Patents

Literature

40 results about "Superinsulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Superinsulation is an approach to building design, construction, and retrofitting that dramatically reduces heat loss (and gain) by using much higher levels of insulation and airtightness than normal. Superinsulation is one of the ancestors of the passive house approach.

Multi-Layer Thermal Insulation Composite

A multilayer thermal insulation composite for fire protection applications. The composite includes a fibrous insulation layer, at least one inorganic heat absorbing layer disposed on one side of the fibrous insulation layer, and at least one superinsulation layer disposed on at least one side of the composite adjacent the heat absorbing layer or the fibrous insulation layer. The composite may further include a scrim layer comprising a high temperature resistant, flexible, woven or non-woven scrim or scrim and high temperature resistant material disposed around the multilayer thermal insulation composite partially or substantially totally encapsulating the composite. The composite is lightweight and flexible, exhibits reduced heat transfer to the cold-face, with improved thermal insulation capability.

Owner:UNIFRAX I LLC

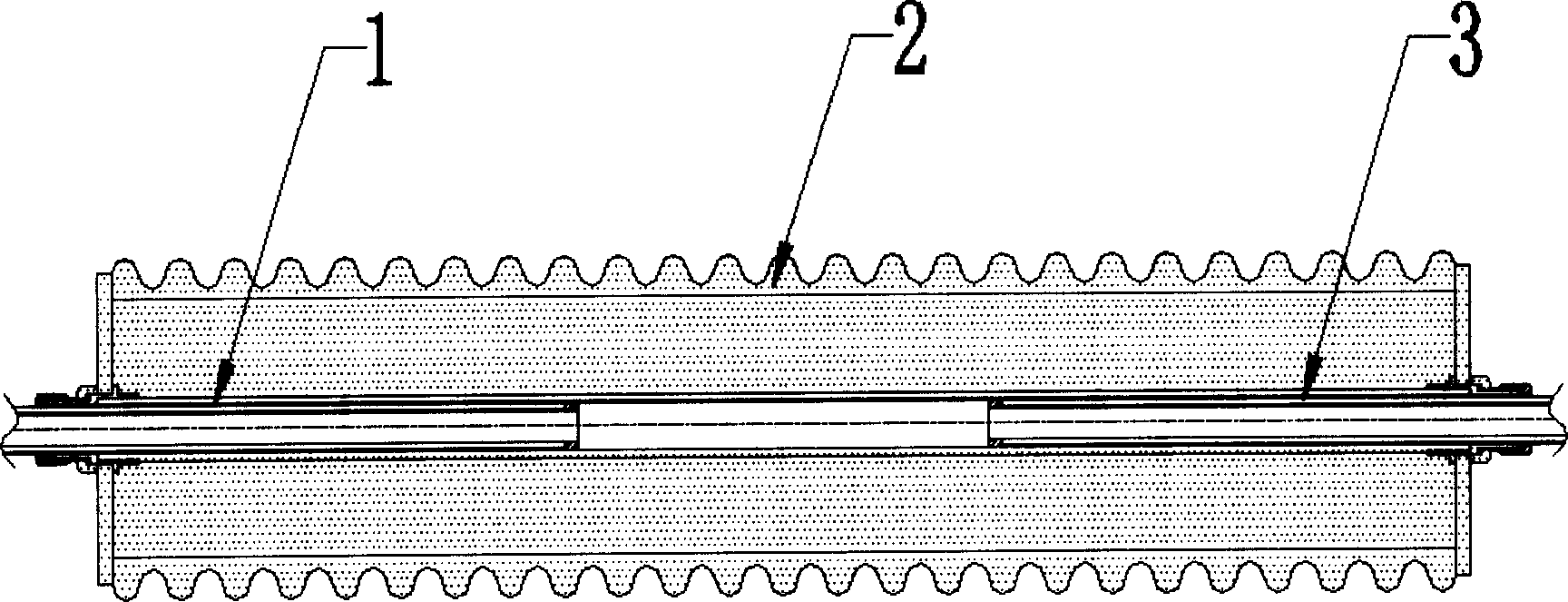

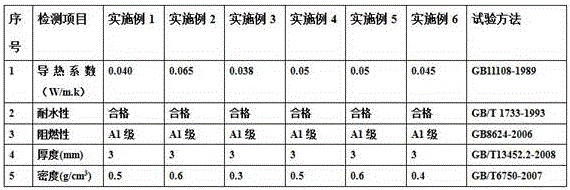

Production method of no-powder-falling interlayer structure super heat insulation gas gel composite material

ActiveCN103192582ASimple processExtended service lifeLaminationLamination apparatusAircraft industryAirplane

The invention belongs to the field of heat insulation and sound-proof material manufacturing, and in particular relates to a production method of a no-powder-falling interlayer structure super heat insulation gas gel composite material. According to the invention, inorganic fireproof cloth is pasted on the outer surface of a nano porous gas gel material; the performances of light quality, super heat insulation and the like of the gas gel material are kept, and meanwhile the problem of easiness in powder falling is solved, and nano dust is prevented from generating during the production and using process of the gas gel material, so that the gas gel material is more safe, healthy and environment-friendly, and compared with the non-composite gas gel material, the gas gel material is more even and uniform, and the appearance is more beautiful. The no-powder-falling interlayer structure super heat insulation gas gel composite material provided by the invention has the characteristics of chip and easily obtained raw materials, safe and simple production process, low cost and the like; the obtained material has the advantages of excellent nano porous material heat insulation performance and durable common material, and is widely applied to the heat insulation field of ship cabins, vehicle bodies, airplanes, industrial pipelines, building wall bodies and the like.

Owner:SHANGHAI GRAND SOUND BEYOND NOISE NEW MATERIAL

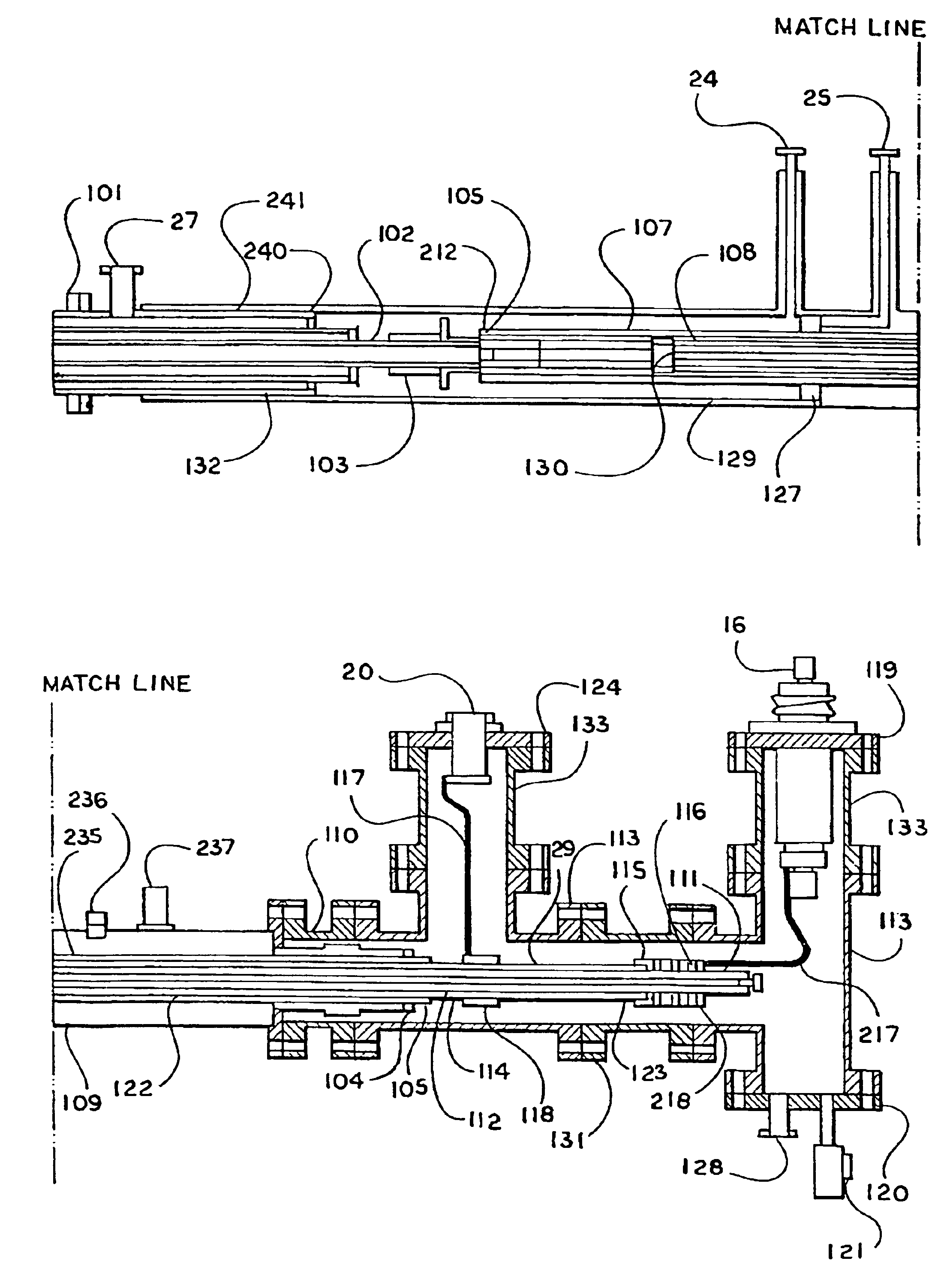

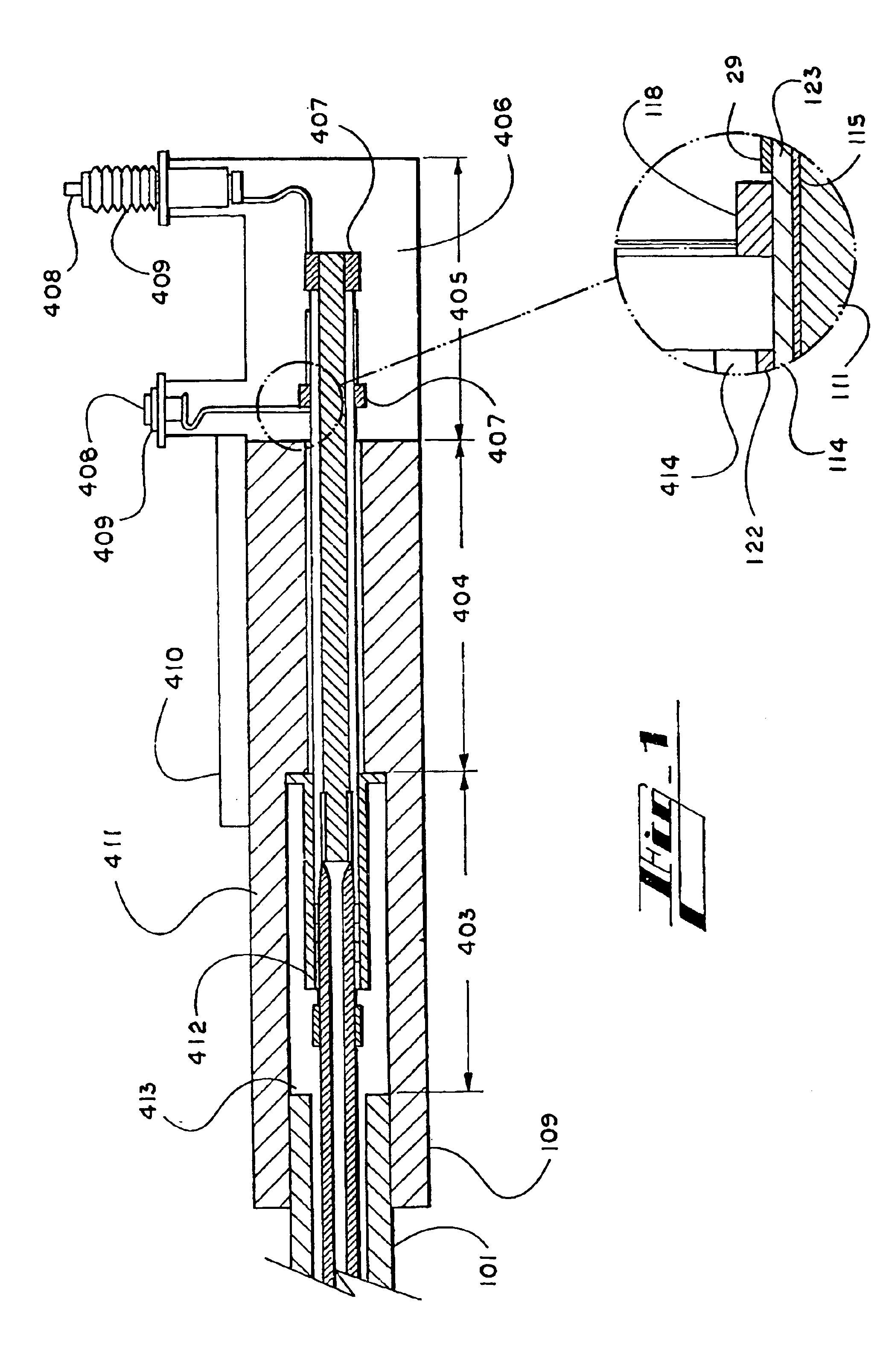

Superconducting cable termination

InactiveUS6936771B2Minimize flow of heatControl flowSuperconductors/hyperconductorsTransit-time tubesElectrical conductorHeat leak

Disclosed is a termination that connects high temperature superconducting (HTS) cable immersed in pressurized liquid nitrogen to high voltage and neutral (shield) external bushings at ambient temperature and pressure. The termination consists of a splice between the HTS power (inner) and shield (outer) conductors and concentric copper pipes which are the conductors in the termination. There is also a transition from the dielectric tape insulator used in the HTS cable to the insulators used between and around the copper pipe conductors in the termination. At the warm end of the termination the copper pipes are connected via copper braided straps to the conventional warm external bushings which have low thermal stresses. This termination allows for a natural temperature gradient in the copper pipe conductors inside the termination which enables the controlled flashing of the pressurized liquid coolant (nitrogen) to the gaseous state. Thus the entire termination is near the coolant supply pressure and the high voltage and shield cold bushings, a highly stressed component used in most HTS cables, are eliminated. A sliding seal allows for cable contraction as it is cooled from room temperature to ˜72-82 K. Seals, static vacuum, and multi-layer superinsulation minimize radial heat leak to the environment.

