Sliding water gap device capable of preventing vortex

A sliding nozzle and vortex technology, which is applied in casting melt containers, metal processing equipment, casting equipment, etc., can solve the problems of increasing the purchase cost and manufacturing cost of refractory materials, increasing the content of steel inclusions, and reducing the purity of the casting billet, etc. Achieve the effect of improving the quality of the slab, reducing the production cost and reducing the consumption of refractory materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to facilitate a further understanding of the structure and achieved effects of the present invention, preferred embodiments are described in detail below in conjunction with the accompanying drawings.

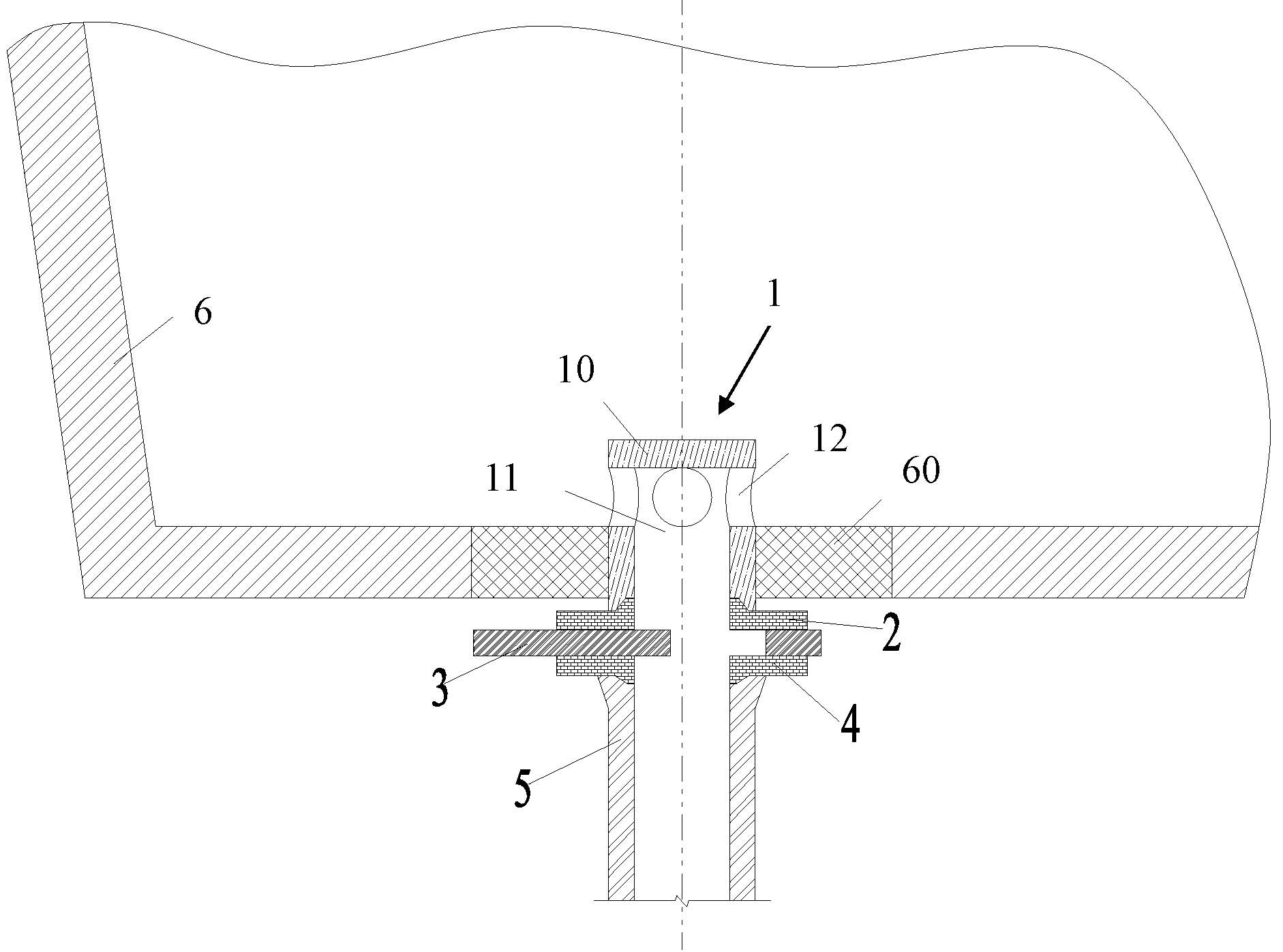

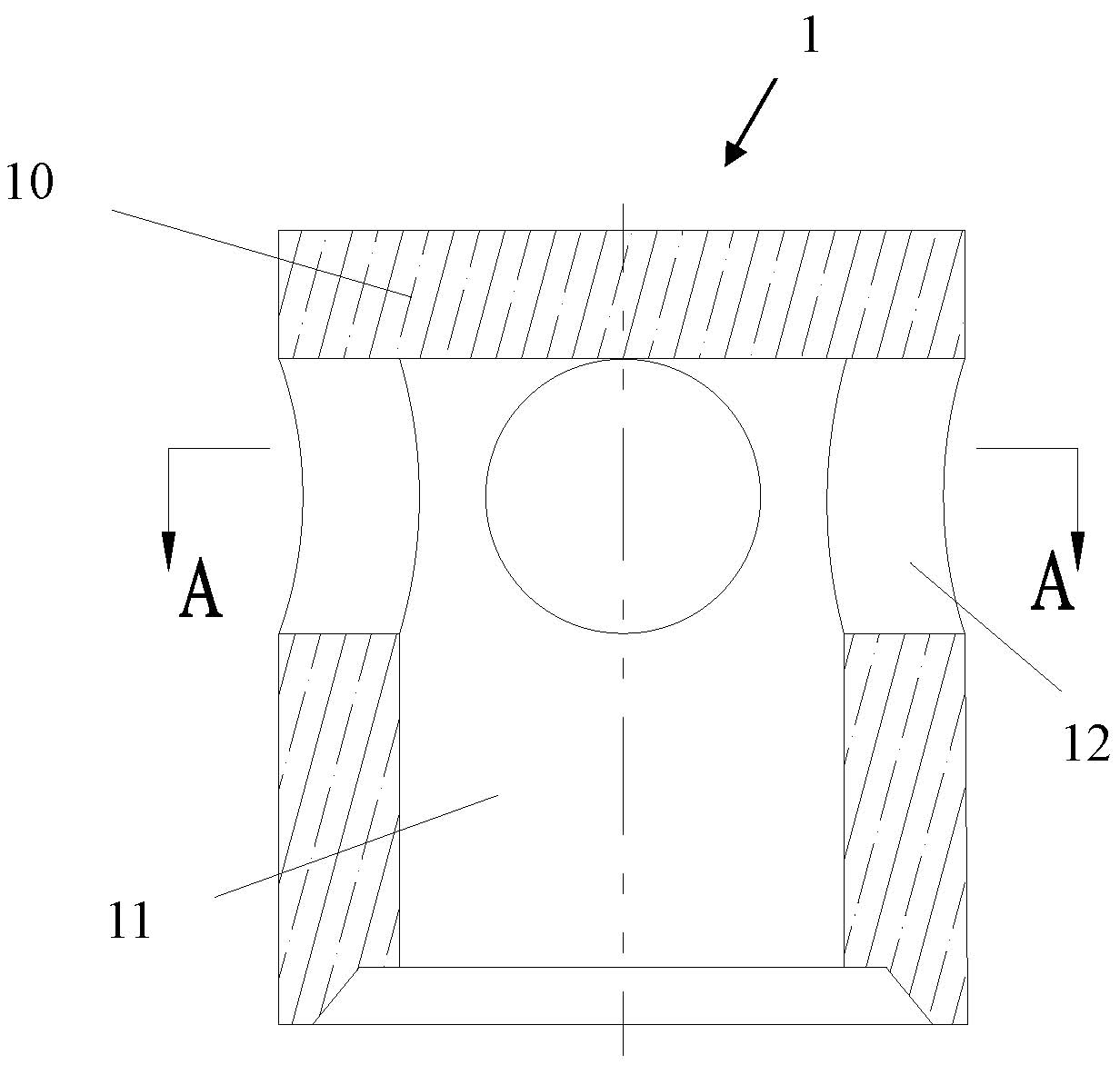

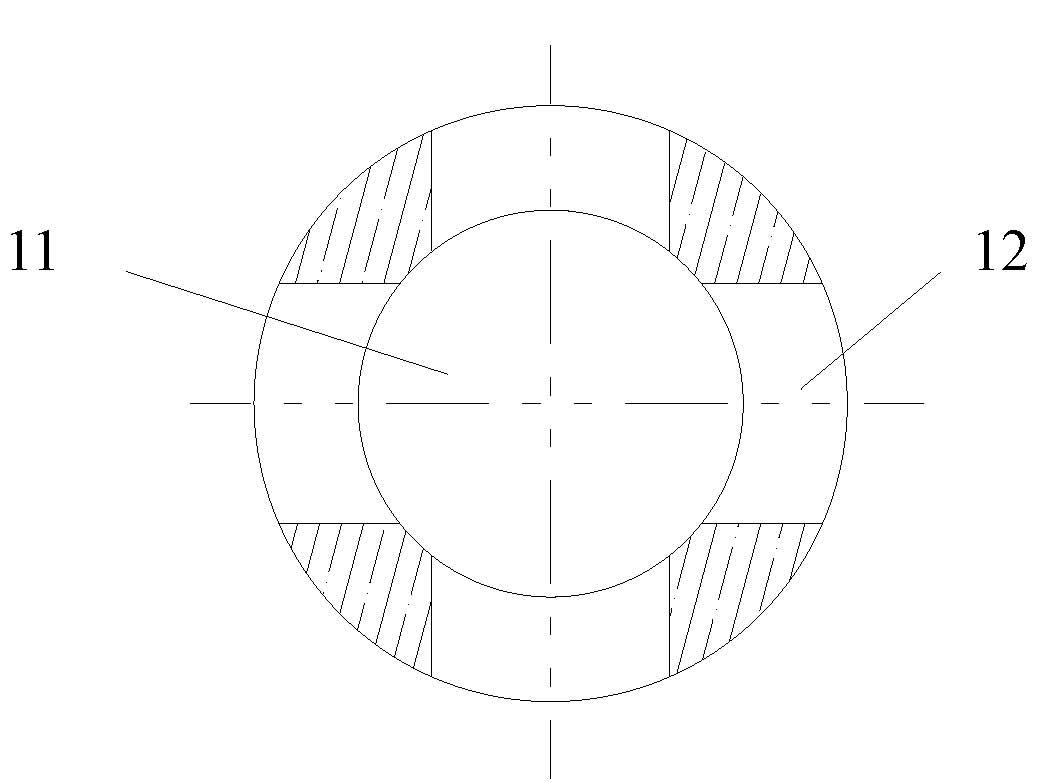

[0025] Such as Figure 1 to Figure 3 As shown, the sliding nozzle device of the present invention includes from top to bottom an upper nozzle 1, an upper sliding plate 2 fixedly connected to the bottom of the upper nozzle, a middle sliding plate 3 connected to the upper sliding plate 2, a lower sliding plate 4 connected to the middle sliding plate 3 and The lower nozzle 5 fixedly connected with the lower plate 4 and the upper nozzle 1 are fixed together with the seat brick 60 on the bottom surface of the pouring container 6 , and the bottom end of the upper nozzle 1 is located at the lower surface of the seat brick 60 . The best shape of the upper nozzle 1 is a cylinder, and in special cases, it can also be a cube with chamfers. The top surface of the upper noz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com