Patents

Literature

31results about How to "Reduce deformation defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

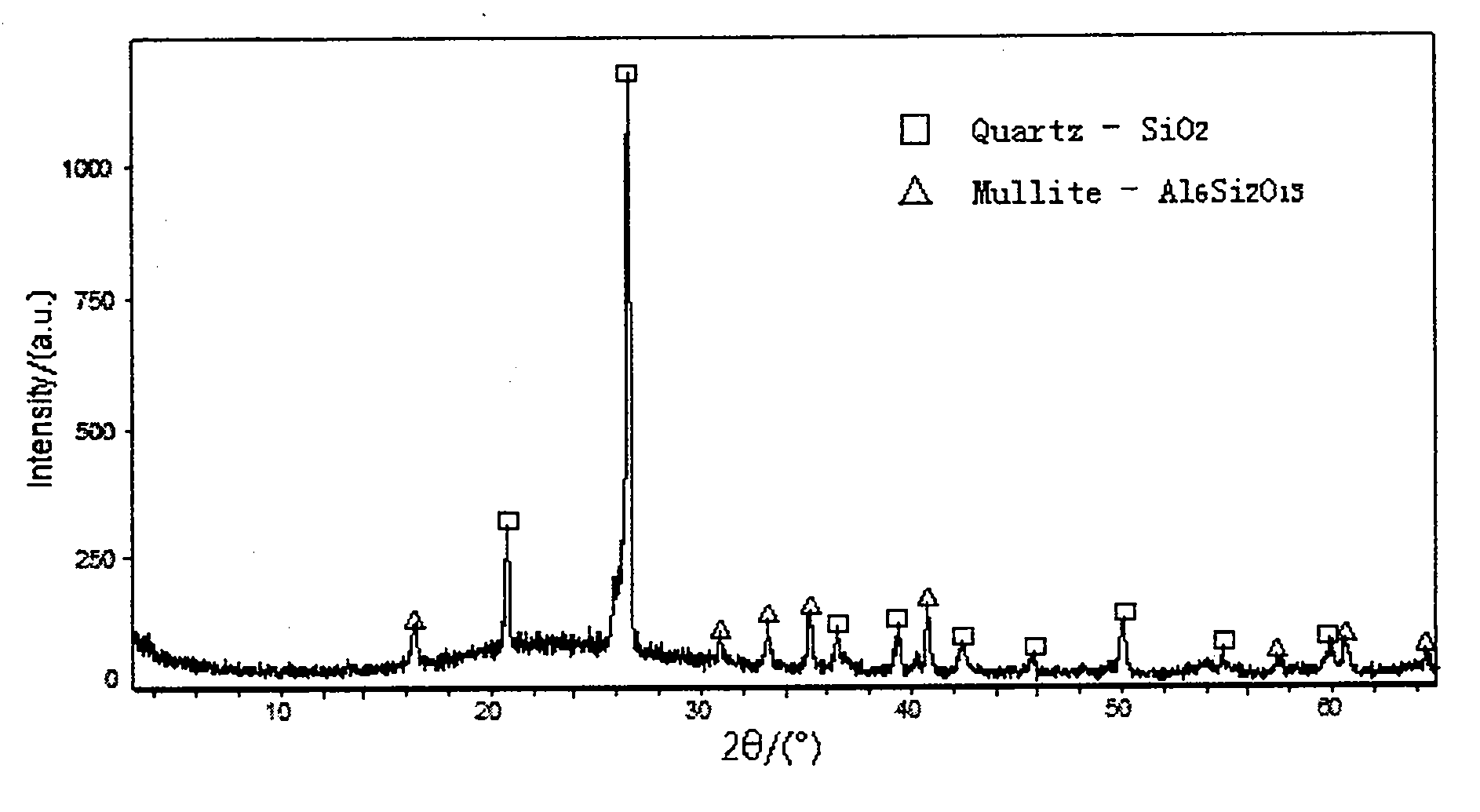

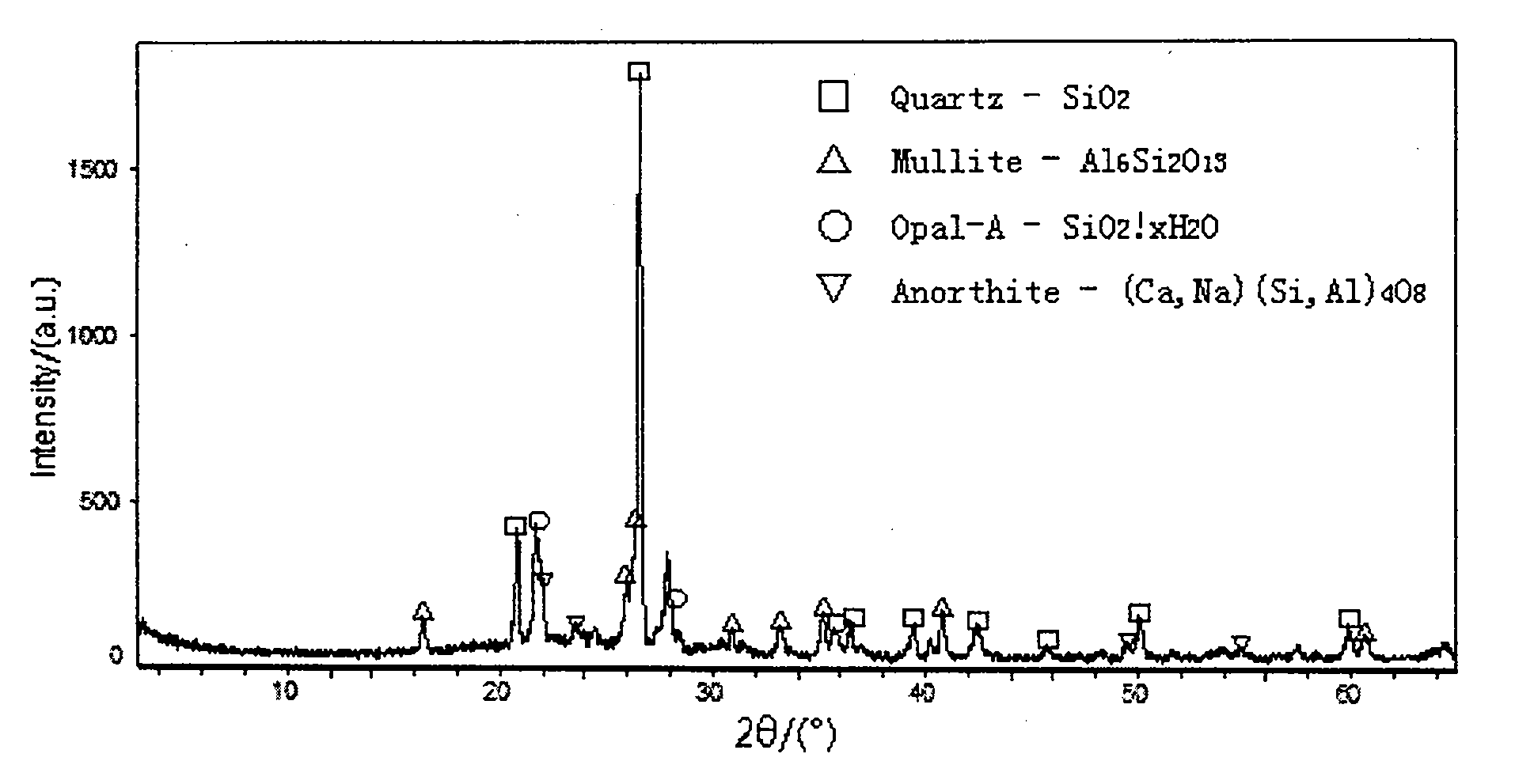

Fine-pottery sanitary ceramic body and manufacturing method thereof

ActiveCN101811858AReduce hygroscopic swellingHigh coefficient of thermal expansionClaywaresGranularityMullite

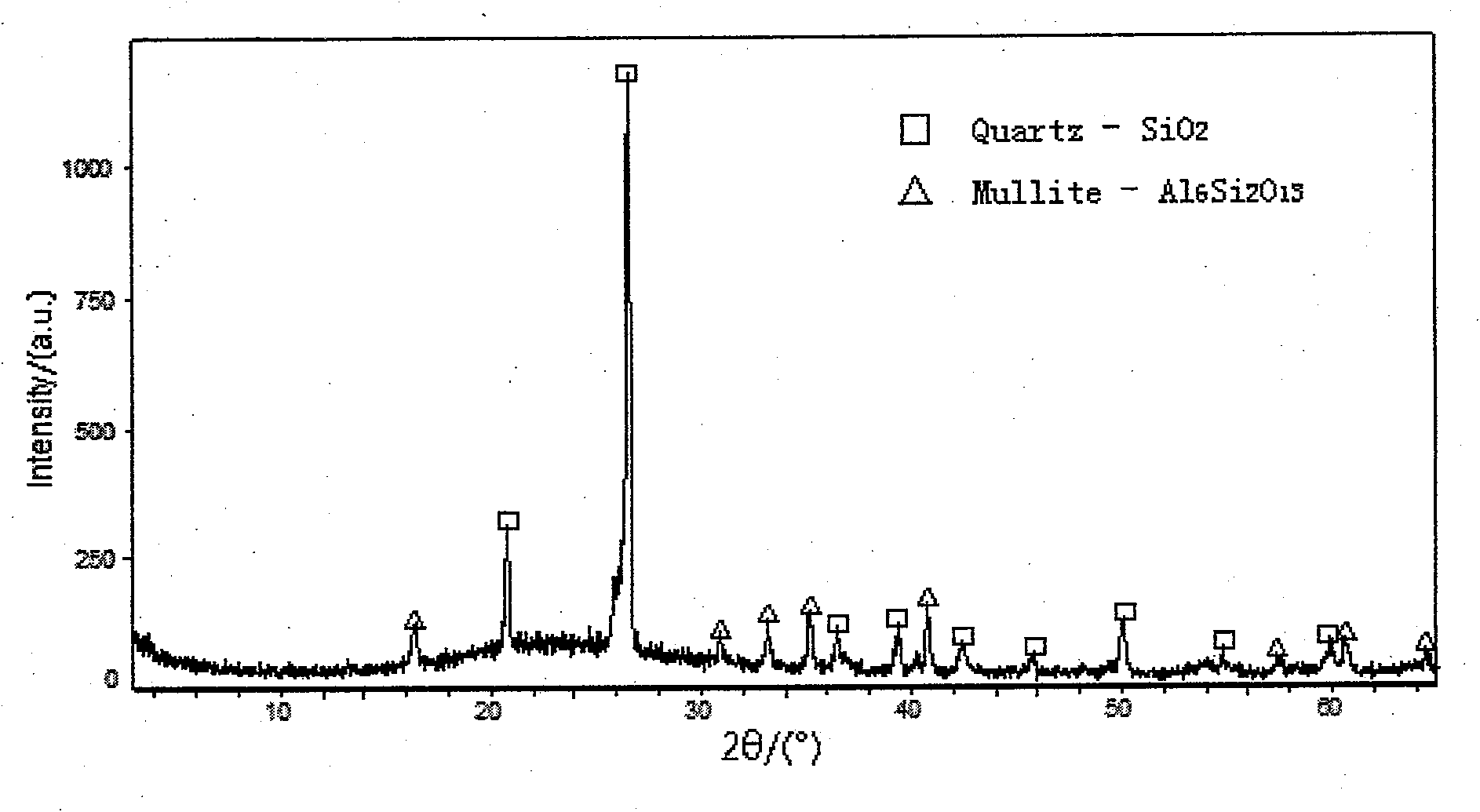

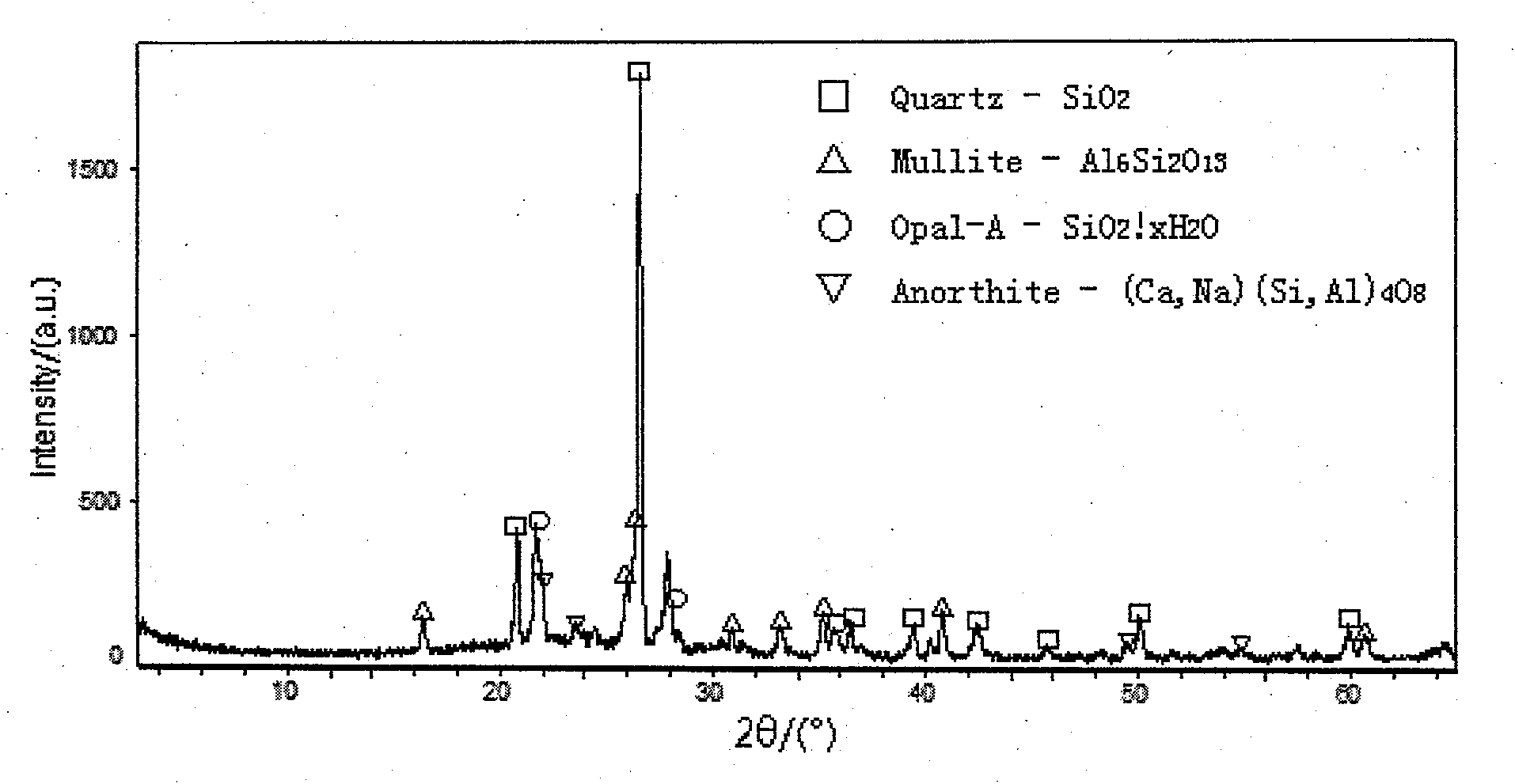

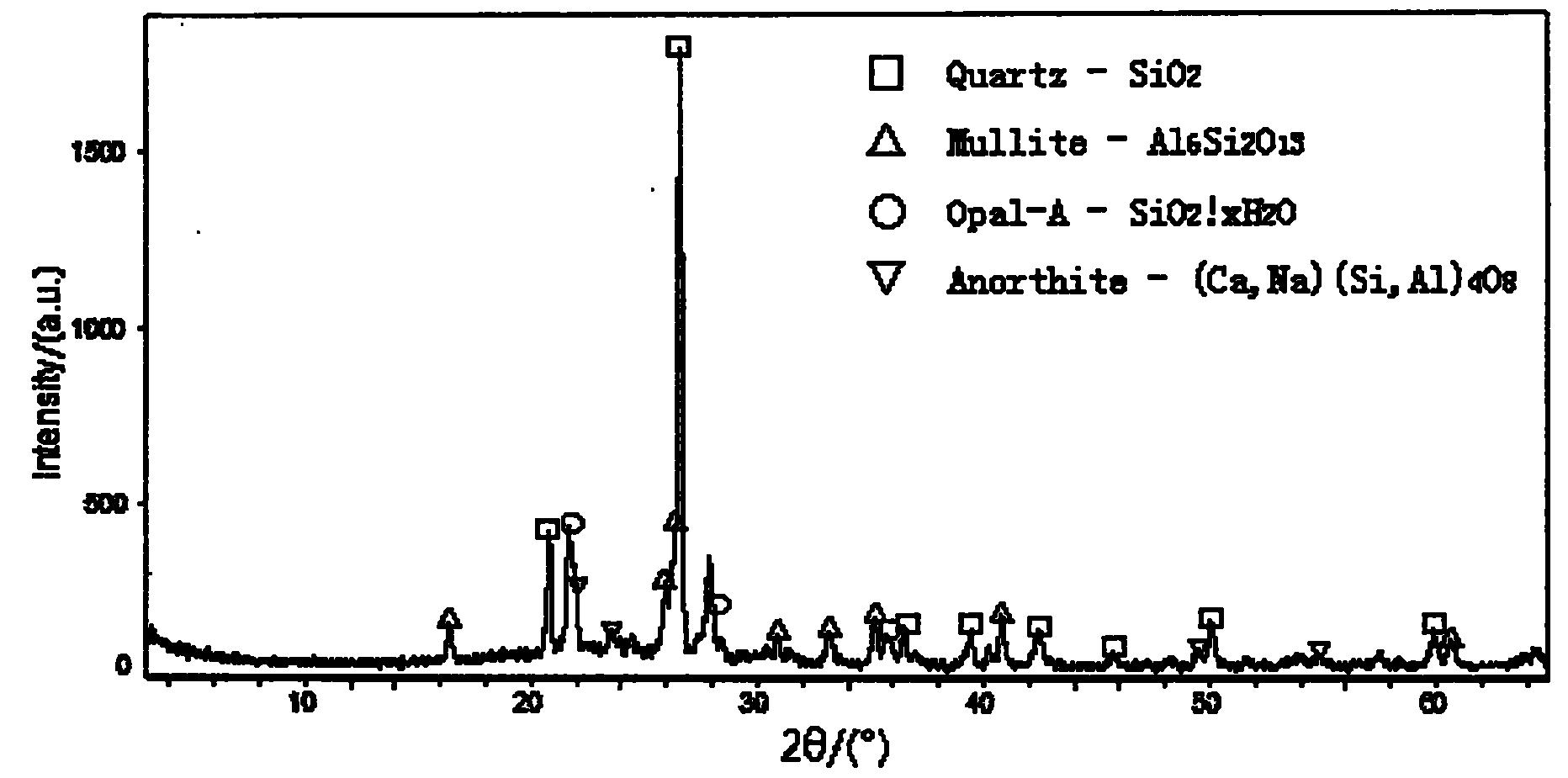

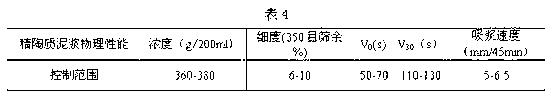

The invention relates to a fine-pottery sanitary ceramic body and a manufacturing method thereof and belongs to the technical field of ceramic products, which is used for reducing the deformation of a sanitary ceramic product and improving the quality of glaze. The fine-pottery sanitary ceramic body is characterized in that a body raw material comprises the following components in part by mass: 10 to 30 parts of ball clay, 30 to 60 parts of kaoline, 5 to 15 parts of porcelain clay, 5 to 15 parts of quartz and 5 to 15 parts of wollastonite, wherein the kaoline comprises 10 to 25 calcined kaoline. In the manufacturing method, the raw materials and the adding proportion of the fine-pottery body are preferably selected, the crystal phase content of mullite, quartz and the like is controlled, and the glass phase content and the high-temperature plastic deformation are reduced so as to fulfill the aim of reducing the deformation of fine-pottery sanitary ceramics; while reducing the hygroscopic expansion of the body, the manufacturing method improve thermal expansion coefficient of the body at the temperature of 200 DEG C to make the glaze bear high compressive stress, thereby improving the anti-cracking performance of products and ensuring enough long service life. Through the refinement of slurry granularity, the method remarkably reduces the occurrence of disadvantage of glaze pinholes, does not need to reduce the pinholes by using engobe, simplifies a production process, and improves the production efficiency and the qualification rate of the products.

Owner:HUIDA SANITARY WARE

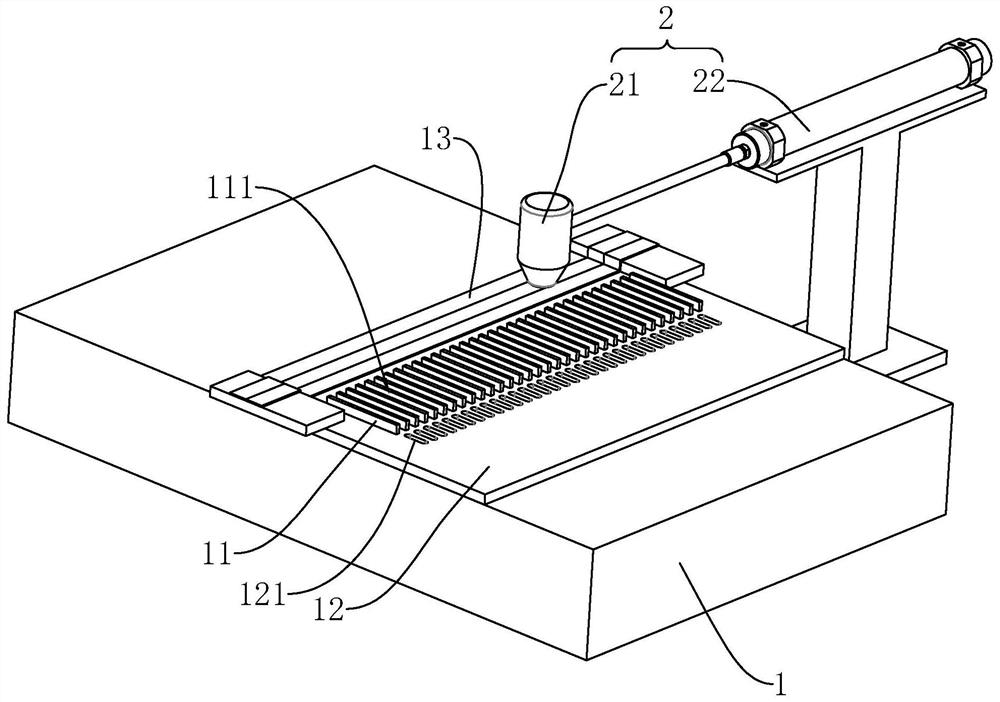

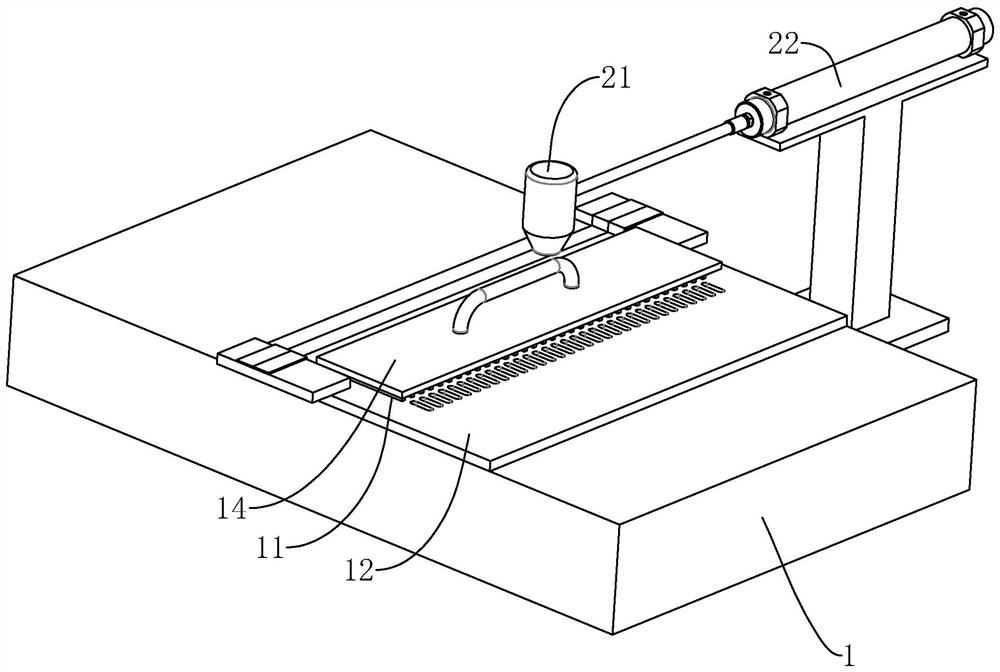

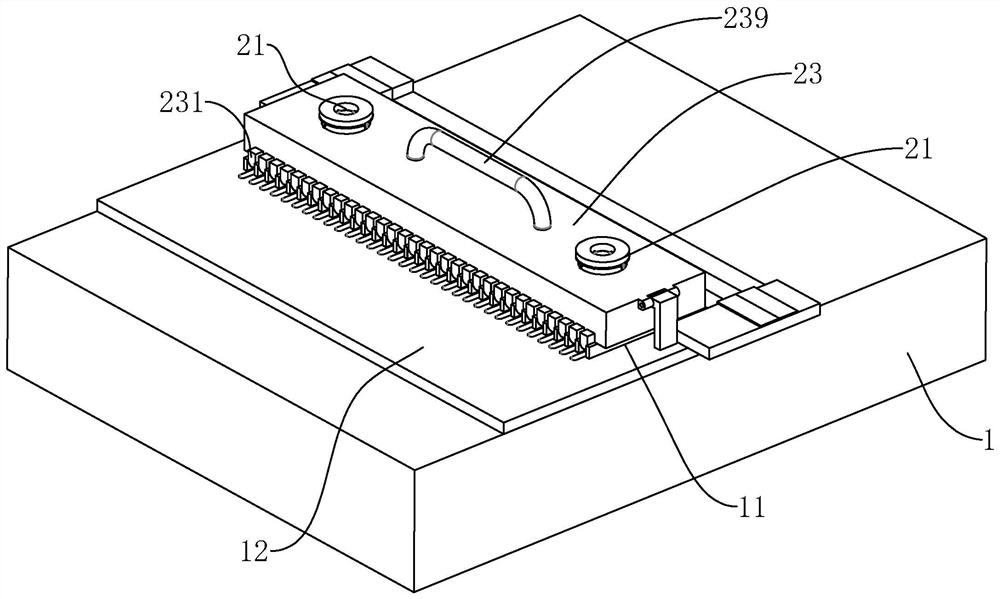

Tool assembly for machining axial flow pump blades, and precision machining method for axial flow pump blades