Owner:SOUTHWIRE CO LLC

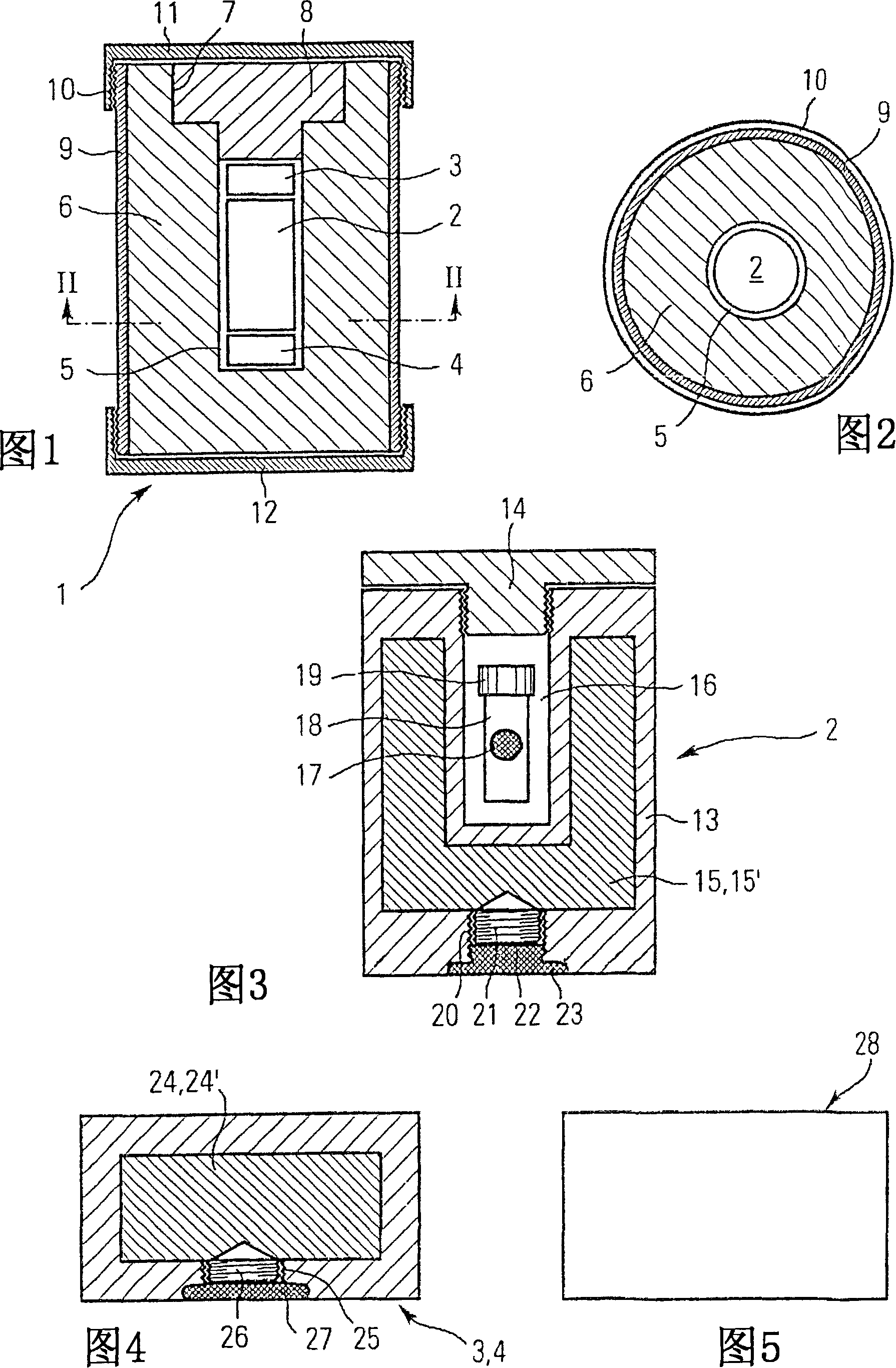

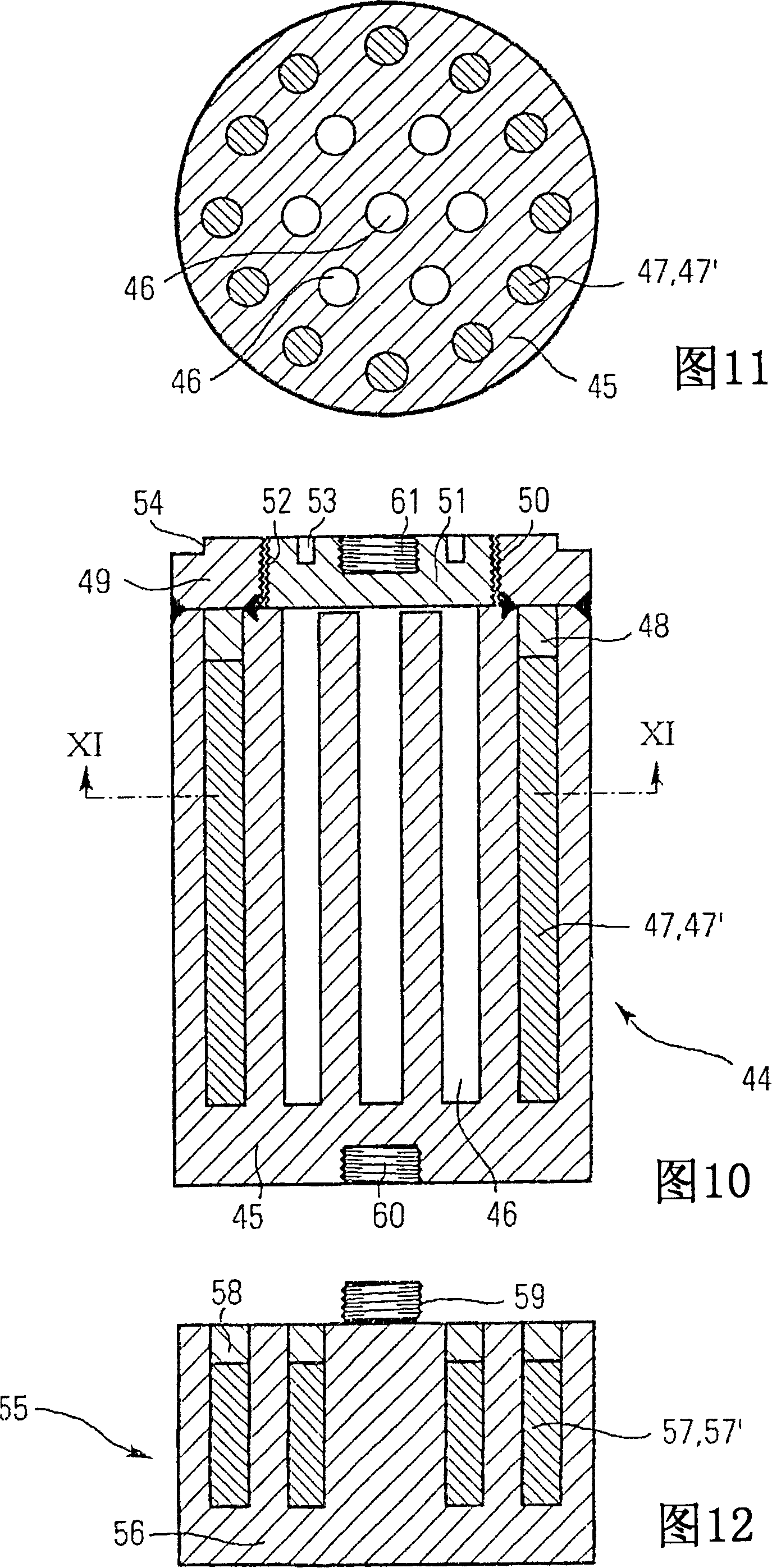

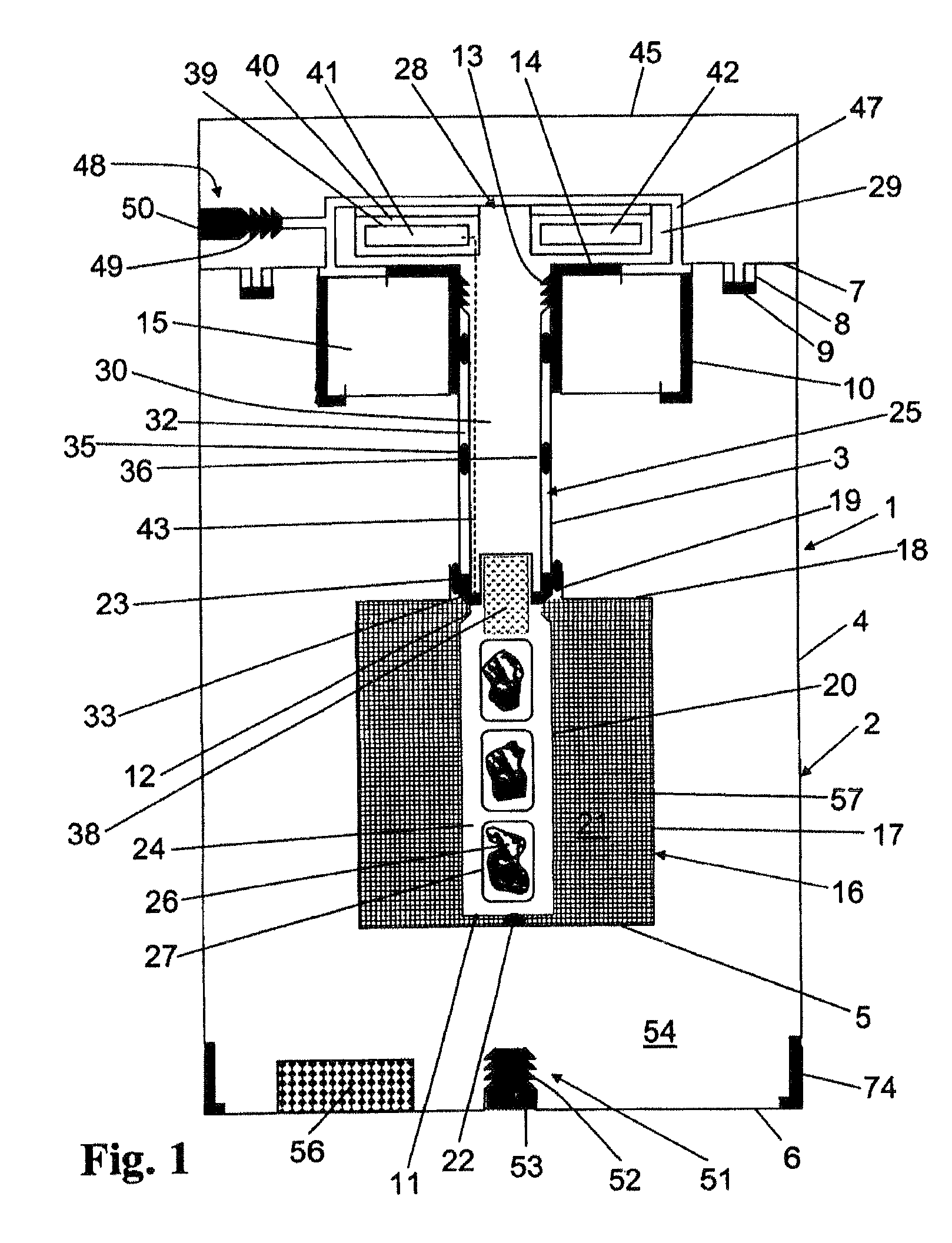

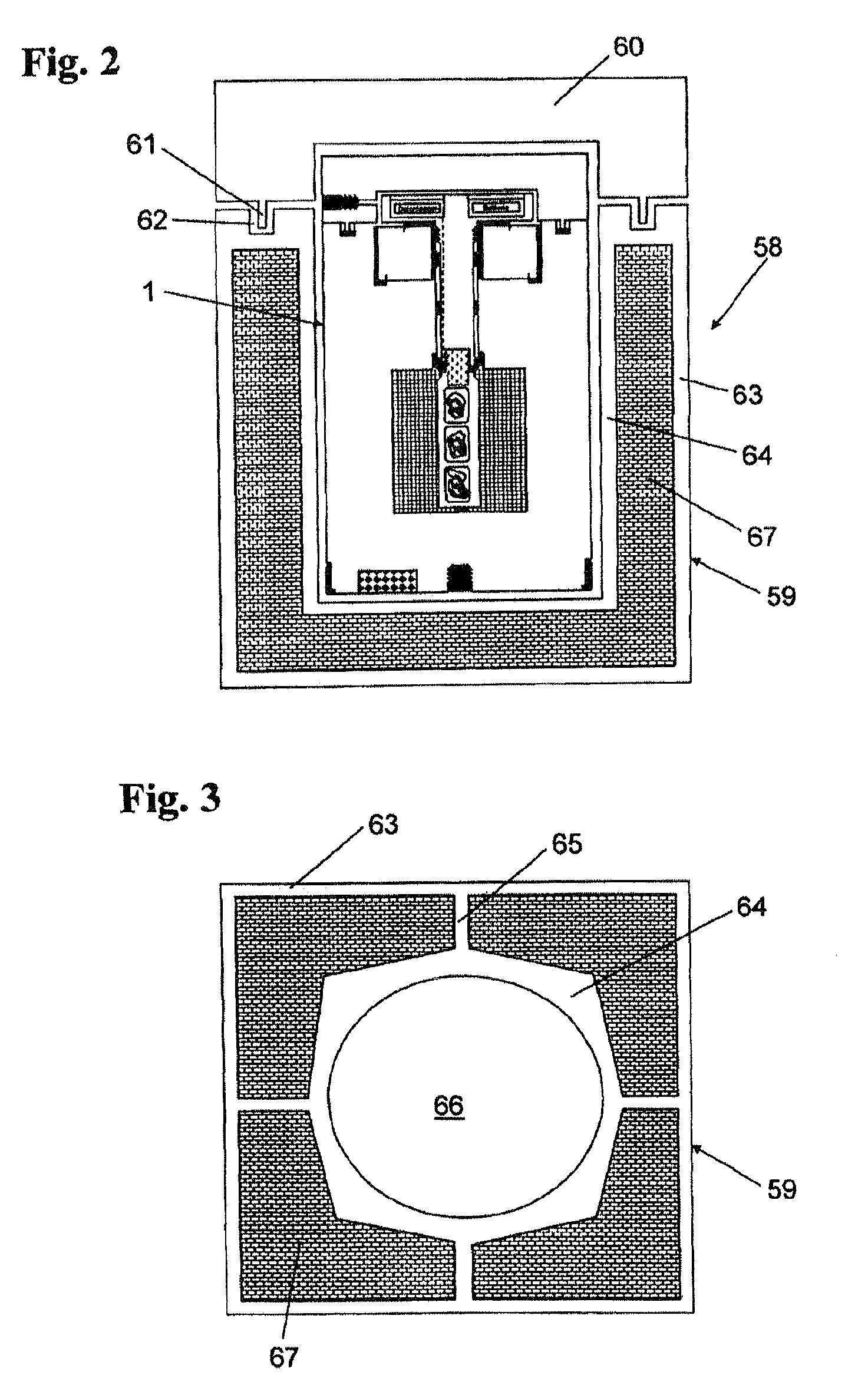

Transport container for keeping frozen material chilled

InactiveCN101124444AEasy to makeEasy to operateLighting and heating apparatusPharmaceutical containersEngineeringCold store

Disclosed is a transport container for shipping frozen material, particularly biological tissue samples. Said transport container comprises a jacket-shaped insulation (superinsulation) and a removable inner container (44) which is provided with at least one coolant chamber (47) with a coolant filling (47'), and at least one chilling chamber (46) that is located inside the coolant chamber (47). The coolant, e.g. mercury having a melting temperature of about -39 DEG C, is permanently and hermetically enclosed in the coolant chamber (47) and is solidified in a freezing process using liquid nitrogen, for example, before being shipped. The chilling chamber (46), and thus the sample, is maintained at said temperature level during shipping while the coolant or mercury melts slowly.

Owner:B・西克斯特

Pressure-proof insulating material

The invention discloses a pressure-proof insulating material which comprises a pressure-proof glass insulating matrix and a nano insulating coating, wherein the pressure-proof glass insulating matrix comprises the following main compositions: quartz sand, sodium carbonate, limestone and feldspar; the nano insulating coating comprises nano modified epoxy resin, nanosize silica and nano ceramic fiber; the silicon dioxide content of the pressure-proof glass insulating matrix is not less than 85%. The pressure-proof insulating material disclosed by the invention has the characteristics of high rigidity, super-toughness, high temperature resistance, low temperature resistance, and superinsulation; the material can resist high-pressure local flashover, and can be used for manufacturing high-pressure glass insulators.

Owner:KUNSHAN FENFA INSULATING MATERIALS

Super heat insulation coating containing polyimide aerogel microspheres and preparation method thereof

The invention relates to a super heat insulation coating containing polyimide aerogel microspheres. The super heat insulation coating is prepared from the following raw materials in parts by weight: 25-30 parts of tetraethoxysilane, a proper amount of hydrochloric acid, a proper amount of ammonium hydroxide, a proper amount of ethyl alcohol, a proper amount of deionized water, 2.2-2.5 part of trimethylchlorosilane, 0.5-0.8 part of 3-aminopropylsilanetriol, 4-5 parts of polyimide aerogel microspheres, 0.1-0.15 part of a silane coupling agent kh-550, 0.2-0.3 part of sulfydryl polysiloxane, 70-75 parts of E-12 epoxy resin, 9-12 parts of ethylene glycol diglycidyl ether and 7-7.5 parts of triethanolamine. According to the preparation method of the super heat insulation coating containing polyimide aerogel microspheres, the polyimide aerogel microspheres and silicon dioxide aerogel are compounded; by virtue of the flexibility of the polyimide aerogel microspheres, the silicon dioxide aerogel can be prevented from being broken and the coating is endowed with the characteristics of lightweight, super heat insulation, superinsulation and the like.

