Novel tea knead entwist plate

A technology for rolling discs and tea leaves, which is applied in the field of new tea rolling discs, which can solve the problems of difficult separation of broken tea and finished tea, low yield of tea leaves, and unreasonable setting of ribs, etc., so as to reduce the complexity of the process and facilitate rolling Yield, easy collection and processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

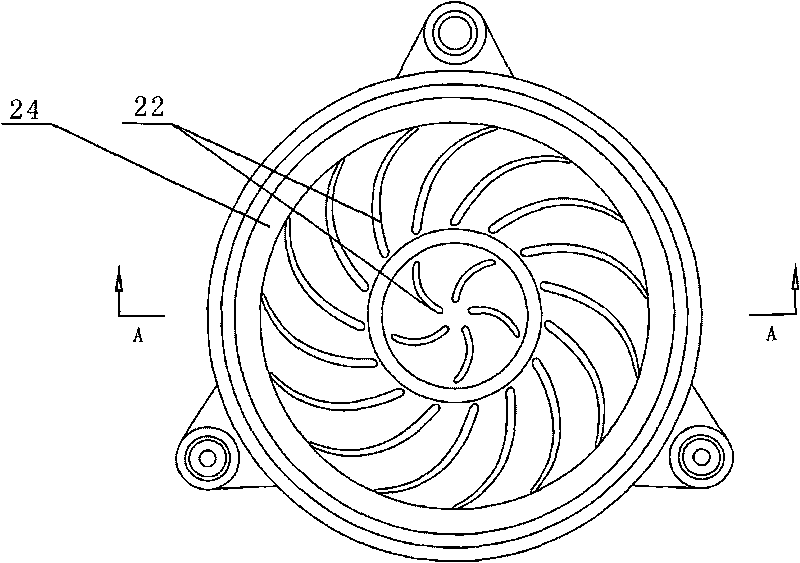

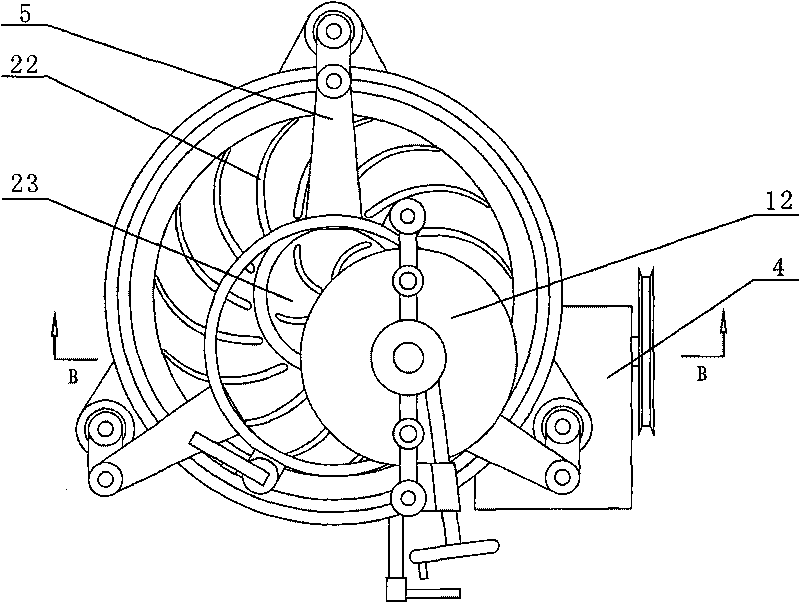

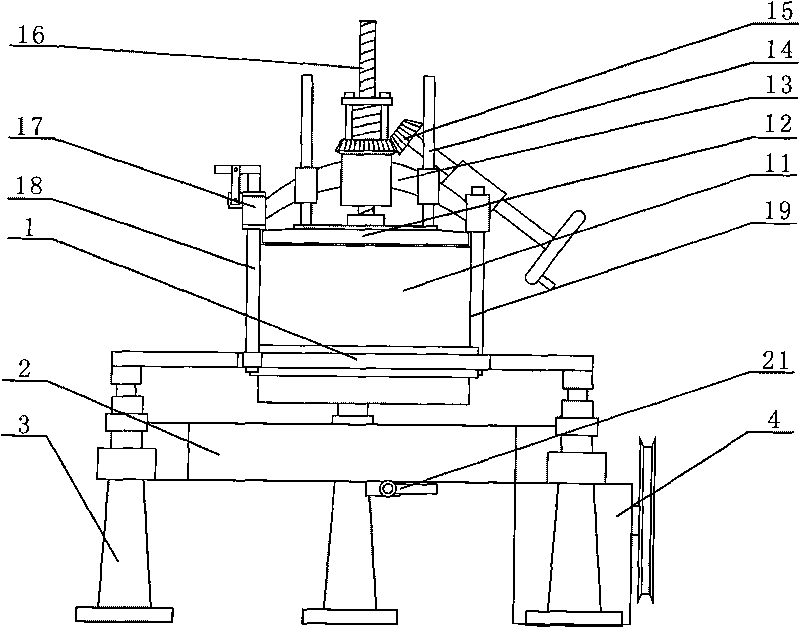

[0024] Such as figure 1 , figure 2 , image 3 with Figure 4 Among them, a new type of tea rolling plate, the rolling plate 2 is divided into a crushed tea platform 24 and a rolling area 25, the angle between the rolling area 25 and the horizontal plane is 3°-8°, and the middle of the rolling plate 2 is provided with a discharge plate 23, The discharge tray 23 is connected with the discharge switch 21, and the kneading tray 2 and the discharge tray 23 are provided with a plurality of ribs 22.

[0025] The ribs 22 are arranged on the kneading disc 2 and the discharge disc 23 radially in an arc.

[0026] One end of the rib 22 close to the center of the discharge tray 23 has a higher height, while the other end has a lower height.

[0027] Such as Figure 5 Among them, the cross section of the rib 22 is nearly semicircular, and the nearly semicircular here means that viewed from the cross section, the top end is an arc-shaped curve, and the bottom end is a straight line.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com