sulfate or sodium dodecyl benzene sulfonate as an anionic surfactant. The preparation method comprises the following steps: screening the bentonite, adding water to prepare bentonite suspension, adding a quaternary ammonium salt solution into the bentonite suspension for once modification, further adding an anionic surfactant solution into the suspension for secondary modification, and finally aging, drying, crushing and screening so as to prepare the organic bentonite. The product is simple in production process and convenient to operate, and is used as drilling fluid as the hydrophobicity, the lipophilicity and the high-temperature resistance are all improved.

Owner:SOUTHWEST PETROLEUM UNIV

Preparation method for hydrophobic lipophilic polyurethane sponge

InactiveCN108192322AImprove hydrophobicity and lipophilicityEnhance the degree of organicPorosityPolymer science

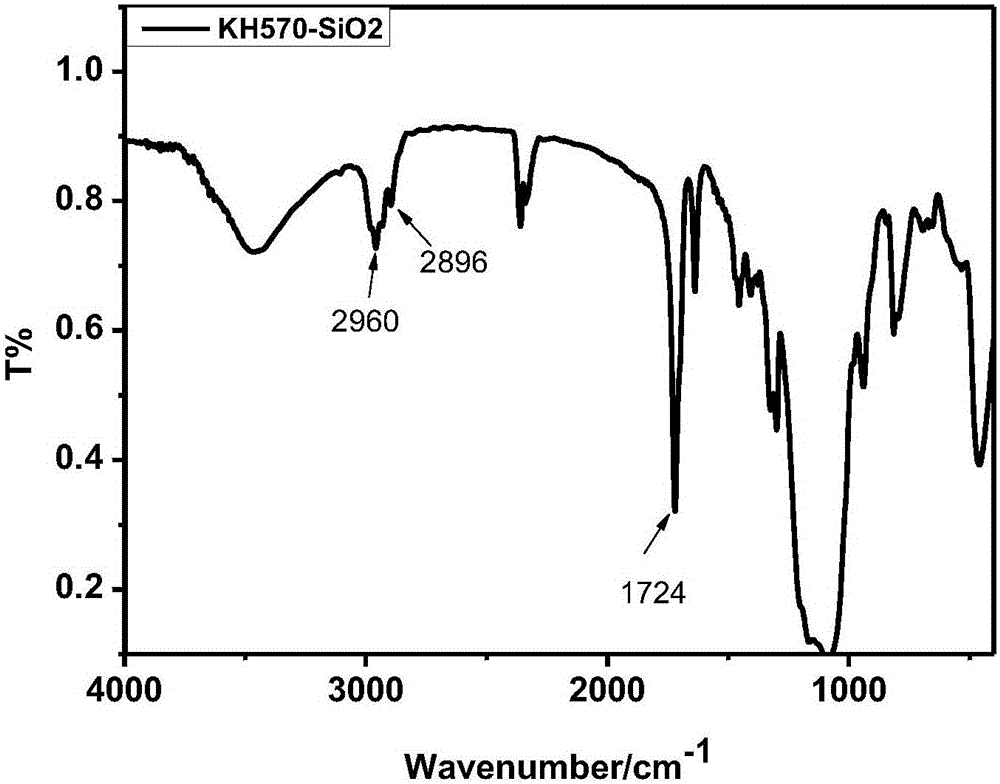

The invention discloses a preparation method for a hydrophobic lipophilic polyurethane sponge, belonging to the technical field of sponge preparation. According to the preparation method, polyurethaneresin is blended with amber powder and a copolymer to prepare a self-made polyurethane sponge; then under the action of a foaming agent and a curing agent, a three-dimensional porous structure is formed and has low density and high porosity; the organification of the surface of molybdenum disulfide powder is enhanced, and a part of stearic acid having not participated in a reaction is to be condensed since the melting point of stearic acid is about 70 DEG C, which is beneficial for improvement of the hydrophobicity and lipophilicity of the polyurethane sponge; and self-made titanium dioxide sol is further modified by using a silane coupling agent KH-570, and since KH-570 is a silane coupling agent with a long hydrophobic chain, a part of covalent bonds generated after a dehydration reaction of the silane coupling agent with hydroxyl groups on the surface of a titanium dioxide sol promotes successful loading of titanium dioxide particles in the modified sol onto the surface of the polyurethane sponge, so a layer of hydrophobic lipophilic protection film is formed, and the hydrophobic lipophilic polyurethane sponge has good application prospects.

Owner:张芸

White carbon black with dyeing groups on surface and preparation method of white carbon black

InactiveCN106566290AAffinity plusImprove performanceAnthracene dyesPigment treatment with macromolecular organic compoundsPolymer sciencePolyolefin

The invention relates to white carbon black with dyeing groups on the surface and a preparation method of the white carbon black. In a formula I, R represents reactive groups of a silane coupling agent, and Dye represents the dyeing groups. The dye modified white carbon black prepared with the method has wide raw material sources and is lower in cost, part of monomers is the industrialized raw material, and a reaction method is mature. Compared with non-modified white carbon black, the dye modified white carbon black prepared with the method has high hydrophobic and lipophilic properties, and can improve combining property with reinforced rubber and improve reinforcement effect; meanwhile, the white carbon black has different colors and can endow the reinforced rubber with different colors, and besides, transference resistance of the dye is better; an obtained copolymer has broad application prospect in the aspect of improvement of flame retardancy and bonding flame retardancy of polyolefin.

Owner:QINGDAO UNIV OF SCI & TECH +1

Preparation method of super-hydrophobic oleophylic material

The invention discloses a super-hydrophobic oleophylic material which comprises a matrix, a reinforcing body, a coupling agent and a nano coating attached to the surface of the matrix, the matrix material is one of a stainless steel mesh, foamed nickel, foamed copper or foamed titanium, the coupling agent is dopamine, and the nano coating on the surface is one or two of hexadecylamine and octadecylamine; and the reinforcing body is graphene. The invention also discloses a preparation method thereof. According to the design thought, a layer of reduced graphene oxide coats a metal wire mesh framework such as foamed nickel and the like, the graphene serving as the reinforcing body plays a role in improving the strength of the matrix material, graphene oxide with a small particle size is adopted for coating of the graphene, and after reduction, the sheet layer of the graphene is thin, so that the excellent performance of the graphene can be played. In addition, the graphene has hydrophobicity, the surface of the graphene is modified with nanoscale low-surface-energy substances, performance integration of the graphene and the low-surface-energy substances is achieved, and hydrophobicity, lipophilicity and use durability are improved.

Owner:UNIV OF JINAN

Preparation method of modified shaddock peel fiber oil absorption material

InactiveCN107899549AHigh porosityImprove hydrophobicity and lipophilicityOther chemical processesPorosityHigh pressure

The invention relates to a preparation method of a modified shaddock peel fiber oil absorption material, and belongs to the technical field of adsorption materials. According to the method, shaddock peels serve as an oil absorption main body, condensation water in fiber cells are rapidly evaporated and expanded by the aid of high-temperature and high-pressure vapor, lignin coating effects and cellulose crystalline structures are broken, the porosity of the material is remarkably increased, fibers are treated by plasmas, more active sites on the surfaces of the fibers are activated, ester exchange modification is further performed, hydroxyl of small-molecular weight on cellulose is replaced by acetyl of large size, hydrogen bond acting force between molecules and hydrogen bond acting forcein the molecule are weakened, steric hindrance is increased, structures of crystalline areas are broken to some extent, condensed state structures of hemi-cellulose and lignin firmly coating crystalline cellulose are expanded, so that the porosity of the material after ester exchange modification is increased, hydrophobic oil affinity of the cellulose is improved, space structures of cellulose materials are enhanced, and oil absorption performance is enhanced.

Owner:吴刚

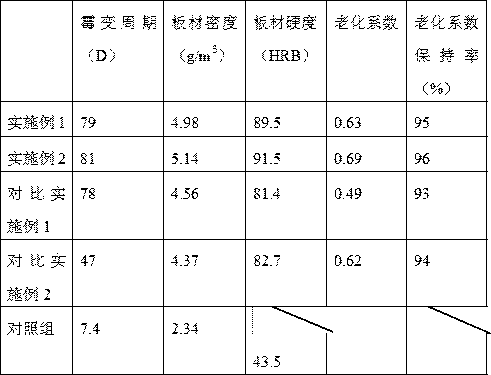

Preparation method of bamboo-based polycaprolactone composite sheet material modified by nano-silica and nano-titanium dioxide

The invention discloses a preparation method of a bamboo-based polycaprolactone composite sheet material modified by nano-silica and nano-titanium dioxide. The preparation method comprises the following steps: polycaprolactone is mixed with modified bamboo powders, hydrophobically modified bamboo fibers, modified nano-silica and a silica immobilized antioxidant in a double-roll plasticator, and the mixture is subjected to compression molding on a hot press with a set hot pressing temperature and a set hot pressing pressure; and the surface of the bamboo material is subjected to pulling film forming using titanium dioxide sol by a dipping-pulling method, and then an anti-bacterial and mildew-resistant modified bamboo material is obtained after a heat treatment of the pulled bamboo material.Silica is modified in toluene solvent using a silane coupling agent KH570 to enhance hydrophobicity and lipophilicity, and dispersibility of the modified silica in the bamboo material is excellent, so that impact-resistance and aging-resistance of the bamboo material are substantially improved. The surface of the bamboo material is subjected to pulling film forming using titanium dioxide sol by adipping-pulling method, so that nano-titanium dioxide modification of the bamboo material is achieved, and after the high temperature treatment, the titanium dioxide modified bamboo material is strong in anti-bacterial and mildew-resistant properties and low in cost.

