Patents

Literature

443results about How to "Prevent getting involved" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

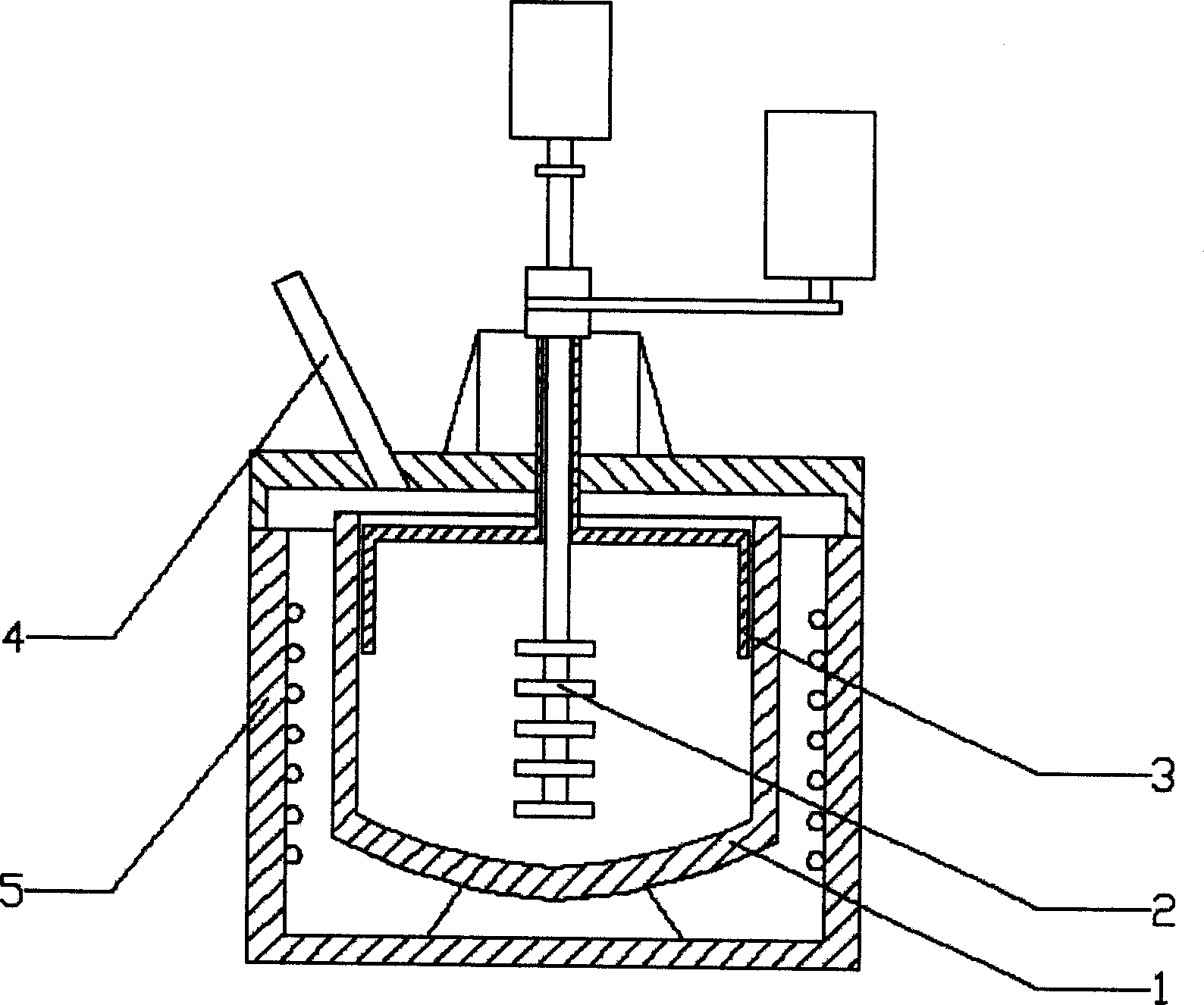

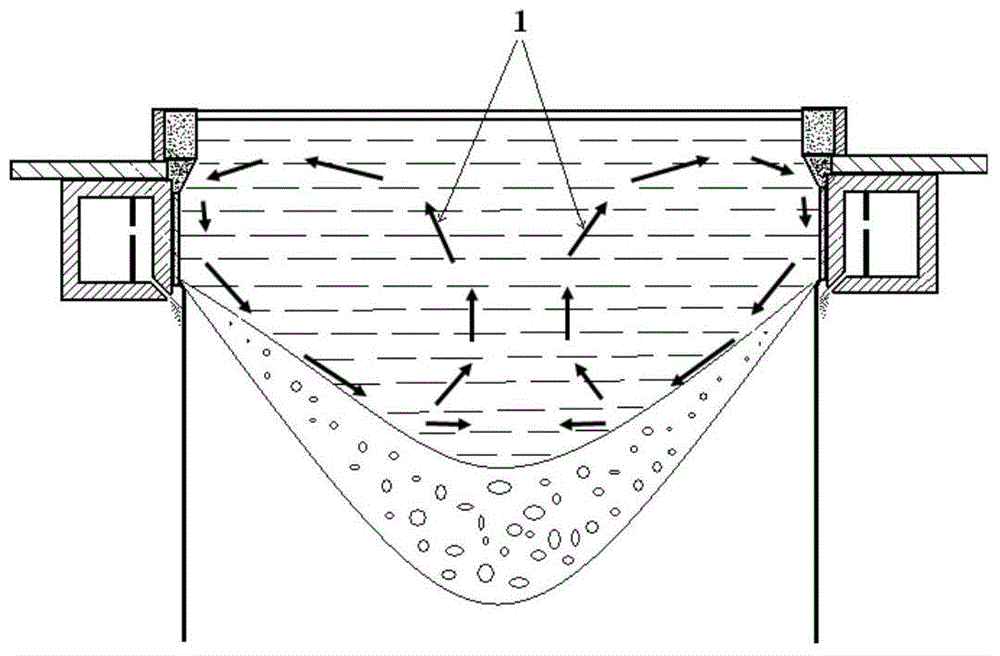

Vacuum mechanical dual-stirring casting method for preparing granule reinforced aluminium-base composite material

The present invention relates to a vacuum mechanical double-stirring casting method for preparing granule reinforced aluminium base composite material. Said method includes the following steps: melting and purifying aluminium material, cooling and deslagging; under the condition of vacuum reverse slowly internal stirring to implement degassing process, adding the pretreated reinforcing granules onto the deslagged aluminium liquid surface, internal and external forward simultaneously stirring, mixing the reinforcing granules into the melt, stoping external stirring, under the condition of retaining stable liquid surface high-speed internal stirring so as to make the reinforcing granules be uniformly distributed in the liquid, heating, internal and external reverse double stirring and slowly rotating to implement degassing; adding alternant and fining agent, internal stirring slowly rotating so as to make them be mixed into melt and uniformly distributed, removing vacuum, tapping and casting to obtain ingot casting.

