Precision casting method for refining aluminum alloy by using adjustable traveling wave magnetic field

A traveling wave magnetic field and precision casting technology, applied in the field of casting, can solve the problems of high cost and difficult control of aluminum alloys, and achieve the effects of increasing nucleation rate, reducing temperature gradient and increasing feeding capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

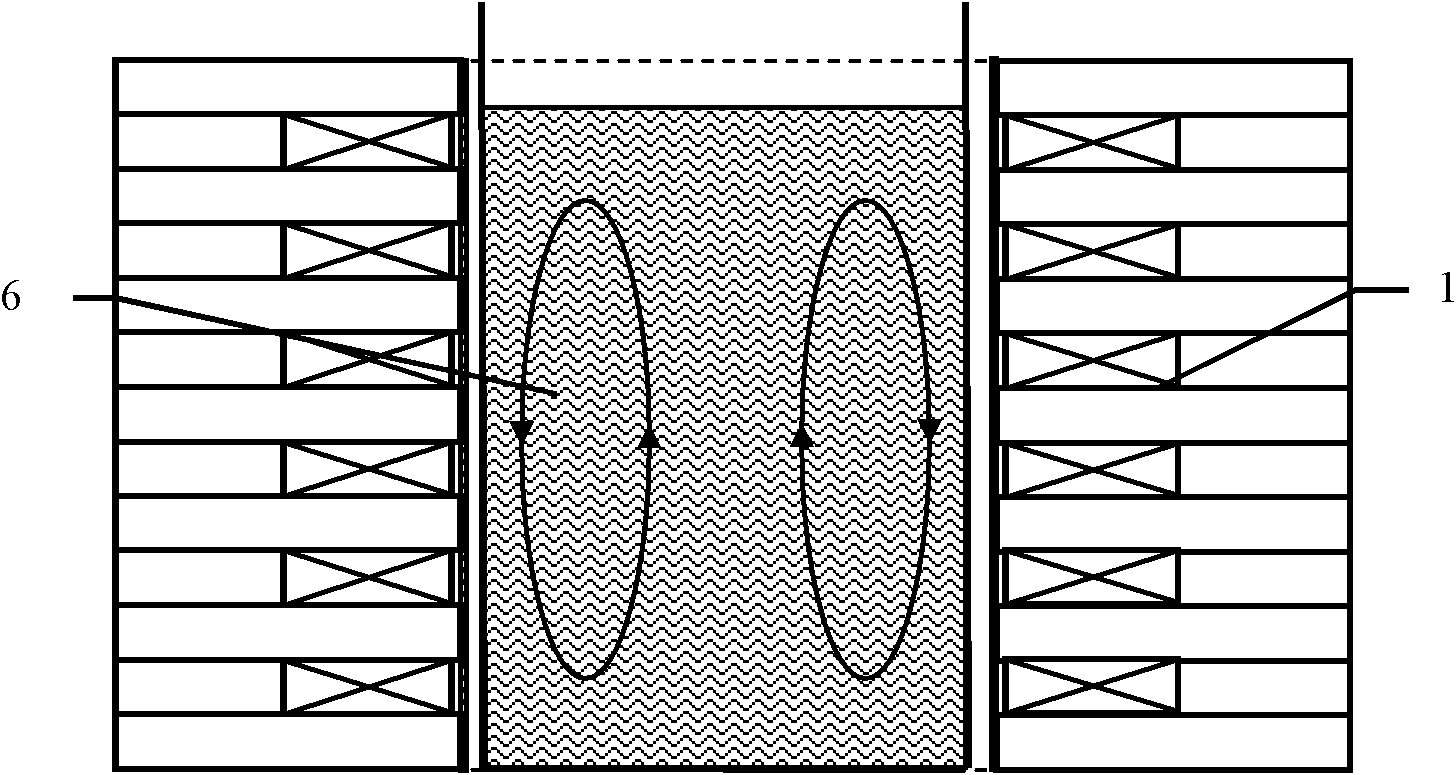

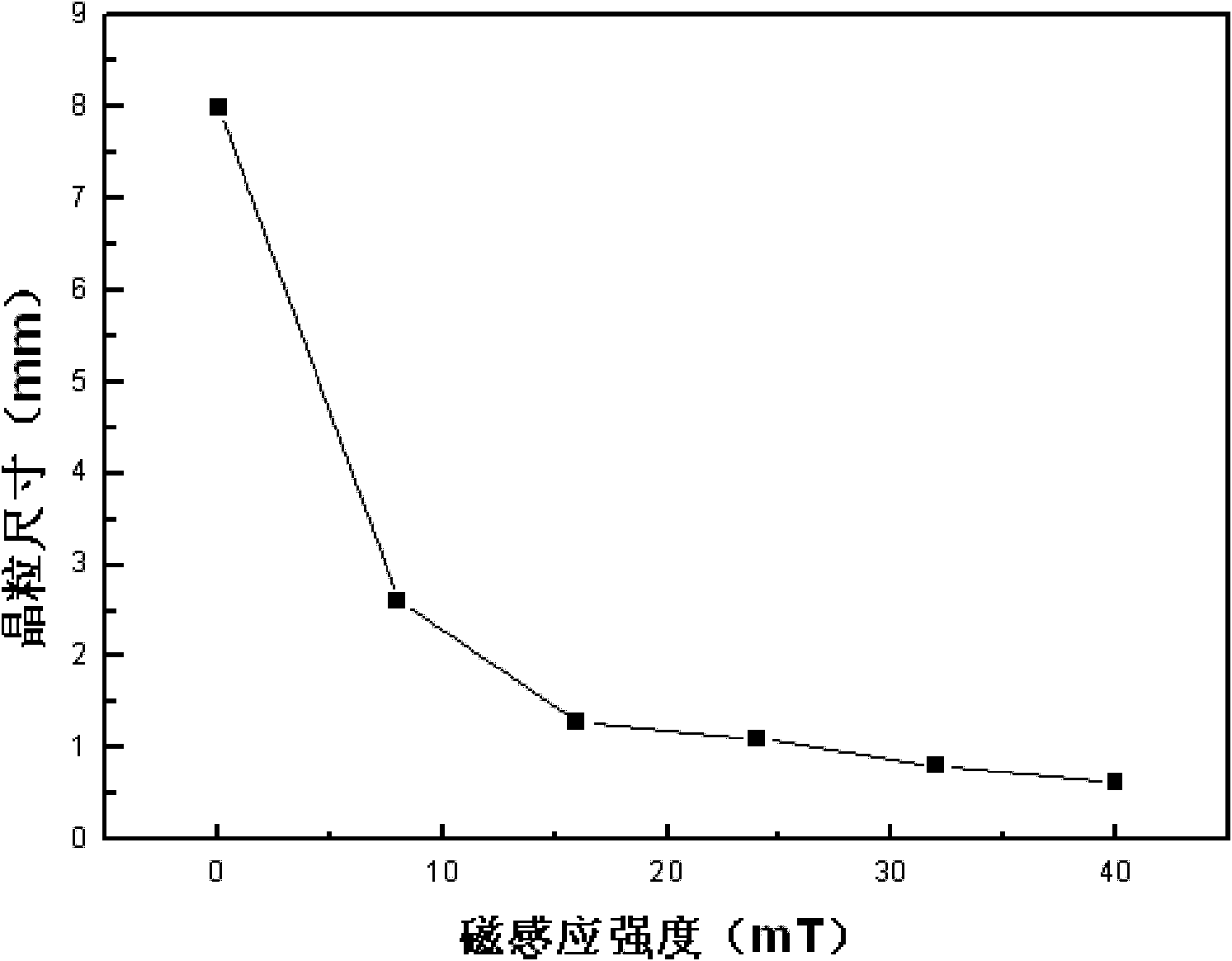

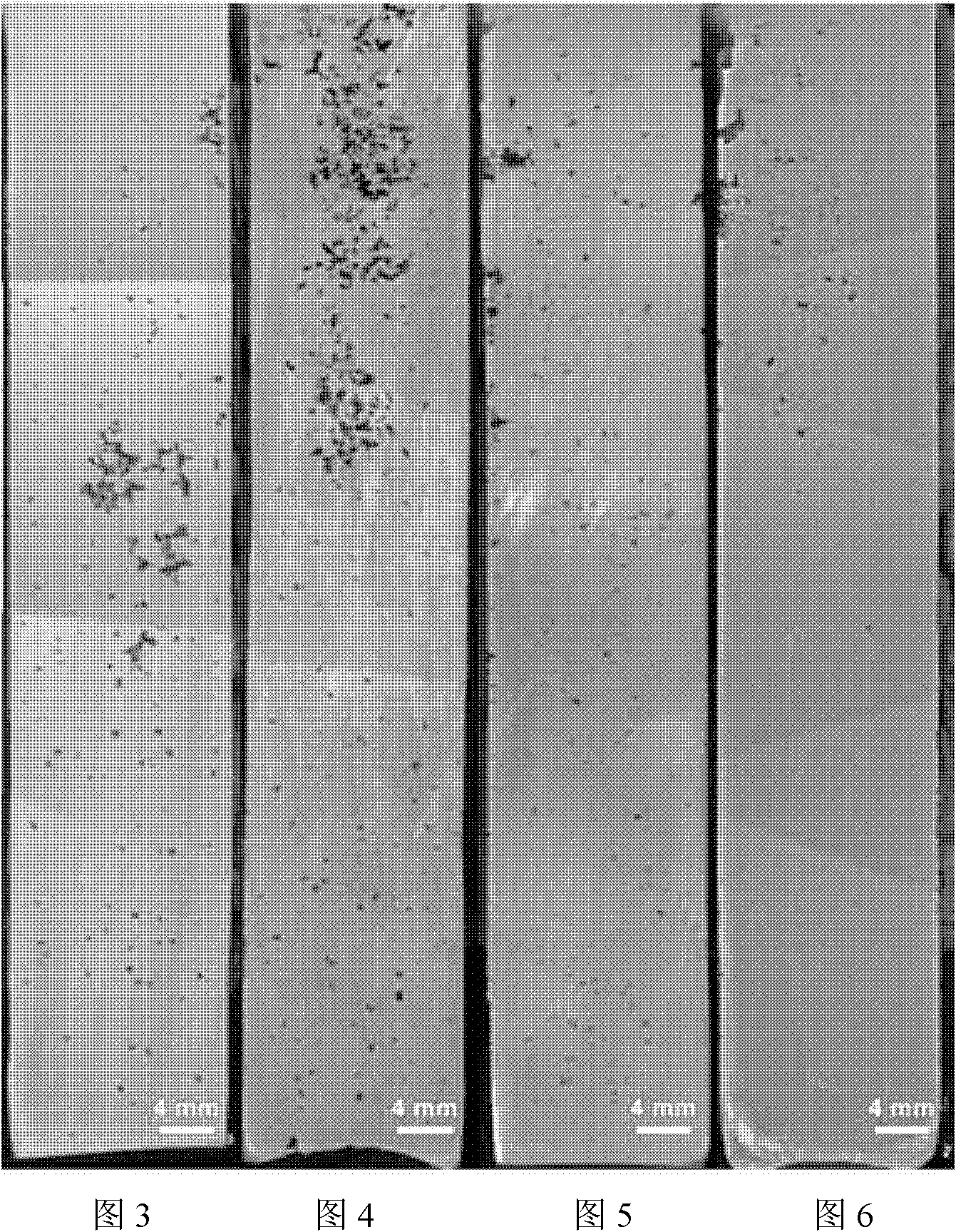

[0008] Specific Embodiment 1: In this embodiment, an adjustable traveling wave magnetic field refinement aluminum alloy precision casting method is realized through the following steps: 1. Heat and melt the aluminum alloy and keep it warm to obtain an aluminum alloy melt; 2. Put the casting mold into the traveling wave magnetic field sensor, the material of the casting mold is a non-magnetic material, turn on the traveling wave magnetic field sensor to adjust the magnetic induction intensity B of the traveling wave magnetic field sensor, and then put the aluminum alloy melt obtained in step 1 Inject into the casting mold, apply a traveling wave magnetic field with the magnetic field direction vertically downward (gravity direction) to the aluminum alloy melt, the magnetic induction intensity is 32-500mT, and the aluminum alloy solidifies under the action of the traveling wave magnetic field; that is, the precision casting of aluminum alloy is completed.

[0009] The method of t...

specific Embodiment approach 2

[0010] Embodiment 2: This embodiment differs from Embodiment 1 in that the non-magnetic material in step 2 is stainless steel, quartz or alumina. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0011] Specific implementation mode three: the difference between this implementation mode and specific implementation mode one or two is that step one is to keep warm for 20 minutes. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com