Patents

Literature

344 results about "Ethylene glycol diglycidyl ether" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ethylene glycol diglycidyl ether (also known as Quetol 651, EGDGE and EGDE) is a bifunctional water-soluble crosslinker for carboxyl, amine and hydroxyl functional polymers.

Fibroin reinforcement process of fragile silk

InactiveCN101487189AGood colorDoes not affect appearanceAnimal fibresProtein solutionAging resistance

The invention provides a silk protein reinforcing method for fragile silk, comprising the steps as follows: A) the fragile silk with the weight ratio of 1:30-200 is put in a silk protein solution with the weight percentage of 0.1-5% and dipped for 1min to 2h at the temperature of 20-35 DEG C and then taken out and naturally dried; B) the fragile silk is put in ethylene glycol diglycidyl ether solution with the weight percentage of 0.001-10%, dipped for 1min to 2h at the temperature of 20-35 DEG C and then taken out; C) after the treatment, the fragile silk is solidified for 24h to 2h at the temperature of 20-60 DEG C; and D) after natural drying, the silk reinforced by the silk protein molecular is obtained. The method has the advantages of simple method, convenient operation, not affecting the appearance of the silk relic, partly recovering the true luster of the relic, having outstanding advantages on high-temperature ageing resistance, and the like.

Owner:ZHEJIANG SCI-TECH UNIV +1

Preparation and application of fibroin strengthening protecting agent

The invention discloses a preparation of a protective agent for reinforcing fibroin and an application thereof. The protective agent is formed by two parts of fibroin solution and an auxiliary agent, namely, an ethylene glycol diglycidyl ether aqueous solution, and the preparation of the protective agent is that A) silk fiber is put into Na2CO3 solution and boiled for degumming; B) the silk fiber after the treatment is put into a CaCl2 solution for dissolution at high temperature, and then dissolving liquor is cooled and filtered, and filtrate is put into a dialysis bag and arranged in deionized water for dialysis to obtain pure fibroin solution; C) the obtained fibroin solution is arranged in a spray drier for spraying and drying to form soluble fibroin powder, and reserved for later use; D) the soluble fibroin powder is used for preparing the fibroin solution by the deionized water; and E) the ethylene glycol diglycidyl ether aqueous solution is prepared; when in use, the fibroin solution is sprayed on silk to be reinforced and then the ethylene glycol diglycidyl ether aqueous solution is sprayed on the silk to be reinforced; the preparation can substantially improve the strength of fragile silk and is applied to the protection of silk cultural relics, and has the advantages of simple method, convenient operation, no influence on the appearance of the silk cultural relics, and the like.

Owner:ZHEJIANG SCI-TECH UNIV +1

Multiple-effect super absorbent resin fertilizer and manufacturing method thereof

ActiveCN103694052AHigh reuse rateFast water absorptionFertilizer mixturesMeth-Sodium hydrogen sulphite

The invention provides a multiple-effect super absorbent resin fertilizer. In the manufacturing process, sodium hydrogen sulfite and ammonium persulfate oxidation-reduction type initiator are used as foundations, and ultraviolet initiation is used as an auxiliary means; N-N'-methylene bisacrylamide is used as a crosslinking foundation, and ethylene glycol diglycidyl ether and glycerol are used as auxiliary means; hydroxyethyl acrylate is added in the polymerized monomer, so that the colloid strength of the high molecular polymer is obviously improved; antioxidant, ultraviolet absorbent and light stabilizer are creatively introduced, thus finally manufacturing super absorbent resin having oxidation resistance, light resistance and degradation resistance; the super absorbent resin is organically combined with humic acid, microbial inoculant and an inorganic fertilizer to perform synergistic action, so that the various effective elements achieve the optimal use effect. Meanwhile, the consumption of the inorganic fertilizer is reduced, the salt content of soil is reduced, the pH value of the soil is improved, the soil environment is improved, and soil hardening is prevented, thus greatly increasing the utilization ratio of nitrogen fertilizers, phosphate fertilizers and potassium fertilizers, and achieving comprehensive effects of water saving, fertilizer saving, yield increase and outcome increase.

Owner:辽宁博科生物科技有限公司

Two-step crosslinking preparation method for keratin/PEO biological nanofiber membrane

The invention provides a two-step crosslinking preparation method for a keratin / PEO biological nanofiber membrane. The two-step crosslinking preparation method for the keratin / PEO biological nanofiber membrane comprises blending keratin powder extracted from waste natural keratin filaments through a reduction method and PEO powder according to the mass ratio of 90 to 50 to 10 to 50, preparing keratin / PEO static spinning solution with the mass percent concentration of 7 to 15% with water serving as solvent, adding ethylene glycol diglycidyl ether crosslinking agent into the static spinning solution to perform initial crosslinking on the static spinning solution, improving the keratin spinnability, performing static spinning, hanging a keratin / PEO nanofiber membrane obtained through static spinning inside a closed container loaded with ethylene glycol diglycidyl ether solution under 25 to 80 DEG C to perform secondary steam crosslinking, or arranging the keratin / PEO nanofiber membrane into a closed container which is full of pure oxygen under normal temperature to perform oxidation crosslinking and obtaining the keratin / PEO biological nanofiber membrane which is insoluble in water.

Owner:TIANJIN POLYTECHNIC UNIV

Amino acid composite reinforcement method for rotten silk cultural relics

The invention relates to an amino acid composite reinforcement method for rotten silk cultural relics, which is characterized by comprising the following steps: A) using a spraying device to uniformly spray amino acid solution with the mass percentage concentration being 0.5-2 percent onto the surfaces of the rotten silk cultural relics until water can drop down; wherein the amino acid is one of L-cysteine, L-alanine, L-lysine, L-histidine and L-arginine; and B) waiting for 10min after completion of Step A, uniformly spraying ethylene glycol diglycidyl ether solution with the mass percentage concentration being 1.5-3 percent onto the surfaces of the rotten silk cultural relics until water can drop down, and naturally drying the rotten silk cultural relics, thereby reinforcing the rotten silk cultural relics. Compared with the prior art, the method has the advantages that: 1) the operation is more convenient; and 2) the reinforcing effect is obviously better than the effect of the original method, the operation is more convenient and complies with the requirements and concepts of bionic reinforcement.

Owner:ZHEJIANG SCI-TECH UNIV

Method for preparing super-hole fibrin microsphere protein absorbing medium

InactiveCN101036876AEvenly distributedImprove stabilityOther chemical processesPeptide preparation methodsCelluloseMicrosphere

The present invention discloses a preparation method for superporous cellulose microglobulin adsorption medium, which belongs to the preparation technology of cellulose gel medium of bioseparation engineering field. The method comprises the steps of: dispersing calcium carbonate particles to the cellulose viscose to form composite water phase; putting the viscose into the transformer oil and adding composite emulsifier potassium oleate and Span 60 and then executing agitating and emulsification; heating and curing to form particles; adding ethylene glycol diglycidyl ether and epichlorohydrin to execute double crosslinking reaction under alkaline condition; removing the calcium carbonate particles by using muriate acid and then using sodium borohydride to reducing so as to prepare superporous cellulose microglobulin adsorption medium. The medium not only maintains the advantages of the quondam cellulose gel medium but also increases a plurality of superporous, so that the resistance to pressure, the mass transfer rate and the dynamic adsorption capacity of the medium are all obviously improved, thereby, the novel superporous cellulose microglobulin adsorption medium has wide application prospect.

Owner:TIANJIN UNIV

Fibroin reinforcement process of fragile silk

InactiveCN101424042AHigh strengthDoes not affect appearanceAnimal fibresAging resistanceRepeated treatment

The invention discloses a fibroin reinforcement technology for brittle silk, which comprises the following steps: A) a fibroin solution is prepared, a soft brush or an atomizing device is used to evenly brush or spray the fibroin solution on the brittle silk until the silk is evenly soaked by the fibroin solution, and then the silk is naturally dried; B) an ethylene glycol diglycidylether water solution is prepared, the soft brush or the atomizing device is used to evenly brush or spray the ethylene glycol diglycidylether aqueous solution on the brittle silk until the silk is evenly soaked by the ethylene glycol diglycidylether aqueous solution, and the silk is naturally dried; C) step A is repeated for n times, step B is repeated for m times, and the repeated steps can perform repeated treatment according to a mode of AB, ABAB,AABAAAB,AAAABAAAB,etc., wherein n is equal to 0, 1, 2, 3, 4, 5, and m is equal to 0, 1, 2, 3, 4, 5; D) the treated brittle silk is solidified; and E) the reinforced silk is obtained after the treatment. The reinforcement technology has the characteristics that the reinforcement technology has a simple method and simple and convenient operation, can greatly improve the strength of the brittle silk, does not affect the appearance of silk relics, can partially recover the silky luster of the relics, and has outstanding advantages in high temperature resistance and aging resistance and so on.

