Patents

Literature

95results about How to "Solve shrinkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

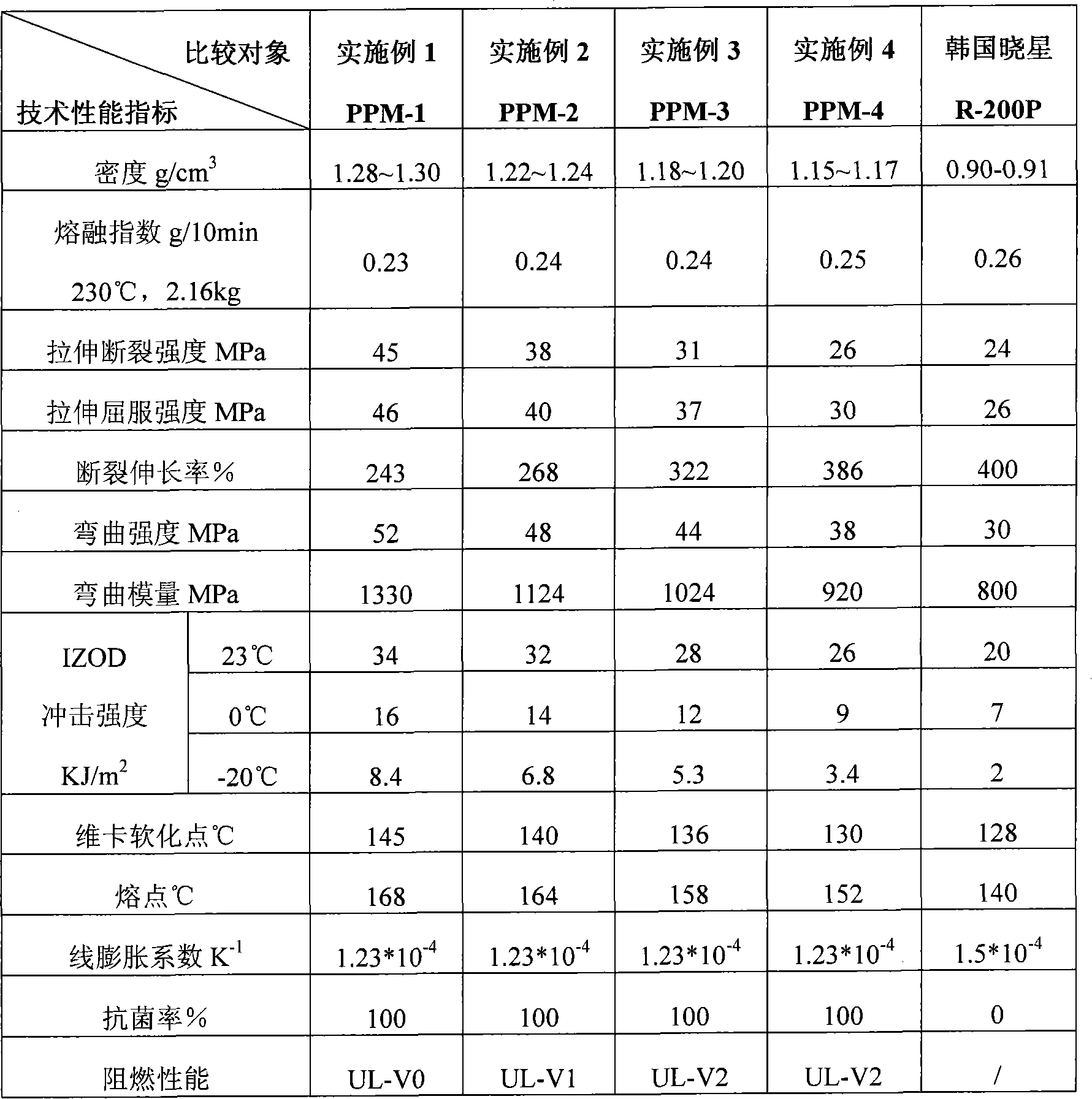

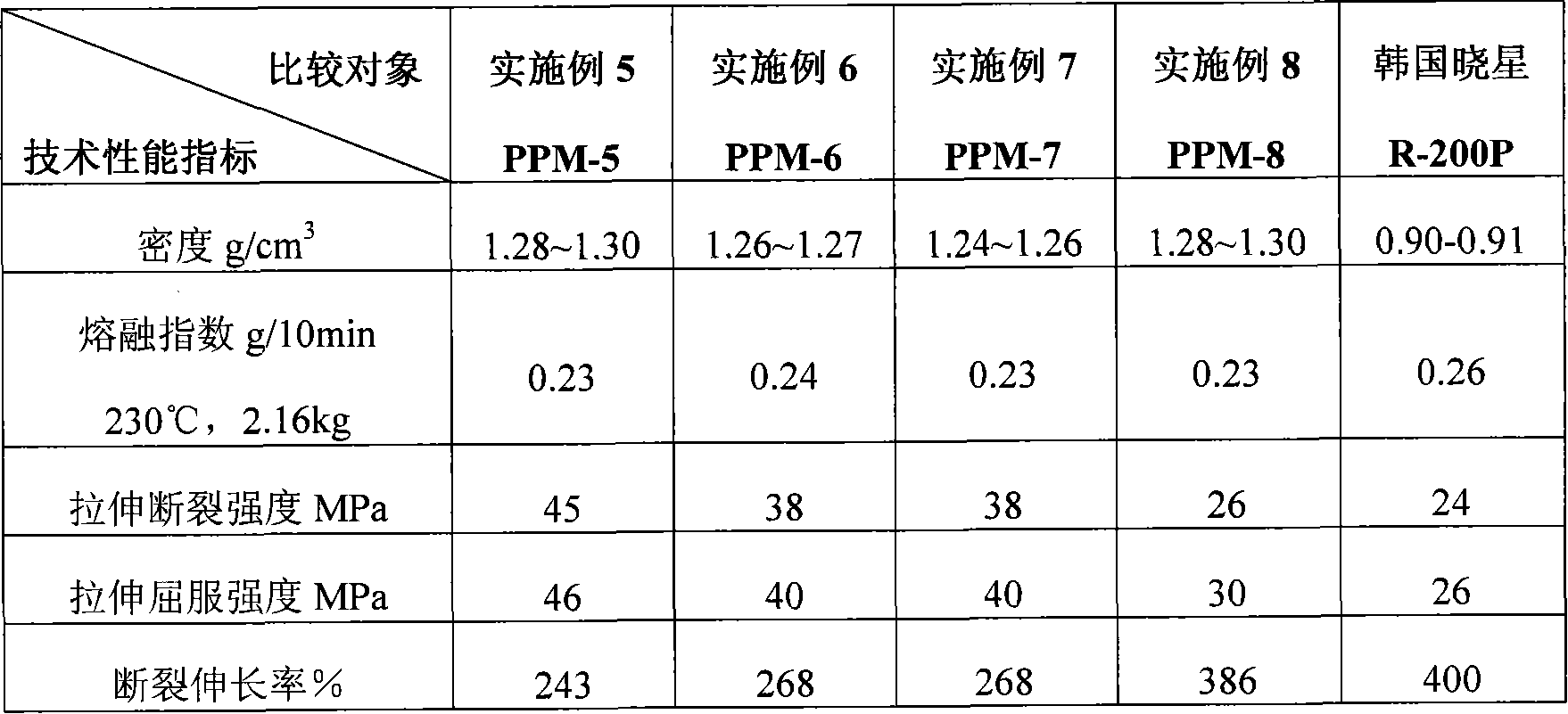

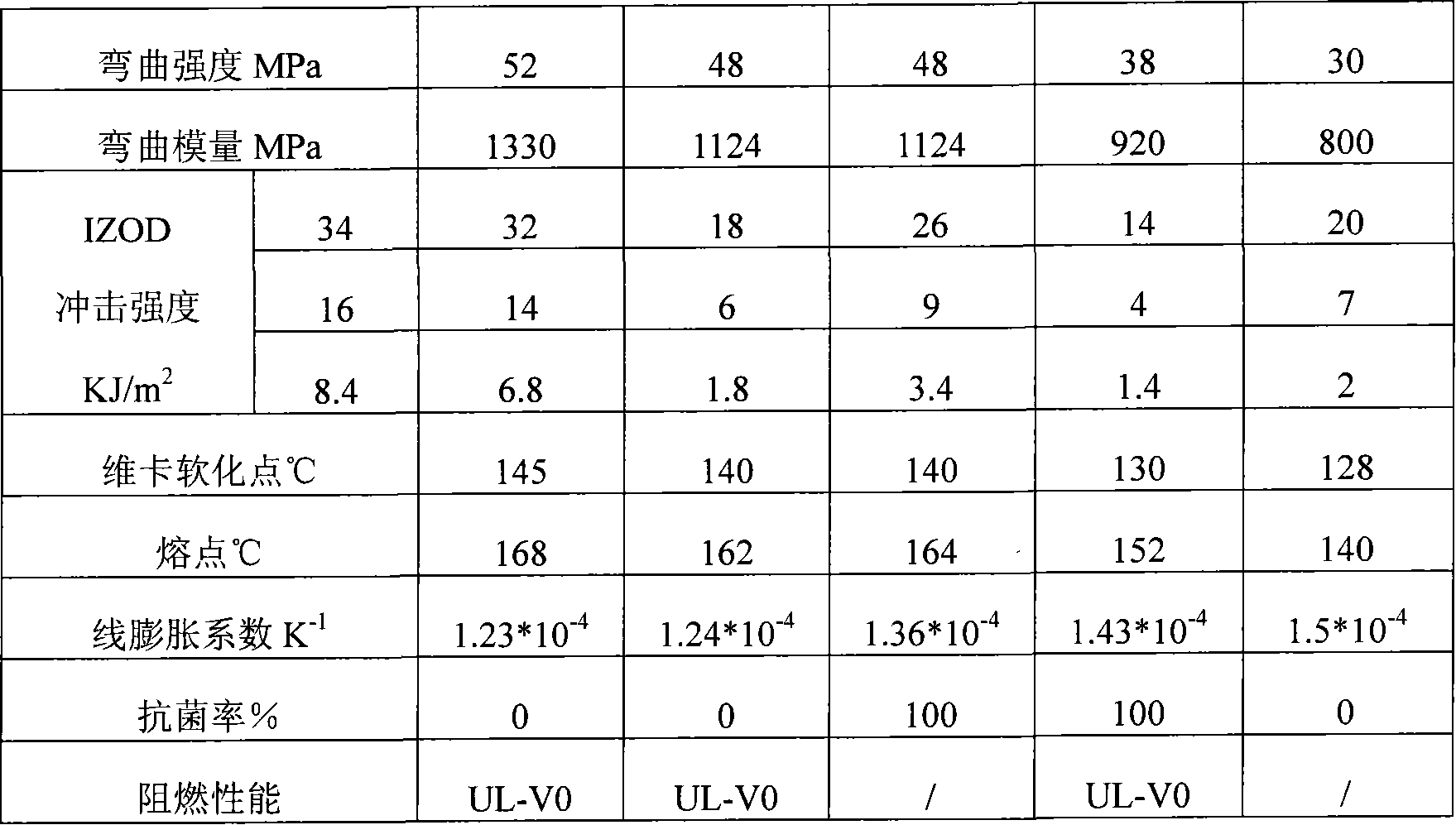

Special-purpose multifunctional modified random polypropylene material for pipe and its preparing process and application

InactiveCN101148530AWith flame retardant and antibacterial functionImprove heat resistanceFood industryHeat stability

The present invention discloses one kind of multifunctional modified atactic polypropylene pipe material and its preparation process. The atactic polypropylene pipe material consists of atactic copolypropylene, environment friendly fire retardant, pre-dispersed master batch of inorganic stuffing, impact modifier, antioxidant, composite antibacterial master batch and dispersant. It is applied in building pipes, pipeline for beverage and food industry, heat supply system and farm irrigation system. It has fire retarding and antibacterial functions, less shrinkage, high low temperature impact resistance, high heat resistance, high mechanical performance and excellent heat stability.

