Patents

Literature

173results about How to "Avoid brittle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

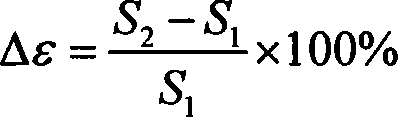

Compounded plasticizer for thermoplastic processing and method for plasticizing polyvinyl alcohol

The invention discloses a compounded plasticizer for thermoplastic processing, which is formed by mixing the components by weight percent: 50-80% of inorganic metal salt plasticizer and 20-50% of organic plasticizer. The invention also discloses a method for plasticizing polyvinyl alcohol using the above compounded plasticizer, which comprises the steps of dissolving 30-50 parts of the compounded plasticizer in 60-70 parts of water to form a solution, adding 100 parts of polyvinyl alcohol with alcoholysis degree higher than or equal to 88% into the solution, then fully swelling the polyving akohol at 20-60 DEG C, and finally drying fully swelled polyvinyl alcohol at 50-60 DEG C until constant weight is reached, so as to obtain the modified plasticizing polyvinyl alcohol to be processed into a product by a thermoplastic processing method. When the compounded plasticizer disclosed by the invention is used for modifying polyvinyl alcohol, the crystal structure of polyvinyl alcohol is damaged, the melting temperature of polyvinyl alcohol can be effectively reduced, thermoplastic processing of polyvinyl alcohol is realized, and the problem of product frangibility caused by phenomena of movement and precipitation of the plasticizer is avoided.

Owner:SICHUAN UNIV

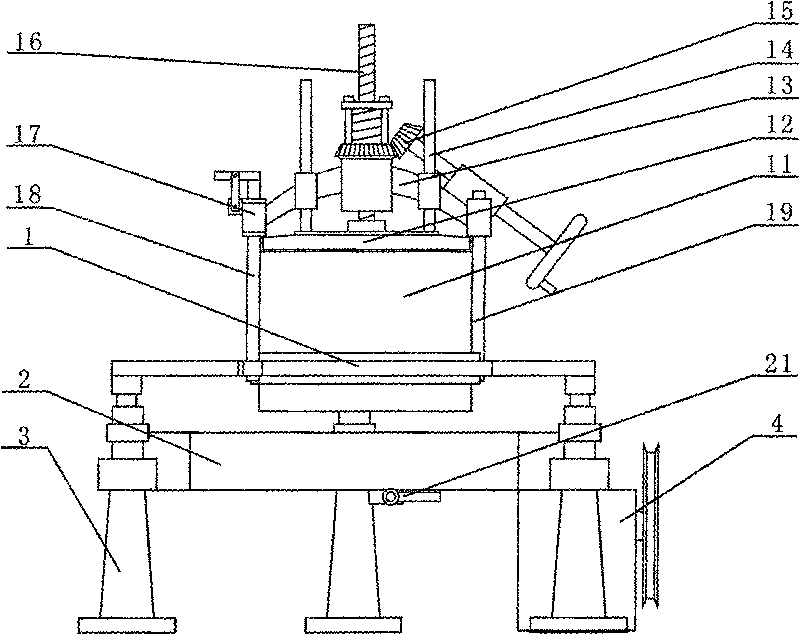

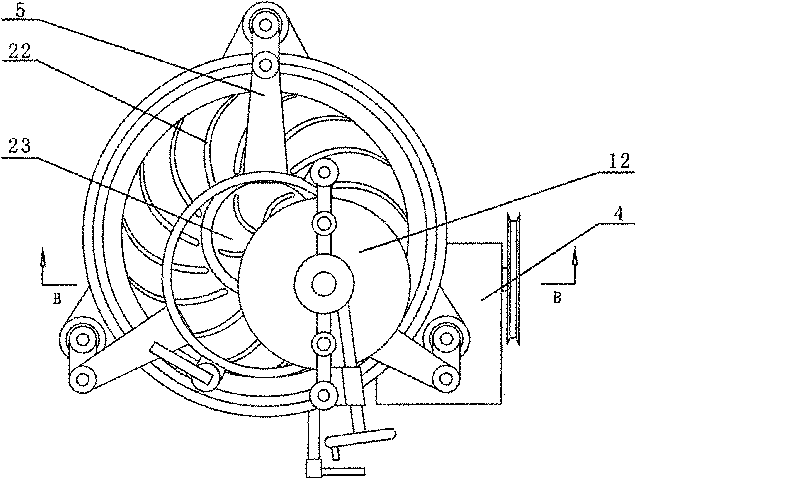

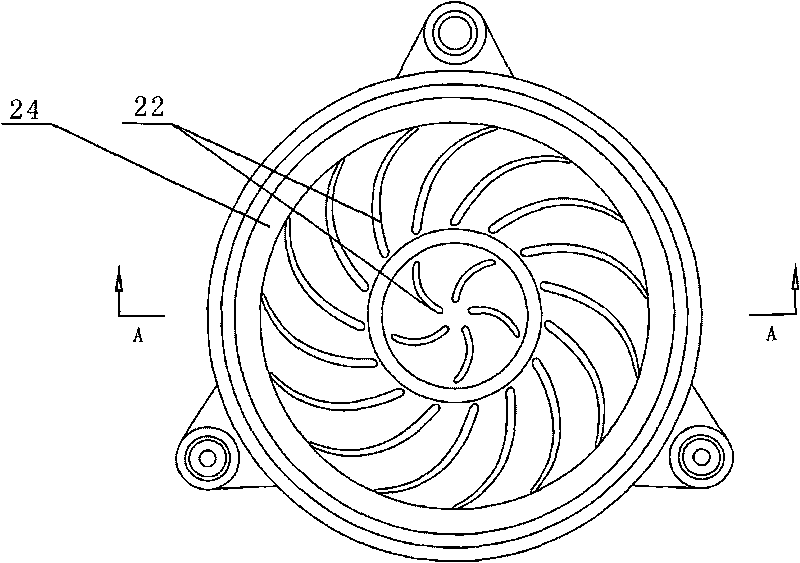

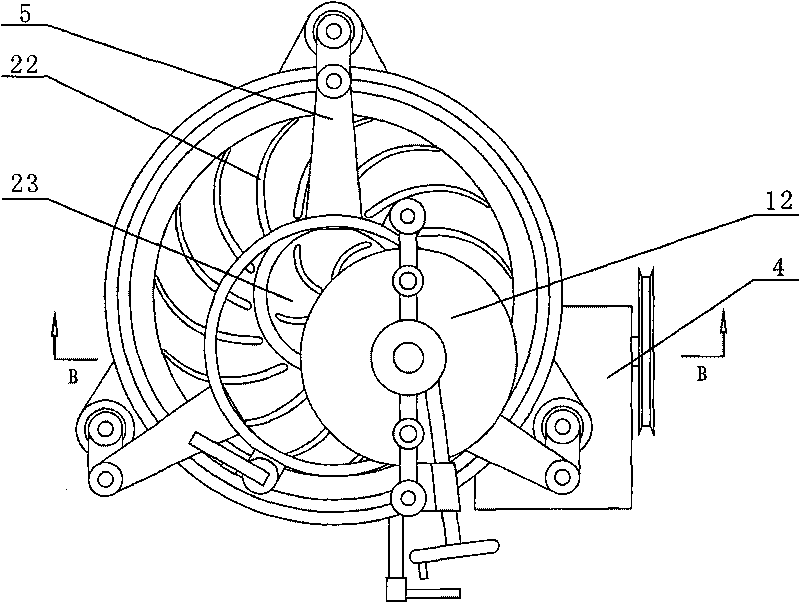

Novel tea knead entwist machine

The invention discloses a novel tea knead entwist machine and relates to tea processing machineries. The circular movement of the knead entwist device above the knead entwist plate can be realized by connecting the knead entwist device with a crank rocker mechanism; and the tailor-made knead entwist plate matches with the screw cover in the knead entwist device. The stripping tea rate of the tea is high, broken tea is little, and the broken tea generated in production can be separated from the mature tea automatically, thus improving tea grade and increasing production efficiency.

Owner:WUFENG TIANCHI TEA MACHINERY

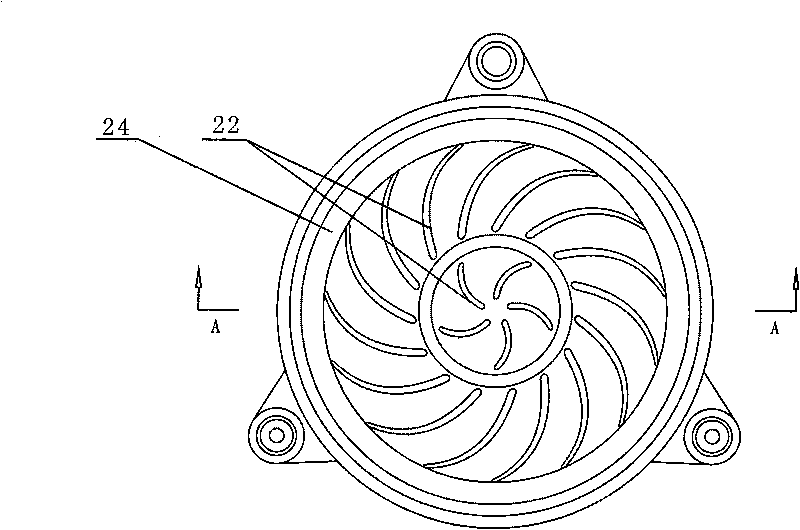

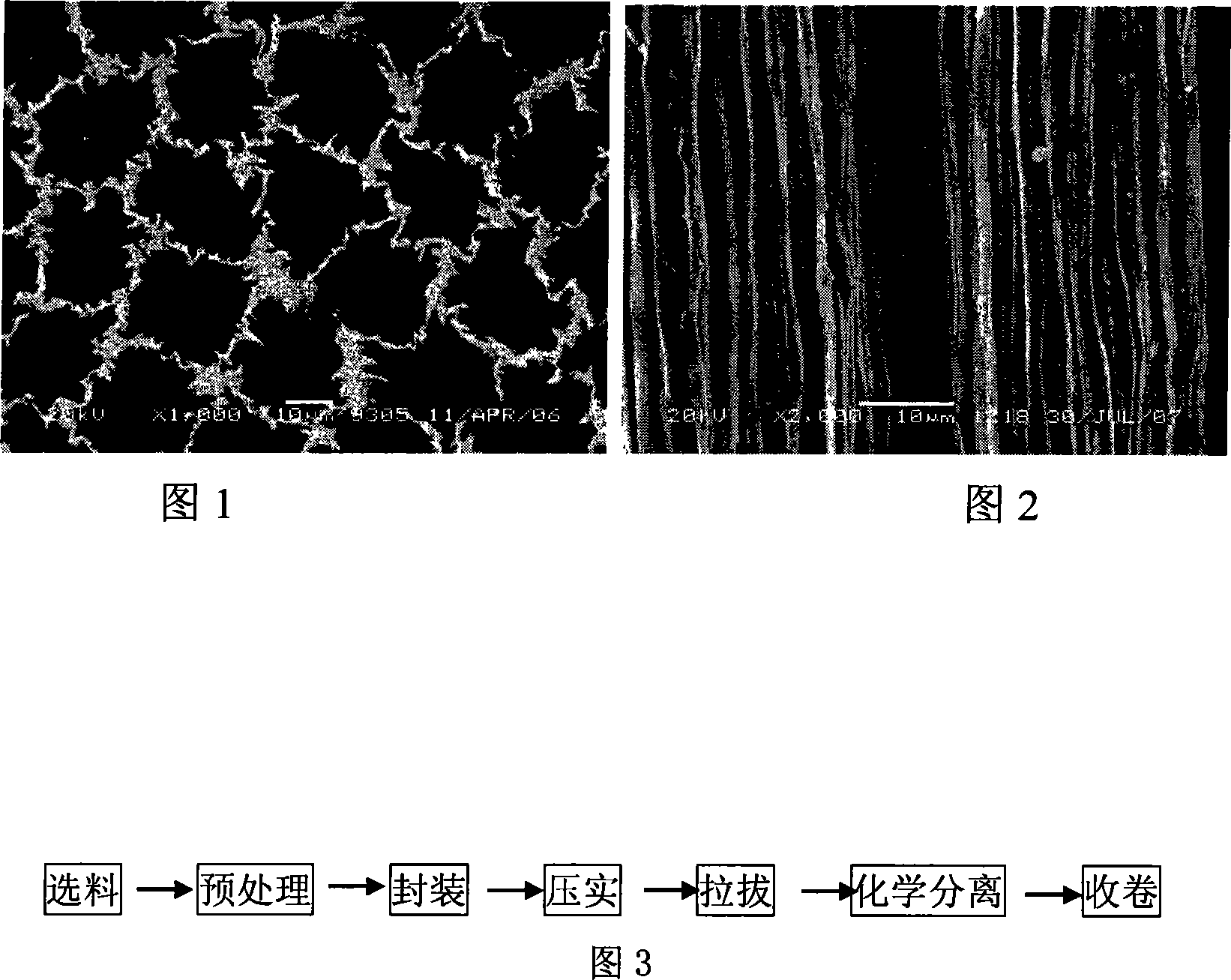

Fire resistant iron chromium aluminum filament and production technique

The invention relates to a high temperature resistant iron-chromium-aluminum fiber yarn and a preparing process, belongs to the field of stainless steel processing and obtains the iron-chromium-aluminum fibers by bundle drawing iron-chromium-aluminum wire rods embedded in base materials; the iron-chromium-aluminum fibers comprise iron and the following components (represented by wt. percent) of more than or equal to 0.005 percent and less than or equal to 0.03 percent of C, more than or equal to 15 percent and less than or equal to 27 percent of Cr, more than or equal to 5.95 percent and less than or equal to 7.0 percent of Al, more than or equal to 0.05 percent and less than or equal to 0.2 percent of Cu, more than or equal to 0.4 percent and less than or equal to 0.6 percent of Si, more than or equal to 0.2 percent and less than or equal to 0.4 percent of Mn, more than or equal to 0.03 percent and less than or equal to 0.04 percent of S, more than or equal to 0.010 percent and less than or equal to 0.045 percent of P and more than or equal to 0.01 percent and less than or equal to 0.04 percent of RE; the manufacturing process comprises the following procedures of material choosing, pretreatment, encapsulation, compaction, drawing, separation and rolling. The manufacturing process of the iron-chromium-aluminum fiber of the invention is suitable for drawing and processing high-aluminum iron-chromium-aluminum wire rods and can reach the yield of 98 percent with little influence on the environment.

Owner:HUNAN HUITONG ADVANCED MATERIALS

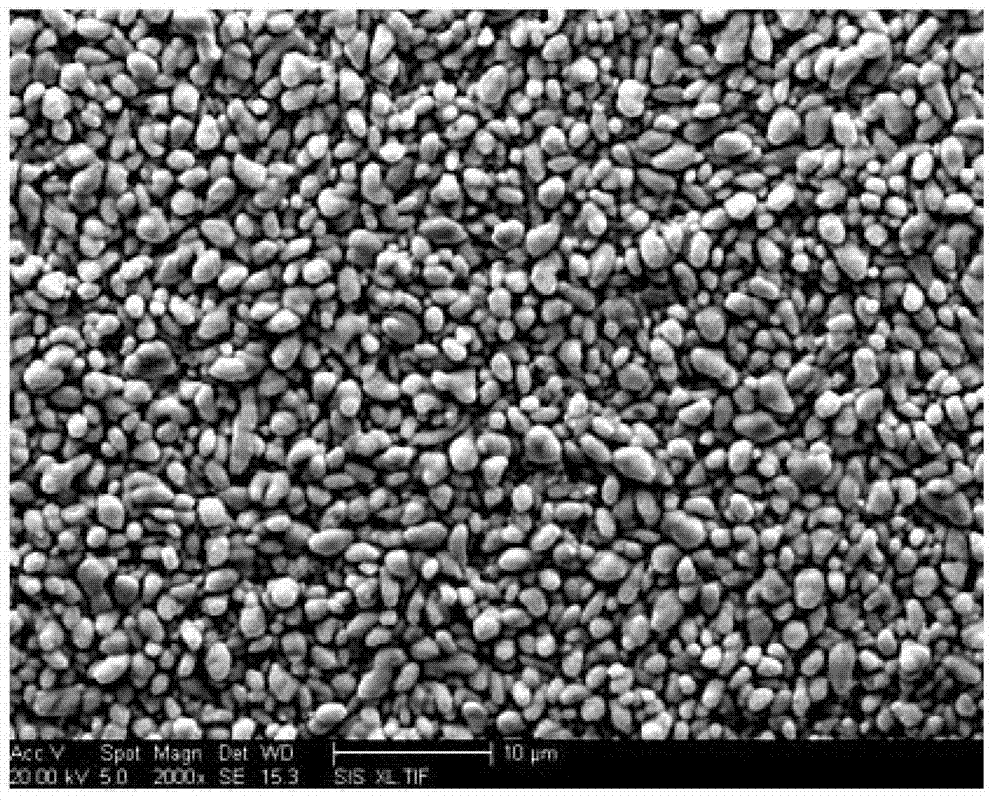

Connection method for metal target material and target holder

InactiveCN101177778ARealize tight and dense connectionAvoid pollutionVacuum evaporation coatingSputtering coatingAtmospheric airHigh pressure

The invention relates to the connecting method of a metallic target and a target holder, essentially comprising the steps of connecting surface processing, brazing material coating and jointing, squeezing, bonding, etc. The target and the target holder are matched through corresponding boss and groove; when the target holder is heated to a temperature higher than the liquidus of the brazing material by 10 DEG C to 50 DEG C, the brazing material is coated at the combined face of the target and the target holder, and a pressure is forced at an axial direction, thus leading the target and the target holder to be matched closely; meanwhile, in the process of squeezing, all parts at the combined face are filled with the brazing material in a target holder groove, thus the rudimental air is exhausted. The steady connection between the target and the target holder can be realized in atmospheric environment by the method and the structure property and dimension of the target are not affected, thus the deformation problems in vacuum, high temperature, high pressure or other environments are avoided.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG +1

Nano modified phenolic aldehyde foam insulation board and preparation method thereof

The invention relates to a nano modified phenolic aldehyde foam insulation board and a preparation method thereof. The nano modified phenolic aldehyde foam insulation board comprises the following raw materials: 50-65 parts of phenolic resin, 20-25 parts of reactivity polyamide resin, 2-8 parts of fumed silica, 5-15 parts of liquid acrylonitrile-butadiene rubber, 4-8.5 parts of a modified surface-active agent, 9-18 parts of a toughness modifying agent, 4-10 parts of a foaming agent, 6-8 parts of a solidifying agent, and 1-5.5 parts of a catalyst promoter. The preparation method for the nano modified phenolic aldehyde foam insulation board comprises the following steps: firstly, raw materials are prepared; the raw materials are uniformly stirred; meanwhile, the solidifying agents and the catalyst promoters are added, so that the raw materials can be uniformly mixed; foaming mixture is placed on a sheet continuous production line and the temperature is kept to be 40-50 DEC G; after the foaming mixture is mixed, the foaming mixture is cross linked, expands foams and is solidified; the thermosetting phenolic resin rigid foam board is formed. According to the invention, properties of the phenolic aldehyde foam insulation boards prepared according to the technical scheme provided by the invention are improved, particularly the fire-resistant property is improved.