Owner:BEIJING JIAOTONG UNIV

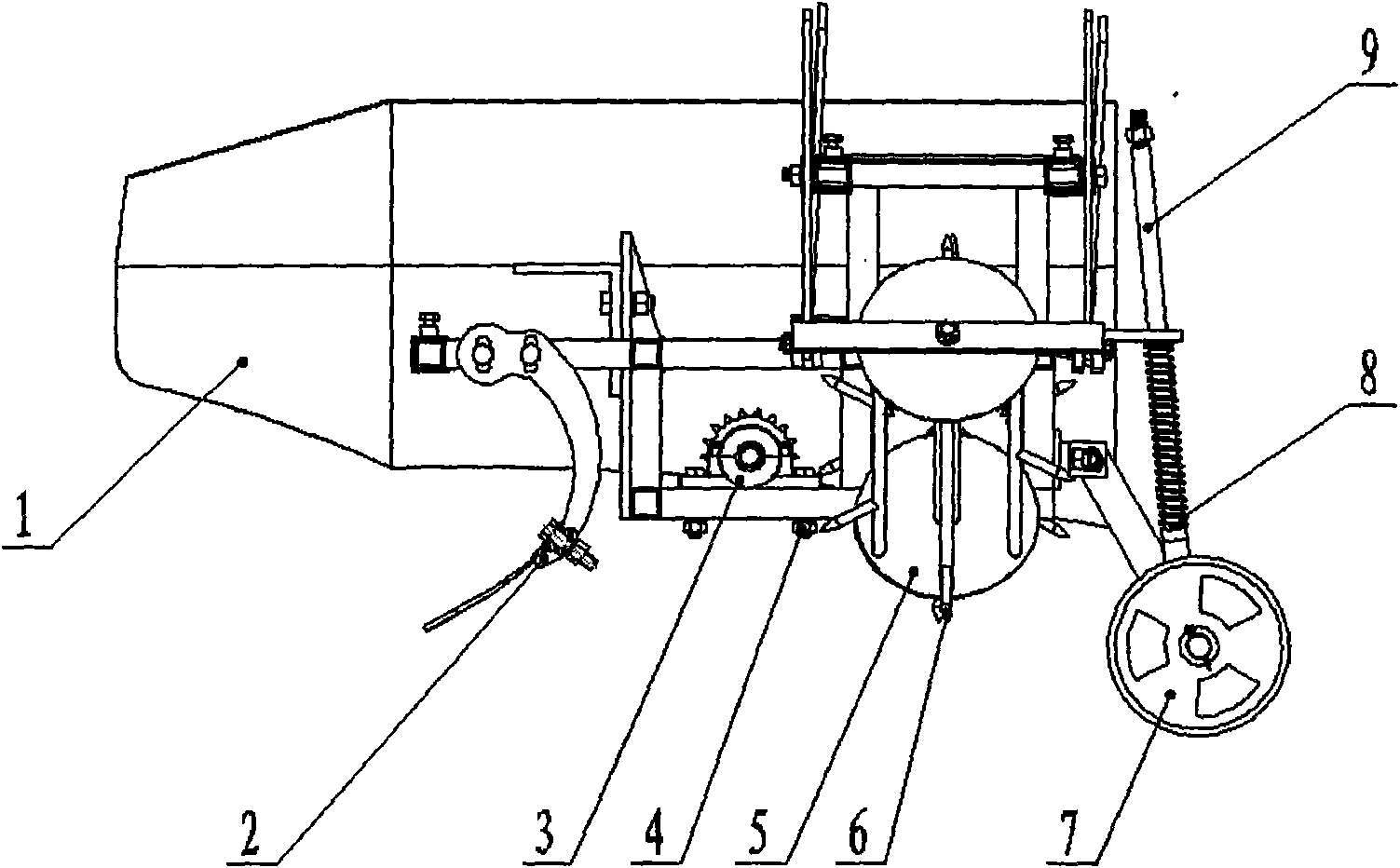

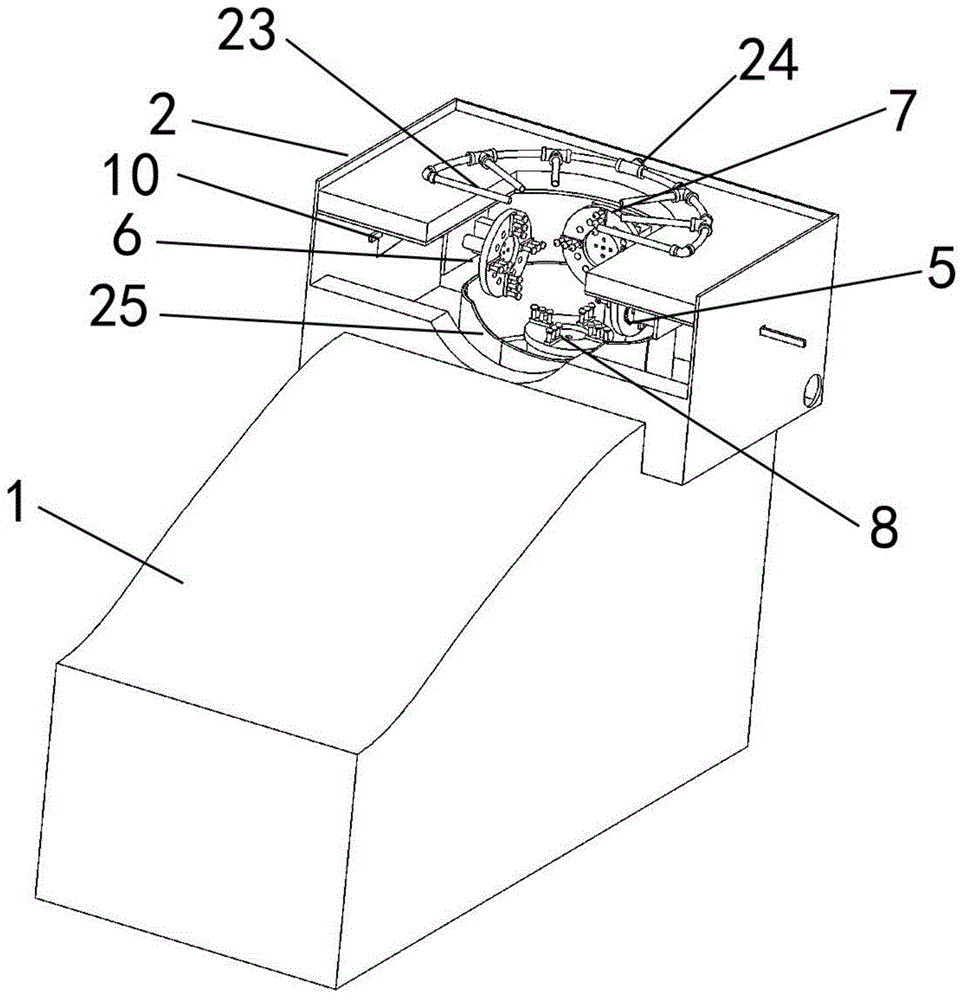

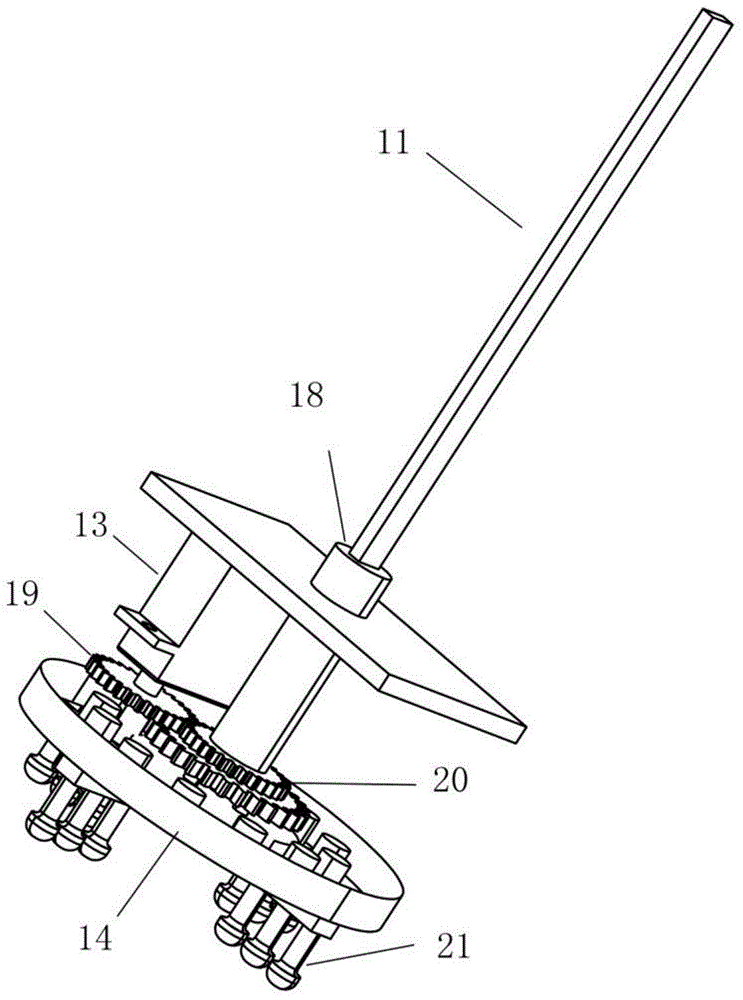

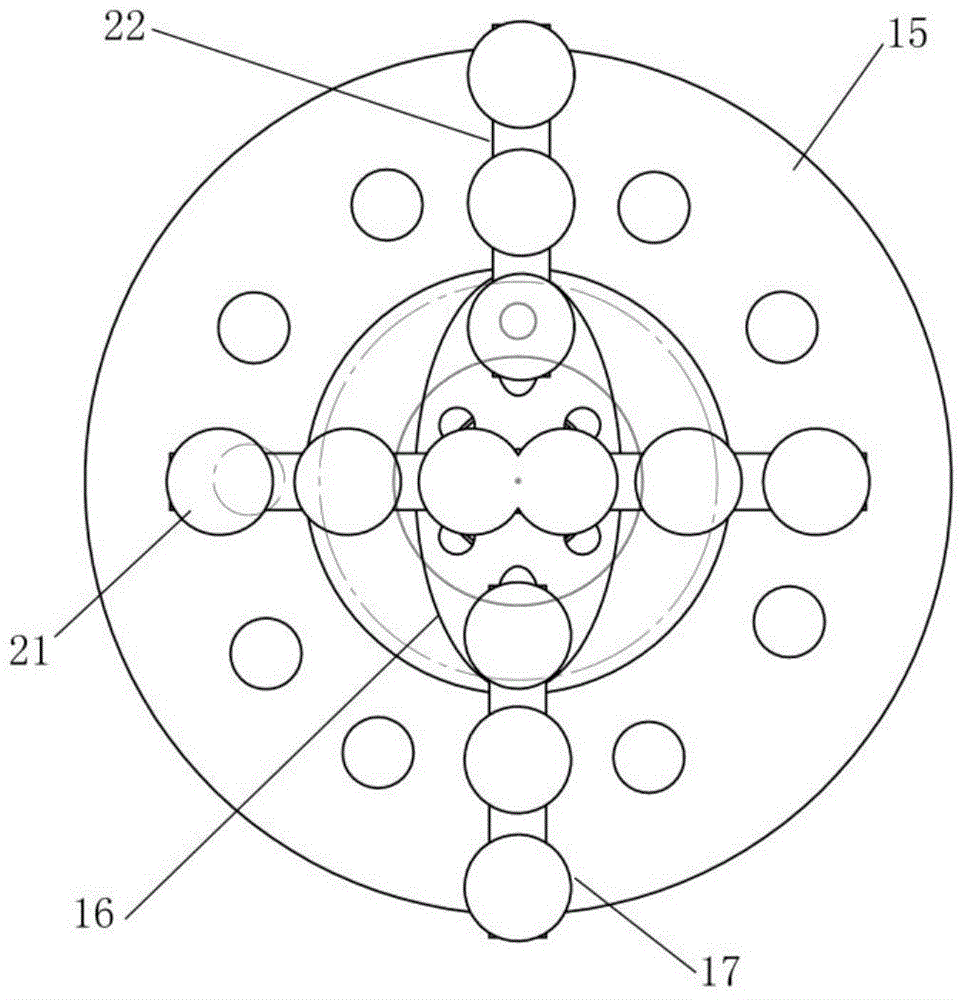

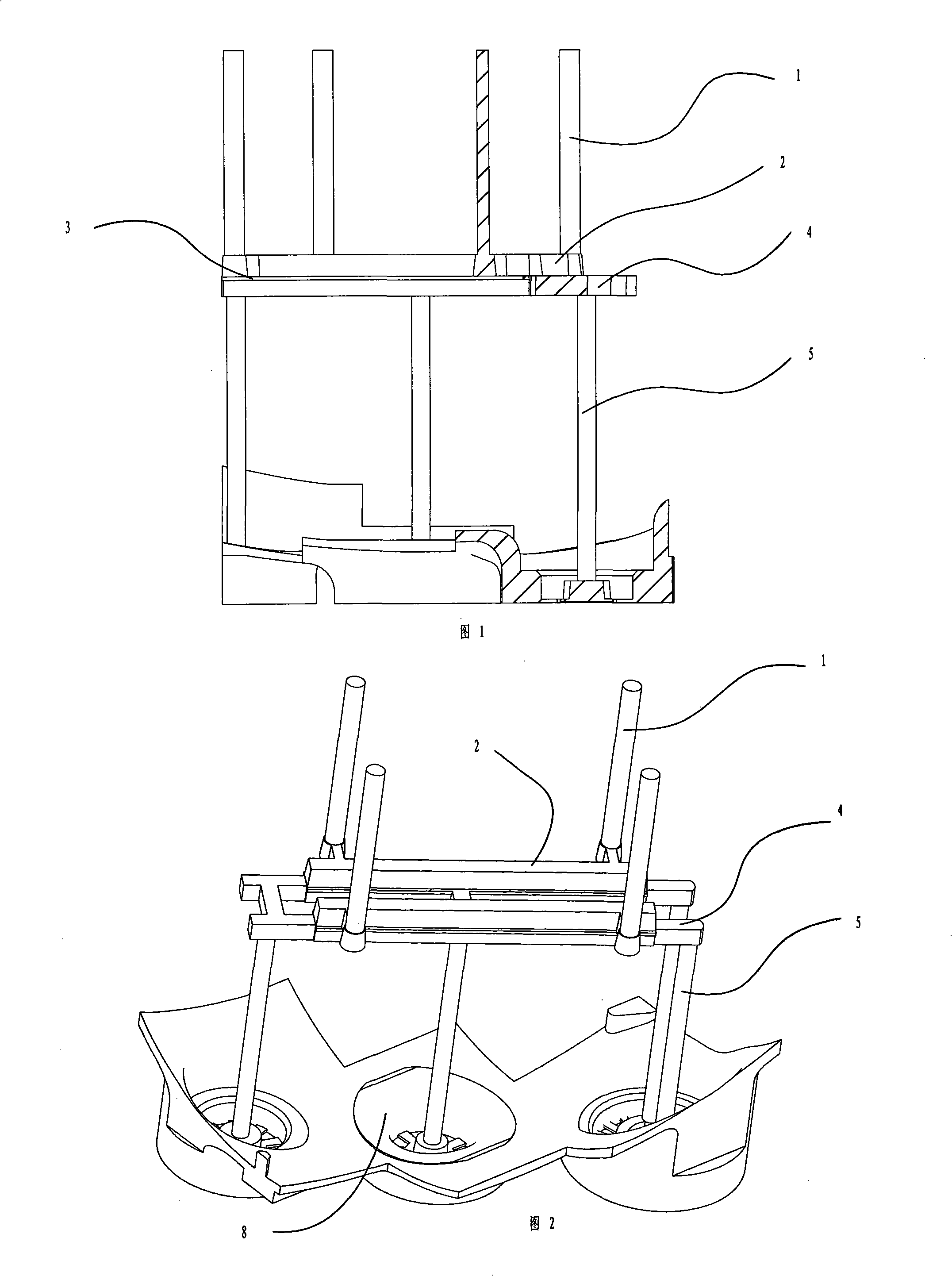

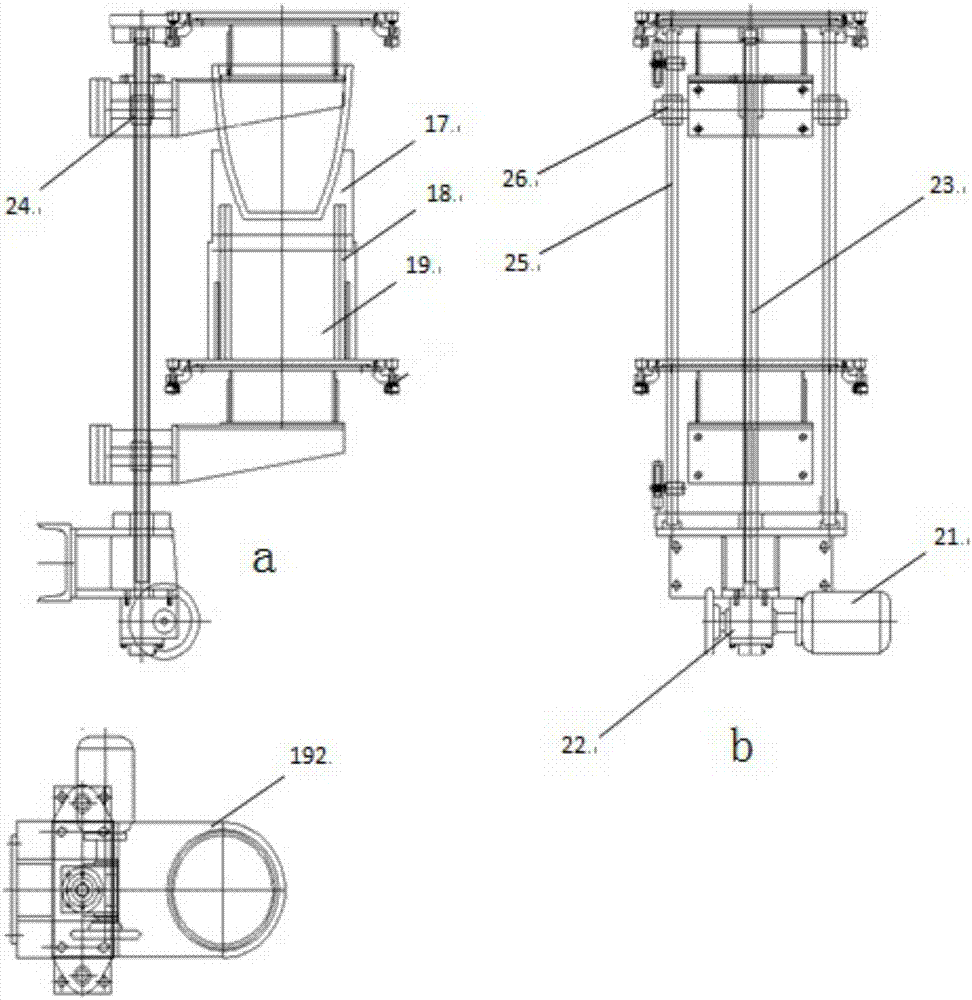

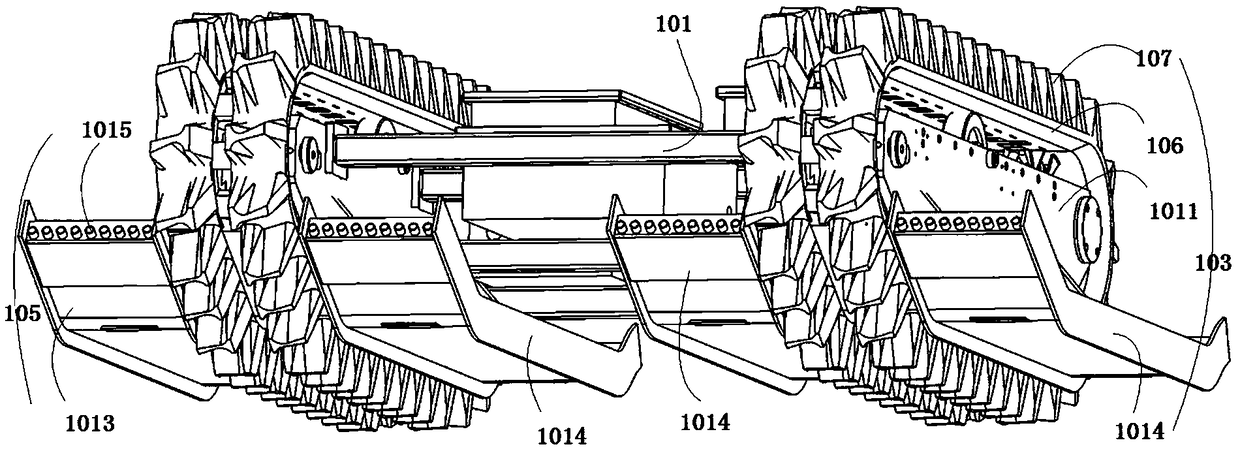

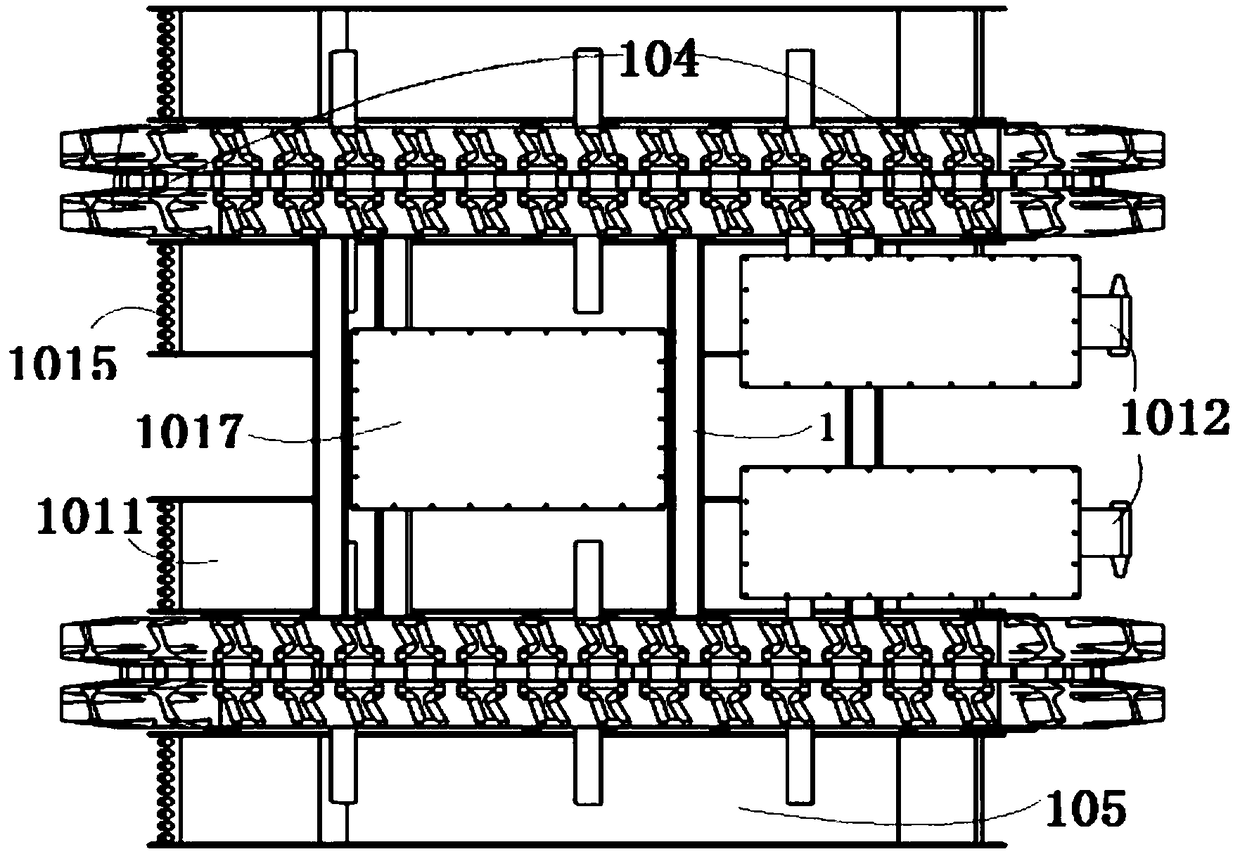

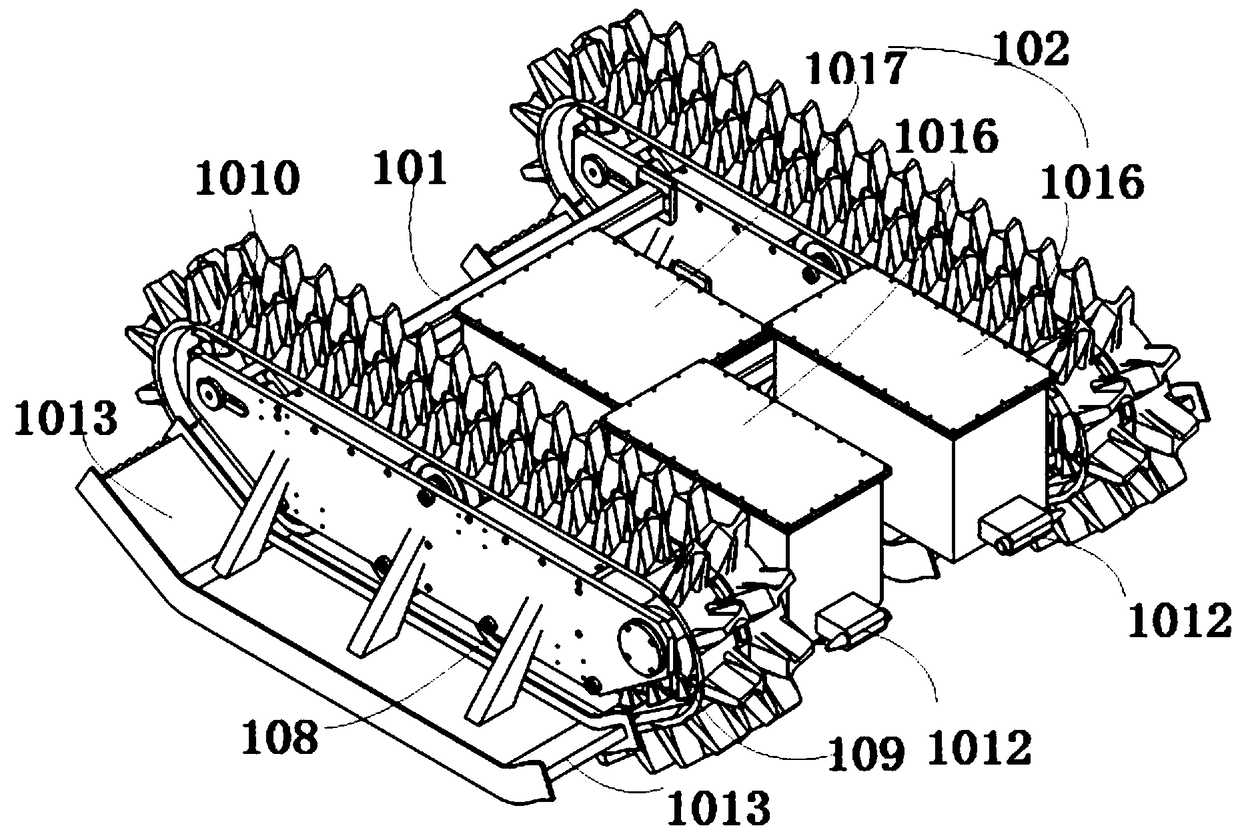

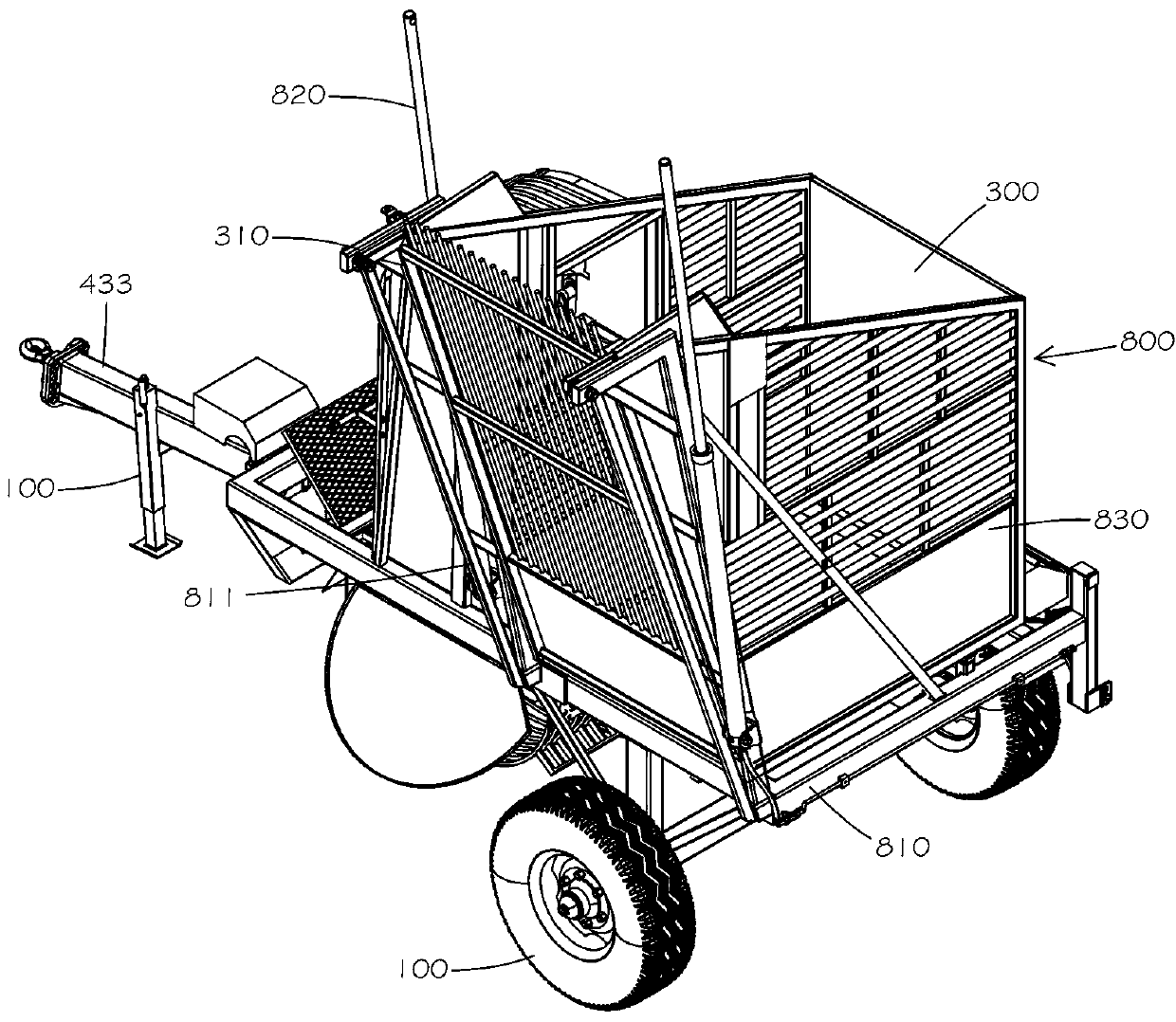

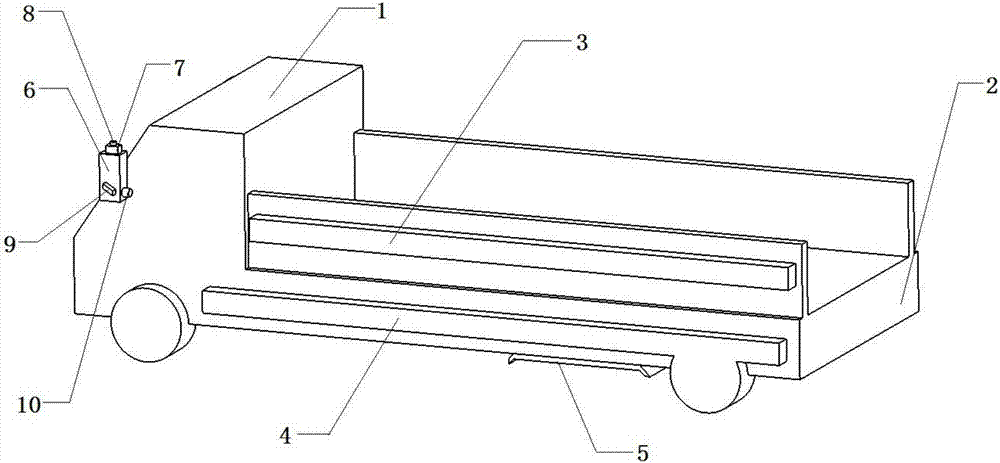

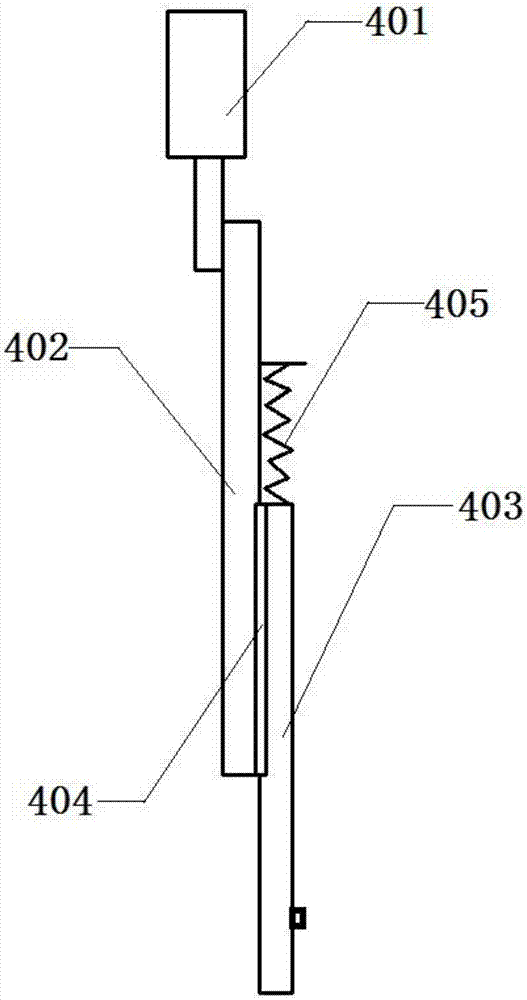

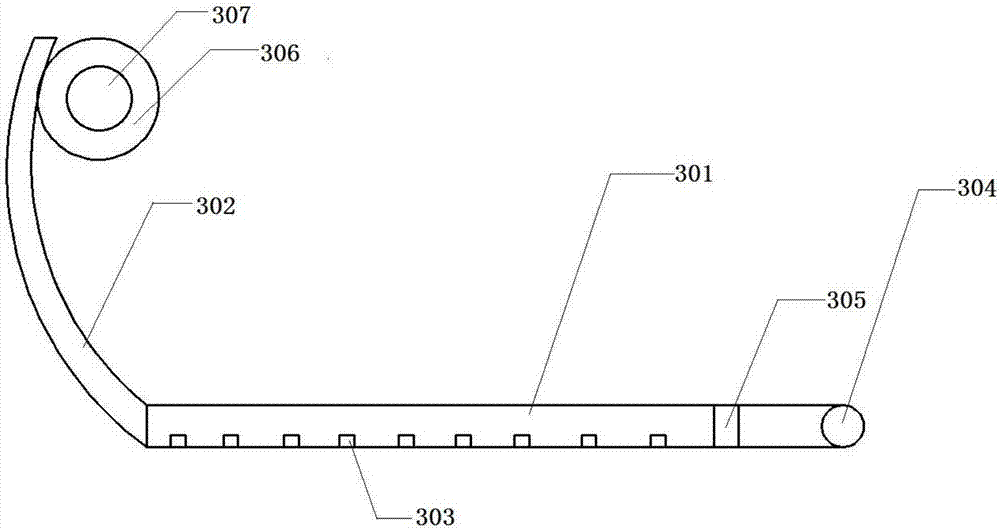

Mini type mulching film recovery machine of tobacco in seedling stage

InactiveCN101658087ASolve the problem of working at a height that cannot enter the groundSolve the problem of profiling and picking filmGatherer machinesDrive wheelGear wheel

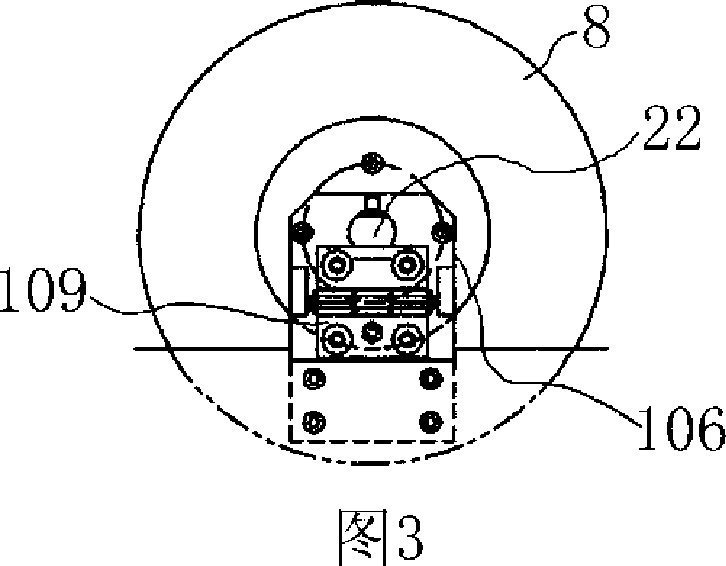

The invention relates to a mini type mulching film recovery machine of tobacco in seedling stage, which mainly comprises a seedling protective plate (1), a depth limiting land wheel (7), a break shovel (2), a stander (11), a large chain wheel (13), a small chain wheel (17), a gear wheel (18), a pinion (22), a film rolling roll (15), a universal joint (16), a position horizontal adjusting rod (20)of the film rolling roll and an angle vertical adjusting rod (25) of the film rolling roll. The gear wheel (18) and the pinion (22) are meshed to make the film rolling roll (15) and a driving wheel toreversely rotate to roll the film, so earth rolling is avoided; the inclined angle of the film rolling roll (15) can be adjusted by the universal joint (16), the angle vertical adjusting rod (25) ofthe film rolling roll and the position horizontal adjusting rod (20) of the film rolling roll according to the inclined angle of a tobacco ribbing surface; and the film rolling roll (15) is always well attached to the inclined plane of tobacco ribbing by the depth limiting land wheel (7) under the action of a depth limiting spring (8). The small tobacco seedling stage mulching recovery machine isused for recovering mulching films of seedling-stage tobacco planted in ridge culture, belongs to field tending machinery and is also suitable for recovering mulching films of cotton and other flat planting crops.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

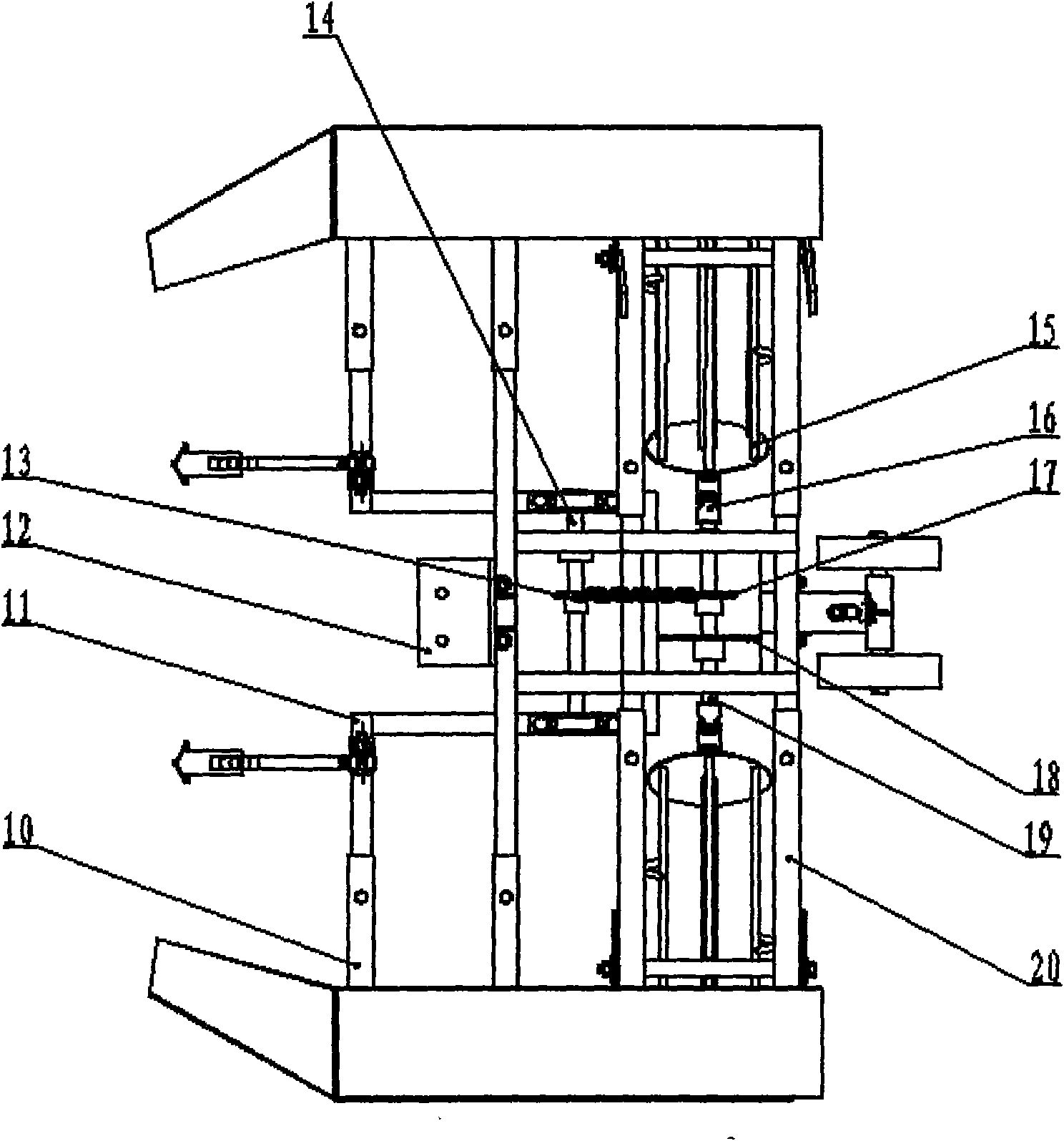

Automatic hair washing machine

InactiveCN104544883AClean upEasy to lie downTravelling articlesHair cleaningRemote controlControl system

The invention relates to an automatic hair washing machine, which comprises a bed body and a hair washing component, a remote control device and a control system; the hair washing component comprises a head left side care component, a head right side care component, a head top care component, a head back care component, a shell and an infrared distance measurement sensor; the care components respectively comprise a cross bar, a steering engine and a care face; each steering engine is fixedly arranged on the corresponding cross bar provided with a ball head structure; each care face comprises a finger plate, a cam and massage finger assemblies; the massage finger assemblies are arranged on the corresponding finger plate; each cam is located at the central position of the corresponding finger plate and is fixed to the corresponding cross bar; the head left side care component and the head right side care component also respectively comprise a stepping motor, so that the head left side care component and the head right side care component can move back and forth along the horizontal direction; the infrared distance measurement sensor is used for controlling the hair washing machine to automatically turn on, and the head form of a user is detected, and proximate head form parameters in a database are called by the control system; the remote control device can be used for controlling outflow water, outflow liquid shampoo, and the motion of the finger plates. The automatic hair washing machine disclosed by the invention is high in degree of automation, omnidirectional and is high in practicability.

Owner:翁凯 +1

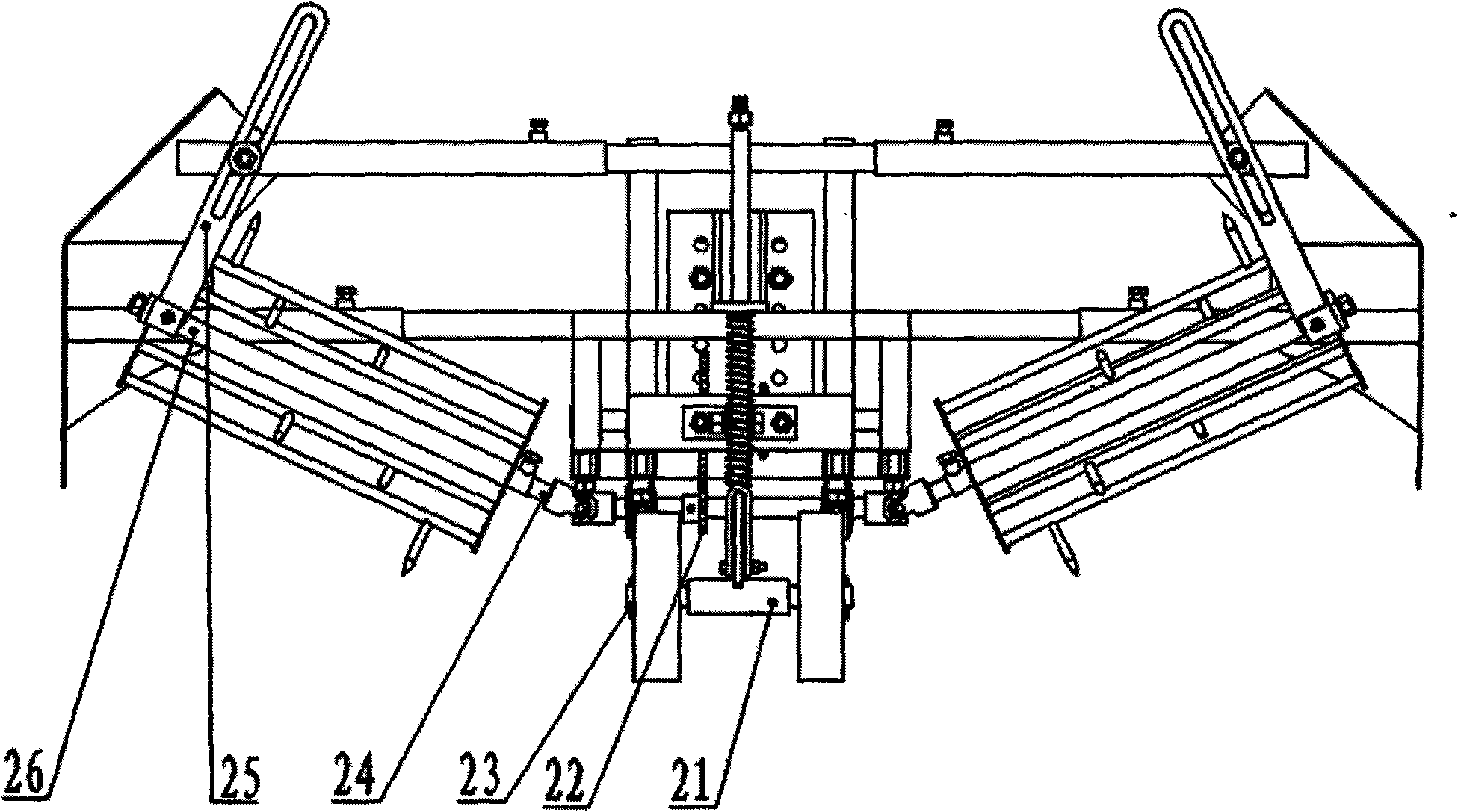

Novel tea knead entwist machine

The invention discloses a novel tea knead entwist machine and relates to tea processing machineries. The circular movement of the knead entwist device above the knead entwist plate can be realized by connecting the knead entwist device with a crank rocker mechanism; and the tailor-made knead entwist plate matches with the screw cover in the knead entwist device. The stripping tea rate of the tea is high, broken tea is little, and the broken tea generated in production can be separated from the mature tea automatically, thus improving tea grade and increasing production efficiency.

Owner:WUFENG TIANCHI TEA MACHINERY

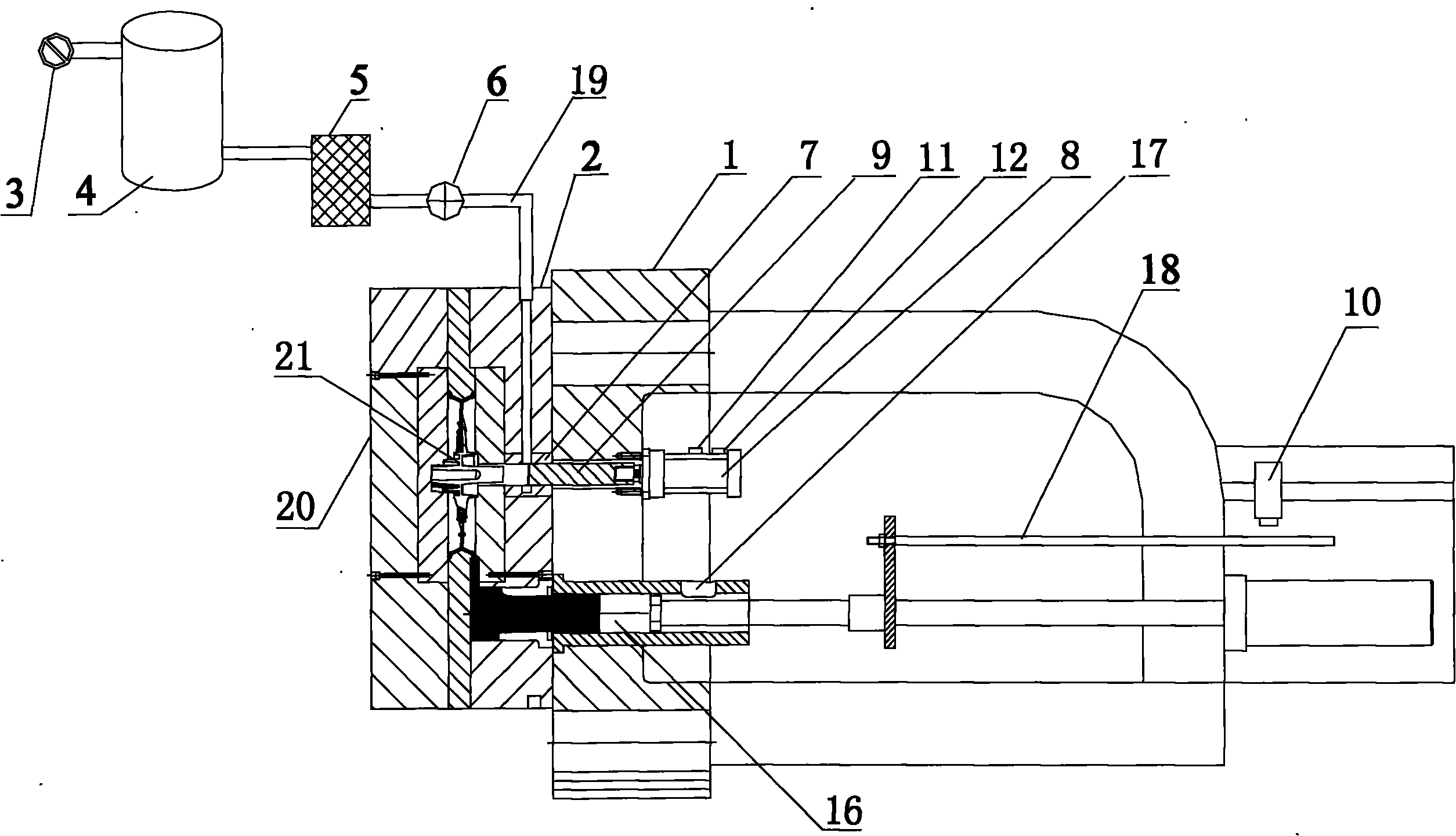

Vacuum die-casting system of die-casting machine

The invention discloses a vacuum die-casting system of a die-casting machine, which comprises the die-casting machine, a fixed-mold wallboard of a die casting mold, and a vacuum program control device of a die-casting system, wherein the vacuum die-casting system of the die-casting machine is arranged on the fixed-mold wallboard, the template of the fixed-mold wallboard of the die casting mold is provided with a channel, the outlet of the channel is connected with a vacuumizing device consisting of a vacuum pump, a negative pressure tank, a filter and a vacuum shut-off valve of the die casting mold by pipes; a channel leading to the center of the template of the die casting mold is connected with a casing pipe, the inner end of the casing pipe is communicated with a cavity of the template of the die casting mold, and a valve rod connected with a piston rod of an oil cylinder on the fixed-mold wallboard is arranged in a hole arranged at the outer end of the casing pipe. When carrying out die assembling on the die casting mold of the die-casting machine, by aid of the negative pressure produced by the vacuum pump of the vacuum die-casting system, the invention instantaneously extracts gases in the cavity and the pipe of the template of the mold, and closes the channel timely when the cavity is filled with molten metals, thereby preventing the molten metals from entering the vacuum pipelines so as to carry out die-casting molding on the molten metals in a vacuum.

Owner:DONGGUAN EONTEC CO LTD

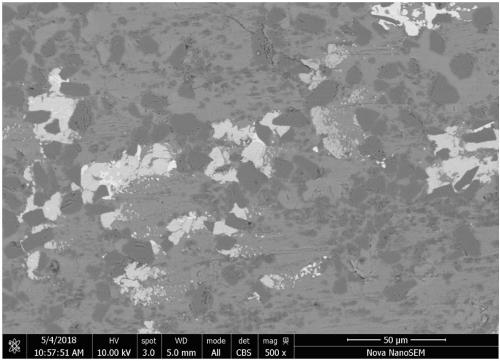

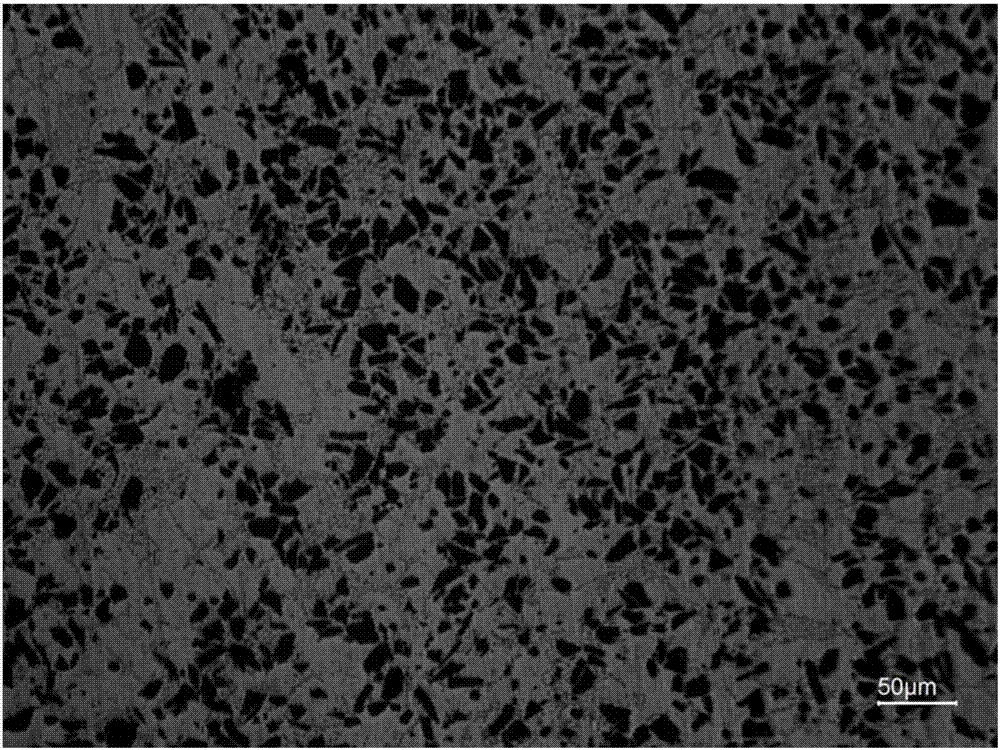

SiC particle-enhanced aluminum based composite with high-temperature wear resistance and preparation method of SiC particle-enhanced aluminum based composite

The invention provides a SiC particle-enhanced aluminum based composite with high-temperature wear resistance and a preparation method of the SiC particle-enhanced aluminum based composite and belongsto the field of aluminum alloy materials. The preparation method comprises the following steps of smelting industrial pure aluminum, aluminum-silicon alloy, aluminum-copper alloy, pure magnesium, thealuminum-copper alloy, aluminum-nickel alloy, aluminum-zinc alloy, aluminum-titanium alloy and aluminum-magnesium alloy at 700-800 DEG C according to a mass ratio; performing degassing refining; performing casting at 700-750 DEG C; using vacuum smelting, stirring and casting equipment to smelt a substrate at 700-800 DEG C; adding micron-size SiC particles; performing semi-solid state stirring at550-570 DEG C; performing casting at 700-750 DEG C; and performing T6 heat treatment. For the SiC particle-enhanced aluminum based composite with the high-temperature wear resistance and the preparation method, the substrate alloy components are designed self according to an alloy phase diagram, and a proper element content is selected, so that a high temperature resistant hard phase occurs aftersubstrate alloy heat treatment, and the substrate hardness at high temperature is ensured; and meanwhile, by adding an SiC-enhanced phase, the high temperature resistance of the composite is further improved.

