Cross-laminated lumber structure and manufacturing method thereof

A technology of laminated lumber and three-layer materials, applied in the structure of cross-laminated lumber and its manufacturing field, can solve problems such as low strength and poor stability, and achieve the goals of increasing material yield, high dimensional stability, and improving drying efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

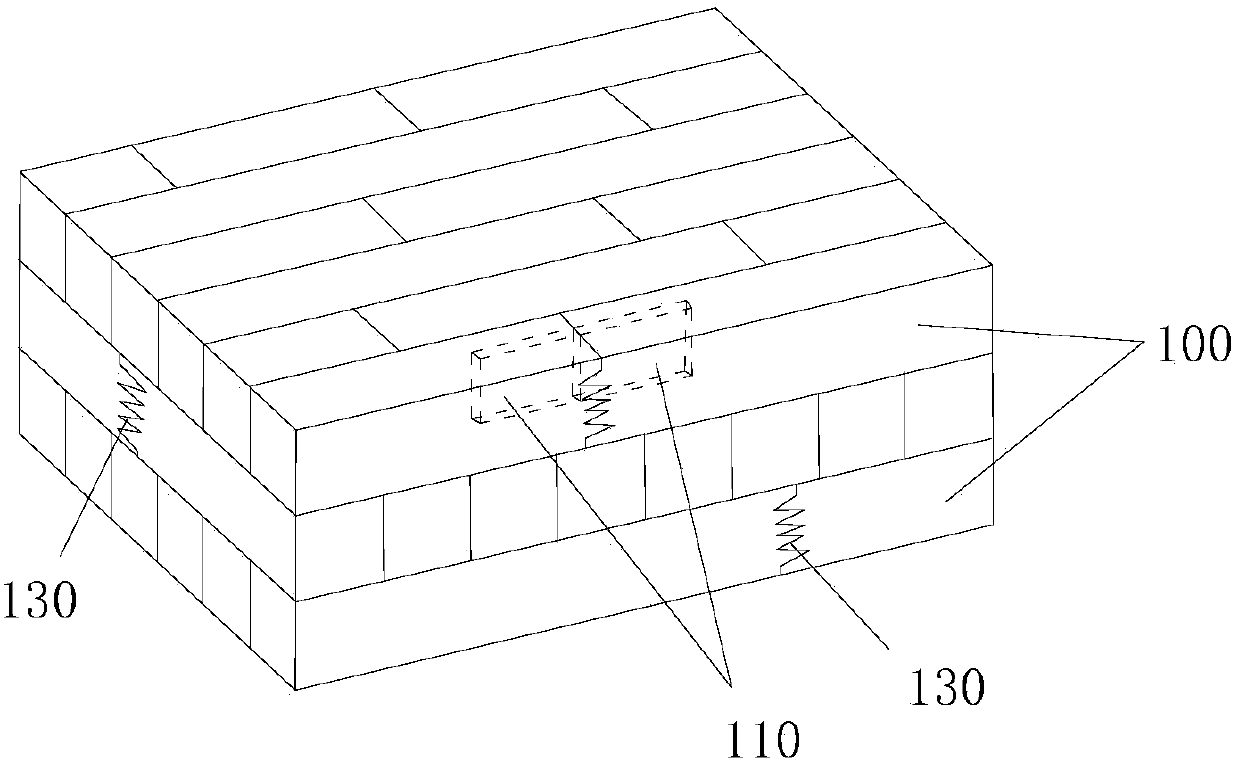

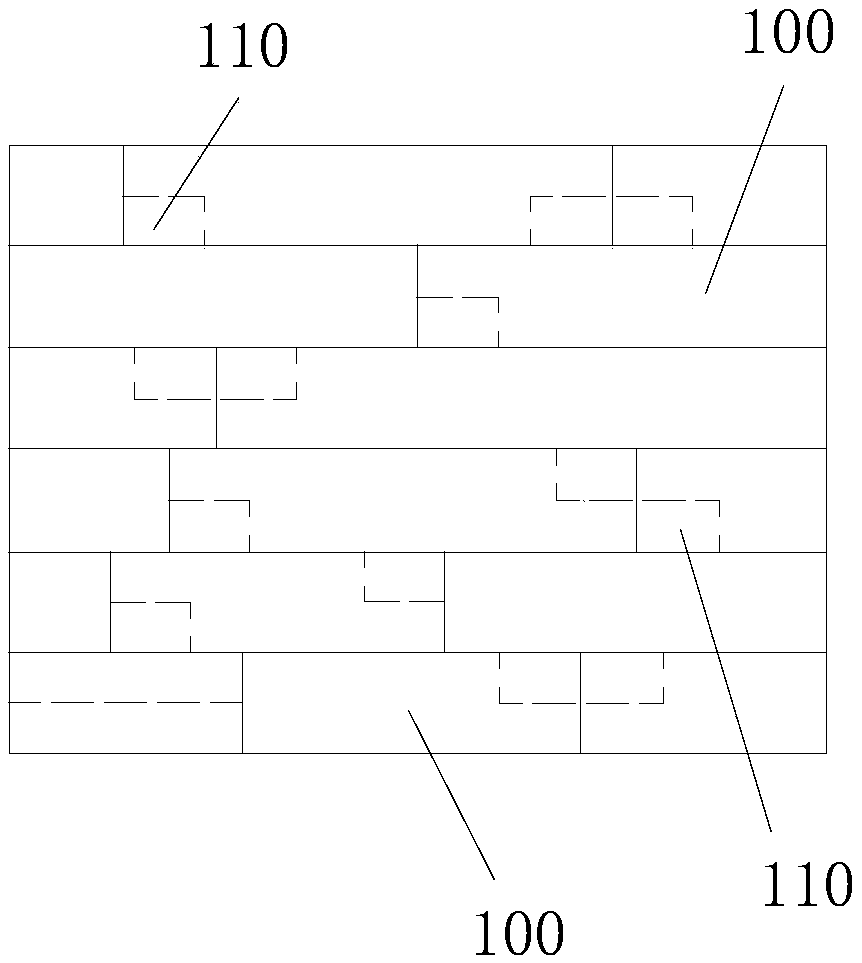

[0069] The cross-laminated lumber described in this embodiment is formed by cross-lamination and pressing of finger-jointed boards, wherein the finger-joined boards are made of eucalyptus small-diameter logs for slotting and drying, and refer to Figure 4 Saw cutting in the same manner, finger-joint the ends of the obtained wood strips 100 and splice them in parallel at the sides, and retain stress relief grooves 110 in the finger-joint boards on the surface of the cross-laminated lumber.

[0070] The concrete preparation steps of described finger joint plate are:

[0071] 1) Material selection: Select fast-growing eucalyptus logs as raw materials for cross-laminated lumber finger-joint laminates according to requirements. Use a rotary cutter to round the logs and remove branches. The diameter of the logs is 8.5 cm to 9.5 cm. The diameter of the round back log is 8 cm to 9 cm, and the length is 600 mm to 800 mm.

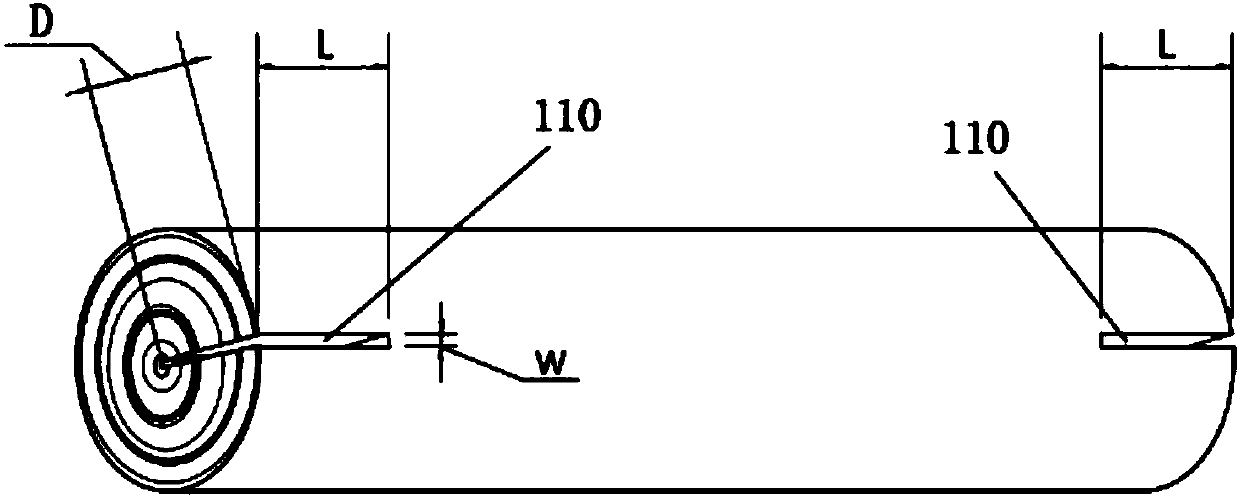

[0072] 2) Stress release grooves 110 are made: draw stress rel...

Embodiment 2

[0081] The concrete preparation steps of described finger joint plate are:

[0082] 1) Material selection: Select fast-growing eucalyptus logs as raw materials for cross-laminated lumber finger-joint laminates according to requirements. Use a rotary cutter to round the logs and remove branches. The diameter of the logs is 9.5 cm to 11.5 cm. After the round, the diameter of the log is 9 cm to 11 cm, and the length is 800 mm to 1000 mm.

[0083] 2) Stress release groove 110 is opened: the stress relief groove 110 with a length of 10% of the length of the round material is drawn at both ends of the required dry round material, and the length is 10 cm. The direction of the stress release groove 110 passes through the pith center, and the depth is 3 cm and a width of 3 mm.

[0084] 3) Drying: The round wood should be dried naturally to a moisture content of 45% in a place with good ventilation and no sunlight exposure; Under the condition of 90%, carry out drying treatment in the...

Embodiment 3

[0092] The concrete preparation steps of described finger joint plate are:

[0093] 1) Material selection: Select fast-growing eucalyptus logs as raw materials for cross-laminated lumber finger-jointed laminates according to requirements. Use a rotary cutter to round the logs and remove branches. The diameter of the logs is 11.5 cm to 12.5 cm. After the round, the diameter of the log is 11 cm to 12 cm, and the length is 1000 mm to 1200 mm.

[0094] 2) Stress release grooves 110 are made: draw stress release grooves 110 whose length is 10% of the length of the round material at both ends of the required dry round material, the length is 10 cm, the direction of the stress release groove 110 passes through the pith center, and the depth is 3.5 cm. cm and a width of 4 mm.

[0095] 3) Drying: The round wood should be dried naturally to a moisture content of 45% in a place with good ventilation and no sunlight exposure; Under the condition of 90%, carry out drying treatment in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com