Owner:锦州市好为尔保温材料有限公司

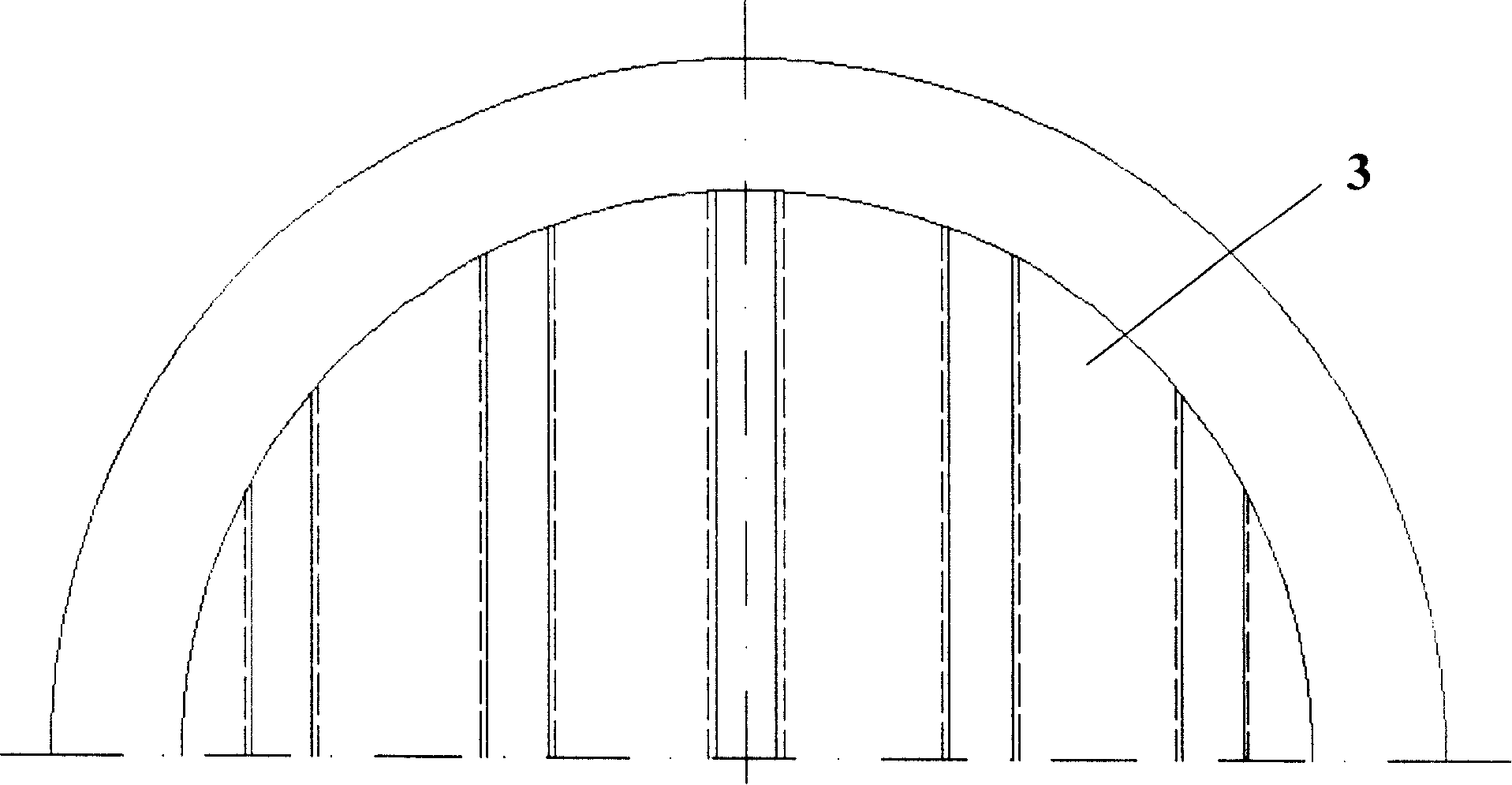

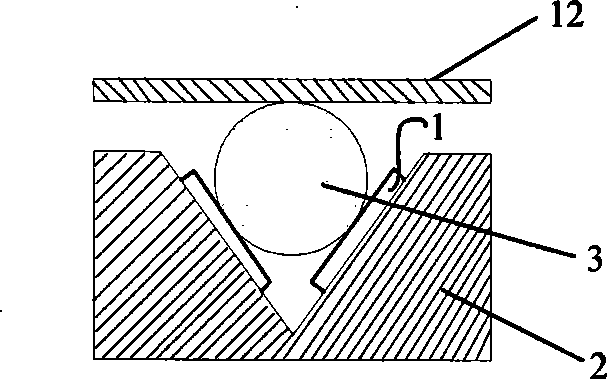

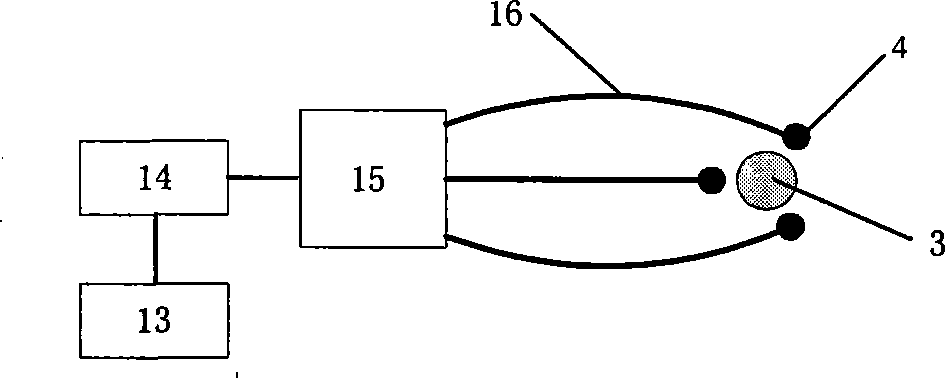

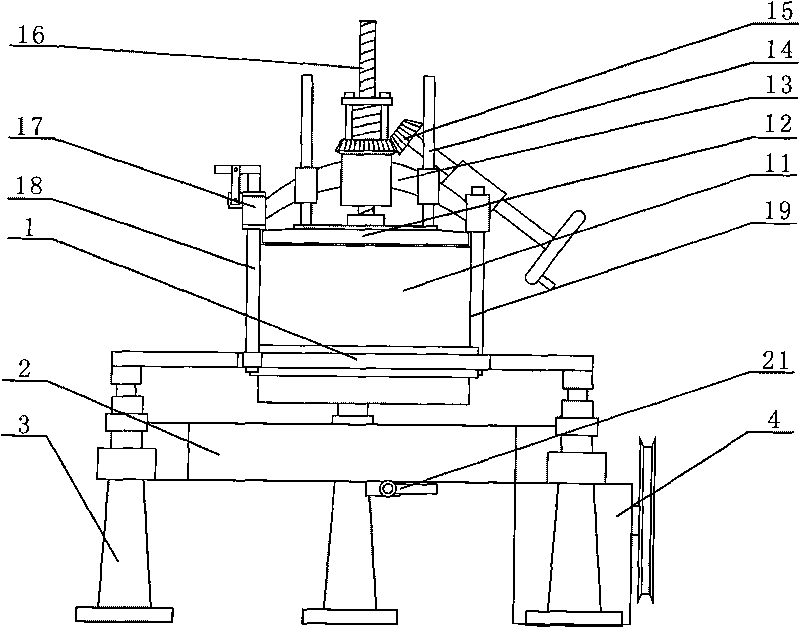

Fusion splicing devices and methods of photon crystal optical fiber

InactiveCN101251623AAvoid brittleControl collapseCoupling light guidesProgramme control in sequence/logic controllersFiber structureThree dimensional motion