Owner:ZHEJIANG SCI-TECH UNIV +1

Cellulose-composite polyethylene diaphragm for lithium ion battery and preparation method thereof

InactiveCN105006539AImprove high temperature resistanceGood dimensional stabilityFinal product manufactureCell component detailsCelluloseMoisture absorption

The invention relates to the technical field of a lithium ion battery diaphragm technology and discloses a cellulose-composite polyethylene diaphragm for a lithium ion battery and a preparation method thereof. The diaphragm comprises a diaphragm base and a coating. The diaphragm base is prepared from 65-75 parts by weight of polyethylene, 5-10 parts by weight of vinyl acrylate, 5-10 parts by weight of natural cellulose slurry, 3-5 parts by weight of keratin, 1-3 parts by weight of ethylene glycol diglycidyl ether and 8-10 parts by weight of brown algae extract. The coating is prepared by coating the surface of the diaphragm base with coating slurry and is prepared from 1-5 parts by weight of a nanometer inorganic filler, 3-5 parts by weight of a binder, 20-30 parts by weight of vinyl acrylate, 1-5 parts by weight of mussel shell powder, 1-5 parts by weight of halloysite nanotubes and 57-67 parts by weight of an organic solvent. The cellulose-composite polyethylene diaphragm can resist a high temperature, keeps size stability after heating, has good moisture absorption and retention capability and good wellability with electrolyte, and has good stabbing strength.

Owner:长兴东方红包装有限公司

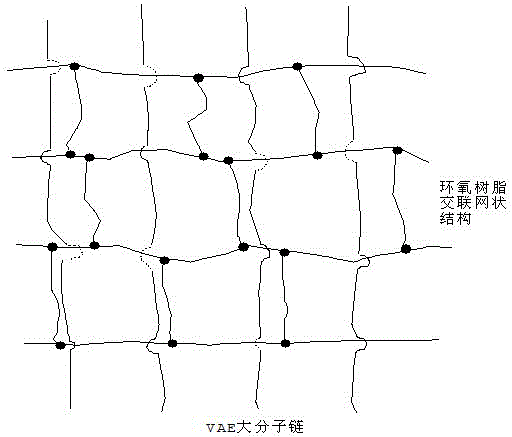

Epoxy resin modified VAE composite waterproof material and preparation method thereof

ActiveCN103555091AImprove water resistanceIncrease crosslink densityFireproof paintsAntifouling/underwater paintsPropanoic acidPhosphoric acid

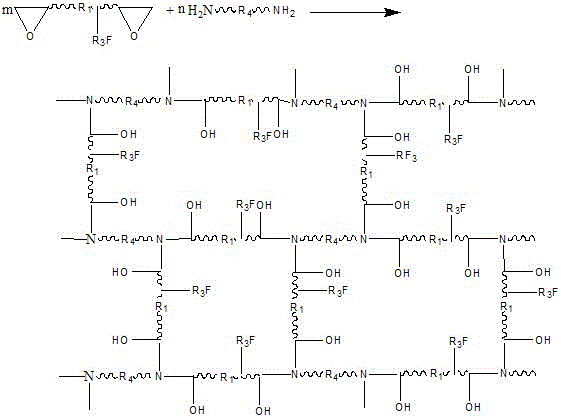

An epoxy resin modified VAE composite waterproof material and a preparation method thereof. The composite waterproof material is composed of a component A and a component B. A preparation method of the component A is as below: adding a vinyl acetate-ethylene copolymer emulsion into a material canister, then adding an epoxy resin emulsion and a defoaming agent, stirring, then adding aluminum hydroxide, phosphoric acid tris(2-chloroethyl) ester, talcum powder, a polytetrafluoroethylene fine powder, tetra [beta-(3,5-di-t-butyl-4-hydroxy phenyl) propionic acid] pentaerythritol ester, 2-(2H-benzo triazoles-2-yl)-6-dodecyl-4-methylphenol and water, and stirring to obtain the component A. A preparation method of the component B is as below: under the protection of nitrogen, adding tetraethylenepentamine into a reactor, dropwise adding ethylene glycol diglycidylether and butyl glycidol ether for a thermal reaction, then adding water to dilute and stirring to obtain the B component. The component A and the component B are stirred according to a part ratio of 100: 5-8 and applied; and after curing, a flame retardant antifouling self-cleaning composite waterproof material with a semi-interpenetrating network macro-molecular structure is obtained.

Owner:太原英可奥笔墨科技有限公司

Stereo lithography rapid prototyping photosensitive resin and preparation method thereof

InactiveCN102436145ALess irritatingIncrease photosensitivityPhotomechanical apparatusLithographic artistIrritation

The invention relates to a stereo lithography rapid prototyping photosensitive resin which is characterized by comprising the following raw materials according to the mass ratio: 5-30% of ethylene glycol diglycidyl ether diacrylate, 5-75% of epoxy resin, 5-55% of oxacyclobutane compound, 1-12% of cationic initiator, 5-50% of acrylic ester prepolymer and 1-10% of radical photopolymerization initiator. A preparation method of the stereo lithography rapid prototyping photosensitive resin comprises the steps of: mixing the raw material components according to the mass ratio; and then, heating andstirring, namely, stirring for 5-120 minutes at the temperature of 20-80 DEG C, and leading the obtained mixture to become transparent faint yellow uniform liquid. The photosensitive resin is low in irritation and less in volatile matter, and has good light sensitivity, wherein the critical exposure Ec is less than 16.5mJ / cm<2>; a molded part is high in accuracy and has the warpage factors CF (6) within the range of 0.01 to -0.01 and CF (11) within the range of 0.03 to -0.03; and parts with any complicated shapes and high accuracy can be directly manufactured, and the manufacturing cost is very low.

Owner:NANCHANG UNIV

Preparation method for biomimetic reinforcing agent of silk relics

The invention relates to a preparation method for a biomimetic reinforcing agent of silk relics. The preparation method is characterized in that: the preparation method comprises the following steps that: A) 1-4 parts by mass of L-lysine, 1 part by mass of L-cysteine and 1 part by mass of L-arginine are mixed and stirred to obtain a uniform mixture; B) the mixture from the step A) is prepared into an aqueous solution of the amino acid with deionized water, wherein the mass percent concentration of the aqueous solution is 0.1-5%; C) an ethylene glycol diglycidyl ether solution is prepared, wherein the mass percent concentration of the ethylene glycol diglycidyl ether solution is 0.1-5%; D) after adopting the preparation steps, the biomimetic reinforcing agent of the silk relics is obtained, wherein the biomimetic reinforcing agent comprises two parts of the amino acid solution and the assistant agent of the ethylene glycol diglycidyl ether solution. Compared to the prior art, the preparation method provided by the present invention has the following advantages: 1) the operation is convenient; 2) a plurality of the amino acids are adopted to replace the silk protein, such that the operation is convenient, and the better reinforcement effect is provided.

Owner:ZHEJIANG SCI-TECH UNIV

Microorganism water treatment agent for heavy metal organic wastewater

ActiveCN106007006AReduce the total dosageReduce usageBiological water/sewage treatmentOyster shellsTherapeutic effect

The invention belongs to the technical field of wastewater environmental-protection treatment, and particularly relates to a microorganism water treatment agent for heavy metal organic wastewater. The microorganism water treatment agent is prepared from the following raw materials: oyster shells, potassium feldspar, olivine, talc, serpentine, chlorite, attapulgite, ammonium molybdate modified bentonite, diatomaceous earth, aluminium polychlorid, magnesium hydrate, gram-negative bacteria, Bacillus mojavensis, polyacrylamide, tartaric acid, malic acid, citric acid, chitosan, ethylene glycol diglycidyl ether, epoxy chloropropane, thiosemicarbazide cellulose, corn starch, calcium alginate, hansenula polymorpha, candida, trailing plant, fagus longipetiolata sawdust, pinus sylvestris sawdust, walnut shell, lupulus, dehalogenase, horseradish peroxidase, urease and propionibacterium pentosaceum. A precipitate (alum floc) produced after treatment with the microorganism water treatment agent has good strippability, no solid particle is released into water basically, and the microorganism water treatment agent has rapid action speed and stable treatment effect, so that the adsorption time is usually not required to be prolonged during use.

Owner:JINING UNIV

Preparation method of high-efficiency compound stabilizer of chlorinated paraffin

A preparation method of a high-efficiency compound stabilizer of chlorinated paraffin comprises the following steps of: (1) uniformly mixing 50-55 parts by weight of glycol diglycidyl ether and methyltin, adding triphenyl phosphite, after intensive and uniform mixing, adding a catalyst, slowly heating to 145-150 DEG C, holding the temperature for 3h, rising the temperature to 160-170 DEG, holding the temperature for 30min, cooling to the room temperature to form a solution A, (2) pouring epoxy soybean oil into the solution A, then adding chlorinated paraffin-52 into the solution A to form a solution B, and (3) slowly heating the solution B to raise the temperature to 50-60 DEG C, continuing stirring for 15-20min, adding an ultraviolet absorber and an antioxidant, and stirring to complete dissolution to form the high-efficiency compound stabilizer of the chlorinated paraffin. The inventor of the invention finds that the solution can form a stable system and the storage stability is better via many repeated tests.

