Fused joint structure in a lamp tube and forming method therefor

A technology of fusion bonding and manufacturing method, which is applied in the manufacture of discharge tubes/lamps, cold cathodes, and electrode systems. It can solve problems such as poor welding peeling and easy fracture of grain boundaries, and achieve poor deformation and stable welding strength. , The effect of reducing welding perforation defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

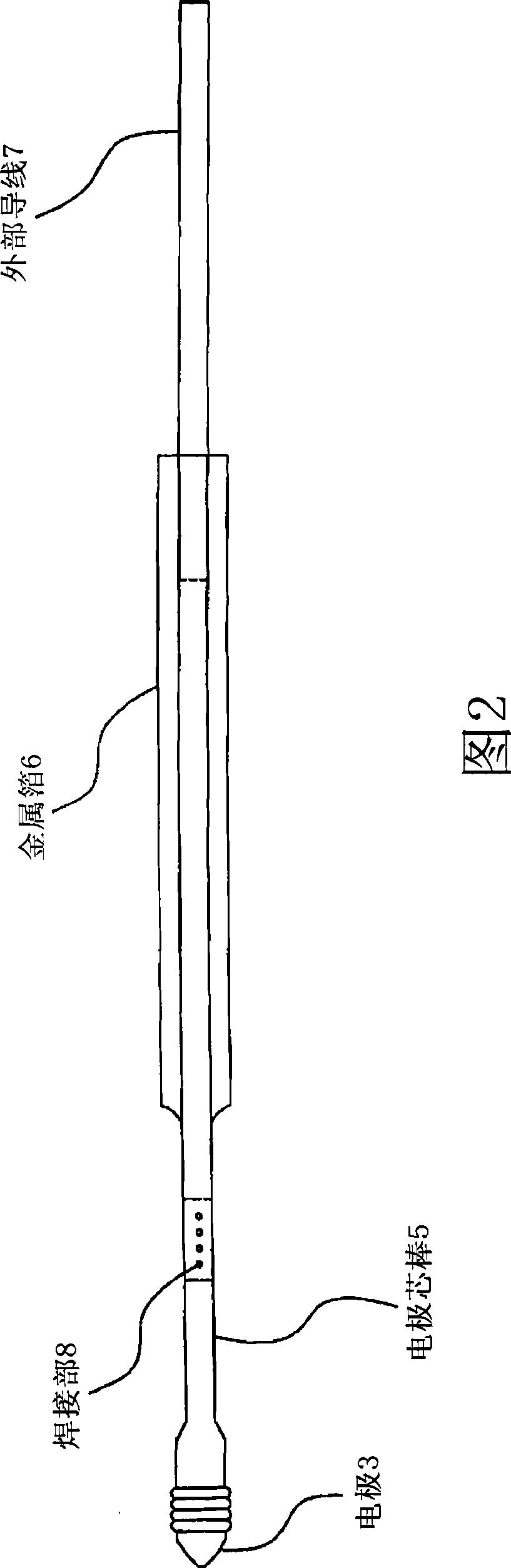

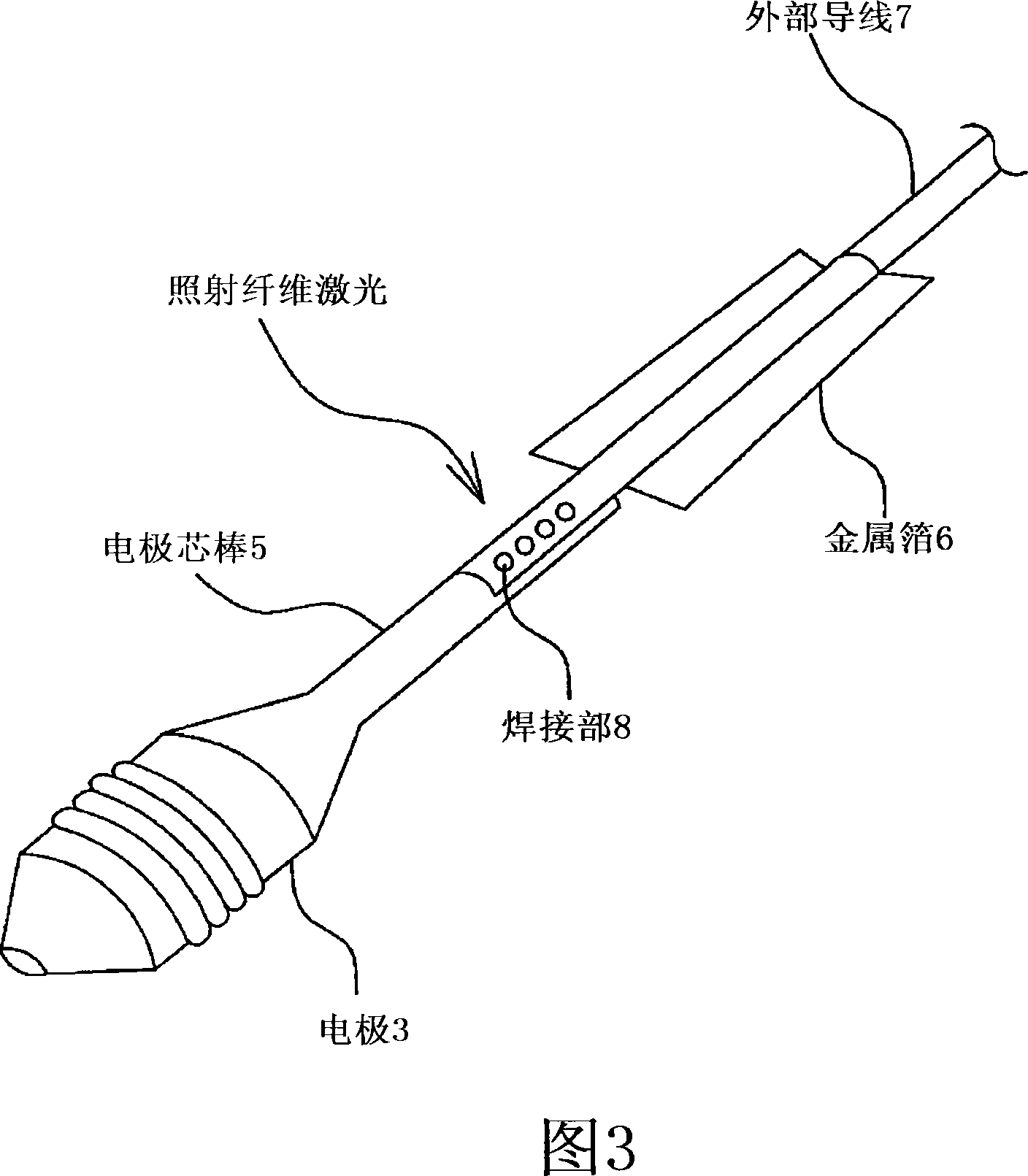

[0024] Lamps to which the fusion-bonded structure of the present invention is applied include incandescent lamps or discharge lamps typified by halogen lamps. In addition, in the present invention, "conductive member" refers to an inner lead rod and an outer lead rod in an incandescent lamp, and refers to an electrode core rod and an outer lead rod in a discharge lamp using a metal foil seal. In the discharge lamp of the foil seal, a plurality of metal foils are welded, a disk-shaped member connected to an electrode mandrel, and a disk-shaped member connected to an external lead.

[0025] refer to Figure 1 to Figure 4 The first embodiment of the present invention will be described.