Owner:WUHU BAOYI AMUSEMENT EQUIP

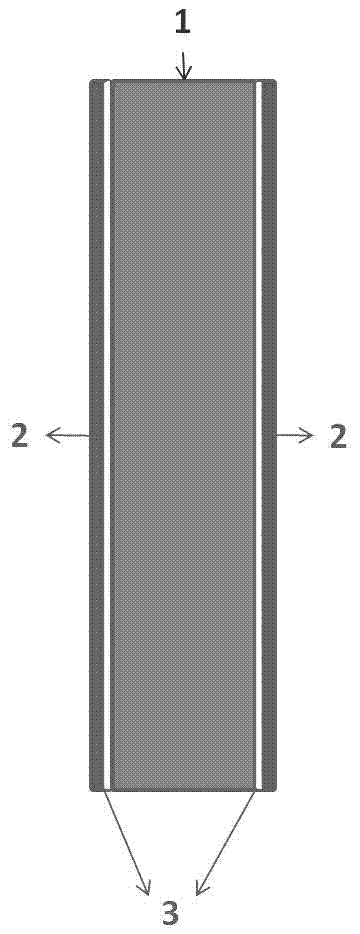

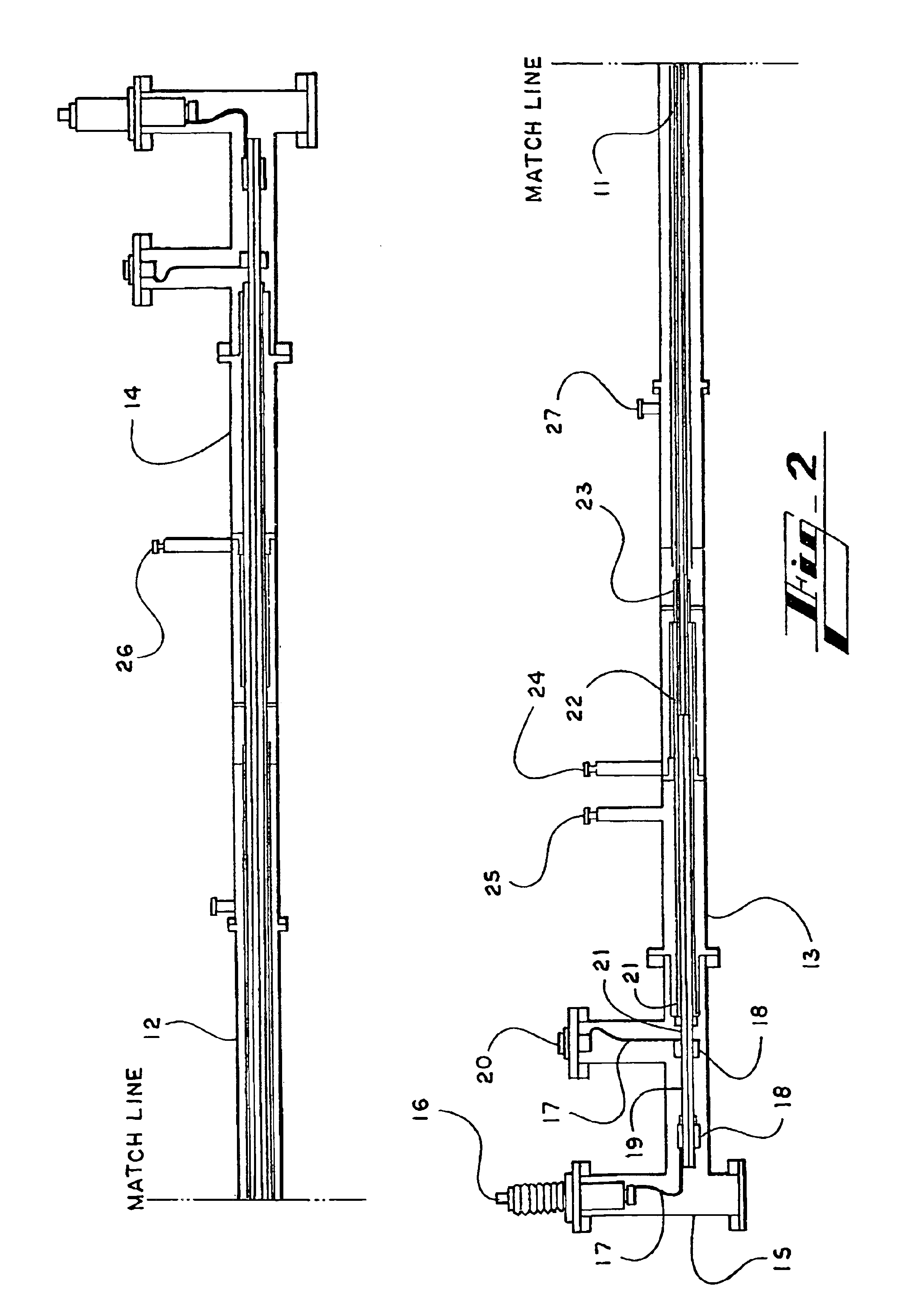

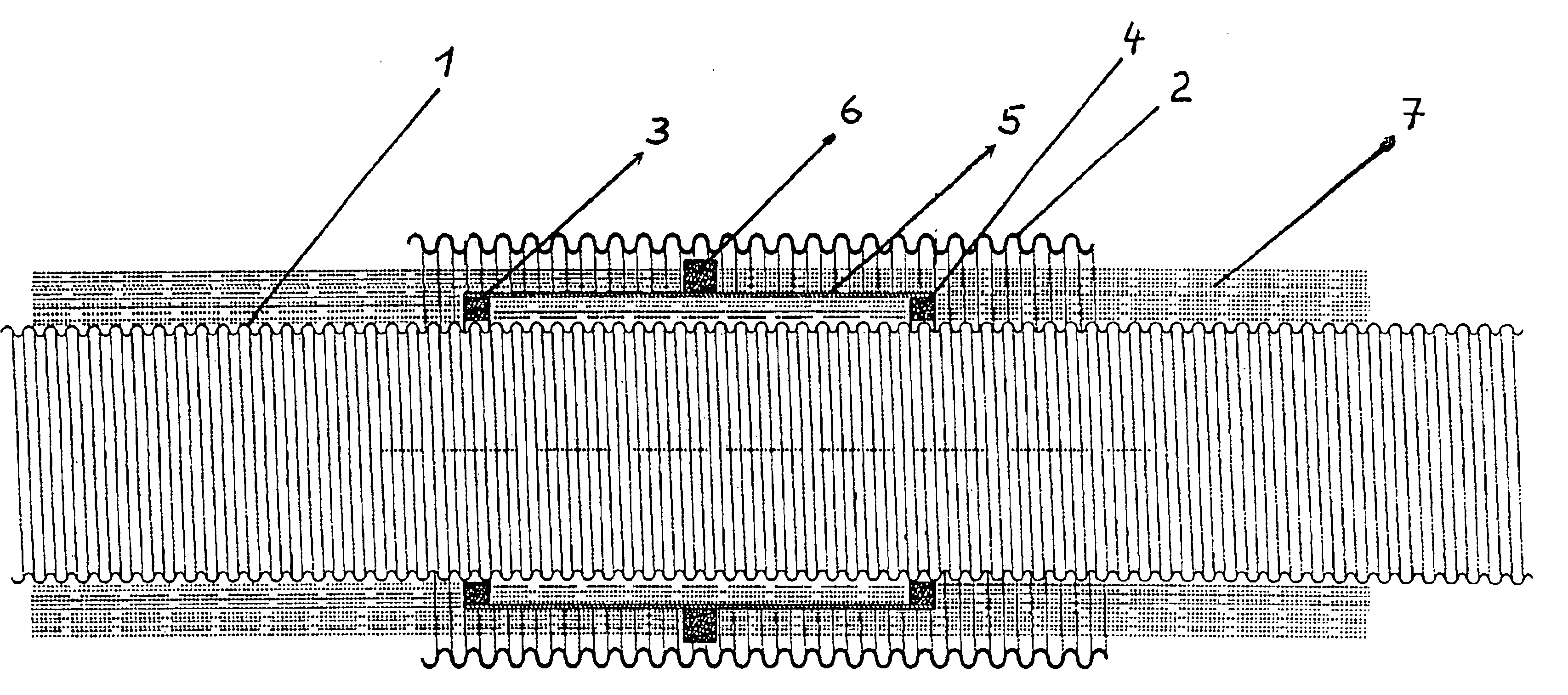

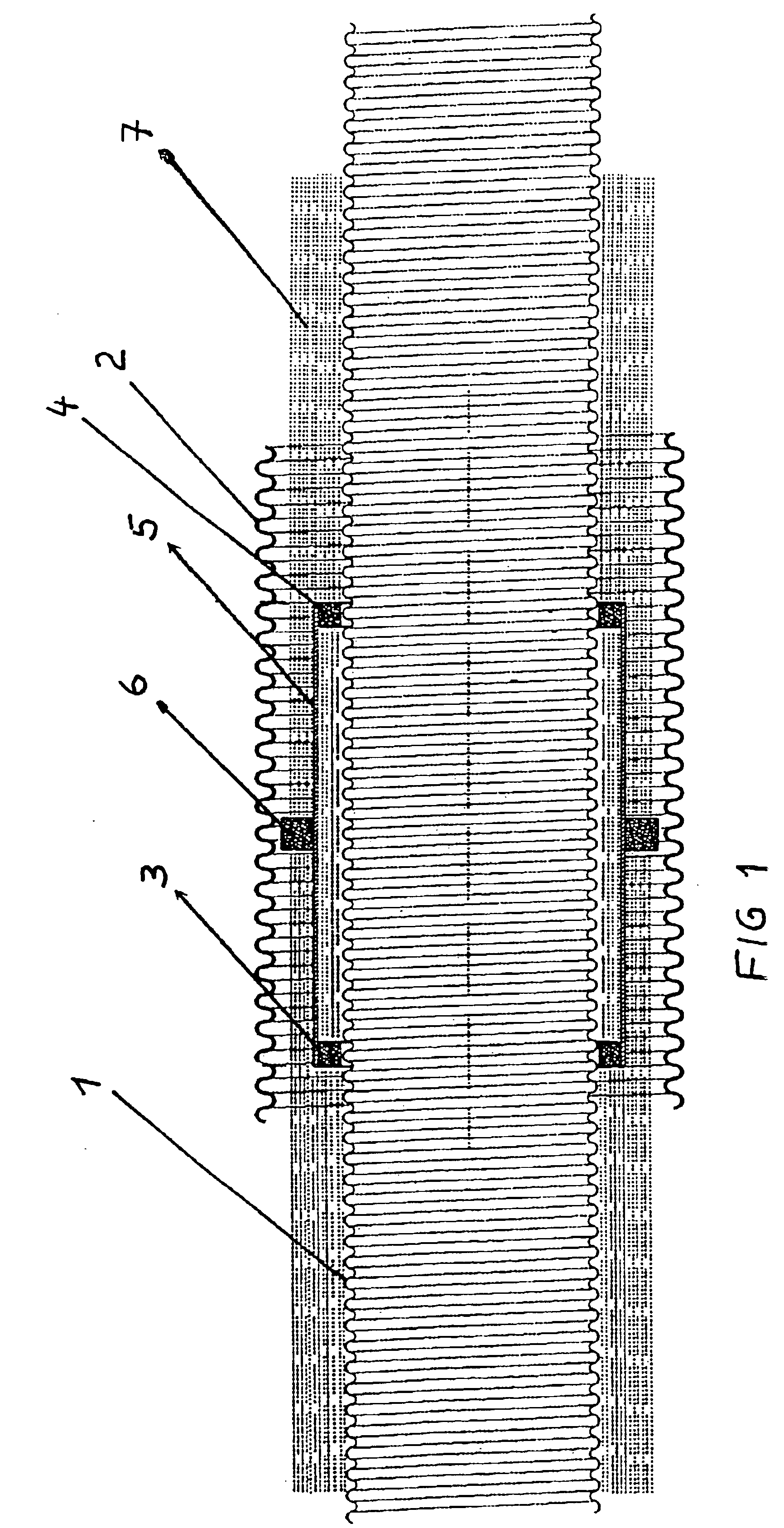

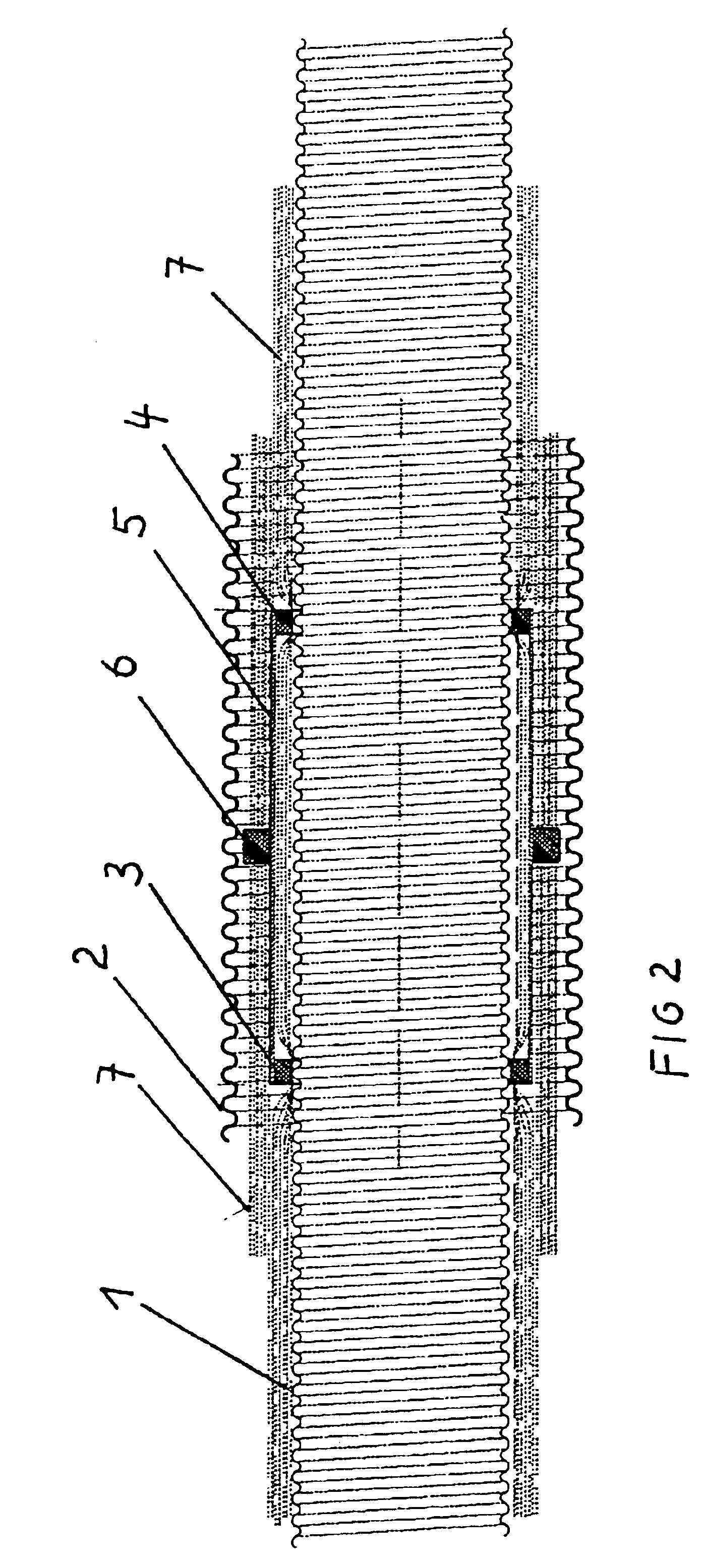

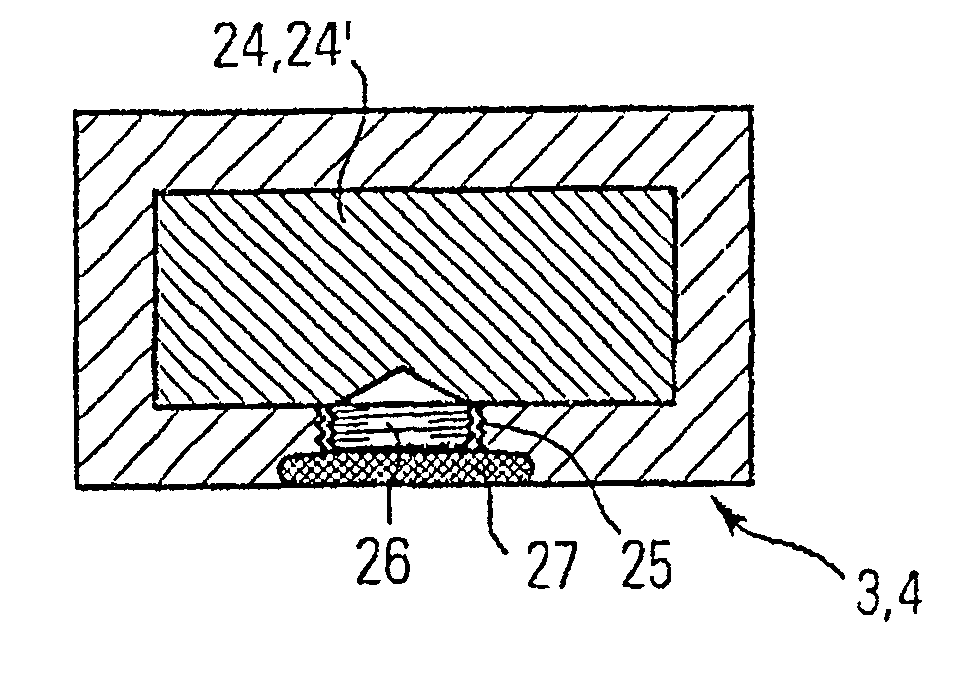

Spacer for a long substrate

InactiveUS6883548B2Good heat insulationHigh mechanical loadThermal insulationFlexible pipesEngineeringAxial distance

A spacer for a long substrate in the interior of a long tube, with a superinsulation material being disposed between the substrate and the tube. The spacer includes two rings (3, 4) seated on the substrate (1) and spaced apart from each other at a longitudinal axial distance, a tube section (5) supported on the rings (3, 4) and a second ring (6) disposed on the tube section (5). The first rings (3, 4), the tube section (5) and the second ring (6) are made of a material with poor thermal conductivity and high mechanical strength.

Owner:NEXANS

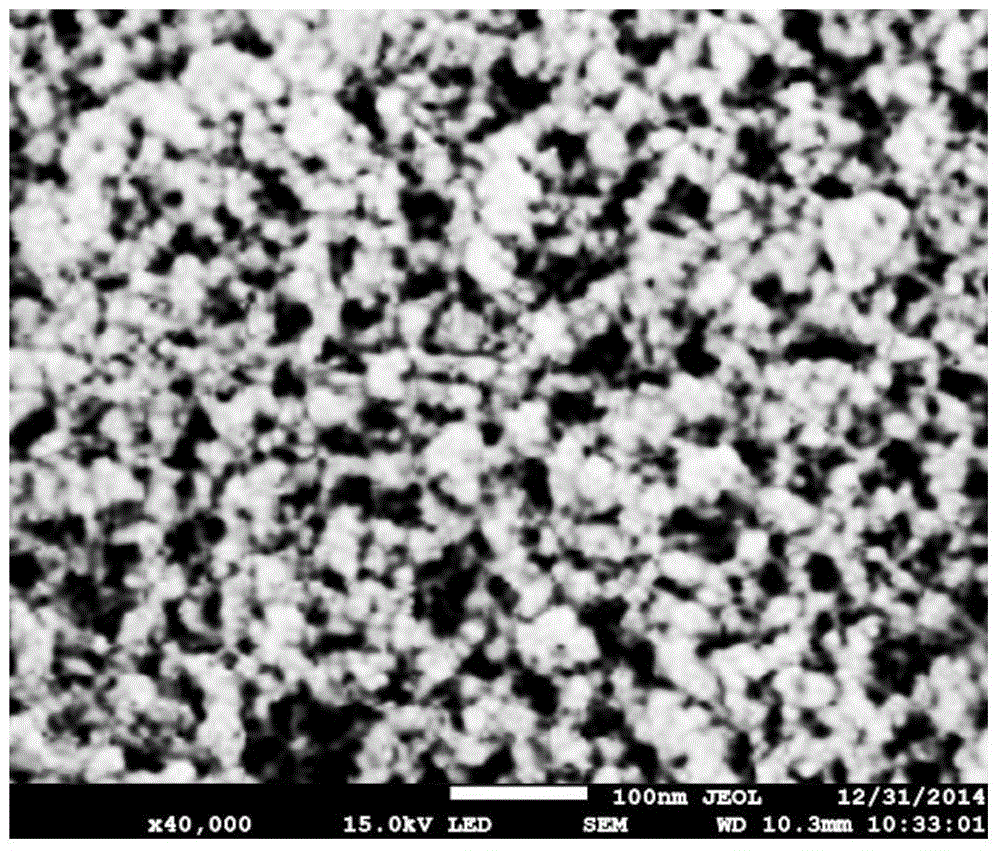

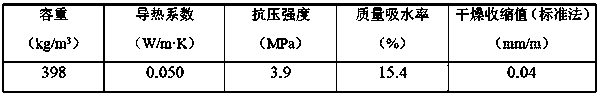

Nano-pore super heat-insulating material and preparation method thereof

InactiveCN102603349AImprove pressure resistanceImprove flexural strengthCeramicwareGlass fiberPore distribution

The invention relates to a nano-pore super heat-insulating material and a preparation method of the nano-pore super heat-insulating material. A technical scheme of the preparation method is as follows: mixing 55-75wt% of silica fume, 10-30wt% of an infrared screening agent, 10-25wt% of glass fiber and 5-10wt% of a bonding agent for 2-6 hours in a room temperature condition; carrying out compression moulding; heating to 200-600 DEG C in a heating rate of 1-5 DEG C per minute; and holding the temperature for 2-4 hours, so as to obtain the nano-pore super heat-insulating material. The volume density of the nano-pore super heat-insulating material prepared by the invention is 0.4-0.7g / cm<3>; the average pore size is 50-70nm; the coefficient of heat conductivity is 0.035-0.06W / m.K at a temperature of 300 DEG C, is 0.05-0.08W / m.K at a temperature of 500 DEG C, and is 0.07-0.09W / m.K at a temperature of 900 DEG C; the breaking strength is 1.20-1.85MPa; and the compression strength is 1.25-1.95MPa. The nano-pore super heat-insulating material provided by the invention has the characteristics of low volume density, uniform pore distribution, good mechanical property and low coefficient of heat conductivity.