Owner:安徽宏润工艺品有限公司

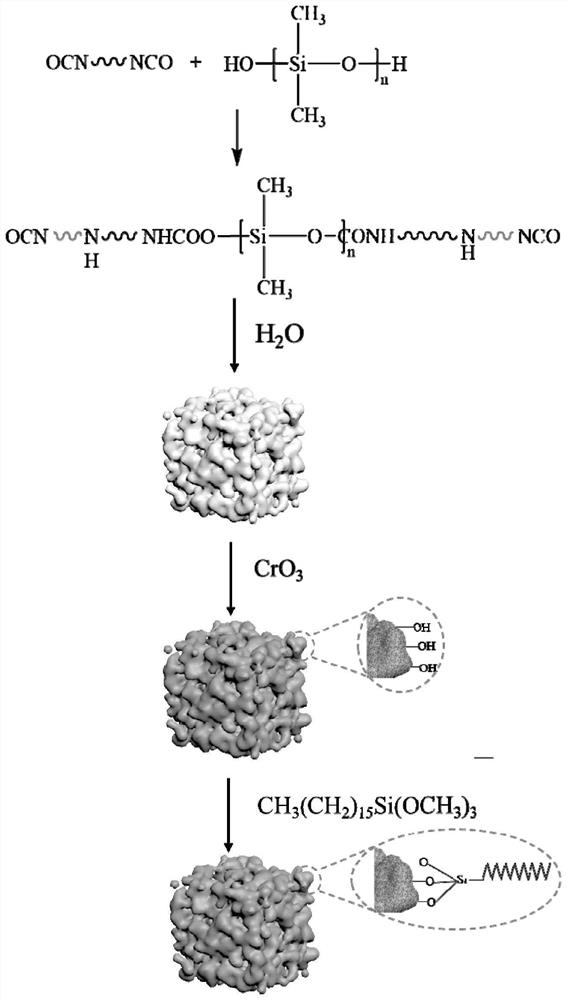

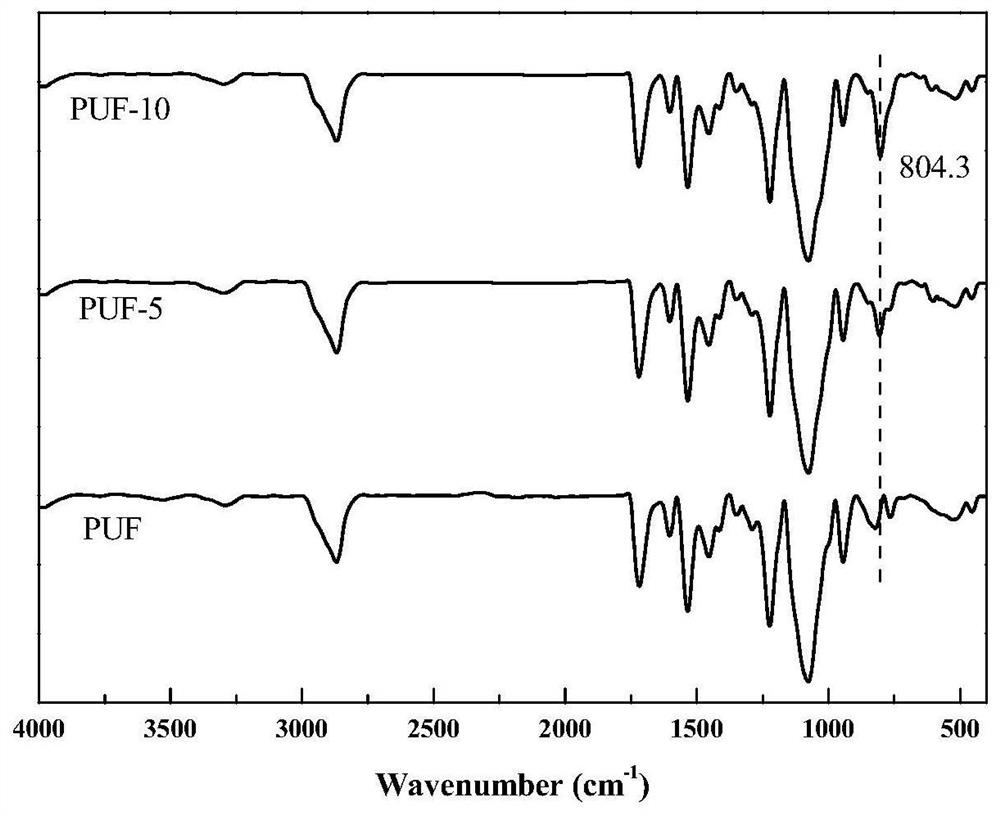

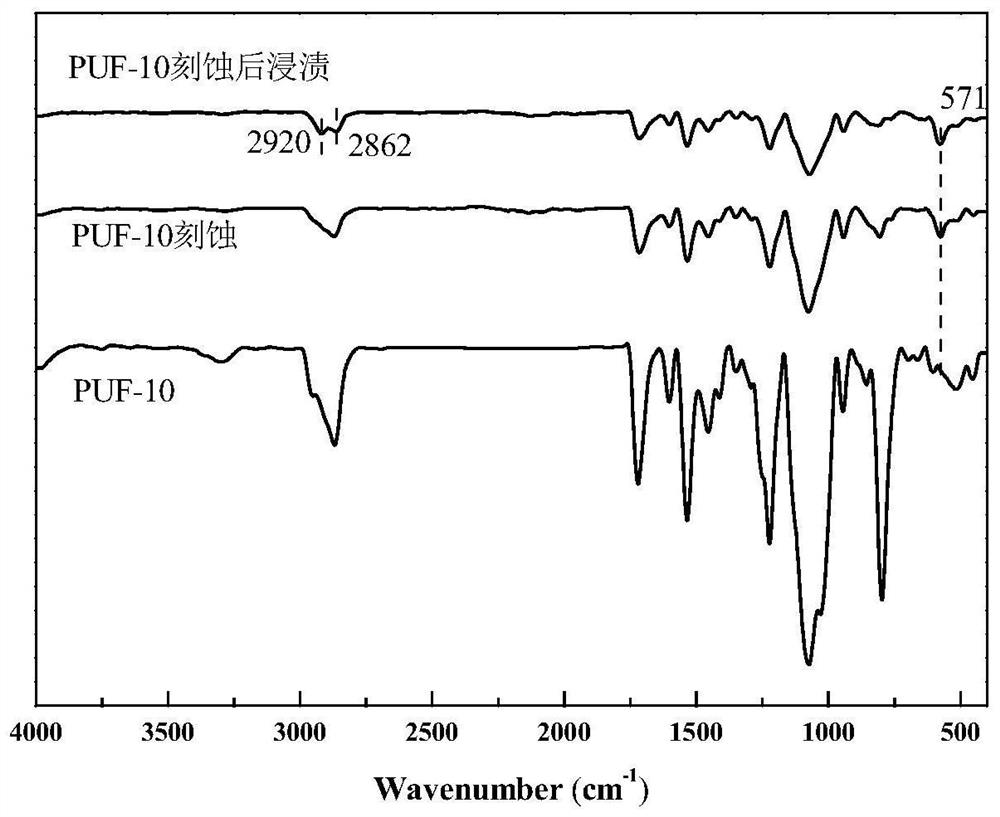

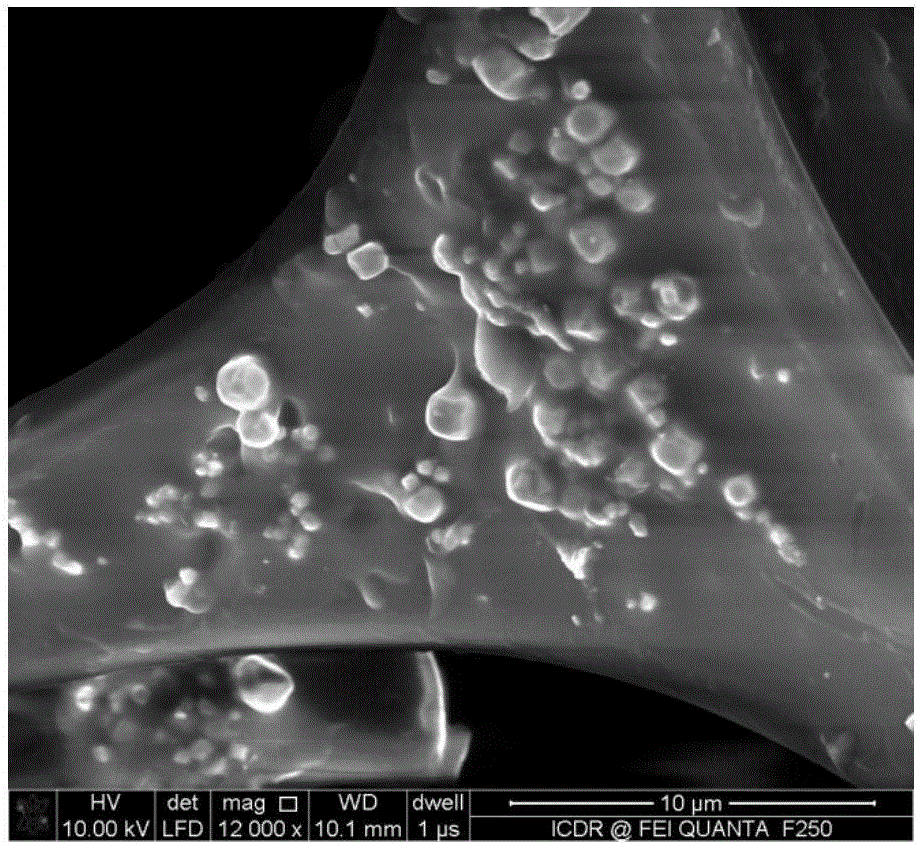

Organosilicon compound modified hydrophobic polyurethane foam and preparation method thereof

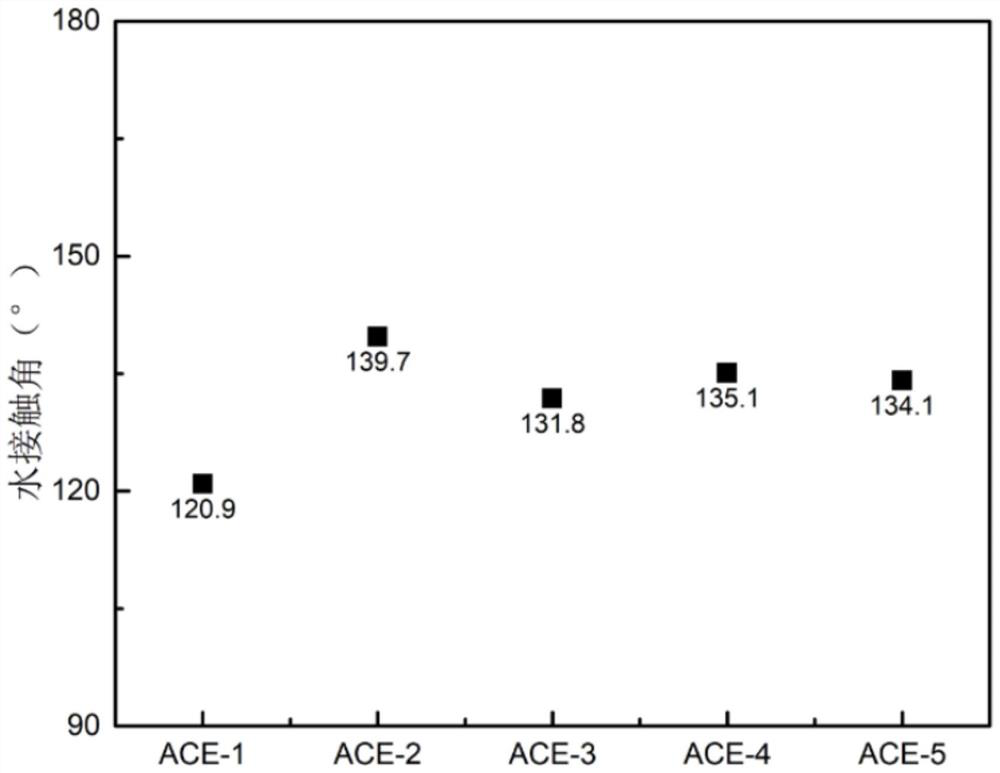

ActiveCN113429620AGood oil and water selectivityImprove hydrophobicity and lipophilicityGeneral water supply conservationPolymer scienceCarbamate

The invention discloses organosilicon compound modified hydrophobic polyurethane foam and a preparation method thereof, and belongs to the field of preparation and application of oil-water separation materials. The preparation method comprises the steps of firstly, reacting an isocyanate group with a hydroxyl group to generate a carbamate group, introducing an organosilicon chain segment into a polyurethane main chain, and then reacting with water to prepare polyurethane foam; and after chromic acid etching, grafting long-carbon-chain silane on the surface of the polyurethane foam, hydrolyzing the long-carbon-chain silane to generate silicon hydroxyl, and enabling the silicon hydroxyl and hydroxyl on the surface of the polyurethane foam to be subjected to dehydration condensation so as to obtain the organic silicon modified hydrophobic polyurethane foam. The silicon compound is reasonably introduced into a polyurethane system, so that the oil-water selectivity of the polyurethane foam is improved, and the hydrophobicity and lipophilicity of the polyurethane foam are improved. The test results of morphology characterization and water contact angle also prove that the hydrophobic polyurethane foam prepared by the invention can significantly improve the problem of poor oil-water selectivity of polyurethane foam in the oil-water separation process.

