Patents

Literature

119results about How to "Improve crosslink strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compound photocatalysis antimicrobial air filter material and preparation method thereof

InactiveCN101745271AImprove wash resistanceImprove crosslink strengthFibre treatmentFiltration separationAir filtrationPolyurethane adhesive

The invention discloses a compound photocatalysis antimicrobial coating air filter material and a preparation method thereof. The method is as follows: respectively preparing nano titanium oxide collosol, nano zinc oxide collosol and nano copper-nickel compound metallic collosol; preparing compound photocatalysis antimicrobial finishing agent; in cationic waterborne polyurethane adhesive emulsion, firstly, adding nano copper-nickel compound metallic collosol, nano titanium oxide collosol and nano zinc oxide collosol, stirring, and then adding deionized water; at room temperature, stirring and dispersing to form stable emulsion compound photocatalysis antimicrobial finishing agent; preparing finishing agent accounting for 5-15 wt% of air filter material to be treated; adding deionized water until reaching 100%; adopting a continuous padding technology to perform dip coating classification to the filter material to be treated; and drying and backing. The invention solves the problems of unfavorable nano photocatalysis antimicrobial effect, single effect and poor laundering durability, and improves the laundering durability of compound coating.

Owner:JIANGSU FILTERTEX FILTER MATERIAL +1

Photo-thermal dual-curing anisotropic conductive adhesive film and preparation method thereof

ActiveCN104673113AImprove crosslink strengthHigh bonding strengthNon-macromolecular adhesive additivesFilm/foil adhesivesEpoxyCross-link

The invention relates to a photo-thermal dual-curing anisotropic conductive adhesive film and a preparation method thereof. The anisotropic conductive adhesive film is prepared from raw materials in percentage by mass as follows: 35%-45% of epoxy resin, 10%-25% of acrylic resin, 5%-10% of a cross-linking agent, 2%-7% of a diluent, 0.6%-1% of a photoinitiator, 2.5%- 4% of a thermal curing agent, 5%-10% of an accelerant, 0.5%-2% of a silane coupling agent and 20%-35% of conductive balls. The preparation method comprises steps as follows: the raw materials are blended, subjected to rotary coating and then subjected to ultraviolet exposure processing, and the anisotropic conductive adhesive film is prepared. The anisotropic conductive adhesive film has good conductive performance, excellent weather fastness, low curing temperature, long storage time, high curing degree and high bonding strength; the preparation process is simple, the cost is low, and the application prospect is broad.

Owner:DONGHUA UNIV

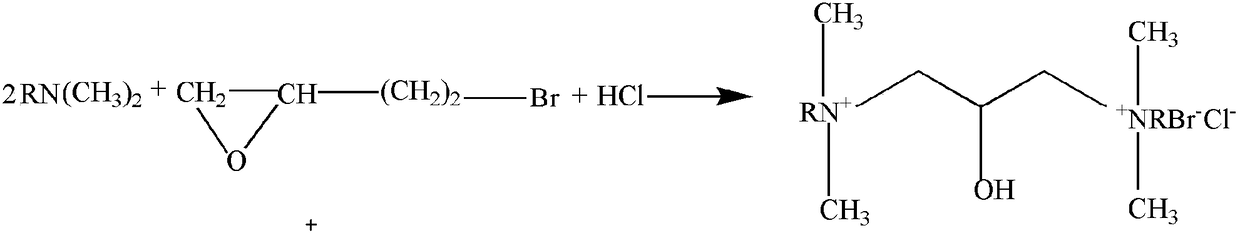

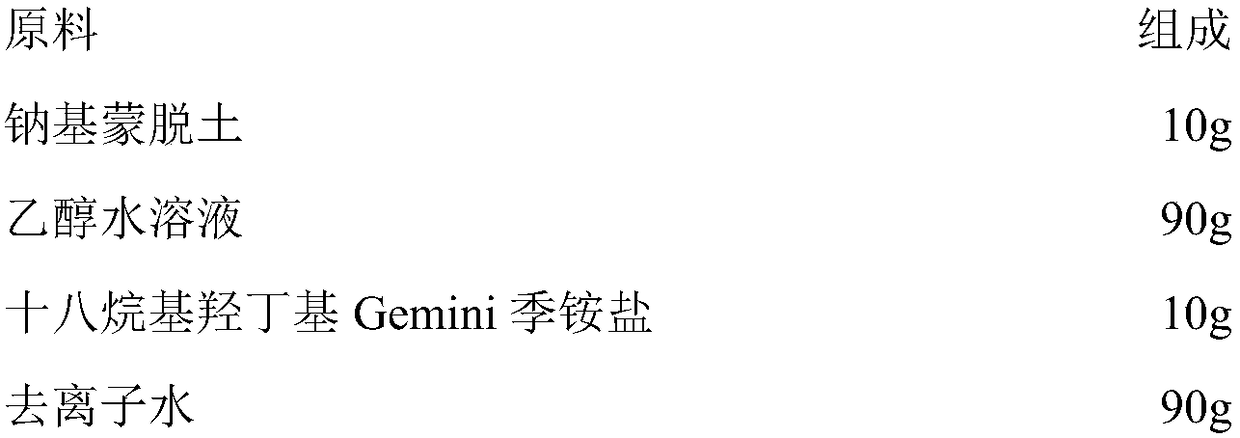

Safe and environment-friendly waterborne antibacterial adhesive with high performance and preparation method thereof

InactiveCN108395867AImprove antibacterial propertiesSafety and environmental protectionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer sciencePolyurethane adhesive

The invention discloses a safe and environment-friendly waterborne antibacterial adhesive with high performance and a preparation method thereof. The method comprises the following steps: enabling polymer polyol, a micromolecular hydrophilic chain extender, isocyanate and a solvent to make polymerization reaction in the presence of a catalyst, thus obtaining a polyurethane prepolymer; adding a neutralizer into the polyurethane prepolymer for neutralizing, and then adding water for emulsification, thus obtaining a polyurethane ionomer; adding dispersion liquid of a silver-carrying nano-clay material into the obtained polyurethane ionomer, regulating a pH value to neutral, performing shearing dispersion under the action of a high-speed dispersion machine, and removing the solvent to obtain the waterborne polyurethane antibacterial adhesive with high performance. The waterborne polyurethane is adopted as a substrate, so damage caused by a volatile organic compound (VOC) can be effectivelyavoided to obtain the safe and environment-friendly waterborne polyurethane adhesive with high performance, and the adhesive has the advantages of being safe and environmentally friendly, and free ofVOC; the mechanical property, thermal stability and antibacterial property of the obtained material far exceed that of similar modified waterborne polyurethane.

Owner:SOUTH CHINA UNIV OF TECH

Waterproof high-hardness waterborne polyurethane coating

InactiveCN104312411AImprove thermal stabilityHigh hardnessAnti-corrosive paintsPolyurea/polyurethane coatingsSilanesCarbon nanotube

The invention discloses a waterproof high-hardness waterborne polyurethane coating which is characterized by comprising the following components in parts by weight: 65-80 parts of modified waterborne polyurethane, 20-35 parts of waterborne polyaniline, 3-6 parts of polyisocyanate, 5-20 parts of nano-silica, 3-9 parts of isopropanol, 5-10 parts of ethylene glycol propyl ether, 0.5-1.6 parts of dipentaerythritol, 15-20 parts of polydimethylsiloxane, 3-8 parts of gamma-isocyanate propyl triethoxy silane, 3-8 parts of polytetrafluoroethylene, 0.5-3 parts of modified carbon nanotubes, 5-20 parts of precipitated barium sulphate, 2-6 parts of amino resin, 3-8 parts of zinc powder and 30-60 parts of water. The waterproof high-hardness waterborne polyurethane coating is good in water resistance, high in harness and long in service life.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

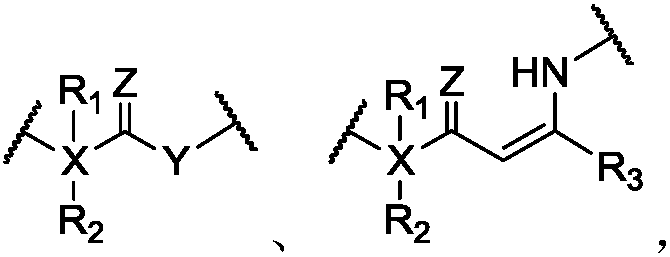

Dynamic polymer with hybrid cross-linked network and application of dynamic polymer

ActiveCN107698748AImprove structural stabilityWith bionic mechanical propertiesCross-linkPolymer science

The invention discloses a dynamic polymer with a hybrid cross-linked network structure. The dynamic polymer contains dynamic covalent bond crosslinking and supermolecular hydrogen bond crosslinking, wherein the dynamic covalent bond crosslinking is realized by associative exchangeable covalent bonds, and the supermolecular hydrogen bond crosslinking is realized by hydrogen bond groups on the sidegroups and / or side chains of a polymer chain framework and hydrogen bond groups on the optional chain frameworks. The polymer integrates dynamic characteristics of a supermolecule and dynamic covalentcharacteristics of glass-like matter; supermolecular hydrogen bonds give stimulative responsibility, energy dissipation performance and self-repairing performance to the material; the associative exchangeable covalent bonds give structural stability and mechanical strength to the covalent cross-linked polymer, and because the associative exchangeable covalent bonds have dynamic reversibility, thepolymer has self-repairing performance, recycling performance, reproducibility and the like. According to the invention, the dynamic polymer with the hybrid cross-linked network structure can be widely applied to vibration-absorptive cushioning materials, impact-resistant protective materials, self-repairing materials, toughness materials, sealing elements and the like.

Owner:厦门逍扬运动科技有限公司

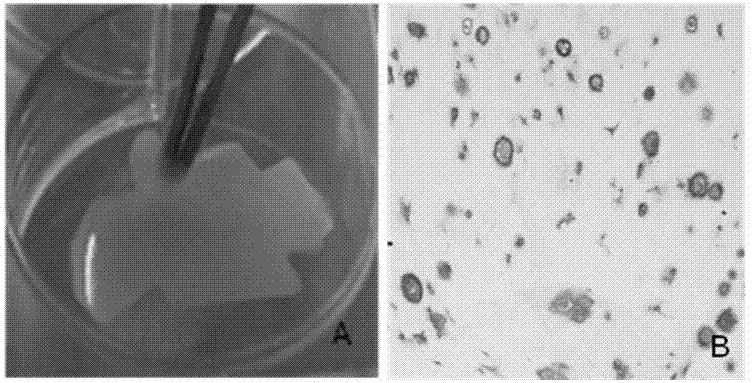

Articular cartilage graft and preparation method thereof

ActiveCN103920190AAvoid allergiesLower immune responseJoint implantsCell-Extracellular MatrixCartilage lesion

An articular cartilage graft and a preparation method thereof are provided. The prepared articular cartilage graft is composed of a superficial layer, a middle layer and a deep layer from outside to inside; the thickness, shape and size of each layer are all matched with a cartilage injury part, and thus preoperative shaping is not required; after grafting, the articular cartilage graft has layer distribution corresponding to distribution of each layer of surrounding normal cartilages, is conducive to intercellular signal transmission, transduction and regulation, and can be better integrated with surrounding normal cartilage tissues; the articular cartilage graft has structure characteristics consistent with those of the natural cartilages, the collagen type II content is gradually decreased from the superficial layer to the deep layer, the GAG content is increased gradually from the superficial layer to the deep layer, and compression resistance and wear resistance are good; and chondrocytes in the cartilage graft are wrapped with an extracellular matrix, have low immunogenicity, allow generation of immunologic rejection to be avoided after grafting, can survive for a long term and exert functions, and improve cartilage repair long-term curative effects.