Owner:WUHAN UNIV OF SCI & TECH

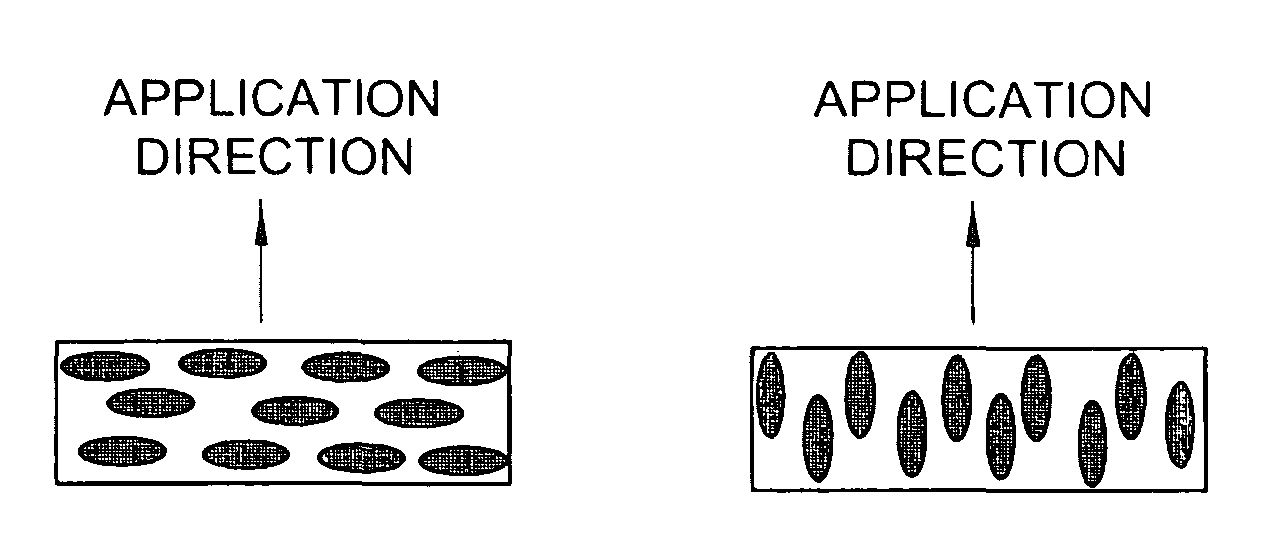

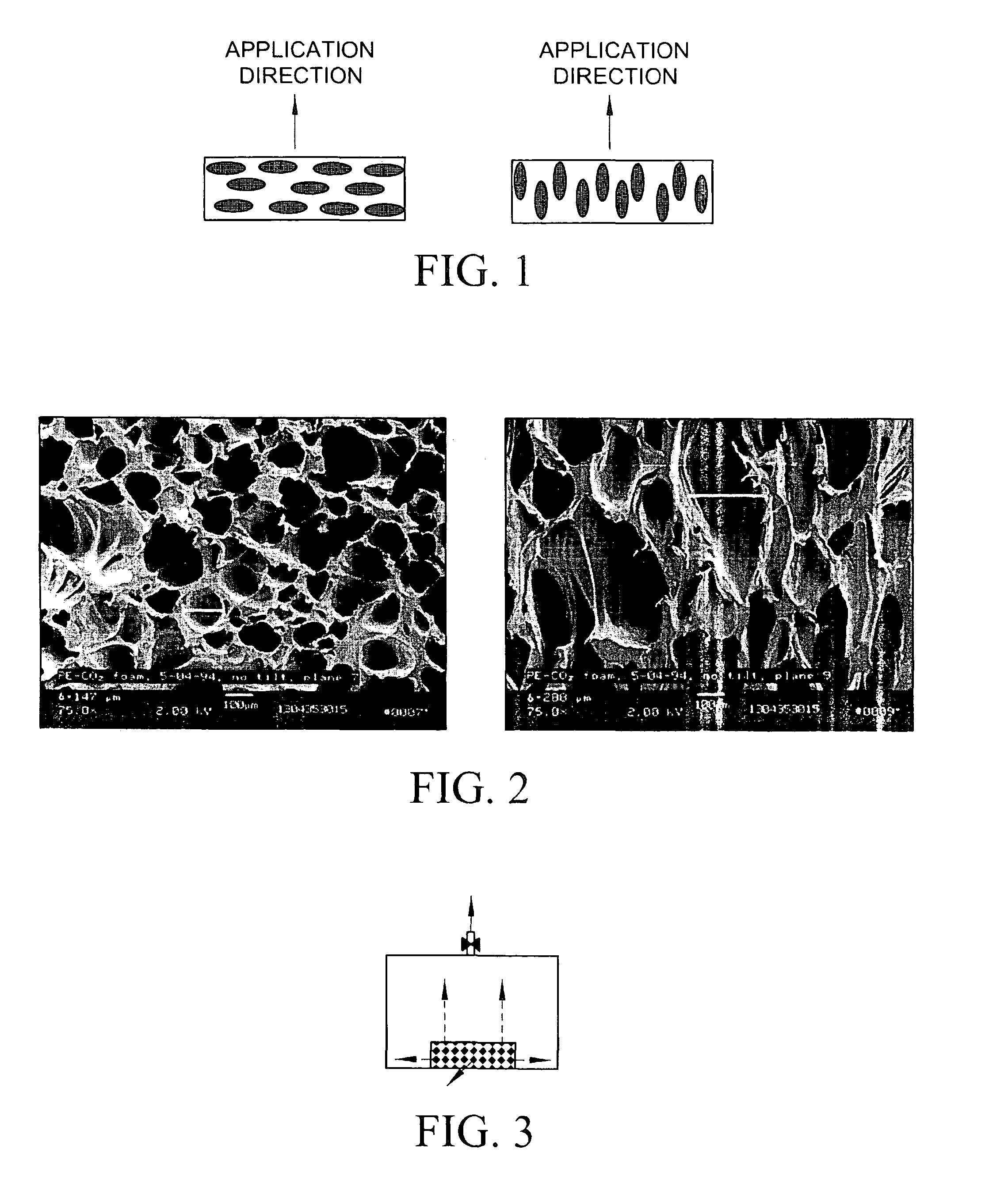

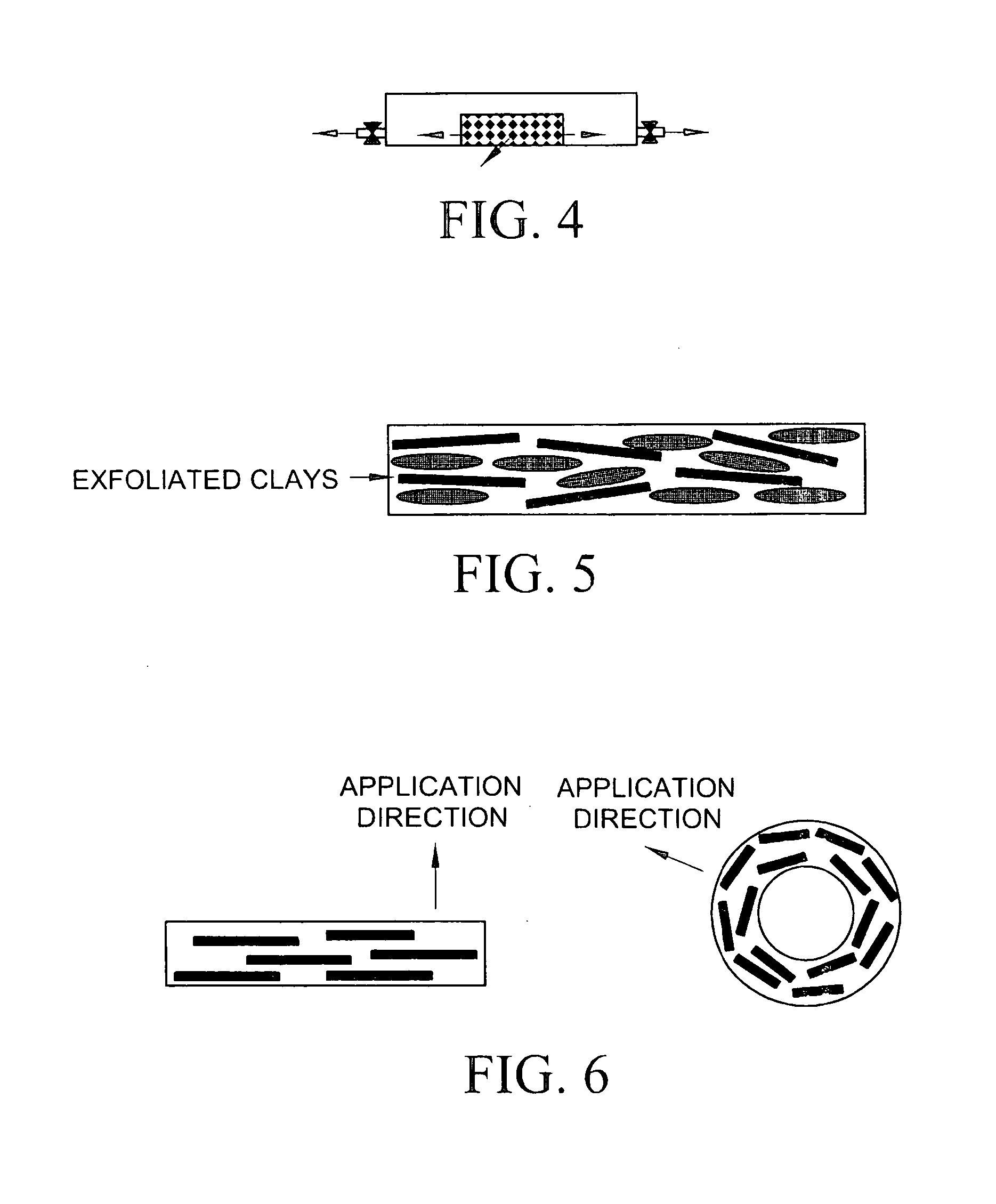

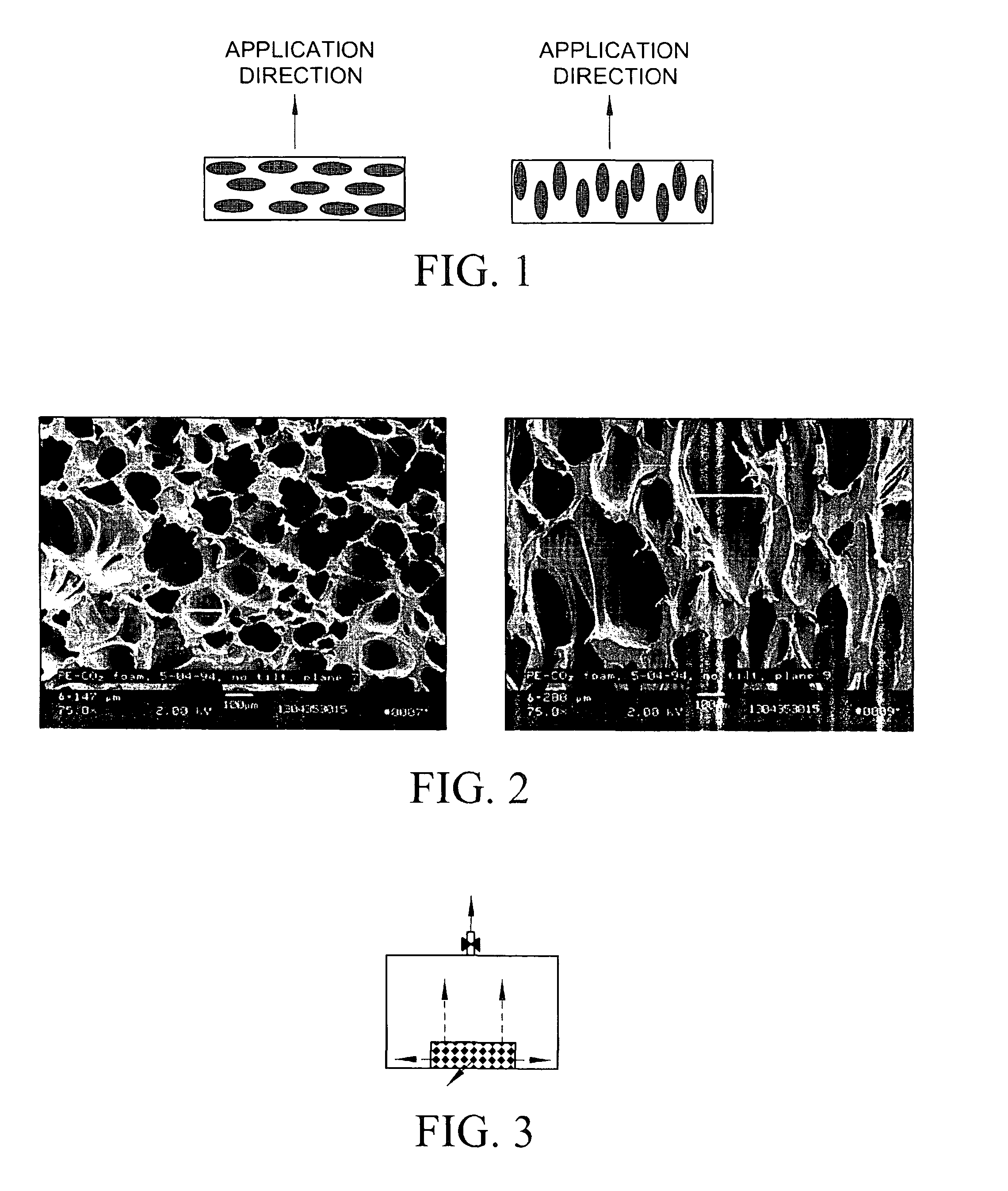

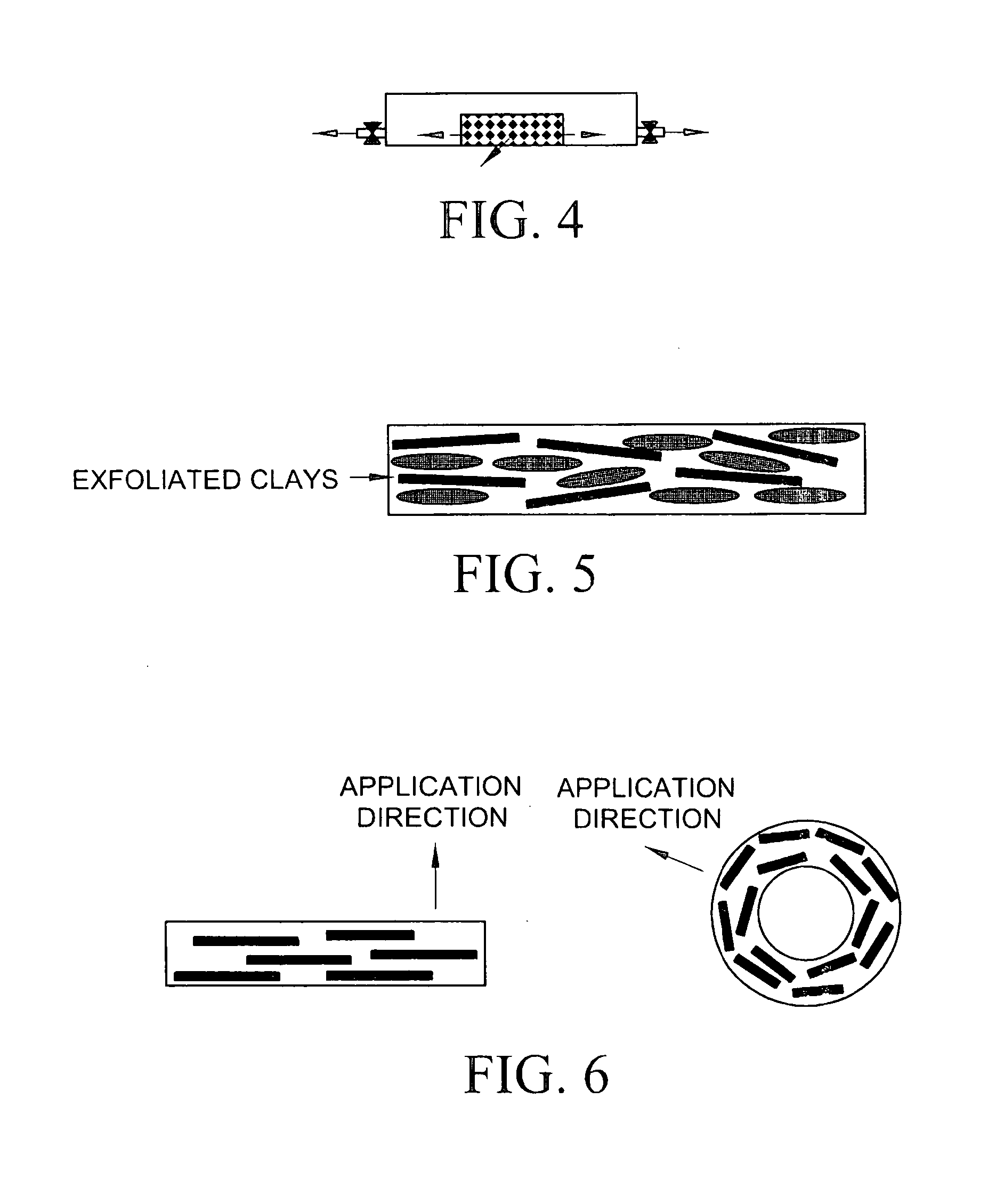

Superinsulation with nanopores

This invention relates to the field of thermal insulation. In particular, the invention describes superinsulation articles having a desired porosity, reduced pore size and cost-effective methods for manufacturing such articles. In one aspect of the present invention, the article may comprise a material system with at least about 20% porosity. In a further aspect of the invention, an article may comprise greater than about 25% of nanopores having a pore size no greater than about 1500 nanometers in its shortest axis.

