Die-casting forming method free from shrinkage cavity and shrinkage porosity defects for thick wall die-casting fitting

A die-casting and defect technology, applied in the field of die-casting parts with large aluminum alloy wall thickness, can solve the problems of inability to effectively compensate for shrinkage cavities and shrinkage porosity, no optimization method, etc., to avoid serious air entrainment at high temperature and solve fluidity The effect of reducing, improving density and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

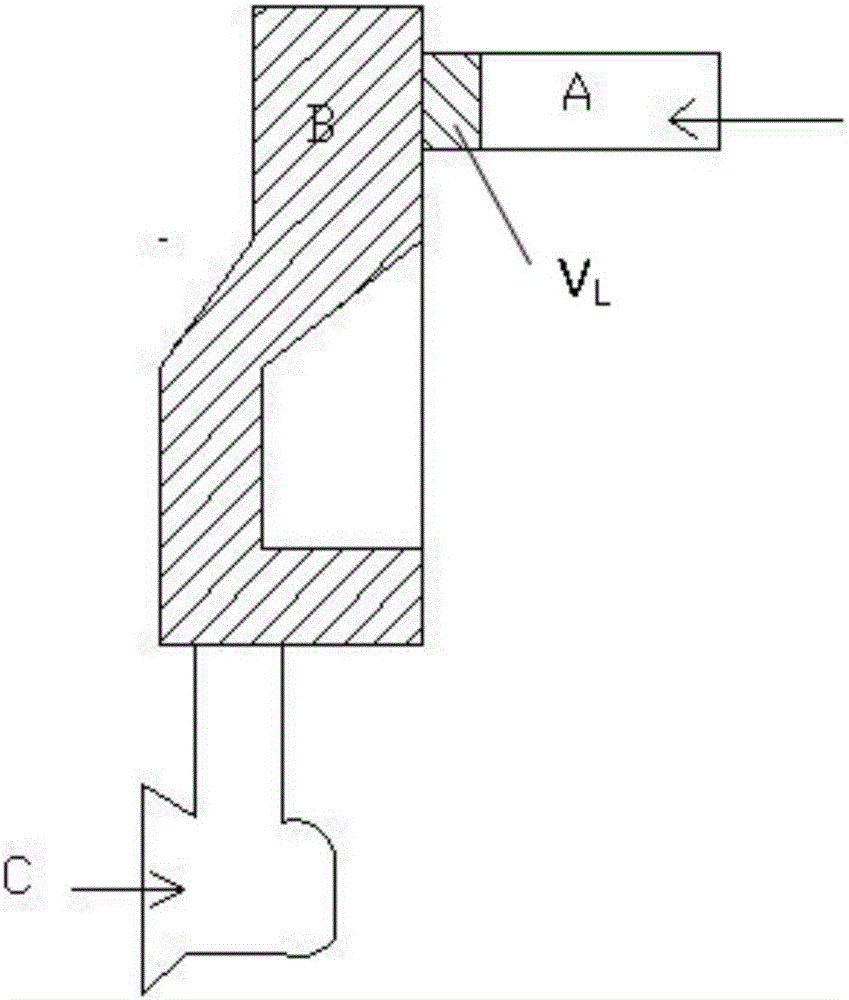

[0031] A defect-free die-casting forming method for aluminum alloy thick-walled parts, such as figure 2 For the thick-walled die-casting parts shown, the maximum wall thickness can reach 15mm, and the die-casting aluminum alloy material is YL112. Put the alloy block into a resistance furnace for 200°C heat preservation for 20 minutes to remove surface dirt, then heat up to 750°C for melting, degassing, refining, and slag removal after melting, and then lower the temperature to 640°C (the liquidus temperature of aluminum alloy Above 20°C) for pouring, the mold preheating temperature is 250°C, the fullness of the pressure chamber is 65% after pouring, the slow injection speed is 0.5m / s, when the stroke of the injection punch is 150mm, perform fast injection filling type, the injection speed is 5m / s, when the stroke is 250mm, pressurization is carried out, the pressure is 90MPa, and at the same time, local pressurization is carried out at the thick wall, and the pressure passes ...