Owner:西安博鸿生物技术有限公司

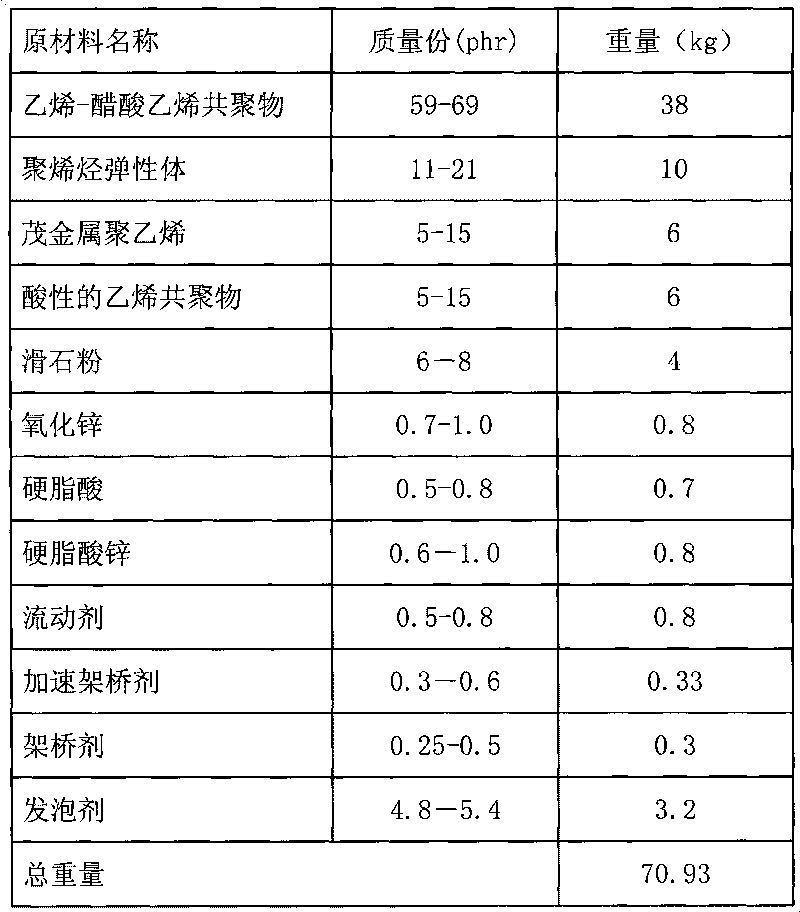

Super-light plastic formula for sports shoe soles

The invention discloses a super-light plastic formula for sports shoe soles, and the formula comprises the following components in parts by weight: 59-69 parts by weight of ethylene-vinyl acetate copolymer, 11-21 parts by weight of polyolefin elastomer, 5-15 parts by weight of metallocene polyethylene, 5-15 parts by weight of acidic ethylene copolymer, 6-8 parts by weight of talc powder, 0.7-1.0 part by weight of zinc oxide, 0.5-0.8 part by weight of stearic acid, 0.6-1.0 part by weight of zinc stearate, 0.5-0.8 part by weight of flowable agent A, 0.3-0.6 part by weight of accelerated bridging agent, 0.25-0.5 part by weight of bridging agent and 4.8-5.4 parts by weight of foaming agent. Plastic soles of sports shoes produced by the technical scheme have super-light performance and the comfort which are unmatched by the ordinary plastic formula, have durable comfort, durable damping performance and other performances and can greatly reduce the consumption of physical strength of athletes.

Owner:ANTA CHINA

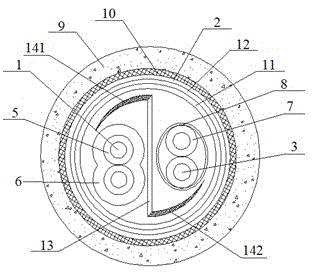

Integrated data cable for power and data transmission

ActiveCN104008797AExtended service lifeImprove balancePower cables with screens/conductive layersInsulated cablesPolyesterCopper conductor

The invention discloses an integrated data cable for power and data transmission. A first insulating layer covers power copper conductors. An inner sheath layer covers the first insulating layer. A second insulating layer covers data copper conductors. A single-face aluminum foil layer covers the second insulating layer. The inner sheath layer and the single-face aluminum foil layer are located on the two sides of a partition plate respectively. A first side tail wing part, the partition plate and a second side tail wing part are sequentially connected. The first side tail wing part and the second side tail wing part are located on the two sides of the partition plate. A polyester belt layer covers the inner sheath layer, the single-face aluminum foil layer, the partition plate, the first side tail wing part and the second side tail wing part. A double-face aluminum foil layer covers the polyester belt layer. A flame retarding layer covers the double-face aluminum foil layer. By the adoption of the mode, the integrated data cable has long service life, higher balance and reliability, reflection and absorption of high-frequency electromagnetic waves are improved, crosstalk and signal attenuation are improved; meanwhile, crosslinking strength of a base material is enhanced, and the integrated data cable has good physical mechanical performance such as tensile strength and tearing strength.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

Development of controllable cross-linking agent for methanol-based fracturing fluid

InactiveCN102492413AImprove crosslink strengthGood temperature resistanceDrilling compositionSolventSodium polyacrylate

The invention relates to a cross-linking agent for alcohol-based fracturing fluids, in particular to the development of a controllable cross-linking agent for methanol-based fracturing fluid, and the cross-linking time of the controllable cross-linking agent can be adjusted. For certain natural gas wells or oil wells with low formation pressure, low permeability and strong water-locking characteristic, the controllable cross-linking agent for methanol-based fracturing fluid can be used in the fracturing stimulation process. Inorganic zirconium or zirconate ester is adopted as a raw material, isopropanol or water or the mixture of isopropanol and water is adopted as solvent, suitable ligand is added, the materials react according to a certain material proportion under certain conditions for 4 hours, neutralizer is then added for neutralization, and finally, a moderate amount of diluent is added, so that the controllable cross-linking agent for methanol-based fracturing fluid is prepared. The cross-linking agent can be cross-linked with polymer with 60 to 100 percent of methanol content, the application range is wide, the dosage is little, and the controllable cross-linking agent cannot harm the environment. The biggest difference between the cross-linking agent disclosed by the invention and organic zirconium series cross-linking agents sold on the market is that mixed diluent formed by low-molecular weight sodium polyacrylate and low-molecular weight polyacrylic acid is adopted as the diluent of the controllable cross-linking agent.

