A kind of environmental protection hose and preparation method thereof

A kind of rubber hose, environmental protection technology, applied in the field of environmental protection rubber hose and its preparation, can solve the problems such as hardness and light transmission performance are not obvious improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

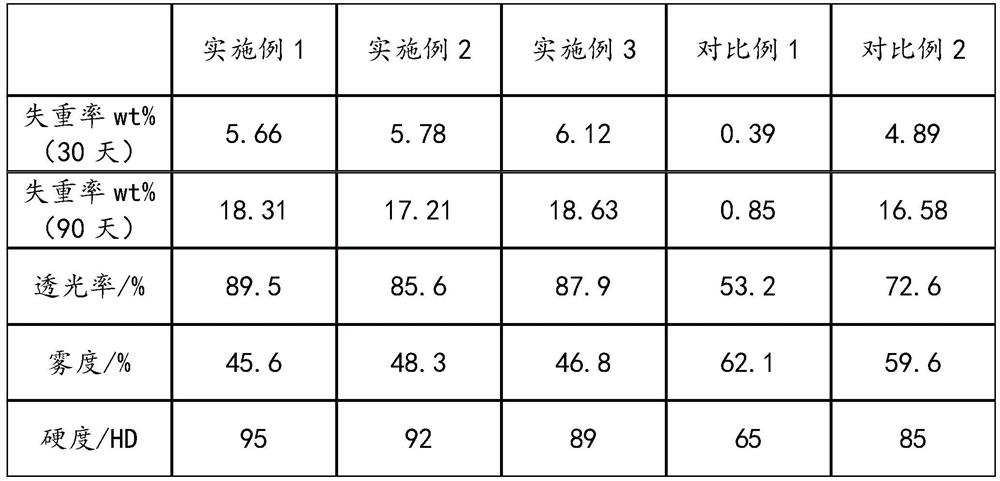

Examples

Embodiment 1

[0030] An environmentally friendly rubber hose, including a modified polypropylene resin tube body and a TPE elastomer back plug;

[0031] The environmentally friendly hose is made by the following steps:

[0032] In step A1, 30 parts of polypropylene, 20 parts of rice straw powder, 6 parts of modified coupling agent, 4 parts of active color masterbatch, 1 part of dioctyl adipate, 1 part of glyceryl tristearate and 1 part of tephrine Pour butyl hydroquinone into a high-temperature reaction kettle, heat it at 120°C and carry out sufficient mechanical stirring and mixing to prepare a mixture, wherein the stirring rate is 180rpm;

[0033] Step A2, feed the mixture prepared in step A1 into the screw extrusion granulator, set the rotation speed of the screw and the temperature of each section, the mixture is extruded and granulated by double-screw rods, and then the granulated material is put into The dryer was dried at 105°C for 30 minutes while stirring, and then the modified po...

Embodiment 2

[0042] An environmentally friendly rubber hose, including a modified polypropylene resin tube body and a TPE elastomer back plug;

[0043] The environmentally friendly hose is made by the following steps:

[0044] Step A1, 33 parts of polypropylene, 23 parts of rice straw powder, 7 parts of modified coupling agent, 5 parts of active color masterbatch, 2 parts of diisodecyl adipate, 2 parts of microcrystalline paraffin and 2 parts of benzene phosphite Pour the diisodecyl ester into a high-temperature reaction kettle, heat it at 125°C and carry out sufficient mechanical stirring and mixing to prepare a mixture, wherein the stirring rate is 190rpm;

[0045] Step A2, feed the mixture prepared in step A1 into the screw extrusion granulator, set the rotation speed of the screw and the temperature of each section, the mixture is extruded and granulated by double-screw rods, and then the granulated material is put into Dry the dryer at 105°C while stirring for 30 minutes and then tak...

Embodiment 3

[0054] An environmentally friendly rubber hose, including a modified polypropylene resin tube body and a TPE elastomer back plug;

[0055] The environmentally friendly hose is made by the following steps:

[0056] Step A1, 35 parts of polypropylene, 25 parts of rice straw powder, 8 parts of modified coupling agent, 6 parts of active color masterbatch, 3 parts of diisodecyl adipate, 3 parts of microcrystalline paraffin and 3 parts of benzene phosphite Diisodecyl ester was poured into a high-temperature reaction kettle, heated at 130°C, and fully mechanically stirred and mixed to obtain a mixture, wherein the stirring rate was 200rpm;

[0057] Step A2, feed the mixture prepared in step A1 into the screw extrusion granulator, set the rotation speed of the screw and the temperature of each section, the mixture is extruded and granulated by double-screw rods, and then the granulated material is put into The dryer was dried at 110°C for 20 minutes while stirring, and then the modif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com