Owner:合诚技术股份有限公司

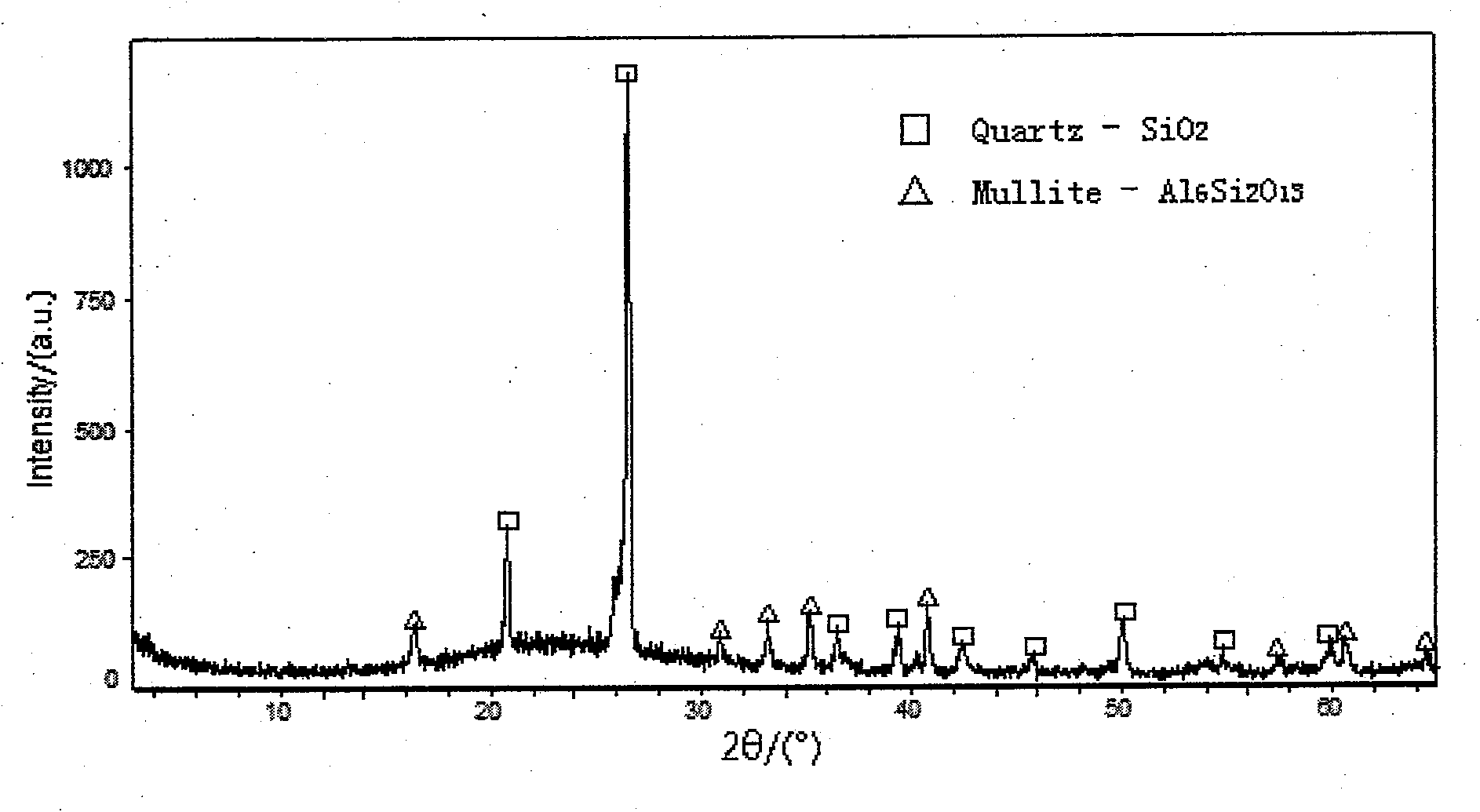

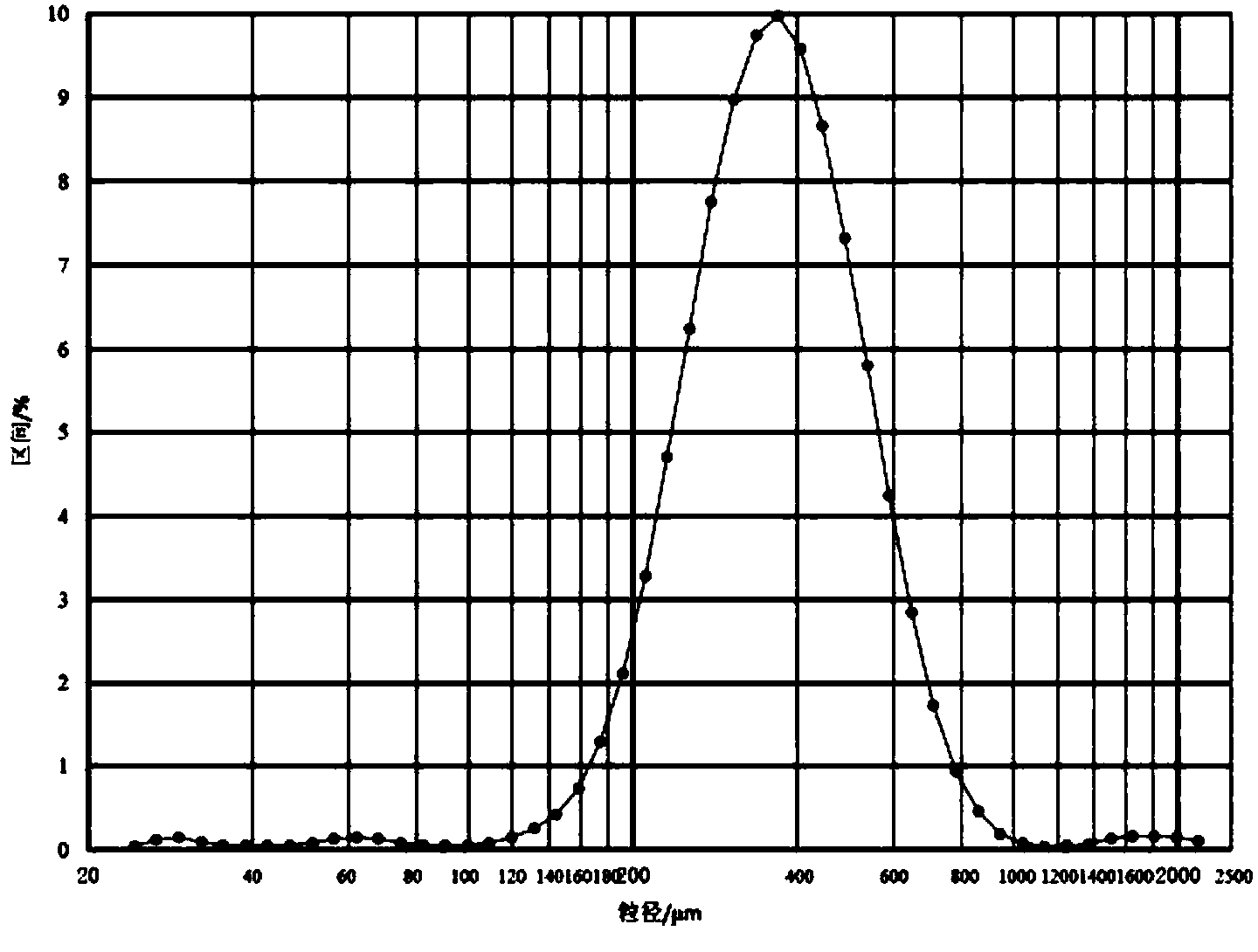

Fine-pottery sanitary ceramic body and manufacturing method thereof

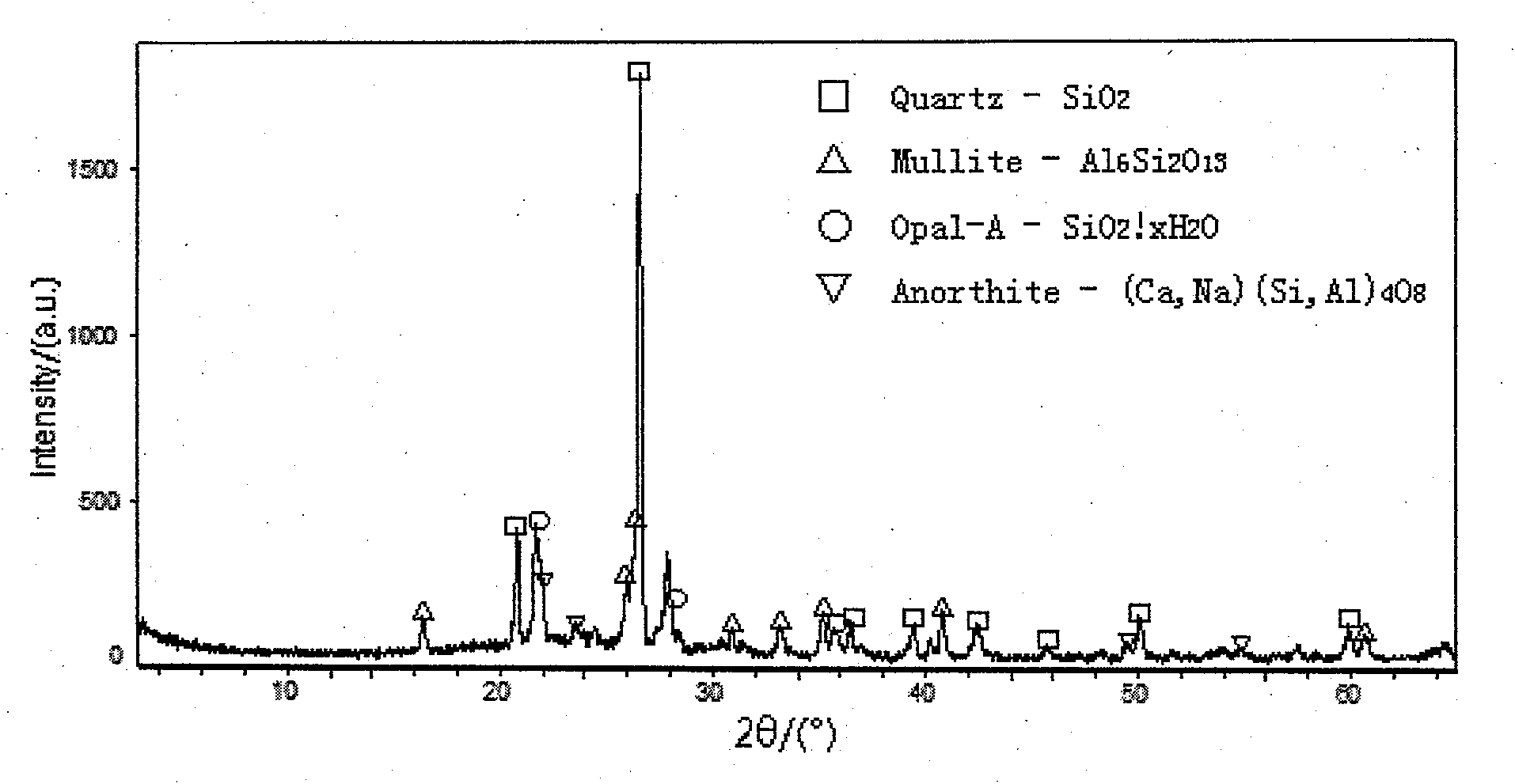

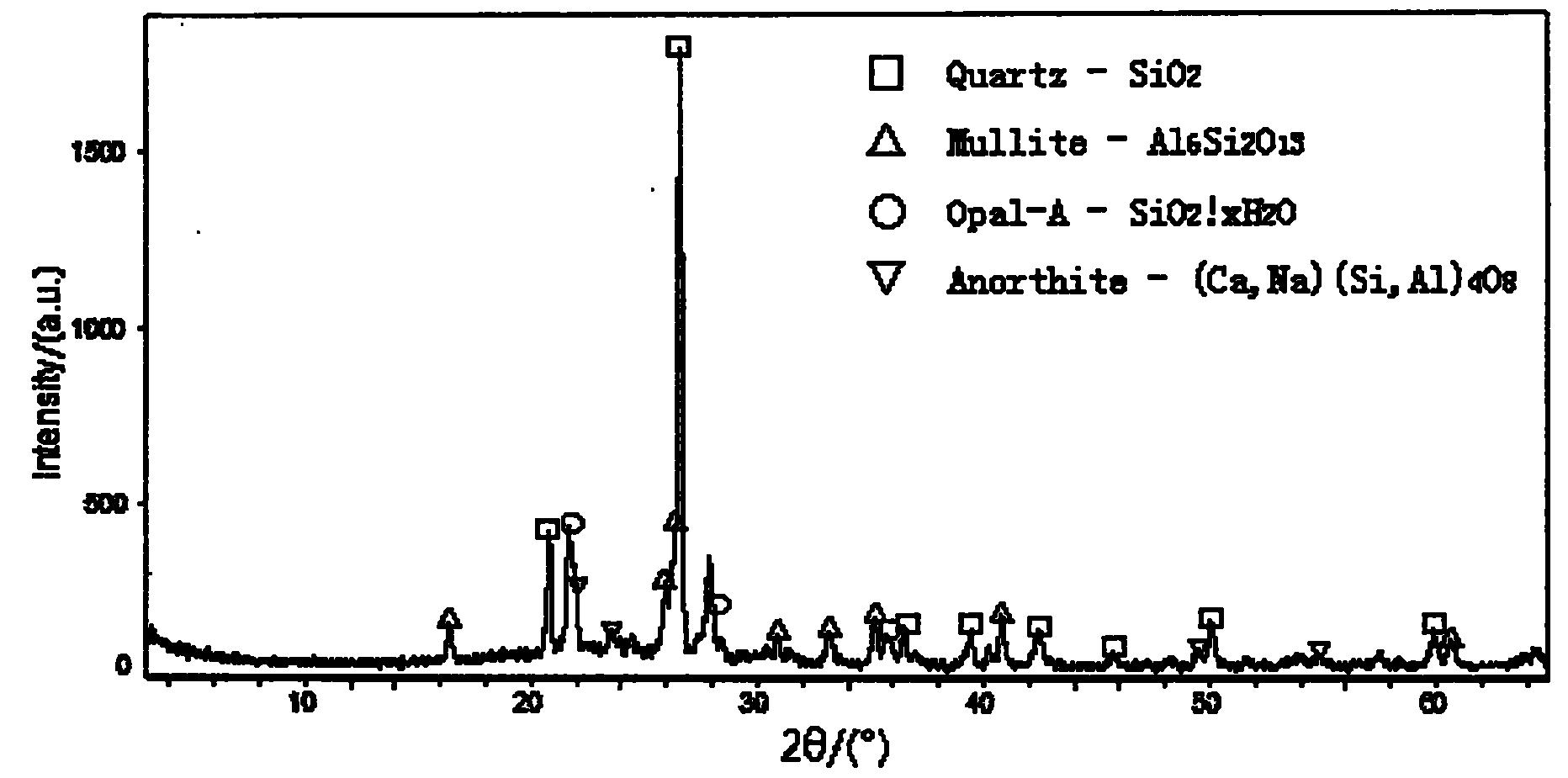

ActiveCN101811858AReduce hygroscopic swellingHigh coefficient of thermal expansionClaywaresGranularityMullite

The invention relates to a fine-pottery sanitary ceramic body and a manufacturing method thereof and belongs to the technical field of ceramic products, which is used for reducing the deformation of a sanitary ceramic product and improving the quality of glaze. The fine-pottery sanitary ceramic body is characterized in that a body raw material comprises the following components in part by mass: 10 to 30 parts of ball clay, 30 to 60 parts of kaoline, 5 to 15 parts of porcelain clay, 5 to 15 parts of quartz and 5 to 15 parts of wollastonite, wherein the kaoline comprises 10 to 25 calcined kaoline. In the manufacturing method, the raw materials and the adding proportion of the fine-pottery body are preferably selected, the crystal phase content of mullite, quartz and the like is controlled, and the glass phase content and the high-temperature plastic deformation are reduced so as to fulfill the aim of reducing the deformation of fine-pottery sanitary ceramics; while reducing the hygroscopic expansion of the body, the manufacturing method improve thermal expansion coefficient of the body at the temperature of 200 DEG C to make the glaze bear high compressive stress, thereby improving the anti-cracking performance of products and ensuring enough long service life. Through the refinement of slurry granularity, the method remarkably reduces the occurrence of disadvantage of glaze pinholes, does not need to reduce the pinholes by using engobe, simplifies a production process, and improves the production efficiency and the qualification rate of the products.