Owner:北京希涛技术开发有限公司

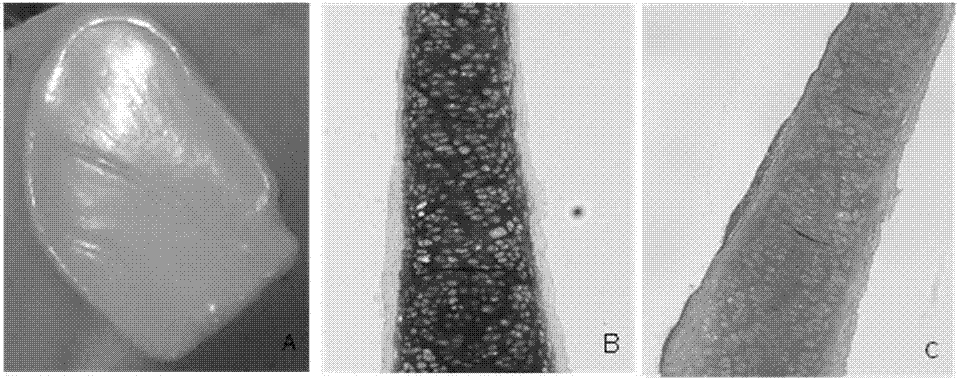

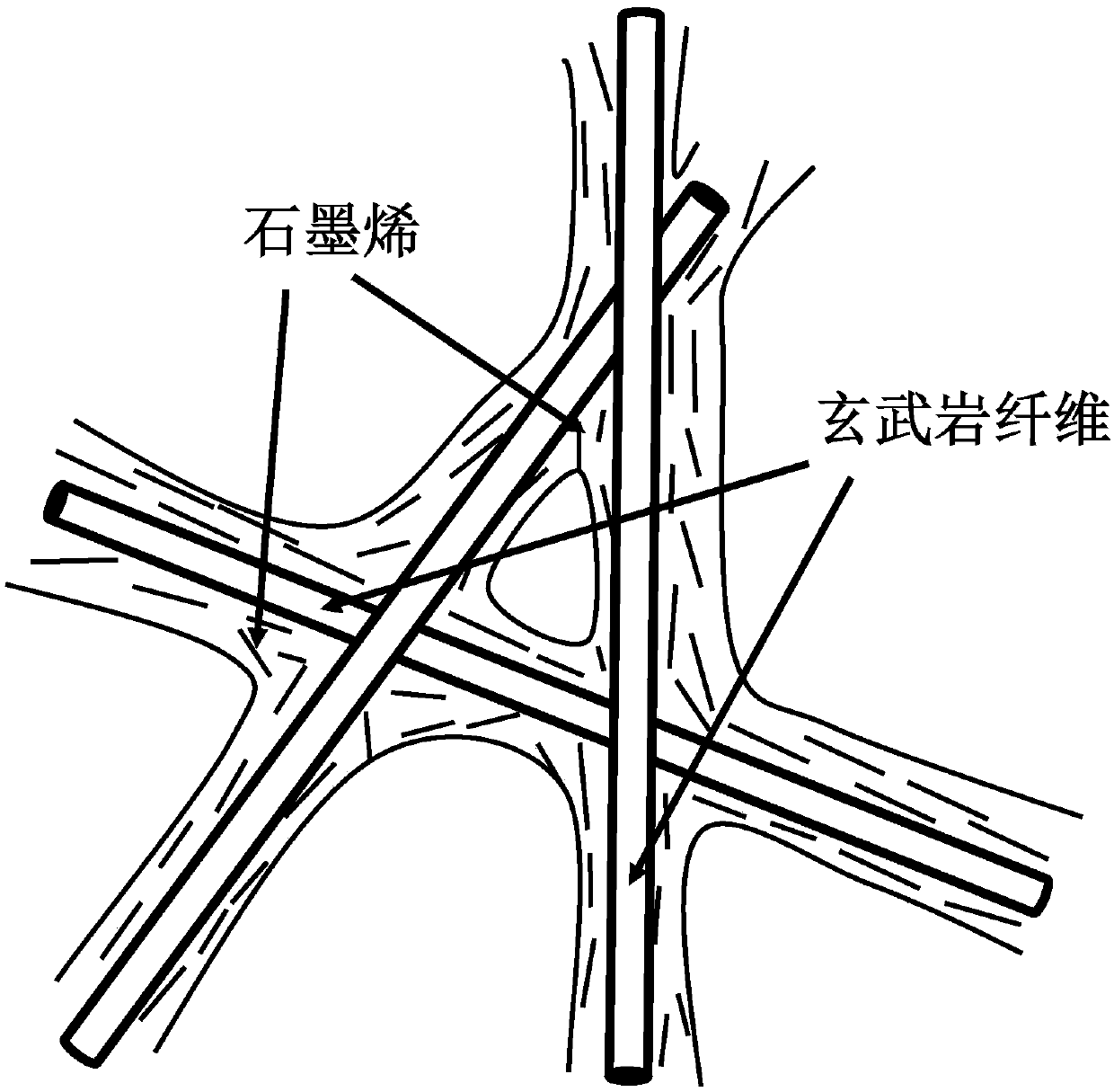

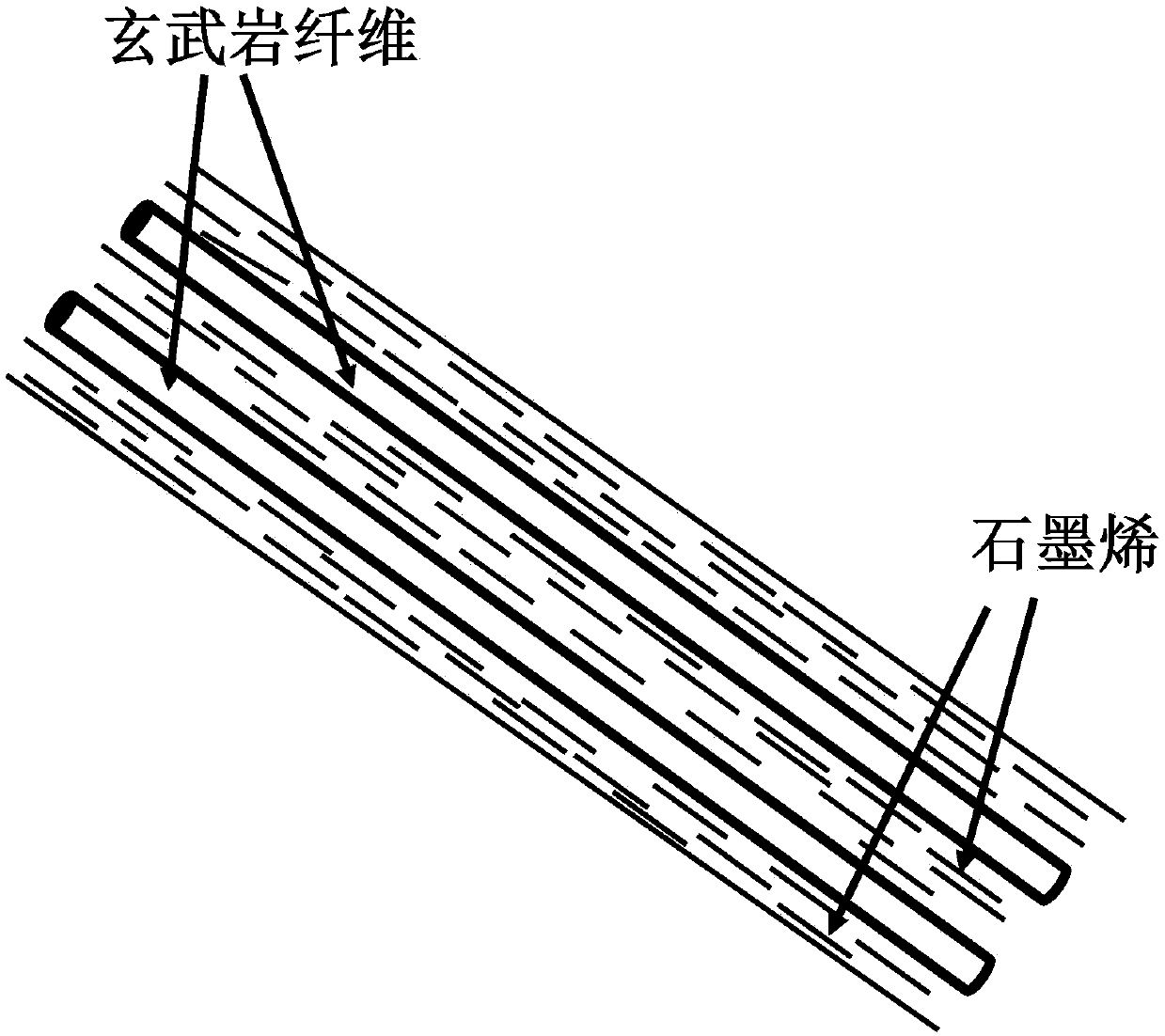

Graphene-basalt fiber composite material and preparation method thereof

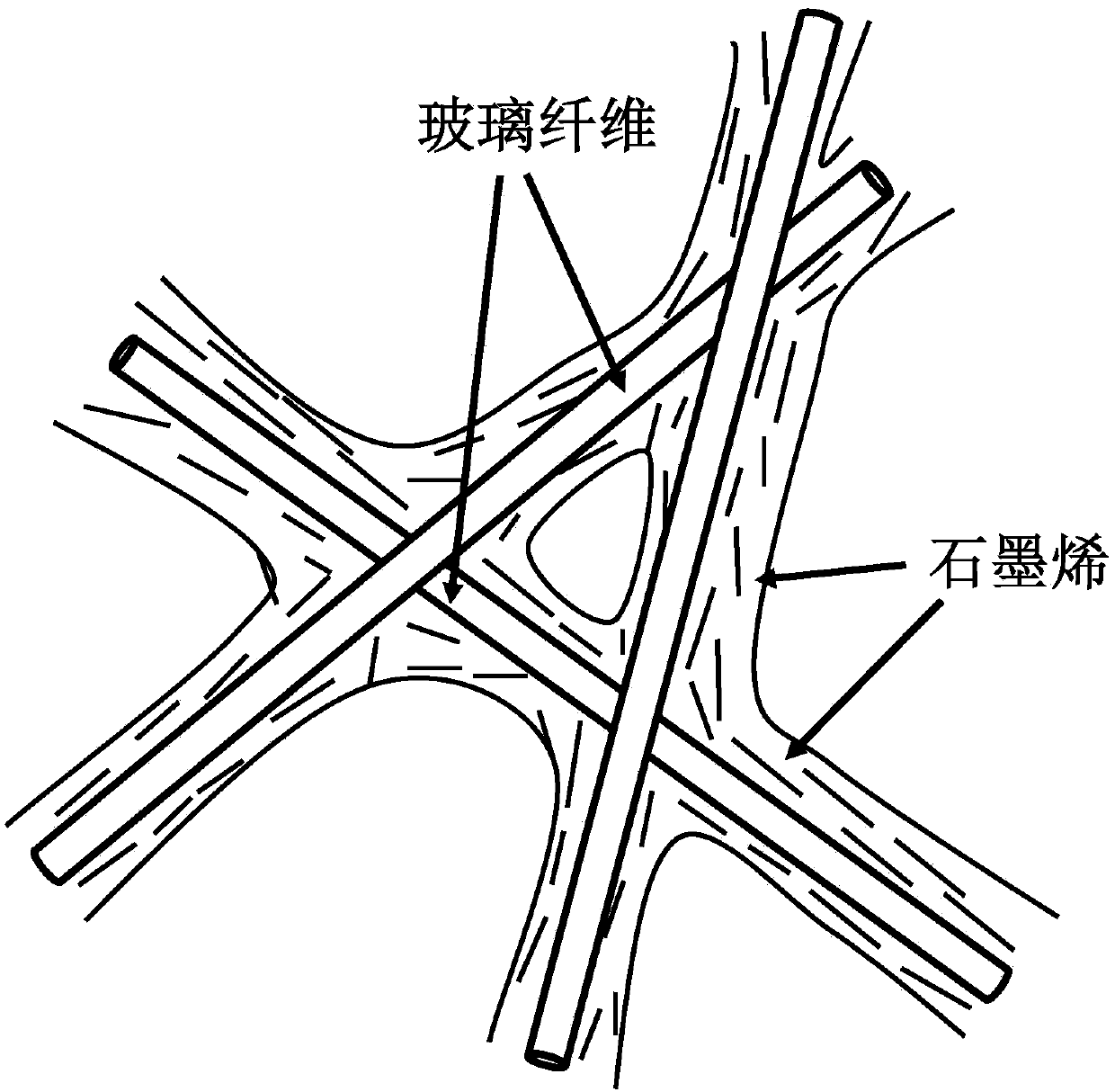

InactiveCN107805886AEvenly distributedHigh interface adhesion strengthGlass making apparatusNon-woven fabricsCross-linkBasalt fiber

The invention discloses a graphene-basalt fiber composite material and a preparation method thereof. The cross-linking of the basalt fiber can be achieved by utilizing the swelling and fusion effectsof graphene oxide coating on the surface of the basalt fiber. The graphene oxide is taken as a sizing agent and a cross-linking agent, the basalt fiber can be evenly coated with the grapheme oxide, the cross-linking process is fast and easy, and the cross-linking intensity is high. After further deoxidization, a grapheme oxide cross-linking layer converts into a graphene cross-linking layer, the interaction between the basalt fibers is enhanced, the contact resistance between fibers is decreased, so that the basalt fiber demonstrates excellent mechanical property and electric and thermal conductivity, which can be used for reinforcement phase of the composite material and differentiated fiber application. The method of cross-linking the basalt fiber with the graphene is of great research value and extensive application prospect.

Owner:HANGZHOU GAOXI TECH CO LTD

Method for extraction of natural plant-based anti-mite antibacterial material and preparation of finishing agent and application

InactiveCN108360255AImprove crosslink strengthImprove wash resistanceBiochemical fibre treatmentGrip property fibresAdhesiveAnti bacterial

The invention discloses a method for extraction of a natural plant-based anti-mite antibacterial material and preparation of a finishing agent and an application. The method comprises the following steps: A, extracting a natural plant anti-mite antibacterial material, and extracting effective components from mixed plant materials of dried houttuynia cordata, coptis chinensis and radix sophorae flavescentis by an ultrasonic reflux low-temperature extraction method; and B, preparing the natural plant anti-mite antibacterial finishing agent; firstly, adding an aqueous acrylate adhesive into a liquid anti-mite antibacterial extraction liquid obtained in the step A according to a certain proportion, and stirring for 1-2 h; and then adding deionized water, and stirring for 1-1.5 h, and thus obtaining the stable natural plant anti-mite antibacterial finishing agent. The invention also aims to provide an application of the natural plant anti-mite antibacterial finishing agent in mite and bacteria prevention of fabrics; the finishing agent is prepared by the natural plant anti-mite and anti-bacterial effective components, the fabrics are finished by a dipping and rolling method; the finishing agent has excellent anti-mite and anti-bacterial dual functions, the original hand feeling style of the fabrics is maintained, and a formed anti-mite and anti-bacterial material coating layer has excellent washing resistance property.

Owner:江苏唐盛纺织科技有限公司

Processing technology for nanometer antifouling and antibacterial coating textile and clothing

InactiveCN1552973AImprove wash resistanceGood flexibilityLiquid/gas/vapor article treatmentUltrasonic/sonic fibre treatmentCross-linkEngineering

A process for nano antifouling and bactericidal fabrics and garment includes: 1) wetting fabrics in the traditional processes due to various fabrics, 2) preparing a nano antifouling bactericidal finishing agent in a container with 100 - 200Kg volume capacity to form the said agent and a solution, the weight of the agent is 3 - 8% of that of the fabrics and the weight of the solution is equal to the that of fabrics, 3) putting the fabrics into the wetting container and soaking to make them coated, and 4) drying. This technology dissolves weaknesses in the prior arts, such as hard feeling, easily stained, worse in bactericidal effect and in water washing resistance. It enhances cross-linking strength of binding material in the nano coating layer and achieves in softness and washing resistance.