Owner:TONGJI UNIV

Medium-pressure heavy-section outer-cylinder iron casting gating system of steam turbine

The invention discloses a gating system of a large-section iron casting for an medium pressure external cylinder in a steam turbine; the gating system comprises a weighing ladle, a sprue, a runner and an ingate, the runner consists of an upper runner and a lower runner, a refractory ceramic filter is arranged between the upper runner and the lower runner, the minimum sectional area ratio of the sprue, the runner, a transition sprue, a transition runner and the ingate is 1.2:1.34:1:1.07:1.24; the sprue, the upper runner and the lower runner are arranged at the middle part of the casting, and the ingate of an ingate is arranged at the inner wall of an axle hole of the casting; and the gating system of the structure mainly plays a role in buffering, decompressing and steady entry of melted iron, the molding sand in the scour cast is avoided, the casting is heated evenly, with the advantages of being not easy to be mingled with impurities, carry sand, produce air gaps and cracks.

Owner:RIYUE HEAVY IND

High manganese steel railway assembled frog centre rail casting process

A technology for casing the high-Mn steel frog of combined switch for railway features that the ferrochromium sand is used as surficial sand and core sand, the alkaline Mg sand powder paint is coated on the surfaces of moulding cavity and core, and an easily cutting plate is added under the insulating siser head. It includes such steps as applying the insulating and heat generating agent to the surface of riser head, horizontal pouring, cutting off the riser head, burying it is sand, and heat treating.

Owner:中科西王特钢有限公司

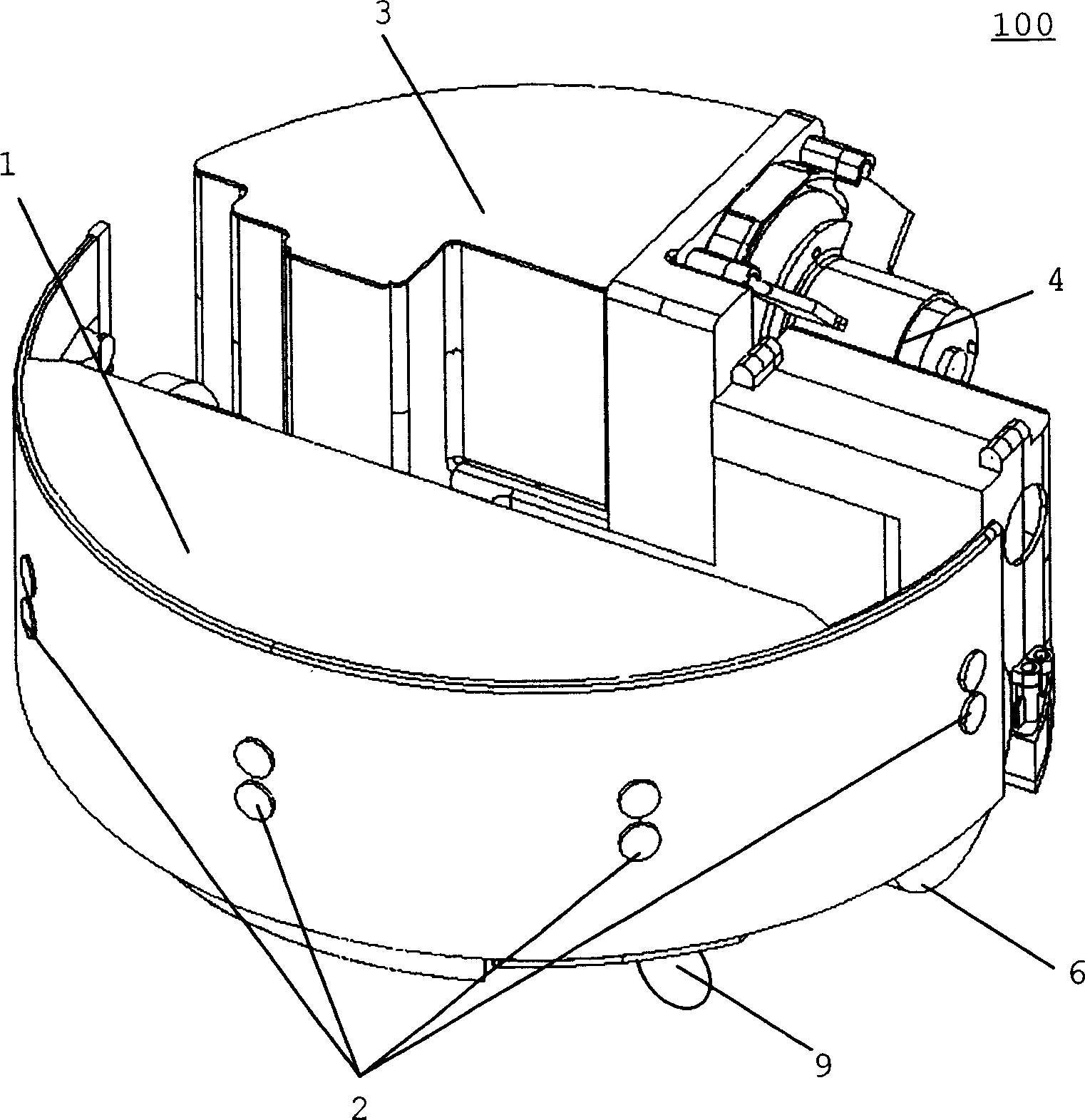

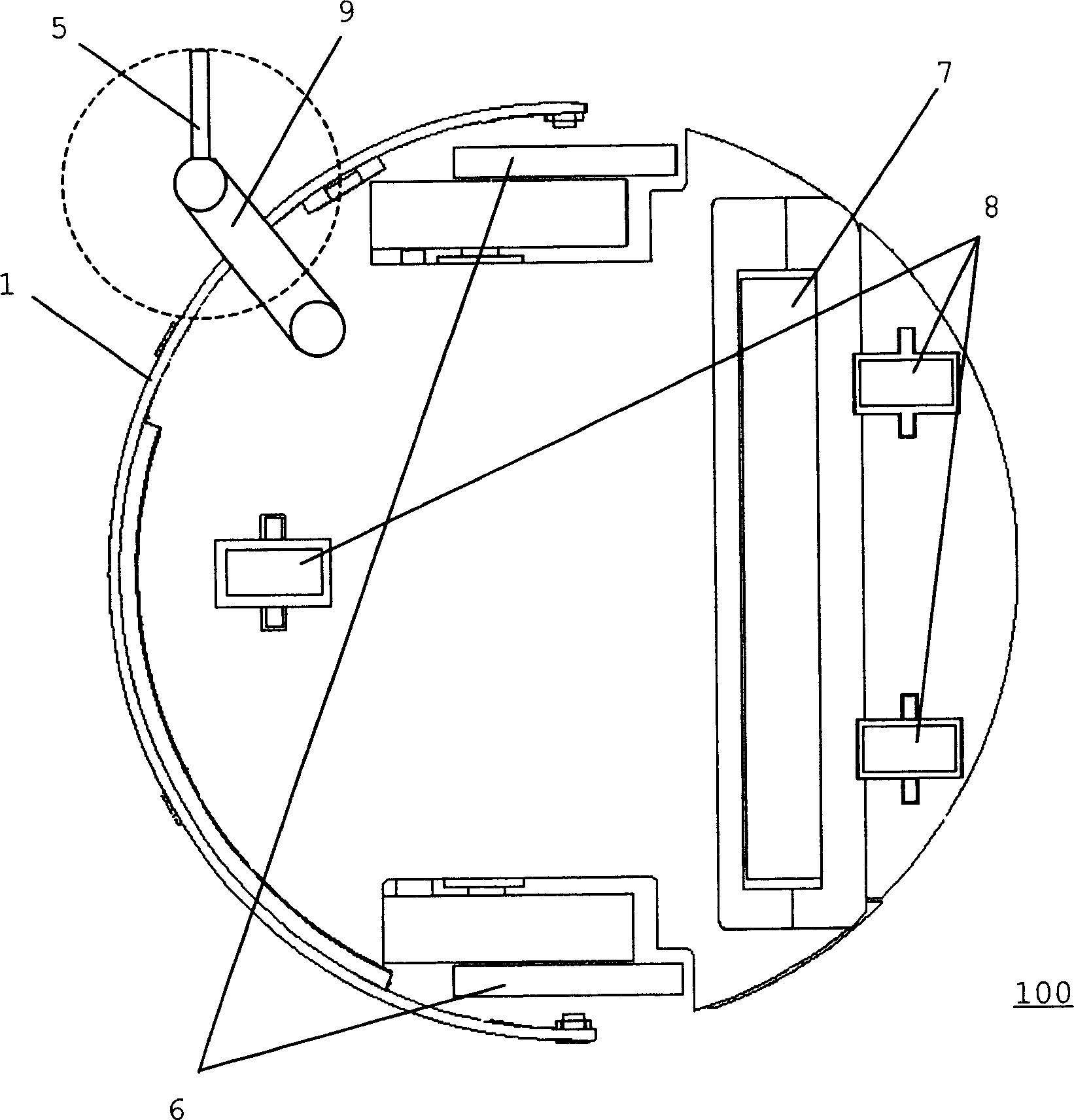

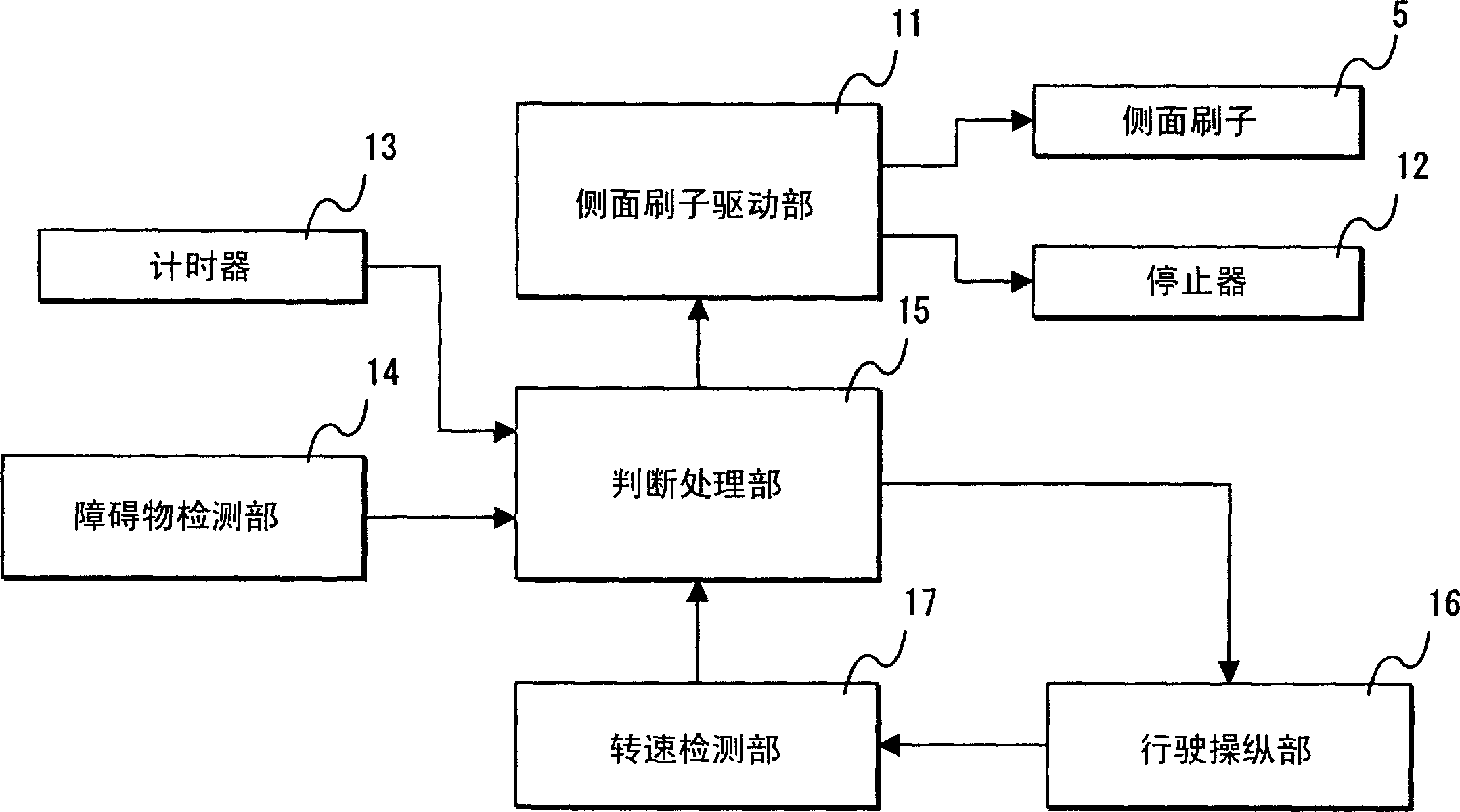

Cleaner

InactiveCN1720852AImprove dust collection effectReduce power consumptionAutomatic obstacle detectionTravelling automatic controlMechanical engineeringPower consumption

Only when a wall side and the vicinity of an obstacle are cleaned, a side brush is operated and the cleaning is carried out, and when any other place than the wall side and the vicinity of the obstacle is cleaned, the side brush is maintained in a stoppage state. When a place such as the wall side or the vicinity of the obstacle in which dust is easy to accumulate is cleaned, the side brush is operated to enhance the dust collecting property. When any other place than the wall side or the vicinity of the obstacle is cleaned, the side brush is stopped to suppress power consumption and generation of a noise. A judgment processing portion detects based on a detection signal from an obstacle detecting portion that a cleaner is approaching a wall or an obstacle. In response to such detection, the judgment processing portion instructs a travel steering portion to carry out immediate rotation and change of a travel direction, or travel along a wall side. Also, the judgment processing portion instructs a side brush driving portion to drive a side brush only in the rotation and in the wall side travel, and to stop the side brush in straight advance travel.