Owner:HUIDA SANITARY WARE

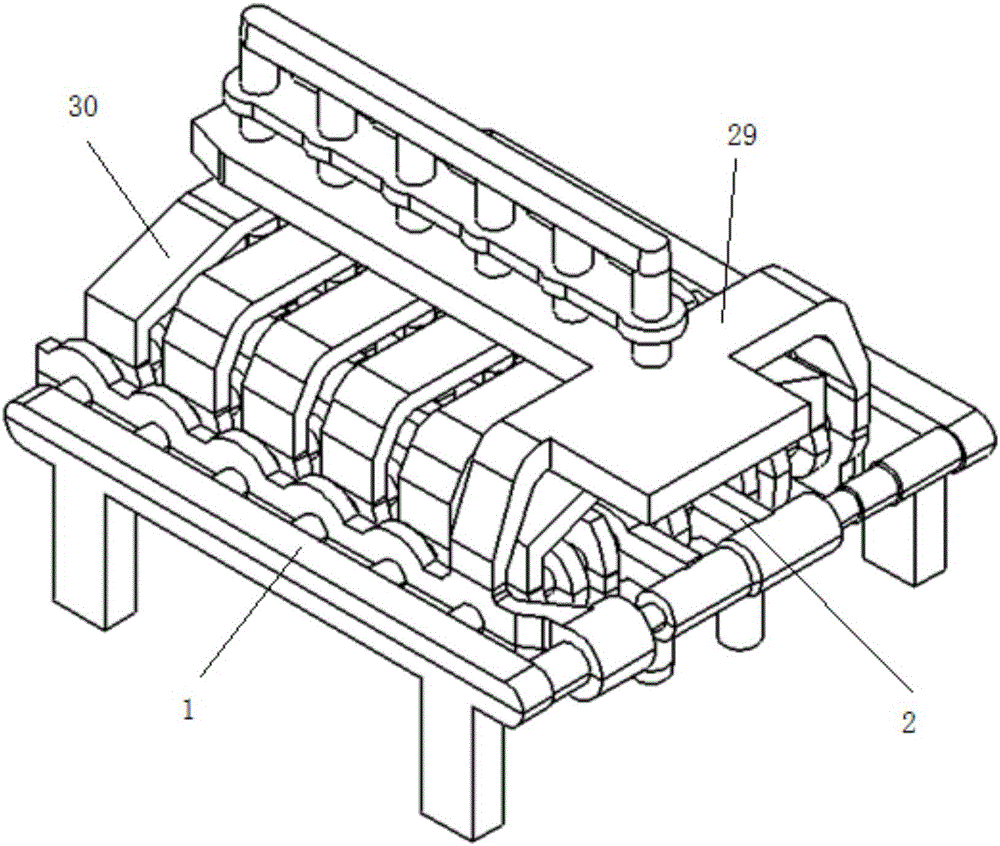

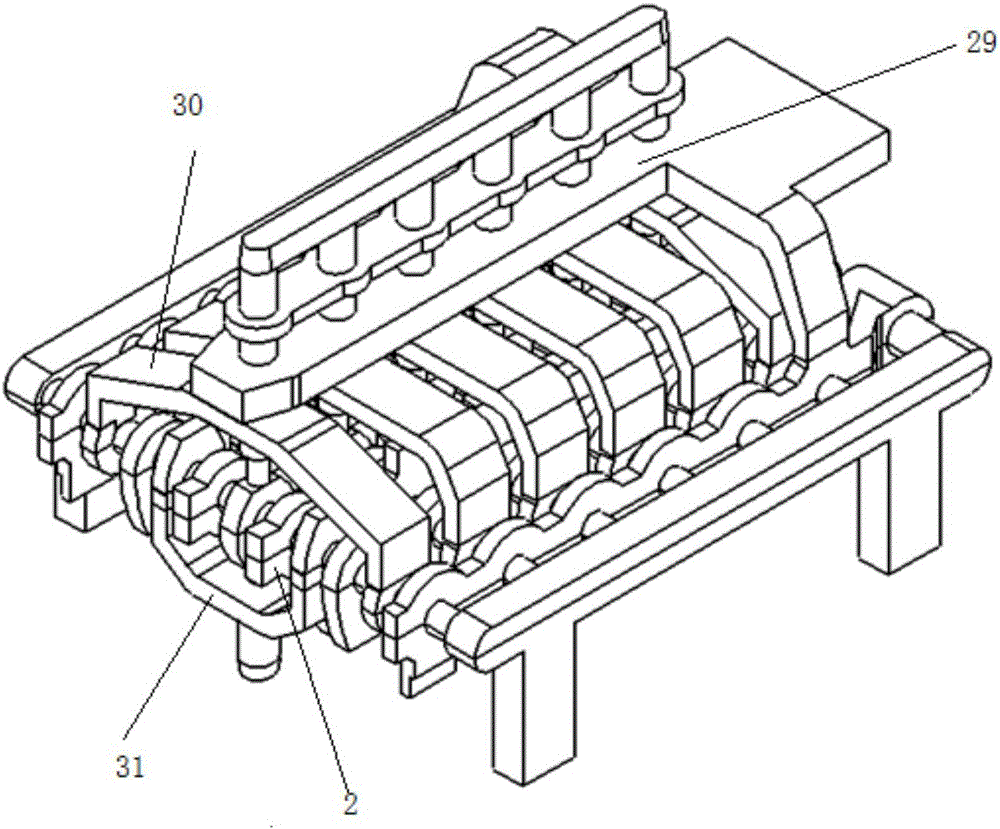

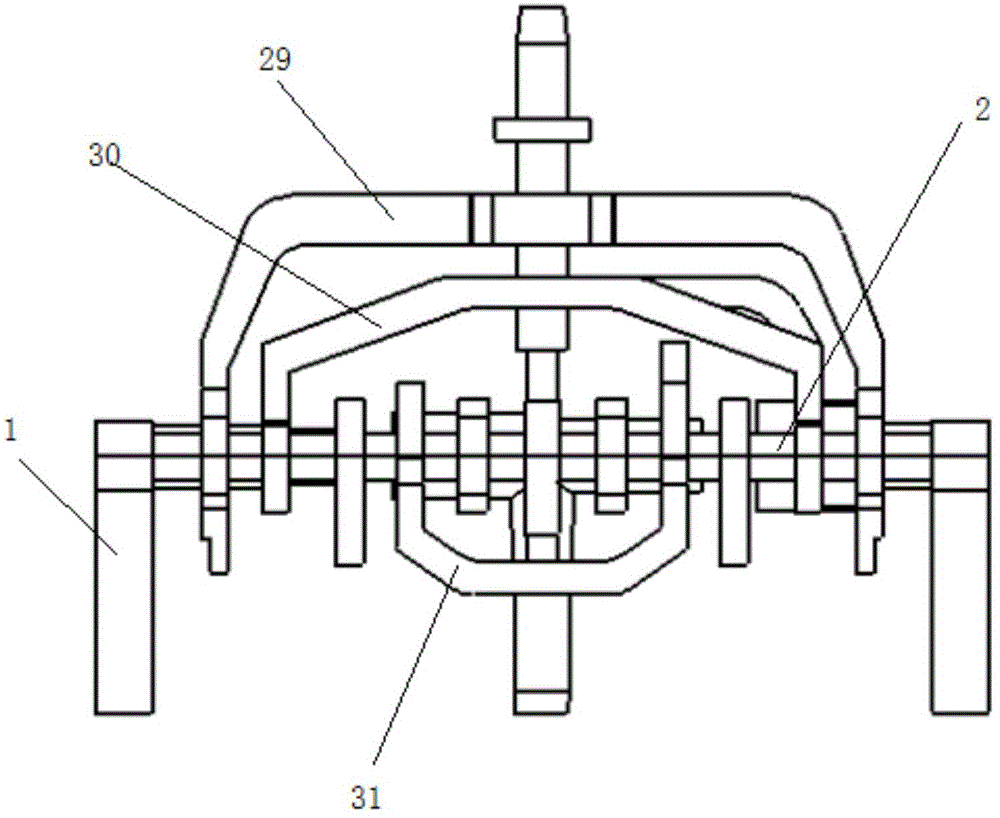

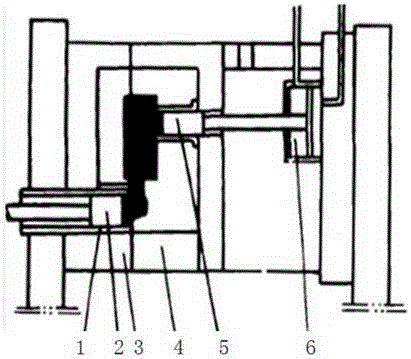

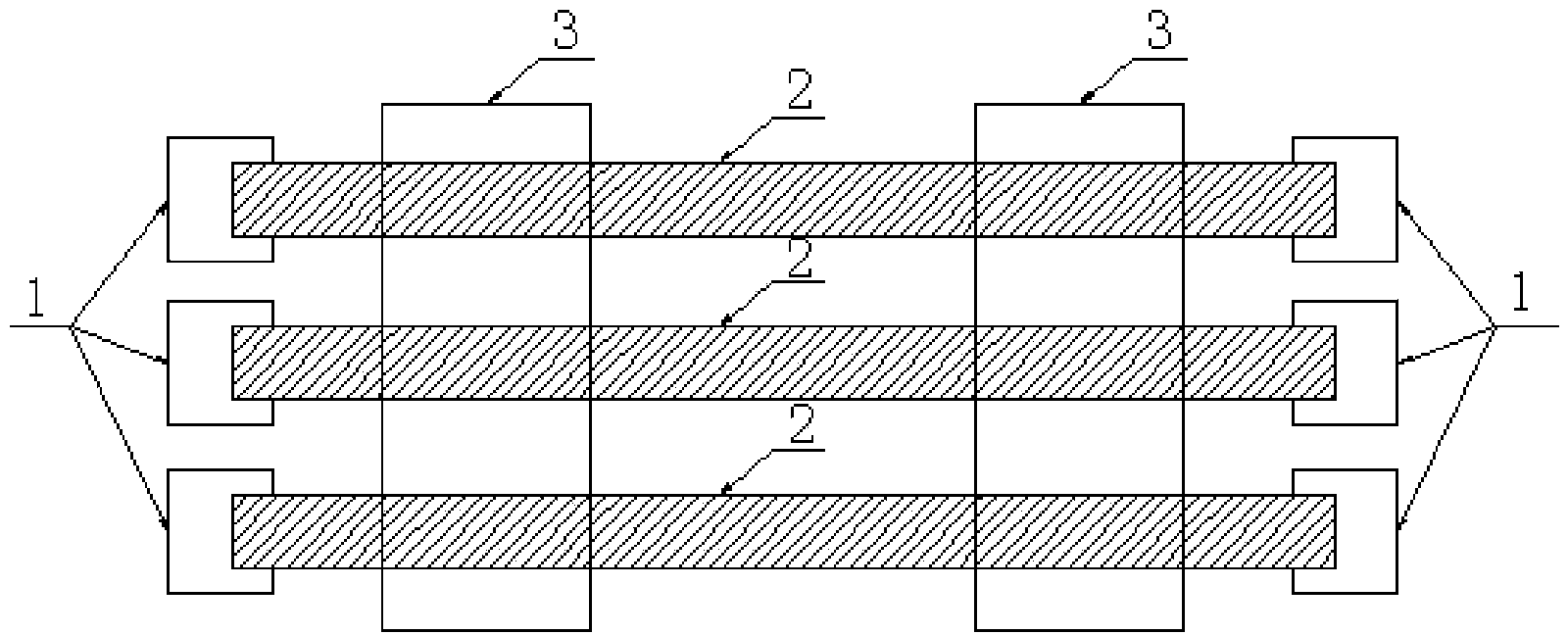

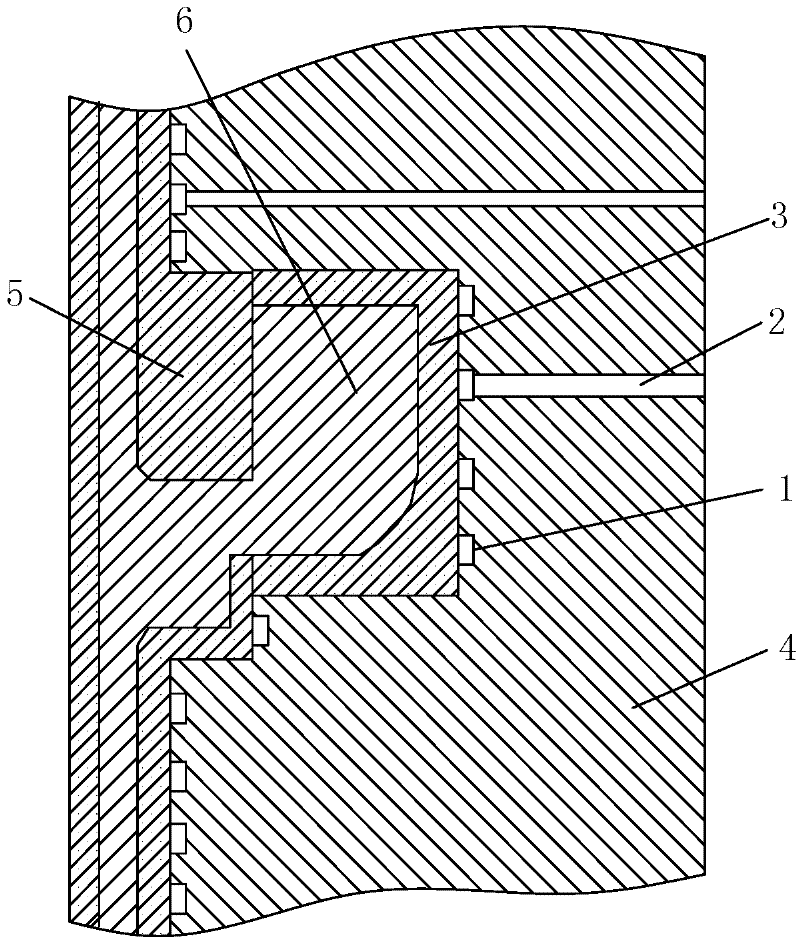

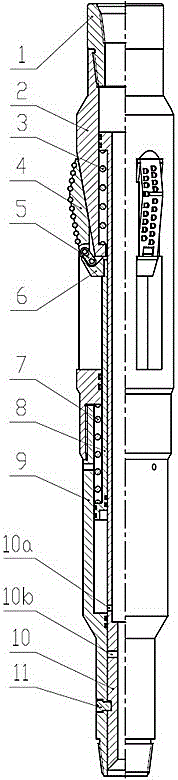

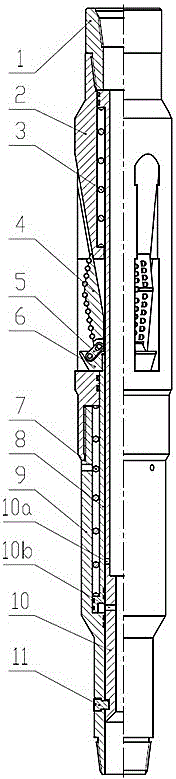

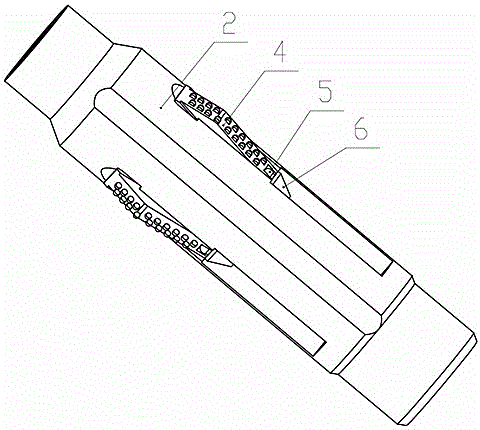

Loose-soft rock soil stratum reverse circulation casing-following drilling tool and drilling process

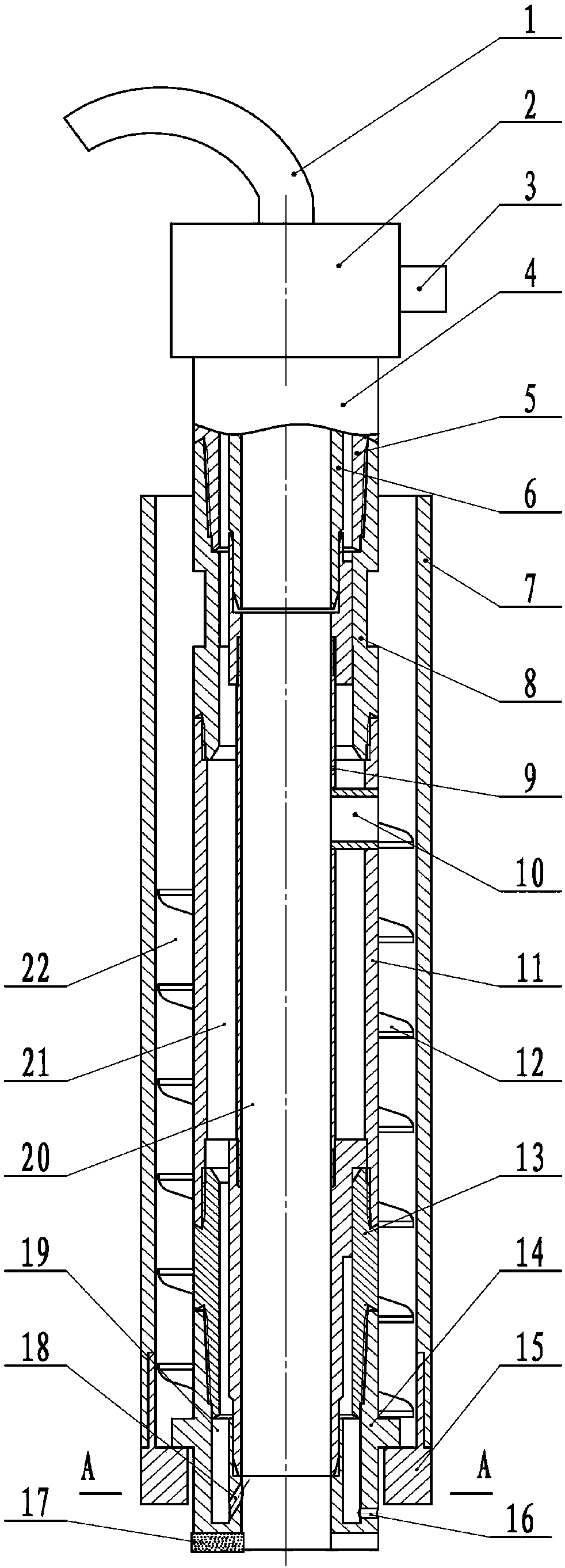

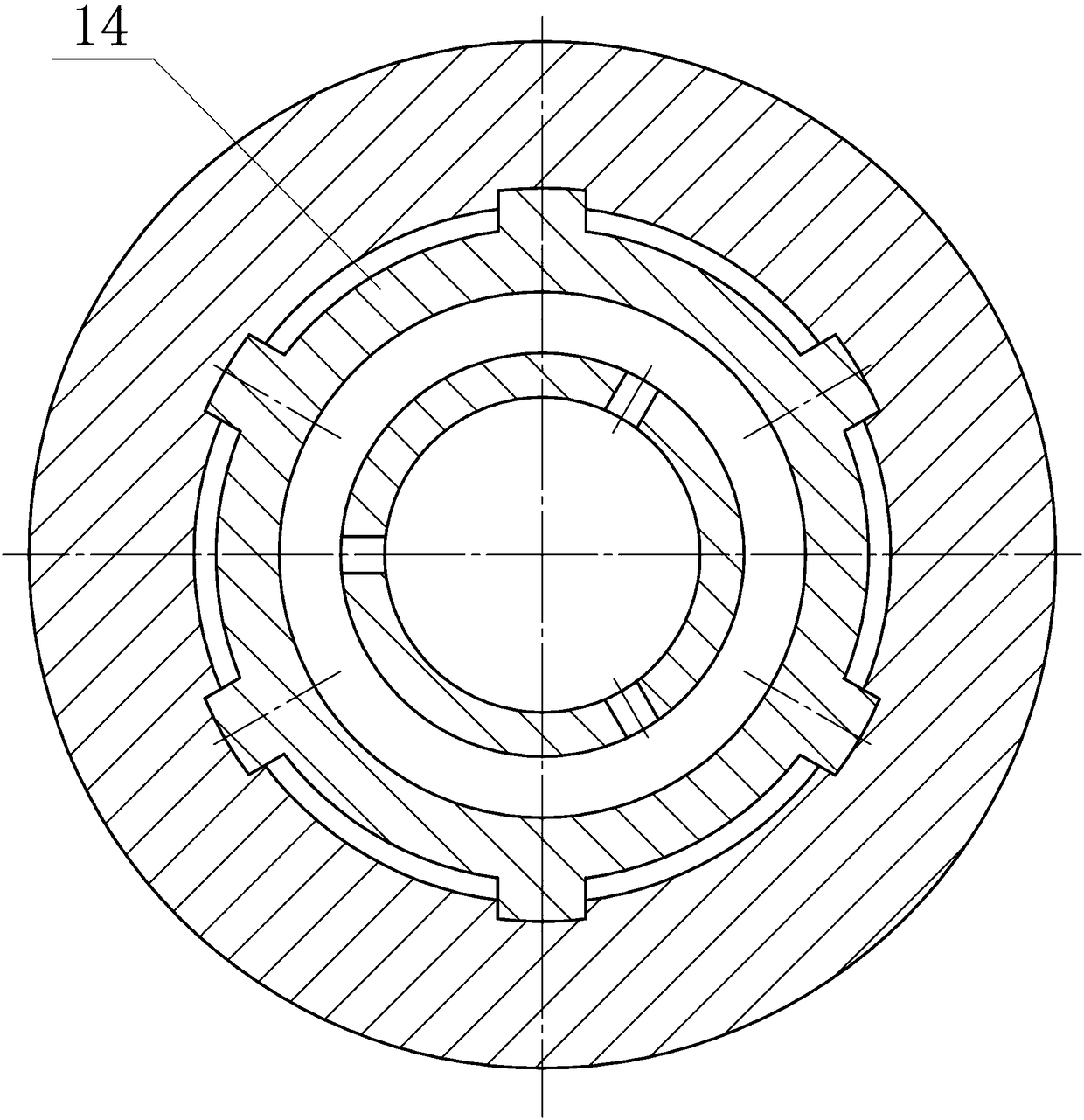

PendingCN108086930AImprove migration efficiencyImprove connection strengthDrilling rodsConstructionsAugerHelical blade

The invention discloses a loose-soft rock soil stratum reverse circulation casing-following drilling tool and a drilling process. The drilling tool is of a coaxial three-passage structure and comprises a double-wall drilling stem, an auger stem, a drilling bit, a casing and a casing shoe, a central hole of an inner tube of the double-wall drilling stem and a central hole of an inner tube of the auger stem form a slag discharging passage, an annular gap between the inner tube of the auger stem and an outer tube of the auger stem forms an air incoming passage, and an annular gap between the outer tube of the auger stem and the casing forms an outer ring passage; compressed air enters the drilling bit through the air incoming passage and then is diverted and used for assisting a cutting bladeto break a stratum and realize reverse circulation deslagging. Drillings suspended in the outer ring passage go up along spiral blades, enters a deslagging passage through a deslagging window and then returns to the ground surface. Reverse circulation deslagging through a fluid medium and deslagging assisted by the spiral blades are adopted in the process of drilling, so that casing-following drilling is realized to protect hole walls, the problems of bit burying and difficulty in deslagging and hole forming in the process of loose-soft rock soil drilling can be solved, and integration of drilling, collapse preventing, dedusting and wall protecting is realized.

Owner:JILIN UNIV

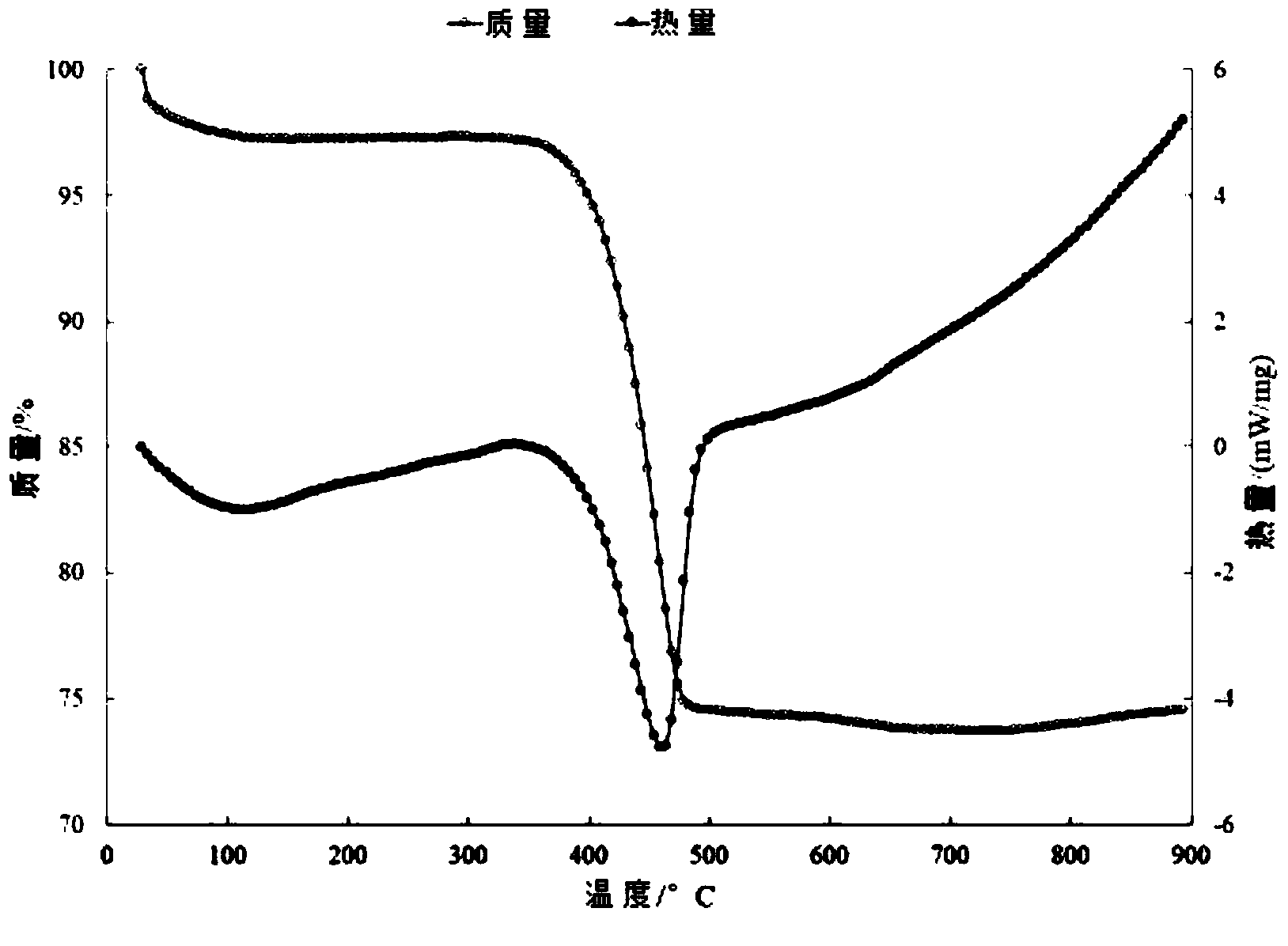

Curing agent capable of rapidly curing sludge at room temperature and use method thereof

The invention discloses a curing agent capable of rapidly curing sludge at room temperature and a use method thereof. The curing agent is prepared from, by weight, 48%-70% of inorganic micro powder, 28%-50% of emulsion, 0.05%-1.8% of high-performance water-absorbent resin and 0.05%-0.5% of triethanolamine. The emulsion can react with the inorganic micro powder and activated silicon dioxide and aluminum oxide in the sludge to form a zeolite-like crystalline substance of a silicon (aluminum)-oxygen tetrahedron structure. The sludge curing agent is capable of improving the curing strength of the sludge and shortening the curing time, small in air shrinkage and good in water resistance, and dosing of materials can be particularly adjusted according to components of the sludge, so that curing of the sludge is not limited by time, the strength, the stability and the like meet the actual engineering requirements, the cost is low, pollution does not exist, and the curing agent can be widely applied and promoted.