Owner:SHAANXI UNIV OF SCI & TECH

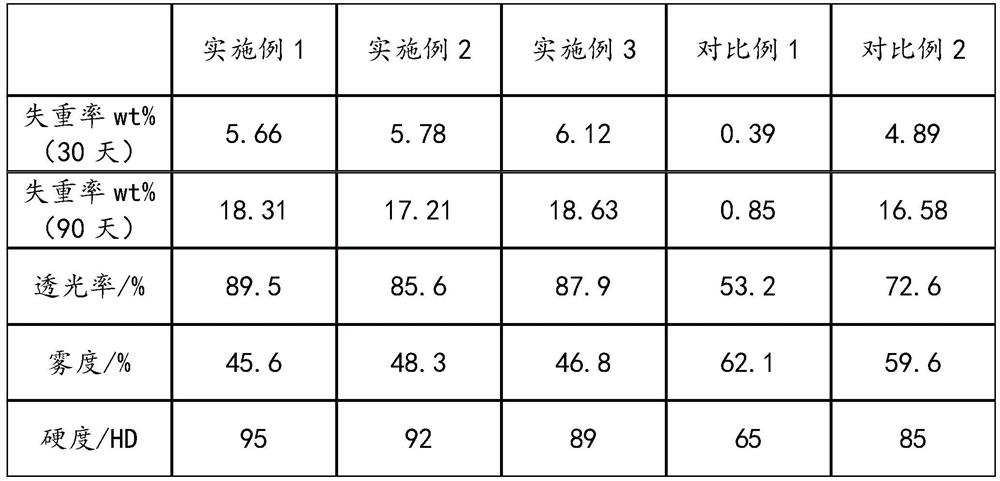

Environment-friendly rubber tube and preparation method thereof

The invention discloses an environment-friendly rubber pipe which comprises a modified polypropylene resin pipe body and a TPE elastomer rear plug. The invention further discloses a preparation method of the environment-friendly rubber tube. Rice straw fibers and polypropylene are subjected to cross-linking polymerization, the composite material is endowed with easily degradable and renewable environment-friendly performance, a modified silane coupling agent is used for modifying the rice straw fibers, so that the number of -OH on the surfaces of the fibers is reduced, the hydrophobicity and lipophilicity of the fibers are increased, the compatibility of the fibers and a polymer matrix is improved, and aluminum sol is thermally decomposed into nano Al2O3; nanometer Al2O3 shows a certain degree of lipophilicity and cooperates with polysiloxane, the affinity of the plant fibers and polypropylene is also improved, in addition, in the preparation process of the TPE elastomer rear plug, the feeding ratio of the SEBS elastomer to the polypropylene is strictly controlled to be 0.03: 1, and a rear plug prepared under the ratio has high light transmittance.

Owner:鑫龙立新材料扬州有限公司

A kind of preparation method of nano-scale organic bentonite

ActiveCN104760968BUndamagedHigh expansion factorMaterial nanotechnologySilicon compoundsSodium BentoniteMass ratio

The invention discloses a preparation method of nanoscale organobentonite, which comprises the following six steps: (1) bentonite raw ore processing, (2) sodium modification, (3) centrifugation purification, (4) inorganic acid modification, (5) organic coating reaction, and (6) a post treatment stage. The preparation method has the characteristics that through substep purification, a mass ratio of a sodium agent to suspending liquid is kept at 0.3%; in an inorganic acid modification process, improvements are performed by adjustment of a PH value to subacid and a charging mode in the organic coating reaction stage; the bentonite is subjected to delaminating dispersion, centrifugation purification and superfine grading to prepare pure montmorillonite with the content greater than 95%; then, double octadecyl dimethyl ammonium chloride is used for performing the organic coating reaction; finally crushing to a nanoscale particle size is performed, that is, the average lamellar thickness is less than 25 nanometers; and the preparation method ensures the product quality, shortens the production cycle greatly, lowers the production cost, and is suitable for large-scale popularization and application.