Owner:SANYO ELECTRIC CO LTD

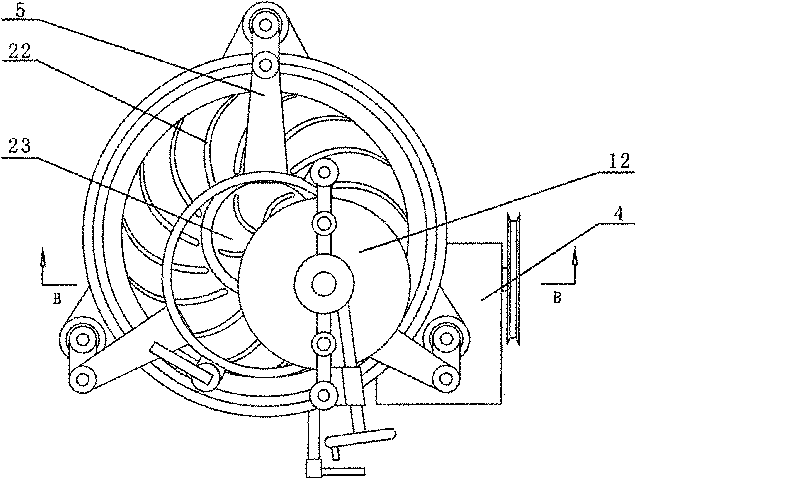

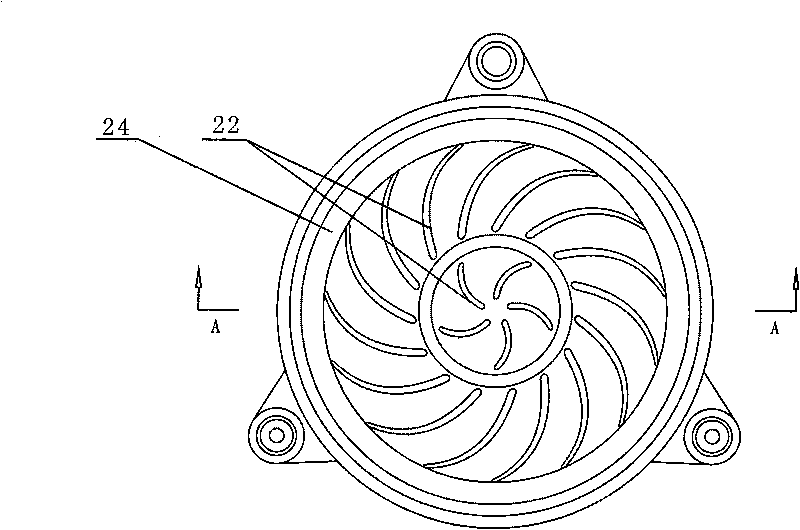

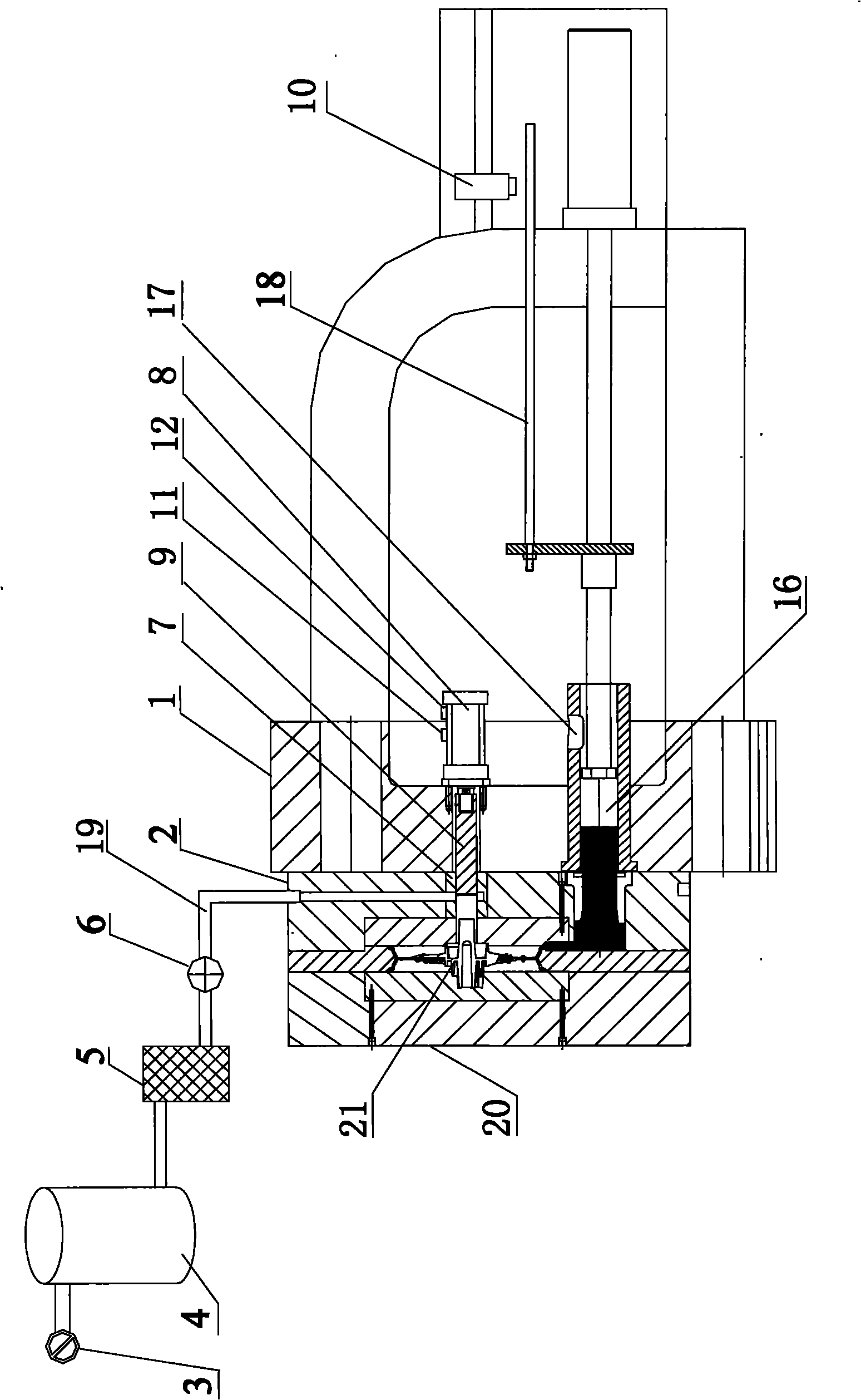

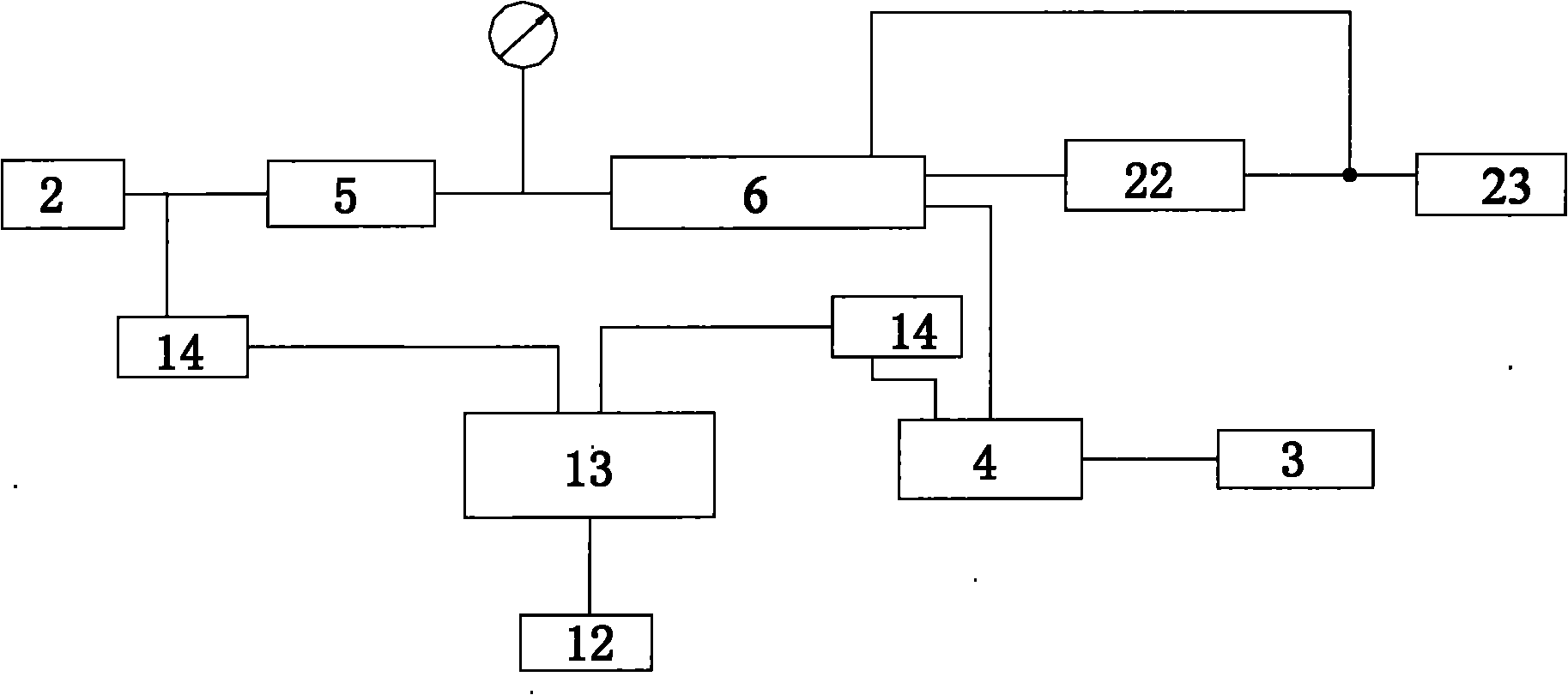

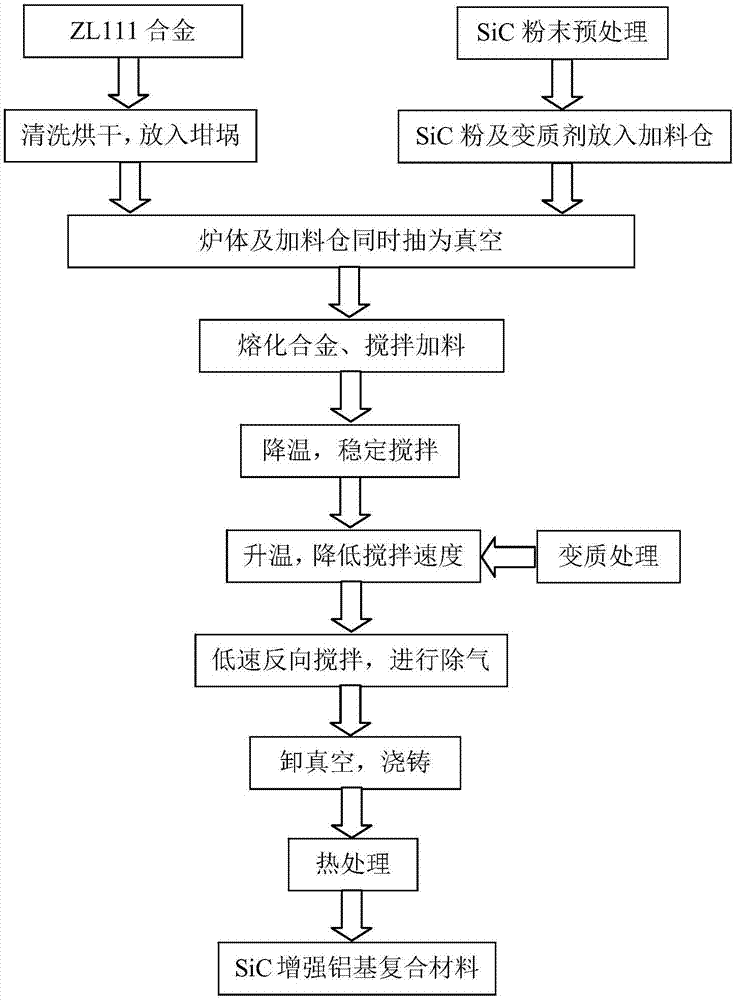

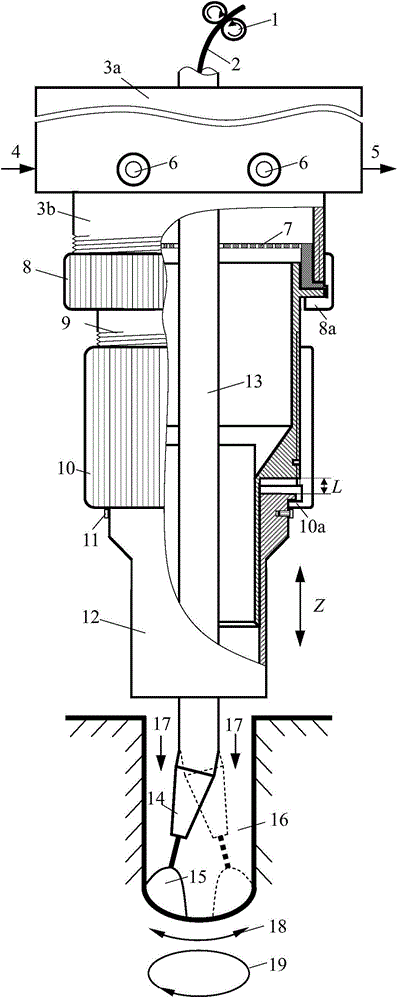

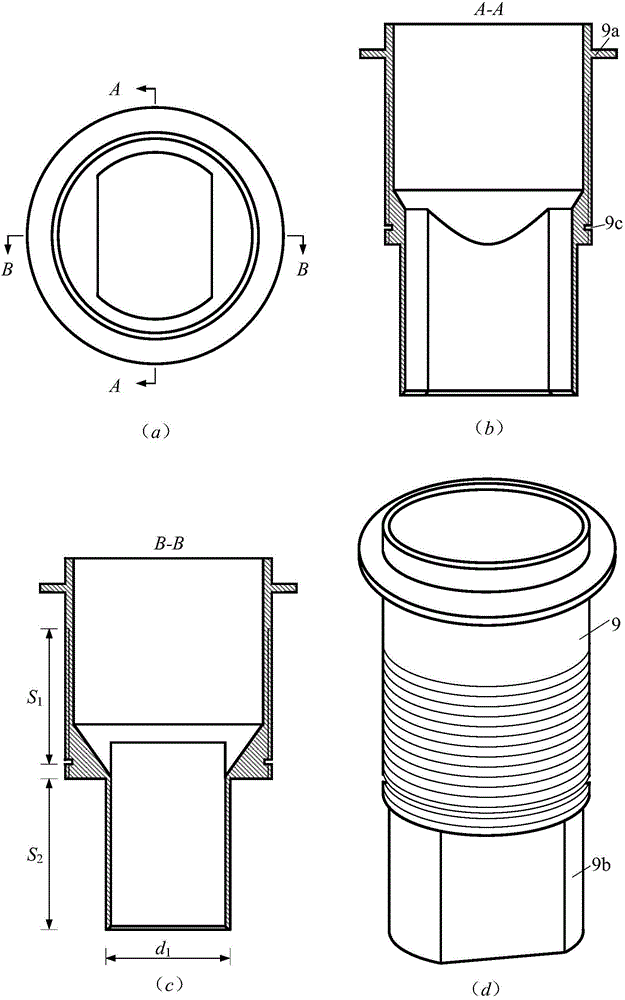

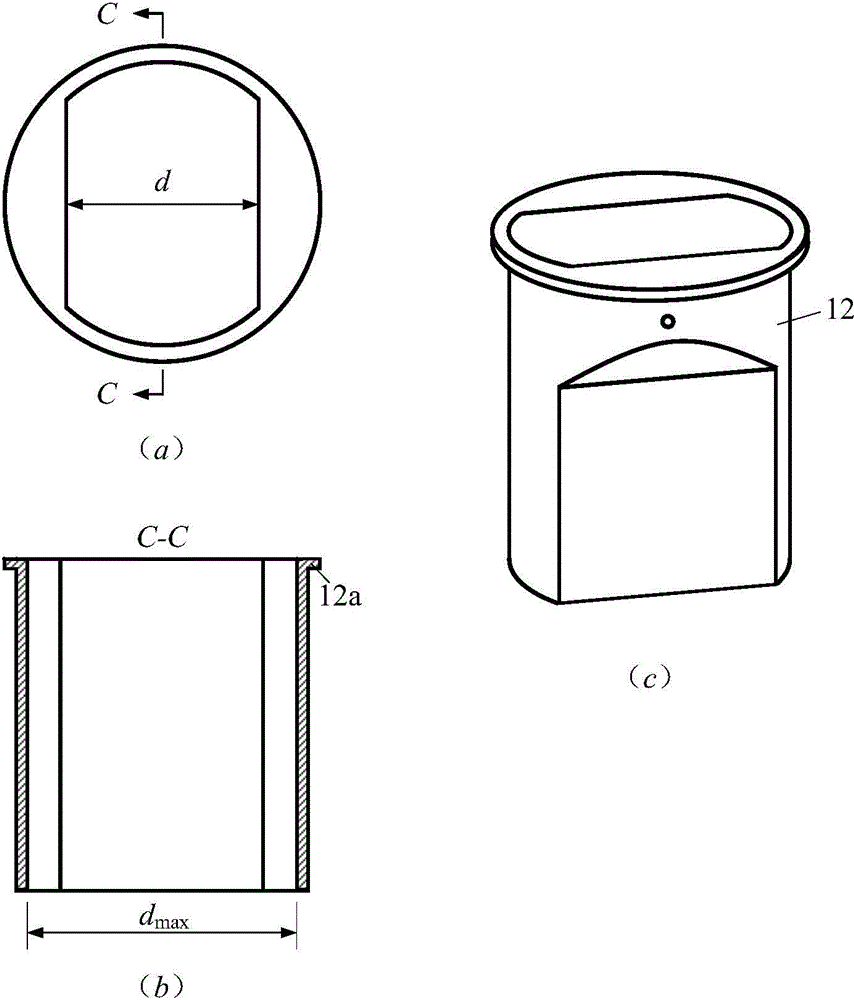

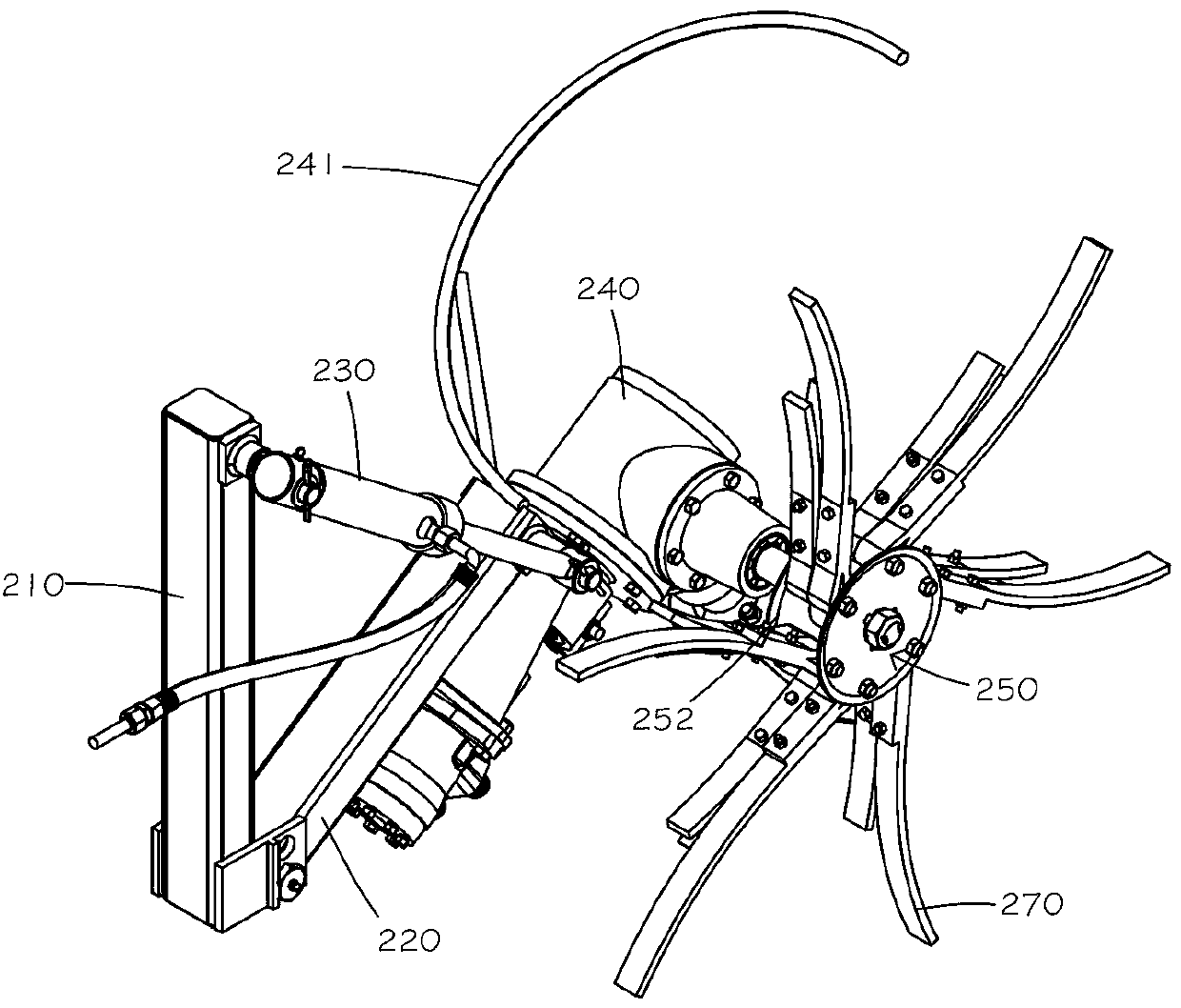

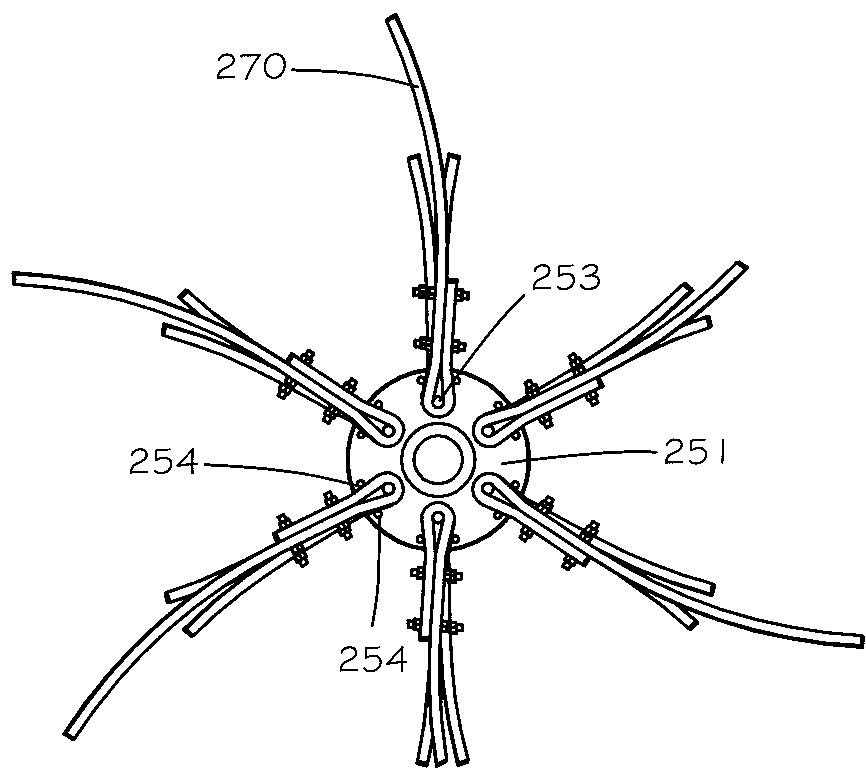

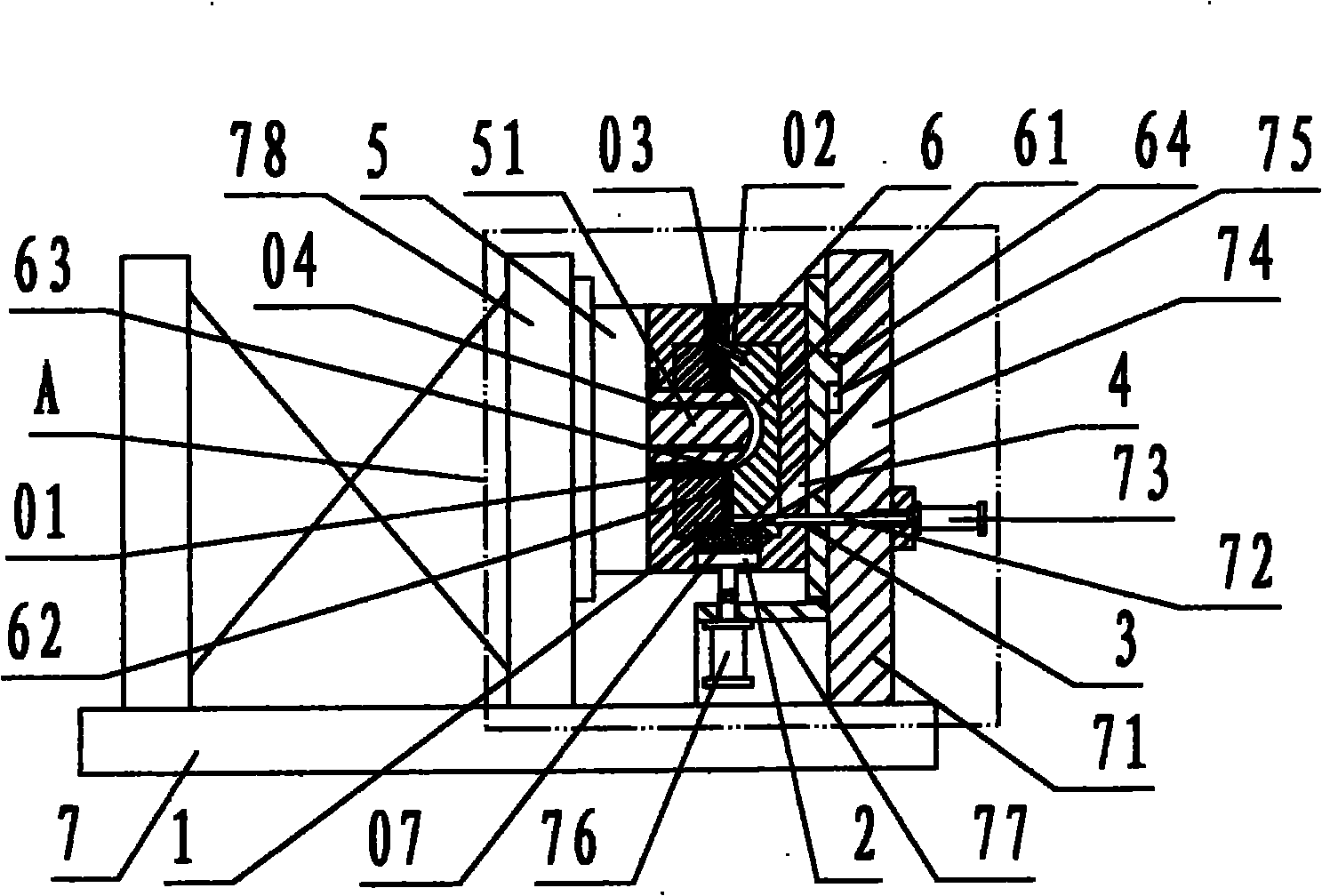

Preparing method for SiC particle enhanced aluminum-base composite material

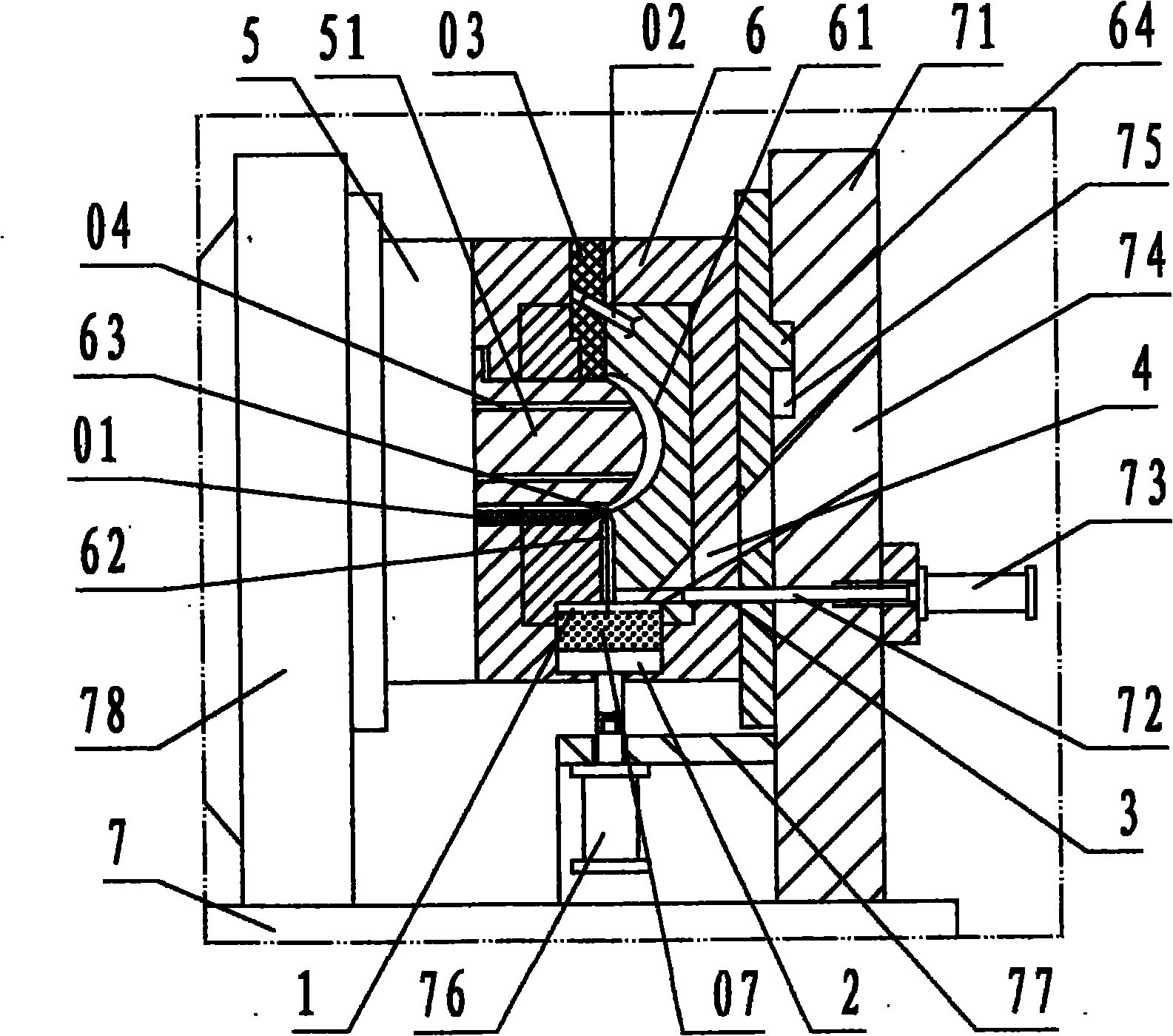

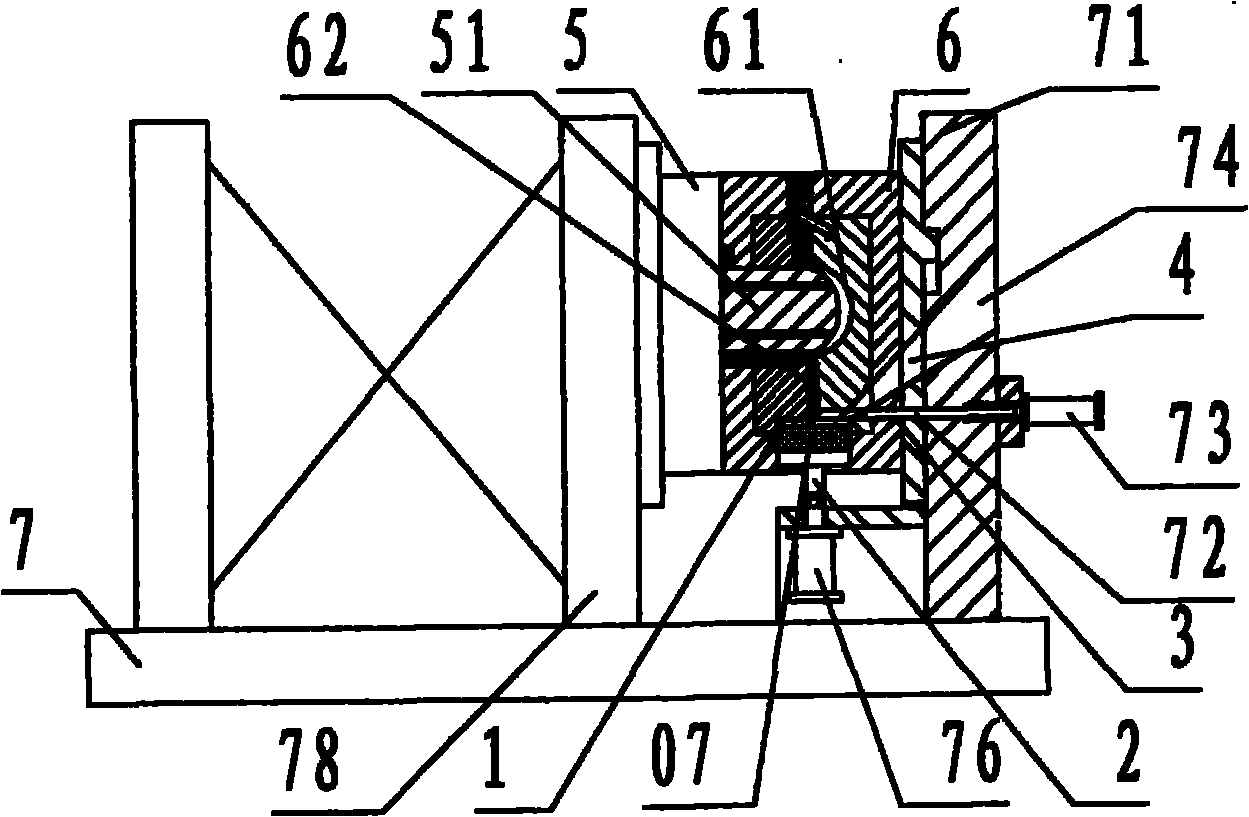

The invention aims at disclosing a specially-made vacuum smelting furnace and a preparing technology for a SiC particle enhanced aluminum-base composite material. A certain component proportion and a special smelting casting technology are adopted. The vacuum smelting furnace is adopted in the technology, overall closing and vacuum-state charging can be achieved, the inner temperature of melt can be measured in real time, the particles accurately fall into a melt vortex center with a certain speed and are evenly distributed in the melt under powerful stirring, the functions of deoxygenation and degassing can be effectively achieved on the composite material melt, and therefore the composite material uniform in component, low in porosity, high in mechanical performance and excellent in heat-conducting property can be produced through the technology. The crucible lifting type vacuum smelting furnace comprises a crucible composite device and lifting platform system, a stirring device and lifting platform system, a charging device, a vacuum system, a handheld lifting thermocouple, a sealing system and an electric control system.

Owner:SUZHOU WUCHUANG MATERIAL TECH DEV CO LTD

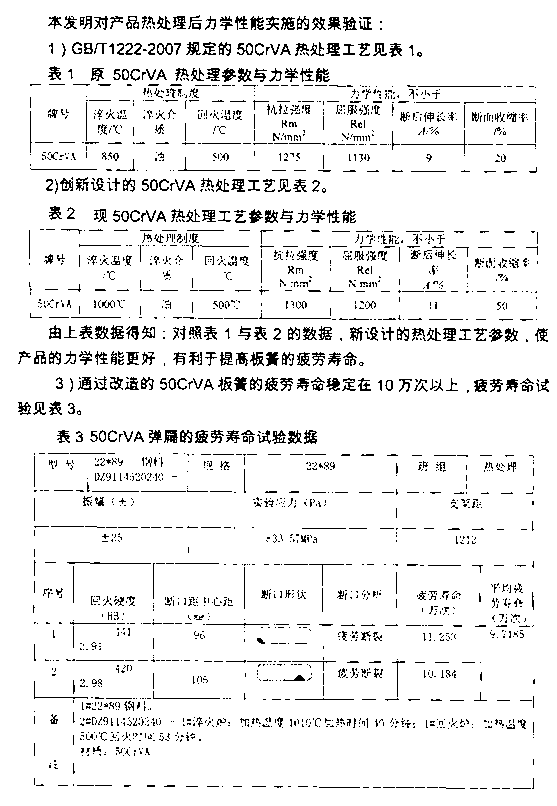

Technique for prolonging fatigue life of 50CrVA plate spring

ActiveCN103014533AGood deoxidation effectAvoid formingFurnace typesHeat treatment furnacesChemical compositionSlag

The invention provides a technique for prolonging the fatigue life of a 50CrVA plate spring. The technique includes the optimal design for the following chemical components of a 50CrVA flat spring steel: 0.49 to 0.53% of C, 0.20 to 0.30% of Si, 0.65 to 0.75% of Mn, 0.90 to 1.05% of Cr, 0.11 to 0.15% of V, 0.006 to 0.009% of Al, 0.018 to 0.020% of P, 0.016 to 0.020% of S, not greater than 0.25% of Ni, and not greater than 0.25% of Cu. The method for controlling and denaturating treatment on nonmetallic inclusion in steel comprises the following steps: (1) sealing a connector between a long nozzle of a large steel ladle and an intermediate submersed nozzle through an argon seal ring; controlling the amount of slag in tapping to 0 to 5kg / t; controlling the weight of the molten steel of the steel ladle to be not less than 7t; and controlling the molten steel level of a crystallizer to fluctuate within the scope of + / -2mm; and (2) carrying out denaturating treatment on inclusion; and adding SiCa wires at 2.1m / t through a wire feeder under a white slag condition, wherein the molten steel is at temperature of 1550 to 1580 DEG C; the parameters in heat treatment of the plate spring include quenching temperature of 1000 DEG C, tempering temperature of 500 DEG C, tensile strength of not less than 1300N / mm<2>, yield strength of not less than 1200N / mm<2>, percentage elongation after fracture of not less than 11%, and percentage reduction of area of not less than 50%.

Owner:XINJIANG BAYI IRON & STEEL

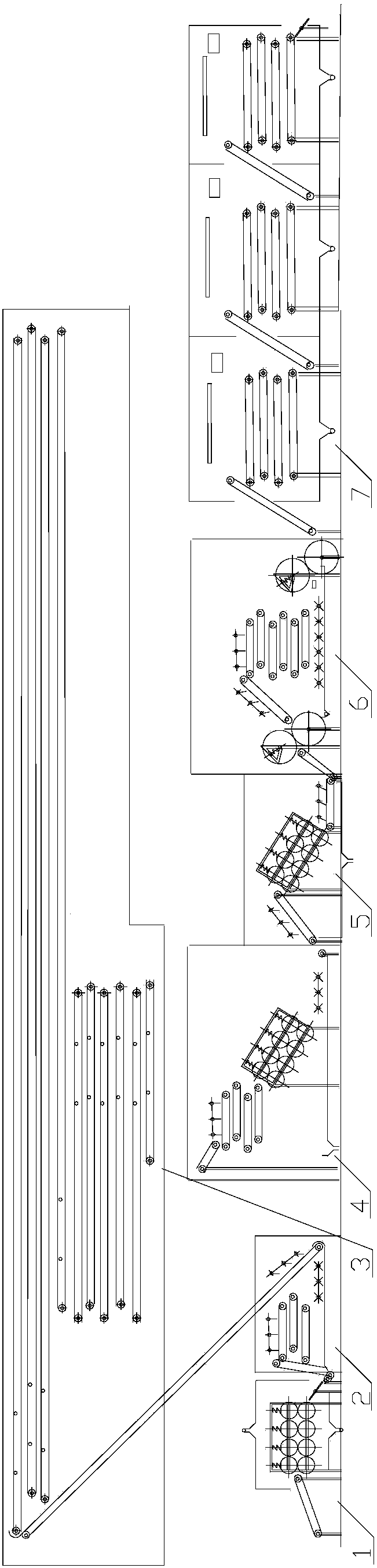

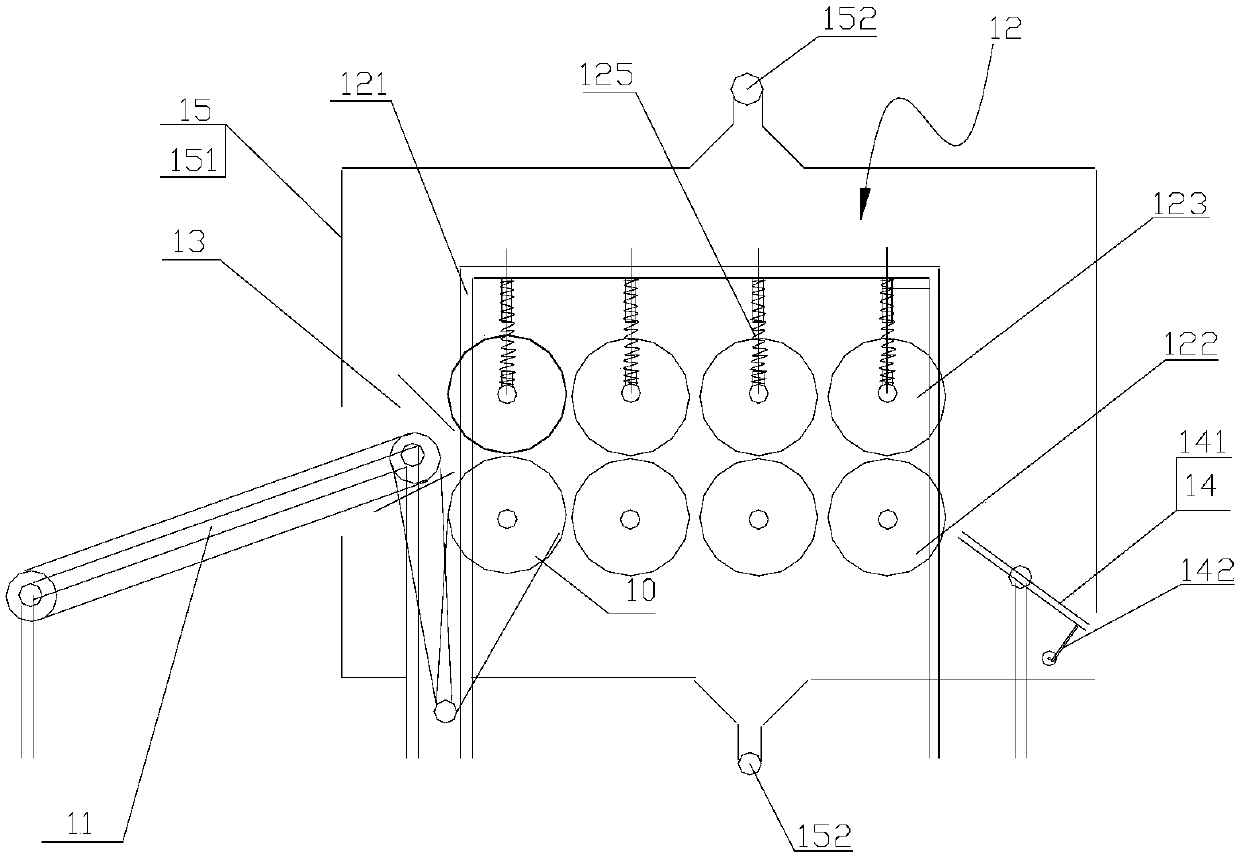

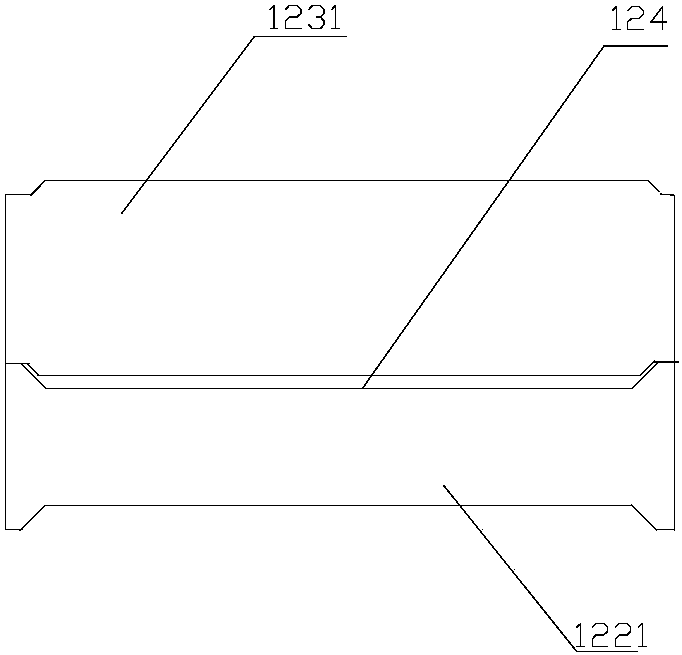

Automatic operation system and method of biologically refined herbal fibers

ActiveCN107142521AFree laborIncrease productivityVegetable materialMechanical fibre separationFiberOutput device

The invention discloses an automatic operation system and method of biologically refined herbal fibers. The system includes herbal-fiber material standardizing and arranging equipment which includes a rolling device, a separation device and a dust collection device; motion-type herbal-fiber material inoculating equipment include a plurality of horizontal transport devices, a first bacteria solution spraying device and an output device; motion-type herbal-fiber material wet-fermentation equipment includes a plurality of horizontal transport devices; motion-type fermentation material inactivating equipment includes plurality of horizontal transport devices, a pressure hot-water comb and a rolling device; motion-type inactivated-product hydraulic equipment includes a pressure water-spraying device, an extrusion device and an output device; motion-type biologically-refined-herbal-fiber oil dipping equipment includes a moisture drying device, a transmission device, a plurality of horizontal transport devices and an oil spraying device; motion-type biologically-refined-herbal-fiber drying equipment includes a drying device and an output device. The technical problem is solved that the automatic operation system and method of the biologically refined herbal fibers are provided.