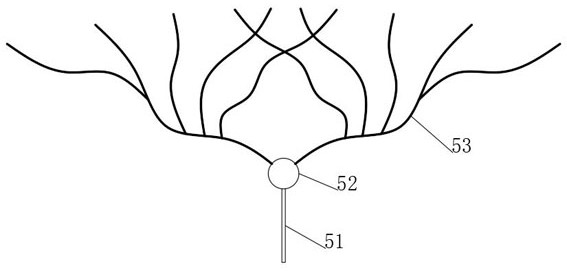

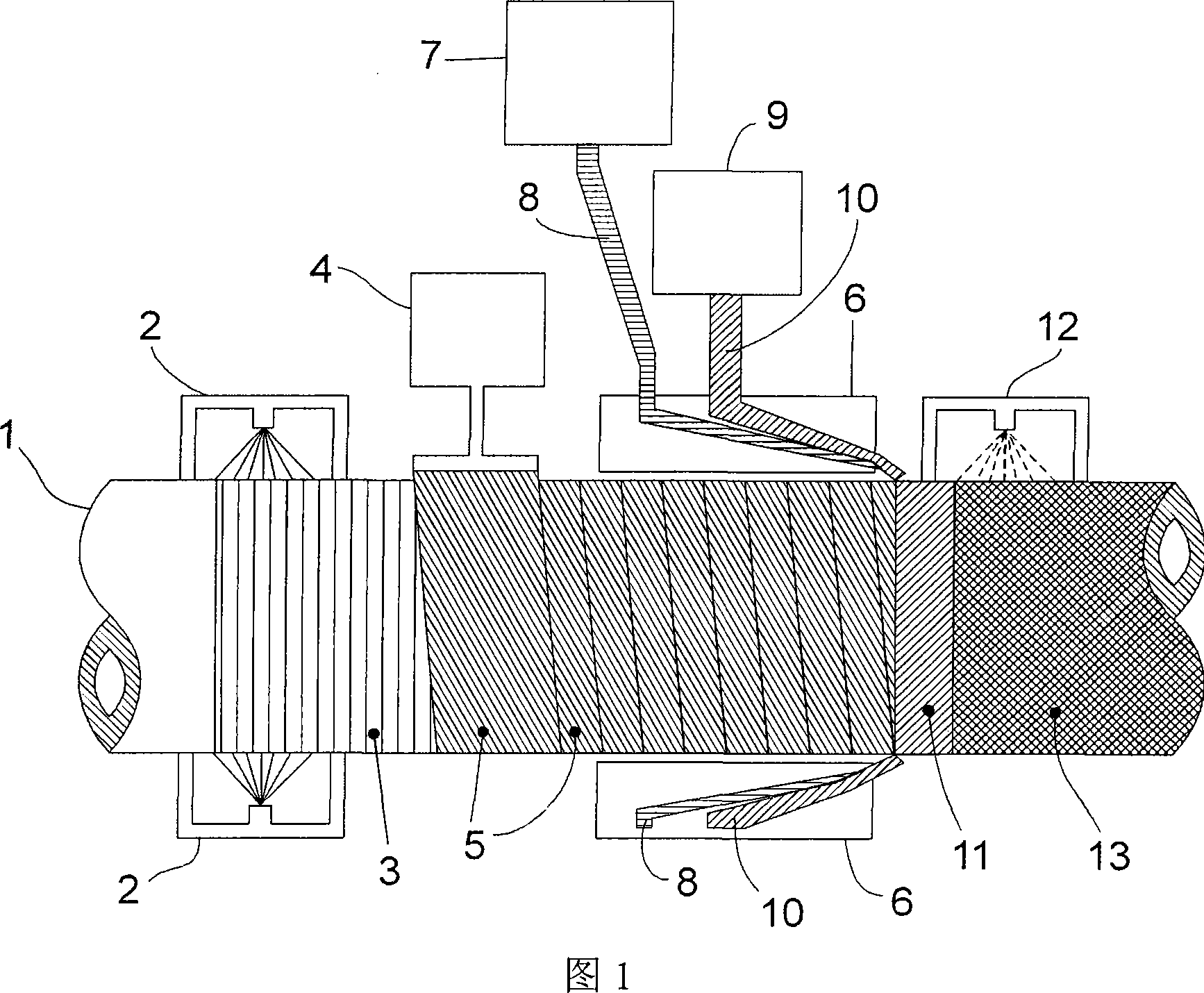

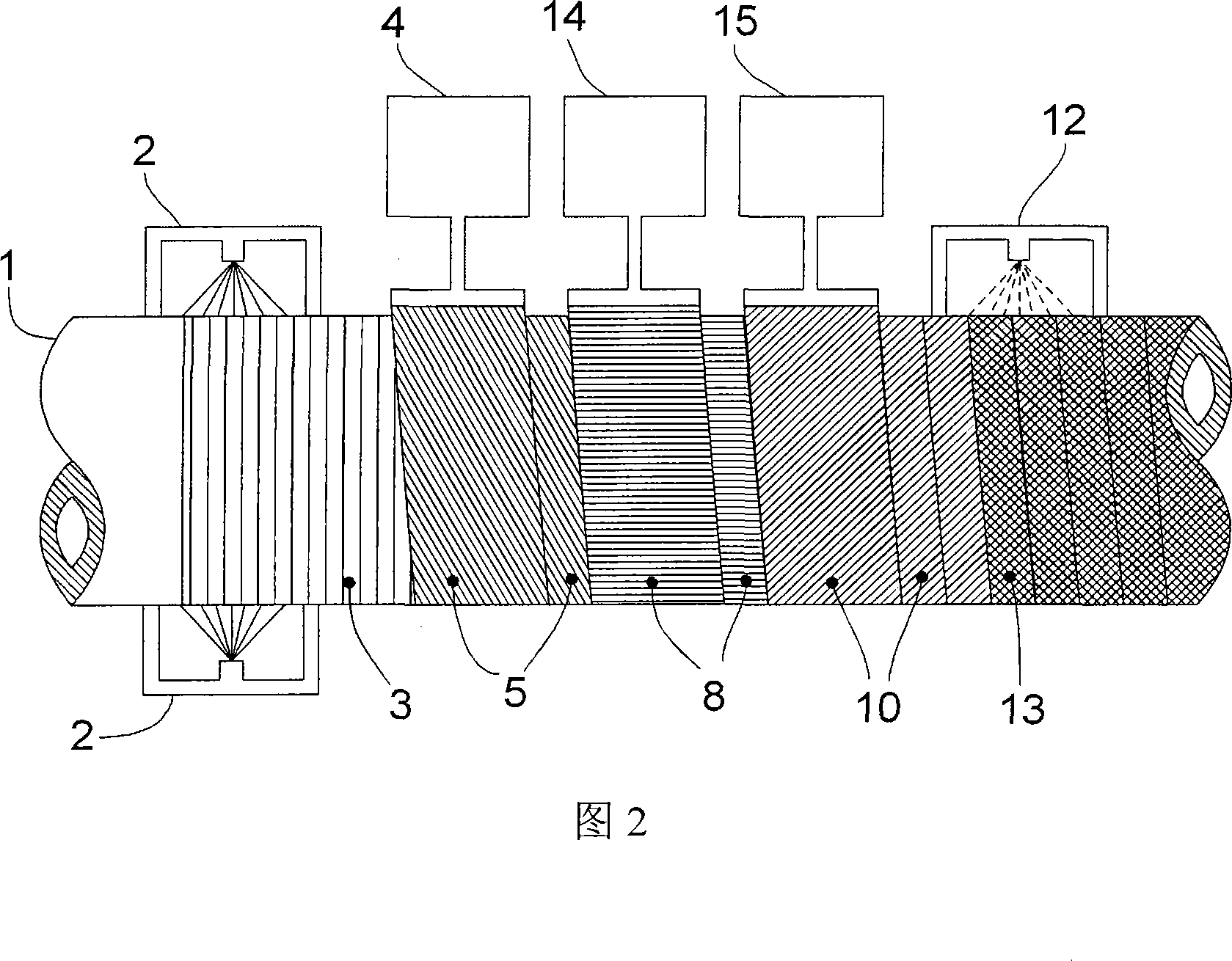

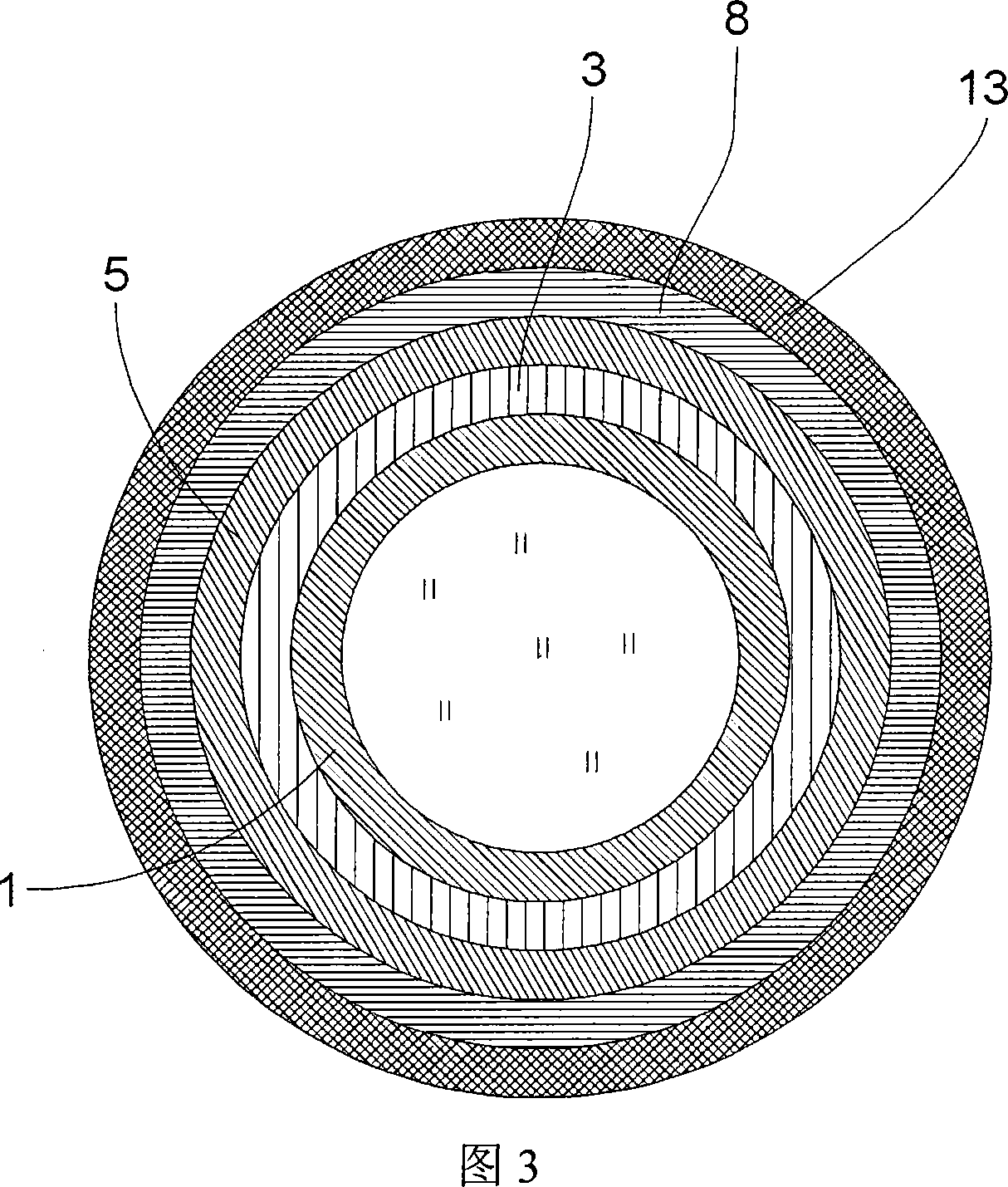

The invention discloses a welding device for photonic crystal fiber and a method thereof. A frequency controller (13) of a carbon dioxide laser modulating unit (8), a stress sensor demodulating unit (11) and a three-dimensional alignment controller and a clamp control unit (10) are connected with a processing and control element (9) of the welding device; mechanical transmission mechanisms of a lower three-dimensional motion V-shaped groove device (2) and an upper three-dimensional motion V-shaped groove device (5) are connected with the three-dimensional alignment controller and the three-dimensional alignment controller of the clamp control unit (10); the carbon dioxide laser modulating unit (8) transmits laser to a fiber output point (4) through a transmitting energy fiber (16) to weld a welded fiber (3). The method comprises the following steps of: 1) selecting a welding parameter according to information of a fiber structure; 2) adjusting a clamping force of the V-shaped groove clamp by using the information of the fiber structure; 3) performing a three-dimensional alignment to two fibers to be welded; 4) modulating a carbon dioxide laser by a frequency modulator with a set frequency to transmit laser to the position of welded fibers for welding through the transmitting energy fiber. The welding device for the photonic crystal fiber has the advantages of simple structure, strong capability of anti-interference of vibration, high sensitivity and easy manufacture, and is suitable for welding between photonic crystal fibers with different specifications and between the photonic crystal fiber and a conventional optical fiber.

Owner:YANSHAN UNIV

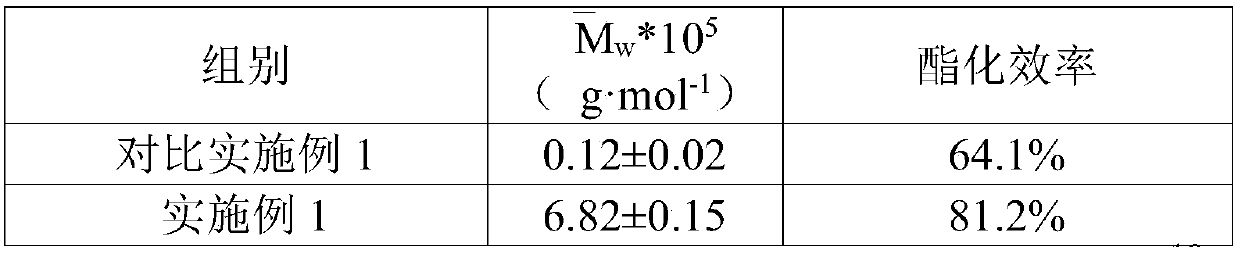

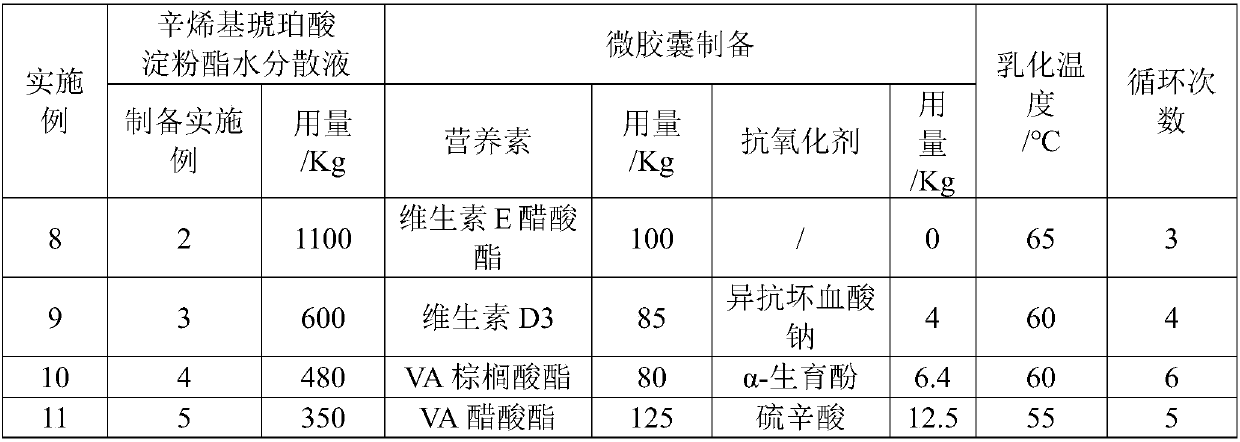

Octenyl succinic acid starch ester, lipid-soluble nutrient microcapsule as well as preparation method application of lipid-soluble nutrient microcapsule

ActiveCN109517080AHigh esterification rateGood emulsifying effectAccessory food factorsFood ingredientsChain lengthSuccinic acid

The invention relates to octenyl succinic acid starch ester, a lipid-soluble nutrient microcapsule as well as a preparation method application of the lipid-soluble nutrient microcapsule. A preparationmethod of octenyl succinic acid starch ester comprises the step of carrying out esterification reaction on gelatinized starch and octenyl succinic anhydride in a cavitation emulsification process, soas to obtain octenyl succinic acid starch ester. According to the preparation method, the esterification reaction is promoted and intensified by virtue of the cavitation emulsification process, remarkably substitution occurs in a crystallization region and an amorphous region of the starch through the molecular collision of the collision between gelatinized starch and octenyl succinic anhydride,so that the esterification rate of prepared octenyl succinic acid starch ester is increased, and the emulsifying property is greatly improved. The method is rapid and efficient, and a hydrolysis stepis omitted after the esterification, so that the problems that molecular chains are damaged in different degrees due to the hydrolysis, the chain length and content of amylose are remarkably decreased, the compactness of a film formed by octenyl succinic acid starch ester is decreased, and the film easily absorbs moisture and conducts heat and is crispy are avoided, and the application performanceof octenyl succinic acid starch ester is improved.

Owner:ZHEJIANG UNIV +2

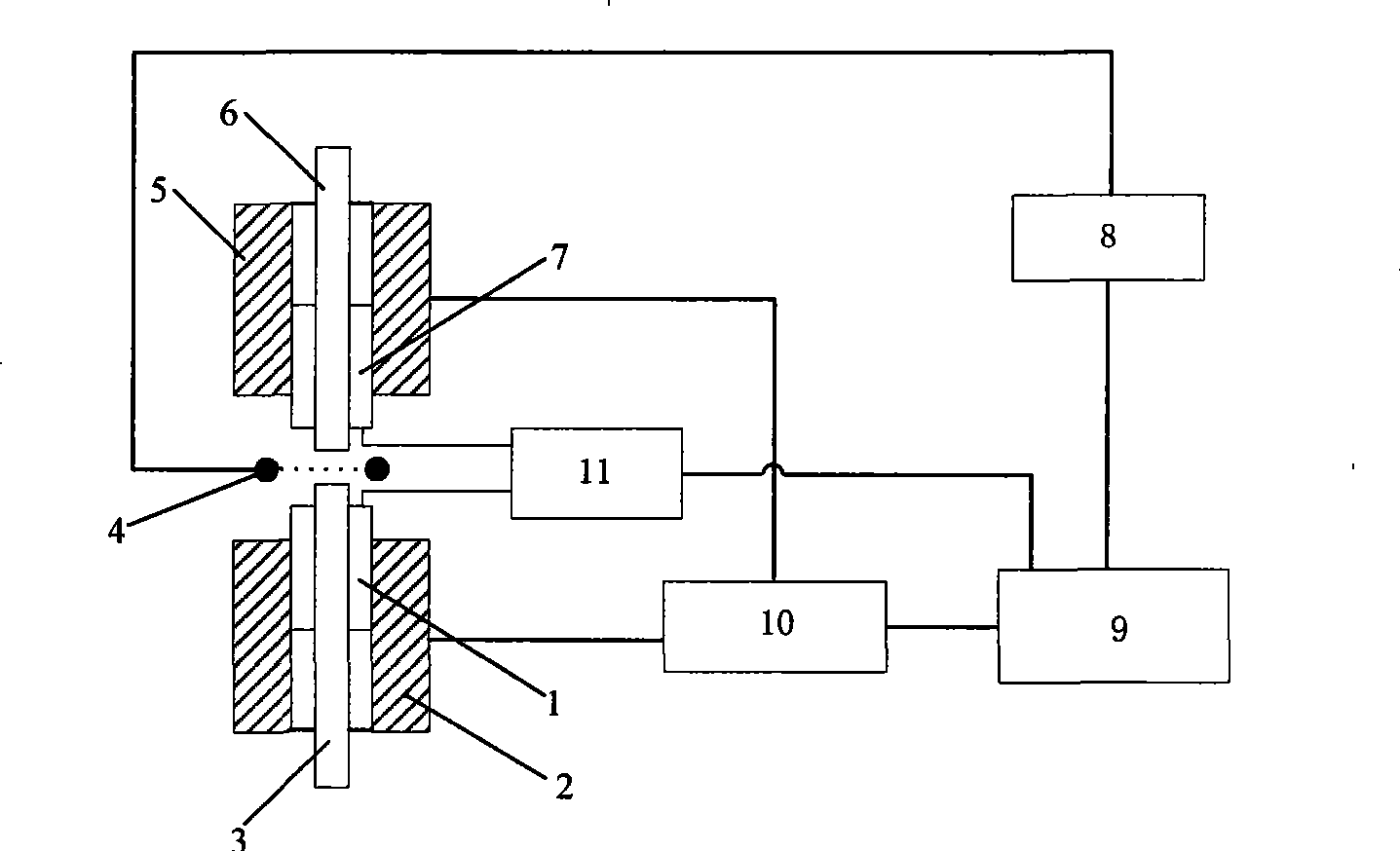

Vacuum adsorption clamp used for aspheric surface machining

InactiveCN103341818AUniform adsorptionImprove rigidityLapping machinesWork carriersTarget surfaceSurface type

A vacuum adsorption clamp used for aspheric surface machining comprises a clamp body and a profiling mold, wherein a plurality of concentric circle grooves with radial slots are formed in the upper surface of the clamp body, a vacuum connector is arranged on the lower surface of the clamp body and communicated with the upper surface of the clamp body, and the vacuum connector is connected with an outer vacuum adsorption system through a vacuum connector clamp. The upper surface of the profiling mold is a profiling mold face, the profiling mold face is machined to be a curved surface which is opposite to a target surface shape and extends to the periphery of the clamp body, and the profiling mold is fixed on the concentric circle grooves in the upper surface of the clamp body. The vacuum absorption clamp used for the aspheric surface machining has the advantages that porous ceramics material is used, the problem that a workpiece in a groove profiling mold made of hard material is prone to cracking can be avoided, and stability and reliability of the process of elastic deformation surface type copying and machining are ensured; meanwhile, the porous ceramics material has the advantages of being even in adsorption and good in rigidity, and therefore surface type accuracy of the aspheric surface machining can be ensured.

