Patents

Literature

153results about How to "Enhanced feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

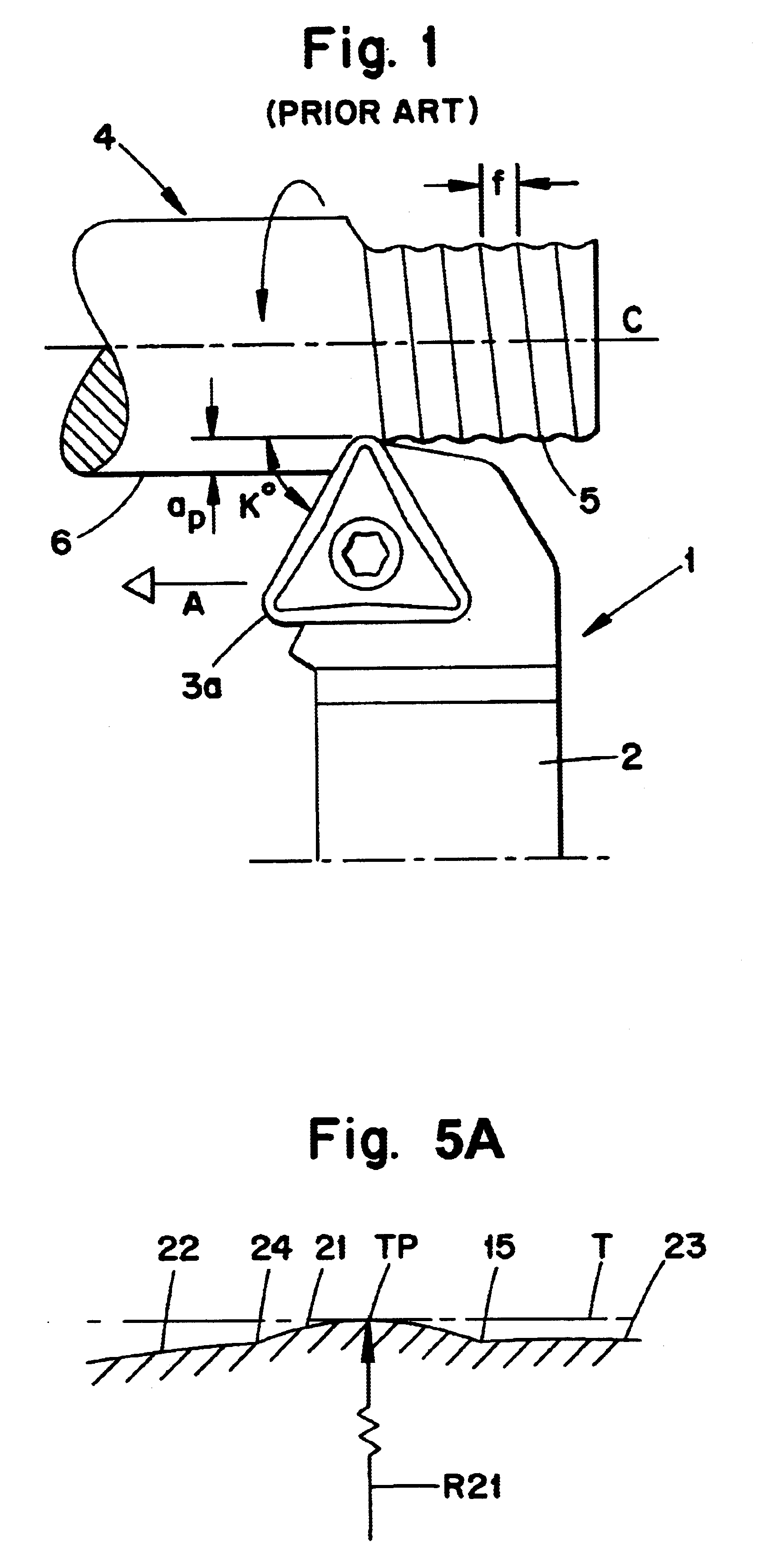

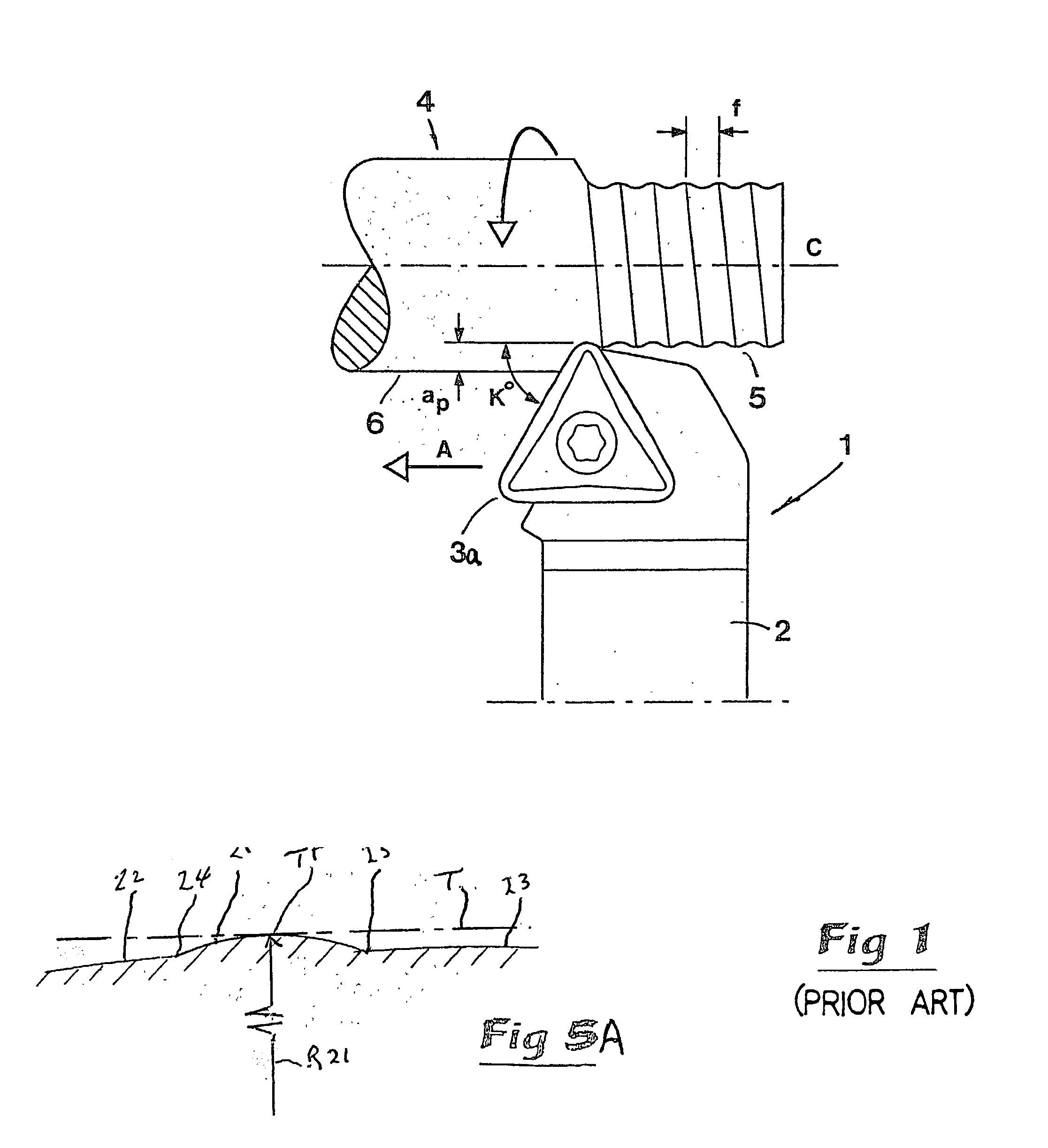

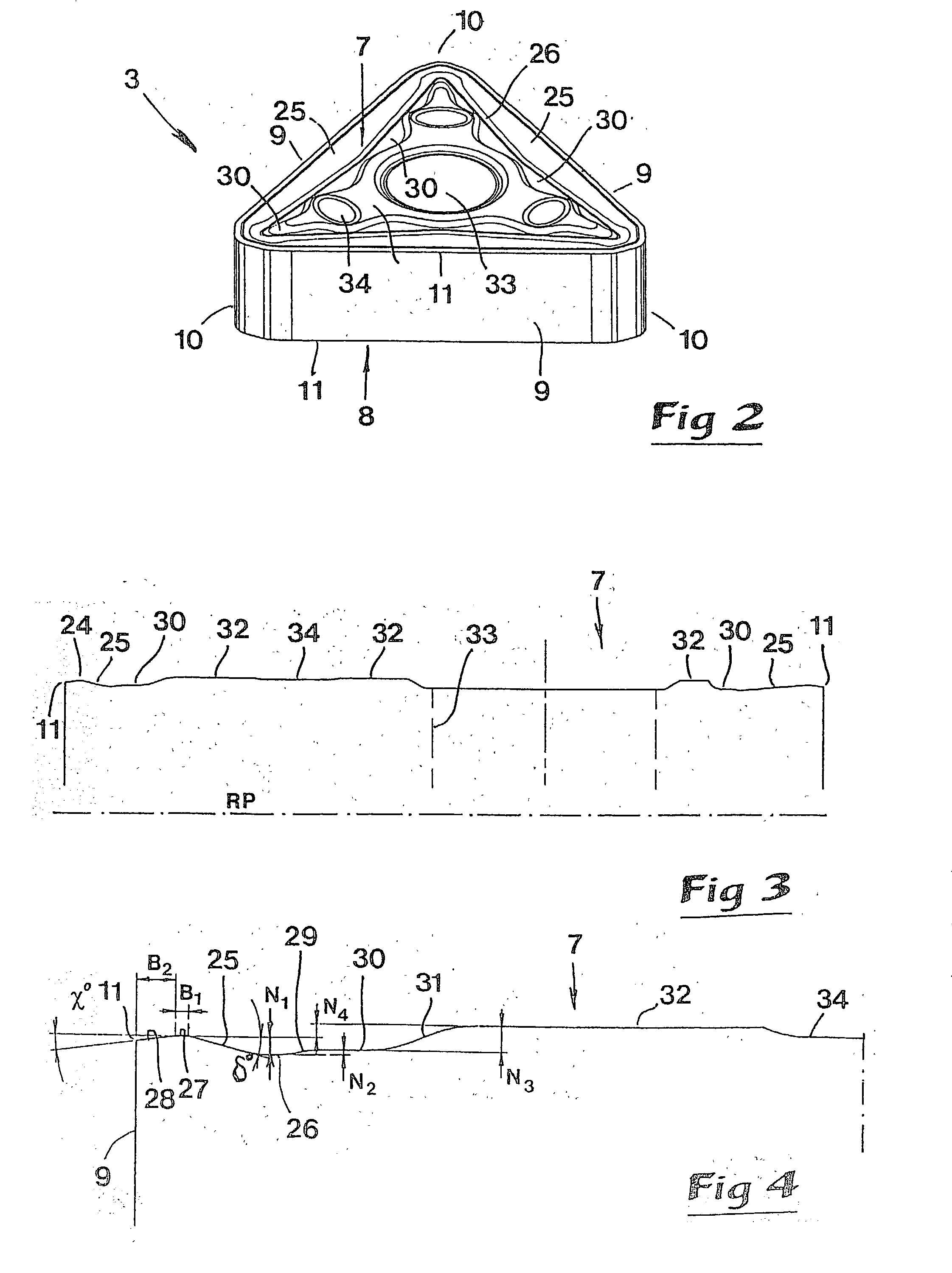

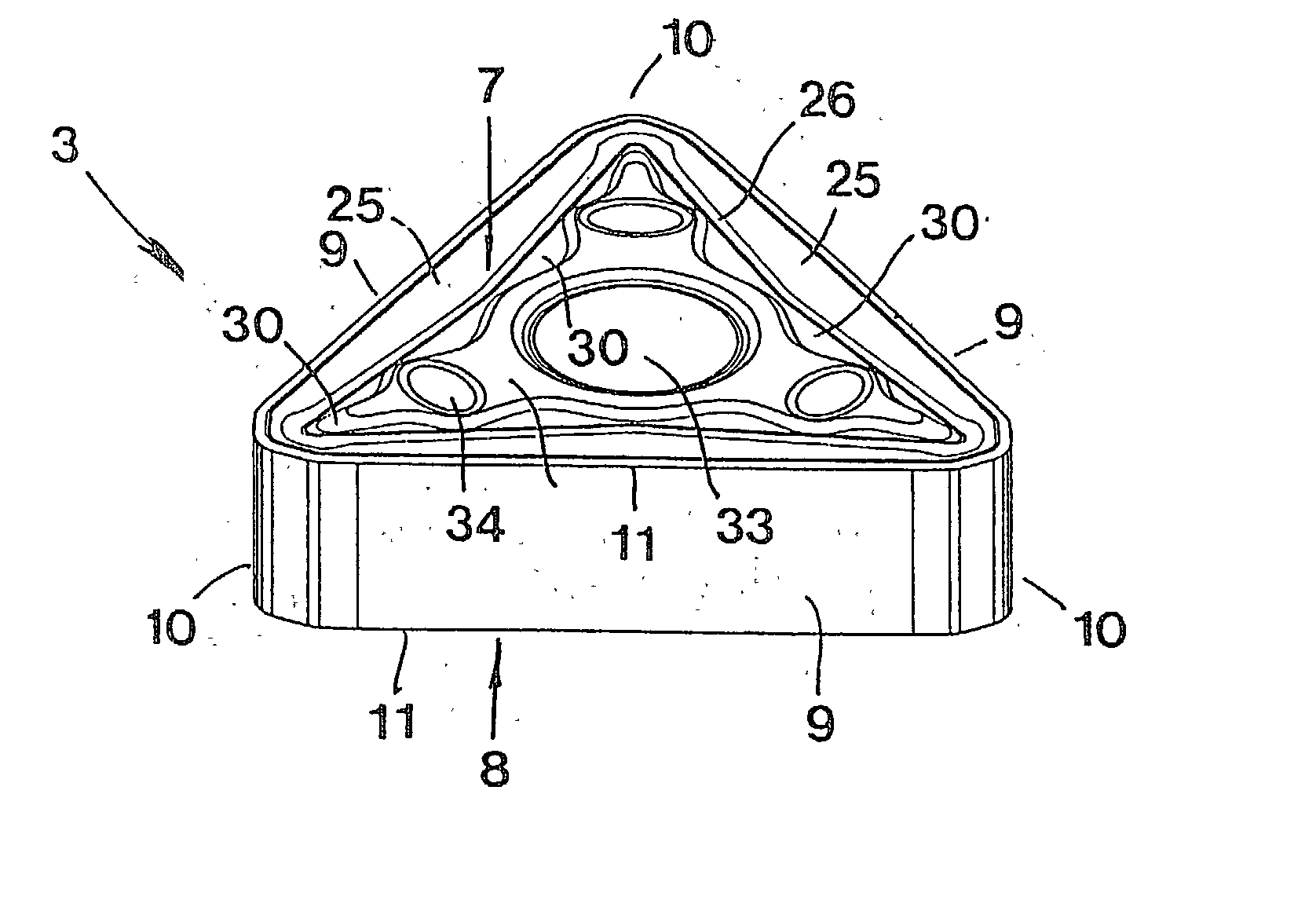

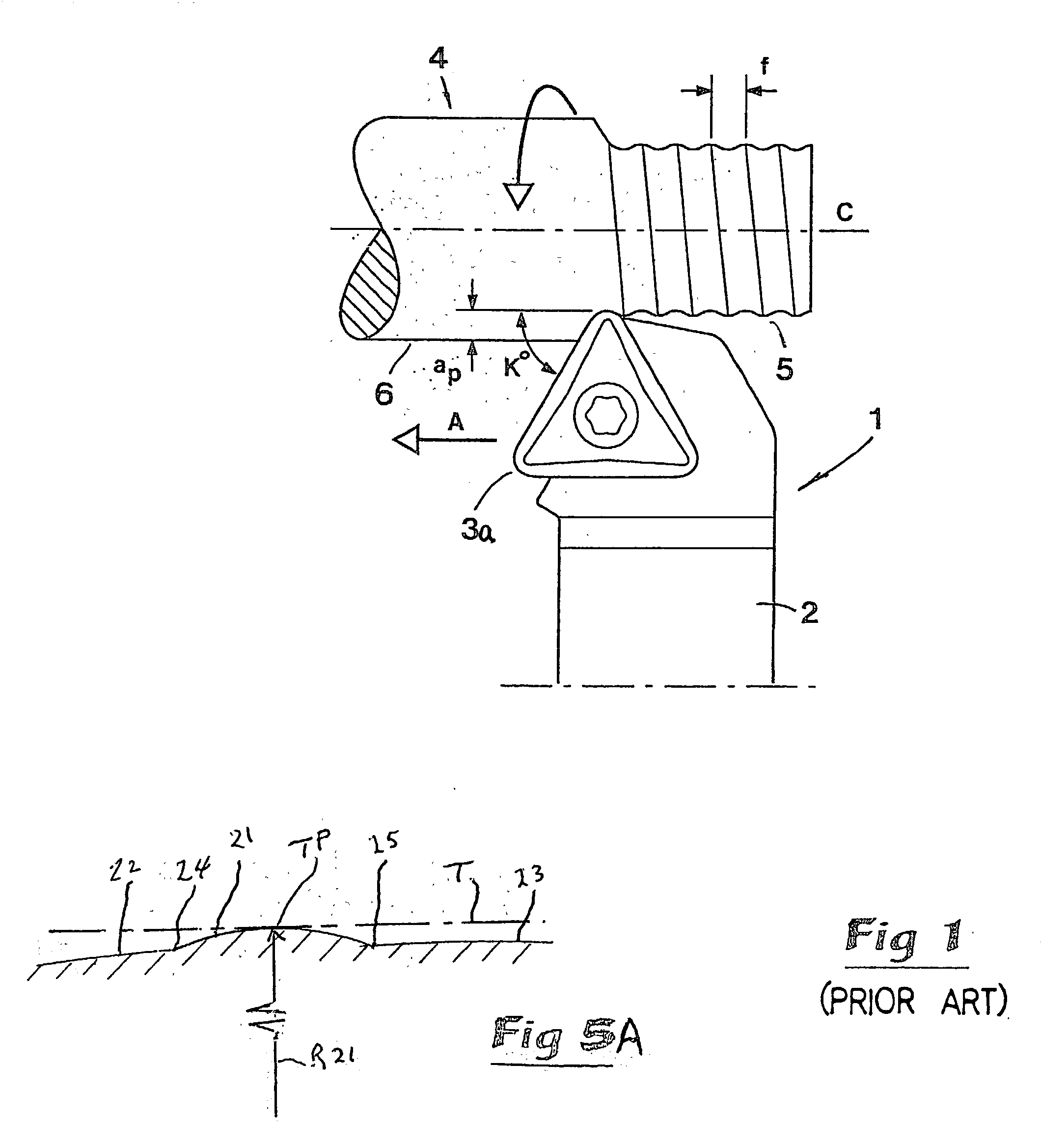

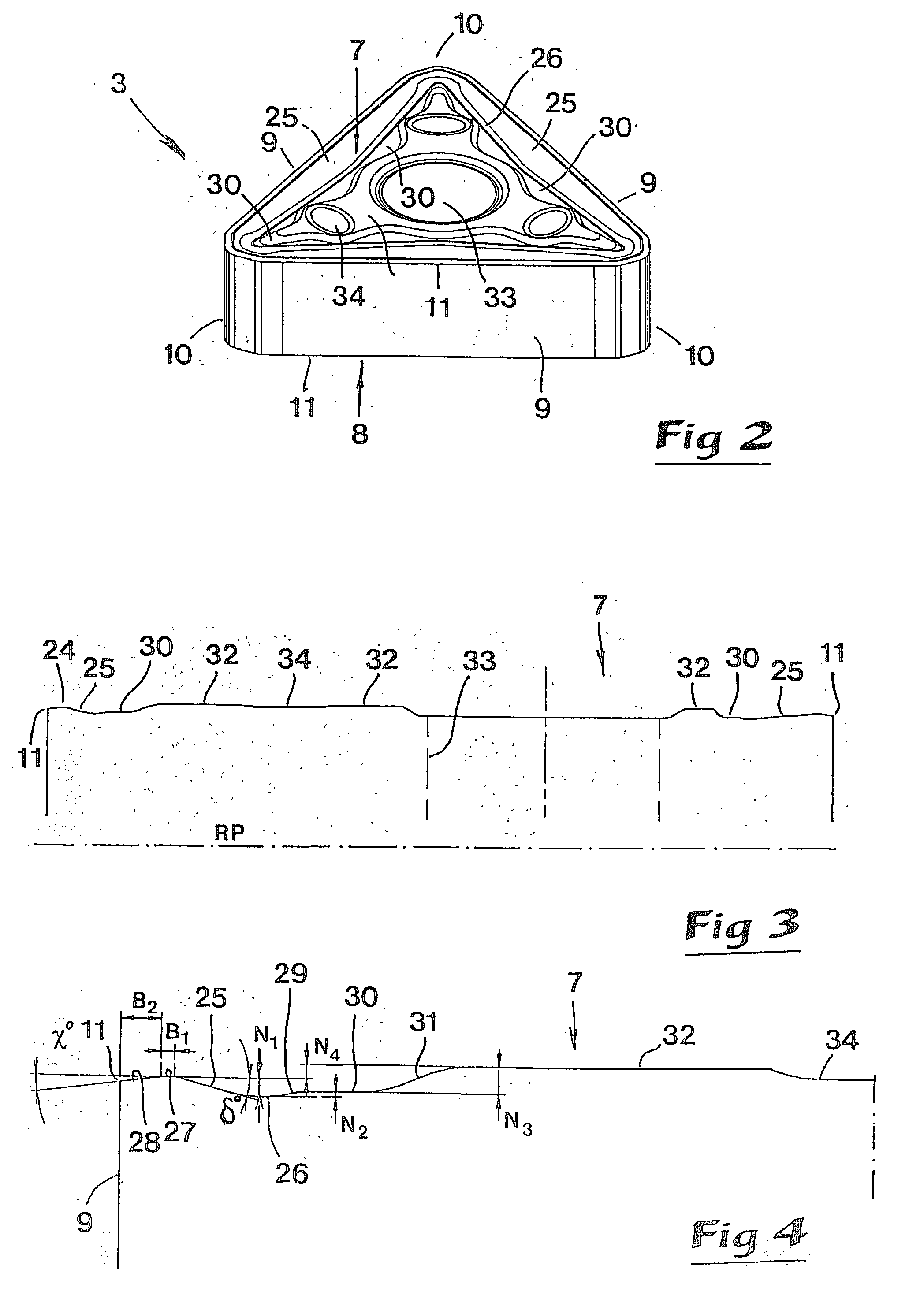

Cutting insert for chip removing machining

InactiveUS6715967B2Risk minimizationHigh surface finishCutting insertsTurning toolsEngineeringMachining

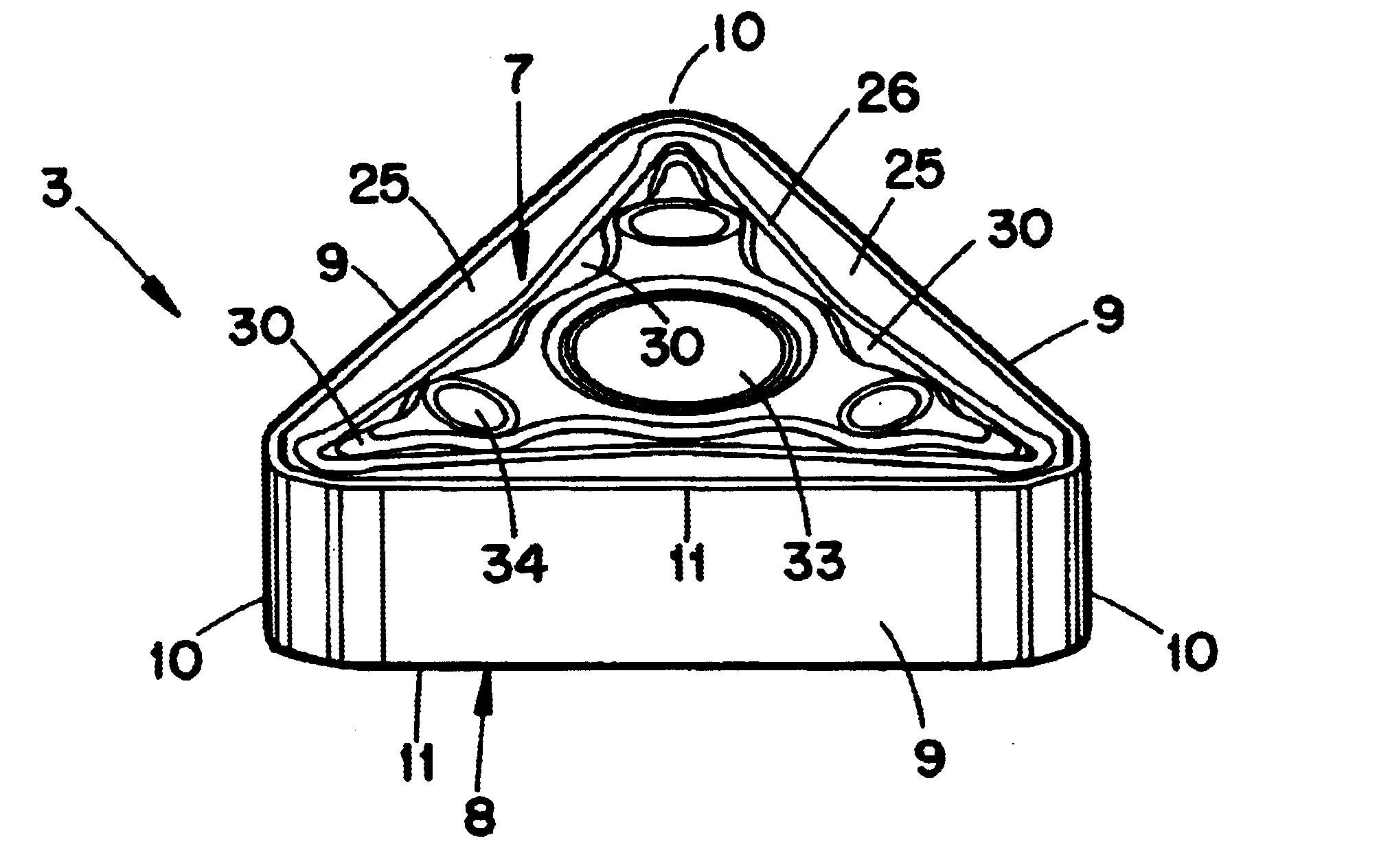

A cutting insert, intended for chip removing machining includes a cutting geometry surface having a cutting edge from which extends a primary chamfer that transforms into a chip removing surface. The chip removing surface is inclined in a inwards / downwards direction in order to permit sinking of a chip being formed, and transforms into a deflection surface arranged to initiate deflection of the chip from the cutting insert. The angle of inclination of the chip removing surface does not exceed 18°. The level difference in elevation between the primary chamfer and the chip deflection surface amounts to maximally 0.20 mm.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