Owner:DAQING SKY GREEN BIOLOGICAL NEW MATERIAL TECH CO LTD

Floatable track type special underwater operation robot suitable for extremely soft geology

ActiveCN109291743AKeep goingGuaranteed smooth progressAmphibious vehiclesEndless track vehiclesOcean bottomHead pressing

Owner:SHANGHAI JIAO TONG UNIV

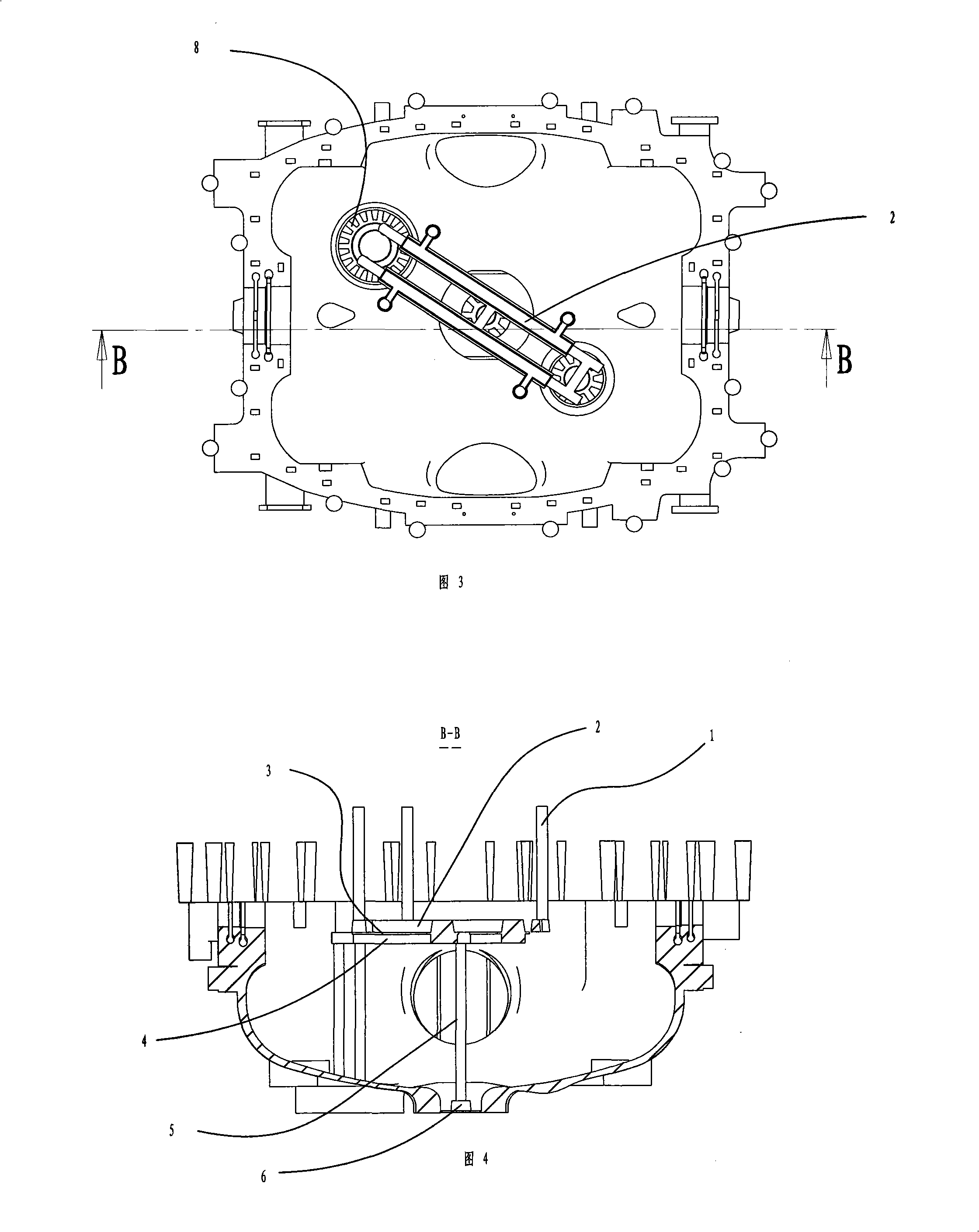

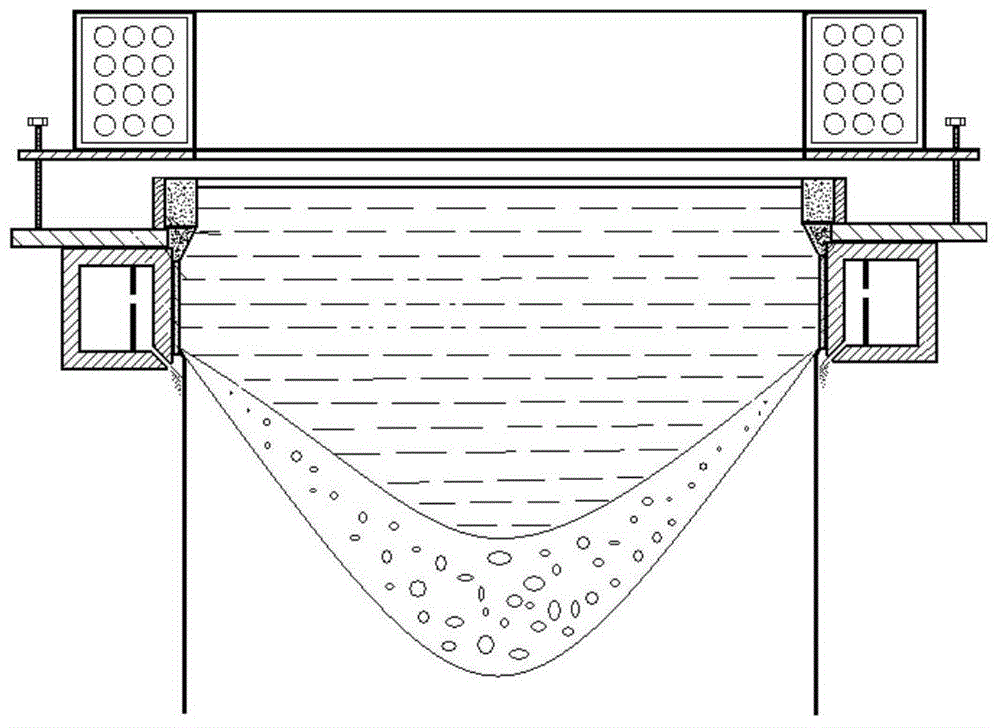

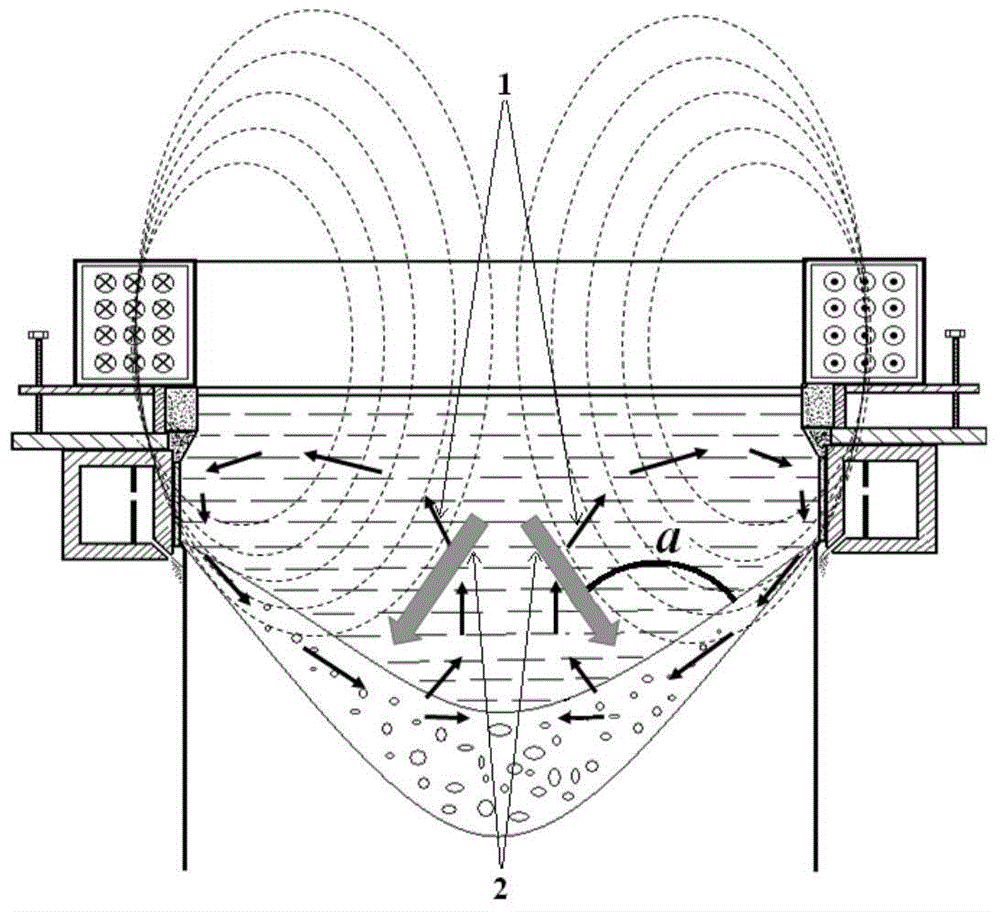

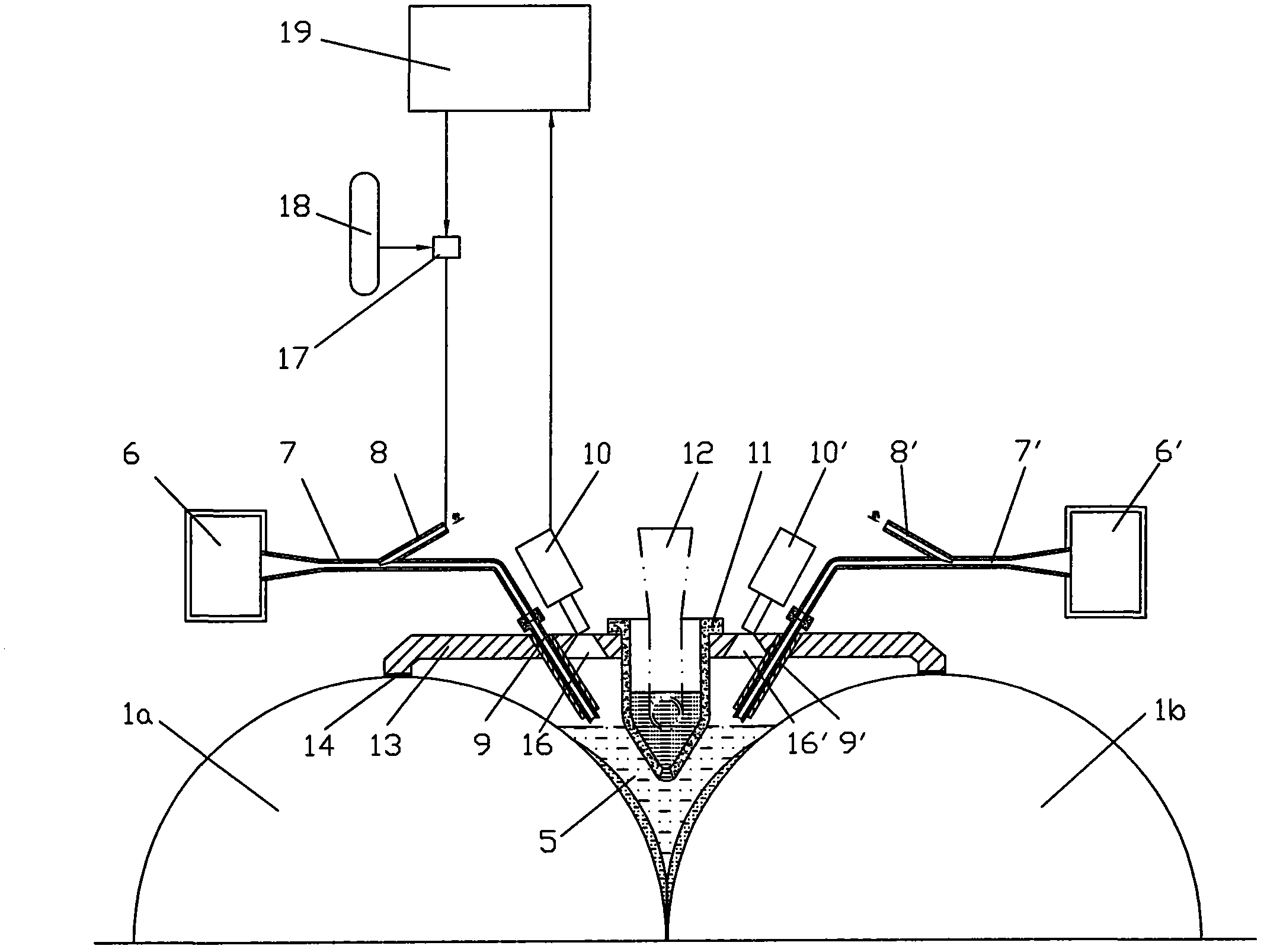

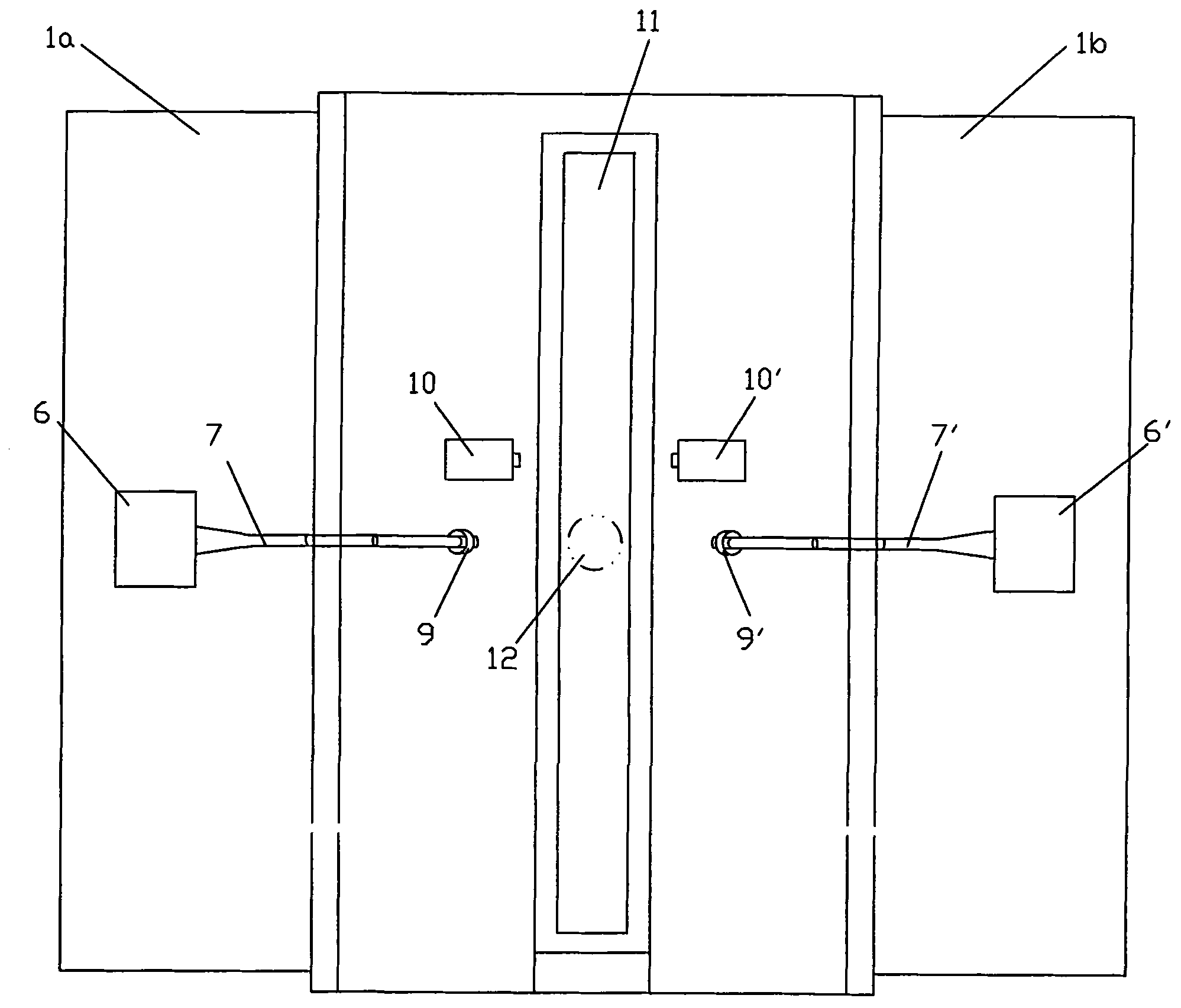

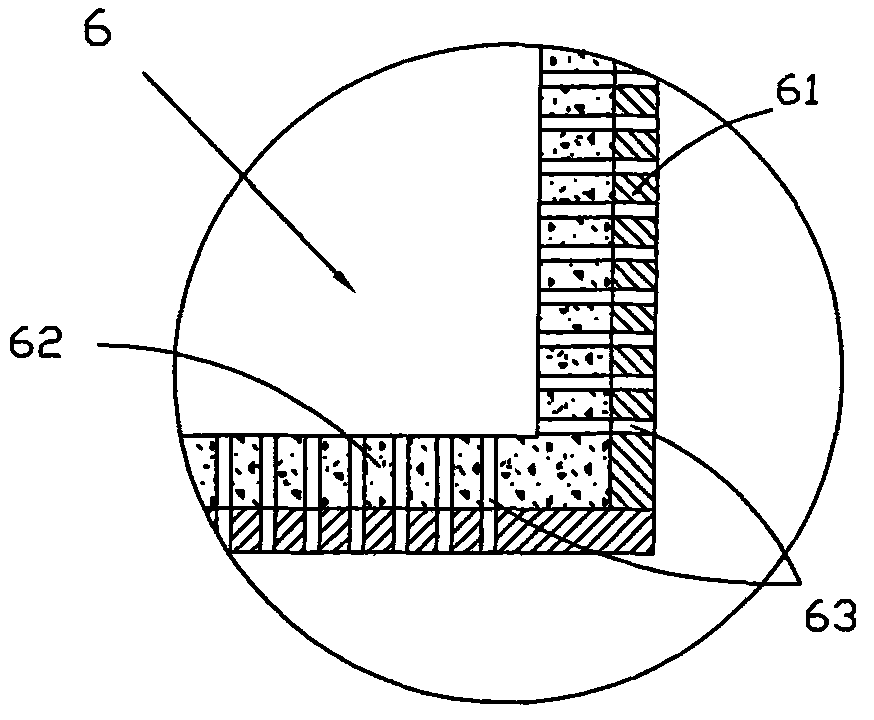

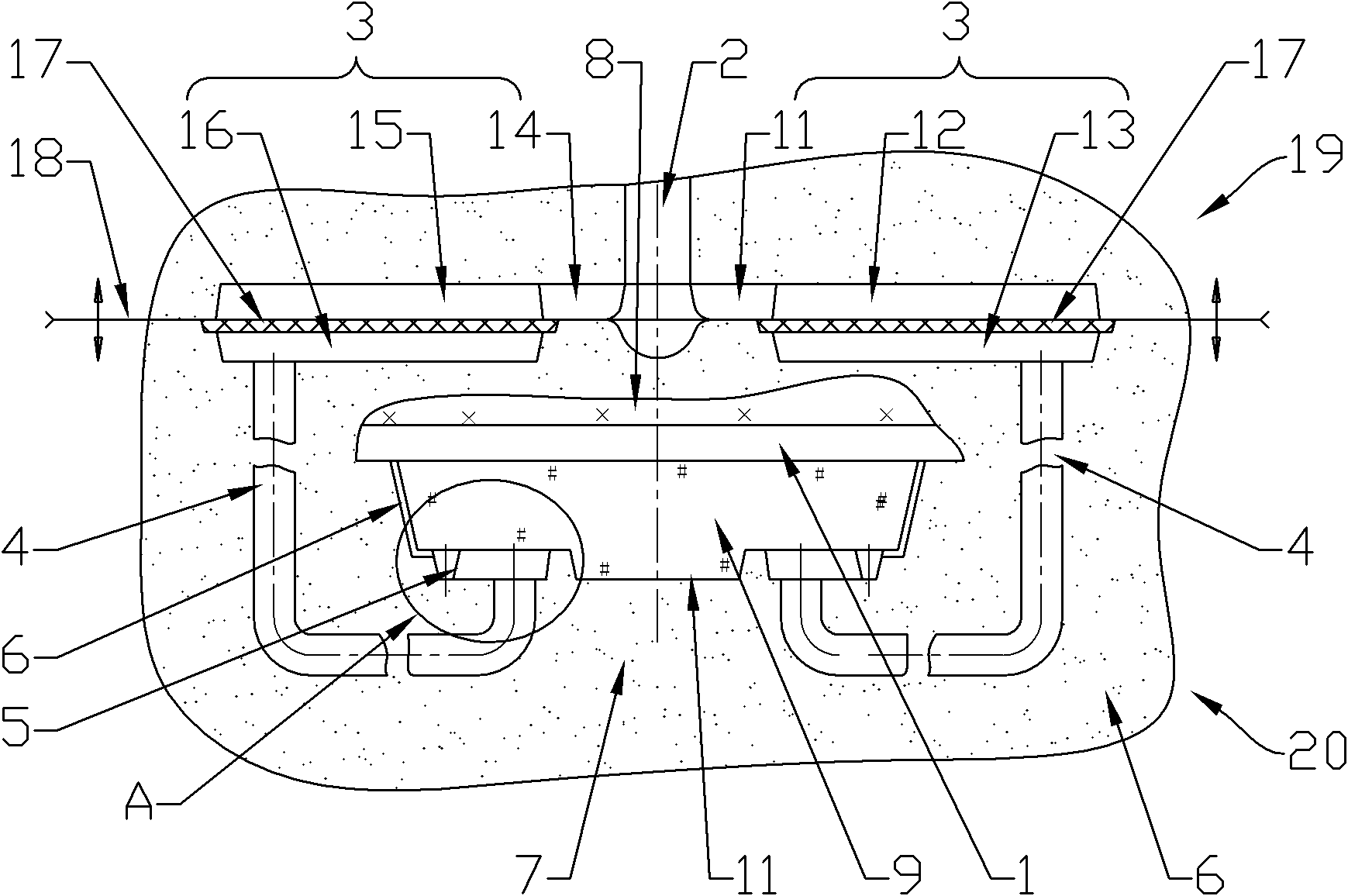

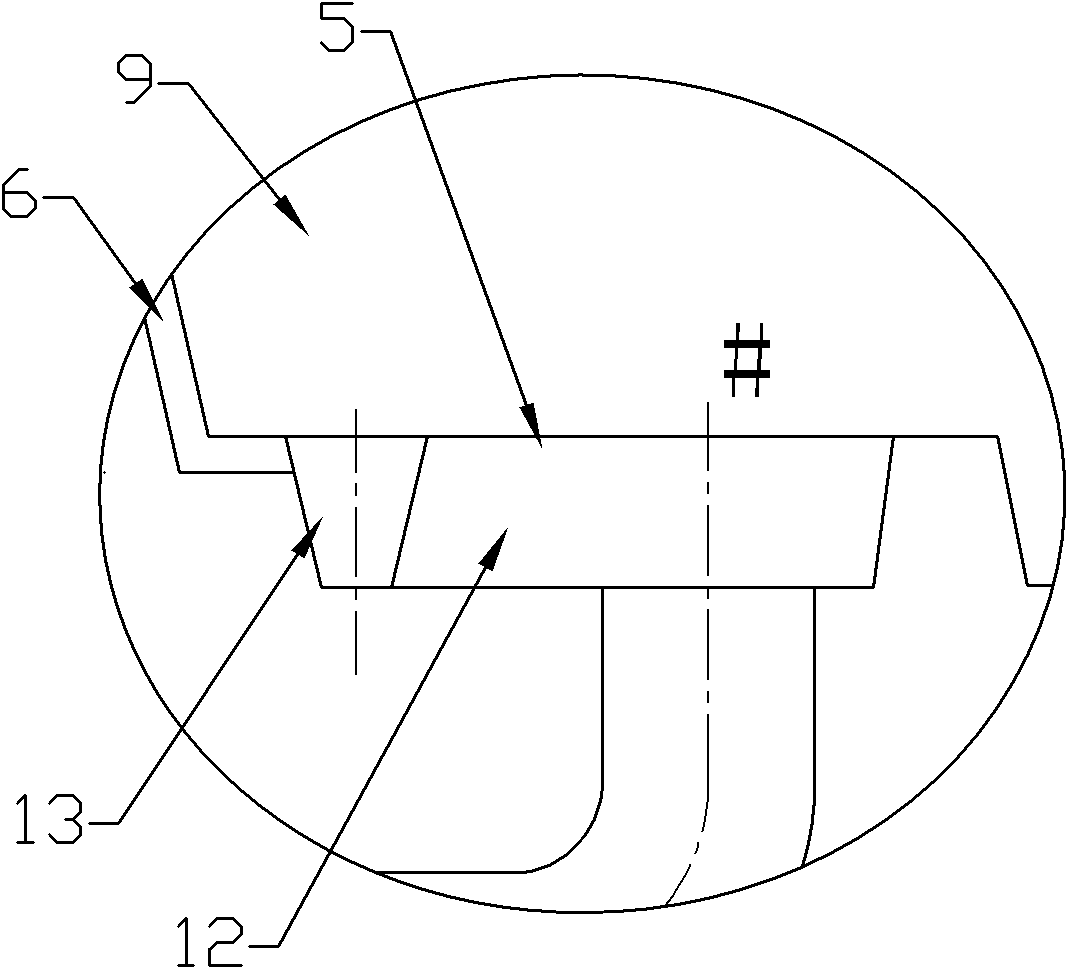

Method and device for restraining macrosegregation of cast aluminum alloy cast ingots in direct chill (DC) casting

The invention discloses a method and device for restraining macrosegregation of cast aluminum alloy cast ingots in direct chill (DC) casting. The method includes the steps that an electromagnetic stirrer is arranged over a crystallizer, and in the casting process, the included angle alpha of the magnetic line of force of the electromagnetic stirrer and the slope of a liquid cave is adjusted to be greater than or equal to 90 degrees until the DC casting process is finished. An additional flow field formed by the electromagnetic stirrer in aluminum alloy melt can weaken or eliminate an aluminum alloy melt flow field caused by heat convection of aluminum alloy melt in the crystallizer, the aluminum alloy melt in the crystallizer and solute atoms at a solidification front of the liquid cave are promoted to be distributed evenly, macrosegregation of the aluminum alloy cast ingots is restrained, meanwhile, the slope of the solidification front of the liquid cave and the depth of the liquid cave are reduced, the temperature field in the aluminum alloy melt in the liquid cave is promoted to be even, and thus the structure and property homogeneity of subsequent processed products of oversized aluminum alloy cast ingots is remarkably improved. Compared with the prior art, relative macrosegregation of alloy elements of the cast ingots can be reduced from 10-17% to be within 5%, the problem of poor structure and property homogeneity of the oversized aluminum alloy cast ingots and the subsequent processed products of oversized aluminum alloy cast ingots in DC casting is solved, and the method and device are suitable for being applied to industries.

Owner:深圳卓聚新材料有限责任公司

High-breathability lost foam coating and preparing method thereof

ActiveCN105268911AGood high temperature breathabilityGood slagging abilityFoundry mouldsFoundry coresSurface-active agentsPolystyrene

The invention provides a high-breathability lost foam coating prepared through cast waste resin sand and a preparing method of the high-breathability lost foam coating. The high-breathability lost foam coating comprises the cast waste resin sand, aluminum silicon series refractory aggregate, crystalline flake graphite, polystyrene resin particles, aluminum powder, an oxidizing agent, fluoride, carbon fibers, a suspending agent, a bonding agent, a surface active agent, a defoaming agent and water. The high-breathability lost foam coating comprises 100 parts of cast waste resin sand, 60-100 parts of aluminum silicon series refractory aggregate, 5-25 parts of crystalline flake graphite, 2-6 parts of polystyrene resin particle, 1-3 parts of aluminum powder, 2-10 parts of oxidizing agent, 1-5 parts of fluoride, 1-5 parts of carbon fiber, 3-10 parts of suspending agent, 5-15 parts of bonding agent, 0.2-0.5 part of surface active agent, 0.5-1.5 parts of defoaming agent and 80-120 parts of water. The cast waste resin sand is used as the main refractory material of the lost foam coating, casting wastes are effectively utilized, the green casting and circulation sustainable principles are met, the problems of carbon defects and contraction defects of the waste resin sand lost foam coating are solved, and good application prospects are achieved.

Owner:GANSU KOCEL CHEM

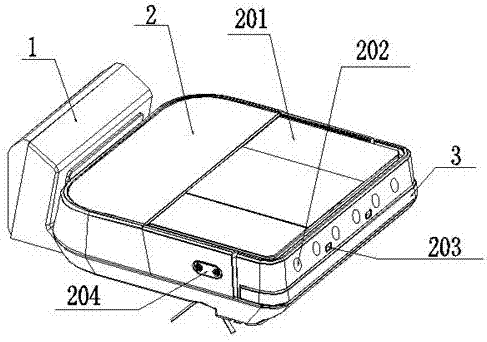

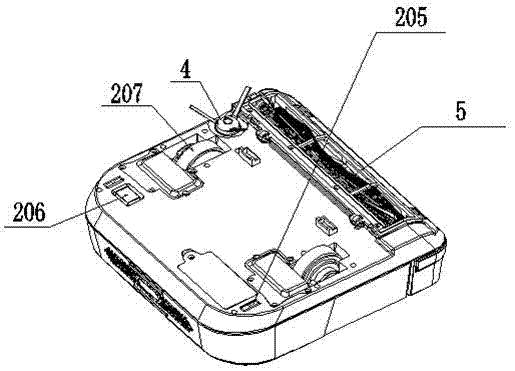

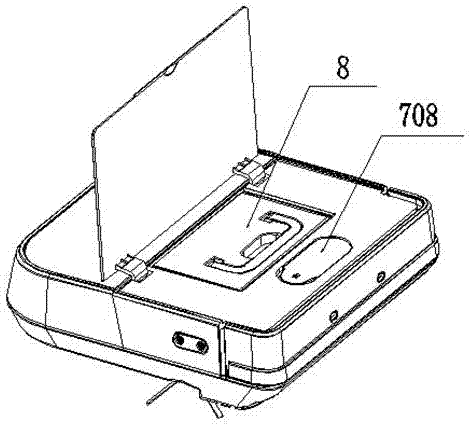

Intelligent dry-wet cleaning dust collection and mopping integrating robot

InactiveCN107440613AAvoid structural designPrevent getting involvedAutomatic obstacle detectionTravelling automatic controlWater storage tankPulp and paper industry

The invention aims at providing an intelligent dry-wet cleaning dust collection and mopping integrating robot, which comprises a charging stand and a host machine, and further comprises an anti-collision elastic tongue, a side brush, a rolling brush module, a mopping module, a water storage tank and a dust collection box which are arranged on the host machine, wherein the charging stand is connected to the host machine by virtue of a charging contact elastic sheet; the host machine further comprises a flip, an infrared anti-collision module, a water spraying hole, an ultrasonic module, infrared anti-falling modules, a power switch, walking wheels and infrared abutting-joint modules; the flip is arranged at the bottom of the host machine; the infrared anti-collision module and the water spraying hole are arranged at one end of the host machine; the ultrasonic module is arranged at one side of the host machine; the four infrared anti-falling modules are arranged at four corners of the bottom of the host machine; the power switch is arranged at the bottom of the host machine; the walking wheels are arranged at two sides of the bottom of the host machine; and the infrared abutting-joint modules are arranged at one end of the host machine. The robot provided by the invention integrates cleaning and mopping, and dry-wet integrated cleaning can be effectively implemented.

Owner:深圳市浦硕科技有限公司

Telescopic nozzle device for narrow gap welding and adjusting method of telescopic nozzle device

ActiveCN103600160APrevent getting involvedNovel adjustment methodShielding gas supply/evacuation devicesCooled electrode holdersWeld seamEngineering

The invention discloses a telescopic nozzle device for narrow gap welding and an adjusting method of the telescopic nozzle device. The nozzle device sequentially comprises a nozzle holder, an air sifter cover, a locking nut, a gas calm sleeve, a telescopic adjusting nut and a movable nozzle sleeve from top to bottom, one end of the gas calm sleeve is fixedly connected with the nozzle holder through the locking nut, the other end of the gas calm sleeve is in transmission connection with the telescopic adjusting nut through a thread pair, the movable nozzle sleeve can vertically move along the axial direction of a nozzle under driving of the telescopic adjusting nut, so that the extending length of the movable nozzle sleeve is changed, and the overall axial length of the nozzle is telescopically adjusted. The telescopic nozzle device is compact in structure, convenient to telescopically adjust and wide in effective gas protection range, an inner cavity of the nozzle is fine in gas tightness, and gas protection can be provided for welding seams with different depths in narrow gap grooves.