Owner:ZHEJIANG UNIV OF TECH

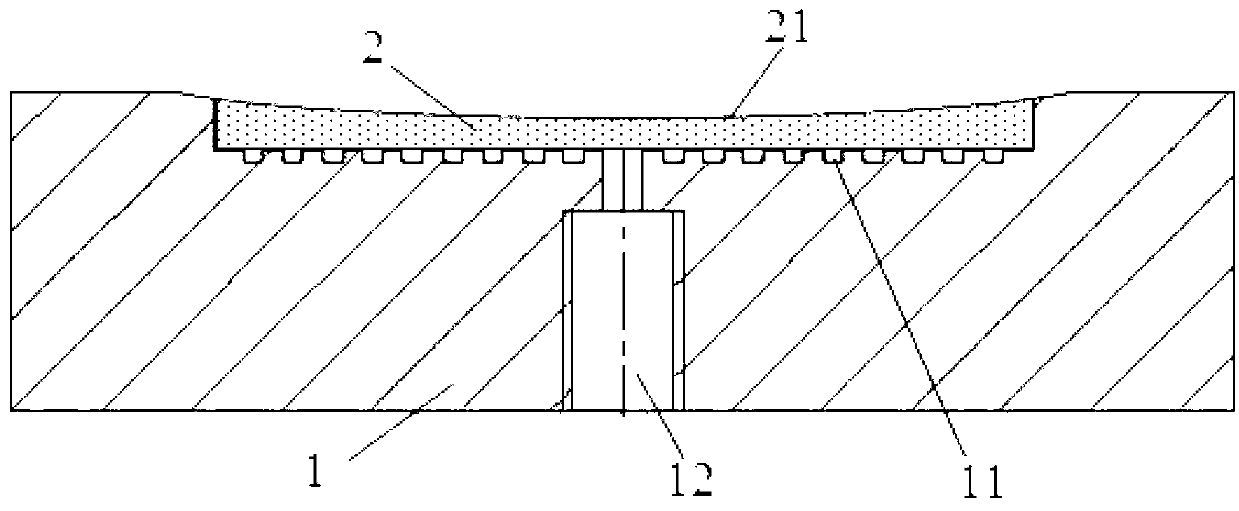

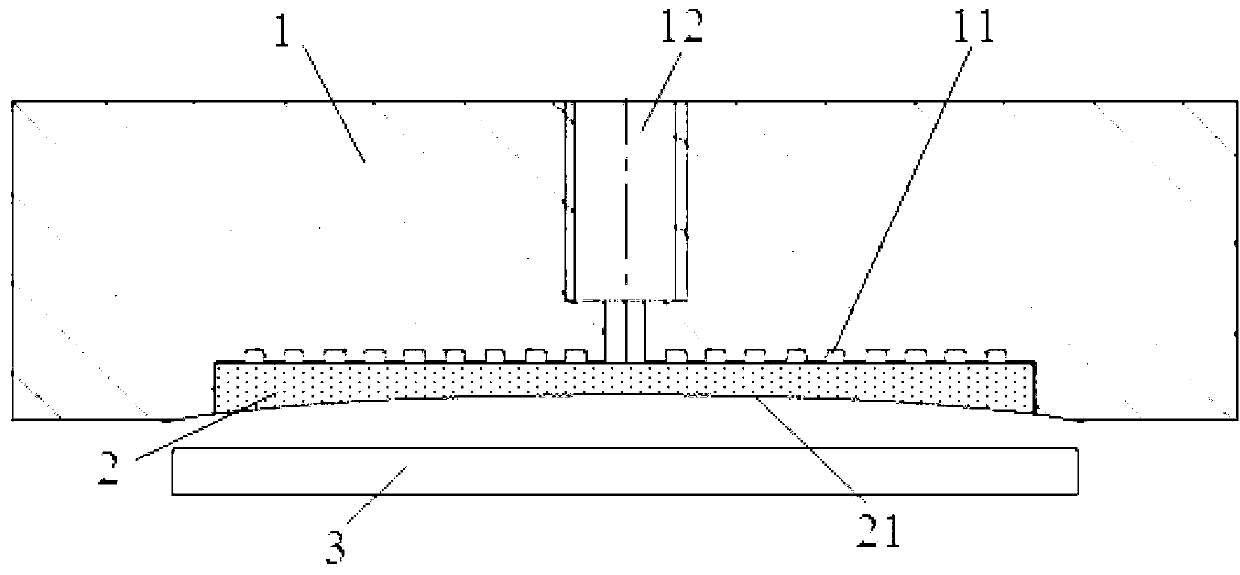

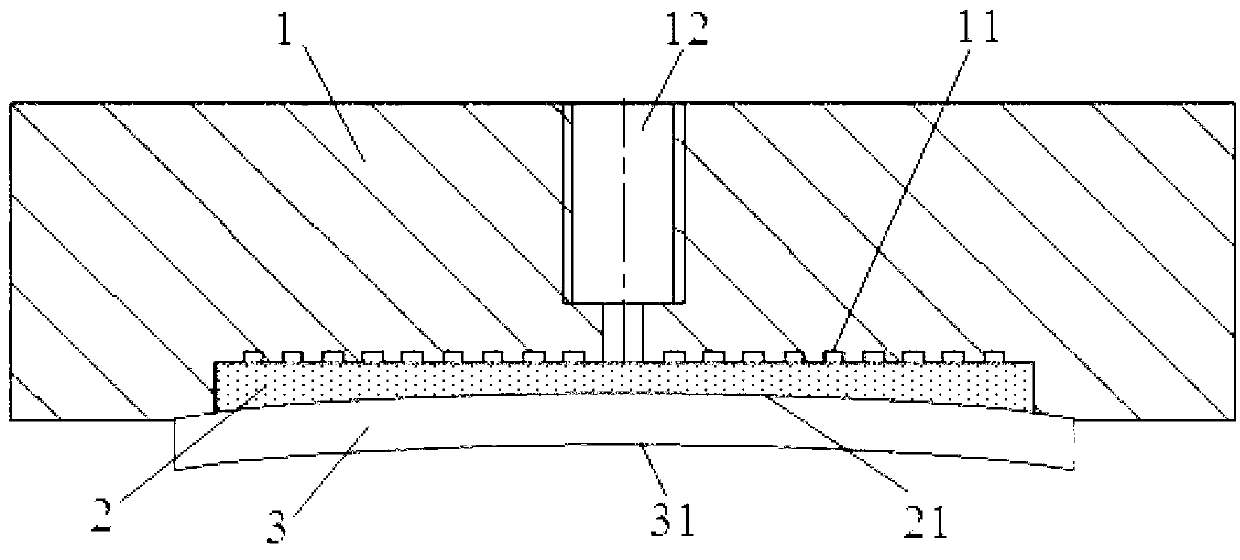

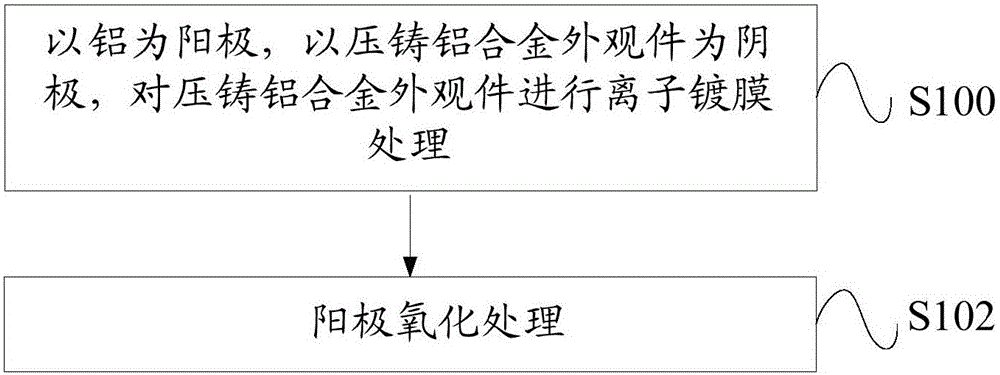

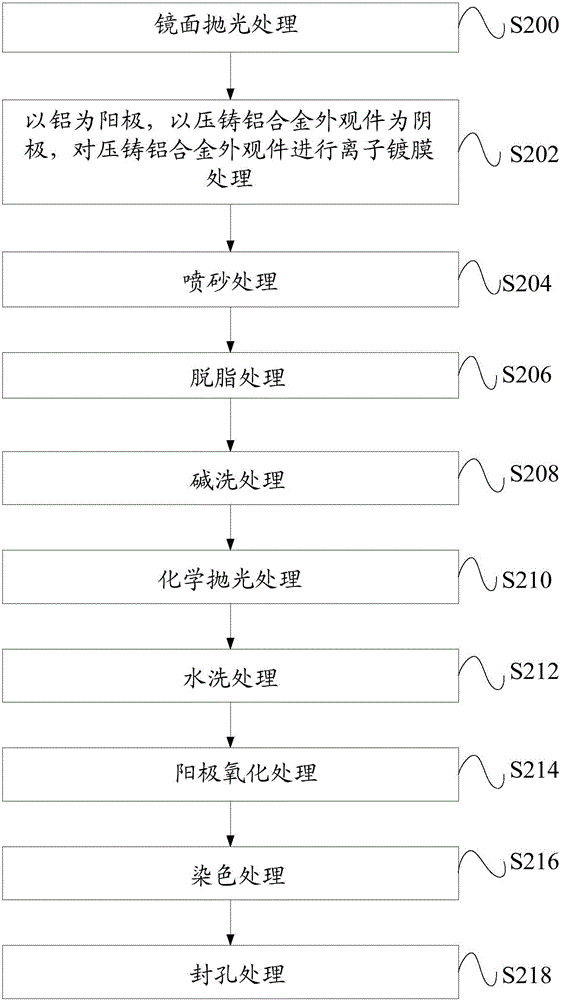

Surface treatment method of die-cast aluminum alloy exterior part and die-cast aluminum alloy exterior part product

InactiveCN105839059AImprove the authenticity rateAvoid brittleAnodisationVacuum evaporation coatingAnodic oxidationDyeing

The invention provides a surface treatment method for a die-casting aluminum alloy exterior part and a die-casting aluminum alloy exterior part product. The surface treatment method comprises: using aluminum as an anode, using the die-casting aluminum alloy exterior part as a cathode, and performing the die-casting aluminum alloy exterior part on the die-casting aluminum alloy exterior part. Ion plating treatment is performed to form an aluminum coating layer on the surface of the die-casting aluminum alloy exterior parts; anodizing treatment is performed on the die-casting aluminum alloy exterior parts after the ion plating treatment to form an oxide film layer on the surface of the die-casting aluminum alloy exterior parts. In the surface treatment method for die-casting aluminum alloy exterior parts provided by the present invention, an aluminum coating layer is formed on the surface of the exterior parts before anodizing treatment. The anodic oxidation effect and the subsequent dyeing effect are guaranteed, and the process is simple, the cost is low, and the authenticity rate of the appearance parts is high.

Owner:DONGGUAN COOLPAD SOFTWARE TECH

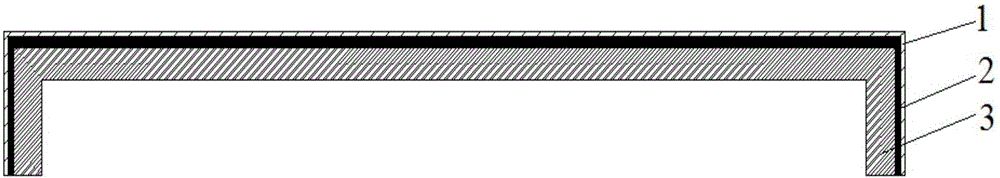

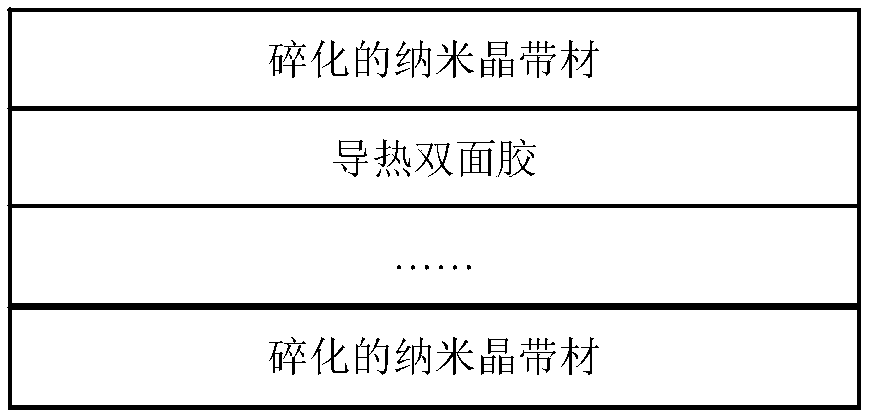

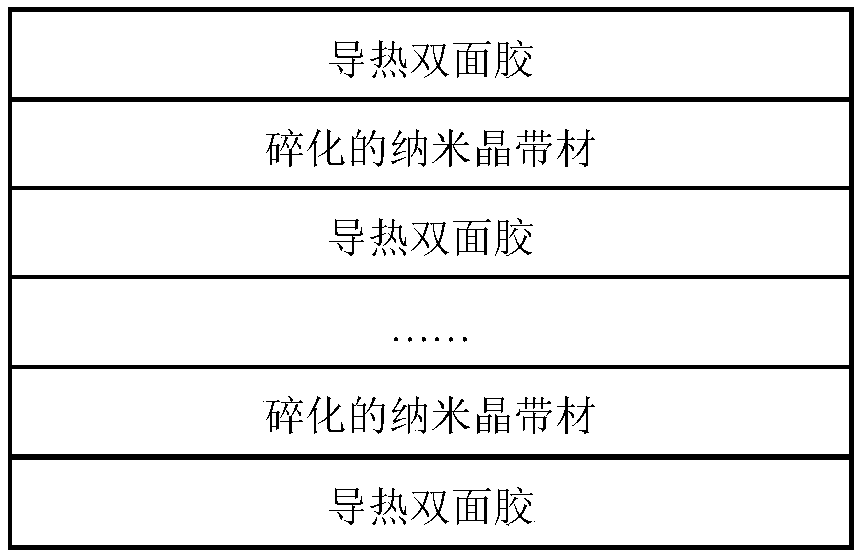

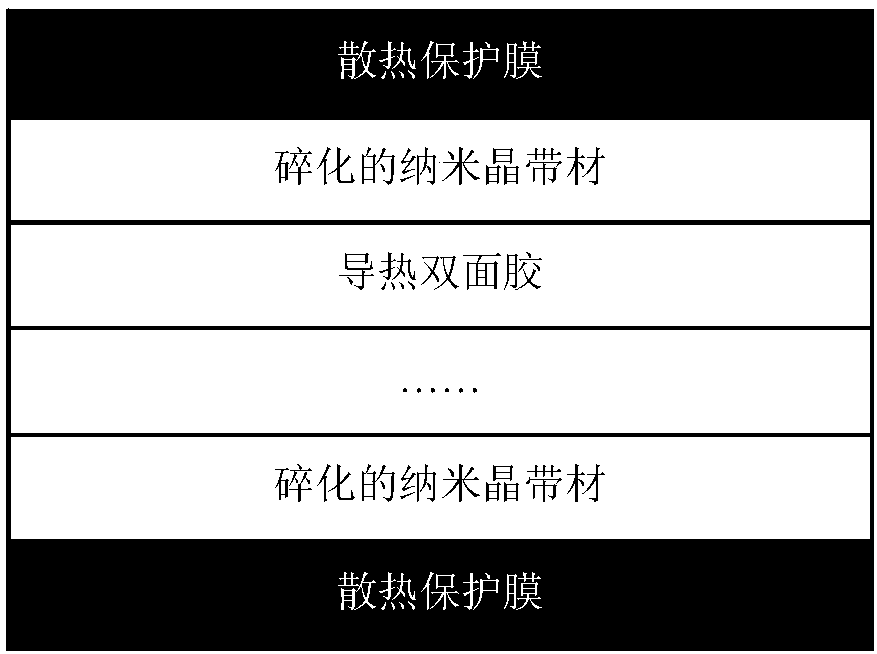

Ultrathin magnetic field shielding sheet excellent in heat dissipation performance and preparation method of ultrathin magnetic field shielding sheet excellent in heat dissipation performance

InactiveCN108235677AThe overall thickness is thinReduce thicknessMagnetic/electric field screeningCircuit arrangementsMetal foilHeat conducting

The invention belongs to the field of electronic materials and discloses an ultrathin magnetic field shielding sheet excellent in heat dissipation performance and a preparation method of the ultrathinmagnetic field shielding sheet excellent in heat dissipation performance. The method includes: subjecting an amorphous-nanocrystalline strip to heat treatment at 550-650 DEG C to obtain a nanocrystalline strip in thickness of 7-22micron; using a heat-conducting double-sided adhesive tape in thickness of 3-5micron for adhesive lamination treatment of one or both faces of the nanocrystalline strip;fragmenting the nanocrystalline strip into discontinuous single parts at intervals of 0.1-5micron; finally laminating the multilayer fragmented nanocrystalline strip to obtain the ultrathin magneticfield shielding sheet excellent in heat dissipation performance. According to the method, the nanocrystalline strip can be thinned to 7-22micron from 25micron, and metal foils or graphite flaks are further adopted for edge covering treatment, so that thickness of the magnetic field shielding sheet is greatly reduced while the heat dissipation performance is improved.

Owner:SHENZHEN YN TECH CO LTD +1

Preparation method of conductive 3D printing supplies by using double screw extruder

ActiveCN105542377AAvoid brittleReduce the amount of carbon nanotubesElectrically conductiveCarbon nanotube

The invention discloses a preparation method of conductive 3D printing supplies by using a double screw extruder. The method is as below: dispersing multi-walled carbon nanotubes in acetone, mixing uniformly into an ink-like state; adding a thermoplastic resin particles in a stirring tank, uniformly spraying the multi-walled carbon nanotube acetone dispersion liquid on the surface of the resin particles in the stirring process, and continuing stirring; taking out the thermoplastic resin particles coated by the multiple-walled carbon nanotube dispersion liquid, putting in a constant temperature drying box, and drying at the temperature of 60-80 DEG C for 2-6 h; directly adding the dried multi-walled carbon nanotube / resin composite particles into the hopper of a double screw extruder, extruding continuously and uniformly, and adjusting the traction force and traction speed to control the diameter of an extrudateat 1.75mm or 3.0mm, so as to finally obtain the conductive 3D printing supplies. The method of the present invention is simple to operate, and the obtained conductive 3D printing supplies have both good conductivity and mechanical properties.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

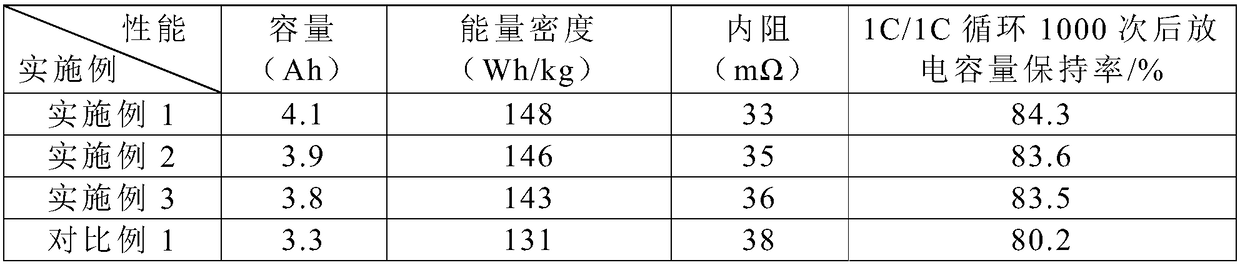

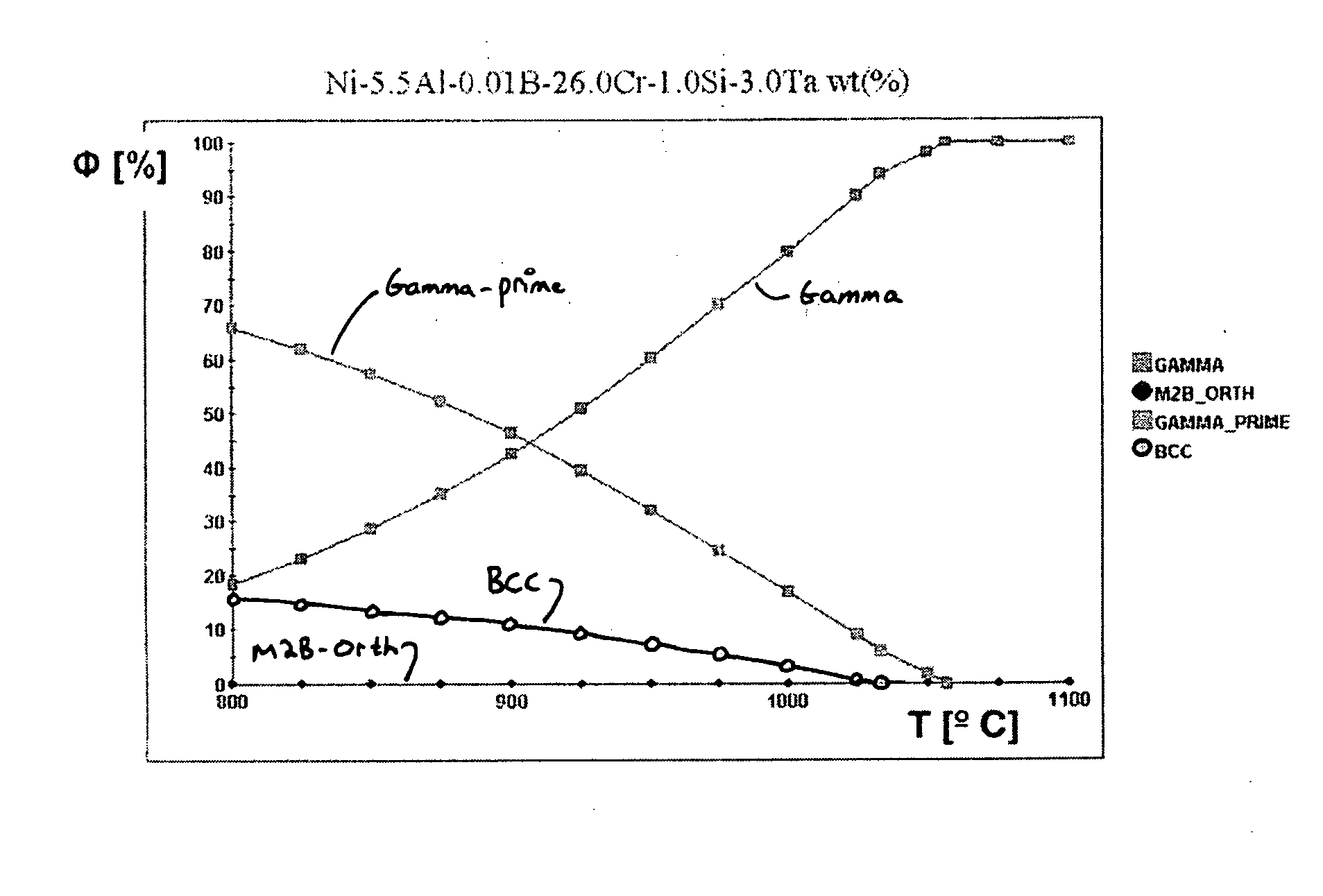

High-energy-density lithium ion battery

ActiveCN108899475AIncrease capacityImprove cycle lifeCell electrodesSecondary cellsHigh energyPole piece

The invention relates to a high-energy-density lithium ion battery, belonging to the technical field of lithium batteries. The high-energy-density lithium ion battery comprises an anode pole piece, acathode pole piece and a diaphragm, wherein the anode pole piece is coated with an anode active material; and the cathode pole piece is coated with a cathode active material. The high-energy-density lithium ion battery is characterized in that the limiting compaction density of the anode pole piece is 2.4g / cm<3>-2.55g / cm<3>, and the surface density is 360g / m<2>-380g / m<2>; and the limiting compaction density of the cathode pole piece is 1.4g / cm<3>-1.50g / cm<3>, and the thickness is 115-125 microns. By virtue of the reasonable configuration of anode and cathode materials of the lithium batteries,the anode pole piece can reach the limiting compaction density, the high-magnifying power charging and discharging of the batteries are effectively guaranteed under the conditions, and meanwhile, battery capacity is increased, so that the battery performance is effectively improved.