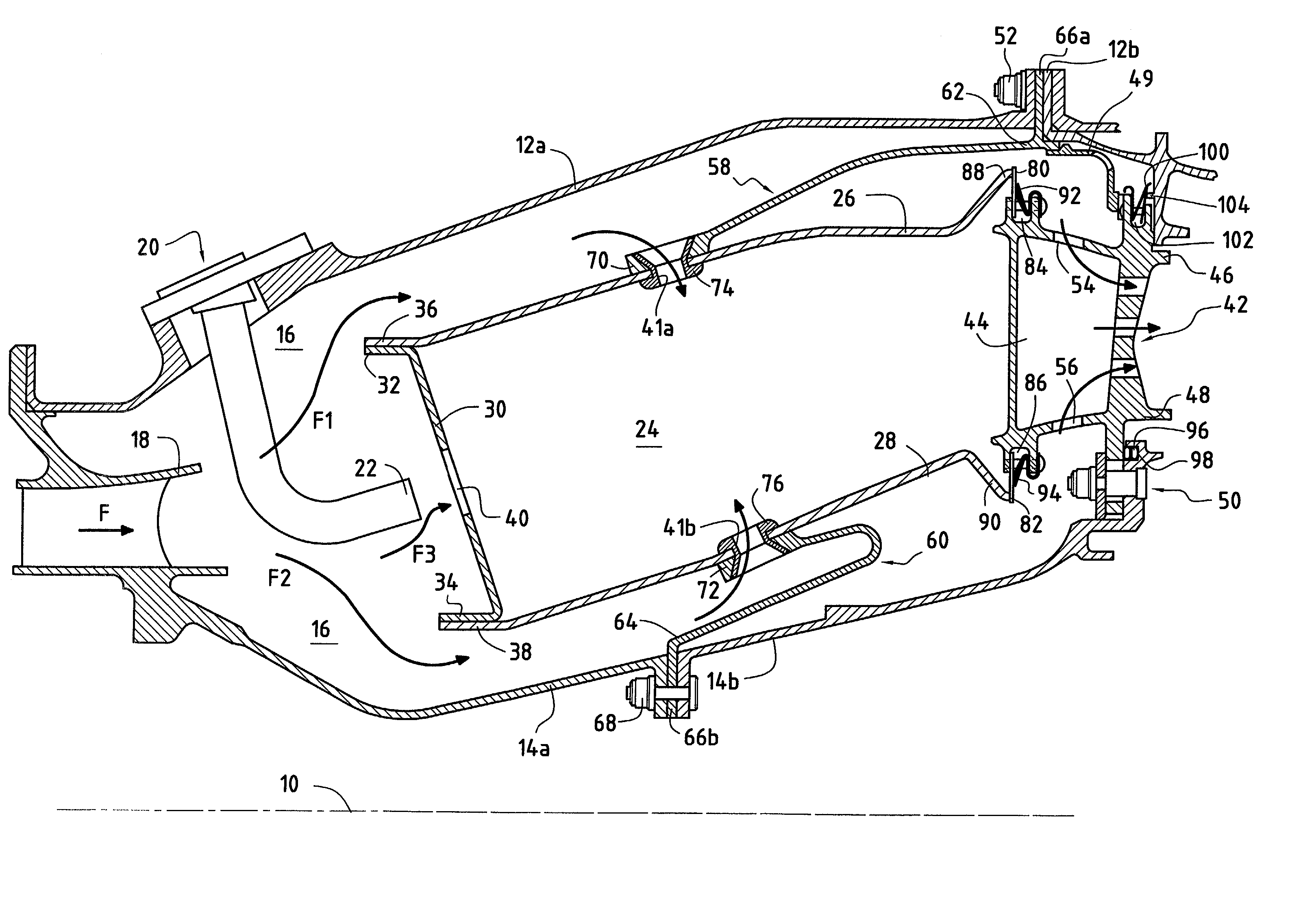

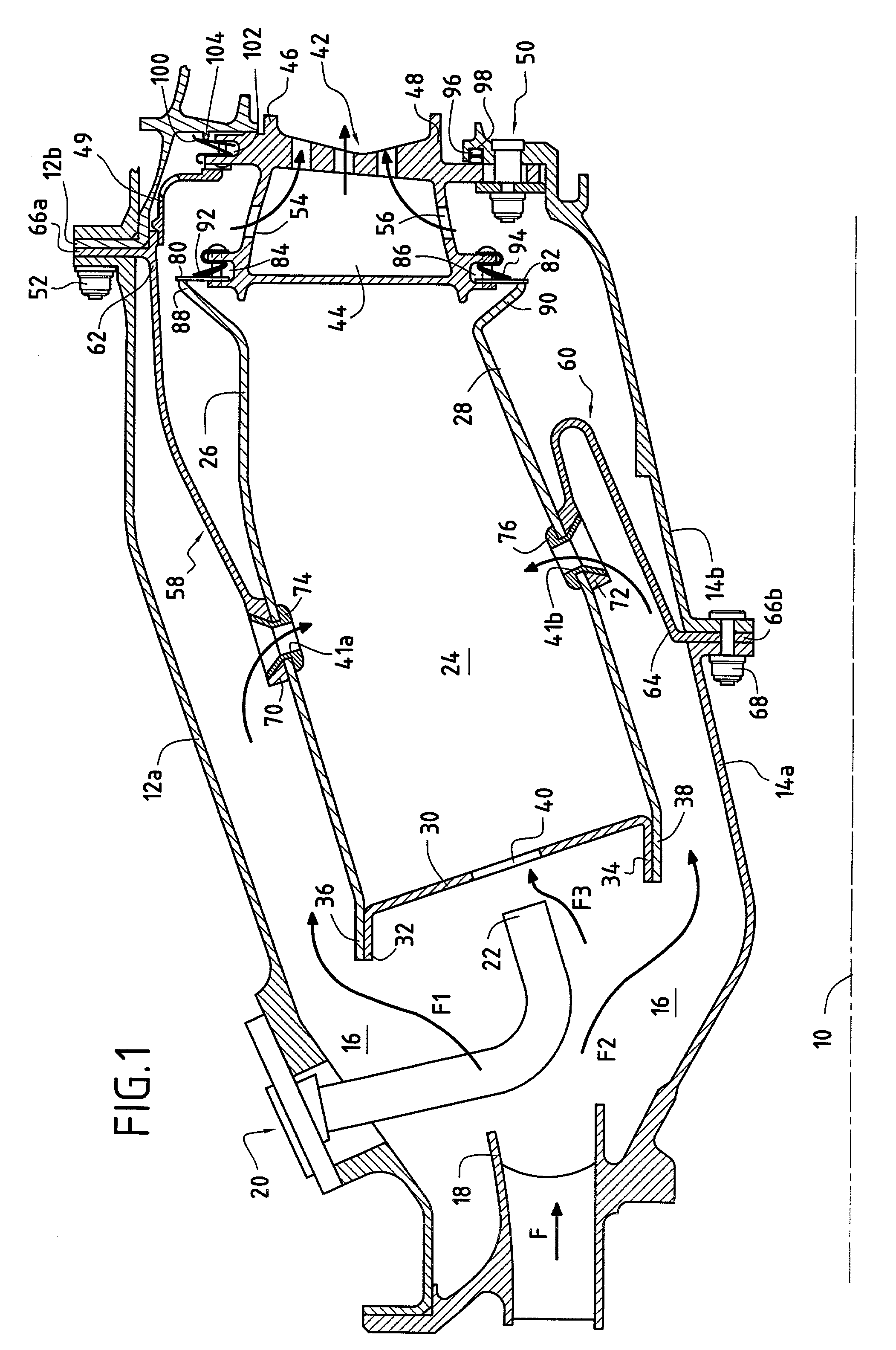

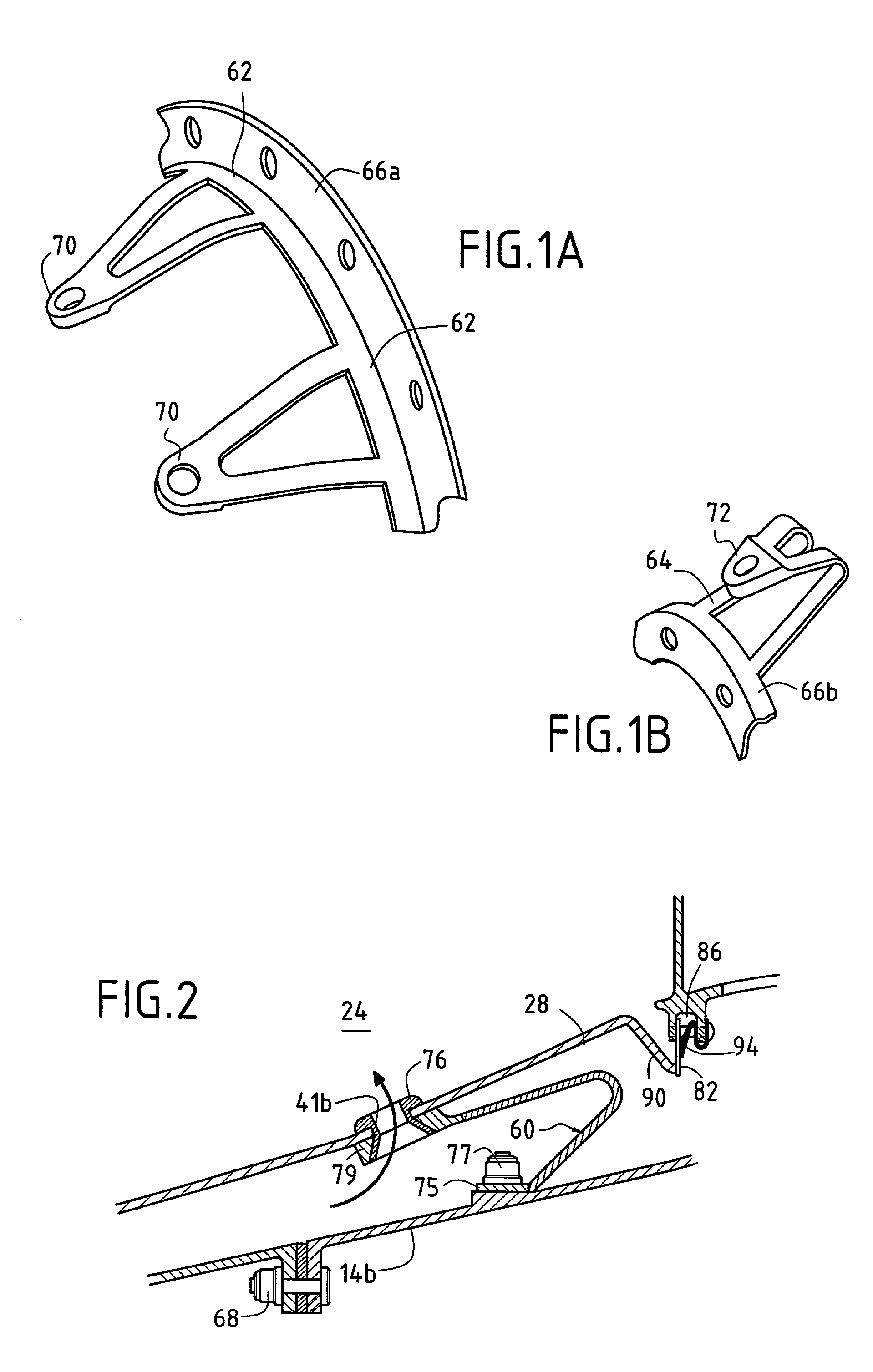

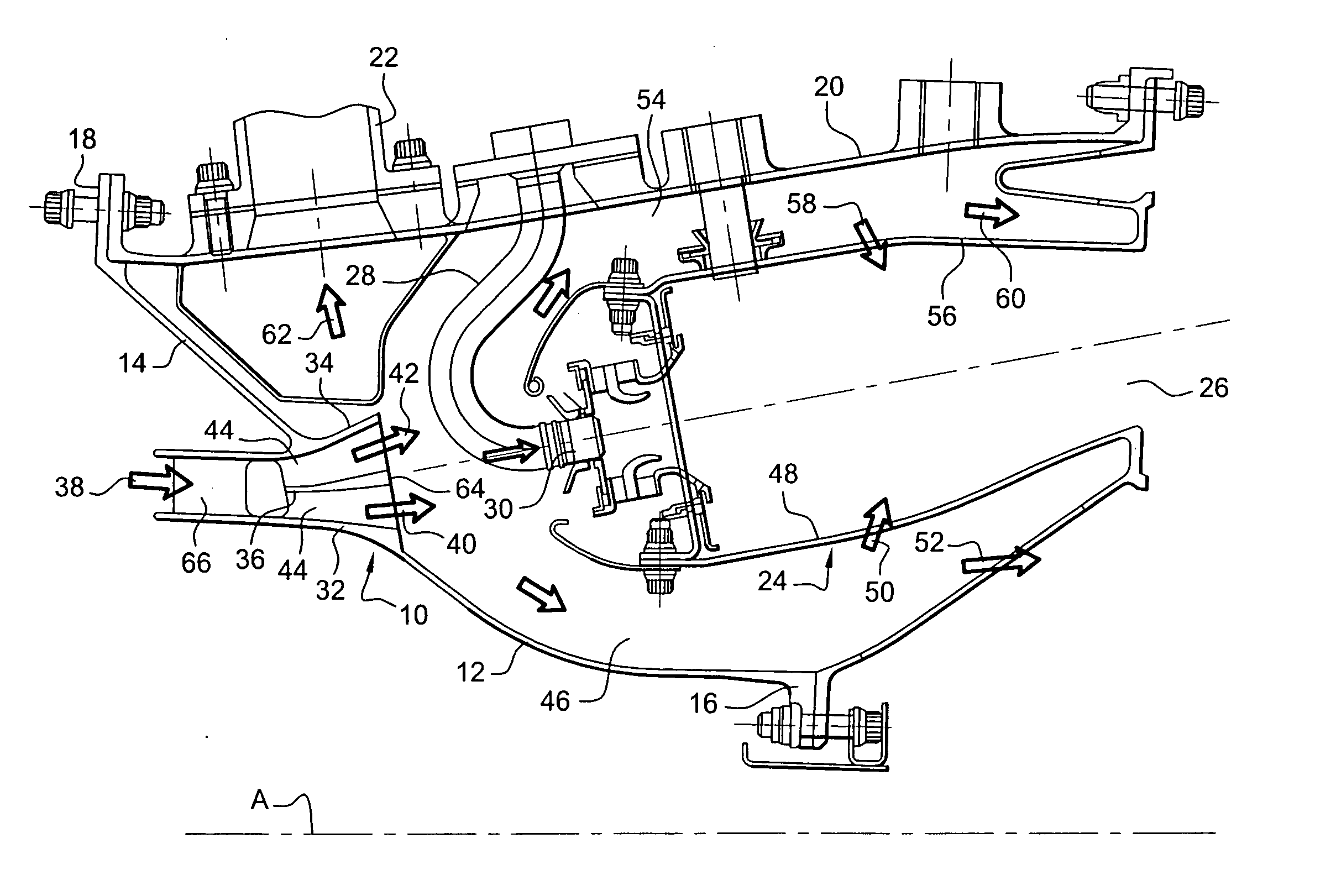

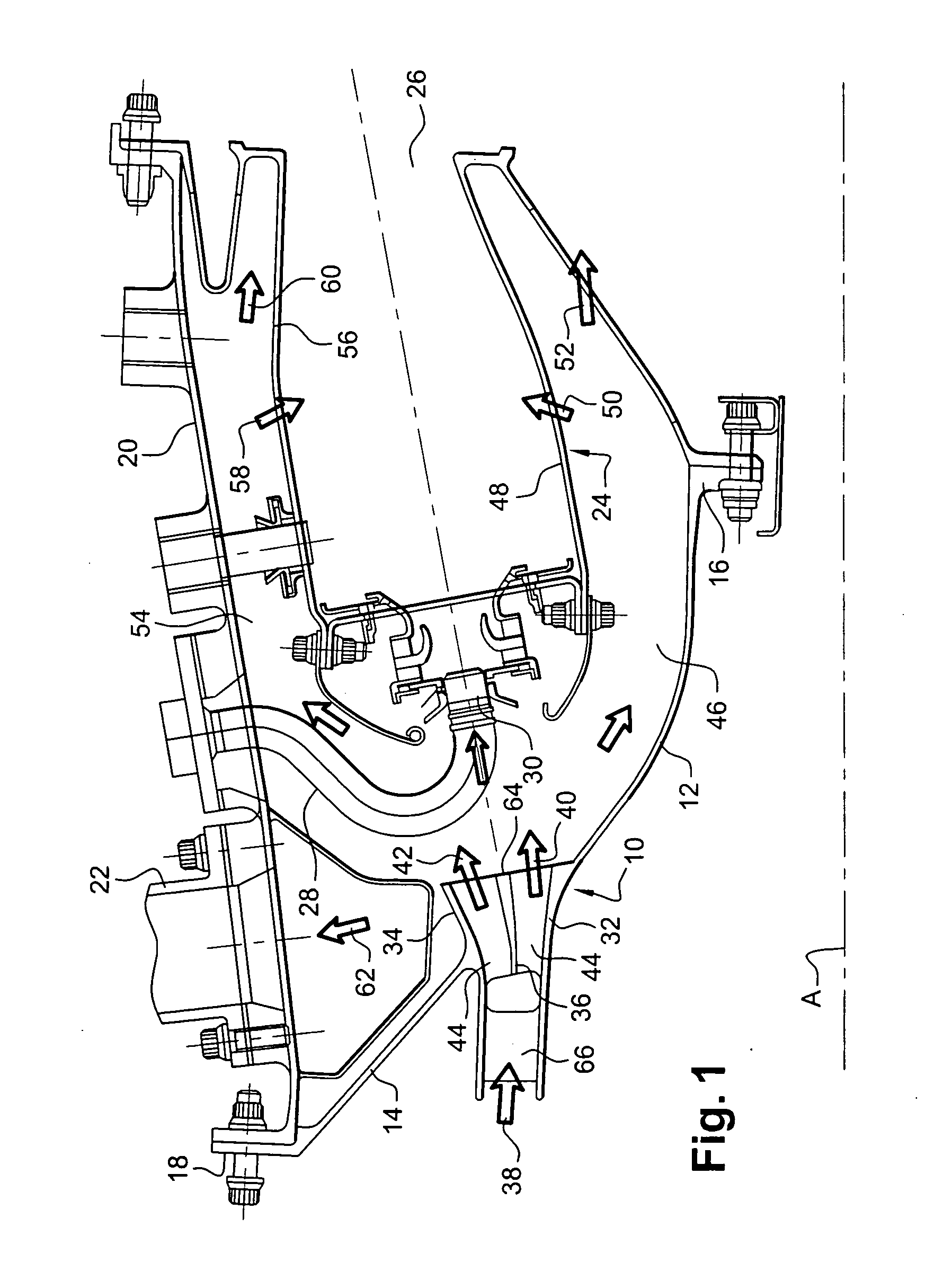

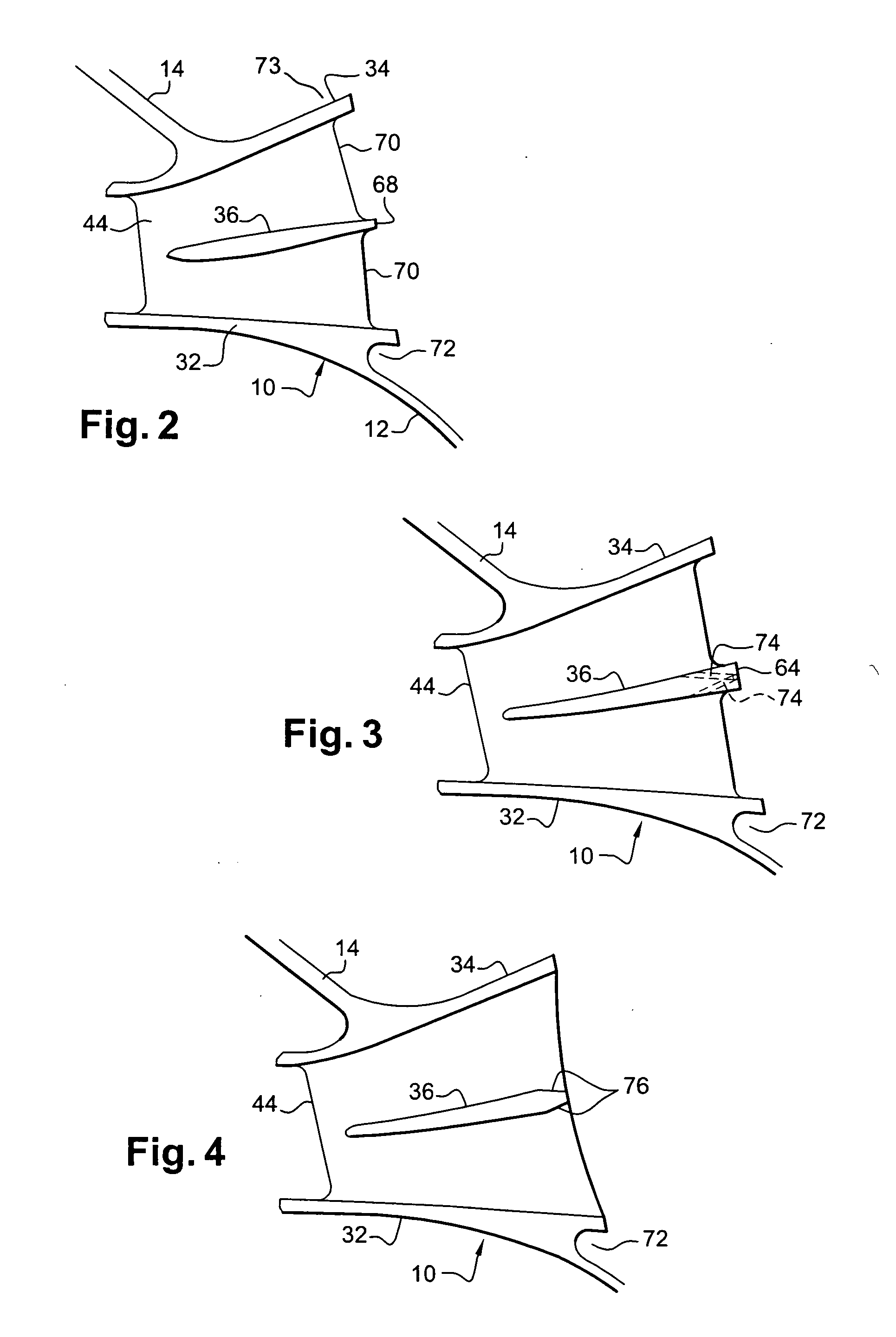

Fastening a CMC combustion chamber in a turbomachine using the dilution holes

InactiveUS20020184889A1Mitigate such drawbackEasy to useContinuous combustion chamberEngine manufactureCombustion chamberMetallic materials

In a turbomachine comprising inner and outer annular shells of metal material containing, in a gas flow direction F: a fuel injection assembly; an annular combustion chamber of composite material having a plurality of air feed orifices in a primary zone and / or in a dilution zone; and an annular nozzle of metal material forming the inlet stage with fixed blades for a high pressure turbine, provision is made for the combustion chamber to be held in position between the inner and outer annular metal shells by means of a plurality of flexible metal tongues having first ends interconnected by respective metal rings fixed securely to said inner and outer annular shells by first fixing means, and second ends fixed securely to the composite material combustion chamber at it air feed orifices by second fixing means.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

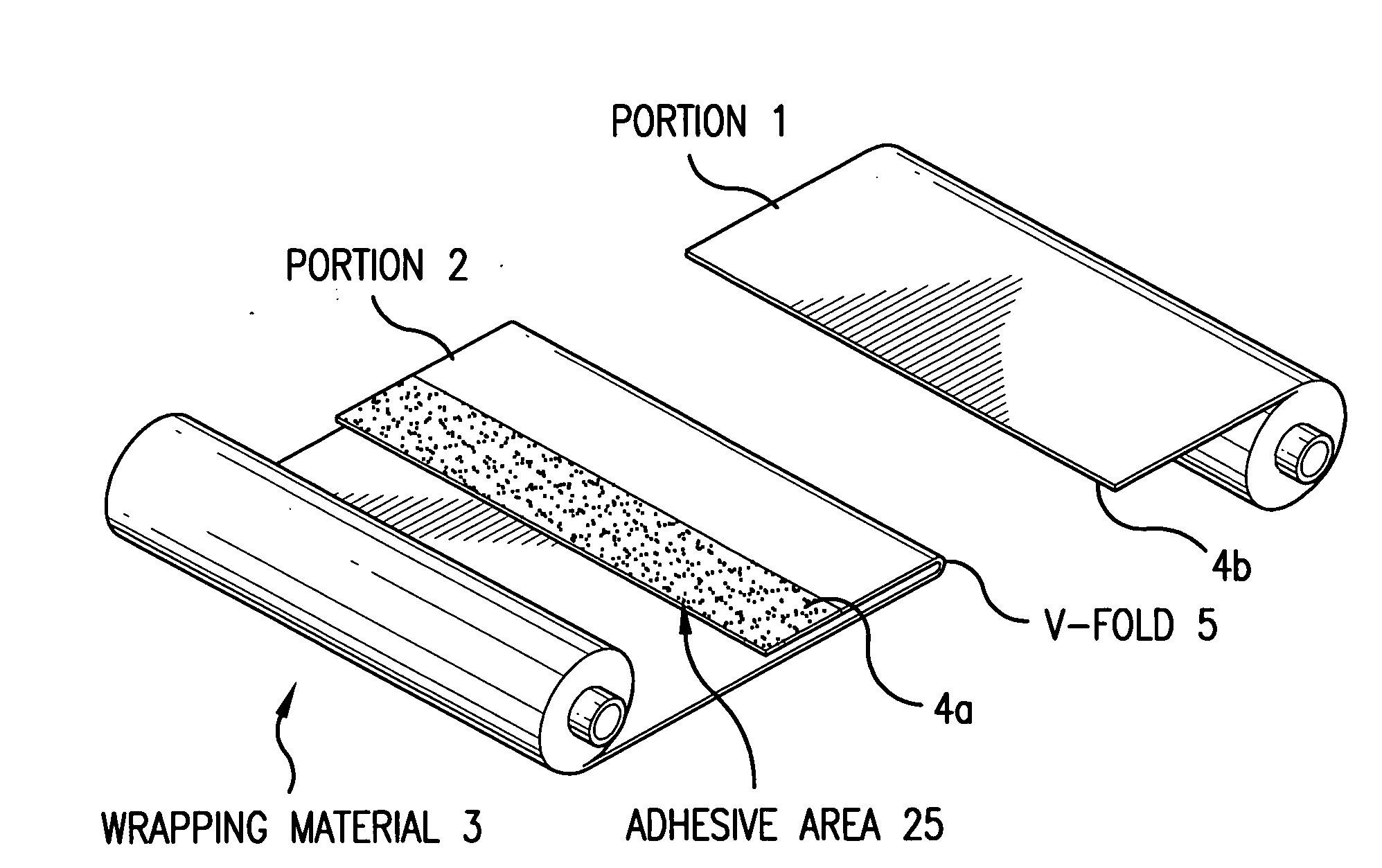

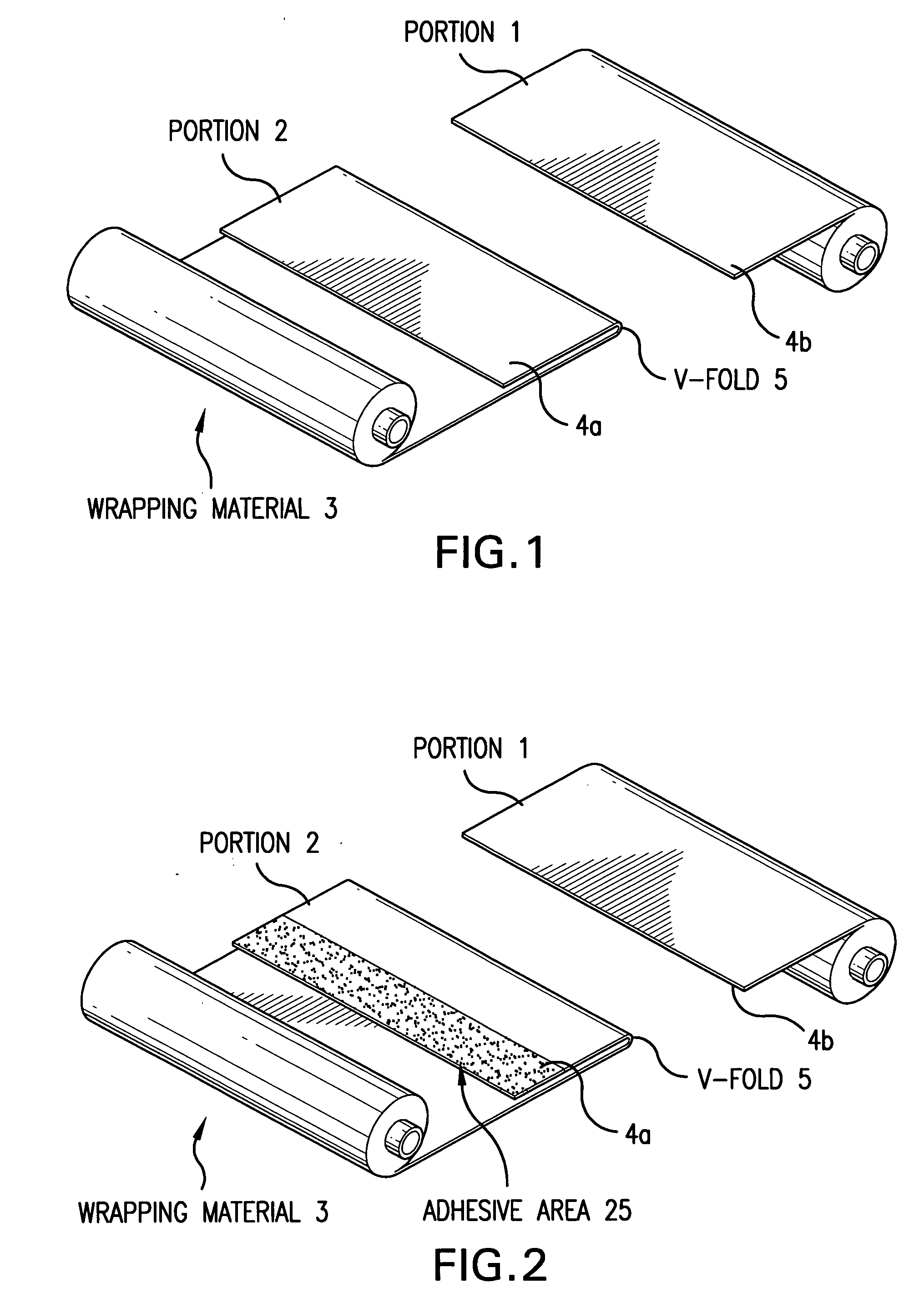

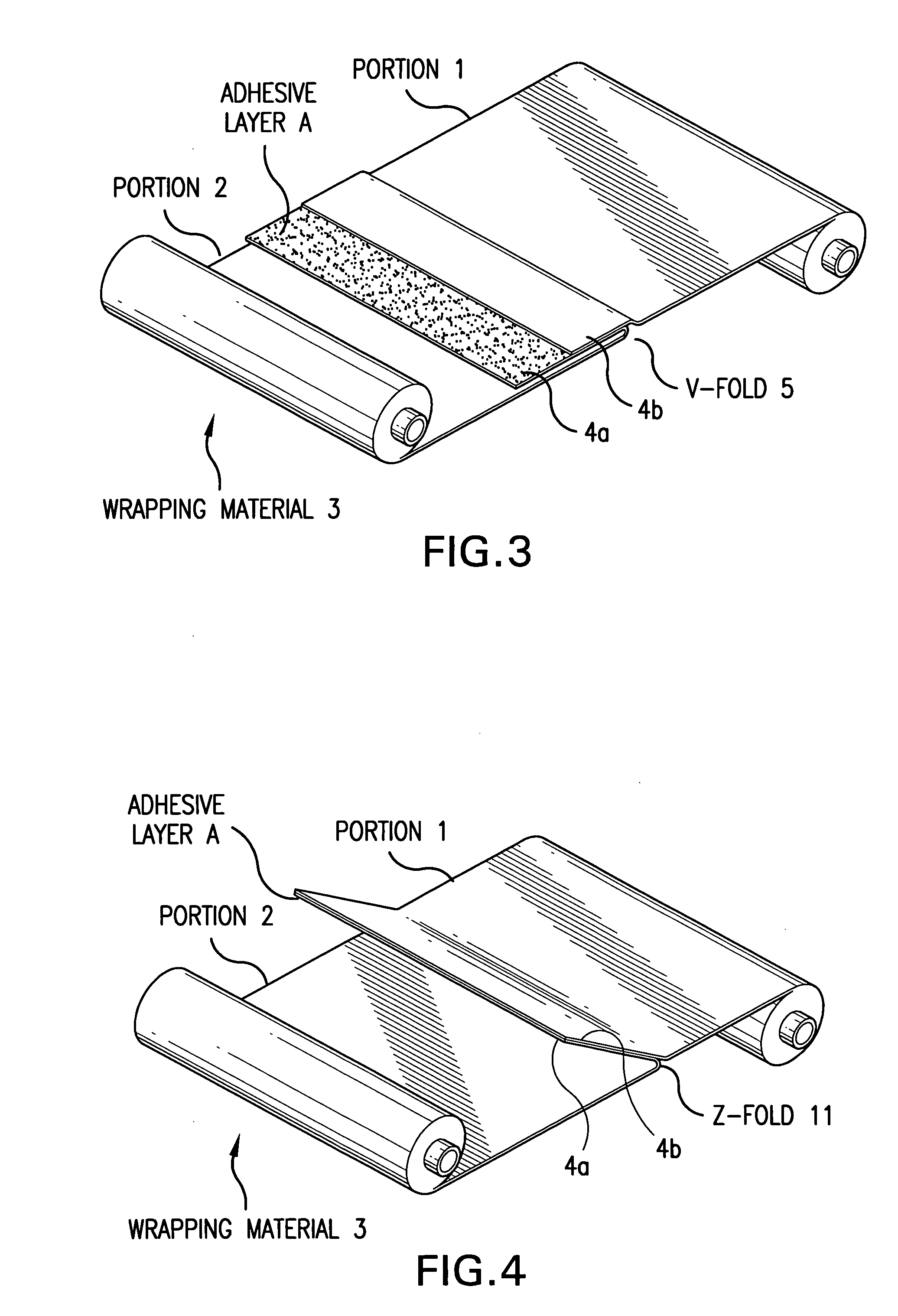

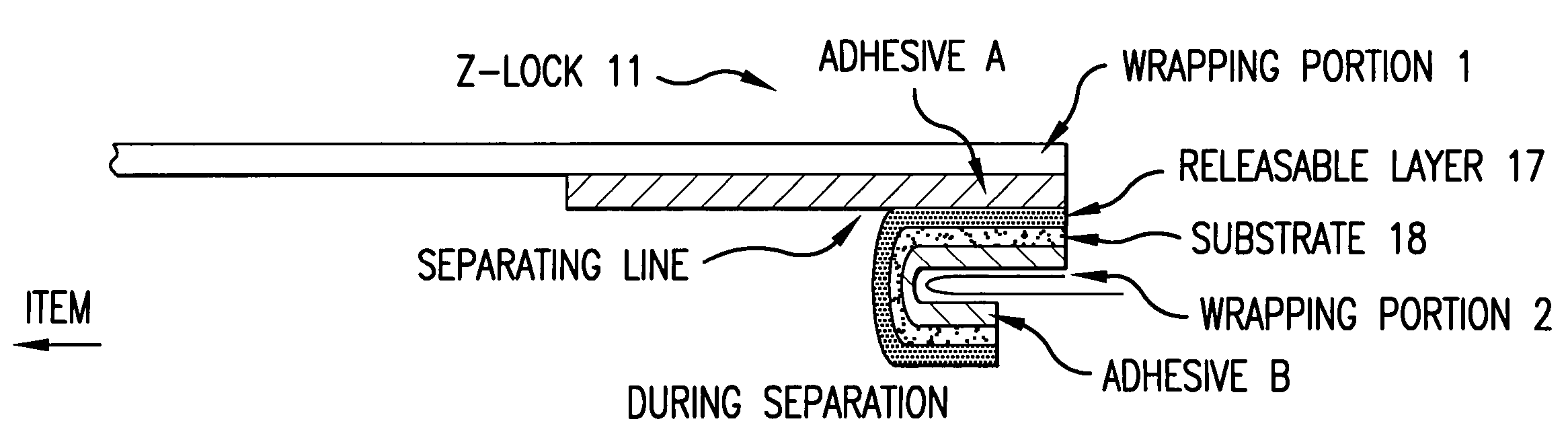

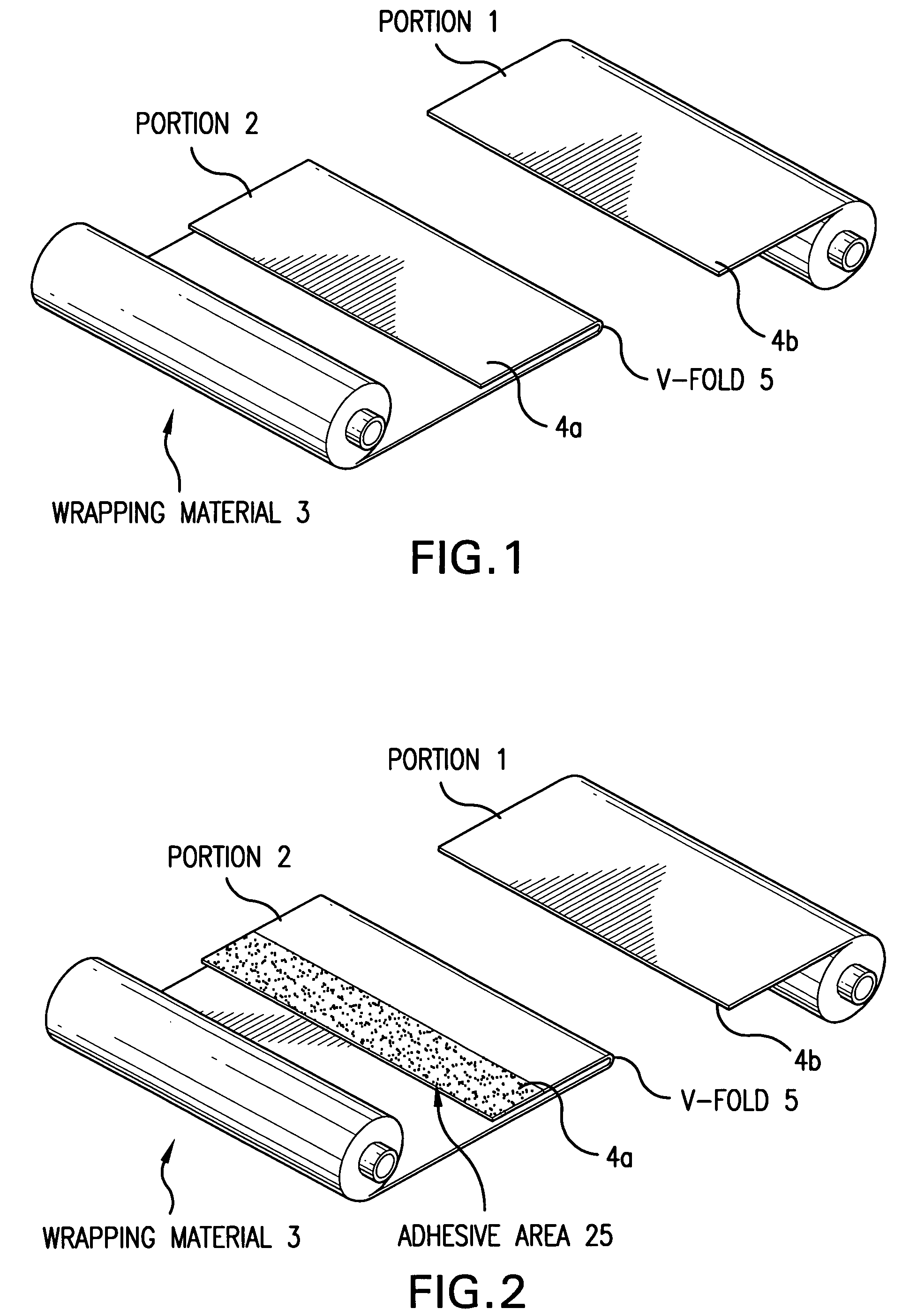

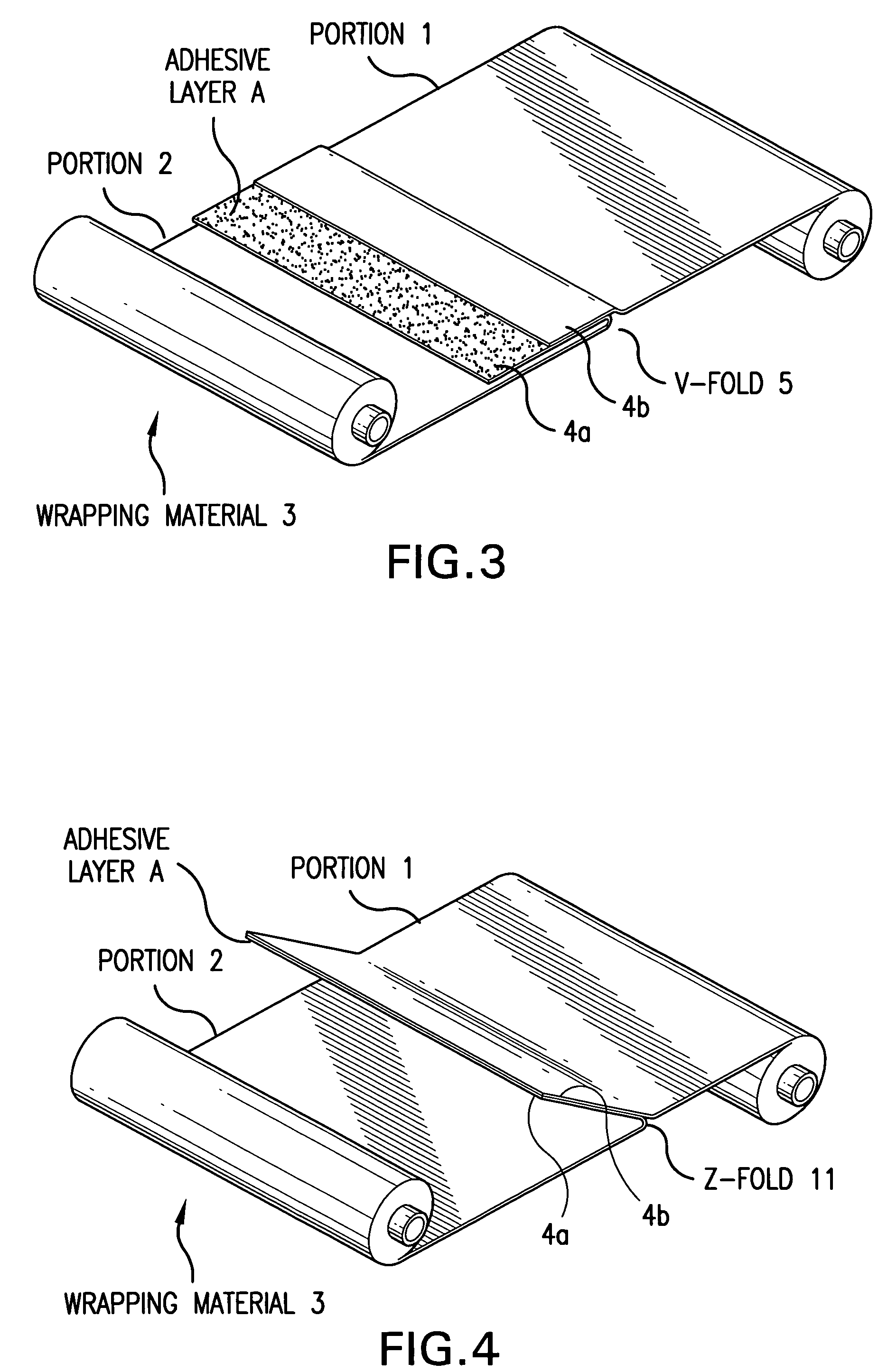

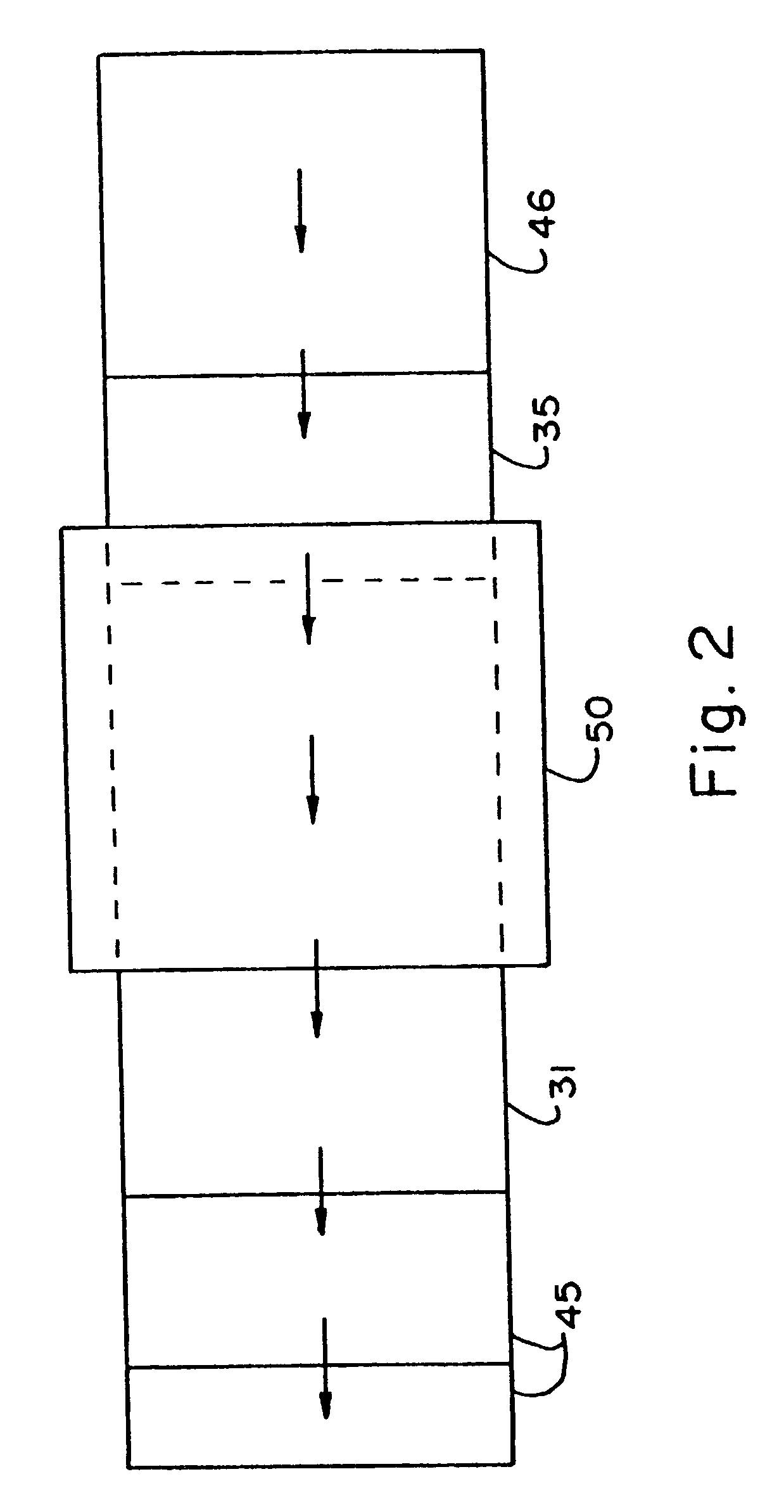

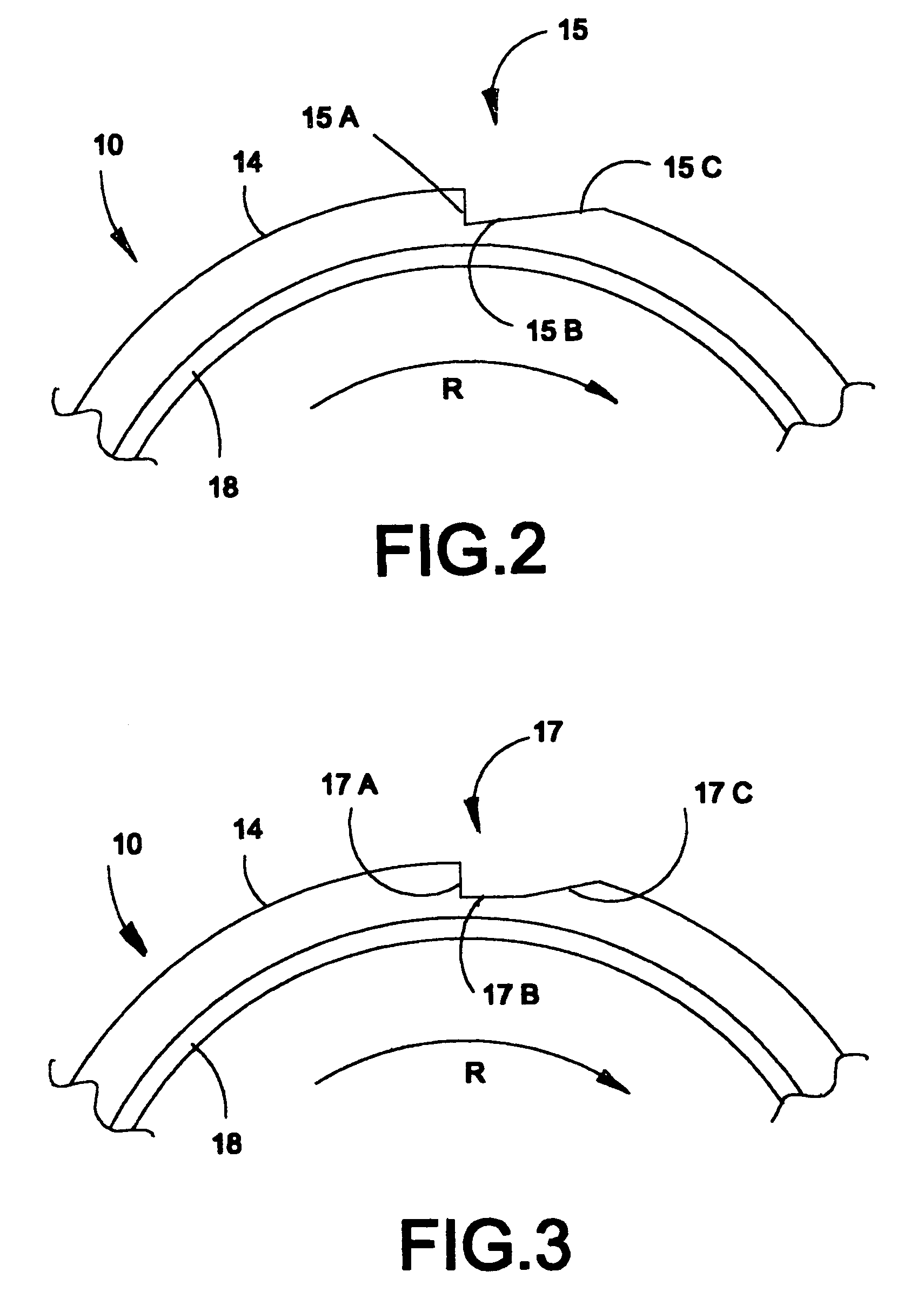

Wrapping material with a Z-lock system and methods of making and using the same

InactiveUS20050034429A1Avoid possibilityAvoid premature separationEnvelopes/bags making machineryWrappersPartial systemAdhesive

Method and material for wrapping items using a wrapping material made up of separate wrapping portions of a predetermined length. The wrapping portions are attached and released at their ends using a Z-lock system including a discrete laminate. The discrete laminate of the Z-lock system holds the wrapping portions together during manufacturing but can also easily release or separate the wrapping portions at a desired point in the wrapping process. The separating of the wrapping portions exposes an adhesive that is use to securely bond at least one wrapping portion to the item being wrapped at the end of a wrapping cycle.