ActiveCN109807572AAchieve vibrationEliminate internal stressEdge grinding machinesPositioning apparatusAxial-flow pumpSpray nozzle

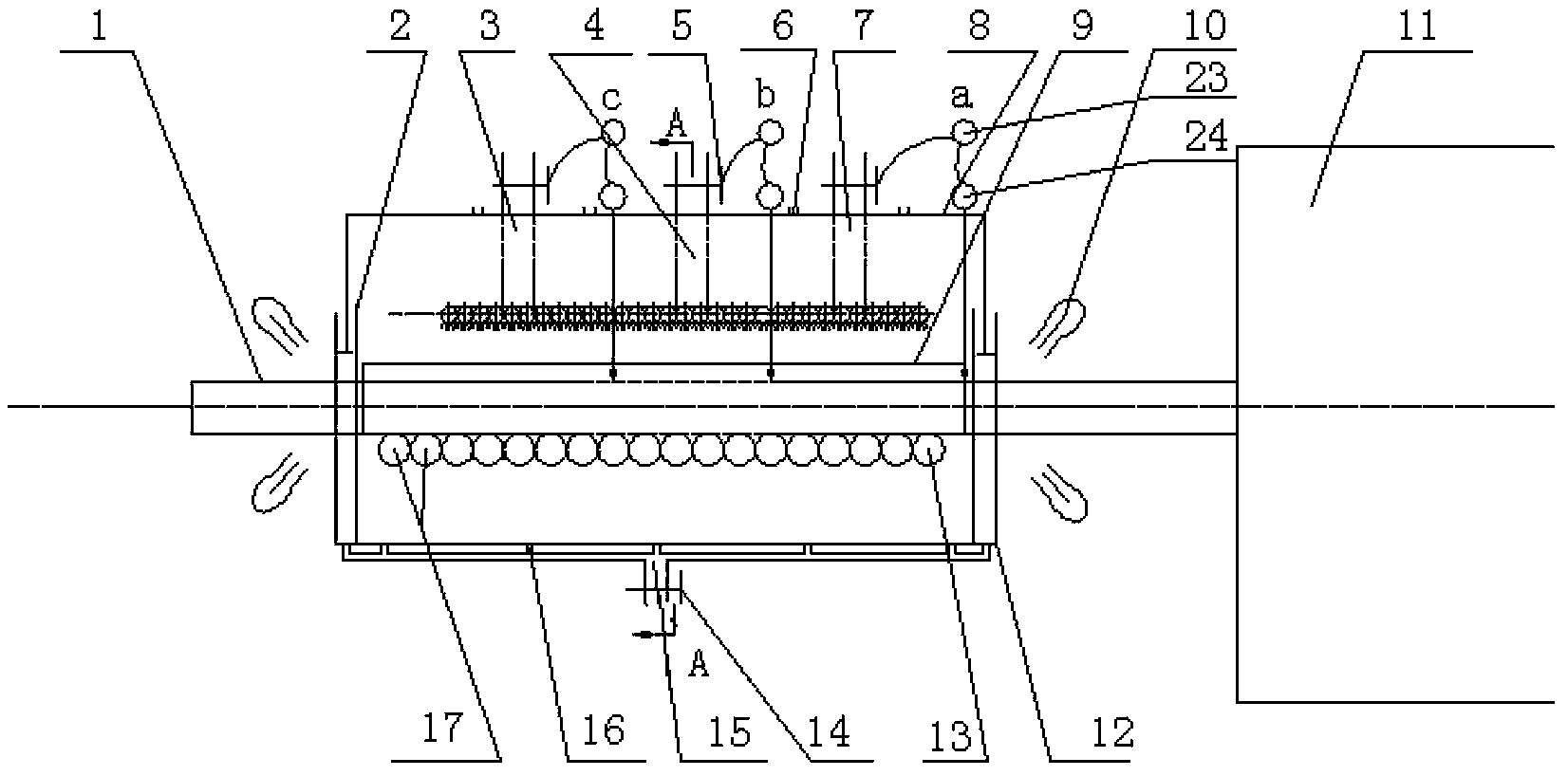

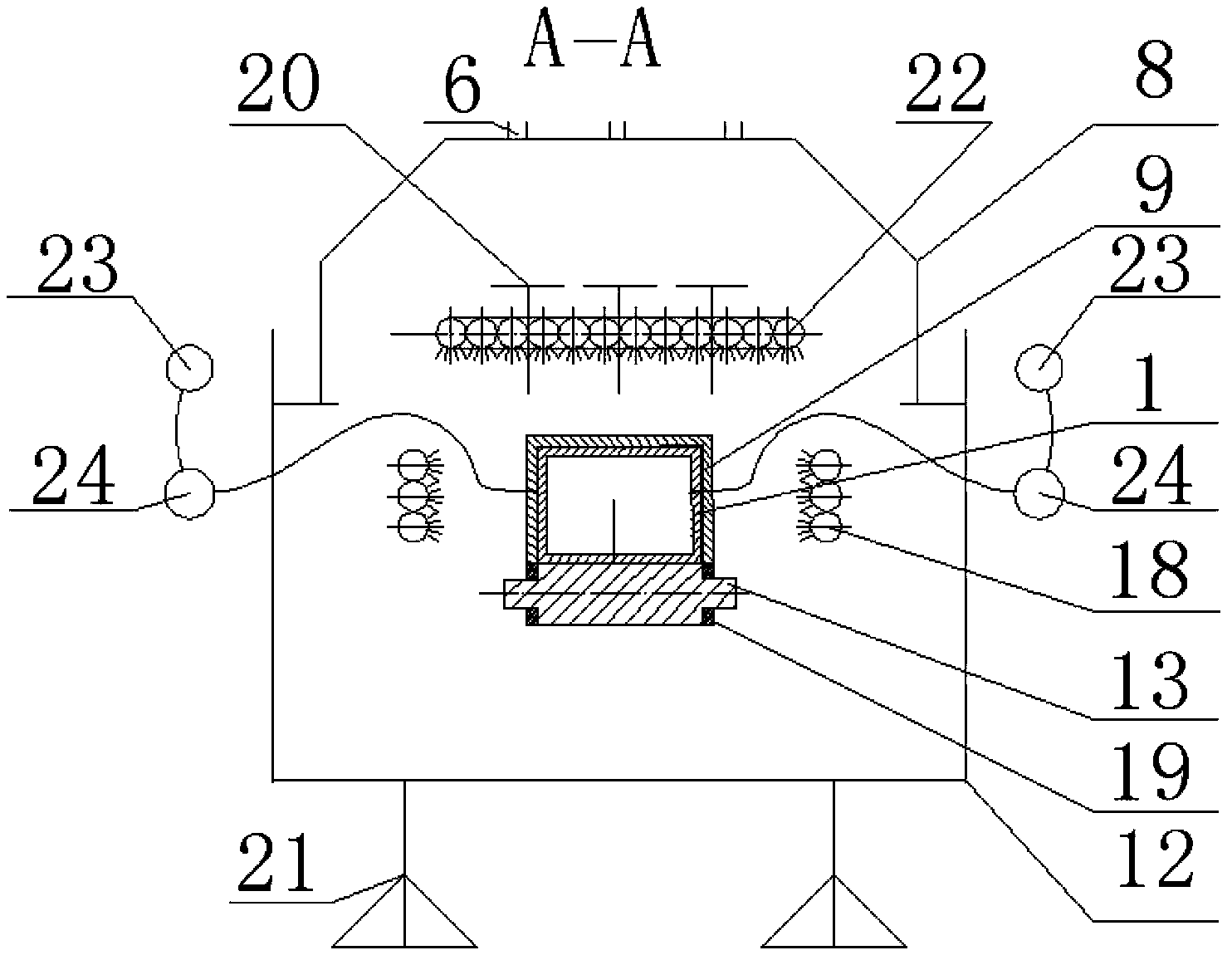

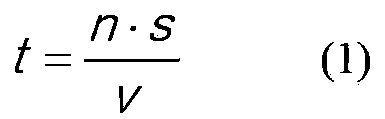

The invention discloses a tool assembly for machining axial flow pump blades, and a precision machining method for axial flow pump blades, and belongs to the technical field of machining. The tool assembly is composed of a rough milling tool, a vibration aging tool, a grinding tool, a semi-fine milling tool, a combined type pneumatic tool and a shot blasting nozzle tool together. The tool assemblyis used for completing the machining procedure of rough machining, aging, semi-fine machining, linear cutting outline, aging, fine machining and high-speed shot blasting surface strengthening. The tool assembly is novel, easy and convenient to operate and reasonable in precision machining method, the machining efficiency and machining accuracy are improved, the corrosion resistance and fatigue strength of blades are improved, the deformation defects in the use process are lessened, and the service life of the pump blades is further improved.

Owner:YANGZHOU UNIV

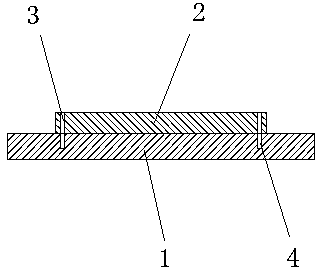

Decorative sheet structure and manufacturing method

ActiveCN105666597AReduce deformation defectsSmall machining allowanceWood veneer joiningFinger jointStress relief

The invention discloses a decorative sheet structure and a manufacturing method. The decorative sheet structure is formed by a finger joint sheet, veneers and facing paper in a composite mode; the finger joint sheet is formed by splicing a plurality of wood sheets with finger type teeth and stress relief grooves, wherein the finger type teeth and the stress relief grooves are located at the ends of the wood sheets; the finger joint sheet is connected through the finger type teeth for being longitudinally spliced and is fixed through glue for being transversely spliced. The manufacturing method mainly comprises the steps of cutting, rounding, stress groove forming and manufacturing, drying, board cutting, comb tooth treating, length jointing and width splicing, repairing, sanding, veneer gluing, paper gluing and sheet cutting. The decorative sheet structure has the advantages of being high in strength and good in stability. The manufacturing method of the decorative sheet structure has the advantages that the outturn percentage is high, the production technology is simple, the production efficiency is high, the labor intensity is low and the production cost is low, and the technical problems that the utilization rate of wood is low, the strength of decorative sheets is low and the stability is poor in the existingmanufacturing technology of the decorative sheets are well solved.