Owner:ZHEJIANG QIANJIANG LITHIUM TECH CO LTD

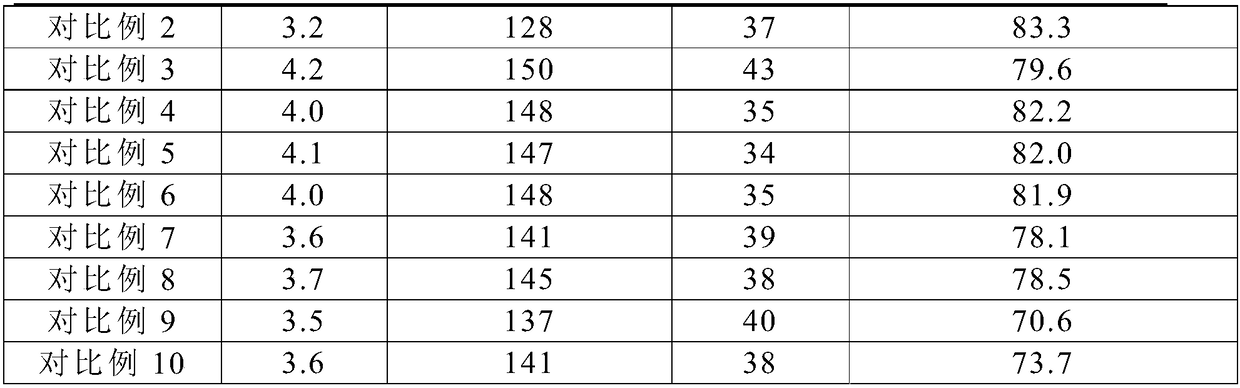

High-temperature protection layer

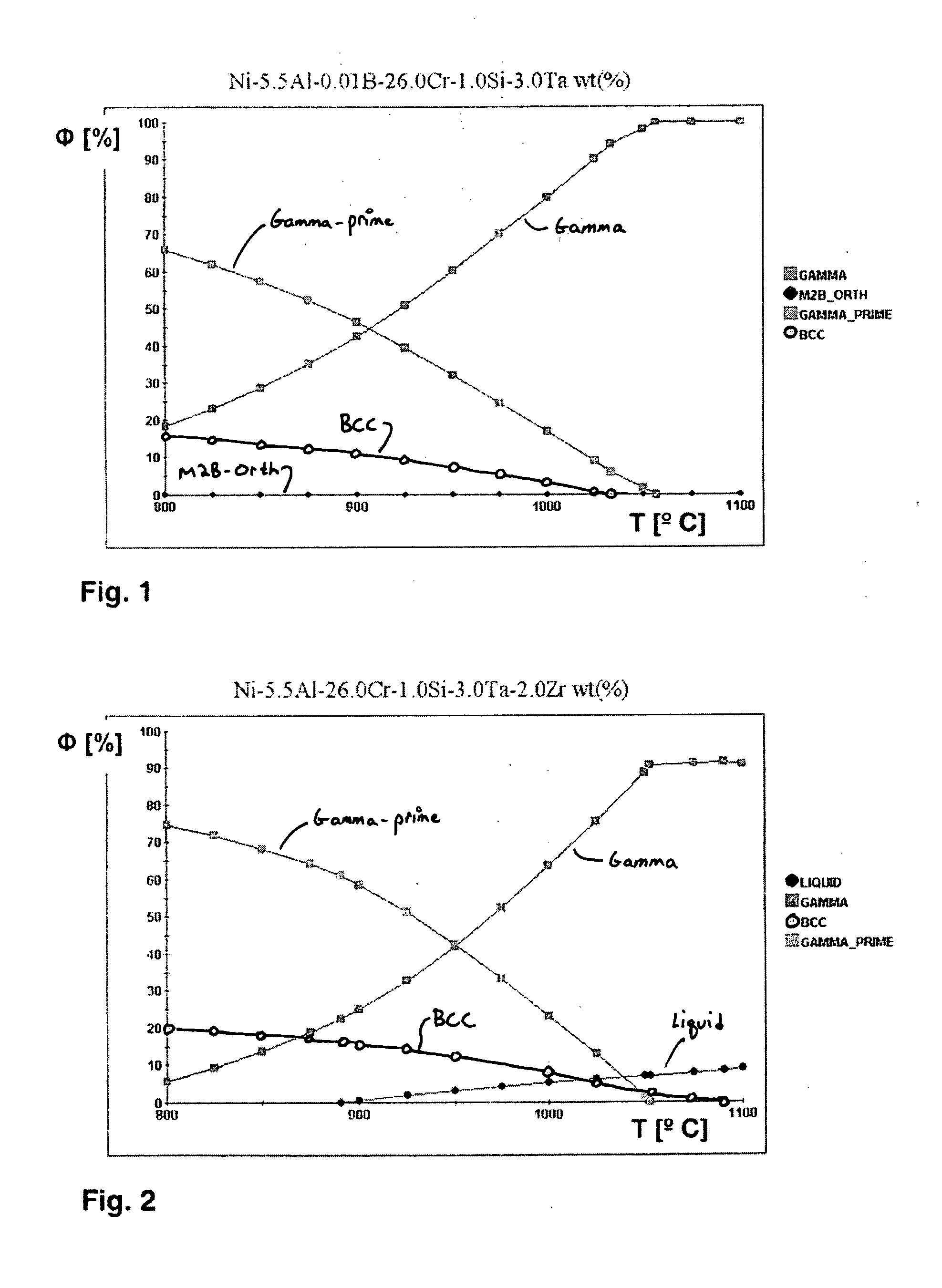

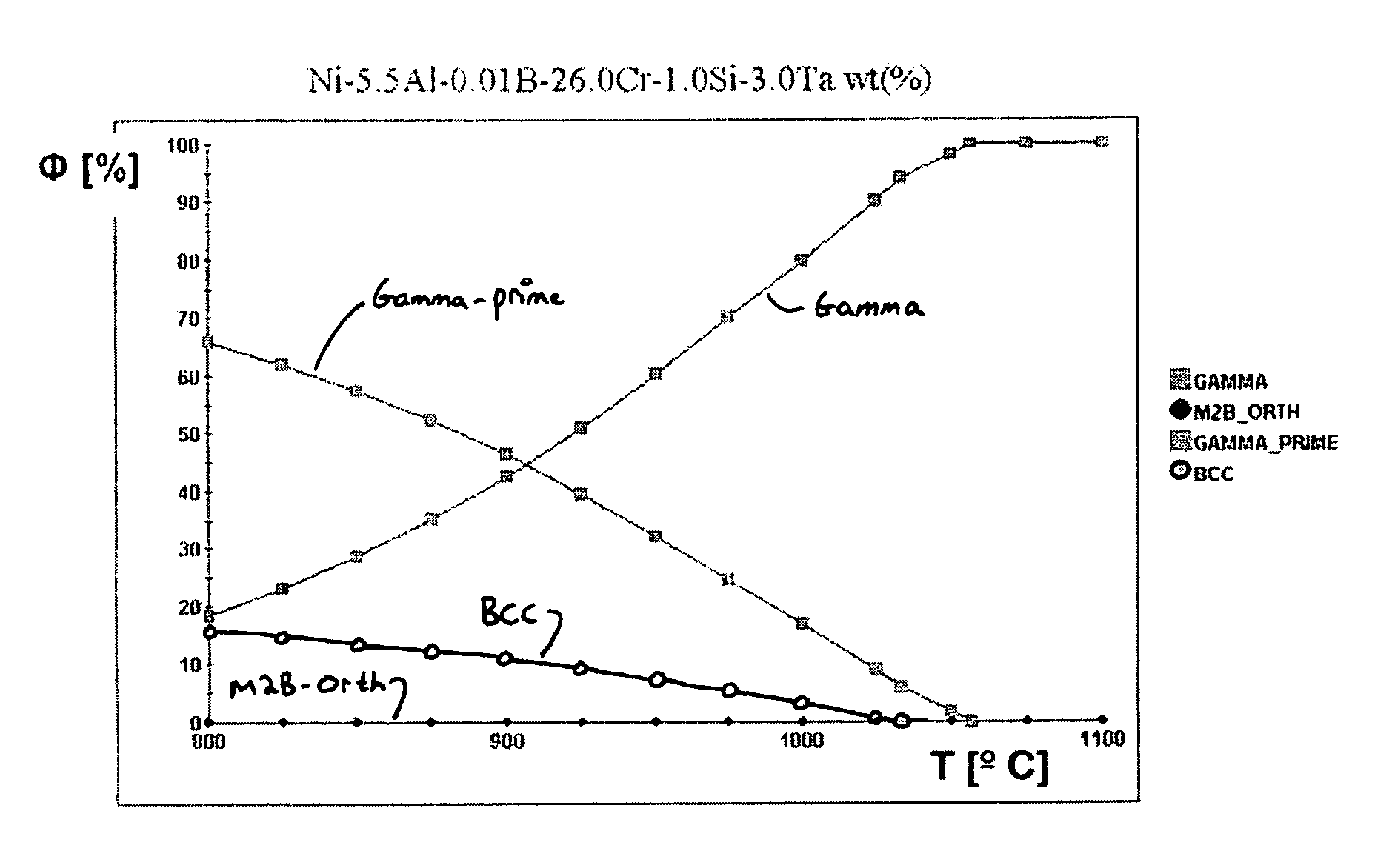

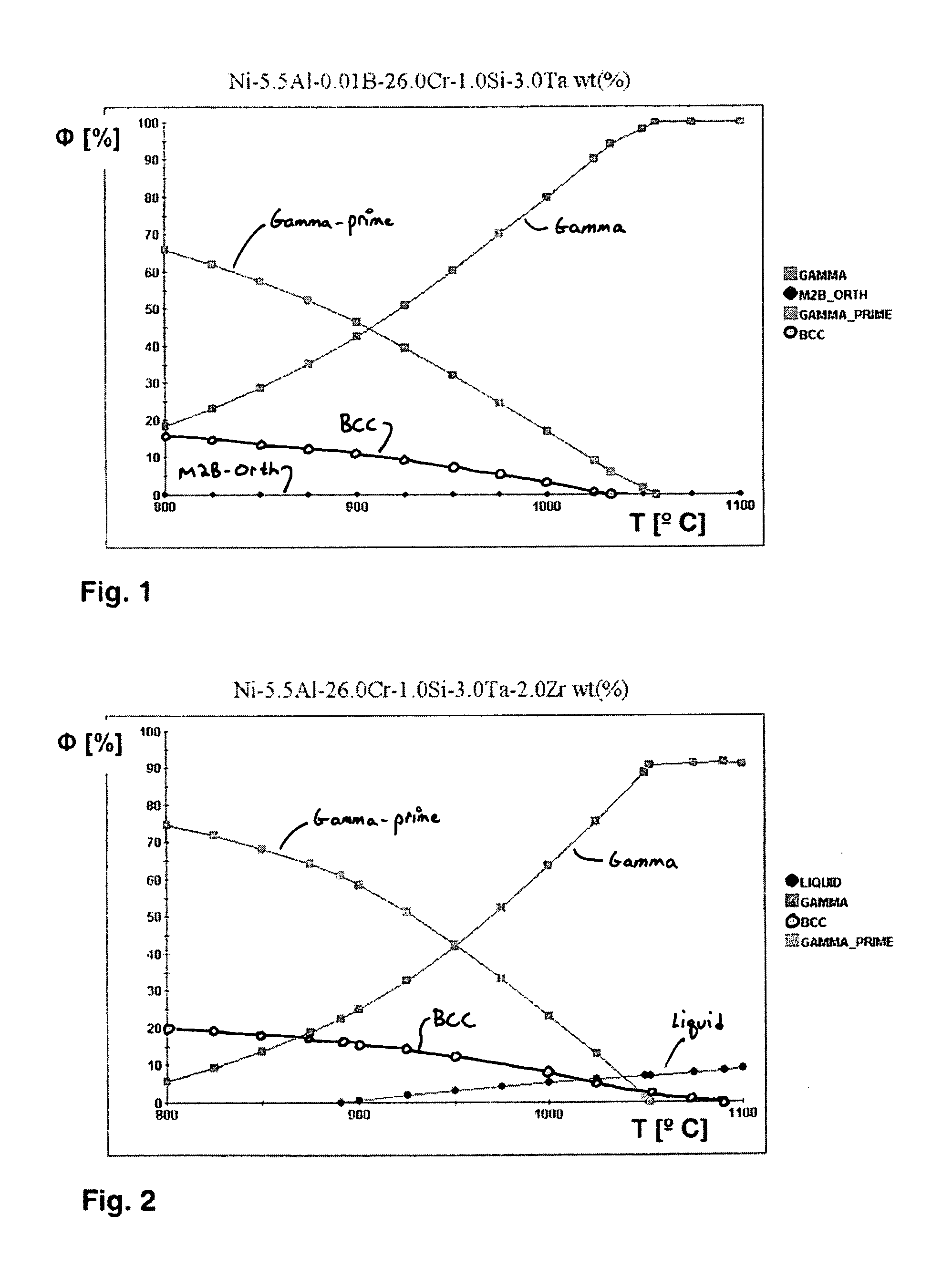

InactiveUS20050042474A1Resistance to oxidation and corrosion is significantly improvedAvoid brittleContinuous combustion chamberMolten spray coatingProtection layerImpurity

A high-temperature protection layer contains (% by weight) 23 to 27% Cr, 4 to 7% Al, 0.1 to 3% Si, 0.1 to 3% Ta, 0.2 to 2% Y, 0.001 to 0.01% B, 0.001 to 0.01% Mg and 0.001 to 0.01% Ca, remainder Ni and inevitable impurities. Optionally, the Al content is in a range from over 5 up to 6% by weight.

Owner:ANSALDO ENERGIA IP UK LTD

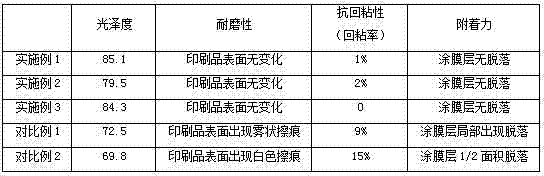

Novel printed product gloss oil

ActiveCN104845500AImprove flexibility and other problemsImprove stabilityEpoxy resin coatingsProtein coatingsEpoxyWater soluble

The invention belongs to the technical field of printing and particularly relates to novel printed product gloss oil. The gloss oil consists of the following raw materials including water-soluble crylic acid epoxy resin, mussel mucoprotein, calcium acetate, acrylics, a solvent and a function additive and is specifically prepared by the steps of adding the acrylics into water-soluble crylic acid epoxy resin according to the proportion, evenly mixing the solvent, then adding the function additive into the solvent, performing even mixing, adding a mixed solution formed by the mussel mucoprotein and the calcium acetate and then performing even stirring. A preparing method is simple, prepared and synthesized gloss oil is good in waterproof performance and glossiness and enables printed products to be good in adhesion and abrasion resisting performance.

Owner:山东济清科技服务有限公司

Foam insulation board with flame retardation function

InactiveCN105694253AHigh strengthReduce dosageNon-macromolecular adhesive additivesMacromolecular adhesive additivesCompression moldingAdhesive

The invention discloses a foam insulation board with a flame retardation function. A preparation method for the foam insulation board comprises the following steps: (1) coating of EPS particles: weighing 100 parts of prefoamed and cured EPS particles and 150 to 200 parts of a flame-retardant adhesive, carrying out uniform mixing under stirring, adding 10 to 15 parts of a curing agent and continuing stirring so as to obtain uniformly coated EPS particles; (2) gelation: subjecting the uniformly coated EPS particles to microwave heating for drying for 0.5 min and then delivering hot air for drying for 1 to 2 min so as to obtain gelated foam EPS particles; and (3) compression molding: putting the uniformly coated EPS foam particles into a die, closing the die, introducing water vapor with pressure intensity of 0.06 to 0.08 Mpa, maintaining the pressure for 1 to 2 min and then successively carrying out pressure relief, cooling and die-opening. The foam insulation board provided by the invention has good production efficiency, good flame retardation effect and high comprehensive properties.

Owner:SHANGHAI YIZUN WOOD

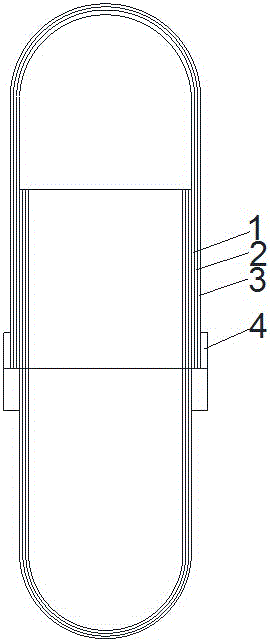

Enteric hollow capsule and preparation method thereof

InactiveCN106265587AImprove sealingReduce lossPharmaceutical non-active ingredientsCapsule deliveryEnteric coatingBiomedical engineering

The invention discloses an enteric hollow capsule and a preparation method thereof. The enteric hollow capsule comprises a capsule shell (1) and an enteric coating (3), the outer surface of the capsule shell (1) is wrapped by the enteric coating (3), the capsule shell (1) comprises a capsule cap and a capsule body which are inserted together, the capsule cap and the capsule body are sealed through a sealing film (4), and an isolating layer (2) is arranged between the capsule shell (1) and the enteric coating (3). The preparation method comprises the steps that a capsule liquid glue dipping mold is dipped with glue for forming, and the capsule shell is obtained; then the capsule shell is dipped with isolating liquid and dried; then the capsule shell is dipped with enteric coating liquid and dried; the capsule shell is placed on a sealing machine after demoulding, cutting and sleeving, and sealing liquid is added to the combination position of the capsule cap and the capsule body. The isolating layer for isolating water loss is additionally arranged between the enteric coating and the capsule shell to reduce loss of water of the capsule shell and improve the sealing performance of the enteric capsule.