Owner:IND SCI & TECH NETWORK INC

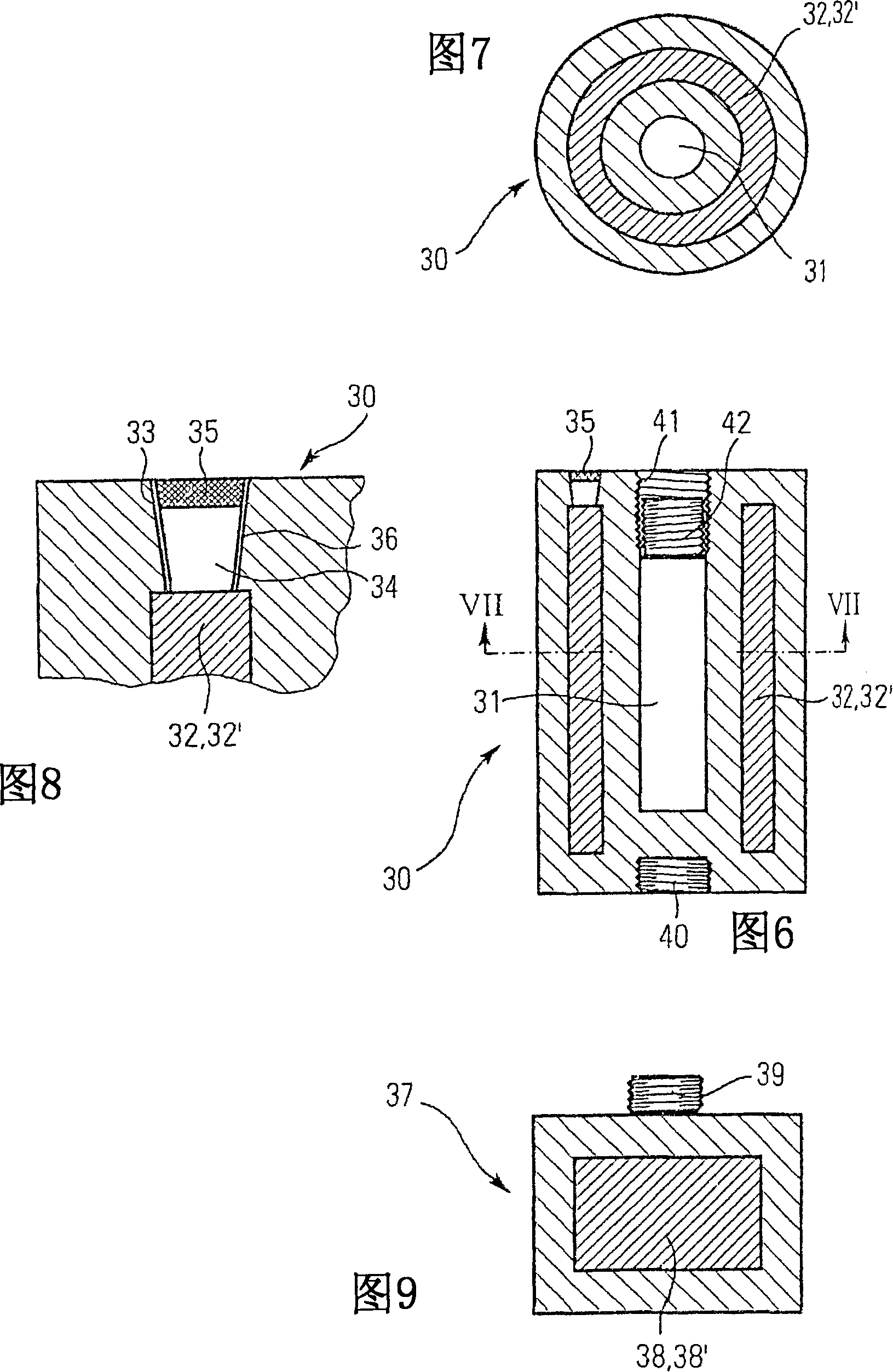

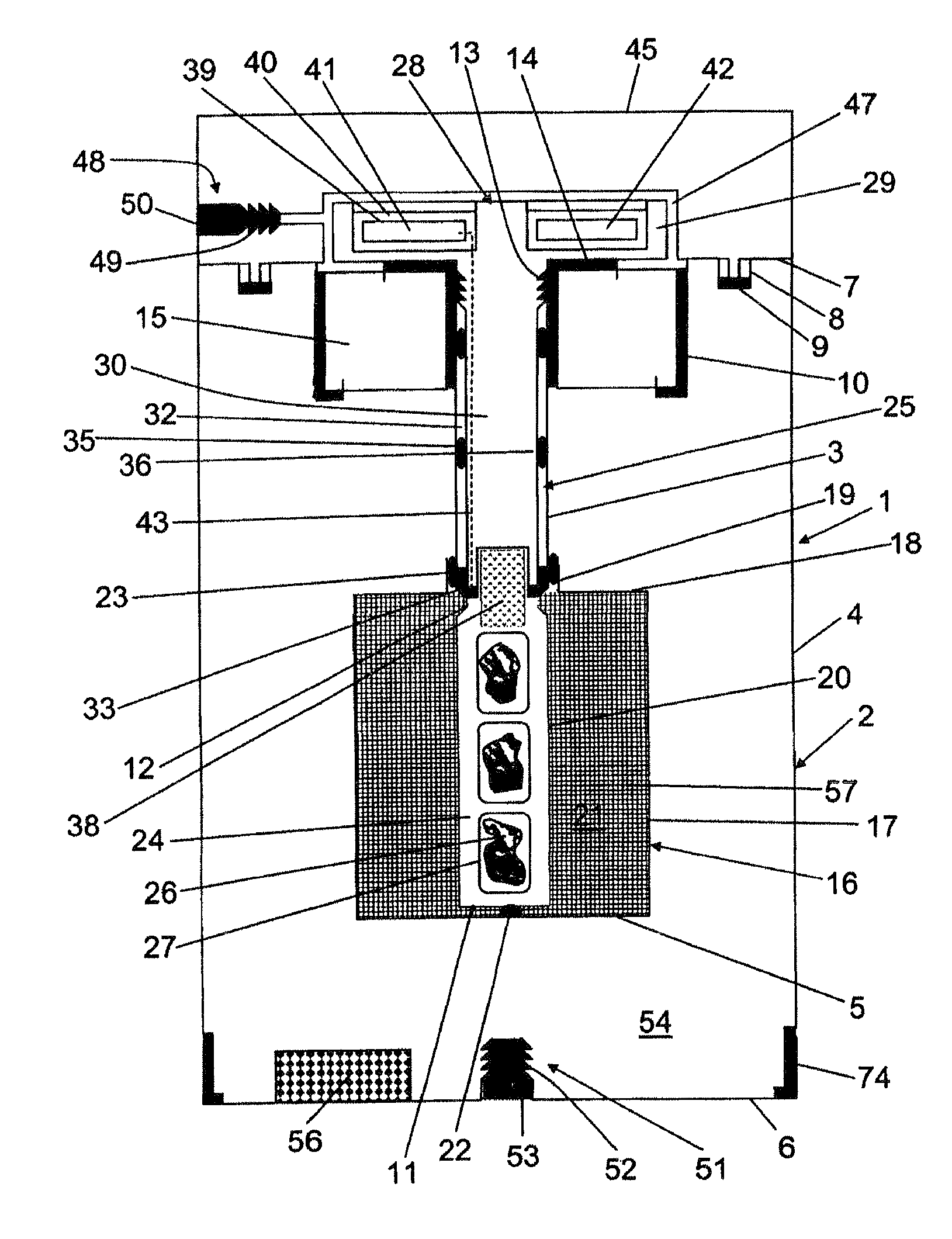

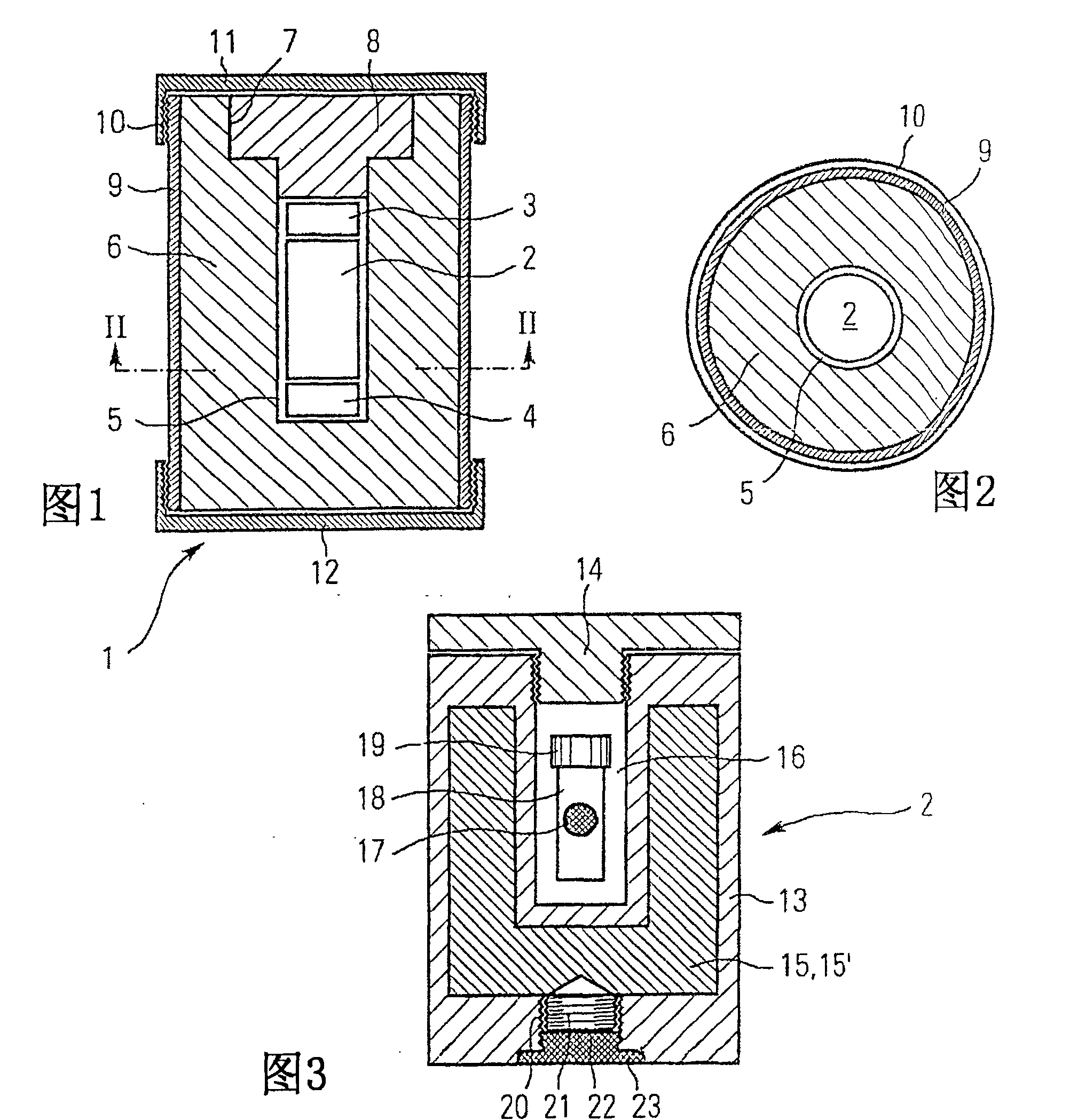

Transport container for maintaining the temperature of frozen goods

ActiveUS8151599B2Without their problemImprove performanceContainer filling methodsDead animal preservationHeat conductingDeep frozen

The invention relates to a transport container (1) comprising a superinsulation in the form of an evacuated insulating container (2) comprising a vacuum maintaining material (55). The transport container is provided with a cooling container (16) comprising a heat-conducting metal wool filling (57) and an organic coolant which undergoes a solid / liquid phase change in the temperature range of between −30° C. and −850° C. and has a heat of fusion of at least 50 J / ml. A slim cylindrical sample chamber (24) is used to receive deep-frozen tissue samples (26), said chamber being surrounded by the cooling container (16) and merging into a long neck opening (25) forming a single component therewith, said opening being largely filled by the insulating shaft (30) of a screwable plug (28) and sealed from the sample chamber (24). The air in the ring gap (32) created can be evacuated by means of an evacuating system (48). The plug (28) is provided with a stopper (38) protruding into the sample chamber (24) and a data logger (41) for recording the temperature in the sample chamber (24). Following the freezing of the coolant, the transport container (1) enables distribution times and intermediate storage of up to 14 days without any risk of damage to the tissue samples (26) received therein.