Owner:GUANGZHOU INSTITUTE OF BUILDING SCIENCE CO LTD

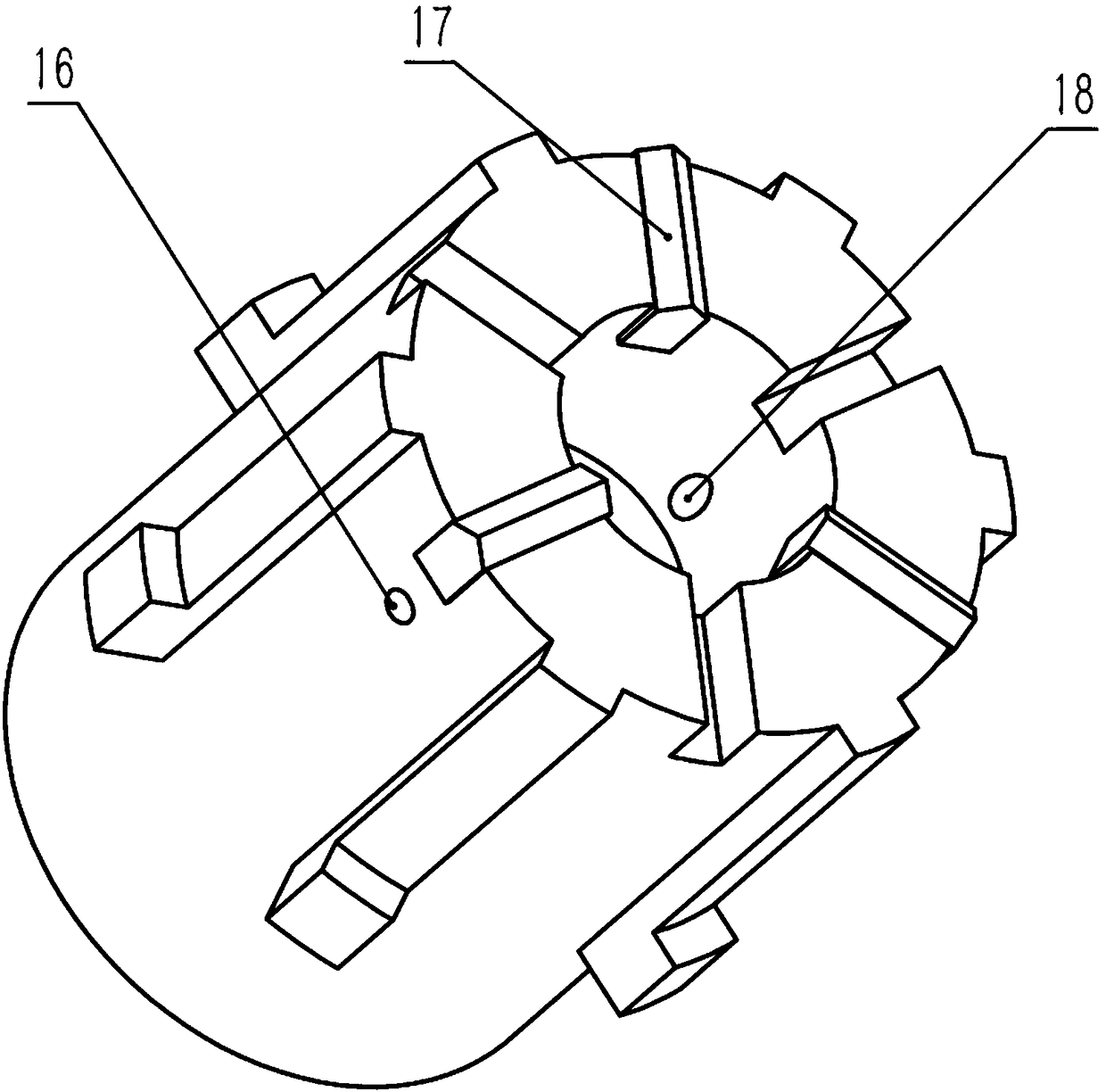

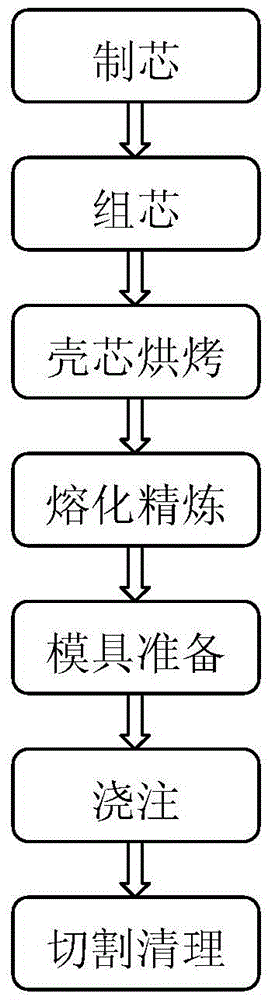

Casting method of turbine housing

ActiveCN105458182AIncrease productivityEffective control of solidification sequenceFoundry mouldsFoundry coresSlagTurbine

The invention provides a casting method of a turbine housing. The casting method includes the following steps of firstly, core manufacturing, secondly, core assembly, thirdly, shell core baking, fourthly, smelting and refining, fifthly, mold preparation, sixthly, casting and seventhly cutting and cleaning. In the core manufacturing process, a riser sand core mold is arranged on a core shooting machine, the core shooting machine is powered on to heat the mold, a layer of precoated sand is cured on a cavity of the riser sand core mold, and a riser sand core is obtained after mold opening. In the core assembly process, the riser sand core and a turbine housing core are assembled and bonded. In the shell core baking process, shell cores painted with coatings are put into a baking kiln. In the smelting and refining process, raw materials are added to a melting and heat preservation furnace, and the melting and heat preservation furnace is powered on for melting. In the casting process, the shell cores are put in a mold, and tilt casting is conducted after mold combination. In the cutting and cleaning process, a casting is cut, the riser is cast, and burrs and fins of the casting are ground and cleaned. The metal tilt casting method of an aluminum alloy turbine housing body can solves the problems of shrinkage porosities and cavities and slag holes in a big flange face of the aluminum alloy turbine housing; open risers and blind risers are arranged, in combination with the riser sand core, an ideal temperature field is formed after the casting is cast, and solidification can be conducted from the casting to the risers in sequence.

Owner:XIAN AERO ENGINE CONTROLS

Die casting technology for shrinkage-prevention die casting

InactiveCN105817599AIncrease fullnessSolve shrinkage cavity, shrinkage porosityPush outShrinkage porosity

The invention discloses a die-casting process for anti-shrinkage cavity die-casting parts. The die-casting method comprises the following steps: starting the die-casting machine → installing the mold → debugging the mold → cleaning the preheated mold → spraying paint → closing the movable mold and the fixed mold → pouring →holding pressure→feeding and compaction→pressurization→separation of movable mold and fixed mold→push out the die casting→cut off the riser and gate on the die casting→saturate the die casting→surface the die casting. The die-casting process of this kind of anti-shrinkage cavity die-casting effectively solves the problems of product shrinkage and porosity, and finally obtains dense and intact parts, reducing the defective rate.

Owner:安徽纯启动力科技有限公司

Modified glutinous rice mortar for perfusion and preparation method of modified glutinous rice mortar

The invention discloses modified glutinous rice mortar for perfusion and a preparation method of the modified glutinous rice mortar. The glutinous rice mortar comprises the following raw materials in parts by weight: 100 parts of calcium hydroxide powder, 220-400 parts of calcium carbonate particles, 5-54 parts of metakaolin, 5-18 parts of pre-gelatinized glutinous rice powder, 0.5-1.5 parts of a water-reducing agent and 80-150 parts of water. By adopting the modified glutinous rice mortar for perfusion, the problems of complicated preparation process, slow curing, great shrinkage and relatively low strength of traditional glutinous rice mortar are solved and a novel grouting and reinforcing material is provided for protection and maintenance of heritage.

Owner:ZHEJIANG UNIV

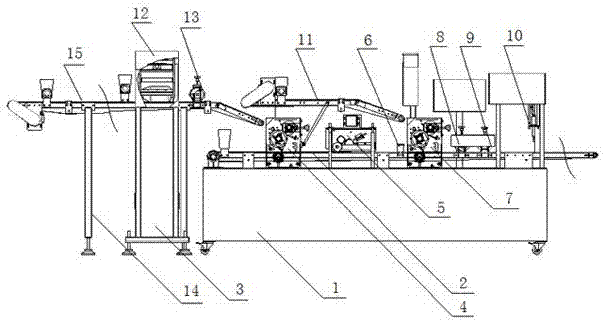

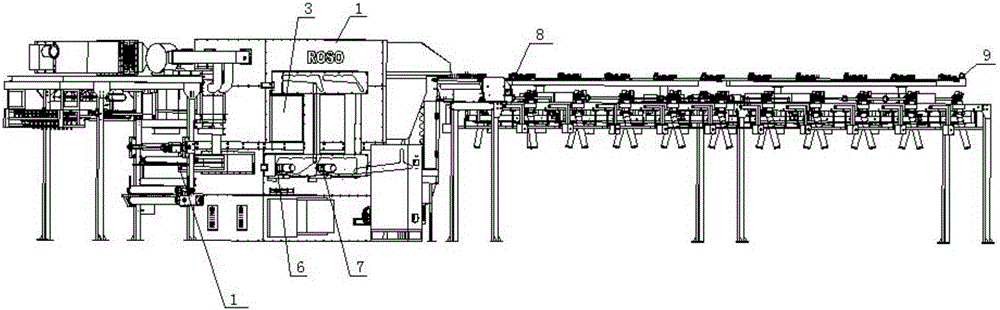

Double-layer fried bread stick machine and method of making fried bread sticks

ActiveCN107439626AEasy to startMeet size requirementsOil/fat bakingDough shaping and dividing combinationEngineeringConveyor belt

The invention discloses a double-layer fried bread stick machine. The method comprises a rack and a conveyor belt mounted on the rack, a front dough feeding mechanism located in a material feeding end of the conveyor belt, and a first dough pressing mechanism, an oil brushing mechanism, a water brushing mechanism, a second dough pressing mechanism, a round cutter mechanism, a medium press roller mechanism, a cutting table mechanism which are arranged from the material feeding end to a material discharging end; a rear dough feeding mechanism is located on the conveyor belt, and the output end of the rear dough feeding mechanism is located at an input end of the second dough pressing mechanism; a dough rolling mechanism and a three circular cutter mechanism are at least arranged on the front dough feeding mechanism. According to the double-layer fried bread stick machine, imitating manual rolling of the fried bread stick dough can be achieved; through brushing oil and water alternately, the edges of the fried bread sticks can rise easily when fried, the middle connections are good and do not explode, so that two layers of fried bread sticks stick well together, and it is not possible to cause dough stickiness for the fried bread sticks; the rising effect is good, it is ensured that the yield of finished products is 100%, the appearance is beautiful, the prepared double layer fried bread sticks are fed into a frying pan mechanism automatically, and the degree of automation is higher.

Owner:SUZHOU GUOEN FOOD MACHINERY

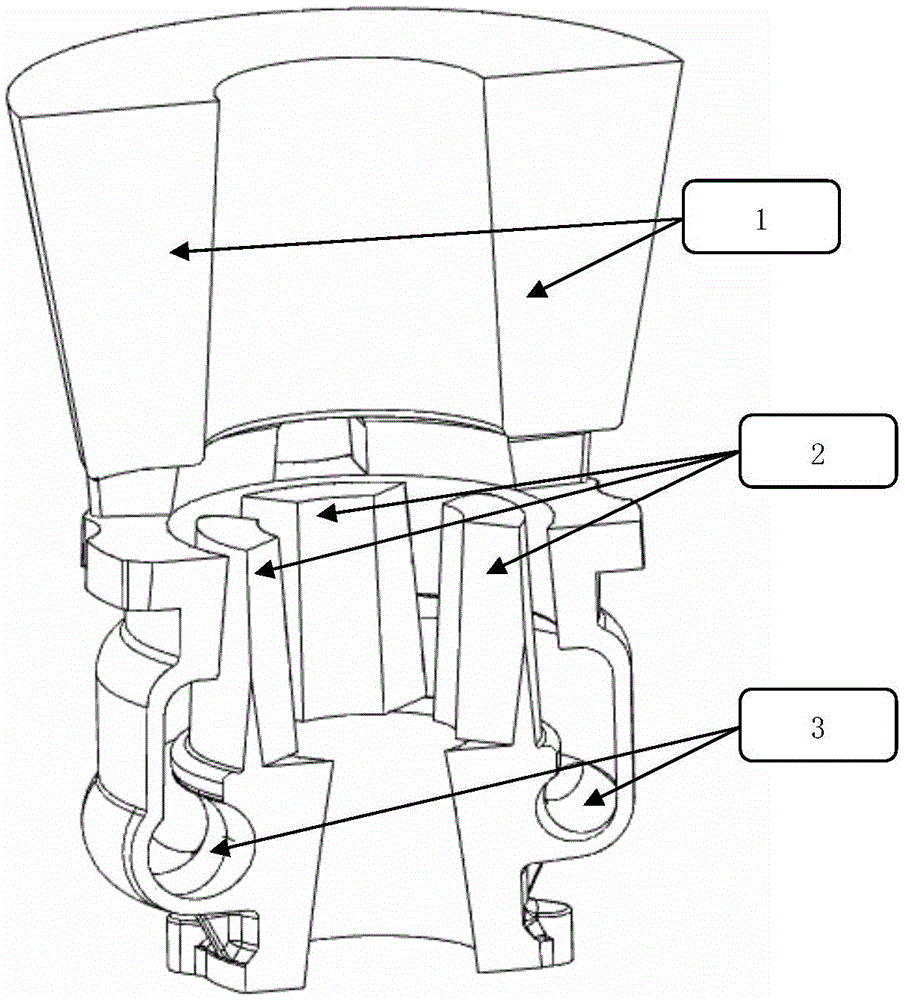

Precision casting process of high-temperature alloy turbine

InactiveCN110181001ALow shrinkageSolve Oxidation ProblemsFoundry mouldsFoundry coresPorosityAviation

The invention belongs to the technical field of aviation precision casting, and particularly relates to a precision casting process of a high-temperature alloy turbine. The precision casting process of the high-temperature alloy turbine comprises the following steps of designing and manufacturing a part mold, preparing a ceramic core, preparation of a shell slurry, preparation of a part shell, dewaxing of a shell, pre-roasting of the shell and casting of the part, wherein the part mold is designed to ensure the integral punching of a wax mold by adopting a bottom injection type design. An inner cavity of the part is filled with the ceramic core, the ceramic core is an aluminum-based ceramic coated with cobalt aluminate on the surface, the surface of the inner cavity of the part can be effectively reduced by coating the surface of the ceramic core with cobalt aluminate, so that the problems of oxidation and shrinkage in the inner cavity of a traditional casting process casting are successfully solved, and meanwhile, the high porosity can ensure that the ceramic core can be removed by a high-pressure water gun after being poured.

Owner:鹰普航空科技有限公司

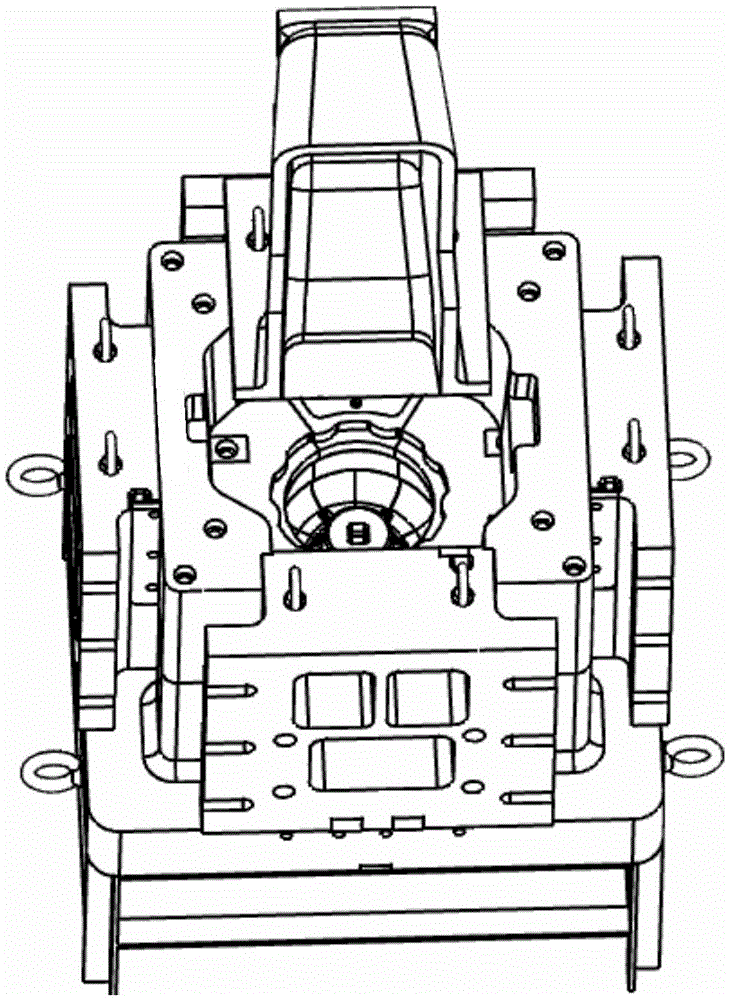

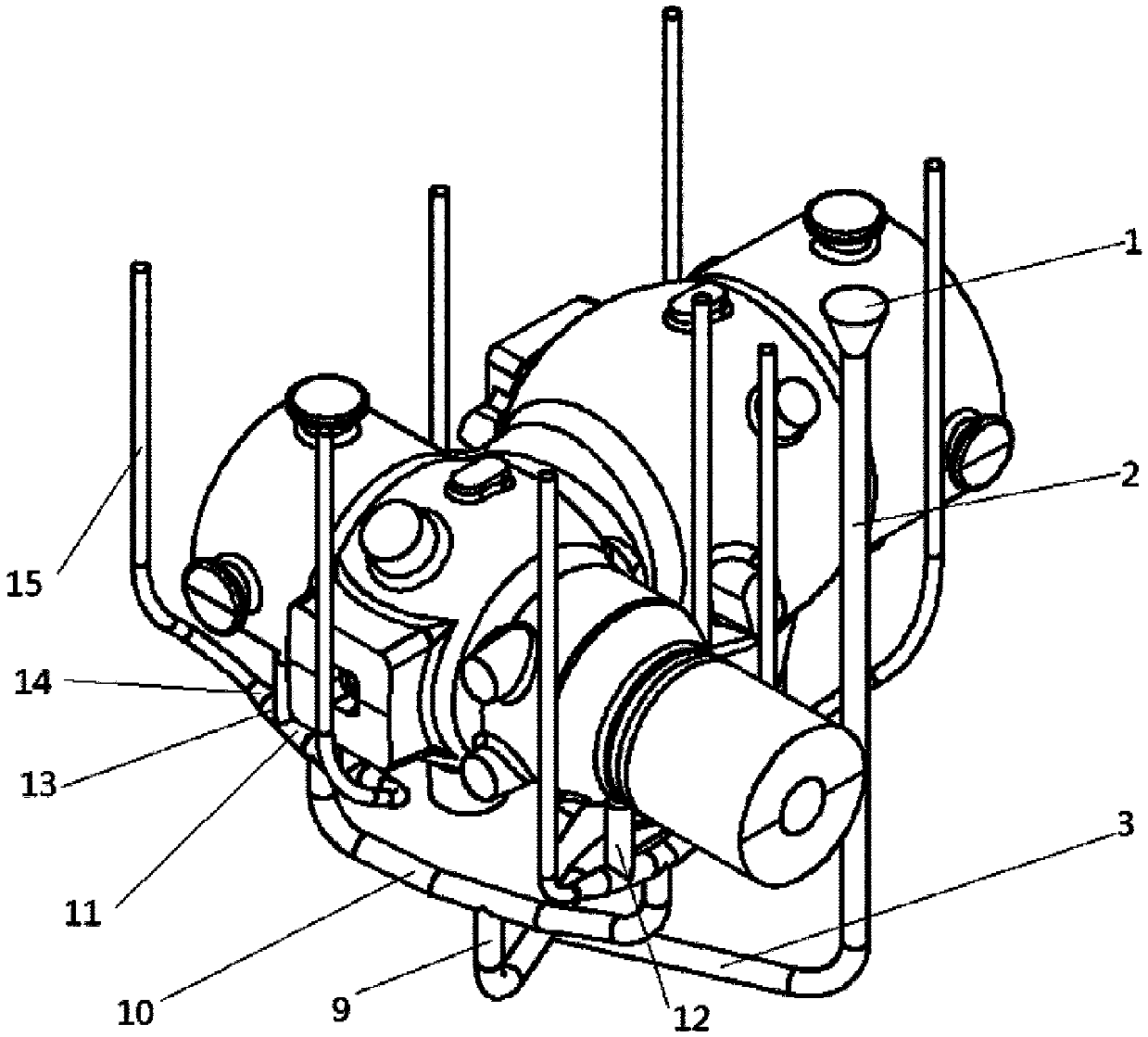

Large-duty loader hydraulic valve body casting mold and manufacturing method

ActiveCN105772646ACompact and reasonable structureStrong reliabilityFoundry mouldsFoundry coresCasting moldCasting defect

The invention discloses a large-duty loader hydraulic valve body casting mold. The large-duty loader hydraulic valve body casting mold comprises an upper shell mold body, a lower shell mold body, a sand core and a pouring and riser system. The sand core comprises a core head, a main core body and small core bodies. The main core body is composed of seven longitudinal arbors and four transverse arbors, and the longitudinal arbors and the transverse arbors are horizontally arranged in the same plane. The main core is provided with a plurality of convex blocks. Installation grooves are formed in the convex blocks. The small core bodies are fixed to the main core body through the installation grooves. The pouring and riser system comprises two exothermic and insulating risers with the diameter being 90 mm and the height being 120 mm. The large-duty loader hydraulic valve body casting mold has the advantages of being reasonable and compact in structure, high in reliability and convenient to assemble and cast, the straightness of a blank casted through a main valve hole is controlled to be smaller than 0.8 mm, assembly errors of a complex sand core are avoided, the casting defects of shrinkage cavities, shrinkage porosity, internal pores and the like of a casting piece are overcome, and the compactness of the internal structure is improved, so that leakage is avoided under a high-pressure working condition with the rated pressure being larger than or equal to 35 Mpa; and the casting qualified rate is improved greatly, and the casting cost is reduced.