Owner:HUANGSHAN BAIYUE ACTIVATED CLAY

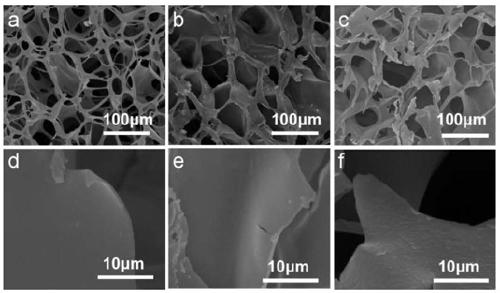

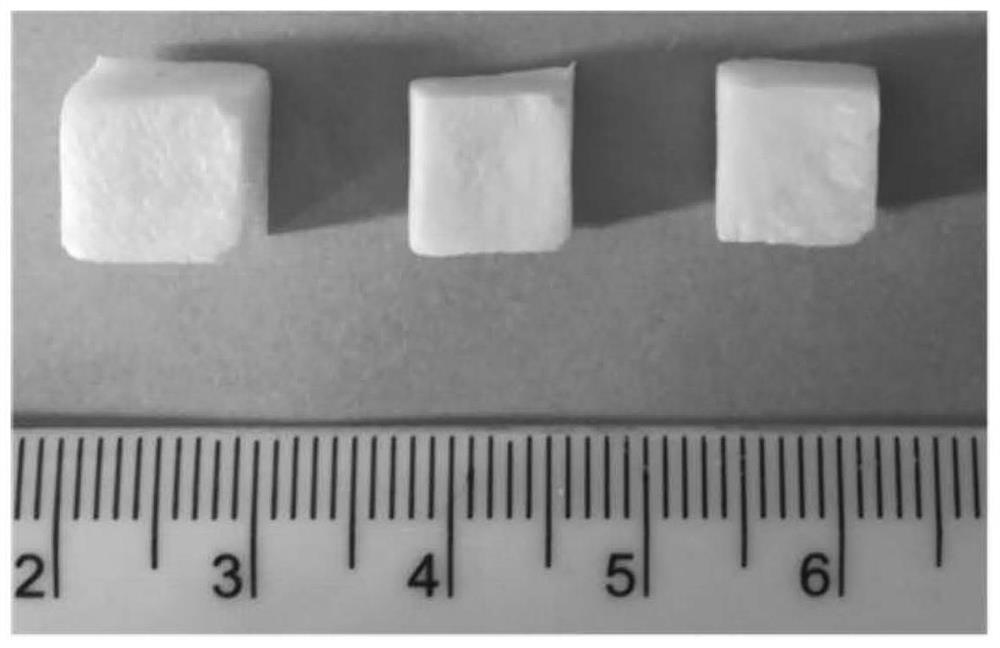

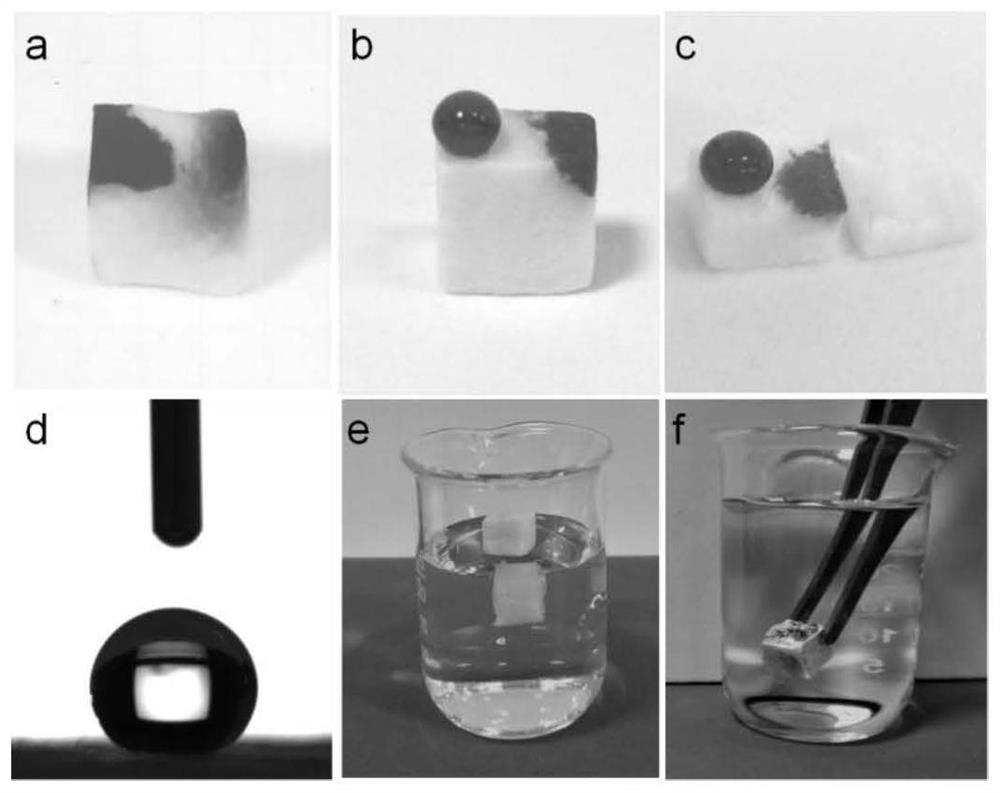

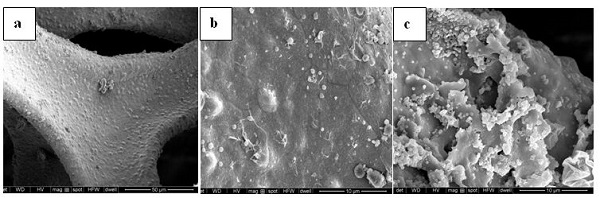

Preparation method of cuprous oxide/melamine sponge for recycling oil spill

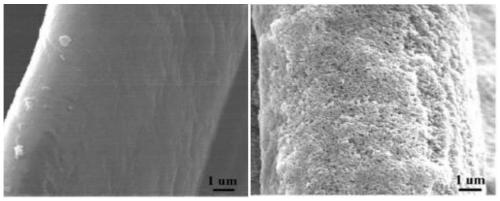

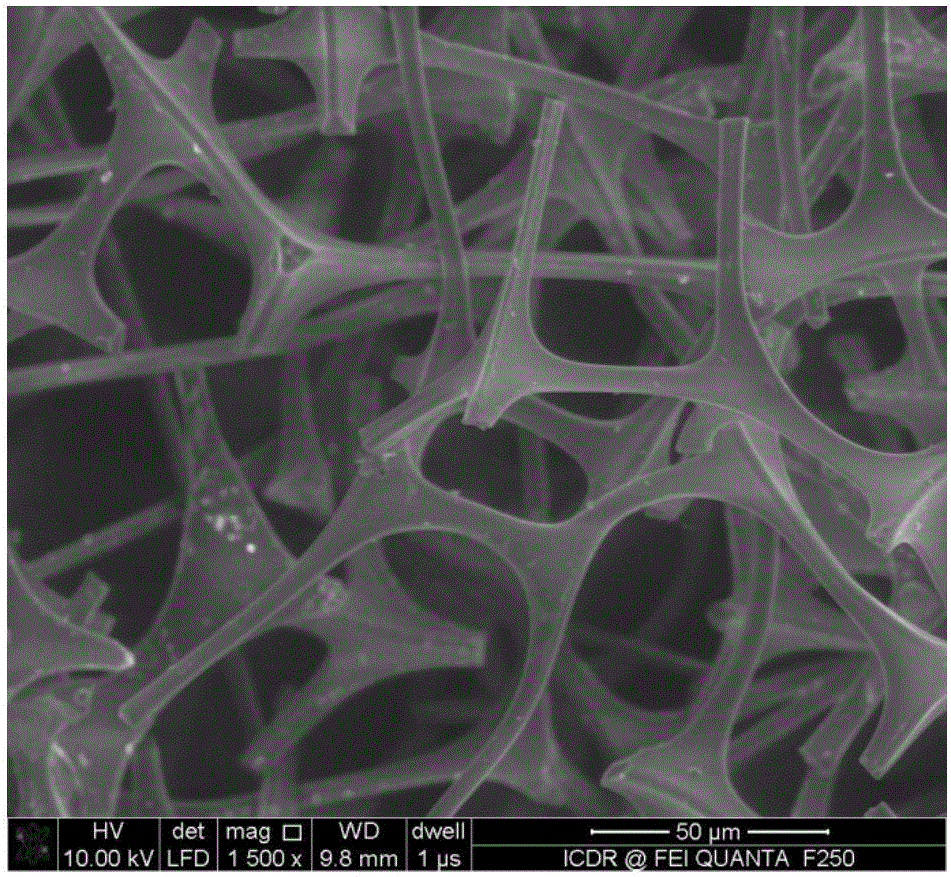

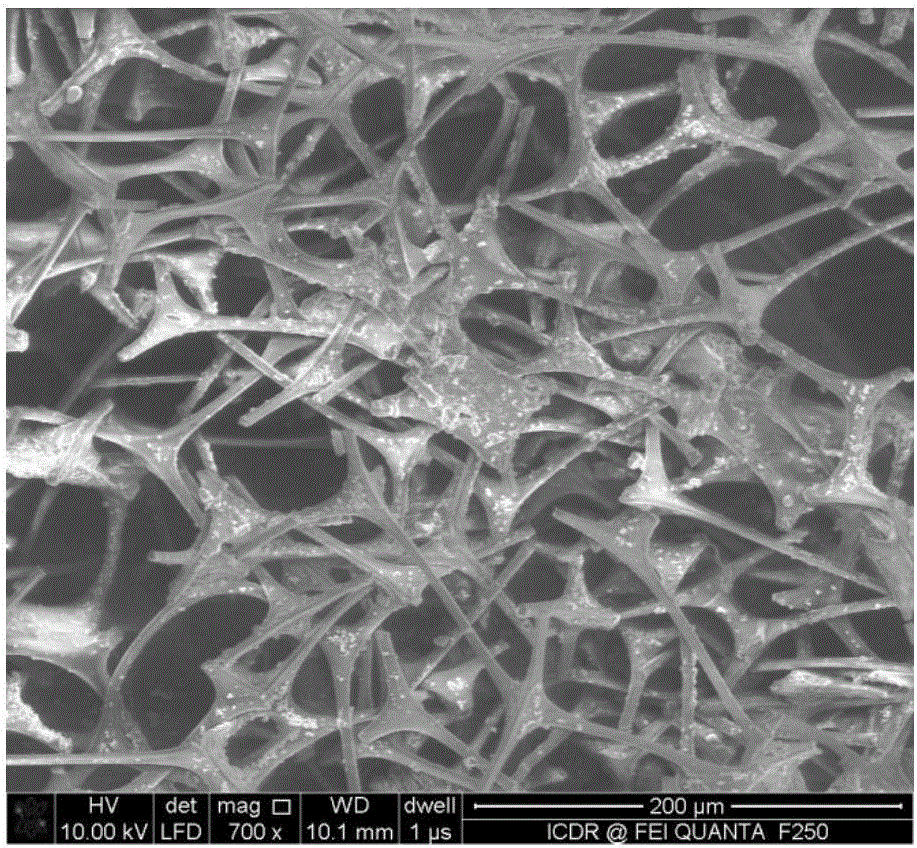

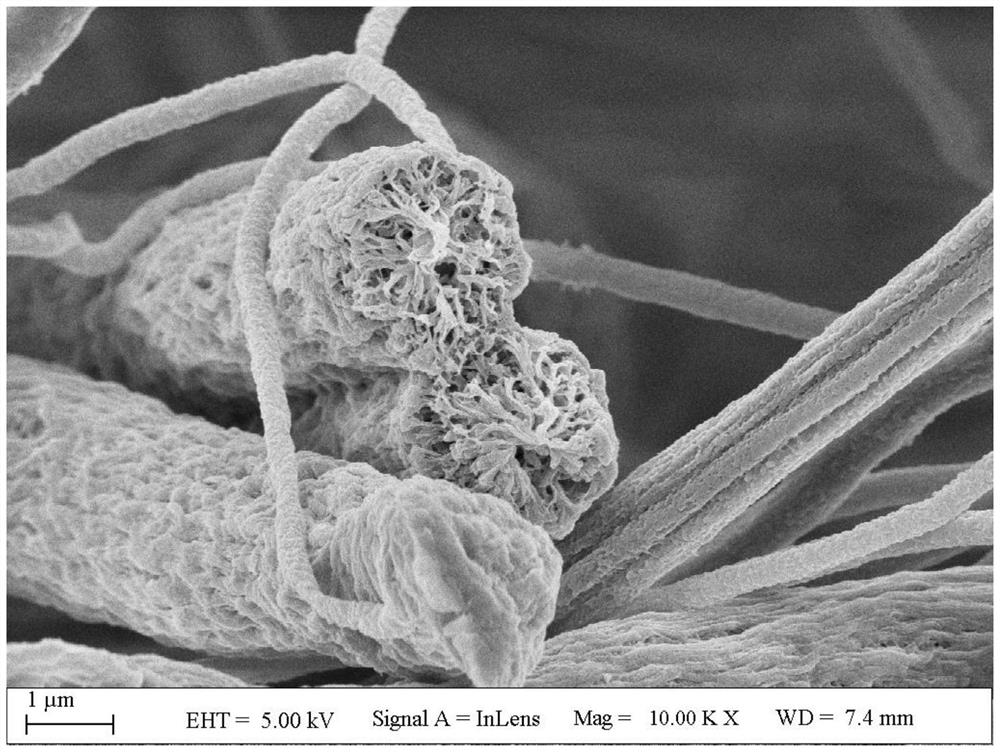

InactiveCN106622146AExcellent hydrophobic and lipophilic propertiesEasy to makeOther chemical processesAlkali metal oxides/hydroxidesScanning electron microscopeOil water

The invention discloses a preparation method of cuprous oxide / melamine sponge for recycling oil spill; high-hydrophobic high-oleophilic sponge is prepared by compositing cuprous oxide and melamine, wherein Dow Corning silica gel is used as a binder to more tightly bind cuprous oxide and melamine, Dow Corning silica gel is also used as a modifier, and hydrophobicity of the melamine sponge can be further improved. The sponge is prepared mainly by compositing melamine sponge as a carrier to cuprous oxide, the hydrophobicity and oleophilicity of the sponge are judged through contact angle test and oil-water adsorption test, and the composition condition of the cuprous oxide on the surface of the modified melamine sponge is characterized through an SEM (scanning electron microscope). The preparation process is simple, the cost is low, the prepared material has good hydrophobicity and oleophilicity, it is easy to desorb and recycle oil, reuse is available, and the sponge may be effectively applied to the controlled recycling for oil spill incidents.

Owner:XI AN JIAOTONG UNIV

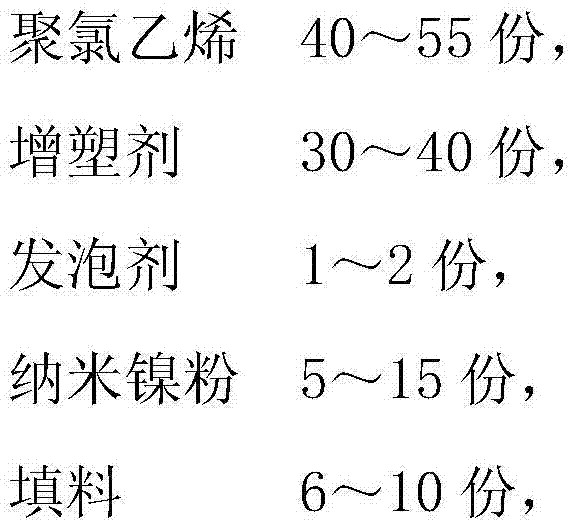

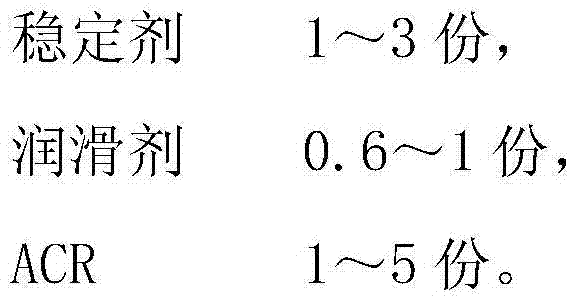

Anti-static polyvinyl chloride foamed shoe material and preparation method thereof

The invention provides an anti-static polyvinyl chloride foamed shoe material, comprising the following components in parts by weight: 40-55 parts of polyvinyl chloride, 30-40 parts of a plasticizer, 1-2 parts of a foaming agent, 5-15 parts of nano nickel powder, 6-10 parts of packing, 1-3 parts of a stabilizer, 0.6-1 part of a lubricating agent and 1-5 parts of ACR. The invention also discloses a preparation method of the anti-static polyvinyl chloride foamed shoe material. The anti-static performance of the anti-static polyvinyl chloride foamed shoe material provided by the invention is relatively good.

Owner:SUZHOU JINGRO TECH

Recyclable oil absorbing composite material and preparation method therefor

InactiveCN105001516AHigh selectivityImprove adsorption capacityOther chemical processesSodium bicarbonatePotassium persulfate

The present invention discloses a recyclable oil absorbing composite material and a preparation method therefor. The ecyclable oil absorbing composite material is characterized by being prepared by using the following raw materials in parts by weight: 3-5 parts of sodium bentonite, 0.3-0.5 parts of cetyl trimethyl ammonium bromide (CTAB), 4-6 parts of methacrylate, 3-5 parts of styrene, 0.1-0.5 parts of 1,6-hexanediol diacrylate, 3-4 parts of ethyl acetate, 1-3 parts of polyvinyl alcohol, 0.8-1.2 parts of organophosphorus ester, 0.01-0.05 parts of potassium persulfate, 0.5-1 parts of sodium bicarbonate, 2-5 parts of polyethylene wax, 2-3 parts of stearic acid, 1-2 parts of calcium sulfate, 80-95 parts of polypropylene, 0.1-0.3 parts of antioxidant 1010, 10-15 pats of azodicarbonamide, 0.5-1 parts of silane coupling agent KH550, 2-3 parts of peat, 0.5-1 parts of lanthanum nitrate, 1-2 parts of silicone acrylic emulsion and an appropriate amount of water. The recyclable oil absorption composite material provided by the present invention has characteristics of high oil absorption multiple, fast oil absorption speed, good oil-water selectivity, high oil retention, reusability and the like, and can be widely used in treating pollution of oil on water surface and recycling oil in sewage.