Owner:JIANGSU LEFAN CAPSULE

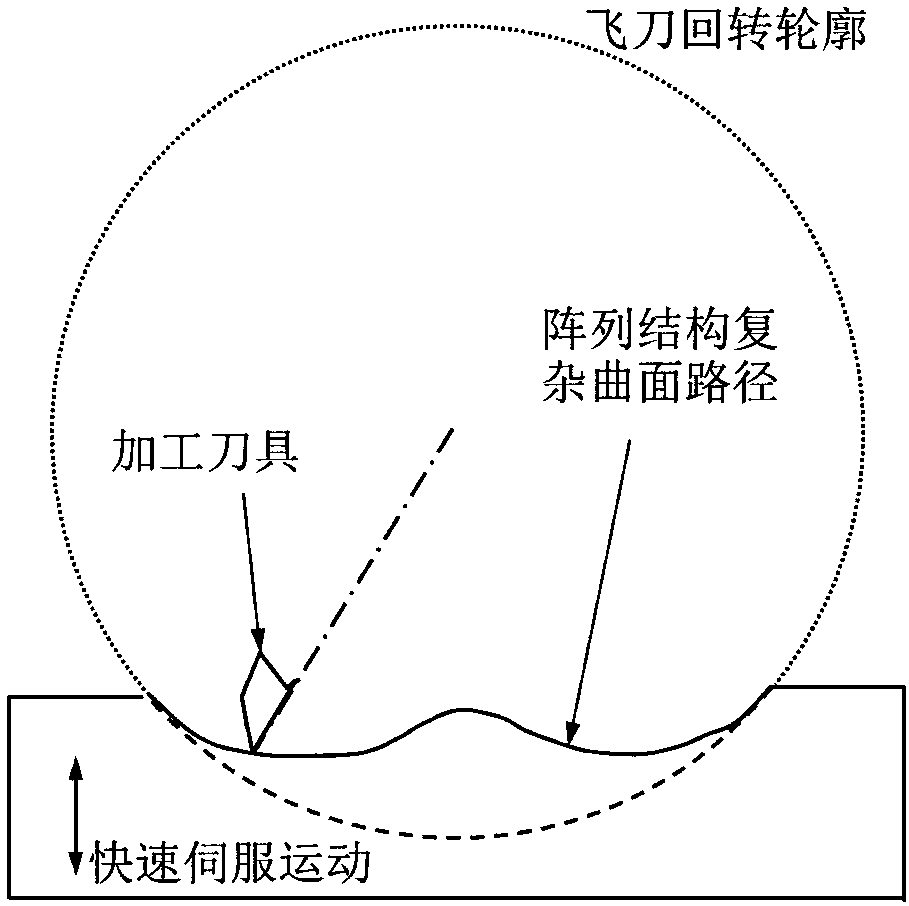

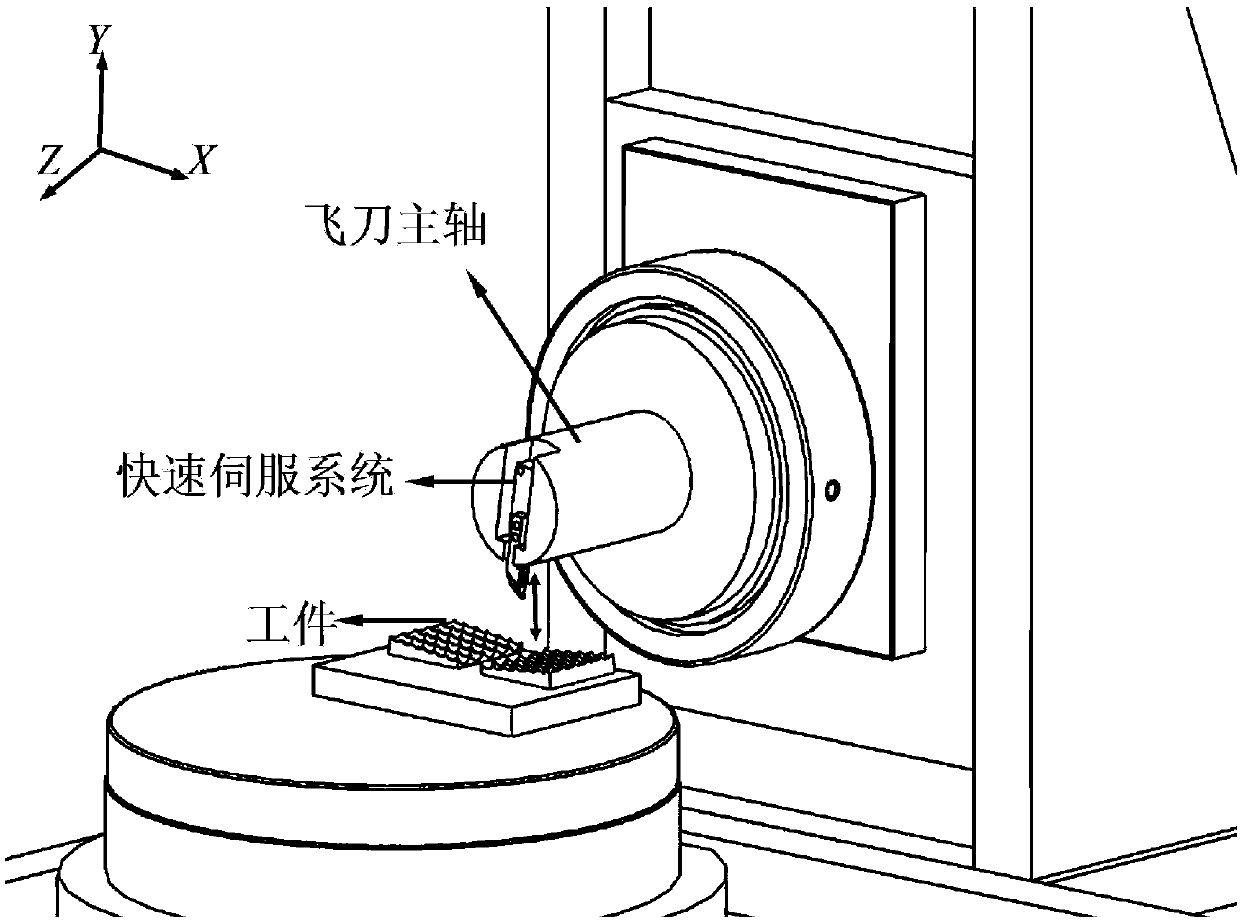

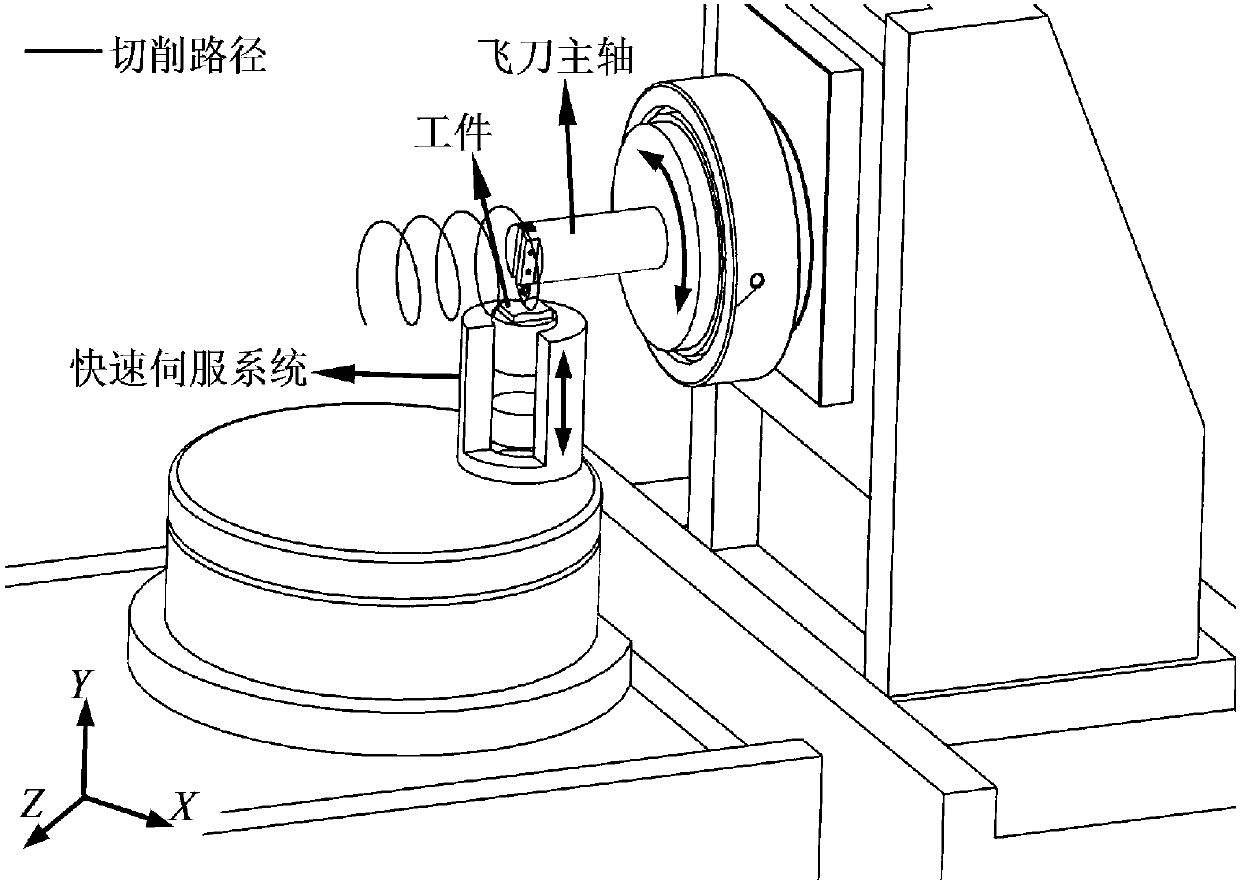

Fast servo ultraprecise fly cutting machining method for brittleness material complex curved surface

The invention relates to a fast servo ultraprecise fly cutting machining method for a brittleness material complex curved surface. The method includes the following steps that a machining system with a fast servo mechanism and fly cutting being combined is established; when a machined device is subjected to fly-cutter machining, a cutter is provided with an area nearest to the machined device every time a spindle is rotated once; at the area, due to the fact that the rotating speed of the fly-cutter spindle is unchanged, when the cutter makes contact with the surface of a workpiece, the fast servo mechanism can be used for driving the workpiece to make single-degree-of-freedom high-frequency motion in the cutting-in direction or make multi-degree-of-freedom high-frequency motion in the cutting-in direction and transverse feeding direction so as to be matched with fly-cutter rotation, and an array structure and complex surface can be machined; the proper cutting parameters and cutter geometrical parameters are designed; motion synchronization is achieved by controlling the servo motion and fly-cutter rotation angle, and thus the back cutting depth can be controlled when materials are cut; and finally cutter motion trajectories make fast and smooth traverse motion on the surface of the machined device.

Owner:TIANJIN UNIV

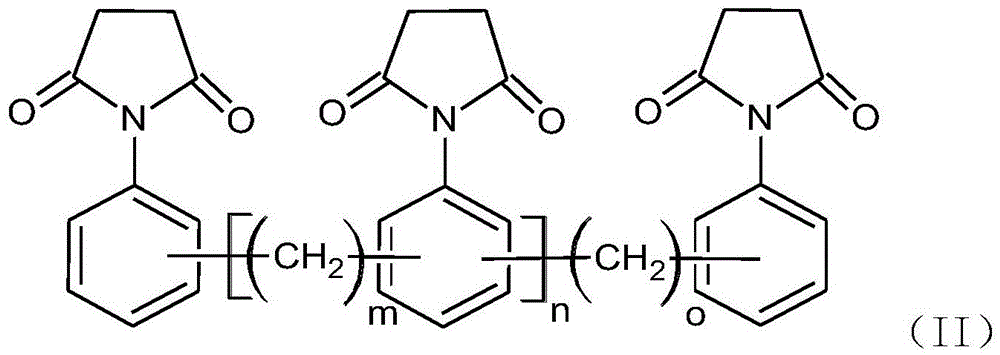

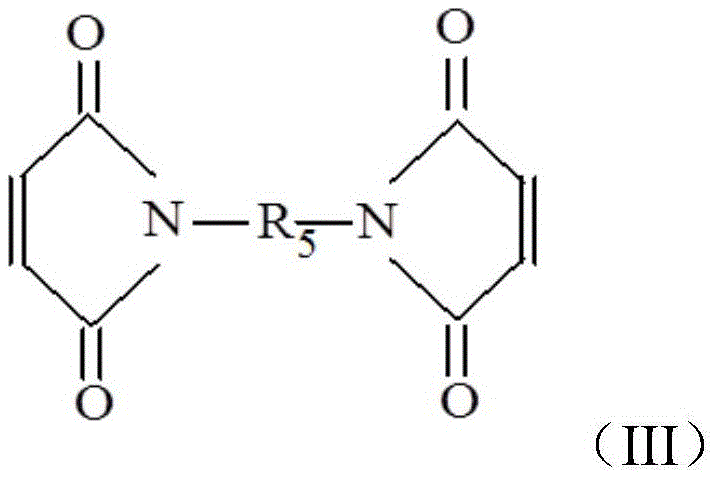

Battery electrode paste composition

The invention relates to a battery electrode paste composition, containing a silane coupling agent-modified active substance, that contains a silane coupling agent-modified active substance, a conductive additive, an adhesive, and a maleimide additive. This composition may provide better battery safety and longer cycle life.