Owner:TAMA GRP

Reversible feed roller with radially extendible fingers

Owner:MACDON INDS

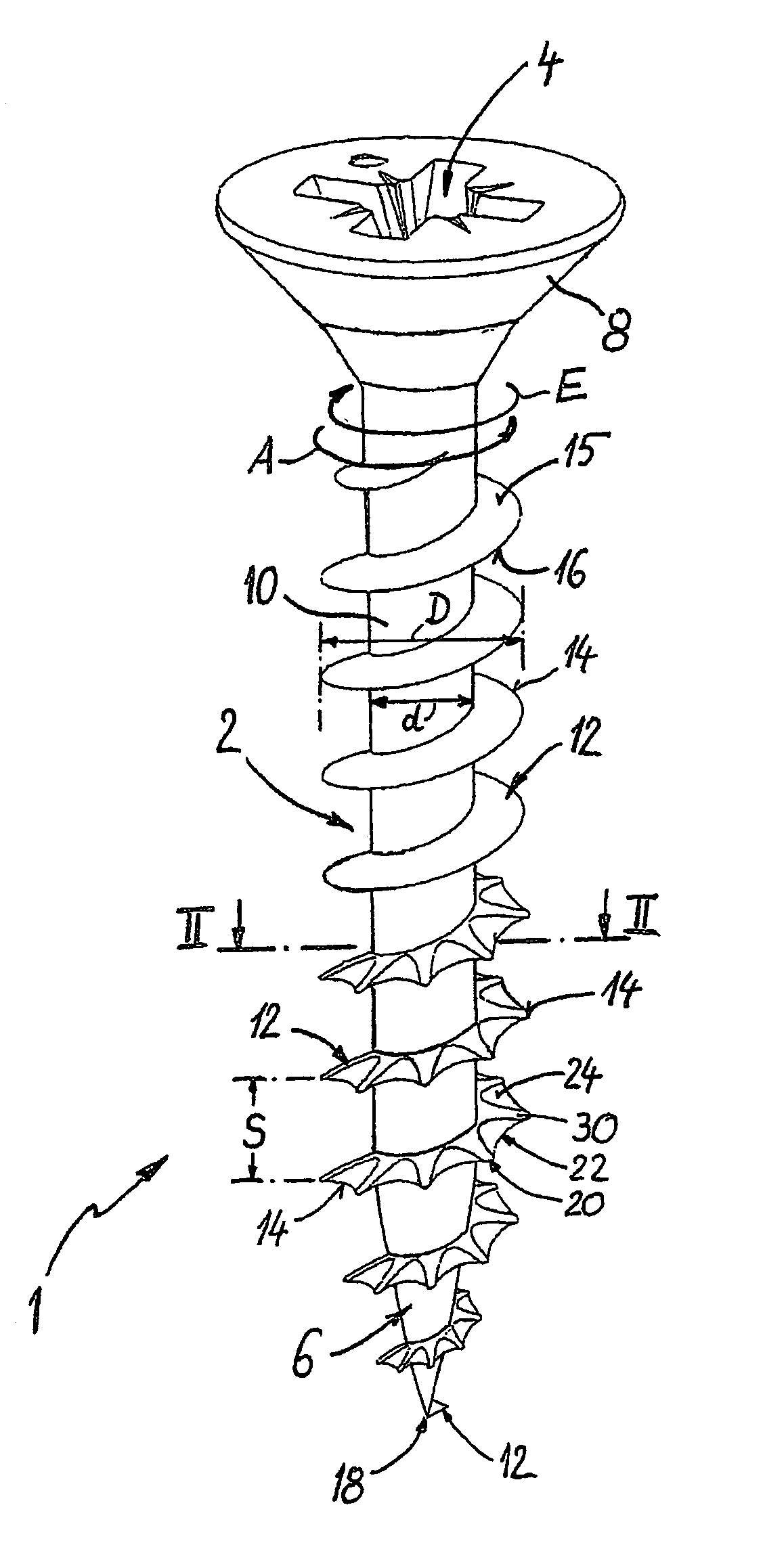

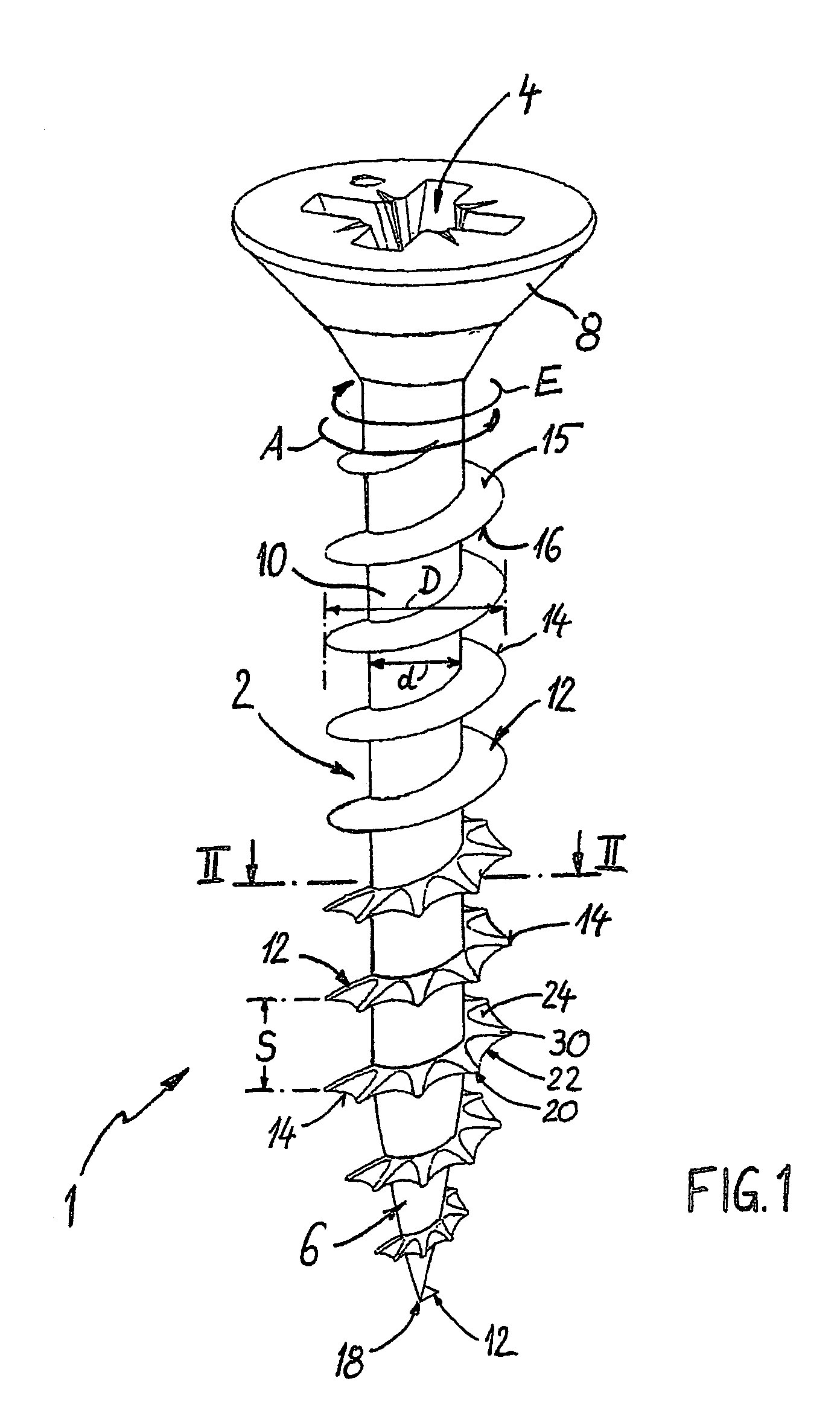

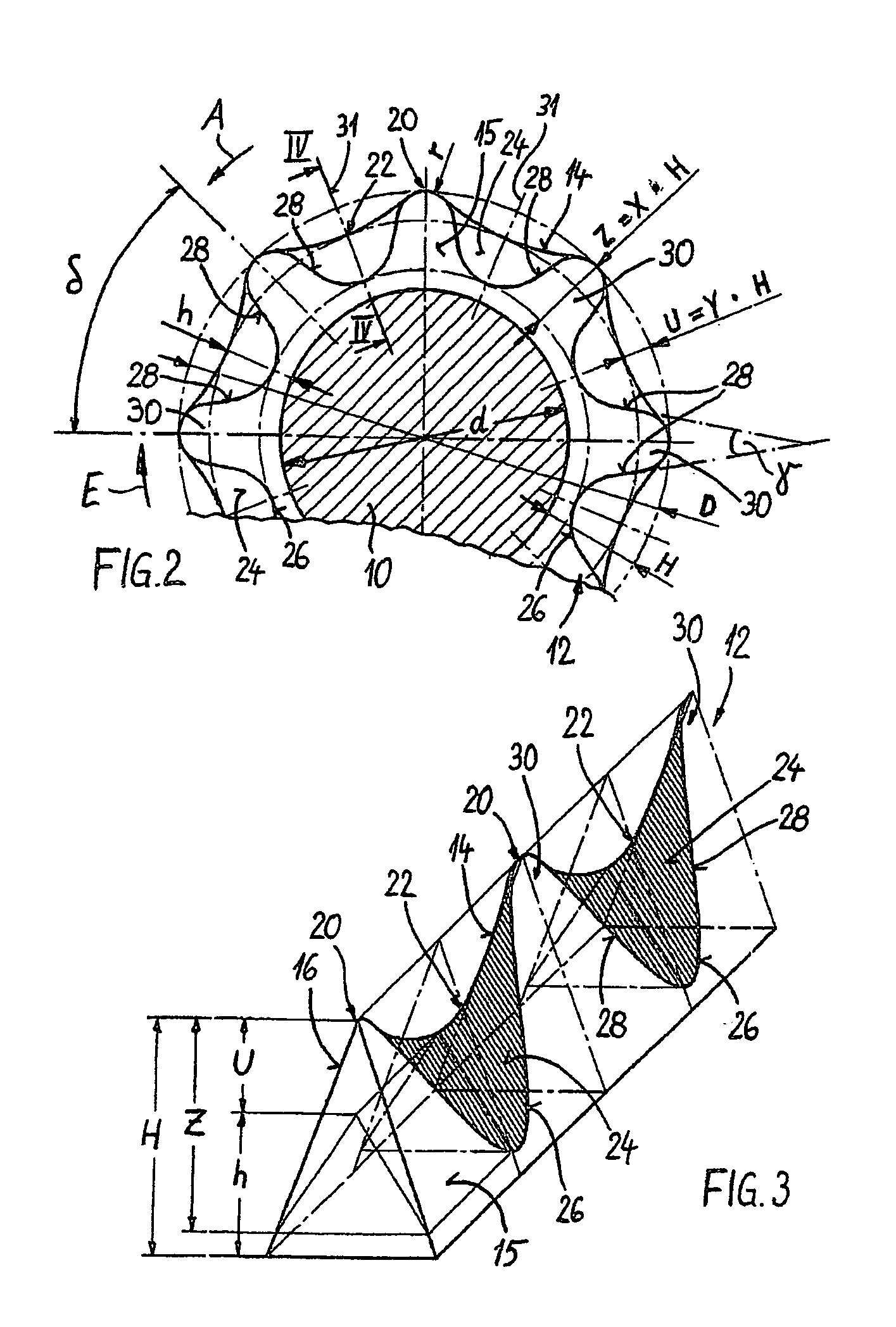

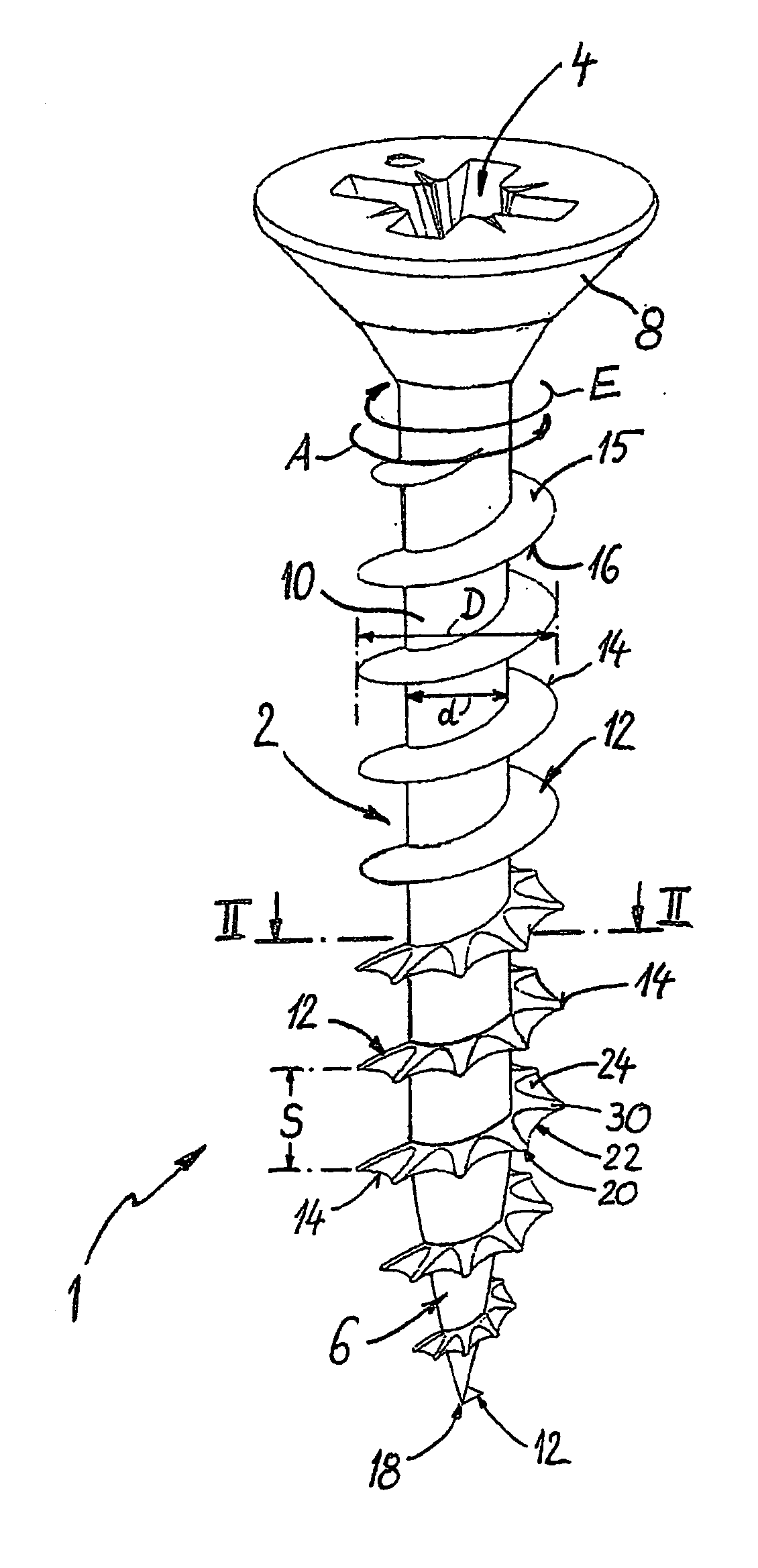

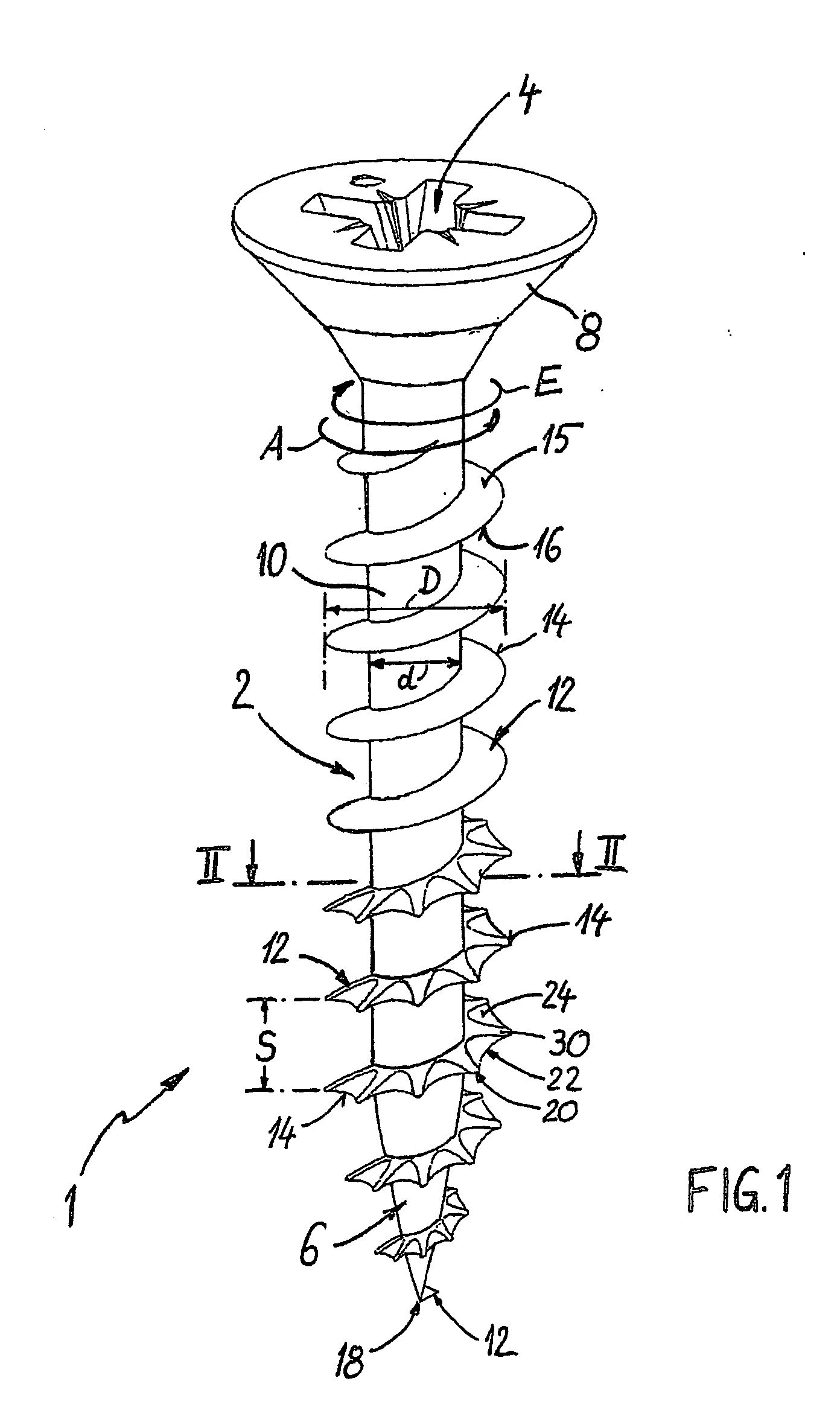

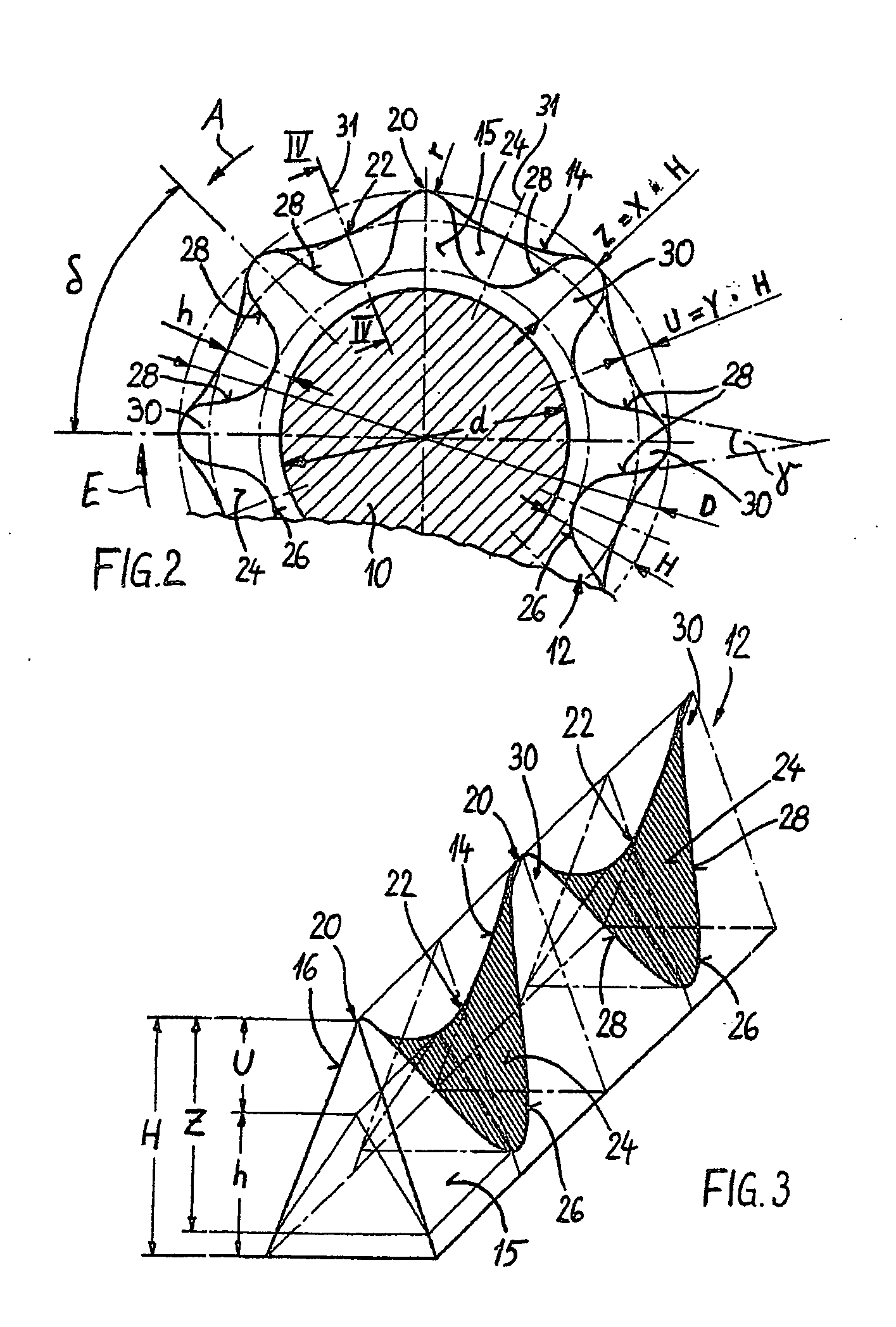

Thread-forming screw fastener

The invention relates to a screw fastener comprising a threaded shank having a force application means for torque transmission and a screw fastener point. The threaded shank consists of a shank core and a self-tapping thread, and the thread is designed as a prominence which runs helically over the shank core, is defined by two flanks meeting in an outer thread edge and has a radial height (H). The outer thread edge, at least in a section of the thread, runs in a wavelike manner in the radial direction with an amplitude between wave crests having the height (H) and wave troughs having a height (h) reduced by the amplitude. The thread, at least in the region of one of its flanks, has niches in the region of the wave troughs of the thread edge, which niches interrupt the surface of the flank and their outer boundary is the thread edge, the thread in each case having a certain first apex angle (α), formed between the flanks, in those regions of the wave crests of the thread edge which are not interrupted by niches and a second apex angle (α′) in the deepest regions of the wave troughs of the thread edge. The first apex angle (α) between the flanks is approximately within the range of 30° to 35°, the second apex angle (α′) being 30° up to at most 58°.

Owner:SPAX INT

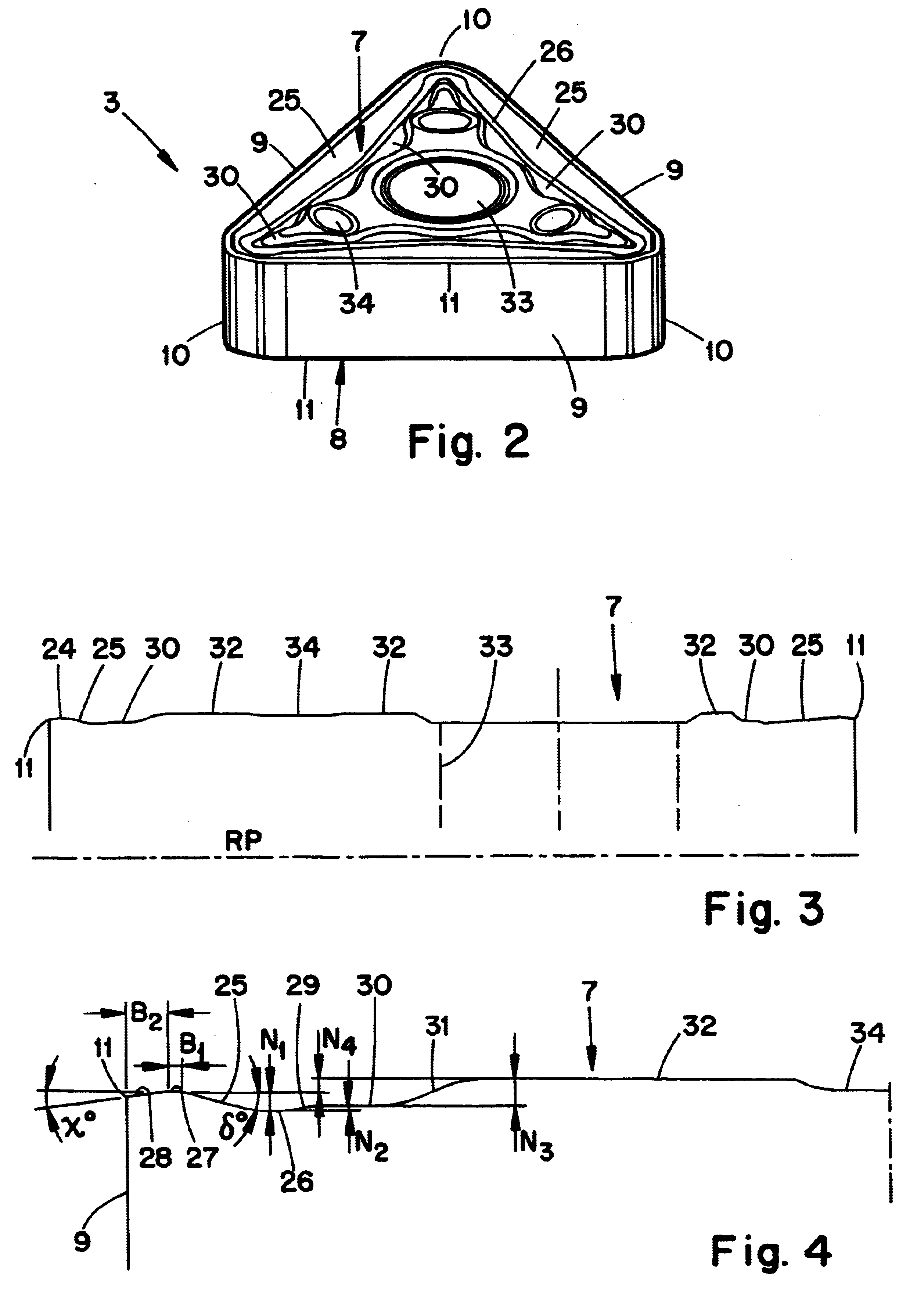

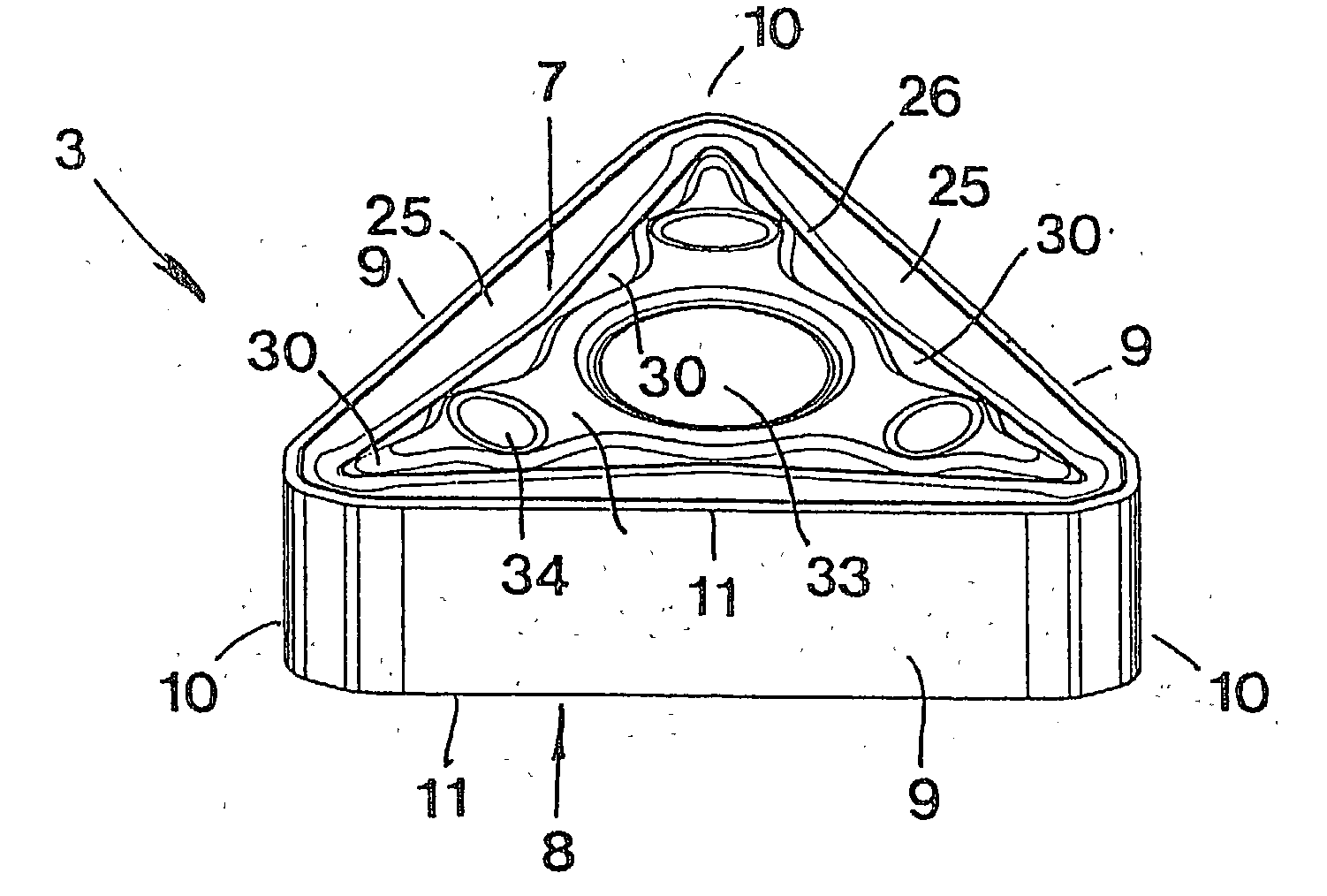

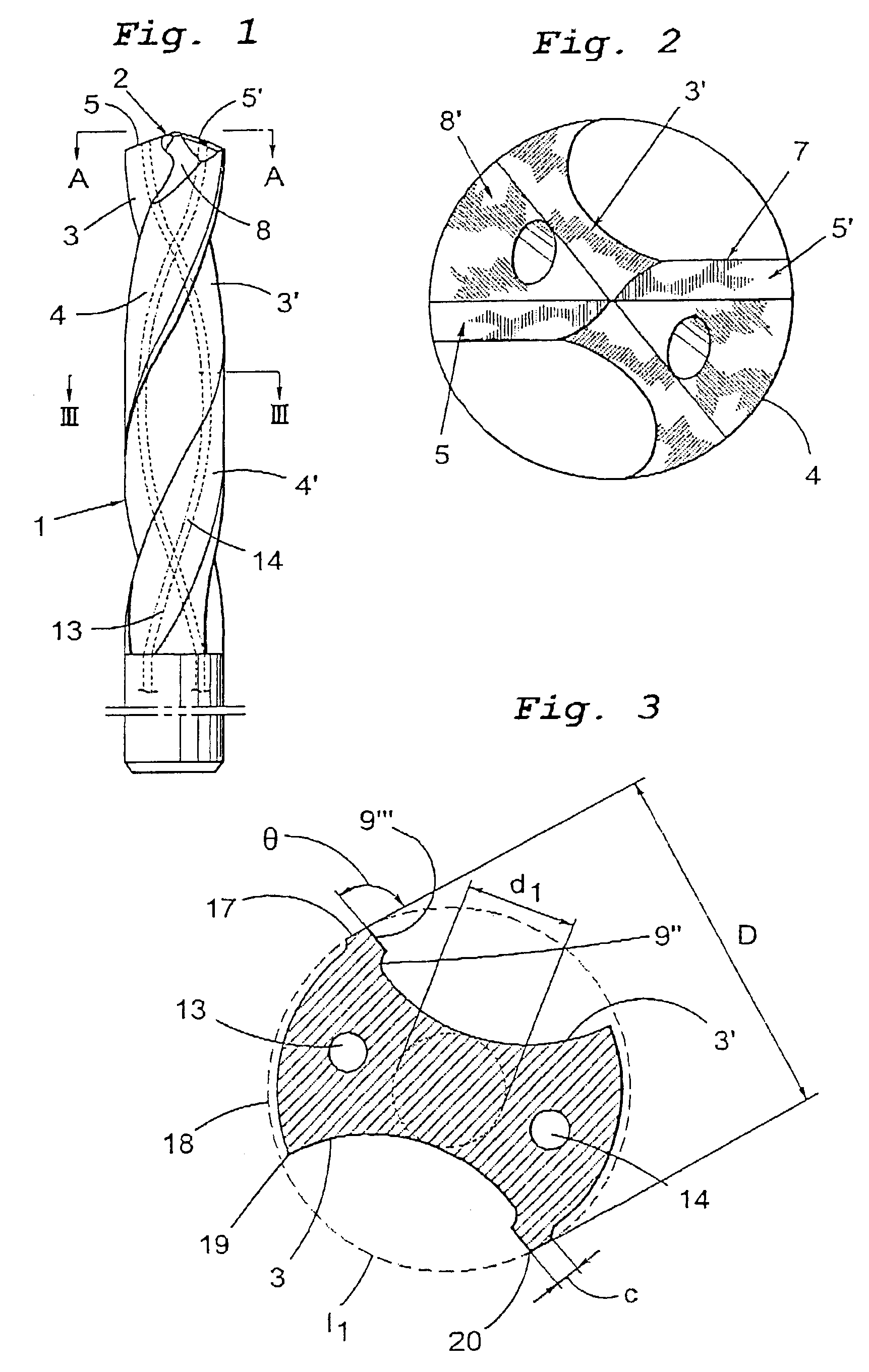

Cutting insert for chip removing machining

InactiveUS20030077131A1Improved cutting insertHigh surface finishCutting insertsTurning toolsEdge segmentMachined surface

A cutting insert, intended for chip removing machining, includes a body delimited by two opposite, first and second surfaces, which in the operative state of the cutting insert form an actively chip removing top surface and a bottom surface, respectively. The insert also includes at least one side surface, serving as a flank surface, which extends between the first and second surfaces. A cutting edge is formed between the flank surface and at least one of said first and second surfaces, in which a segment is included, which has the purpose of smoothening and facing the machined surface of the workpiece. The smoothening edge segment is divided into at least three different part edge segments, a first of which forms a tangent point and is surrounded by two part edge segments having longer radii (R22, R23) than the first edge part segment.