Owner:ANHUI CHENGFANG NEW MATERIAL TECH

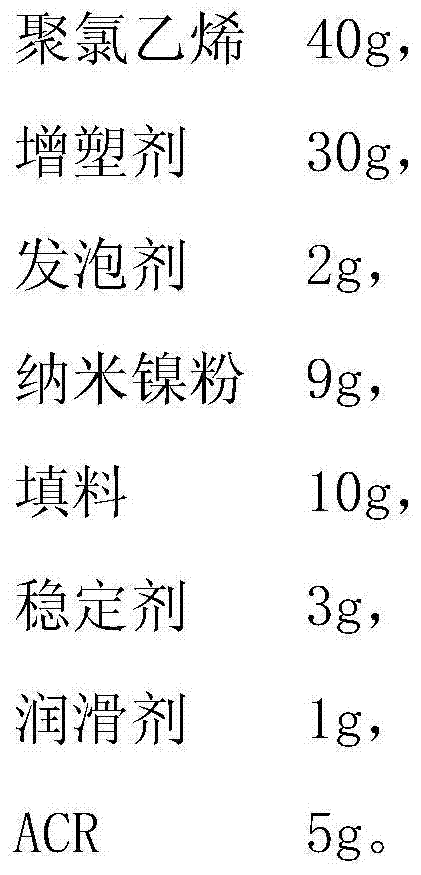

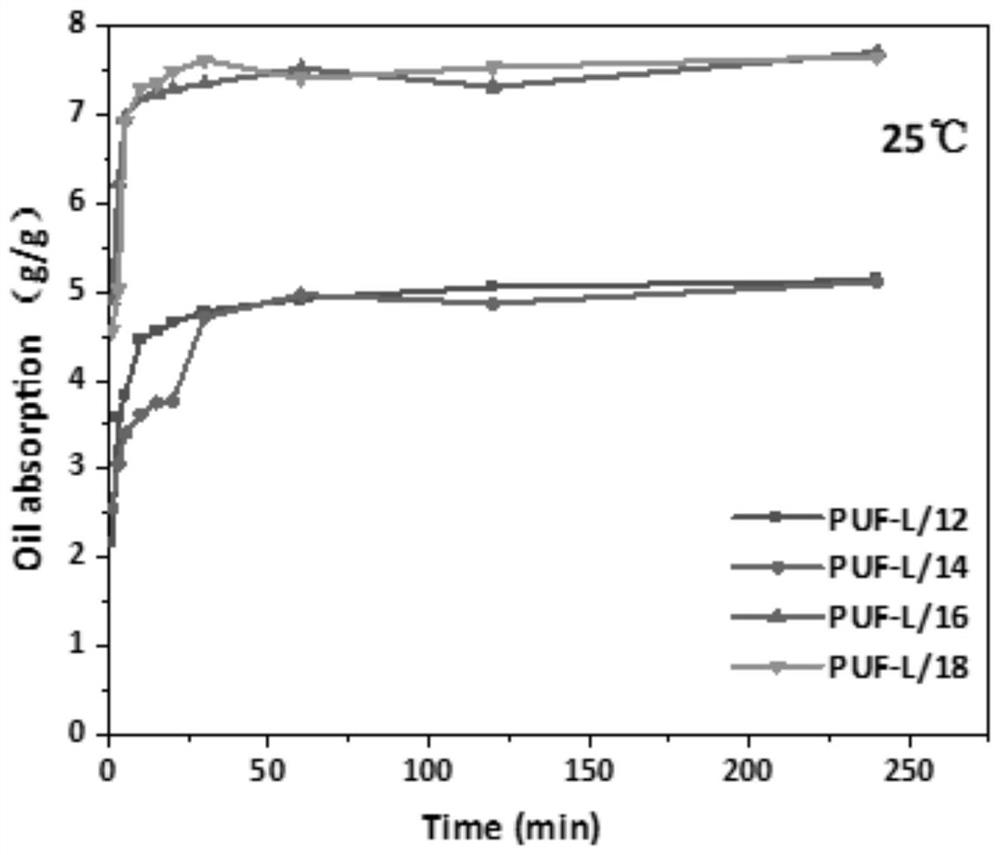

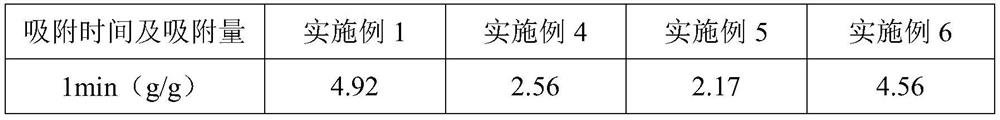

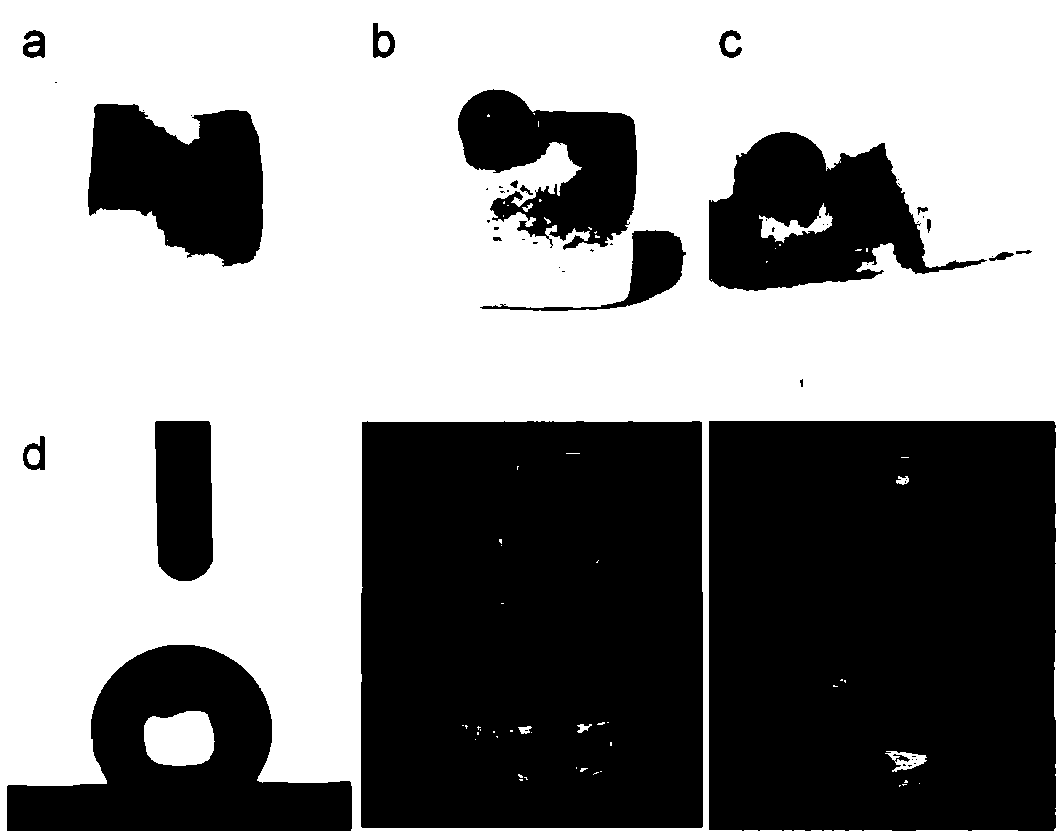

Aminated modified lignin-based polyurethane foam, and preparation method and application thereof

PendingCN113999364AImprove hydrophobicity and lipophilicityImprove adsorption capacityOther chemical processesAlkali metal oxides/hydroxidesPolymer sciencePtru catalyst

The invention discloses an aminated modified lignin-based polyurethane foam, and a preparation method and application thereof. The preparation method comprises the following steps: firstly, adding formaldehyde and an amination reagent into a lignin solution for amination treatment, then adjusting the pH value of the solution to 2-3, standing, precipitating and drying to obtain aminated lignin; and then, uniformly mixing the aminated lignin with polyether polyol, a surfactant, a catalyst and a foaming agent, and adding isocyanate for reaction to form the aminated modified lignin-based polyurethane foam, wherein the temperature of the amination reaction is 70-100 DEG C, and the reaction time is 2-6 hours; and the addition amount of the amination reagent is 15-25% of the mass of the lignin. The prepared aminated modified lignin-based polyurethane foam can be used for adsorbing and separating oil substances with relatively high viscosity (the viscosity is 95 mm<2> / s at the temperature of 40 DEG C), the maximum adsorption capacity is as high as 7.70 g / g, and high adsorption of the oil substances is realized.

Owner:GUANGDONG UNIV OF TECH

Hydrophobic modification method of sodium alginate sponge as well as product and application thereof

ActiveCN108976468AImprove hydrophobicity and lipophilicityHigh porosityOther chemical processesAlkali metal oxides/hydroxidesAtherion elymusMetal-organic framework

The invention discloses a hydrophobic modification method of sodium alginate sponge as well as a product and application thereof. The method comprises the steps: soaking the sodium alginate sponge into calcium ion solution, and then soaking in zirconium ion solution to obtain modified sodium alginate sponge. Relative to a method for hydrophobic modification of materials such as graphene, polysiloxane, organo-siloxane and a metal organic skeleton (these modification agents are high in price, toxic, and complicated in synthesis process, and are not beneficial to large-scale production and application) on the sodium alginate sponge, the porous sodium alginate sponge prepared according to the invention is simple in method, green and environmental-friendly and easy to produce in large scale. Next, sodium alginate is rich in natural resource, can replace petroleum-based sponge, and solves the problem that the current petroleum resource is scanty. Subsequently, hydrophobic three-dimensional porous sodium alginate sponge has a good adsorption effect on various oils or organic solvents, and is easy to desorb and can be repeatedly used.

Owner:NANJING FORESTRY UNIV

Modified silicon carbide nanowire-rare earth salt conversion liquid for magnesium alloy surface treatment and application method thereof

InactiveCN106756951AGood dispersionImprove corrosion resistanceMetallic material coating processesNanowireRare earth

The invention discloses modified silicon carbide nanowire-rare earth salt conversion liquid for magnesium alloy surface treatment. The conversion liquid uses rare earth salt as a main film forming agent, and uses sodium molybdate, tartaric acid, sodium fluoride and the like as assistants; on the basis, a stearic acid surface modified silicon carbide nanowire is added; and the modified nanowire is easier to disperse in a solution, so that the uniform and stable reinforcement effect is obtained, the corrosion resistance and the wear resistance of a rare earth salt conversion film can be prominently improved, meanwhile, the surface hydrophobic lipophilicity of the film layer can be improved, the magnesium alloy surface cleanness is further improved, and the compatibility with an organic coating layer is better.