Embodiment 2

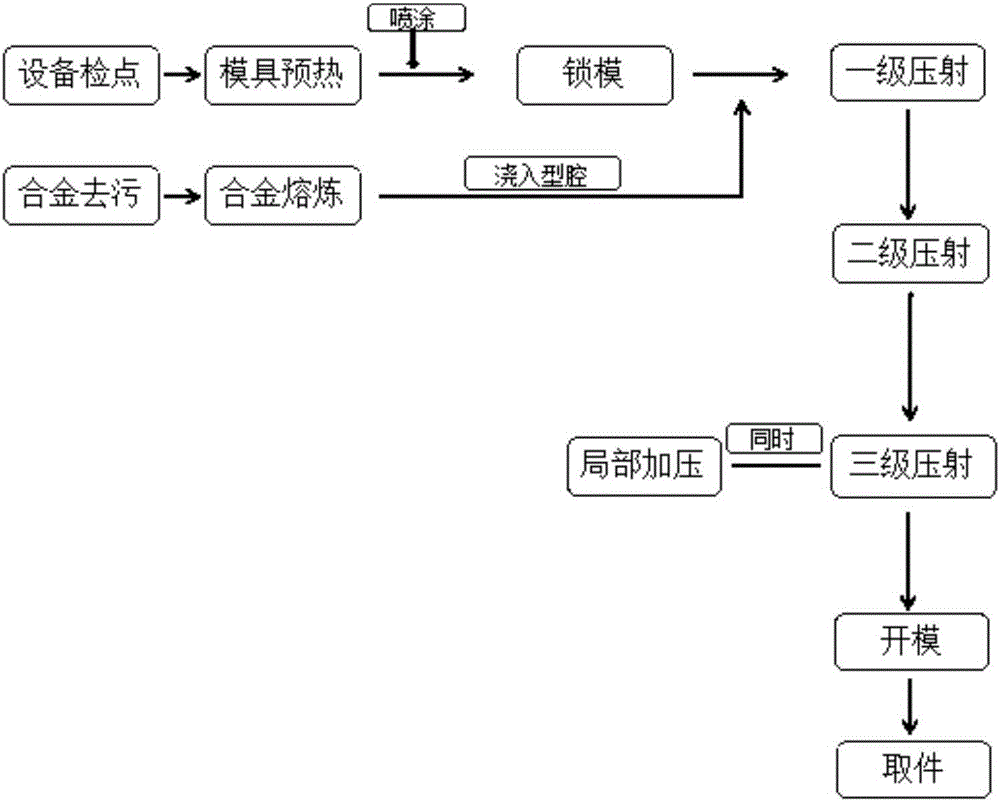

[0033] Parts are parts with uneven wall thickness, the maximum wall thickness can reach 12mm, and a local booster device is added at the wall thickness. The specific die-casting process is as follows: figure 1shown. The die-casting aluminum alloy material is YL112. The die-casting filling process is as follows: After closing the mold, inject the aluminum alloy liquid with a temperature of 650°C into the mold cavity, and the mold preheating temperature is 200°C. The injection speed is 0.3m / s. When the stroke of the injection punch is 200mm, fast injection filling is performed, and the injection filling speed is 3m / s; the pressure in the pressurization and feeding stage is 80MPa, and the injection is carried out at the thick wall. Partial pressurization, the pressure is transmitted to the mold wall through the local pressurization punch, the size is 40MPa, the volume of the local pressurization chamber is 10% of the volume of the thick wall, and the pressurization time is 1.5s. ...

Embodiment 3

[0035] The part is a large-area thick-walled part with a maximum wall thickness of 18mm. The die-casting aluminum alloy material is A380. The die-casting filling process is as follows: preheat the mold to 250°C, and after closing the mold, set the temperature to 660°C (above the liquidus line) 40°C) the aluminum alloy liquid is injected into the mold cavity, the fullness of the pressure chamber is 70% after pouring, the slow injection speed is 0.5m / s, when the stroke of the injection punch is 200mm, perform fast injection filling, The injection speed is 8m / s. When the stroke is 300mm, pressurization and feeding are carried out, and the pressure is 70MPa. At the same time, local pressure is carried out at the thick wall. The volume of the pressurization chamber is 8% of the volume of the thick wall, and the pressurization time is 2s. The above method optimizes the die-casting process and eliminates shrinkage cavity and porosity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com