Solvent-free adhesive, printing platform and manufacturing method thereof for preventing FDM printing device from warping

A printing platform and adhesive technology, applied in the direction of adhesive type, ester copolymer adhesive, etc., can solve the problems of high bonding strength between the device and the masking tape, difficulty in removing the printed device, and difficulty in coating, etc. , to achieve the effect of improving peelability, increasing crystallization effect and reducing heat shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

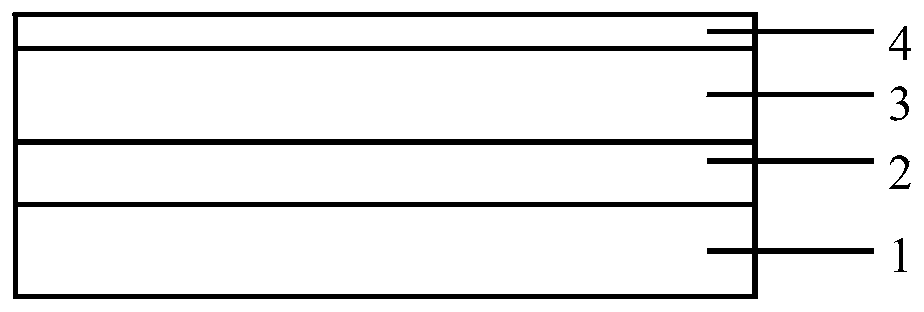

Image

Examples

Embodiment 1

[0046] A solvent-free adhesive for preventing warpage of FDM printed polylactic acid devices, comprising the following components in parts by weight:

[0047] Ethylene glycol diglycidyl ether 18

[0048] Isooctyl acrylate 14

[0049] 1,2-Epoxy-4-vinylcyclohexane 12

[0050] Octadecyl acrylate 20

[0051] Acrylic 4

[0052] Hydroxyethyl Acrylate 5

[0053] Cetyl acrylate 8

[0054] Lauryl Acrylate 12

[0055] Glycidyl methacrylate 6

[0056] Dibenzoyl peroxide 0.3

[0057] Erucamide 0.7.

[0058] The preparation method of the solvent-free adhesive for preventing warpage of FDM printed polylactic acid devices comprises the following steps:

[0059] (1) Under a nitrogen atmosphere, stir isooctyl acrylate, acrylic acid, 1,2-epoxy-4-vinylcyclohexane, octadecyl acrylate, hexadecyl acrylate and lauryl acrylate at a low speed at 70°C, Obtain mixture; The rotating speed of described low-speed stirring is 60rpm;

[0060] (2) Under the condition of stirring at 200rpm, add the ...

Embodiment 2

[0065] A solvent-free adhesive for preventing warpage of FDM printed ABS devices, comprising the following components in parts by weight:

[0066] Ethylene glycol diglycidyl ether 12

[0067] Isooctyl acrylate 10

[0068] 1,2-Epoxy-4-vinylcyclohexane 15

[0069] Octadecyl acrylate 31

[0070] Acrylic 8

[0071] Hydroxyethyl Acrylate 3

[0072] Cetyl acrylate 5

[0073] Lauryl Acrylate 8

[0074] Glycidyl methacrylate 6

[0075] Cyclohexanone peroxide 0.4

[0076] Stearic acid amide 1.6.

[0077] The preparation method of the solvent-free adhesive for preventing warpage of FDM printing ABS devices comprises the following steps:

[0078] (1) Under a nitrogen atmosphere, stir isooctyl acrylate, acrylic acid, 1,2-epoxy-4-vinylcyclohexane, octadecyl acrylate, hexadecyl acrylate and lauryl acrylate at a low speed at 70°C, Obtain mixture; The rotating speed of described low-speed stirring is 60rpm;

[0079] (2) Under the condition of stirring at 200rpm, add the mixed solut...

Embodiment 3

[0083] A solvent-free adhesive for preventing warpage of FDM printed PETG devices, comprising the following components in parts by weight:

[0084] Ethylene glycol diglycidyl ether 12

[0085] Isooctyl acrylate 11

[0086] 1,2-Epoxy-4-vinylcyclohexane 14

[0087] Octadecyl acrylate 31

[0088] Acrylic 7

[0089] Hydroxyethyl Acrylate 5

[0090] Cetyl acrylate 3

[0091] Lauryl Acrylate 8

[0092] Glycidyl methacrylate 6

[0093] Dibenzoyl peroxide 0.6

[0094] Hydrogenated tallow primary amines 2.4.

[0095] The preparation method of the solvent-free adhesive for preventing warpage of FDM printing PETG devices comprises the following steps:

[0096] (1) Under a nitrogen atmosphere, stir isooctyl acrylate, acrylic acid, 1,2-epoxy-4-vinylcyclohexane, octadecyl acrylate, hexadecyl acrylate and lauryl acrylate at a low speed at 70°C, Obtain mixture; The rotating speed of described low-speed stirring is 60rpm;

[0097] (2) Under the condition of stirring at 200rpm, add t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com