Owner:衡阳市骏杰化工有限公司

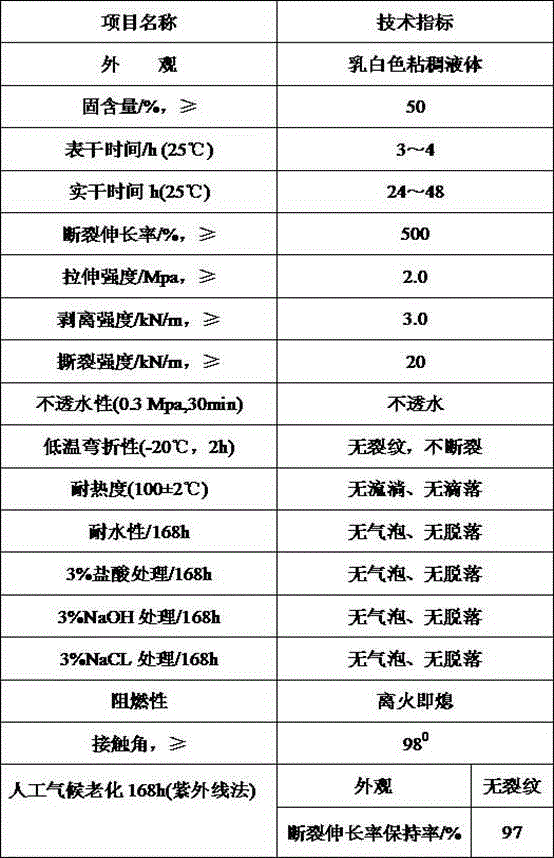

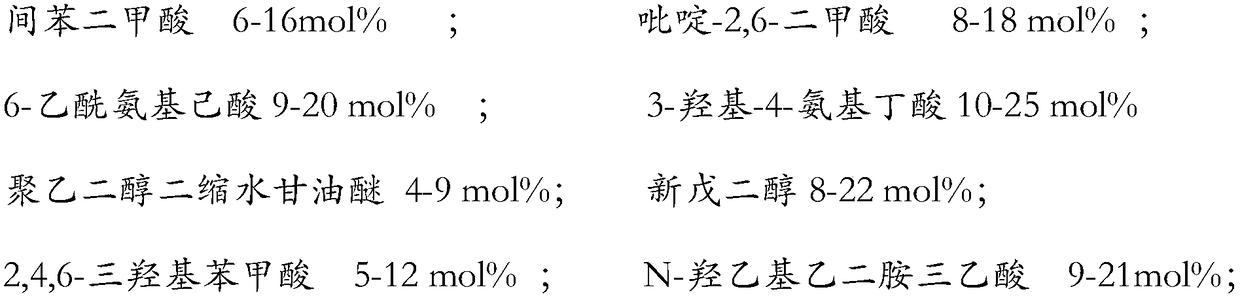

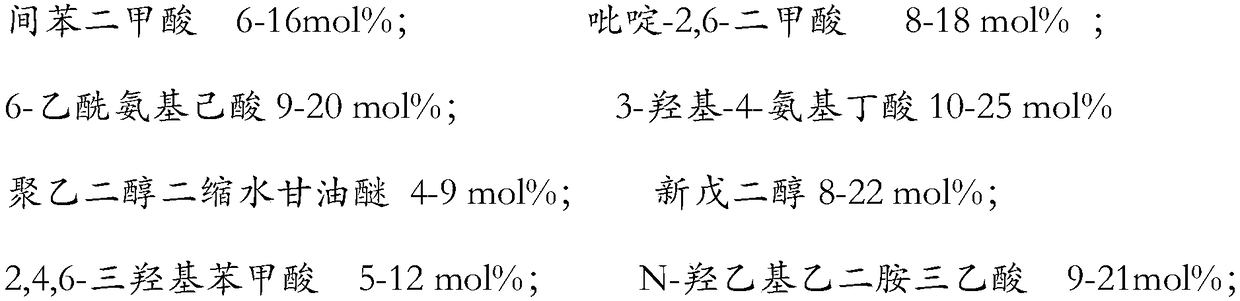

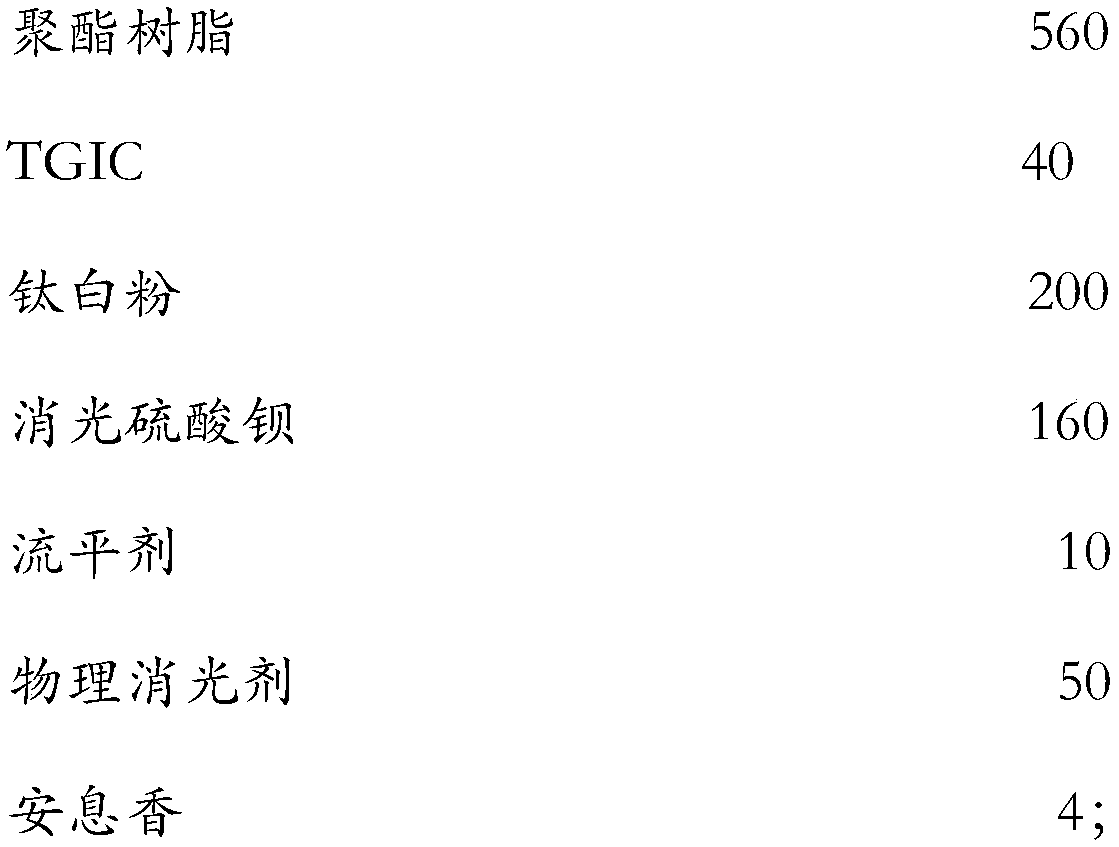

Polyester resin for low-gloss TGIC system powder coating and preparation method and application thereof

InactiveCN109320705AExcellent flatness and smoothnessImprove stabilityPowdery paintsPolyester coatingsEthylenediamineAntioxidant

The invention belongs to the technical field of resin production, and specifically relates to polyester resin for low-gloss TGIC system powder coating, a preparation method of the polyester resin, andapplication of the polyester resin. The polyester resin is mainly prepared from isophthalic acid, pyridine-2,6-dicarboxylic acid, 6-acetylaminocaproic acid, 3-hydroxy-4-aminobutyric acid, polyethylene glycol diglycidyl ether, neopentyl glycol, 2,4,6-trihydroxybenzoic acid, N-hydroxyethyl ethylenediamine tri-acetic acid, an esterification catalyst and an antioxidant. The molecules of the polyesterresin prepared by the method disclosed by the invention simultaneously contain active amino groups, hydroxyl groups and carboxyl groups, difference between the three kinds of base groups and epoxidegroups in TGIC molecules in curing reaction rate can be used for preparing low-gloss powder coating (gloss<20%), and the film coating properties can completely reach various requirements of powder coating.

Owner:周鹤洋

Preparation method of hydrophilic antibacterial modified polyester fiber

ActiveCN102400245AImprove antibacterial propertiesImprove water absorptionMonocomponent polyesters artificial filamentArtifical filament manufactureFiberPolyester

The invention discloses a preparation method of a hydrophilic antibacterial modified polyester fiber, which adopts the following steps: (A), taking and uniformly mixing 1-3 parts of aluminum oxide, 1-3 parts of diatomite, 1-3 parts of activated sepiolite and 0.01-0.5 part of silver sulfide in part by mass to obtain a mixture; (B), taking 0.1-0.5 part of ethylene glycol diglycidyl ether, 0.5-1.5 parts of sodium carboxymethylcellulose, 4-6 parts of sodium polyacrylate, 0.05-0.15 part of potassium peroxydisulfate, 1-3 parts of the mixture obtained in the step (A) and 6-10 parts of water in the part by mass in the step (A), agitating and reacting the obtained mixture for 1-3 hours at a temperature of 70-90 DEG C, drying a product, and grinding the product to obtain a hydrophilic antibacterial modified material with particle sizes being not more than 15 [mu]m; and (C), adding the hydrophilic antibacterial modified material obtained in the step (B) to a polyester fused mass, agitating the obtained mixture uniformly, and spinning the mixed mixture to obtain a modified polyester fiber, wherein the addition amount of the hydrophilic antibacterial modified material obtained in the step (B) is 5-15% of that of the polyester fused mass in percentage by weight.