Owner:广州市欧亚床垫家具有限公司

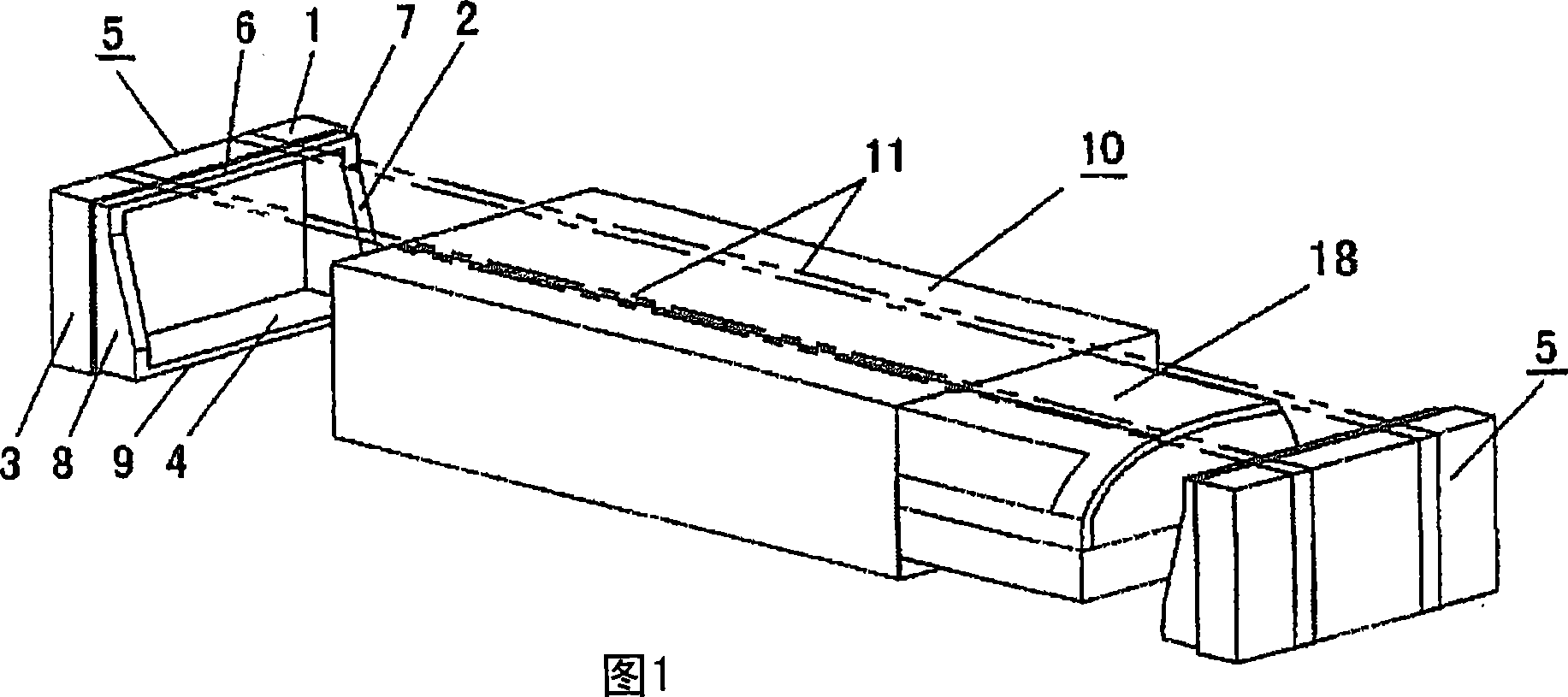

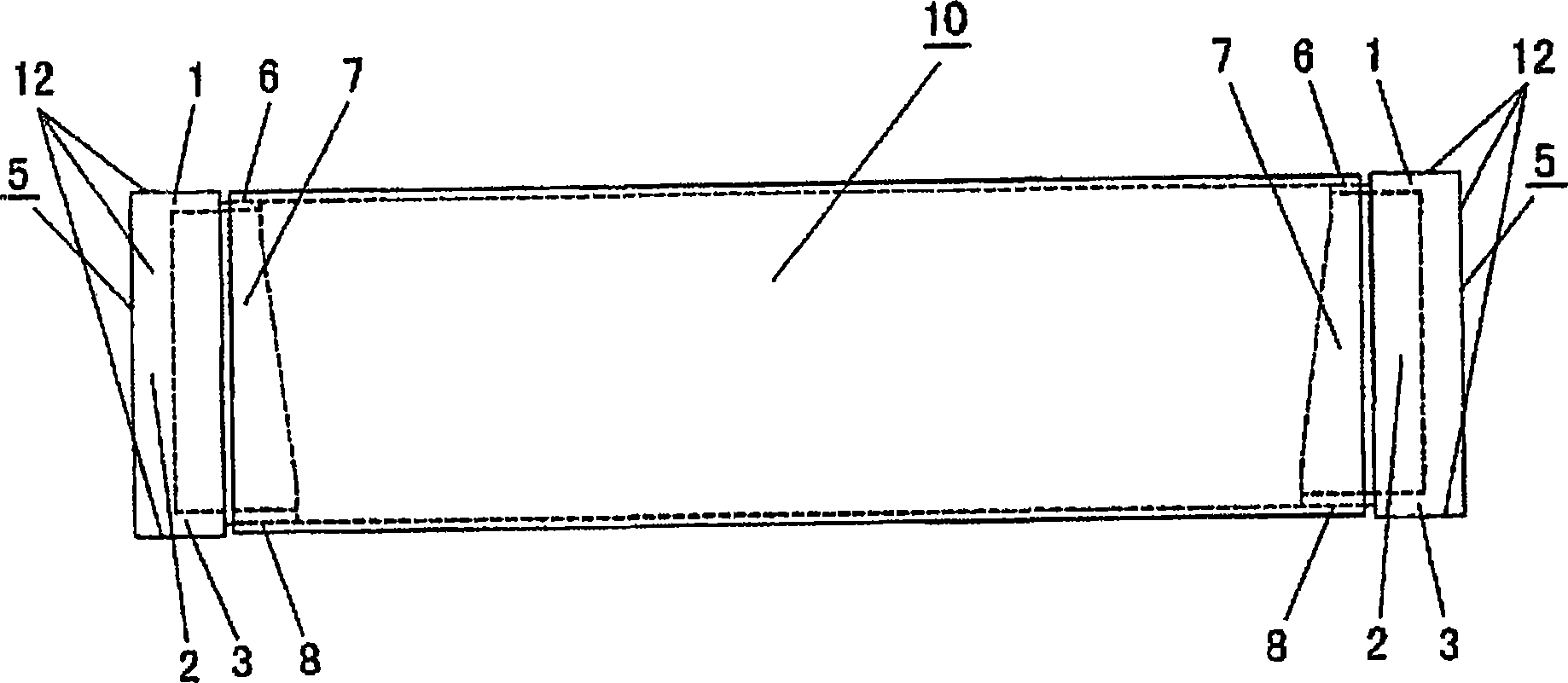

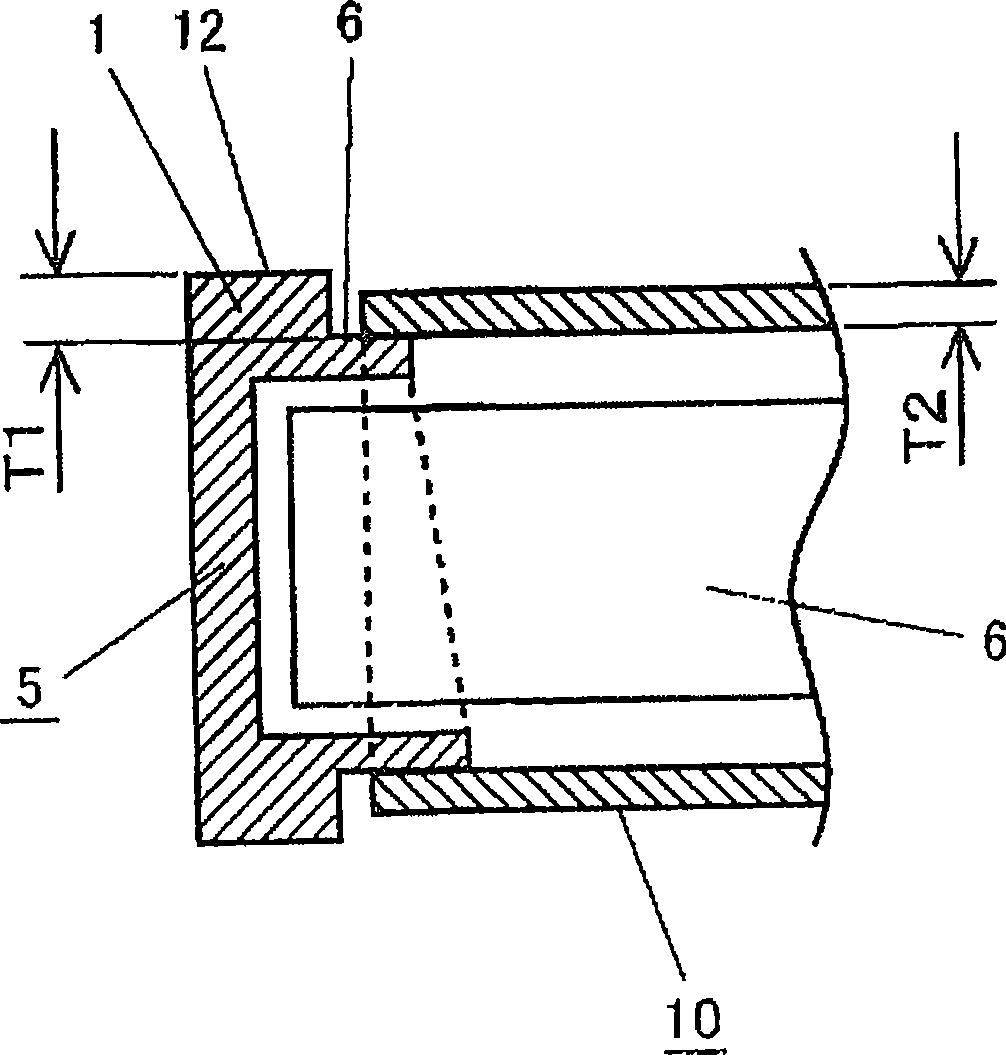

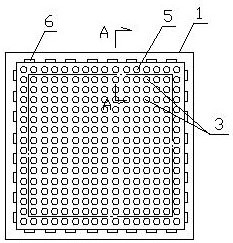

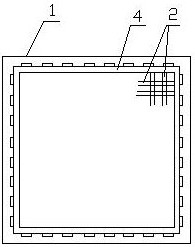

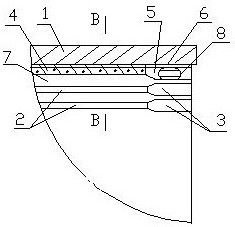

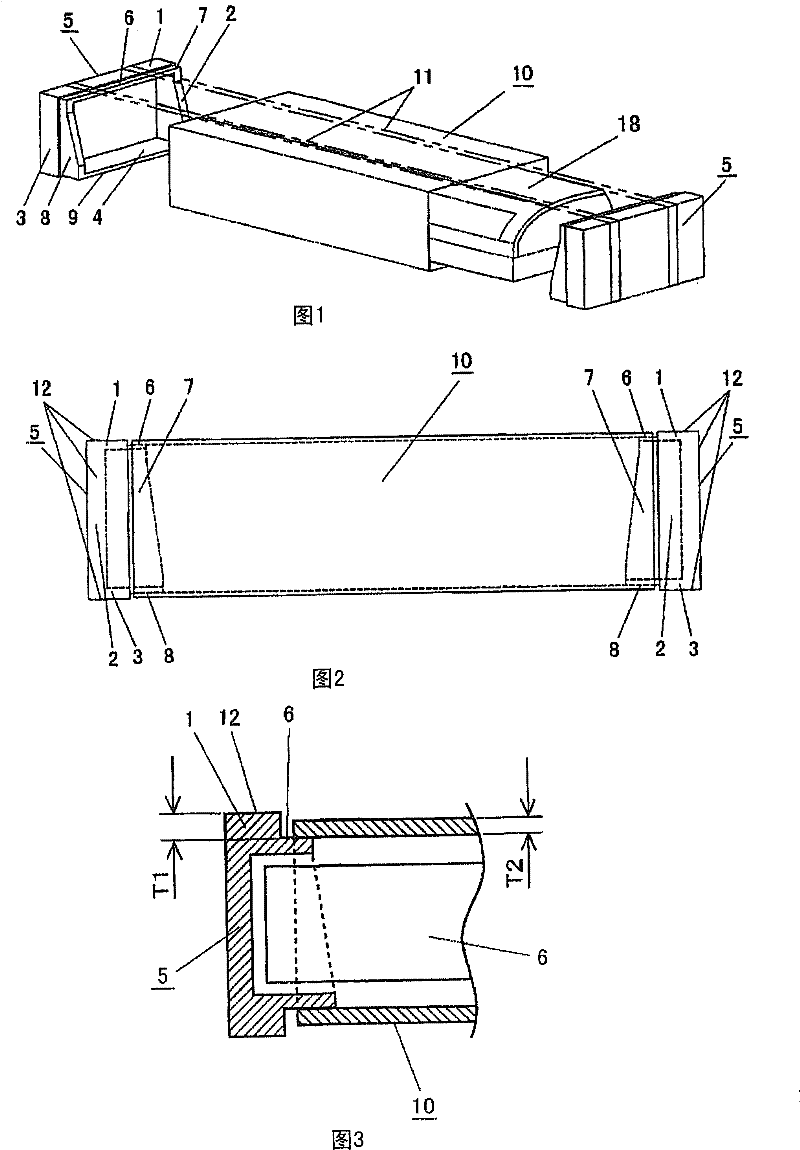

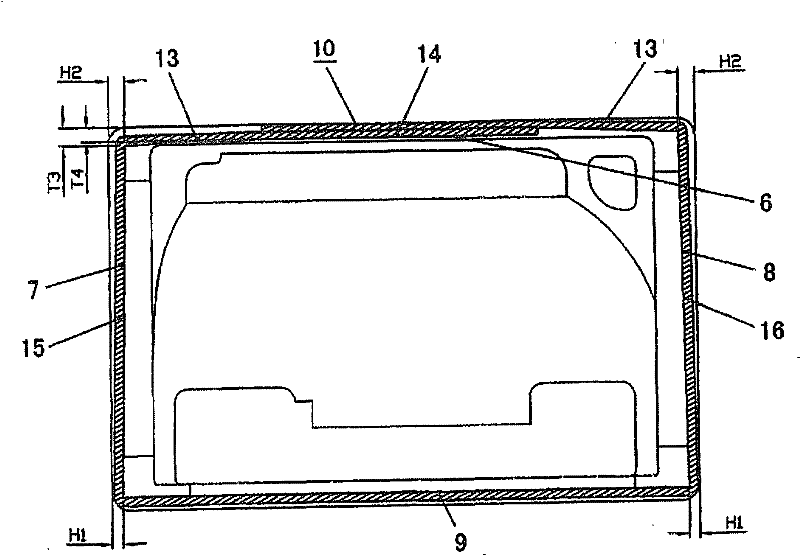

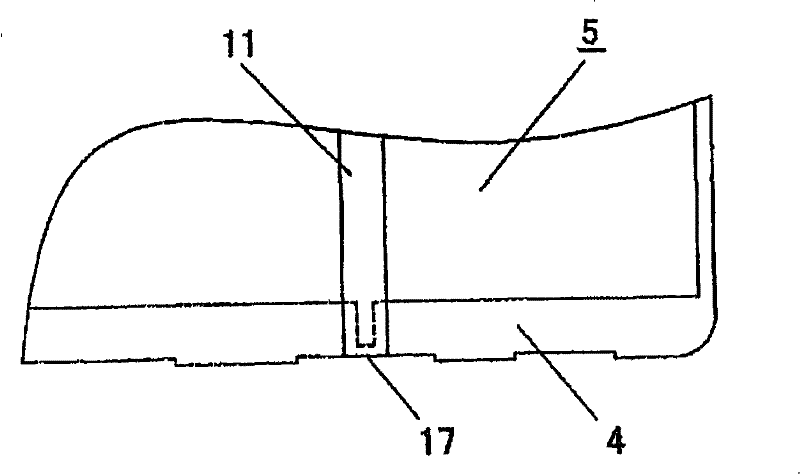

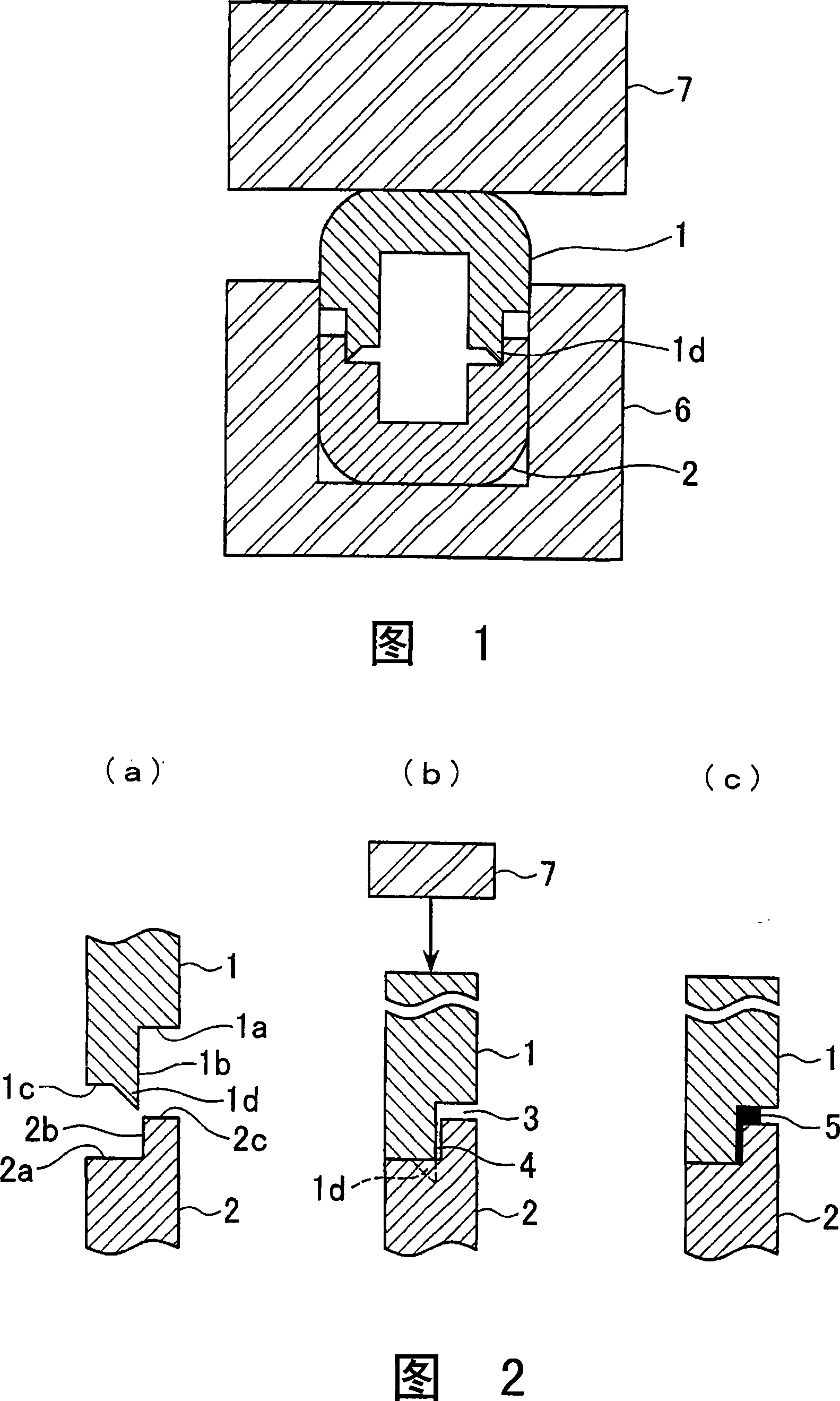

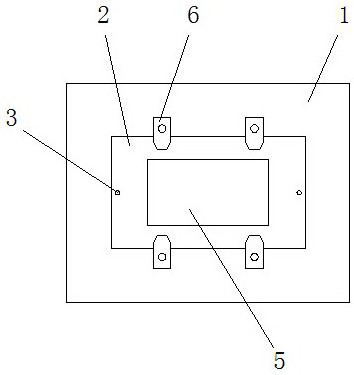

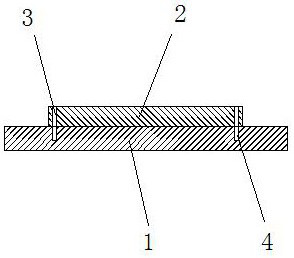

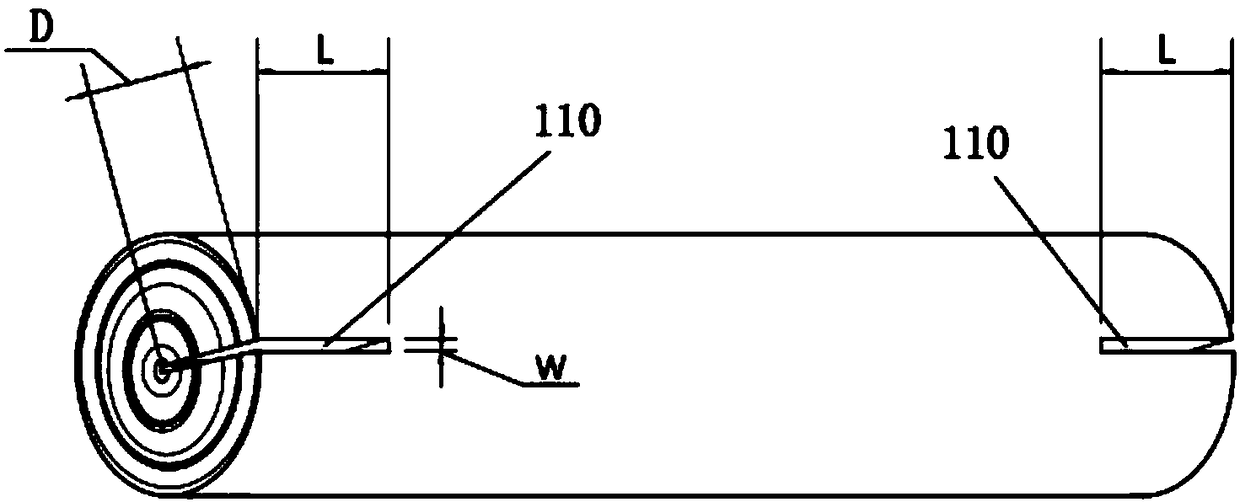

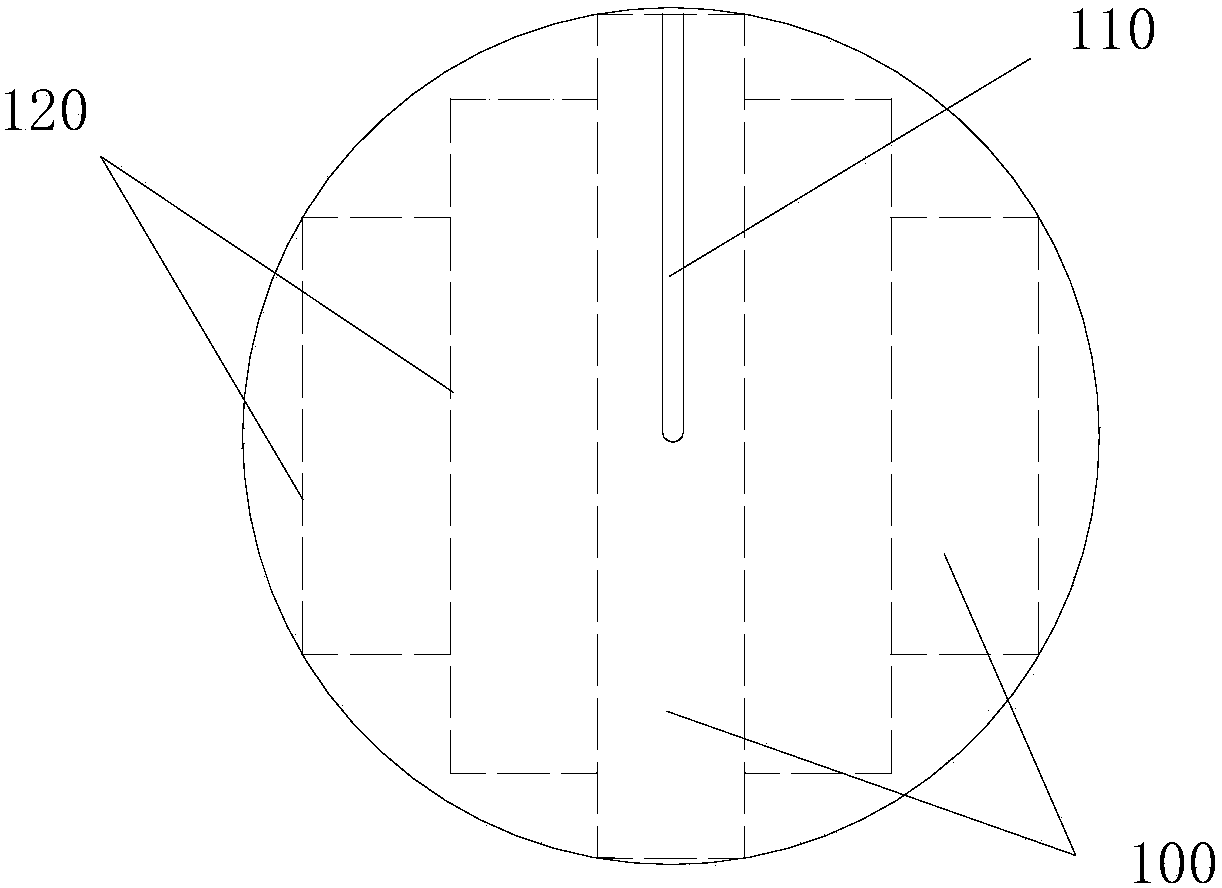

Packaging apparatus

A packaging apparatus comprises tray-like damping members (5) and a pipe-shaped outer box (10). Steps (6, 7, 8, 9) formed by reducing the thicknesses of rise parts (1, 2, 3, 4) on all the outer peripheries of the ends of the rise parts are formed in the tray-like damping members (5) having the rise parts (1, 2, 3, 4) therearound. Both ends of an article (18) to be packaged are supported by the damping members (5). The steps (6, 7, 8, 9) and the article (18) are covered and the damping members (5) are connected to each other by the outer box. A band (11) is fixedly wrapped and tied around the entire part of the packaging device to package the article (18). Since the end faces of the outer box (10) are protected by the damping members (5), the outer box (10) is prevented from being damaged during the transportation. Consequently, the quality of the article during the transportation can be improved.

Owner:PANASONIC CORP

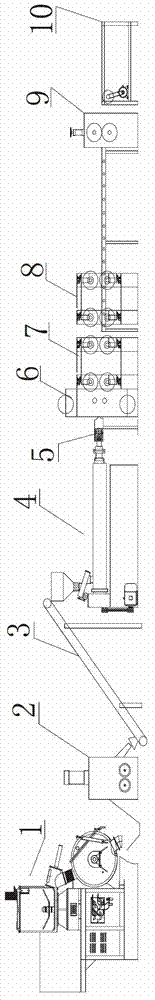

Wood plastic environment friendly ecological material and production technology thereof

InactiveCN102757657AReduce Deformation DefectsConsistent qualityWood layered productsThermoplasticFiber

The invention discloses a wood plastic environment friendly ecological material and a production technology of the wood plastic environment friendly ecological material, belongs to the technical field of material design, and aims to provide a firm wood plastic environment friendly ecological material with consistent quality. The material comprises, by mass, 60 to 70 parts of plant fiber, 30 to 40 parts of hot melt plastic and 3 to 8 of additives. The preparation method includes weighing each component; pouring plant fiber powder into a mixer set to be subjected to coupling dehydration, then adding plastic powder and additives to subject the powder to preplasticization mixing, and obtaining a pre-polymer; adding the pre-polymer into an internal mixer to be plasticized fully and mixed evenly, placing the pre-polymer into an insulation hopper of an extruder through a delivery tray, so that plant fiber and thermoplastic polymer blends and surfaces pass through co-extrusion plastic; performing surface coating through a surface functional material coating device, and manufacturing products through a hot rolling device, a cool rolling device and a tractor; and cutting a needed length through a cutting machine.

Owner:吴国书

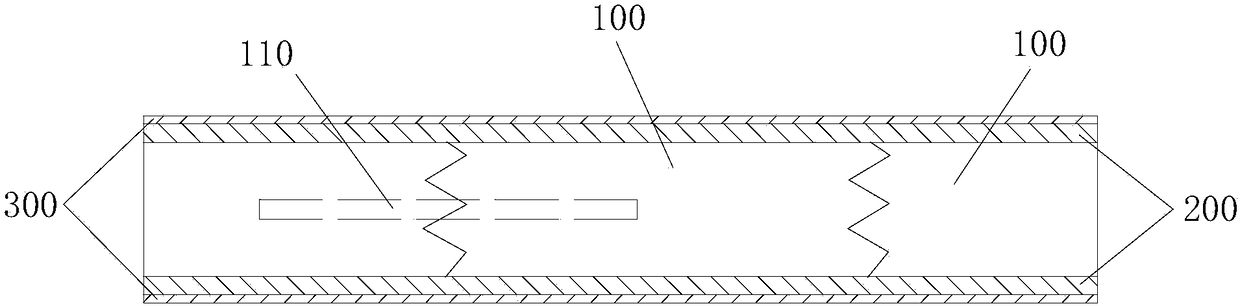

Cross laminated wood structure and manufacture method

ActiveCN105773737AGood dimensional stabilityLow dimensional stabilityWood veneer joiningWood layered productsSurface layerFinger joint

The invention discloses a cross laminated wood structure and a manufacture method thereof. The cross laminated wood is formed by combining at least three layers of materials which are respectively an upper first surface layer, a middle core layer and a lower second surface layer, wherein the first surface layer, the core layer and the second surface layer are fixed through glue. The manufacture method comprises the following steps: selecting materials; performing rounding; forming stress release grooves; drying; performing rough shape cutting; performing broaching; assembling a blank; pressing a plate and the like. According to the cross laminated wood structure and the manufacture method thereof, the drying stress is effectively released, the drying defects are reduced, and the drying energy consumption is reduced; and as the stress release grooves are reserved in two surface finger joint laminated boards of the cross laminated wood, it is ensured that the moulded cross laminated wood is relatively high in dimensional stability in a humid and dry environment. In addition, the stress release grooves are relatively scattered in the cross laminated wood, and the mechanical strength of the cross laminated wood is not affected, so that the technical problems that the strength is low and the stability is poor in an existing cross laminated wood technology are solved well.