Owner:NANTONG ENMAI PRECISION MACHINERY SCI & TECH CO LTD

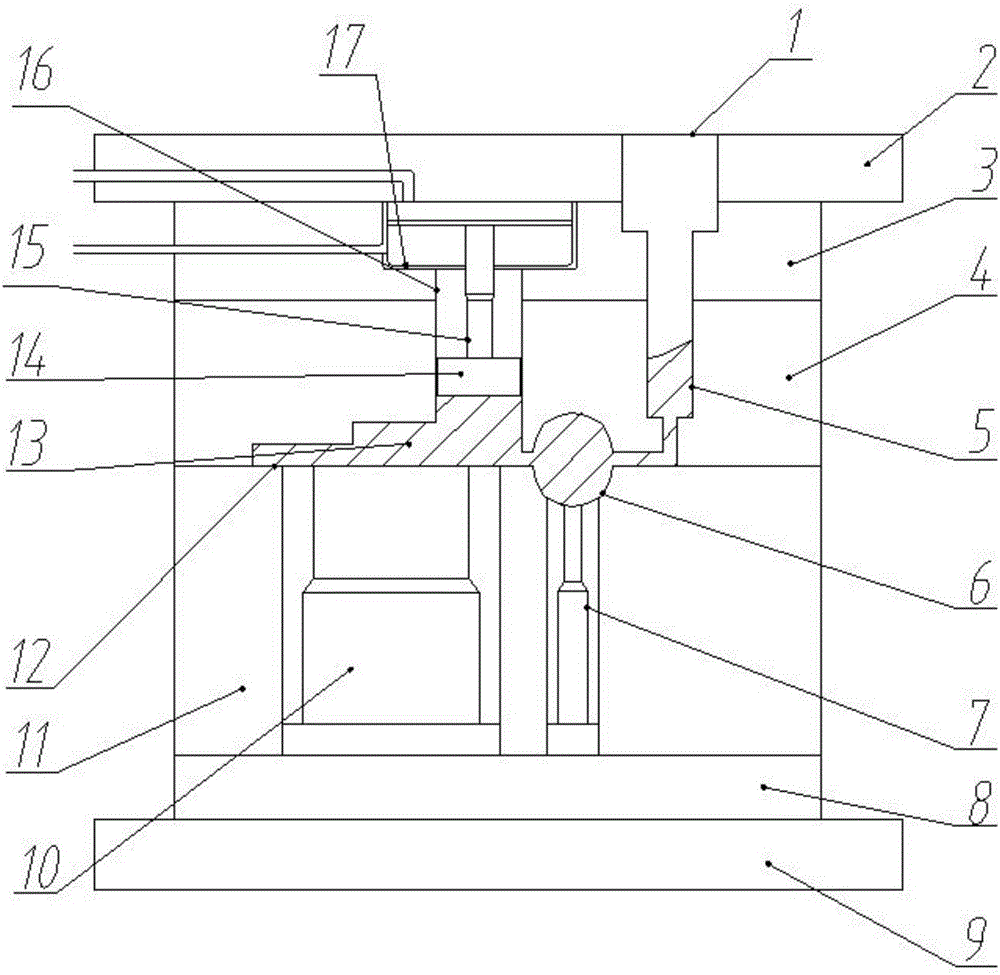

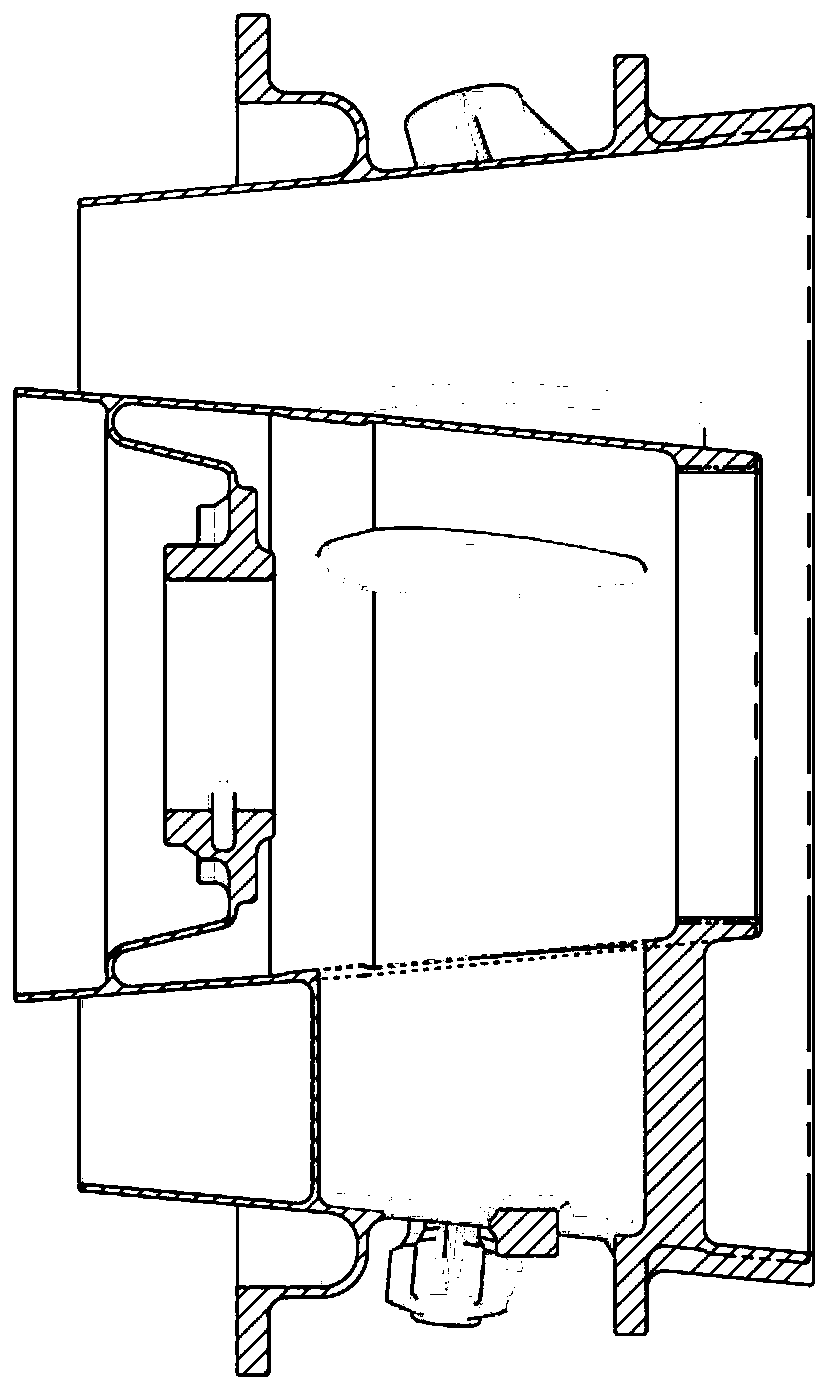

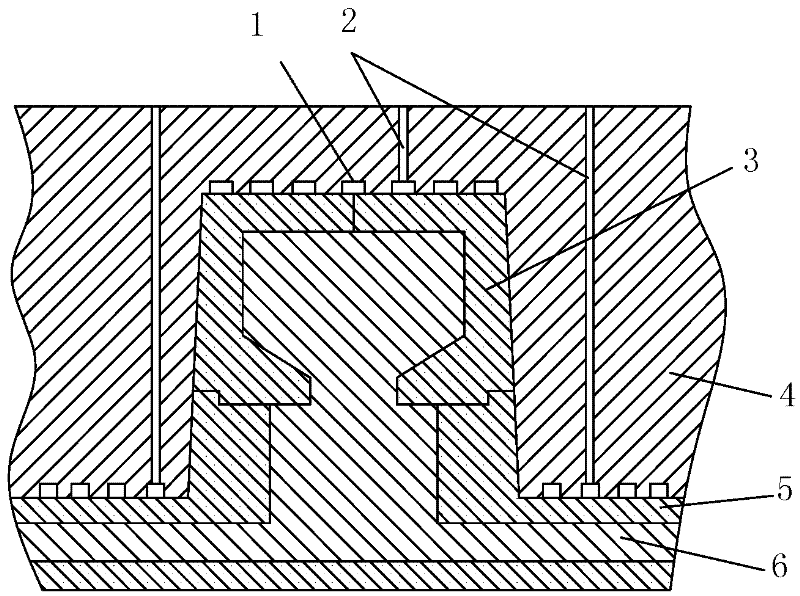

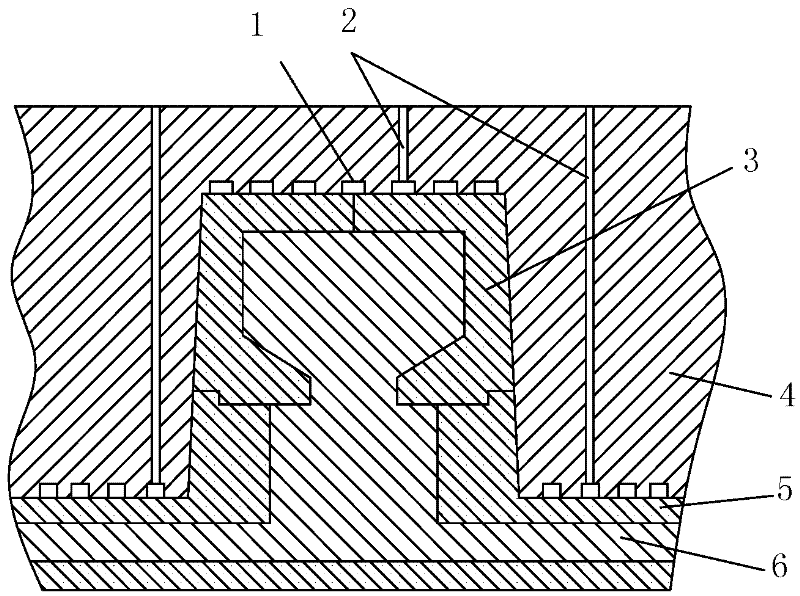

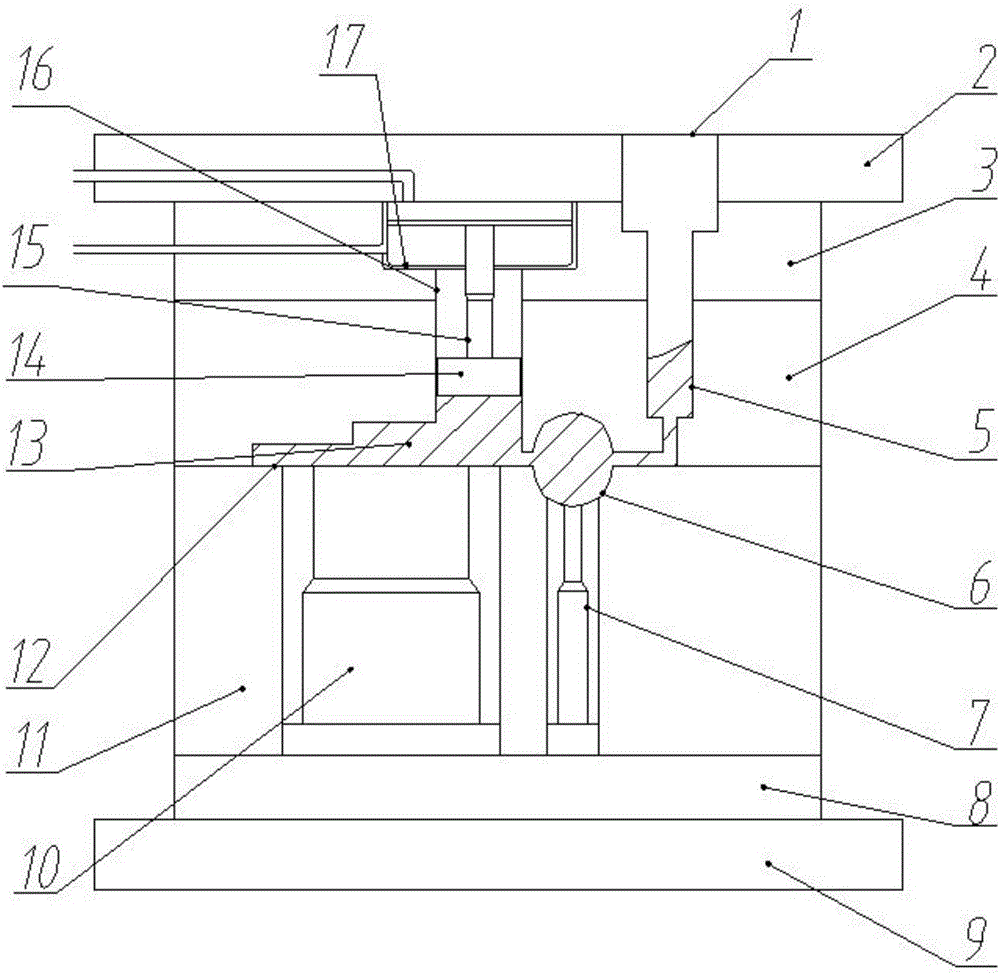

Cavity-shrinkage-prevention die-casting mold of aluminum alloy component

The invention discloses a cavity-shrinkage-prevention die-casting mold of an aluminum alloy component. The die-casting mold comprises a fixed mold body and a movable mold body, wherein the fixed mold body and the movable mold body are oppositely arranged; a cavity corresponding to the aluminum alloy component is formed at the combining position of the fixed mold body and the movable mold body; an extrusion hole communicated with the cavity is formed in the movable mold body, and an extrusion pin is arranged in the extrusion hole; and a pressing chamber connected with the cavity is arranged on the fixed mold body, and a punch for die casting is arranged in the pressing chamber. By means of the manner, according to the cavity-shrinkage-prevention die-casting mold of the aluminum alloy component, on the basis of the principle of shrinkage cavity and shrinkage porosity generation, the extrusion pin is arranged at the position, located at the position with the large product wall thickness, of the movable mold body, and in the die-casting molding process, the aluminum alloy is solidified into the semi-solid state from the liquid state; and the extrusion pin carries out extrusion towards the product wall-thickness position, the feeding and compaction effect is achieved, the problems of product cavity shrinkage and shrinkage porosity are effectively solved, and the product quality is improved.

Owner:江苏宏马科技股份有限公司

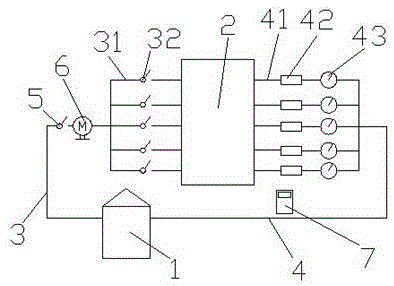

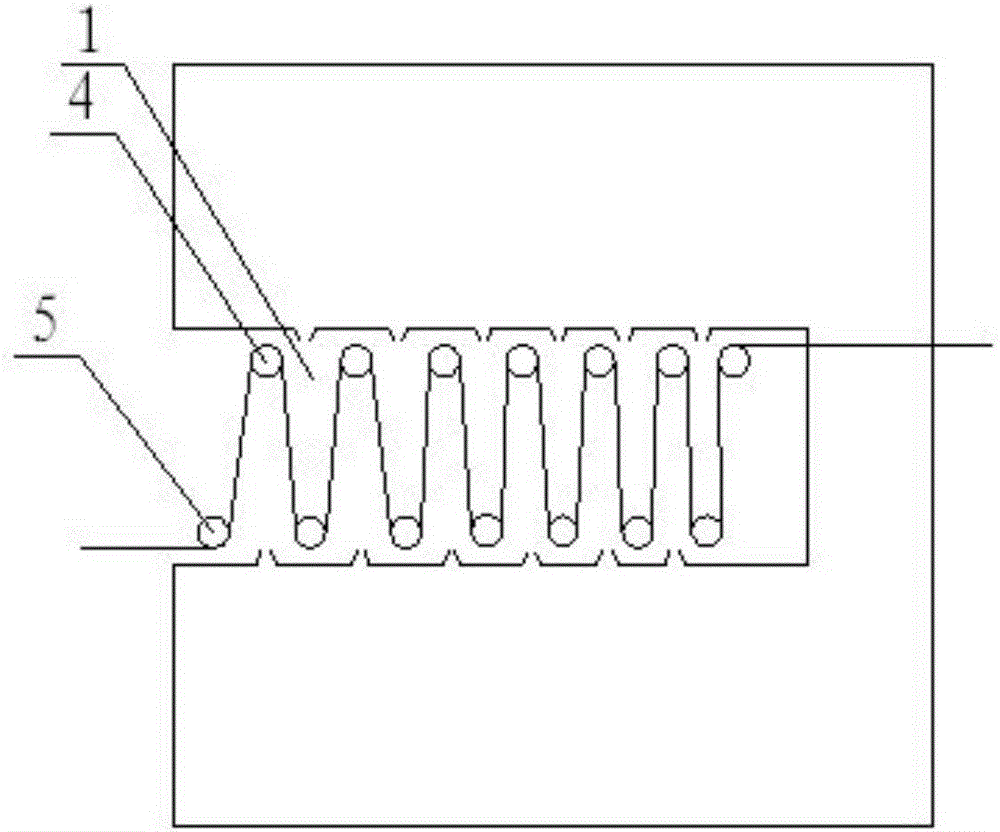

Die-casting die circulation cooling system

The invention discloses a die-casting die circulation cooling system, comprising a die-casting die, a cooling water tower, a water supplying pipeline and a water returning pipelines; a plurality of cooling water channels are formed in the die-casting die; the water inlet ends of the cooling water channels are provided with a plurality of water inlet pipes; the water outlet ends of the cooling water channels are provided with a plurality of water outlet pipes corresponding to the water inlet pipes respectively; the water supplying pipeline is connected between a water supply end port and the tail ends of the water inlet pipes; the water returning pipeline is connected between a water returning end port of the cooling water tower and the tail ends of the water outlet pipes. The die-casting die circulation cooling system also comprises infrared die temperature measuring equipment. Through the mode, the die-casting die circulation cooling system specifically performs flow regulation on each cooling water loop, thus improving the pertinence and balance of die temperature control, improving product quality and greatly prolonging the service life of a die-casting die.