Owner:SANDVIK INTELLECTUAL PROPERTY AB +1

Wrapping material with a Z-lock system

InactiveUS7541080B2Avoid stickingFacilitates attachment/connectionEnvelopes/bags making machineryWrappersAdhesiveMechanical engineering

Method and material for wrapping items using a wrapping material made up of separate wrapping portions of a predetermined length. The wrapping portions are attached and released at their ends using a Z-lock system including a discrete laminate. The discrete laminate of the Z-lock system holds the wrapping portions together during manufacturing but can also easily release or separate the wrapping portions at a desired point in the wrapping process. The separating of the wrapping portions exposes an adhesive that is use to securely bond at least one wrapping portion to the item being wrapped at the end of a wrapping cycle.

Owner:TAMA GRP

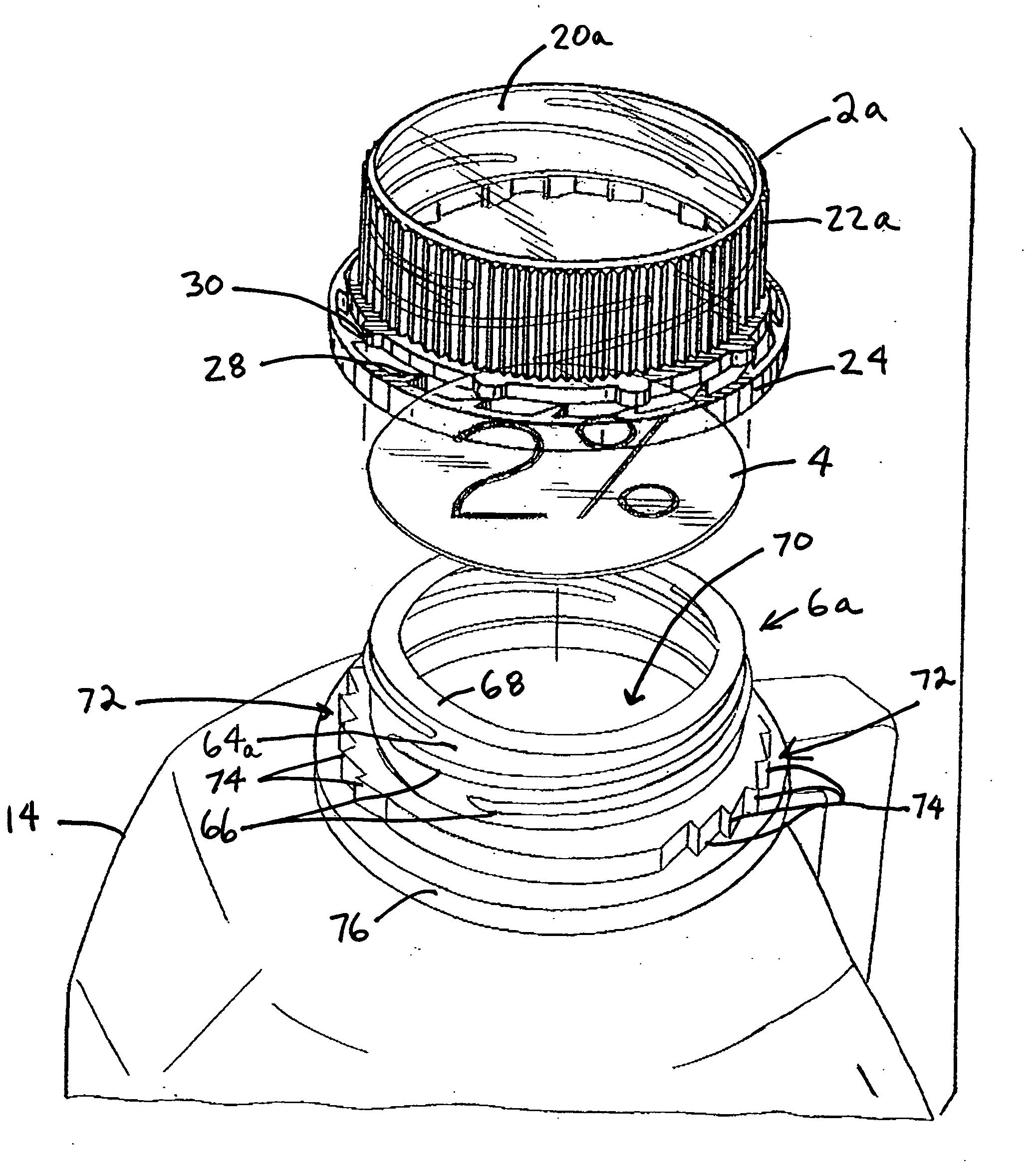

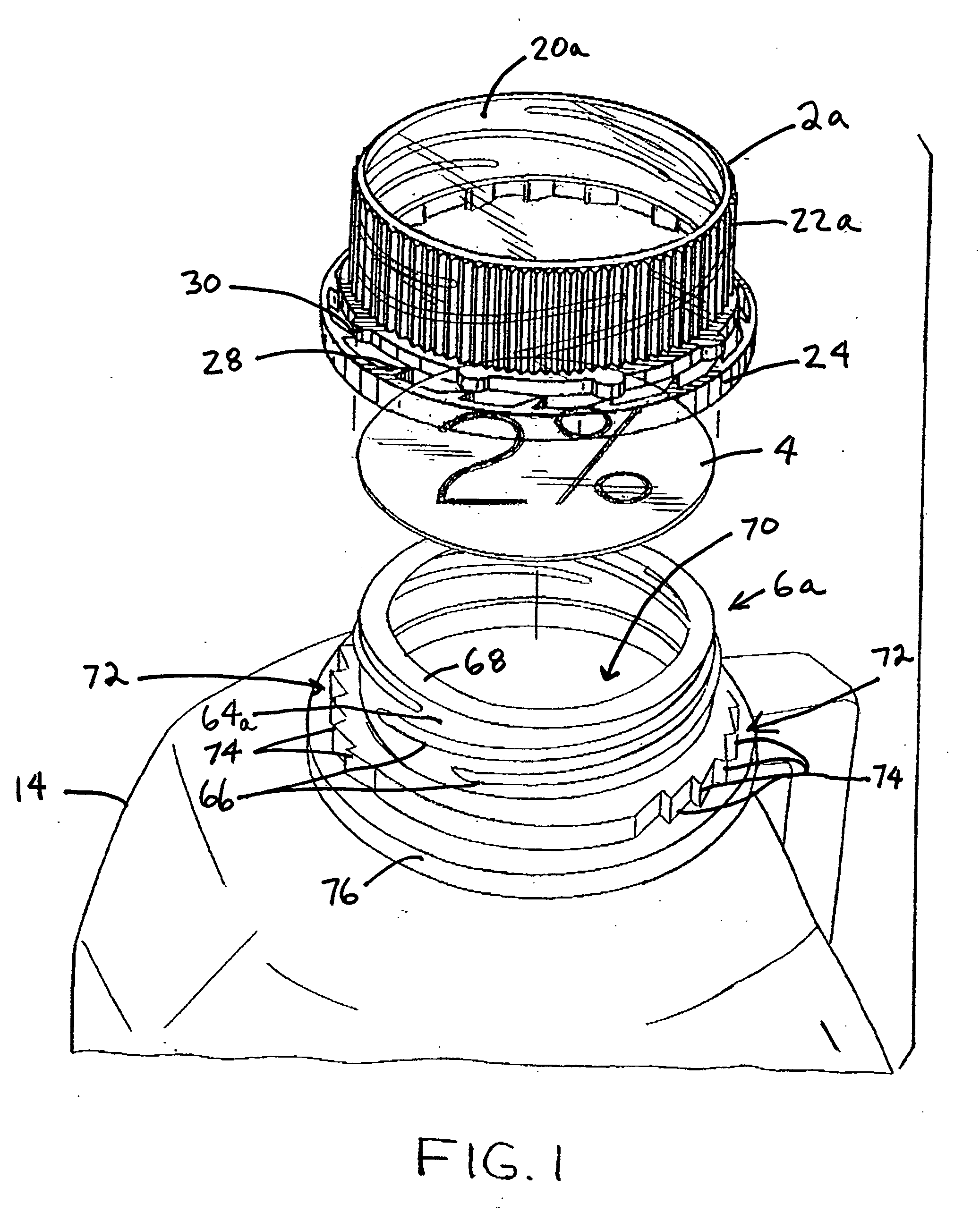

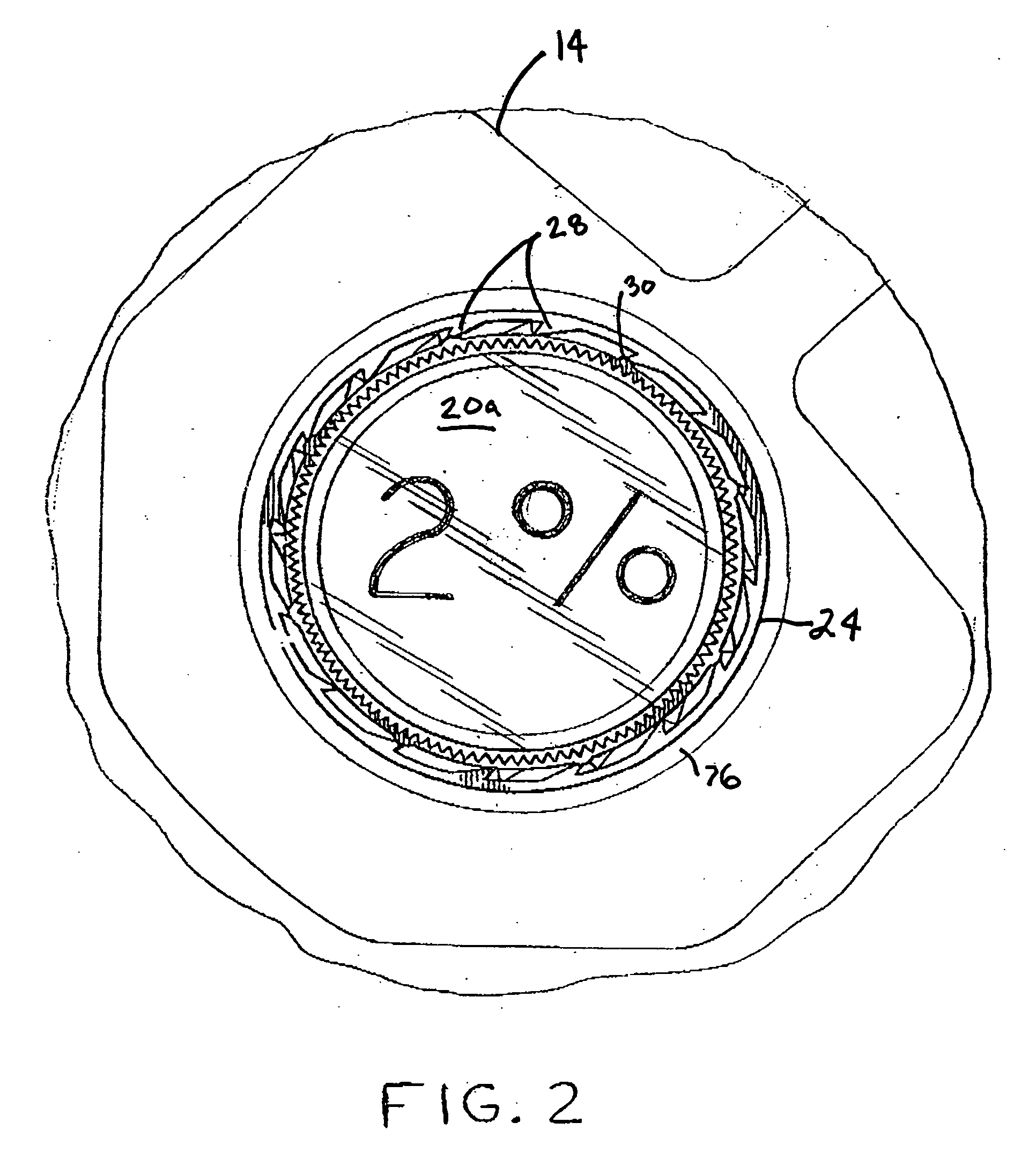

Cap with visible tamper-indicating seal

InactiveUS20070051691A1Easy to customizeImprove efficiencyCapsContainer decorationsMechanical engineeringRidge

The inventions disclosed herein include a clear cap and tamper-indicating seal combination, a translucent cap and seal combination, an improved cap embodying a raised ridge for providing a contact surface on the top of the cap, among other inventions. The preferred cap is at least partially non-opaque to allow a customer to perceive the tamper-indicating seal through the cap at the point of purchase. In a first embodiment, the tamper-indicating seal serves as a label, wherein the customer can perceive, through the cap, information such as printing which is indicative of the contents of the container. In a second embodiment, the tamper-indicating seal serves as a tamper evident seal, wherein the customer can perceive, through the cap, at the point of purchase, whether the seal has been breached. In a third embodiment, the tamper-indicating seal serves as both a label and a seal, wherein the tamper-indicating seal creates a liquid resistant seal between the cap and the opening of the container. In a forth embodiment, the tamper-indicating seal serves as both a label and a tamper evident seal. In a fifth embodiment of the present invention, a cap is provided with a raised portion on a top surface of the cap for reducing the frictional surface area of the cap during capping operations.

Owner:BLACKHAWK MOLDING

Thread-forming screw fastener

The invention relates to a screw fastener comprising a threaded shank having a force application means for torque transmission and a screw fastener point. The threaded shank consists of a shank core and a self-tapping thread, and the thread is designed as a prominence which runs helically over the shank core, is defined by two flanks meeting in an outer thread edge and has a radial height (H). The outer thread edge, at least in a section of the thread, runs in a wavelike manner in the radial direction with an amplitude between wave crests having the height (H) and wave troughs having a height (h) reduced by the amplitude. The thread, at least in the region of one of its flanks, has niches in the region of the wave troughs of the thread edge, which niches interrupt the surface of the flank and their outer boundary is the thread edge, the thread in each case having a certain first apex angle (α), formed between the flanks, in those regions of the wave crests of the thread edge which are not interrupted by niches and a second apex angle (α′) in the deepest regions of the wave troughs of the thread edge. The first apex angle (α) between the flanks is approximately within the range of 30° to 35°, the second apex angle (α′) being 30° up to at most 58°.

Owner:SPAX INT

Method for preparing hydroxyethyl cellulose

The invention discloses a method for using plugh mixing type horizontal reactor to produce hydroxyethylcellulose, which comprises adding cellulose at 50-90% of reactor volume, solvent at 0.5-5.0 mass times of the cellulose, water and sodium hydroxide into a reactor, exchanging the air in the reactor via nitrogen gas, processing alkalization reaction, adding ethylene oxide into the reactor, processing etherification reaction, adding acid into the reactor to neutralize, and controlling pH value at 4.5-8.0, to obtain the paste containing hydroxyethylcellulose, and refining to obtain the hydroxyethylcellulose whose hydroxyethyl MS (mol substituent degree) is 1.6-3.5. The invention has the advantages of low solvent consumption, high device effective utilization, high product yield, high purity, low energy consumption, low solvent loss and low compressive cost, which is suitable for energy saving and low pollution discharge.

Owner:JIANGSU FEIXIANG CHEM

Casting method of metal substrate cooling wall

InactiveCN1513622AEnhanced feedingImprove feeding capacityFoundry mouldsCooling devicesIron powderChemical reaction

A technology for casting the steel-based cooling wall features that the cooling medium which is the mixture of corundum powder, iron powder and electrode powder is filled in its cooling pipeline. Said cooling medium features strong cooling action, low thermal expansibility, not adhering to pipe wall, and easy removing it.

Owner:MAANSHAN IRON & STEEL CO LTD

Diffuser for an annular combustion chamber, in particular for an airplane turbine engine

ActiveUS20060162336A1Minimizing head lossMinimize disturbanceContinuous combustion chamberPump componentsJet aeroplaneCombustion chamber

A diffuser for a single-head annular combustion chamber of an airplane engine, the diffuser comprising a separator formed by a thin sheet connected by structural arms to inner and outer circularly-symmetrical walls of the diffuser, the diffuser angle for each diffusion stream defined by the separator lying in the range about 12° to about 13°.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

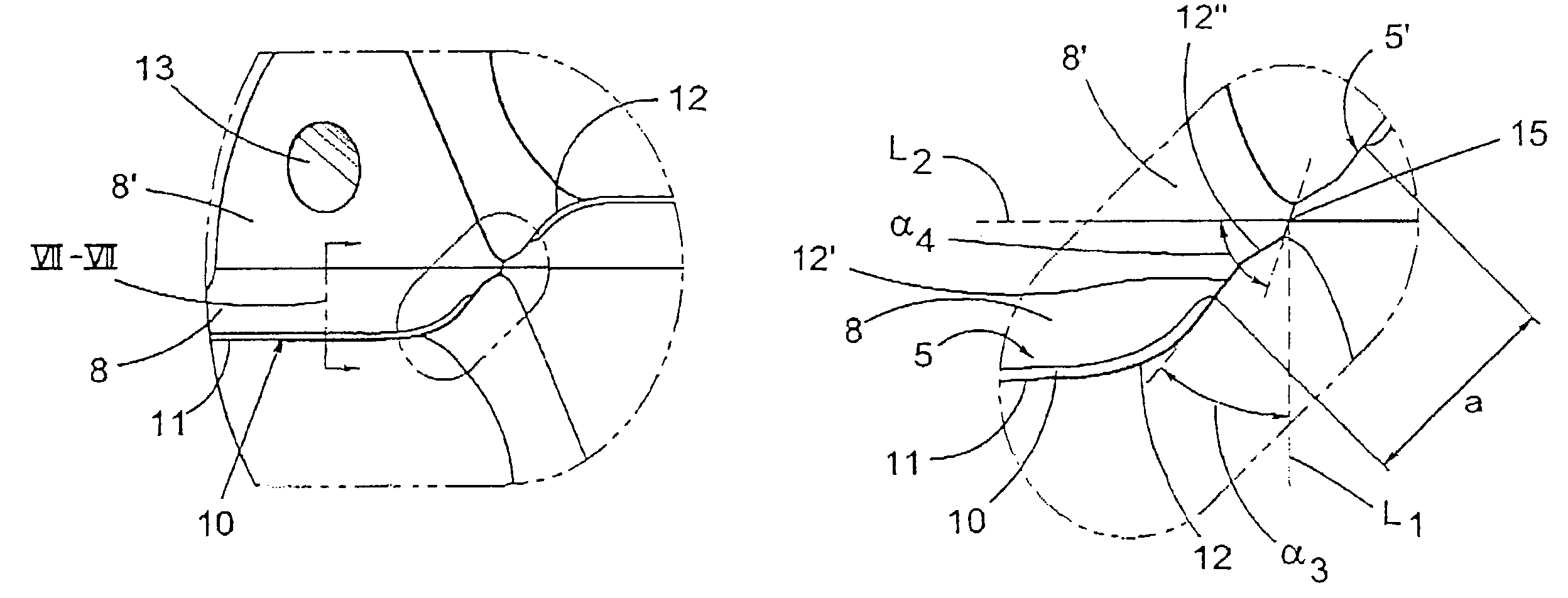

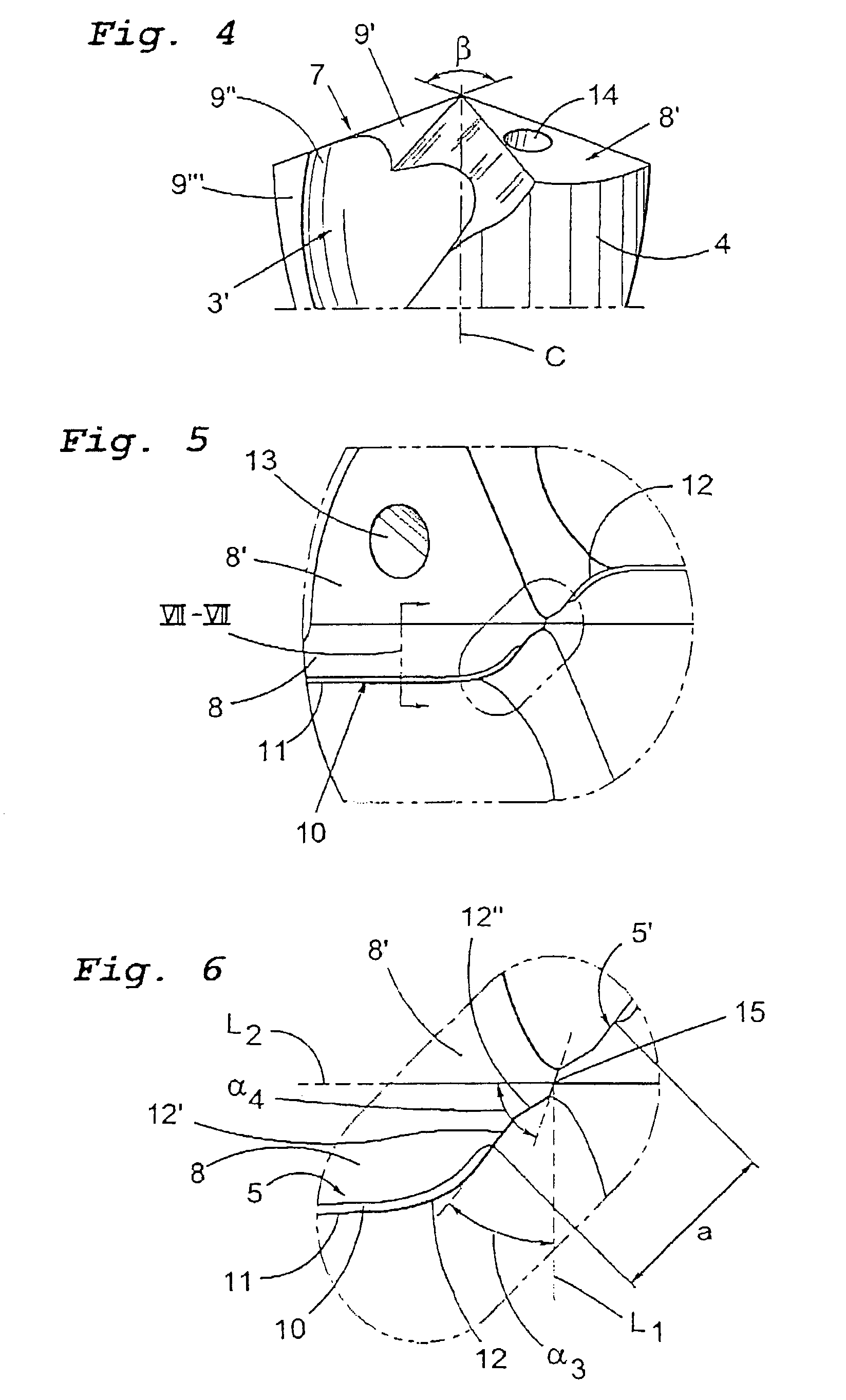

Drilling tool for holemaking in metallic workpieces

ActiveUS7241085B2Improve centering abilityGood centering abilityWood turning toolsTransportation and packagingFluteLevel line

A drill comprises a shaft with chip conveying flutes and a drill head at its forward end with at least two cutting inserts. Each cutting insert is provided with at least one cutting edge which is delimited between a chipbreaking surface and first relief surface and which includes an outer straight edge. In the proximity of the center axis of the shaft, a curved cutting edge section is provided, to which there is connected an adjacent enforcement bevel. The cutting edge is in direct proximity to a center axis, and is terminated by a chisel edge between the cutting inserts to serve as a centering core portion. The curved cutting edge section is inwardly followed by a primary straight portion without an adjacent enforcement bevel in a direction that is oriented at an angle of between approximately 40–50° in relation to a horizontal line that extends through the center axis of the drill.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