Owner:JIANGSU UNIV OF SCI & TECH

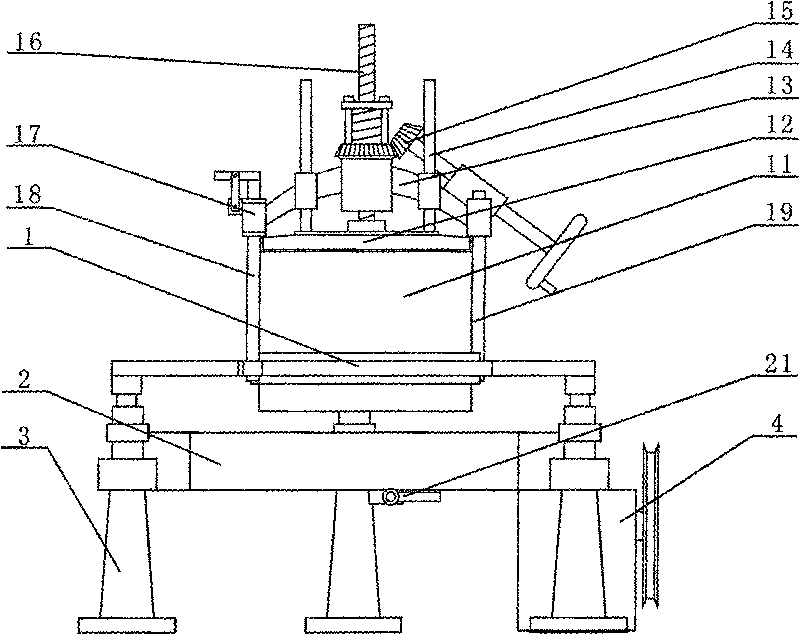

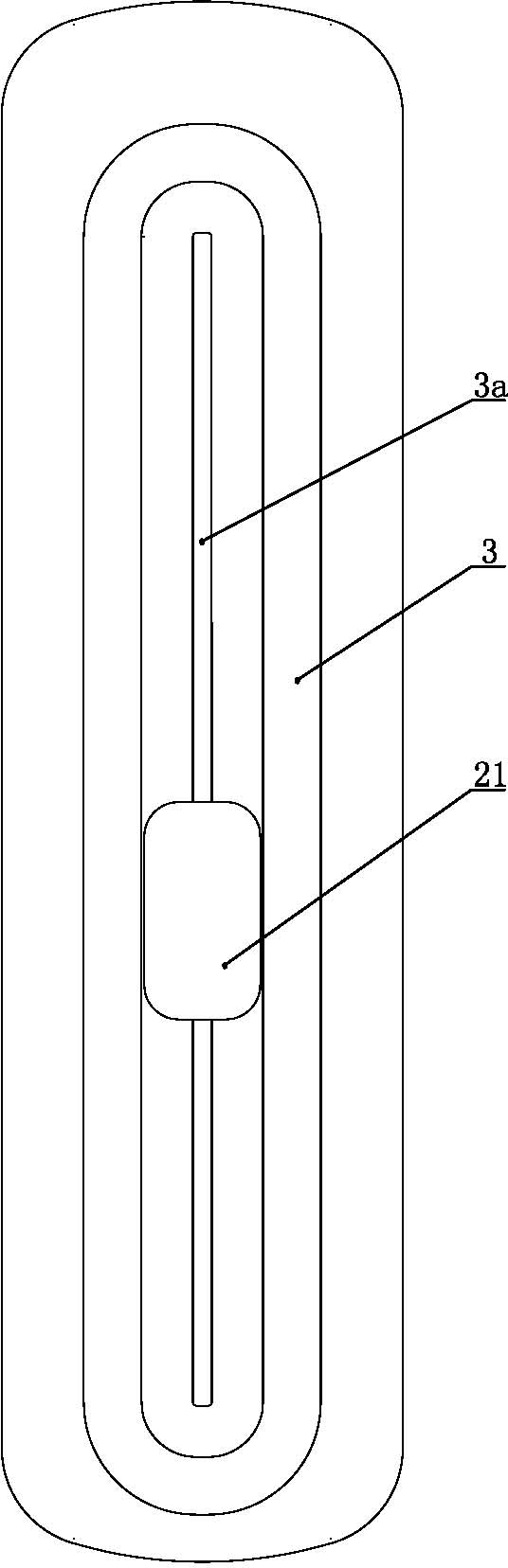

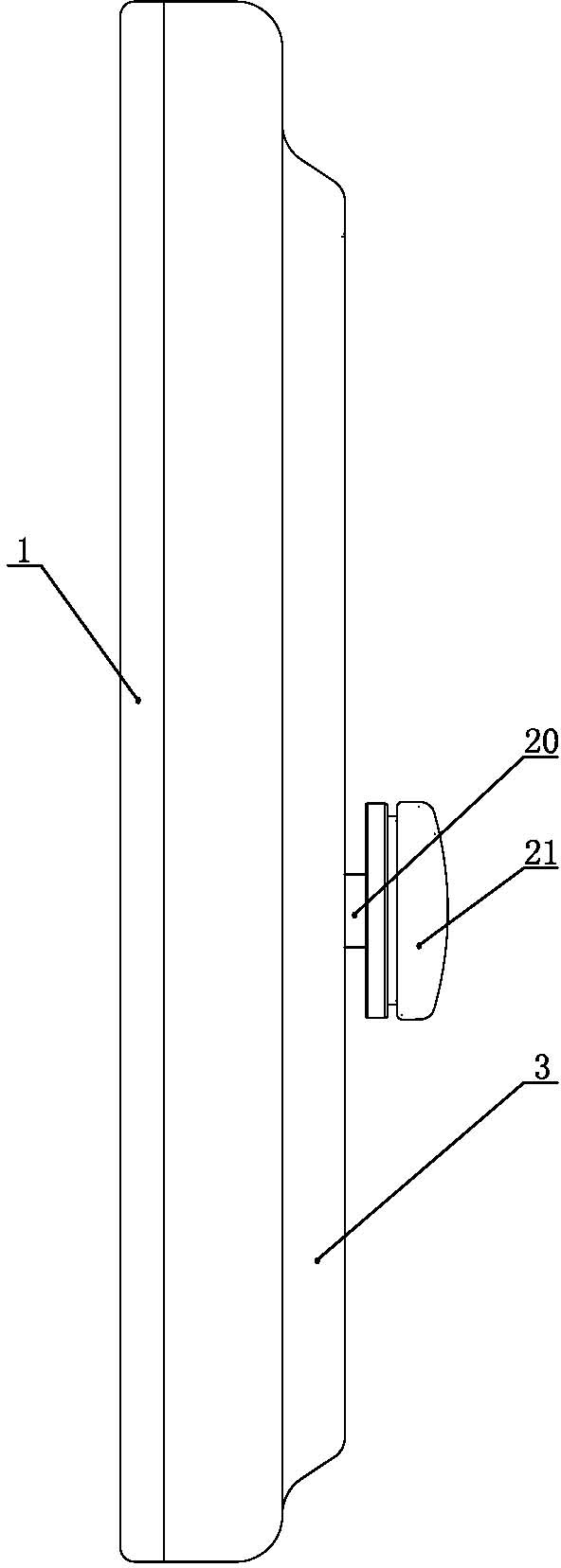

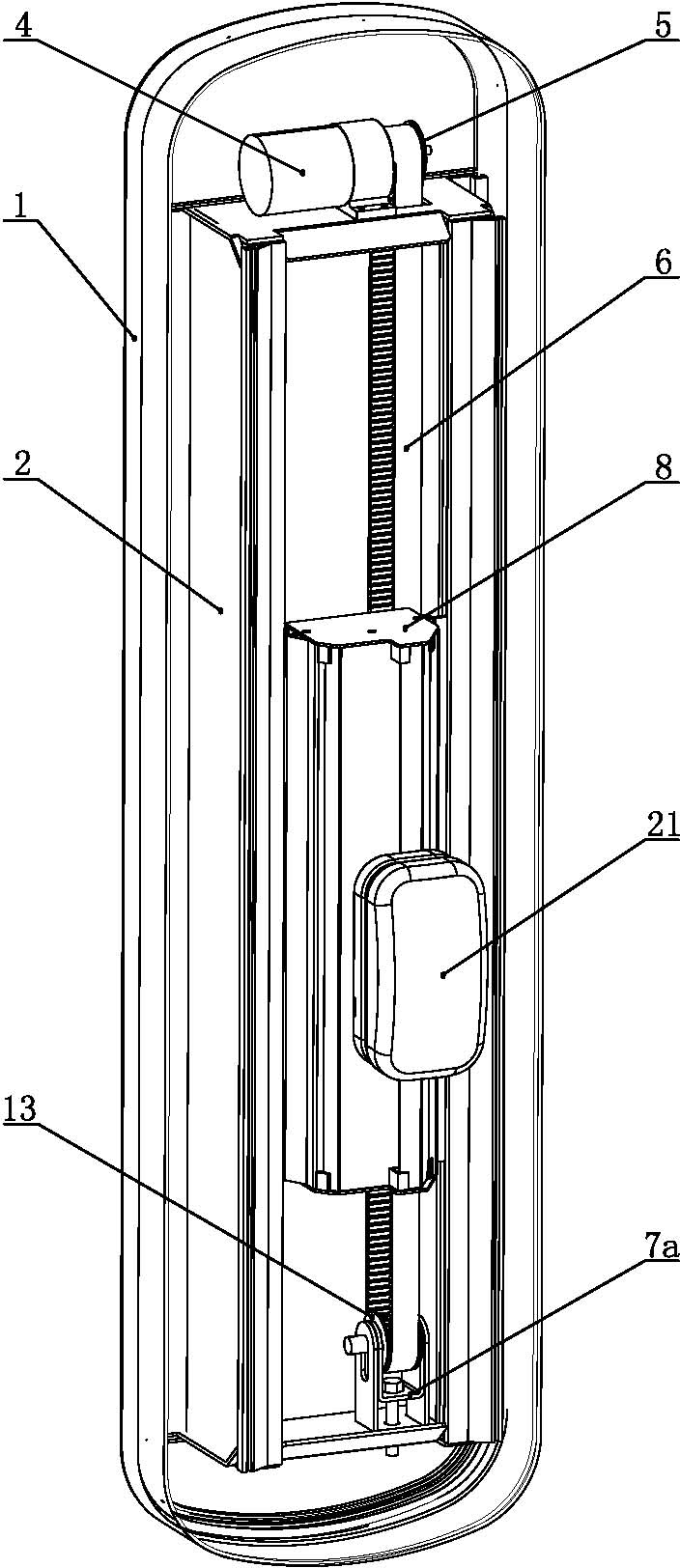

Automatic back scrubbing machine

The invention relates to an automatic back scrubbing machine, comprising a back plate, a cover shell, a back scrubbing head and a large slider moving along the height direction of the back plate, wherein the large slider is of a hollow cuboid structure; the inner walls of the two sides of the large slider are respectively provided with a small slider seat guide groove; an inner cavity of the large slider is provided with a driving chain wheel, a driven chain wheel and a chain which connects the driving chain wheel and the driven chain wheel in a transmission manner; the driving chain wheel is arranged on an output shaft of a motor of the back scrubbing head; a chain wheel shaft of the driven chain wheel is supported on a bearing block; the motor of the back scrubbing head and the bearing block are arranged at the outer side of the bottom wall of the large slider; the chain is connected with a cylindrical boss lower block by a chain long pin; a boss upper block is sheathed outside the periphery of the boss lower block and is embedded in the back of a small slider seat; the two sides of the small slider seat are respectively positioned in the small slider seat guide grooves and can move respectively along the small slider seat guide grooves; the front surface of the small slider seat is connected with a small slider; and the top end of the small slider is fixedly connected with the back scrubbing head. A boss moves along the chain and drives the back scrubbing head to move up and down, so that a larger reciprocating stroke can be realized.

Owner:YANGZHOU WEIBANG GARDEN MACHINE

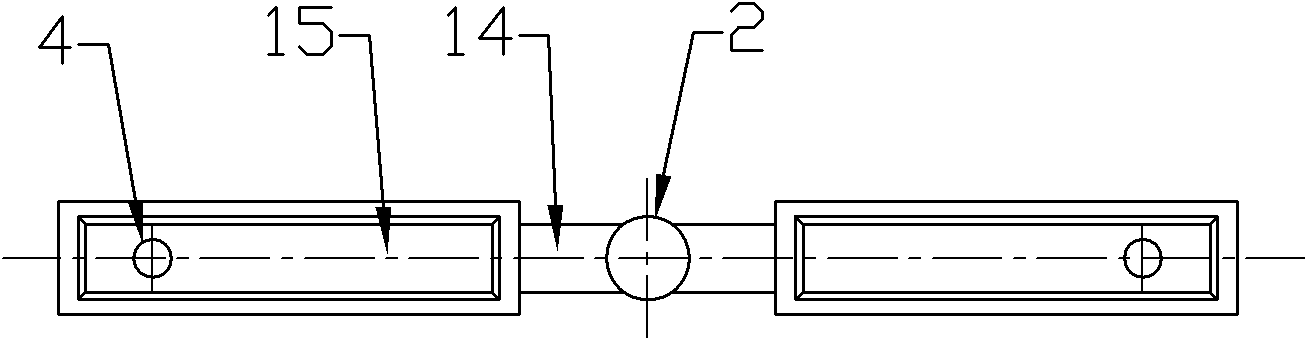

Sliding water gap device capable of preventing vortex

InactiveCN102554207ASuppression of Confluence VortexPrevent getting involvedMelt-holding vesselsReciprocating motionSlag

The invention discloses a sliding water gap device capable of preventing vortex. The sliding water gap device comprises an upper water gap, an upper sliding plate fixedly connected to the bottom of the upper water gap, a middle sliding plate which is connected with the upper sliding plate and capable of doing reciprocating motion in a horizontal direction, a lower sliding plate connected with the middle sliding plate and a lower water gap fixedly connected with the lower sliding plate, wherein a sealed cover plate is arranged on the top of the upper water gap; an opening is formed at the bottom of the upper water gap; a vertical middle hole is formed in the upper water gap; a plurality of circular side holes with the same shape and size are uniformly formed in the side face of the upper water gap and communicated with the middle hole; longitudinally perforative inner holes are formed in the middles of the upper sliding plate, the middle sliding plate, the lower sliding plate and the lower water gap; and the inner holes and the middle hole form steel liquid flow channels. According to the sliding water gap device, the residual steel quantity in a casting container can be reduced, the metal yield can be increased, and involved slag and air can be reduced.

Owner:WISDRI ENG & RES INC LTD

Sugar beet harvester with front threshing mechanism

InactiveCN108029316APrevent getting involvedEasy to cutLiftersTopping machinesMotor driveEngineering

The invention discloses a sugar beet harvester with a front threshing mechanism. The sugar beet harvester comprises a support, the front threshing mechanism, a profiling mechanism, an impurity cleaning mechanism and a pulling mechanism. The front threshing mechanism comprises a first supporting rod, a second supporting rod, a cylinder, a motor, a rotating disk, a cutter shaft, a plurality of threshing rods and a cutter. The motor drives the rotating disk and the cutter shaft which are perpendicular to each other, and the threshing rods are mounted on the rotating disk. The cutter is mounted onthe cutter shaft and positioned in front of the threshing rods, the front threshing mechanism is provided with a stem leaf cutter, and parts of stem leaves higher than a preset height can be cut offbefore a working part enters the sugar beet harvester. The cut stem leaves are scattered by the threshing rods and prevented from being drawn into the working part.

Owner:王友芳

Method and device for preventing thin-strip continuous casting molten bath surface from contaminating

ActiveCN102371349AGuaranteed cleanlinessPrevent getting involvedCasting cleaning apparatusMelting tankSlag

The invention provides a method and a device for preventing a thin-strip continuous casting molten bath surface from contaminating. The method comprises the following steps of arranging molten bath liquid level detecting devices on the both ends of a molten bath, respectively observing the situations of floating slag on a molten bath surface of a driving side and a driven side of a casting roller and liquid height of the molten bath, if the distance between the floating slag edge of the molten bath surface and the junction line of molten steel and the rolling surface of the casting roller surface is monitored less than 25 mm, removing the floating slag from the molten bath surface through a floating slag removing device, thereby keeping cleaness of a thin-strip continuous casting molten bath, avoiding the floating slag to be drawn in a solidified steel billet shell, and improving the quality of a cast strip. With the adoption of the method and device provided by the invention, the molten steel on the molten bath surface can be avoided to be solidified; the cleanness situation of the surface of the thin-strip continuous casting molten bath can be observed, so that after the floating slag is accumulated to a certain extent, the floating slag can be removed through the floating slag removing device, thereby keeping the thin-strip continuous casting molten bath tidy, avoiding the floating slag to be drawn in the solidified steel billet shell and improving the quality of the cast strip.

Owner:BAOSHAN IRON & STEEL CO LTD

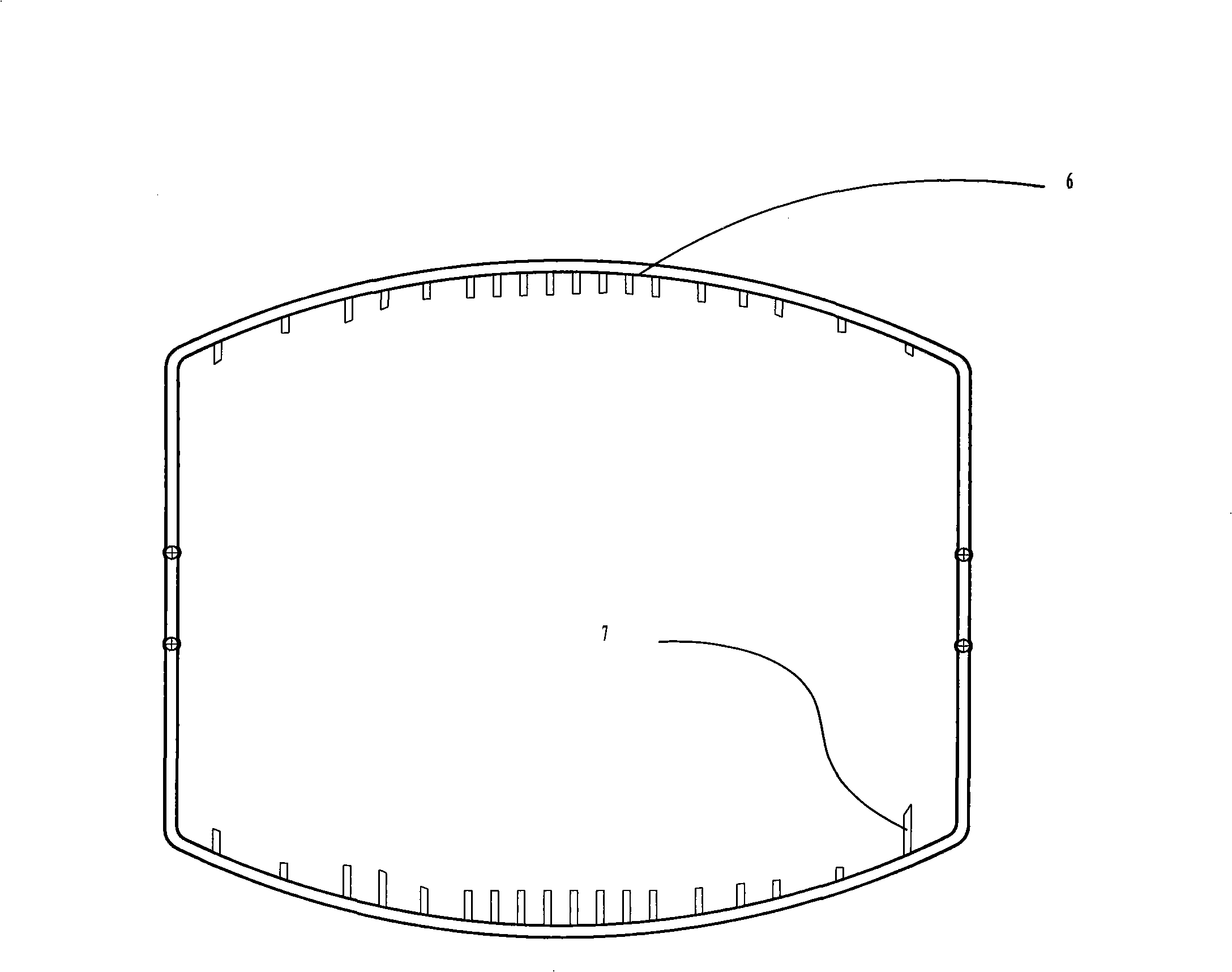

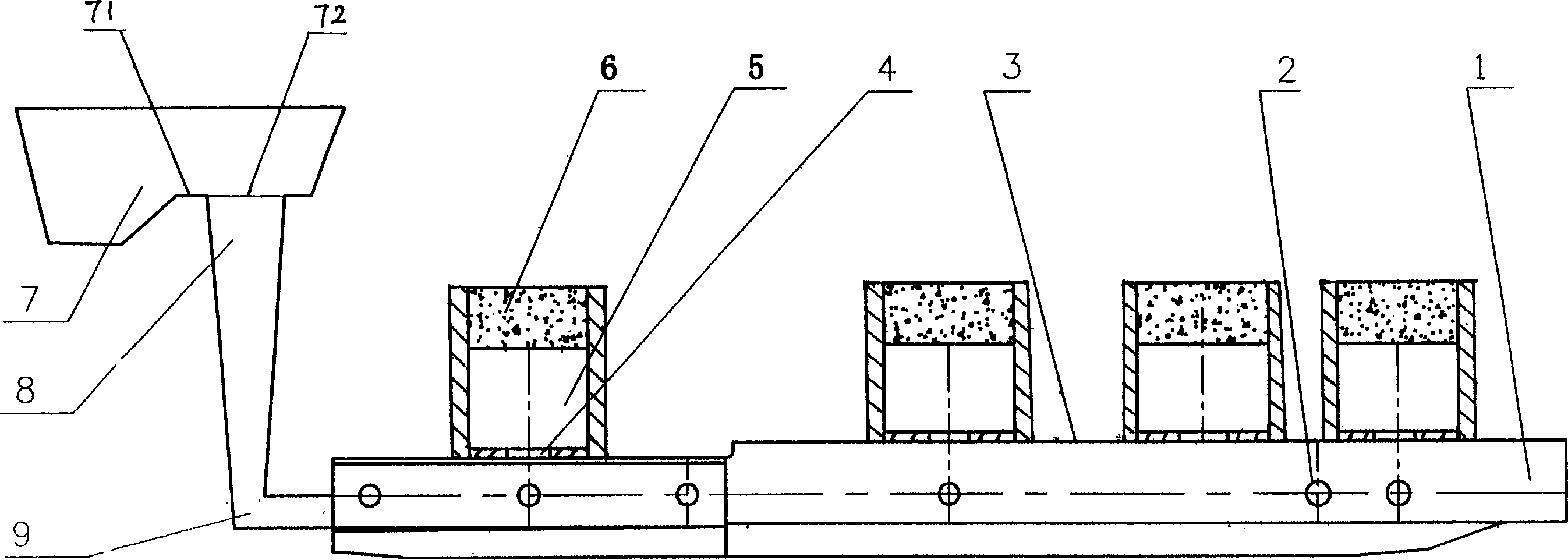

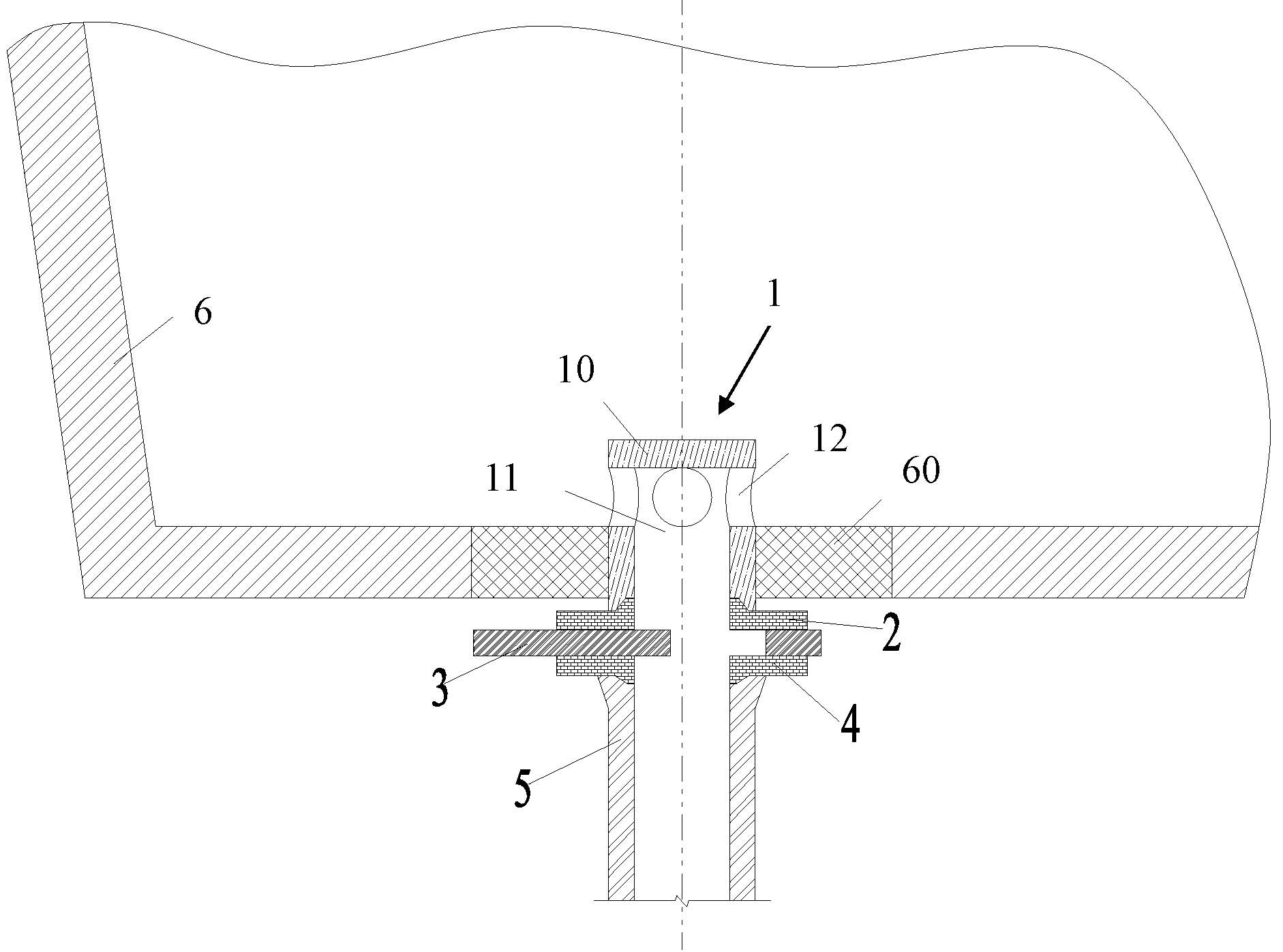

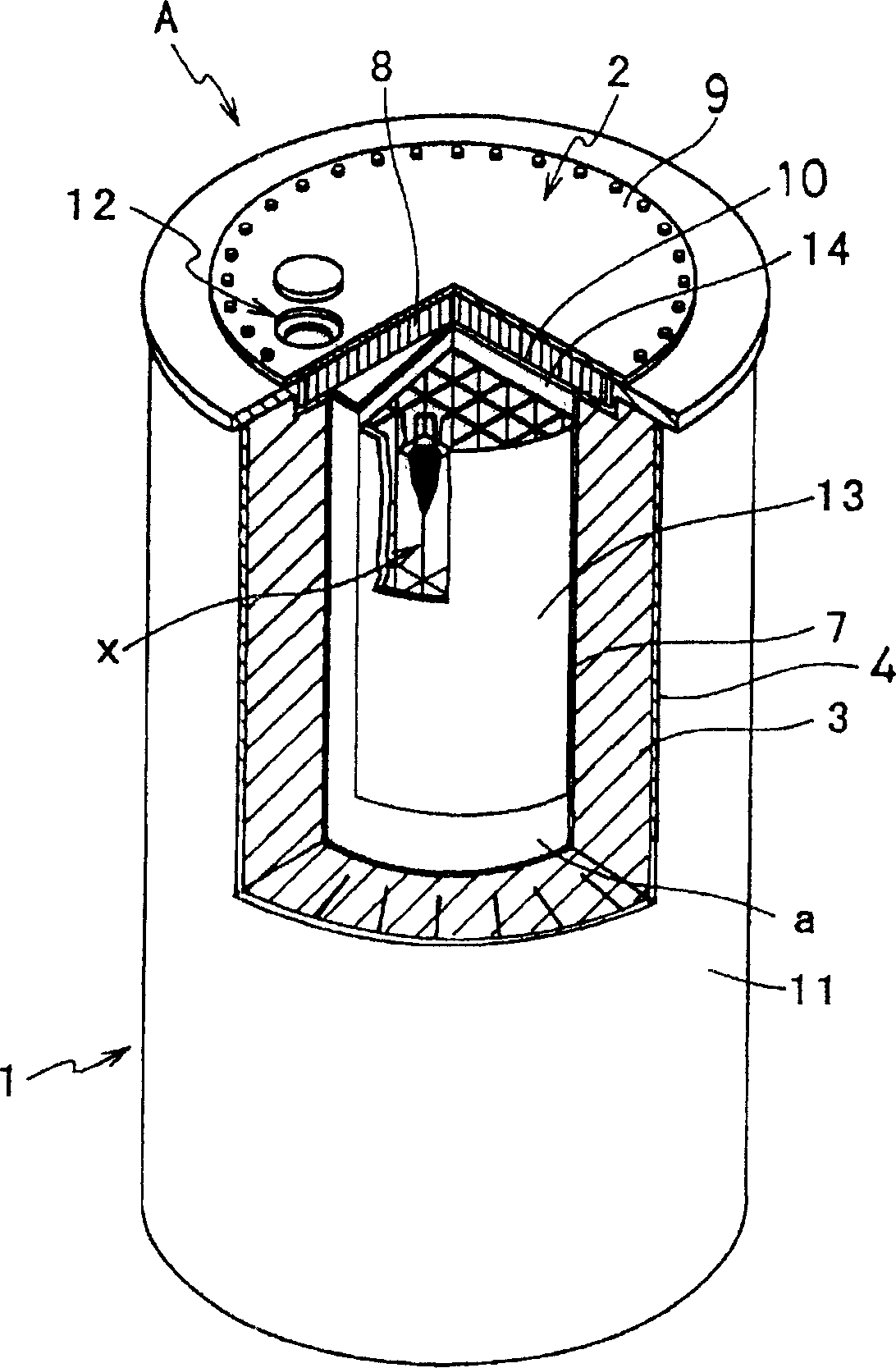

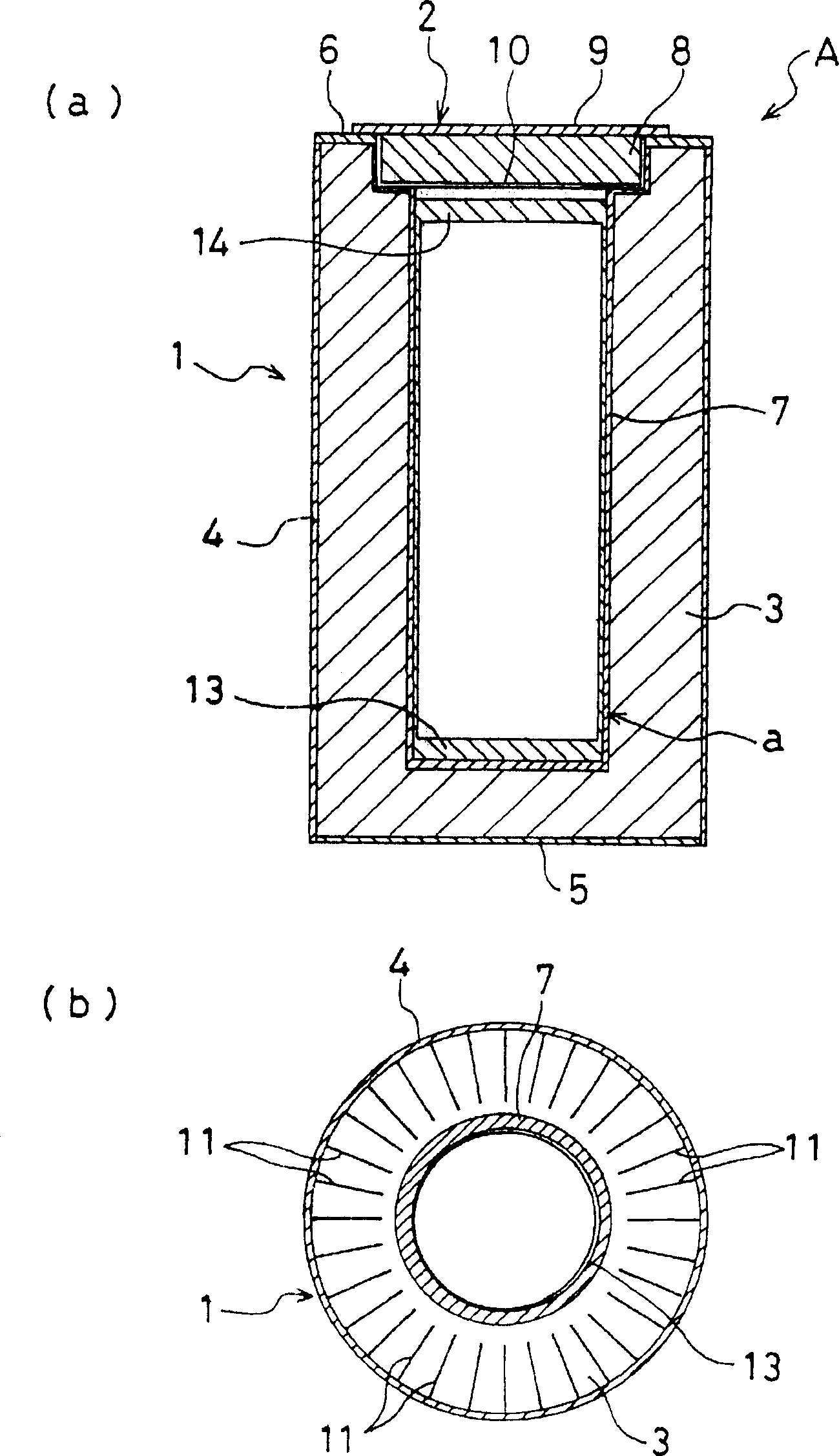

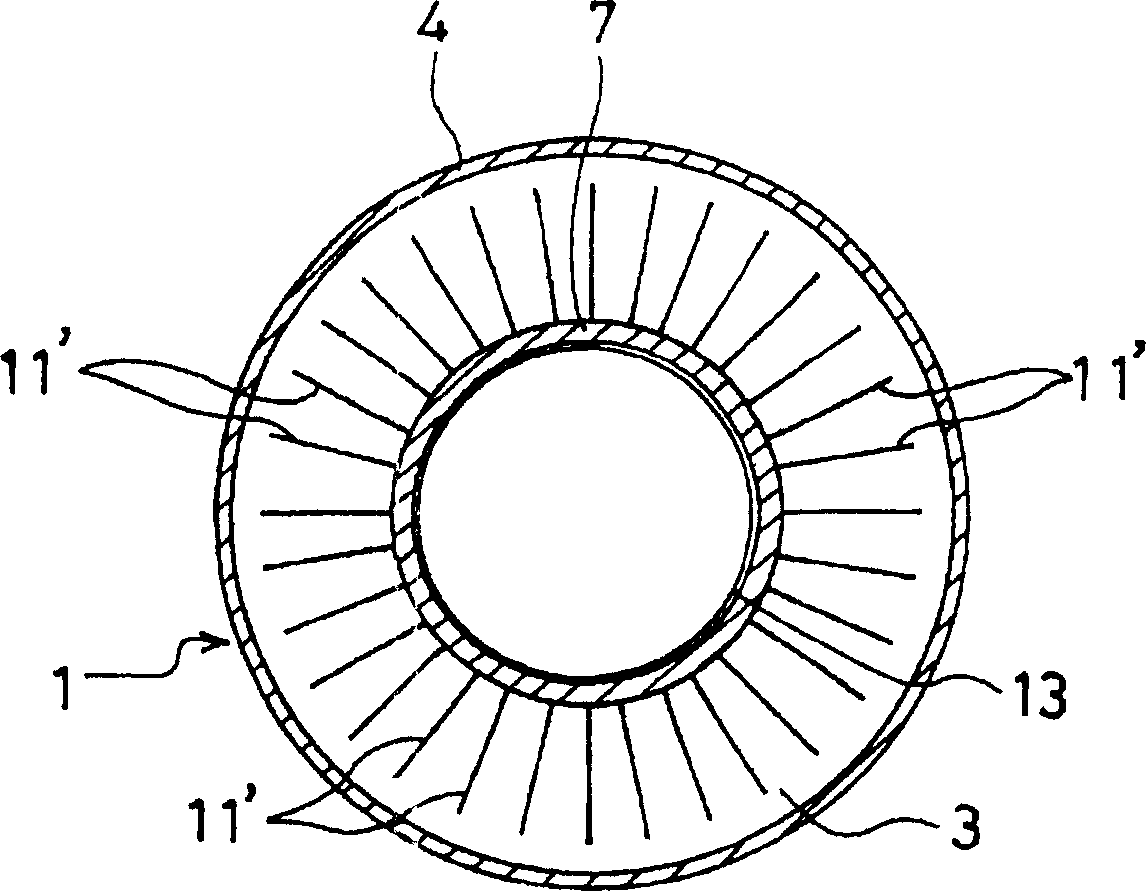

Concrete cylinder-like vessel and its mfg. method

InactiveCN1519864AEliminate voidsPrevent getting involvedShieldingKitchen equipmentRadioactive agentMetallic materials

Provided is a sealed type concrete cask keeping a conventional heat removal performance or having a higher heat removal performance than hitherto, and preventing leak of radioactivity to the outside. This concrete cask A has a formation wherein a shielding body 3 made of concrete and a metal heat-transfer fin 11 are provided between a metal inner cylinder 7 and an outer cylinder 4, and a storage part for storing a radioactive material x is provided inside the inner cylinder 7. The storage part has a sealed structure so as to be blocked from the cask A outside. The heat-transfer fin 11 is provided so that its outer cylinder 4 side part is in contact with the outer cylinder 4, and is notched so that its inner cylinder 7 side part forms a separate part relative to the inner cylinder 7.