Owner:江苏宏马科技股份有限公司

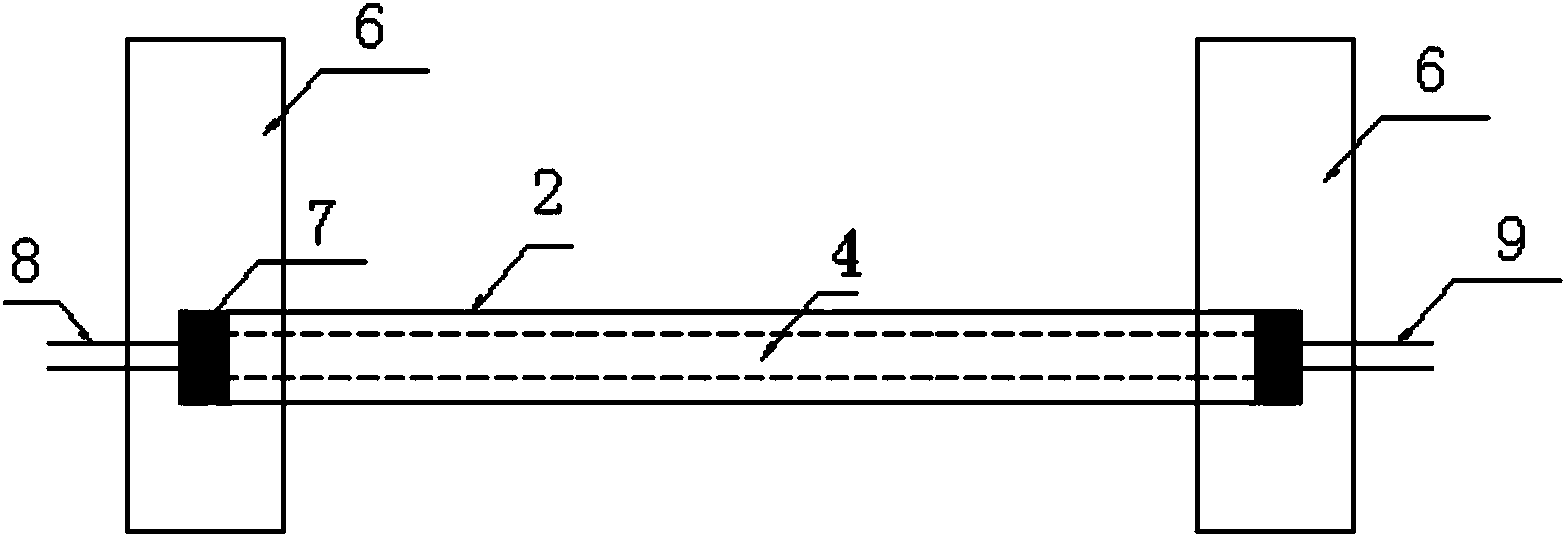

Casting method of sand core oil tube of internal combustion engine

ActiveCN104070135ASolve sticky sandSolve shrinkageFoundry mouldsFoundry coresInternal combustion engineRejection rate

The invention relates to a casting method, and particularly relates to a casting method of a sand core oil tube of an internal combustion engine. The casting method comprises the steps of molding, core making, mold assembling and casting. The casting method is characterized in that in the core making process, an oil tube sand core is adopted to position, i.e. the oil tube sand core passes through all inner cavity cores, so as to determine the position of an oil tube by positioning outer mold core heads on both sides, a steel tube is selected as core iron, and chromite sand is used as raw materials of the oil tube core; in the mold assembling process, the oil tube sand core is prevented from being bent and deformed, i.e. ends are additionally arranged, a mold shrinkage joint disappears, forced cooling is performed by blowing compressed air, and a special leakproof chaplet is additionally arranged in the position of the oil tube in the mold assembling process. The casting method has the advantage of unique process, the casting quality can be increased, and the product rejection rate can be reduced.

Owner:KOCEL EQUIP

Metal type covered shell casting mold and casting method thereof

InactiveCN102389945AIncrease roughnessHigh dimensional accuracyFoundry mouldsFoundry coresCasting moldSuperalloy

The invention discloses a metal type covered shell casting mold comprising a metal type body. At leas tone layer of resin sand shell is arranged in the metal type body; the outer surface of the resin sand shell is attached to the inner surface of the metal type body; and an inner pouring cavity anastomotic with a casting piece in shape is arranged in the resin sand shell. The metal type shell casting mold not only is applicable to the pouring of low-temperature alloy, but also can be improved to be applicable to the pouring of a high-temperature alloy material by adopting the resin sand shell, and realizes the continuous production of multiple molds, thereby improving the production efficiency, and solving the problem of not being applicable to thin castings with large areas due to the quickly fast radiating of metal.

Owner:陈显鹏

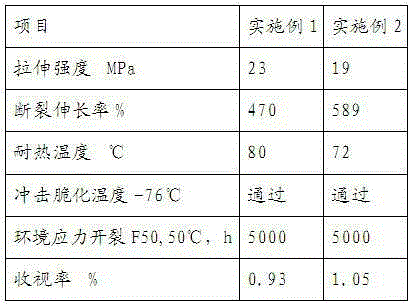

Cracking resistance modified polyethylene material and preparation method therefor

InactiveCN105237853AFormula refiningSolve the problem of poor environmental cracking resistanceLinear low-density polyethyleneElastomer

The invention discloses a cracking resistance modified polyethylene material and a preparation method therefor. The cracking resistance modified polyethylene material is prepared from linear low-density polyethylene, high-density polyethylene, POE (Polyolefin Elastomer) and modified masterbatch. Through polyethylene material modification and a micro cross-linking technology, the problem that polyethylene outer layers of composite metal plastic pipes crack is solved.

Owner:山东融汇管通股份有限公司

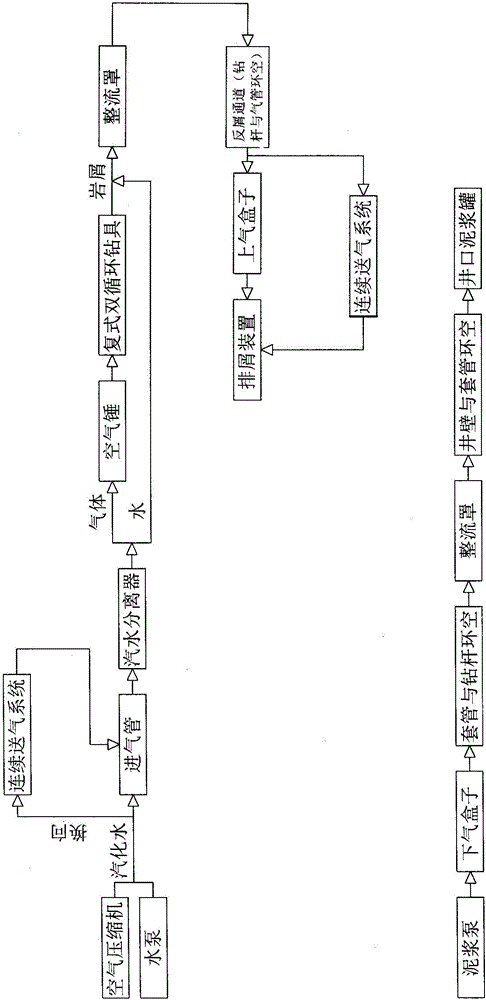

Compound double-circulation under-balanced casing pipe while-drilling drilling technology

ActiveCN104453716APrevent landslidesAvoid problems such as stuck main drill pipeConstructionsFlushingWell drillingAir compressor

The invention relates to a compound double-circulation under-balanced casing pipe while-drilling drilling technology. The compound double-circulation under-balanced casing pipe while-drilling drilling technology is characterized in that a drilling and make-a-connection drilling technology is adopted, an air compressor and a water pump are started, vaporous water in a pipeline pushes an air hammer to work through an air inlet pipe, a compound double-circulation drilling tool is driven to work, finally vaporous water is drained through a chip removal device, a slush pump is started at the same time, slush enters the annular part of a casing pipe and the annular part of a drilling rod through an air exhaust box, flows to the well wall and the annular part of the casing pipe through a fairing, upwards returns to a wellhead slush tank and circulates repeatedly, and it is ensured that pressure of the well wall is balanced; when make-a-connection is performed, a three-way valve is opened, and vaporous water formed by the air compressor and the water pump is reversed by the three-way valve, enters a continuous air supplying system and enters the air inlet pipe through the continuous air supplying system to push the air hammer to work and drive the compound double-circulation drilling tool to work. The difficult problems such as collapse, air leakage, hole shrinkage, chip off-falling, deviation control, straight hitting, water coning, drilling tool jamming and blowout in the under-balanced drilling process are solved, and the drilling speed is greatly increased.

Owner:上海万维亿通装备制造有限公司

Casting method of complex-structure ductile iron thin-wall casting of ship turbocharger

ActiveCN102784889ABottom shrinkage improvementImprove pass rateFoundry mouldsFoundry coresTurbochargerDuctile iron

The invention relates to the casting technology of complex-structure ductile iron thin-wall castings, such as a fuel feed case, which are important parts of a ship turbocharger, and in particular relates to a casting method of a complex-structure ductile iron thin-wall casting of the ship turbocharger. The casting method includes the steps of, in sequence, fabricating moulds, modeling, making a core, assembling the moulds, pouring and clearing the sand shakeout. The method is characterized in that a pouring system used in the pouring process consists of a riser runner, a chilling block, a live riser arranged on a bottom flange of the fuel feed case and a feeding head arranged at the lateral side of the bottom flange. A filter screen is arranged on the pouring system. With the casting method disclosed by the invention, the defect of shrinkage porosity of the bottom flange of the fuel feed case is solved, the conventional idea of changing the entire cast solidification sequence by increasing the number the chilling blocks is thoroughly changed, the problem of shrinkage porosity at the bottoms of the castings is completely improved by adopting the new feeding scheme, the percent of pass of the castings is improved, and regular batch production of the castings is ensured.

Owner:KOCEL EQUIP

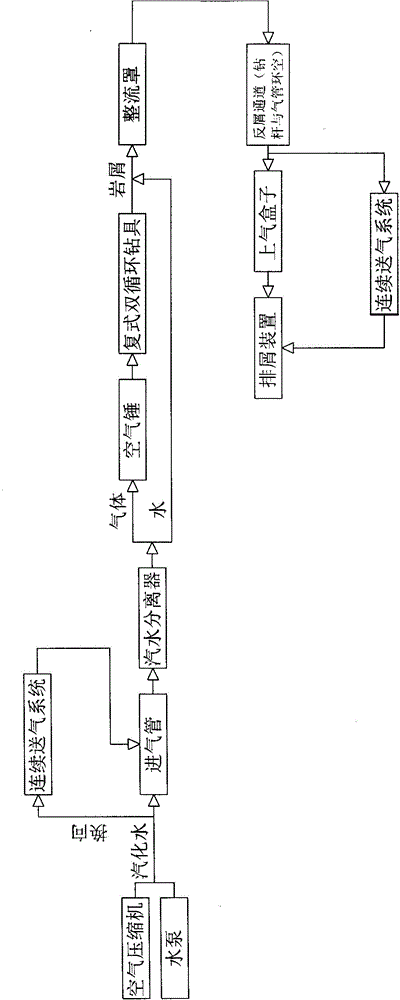

Duplex double-circulating under-balanced drilling technology

ActiveCN104533282APrevent landslidesAvoid problems such as stuck main drill pipeDrilling rodsConstructionsWell drillingProduct gas

The invention relates to a duplex double-circulating under-balanced drilling technology. The duplex double-circulating under-balanced drilling technology is characterized by comprising the steps of drilling and making up a joint for drilling; an air compressor and a water pump are started; vaporous water generated in the pipeline enters a steam-water separator through an air inlet pipe; the separated air is used for propelling an air hammer to drive a duplex double-circulating drill to work; the separated water is mixed with rock debris generated in the work of the duplex double-circulating drill to form slurry which flows through a rectifying cover; the slurry flows through a debris returning channel formed between a drilling rod and the air inlet pipe to be returned to an upper air box and then is discharged through a debris discharging device; the step of making up the joint is that the vaporous water is reversed through a three-way valve and then enters a continuous air supply system; the vaporous water in the continuous air supply system enters a steam-water separator through the air inlet pipe; the separated air propels the air hammer to drive the duplex double-circulating drill to work. According to the technology, the separated water is mixed with the with rock debris generated in the work of the duplex double-circulating drill to form slurry which flows through the rectifying cover; the slurry flows through the debris returning channel formed between the drilling rod and the air inlet pipe to be returned to the upper air box and then the discharged through the debris discharging device.

Owner:上海万维亿通装备制造有限公司

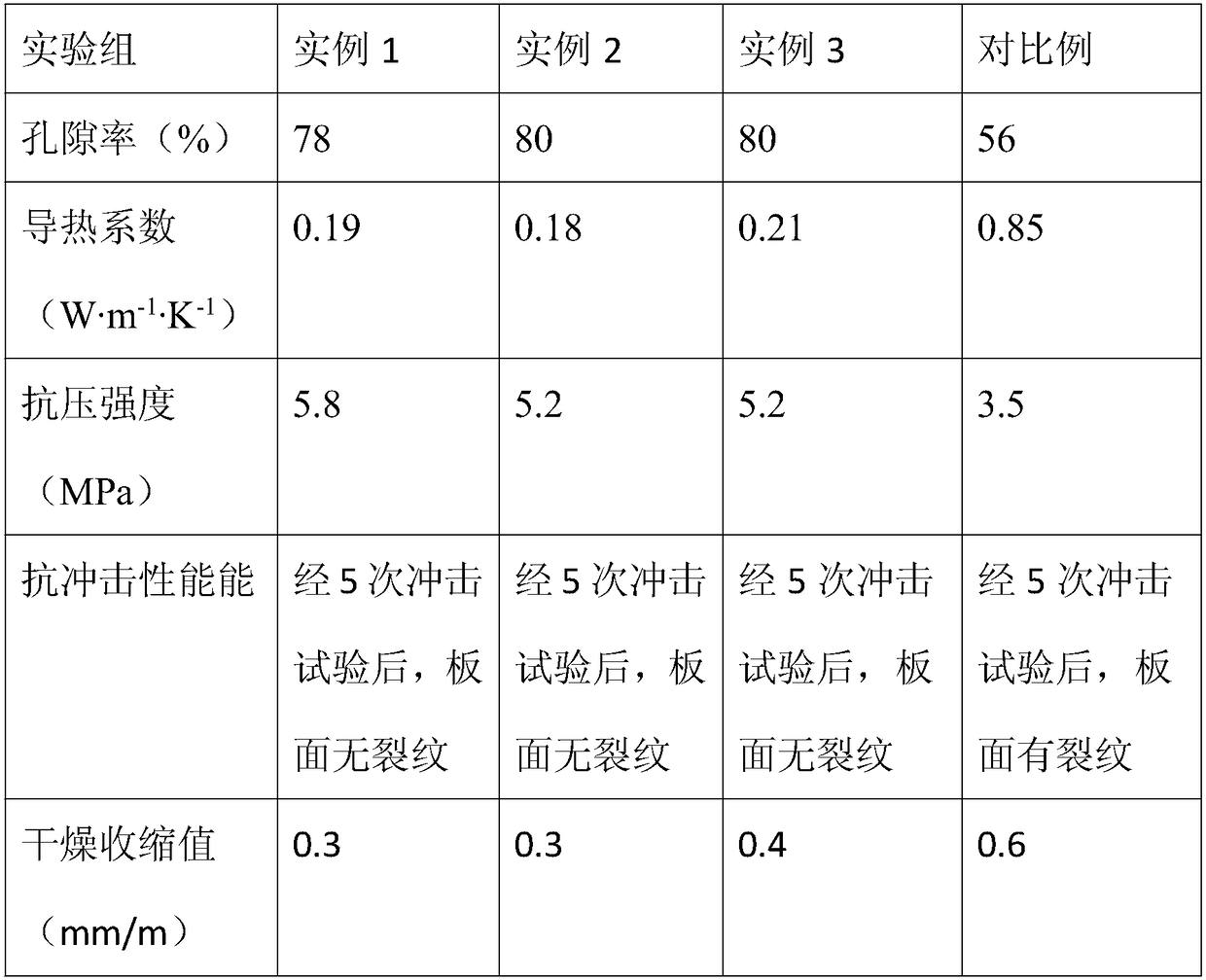

Foam concrete and preparation method thereof

InactiveCN108314365AShear stress dissipationEffective controlSolid waste managementCeramicwareFiberFoam concrete

The invention belongs to the field of building materials, and particularly relates to foam concrete and a preparation method thereof. The foam concrete is prepared from the following raw material components in parts by weight: 70-90 parts of cement, 3-5 parts of perlite, 8-10 parts of attapulgite, 5-8 parts of anti-cracking fiber expansion agent, 3-5 parts of light calcium carbonate, 5-10 parts ofactivated sludge, 4-6 parts of natural latex, 0.1-0.3 part of foaming aid, 1-3 parts of surfactant, 0.3-0.5 part of a foam stabilizer and 30-35 parts of water. The foam concrete prepared according tothe preparation method is high in volume stability, does not crack in setting and hardening, is high in water resistance and low in heat conductivity coefficient, realizes integration of light weight, high strength, heat insulation and fire protection, and belongs to an environment-friendly heat-insulated energy-saving material.

Owner:佛山杰致信息科技有限公司

Waterborne dipping paint for engineering tracks and preparation method for waterborne dipping paint

InactiveCN102241934ASolve saggingSolve shrinkageAntifouling/underwater paintsPaints with biocidesHuman healthRutile

The invention discloses a waterborne dipping paint for engineering tracks, and a preparation method for the waterborne dipping paint, and relates to engineering track protective paints. The invention provides a waterborne dipping paint for the engineering tracks, and the volatile organic compounds (VOC) are less than 20g / L. The paint belongs to an environment-friendly coating, has low VOC content and small odor, is noninflammable and inexplosive, solves the problems that a solvent-based dipping paint and a water soluble dipping paint has harm to environment and human health, has the advantages of stable bath solution, convenience in construction, wide application range and suitability for large-scale industrial continuous production, solves various problems of sagging, edge shrinkage, bottom leakage, blur and the like of the dipping paint, and accords with the construction condition of low temperature drying or air drying. In the waterborne dipping paint for the engineering tracks, waterborne acrylic emulsion is taken as a base material, propylene glycol, a pH regulator, a dispersing agent, a wetting agent, a defoaming agent I, a defoaming agent II, an antiseptic, a film forming aid, a flashrust inhibitor, a base material wetting agent and a thickening agent are taken as aids, and carbon black and rutile type titanium dioxide are taken as pigments and fillers.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD +1

