Sugar beet harvester with front threshing mechanism

A harvester, sugar beet technology, used in excavator harvesters, harvesters, topping machines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

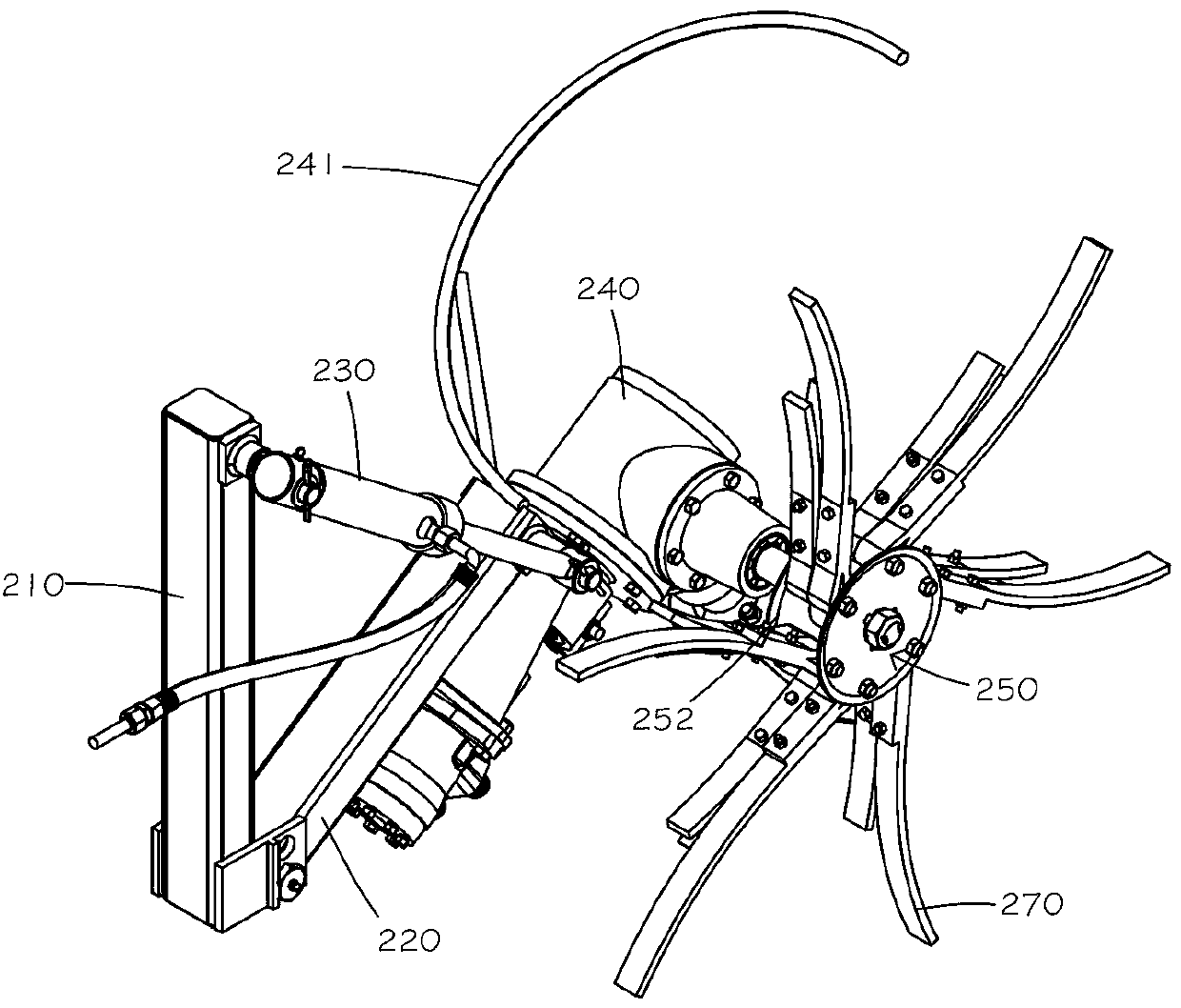

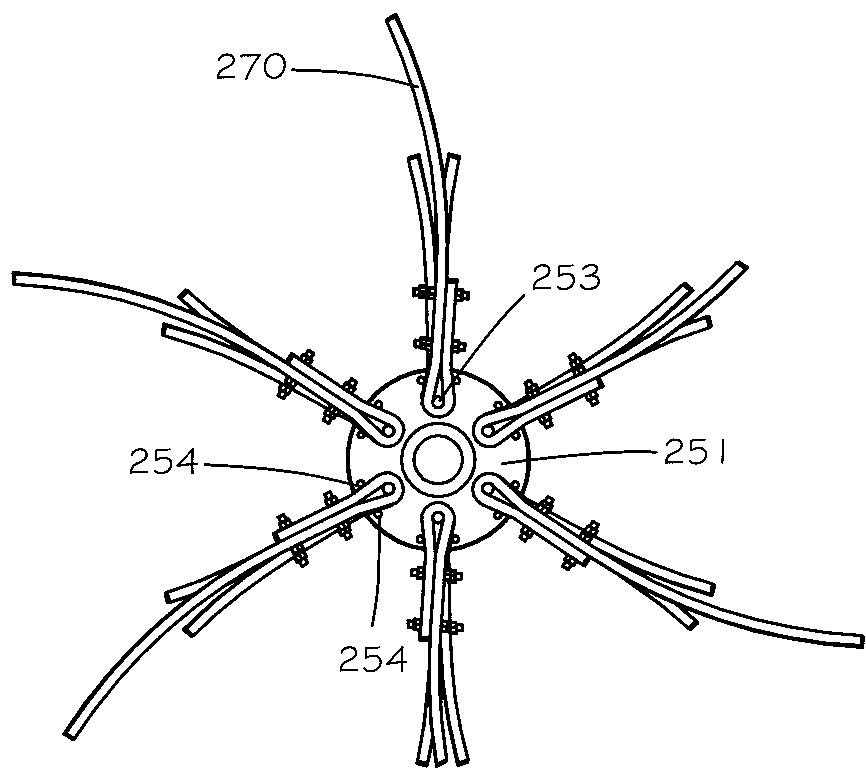

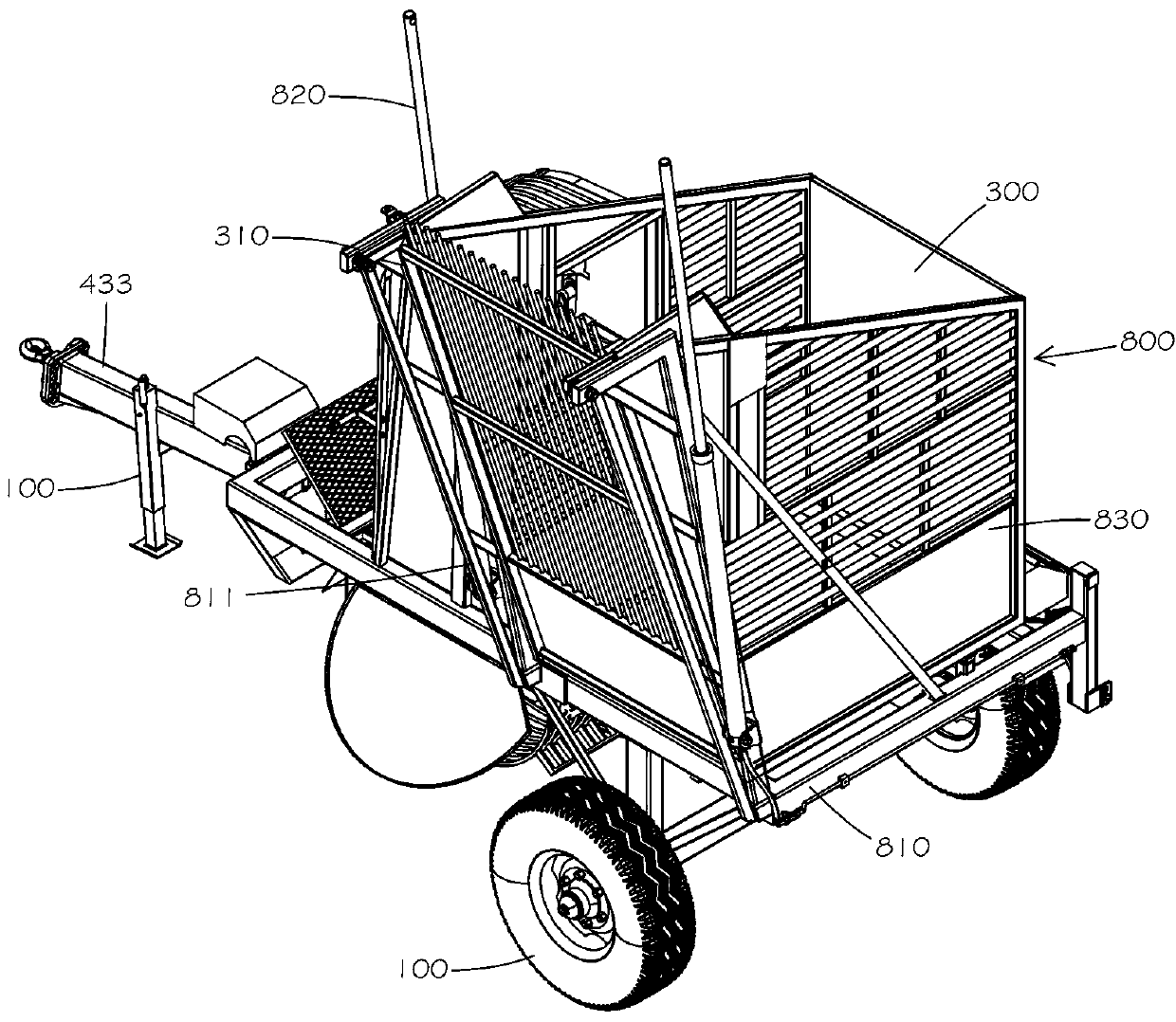

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0028] In the prior art, "Mechanized Stem and Leaf Cutting Technology for Sugar Beet Harvesting" (Crop Research Institute of Heilongjiang University, Lu Bingfu, etc.) discloses the structure of the beet root cleaning part of the main stem and leaf cutting device. The author believes that the working effect of the sugar beet harvester depends to a large extent on the cutting quality of the root head, and it is very important to improve the working process of removing the residual stems, leaves and petioles on the root head. But no reasonable solution was proposed. 201710117605.2 discloses a harvester. It includes a frame-type frame, eccentric wheels, ground wheels, digging shovels, three tassel sweepers, driving double sprockets, driven sprockets, and two chain tensioning devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com