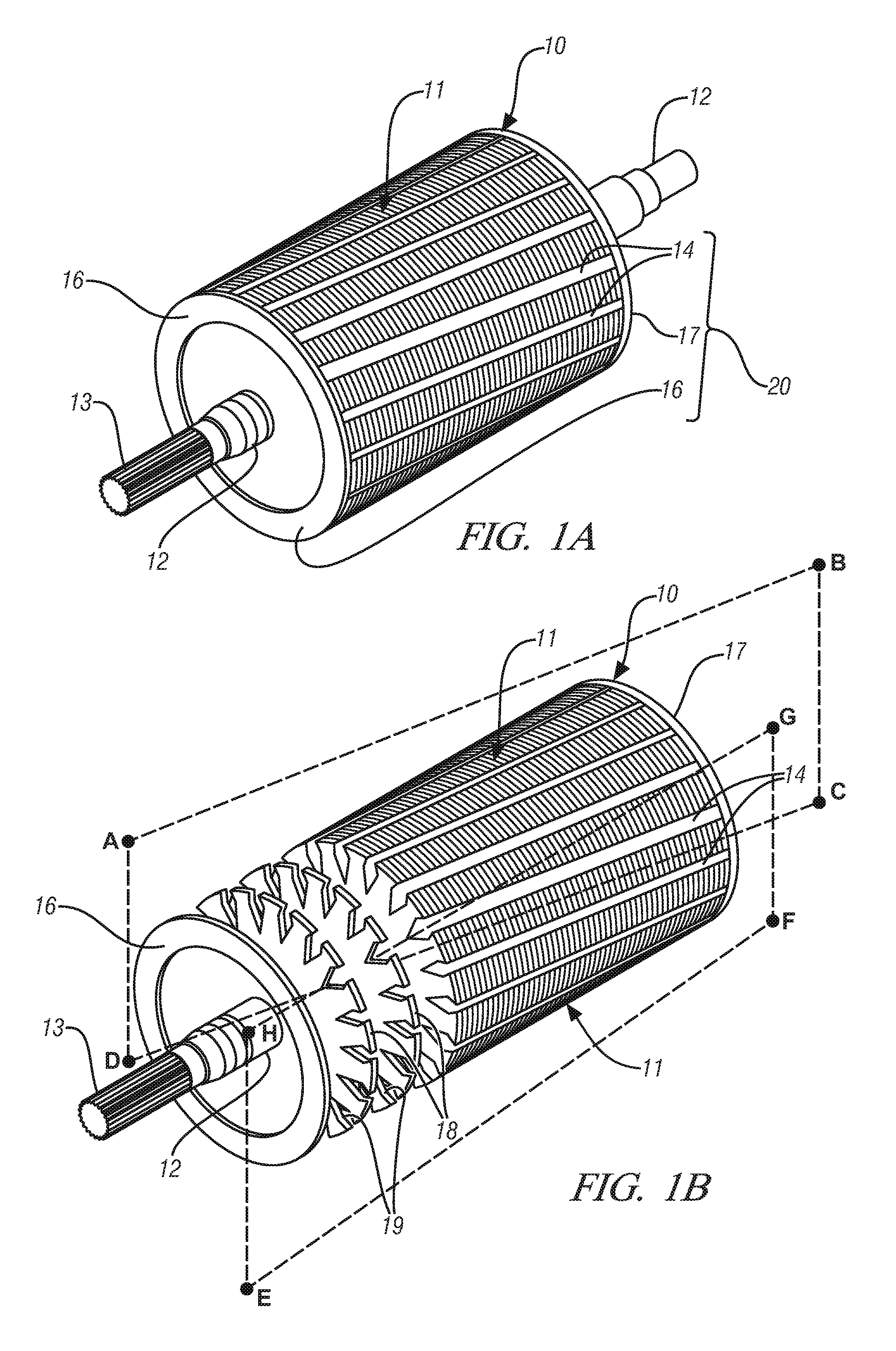

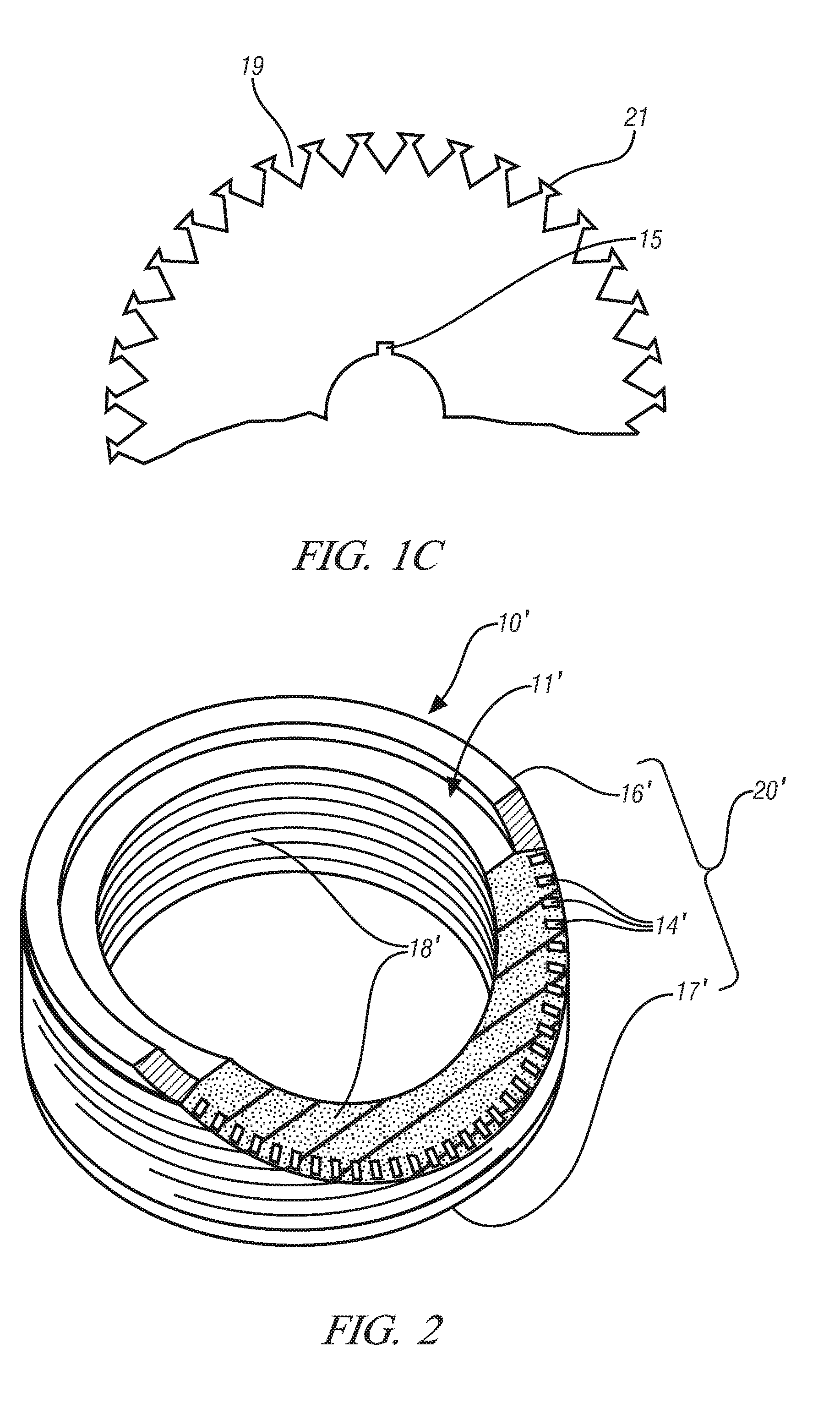

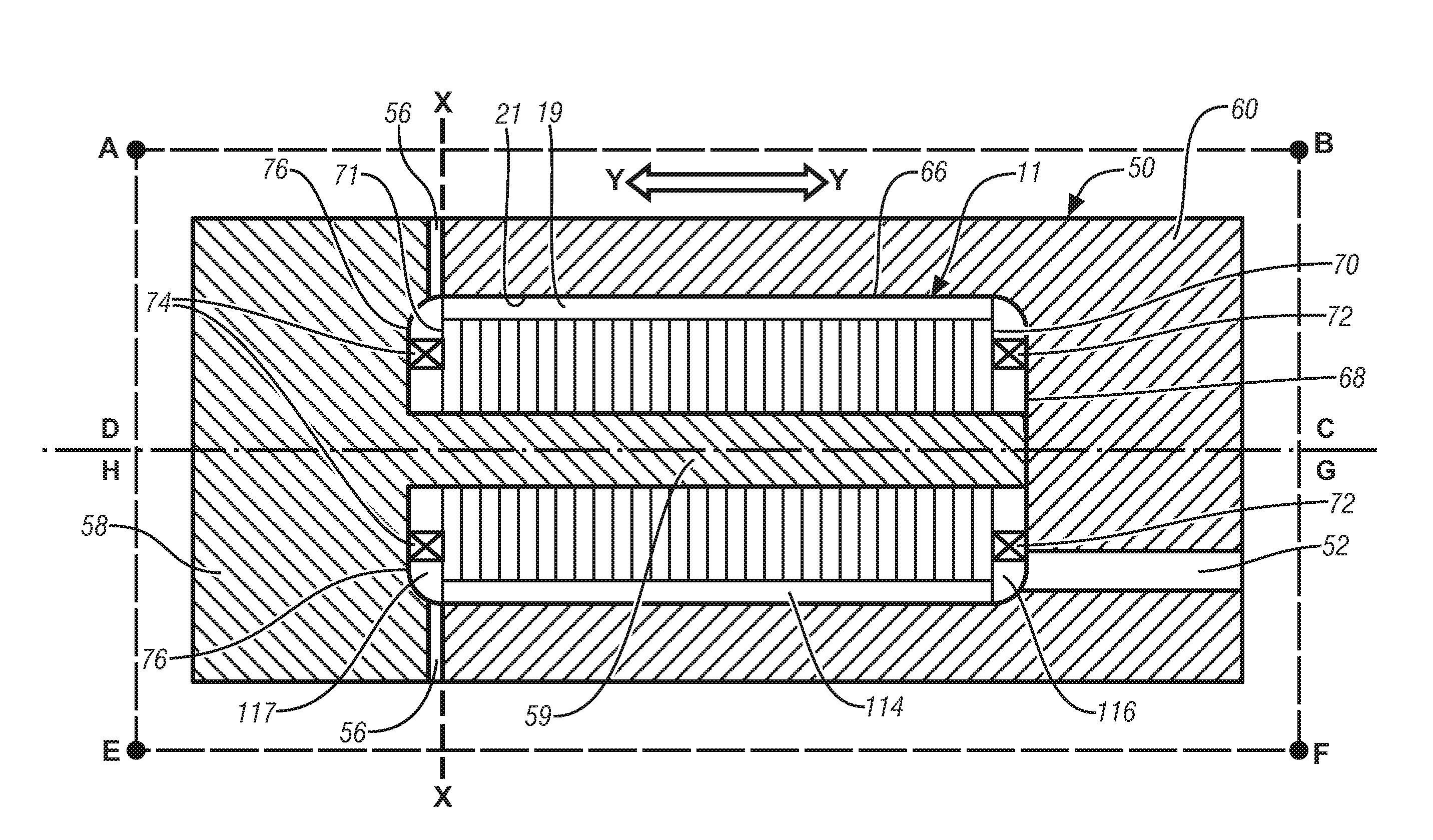

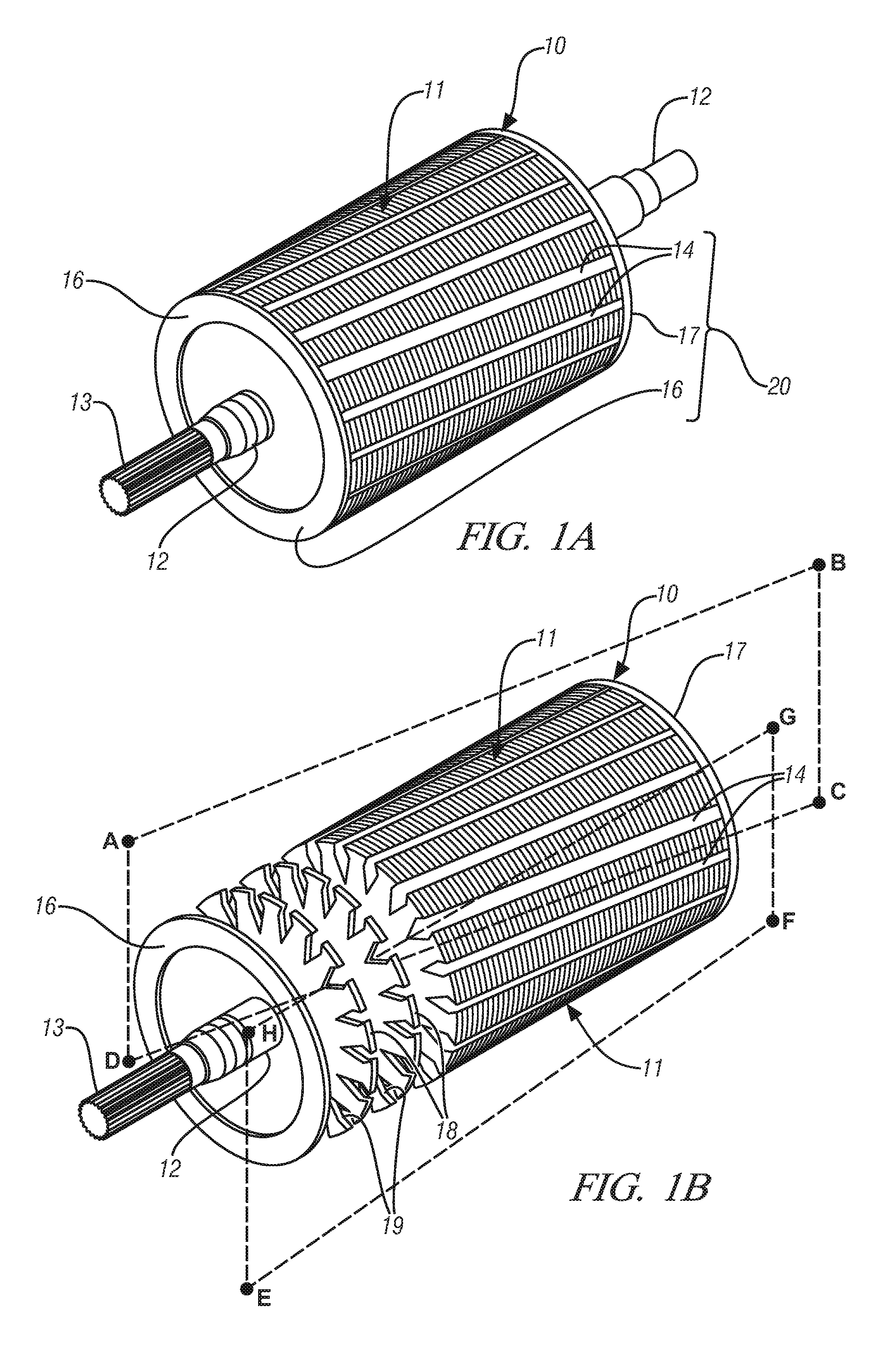

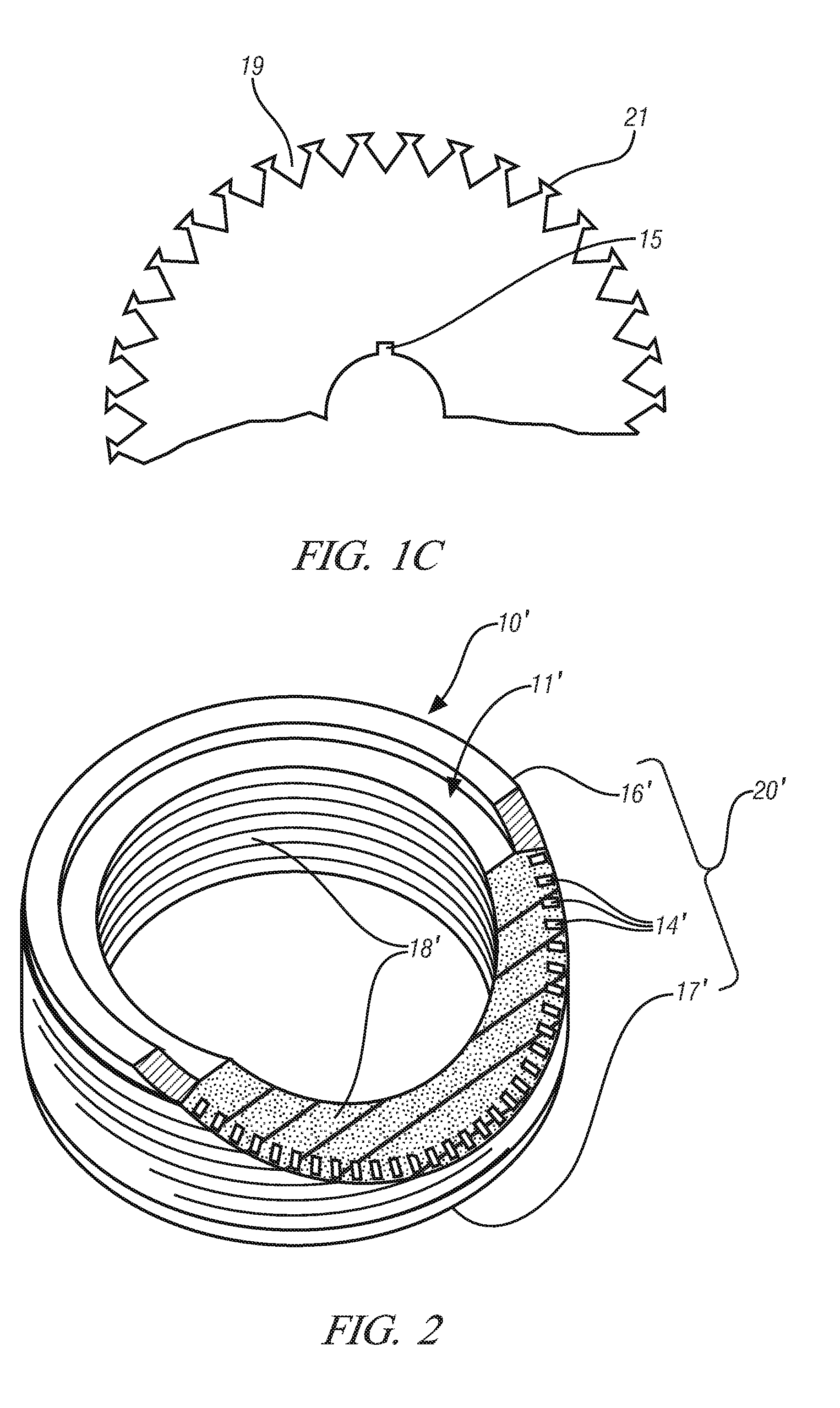

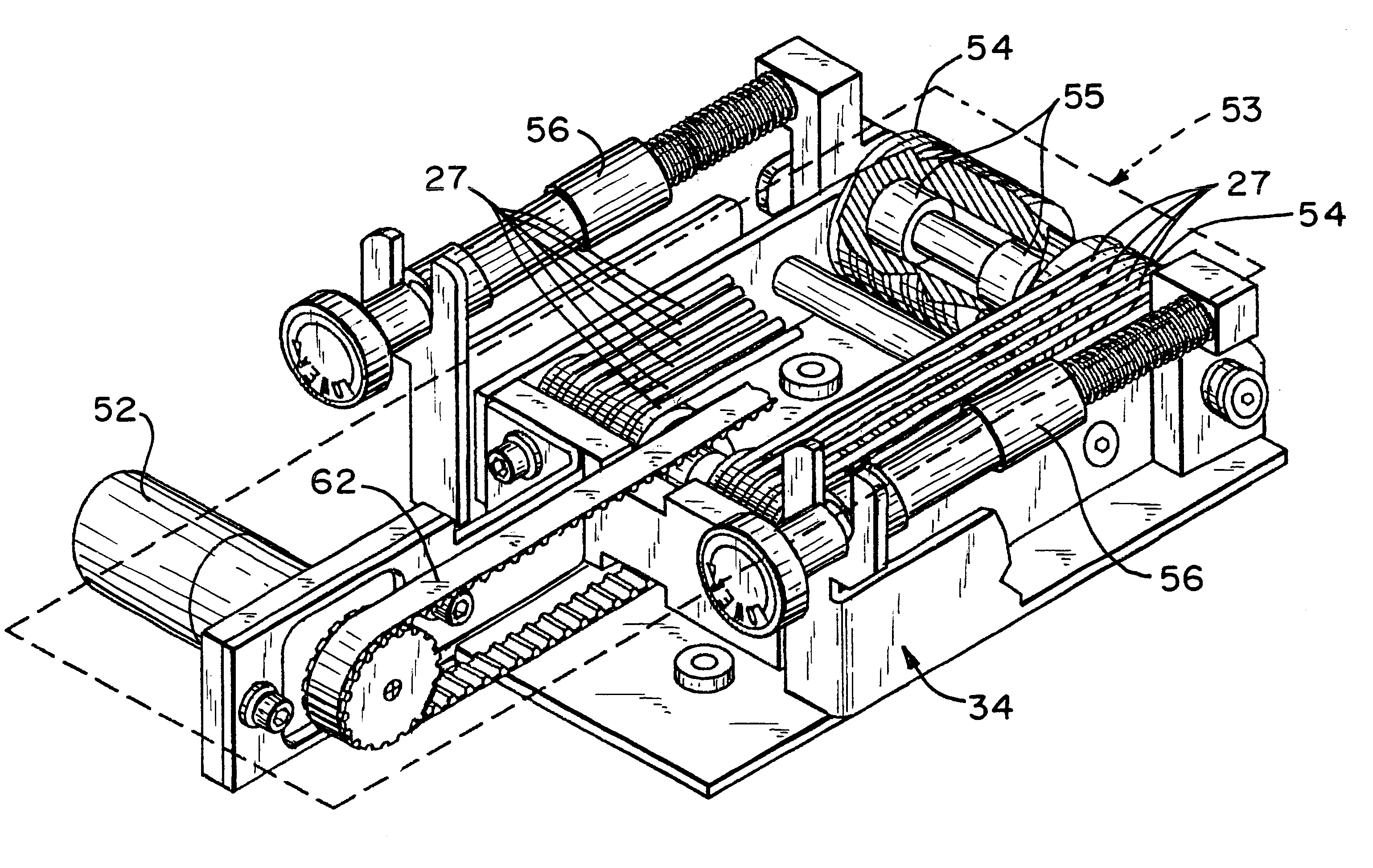

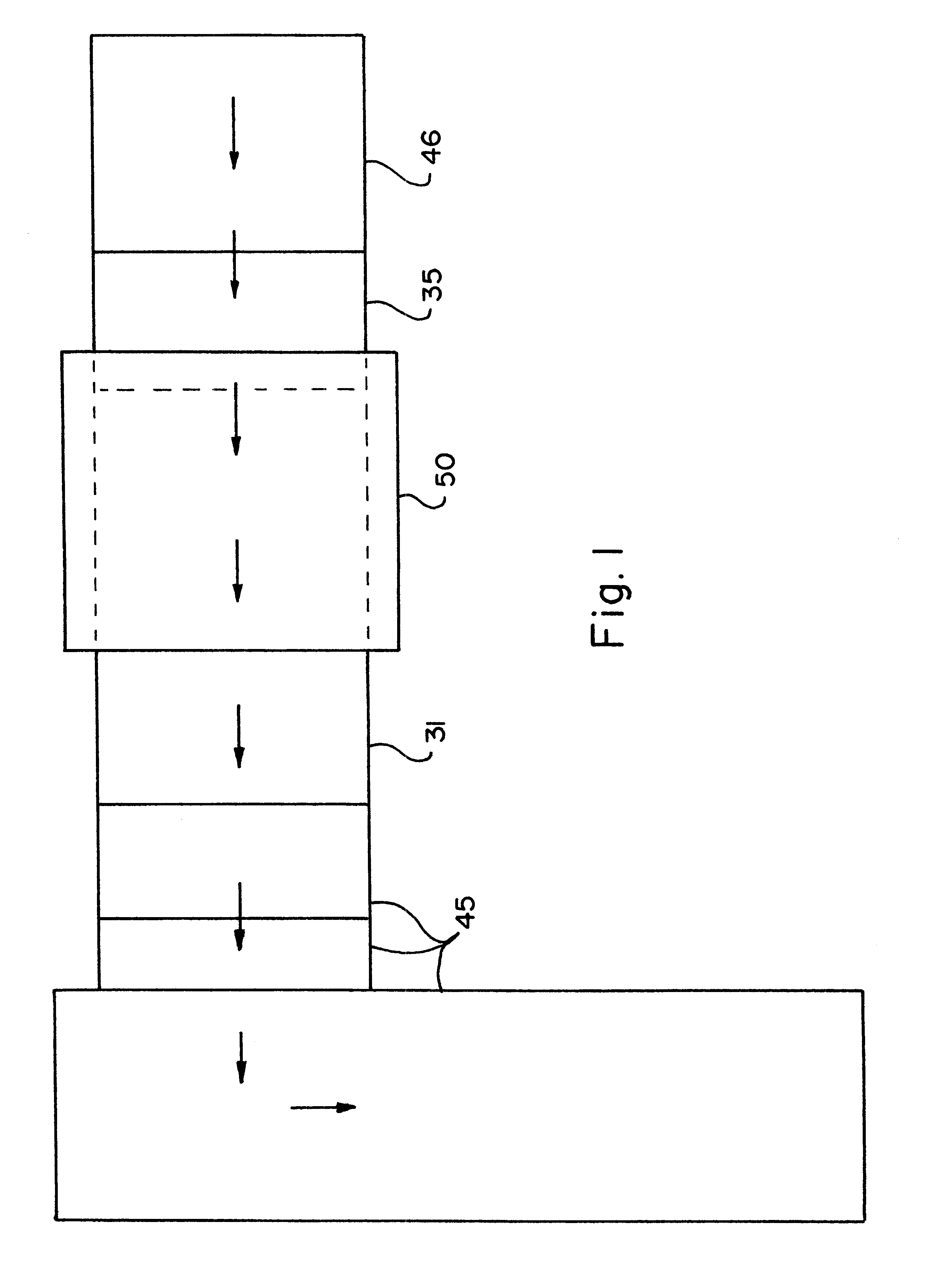

Investment casting of induction motor rotors

ActiveUS20110198964A1Improve productivityQuality improvementSynchronous motorsFoundry mouldsWaxInduction motor

A procedure for casting a shorted structure around a plurality of induction motor rotors is described. The method comprises forming a wax representation of the shorted structure around a lamination stack; mounting a plurality of such lamination stacks in a mounting fixture and attaching a suitable gating and runner system; forming an investment by coating the structure with refractory followed by melting out the wax; casting molten metal into the investment while it is rotating and aligning the mold to allow the centrifugal force generated to promote mold filling; and, continuing to rotate the investment until solidification is substantially complete.

Owner:GM GLOBAL TECH OPERATIONS LLC

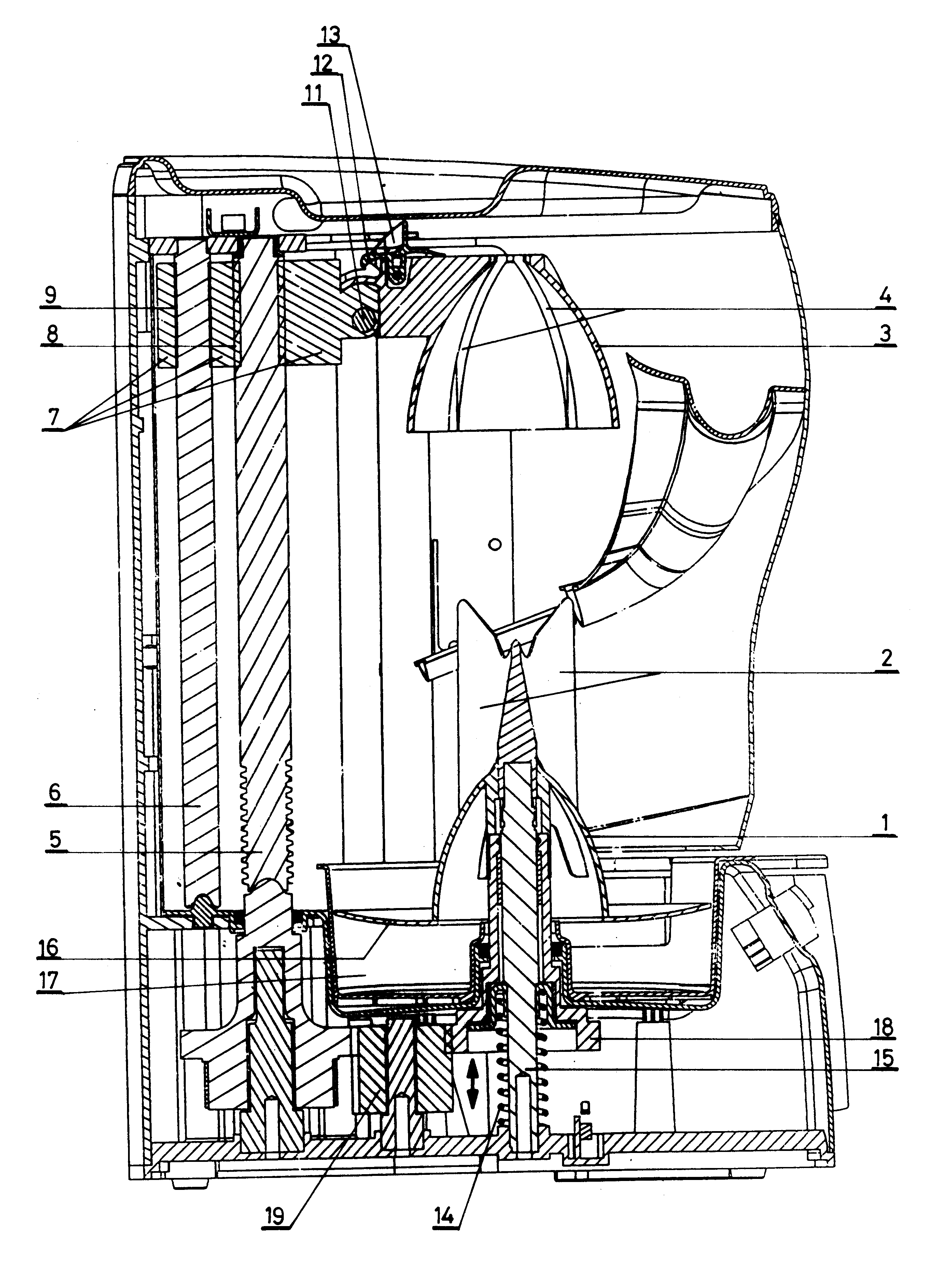

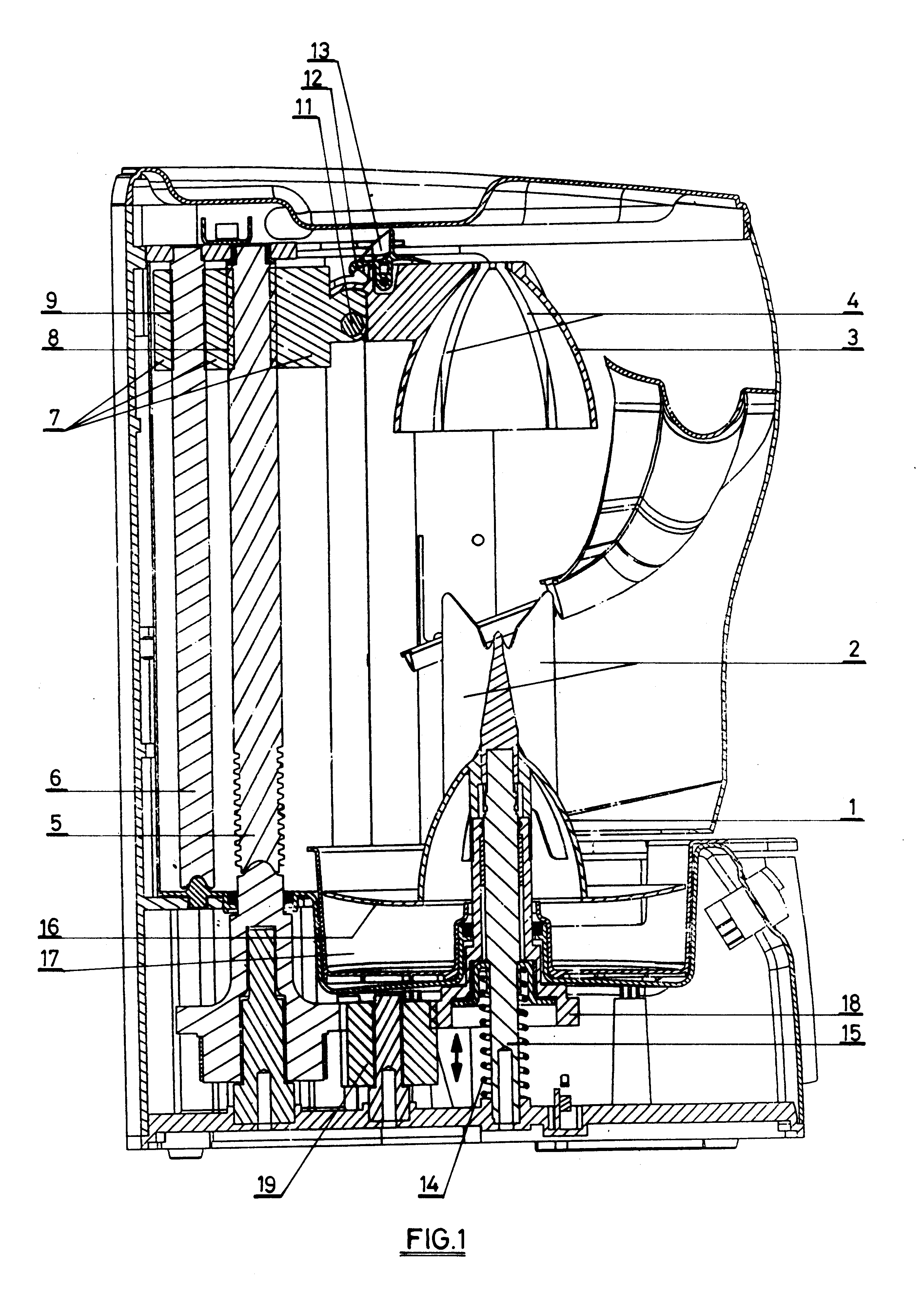

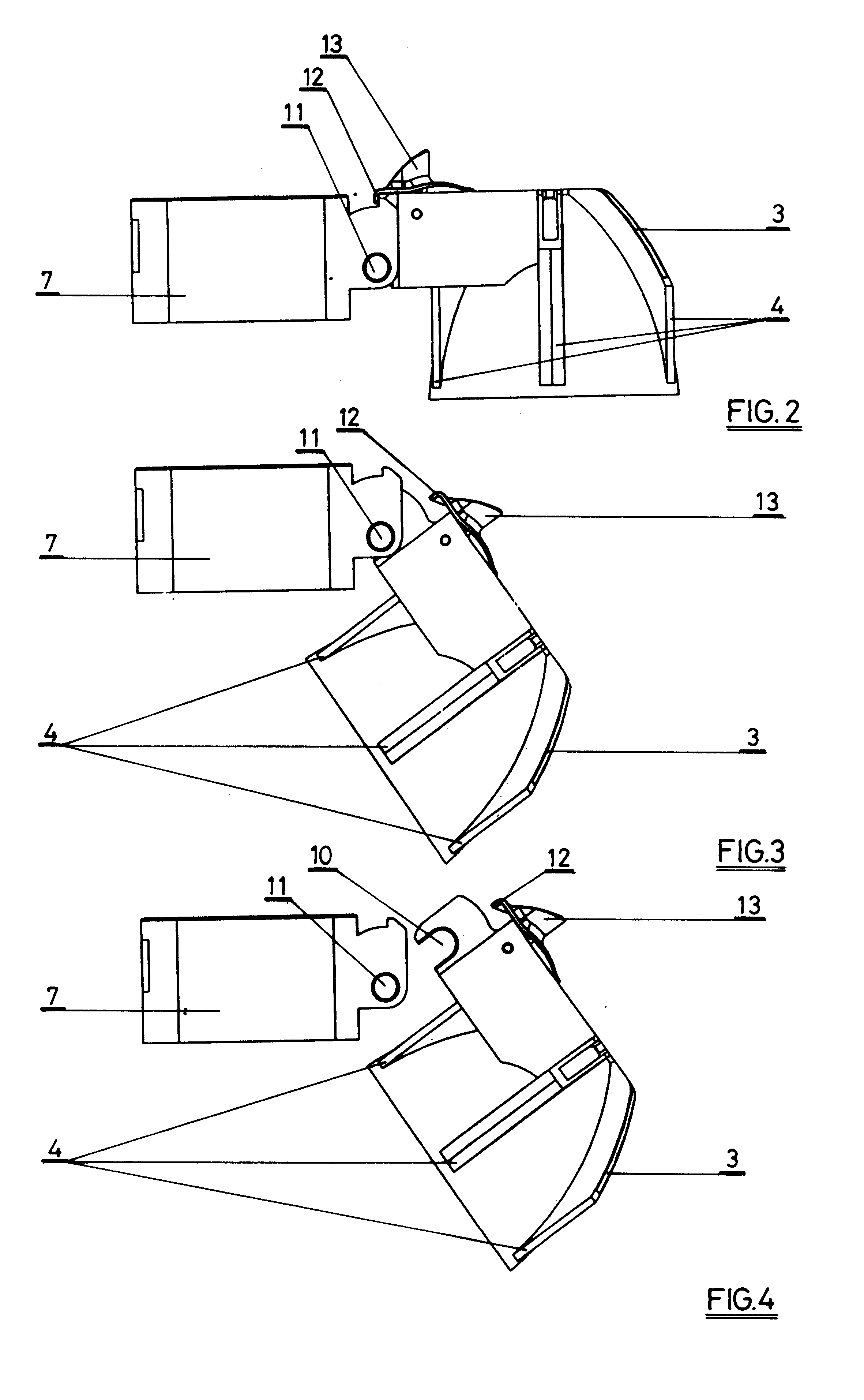

Automatic citrus juice squeezer

The improvements to the automatic citrus juice squeezer consist of: a movement of the pressure cup (3) by means of a drive screw (5) and a guide column (6); the cup being removably-mounted and detachable from its holder (7) by raising a trip fastener (12) using a catch (13); it has five angularly equidistant blades (2); a squeezer-filter (16) and support assembly (1) can descend against the action of an axial spring (14), maintaining the dynamic connection with the drive shaft by means of gears (18) that may slide along an intermediate sprocket (19); the juice collector (17) empties into a dish (20) which opens / closes a tilting plug (21) as it is introduced / extracted: the blades (2) are connected to the fixed shaft (15) by elastic legs (23) with internal strengtheners (24) which fit into a peripheral neck (25) of the said shaft; and the cup's (3) profile has an enlarged lower curvature to prevent its separation from the squeezer support (1) from narrowing.

