Mini type mulching film recovery machine of tobacco in seedling stage

A technology of tobacco seedlings and recycling machines, which is applied in the field of tobacco machinery, and can solve problems such as large slope angles of ridges, small ground clearance of tractors, and inability to perform cross-row film harvesting operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

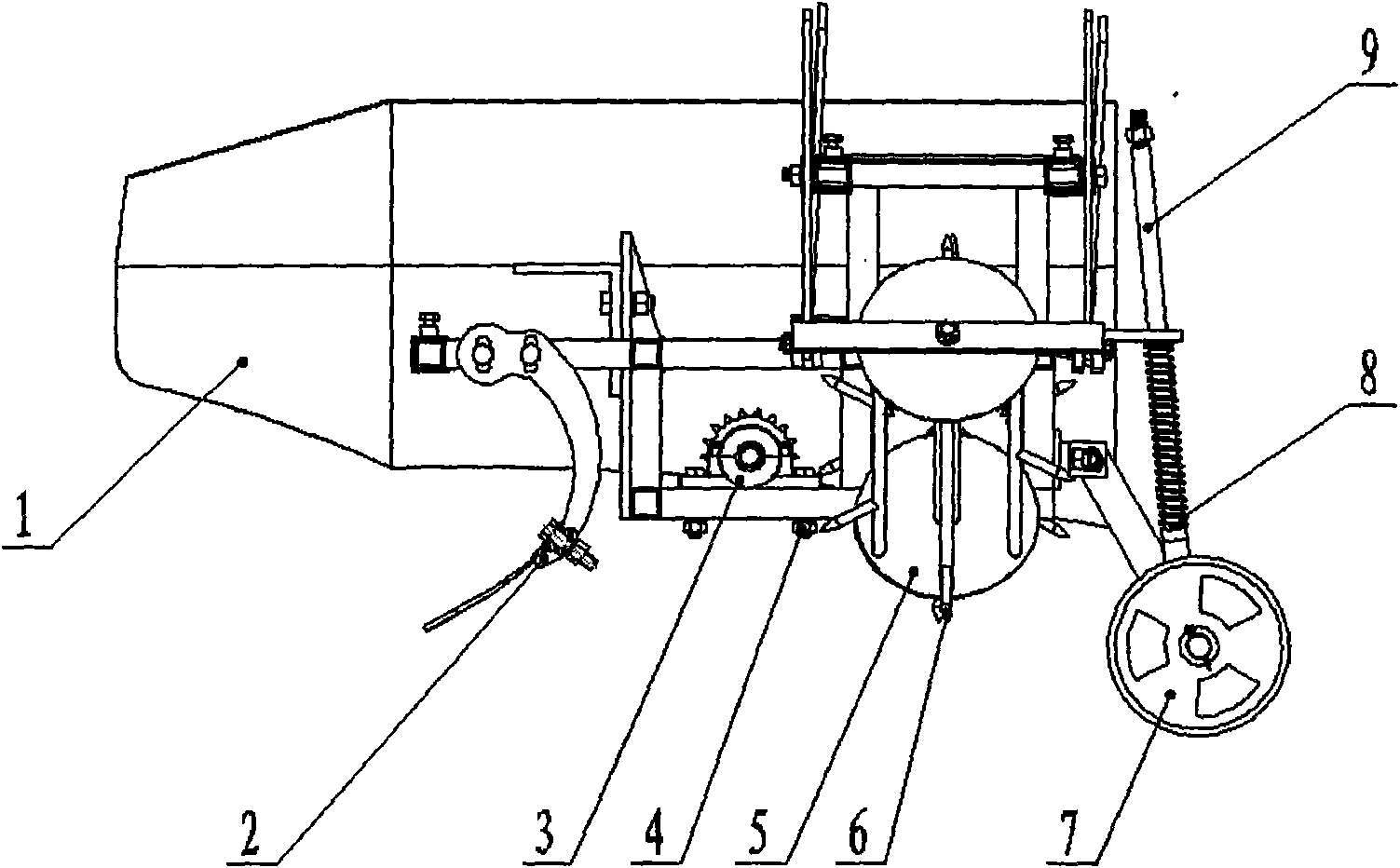

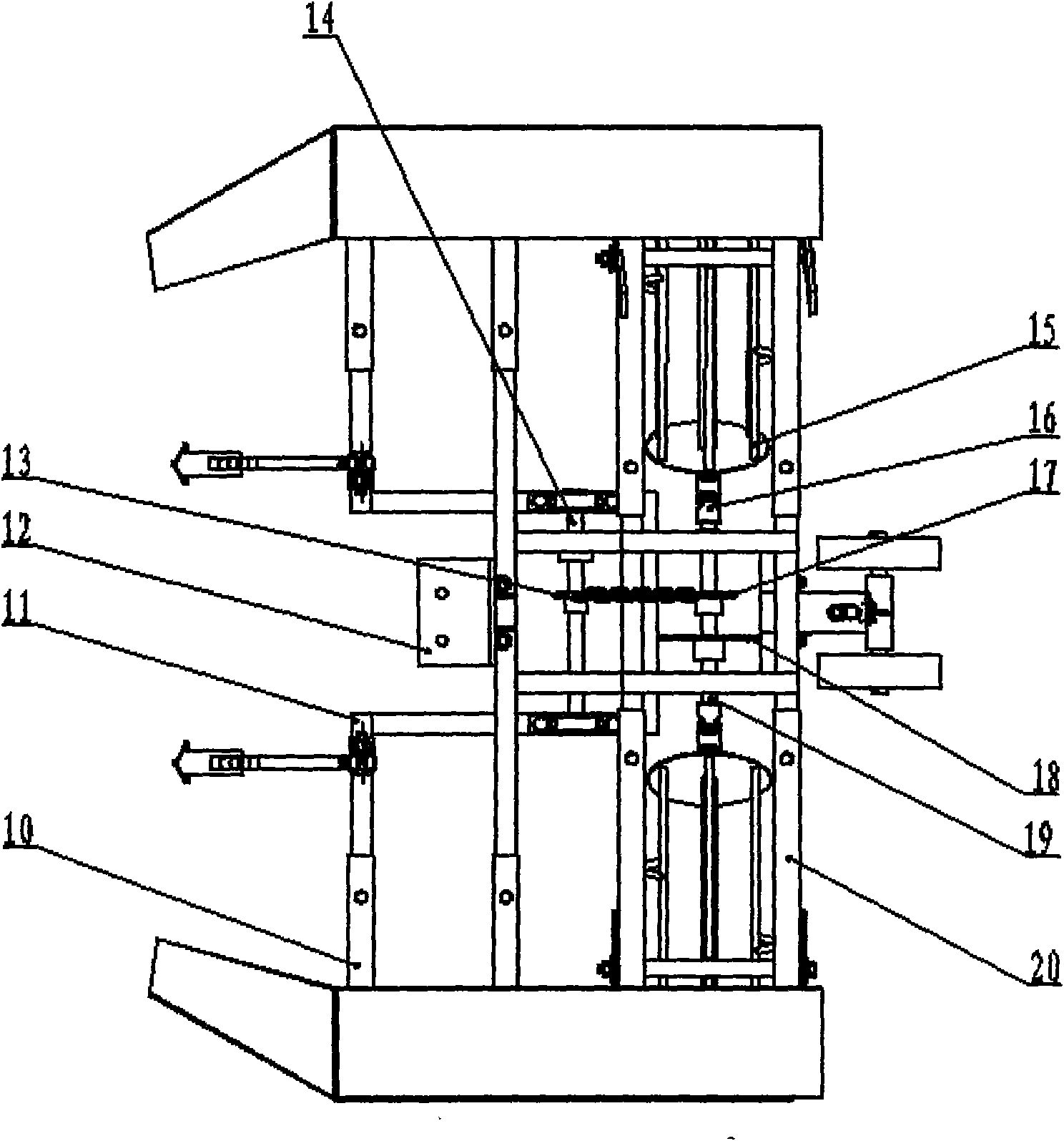

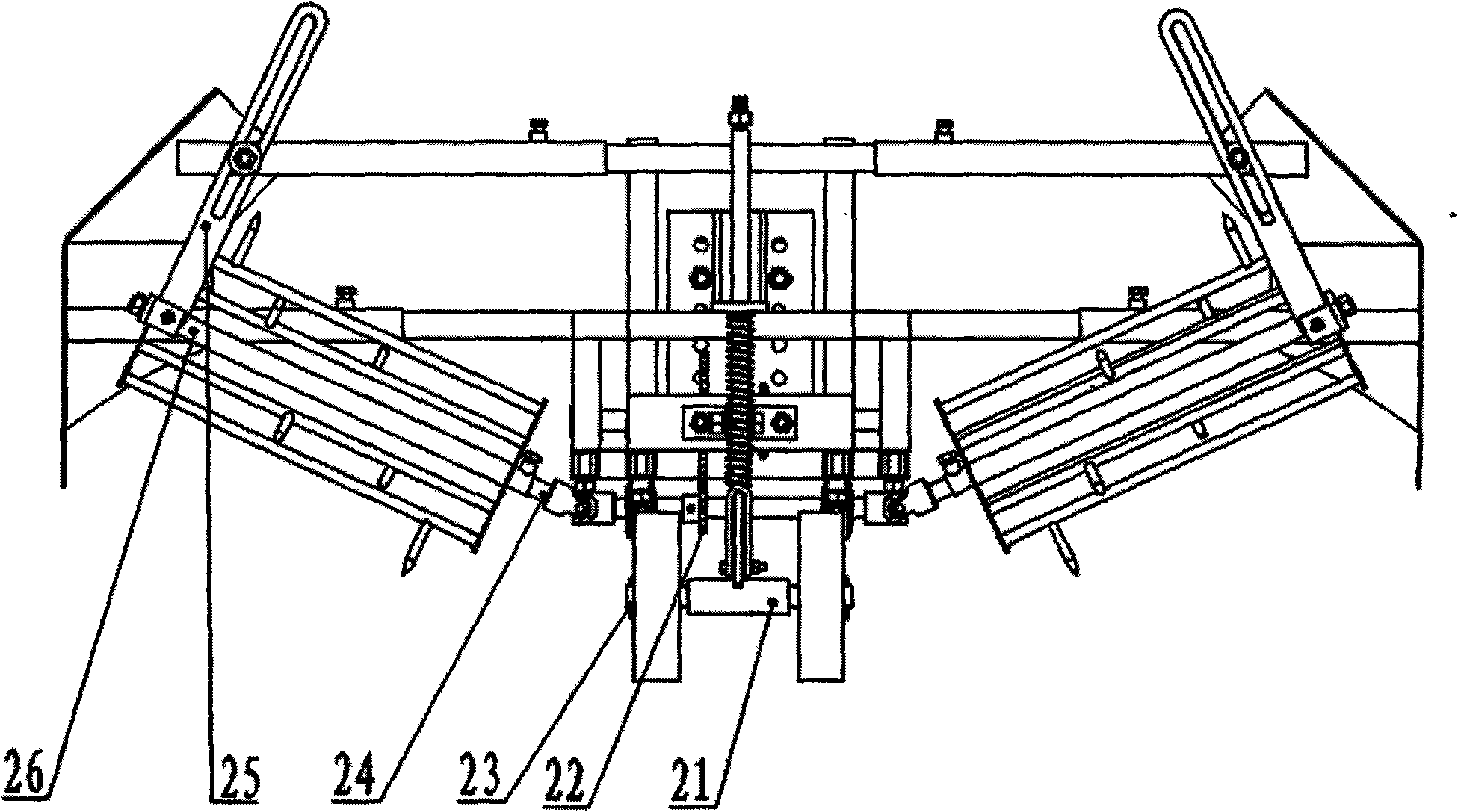

[0016] refer to figure 1 , figure 2 and image 3 , the present invention mainly consists of seedling protection plate (1), depth-limiting ground wheel (7), soil loosening shovel (2), frame (11), sprocket wheel (13) (17), sprocket wheel transmission shaft (14), Gear transmission shaft (19), large gear (18), pinion gear (22), film rolling roller (15), universal joint (16), film rolling roller position horizontal adjustment lever (20), film rolling roller angle vertical adjustment Rod (25) forms.

[0017] Frame (11) is welded with square tube. Be connected to the power machine by hitch plate (12). Loose soil shovel (2) is fixedly connected on the frame (11) by bolt.

[0018] The seedling protection plate (1) and the seedling protection plate position adjustment rod (10) are welded into one, and are fixedly connected on the frame (11) by bolts. The seedling protection plate (1) is arc-shaped, and the bottom has a cutting edge. (1) The position on the frame (11) is adjustabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com