Central bundle tubular optical cable with special-shaped reinforcement pieces

A reinforcement and tube-type technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of easy gasification at high temperature, sheath porosity, poor bonding performance, etc., and achieve the effect of good water resistance, stable process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

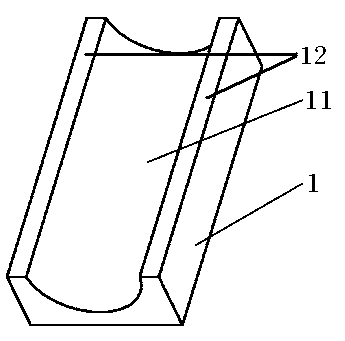

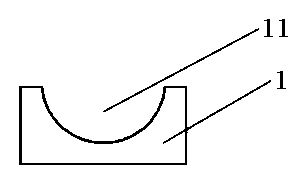

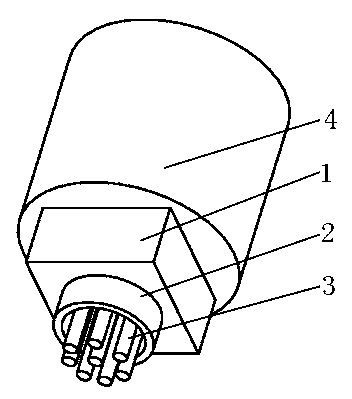

[0032] see Figure 1 to Figure 4 , a central bundle tube optical cable with a special-shaped strength member, which includes: a loose tube 2 located in the center, a special-shaped strength member 1 coated outside the loose tube, and a sheath layer coated on the special-shaped strength member by extrusion 4 and at least one optical fiber 3 in the loose tube; it is characterized in that: the special-shaped reinforcement is a rectangular parallelepiped strip, and the strip has a semicircular cylindrical groove 11, and the special-shaped reinforcement The upper surface 12 is coated with an adhesive coating; there are two special-shaped strength members in the optical cable, and the grooves of the two special-shaped strength members are placed oppositely, the loose tube is located in the groove, and the top of the two special-shaped strength members The surfaces are bonded together; the special-shaped reinforcement is made of raw materials containing the following components and w...

Embodiment 2

[0041] see figure 1 , figure 2 and Figure 5 to Figure 6 , a central bundle tube optical cable with a special-shaped strength member, which includes: a loose tube 2 located in the center, a special-shaped strength member 1 coated outside the loose tube, and a sheath layer coated on the special-shaped strength member by extrusion 4 and at least one optical fiber 3 in the loose tube; it is characterized in that: the special-shaped reinforcement is a rectangular parallelepiped strip, and the strip has a semicircular cylindrical groove 11, and the special-shaped reinforcement The upper surface 12 is coated with an adhesive coating; there are two special-shaped strength members in the optical cable, and the grooves of the two special-shaped strength members are placed oppositely, the loose tube is located in the groove, and the top of the two special-shaped strength members The surfaces are bonded together; the special-shaped reinforcement is made of raw materials containing the...

Embodiment 3

[0050] see figure 1 , figure 2 , Figure 5 and Figure 7 , the central beam tube type optical cable with special-shaped strengthening member is basically the same as the implementation example 2, one of the differences is that the special-shaped strengthening member is covered with an insulating tape 5, and the insulating tape is located between the special-shaped strengthening member and the sheath layer; The insulating belt is a water-blocking belt or a non-woven fabric or a polyester belt; the second difference is that there is a tear rope 6 between the loose tube and the special-shaped reinforcement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com