Owner:陕西班博实业集团有限公司

Soybean-protein-containing aldehyde-free adhesive and preparation method thereof

InactiveCN106905919AImprove crosslink strengthImprove water resistanceNon-macromolecular adhesive additivesProtein adhesivesPolymer scienceAdhesive

To overcome the defects of a soybean adhesive in the prior art, the invention provides a soybean-protein-containing aldehyde-free adhesive and a preparation method thereof, and belongs to the technical field of an aldehyde-free adhesive used for timber. The aldehyde-free adhesive takes soybean protein as a main component, and contains a surfactant, the weight of which is 1-10% of that of soyabean protein, an alkaline compound, the weight of which is 3-15% of that of soyabean protein, metal oxide, the weight of which is 5-20% of that of soyabean protein, polyamide epoxy haloalkane resin, the weight of which is 3-20% of that of soyabean protein, and water the weight of which is 2-5 times of that of soyabean protein. Soybean protein is taken as a substrate, and the surfactant, the modifier of metal oxide and hydroxide and a cross-linking agent are used for comprehensive modification of soybean protein, so that the adhesive strength and water proofness of the soybean protein adhesive are improved.

Owner:UNIV OF SCI & TECH LIAONING

Ethylene-propylene rubber particles of active hydrogen-containing compound, and production method thereof

ActiveCN103421248AImprove adhesionImprove adhesion, its tear strengthPolyureas/polyurethane adhesivesHydrogenPolymer science

The present invention discloses ethylene-propylene rubber particles of an active hydrogen-containing compound, and a production method thereof. The ethylene-propylene rubber particles comprise color master batch of an active hydrogen-containing compound, a reinforcing agent comprising an active hydrogen bond-containing nanometer reinforcing agent and a reinforcing agent, and an activator material. The production method comprises: preparing color master batch, wherein an active hydrogen-containing compound is added to a pigment, a color master batch carrier and an anti-ultraviolet ray agent are added, complete dispersion and mixing are performed, and extrusion granulation is performed through an extruder; preparing a reinforcing agent material and an activator material; and preparing ethylene-propylene rubber color particles, wherein a vulcanizing agent is added to the color master batch while the reinforcing agent material, the activator material, an accelerator, a plasticizer and an anti-aging agent are added, opening type mixing and sealed mixing are performed through a roll mill, the obtained material enters a vulcanizing cylinder to be subjected to a vulcanizing treatment to prepare a vulcanizing film, and the vulcanizing film is broken. The ethylene-propylene rubber particles have characteristics of good cross-linking strength with the polyurethane adhesive, strong ultraviolet ray resistance, and bright color.

Owner:江阴市文明体育塑胶有限公司

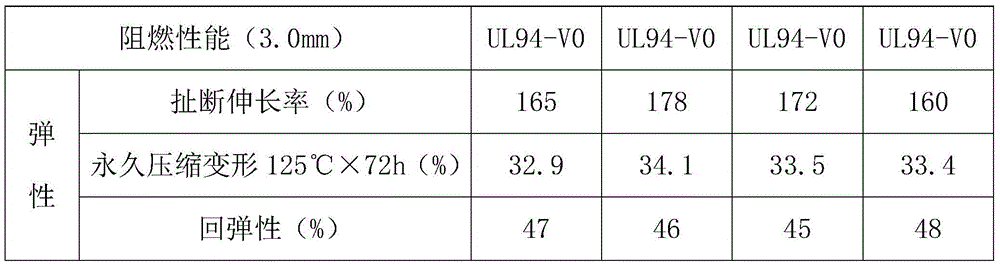

High-elasticity environmentally-friendly flame-retardant rubber material

The present invention discloses a high-elasticity environmentally-friendly flame-retardant rubber material comprising the raw materials of hydrogenated nitrile rubber, EPDM rubber, butadiene styrene rubber, vinyl chloride thermoplastic elastomers, ABS resin, di-tert-butyl peroxide DTBP, sulfur, divinylbenzene, accelerator DM, modified clay, carbon masterbatch, magnesium oxide, stearic acid, a modified flame retardant, polyphenyl ether, diisononyl phthalate DINP, antioxidant D-50, antioxidant SP and epoxy soybean oil. The high-elasticity environmentally-friendly flame-retardant rubber material has excellent flame retardant properties, and is halogen-free, low in toxicity, environmentally-friendly, good in elasticity and other mechanical properties and processing performances, and suitable for a variety of production and living areas.

Owner:宁国市开源橡塑汽车零部件有限公司

Superhigh temperature weighted fracturing fluid and preparation thereof

ActiveCN104232059AIncrease liquid viscosityImprove temperature resistanceDrilling compositionFracturing fluidCross linker

The invention belongs to a superhigh temperature weighted fracturing fluid and preparation thereof. The liquid is prepared from the following raw materials in parts by weight: 500 parts of water, 12-15 parts of a temperature-resistant thickener, 15-30 parts of a high-temperature crosslinking agent, 125-195 parts of an inorganic weighting agent, 20-30 parts of a discharge aiding agent, 8-15 parts of a bactericide, 5-10 parts of a temperature stabilizer and 0.1-0.3 part of a gel breaker, wherein the temperature-resistant thickener is carboxymethyl and hydroxypropyl guanidine glue, the high-temperature crosslinking agent is an organic zirconium crosslinking agent, and the inorganic weighing agent is any one of sodium chloride or sodium bromide. The superhigh temperature weighted fracturing fluid has the advantages of low content of residues and good temperature resistance and shear resistance.

Owner:北京国海能源技术研究院

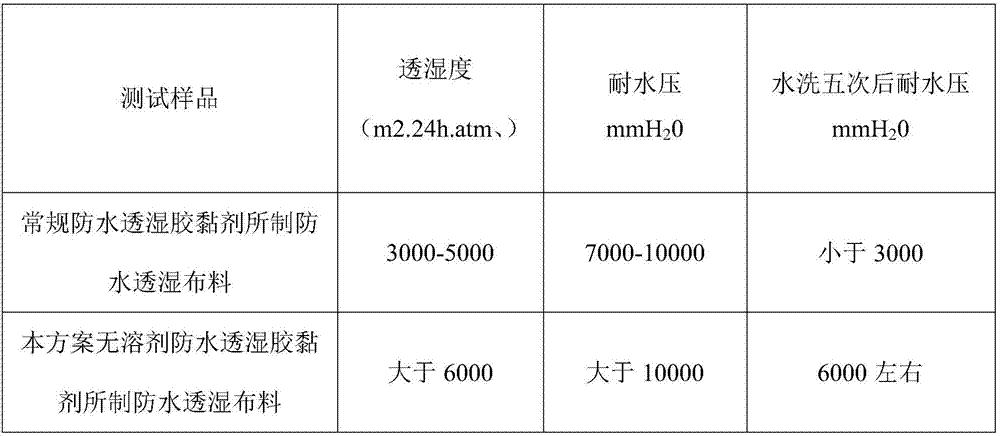

Blocked double-component, solvent-free, waterproof and moisture-permeable polyurethane resin and preparation method thereof

ActiveCN107417874ALong storage time and stableImprove hydrolysis resistancePolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsAntioxidantSolvent free

The invention relates to the technical field of polyurethane resin preparation, in particular to blocked double-component, solvent-free, waterproof and moisture-permeable polyurethane resin and a preparation method thereof. The blocked double-component, solvent-free, waterproof and moisture-permeable polyurethane resin comprises components A and B, wherein the component A is prepared from toluene isocyanate, 4,4-diphenylmethane diisocyanate, an antioxidant, neopentyl glycol polyester polyol, polytetrahydrofuran polyol, polyoxyethylenepolyol, an organic bismuth catalyst and diacetylmonoxime through reactions; the component B is a mixture of diethylenetriamine and isophorone diamine, and the weight percentage of diethylenetriamine is 40%-70%; the weight ratio of the component A to the component B is 1:(0.05-0.1). The waterproof and moisture-permeable polyurethane resin has long storage time and stable finished product performance and has excellent moisture permeability, hydraulic pressure resistance and wash resistance.

Owner:ZHEJIANG JOYA POLYMER TECH

Graphene-glass fiber composite material and preparation method thereof

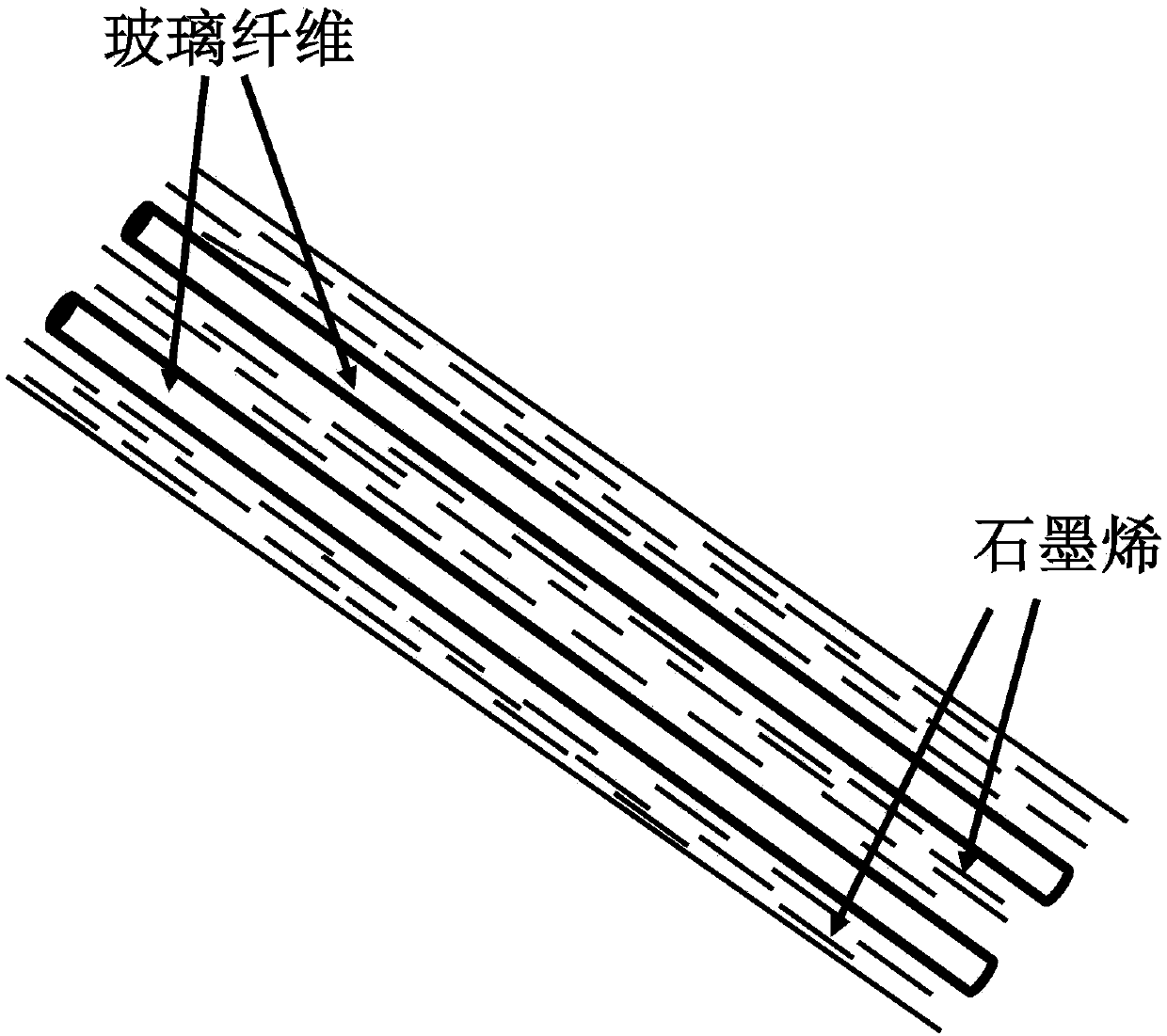

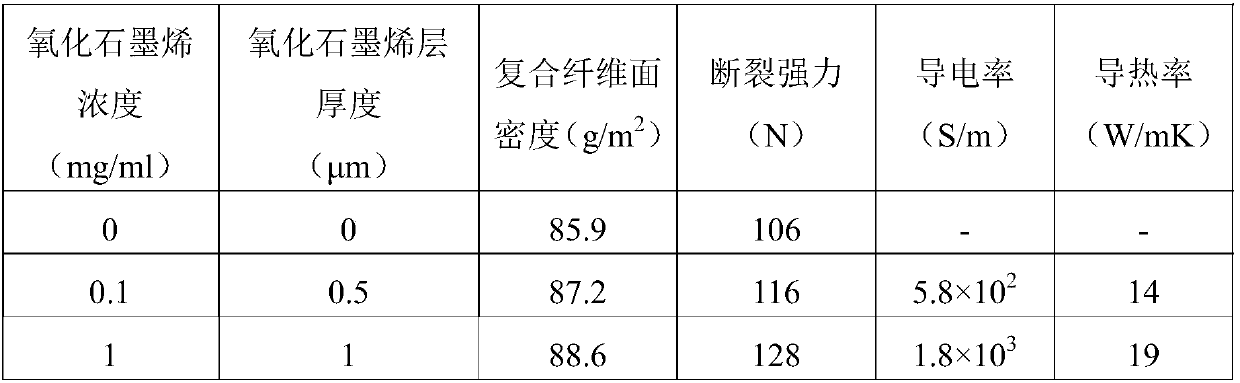

InactiveCN107761249AEvenly distributedHigh interface adhesion strengthGlass making apparatusNon-woven fabricsFiberGlass fiber