Owner:SIXT BERNHARD

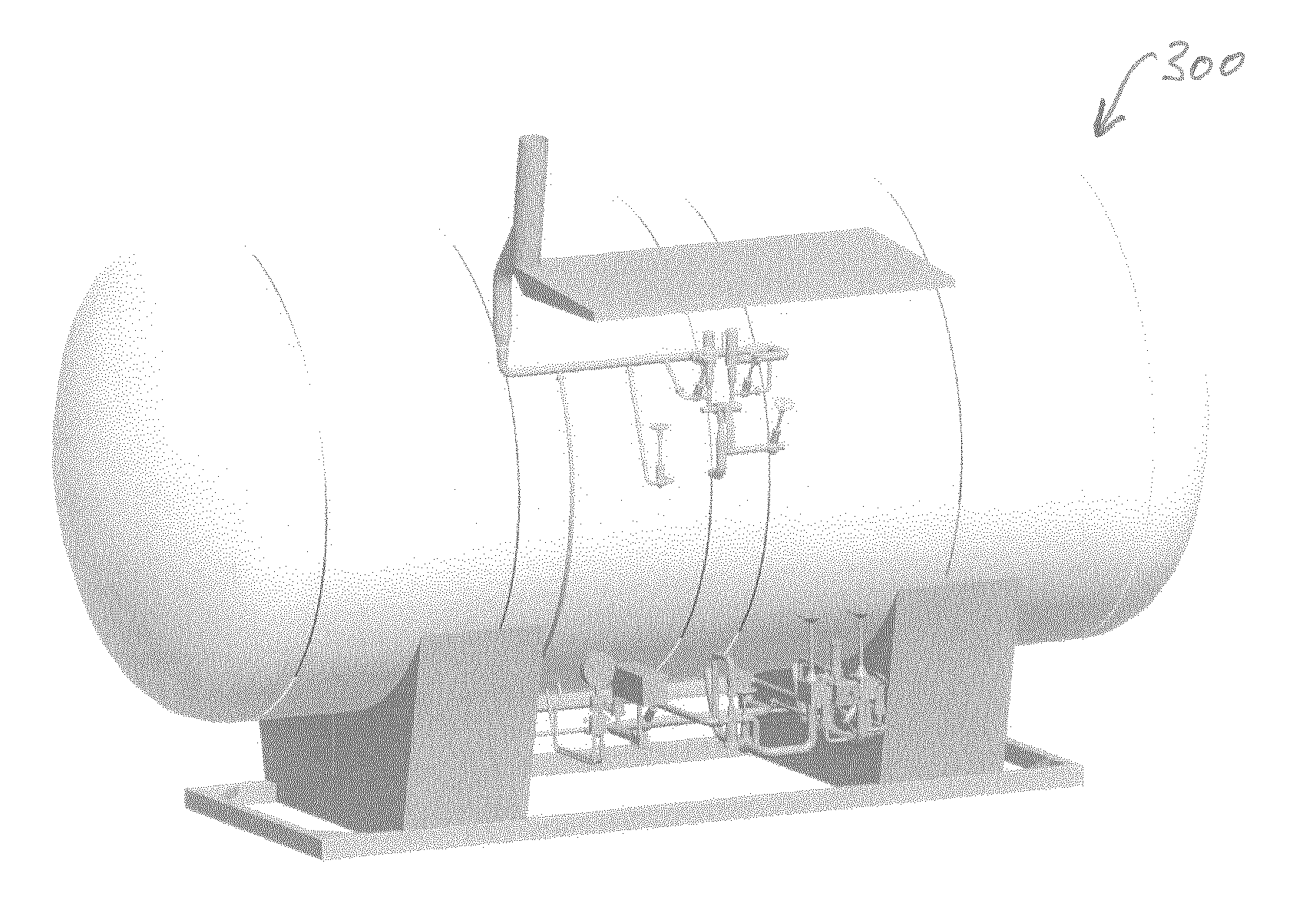

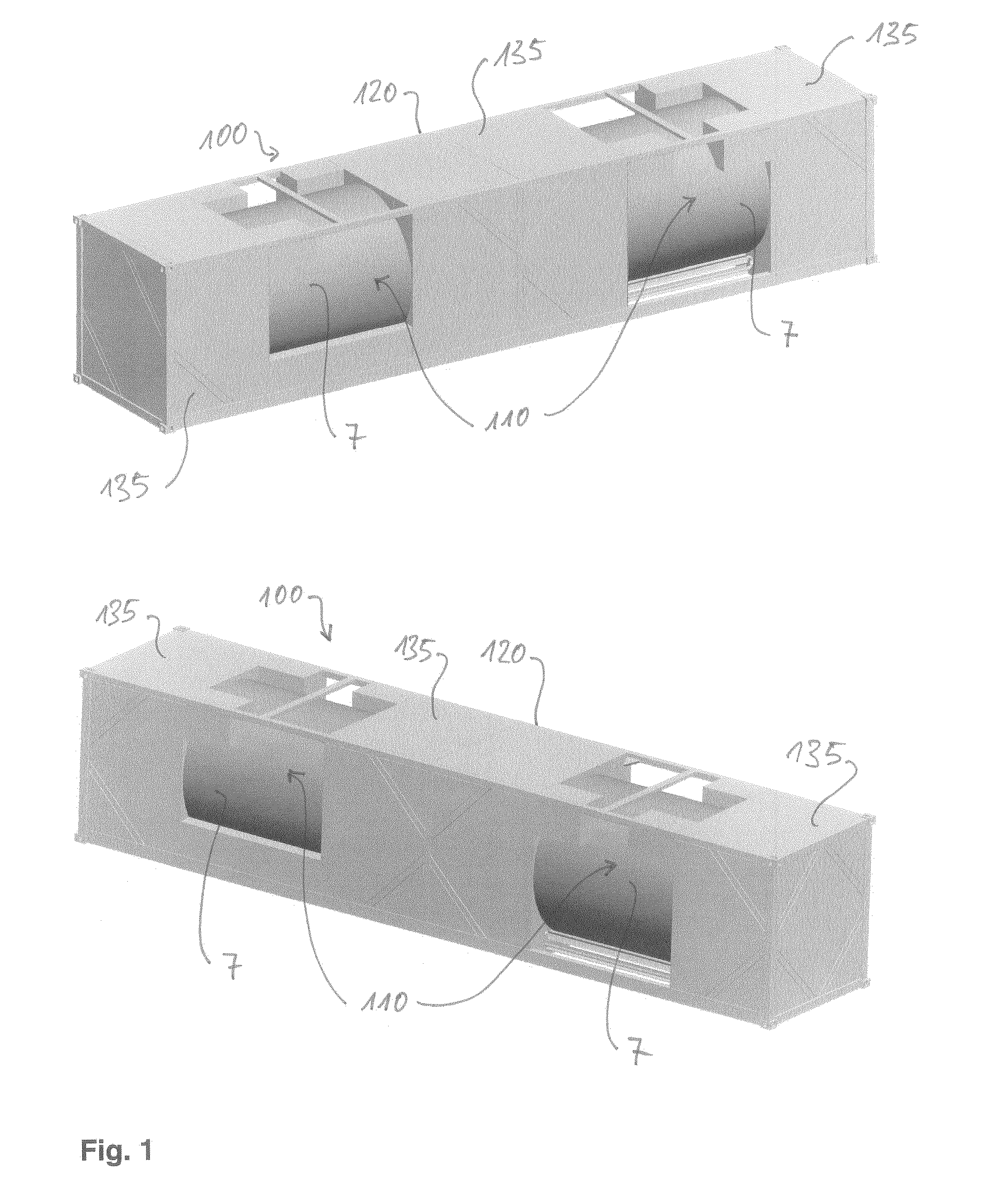

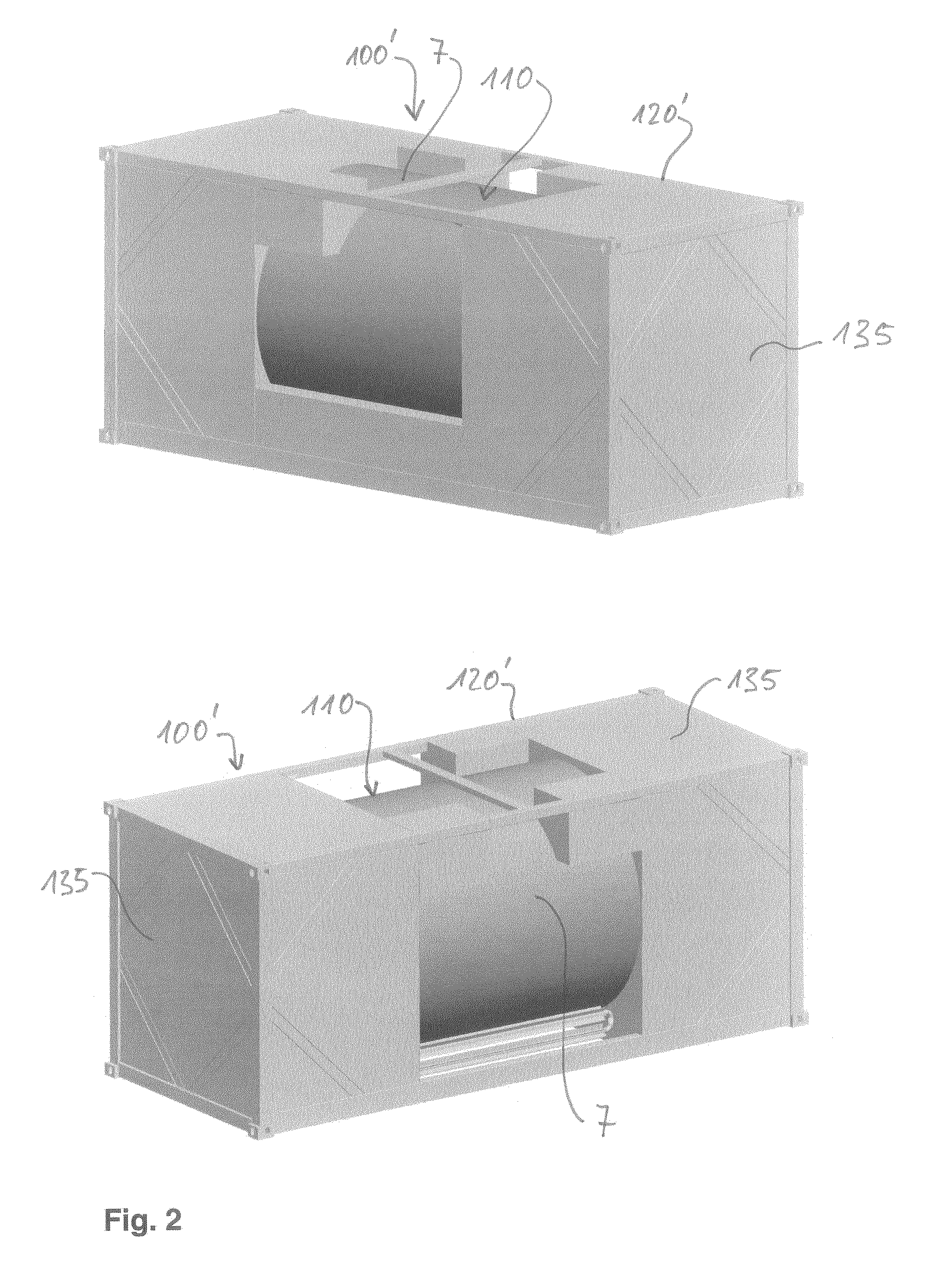

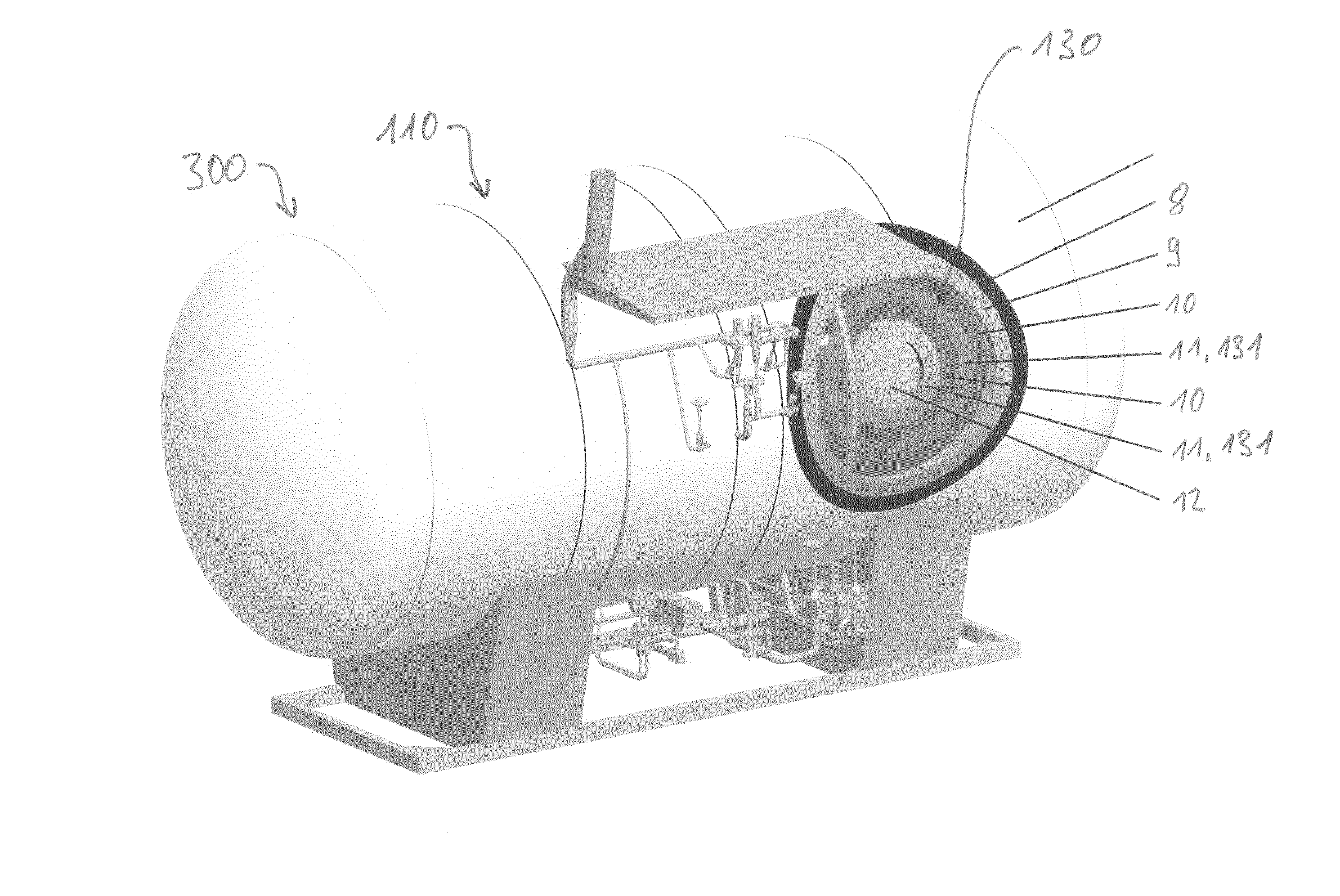

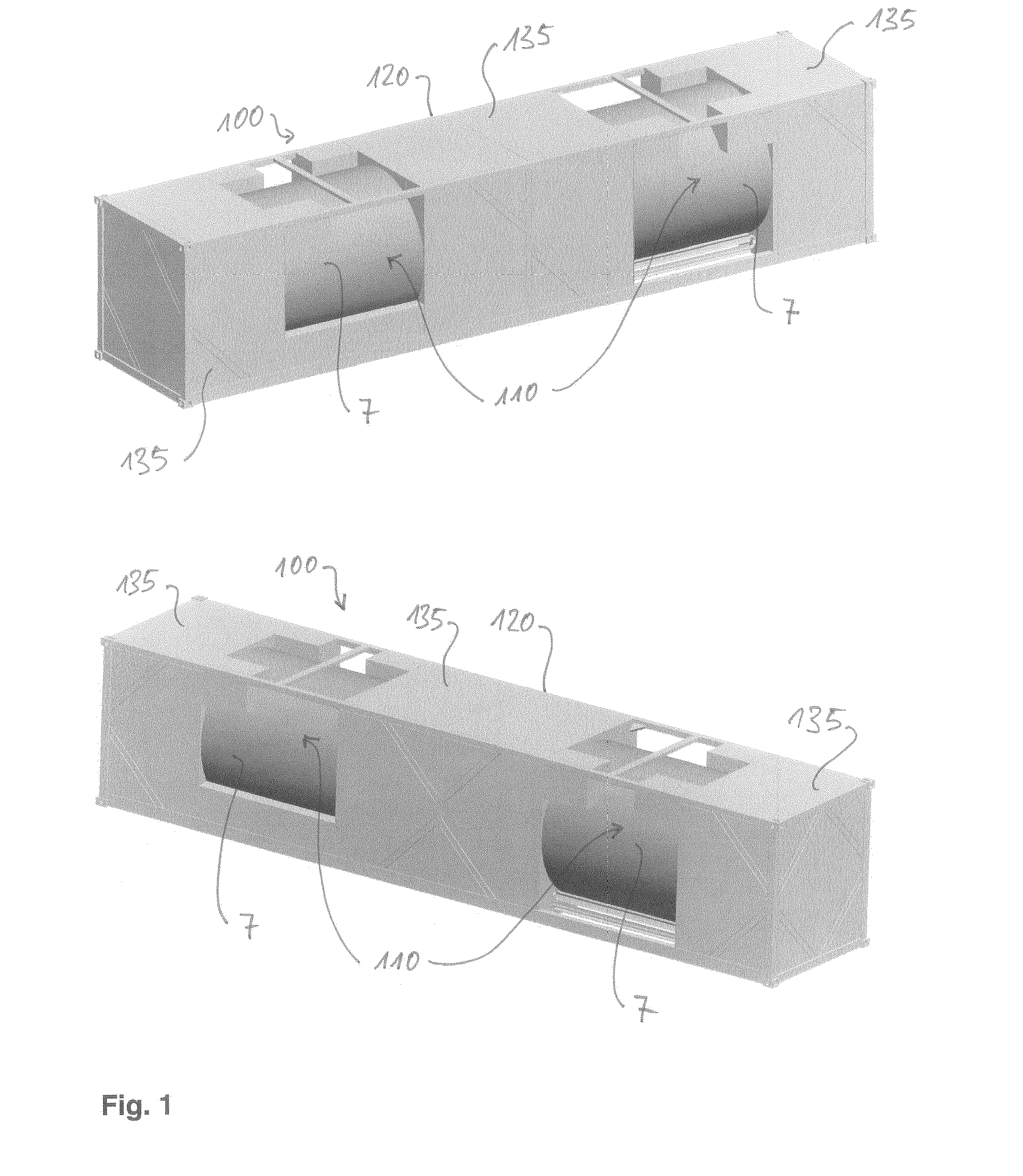

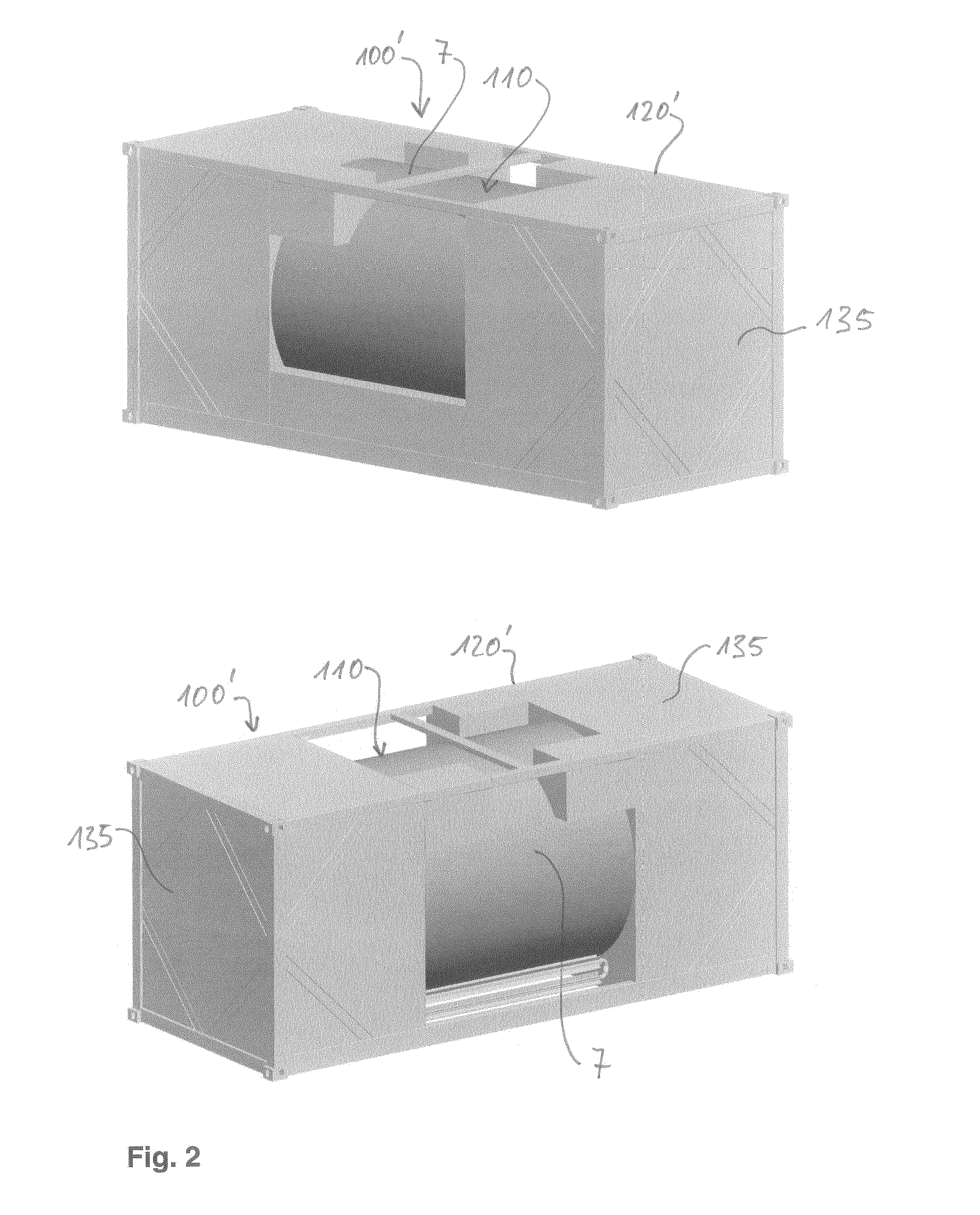

Tank container for transport and storage of cryogenic liquefied gases

The invention relates to a tank container (100; 100′) for the transport and storage of cryogenic liquefied gas, comprising a framework (120) and a cylindrical vessel (110) connected to the framework (120), wherein the vessel (110) is covered by a superinsulation arrangement (130) based on an aerogel composition, and the vessel (110) is connected to the framework (120) by a clamping device (30) which is adapted to allow for a relative movement between the framework (120) and the vessel (110) due to thermal expansion or contraction of the vessel (110).

Owner:ASPEN AEROGELS INC

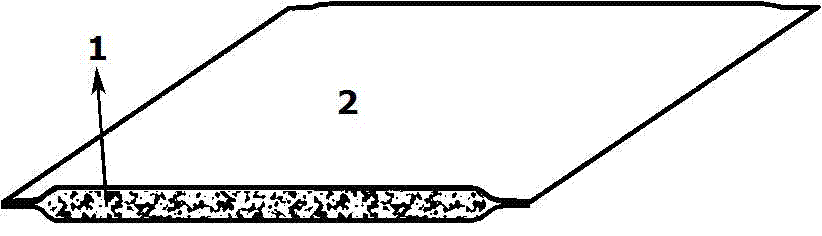

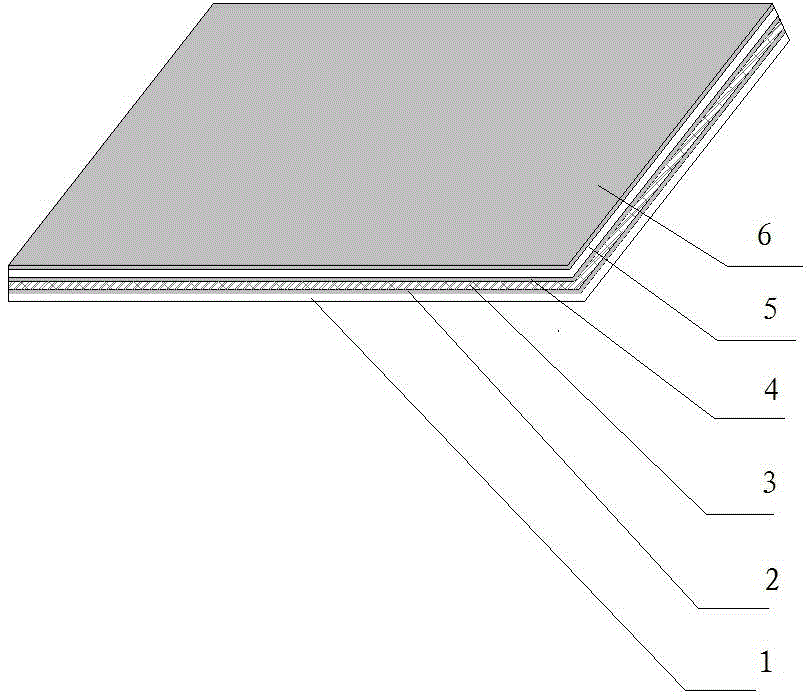

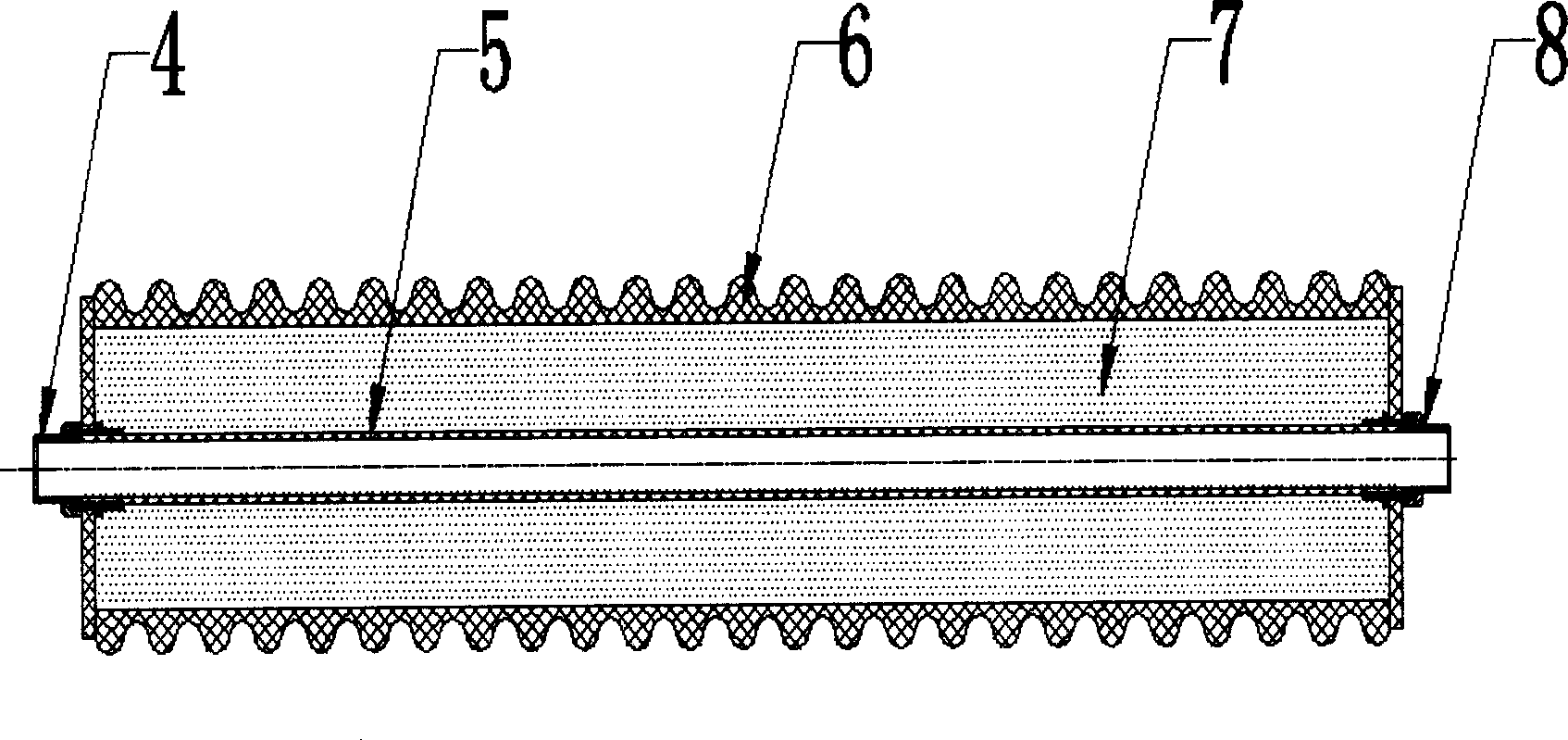

High-strength nano-ceramic fiber anti-radiation heat insulating plate and preparation method of high-strength nano-ceramic fiber anti-radiation heat insulating plate

ActiveCN104553164ADoes not expand when heatedSmall sizeLaminationLamination apparatusFiberMetal foil

The invention provides a high-strength nano-ceramic fiber anti-radiation heat insulating plate and a preparation method of the high-strength nano-ceramic fiber anti-radiation heat insulating plate. A plurality of ceramic fiber layers containing ceramic fibers are formed through binding agents by means of hot-pressing curing; a metal foil also can be paved between the two adjacent ceramic fiber layers so as to improve a using effect. When the high-strength nano-ceramic fiber anti-radiation heat insulating plate is used, three heat energy transfer ways of heat conduction, convective heat transfer and radiation heat transfer can be effectively prevented, a super heat insulation and heat storage performance is achieved, a heat conduction coefficient is far lower than that of the heat conduction coefficient of traditional heat insulation material, and the strength of the heat insulating plate can reach 4-6 times that of the traditional product.

