Novel printed product gloss oil

A printed matter and a new type of technology, applied in the field of printing, can solve the problems of complex process of benzene-propylene-silicon copolymer emulsion, increase in waterproofness and adhesion, and poor adhesion of printed matter, so as to increase the adhesion effect, enhance the adhesion performance, The effect of increased protein cross-linking properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

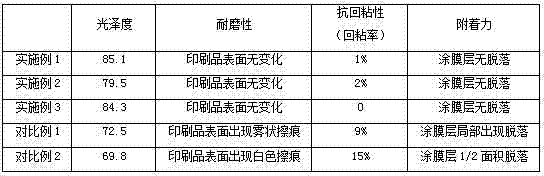

Examples

Embodiment 1

[0023] A new printing varnish is composed of the following raw materials in percentage by weight: 50% water-soluble acrylic epoxy resin; 6% mussel mucin, 5% calcium acetate, 10% methyl acrylate; 28% ethanol; Agent 1% (leveling agent: alkyl modified organosiloxane; defoamer: polyoxyethylene polyoxypropanolamine ether; dispersant: acrylic acid amide; brightener: organosiloxane; plasticizer: o phthalates).

[0024] The preparation method of above-mentioned novel printed matter varnish specifically comprises the following steps:

[0025] (1) Synthesis of water-based coating resin: Slowly add 16g of acrylic acid to 41g of epoxy resin dropwise at 50°C, adjust the stirring speed to 150r / min, wait until the temperature is evenly stirred to 102°C to speed up the reaction, and the acid value is less than 5mgKOH When the temperature is lowered to 55°C, add 21g of maleic anhydride and 1g of acetone, stir evenly at a medium speed of 200r / min, then heat up to 90°C, and cool down naturally ...

Embodiment 2

[0029] A new printing varnish is composed of the following raw materials in weight percentage: 50% water-soluble acrylic epoxy resin; 6% mussel mucin, 3% calcium acetate, 20% methyl methacrylate; 19% ethanol; Functional additive 2% (leveling agent: carboxymethyl cellulose; defoamer: polysiloxane; dispersant: sodium lauryl sulfate; brightener: organosiloxane; plasticizer: phthalate formic acid diester).

[0030] The preparation method of this novel printed matter varnish is the same as in Example 1.

Embodiment 3

[0032] A new printing varnish, which is composed of the following raw materials in weight percentage: 40% water-soluble acrylic epoxy resin; 7% mussel mucin, 4% calcium acetate, 8% methyl acrylate, 8% methyl acrylate %; ethanol 30%; functional additives 3% (leveling agent: alkyl modified organosiloxane and carboxymethyl cellulose; defoaming agent: polyoxyethylene polyoxypropanolamine ether and polysiloxane; Dispersants: Acrylamide, Sodium Lauryl Sulfate, and Methylamyl Alcohol; Brightener: Organosiloxane; Plasticizer: Diester Phthalate).

[0033] The preparation method of this novel printed matter varnish is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com