The invention discloses a graphene-glass fiber composite material and a preparation method thereof. Crosslinking of glass fibers can be realized by means of the swelling and fusing actions of grapheneoxide coatings on the surfaces of the glass fibers. Graphene oxide is taken as a sizing agent as well as a crosslinking agent with which the glass fibers can be coated uniformly, the crosslinking process is rapid and easy, and high crosslinking strength is achieved. Through further reduction, a graphene oxide crosslinking layer is turned into a graphene crosslinking layer, so that mutual action among the glass fibers is enhanced, contact resistance among the fibers is lowered, and the glass fibers show excellent mechanical performance, electric conductivity and heat conductivity and can be applied to a wild phase of the composite material. The method for crosslinking the glass fibers with the graphene has a great researching value and a wide application prospect.

Owner:HANGZHOU GAOXI TECH CO LTD

Flame retardant modified polyurethane metallic paint

InactiveCN105482671AImprove lipophilicityImprove crosslink strengthFireproof paintsPolyurea/polyurethane coatingsPhosphoric Acid EstersPolymer science

The present invention discloses a flame retardant modified polyurethane metallic paint, which comprises raw materials of organic phosphorus-modified polyurethane, water-based phenolic resin, water-based alkyd resin, sodium carboxymethyl cellulose, montmorillonite, calcined kaolin, nanometer nitride aluminum, melamine polyphosphate, nano magnesium hydroxide, a defoamer, a levelling agent and a pigment. The preparation method of the organic phosphorus-modified polyurethane is as follows: heating tung oil polyol and N,N-diethyl bis(2-hydroxyethyl)aminomethylphosphonate, insulating, conducting vacuum dehydration, adding dicyclohexylmethylmethane-4,4'-diisocyanate, introducing N2 protection, heating, insulating, cooling, adding 1,5-pentanediol, dimethylolpropionic acid, pentaerythritol and acetone, and then adding zinc naphthenate, heating, insulating, cooling, dropwise adding a mixed solution containing dimethylethanolamine and triethanolamine, heating, insulating, neutralizing, adding water for emulsified dispersion, and conducting vacuum distillation to obtain organic phosphorus-modified polyurethane. The flame retardant modified polyurethane metallic paint has excellence flame retardant property.