Owner:广东联塑日利门业有限公司

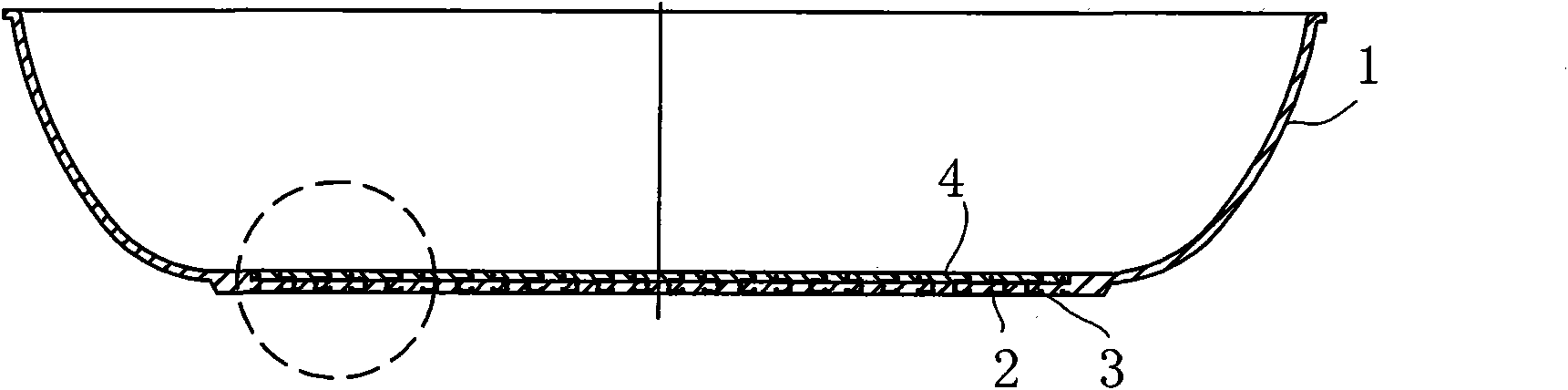

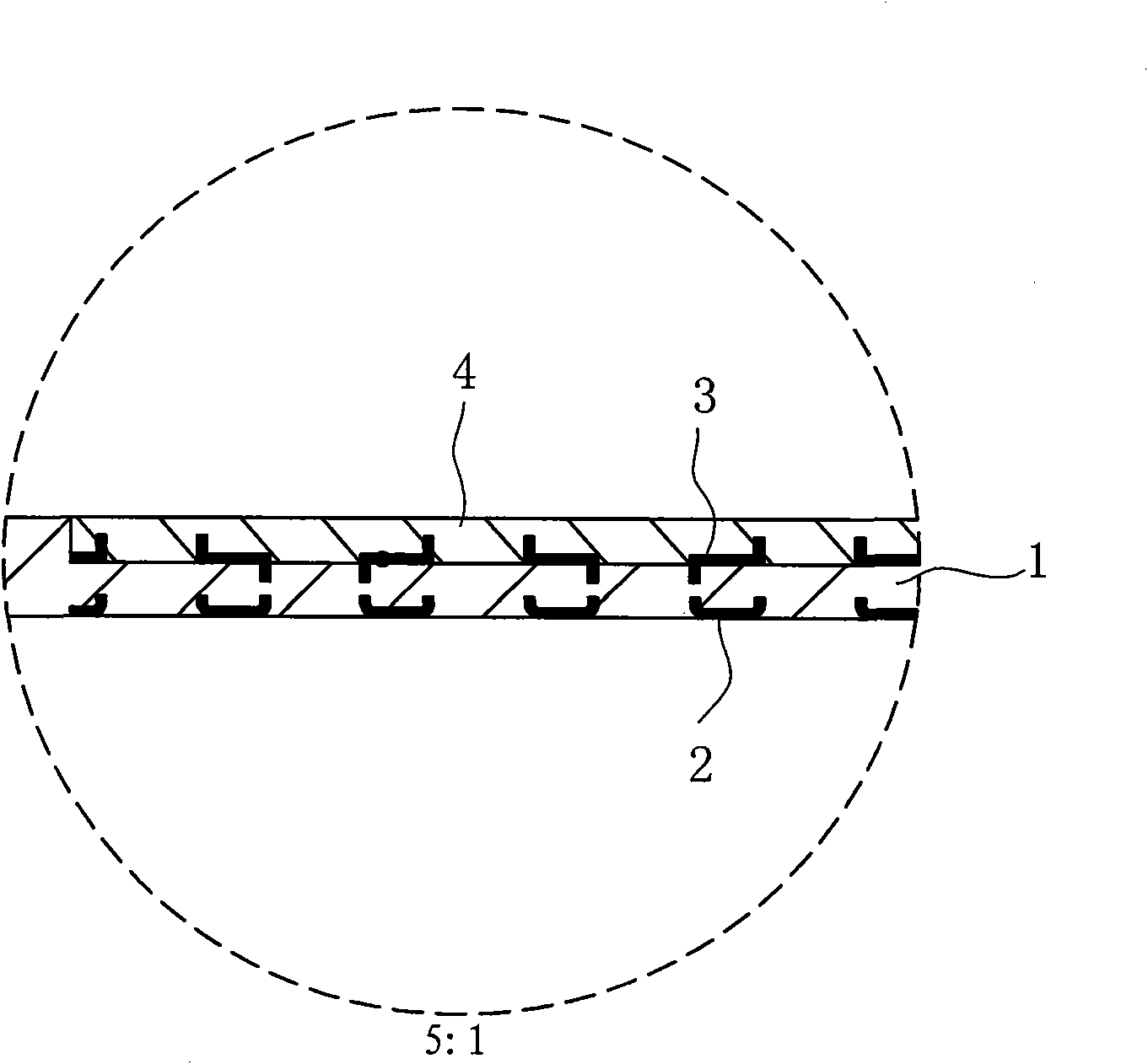

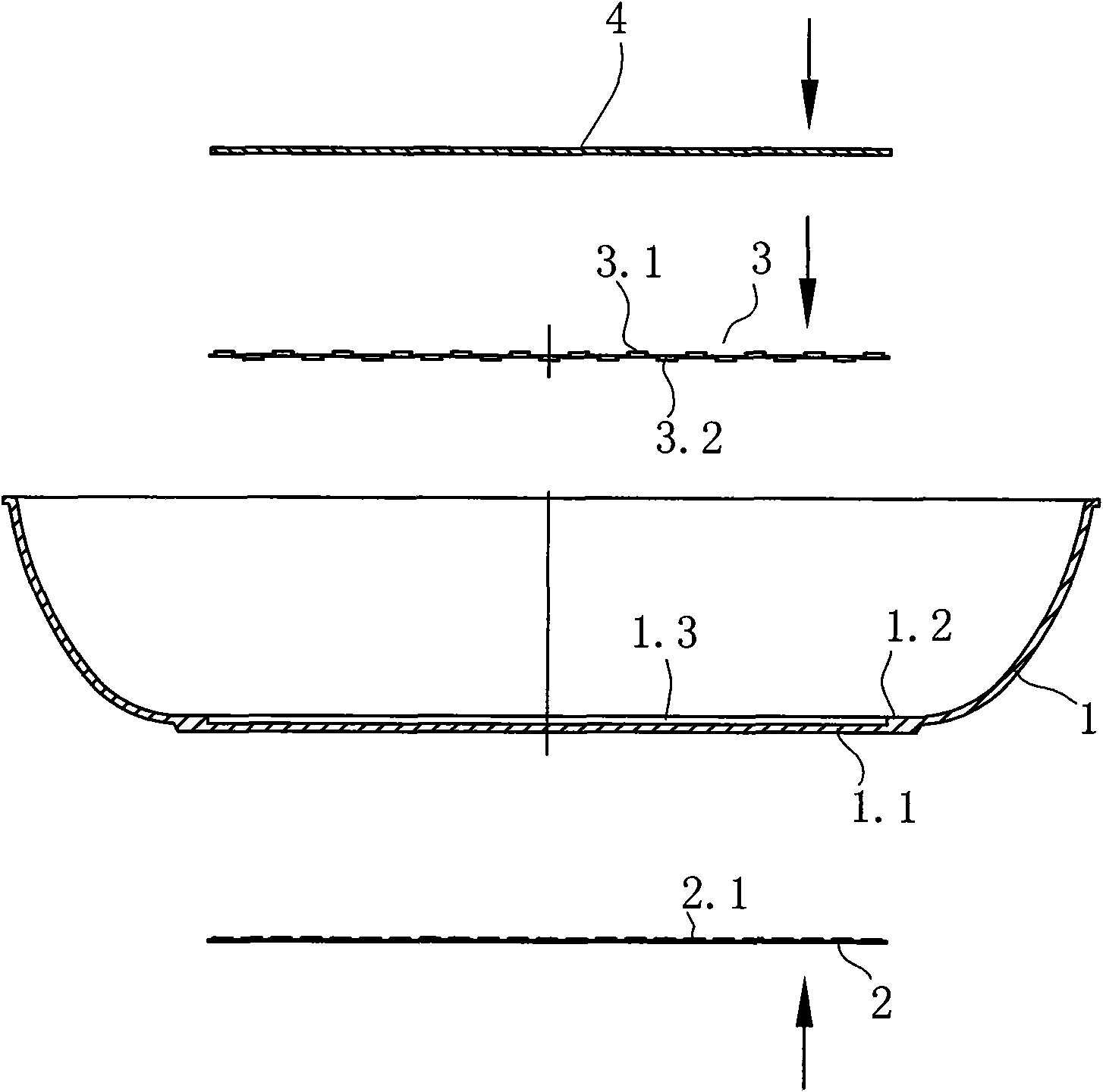

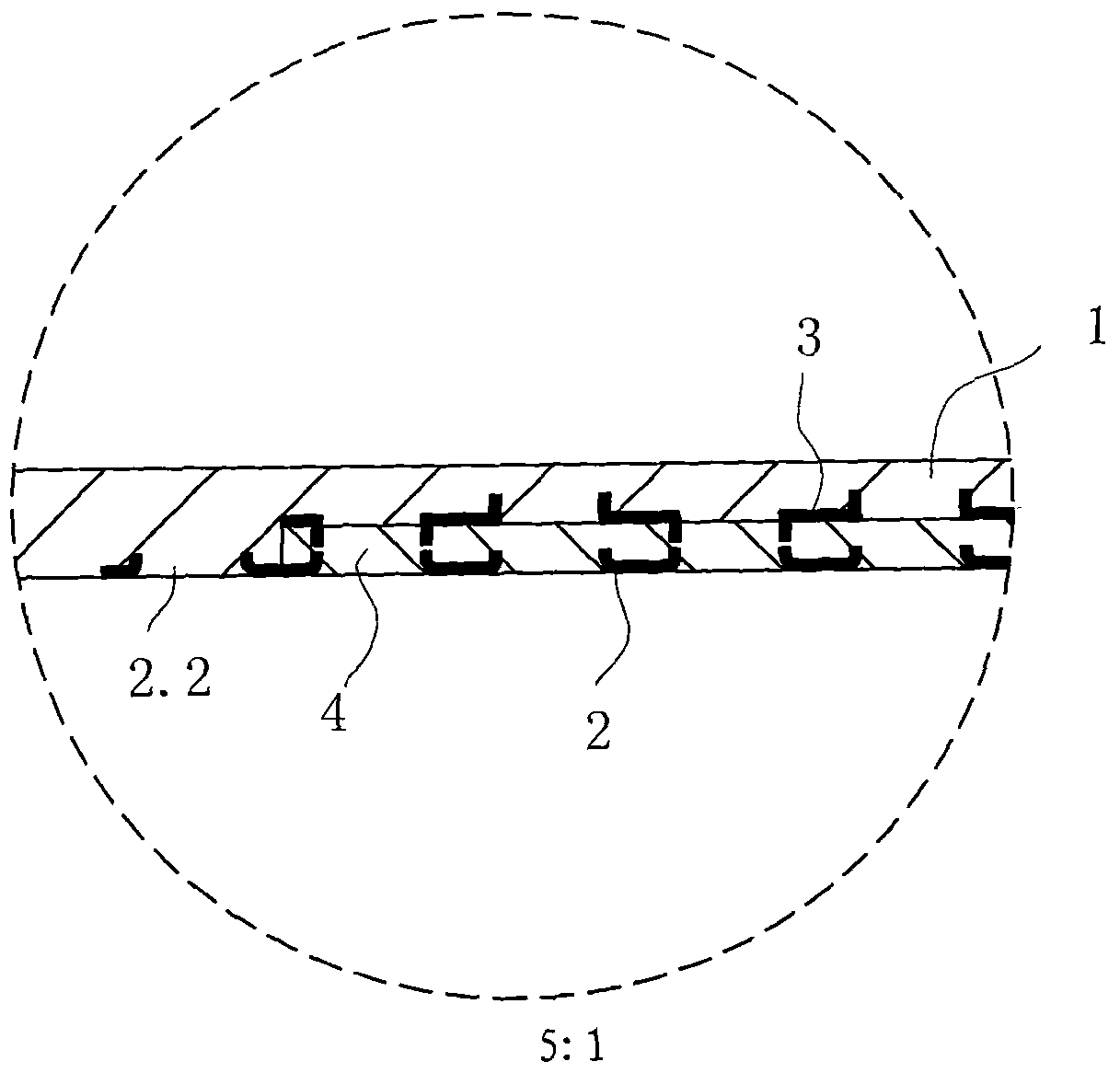

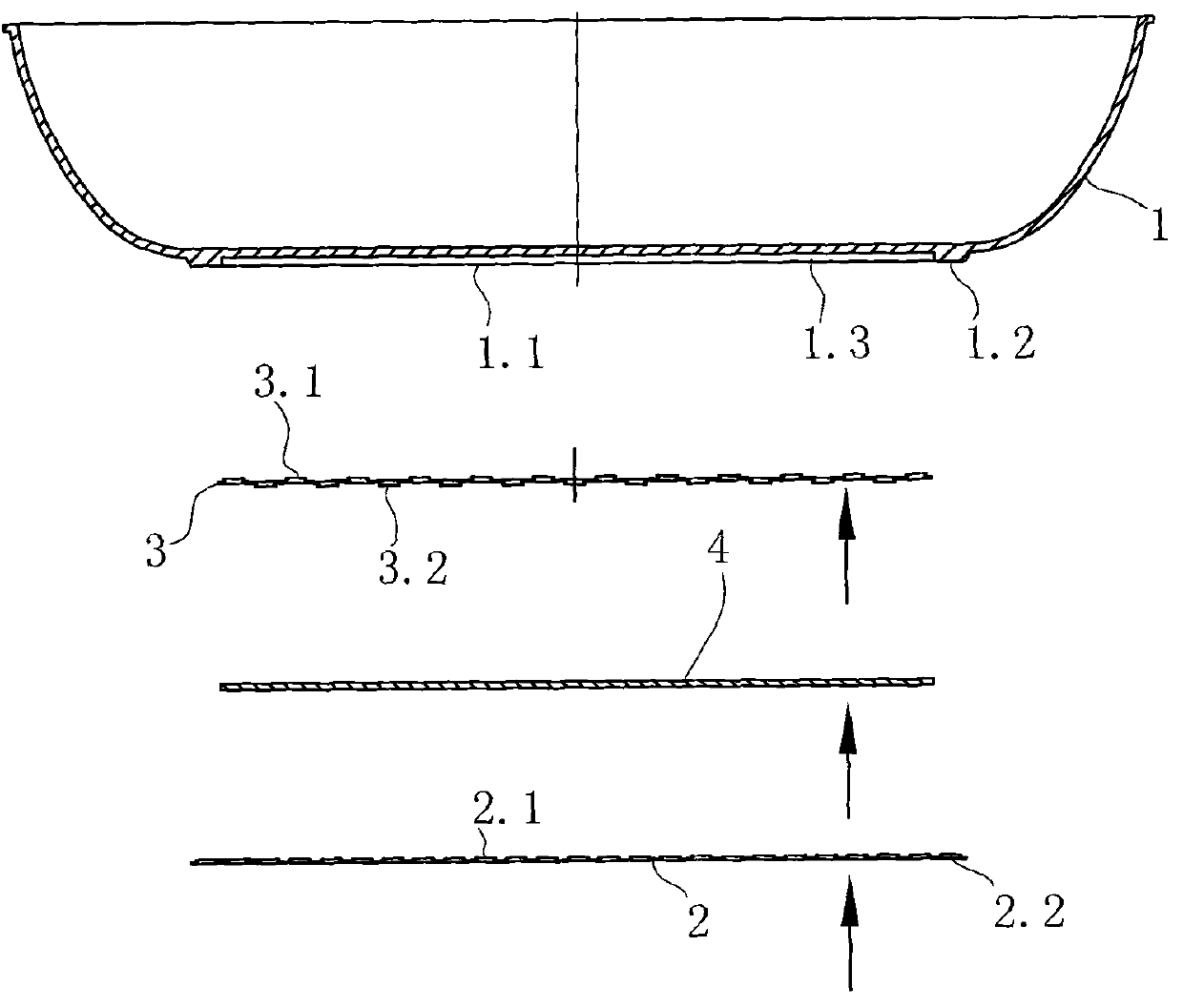

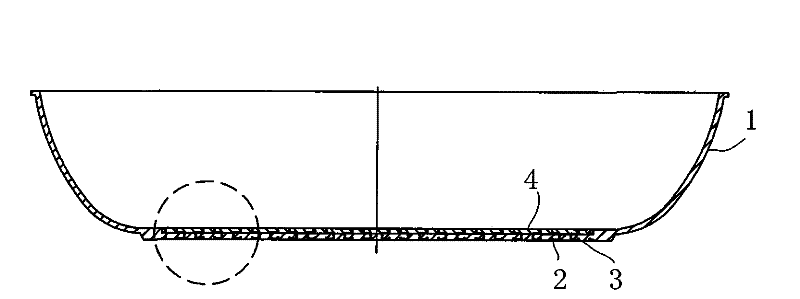

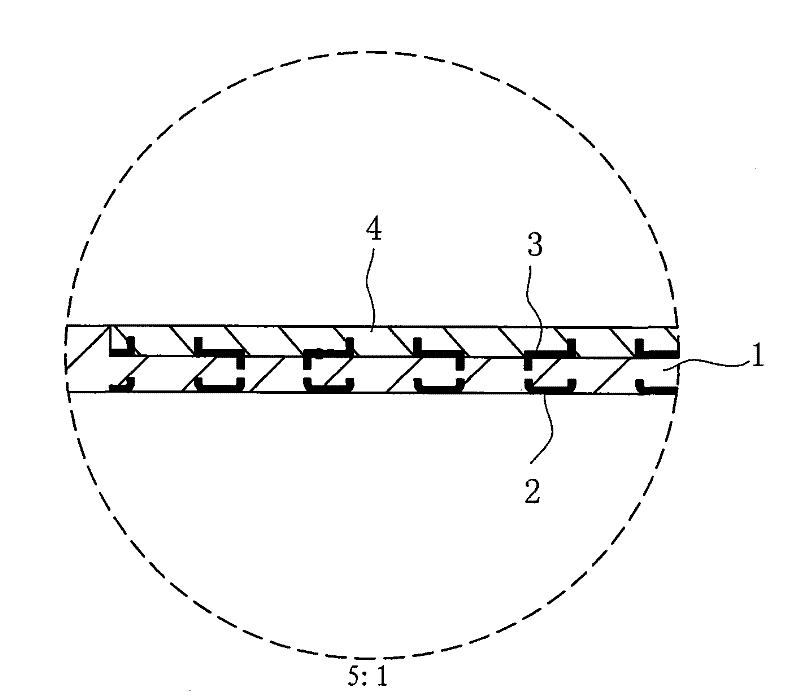

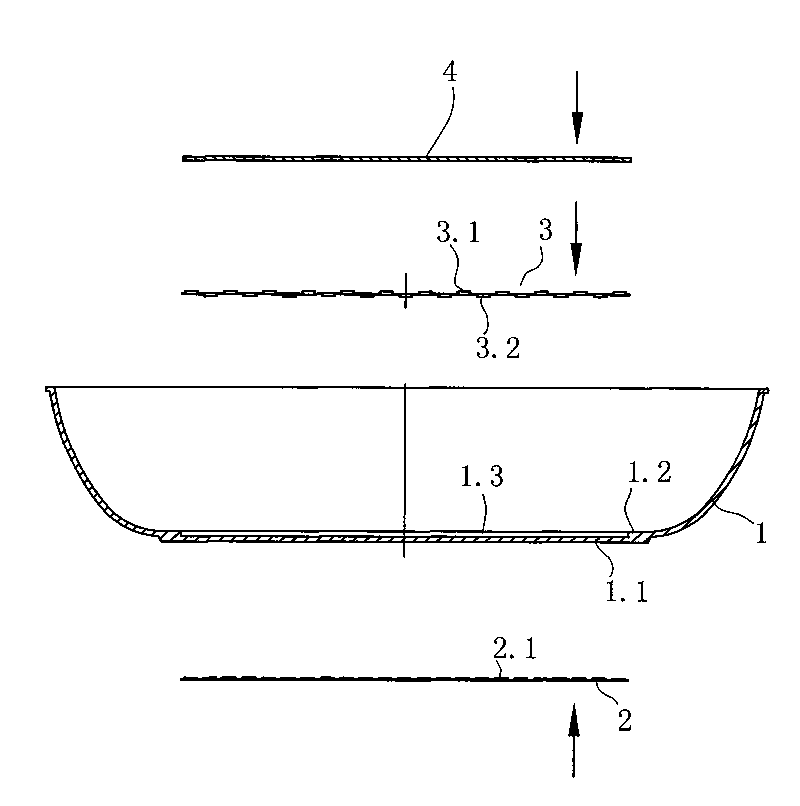

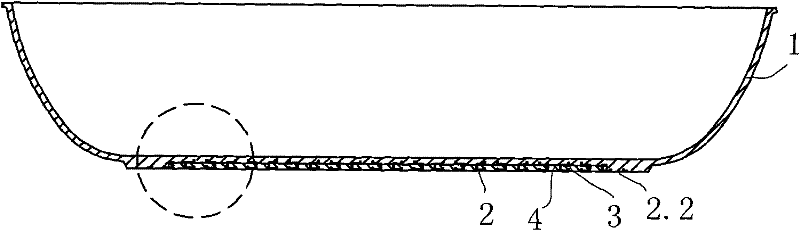

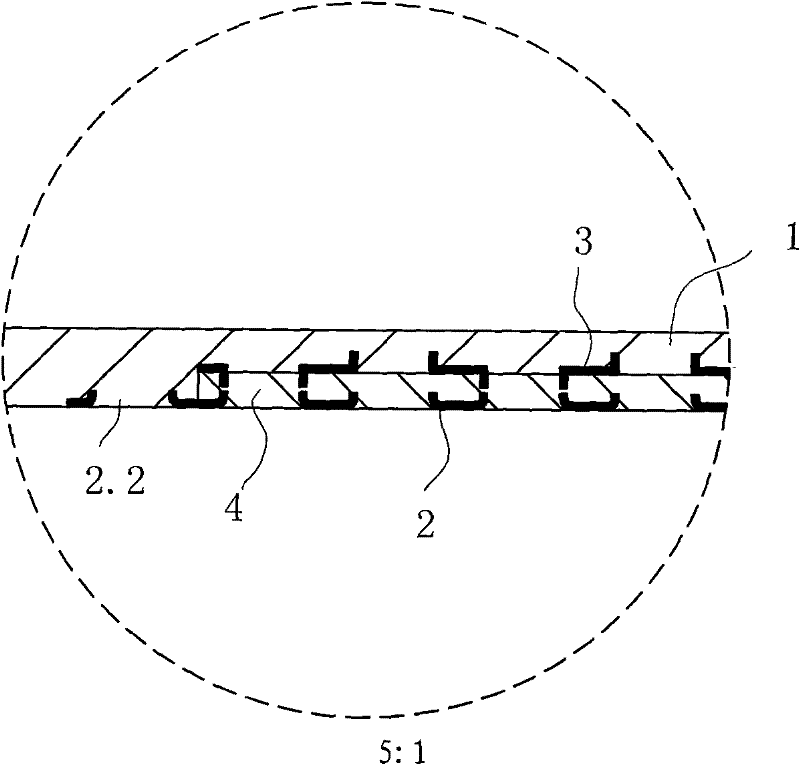

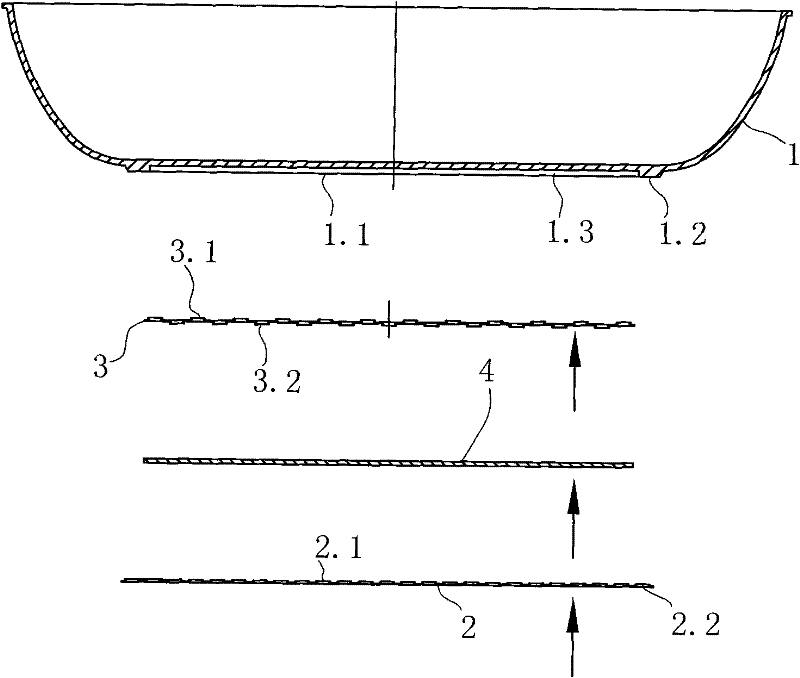

Aluminum pot

InactiveCN101986989AImprove heating effectReduce deformation defectsCooking-vessel materialsMetallurgyDouble bottom

The invention relates to an aluminum pot. The aluminum pot comprises an aluminum pot body and a magnetic conducting heating plate, wherein a lower surface at the bottom of the pot body is a surface for compounding, and an accommodating groove is formed on an upper surface at the bottom of the pot body; and the magnetic conducting heating plate is made of sheets of which flanging holes face upwards and is fixed on the bottom surface of the pot body by compounding. The aluminum pot is characterized by also comprising a metal connection plate and an aluminum plate, wherein the upper and lower flanging holes which face upwards and downwards are formed on the surface of the metal connection plate; the size and shape of the aluminum plate are matched with those of the accommodating groove; and the aluminum plate and the metal connection plate are arranged in the accommodating groove from top to bottom, the upper flanging hole of the metal connection plate is connected with the aluminum plate, and the lower flanging hole of the metal connection plate is connected to the bottom of the accommodating groove. In the aluminum pot, due to the adoption of a structure of the relative arrangement of the magnetic conducting heating plate arranged on the lower part and the metal connection plate arranged on the upper part, heat stress caused by the magnetic conducting heating plate and the aluminum pot body which are made of different materials can be eliminated effectively, the defect that pots with double bottoms are easy to deform due to high temperature of the bottoms is overcome, and the safety performance is improved.

Owner:陆意祥

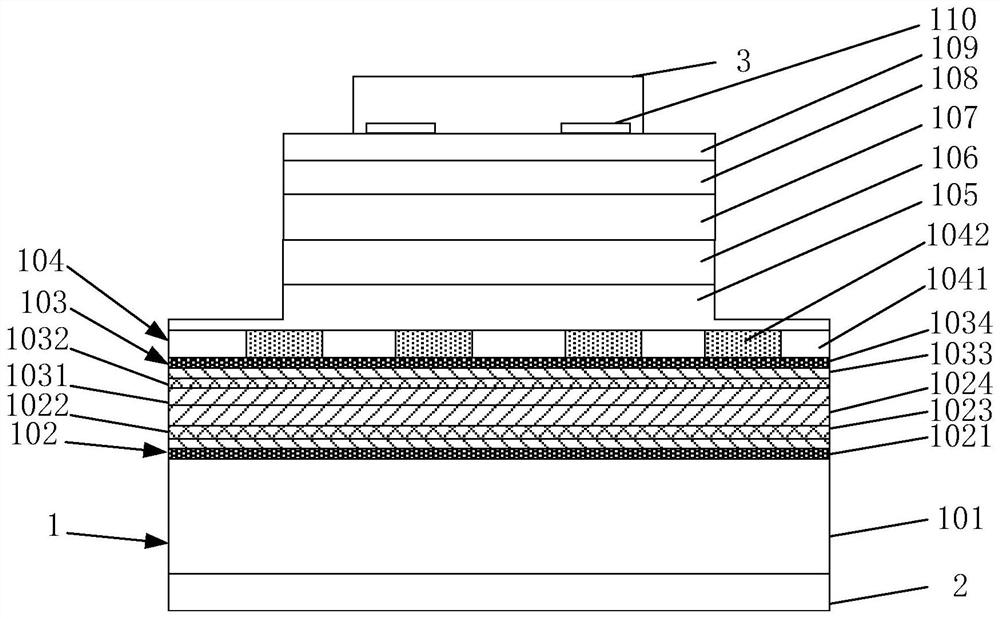

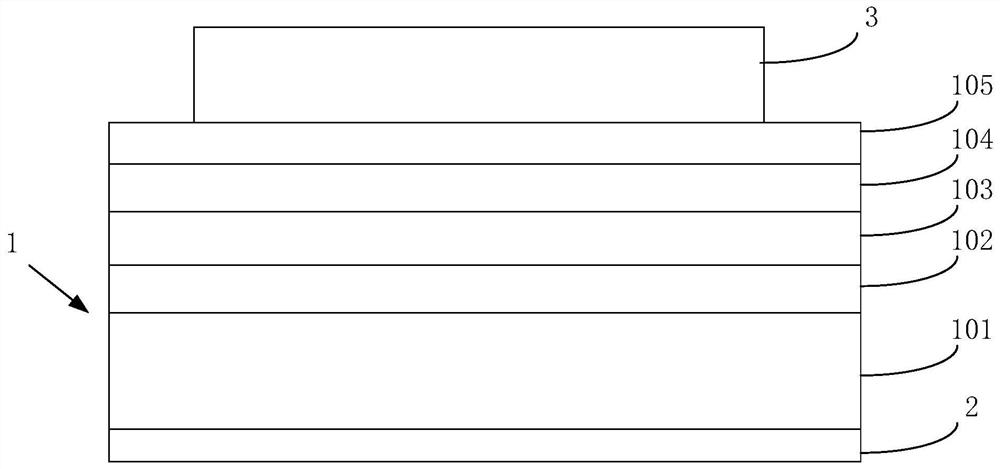

Flip red light diode chip and preparation method thereof

ActiveCN113903844AImprove light extraction efficiencyReduce thermal stressFinal product manufactureSemiconductor devicesEngineeringLight-emitting diode

The invention provides a flip red light diode chip and a preparation method thereof, and belongs to the technical field of light emitting diodes. After a substrate bonding metal layer and an epitaxial bonding metal layer are bonded on a supporting substrate, the supporting substrate supports an epitaxial structure on the epitaxial bonding metal layer, and the substrate bonding metal layer comprises a substrate Cr metal sub-layer, a substrate Pt metal sub-layer, a substrate Ag metal sub-layer and a substrate In metal sub-layer which are stacked in sequence; the epitaxial bonding metal layer comprises an epitaxial In metal sub-layer, an epitaxial Ag metal sub-layer, an epitaxial Pt metal sub-layer, an epitaxial Ti metal sub-layer and an epitaxial Cr metal sub-layer which are stacked in sequence, and an Ag material effectively reflects light to a light emitting surface. The In metal sub-layer reduces the thermal stress generated by high temperature in an obtained red light diode, so that the quality of the red light diode is improved, and the light emitting efficiency of the red light diode is improved.

Owner:HC SEMITEK ZHEJIANG CO LTD

Processing technology for reducing deformation defects in coal gangue hollow brick production

InactiveCN112266231AImprove uniformityShrink evenlyCeramic materials productionClaywaresCoal gangueHydrotalcite

The invention discloses a processing technology for reducing deformation defects in coal gangue hollow brick production, and relates to the technical field of wall materials, and the processing technology comprises the following specific steps: 1), performing processing to prepare zinc-aluminum hydrotalcite; 2), preparing a zinc-aluminum hydrotalcite colloidal solution and a graphene oxide colloidal solution; 3), preparing a graphene oxide / zinc-aluminum hydrotalcite compound; and 4), crushing the raw materials of the coal gangue hollow brick, uniformly mixing the crushed raw materials with thegraphene oxide / zinc-aluminum hydrotalcite compound, adding an N, N-dimethyldiacridine nitrate solution, uniformly performing mixing to obtain a mixture, and performing processing. According to the preparation method, the N, N-dimethyldiacridine nitrate solution is used for wetting the green brick raw material, and the graphene oxide / zinc-aluminum hydrotalcite compound is introduced into the greenbrick, so that water can be quickly discharged from the green brick, the distribution uniformity of residual water in the green brick can be improved, and the green brick can be uniformly shrunk in the roasting process; therefore, the effect of reducing the deformation defect after the green brick is fired is achieved.