Owner:ZUMEX MAQUINAS & ELEMENTOS

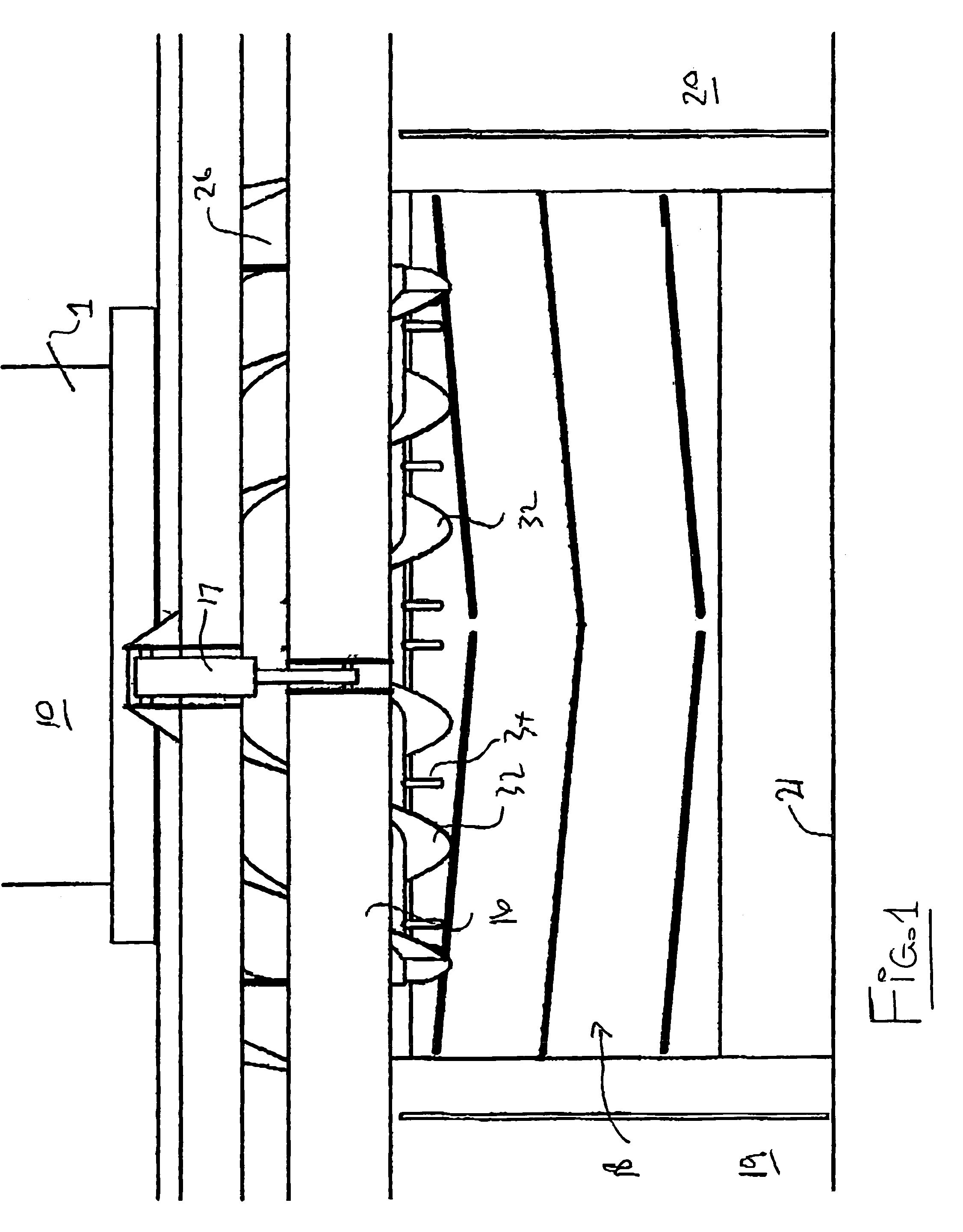

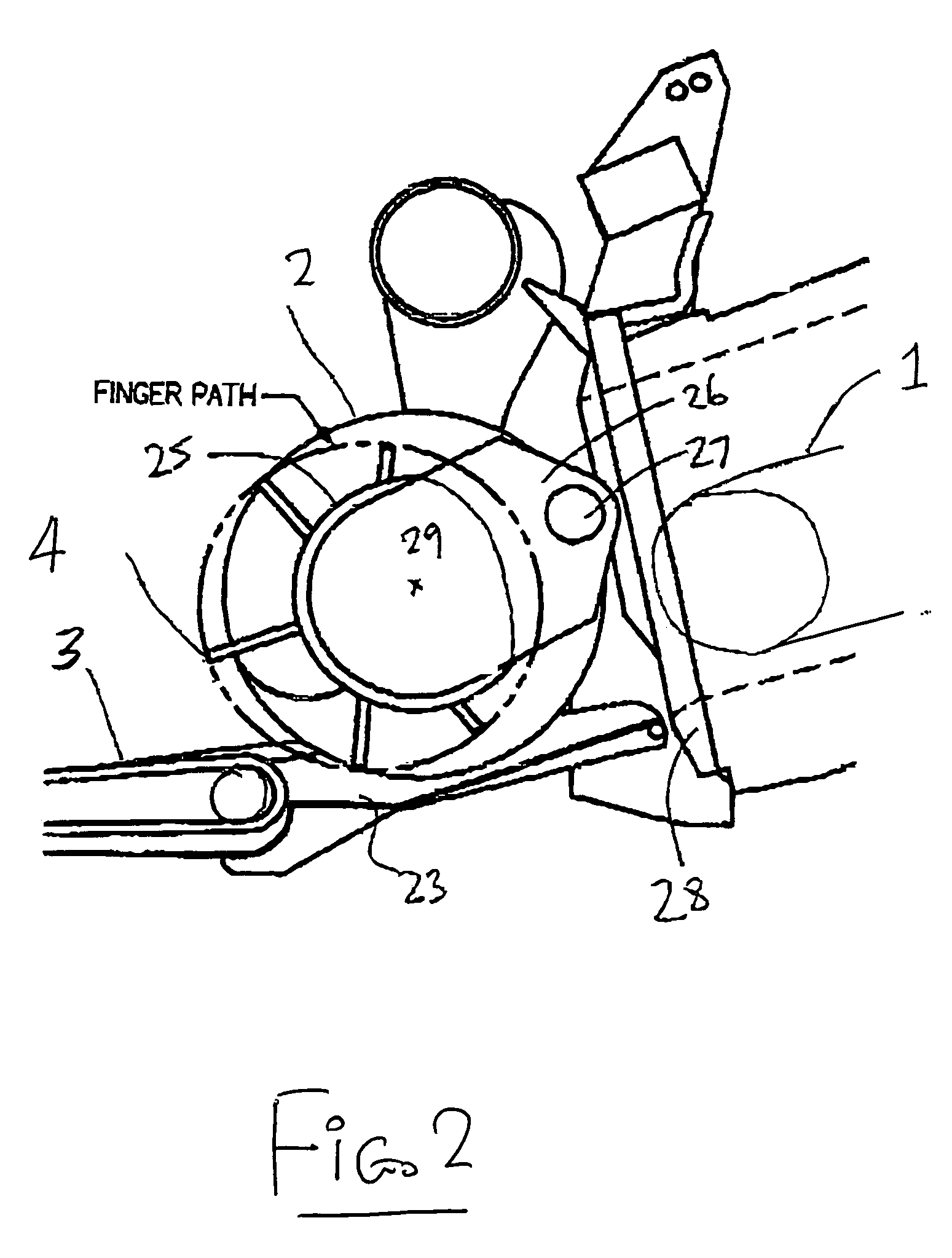

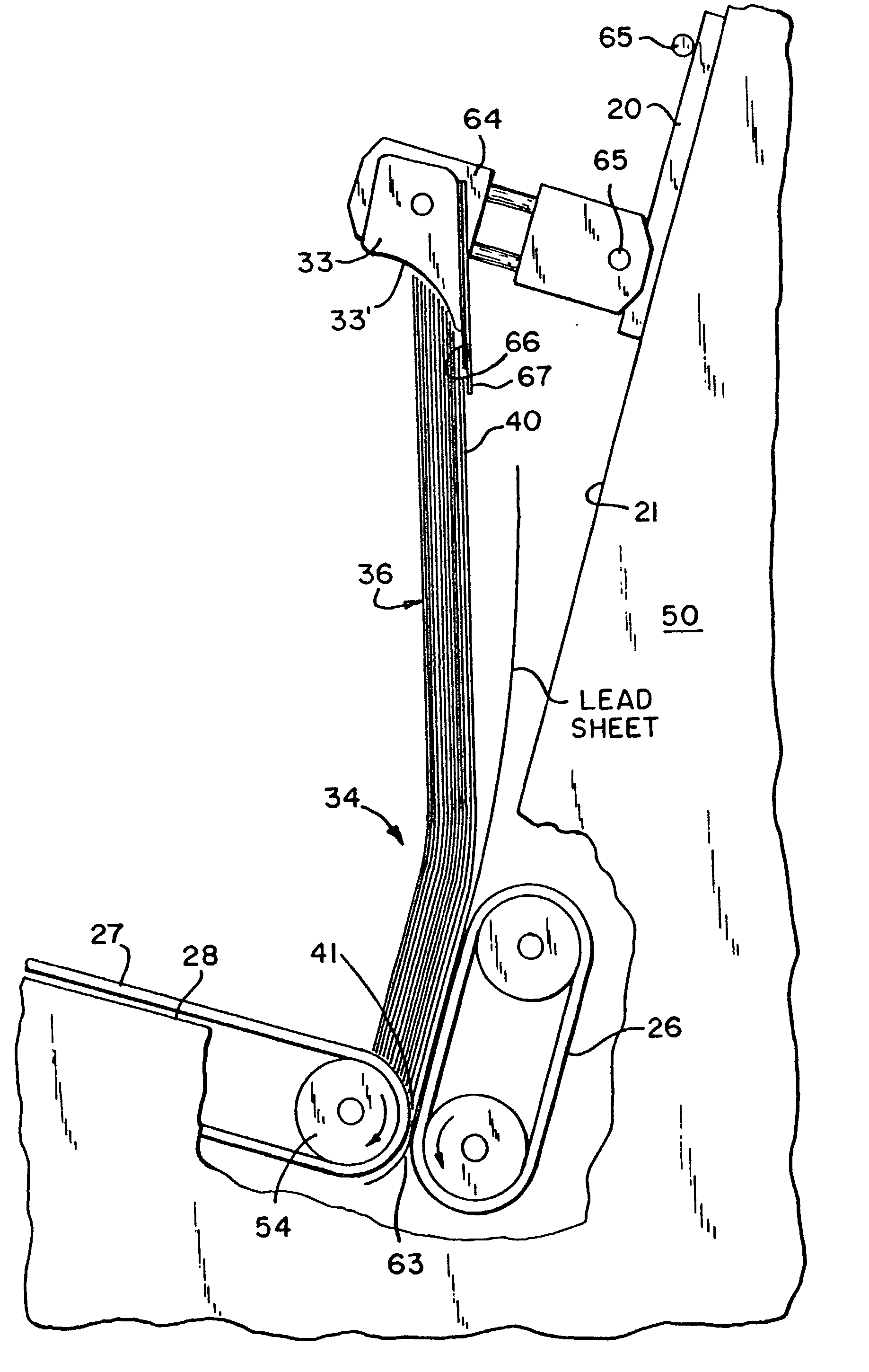

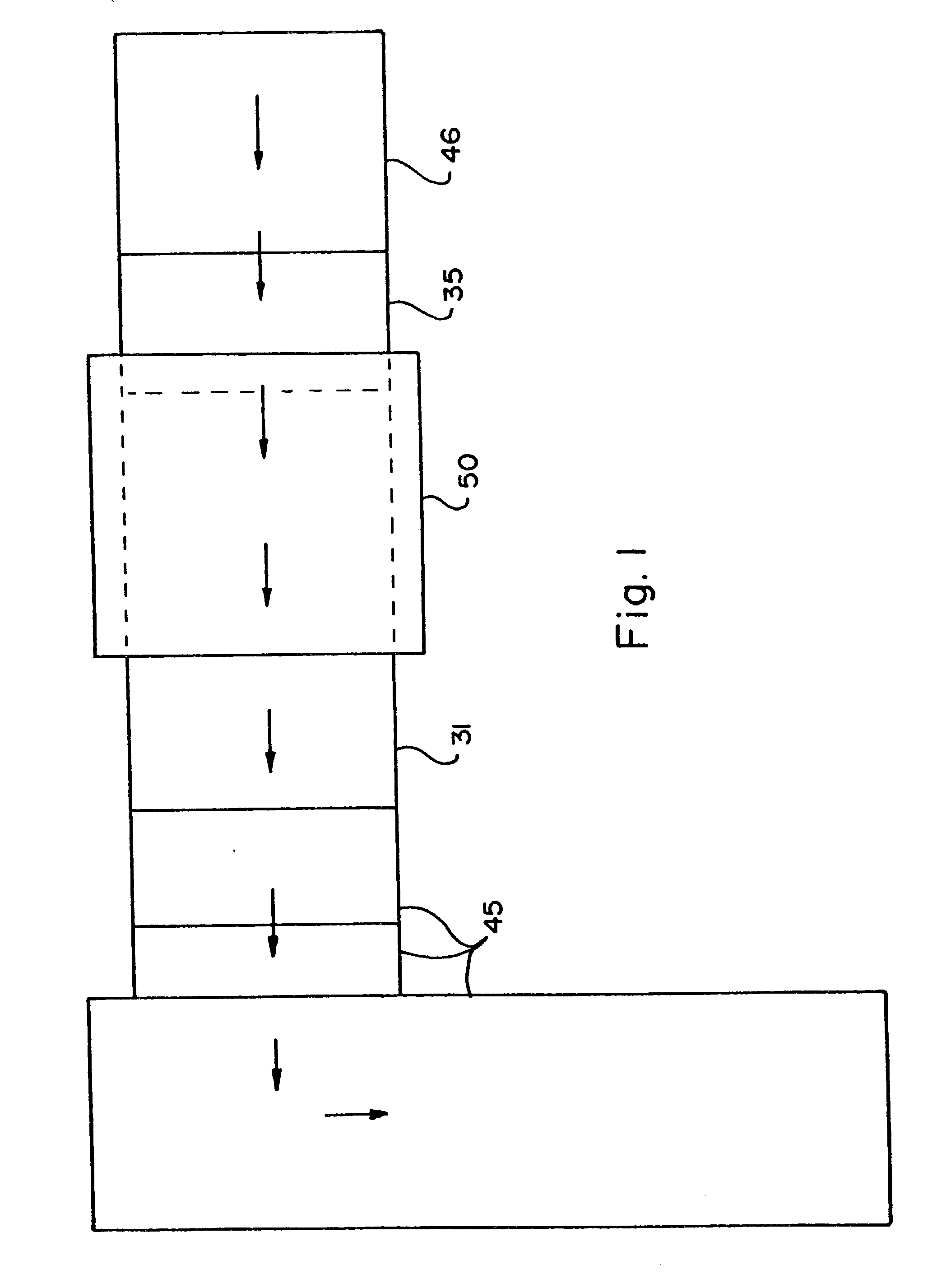

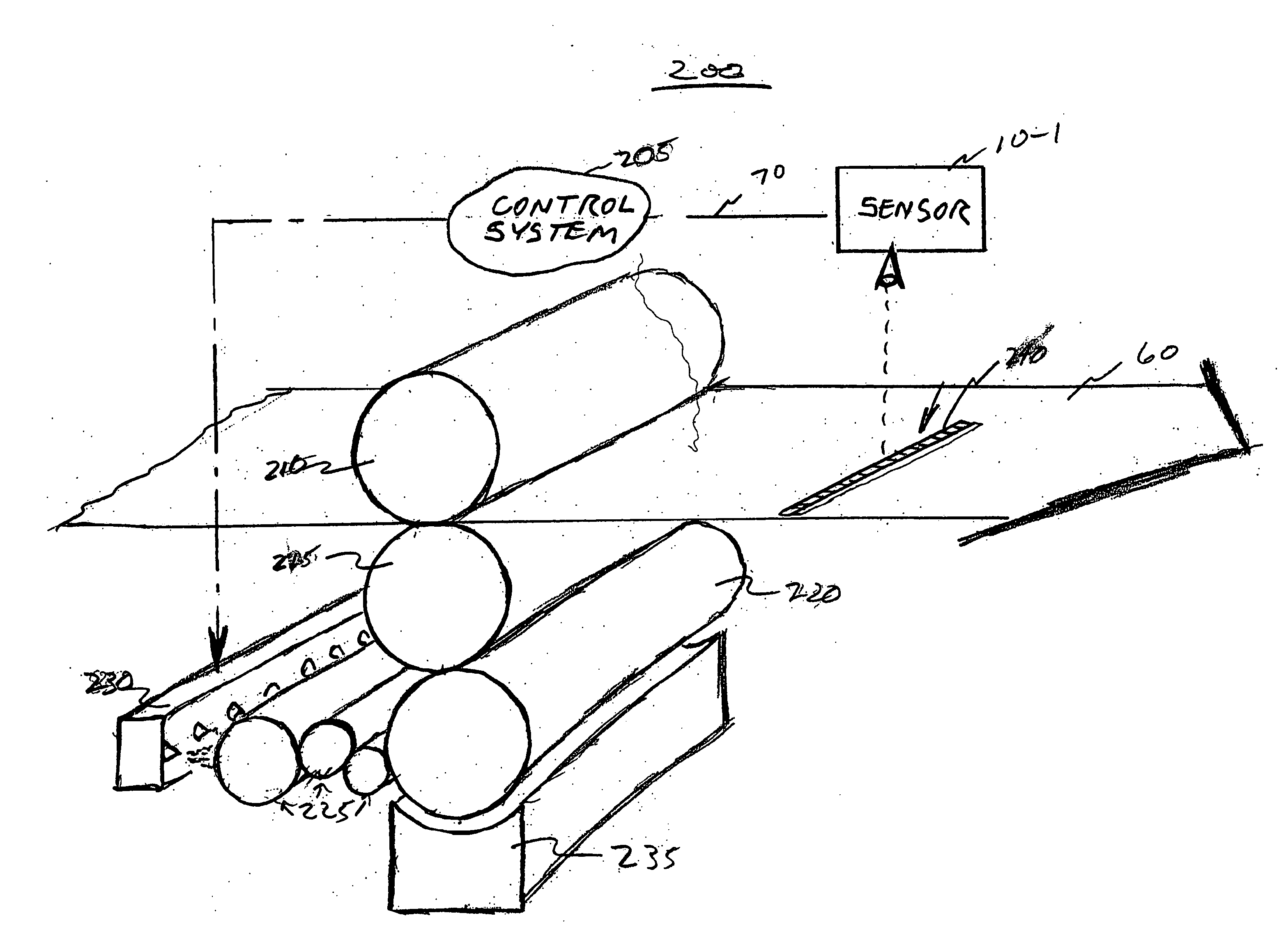

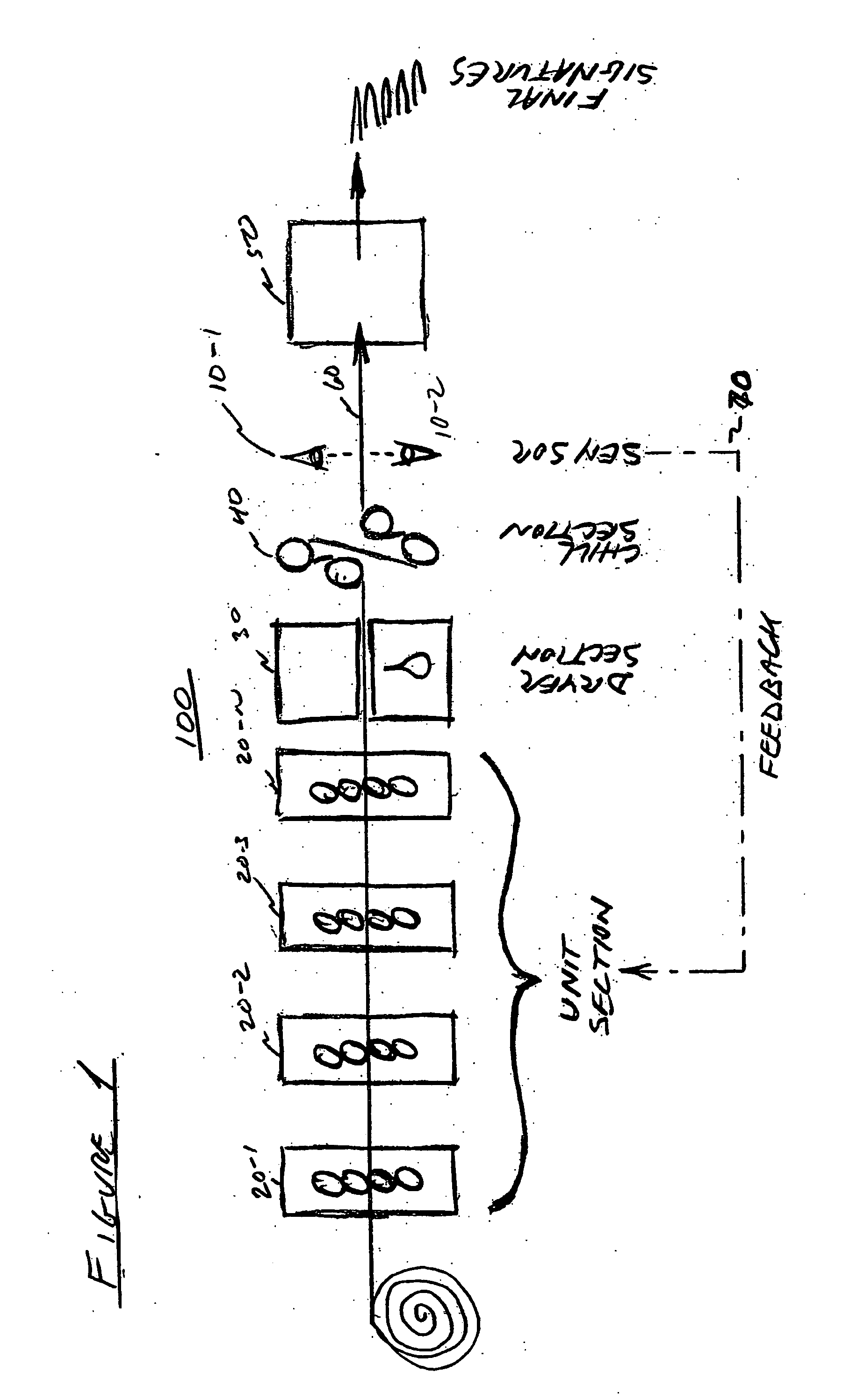

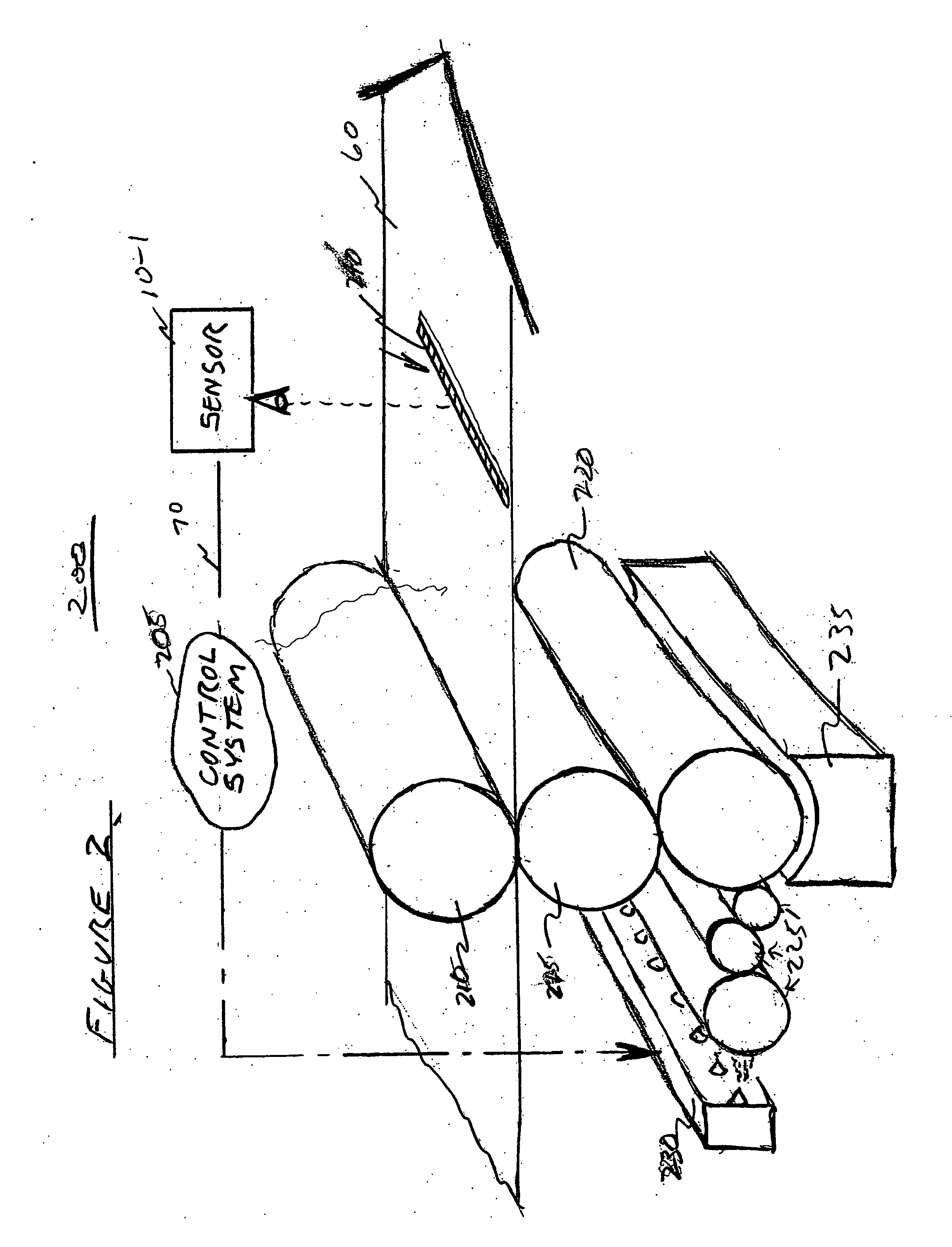

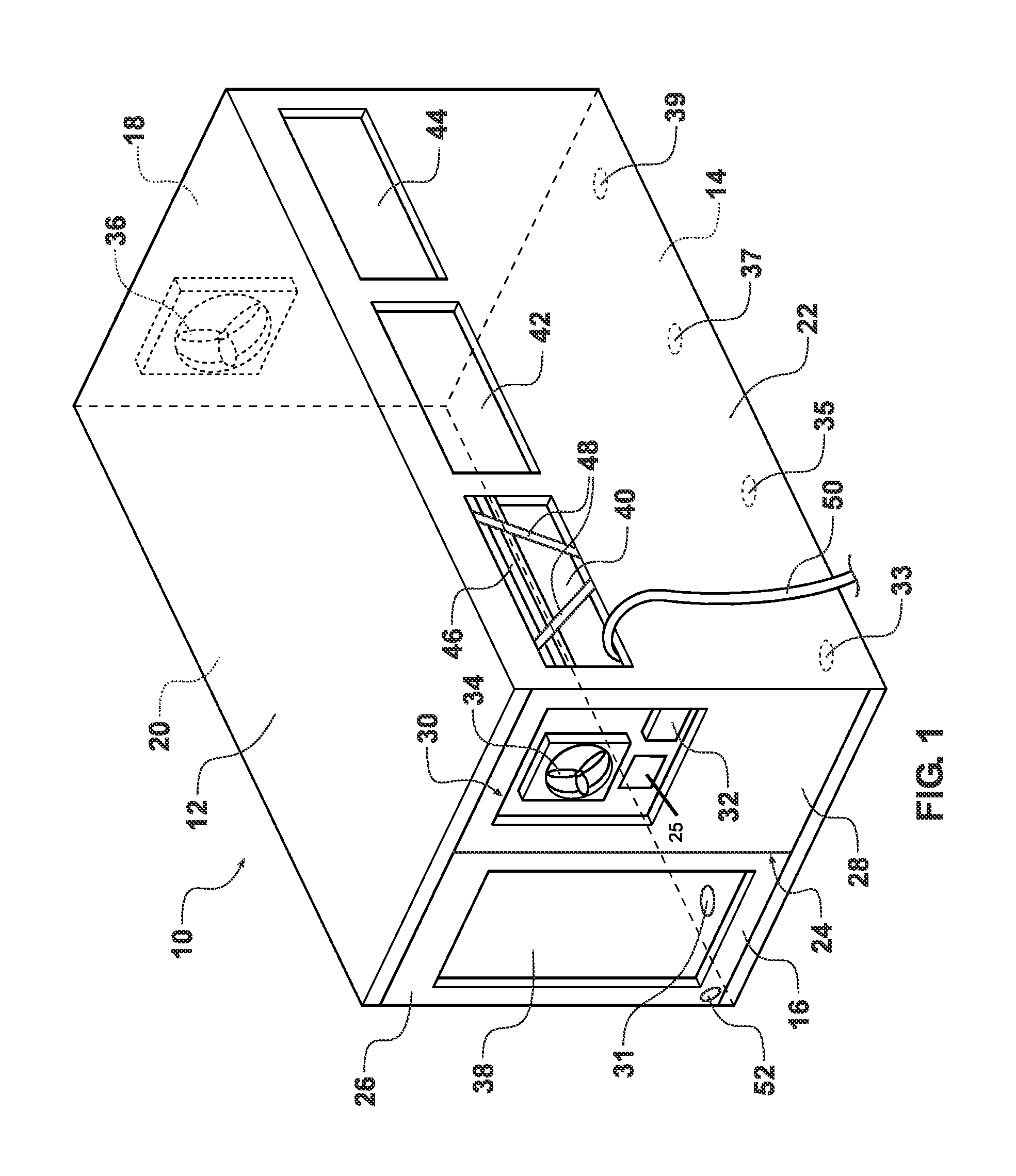

High capacity document sheet processor

InactiveUS20030025266A1Improve accuracyOptimized for speedRegistering devicesDispensing apparatusPaper documentDocument preparation

A high capacity document sheet processor combines significant speed and efficiency enhancing improvements in existing approaches to stack feeding particularly in the stack loading, feeding and singulating functions with novel operational arrangements adaptable to a universal paper handling and envelope inserting system.

Owner:EMC DOCUMENT TECH

Breeding method of under-forest ecological pigs

The invention discloses a breeding method of under-forest ecological pigs. The breeding method comprises the first step of preparation of forest land, the second step of selection of pig variety, the third step of breeding outside cages in a rotational grazing mode, the fourth step of daily management and the fifth step of disease prevention and cure. The breeding method of the under-forest ecological pigs is ecological and healthy, environmentally friendly and pollution-free, obtained under-forest ecological pork is tender and fresh, good in palatability and high in nutrient value, and has no pollution, and the breeding method greatly improves the disease resistance of the ecological pigs. According to the breeding method, a medicated bath pool is arranged in a rotational grazing area, according to the characteristic that pigs like to take a bath, the pigs are cleaned and sterilized under an original ecology environment, and the occurrence of taenia solium is effectively avoided; through a reasonable composition, a Chinese herbal medicine bath lotion is remarkable in disinfection effect, and the immunity of the ecological pigs is effectively improved through frequent bathing.

Owner:凤庆县绿康牧业有限公司

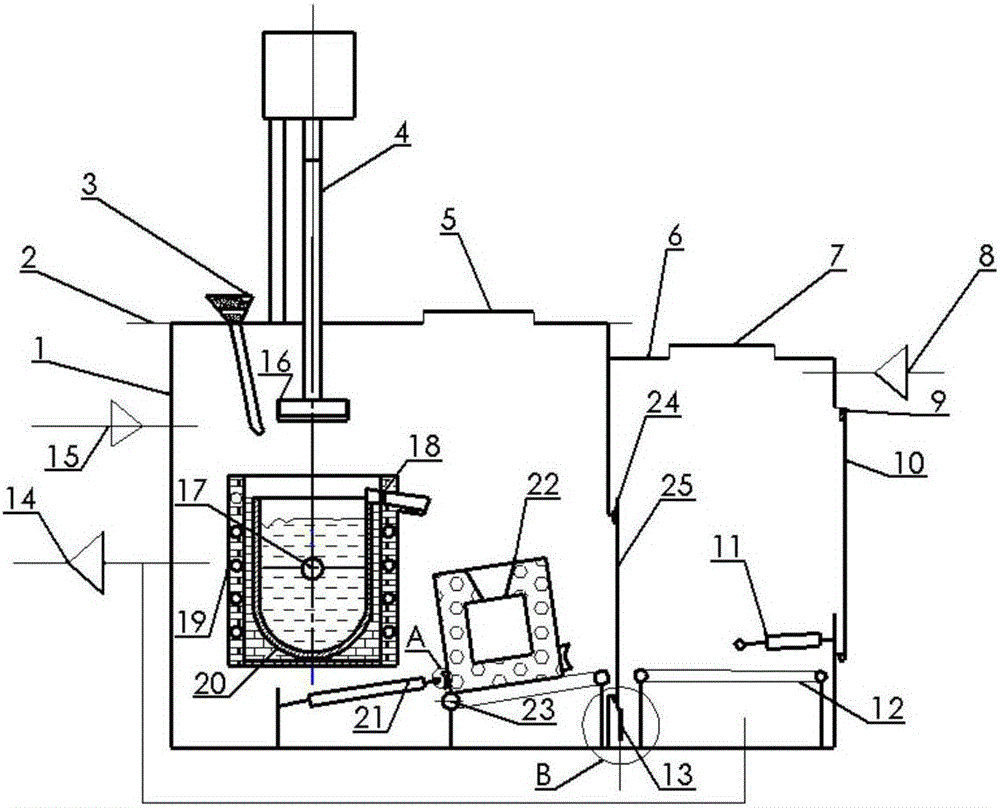

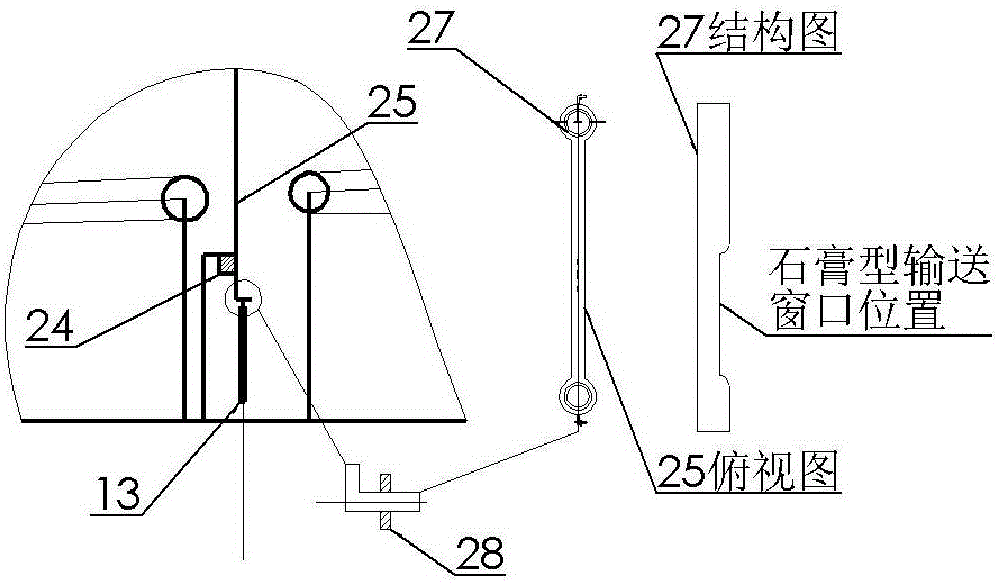

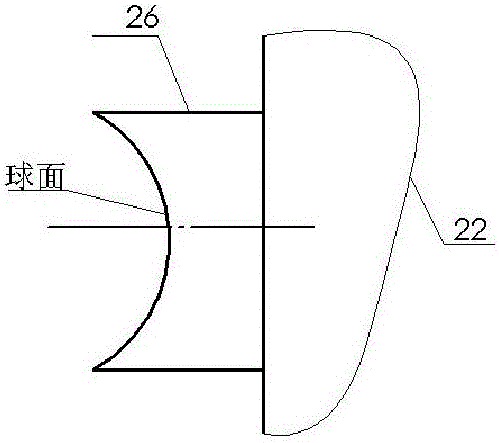

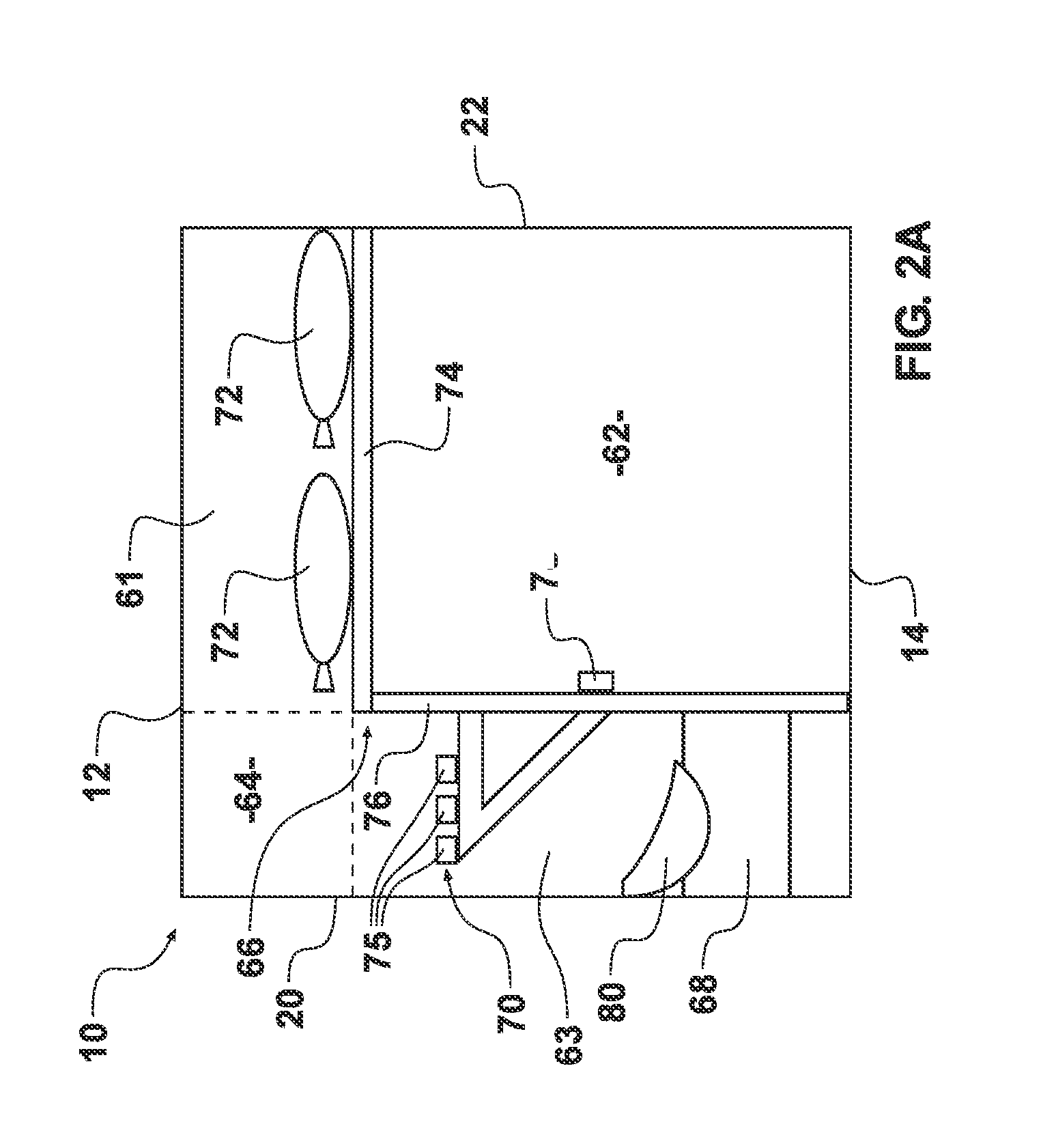

Integrated preparing and forming device for magnesium alloy thin-walled pieces

The invention relates to an integrated preparing and forming device for magnesium alloy thin-walled pieces. The forming device comprises a smelting-pouring tank and a protective atmosphere solidification tank, wherein the smelting-pouring tank and the protective atmosphere solidification tank are used for preparing a magnesium alloy. The smelting-pouring tank and the protective atmosphere solidification tank are both connected with a vacuumizing device and a protective gas injection device. By means of the integrated preparing and forming device, the magnesium alloy can be smelted under the vacuum condition, preparation is completed and pouring is conducted under the condition that the protective gas is injected, and pressurized solidification is conducted under the condition that the protective gas is injected in the protective atmosphere solidification tank. The integrated preparing and forming device is suitable for producing complex and thin-walled magnesium alloy castings, the production safety is high, the surfaces of the castings are free of oxidation defects, internal defects such as slag inclusion, shrinkage porosity and cold shut are basically solved, the structure is compact, performance is good, production requirements are met, the integrated preparing and forming device is easy to popularize, and the yield of the castings is high.

Owner:HENAN POLYTECHNIC UNIV

Apparatus and method for controlling delivery of dampener fluid in a printing press

An apparatus and method in accordance with the invention for automatically controlling dampener settings. Specifically, the apparatus and method detects scumming on a material to be printed and using that information to set the dampener solution flow.

Owner:GOSS INT AMERICAS

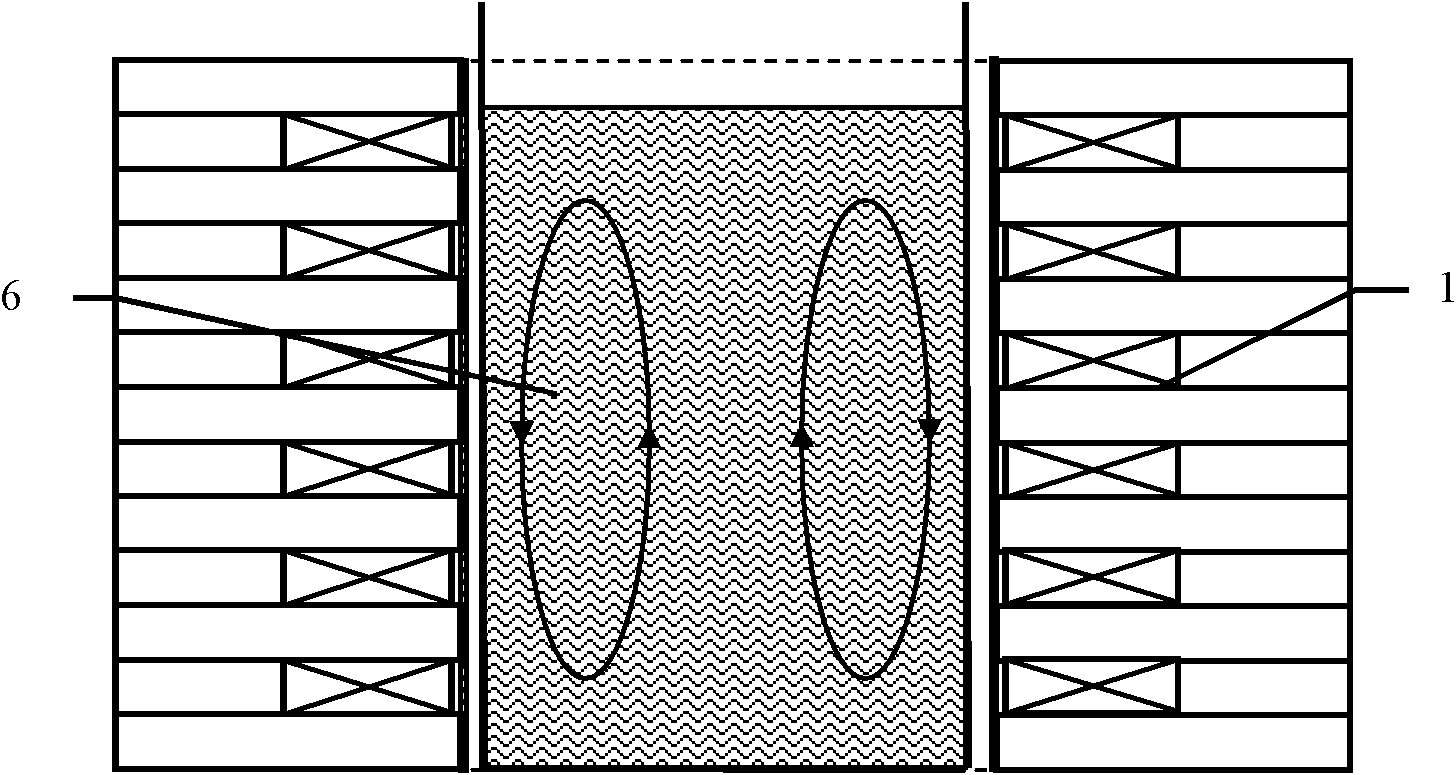

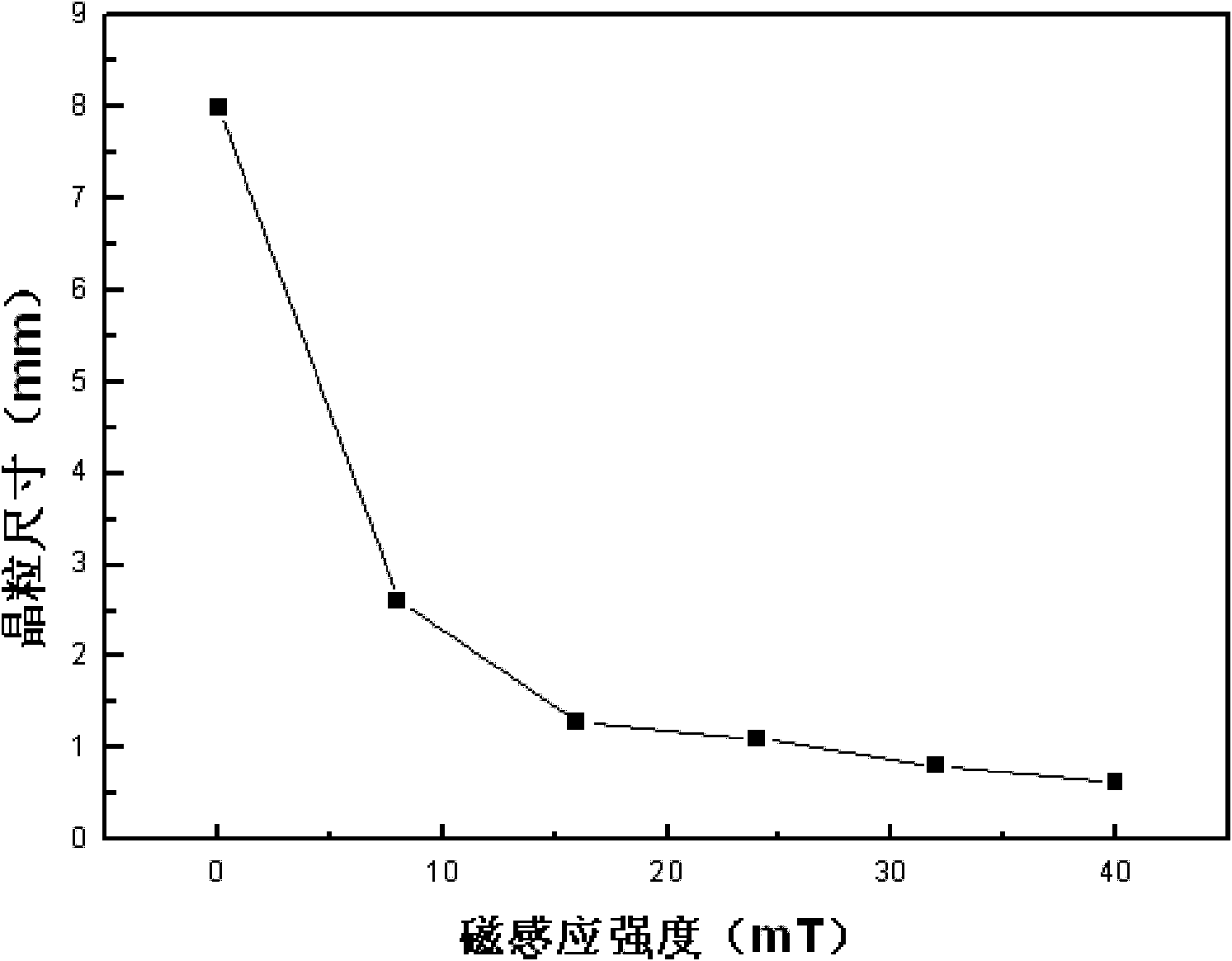

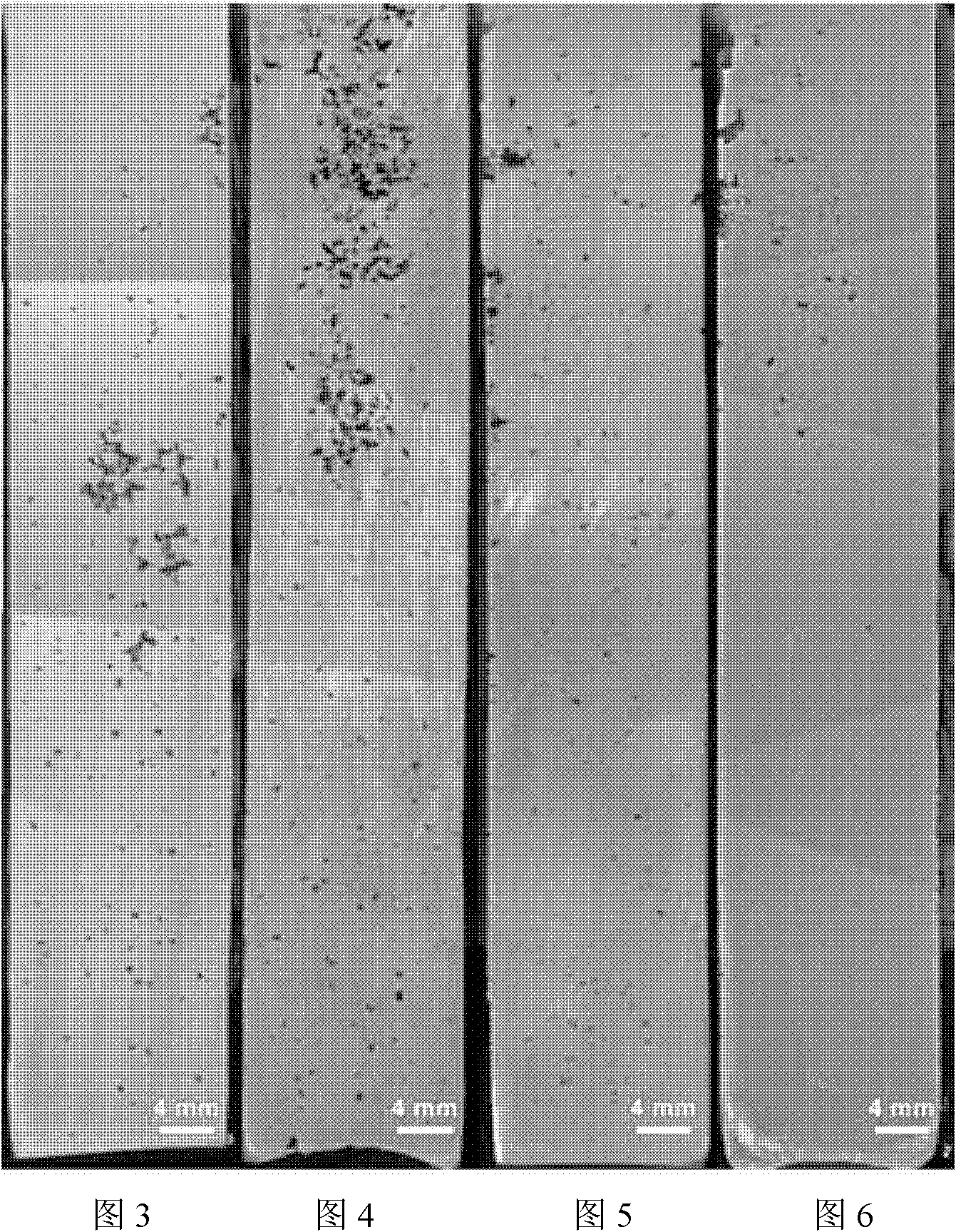

Precision casting method for refining aluminum alloy by using adjustable traveling wave magnetic field