Owner:NINGGUO LONGSHI METAL PROD CO LTD

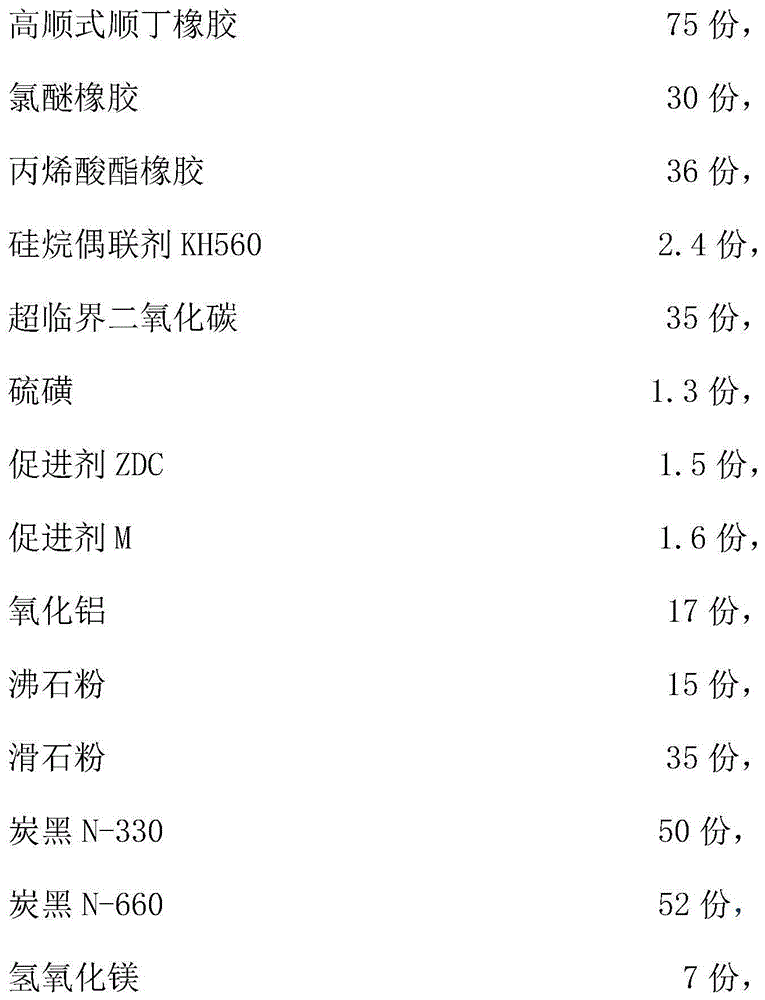

High-elasticity foamed rubber

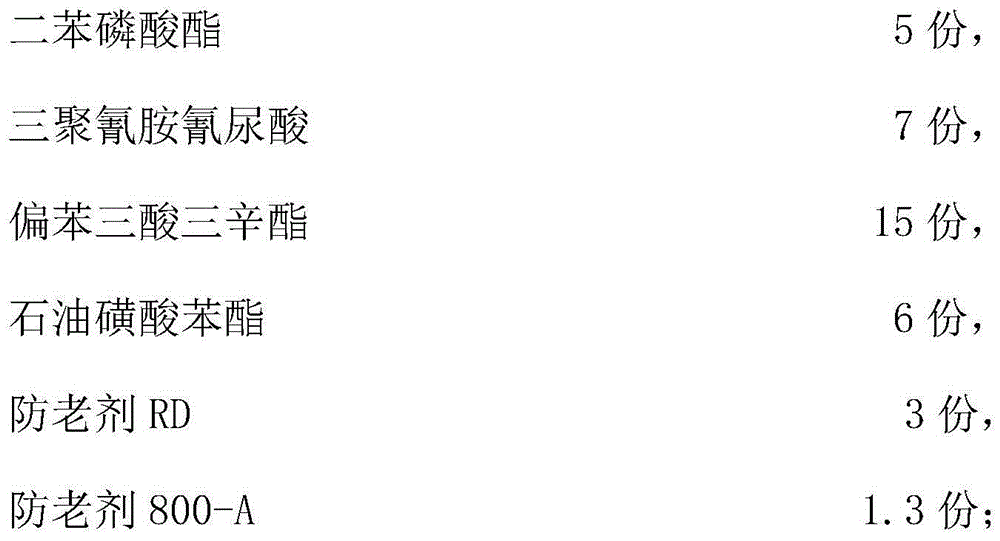

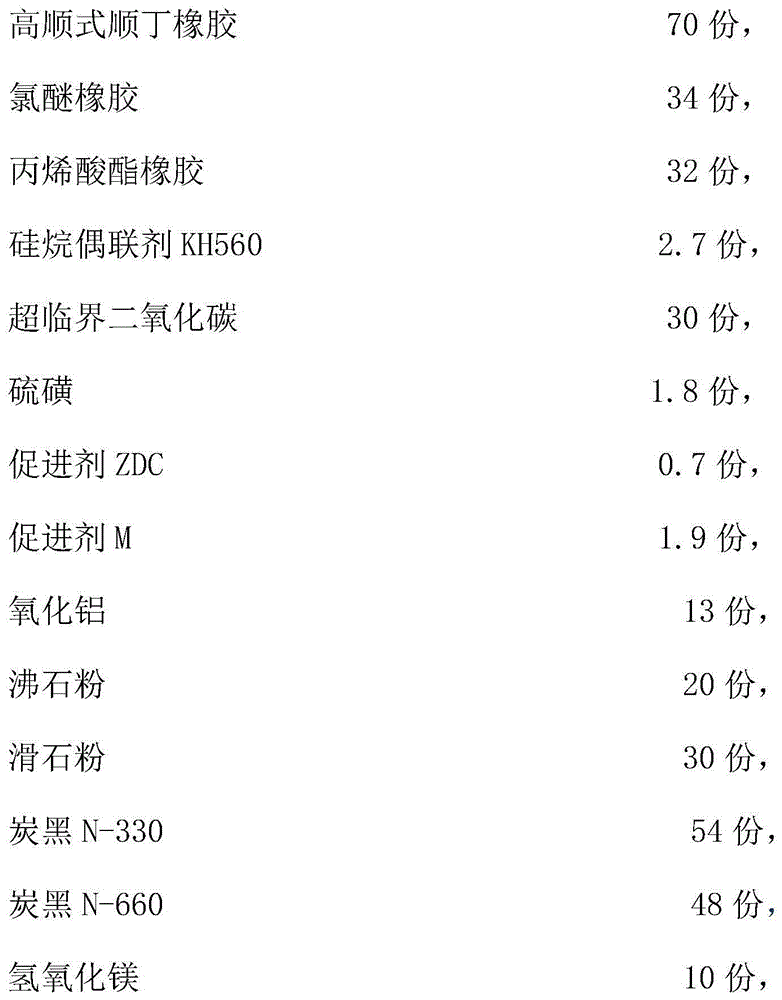

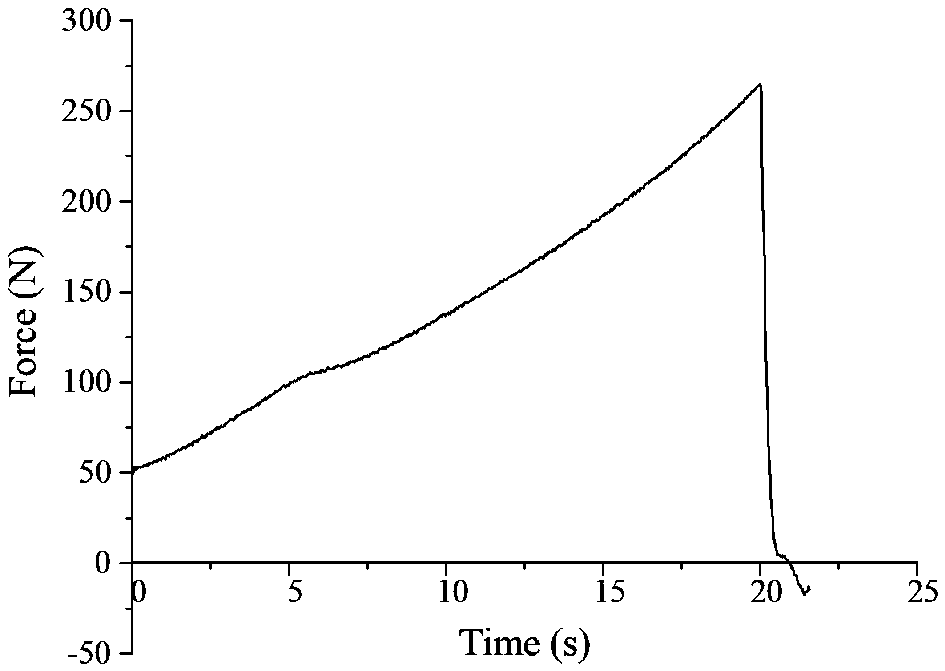

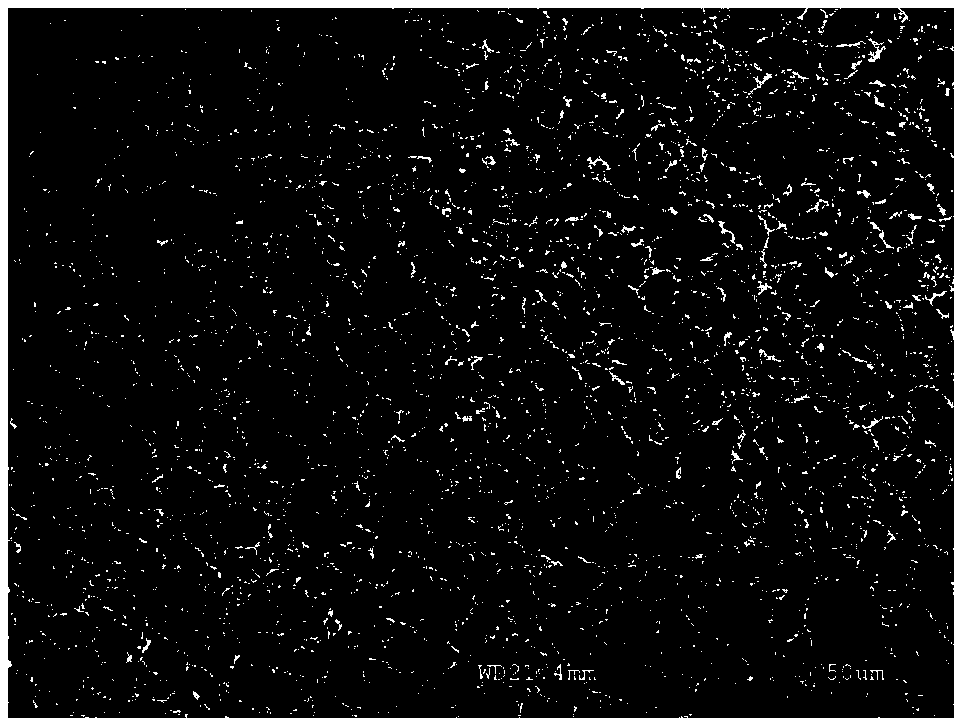

The invention discloses high-elasticity foamed rubber which comprises the following raw materials in parts by weight: 70-75 parts of cis-butadiene rubber, 30-34 parts of epichlorohydrin rubber, 32-36 parts of polyacrylate rubber, 2.4-2.7 parts of a silane coupling agent KH560, 30-35 parts of supercritical CO2, 1.3-1.8 parts of sulfur, 0.7-1.5 parts of an accelerator ZDC, 1.6-1.9 parts of an accelerator M, 13-17 parts of aluminum oxide, 15-20 parts of zeolite powder, 30-35 parts of talcum powder, 50-54 parts of carbon black N-330, 48-52 parts of carbon black N-660, 7-10 parts of magnesium hydroxide, 3-5 parts of diphenyl phosphate, 7-9 parts of melamine cyanurate, 13-15 parts of trioctyl trimellitate, 6-8 parts of phenyl petroleum sulfonate, 2-3 parts of an antioxidant RD and 1.3-1.5 parts of an antioxidant 800-A. The foamed rubber is high in elasticity and good in impact resistance, the foaming is sufficient, and foaming holes are uniform and fine.

Owner:际华中晟材料科技(岳阳)有限公司

Method for preparing milk gel

PendingCN110495600AHigh strengthImprove water retentionMilk preparationFood ingredient as coagulantCross-linkNetwork structure

The invention belongs to the technical field of dairy products and particularly relates to a method for preparing acidified milk gel. According to the method for preparing the milk gel, milk and a casein solution are sufficiently dissociated by utilizing a calcium ion chelating agent, and are crosslinked with cross-linked enzyme after more junction sites are released, the crosslinking strength canbe improved, the compactness and uniformity of a network structure of the gel formed by acidifying can be improved, and a milk gel product with high strength and good water locking performance can befinally obtained. Compared with a gel product which is formed by directly acidifying a casein solution after enzyme crosslinking, the method can be used for preparing a milk gel product with more compact network structure, higher strength and better water locking performance. The final dairy product can solve the water separating problem, has an elastic taste, and is chewy.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Method of producing acidic crosslinking agent for CO2 foam compression fracture

ActiveCN101220264AUse low concentrationImprove crosslink strengthDrilling compositionUltimate tensile strengthZirconium

The invention relates to a fracturing liquid system for an oil and gas field, in particular to a manufacturing method of acid crosslinking agent used for CO2 foam fracturing. The invention is characterized in that the acid crosslinking agent is produced by confecting the raw material in the following weight percentage: 5.0 to 30.0 percent of inorganic zirconium salt; 1.0 to 10.0 percent of organic assistant; 0.1 to 20.0 percent of inorganic assistant; 40.0 to 95.0 percent of water. The invention has the advantages of high crosslinking intensity, low cost, easy manufacturing technique, and being easy to operate. .

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

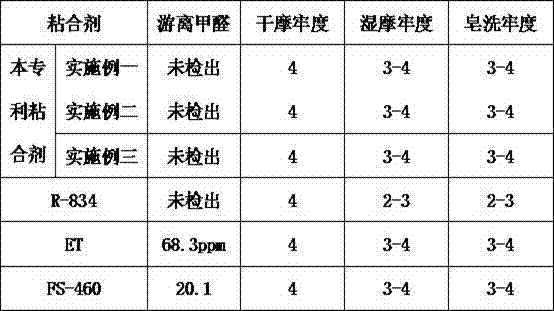

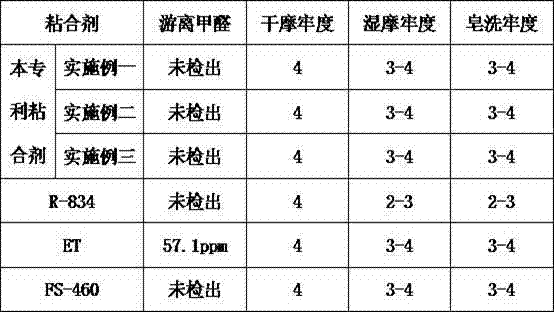

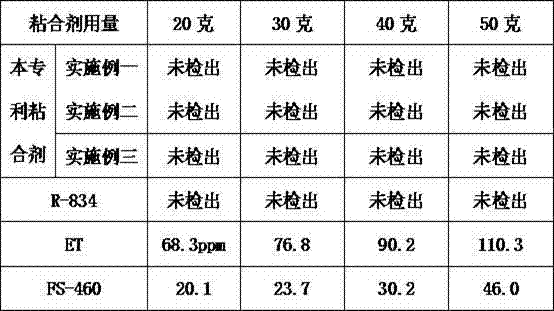

Binder used for pigment printing of textiles and preparation method thereof

InactiveCN102504090AHigh fastnessImprove film water resistanceDyeing processTextile printerPolymer science

The invention discloses a binder used for pigment printing of textiles and a preparation method thereof. The binder is prepared by seed emulsion polymerization of fatty alcohol polyoxyethylene ether sodium sulfate, diethylaminoethyl methacrylate, methacryloyloxy ethyl acetoacetate, sodium lauryl sulfate, acrylic acid, acrylic ester, ammonium persulfate and deionized water. The binder is free of formaldehyde or alkylphenol polyoxyethylene and has soft hand-feeling and good soaping fastness.

Owner:LIAONING FIXED STAR FINE CHEM

PP foaming composite additive

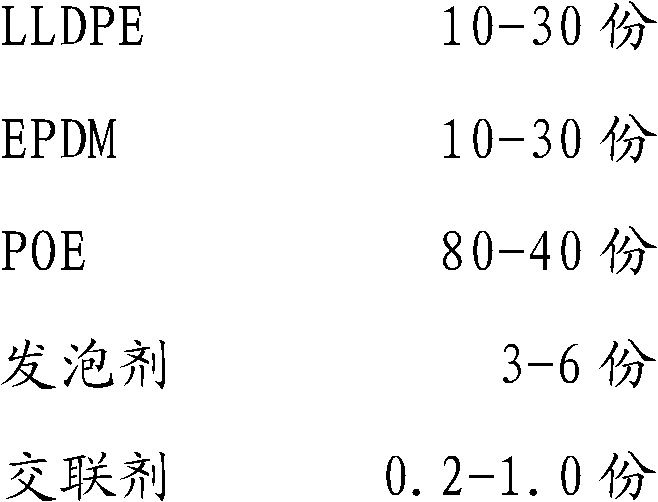

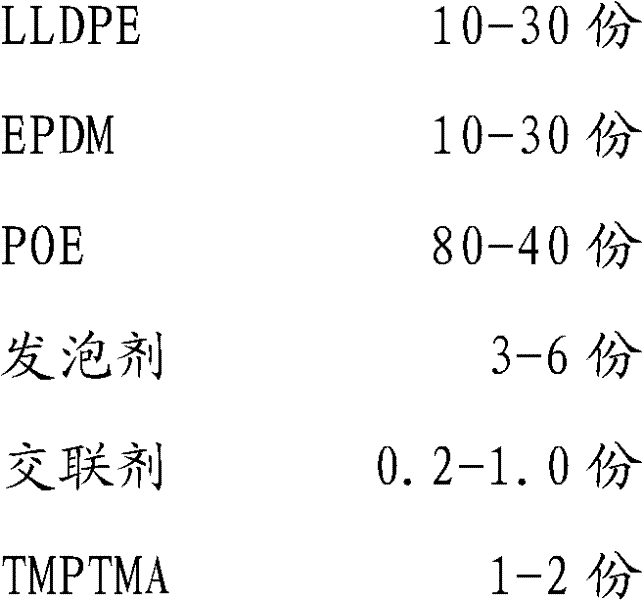

The invention discloses a PP foaming composite additive, which comprises the following raw materials by weight: 10-30 parts of LLDPE, 10-30 parts of EPDM, 80-40 parts of POE, 3-6 parts of foaming agent, 0.2-1.0 part of cross-linking agent, 1-2 parts of TMPTMA, 0.2-1.0 part of nano zinc oxide; PP enables a rapid degradation while crosslinking foaming, the TMPTMA is taken as a crosslinking auxiliary agent which effectively increases the crosslinking speed, meanwhile, a reactivity reaction is generated between the crosslinking and degrading of PP, and the crosslinking speed is greater than degradation speed. The speed for decreasing the PP melt-strength is alleviated which is beneficial to ideal foaming of PP, in addition, bubble strength and uniformity can be increased by adding nano zinc oxide, and the reaction process can be accelerated, the crosslinking temperature of the cross-linking agent can be reduced, the heat transfer and the crosslinking degree can be increased, the composite additive is benefit for harmless degradation, recovery and treatment of waste PP foaming plastics.