Owner:IND TECH RES INST

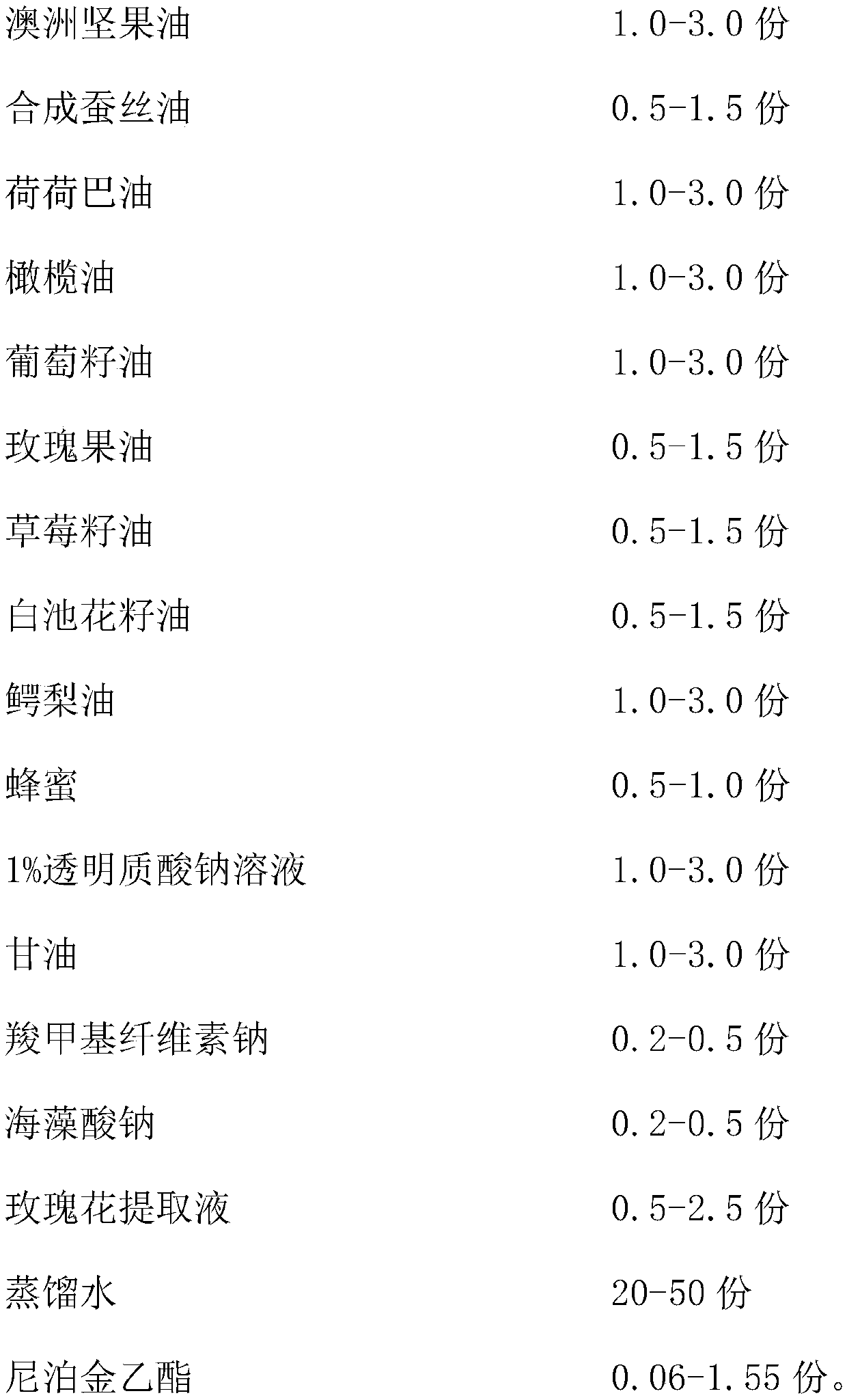

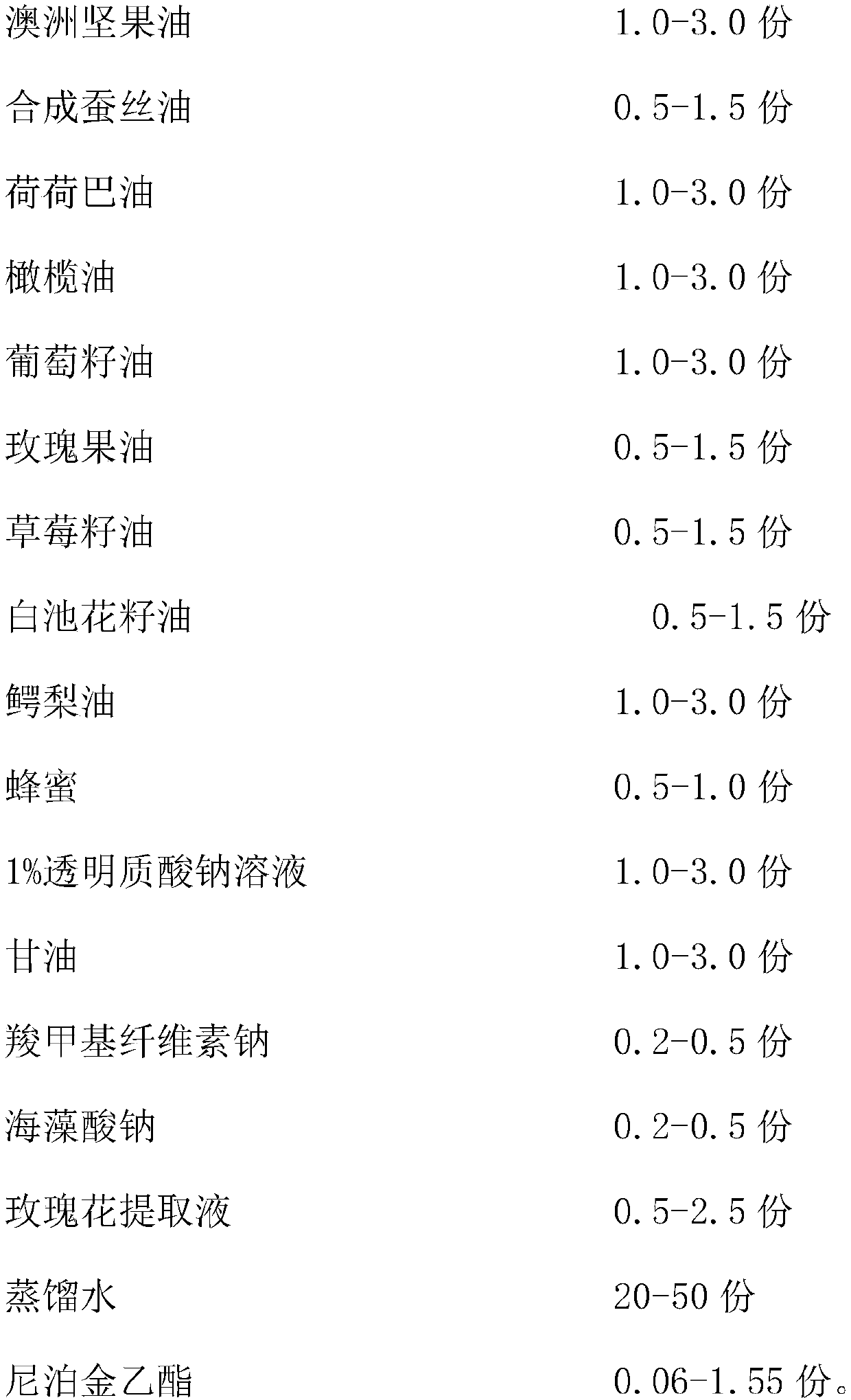

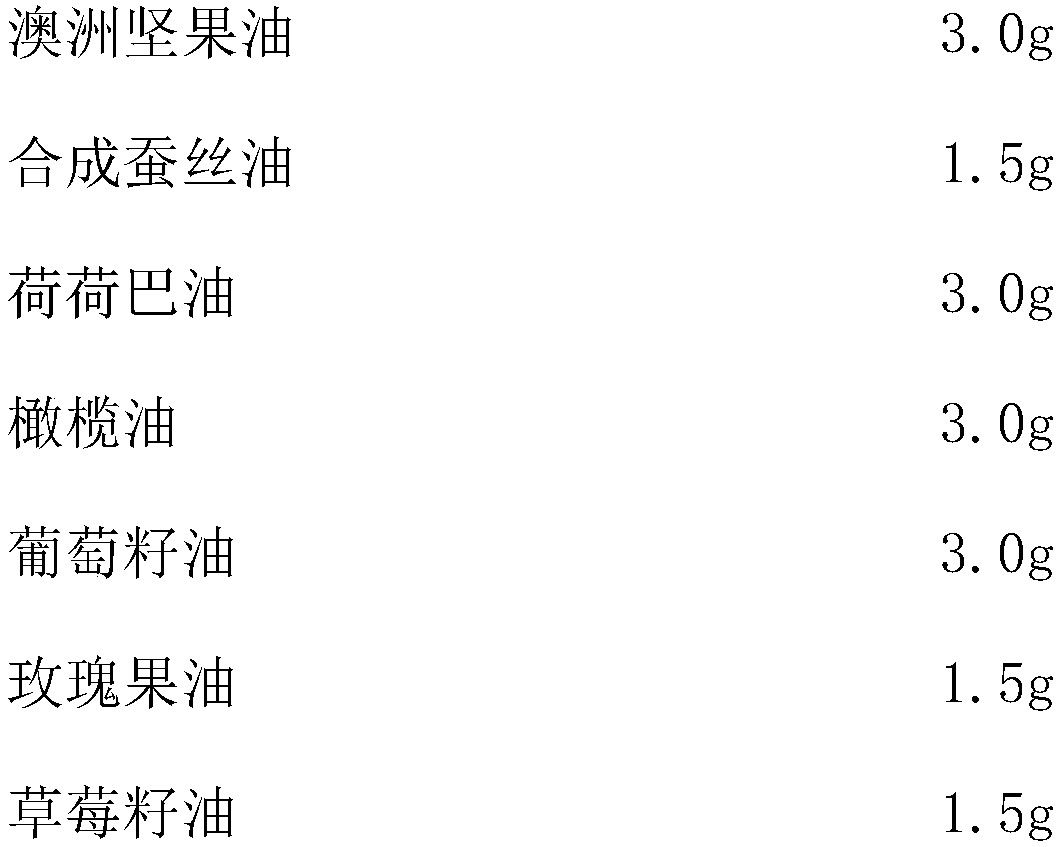

Toxin-free nail-care oil capable of repairing nails and preparation method of toxin-free nail-care oil

ActiveCN107661269AInhibit the production of melaninPrevent dark spotsCosmetic preparationsToilet preparationsChemistryAdemetionine

The invention provides toxin-free nail-care oil capable of repairing nails and a preparation method of the toxin-free nail-care oil. The toxin-free nail-care oil is prepared from the following substances: macadamia nut oil, synthetic silk oil, jojoba oil, olive oil, grape seed oil, rosehip seed oil, strawberry seed oil, meadowfoam seed oil, avocado oil, a rose flower extracting solution, honey, a1 percent sodium hyaluronate solution, glycerol, sodium carboxymethyl cellulose, sodium alginate, distilled water and ethyl 4-hydroxybenzoate. Compared with the prior art, the toxin-free nail-care oilprovided by the invention has stable properties, is moderate, has nourishing and moisture-keeping properties, has no toxin and no harms and is green and natural; the toxin-free nail-care oil can be used for improving a nail structure and nail strength and the elasticity and moisture-keeping degree of nail cuticles and remarkably improving the appearance of nails. Only if one thin layer of the nail-care oil is covered, the nails are bright as if the nails are manicured; meanwhile, the nail-care oil also can be used for nourishing and protecting the nails and protection layers are formed on thesurfaces of the nails to prevent the nails from being invaded by sunlight, so that the surfaces of the nails are smoother and tougher.

Owner:WANNAN MEDICAL COLLEGE

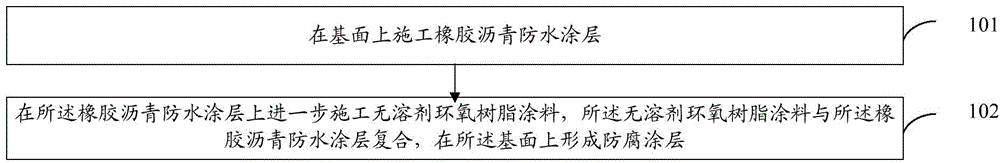

Construction method of novel anticorrosive coating layer

ActiveCN104945991AIncrease shear forceDoes not cause swellingUnspecified rubber coatingsAnti-corrosive paintsSolvent freeResin coating

The invention provides a construction method of a novel anticorrosive coating layer. The method comprises the following steps: constructing a rubber asphalt waterproof coating layer on a base surface; and further constructing a solvent-free epoxy resin coating on the rubber asphalt waterproof coating layer, and compounding the solvent-free epoxy resin coating with the rubber asphalt waterproof coating layer in order to form the anticorrosive coating layer on the base surface. The solvent-free epoxy resin coating comprises a component A and a component B; the component A comprises epoxy resin, an epoxy active diluent, an additive, a filler and a pigment; the component B comprises modified polyamine; the epoxy active diluent is at least one of dodecyl glycidyl ether, 1,4-butanediol diglycidyl ether and ethylene glycol diglycidyl ether; the additive comprises at least one of a leveling agent, a rheological assistant, a dispersant, a substrate wetting agent, an antifoaming agent and an ultraviolet ray absorber; and the filler comprises titanium dioxide, talcum powder, wet sericite powder, wollastonite powder and ceramic powder.

Owner:YUGREAT (BEIJING) INTERNATIONAL TECHNOLOGY CO LTD

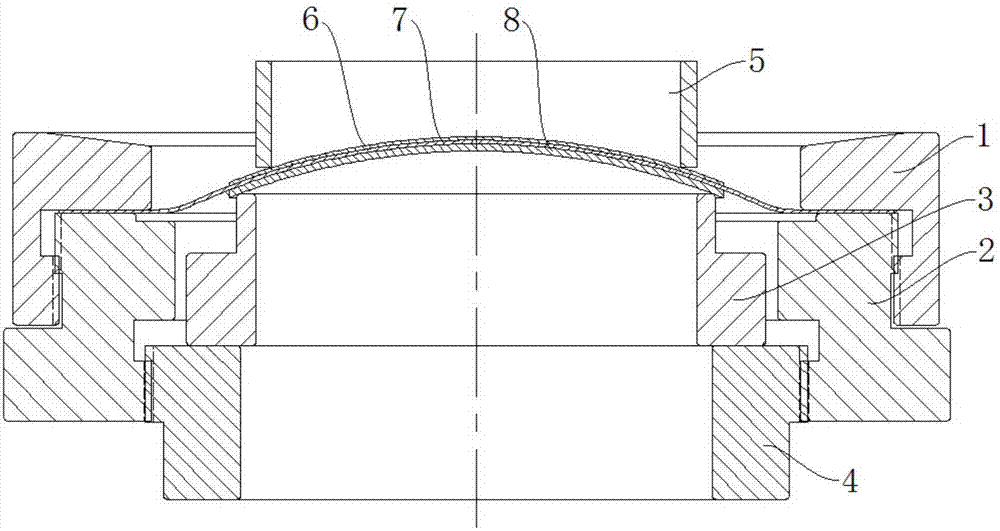

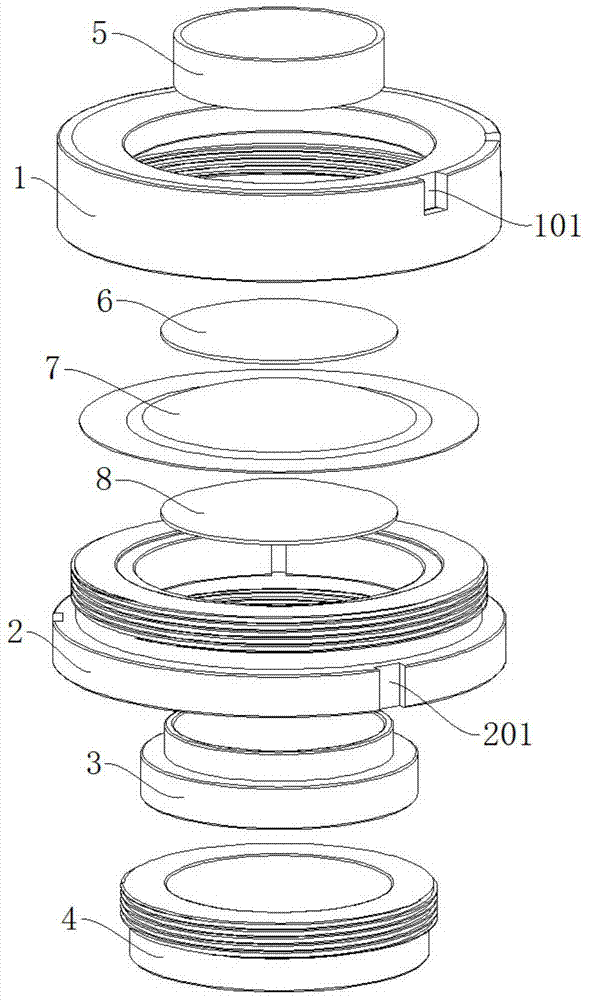

Method and die for manufacturing glass polarizing lens

ActiveCN103885113AReduce manufacturing costSimple molding processPolarising elementsEngineeringThin sheet

The invention discloses a method for manufacturing a glass polarizing light lens, and belongs to the field of lens manufacturing. The method comprises the first step of clamping a polarizing film and heating and humidifying the polarizing film until the polarizing film is softened, the second step of bonding the convex plane of a back glass thin sheet with one face of the polarizing film to enable the curve radian of the polarizing film to be consistent with the radian of the convex plane of the back glass thin sheet and removing dust on the surface of the polarizing film and bubbles between the polarizing film and the back glass thin sheet, the third step of bonding the concave plane of a front glass thin sheet with the other face of the polarizing film and removing the bubbles between the polarizing film and the front glass thin sheet, the fourth step of roasting and solidifying the glass polarizing lens, and the fifth step of cutting the unnecessary polarizing film and carrying out washing and testing. The invention further discloses a die for manufacturing the glass polarizing lens, the forming technology of the glass polarizing light lens is simplified, and the production efficiency and the finished product yield are improved; the special forming die is adopted, and the die is simple in structure, convenient to machine and manufacture and low in cost.

Owner:夏正华

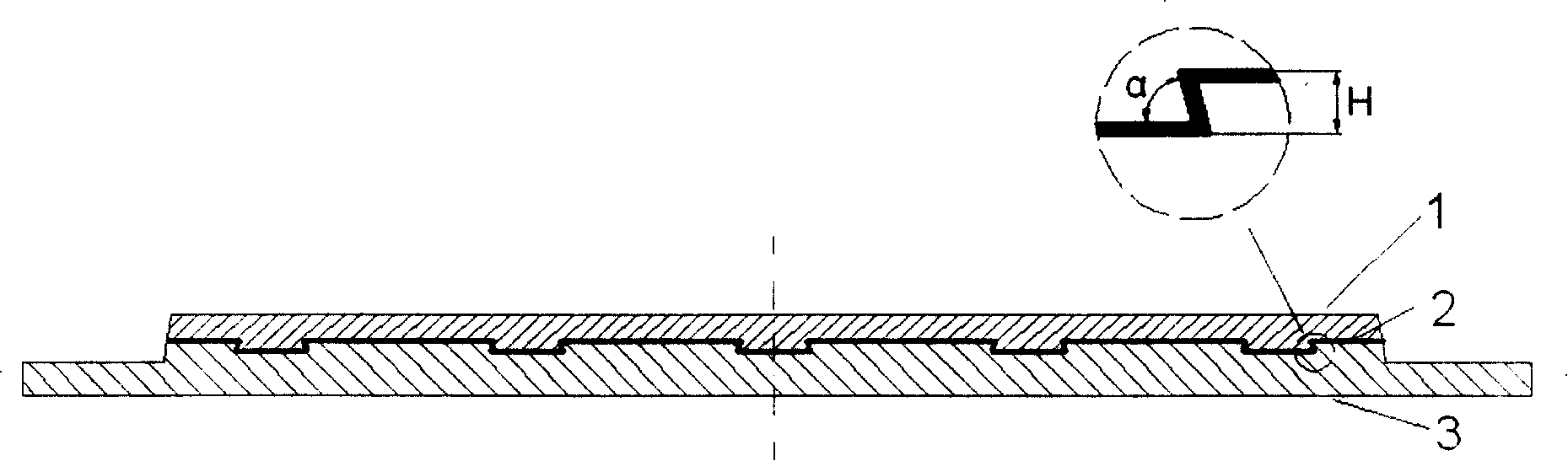

Novel tea knead entwist plate

InactiveCN101700085AReduce generationPrevent getting involvedPre-extraction tea treatmentSEMI-CIRCLESurface roughness

The invention discloses a novel tea knead entwist plate and relates to tea processing machinery parts. The knead entwist plate, an unloading plate and an edge bone are manufactured by adopting a casting method with the purposes of not only lowering the complexity of the technology, but also being convenient for molding, in particular to the molding of the broken tea terrace and the knead entwist area with an inclined angle. The knead entwist area with an inclined angle is in match with the edge bones which are arranged in a radiation shape, and the shape that the end of the edge bone close to the knead entwist plate is higher and the end close to the edge thereof is lower is beneficial for the separation of broken tea and mature tea, can improve stripping tea rate and can also reduce the generation of broken tea; the casting pieces have higher surface roughness and greater friction force, thus being beneficial for the improvement of knead entwist stripping tea rate. The section of the edge bone is approximately a semi circle, then in the processing of kneading and entwisting tea, the force transits smoothly, the kneading and entwisting and rolling speed of tea is even, and broken tea is not easy to generate, and the effect is particularly obvious in the central area in which the edge bone is higher and the tea rolls more frequently.

Owner:WUFENG TIANCHI TEA MACHINERY

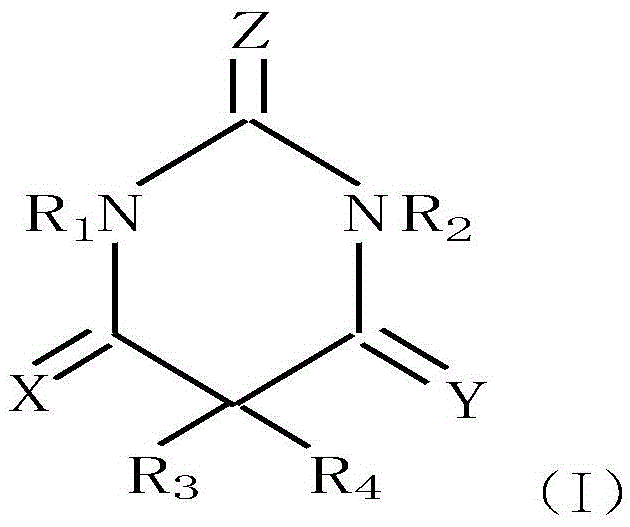

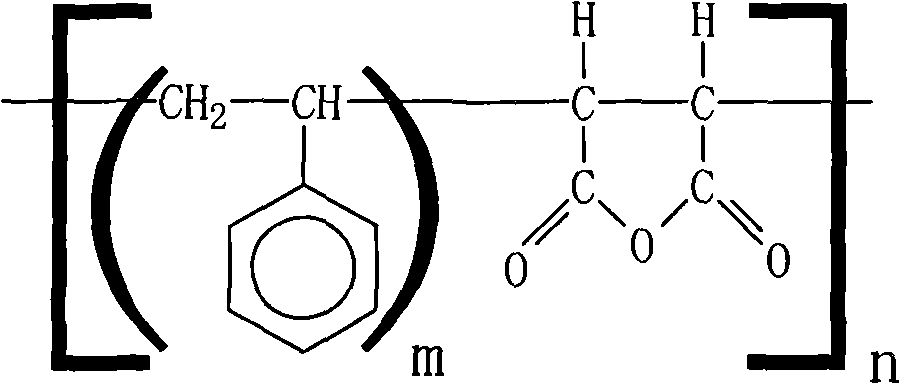

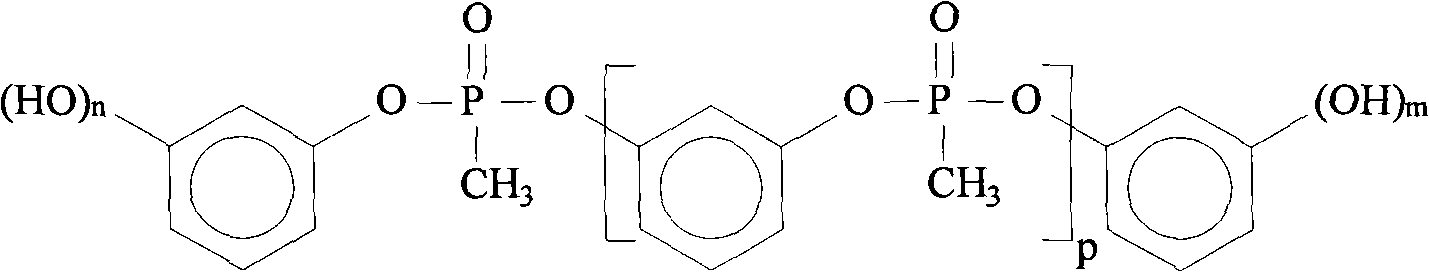

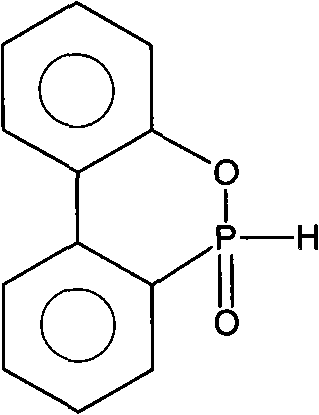

Halogen-free fire resistance epoxy resin composite as well as prepreg material and printed circuit board therefrom

ActiveCN102250447AGood solder dip resistanceAvoid brittle problemsCircuit susbtrate materialsMetal layered productsPhosphoric acidEpoxy resin composite

The invention discloses a halogen-free fire resistance epoxy resin composite comprising halogen-free epoxy resin (a), styrene-maleic anhydride copolymer (b) serving as a hardening agent, polymethyl methacrylate phosphoric acid 1,3-phenylene ester (c) serving as a fire retardant, a hardening accelerator (d) and an inorganic filling agent (e).