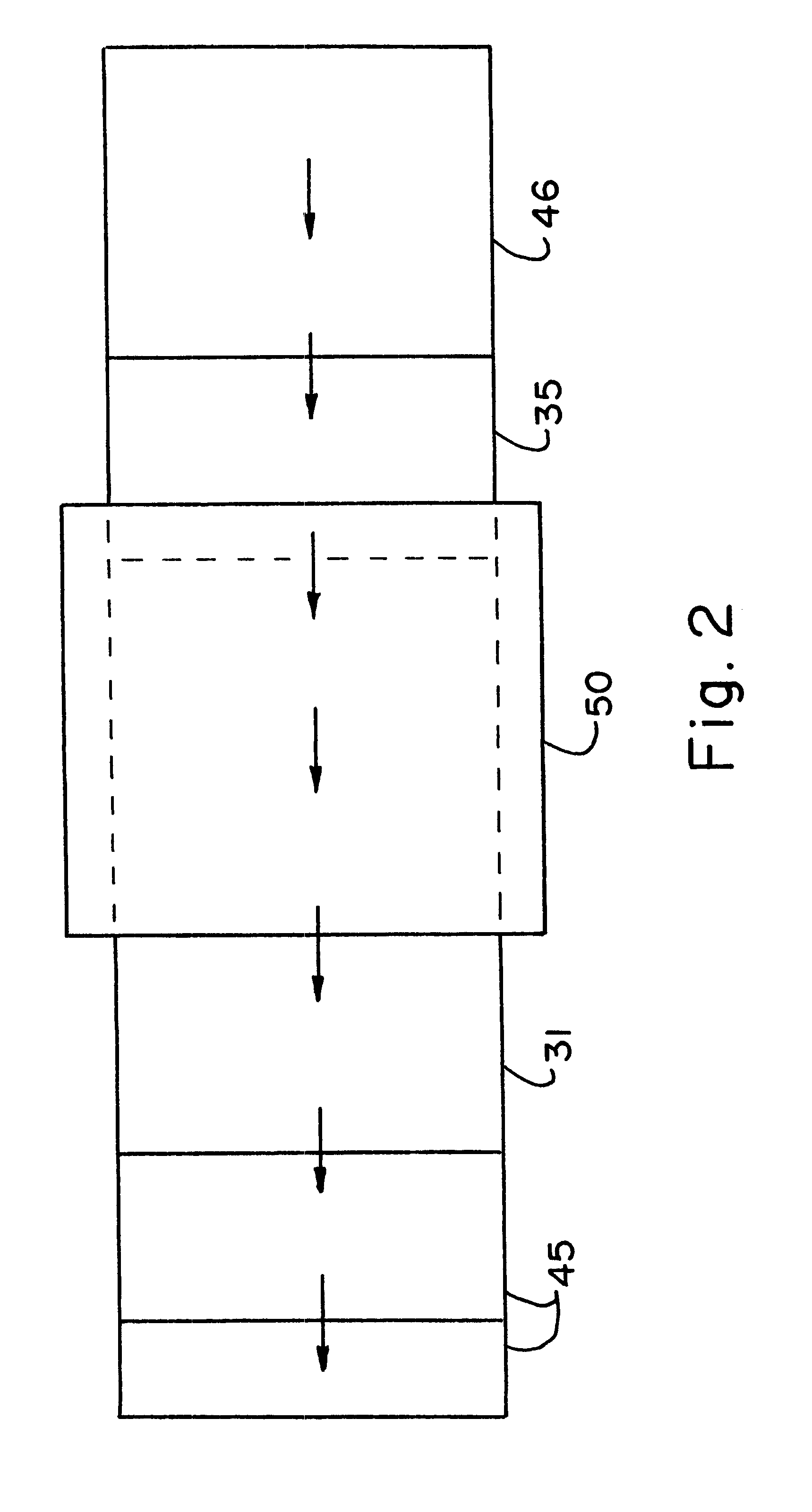

The invention relates to a precision casting method for refining aluminum alloy by using an adjustable traveling wave magnetic field, belonging to the technical field of casting. The invention aims to solve the technical problems of high cost and difficulty in control in the process of grain refining and compacting for changing the properties of aluminum alloy in the prior art. The method provided by the invention comprises the following steps: 1. heating to melt aluminum alloy, and carrying out heat preservation,, thus obtaining an aluminum alloy molten mass; and 2. putting a casting mold, which is made of a non-magnetic material, in a traveling wave magnetic field inductor, turning on the traveling wave magnetic field inductor, adjusting the magnetic field intensity of the traveling wave magnetic field inductor, injecting the aluminum alloy molten mass obtained in the step 1 into the casting mold, and applying a traveling wave magnetic field, of which the magnetic field direction is vertically downward and the magnetic induction intensity is 32-500mT, onto the aluminum alloy molten mass to solidify the aluminum alloy under the traveling wave magnetic field, thereby completing the precision casting of the aluminum alloy. The method provided by the invention is easy to control and low in cost; and by utilizing the method provided by the invention, the obtained alloy crystal grains are fine, bubbles and voids can be effectively reduced, and the metal feeding capacity in the solidification process can be enhanced.

Owner:HARBIN INST OF TECH

Breeding method for under-forest ecological chicken

The invention discloses a breeding method for under-forest ecological chicken. The breeding method comprises the following steps: 1) forest land preparation; 2) chicken variety selection; 3) rotational grazing type breeding outside cages; 4) daily management; and 5) disease prevention and treatment. The breeding method disclosed by the invention is ecological, healthy, green, environment-friendly and pollution-free, the obtained under-forest ecological chicken are fresh and tender in meat, good in mouthfeel, high in nutritional value and pollution-free; and by using the breeding method disclosed by the invention, the disease resistance of the ecological chicken is greatly improved, and the final survival rate reaches 97% or above. Due to the matched use of feeds for feeding the chicken in the morning and evening and the use of organically-ecological succulence and coarse grains, the defect that the existing feed is single is effectively avoided; in addition, due to the use of a scientific formula, the under-forest ecological chicken is comprehensive in nutrition and good in development, and the real green breeding of the under-forest ecological chicken is realized.

Owner:凤庆县绿康牧业有限公司

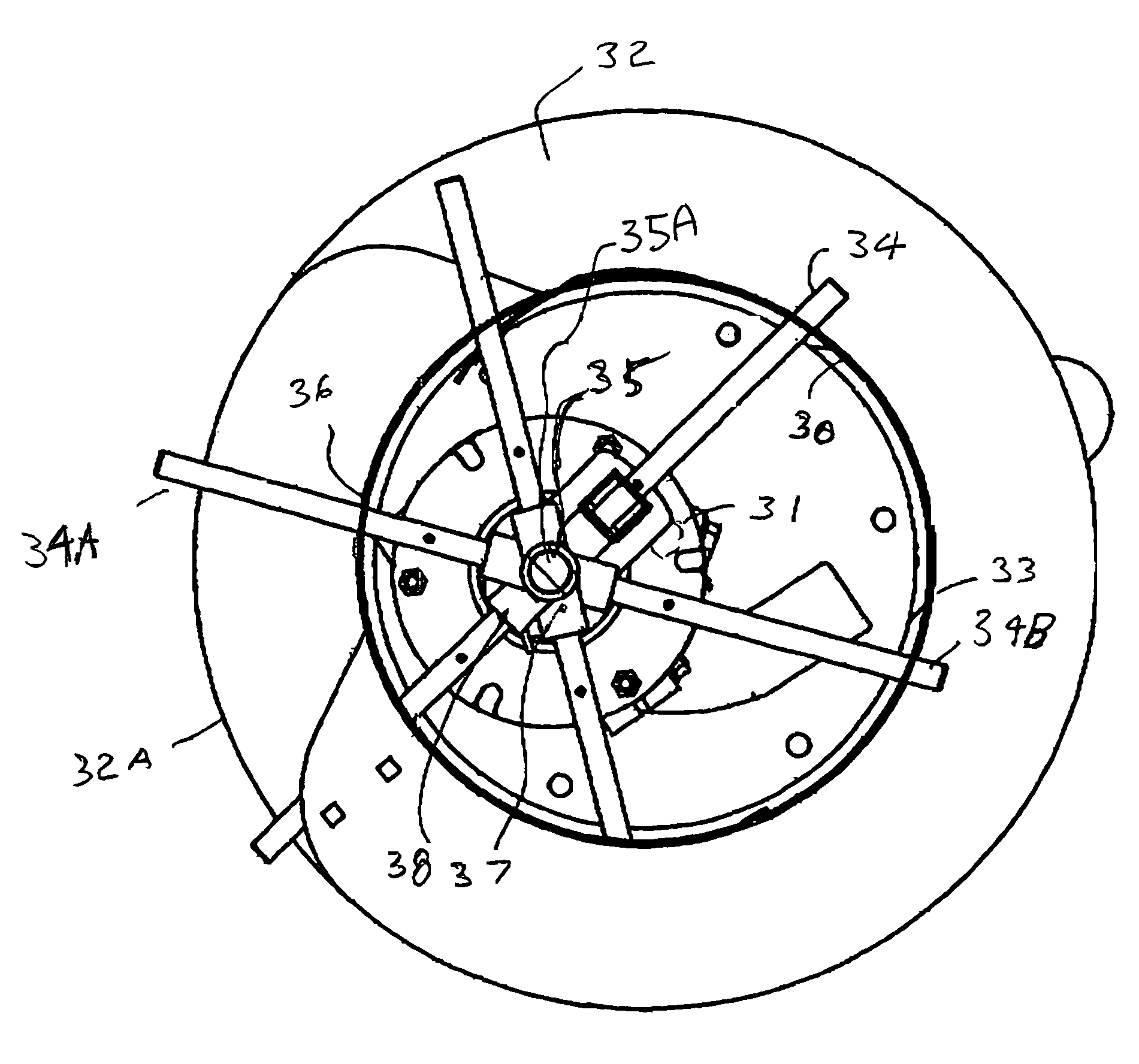

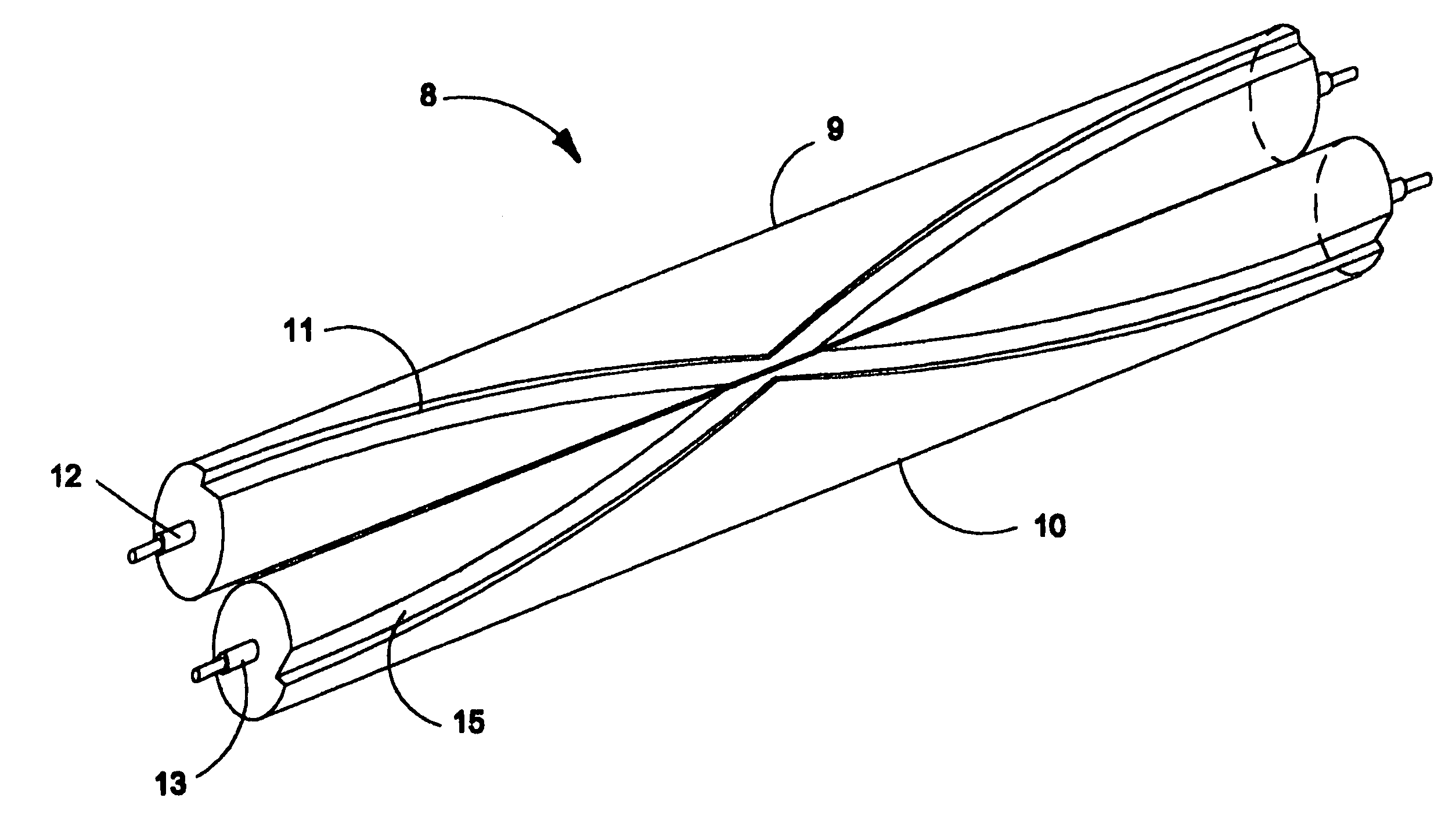

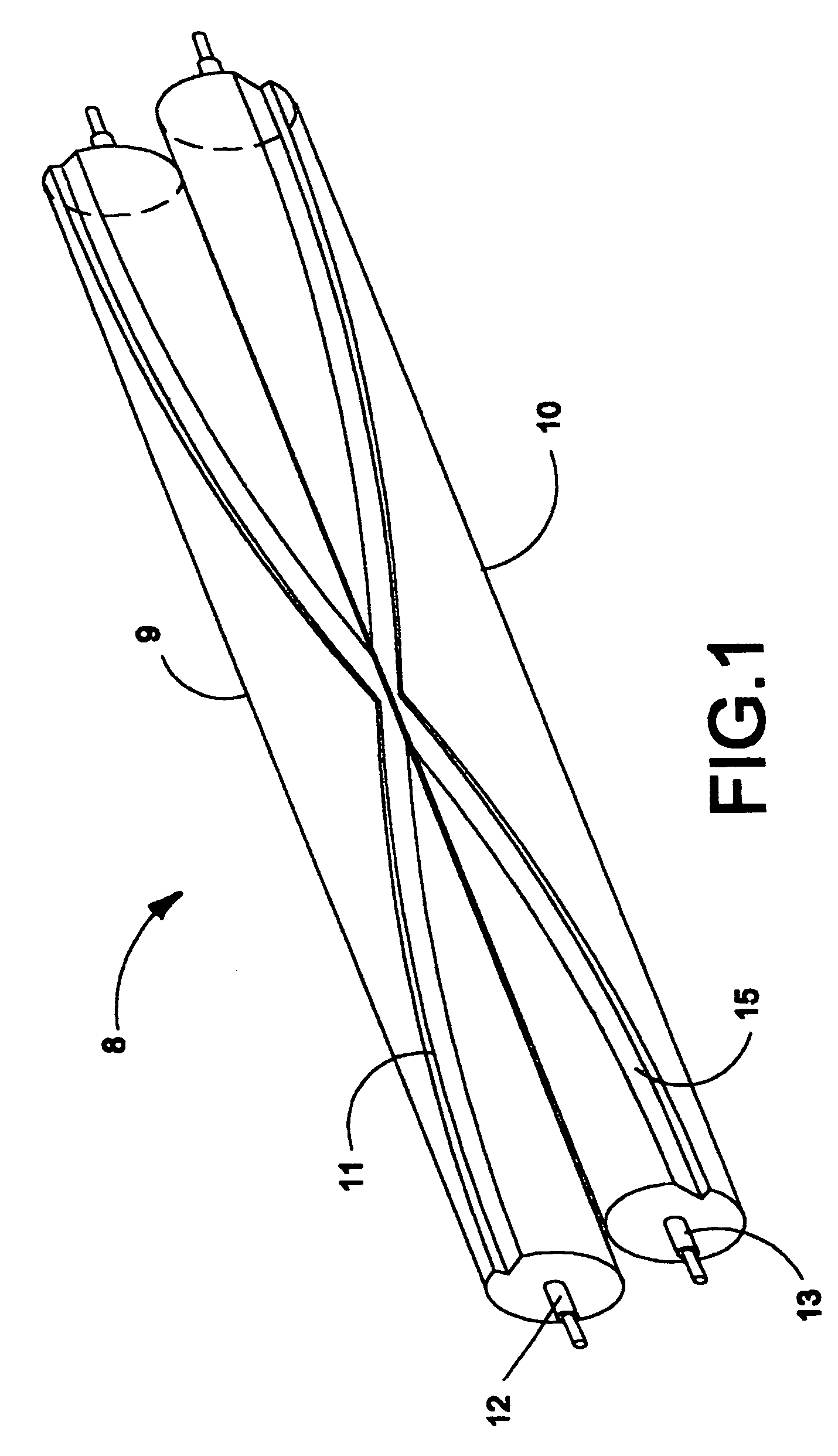

Groove design for precision rubber/urethane conditioning rolls

InactiveUS6904741B2Improve crushing effectEnhanced feedingCrop conditionersMowersLeading edgeEngineering

A conditioner roll design is provided that employs unique spiraled stepped grooves that enhance feeding of the crop mat when the rolls are abutted or at precise gaps. The groove has a leading edge and increased depth that allow expansion of the crop mat into the trailing gripper edges to provide gripping without intermeshing. The gripping side of the groove is nearly perpendicular to the direction of crop travel for positive gripping and advancing the crop. The grooves on the two rolls may be selectively timed to either mate at the point of contact or align a groove on one roll with a smooth surface on the other.