Owner:安徽滨江新型墙材有限公司

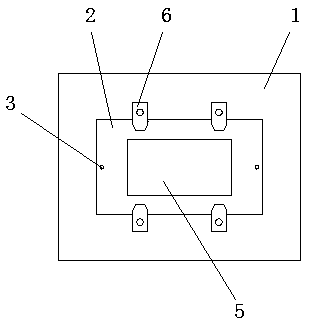

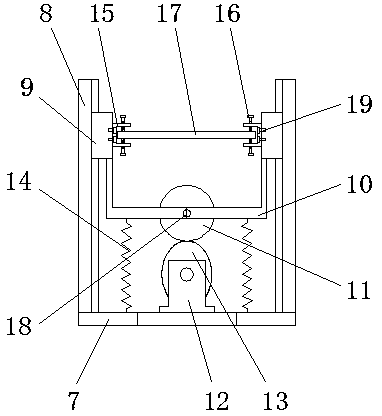

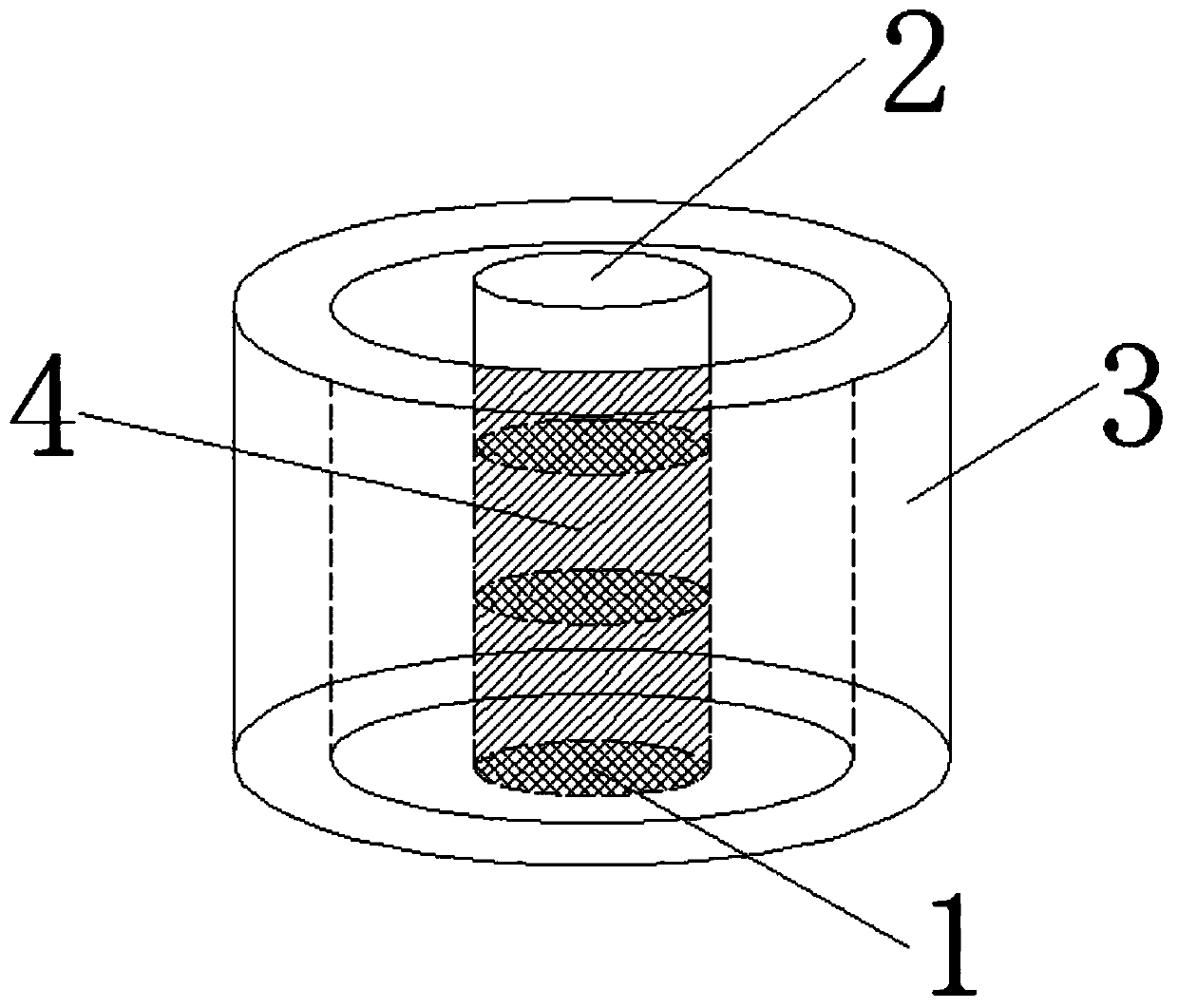

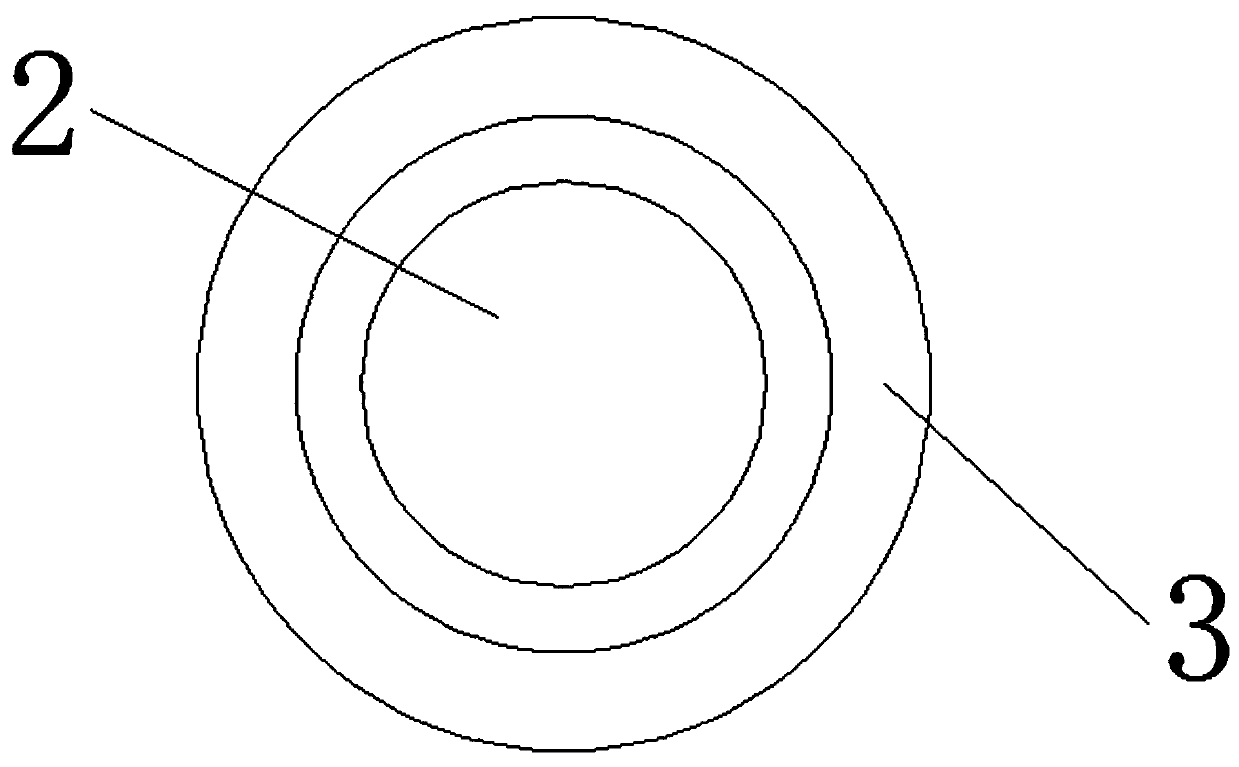

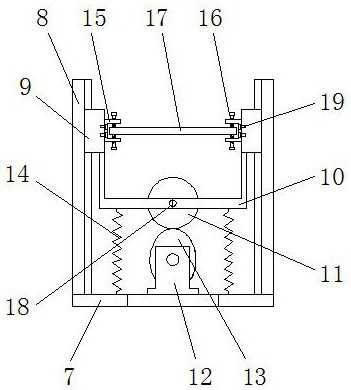

Aluminum-based composite material multi-direction double-level deformation restraining device and application method thereof

InactiveCN110076337AReduce deformation defectsGuaranteed field of applicationInterference fitSize increase

The invention discloses an aluminum-based composite material multi-direction double-level deformation restraining device and an application method thereof, particularly relates to an aluminum-based composite material multi-direction double-level deformation restraining device and an application method thereof, and aims at solving the problem that according to a traditional aluminum-based compositematerial extrusion forming method, material diameter-direction size increasing is hard to achieve. The aluminum-based composite material multi-direction double-level deformation restraining device iscomposed of a lower pressing head, an upper pressing head and an annular restraint die. The method comprises the steps that firstly, a cylindrical blank and a cylinder annular wrapping sleeve material which are the same in height are prepared and are in interference fit, and blank preparing is finished; secondly, preheating is conducted, the blank, the upper pressing head, the lower pressing head, a heat preservation bottom plate and the annular restraint die are preheated to the assigned temperature; thirdly, the heat preservation bottom plate, the lower pressing head, the blank and the upper pressing head are placed on a press machine platform; fourthly, the press machine is controlled, and the blank is compressed and deformed; and fifthly, heat treatment is conducted. According to thealuminum-based composite material multi-direction double-level deformation restraining device and the application method thereof, after multi-direction double-level deformation restraining, the comprehensive performance of a composite material can be effectively improved, and the composite material radial size is increased by 15%-25%. The aluminum-based composite material multi-direction double-level deformation restraining device and the application method thereof are used in the aerospace industry.

Owner:QIQIHAR XIANGKE NEW MATERIAL CO LTD

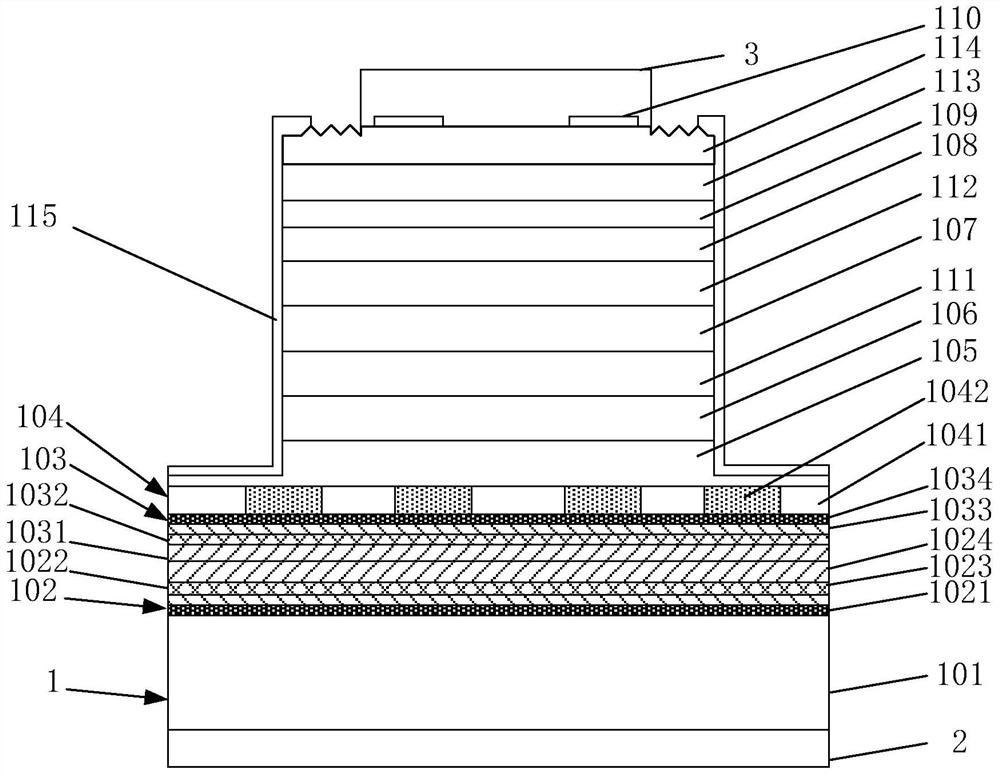

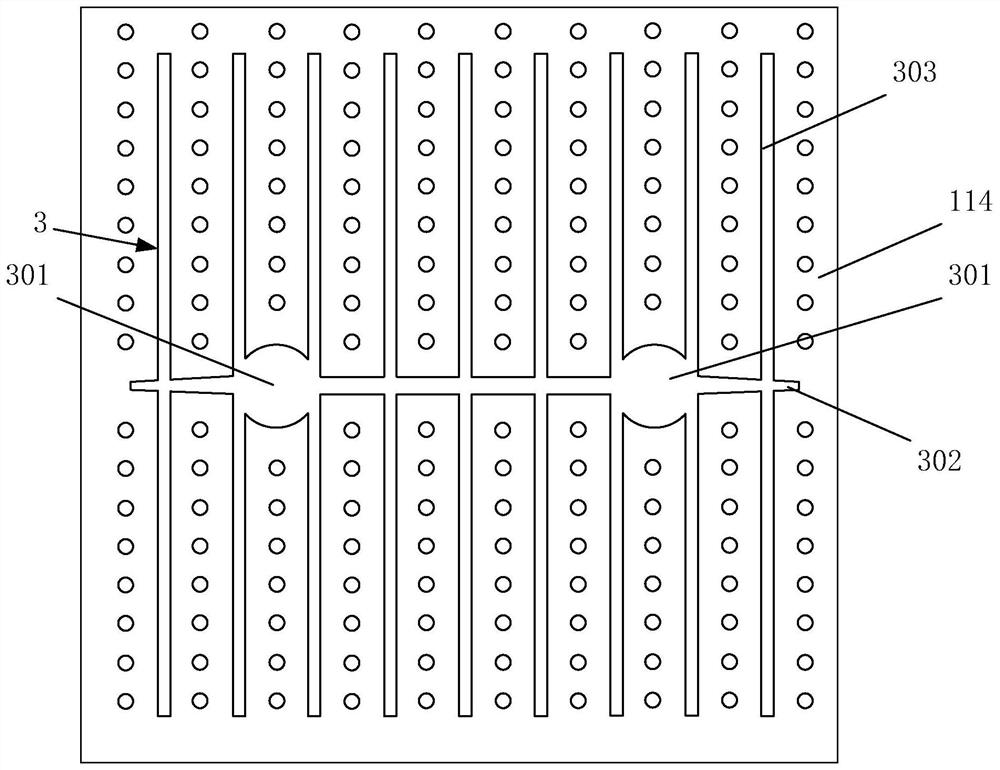

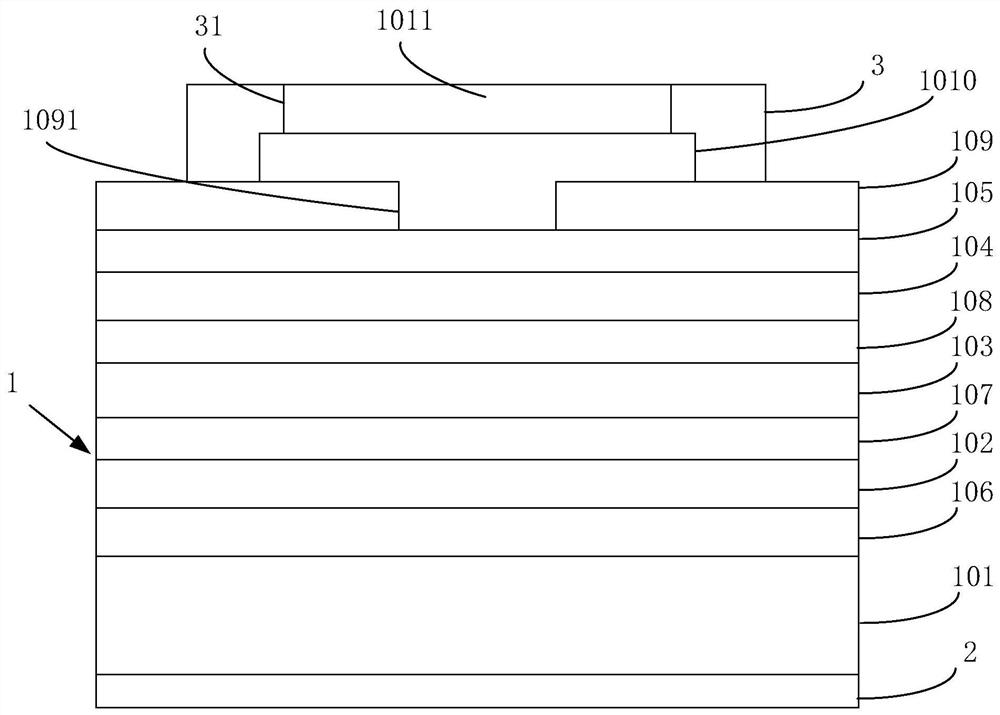

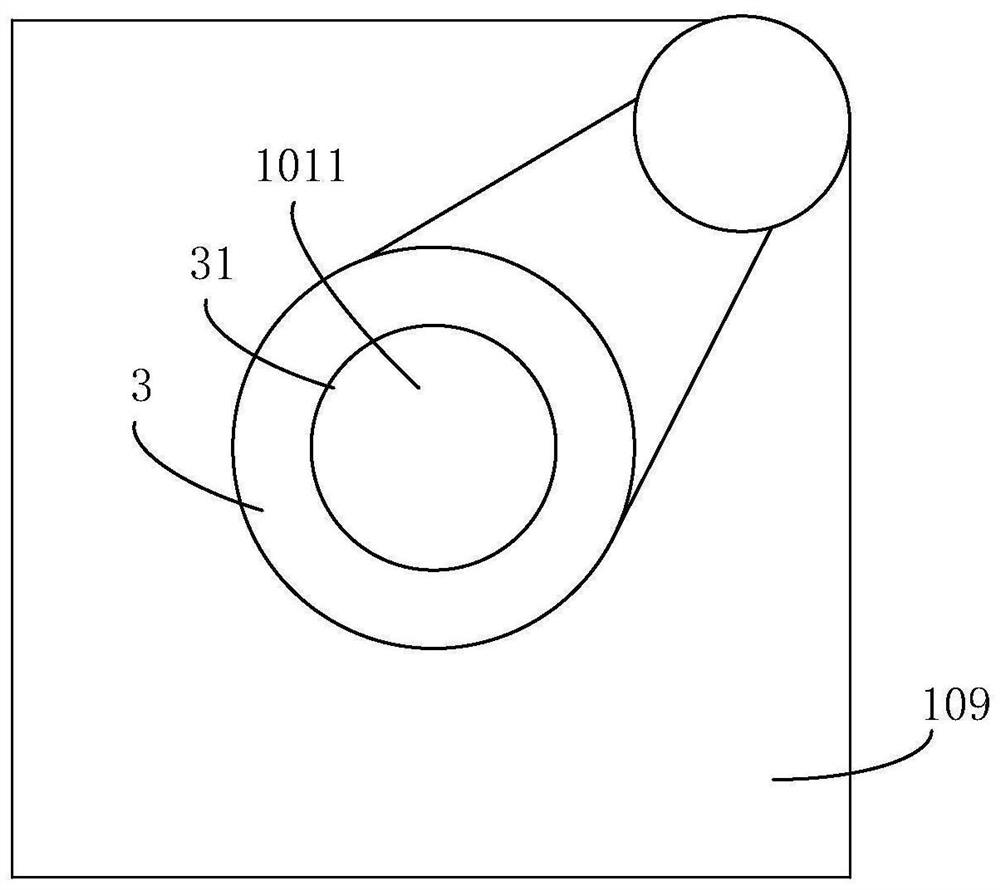

GaN-based blue-violet light vertical cavity surface emitting laser chip and manufacturing method thereof

PendingCN113922208AQuality improvementImprove light outputLaser detailsSemiconductor lasersVertical-cavity surface-emitting laserDistributed Bragg reflector

The invention provides a GaN-based blue-violet light vertical cavity surface emitting laser chip and a manufacturing method thereof, and belongs to the field of semiconductor manufacturing. The first distributed Bragg reflector on the n-GaN substrate is arranged to comprise the non-doped AlN / GaN superlattice structure, the reflectivity is high, the quality is good, and the light extraction rate is improved. On the other hand, the second distributed Bragg reflector is arranged between the quantum well active layer and the p-GaN ohmic contact layer, stress is released, carrier overflow is inhibited, meanwhile, the hole barrier height is reduced, hole transmission is facilitated, and the device performance is improved. The quality and the light emitting efficiency of the obtained GaN-based blue-violet light vertical cavity surface emitting laser can be effectively improved on the whole, and stable use of the GaN-based blue-violet light vertical cavity surface emitting laser is ensured.

Owner:HC SEMITEK ZHEJIANG CO LTD

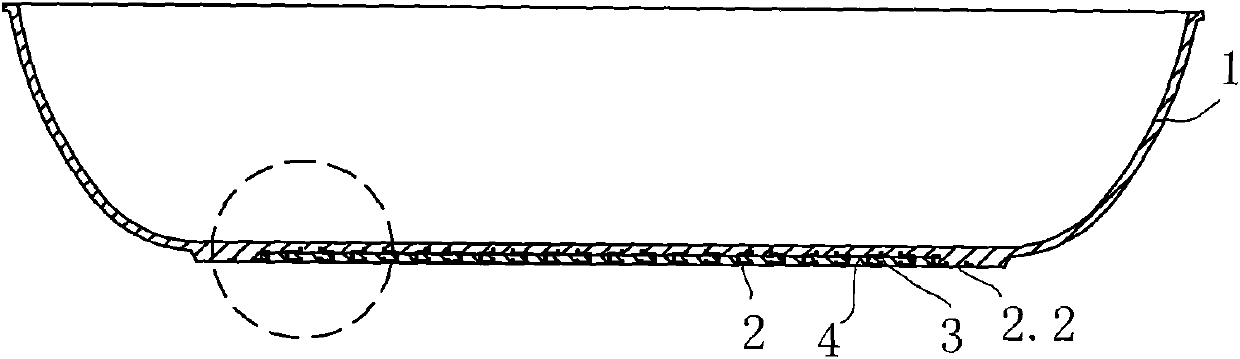

Aluminum pan

ActiveCN102018450AImprove heating effectReduce deformation defectsCooking-vessel materialsMetallurgyHigh heat

The invention relates to an aluminum pan. The lower surface of the bottom of the aluminum pan is a composite surface and is provided with an accommodating groove. The aluminum pan comprises a magnetic conduction heating plate made of a plate with upward flanged holes, and is characterized by also comprising a metal connecting plate and an aluminum plate, wherein upward flanged holes and downward flanged holes are distributed on the surface of the metal connecting plate; the size and the shape of the aluminum plate are matched with those of the accommodating groove; the aluminum plate and the metal connecting plate are filled in the accommodating groove from bottom to top, the upward flanged holes of the metal connecting plate are connected with the bottom of the accommodating groove, and the downward flanged holes of the metal connecting plate are connected with the aluminum plate; the magnetic conduction heating plate is larger than the accommodating groove, at least one circle of flanged holes are fixedly connected with the bottom of a pan body while the magnetic conduction heating plate is fixedly connected with the lower surface of the aluminum plate through the flanged holes; and a structure that the lower magnetic conduction heating plate is arranged opposite to the upper metal connecting plate is adopted, so the thermal stress caused by different materials of the magnetic conduction heating plate and the aluminum pan body can be effectively eliminated, the defect that the bottom of the pan with the composite bottom is easy to deform after being heated is overcome, and the safety performance is improved.

Owner:NINGBO VASON LIGHT IND GRP

Aluminum pot

InactiveCN101986989BImprove heating effectReduce deformation defectsCooking-vessel materialsMetallurgyFlanging

The invention relates to an aluminum pot. The aluminum pot comprises an aluminum pot body and a magnetic conducting heating plate, wherein a lower surface at the bottom of the pot body is a surface for compounding, and an accommodating groove is formed on an upper surface at the bottom of the pot body; and the magnetic conducting heating plate is made of sheets of which flanging holes face upwards and is fixed on the bottom surface of the pot body by compounding. The aluminum pot is characterized by also comprising a metal connection plate and an aluminum plate, wherein the upper and lower flanging holes which face upwards and downwards are formed on the surface of the metal connection plate; the size and shape of the aluminum plate are matched with those of the accommodating groove; and the aluminum plate and the metal connection plate are arranged in the accommodating groove from top to bottom, the upper flanging hole of the metal connection plate is connected with the aluminum plate, and the lower flanging hole of the metal connection plate is connected to the bottom of the accommodating groove. In the aluminum pot, due to the adoption of a structure of the relative arrangement of the magnetic conducting heating plate arranged on the lower part and the metal connection plate arranged on the upper part, heat stress caused by the magnetic conducting heating plate and the aluminum pot body which are made of different materials can be eliminated effectively, the defect that pots with double bottoms are easy to deform due to high temperature of the bottoms is overcome, and the safety performance is improved.