Owner:YINGKOU CHUANGXING TECH

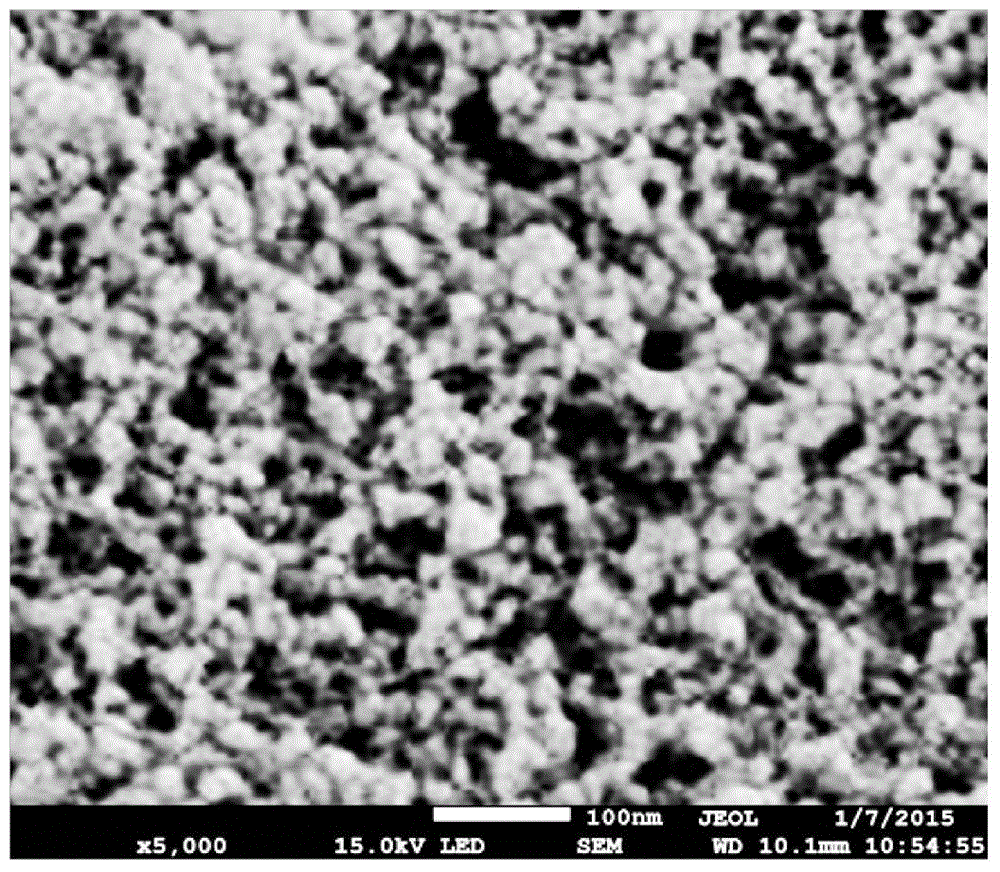

Highly-impact-resistant highly-light-transmitting highly-heat-insulating polymethylmethacrylate composite material and preparation method thereof

InactiveCN105566583AHigh impact strengthImprove insulation performanceBulk polymerizationTransmittance

The invention discloses a highly-impact-resistant highly-light-transmitting highly-heat-insulating polymethylmethacrylate composite material and a preparation method thereof. Silicon dioxide aerogel serving as a super heat-insulation material is adopted to be subjected to surface chemical state regulation and is composited with a PMMA (polymethylmethacrylate) bulk polymerization system to prepare the composite material, and the prepared polymethylmethacrylate composite material with the silicon dioxide aerogel being functionalized is highly resistant to impact, high in heat insulation and light transmission and the like. The highly-impact-resistant highly-light-transmitting highly-heat-insulating polymethylmethacrylate composite material and the preparation method thereof have the advantages that since the silicon dioxide aerogel serves as a PMMA functionalized phase, impact strength, heat insulation performance and visible light transmittance of PMMA can be enhanced, and conditions are created for popularizing the PMMA to the field of heat insulation of transparent building envelopes.

Owner:TIANJIN CHENGJIAN UNIV

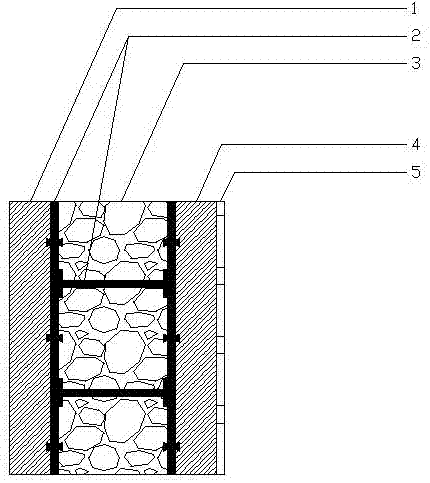

Super heat insulation aerogel sandwich composite wall plate with decorative face and preparation method of super heat insulation aerogel sandwich composite wall plate

InactiveCN107268840AImprove thermal insulationImprove sound insulationWallsClimate change adaptationAssembly lineMaterial distribution

The invention provides a super heat insulation aerogel sandwich composite wall plate with a decorative face and a preparation method of the super heat insulation aerogel sandwich composite wall plate. The super heat insulation aerogel sandwich composite wall plate comprises an internal high-strength inorganic plate, high-strength material separation plate components, an aerogel heat insulation core material, an external high-strength inorganic plate and a facing layer from inside to outside. The preparation method of the super heat insulation aerogel sandwich composite wall plate comprises the following steps that (1) cavity preparation is conducted, specifically, molds are placed on the two sides, the high-strength material separation plate components and pre-buried parts are placed in the molds to form a cavity; (2) material distribution is conducted, specifically, an internal high-strength inorganic plate wet material, the aerogel heat insulation core material and an external high-strength inorganic plate wet material are added in the cavity in the step (1); (3) the forming technique is conducted; (4) mold removing is conducted, specifically, after the strength of the high-strength inorganic plates is formed, and mold removing is conducted; and (5) the facing layer is manufactured on the surface of the external high-strength inorganic plate. The super heat insulation aerogel sandwich composite wall plate with the decorative face is small in weight, low in heat conductivity coefficient, simple in preparation technique, suitable for factory assembly line production and suitable for the field of outer walls, curtain walls, indoor separation walls and the like of heat-preservation fireproof and decoration integration.

Owner:NANJING WEICAI NEW ENERGY TECH

High-voltage isolator for high-temperature superconductive power-supply cable

A high voltage isolator used on high temperature superconductive power cable consists of one heat insulation sleeve including internal tube and external tube as both being prepared by glass fiber reinforced plastic, and heat insulation layer; two liquid conveying sleeves including two layers of thin stainless steel tubes. It is featured as erecting said heat insulation sleeve with two liquid conveying sleeves in series-coaxial way, forming heat insulation sleeve by insulation material and forming liquid conveying sleeve by metal material.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

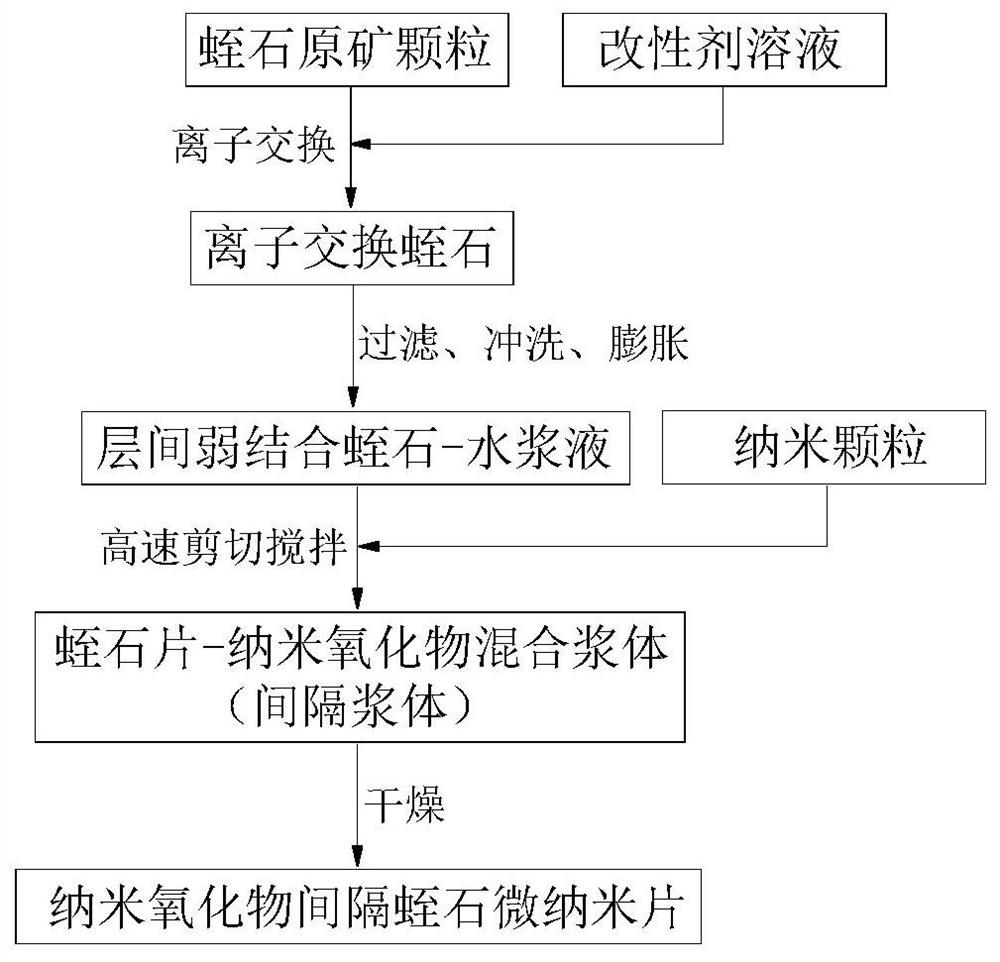

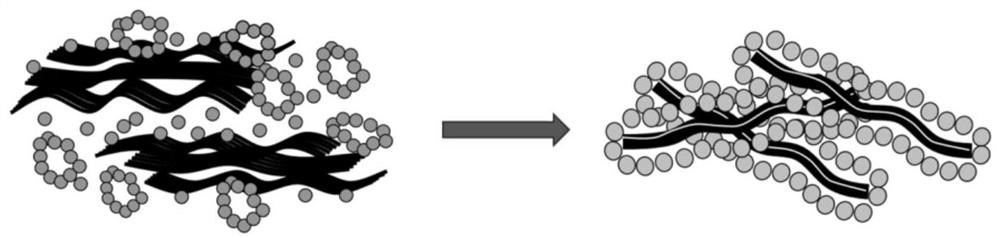

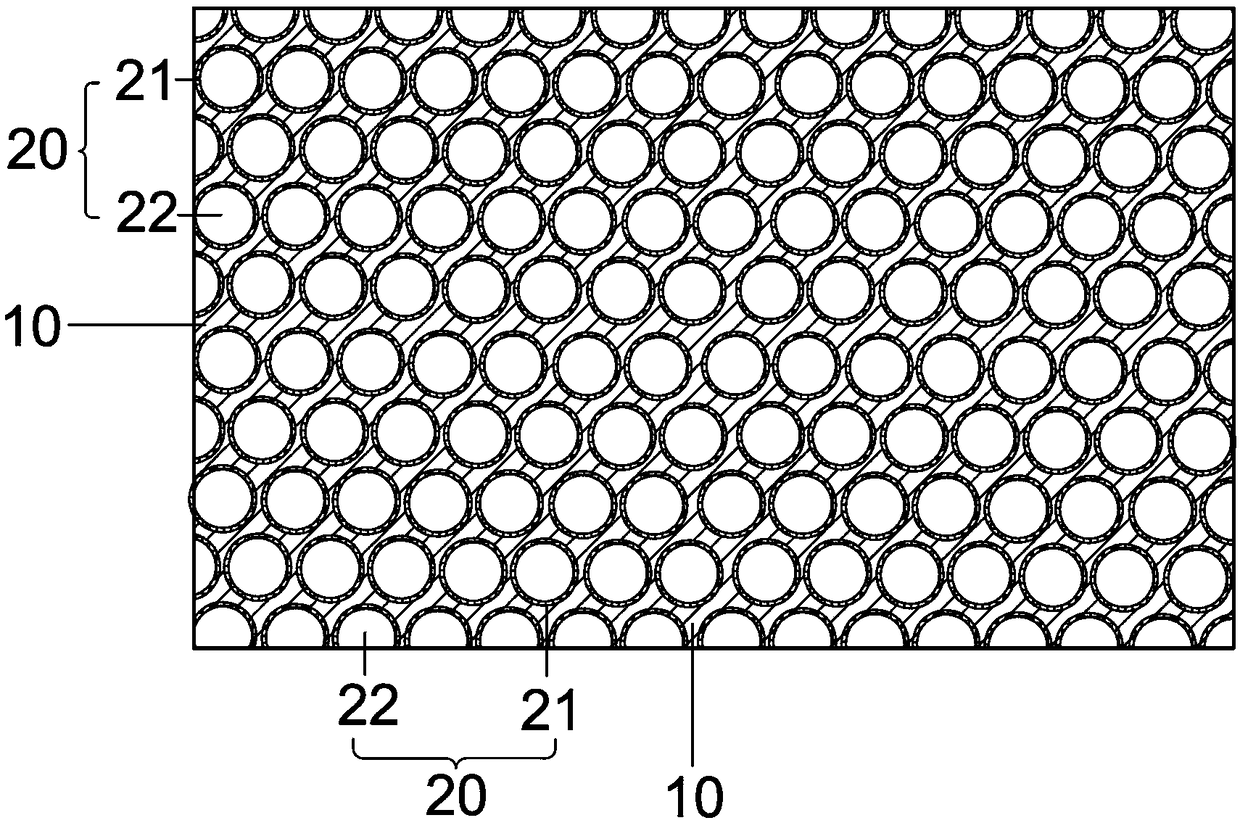

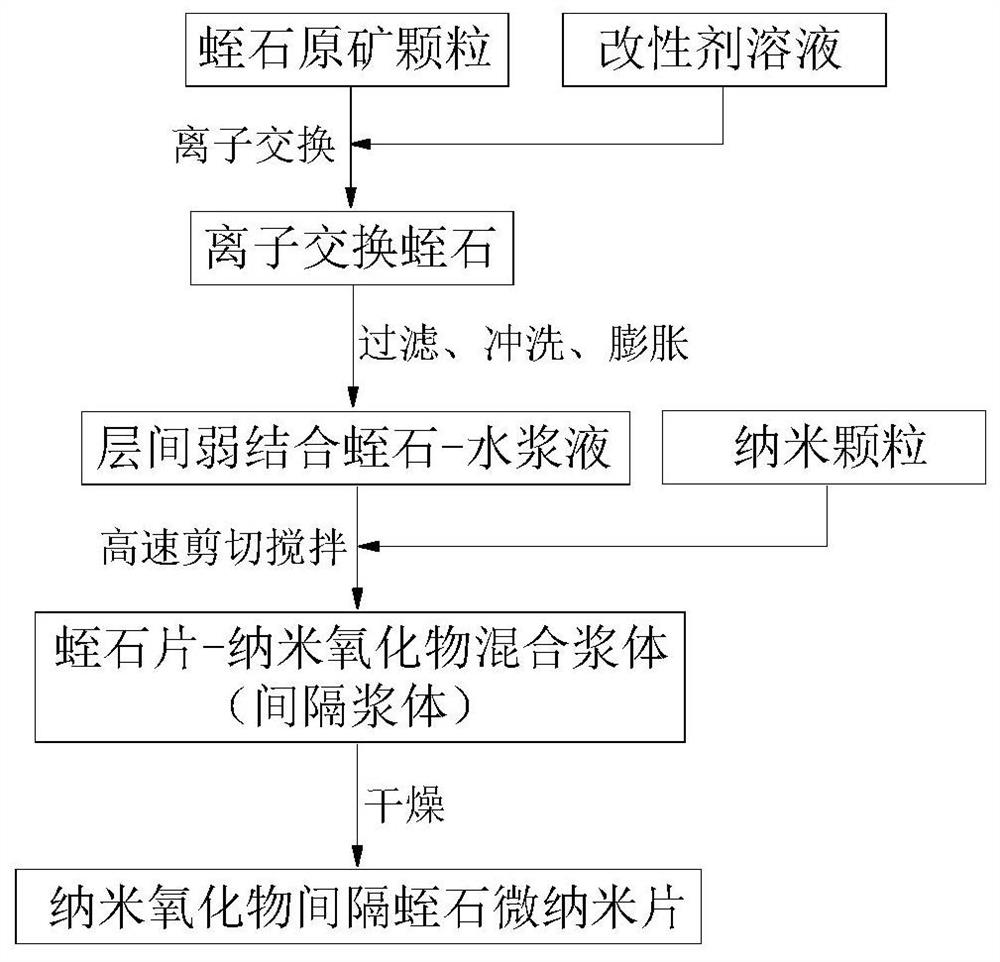

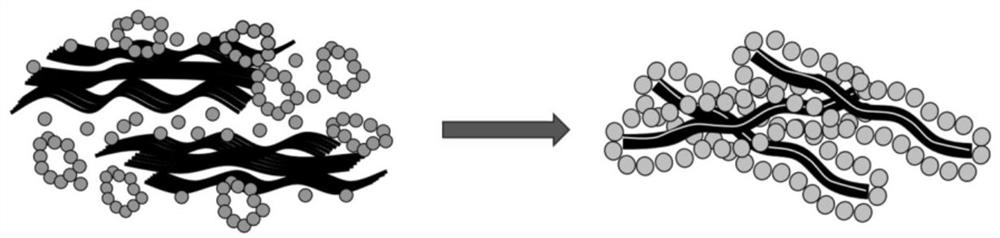

Preparation method of high-temperature oxide nano-particle spaced vermiculite micro-nano sheet

ActiveCN113184866AControl granularityControl thicknessFireproof paintsMaterial nanotechnologyMicro nanoSlurry

The invention discloses a preparation method of a high-temperature oxide nano-particle spaced vermiculite micro-nano sheet, and belongs to the technical field of preparation of heat-insulating and fireproof materials. The preparation method comprises the steps of replacing interlayer ions of vermiculite by adopting a chemical modifier, and weakening interlayer binding force through hydration so as to obtain interlayer weak binding vermiculite-water slurry; dispersing high-temperature oxide nanoparticles in the vermiculite-water slurry, and adjusting the consistency of the slurry; and then under the action of high-speed shearing and stirring, separating vermiculite lamellas, and highly dispersing in the nano oxide slurry. The mixed slurry has high viscosity, and vermiculite sheets are stripped into lamellar shapes with micro-nano thickness, are separated by nano-particles and are stably suspended in the slurry. According to the method, the granularity and thickness of the vermiculite sheets can be controlled, the stripping degree is better, and the prepared vermiculite micro-nano sheet-nano oxide mixed slurry can be used as a fireproof coating for fireproof protection of inflammable building materials. The mixed slurry is dried to obtain the nano-particle spaced vermiculite micro-nano sheet which can be used for a high-temperature nano oxide powder-based super thermal insulation material of a dry process.