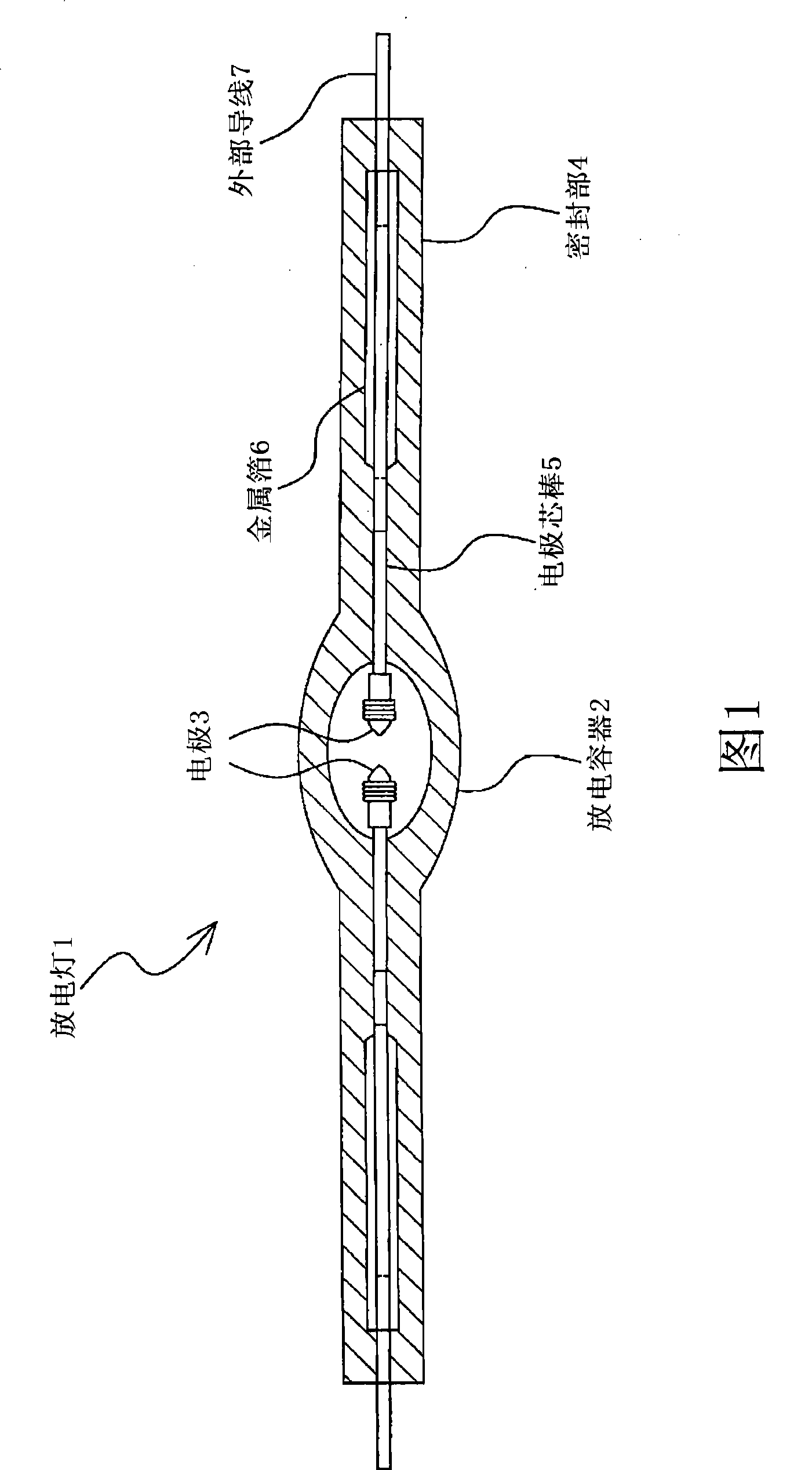

[0026] figure 1 It is a cross-sectional view showing the configuration of a both-ends-sealed type discharge lamp using one metal foil seal.

[0027] As shown in the figure, a pair of electrodes 3 are disposed in the discharge vessel 2 of the discharge lamp 1, and a metal foil of an electrode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com