Owner:陆意祥

Aluminum pan

ActiveCN102018450BImprove heating effectReduce deformation defectsCooking-vessel materialsMetalMaterials science

The invention relates to an aluminum pan. The lower surface of the bottom of the aluminum pan is a composite surface and is provided with an accommodating groove. The aluminum pan comprises a magnetic conduction heating plate made of a plate with upward flanged holes, and is characterized by also comprising a metal connecting plate and an aluminum plate, wherein upward flanged holes and downward flanged holes are distributed on the surface of the metal connecting plate; the size and the shape of the aluminum plate are matched with those of the accommodating groove; the aluminum plate and the metal connecting plate are filled in the accommodating groove from bottom to top, the upward flanged holes of the metal connecting plate are connected with the bottom of the accommodating groove, and the downward flanged holes of the metal connecting plate are connected with the aluminum plate; the magnetic conduction heating plate is larger than the accommodating groove, at least one circle of flanged holes are fixedly connected with the bottom of a pan body while the magnetic conduction heating plate is fixedly connected with the lower surface of the aluminum plate through the flanged holes;and a structure that the lower magnetic conduction heating plate is arranged opposite to the upper metal connecting plate is adopted, so the thermal stress caused by different materials of the magnetic conduction heating plate and the aluminum pan body can be effectively eliminated, the defect that the bottom of the pan with the composite bottom is easy to deform after being heated is overcome, and the safety performance is improved.

Owner:NINGBO VASON LIGHT IND GRP

Preparation method of a honeycomb ceramic regenerator with ultra-thick outer wall

ActiveCN110696152BStored heat increasedReduced inner wall thicknessCeramic extrusion diesClay processing apparatusMolding machineRaw material

Owner:JIANGXI BOCENT TEC CO LTD

Packaging apparatus

A packaging apparatus comprises tray-like damping members (5) and a pipe-shaped outer box (10). Steps (6, 7, 8, 9) formed by reducing the thicknesses of rise parts (1, 2, 3, 4) on all the outer peripheries of the ends of the rise parts are formed in the tray-like damping members (5) having the rise parts (1, 2, 3, 4) therearound. Both ends of an article (18) to be packaged are supported by the damping members (5). The steps (6, 7, 8, 9) and the article (18) are covered and the damping members (5) are connected to each other by the outer box. A band (11) is fixedly wrapped and tied around the entire part of the packaging device to package the article (18). Since the end faces of the outer box (10) are protected by the damping members (5), the outer box (10) is prevented from being damaged during the transportation. Consequently, the quality of the article during the transportation can be improved.

Owner:PANASONIC CORP

A kind of red ceramic tile and its manufacturing method

InactiveCN104944914BHigh priceLow priceCeramic materials productionClaywaresAndraditeEnvironmental resistance

The invention discloses a red ceramic tile and a manufacturing method thereof. The ceramic tile is prepared from the following raw materials in parts by mass: 50-60 parts of red mud, 15-25 parts of kaolin, 15-25 parts of perlite, 10-15 parts of quartz sand, 5-10 parts of fly ash, 2-5 parts of andradite, 2-5 parts of gehlenite and 2-5 parts of diopside. The manufacturing technique comprises the following steps: material selection, powder preparation, compaction, drying, glazing and firing to obtain the finished product. The use proportion of the red mud is greater than one half of the total raw materials; and the consumption of the red mud is maximally increased, thereby relieving the abundant discharge of the red mud which has no place to arrange, changing wastes into valuable substances, utilizing the waste, lowering the production cost and reducing the environmental pollution. The red ceramic tile is corresponding to new product research, development and application in the whole ceramic brick industry around the environment-friendly problems of energy saving, emission reduction, waste slag utilization and the like.

Owner:绥阳县华夏陶瓷有限责任公司

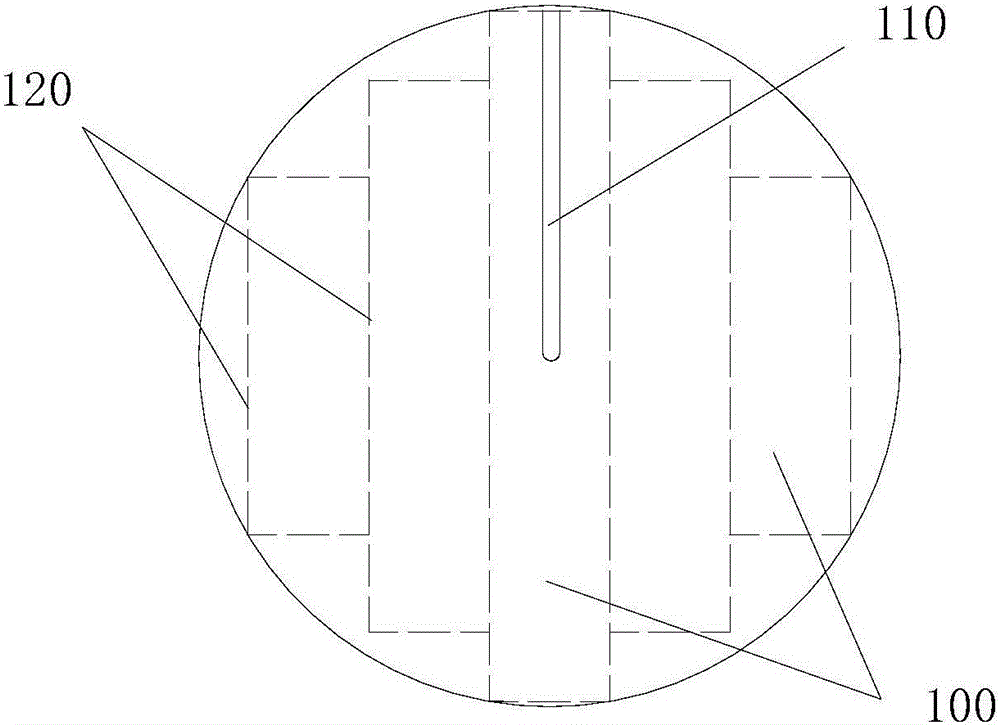

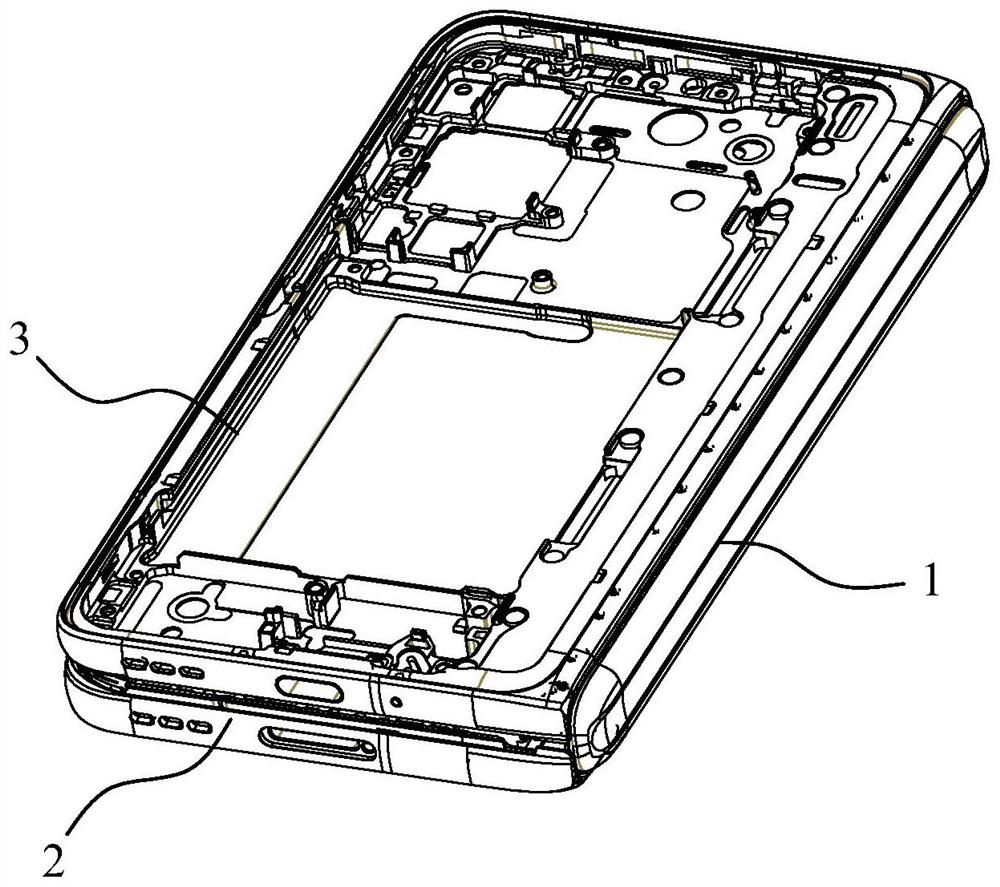

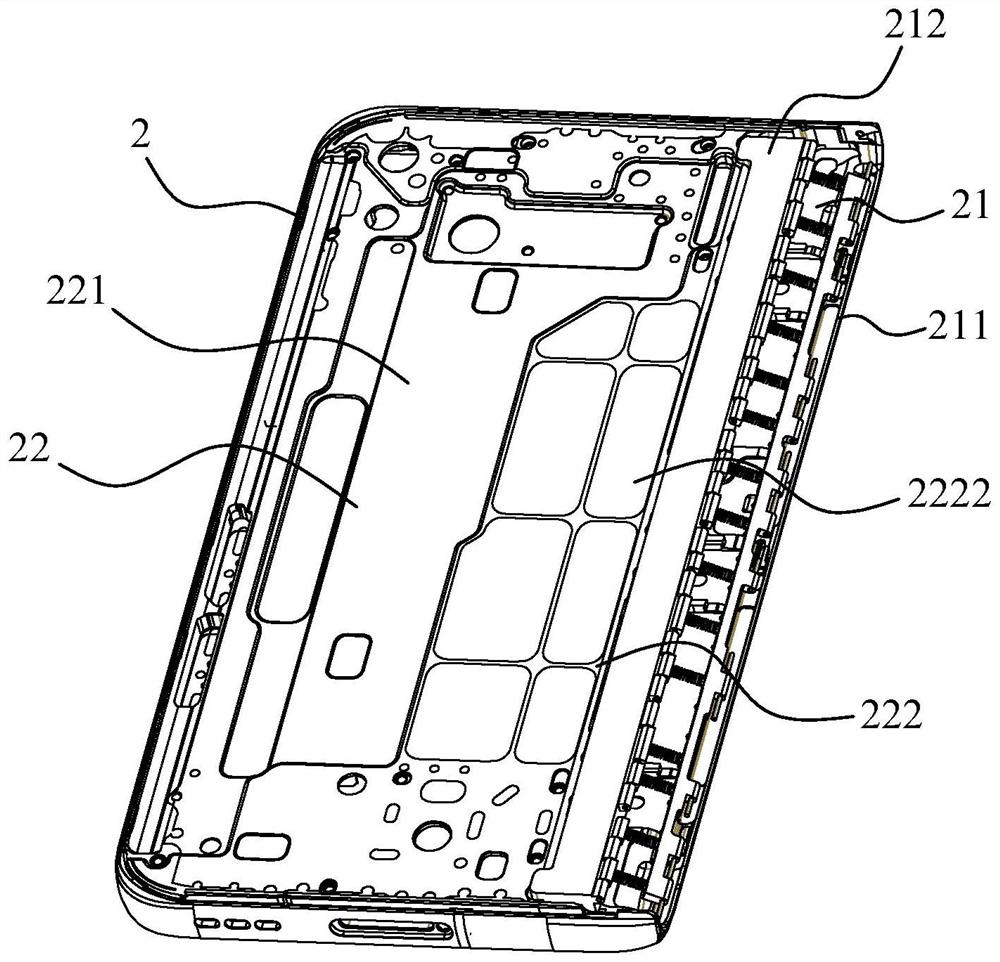

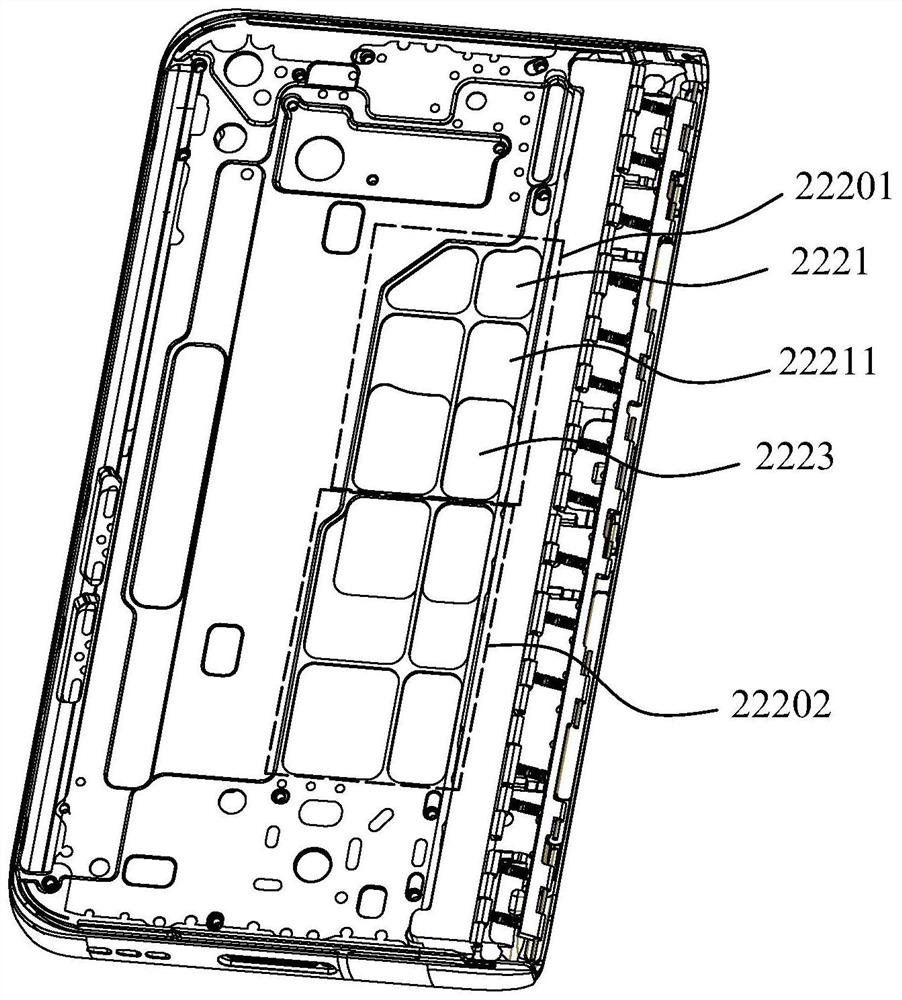

Folding screen middle frame structure and display equipment

PendingCN114679506AIncrease the gapReduce deformation defectsTelephone set constructionsStructural engineeringMechanical engineering

The invention relates to a folding screen middle frame structure and display device.The folding screen middle frame structure comprises a rotating shaft, a first frame body and a second frame body, and the first frame body and the second frame body are arranged on the two opposite sides of the rotating shaft respectively and rotationally connected with the rotating shaft; a first rotating shaft surface is formed on the inner side, close to the edge of the rotating shaft, of the first frame body, and the first rotating shaft surface gradually protrudes towards the inner side of the first frame body from the edge to the center; a second rotating shaft surface is formed on the inner side, close to the edge of the rotating shaft, of the second frame body, and the second rotating shaft surface gradually protrudes towards the inner side of the second frame body from the edge to the center. According to the middle frame structure of the folding screen, the rotating shaft surfaces of the two frame bodies are changed from the existing planes into the curved surfaces which are smoothly and upwards convex from the edges to the centers, so that the centers of the rotating shaft surfaces are higher than the edges, gaps between the rotating shafts and the frame bodies after the rotating shafts are assembled are structurally improved, and bad product deformation is reduced.

Owner:DONGGUAN CHANGYING PRECISION TECH CO LTD

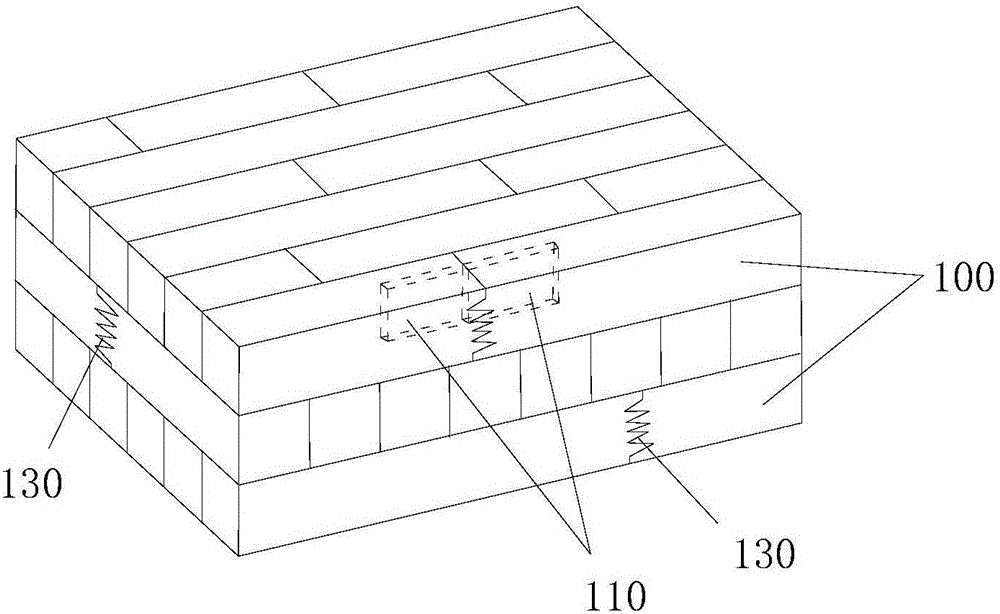

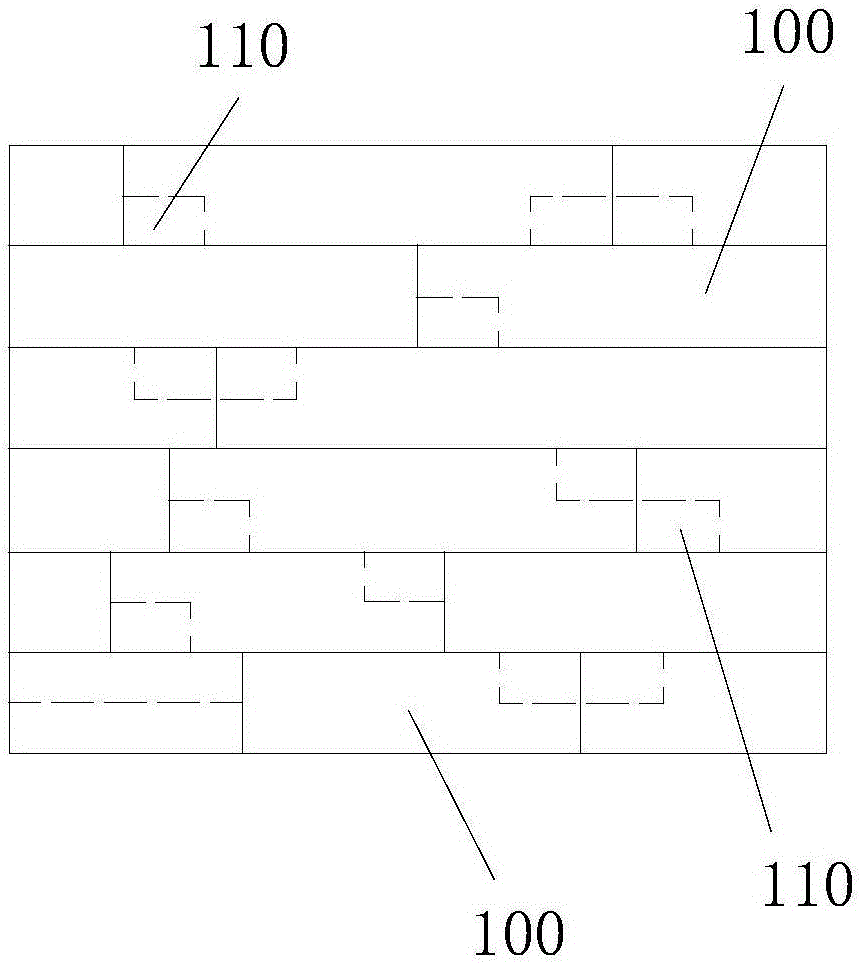

Cross-laminated lumber structure and manufacturing method thereof

ActiveCN105773737BReduce deformation defectsHigh yieldWood veneer joiningWood layered productsSurface layerFinger joint

The invention discloses a cross laminated wood structure and a manufacture method thereof. The cross laminated wood is formed by combining at least three layers of materials which are respectively an upper first surface layer, a middle core layer and a lower second surface layer, wherein the first surface layer, the core layer and the second surface layer are fixed through glue. The manufacture method comprises the following steps: selecting materials; performing rounding; forming stress release grooves; drying; performing rough shape cutting; performing broaching; assembling a blank; pressing a plate and the like. According to the cross laminated wood structure and the manufacture method thereof, the drying stress is effectively released, the drying defects are reduced, and the drying energy consumption is reduced; and as the stress release grooves are reserved in two surface finger joint laminated boards of the cross laminated wood, it is ensured that the moulded cross laminated wood is relatively high in dimensional stability in a humid and dry environment. In addition, the stress release grooves are relatively scattered in the cross laminated wood, and the mechanical strength of the cross laminated wood is not affected, so that the technical problems that the strength is low and the stability is poor in an existing cross laminated wood technology are solved well.

Owner:广东联塑日利门业有限公司

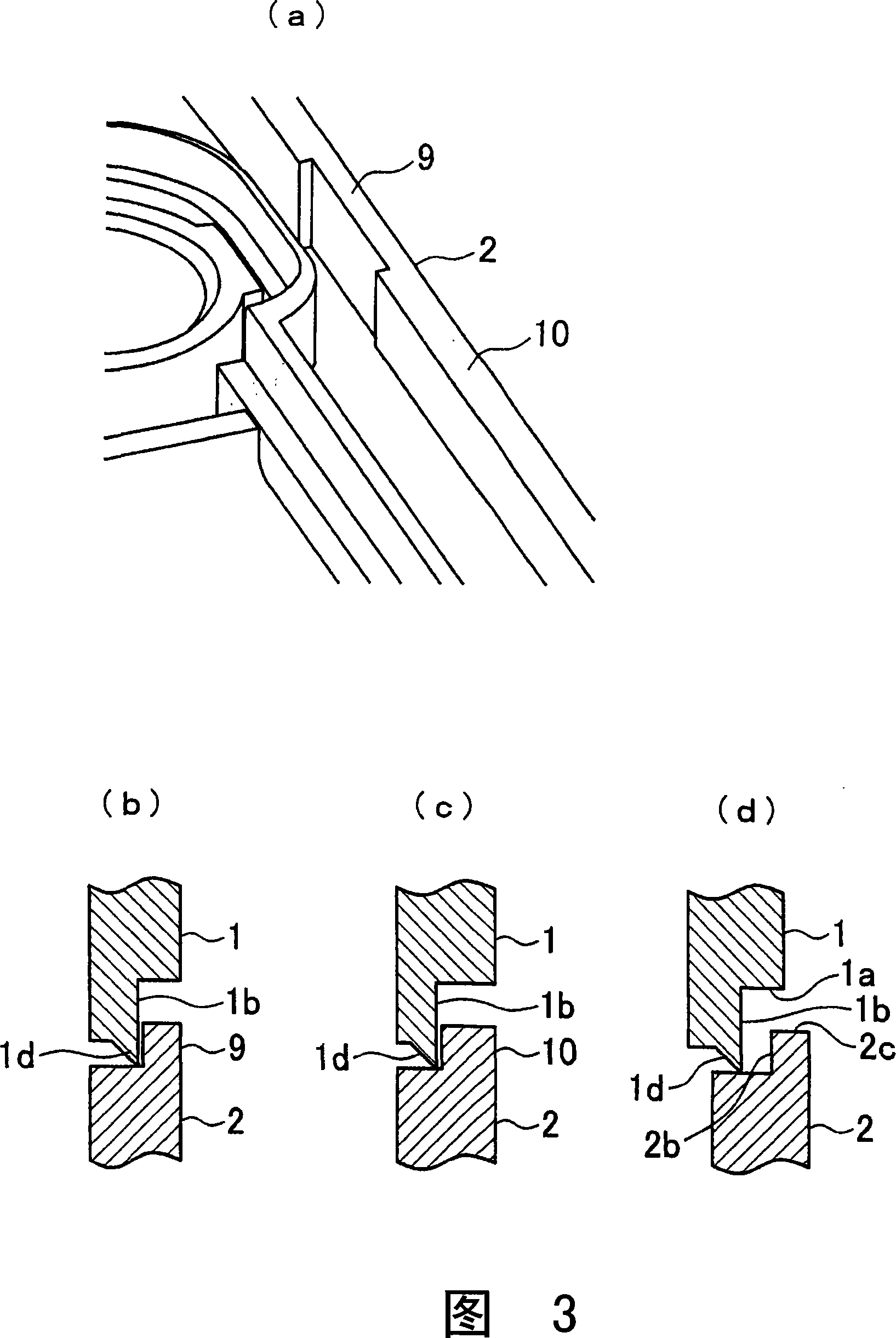

Ultrasonic wave fusion jointing method for speaker case

InactiveCN101150887BEasy to adjustFull joint strengthElectrical transducersRight triangleLoudspeaker

The present invention relates to a loudspeaker case ultrasonic deposition joining method, forming steps at the peripheral wall of a pair of case sheets (1), (2) of cutting mechanism composed of same thermoplastic resin thereby forming intermeshably embedded joining part, and forming projecting shape rib whose section is right-angle-triangle projecting from at least one joining end surface of the case sheets playing as said energy guiding piece function, applying ultrasonic vibrating energy and pushing-pressing force, to melt the projecting shape rib, depositing the joining part and joining each case sheet to integral. Using the present invention, when using ultrasonic deposition joining two each case sheet of case made from resin with two-divided mechanism and making, can prevent asymmetric deposition, deposition quantity deficiency, strength deficiency from generating, or prevent air leakage and airtight damage from generating, prevent melting resin more, the residual resin overflowing leading bad appearance.