Owner:JIANGSU WENFENG CHEM FIBER GROUP

Method for extracting regenerated cotton from waste cloth corner

ActiveCN105088424AStrengthen the cardIncrease productivityTextile disintegration and recoveryFibre disintegrationEnvironmental resistanceCarding

The invention relates to the generated cotton manufacturing field, and discloses a method for extracting generated cotton from waste cloth corners by using waste cloth corners of cotton material as raw material. The method comprises following steps: (1) selecting material; (2) pre-processing: spraying ecological agent on the waste cloth corners; the ecological agent is constituted of 60 to 80 parts of water, 5 to 25 parts of ethyl alcohol, 0.2 to 0.5 part of penetrating agent, 1 to 2 parts of lubricating agent, o.2 to 1.2 parts of swelling agent, 0.5 to 0.8 part of surface active agent, 6 to 8 parts of sea algae extract, 2 to 4 parts of wool extract, 1 to 2 parts of camellia oleifera shell extract and 0.2 to 0.4 part of ethylene glycol diglycidyl ether; the waste cloth corners are stacked to stew after being sprayed; during the stewing process, the highest temperature at the center of the waste cloth corners should be 25 to 50 DEG C and the stewing time is 24 to 72 hours; (3) pre-dissociating and opening; (4) opening and carding; (5) and packing. The method for extracting regenerated cotton from the waste cloth corners has the advantages of environmental protection, high recovery rate and small damage to cotton fiber; the cleanliness of extracted cotton fiber is high; the physical property is good; and the spinnability is high.

Owner:浙江立天科技有限公司

High-strength impact resistance oil paint

InactiveCN105255353AOvercoming impact resistanceOvercome the problem of large shrinkage during curingFireproof paintsPolyurea/polyurethane coatingsAcrylic resinPolyethylene glycol

The invention discloses high-strength impact resistance oil paint. The high-strength impact resistance oil paint is prepared from polyurethane acrylic resin, epoxy-acrylic resin, bisphenol A epoxy resin, ethylene diglycidyl ether, polyethylene glycol, 2-propenoic acid,1,1'-[(1-methyl-1,2-ethanediyl)bis[oxy(methyl-2,1-ethanediyl)]]ester, pentaerythritol triacrylate, azodiisobutyronitrile, 1-hydroxycyclohexylphenylketone, triarylsulfonium hexafluoroantimonate salt, carbon black, graphene oxide, carbon nanotubes, cresyl diphenyl phosphate, a flatting agent, an antifoaming agent, a thickening agent, a silane coupling agent, phenolic epoxy acrylate, solvent and corrosion inhibitor. The high-strength impact resistance oil paint is good in impact resistance, excellent in anti-static property, high in strength, high in adhesive force with a base material and not prone to be disengaged in the using process.

Owner:安徽嘉年华漆业有限公司

Fabricating method of anti-bacteria health clothes

InactiveCN101617865ANo pollution in the processAntibacterial function is safe and effectiveFibre treatmentProtective garmentPolyesterEngineering

The invention relates to a fabricating method of anti-bacteria health clothes, which is characterized by comprising the following steps: A), weaving and processing by using high moisture absorption polyester fibers as warp yarns and using real silk fibers as weft yarns to obtain clothing material; B), dipping the clothing material into a chitosan solution, taking out after wetting, pre-drying for 1-3min at 70 DEG C, and then baking for 2-4min at 140-160 DEG C; C), placing the clothing material which is processed by the B) into a glycol diglycidyl ether solution, dipping for 20-60min and then taking out, evening up, drying and dyeing; D), making the clothing material which is processed by the C) into clothes with different specifications to obtain the anti-bacteria health clothes. Compared with the prior art, the anti-bacteria health clothes fabricated by the invention has the advantages of polyester fiber and silk fiber clothes, safe and effective anti-bacteria function, multiple functions of protecting the environment and the health, no toxicity or harm or pollution to the human body and the environment, and meets the requirement of the green textile.

Owner:ZHEJIANG SCI-TECH UNIV

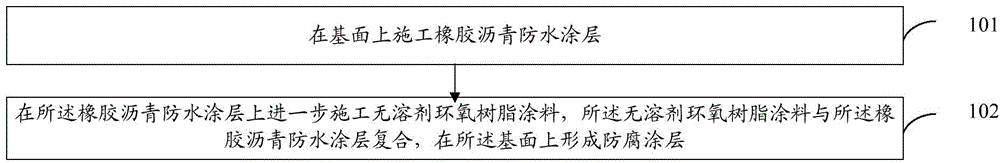

Construction method of novel anticorrosive coating layer

ActiveCN104945991AIncrease shear forceDoes not cause swellingUnspecified rubber coatingsAnti-corrosive paintsSolvent freeResin coating

The invention provides a construction method of a novel anticorrosive coating layer. The method comprises the following steps: constructing a rubber asphalt waterproof coating layer on a base surface; and further constructing a solvent-free epoxy resin coating on the rubber asphalt waterproof coating layer, and compounding the solvent-free epoxy resin coating with the rubber asphalt waterproof coating layer in order to form the anticorrosive coating layer on the base surface. The solvent-free epoxy resin coating comprises a component A and a component B; the component A comprises epoxy resin, an epoxy active diluent, an additive, a filler and a pigment; the component B comprises modified polyamine; the epoxy active diluent is at least one of dodecyl glycidyl ether, 1,4-butanediol diglycidyl ether and ethylene glycol diglycidyl ether; the additive comprises at least one of a leveling agent, a rheological assistant, a dispersant, a substrate wetting agent, an antifoaming agent and an ultraviolet ray absorber; and the filler comprises titanium dioxide, talcum powder, wet sericite powder, wollastonite powder and ceramic powder.