Owner:KOBE STEEL LTD +1

Alloy liquid extrusion casting and forming device and technical method thereof

Owner:中建投(绍兴)机械科技有限公司

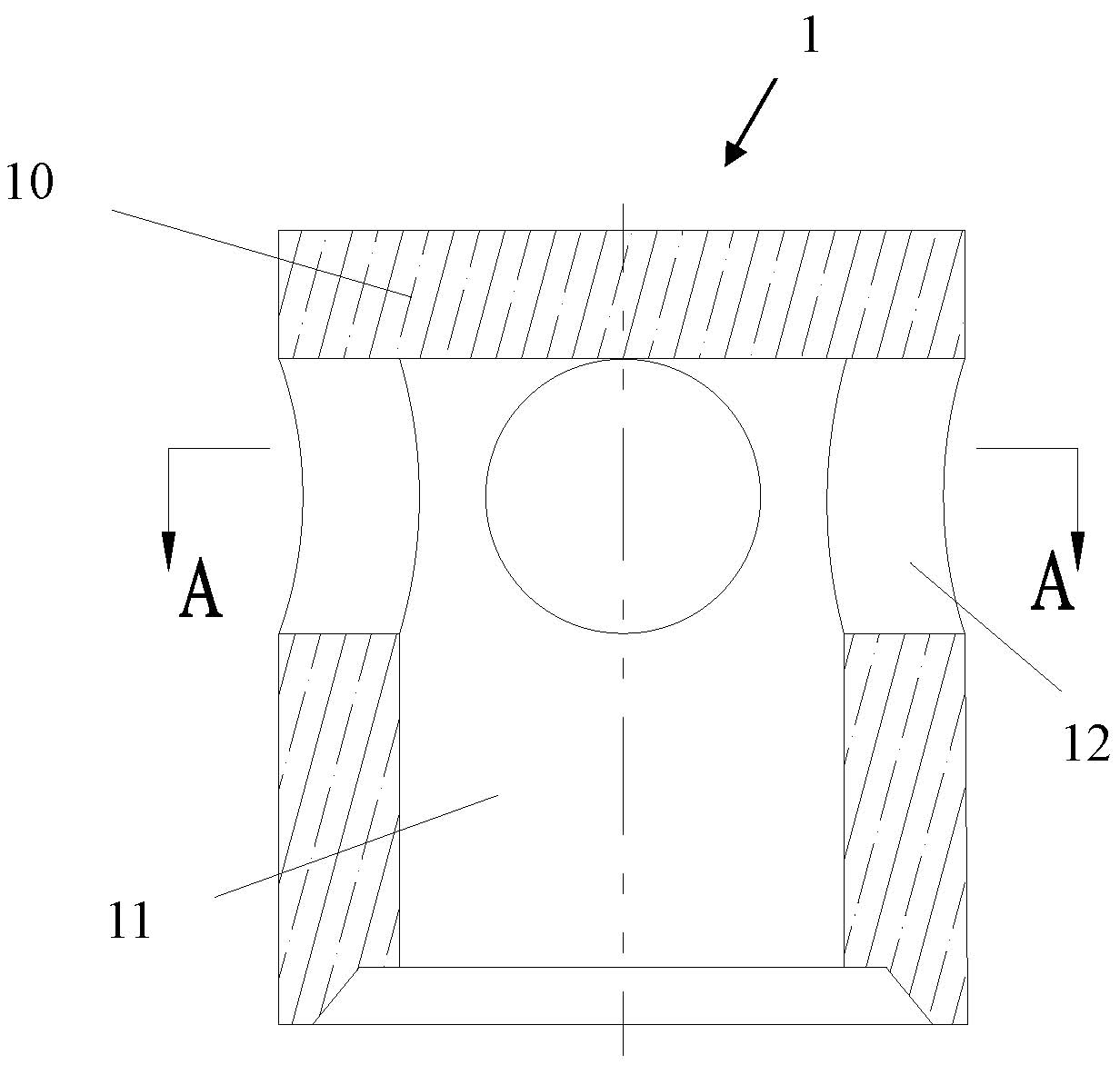

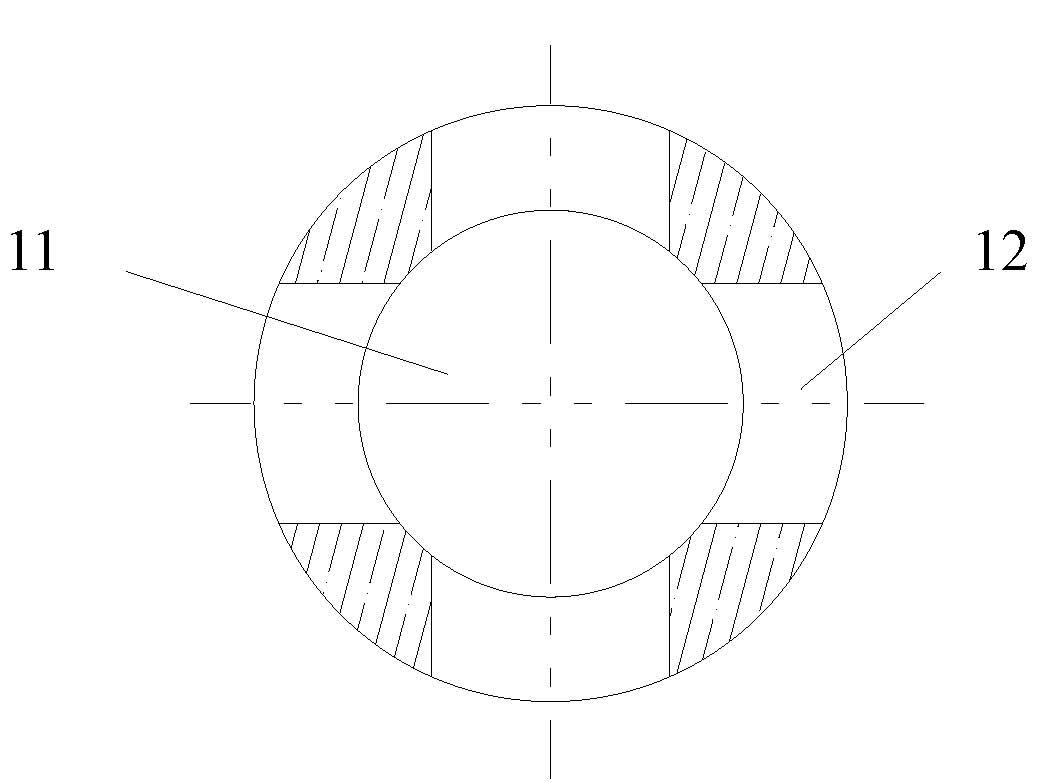

Bottom gating system with ingate in circular cross section

The invention discloses a bottom gating system with an ingate in circular cross section, which belongs to the technical field of casting, the existing gating system is not applicable to gating large casts, high in rejection rate and easy to lead the casts to produce stress and porosity so as to cause the high rejection rate of the casts. The bottom gating system comprises a mold cavity and a main sprue, a runner, a sub-sprue and a sub-runner in sequential connection, and is characterized in that the sub-runner is connected to the bottom part of the mold cavity via the ingate in the circular cross section. The bottom gating system can reduce the volume of a sand box, reduce the consumption of molding sand and further greatly reduce the production cost by adopting the ingate in the circular cross section; the bottom gating system can further lead molten metal to flow into the mold cavity smoothly, effectively prevent oxidizing slag which is produced by turbulent flow of the molten metal from being entangled into the mold cavity, prevent the production of slag inclusion in the cast, and further improve the quality of the cast; as molten iron enters into the mold cavity through the ingate in the circular cross section, the bottom gating system is difficult to produce temperature difference, and can reduce the production of the porosity and ensure the quality of the cast; and the operation is convenient.

Owner:ZHEJIANG JIALI WIND POWER TECH

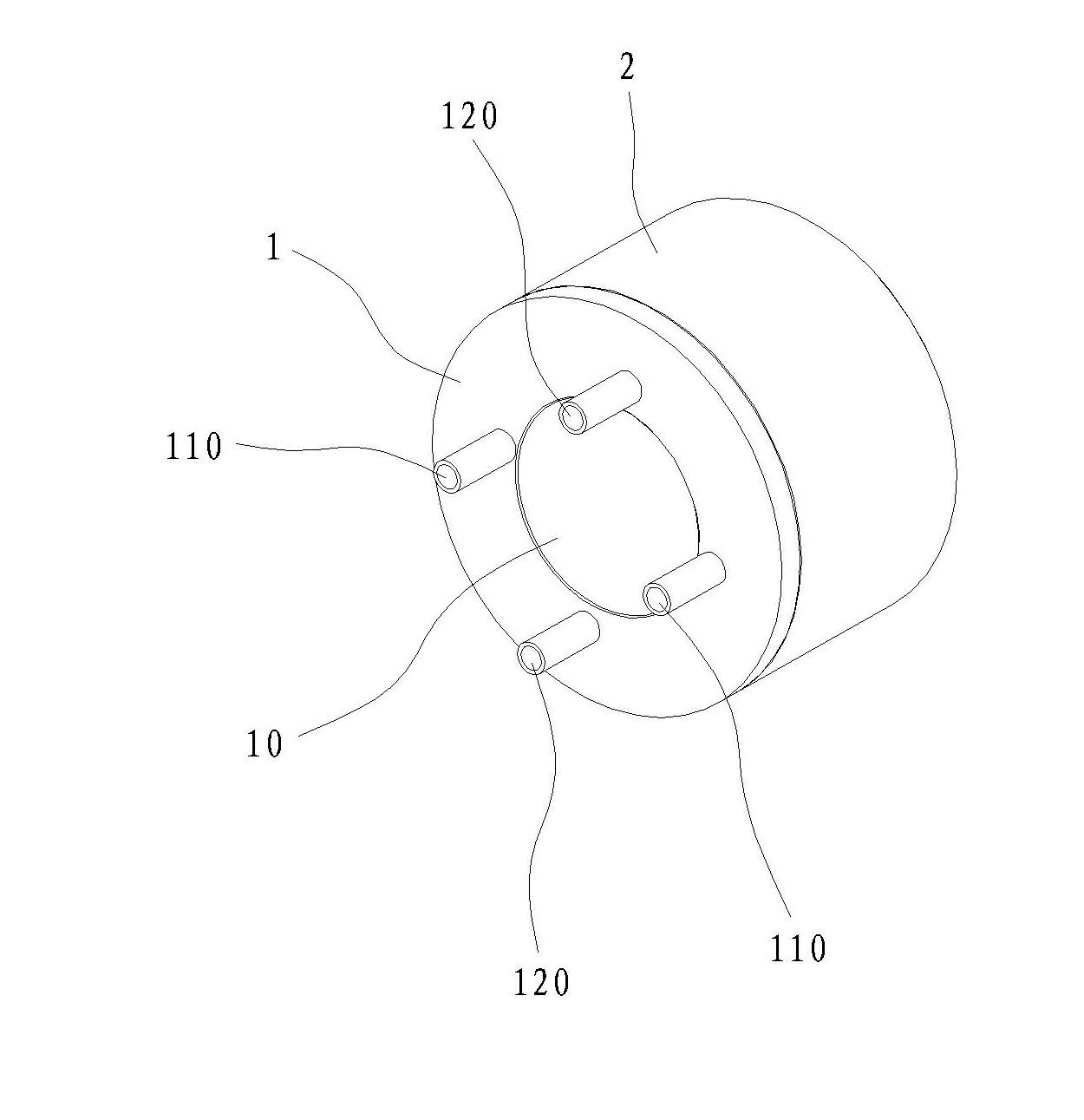

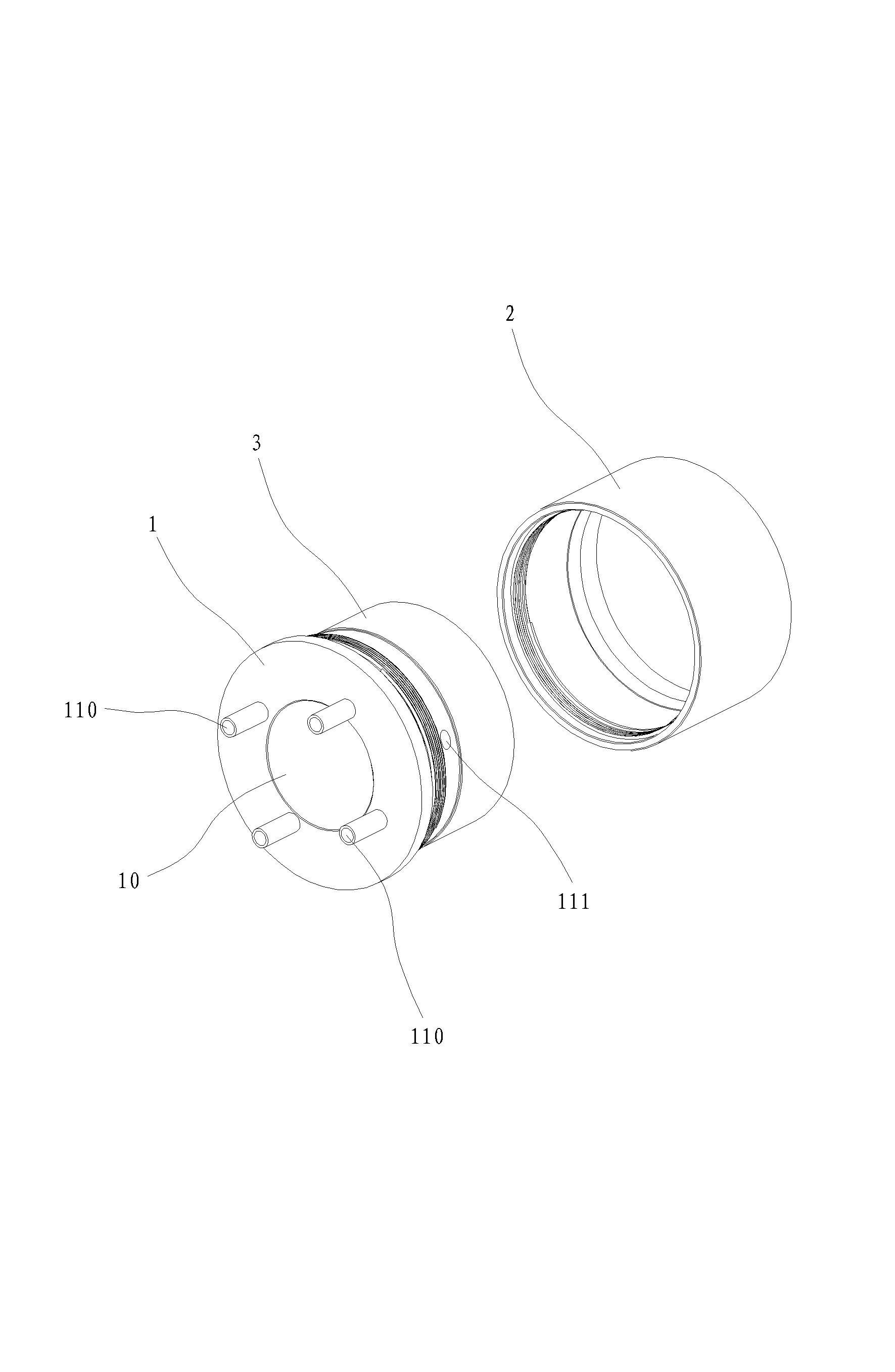

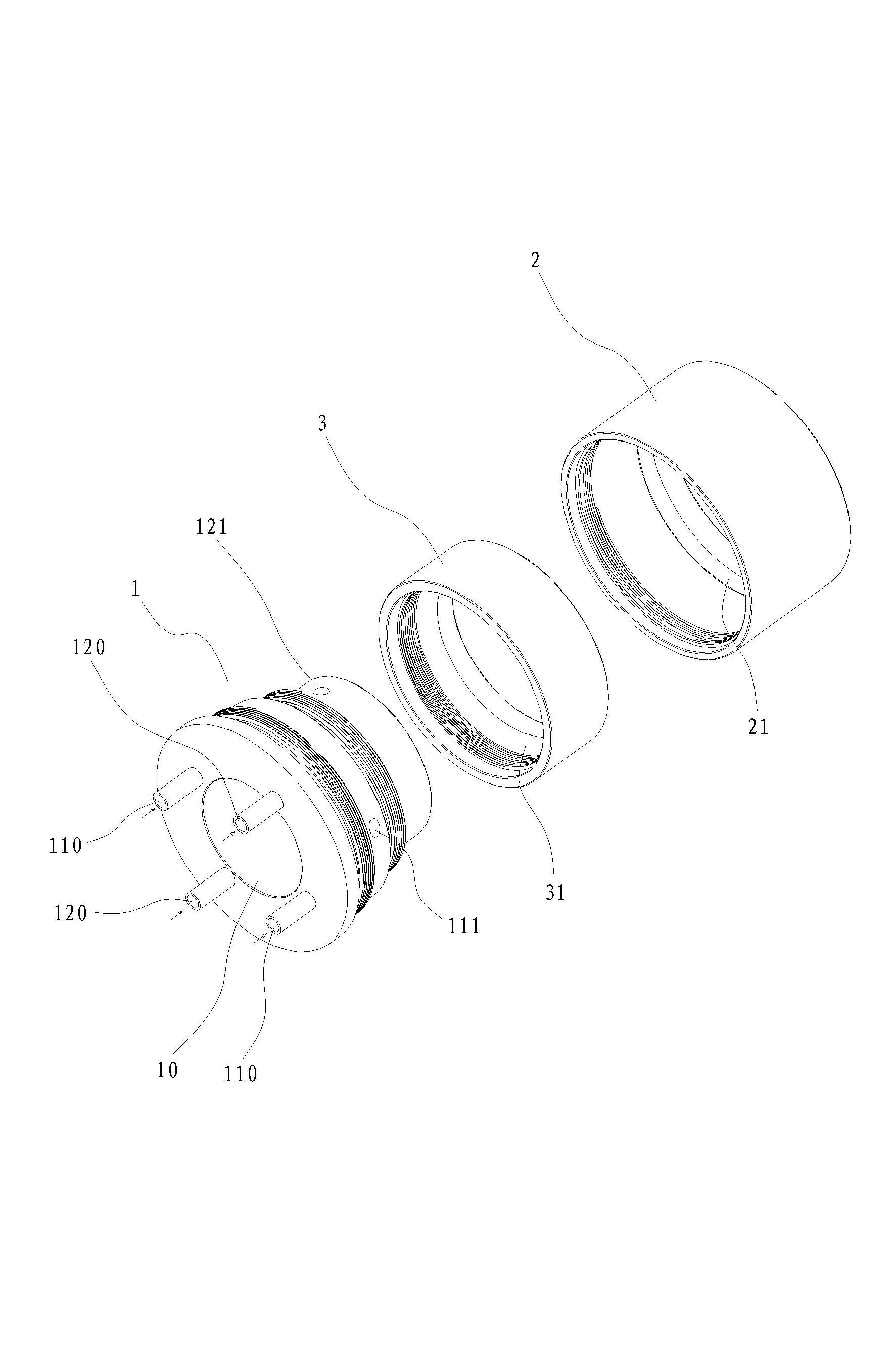

Plasma jet-stream protective cover

InactiveCN102618815APrevent getting involvedPrevent oxidationMolten spray coatingPlasma jetEngineering

The invention discloses a plasma jet-stream protective cover, which comprises a jet-stream core body and a jet-stream core body center axial direction through hole. One end face of the core body is provided with two groups of air intakes. A core body perisporium is correspondingly provided with two groups of air outtakes. The two groups of air outtakes are communicated with the corresponding air intakes so as to form an inner layer of protection air and an outer layer of protection air. An inner ring is connected to the jet-stream core body and is cooperated with one group of air outtakes on the front end of the core body perisporium. An outer ring is connected to the jet-stream core body and is cooperated with the other group of air outtakes of the core body perisporium. The jet-stream core body, the inner ring and the outer ring are together assembled into a cover structure. One end of the cover structure is used for air suction, and the other end forms two layers of protection air rings and is extended forward so as to enable the plasma jet-stream to be effectively separated from the atmosphere. One protective device is installed on one spray gun of an atmosphere plasma spray coating device, completely-molten or half-molten powder is protected inside the protective air along with the flame through the protection of the air so as to be separated from the atmosphere, the oxidization and nitrogenization of the powder in a high temperature can be reduced, and the quality of a target coating can be improved.