Owner:巢湖云海镁业有限公司

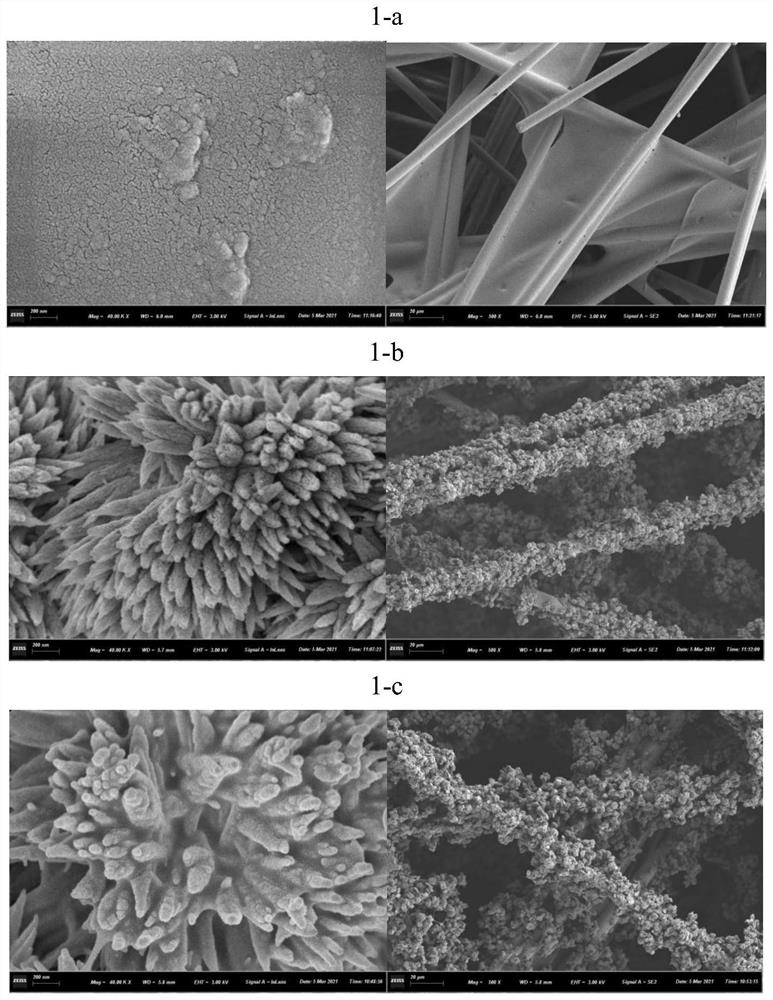

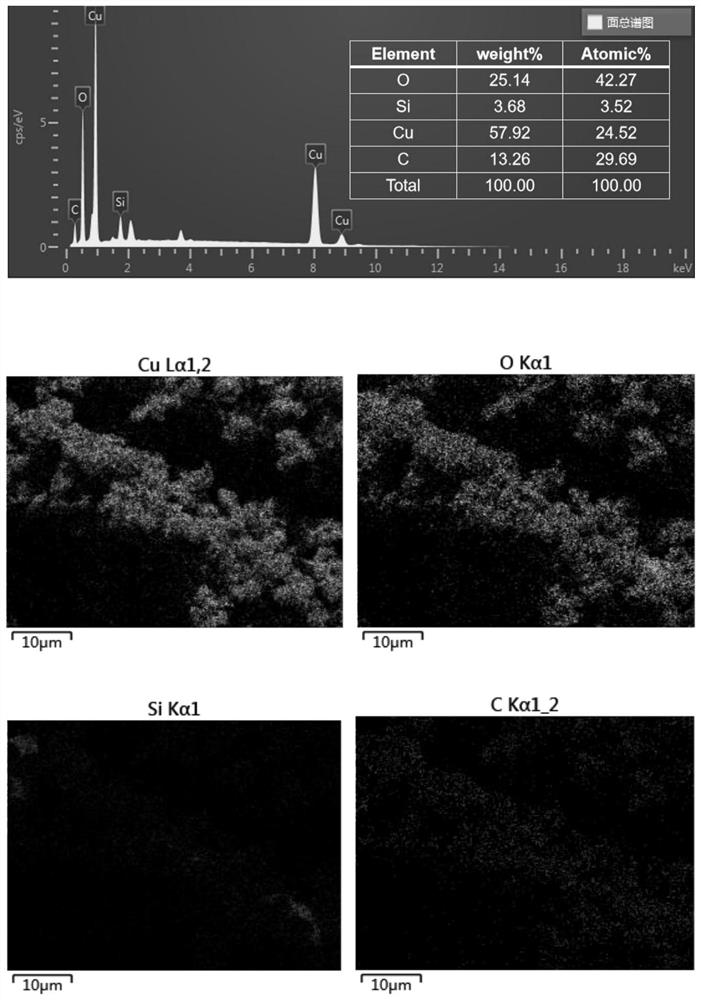

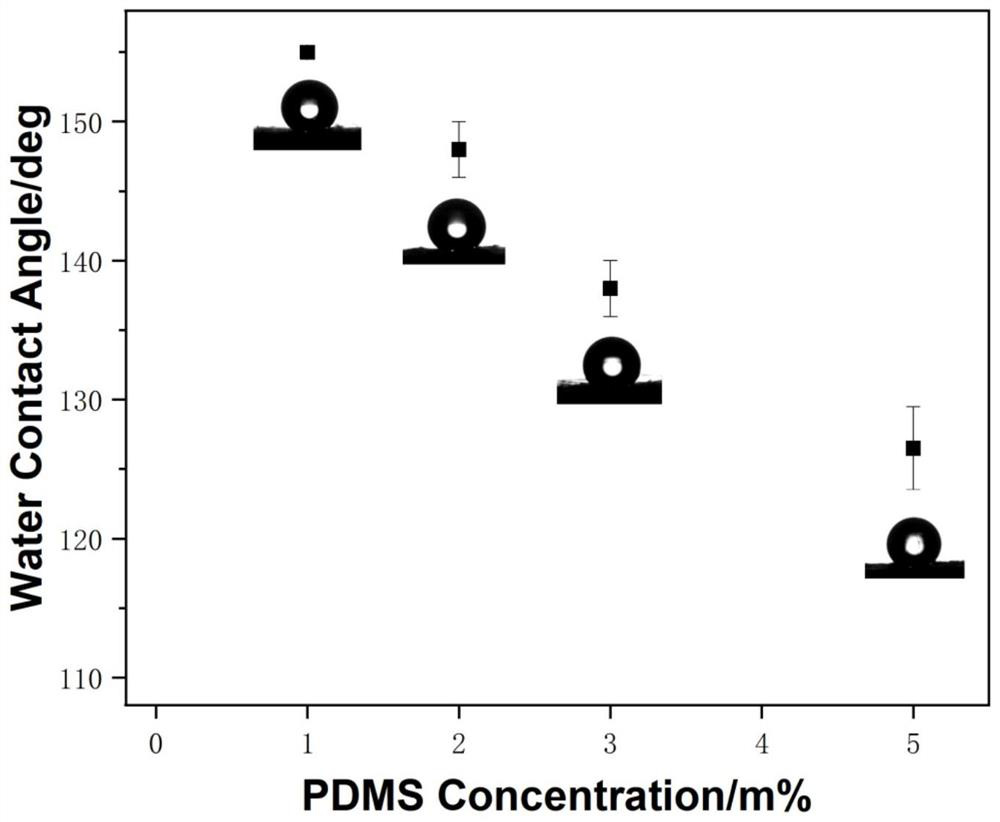

Super-hydrophobic glass fiber composite oil-water separation material as well as preparation method and application thereof

InactiveCN114432899AImprove hydrophobicity and lipophilicityEasy to separateMembranesSemi-permeable membranesBASIC CUPRIC CARBONATEGlass fiber

The invention discloses a preparation method and application of a super-hydrophobic glass fiber composite oil-water separation material, and the material preparation method comprises the following steps: dissolving basic cupric carbonate in an alkali solution to obtain a mixed solution I; impregnating a glass fiber felt in the mixed solution I to obtain a CuO glass fiber felt; dissolving polydimethylsiloxane in an organic solvent to obtain a mixed solution II; and soaking the CuO glass fiber felt in the mixed solution II, and carrying out high-temperature curing treatment to obtain the super-hydrophobic glass fiber composite oil-water separation material. The super-hydrophobic glass fiber composite oil-water separation material is prepared by loading a copper oxide crystal and a polydimethylsiloxane (PDMS) solution onto the surface of a glass fiber composite material by using a hydrothermal deposition method and an excessive impregnation method respectively. Due to ultrahigh hydrophobic and oleophylic properties and a superposable combination mode, the material has a good demulsification effect on various emulsified oil, and can be widely applied to oil-water separation operation.