Owner:FENGDA ELECTRIC MACHINERY HONG KONG

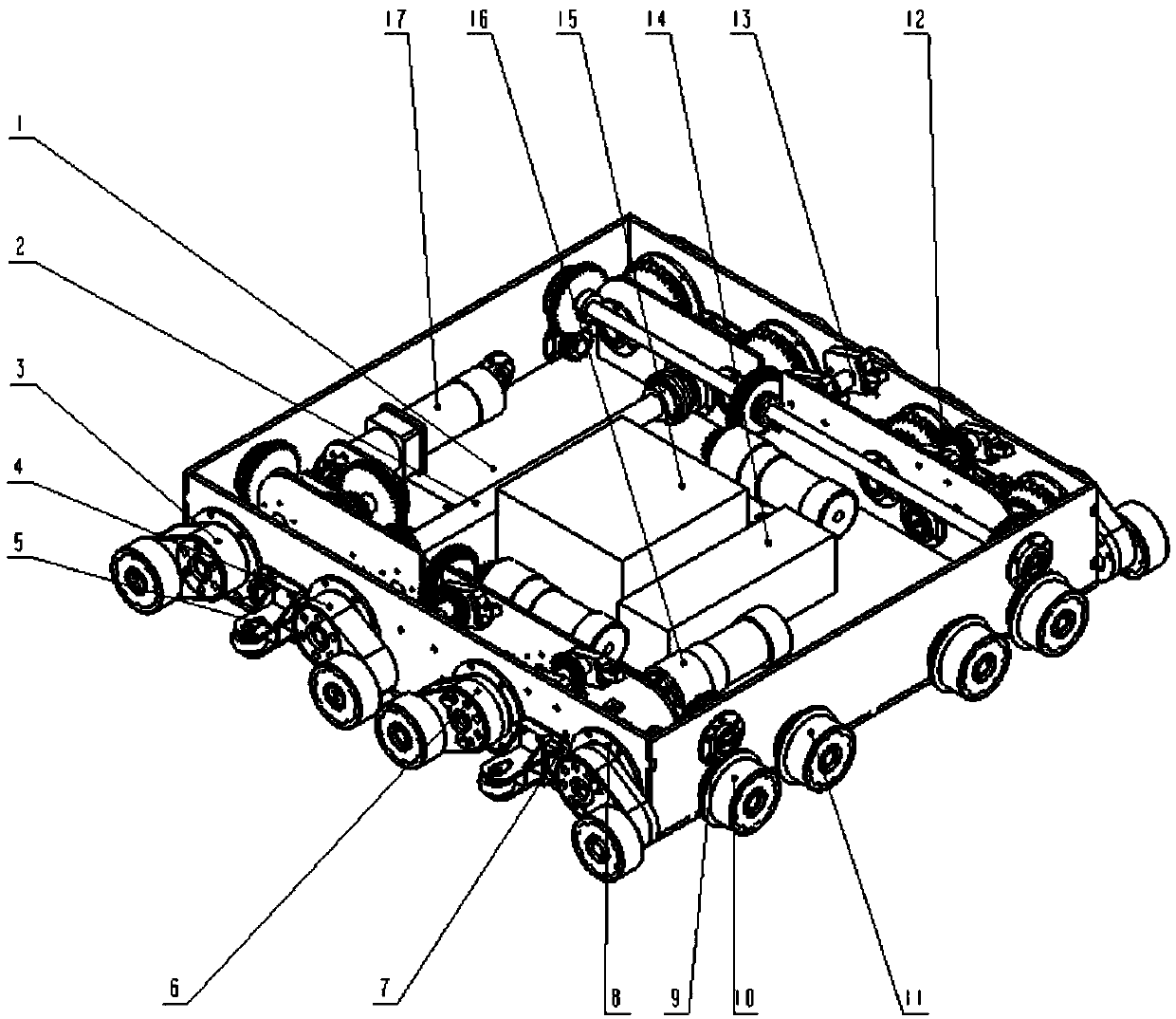

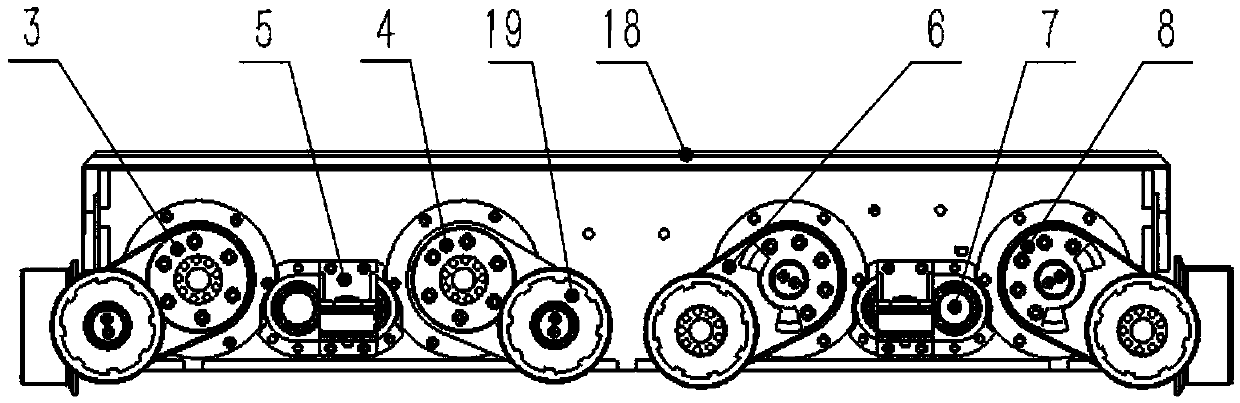

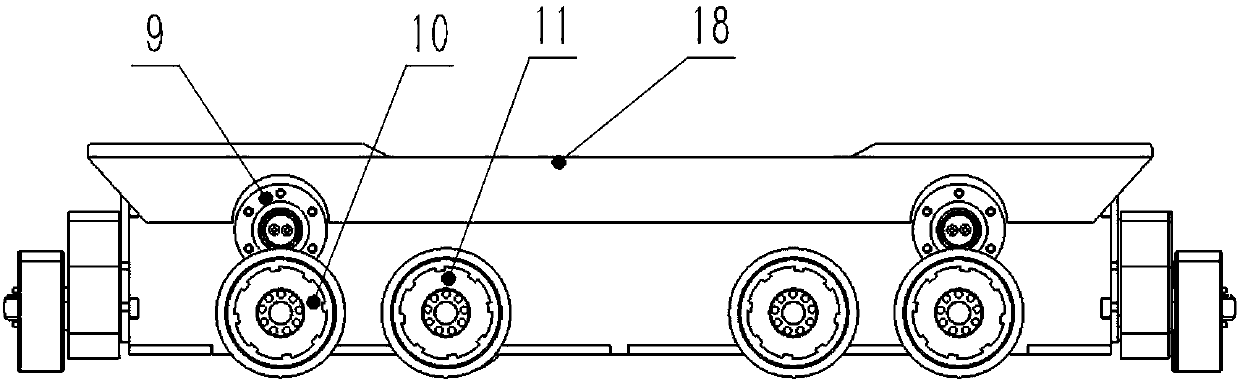

Swing arm intelligent pallet truck

PendingCN110466926AGuaranteed uptimeSmooth transitionConveyorsStorage devicesCommunication interfaceControl system

The invention relates to a swing arm intelligent pallet truck comprising a truck body, a main passage travelling mechanism, an auxiliary passage travelling lifting mechanism, a travelling tensioning mechanism, a lifting tensioning mechanism, a control system and a battery. The left and right sides of the truck body are provided with main passage wheels, the front and rear sides of the truck body are provided with auxiliary passage wheels, the auxiliary passage wheels are mounted on eccentric swing arms, the main passage travelling mechanism drives the main passage wheels through travelling servo motors, the four eccentric swing arms are provided with the auxiliary passage wheels, the eccentric swing arms are driven by lifting servo motors, the auxiliary passage wheels are driven by auxiliary passage travelling servo motors, and the control system is provided with a program encoder, control software and a wireless communication interface. The swing arm intelligent pallet truck has the advantages that the 16 wheels are adopted for realizing bidirectional operation of the swing arm intelligent pallet truck in main and auxiliary passages, the auxiliary passage wheels are arranged in asplayed shape, the structure is simple, reliable and durable, the local concentrated load of the wheels on a supporting guide rail is effectively reduced, and the truck steering and lifting stabilityis improved.

Owner:WAP INTELLIGENCE STORAGE EQUIP SHANGHAI CORP LTD

Fine-pottery sanitary ceramic body and manufacturing method thereof

ActiveCN101811858BReduce hygroscopic swellingHigh coefficient of thermal expansionClaywaresGranularityMullite

Owner:HUIDA SANITARY WARE

Aluminum profile quenching device

ActiveCN103397285BReduce temperature distribution non-uniformityReduce deformation defectsQuenching devicesProportional integral differentialStructure property

Owner:NORTHEASTERN UNIV LIAONING

A tooling combination for machining axial flow pump blades and a precision machining method for axial flow pump blades

ActiveCN109807572BExtended service lifeImprove corrosion resistanceEdge grinding machinesPositioning apparatusAxial-flow pumpWire cutting

A tooling combination for machining axial flow pump blades and a precision machining method for axial flow pump blades, belonging to the technical field of mechanical processing, the tooling combination consists of rough milling tooling, vibration aging tooling, grinding tooling, semi-finishing tooling, and combined pneumatic suction cups The tooling and shot blasting nozzle tooling are combined, and the tooling combination is used to complete the roughing-aging-semi-finishing-wire cutting shape-aging-finishing-high-speed shot peening surface strengthening process. The tooling combination is novel, the tooling is easy to operate, and precision machining The method is reasonable, improves processing efficiency and processing precision, improves the corrosion resistance and fatigue strength of the blade, reduces deformation defects during use, and further improves the service life of the pump blade.