Owner:YUGREAT (BEIJING) INTERNATIONAL TECHNOLOGY CO LTD

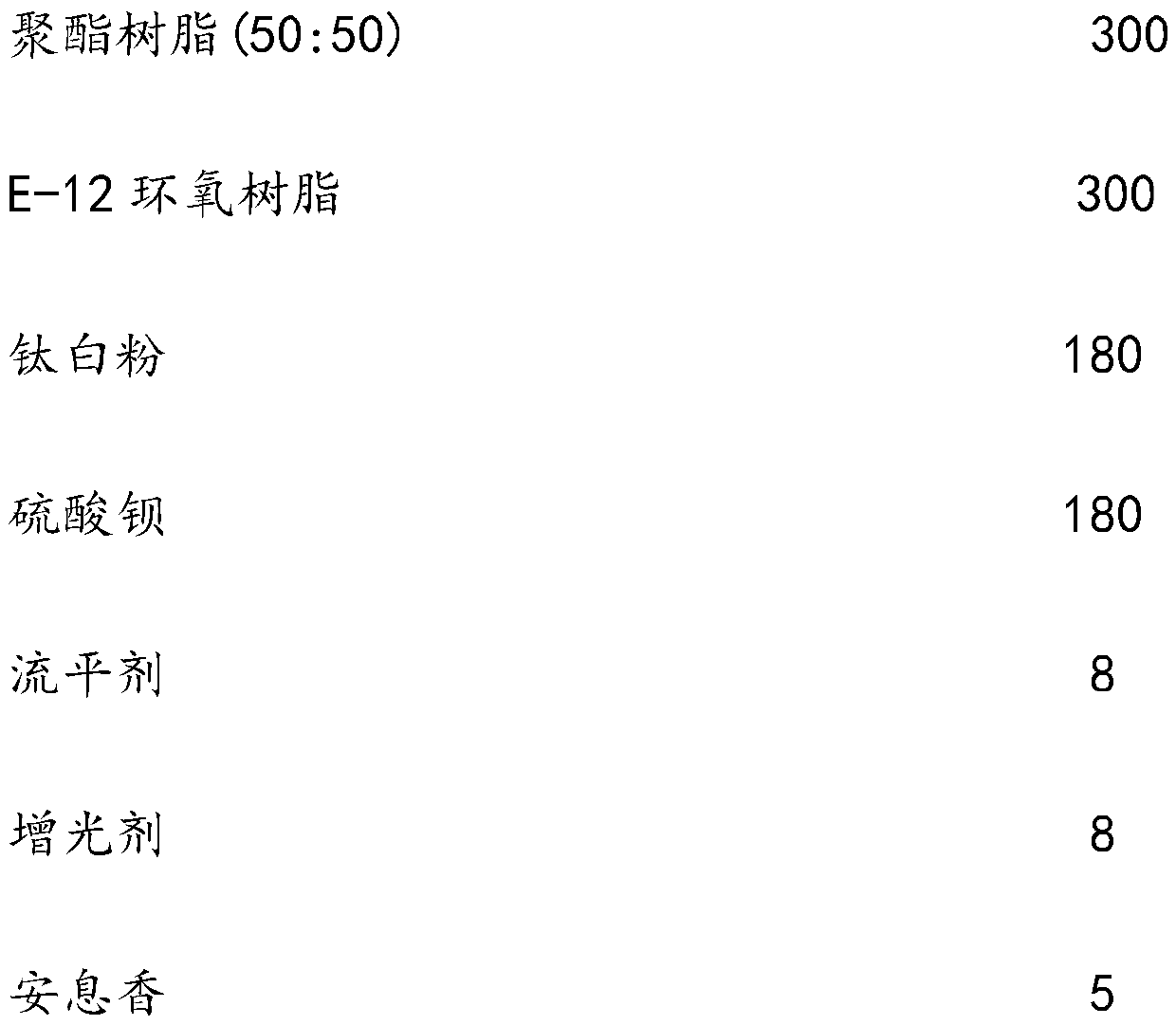

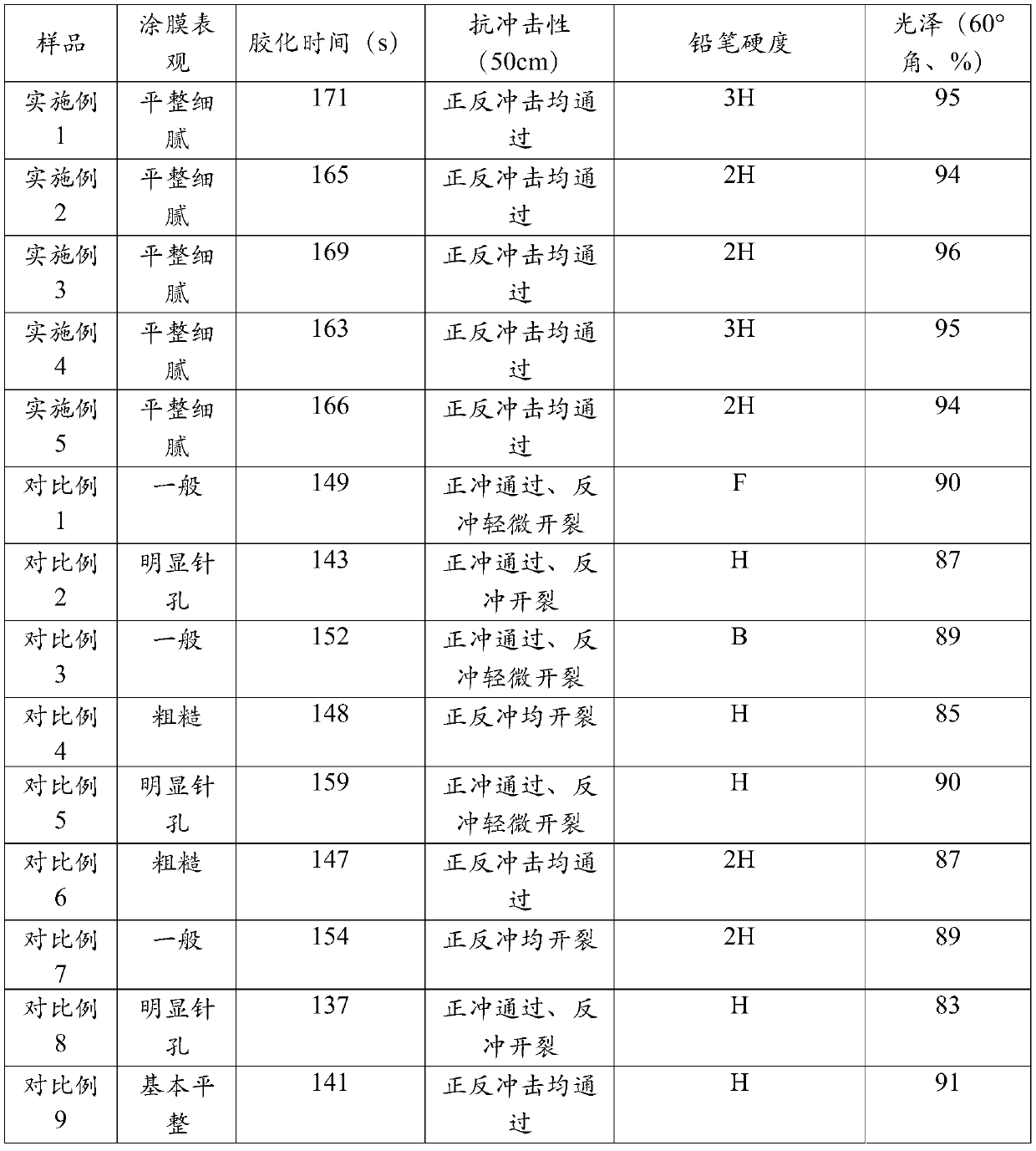

50:50 polyester resin for indoor high-hardness and high-gloss powders, and preparation method thereof

The invention belongs to the field of coatings, concretely relates to a 50:50 polyester resin for indoor powdery coatings with high requirements for the gloss and hardness, and also relates to a preparation method of the polyester resin. The 50:50 polyester resin for indoor powdery coatings is characterized in that the acid value of the polyester resin is 67-75 mgKOH / g, and the softening point is100-115 DEG C. The polyester resin is formed by copolymerizing the following main raw materials: dimethyl cyclohexane-1,2-dicarboxylate, terephthalic acid, neopentyl glycol, glycerol 5-hydroxydodecanoate, dipentaerythritol, tris(trimethylsilyl) phosphate, ethylene glycol diglycidyl ether and (2,7-octadien-1-yl)succinic anhydride. The polyester resin of the invention is used in indoor 50:50 mixed powder coatings, has a good apparent levelability, allows films formed after curing film formation of the coatings to have a high hardness, and can be used to obtain coated plate surfaces with high hardness and high gloss.

Owner:安徽永利新材料科技有限公司

Super heat insulation coating containing polyimide aerogel microspheres and preparation method thereof

The invention relates to a super heat insulation coating containing polyimide aerogel microspheres. The super heat insulation coating is prepared from the following raw materials in parts by weight: 25-30 parts of tetraethoxysilane, a proper amount of hydrochloric acid, a proper amount of ammonium hydroxide, a proper amount of ethyl alcohol, a proper amount of deionized water, 2.2-2.5 part of trimethylchlorosilane, 0.5-0.8 part of 3-aminopropylsilanetriol, 4-5 parts of polyimide aerogel microspheres, 0.1-0.15 part of a silane coupling agent kh-550, 0.2-0.3 part of sulfydryl polysiloxane, 70-75 parts of E-12 epoxy resin, 9-12 parts of ethylene glycol diglycidyl ether and 7-7.5 parts of triethanolamine. According to the preparation method of the super heat insulation coating containing polyimide aerogel microspheres, the polyimide aerogel microspheres and silicon dioxide aerogel are compounded; by virtue of the flexibility of the polyimide aerogel microspheres, the silicon dioxide aerogel can be prevented from being broken and the coating is endowed with the characteristics of lightweight, super heat insulation, superinsulation and the like.

Owner:WUHU BAOYI AMUSEMENT EQUIP

Modified metal organic framework composite material and preparation method and application thereof

ActiveCN109569520AHigh adsorption rateGood choiceIon-exchange process apparatusOther chemical processesN dimethylformamideSorbent

The invention discloses a modified metal organic framework composite material, a preparation method and application, and belongs to the technical field of preparation of porous materials. The structural formula of the material is as shown in specification. The preparation method comprises the following steps: adding a metal organic framework composite material UiO-66-NH2 into N,N-dimethylformamide, then adding ethylene glycol diglycidyl ether and carrying out refluxing reaction, after reaction is finished, washing, separating and drying to obtain MOF-EGD; successively adding MOF-EGD and 2-amino-5-mercapto-1,3,4-thiadiazole in N,N-dimethylformamide solution and carrying out refluxing reaction, and after reaction is finished, washing, separating and drying to obtain the modified metal organic framework composite material MOF-EGD-TTA. The method is simple and is easy to operate, and the prepared modified metal organic framework composite material can serve as an adsorbent to adsorb gold ions in a solution, is simple and convenient to operate, is easily synthesized, is easily separated from an aqueous solution, has high adsorbability and can be recycled.

Owner:KUNMING UNIV OF SCI & TECH

Bionic reinforcement method for rotten silk cultural relics

InactiveCN102433740AEasy to operateImprove reinforcement effectAnimal fibresGlycylxylidideAqueous solution

The invention relates to a bionic reinforcement method for rotten silk cultural relics, which is characterized by comprising the following steps: A) adding 1-3 portion(s) by mass of L-lysine, one portion by mass of L-histidine and one portion by mass of L-cysteine sequentially into a reactor, mixing the materials into a well-mixed mixture; B) preparing amino acid solution with the mass percentageconcentration being 0.5-3.5 percent with the mixture and deionized water; C) using a spraying device to uniformly spray the amino acid solution onto the surfaces of the rotten silk cultural relics until water can drop down; and D) uniformly spraying ethylene glycol diglycidyl ether solution with the mass percentage concentration being 1.5-3 percent onto the surfaces of the rotten silk cultural relics after 10min of completion of Step C until water can drop down, and naturally drying the rotten silk cultural relics. Compared with the prior art, the method has the advantages that: 1) the operation is more convenient; and 2) the amino acid is used instead of silk protein, thereby facilitating the operation and achieving better reinforcing effects.