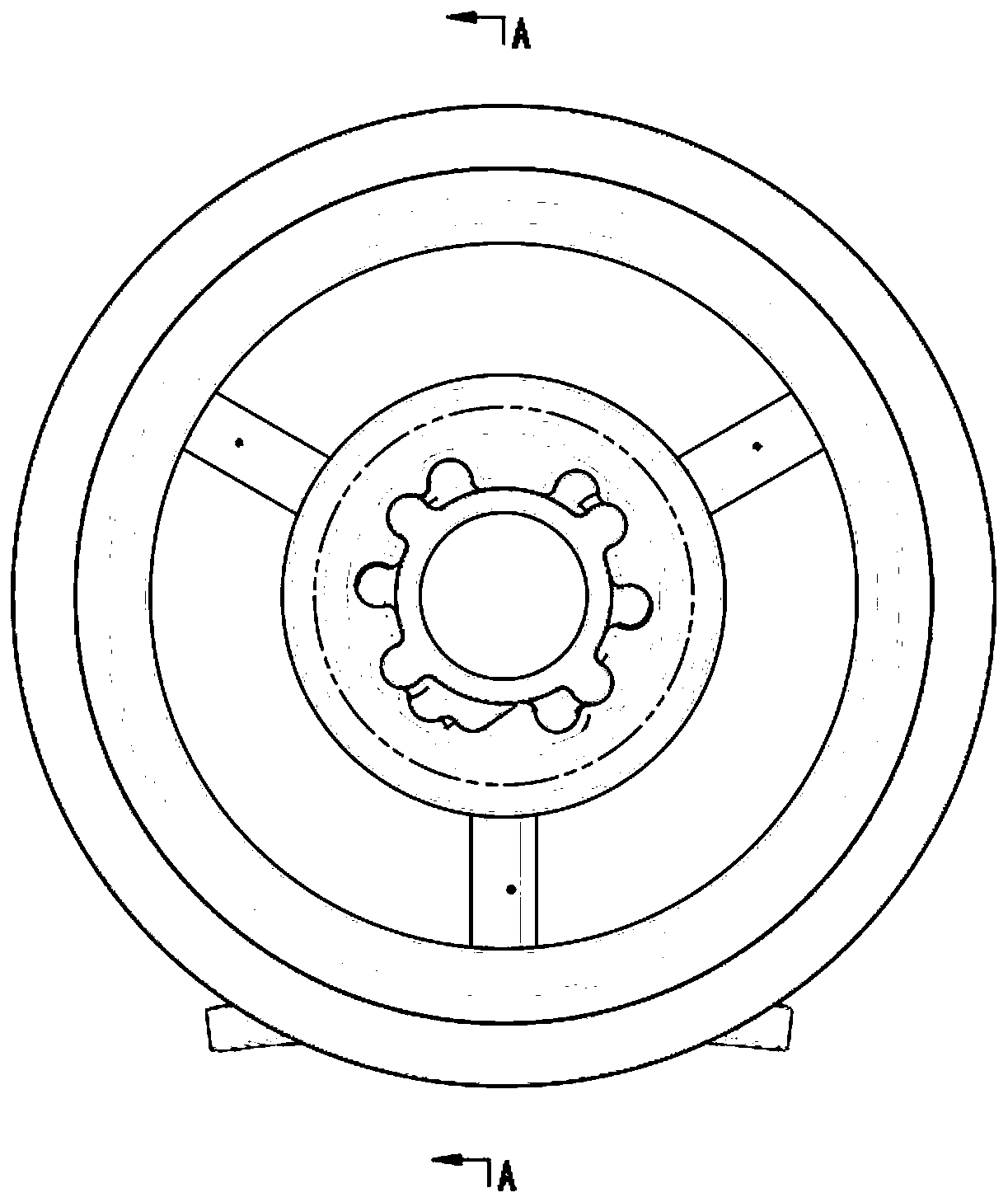

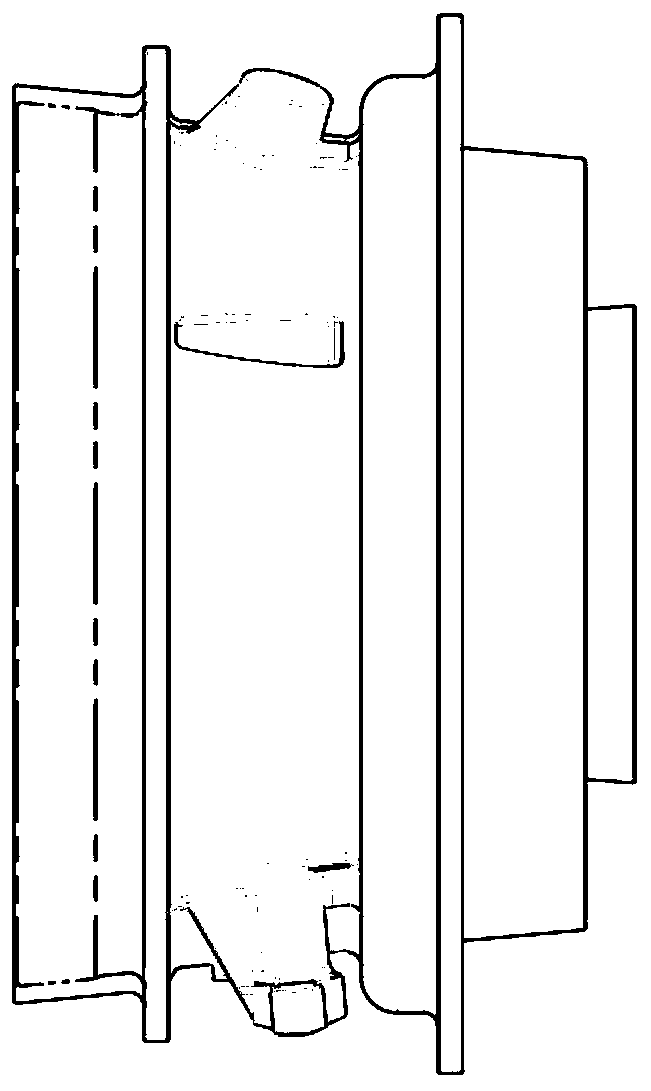

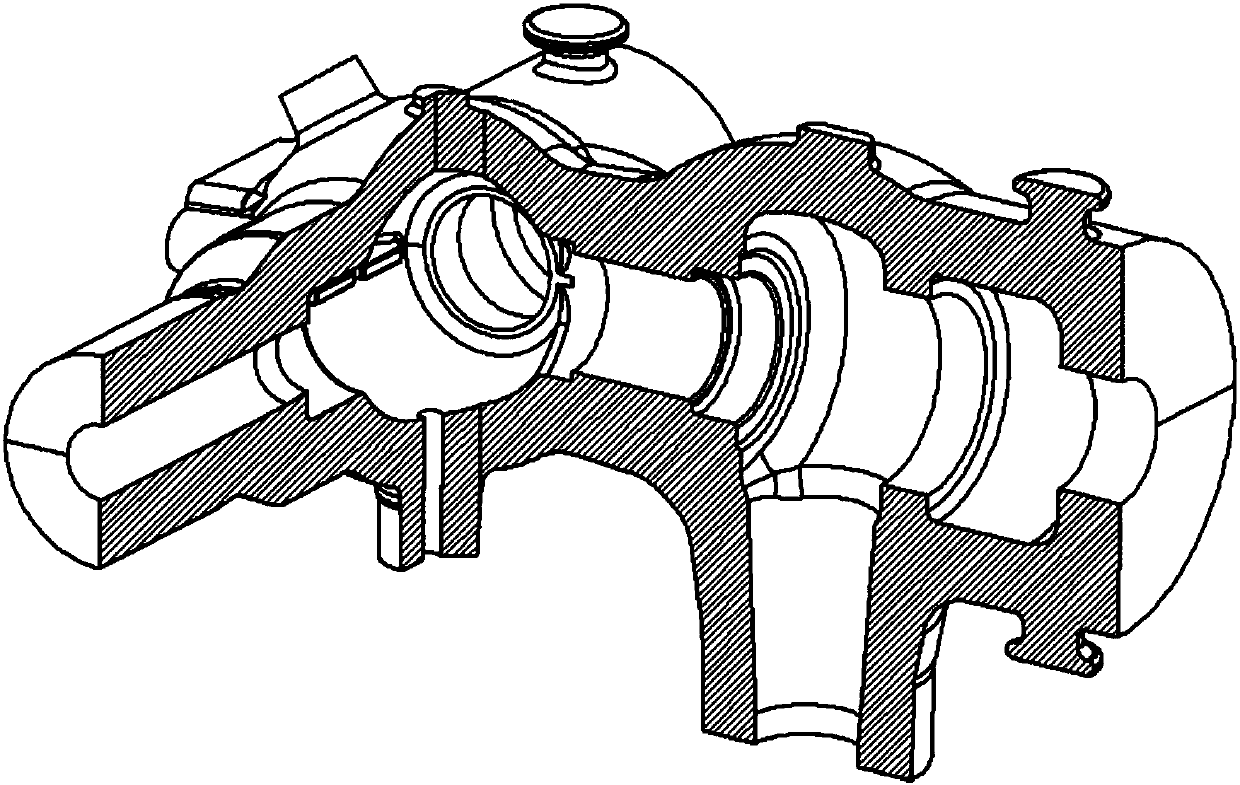

Hydraulic control type reaming tool during drilling

InactiveCN105863514AEffective expansionSolve shrinkageDrilling machines and methodsWell drillingUpper joint

The invention relates to a hydraulic control type reaming tool during drilling. The hydraulic control type reaming tool during drilling is used for enlarging the diameter of a wellbore in the petroleum and natural gas industry and solves the problem of wellbore diameter reduction generated in the well drilling process. According to the technical scheme of the hydraulic control type reaming tool during drilling, the upper end of an upper shaft body and the lower end of an upper joint are in screwed connection, and the lower end of the upper shaft body and the upper end of a lower shaft body are in screwed connection; one end of a connecting rod is hinged to the lower end of a reamer wing, and the other end of the connecting rod is hinged to a corresponding hinging support at the outer portion of a reamer wing seat; the three hinging supports at the outer portion of the reamer wing seat are installed in three grooves in the middle portion of the upper shaft body, the reamer wing is installed on a slope of the middle groove of the upper shaft body, and a piston cylinder is installed at the upper portion of an inner cavity of the lower shaft body; a center pipe is installed in inner cavities of the upper shaft body and the lower shaft body; and one ends of two sliding pins are fixed to two threaded holes in the lower portion of the lower shaft body, and the other ends of the two sliding pins are inserted in sliding groove rails at the lower end of the center pipe. By the adoption of the hydraulic control type reaming tool during drilling, well drilling fluid is used for control, operation is easy, control is effective, wellbore diameter enlarging can be effectively conducted, the quality of an oil and gas well is improved, and the well drilling cost is greatly reduced.

Owner:SOUTHWEST PETROLEUM UNIV

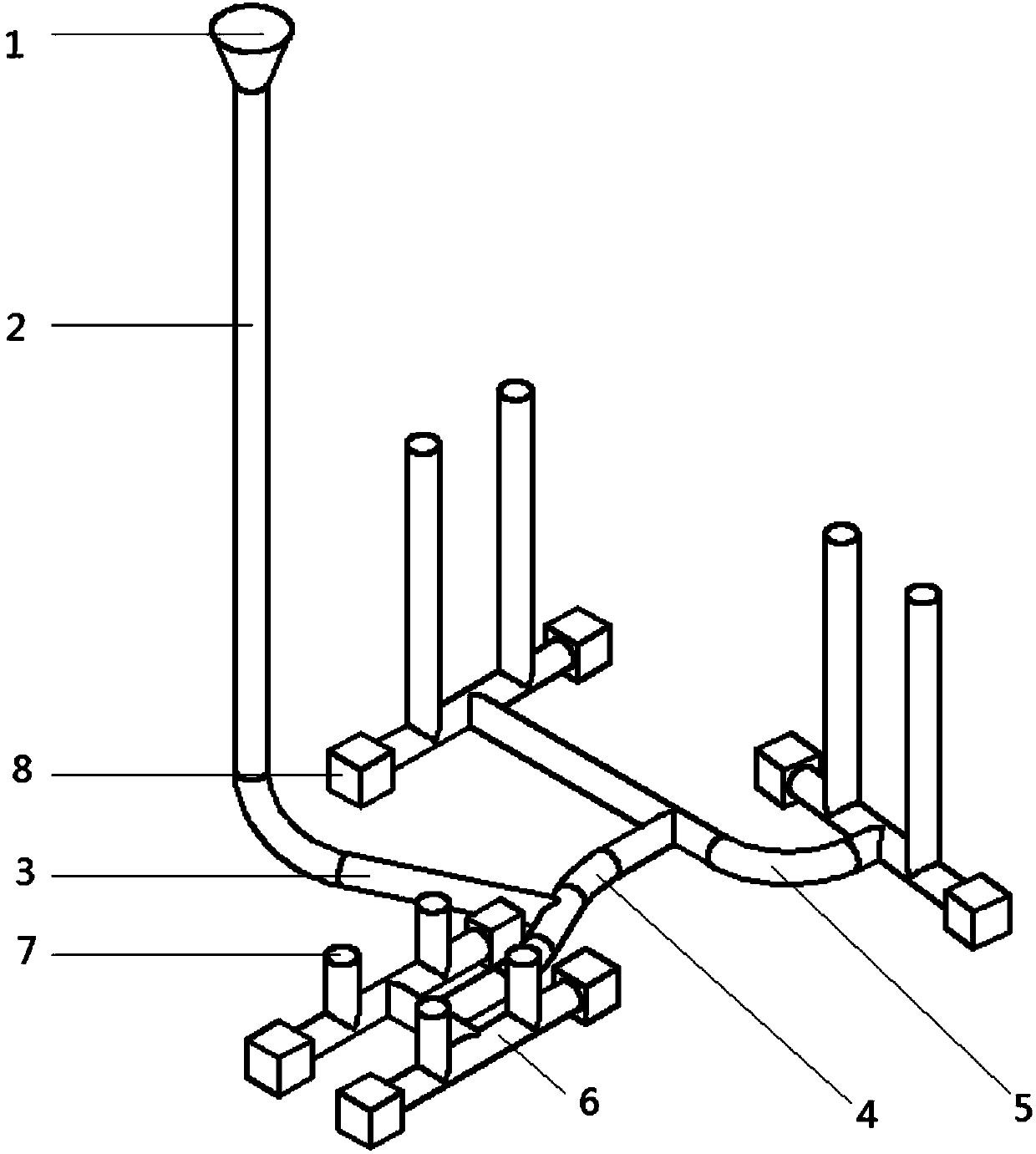

Pouring system for large valve casing type steel castings

The invention provides a pouring system for large valve casing type steel castings. The pouring system structurally comprises a sprue cup, a sprue, a slow-flow cross gate, a cross gate and an inner gate which are connected sequentially; the slow-flow cross gate is a first-class cross gate and is connected with a second-stage cross gate above the slow-flow cross gate through a vertical drainage gate; the second-stage cross gate has the V-shaped longitudinal section; the tail end of the second-stage cross gate is connected with a third-stage cross gate at the upper end of the second-stage crossgate through the vertical drainage gate; the third-stage cross gate has the V-shaped longitudinal section; the inner gate is perpendicularly connected with the third-stage cross gate and faces vertically upwards; and the tail end of the third-stage cross gate is sequentially connected with a slag guiding gate, a reducing gate and a slag collecting gate which is perpendicularly connected with the reducing gate and faces vertically upwards. By the aid of the pouring system, the mold filling process of molten steel is stable, the slag collecting effect is remarkable, and slag inclusion and impurity inclusion defects on the surfaces of the castings are reduced.

Owner:KOCEL STEEL

High-frequency micro vibration negative pressure pouring technology

InactiveCN107008858ASolve the shrinkage cavitySolve shrinkageFoundry mouldsFoundry coresVacuum pumpingVibration amplitude

The invention discloses a high-frequency micro vibration negative pressure pouring technology. The high-frequency micro vibration negative pressure pouring technology comprises the steps of during pouring, pouring melt water into a sand box, then, starting a high-frequency vibration motor at negative pressure, increasing compactness in the sand box, enabling the high-frequency vibration motor, the sand box and foam to form an integral body, and regulating vibration frequency and time. The high-frequency micro vibration negative pressure pouring technology comprises the specific steps of A1, treating air in the sand box through a vacuum extraction system, and applying negative pressure to the sand box through vacuum purified flue gas; A2, starting the high-frequency vibration motor, and guaranteeing that vibration amplitude of the high-frequency vibration motor is 5000 r / min to 5500 r / min; and A3, while air in the sand box is extracted through the vacuum extraction system, starting the high-frequency vibration motor again to continuously vibrate till a casting is primarily solidified. According to the high-frequency micro vibration negative pressure pouring technology, high-frequency vibration negative pressure pouring during the pouring process is achieved, heavy section problems of a nodular iron casting or shrinkage cavity and shrinkage porosity problems of hot spot parts are solved, working efficiency is effectively improved, and unnecessary waste of resources during the pouring process is avoided.

Owner:SHIYAN ZHIMING INDAL DEV

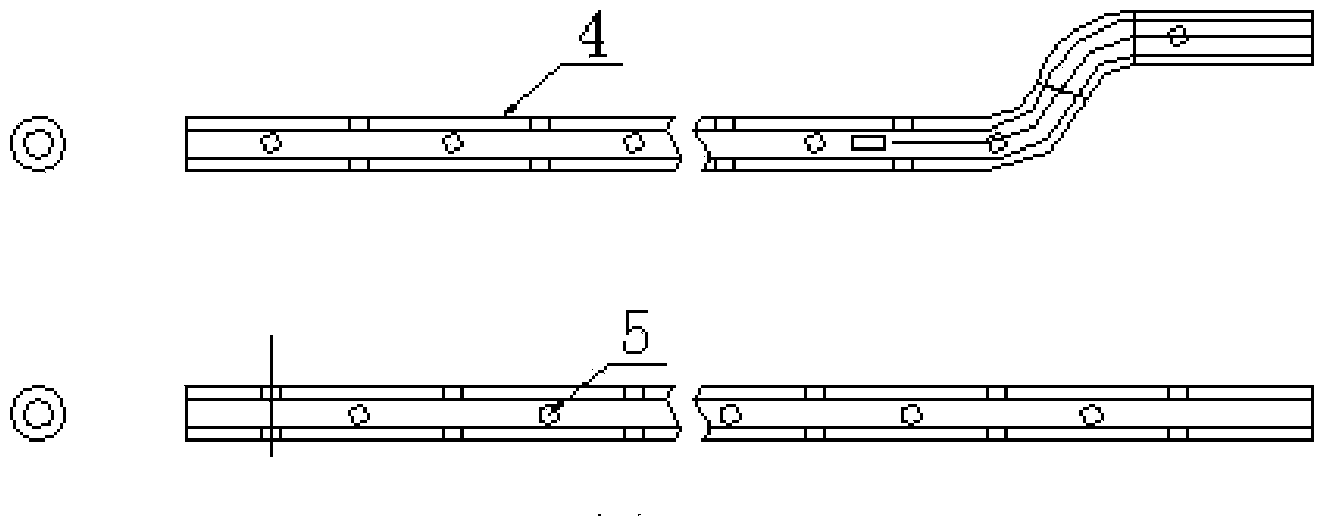

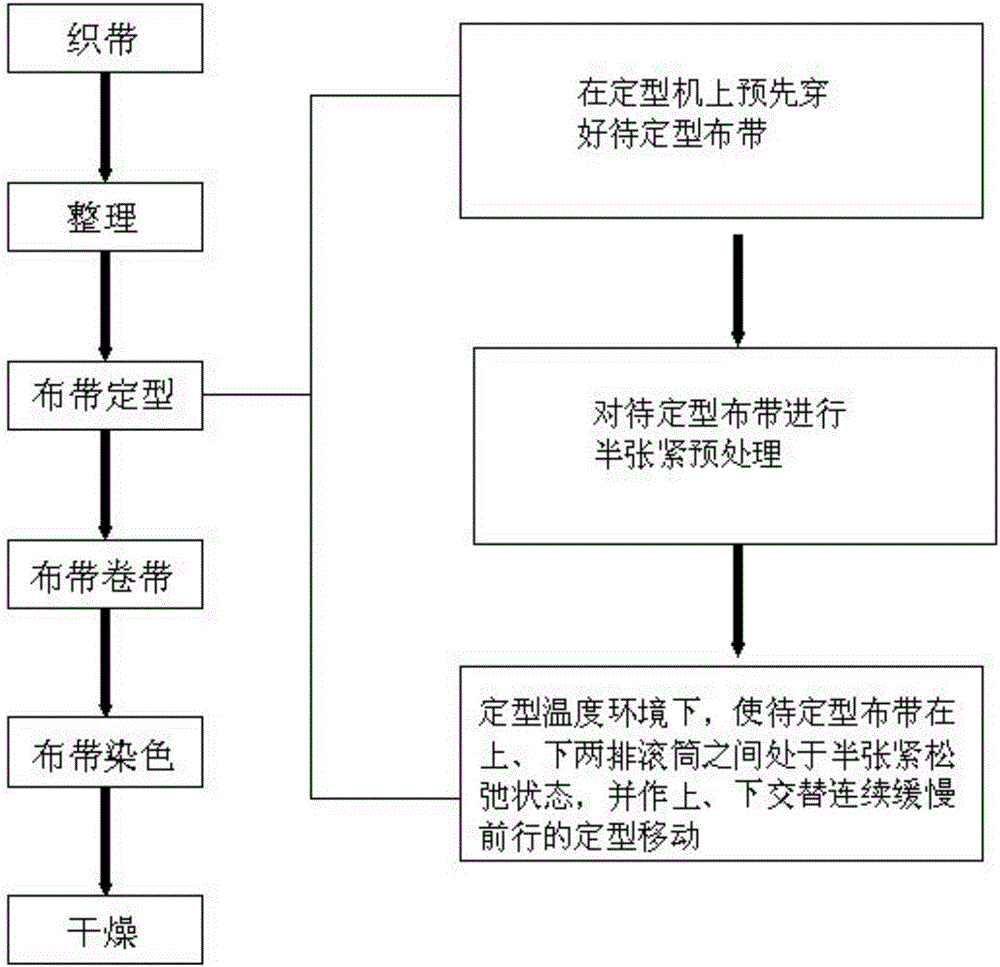

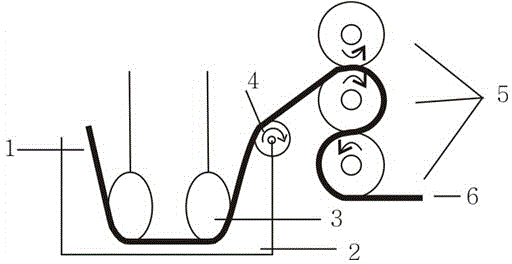

Production technology of zipper cloth tape

InactiveCN105220388AAvoid color differencesTraining step improvementsHeating/cooling textile fabricsElectric machineryEngineering

The invention discloses a production technology of a zipper cloth tape. The production technology comprises a cloth tape setting process, wherein the cloth tape setting process comprises the following steps: penetrating a to-be-set cloth tape on a setting machine in advance, carrying out semi-tensioning pretreatment on the to-be-set cloth tape, starting the setting machine, continuously feeding the to-be-set cloth tape into a setting chamber of the setting machine in a semi-tensioning state by using a tension constant control device driven by a first motor; enabling the to-be-set cloth tape to be in a semi-tensioning relaxed state between upper and lower rows of rollers in the setting chamber, and carrying out up-and-down alternately continuous and slow forward setting movement to a tape outlet direction of the setting chamber, so as to obtain the set cloth tape with the shrinking percentage of 1%-7%; and controlling the rotating speeds of the motors, and enabling the set cloth tape to reach the required shrinking percentage. According to the production technology, the cloth tape is shrunk in set in advance, so that the shrinkage amount is reduced in subsequent dyeing process, and further cloth tape indentation is prevented; the color difference of a zipper among the upper layer, the middle layer and the lower layer in the dyeing process is avoided; and the cloth tape dyeing uniformity is improved.