Owner:YANGZHOU UNIV

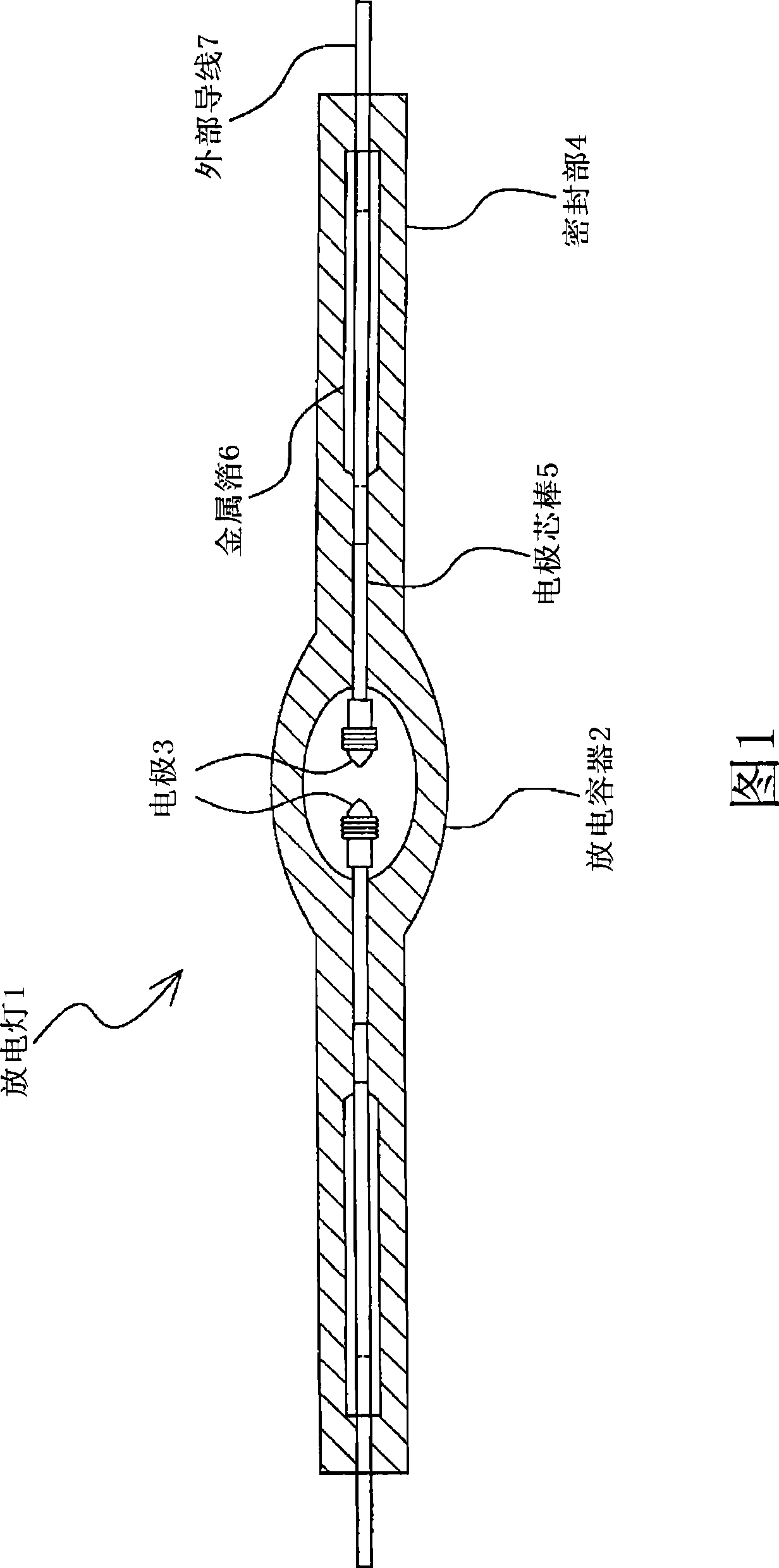

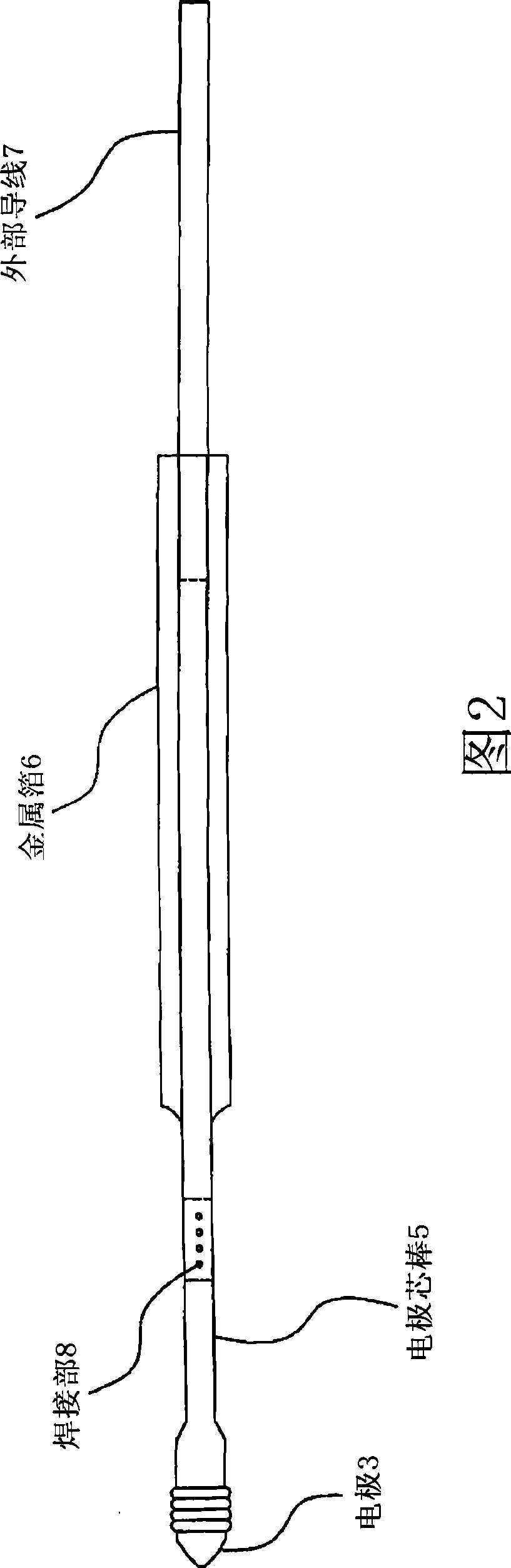

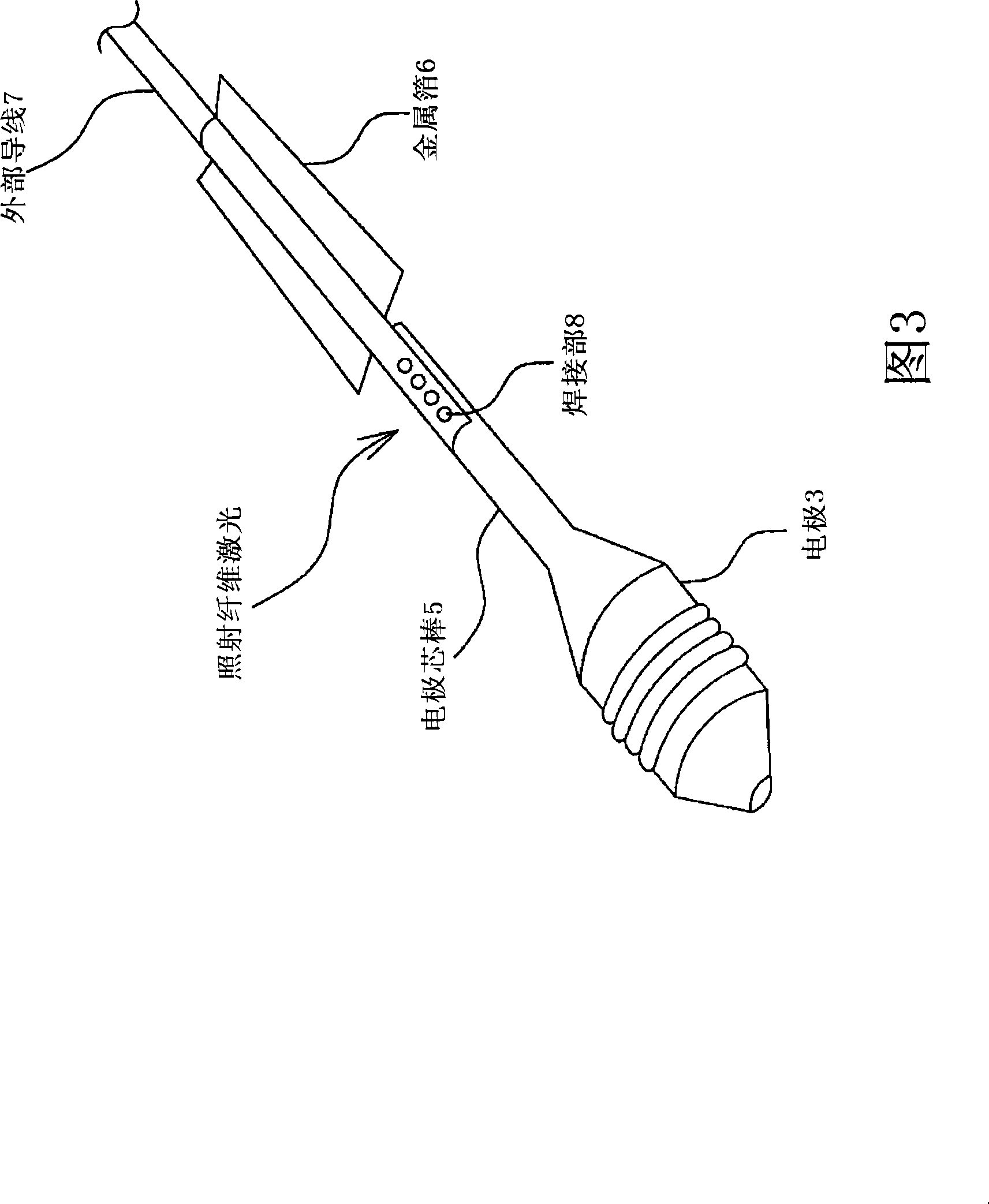

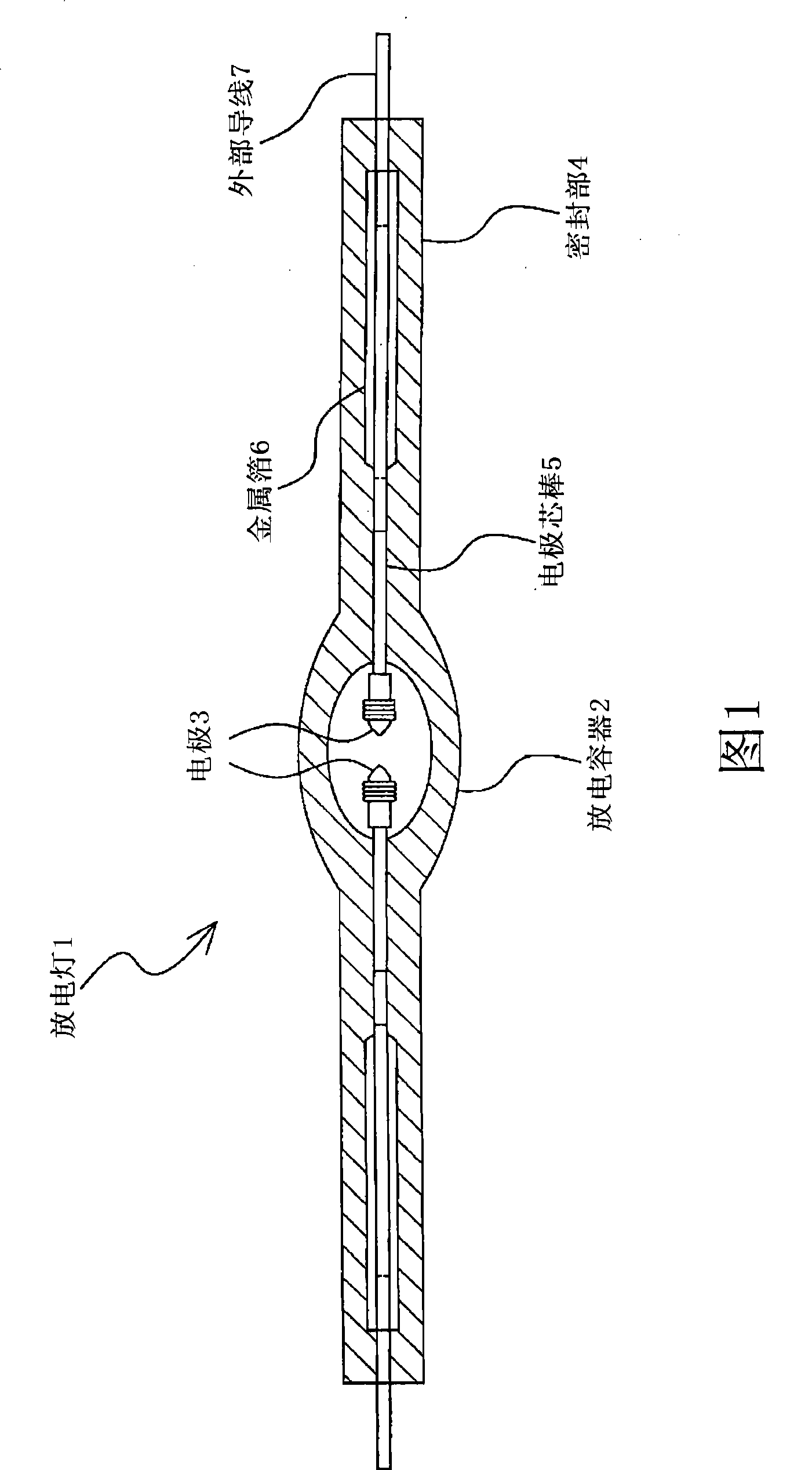

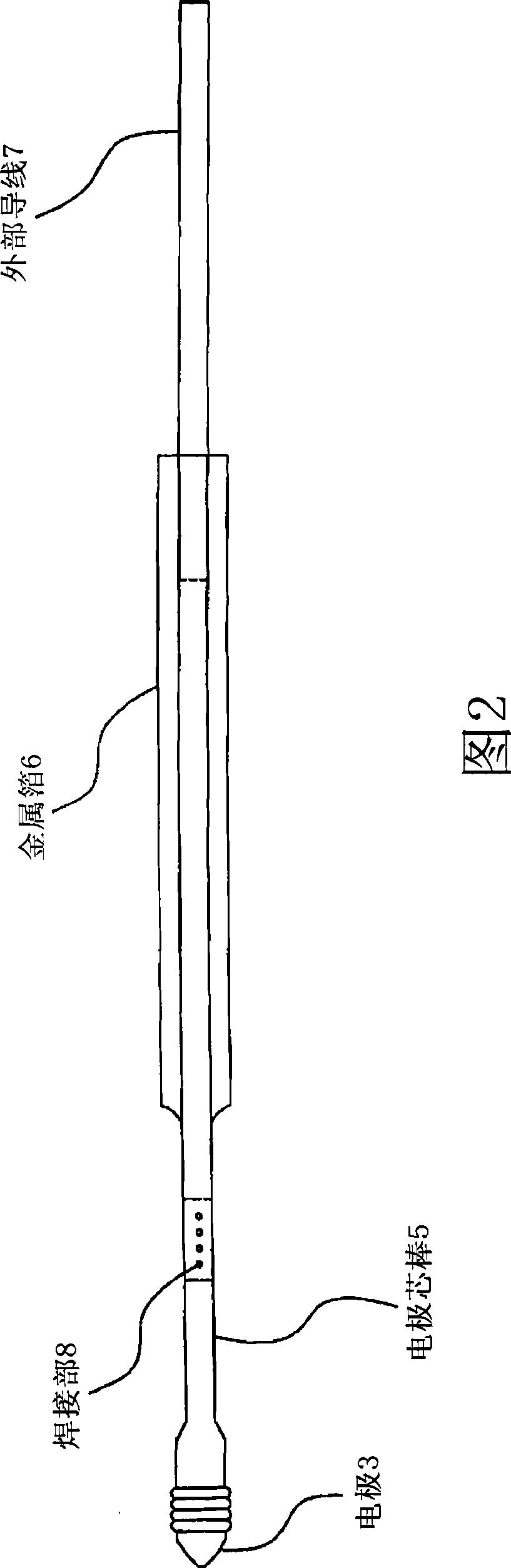

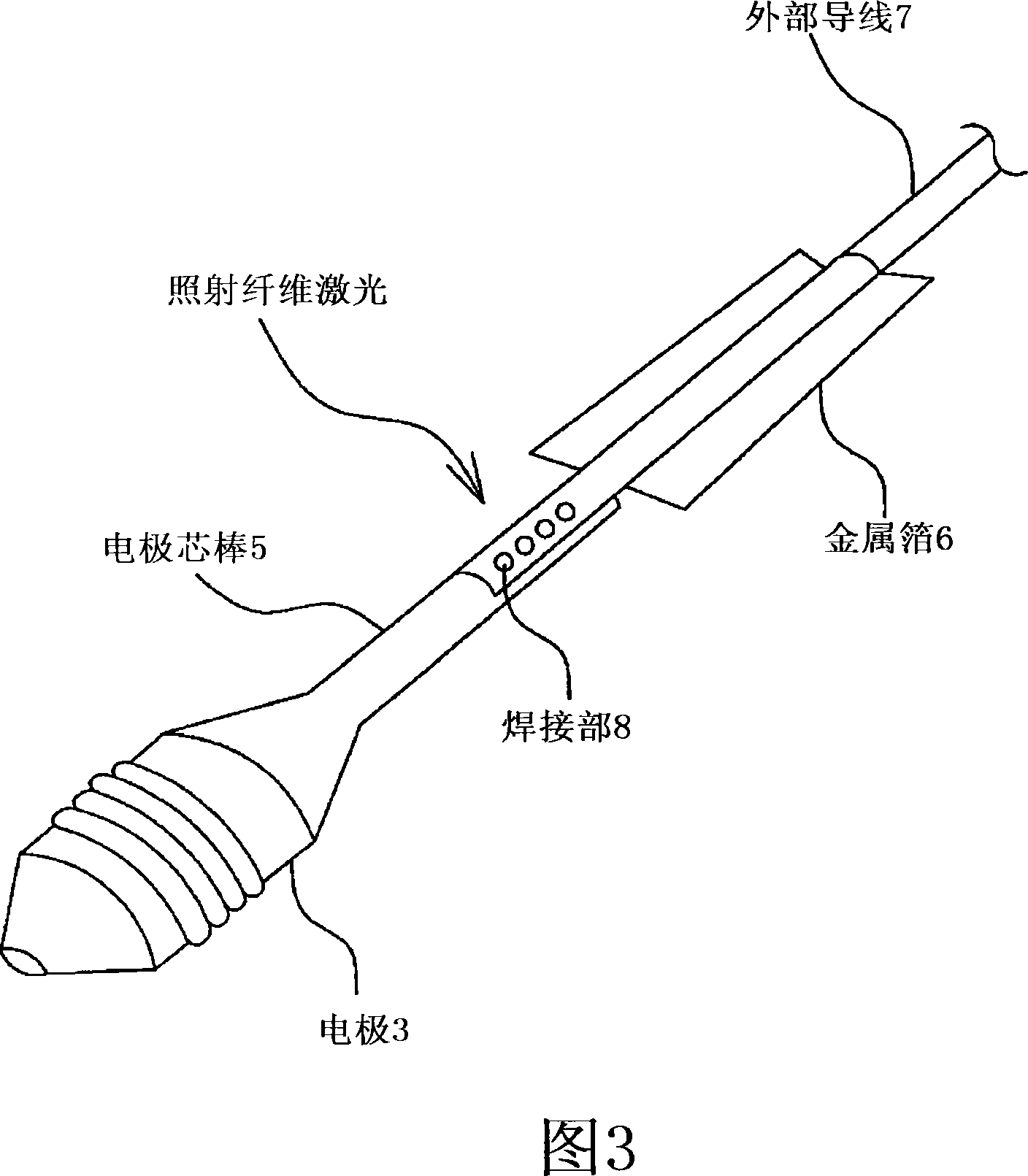

Fused joint structure in a lamp tube and forming method therefor

ActiveCN101436518AHigh strengthStable welding strengthGas discharge lamp detailsCold cathode manufactureMetallic foilOptoelectronics

The invention provides a fused joint structure for a lamp, capable of obtaining stable high welding strength, reducing bad distortion and lack welding strength as well as bad welding through hole, and a method for manufacturing the same. The fused joint structure comprises a conductive member (5) made of high melting point metal, and a metallic foil (6), and is characterized in that the high melting point metal of the conductive member (5) is fused with the metallic foil (6) on an area where the metallic foil (6) is put together on a surface of the conductive member (5), and a circumferential edge of the concave portion of the metallic foil (6) is covered with the high melting point metal of the conductive member (5). Moreover, the method for manufacturing the fused joint structure is characterized in that a laser of more than 40MW / cm<2> energy is illuminated into the area where the metallic foil (6) is put together on a surface of the conductive member (5), from one side of the metallic foil (6) by a fiber laser device, to joint the conductive member (5) and the metallic foil (6).

Owner:USHIO DENKI KK

Solvent-free adhesive, printing platform and manufacturing method thereof for preventing FDM printing device from warping

ActiveCN108559425BLow peel strengthImprove printing qualityEster polymer adhesivesPolymer scienceGlycidyl methacrylate

The invention belongs to the technical field of fused deposition printing and discloses a solvent-free adhesive preventing warping of an FDM (fused deposition modeling) printing device, a printing platform and a preparation method of the adhesive. The adhesive comprises the following ingredients: ethylene diglycidyl ether, ethylhexyl acrylate, 1,2-epoxy-4-vinyl-cyclohexane, octadecyl acrylate, acrylic acid, hydroxyethyl acrylate, hexadecyl acrylate, lauryl acrylate, glycidyl methacrylate, a radical initiator and an acrylate cross-linking agent. The printing platform comprises the adhesive anda substrate, wherein the substrate is coated with the adhesive. The initial adhesion and stripping strength of the adhesive are very low at a temperature less than 40 DEG C; the printing device is easily taken down from the platform; the adhesive has better adhesion ability at the high temperature; and the printing device is tightly bonded with the platform and is free from warping.

Owner:SOUTH CHINA INST OF COLLABORATIVE INNOVATION

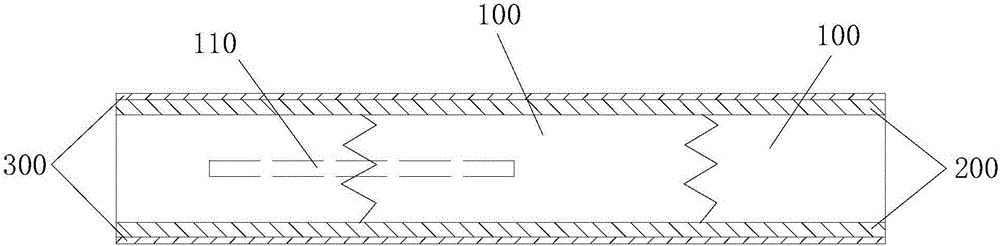

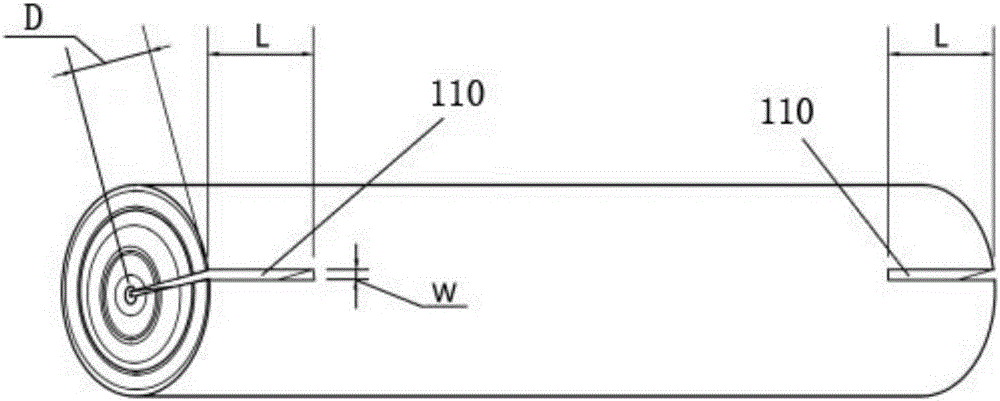

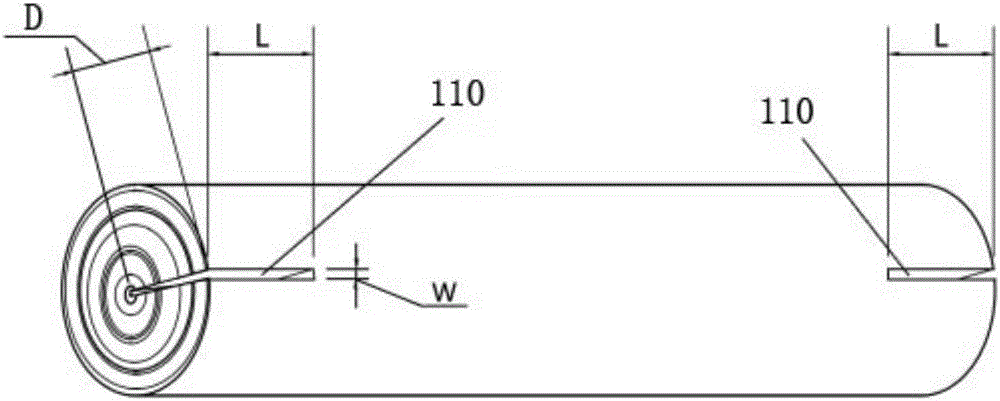

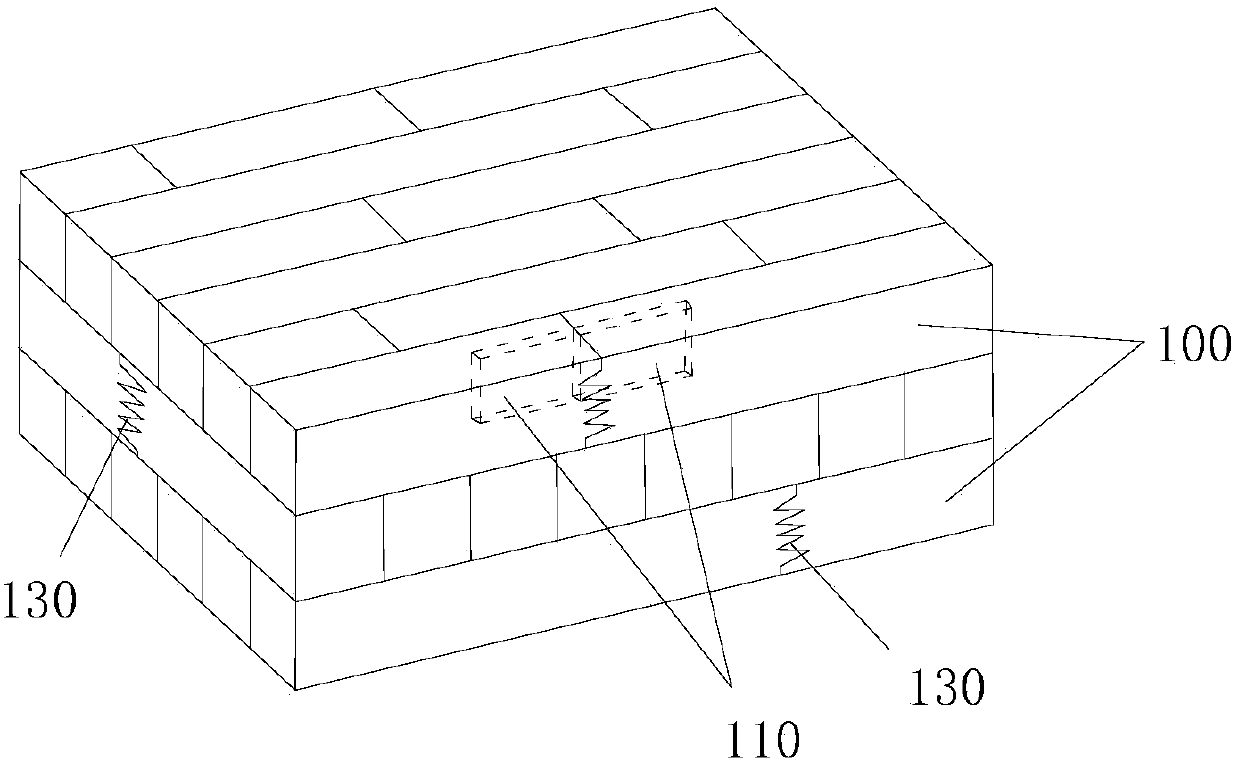

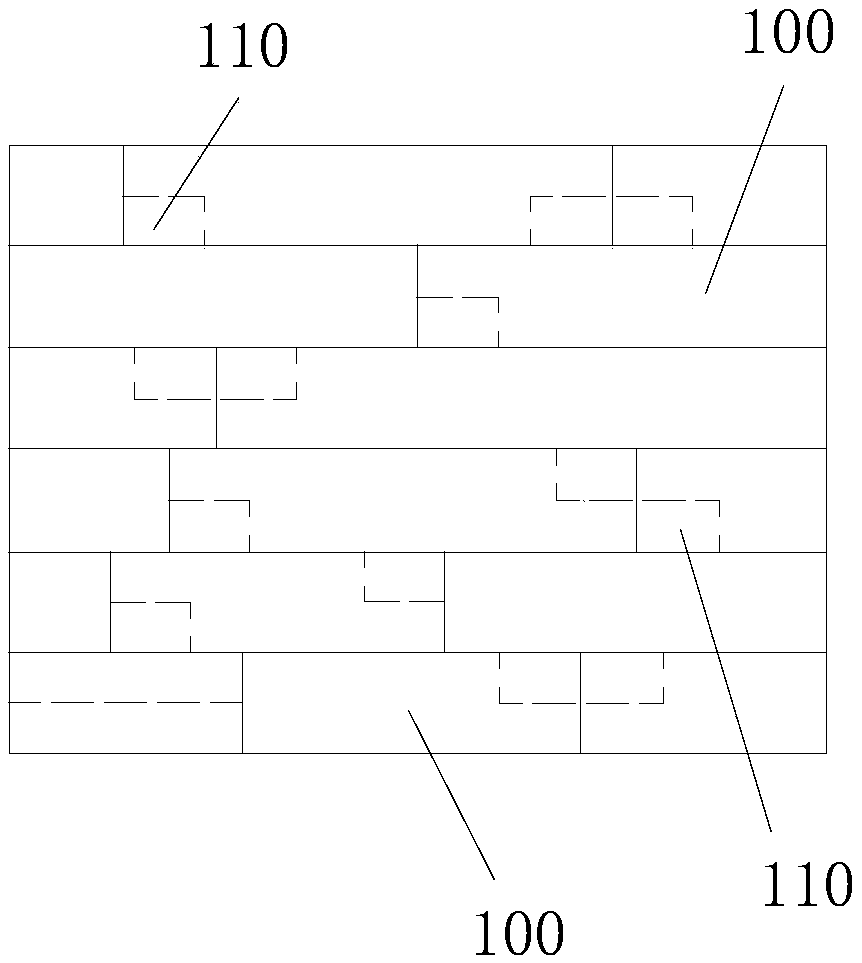

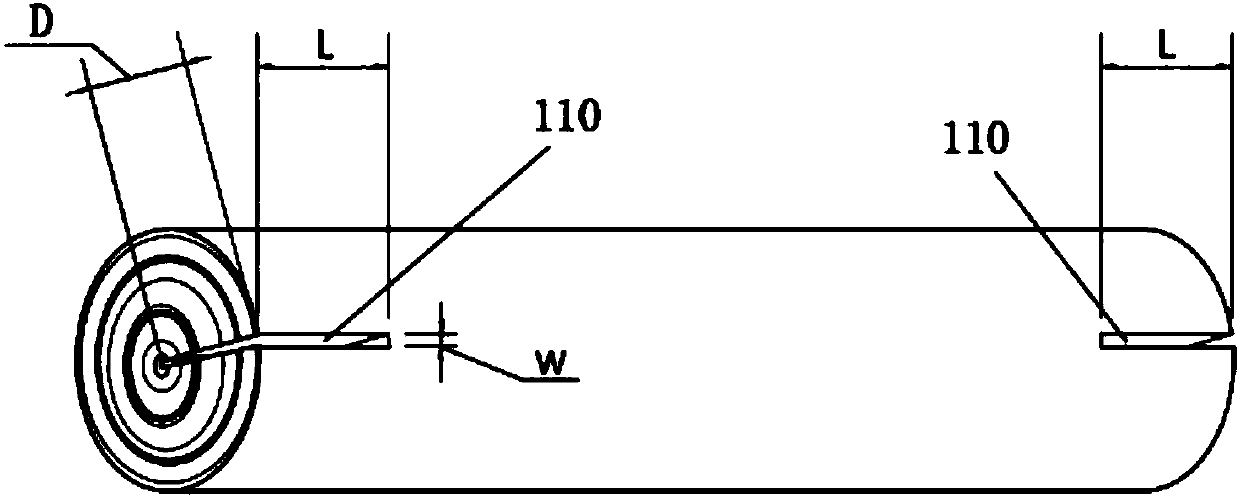

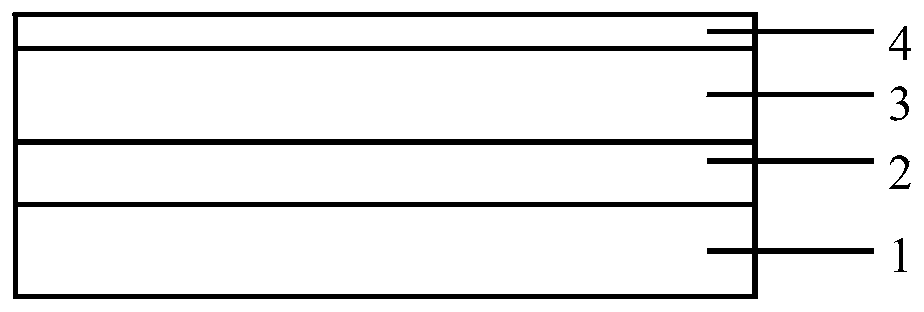

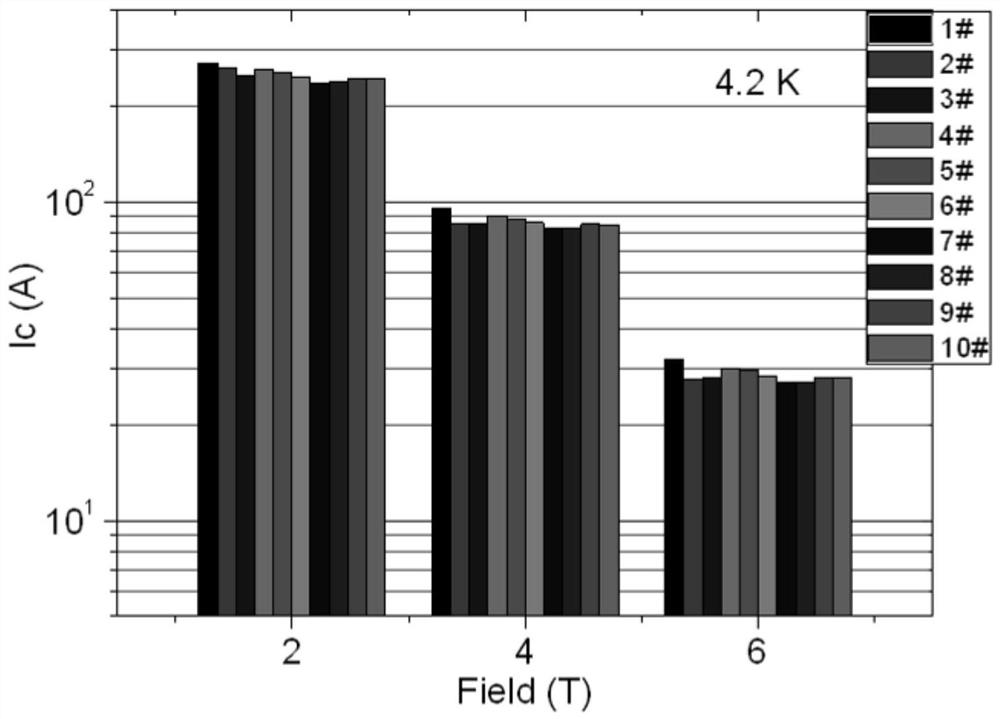

Preparation method of kilometer-level multi-core MgB2 superconducting wire

PendingCN112967845AReduce deformation defectsUniform performanceSuperconductors/hyperconductorsSuperconductor devicesWire breakageHeat treated

The invention belongs to the technical field of superconducting wire preparation, and relates to a preparation method of a kilometer-level multi-core MgB2 superconducting wire. The preparation method comprises the steps of mixing Mg powder and B powder according to an atomic ratio of 1: 2, and grinding to obtain precursor powder; loading the precursor powder into a Cu / Nb tube to be assembled into a Cu / Nb / MgB2 single-core rod, and machining the Cu / Nb / MgB2 single-core rod to be the same as a Cu center rod in size through rotary swaging; sequentially sizing and cutting off the Cu / Nb / MgB2 single-core rod and the Cu center rod which are the same in size, and putting the Cu / Nb / MgB2 single-core rod and the Cu center rod into a Monel pipe to be assembled into a multi-core composite sheath; performing rotary swaging processing on the multi-core composite sheath to obtain a finished wire; and carrying out heat treatment on the finished wire rod to obtain the MgB2 multi-core superconducting wire. According to the method, the deformation defect in the wire is overcome in a rotary swaging machining mode, the phenomenon of core breakage or wire breakage is reduced, and the kilometer-level MgB2 superconducting wire which is uniform in performance and meets actual requirements is prepared.

Owner:西部超导材料科技股份有限公司

A heat shrink curing device

ActiveCN113467006BImprove heat shrink curing efficiencyImprove the effect of heat shrink curingCoupling light guidesThermodynamicsHeat conducting

Owner:SHENZHEN ADTEK TECH CO LTD

A decorative panel structure and manufacturing method

ActiveCN105666597BReduce deformation defectsSmall machining allowanceWood veneer joiningFinger jointStress relief

The invention discloses a decorative sheet structure and a manufacturing method. The decorative sheet structure is formed by a finger joint sheet, veneers and facing paper in a composite mode; the finger joint sheet is formed by splicing a plurality of wood sheets with finger type teeth and stress relief grooves, wherein the finger type teeth and the stress relief grooves are located at the ends of the wood sheets; the finger joint sheet is connected through the finger type teeth for being longitudinally spliced and is fixed through glue for being transversely spliced. The manufacturing method mainly comprises the steps of cutting, rounding, stress groove forming and manufacturing, drying, board cutting, comb tooth treating, length jointing and width splicing, repairing, sanding, veneer gluing, paper gluing and sheet cutting. The decorative sheet structure has the advantages of being high in strength and good in stability. The manufacturing method of the decorative sheet structure has the advantages that the outturn percentage is high, the production technology is simple, the production efficiency is high, the labor intensity is low and the production cost is low, and the technical problems that the utilization rate of wood is low, the strength of decorative sheets is low and the stability is poor in the existingmanufacturing technology of the decorative sheets are well solved.

Owner:广州市欧亚床垫家具有限公司

Fused joint structure in a lamp tube and forming method therefor

ActiveCN101436518BHigh strengthStable welding strengthGas discharge lamp detailsCold cathode manufactureFiberMetallic foil

A fused joint structure comprises a metallic foil; and a conductive member made of high melting point metal, wherein a concave portion is formed in the metallic foil and the conductive member on an area where the metallic foil is put together on a surface of the conductive member, and wherein a circumferential edge of the concave portion is covered with the conductive member.

Owner:USHIO DENKI KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com