Owner:HUAQIAO UNIVERSITY

Degradable spinning material and preparation method thereof

InactiveCN101949069AReduce pollutionTake advantage ofMonocomponent protein artificial filamentSpinning solutions preparationWater bathsGlycerol

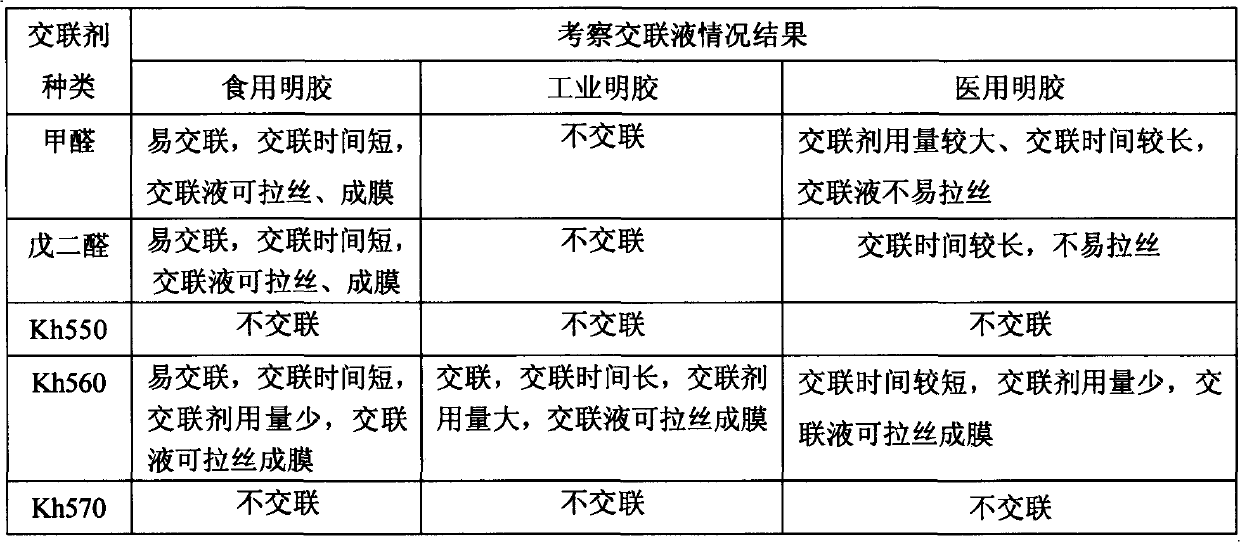

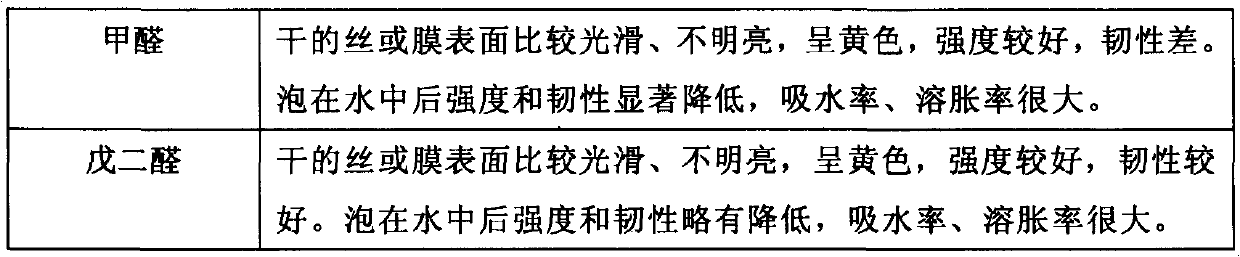

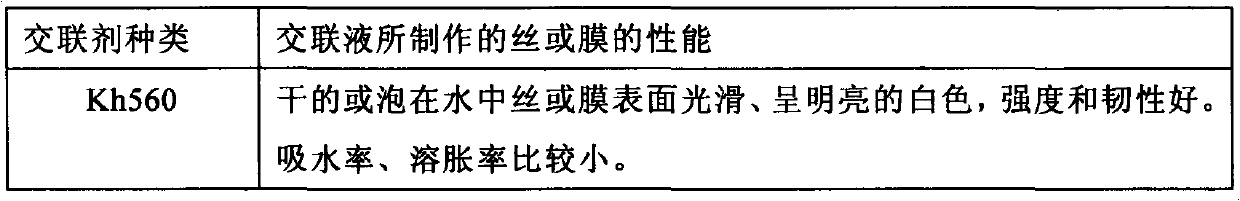

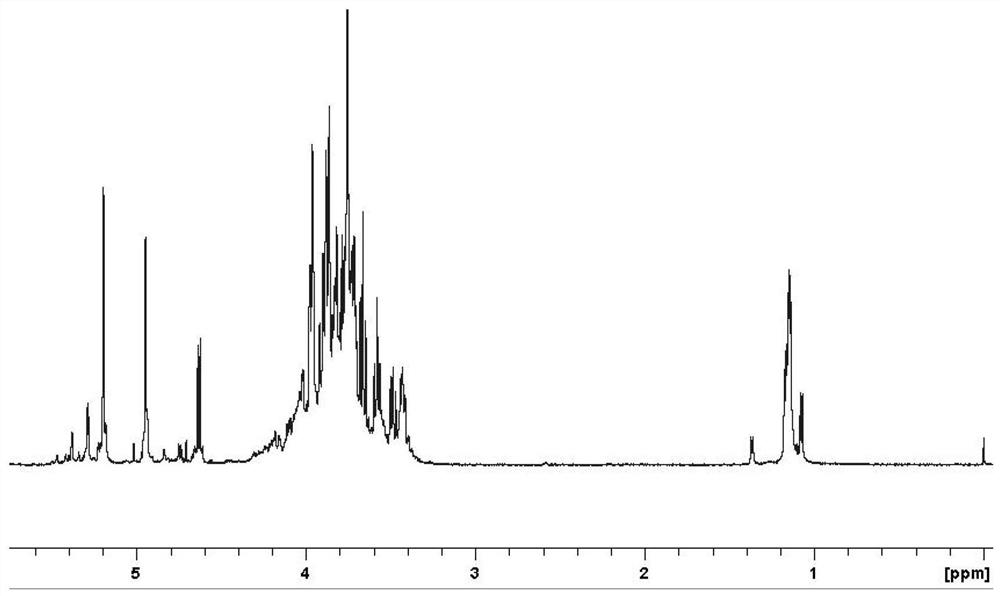

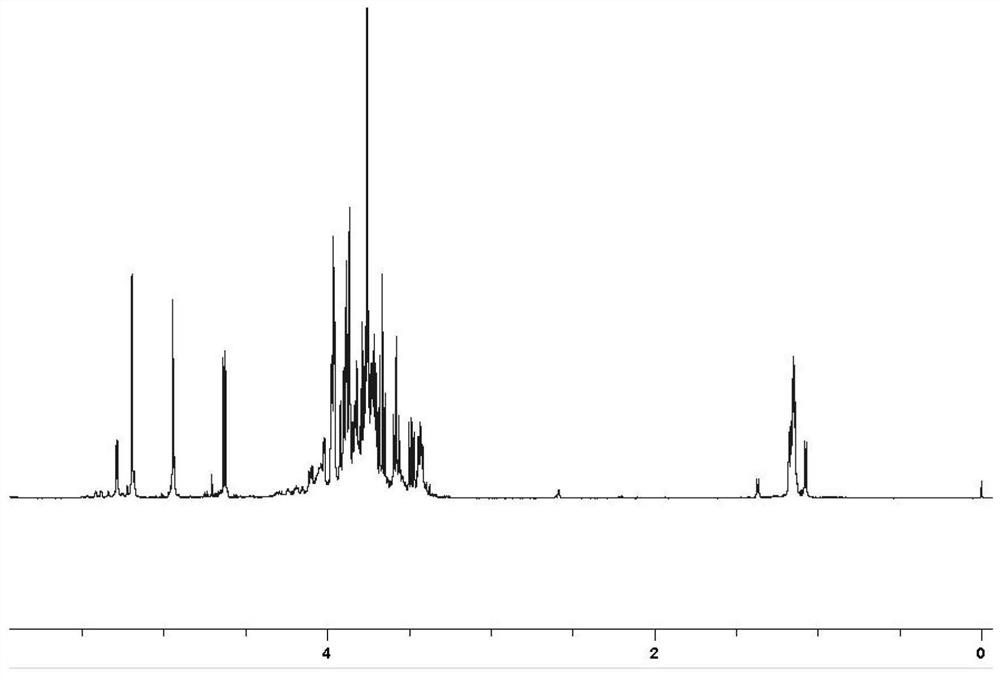

The invention provides a degradable spinning material and a preparation method thereof. The material takes gelatine and a small quantity of melamine as raw material and is prepared by certain crosslinking technology, can satisfy the requirement of daily clothes, and has no pollution in the production and use processes. The product is degradable after used, so that the degradable spinning material is safe and healthy to use. The material takes gelatine as raw material. The preparation method comprises the following steps: putting the raw material into a kettle; adding deionized water the weight percent of which is 8-10 times of the ram materials; heating by a water bath of 50-65 DEG C; after stirring and dissolving, preparing the aqueous solution of gelatine for later use; adding 100 parts by weight of aqueous solution of gelatine into the kettle; adding 0.1-0.2 part by weight of glycerol and 1-2 parts by weight of polysiloxane defoamer; heating by a water bath of 50-65 DEG C; under the condition of stirring, adding 0.5-1 part by weight of melamine and 0.1-0.3 part by weight of crosslinker Kh-560; keeping temperature, and stirring for 3-9 hours until filaments is dripped and drawn out; and obtaining the gelatine crosslinking spinning solution.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Guar gum derivative and preparation method and application thereof

The invention provides a guar gum derivative and a preparation method and application thereof, and belongs to the technical field of petroleum fracturing. The guar gum derivative not only contains hydroxyalkyl, but also contains a dicarboxyl structural group, the hydroxyalkyl and the dicarboxyl structural group both can appear at positions 2, 3 and 6 in mannose and positions 2, 3, 4 and 6 in galactose, and the dicarboxyl group is introduced, so that the density of crosslinkable sites is higher, the crosslinking strength is higher, under the combined action of hydroxyalkyl and dicarboxyl structural groups, the guar gum derivative not only has excellent properties of fast tackifying and shear resistance, but also can generate a cross-linked network with higher density with zirconium and aluminum cross-linking agents under a low-concentration condition, so that jelly is more stable, and the cross-linking strength is higher.

Owner:昆山京昆油田化学科技有限公司

Fishing net thread use quality improvement processing process

InactiveCN107641955AImprove the effect of modified treatmentImprove physical and chemical propertiesPhysical treatmentFibre typesPhosphoric acidEngineering

The invention discloses a fishing net thread use quality improvement processing process. The process includes steps: (1) cleaning and deoiling treatment; (2) phosphoric acid solution soaking treatment; (3) treating fluid A soaking treatment; (4) ultraviolet irradiation treatment; (5) treating fluid B soaking treatment; (6) flushing and drying treatment. By special processing of fishing net threads, under joint actions in each step, the grafting effect of the fishing net threads is evidently improved, utilization characteristics of the fishing net threads are improved, and the finally treaded fishing net threads are high in coating compatibility, corrosion resistance, strength and comprehensive quality, thereby being high in popularization and utilization value.