Owner:ZHEJIANG UNIV OF TECH

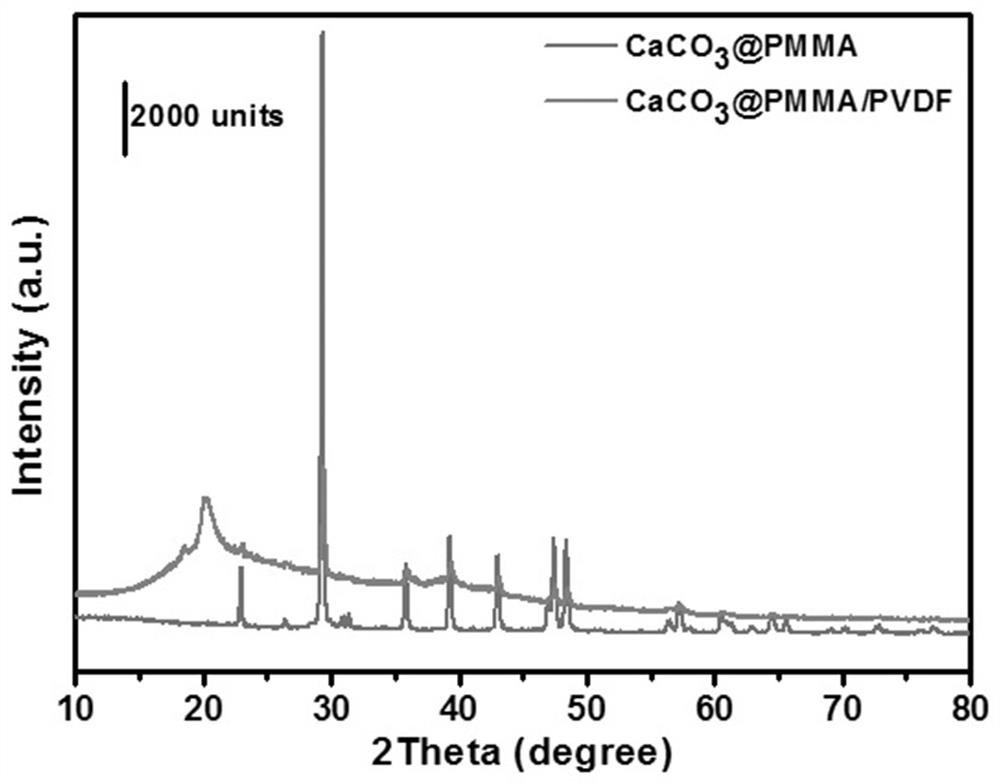

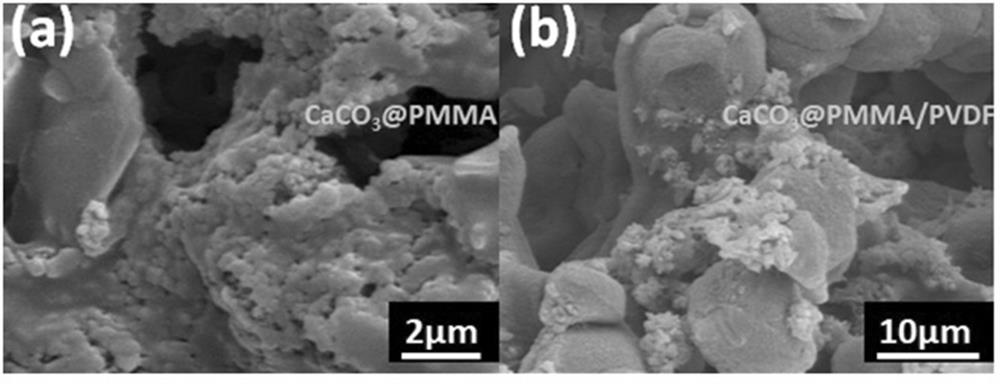

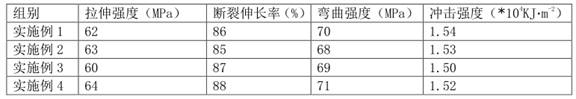

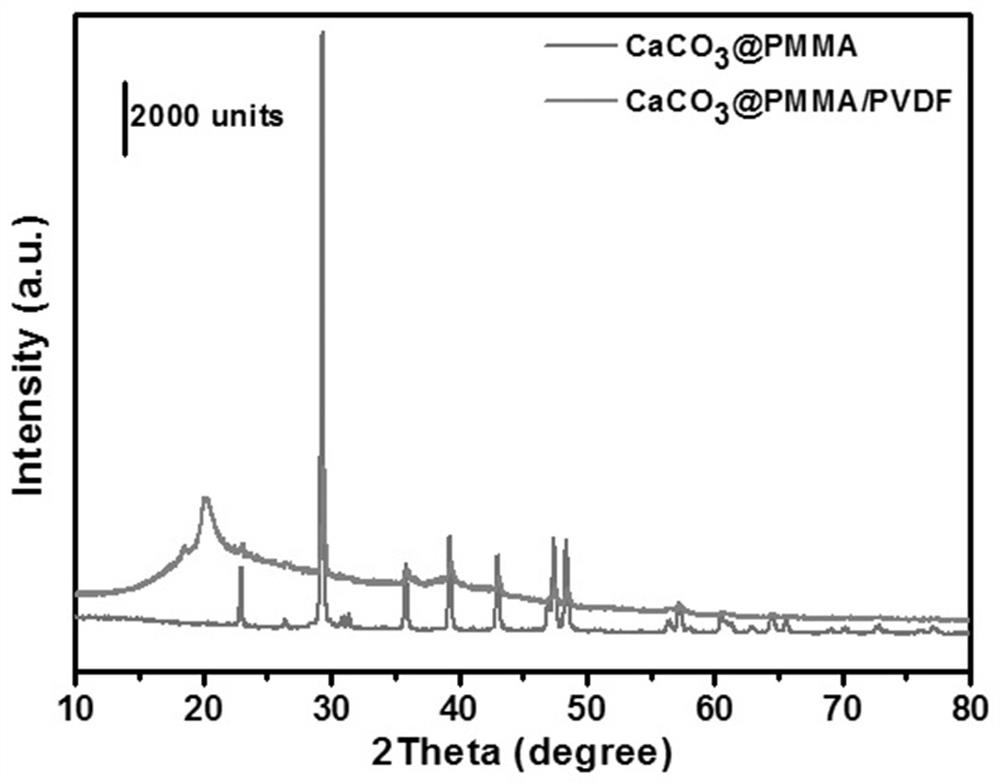

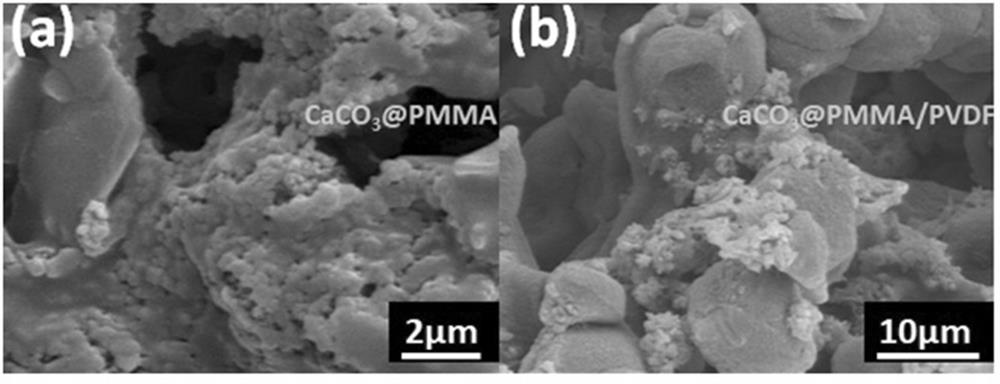

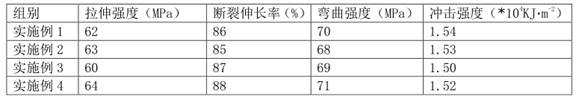

Preparation method and application of modified nano calcium carbonate through MMA in-situ polymerization

ActiveCN113736196AImprove hydrophobic and lipophilic propertiesImprove durabilityChemical industryIn situ polymerizationPolymer chemistry

The invention discloses a preparation method and application of modified nano calcium carbonate through MMA in-situ polymerization. The preparation method comprises steps: firstly, subjecting nano calcium carbonate slurry to uniform polymerization reaction in an MMA monomer solution by adopting a two-phase mixed solution method, secondly, filling slurry CaCO3@PMMA modified by utilizing MMA into a PVDF matrix, and then preparing a CaCO3@PMMA / PVDF composite material by adopting a water vapor induced phase separation method (WVIPs); and carrying out hot pressing to obtain the block-shaped CaCO3@PMMA / PVDF composite material. The hydrophobic and oleophylic properties of the nano calcium carbonate are effectively improved through in-situ polymerization modification, and after hot pressing, the modified calcium carbonate can be dissolved in the matrix PVDF while keeping the original distribution state and is tightly combined with the matrix, so that the durability of the CaCO3@PMMA / PVDF composite material is improved. The preparation method comprises the following steps: preparing CaCO3@PMMA by using an MMA in-situ polymerization modification and two-phase solution mixing method, then uniformly distributing the modified powdery CaCO3@PMMA composite material in a PVDF matrix by using a water vapor induced phase separation method, and finally preparing the blocky CaCO3@PMMA / PVDF composite material by using a hot pressing method.

Owner:中科乐美科技集团有限公司

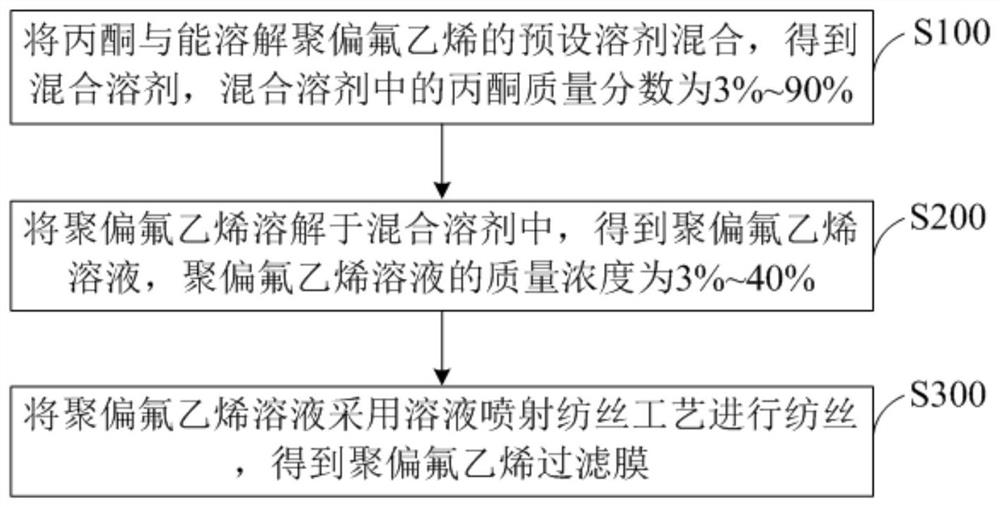

Polyvinylidene fluoride filtering membrane as well as preparation method and application thereof

PendingCN114699927AHigh water contact angleImprove hydrophobicity and lipophilicityMembranesSemi-permeable membranesPolyvinylidene difluoridePolyvinylidene fluoride

The invention provides a polyvinylidene fluoride filter membrane as well as a preparation method and application thereof. The preparation method of the polyvinylidene fluoride filtering membrane comprises the following steps that acetone and a preset solvent capable of dissolving polyvinylidene fluoride are mixed, a mixed solvent is obtained, and the mass fraction of acetone in the mixed solvent is 3%-90%; polyvinylidene fluoride is dissolved in a mixed solvent, a polyvinylidene fluoride solution is obtained, and the mass concentration of the polyvinylidene fluoride solution is 3%-40%; and spinning the polyvinylidene fluoride solution by adopting a solution jet spinning process to obtain the polyvinylidene fluoride filter membrane. After the polyvinylidene fluoride is dissolved by adopting the mixed solvent formed by mixing the acetone and the preset solvent capable of dissolving the polyvinylidene fluoride, the polyvinylidene fluoride solution is spun by adopting a solution jet spinning process to form the polyvinylidene fluoride filter membrane, and the surface appearance of the polyvinylidene fluoride filter membrane can be changed by adding the volatile acetone, so that the surface appearance of the polyvinylidene fluoride filter membrane can be changed. The water contact angle of the polyvinylidene fluoride filtering membrane is increased, the hydrophobic lipophilicity of the polyvinylidene fluoride filtering membrane is enhanced, and the oil filtering effect is enhanced.

Owner:深圳维度新材料有限公司

A kind of hydrophobic modification method of sodium alginate sponge, product and application thereof

ActiveCN108976468BImprove hydrophobicity and lipophilicityHigh porosityOther chemical processesAlkali metal oxides/hydroxidesOrganosolvGraphene

The invention discloses a hydrophobic modification method of sodium alginate sponge as well as a product and application thereof. The method comprises the steps: soaking the sodium alginate sponge into calcium ion solution, and then soaking in zirconium ion solution to obtain modified sodium alginate sponge. Relative to a method for hydrophobic modification of materials such as graphene, polysiloxane, organo-siloxane and a metal organic skeleton (these modification agents are high in price, toxic, and complicated in synthesis process, and are not beneficial to large-scale production and application) on the sodium alginate sponge, the porous sodium alginate sponge prepared according to the invention is simple in method, green and environmental-friendly and easy to produce in large scale. Next, sodium alginate is rich in natural resource, can replace petroleum-based sponge, and solves the problem that the current petroleum resource is scanty. Subsequently, hydrophobic three-dimensional porous sodium alginate sponge has a good adsorption effect on various oils or organic solvents, and is easy to desorb and can be repeatedly used.

