Ship encountering less frictional resistance

一种摩擦阻力、船舶的技术,应用在船舶推进、船体、船只部件等方向,能够解决推进器起振力增大、推进效率低下等问题,达到减小摩擦阻力、维持船体强度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

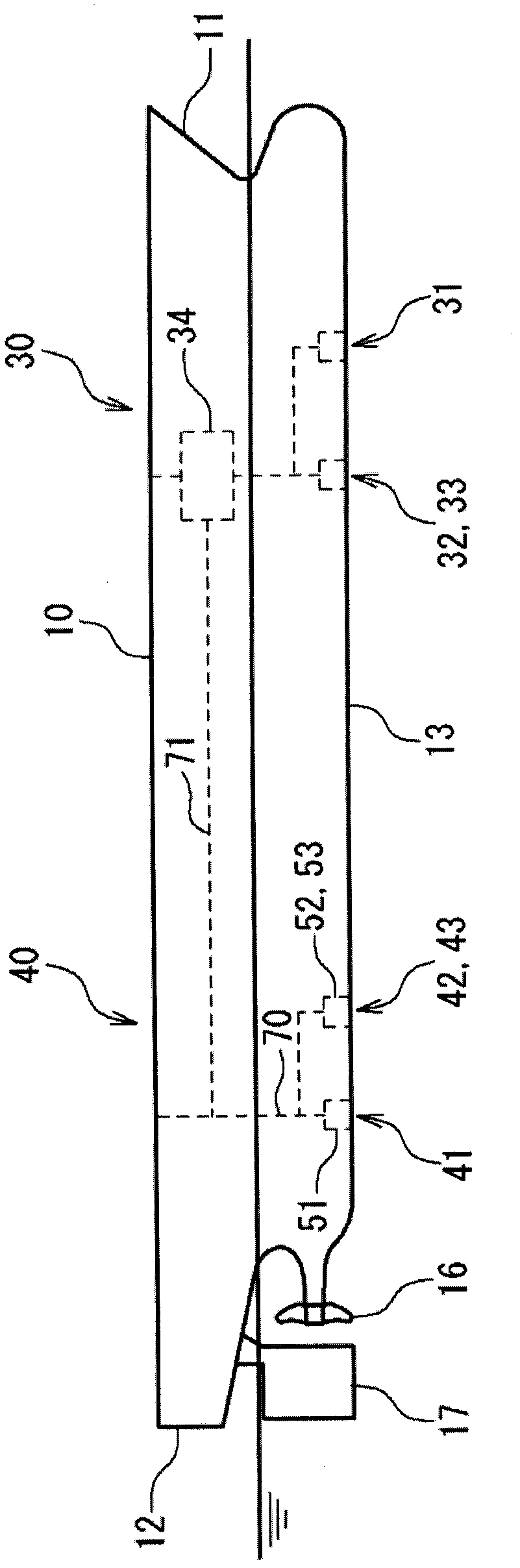

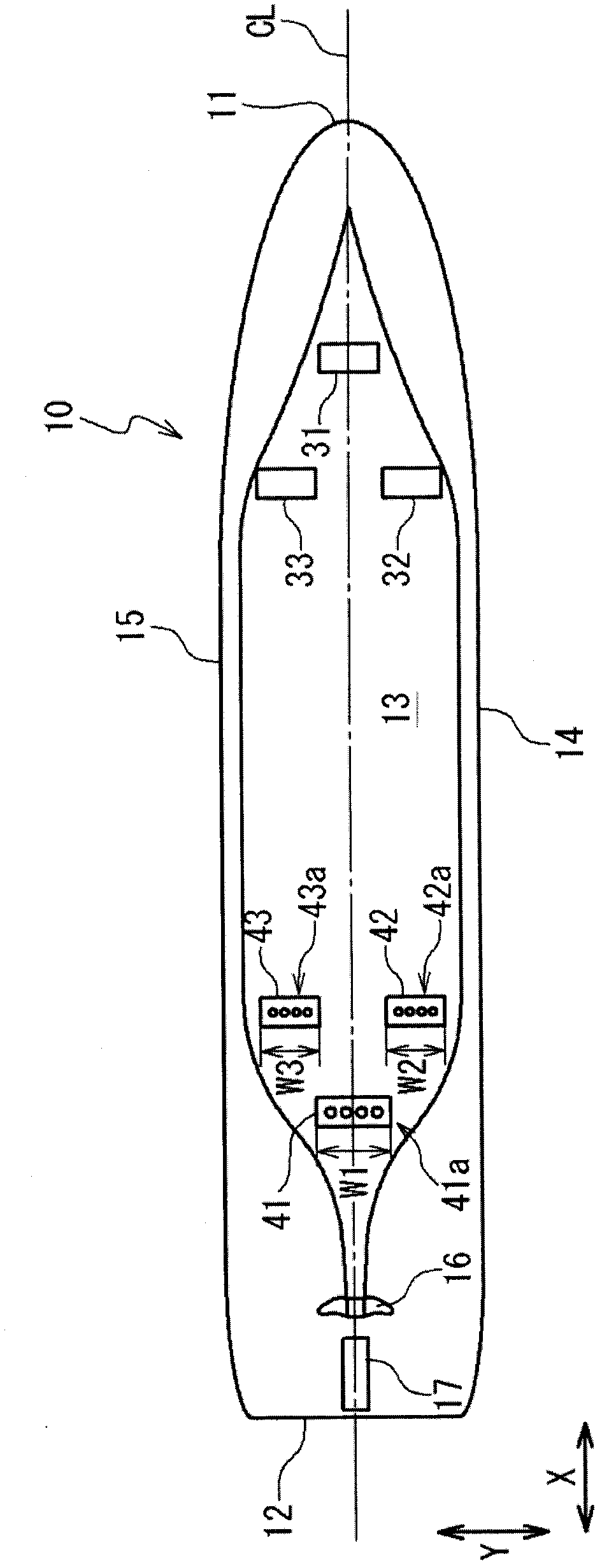

[0033] refer to Figure 1A , the frictional resistance reducing type ship according to the first embodiment of the present invention has a hull 10 , an air injection unit 30 provided in the hull 10 , and an air recovery device 40 provided in the hull 10 . The hull 10 has a bow 11 , a stern 12 , a bottom 13 , propellers 16 and a rudder 17 .

[0034] The air injection unit 30 has air injection ports 31 - 33 provided on the bow 11 side of the ship bottom 13 , and a compressor or blower 34 .

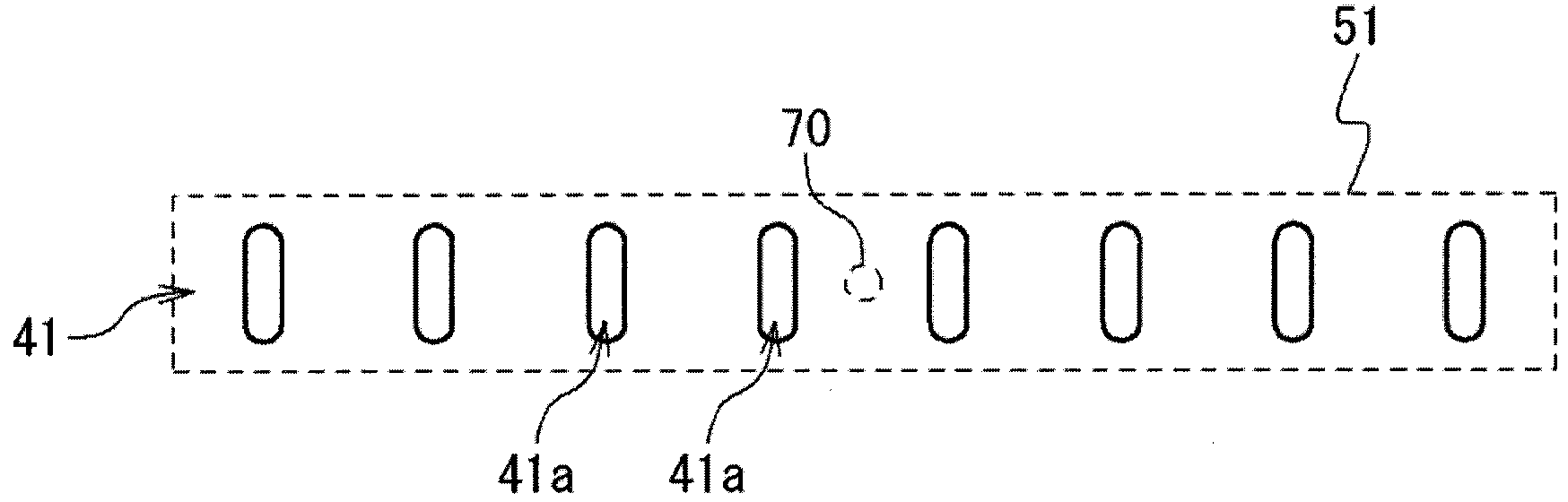

[0035] The air recovery device 40 has air recovery ports 41 - 43 provided on the stern 12 side of the ship bottom 13 , air recovery chambers 51 - 53 , and a flow path 70 . The air recovery chambers 51-53 have a gas-liquid separation function. For example, the gas-liquid separation chamber disclosed in Japanese Patent Publication JP 2009-248831A can be applied to the air recovery chambers 51-53. When the air recovery chambers 51-53 have a gas-liquid separation function, they may be referred...

no. 2 example

[0047] refer to image 3 , the frictional resistance reduction type ship according to the second embodiment of the present invention is the same as the frictional resistance reduction type ship according to the first embodiment except the following points. The port side air recovery port 42 and the starboard side air recovery port 43 are formed in a strip shape extending obliquely with respect to the ship's length direction X so that the respective ends of the port side air recovery port 42 and the starboard side air recovery port 43 on the stern 12 side are closer to each other. centerline CL, and the other end on the bow 11 side is away from the centerline CL.

[0048] According to the present embodiment, the ends of the port side air recovery port 42 and the starboard side air recovery port 43 closer to the propeller 16 are positioned near the center line CL, thereby preventing air bubbles from being drawn into the propeller 16 .

no. 3 example

[0050] refer to Figure 4 , a frictional resistance reduction type ship according to a third embodiment of the present invention will be described. The frictional resistance reduction type ship according to the present embodiment is the same as the frictional resistance reduction type ship according to the first embodiment except for the following points. In this embodiment, the air recovery chambers 51 - 53 have no gas-liquid separation function, and the air recovery device 40 has a single gas-liquid separation chamber 55 . Seawater containing air bubbles flows into the gas-liquid separation chamber 55 through the air recovery ports 41-43. The gas-liquid separation chamber 50 separates air from seawater. Air is exhausted to atmosphere through flow passage 70 as the separated product or supplied to compressor or blower 34 through flow passage 71 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com