Owner:CHAOHU JUNYE FISHING TACKLE CO LTD

Preparation method for polymer cross-linking agent

InactiveCN107353887AControllable cross-linking timeImprove crosslink strengthDrilling compositionCross-linkOrganic acid

The invention relates to a method for preparing a polymer cross-linking agent. The cross-linking agent includes the following components in weight percentage: organic acid: 15-30%, inorganic base: 4-8%, organic amine: 10-18%, three Valence metal ion salt: 4-10%, tetravalent zirconium salt: 7-15%, aldehyde: 1-5%, and the balance is water. The cross-linking agent of the present invention has a controllable cross-linking time of 10-180s, high cross-linking strength, and the temperature resistance of the cross-linked jelly reaches 150°C; it does not contain phenol, which reduces the harm to the environment; Synthesized under certain conditions, and the finished product is produced at one time, without secondary mixing; the cross-linking agent contains triethanolamine, which greatly increases the gel cross-linking stability of the cross-linking agent.

Owner:如皋市玉辉助剂厂

External wall penal with excellent silencing and fireproof performances

InactiveCN105838231AImprove lipophilicityPromote softeningFireproof paintsCovering/liningsAntioxidantPotassium hydroxide

The invention discloses an exterior wall panel with excellent sound-absorbing and fire-proof performance, which comprises a base layer, a sound-absorbing fireproof layer, a plastering mortar layer, a waterproof layer, a decorative coating and a wear-resistant layer; the preparation method of the sound-absorbing fireproof layer is as follows: hydroquinone, Potassium hydroxide and toluene are mixed evenly, and then a toluene solution containing hexachlorocyclotriphosphazene is added dropwise, heated up, kept warm, washed with an alkali solution to obtain an organic phase, then the organic phase is distilled under reduced pressure, dried in vacuum, and recrystallized to obtain material a ; Mix material a and polytetrahydrofuran ether glycol evenly, then add trimethyl-1,6-hexamethylene diisocyanate, fill with dry nitrogen for protection, heat up, keep warm, and cool down to obtain material b; Add trimethylpentanediol, glycerin, bismuth neodecanoate, foaming agent, foaming aid, expanded perlite, palygorskite, diatomaceous earth, glass fiber, flax fiber, zinc borate hydrate, anti-aging agent and Acetone is mixed evenly, coated on the surface of the base layer, then heated up, and kept warm to obtain a sound-absorbing and fire-proof layer.

Owner:ANHUI DEQUAN NEW BUILDING MATERIALS TECH CO LTD

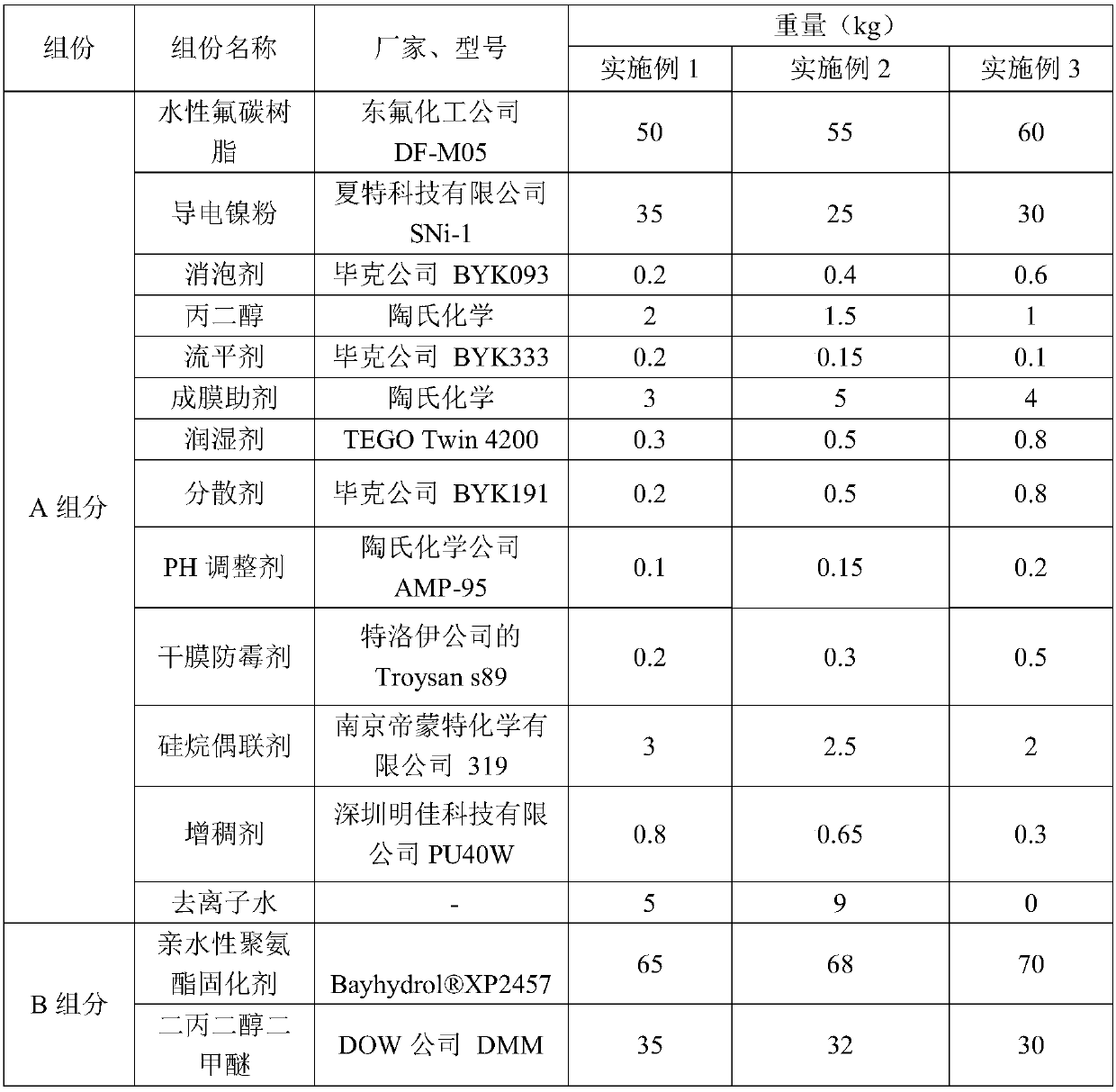

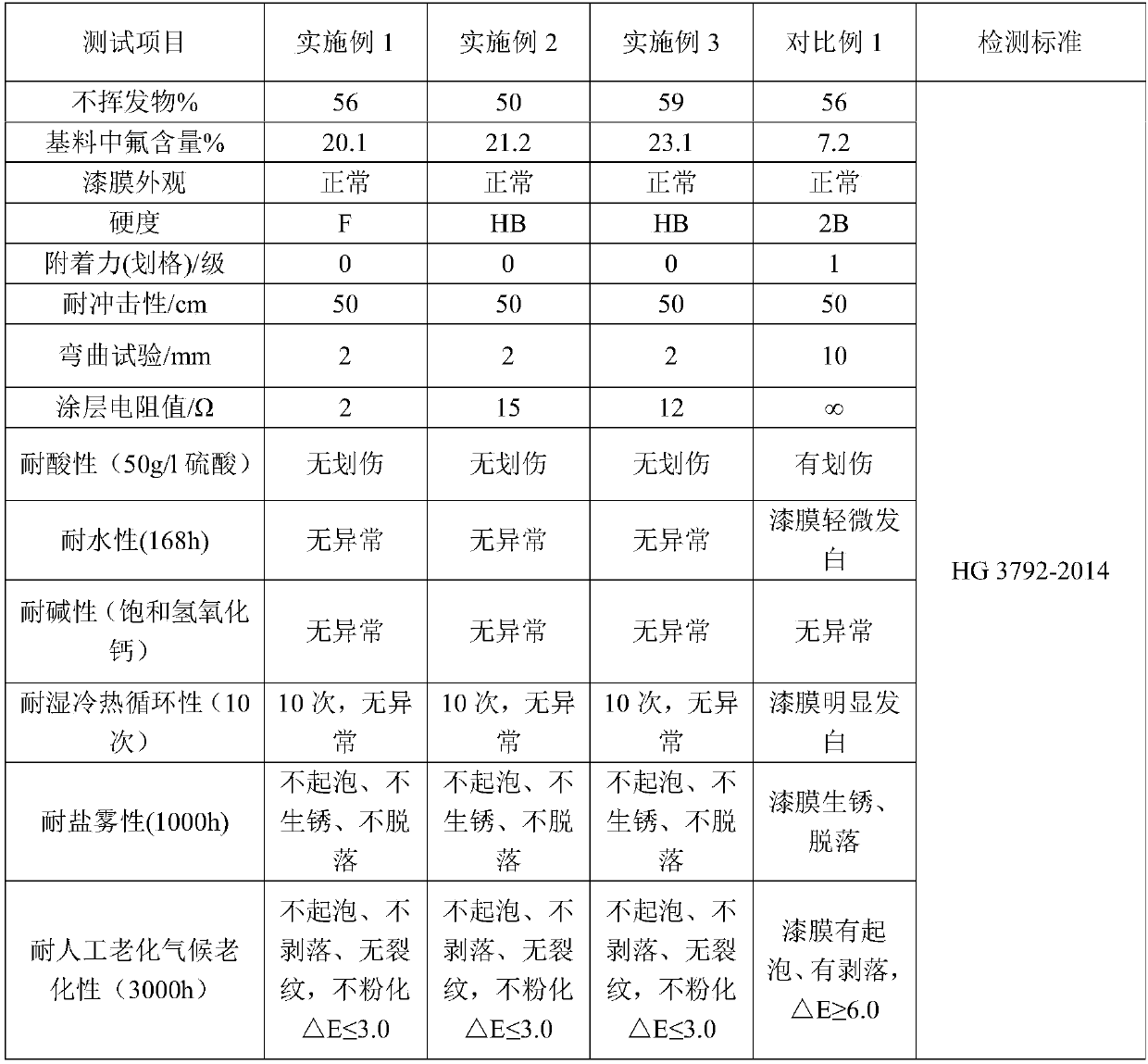

Waterborne bicomponent fluorocarbon conductive anticorrosion paint and preparation method and application method thereof

InactiveCN109575707AImprove crosslink strengthImprove functionalityLiquid surface applicatorsAnti-corrosive paintsDefoaming AgentsMaterials science

The invention provides a waterborne bicomponent fluorocarbon conductive anticorrosion paint, made by mixing component A and component B; the component A comprises, by weight, 50-60 parts of waterbornefluorocarbon resin, 25-35 parts of conductive nickel powder, 1-2 parts of propylene glycol, 0.2-0.6 part of a defoaming agent, 2-3 parts of silane coupling agent, 0.2-0.8 part of a dispersant, 0.1-0.2 part of a leveling agent, 0.1-0.2 part of a PH regulator, 0.3-0.8 part of a wetting agent, 0.2-0.5 part of a dry film mildew preventive, 3-5 parts of a film-forming aid, 0.3-0.8 part of a thickener,and 0-9 parts of deionized water; the component B comprises 65-70 parts of hydrophilic isocyanate curing agent, and 30-35 parts of dipropylene glycol dimethyl ether; the weight ratio of the componentA to the component B is 10:1. film of the waterborne bicomponent fluorocarbon conductive anticorrosion paint has excellent weatherability, water resistance, oil resistance, low temperature resistance, solution resistance, corrosion resistance, and conductivity; static electricity on the surface of a coating layer can be effectively eliminated.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com