Owner:NANJING FORESTRY UNIV

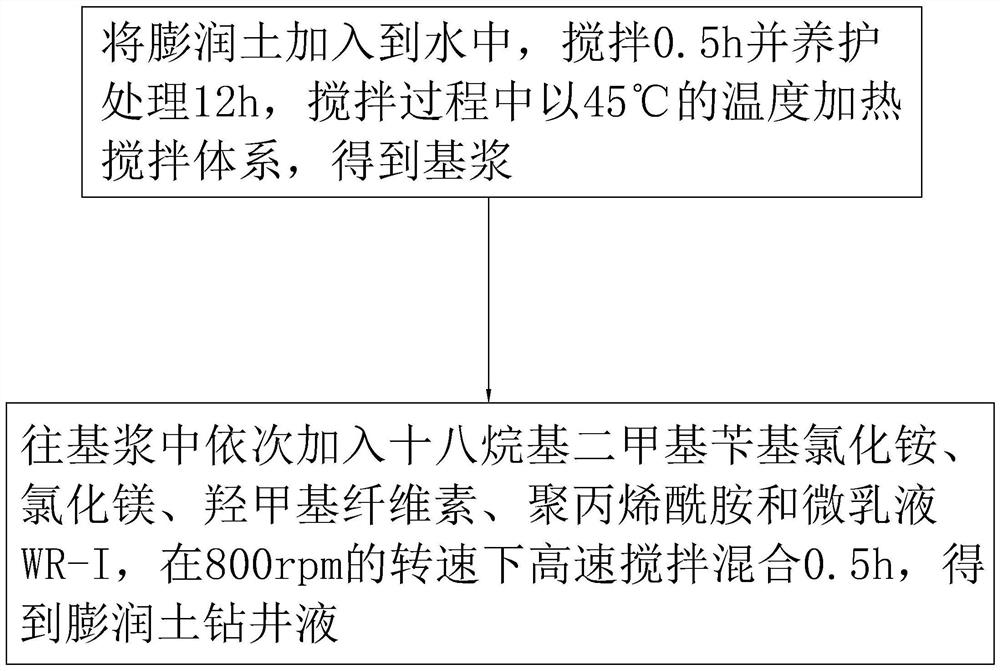

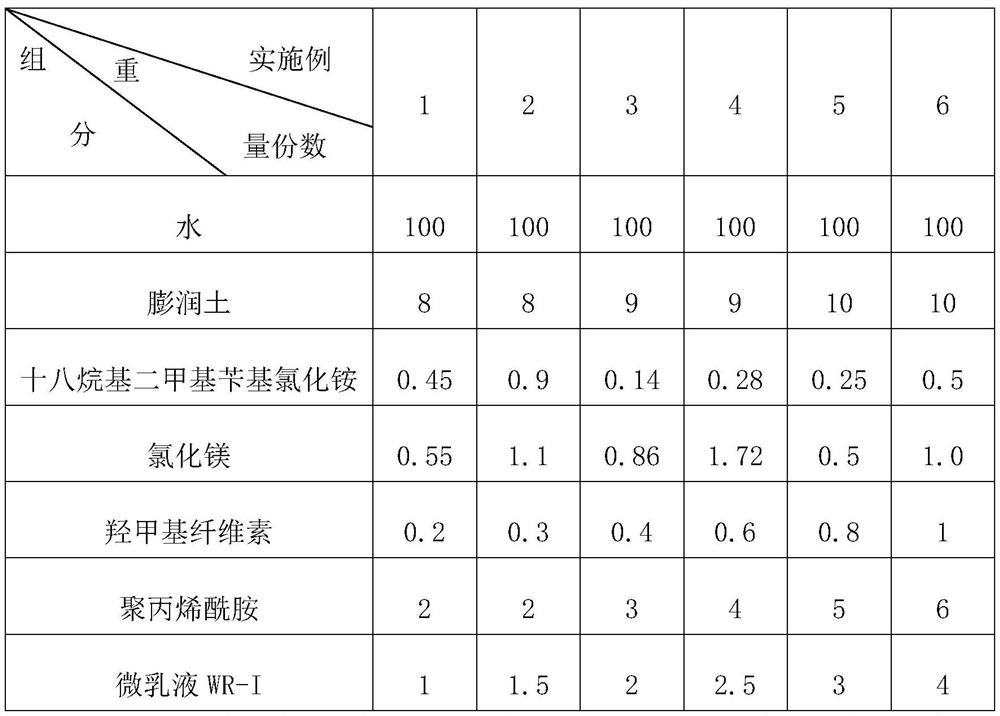

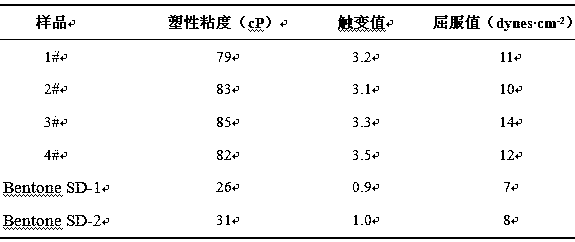

A kind of bentonite drilling fluid and preparation method thereof

ActiveCN110105930BLarge specific surface areaImprove hydrophobicity and lipophilicityDrilling compositionCelluloseWell drilling

The invention discloses a bentonite drilling fluid and a preparation method thereof, and relates to the technical field of drilling and exploitation. The technical point is: a bentonite drilling fluid, comprising the following components in parts by weight: water: 100 parts; bentonite: 8-10 parts; amine compounds: 2-6 parts; cellulose additives: 0.2-1 part ; Lubricant: 1-4 parts; Synergist: 1-2 parts, the invention has the advantages of reducing filtration loss, strong wall-protecting ability and good blocking performance.

Owner:上海勃利燃气设备有限公司

Preparation method of quaternary ammonium salt modified organic magnesium aluminosilicate for thickening oily system

ActiveCN108706605AReplace a large numberImprove hydrophobicity and lipophilicitySilicon compoundsRare earthMontmorillonite

The invention discloses a preparation method of quaternary ammonium salt modified organic magnesium aluminosilicate for thickening an oily system. The preparation method is characterized by comprisingthe following steps: taking montmorillonite in the nature as a reaction base material; firstly, carrying out high-temperature solid-phase reaction to prepare PO4<3-> / rare earth modified montmorillonite; then carrying out quaternary ammonium salt intercalation modification to produce the organic magnesium aluminosilicate which has strong expansibility, great viscosity and high thickening capability in the oily system. The quaternary ammonium salt modified organic magnesium aluminosilicate has an extremely great application prospect in industries including oil paint, printing ink, high-temperature lubricating grease and the like.

Owner:JIANGSU HEMINGS NEW MATERIALS TECH CO LTD

A kind of preparation method and application of nanometer calcium carbonate modified by mma in-situ polymerization

ActiveCN113736196BImprove hydrophobicity and lipophilicityIncreased durabilityChemical industryPolymer scienceIn situ polymerization

The invention discloses a preparation method and application of nano-calcium carbonate modified by in-situ polymerization of MMA. Firstly, a two-phase mixed solution method is used to uniformly polymerize nano-calcium carbonate slurry in MMA monomer solution, and secondly, the modified nano-calcium carbonate slurry is modified by MMA. After curing the slurry CaCO 3 @PMMA was filled into a PVDF matrix, followed by water vapor-induced phase separation (WVIPs) to prepare CaCO 3 @PMMA / PVDF composite material, made of bulk CaCO after hot pressing 3 @PMMA / PVDF composite. In-situ polymerization modification can effectively improve the hydrophobic and lipophilic properties of nano-calcium carbonate, and after hot pressing, the modified calcium carbonate can be dissolved in the matrix PVDF while maintaining the original distribution state, and closely combined with the matrix to improve the CaCO 3 Durability of @PMMA / PVDF composites. The present invention utilizes MMA in-situ polymerization modification and two-phase solution mixing method to prepare CaCO 3 @PMMA, followed by steam-induced phase separation to make modified powdered CaCO 3 The @PMMA composite is uniformly distributed in the PVDF matrix, and finally the bulk CaCO is produced by hot pressing 3 @PMMA / PVDF composite.

Owner:中科乐美科技集团有限公司

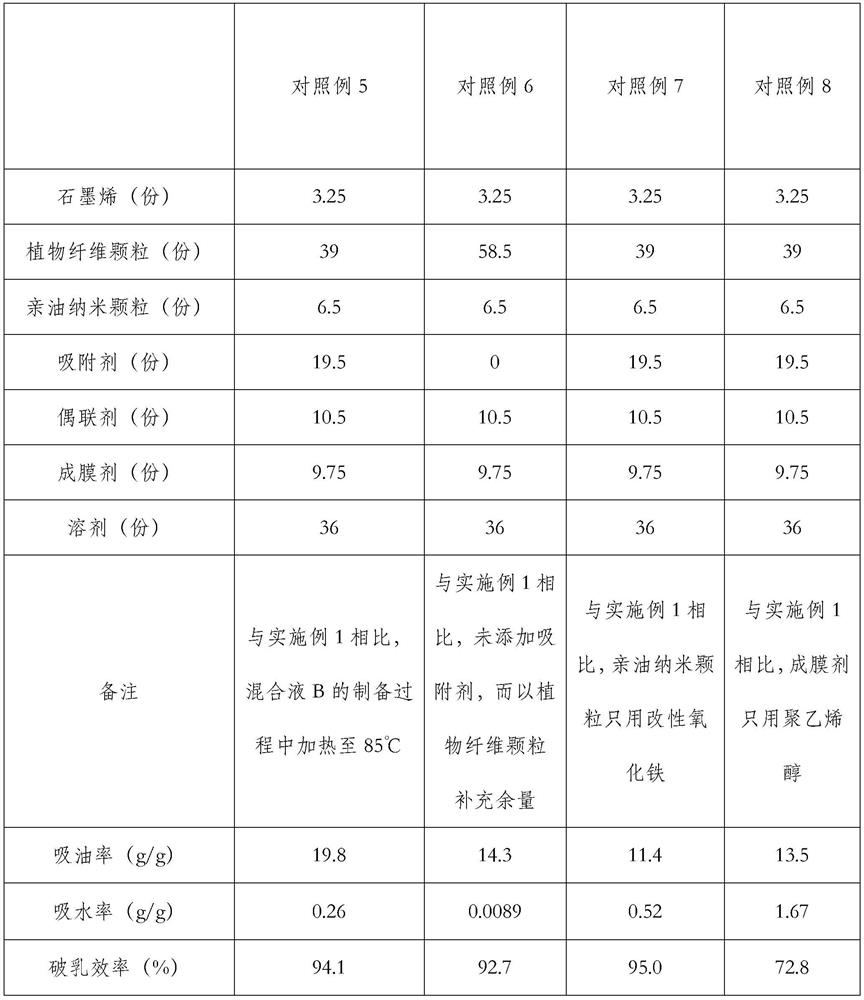

A kind of graphene plant fiber nanocomposite oil-absorbing agent and preparation method thereof

ActiveCN112175580BEasy to separateHigh oil absorptionOther chemical processesLiquid separationPlant fibreNanoparticle

Owner:孙斌

A kind of preparation method of superhydrophobic lipophilic material

The invention discloses a superhydrophobic and lipophilic material, which is composed of a matrix, a reinforcing body, a coupling agent and a nano-coating attached to the surface of the matrix. The matrix material is stainless steel mesh, nickel foam, copper foam or titanium foam One, the linking agent is dopamine, the nano-coating on the surface is one or both of hexadecylamine and octadecylamine; the reinforcing body is graphene. Its preparation method is also disclosed; the design concept of the present invention is to coat a layer of reduced graphene oxide on the wire mesh skeleton such as nickel foam, and the graphene as the reinforcement plays a role in improving the strength of the matrix material. The coating uses graphene oxide with a smaller particle size. After reduction, the graphene sheet is thinner, which can exert the excellent performance of graphene. In addition, graphene itself is hydrophobic, and nano-scale low surface energy substances are modified on its surface to realize the combination of the two properties and improve the hydrophobicity and lipophilicity and the durability of use.

Owner:UNIV OF JINAN

A method for preparing flexible block carbon by carbonization of small wood blocks

ActiveCN110127653BStrong hydrophobic and lipophilicRenewable Hydrophobic LipophilicCarbon preparation/purificationLipophilicityMaterials science

The invention belongs to a method for preparing flexible block charcoal by carbonizing small wood blocks. The method is to remove the lignin in the wood block by chemical reagent treatment, then replace with higher alcohol and freeze-dry to obtain the wood-based skeleton, and finally the obtained wood The base skeleton is carbonized at high temperature under the protection of an inert gas to obtain a flexible bulk carbon with a wavy layered skeleton structure. The invention can obtain high hydrophobicity and lipophilicity, good compressibility and elastic flexible block carbon, and has the advantages of simple preparation process, easy process control, wide source of raw materials, safety and non-toxicity, lower preparation cost and less environmental pollution.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

A kind of environmental protection hose and preparation method thereof

The invention discloses an environment-friendly rubber hose, which comprises a modified polypropylene resin pipe body and a TPE elastomer back plug; the invention also discloses a preparation method of the environment-friendly rubber hose. In the present invention, the rice straw fiber is cross-linked and polymerized with polypropylene, which endows the composite material with easy-to-degrade and renewable environmental performance. The modified silane coupling agent is used to modify the rice straw fiber to reduce the number of OH on the fiber surface, making it hydrophobic and hydrophilic. Increased oiliness, improved compatibility of fibers with polymer matrix, and thermal decomposition of aluminum sol into nano-Al 2 o 3 , nano-Al 2 o 3 It exhibits a certain degree of lipophilicity, and cooperates with polysiloxane to improve the affinity between plant fibers and polypropylene. In addition, during the preparation of TPE elastomer back plugs, the ratio of SEBS elastomer to polypropylene is strictly controlled to 0.03 :1, the back plug made under this ratio has excellent light transmittance.

Owner:鑫龙立新材料扬州有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com