Owner:WUHU YINGRI TECH CO LTD

Cutting device

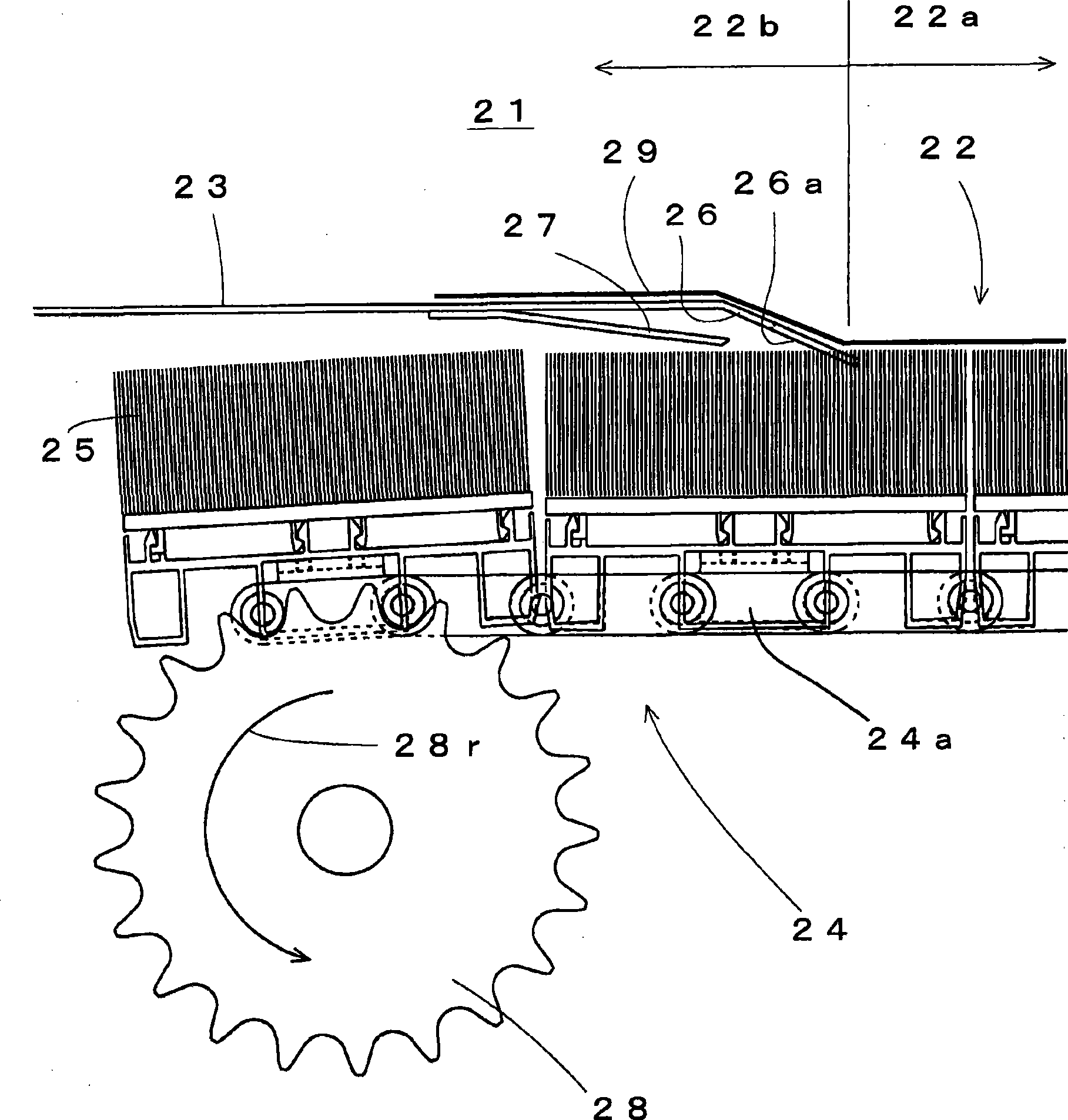

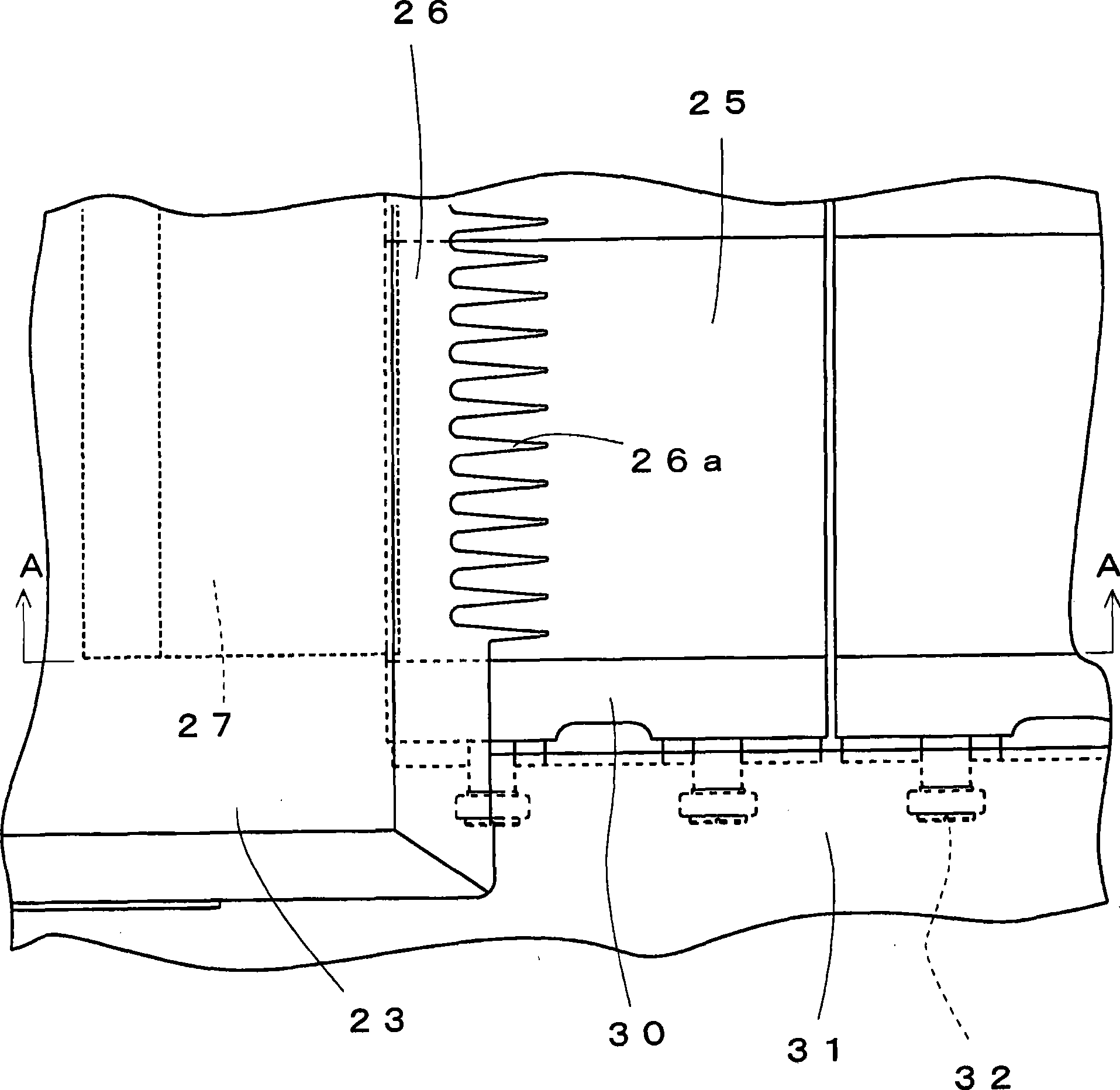

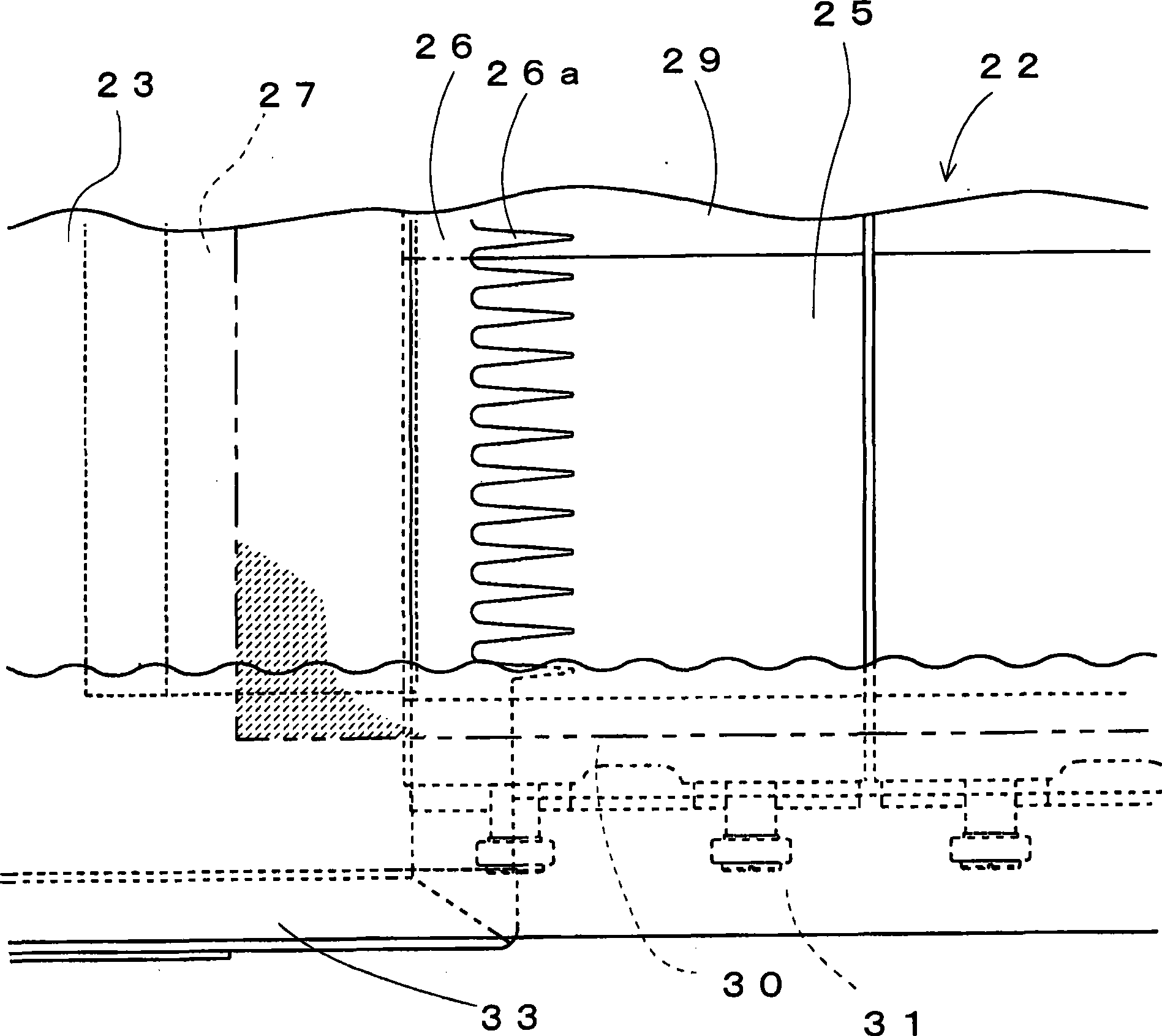

The invention relates to a cutting machine in which a sealing strip can smoothly transfer from the cutting stage to the moving out side without stagnation caused by adsorption even when the sealing strip absorbs the cut slice material and transfers same at the same time. The front end of a wind power working stage (23) of a bending transfer side is used as an inclining portion of a guiding plate (26), the further front end of the guiding plate (26) is used as a guiding pawl (26a) and is formed to be a comb shape. The substrate end side of a shielding plate (27) is welded on the back side of wind power working stage (23) at the moving out side. The shielding plate (27) is fixed at a state that no unevenness is generated on the surface of the working stage (23) at the moving out side by welding. Since the shielding plate (27) exists, wind flow is attenuated, turbulence is formed, and absorption towards the sealing strip (29) near to the guiding pawl (26a) is attenuated, thereby preventing absorption.

Owner:SHIMA SEIKI MFG LTD

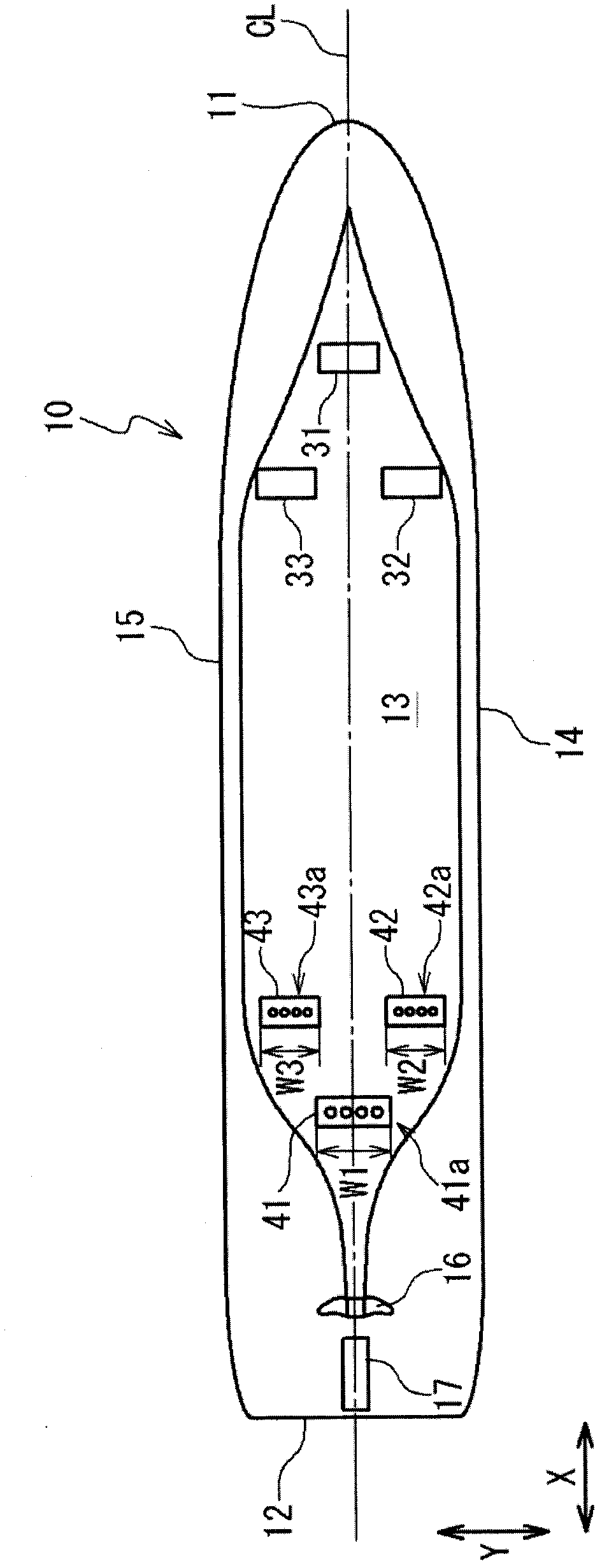

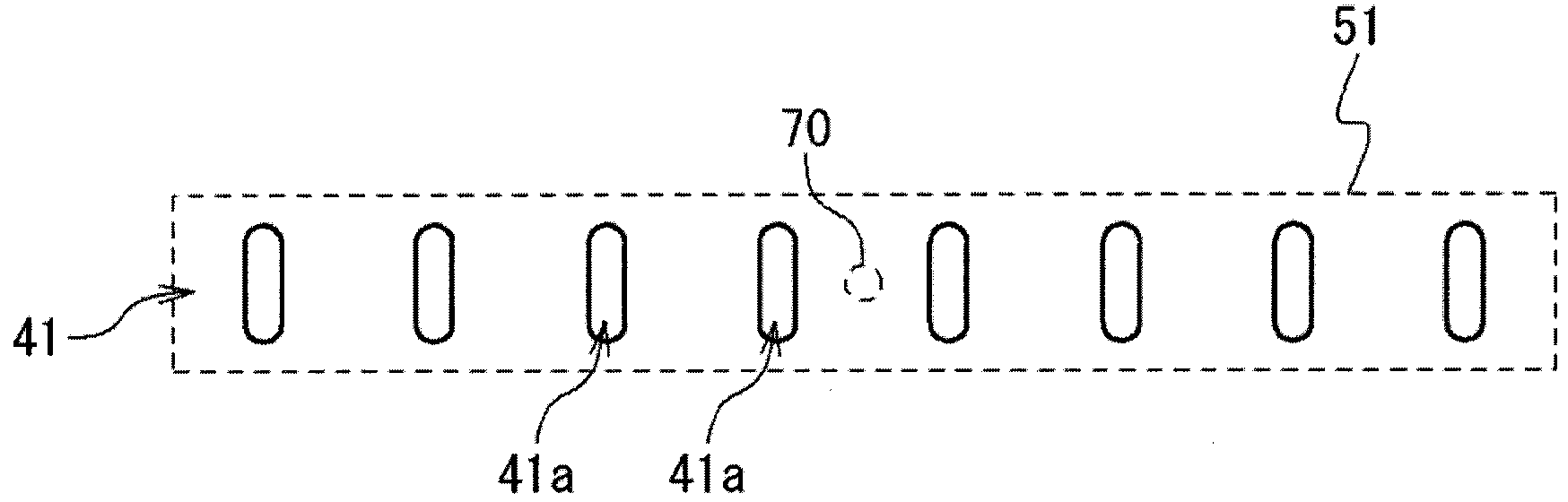

Ship encountering less frictional resistance

InactiveCN102933455AReduce frictional resistanceEnsure and maintain strengthWatercraft hull designPropulsive elementsPropellerUltimate tensile strength

Owner:MITSUBISHI SHIPBUILDING CO LTD

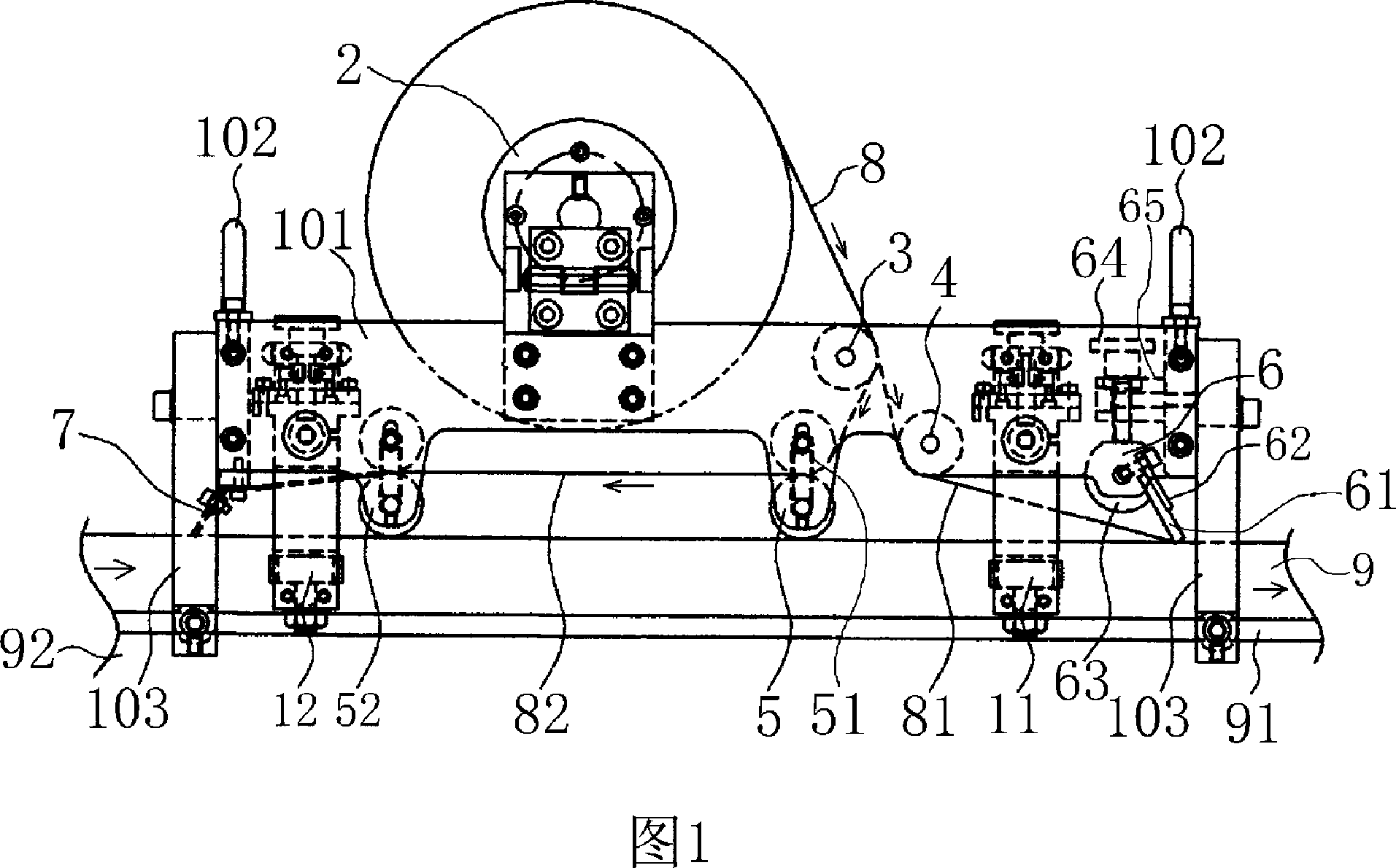

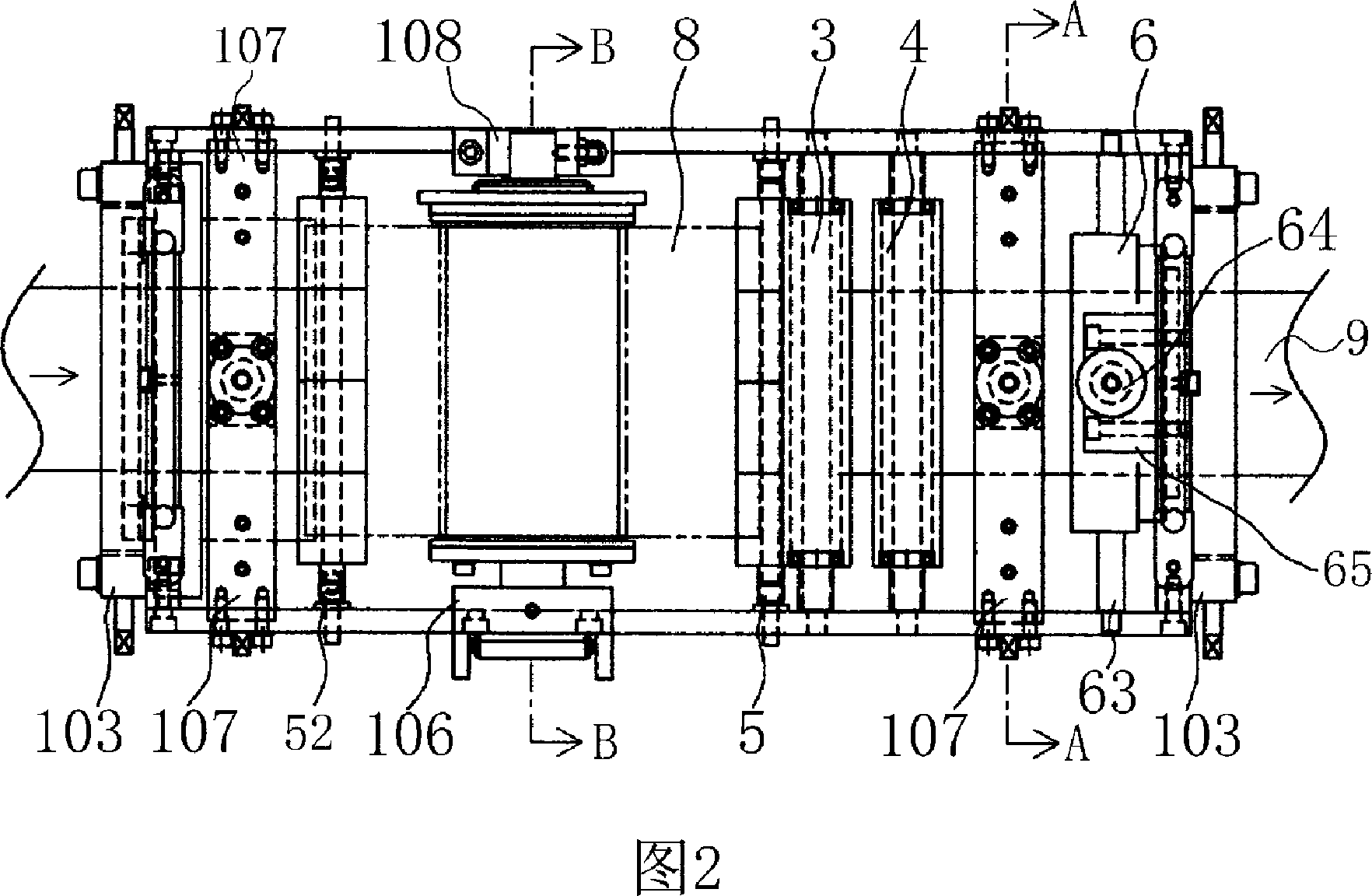

Label sticking device for handrial belt

InactiveCN101066710AEasy to assemble and disassembleReduce disassemblyLabelling flat rigid surfacesLabelling machinesHandrailEngineering

The label sticking device for handrail belt includes a frame, a label supplier, a separating roller, a label guiding wheel, a pair of stripped layer guide wheel, a compressing unit, a stripped layer exhausting unit and a holding unit. The frame includes two parallel borders, portal supports, fixing unit, forcer and other parts; and the label supplier includes label spool and label spool shaft. The present invention can stick label to required portions, and has simple structure, light weight, easy installation and easy disassembling.

Owner:田恩国

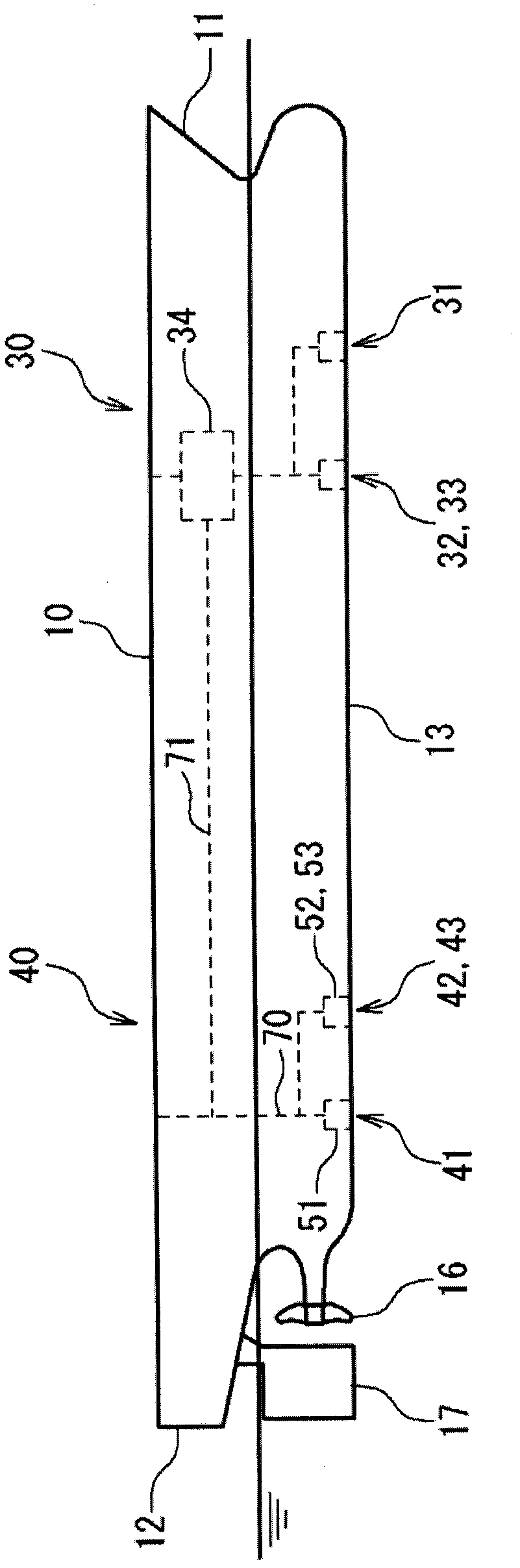

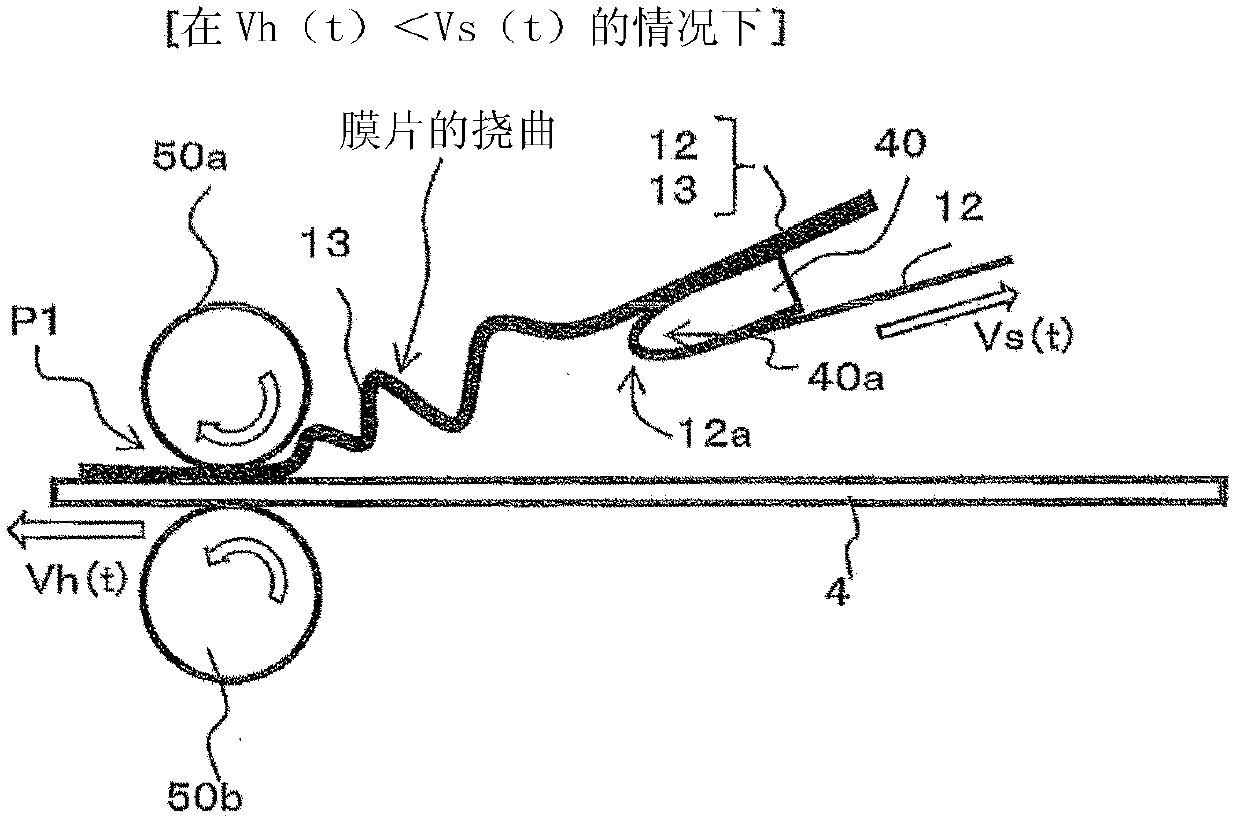

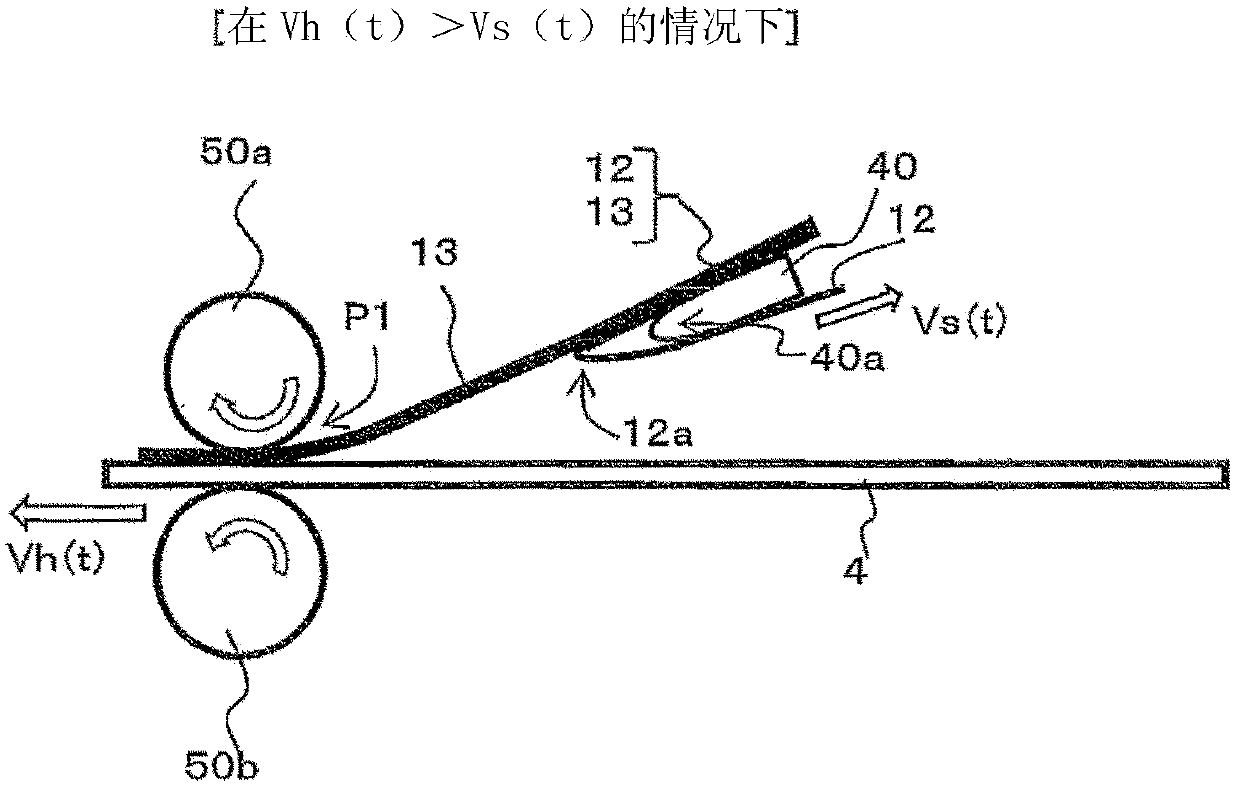

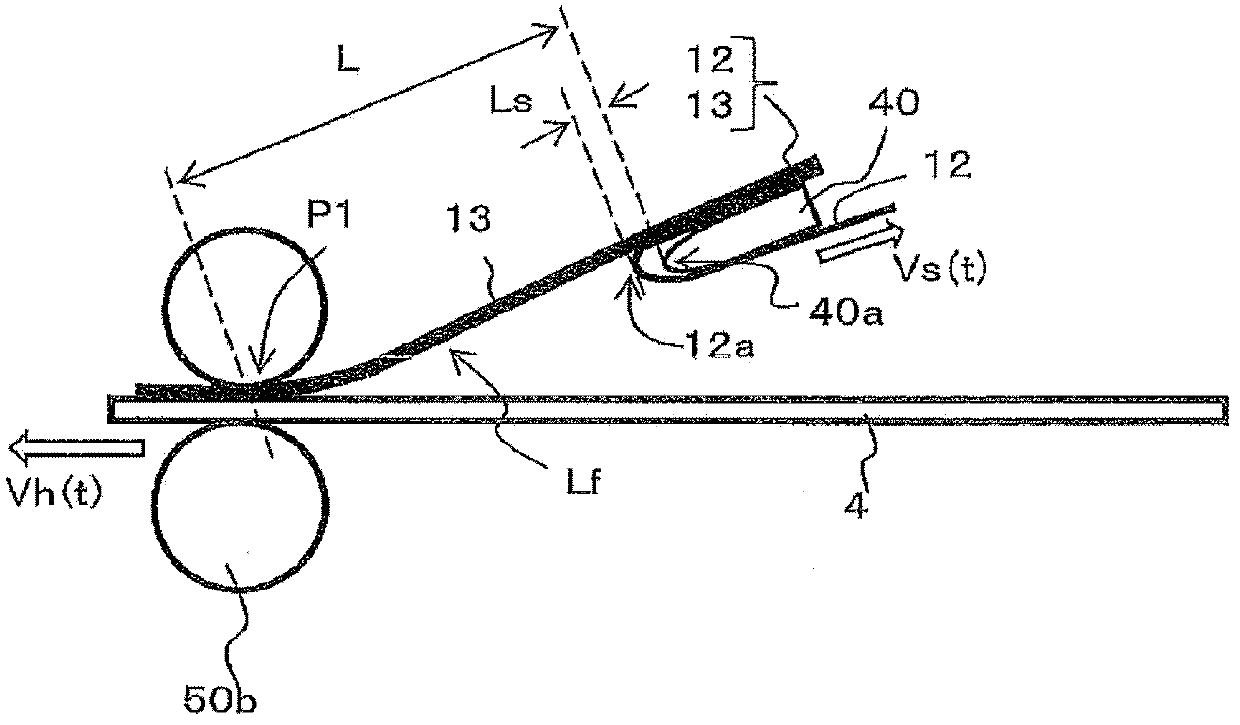

Method and system for continuously manufacturing optical display panel

ActiveCN103373489AAvoid deflectionReduce vibrationLamination ancillary operationsLayered product treatmentAir bubbleElectrical and Electronics engineering

Owner:NITTO DENKO CORP

Semitrailer with turning protection device

InactiveCN107284385APrevent getting involvedEnsure safetyAcoustic signal devicesPedestrian/occupant safety arrangementOvervoltageElectricity

The invention discloses a semi-trailer equipped with a turning protection device. The semi-trailer includes a head, a trailer board, a controller, a turning reminding device, a turning protection device and an anti-pressure protection device. A turning reminder device for personnel, a trailer plate is hung behind the front of the vehicle, and turning protection devices are installed on both sides of the trailer plate, and an anti-pressure protection device is installed at the bottom of the trailer plate. The way of connection is to connect with the controller installed on the trailer board. The invention has the advantages of simple structure and convenient use, can effectively prevent traffic accidents when the trailer is turning, and ensure driving safety.

Owner:利辛县凯盛汽车有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com