Owner:CHINA NAT SILK MUSEUM

Method for improving water and moisture absorbability of polyester fabric by using gamma-polyglutamic acid hydrogel

InactiveCN102677474AImprove water and moisture absorption performanceMoisturizingFibre typesCross-linkPolyester

The invention discloses a method for improving water and moisture absorbability of polyester fabric by using gamma-polyglutamic acid hydrogel which is a biological high-molecular material. The method is a method for finishing the fabric by using gamma-polyglutamic acid as a finishing agent and ethylene glycol diglycidyl ether as a cross-linking agent. The method comprises the steps of: dissolving the gamma-polyglutamic acid in distilled water or tap water to prepare solution with concentration being 4-20%, adding the ethylene glycol diglycidyl ether with mass percent being 20-60% of the gamma-polyglutamic acid, and fully agitating to ensure even mixing; and soaking the polyester fabric in the finishing agent for 5-10 minutes, using a padder for two times of soaking and two times of padding, keeping the padding residual rate to be 60-110%, wrapping the soaked and padded fabric with a preservative film, putting in a drying oven with the temperature being 40-80 DEG C for reaction for 5-25h, removing the preservative film and drying; or baking the soaked and padded fabric in a baking machine with the temperature being 110-140 DEG C for 5-10 minutes. The standard moisture regain and the water regain of the polyester fabric finished by adopting the method are obviously improved and the wearing comfort is obviously improved.

Owner:TIANJIN POLYTECHNIC UNIV

Method for preparing agent of cyclodextrin-cellulose for adsorbing uric acid

InactiveCN1660129AFast adsorption rateImprove bindingOrganic active ingredientsUrinary disorderSorbentCyclodextrin

A uric acid absorbent is prepared through dissolving cellulose in NaOH solution, adding cross-linking agent, polymerizing reaction, proportionally adding cyclodextrin, reaction, drying, and pulverizing. It has high adsorptive speed and power to uric acid.

Owner:TIANJIN UNIV

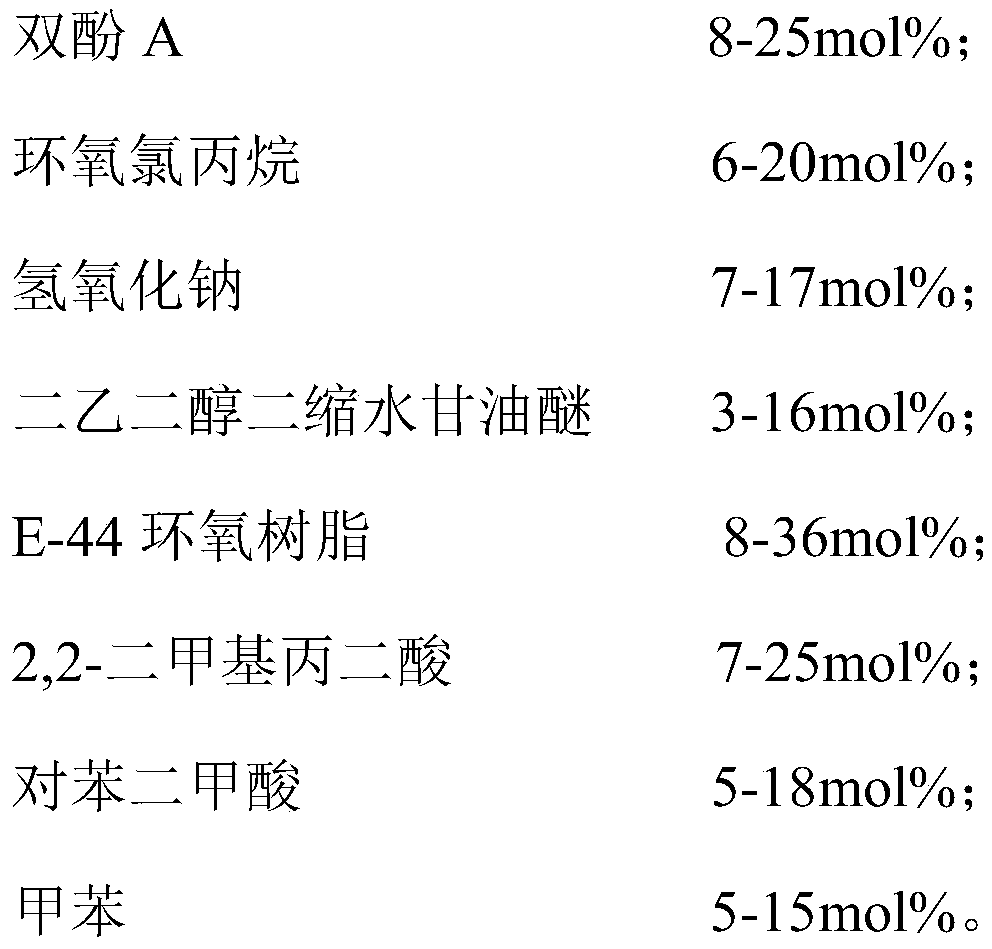

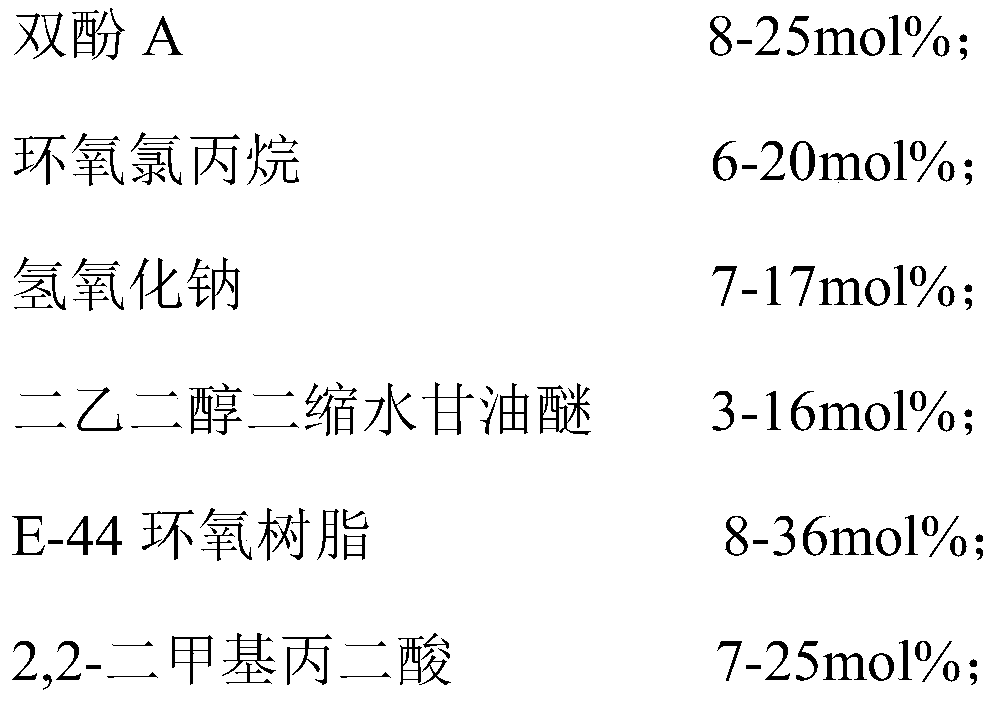

Low-temperature-curable epoxy resin used for matting powder B68, and preparation method and application thereof

ActiveCN110437711AReduced activityThe chain segment is obviousPowdery paintsEpoxy resin coatingsLow temperature curingHigh activity

The invention belongs to the technical field of powder coatings, and specifically relates to low-temperature-curable epoxy resin used for matting powder B68, and a preparation method and an application thereof. According to the low-temperature-curable epoxy resin used for the matting powder B68 provided by the invention, bisphenol A, epoxy chloropropane, sodium hydroxide, 2,2-dimethylmalonic acid,terephthalic acid, toluene, epoxy resin E-44 with high epoxy activity and the like are used as raw materials for polymerization; a high-activity monomer namely diethylene glycol diglycidyl ether is adopted as an end-capping agent for end capping; by adoption of manners of respectively preparing epoxy resin I and epoxy resin II through double formulas and mixing the epoxy resin I and the epoxy resin II, an epoxy resin product with relatively poor dispersion compatibility, soft chain segment and high activity is finally obtained, and a coating film with lower gloss can be easily obtained; meanwhile, due to different molecular chain segments, the epoxy resin product has significant activity difference and relatively-reduced softening point and can realize complete curing at a curing rate of150 DEG C / 20 min, so energy consumption is reduced to a large extent, and the gloss of a coating film can achieve of 5% or even lower.

Owner:黄山五环科技有限公司

Epoxy resin curing agent

The invention relates to the technical field of curing agents, particularly an epoxy resin curing agent. The epoxy resin curing agent comprises the following components in percentage by weight: 40-50% of acid anhydride, 40-50% of boron trifluoride, 5-10% of toughener and 5-10% of diluter. The components above are adopted in combination with any one toughener of carboxyl liquid nitrile-butadiene rubber, carboxyl-terminated liquid nitrile-butadiene rubber, polysulfide rubber, liquid silicone rubber and the like, or any one diluter of polypropylene glycol diglycidyl ether, phenyl glycidyl ether and ethylene glycol diglycidyl ether to further improve the toughness of the epoxy resin curing agent and enhance the bearing strength and temperature tolerance. Therefore, the prepared epoxy resin curing agent has the advantages of high reaction speed, low toxicity, high pressure resistance, corrosion resistance, small shrinkage deformation and the like, and can be widely used in the industries of electrical potting and packaging, electrical casting, electric apparatus impregnation, insulating composite material winding, pulling and extrusion, and the like.