Owner:BLUE LEAF I P INC +1

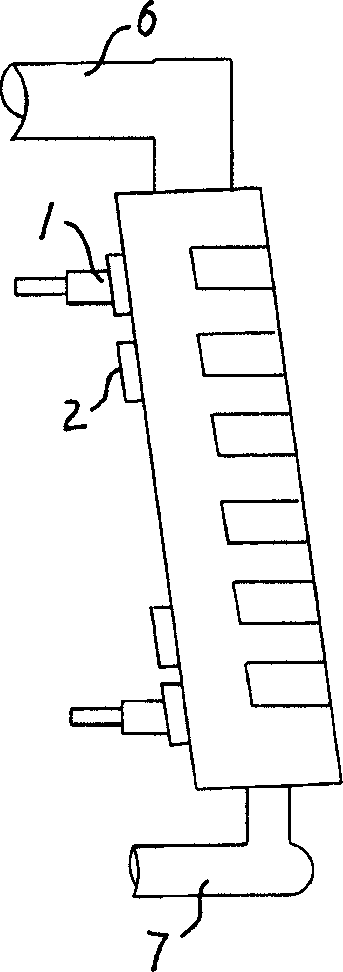

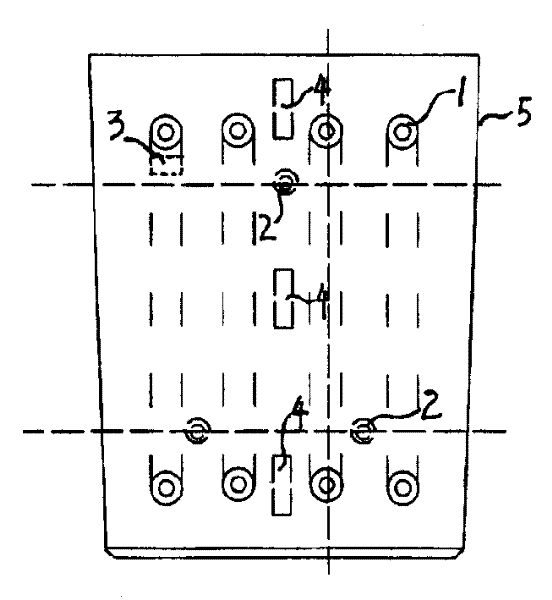

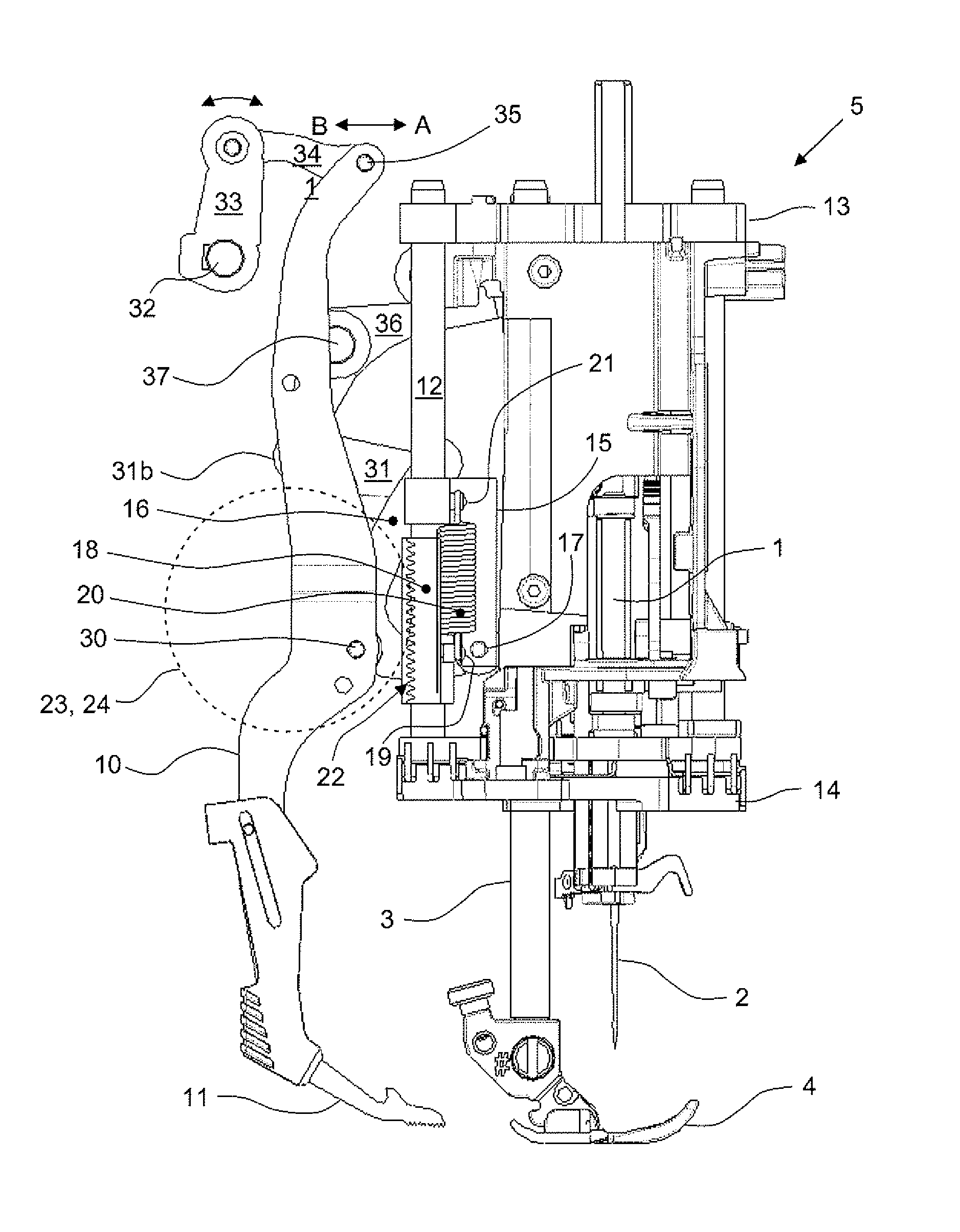

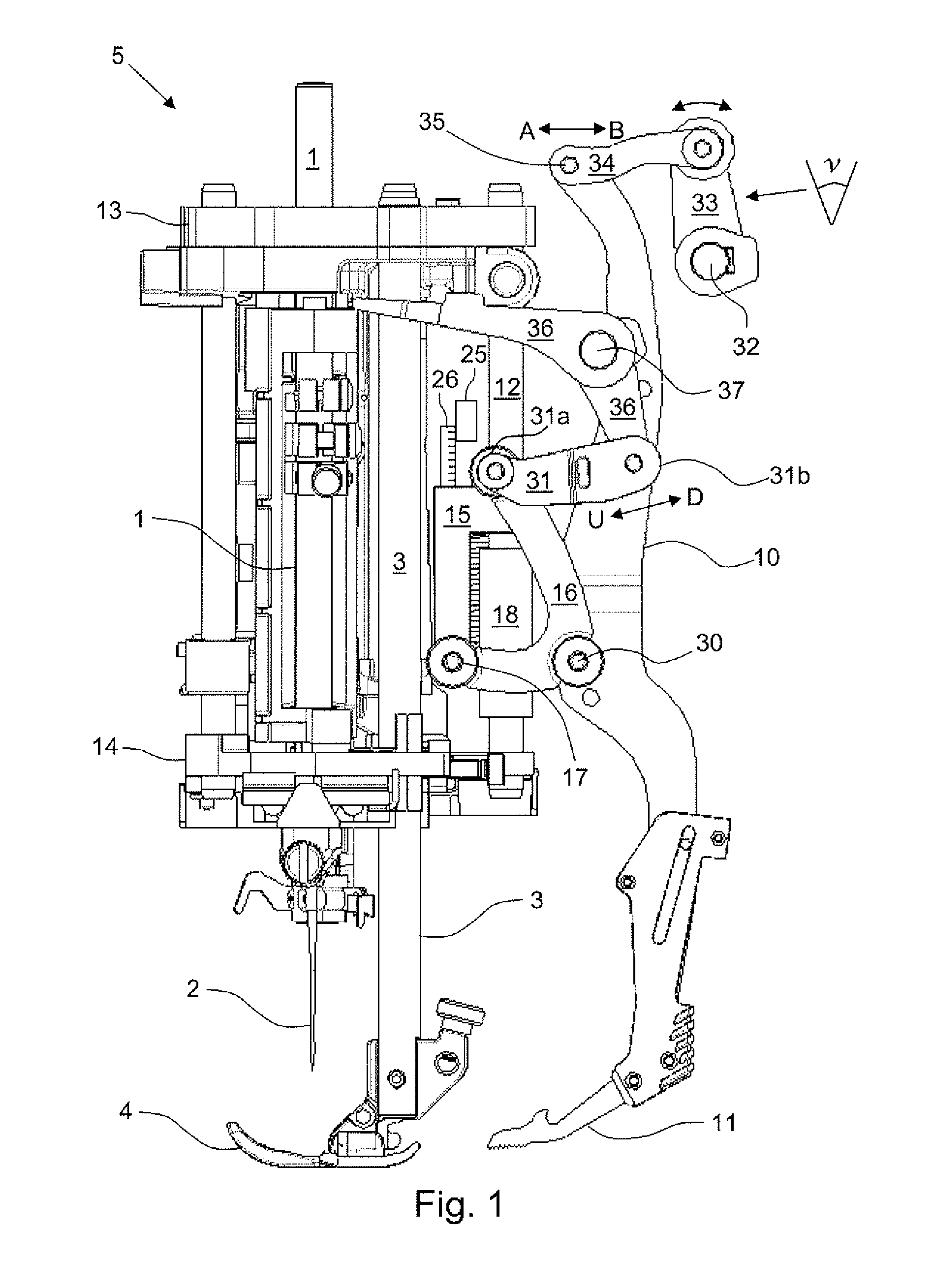

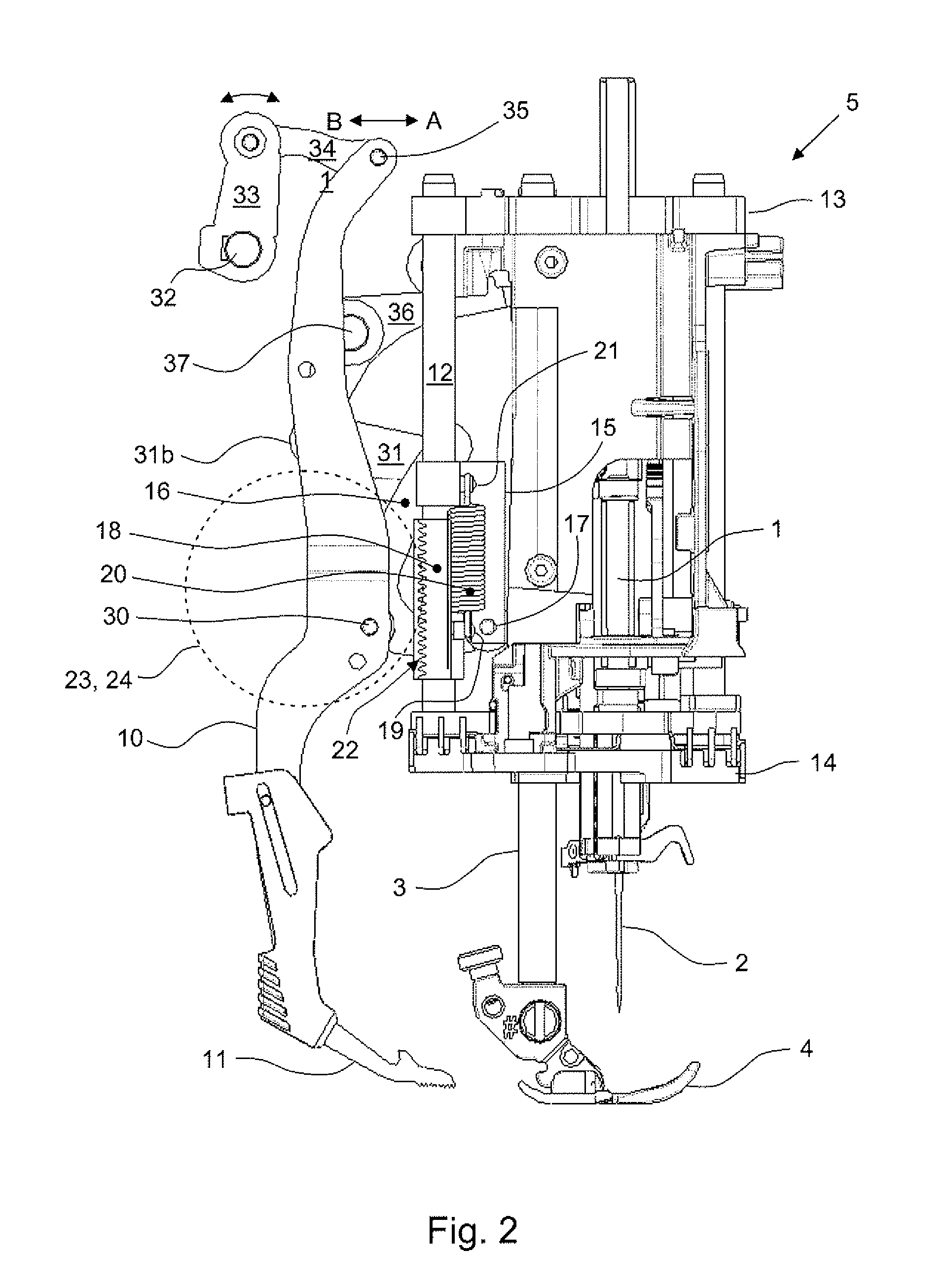

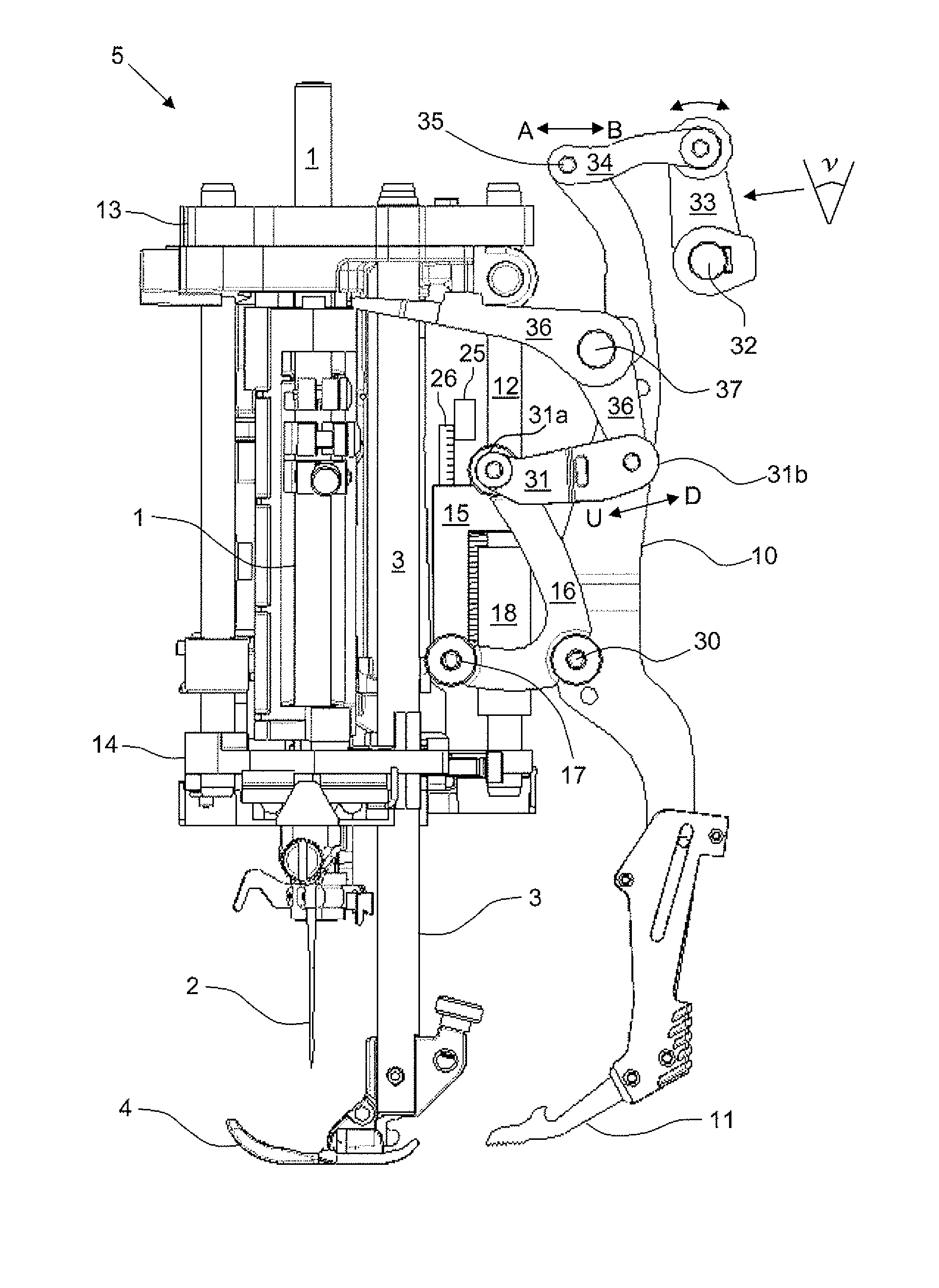

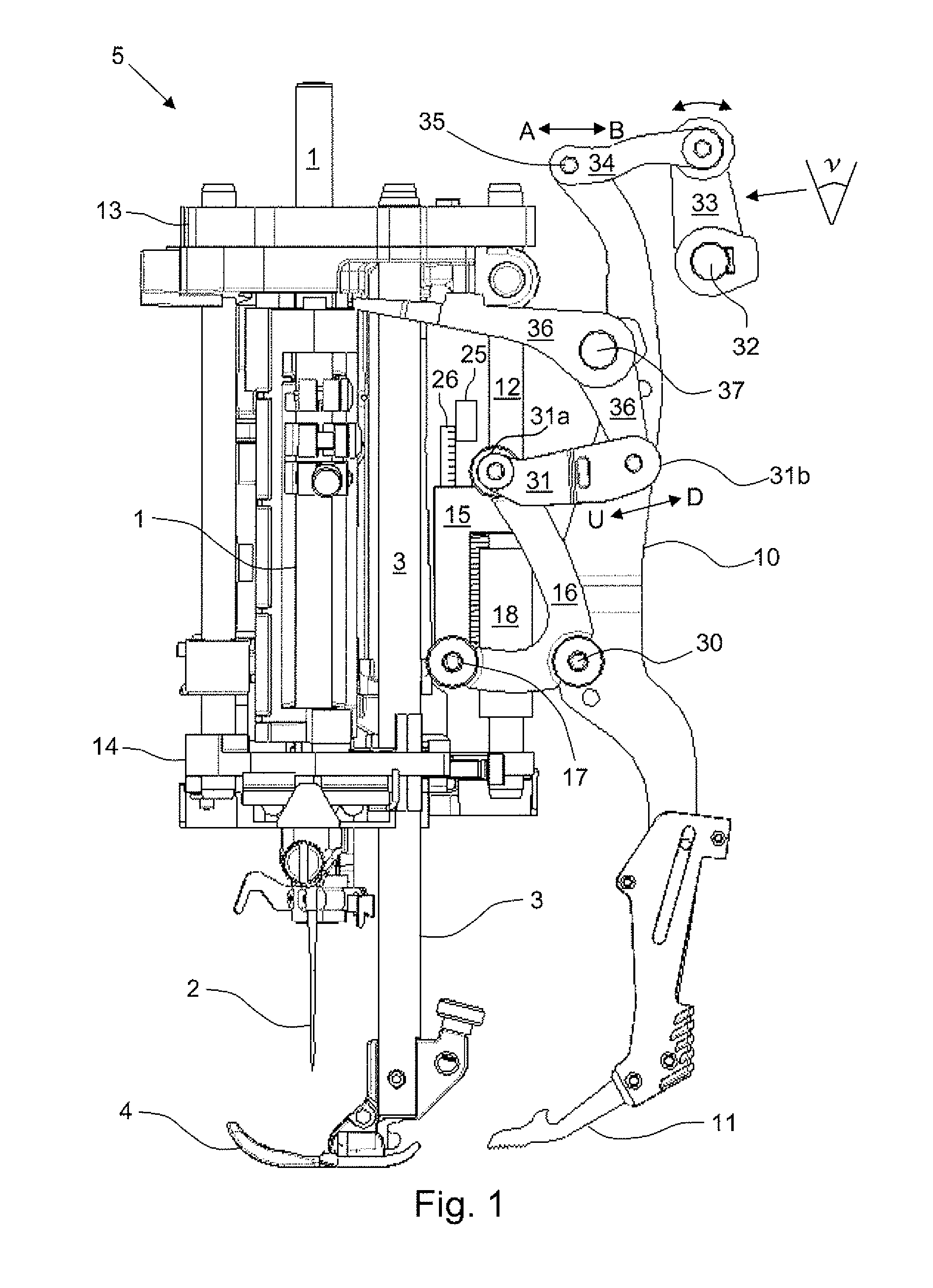

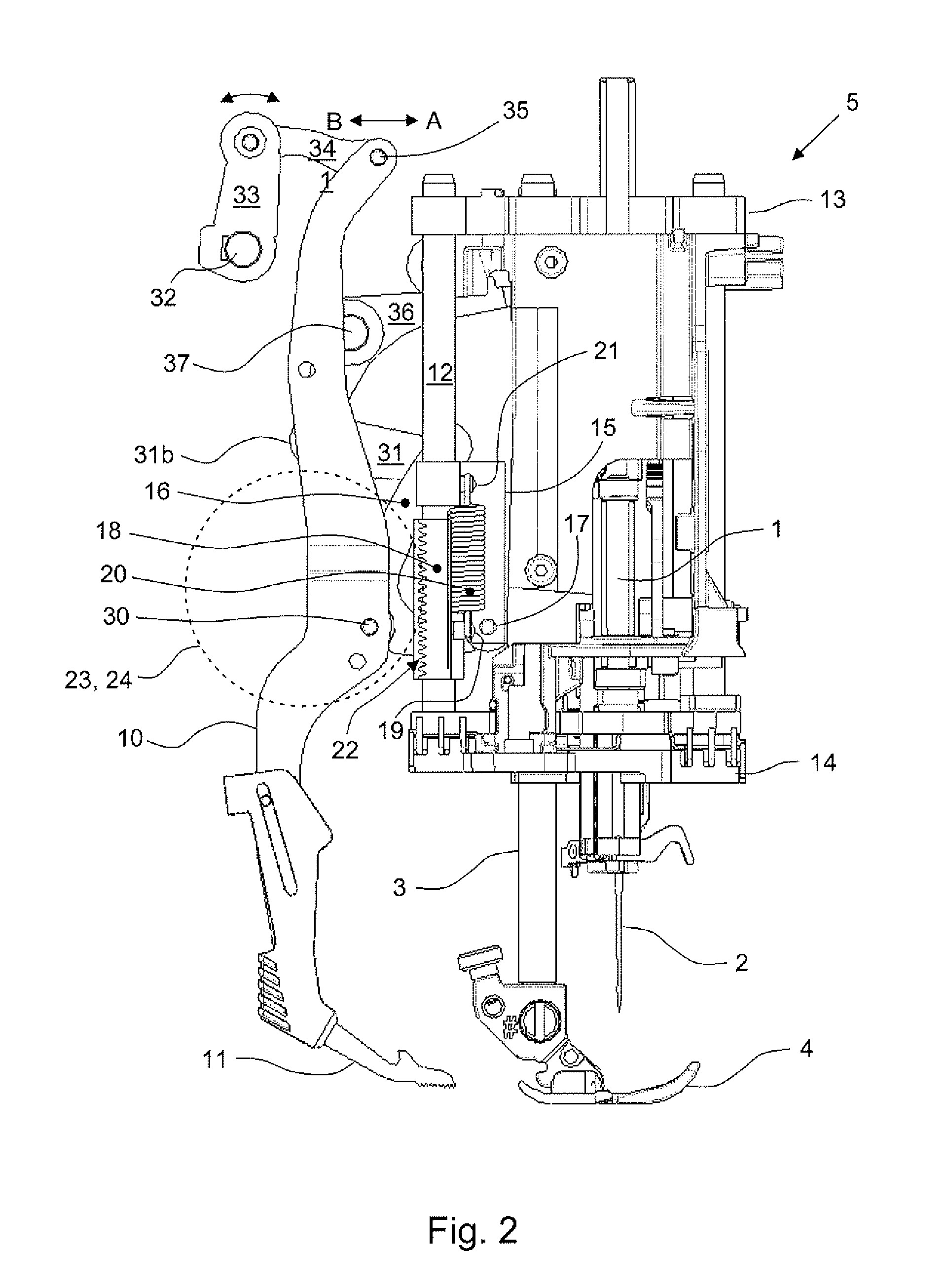

Top feeder for a sewing machine

A top feeder arrangement for a sewing machine provided with a processor for controlling stitches sewn on a cloth, wherein the sewing machine has a sewing machine head which comprises a needle mechanism with a needle bar (1) provided with a needle (2), a presser bar (3) provided with a presser foot (4) and a top feeder arm (10) provided at its lower end with a top feeder (11) acting from an upper surface of a cloth for feeding the cloth in the sewing direction and wherein the sewing machine is provided with a mechanism (12, 15, 17, 18) providing a controllable pressure of the top feeder (11) against the cloth.

Owner:SINGER SOURCING LTD LLC

Cutting insert for chip removing machining

InactiveUS20030086767A1Risk minimizationHigh surface finishCutting insertsTurning toolsEngineeringMachining

A cutting insert, intended for chip removing machining includes a cutting geometry surface having a cutting edge from which extends a primary chamfer that transforms into a chip removing surface. The chip removing surface is inclined in a inwards / downwards direction in order to permit sinking of a chip being formed, and transforms into a deflection surface arranged to initiate deflection of the chip from the cutting insert. The angle of inclination of the chip removing surface does not exceed 18°. The level difference in elevation between the primary chamfer and the chip deflection surface amounts to maximally 0.20 mm.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

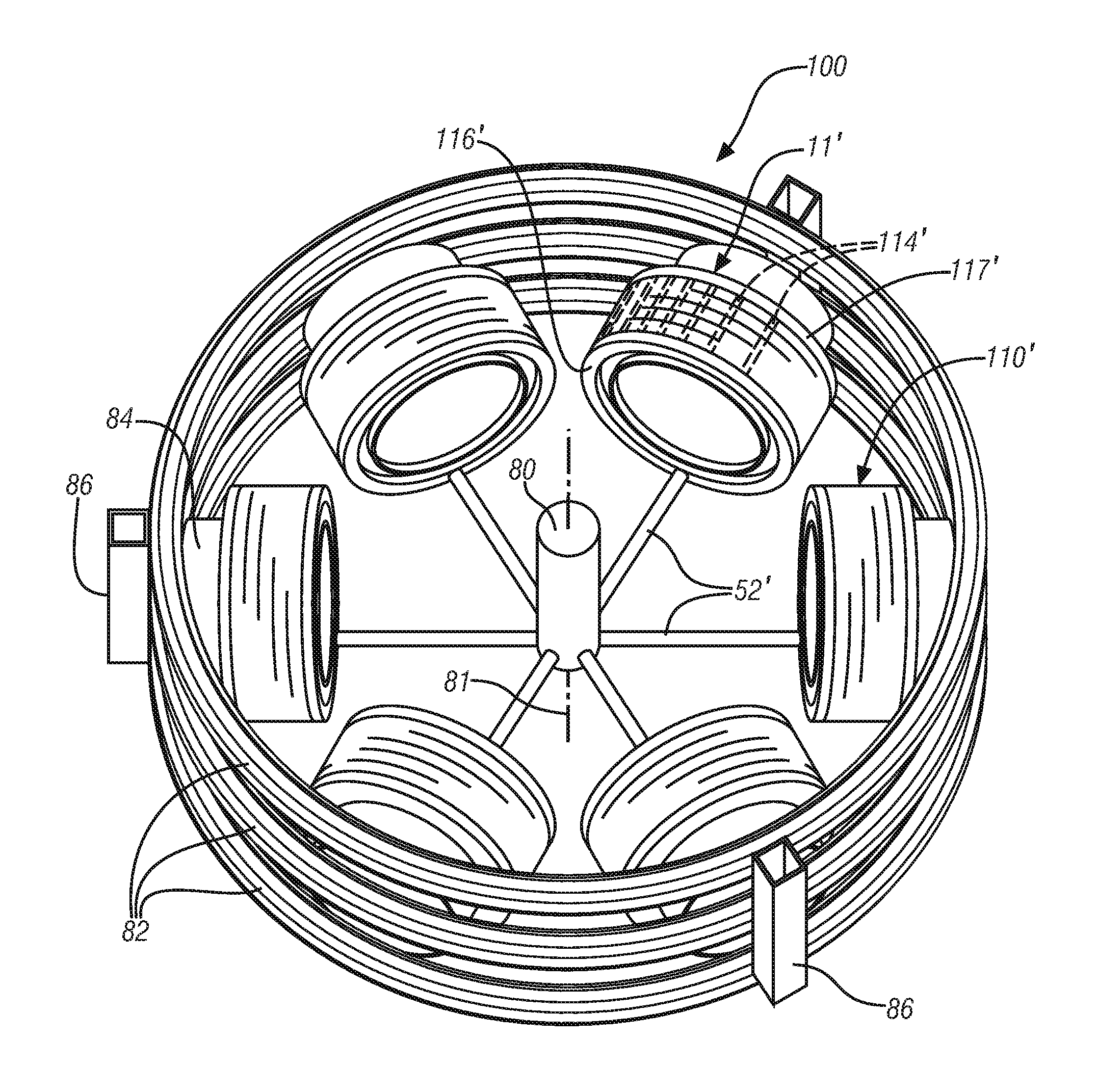

Centrifugally-cast shorted structure for induction motor rotors

A procedure for centrifugally casting a shorted structure around induction motor rotors is described. The method is commonly applied to a plurality of rotors disposed and arranged for rotational balance and supported on a suitable support, or optionally, on a plurality of supports arranged in layered fashion about a common rotational axis. The method comprises forming a wax representation of the shorted structure around a lamination stack; mounting a plurality of such lamination stacks in a mounting fixture and-attaching a suitable gating and runner system; forming an investment by coating the structure with refractory followed by melting out the wax; casting molten metal into the investment while it is rotating and aligning the mold to allow the centrifugal force generated to promote mold filling; and, continuing to rotate the investment until solidification is substantially complete.

Owner:GM GLOBAL TECH OPERATIONS LLC

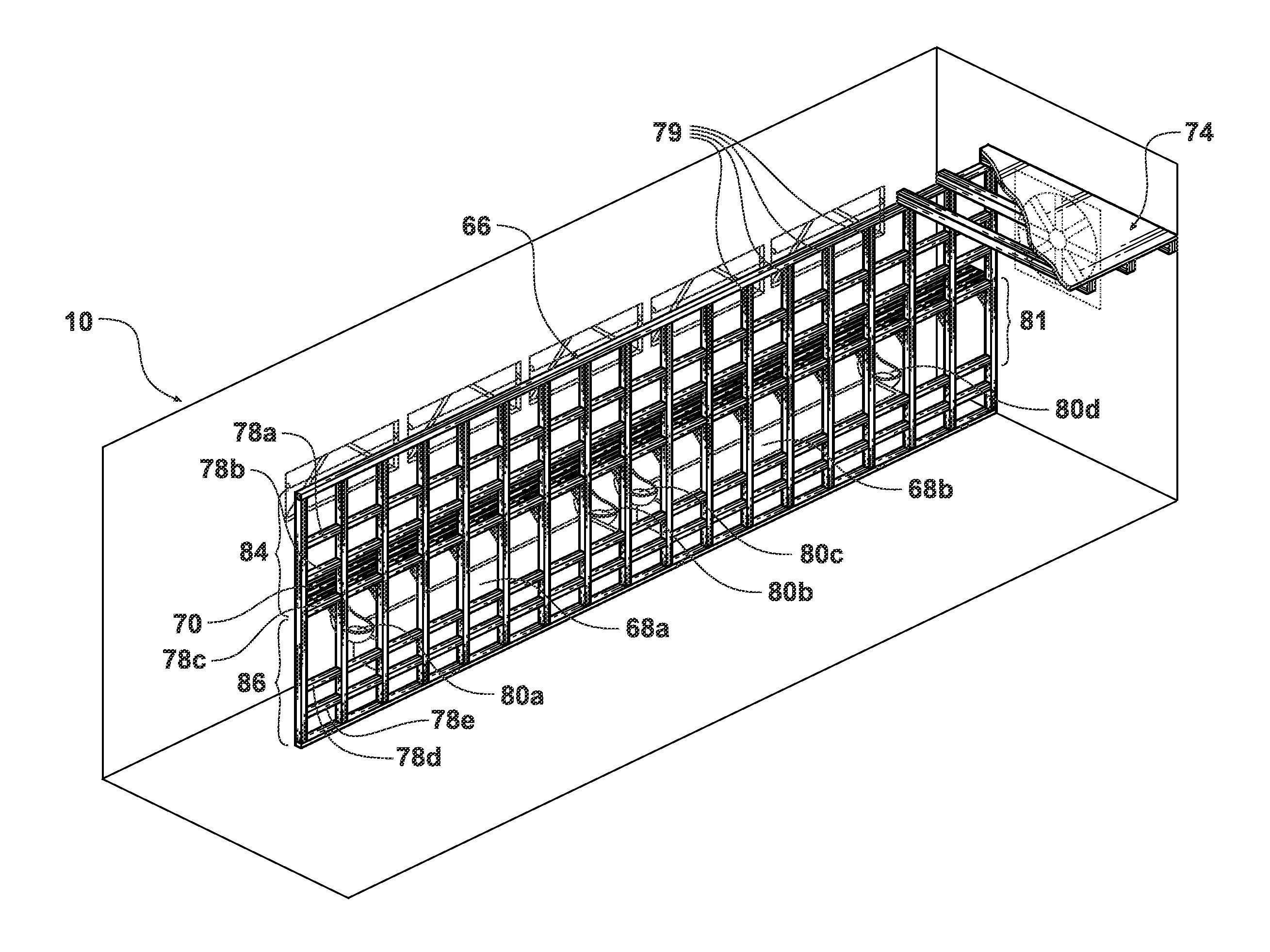

High capacity document sheet processor

InactiveUS6467764B1Improve accuracyOptimized for speedFunction indicatorsArticle feedersPaper documentDocument preparation

A high capacity document sheet processor combines significant speed and efficiency enhancing improvements in existing approaches to stack feeding particularly in the stack loading, feeding and singulating functions with novel operational arrangements adaptable to a universal paper handling and envelope inserting system.

Owner:EMC DOCUMENT TECH +1

Top feeder for a sewing machine

ActiveUS20120085274A1Enhanced feedingAvoid cutsProgramme-controlled sewing machinesHand sewingEngineeringCotton material

A top feeder arrangement for a sewing machine provided with a processor for controlling stitches sewn on a cloth, wherein the sewing machine has a sewing machine head which comprises a needle mechanism with a needle bar (1) provided with a needle (2), a presser bar (3) provided with a presser foot (4) and a top feeder arm (10) provided at its lower end with a top feeder (11) acting from an upper surface of a cloth for feeding the cloth in the sewing direction and wherein the sewing machine is provided with a mechanism (12, 15, 17, 18) providing a controllable pressure of the top feeder (11) against the cloth.

Owner:SINGER SOURCING LTD LLC

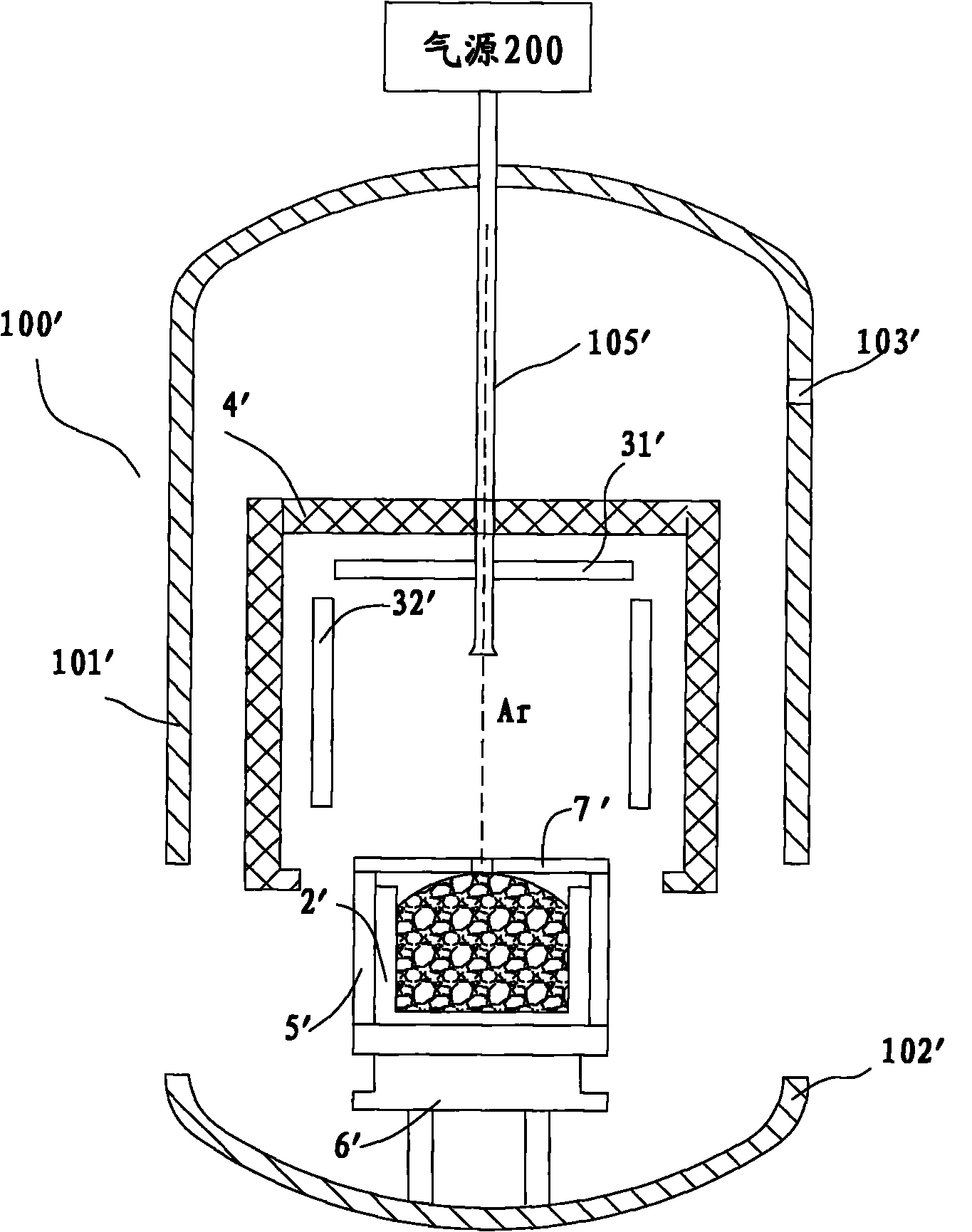

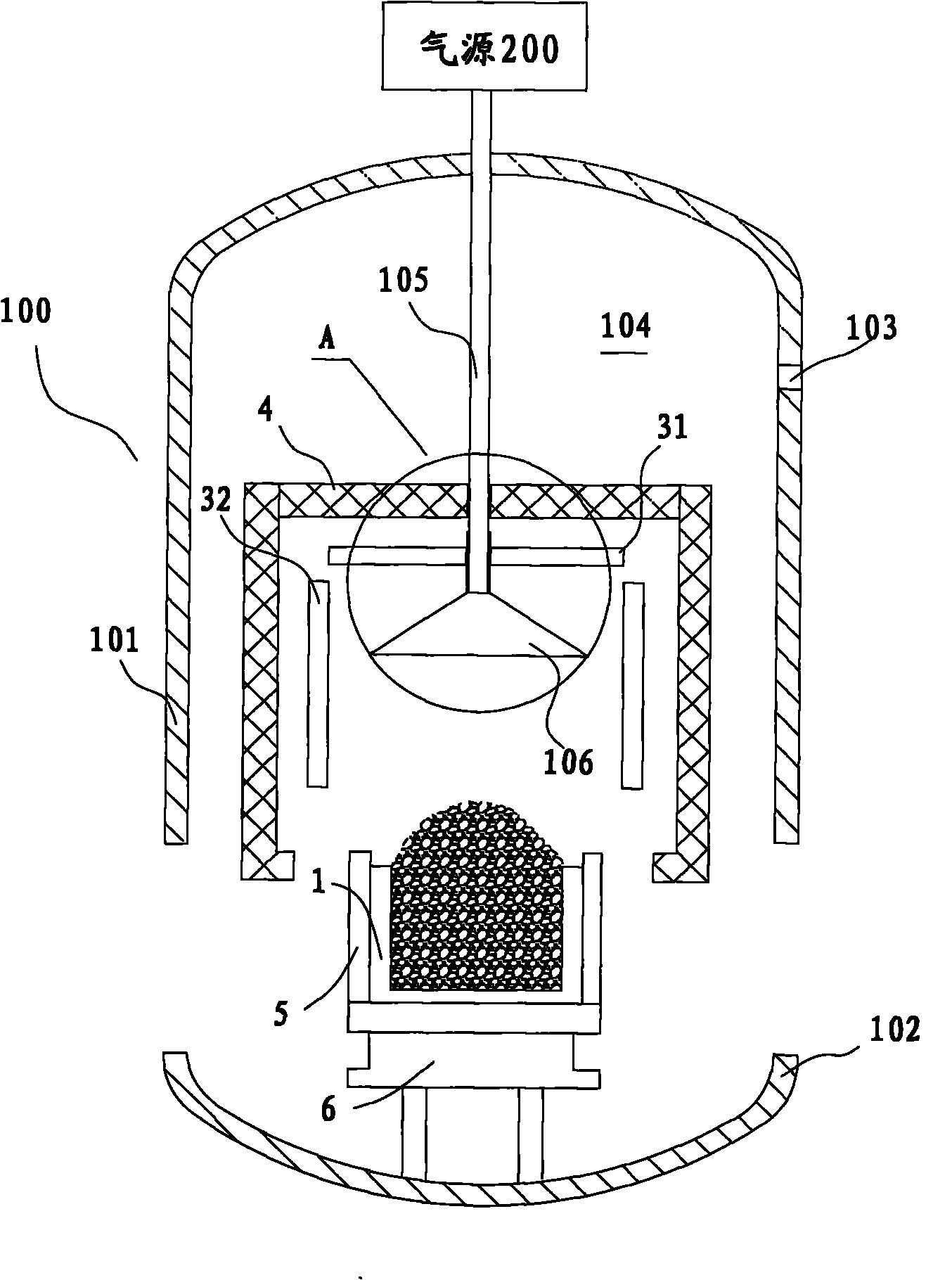

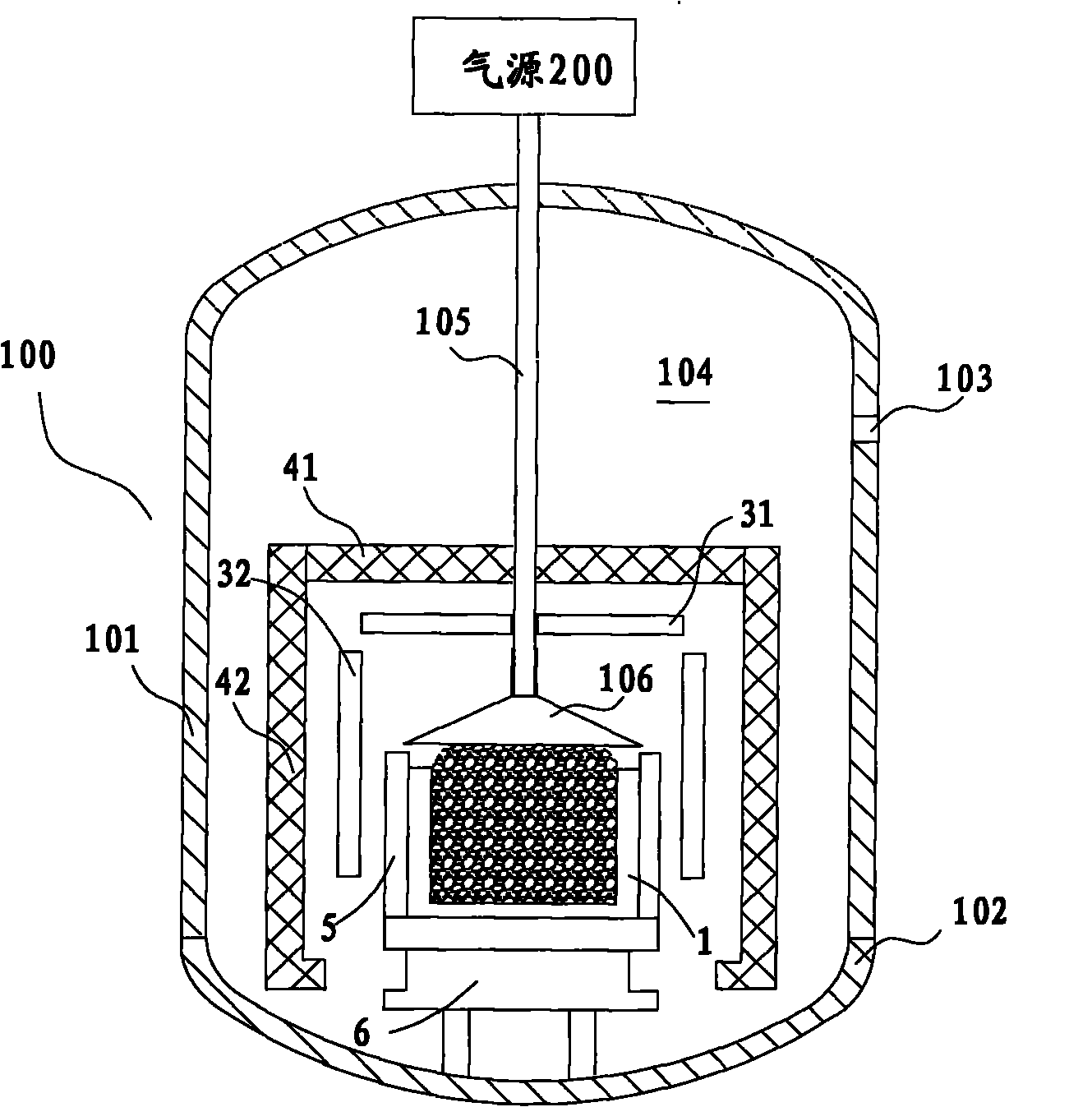

Directional solidification furnace with improved crucible cover part

InactiveCN101914805ANot cause pollutionCreate pollutionPolycrystalline material growthFrom frozen solutionsBreatherCrucible

The invention discloses a directional solidification furnace, which comprises an upper furnace body, a lower furnace body, a crucible, at least one heater, a crucible holder, a heat insulation component, a breather pipe and a crucible cover part, wherein the lower furnace body is matched with the upper furnace body to form a furnace body space; the crucible is arranged in the furnace body space and constructed to accommodate a feedstock; the at least one heater is used for heating the crucible and melting the feedstock accommodated in the crucible; the crucible holder is used for holding the crucible; the heat insulation component is constructed to longitudinally move relative to the crucible so as to control directional solidification of the feedstock in the crucible; the breather pipe is connected with an external gas source and vertically passes through the heat insulation component; and the crucible cover part is detachably arranged at the bottom of the breather pipe, and the sizeof the crucible cover part is adapted to the size of the top of the crucible so as to cover above the crucible. The directional solidification furnace can ensure that the furnace cavity is not polluted at the same time of realizing increment of the feedstock so as to improve the production efficiency and reduce the cost at the same time of ensuring the quality of a produced billet.

Owner:王楚雯

Method of shipping livestock

InactiveUS8550035B2Ensure health and safetyEasy accessAnimal housingBird housingsEngineeringLivestock

Owner:ST REPRODUCTIVE TECH LLC

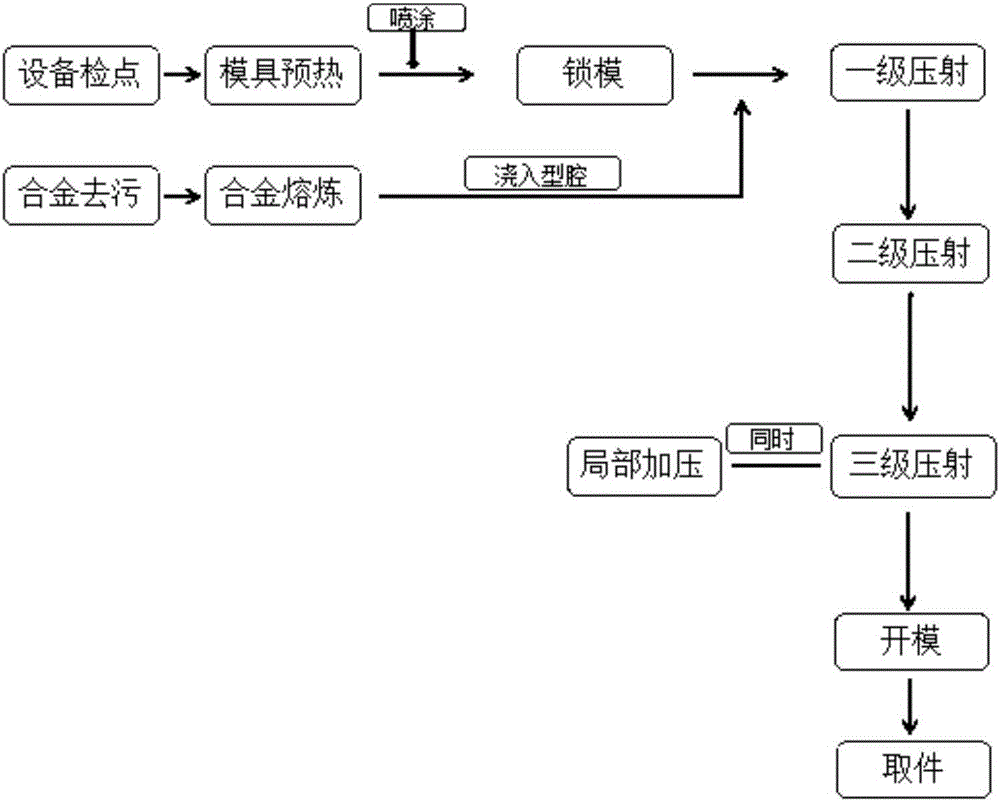

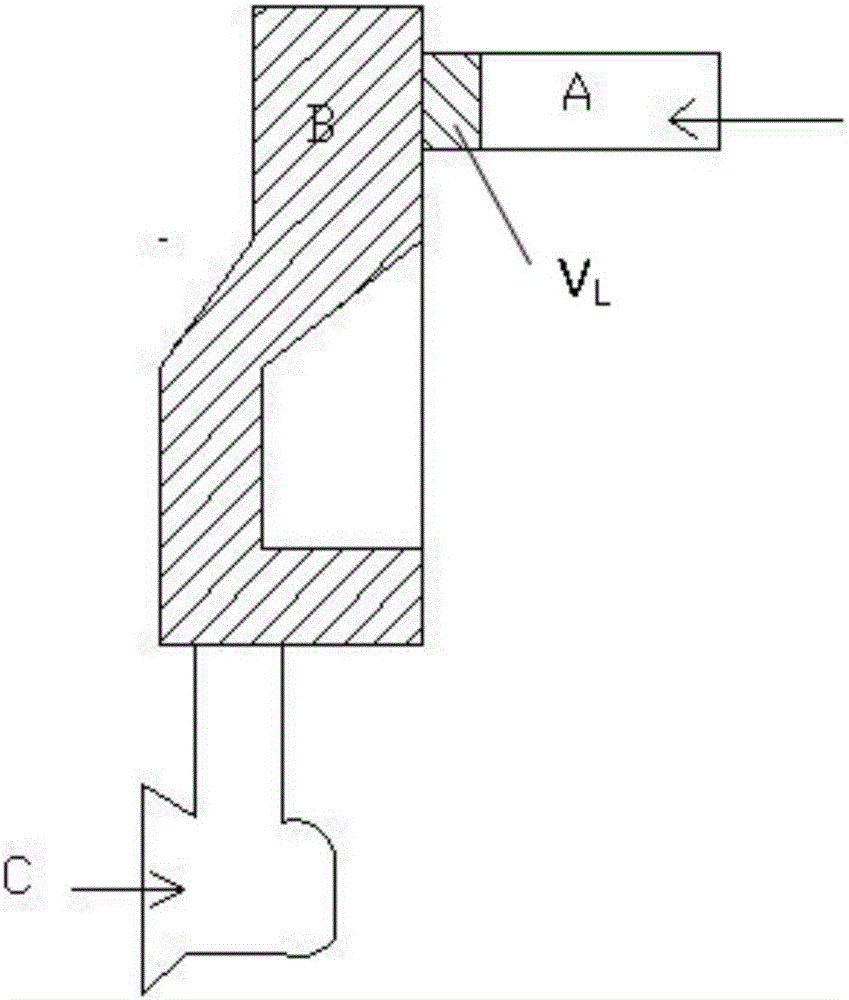

Die-casting forming method free from shrinkage cavity and shrinkage porosity defects for thick wall die-casting fitting

InactiveCN106270441ASolve the shrinkage porosity that is easy to appearSolve defects such as poresMold fillingDie casting

The invention discloses a die-casting forming method free from shrinkage cavity and shrinkage porosity defects for a thick wall die-casting fitting. By the adoption of the method, the problems of shrinkage cavity, shrinkage porosity and air hole defects which are likely to happen to a thick wall aluminum alloy die-casting fitting frequently can be solved effectively. The die-casting forming method includes the main contents that a specific pouring method with the low superheat degree is adopted, large fullness pouring with the pressure chamber fullness being 60%-70% is used, the high-pressure mold filling die-casting technique is utilized, and the internal compactness zero-defect performance of the die-casting fitting is achieved. The local pressurization structure is added in mold design, and pressurization feeding at the thick wall position far away from the position of an inner casting gate is realized. By the adoption of the method, the casting defects of the thick wall die-casting fitting can be reduced, the rejection rate of products is lowered, material wasting is avoided, cost is reduced and benefits are increased.

Owner:GUANGDONG HONGTU TECHNOLOGY (HOLDINGS) CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com