Concrete cylinder-like vessel and its mfg. method

一种制造方法、混凝土的技术,应用在混凝土筒状容器领域,能够解决导热片没有屏蔽体、放射线流出、增加制造的麻烦等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] Embodiments of the present invention are described below.

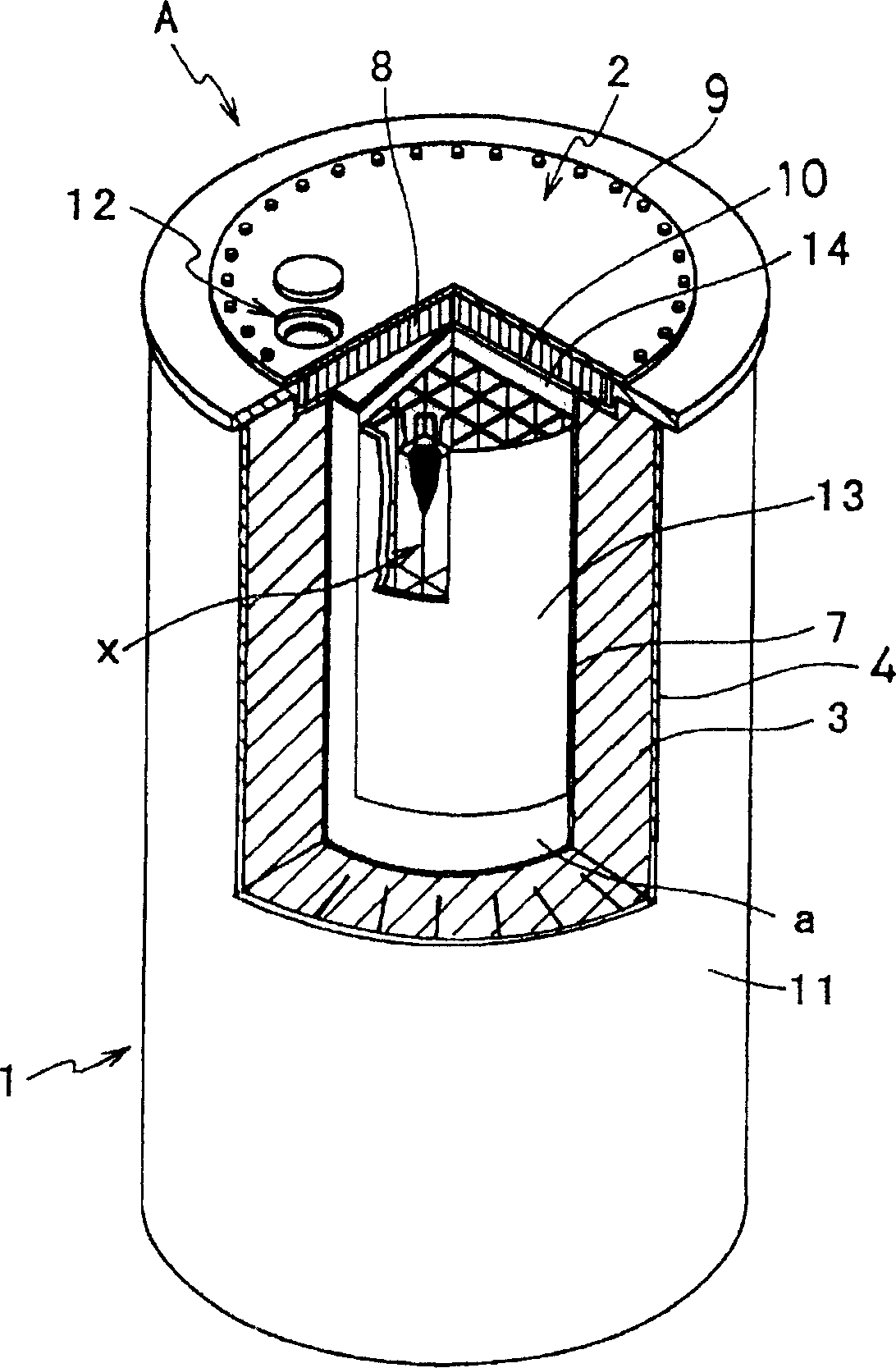

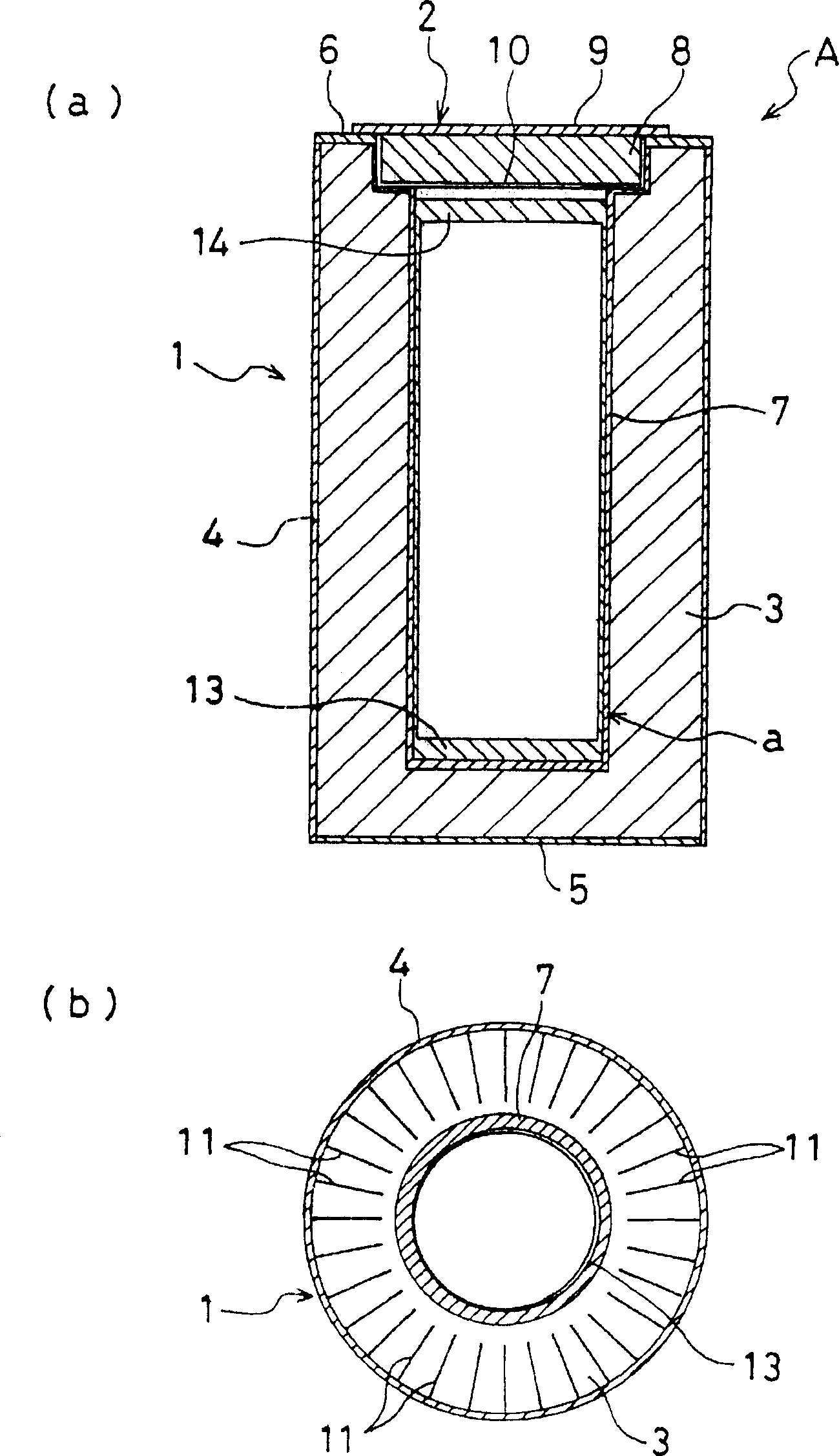

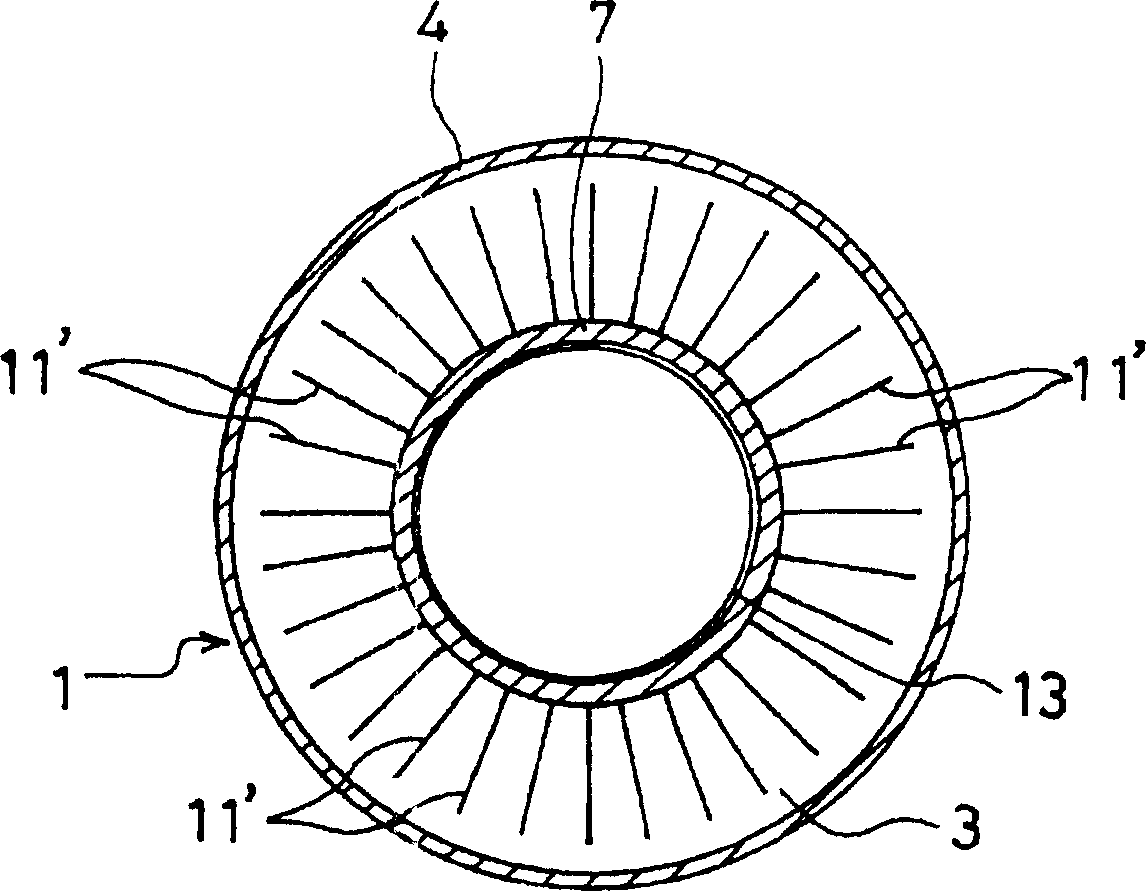

[0065] First, the basic structure of the concrete cylindrical container and the structure of the heat conducting fins in the concrete cylindrical container will be described. figure 1 It is a partially cutaway perspective view showing the storage state of the concrete cylindrical container in the first embodiment of the present invention. figure 2 (a) is a vertical cross-sectional view of the concrete cylindrical container of the first embodiment, and (b) is a cross-sectional view.

[0066] figure 1 and figure 2 The concrete cylindrical container A of the first embodiment shown is composed of a cylindrical container body 1 and a cover 2 with a bottom and no cover. Inside this concrete cylindrical container A is a sealed cylinder a.

[0067] The container body 1 is constructed by covering a concrete container 3 with an outer cylinder 4 made of carbon steel, a bottom cover 5 made of carbon steel, a thicker ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com