Owner:南通市福来特化工有限公司

Preparation method of waterborne urushiol epoxy emulsion

InactiveCN108003749AAlkali resistantStrong alkali resistanceNatural resin coatingsEpoxy resin coatingsEmulsionProcess equipment

The invention provides a preparation method of a waterborne urushiol epoxy emulsion. The method comprises the following steps that 1, urushiol epoxy resin is prepared; 2, an adduct of ethanolamine-glycol diglycidyl ether ethanolamine is prepared; 3, waterborne urushiol epoxy resin is prepared; 4, a finished product is obtained. Accordingly, adopted process equipment is simple, the reaction condition is mild, and paint film obtained after the prepared urushiol epoxy emulsion is cured has the high alkaline resistance property; meanwhile, a new way is opened up for application of raw lacquer, andthe method has the important significance on high-value utilization of the raw lacquer.

Owner:佛山市极加互动科技有限公司

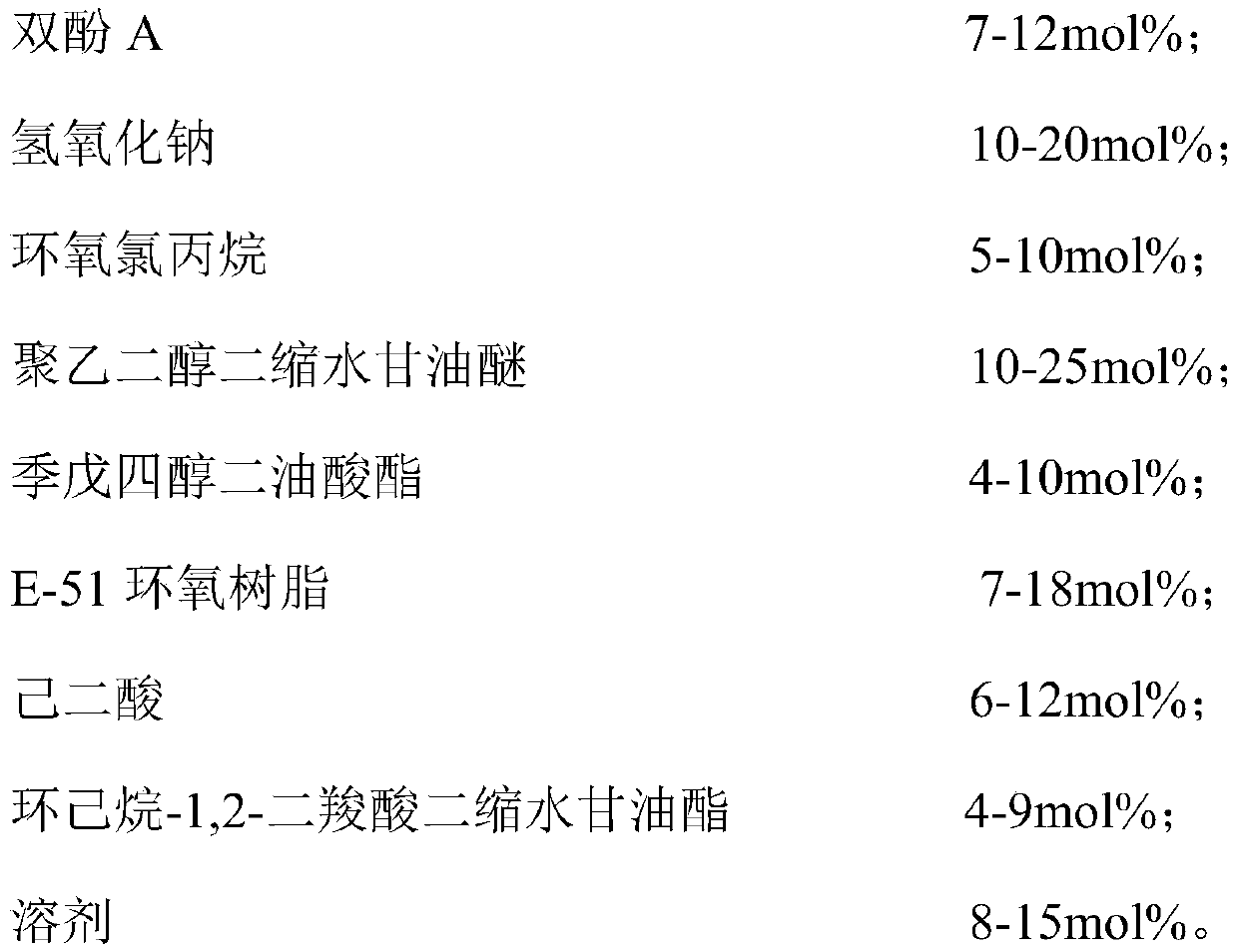

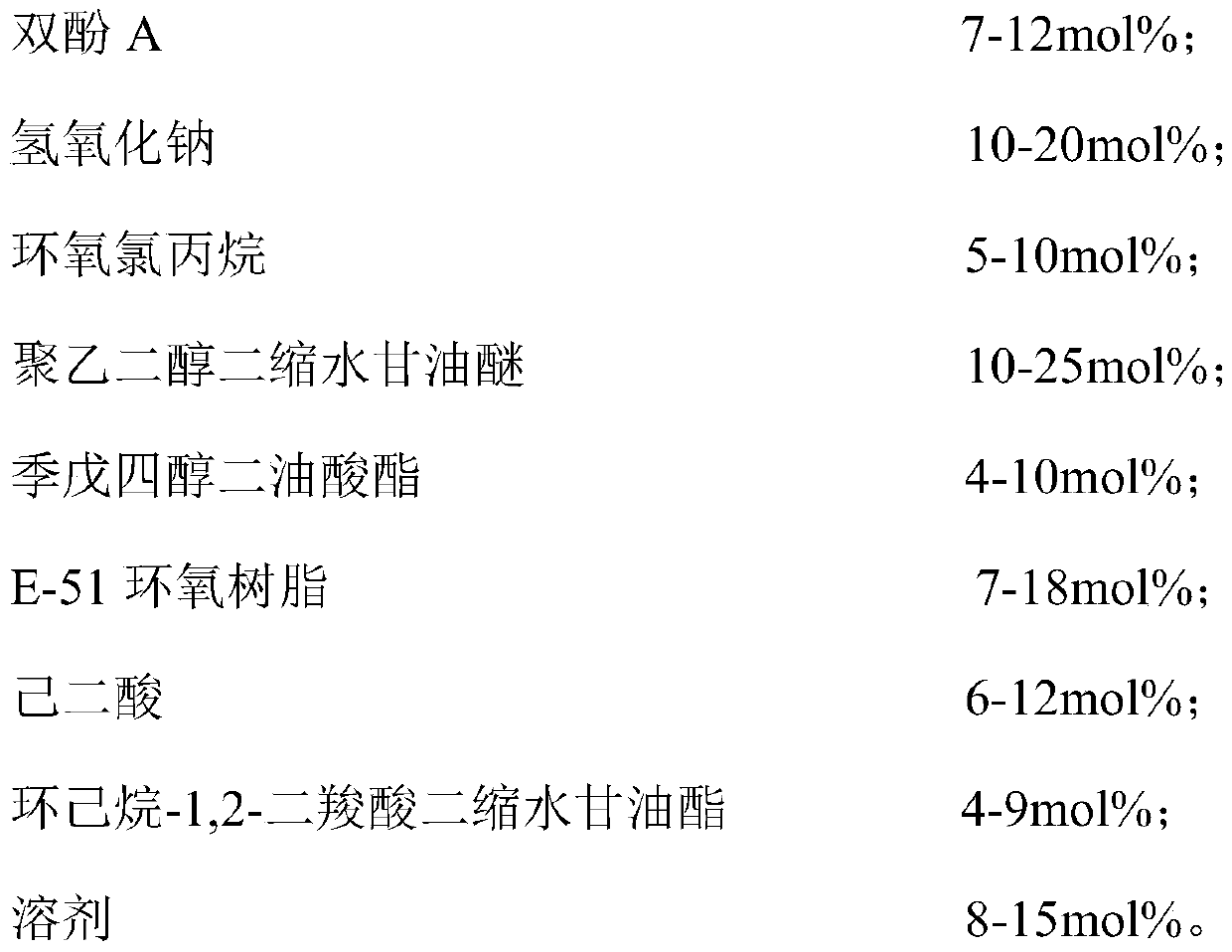

Epoxy resin for 50: 50 indoor powdery paint with high leveling grade, and preparation method thereof