Owner:TAIWAN POWDER TECH CO LTD

High-chromium wear-resistant steel ball and preparation method thereof

InactiveCN106191703AIncrease temperatureToughness to avoidFurnace typesHeat treatment furnacesWear resistantSteel ball

The invention discloses a high-chromium wear-resistant steel ball. The high-chromium wear-resistant steel ball comprises, by weight percentage, 1-1.5% of C, 0.5-0.7% of Si, 1.2-1.4% of Mn, 12-14% of Cr, 0.03-0.05% of Ni, 0.1-0.12% of Mo, 0.1-0.3% of W, 0.08-0.1% of Al, 0.1-0.2% of Cu, 0.003-0.004% of B, 0.02-0.03% of Ti, 0.2-0.3% of Nb, 0.15-0.2% of V, not larger than 0.2% of P, not larger than 0.01% of S and the balance Fe, wherein the expression of Nb+10.3(C / Cr)<1.55% is met. The invention further discloses a preparation method of the high-chromium wear-resistant steel ball. The high-chromium wear-resistant steel ball and the preparation method have the beneficial effects that wear resistance is good and toughness is high.

Owner:ANHUI RUITAI NEW MATERIALS TECH

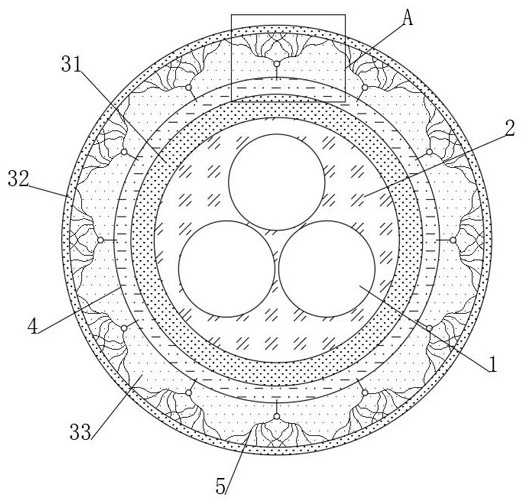

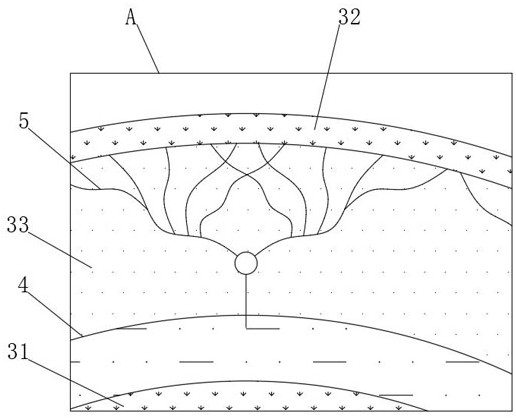

Tip self-heating type anti-freezing self-repairing cable

PendingCN112435792AReduce the probability of crackingExtended service lifeClimate change adaptationInsulated cablesEngineeringElectric cables

The invention discloses a tip self-heating type anti-freezing self-repairing cable, and belongs to the field of cables. The tip self-heating type anti-freezing self-repairing cable is characterized inthat in winter, under the condition of low temperature, through self-heating repairing particles, on one hand, self-cracking water balls in the self-heating repairing particles are solidified at lowtemperature and are gradually dissolved when the midday air temperature rises again, under the alternating of continuous thermal expansion and cold contraction, deionized water in the self-cracking water balls overflows and reacts with the self-heating repairing particles to generate heat, so that the surface of the cable has a certain temperature, and the cracking probability of the cable due toembrittlement in winter is further effectively reduced; and on the other hand, when the cable is locally damaged, capillary dispersion bundles transport a repair glue solution to the damaged part to simulate the incrustation phenomenon of the skin broken part, the effect of fixed-point coagulation repair of the damaged part is achieved, the service life of the tip self-heating type anti-freezing self-repairing cable can be effectively prolonged, meanwhile, the situation that a wire core is accidentally exposed can be effectively avoided, and compared with the prior art, the potential safety hazard is remarkably reduced.

Owner:高双兵

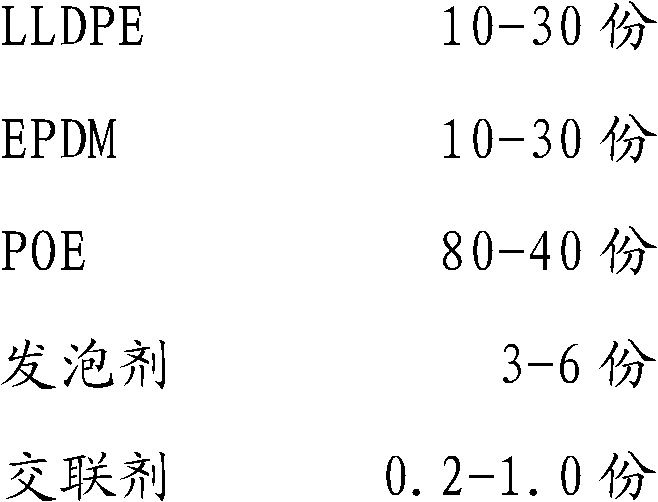

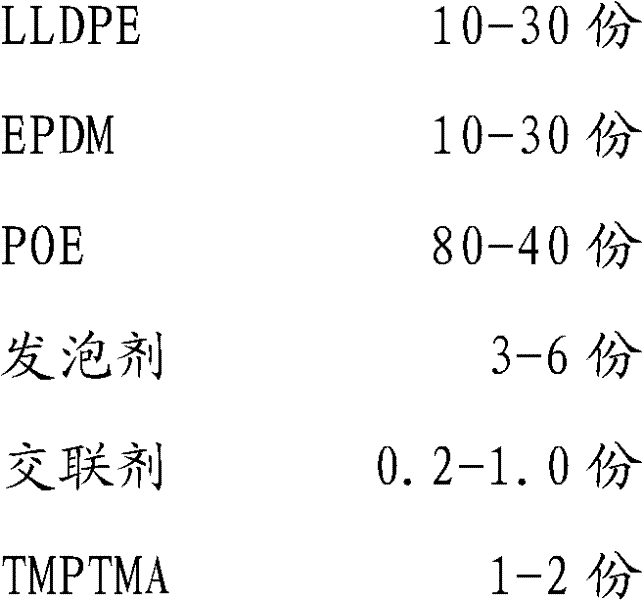

PP foaming composite additive

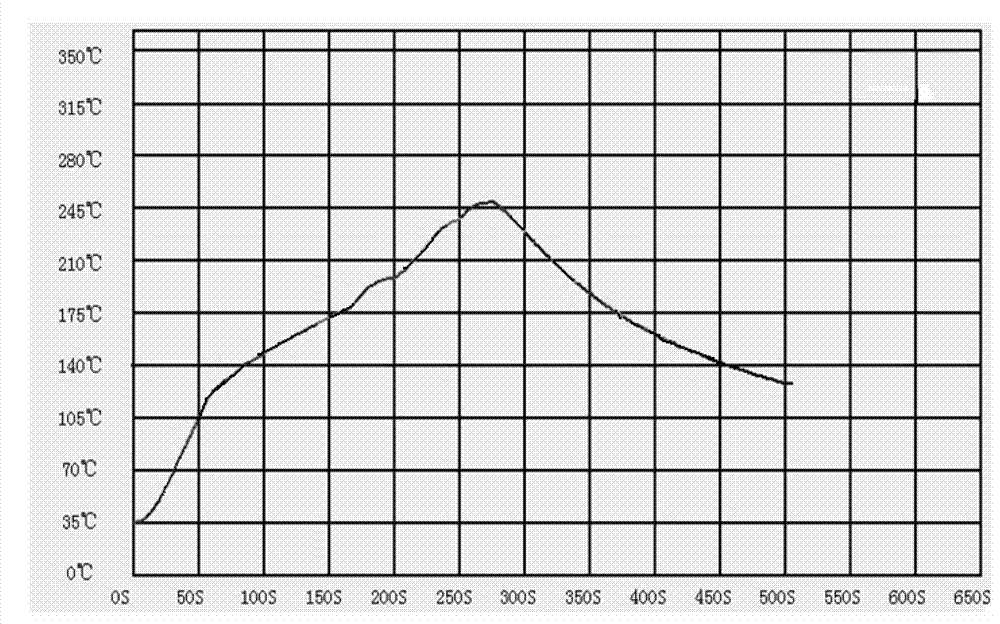

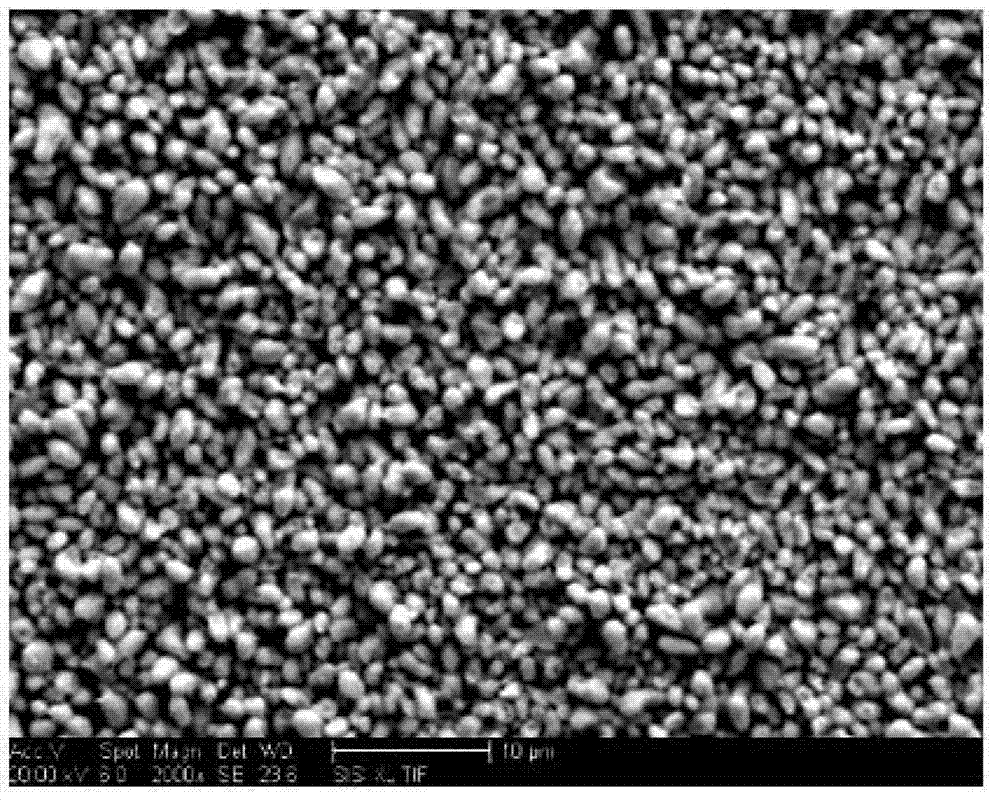

The invention discloses a PP foaming composite additive, which comprises the following raw materials by weight: 10-30 parts of LLDPE, 10-30 parts of EPDM, 80-40 parts of POE, 3-6 parts of foaming agent, 0.2-1.0 part of cross-linking agent, 1-2 parts of TMPTMA, 0.2-1.0 part of nano zinc oxide; PP enables a rapid degradation while crosslinking foaming, the TMPTMA is taken as a crosslinking auxiliary agent which effectively increases the crosslinking speed, meanwhile, a reactivity reaction is generated between the crosslinking and degrading of PP, and the crosslinking speed is greater than degradation speed. The speed for decreasing the PP melt-strength is alleviated which is beneficial to ideal foaming of PP, in addition, bubble strength and uniformity can be increased by adding nano zinc oxide, and the reaction process can be accelerated, the crosslinking temperature of the cross-linking agent can be reduced, the heat transfer and the crosslinking degree can be increased, the composite additive is benefit for harmless degradation, recovery and treatment of waste PP foaming plastics.

Owner:HUAQIAO UNIVERSITY

Lead-free solder for electronic packaging

InactiveCN102962599AHigh melting pointImprove wettabilityWelding/cutting media/materialsSoldering mediaElectronic packagingMechanical property

The invention relates to a lead-free solder for electronic packaging. The invention solves the technical problems that: the cost of the conventional high-silver solder is higher, and the mechanical property of the conventional low-silver solder is poor. According to percentage by weightmass, the lead-free solder for electronic packaging is composed of Ag, Cu, Ni, Bi, Sb, Ti and the balance of Sn. By designing and optimizing the solder ingredients, the lead-free solder for electronic packaging, which has excellent properties and is low in cost, is obtained. The addition of a variety of elements takes the complementation between the elements into consideration, consequently, while the properties of a certain element are improved, the other adverse affection is reduced, and thereby therefore the comprehensive properties of the solder are effectively enhanced.

Owner:HARBIN UNIV OF SCI & TECH

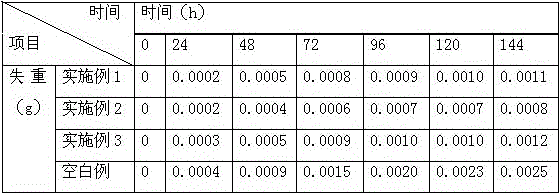

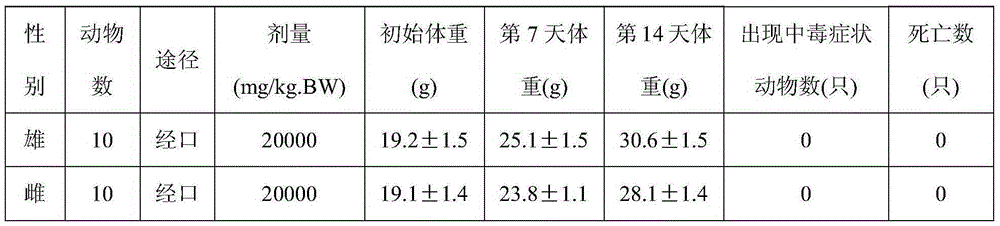

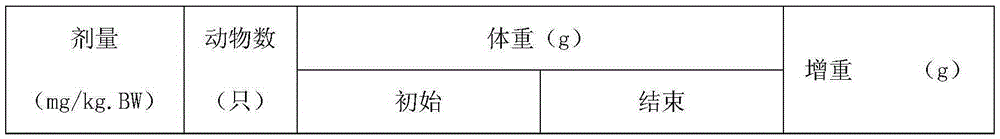

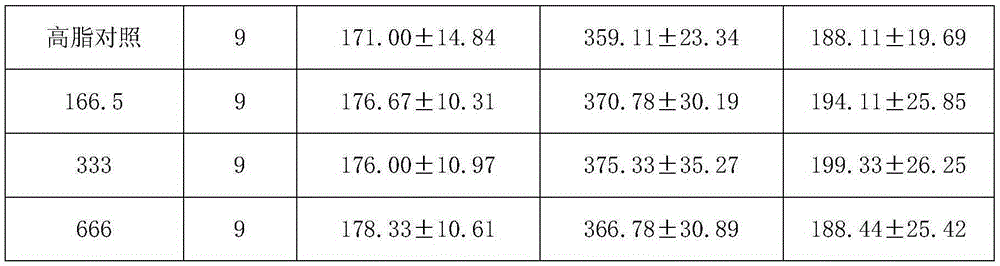

Unsaturated fatty acid dietary supplement and preparing method thereof

InactiveCN105412227AAvoid brittlePrevent hardeningSenses disorderNervous disorderDietary supplementAdditive ingredient

The embodiment of the invention discloses an unsaturated fatty acid dietary supplement. The unsaturated fatty acid dietary supplement is mainly prepared from 5-30 parts of krill oil, 30-100 parts of fish oil and 5-20 parts of chia oil. The invention provides a preparing method for the unsaturated fatty acid dietary supplement. The preparing method comprises the steps of glue liquor preparing, pill pressing, setting, drying and final product obtaining in sequence. According to the unsaturated fatty acid dietary supplement, the three effective ingredients supplement one another, the effect of unsaturated fatty acid is given into full play, the unsaturated fatty acid is well absorbed by the human body, and the efficacy is improved. The preparing method is easy to operate, convenient, safe, efficient and suitable for industrialized popularization, and saves energy.

Owner:北京世纪合辉医药科技股份有限公司

High-temperature protection layer

InactiveUS7052782B2Resistance to oxidation and corrosion is significantly improvedAvoid brittleContinuous combustion chamberMolten spray coatingProtection layerImpurity

A high-temperature protection layer contains (% by weight) 23 to 27% Cr, 4 to 7% Al, 0.1 to 3% Si, 0.1 to 3% Ta, 0.2 to 2% Y, 0.001 to 0.01% B, 0.001 to 0.01% Mg and 0.001 to 0.01% Ca, remainder Ni and inevitable impurities. Optionally, the Al content is in a range from over 5 up to 6% by weight.

Owner:ANSALDO ENERGIA IP UK LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com