Owner:CHENGDU ROCK SOLID AUTOMATION TECH

Low-carbon green ultra-high performance concrete and preparation method thereof

InactiveCN114368953AImprove compactnessReduce autogenous shrinkageSolid waste managementBrickEnvironmental engineering

The invention provides low-carbon green ultra-high performance concrete and a preparation method thereof, and relates to the technical field of building materials. The low-carbon green ultra-high performance concrete provided by the invention is prepared from the following preparation raw materials in parts by weight: 550 to 650 parts of cement, 250 to 350 parts of regenerated red brick powder, 100 to 200 parts of fly ash, 90 to 110 parts of silica fume, 550 to 650 parts of natural sand, 450 to 550 parts of regenerated red brick sand, 40 to 50 parts of an additive, 160 to 180 parts of steel fiber and 170 to 190 parts of water. The problems of stacking and discarding of the construction waste red bricks are solved, the waste red bricks are subjected to processing of the regenerated red brick powder and the regenerated red brick sand, the problem of resource utilization is solved, and environmental protection benefits are improved. Meanwhile, the problems that existing ultra-high performance concrete is large in shrinkage, high in energy consumption, high in cost and poor in environmental protection property are solved.

Owner:建研建硕(北京)科技有限公司

Shrinkage-prevention die casting die

The invention discloses a shrinkage-prevention die casting die which comprises a fixed die seat plate and a movable die seat plate. A die casting cavity for forming a die casting is formed between a fixed die sleeve plate and a movable die sleeve plate. A spherical dead head is arranged beside the die casting cavity and is provided with a pouring gate. The pouring gate is connected with a sprue, and the sprue is formed in the fixed die seat plate. The spherical dead head is arranged beside the thickest part of the die casting. An extrusion hole communicating with the die casting cavity is formed in the fixed die sleeve plate and a fixed die fixing plate. An extrusion punch is arranged in the extrusion hole. By means of the shrinkage-prevention die casting die, the spherical dead head is arranged beside the thickest wall part of the casting for the causes of shrinkage and shrinkage porosity, meanwhile, in the die casting molding process, pouring liquid is solidified into a semi-solid state, the extrusion punch conducts extrusion on the wall thickness position of the product, the functions of feeding and compacting are achieved, the problems of shrinkage and shrinkage porosity of the casting are effectively solved, and the quality of the casting is improved.

Owner:安徽纯启动力科技有限公司

Preparation method of anti-shrink silk-linen fabric

ActiveCN104988710AImprove performanceDoes not affect the feelPhysical treatmentVegetal fibresWeight gainingWrinkle skin

The invention discloses a preparation method of an anti-shrink silk-linen fabric, and belongs to the technical field of textile post treatment. In the provided preparation method, a physical pre-shrinking and chemical finishing combined method is adopted to carry out a post treatment on silk-linen fabrics. The post-treatment method comprises a physical technology and a chemical technology, the used finishing agent is an environment-friendly flame retardant, and the whole finishing process is easy and simple. After the treatment, the warp-direction shrinkage rate is reduced from 6.8% to 0.7% or less; the weft-direction shrinkage rate is reduced from 2.5% to 0.7% or less, the textile drape coefficient is 0.58 U or less, warp-direction wrinkle recovery angle is 130 to 150 degrees, the weft-direction wrinkle recovery angle is 74.6 to 85 degrees, the textile weight gain rate is 2.5 to 3.6%; the application performance of the silk-linen fabrics is enhanced, and the provided method is an ideal method for silk-linen fabric anti-shrink treatment.

Owner:TAIYUAN UNIV OF TECH

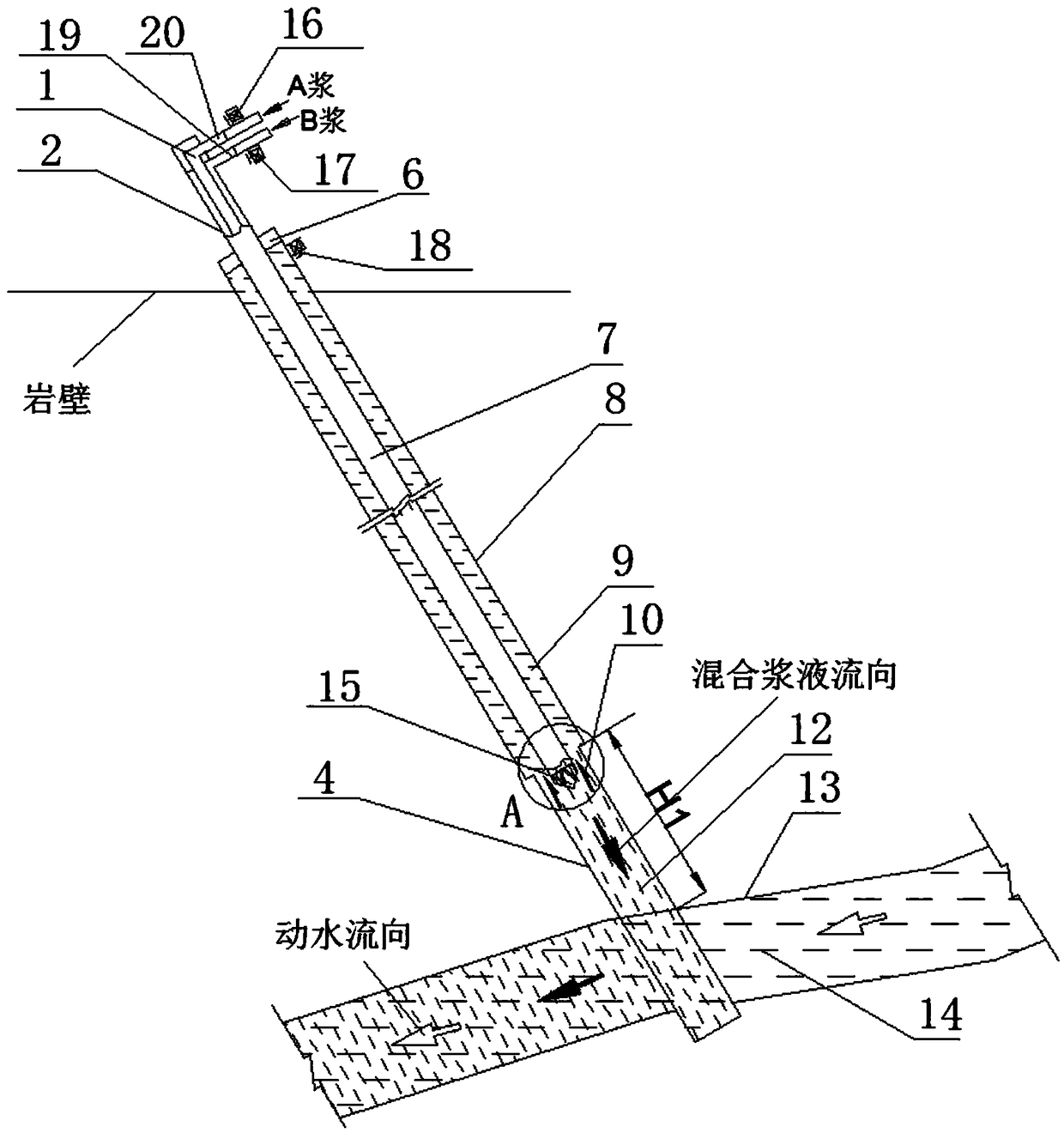

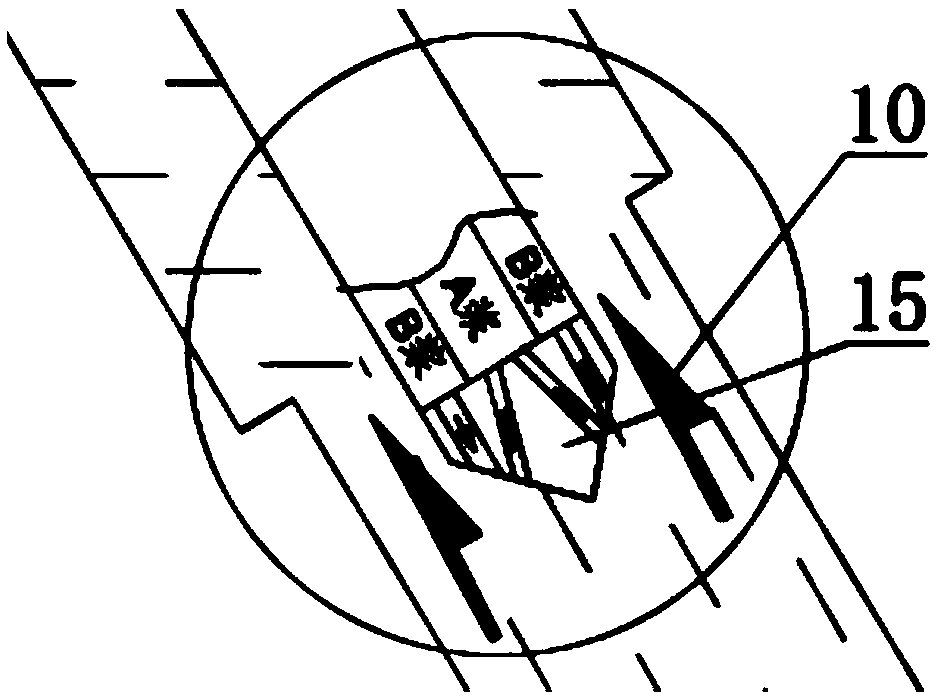

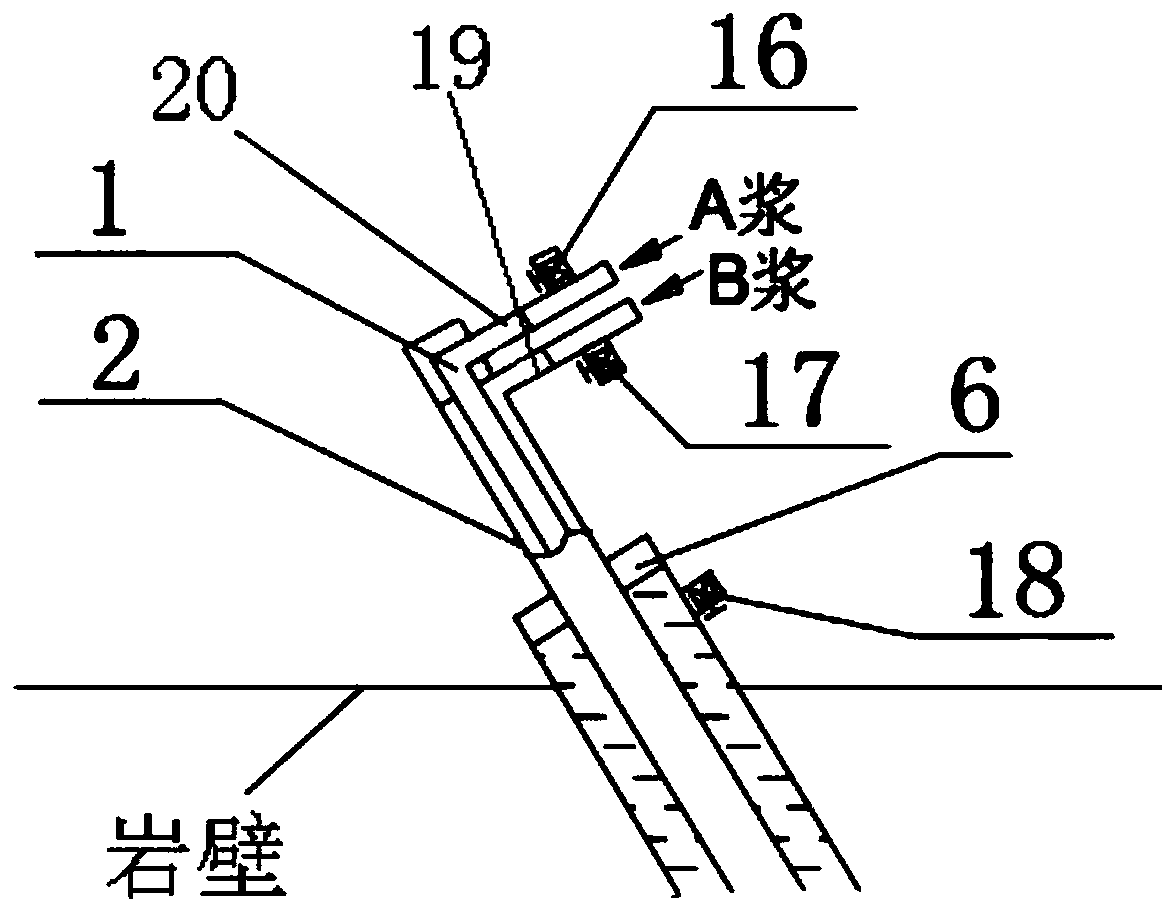

Double-liquid grouting method utilizing water column to stop grout in ultra-deep borehole under mine

ActiveCN109403914AEliminate backflow into the casing and seal the disadvantages of blocking the casingSolve shrinkageSealing/packingWater flowSlurry

This invention relates to a double-liquid grouting method utilizing a water column to stop grout in an ultra-deep borehole under a mine and belongs to the field of prevention and control of mine waterhazard. The double-liquid grouting method comprises a step of constructing a water-stopping and grouting drilled hole according to design parameters, a step of judging the exact position of a water storing and guiding channel, a step of estimating the water flow area of the water storing and guiding channel, a step of calculating the designed depth position of the bottom end of a second-stage aperture casing in the drilled hole, a step of lowering the second-stage aperture casing and sealing, a step of connecting and lowering a double-grout grouting pipe, a step of installing a sealing device, a step of performing grouting and water stopping after installation is completed and a step of detaching the double-grout grouting pipe and the sealing device after grouting is completed. The double-liquid grouting method effectively solves the difficult problems of diameter shrinkage and hole wall collapse in the water-sensitive formation section of the drilled hole, the transporting and movingdistance of mixed grout is greatly shortened, and the purpose of injecting double-grout mixed grout into the drilled hole below the mine shaft of any depth, and quickly plugging the water storing andguiding channel for realizing grouting can be achieved and water stopping.

Owner:SHANDONG JIAOTONG UNIV

Shrinkage-proof antistatic finishing process for wool fabric

InactiveCN103276587ASolve shrinkageEasy to operateBiochemical fibre treatmentDry-cleaning apparatus for textilesState of artEngineering

The invention discloses a shrinkage-proof antistatic finishing process for a wool fabric, wherein a wool fabric is sequentially subjected to a certain softening treatment water washing, a biological enzyme shrinkage-proof treatment, and a softening agent treatment so as to ensure functions of shrinkage resistance and static electricity resistance of the wool fabric. Compared with the process in the prior art, the process of the present invention has the following characteristics that: problems of easy static electricity generation and shrinkage of the wool fabric are solved, operation is simple, an industrialization degree is strong, substantial advance is provided for the wool fabric functionality finishing process, and strong practicality values are provided.

Owner:太仓市芸芸化纤有限公司

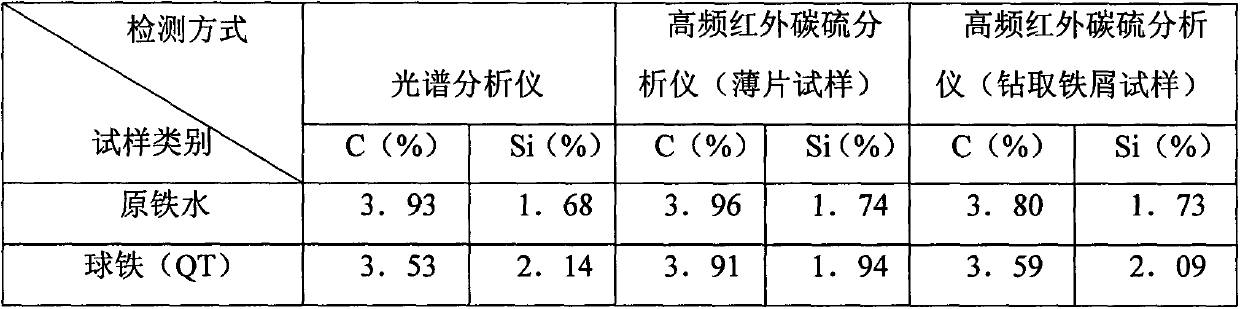

Method for controlling carbon equivalent of base iron and application of method

The invention relates to a method for controlling the carbon equivalent of base iron and an application of the method. According to the method for controlling the carbon equivalent of base iron and the application of the method, the influence of C and Si elements is mainly taken into consideration for calculation of the carbon equivalent and the influence of microelements on the carbon equivalent is ignored; a molten iron treating agent is quantitatively added to enable the Si content change delta Si before and after molten iron treatment to be a constant value, so the theoretical carbon equivalent CE2, namely (CE-delta Si / 3), of the base iron can be calculated according to the theoretical carbon equivalent value CE of the cast iron; the detection value CE1 of the carbon equivalent of the base iron is controlled to be near the theoretical carbon equivalent CE2, so the carbon equivalent of the base iron can be adjusted to an eutectic point quickly and effectively, the qualified rate of the nodulized molten iron is increased, return of nodular iron is avoided, and the production cost is effectively reduced.

Owner:TIANRUN IND TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com