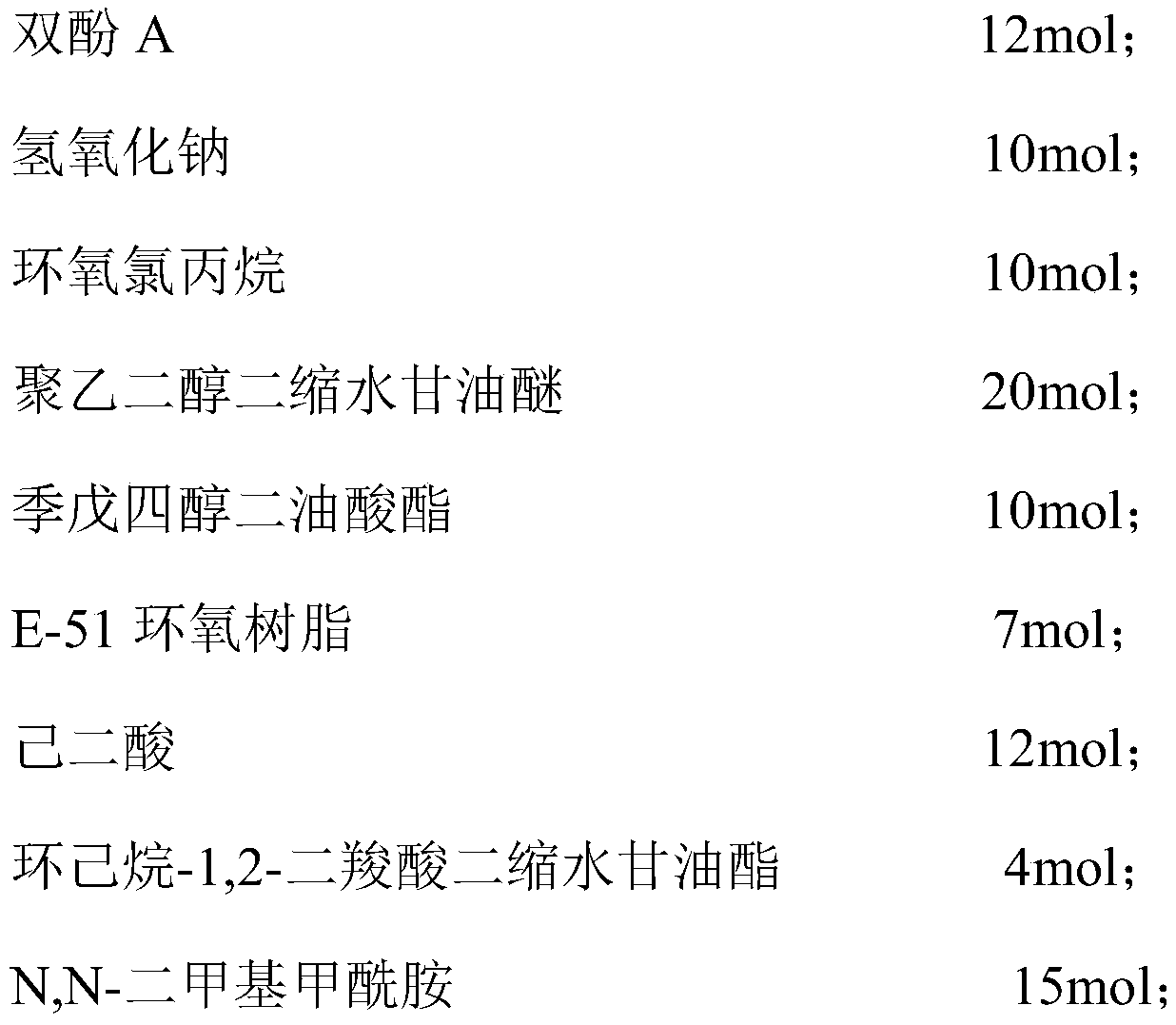

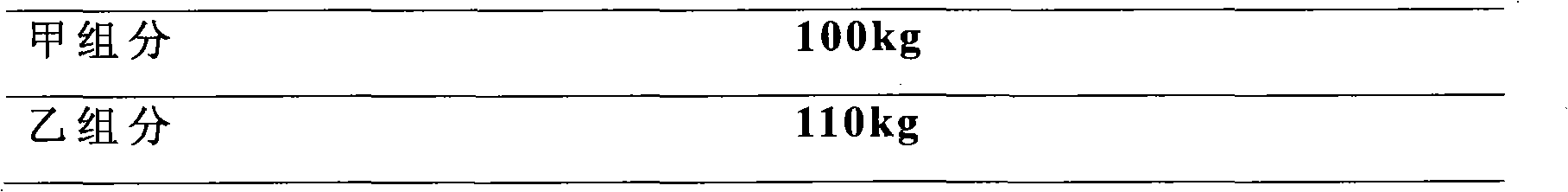

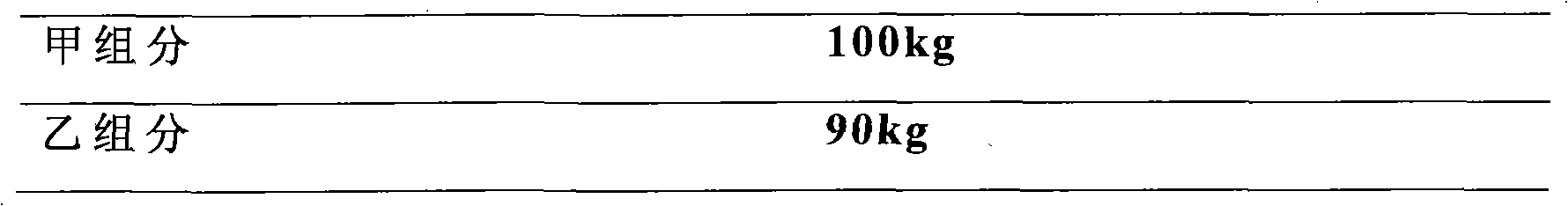

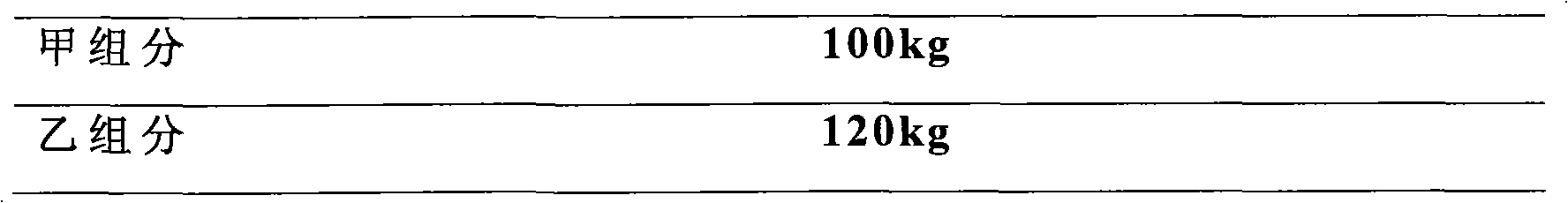

ActiveCN110423539AImprove the level ofSimple structurePowdery paintsEpoxy resin coatingsN dimethylformamideAdipic acid

The invention specifically relates to epoxy resin for a 50: 50 indoor powdery paint with a high leveling grade and further discloses a preparation method thereof, belonging to the technical field of powdery paints. The epoxy resin for the 50: 50 indoor powdery paint with a high leveling grade is prepared through polymerization of bisphenol A, epichlorohydrin, sodium hydroxide, polyethylene glycoldiglycidyl ether, pentaerythritol dioleate, E-51 epoxy resin, adipic acid, cyclohexane-1,2-dicarboxylic acid diglycidyl ester and N,N-dimethylformamide. The synergistic action among the raw materialsensures that the produced epoxy resin has excellent overall performance such as impact resistance, excellent adhesion, water resistance, etc. The epoxy resin is finally applied to the 50:50 indoor powdery paints and allows a coating with excellent comprehensive performance and a high leveling grade to be obtained.

Owner:黄山五环科技有限公司

Normal temperature dipping-type epoxy anhydride heat-resistant resin as well as preparation method and application thereof

ActiveCN101864058AImprove heat resistanceModerate viscosityPlastic/resin/waxes insulatorsManufacturing dynamo-electric machinesTrimethylolpropaneNeopentyl glycol

The invention discloses a normal temperature dipping-type epoxy anhydride heat-resistant resin which is characterized by comprising a component A and a component B according to the weight ratio of 1: (0.8 to 1.2), wherein the component B is liquid anhydride; the component A comprises the following ingredients in percent by weight: 60-90 percent of bisphenol A type epoxy resin and 40 to 10 percent of multi-functional low-viscosity epoxy reactive diluent; and the multi-functional low-viscosity epoxy reactive diluent is selected from one or a mixture of more than two of neopentyl glycol diglycidyl ether, cyclohexanediol diglycidyl ether, ethylene glycol diglycidyl ether, glycerol diglycidyl ether, trimethylolpropane diglycidyl ether and triglycidyl isocyanurate. The resin does not contain volatile styrene reactive diluent, and the solidified resin has good heat-resistance, high mechanical strength and low dielectric loss factor, can make the coil insulation thickness be thin and is beneficial to reducing the motor temperature rise, prolonging the motor service life and reducing the motor size.

Owner:SUZHOU JUFENG ELECTRICAL INSULATION SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com