Owner:UNIV OF SCI & TECH BEIJING

Nano-silica particle packed bed super thermal insulation material and preparation method thereof

ActiveCN107879761AThe thermal conductivity of the solid phase decreasesLow thermal conductivityCeramicwareSilica particleThermal insulation

The invention discloses a nano-silica particle packed bed super thermal insulation material and a preparation method thereof. The method comprises the steps as follows: nano-silica particles A with the particle size of 10-40 nm and nano-silica particles B with the particle size of 50-100 nm are placed in a ball mill in the mass ratio being (5:5)-(8:2) at the room temperature, nano-silica mixed particles A are obtained after uniform mixing and then transferred to an ultrasonic dispersion machine, an infrared shielding agent is added to the ultrasonic dispersion machine for ultrasonic dispersionfor 50-70 min, and nano-silica mixed particles B are obtained, wherein the mass ratio of the infrared shielding agent to the nano-silica mixed particles A is (1:10)-(1:4); the nano-silica mixed particles B are pressed at the room temperature and the nano-silica particle packed bed super thermal insulation material is obtained. The production process can be simplified, the production cost can be reduced and the environmental pollution can be reduced on the basis that the prepared material has high-temperature resistance and excellent mechanical performance.

Owner:CHINA UNIV OF MINING & TECH

Super insulation silicon-titanium thermal insulation board and manufacturing method thereof

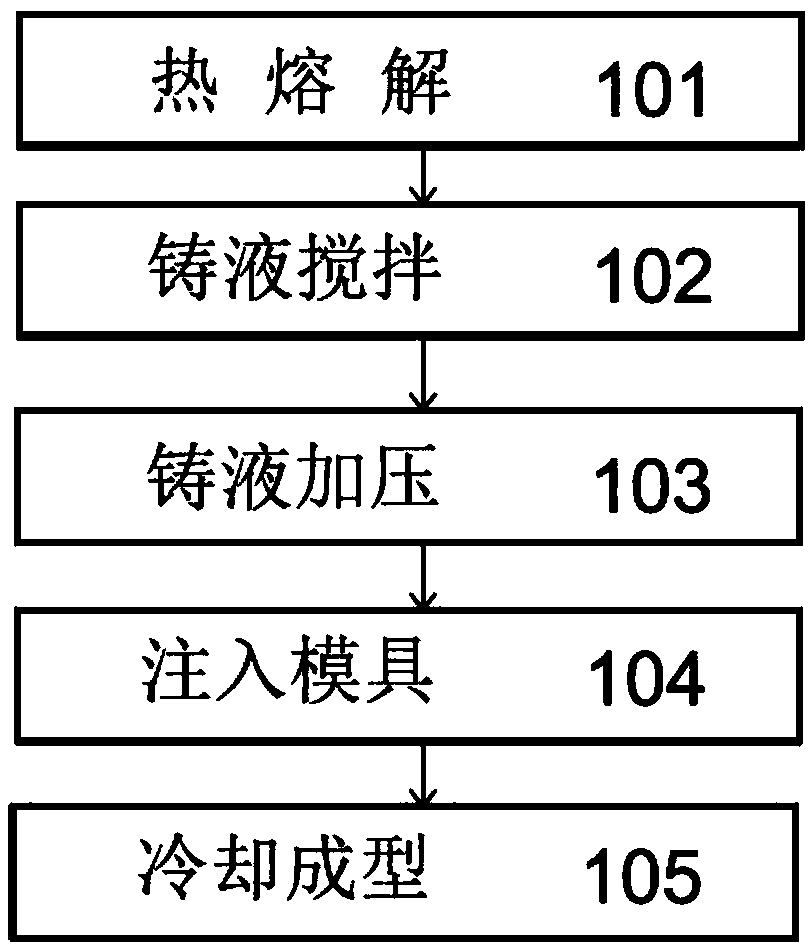

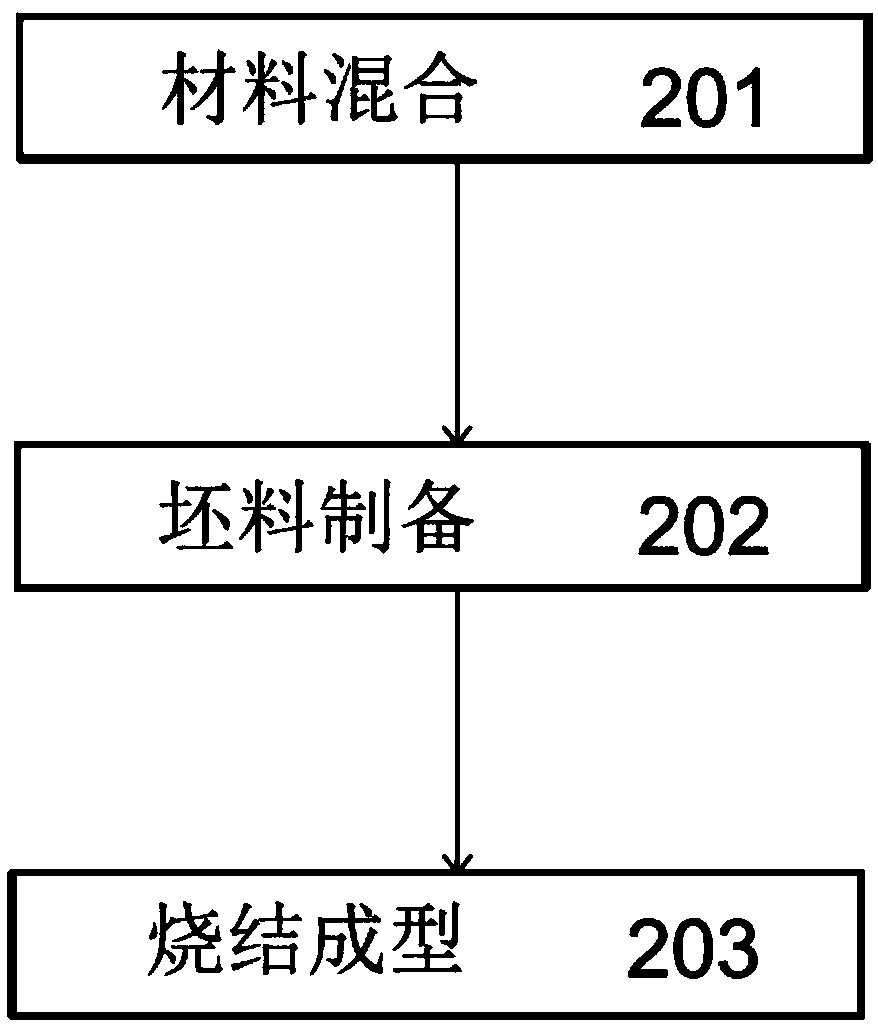

The invention relates to the technical field of thermal insulation materials, and provides a super insulation silicon-titanium thermal insulation board and a manufacturing method thereof. The super insulation silicon-titanium thermal insulation board is formed by casting, sintering or pressing, and comprises 15-35wt% of titanium metal parent metal which is composited on 65-85wt% of nano siliciousthermal insulating material; the nano silicious thermal insulating material is synthesized by 10-30wt% of inorganic fiber material and 70-90wt% of nano silicon dioxide powder; the nano silicon dioxidepowder is a parent material, and the grain diameter is less than 60 nanometers; under the pressure effect, the void ratio composited by particles is greater than 70%; and the inorganic fiber materialis composited in the nano silicon dioxide powder to improve the strength of the nano silicious thermal insulating material. By virtue of the compositing of the various materials, the technical effects of wearing resistance, high thermal conductivity and improved material rigidity are achieved, and the effects of super insulation and easiness in manufacturing are achieved.

Owner:中亨新型材料科技有限公司

Superinsulation with nanopores

Owner:IND SCI & TECH NETWORK INC

Transport container for keeping frozen material chilled

InactiveCN100594347CEasy to makeEasy to operateLighting and heating apparatusPharmaceutical containersEngineeringCold store

Disclosed is a transport container for shipping frozen material, particularly biological tissue samples. Said transport container comprises a jacket-shaped insulation (superinsulation) and a removableinner container (44) which is provided with at least one coolant chamber (47) with a coolant filling (47'), and at least one chilling chamber (46) that is located inside the coolant chamber (47). Thecoolant, e.g. mercury having a melting temperature of about -39 DEG C, is permanently and hermetically enclosed in the coolant chamber (47) and is solidified in a freezing process using liquid nitrogen, for example, before being shipped. The chilling chamber (46), and thus the sample, is maintained at said temperature level during shipping while the coolant or mercury melts slowly.

Owner:B・西克斯特

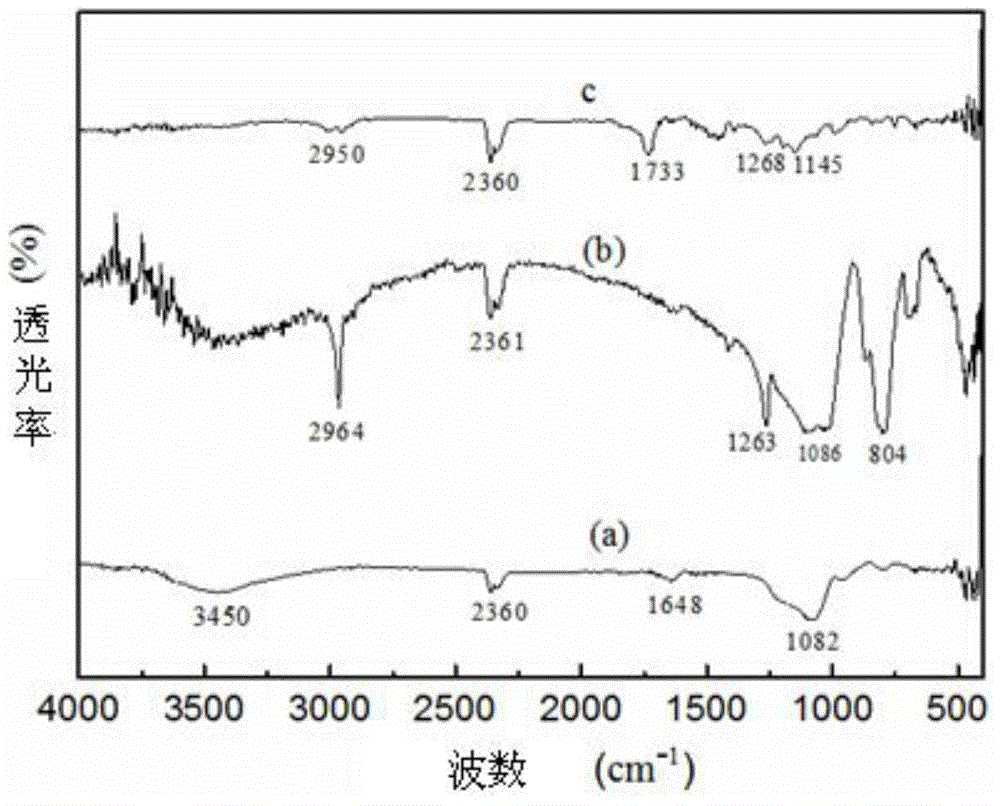

A kind of thermal insulation inorganic coating and preparation method thereof

ActiveCN104609825BLow thermal conductivityImprove water resistanceMagnesium phosphateMagnesium orthophosphate

The invention discloses an inorganic thermal insulation paint and a preparation method thereof. The coating is prepared by combining the super thermal insulation function of the airgel material with the unique water resistance and flame retardancy of the magnesium phosphate cement (MPC). Compared with the existing organic polymer airgel composite coatings and ordinary silicate airgel composite coatings, the inorganic water-based thermal insulation coating of the present invention has low thermal conductivity, good water resistance, flame retardant and fire resistance Good, environmental protection and energy saving advantages. The present invention can be widely used in thermal insulation of inner and outer walls and roof surfaces of public buildings such as residential buildings, schools, hospitals, factories, etc., thermal expansion damage protection of large-volume buildings or facilities such as bridges and dams, and protection of ships, trains, buses, etc. The protection of the top sunshine surface and many other fields.

Owner:泉州三欣新材料科技有限公司

Super heat insulation building material

The invention relates to a super heat insulation building material. The super heat insulation building material includes a wall base layer; the wall base layer is coated with a melamine resin bindinglayer, an algal mud reactive silicate heat insulating layer, and an acrylic acid waterproof layer from inside to outside; the melamine resin binding layer has excellent adhesiveness, and can allow lasting firmness of the heat insulating coating; the algal mud reactive silicate heat insulating layer can lower the thermal transmission ability of the material, or allow the heat transmission ability of the material to be close to a lowest limit, is a super heat insulation material; heat conduction between objects can be achieved through heat transmission, so the heat essential transmission mannerof the algal mud reactive silicate heat insulating layer drops to the lowest level, and the demand of people for the heat insulation performance can be satisfied; and the waterproof layer can preventwater from penetrating to the heat insulation layer, and can effectively prevent the heat insulation layer from being damaged by water.

Owner:秦玲志

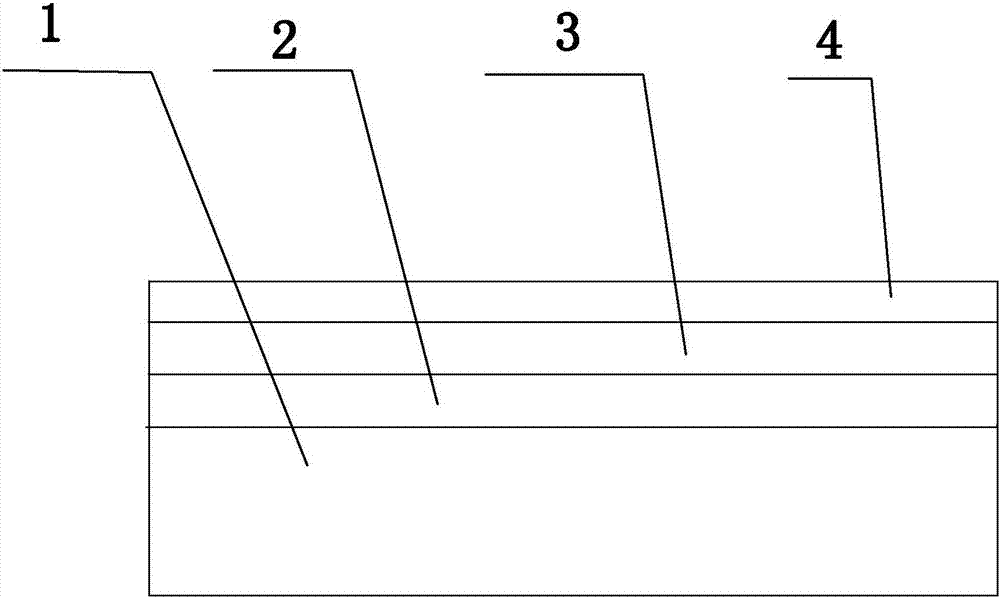

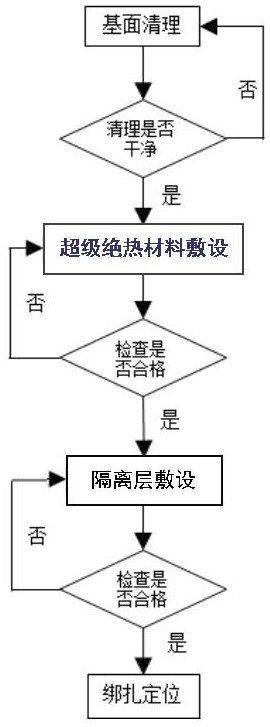

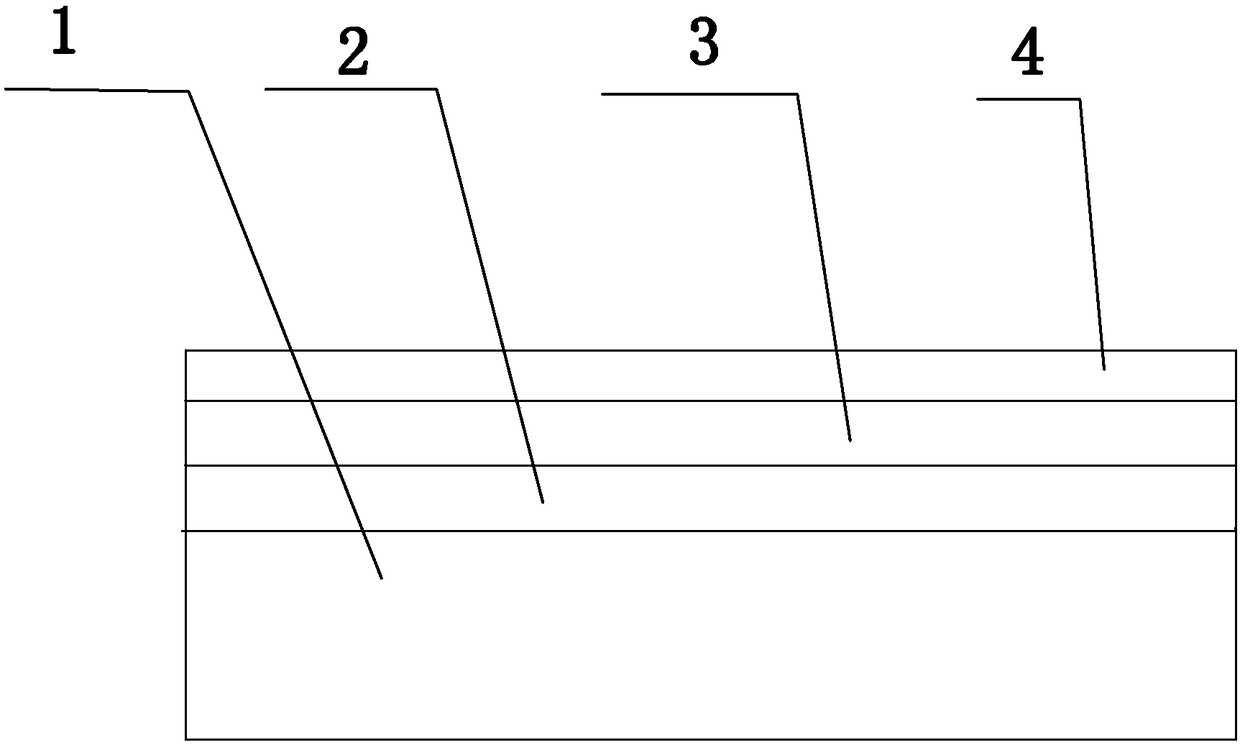

Method for fixing super thermal insulation material of water beam stand column of heating furnace

ActiveCN113819343AIsolation damageGuaranteed to workThermal insulationPipe protection by thermal insulationSurface cleaningStructural engineering

The invention relates to a method for fixing a super thermal insulation material of a water beam stand column of a heating furnace. The method is characterized by comprising the steps of 1, base surface cleaning, 2, thermal insulation material laying, 3, isolation layer laying, and 4, binding and positioning. According to the method for fixing the super thermal insulation material of the water beam stand column of the heating furnace, the super thermal insulation material can be rapidly fixed and tightly combined with the water beam stand column, the hollowing problem is avoided, and the thermal insulation material is a novel super thermal insulation material and can effectively isolate damage of high temperature in the furnace to the water beam stand column, and therefore, the normal working performance and the service life of the water beam stand column are effectively guaranteed.

Owner:SHANGHAI BAOYE GRP CORP

Production method of artificial stone composite board

InactiveCN109138187AGood adhesionAvoid destructionClimate change adaptationHeat proofingLower limitHeat transmission

The invention provides a production method of an artificial stone composite board. The production method of the artificial stone composite board comprises a wall base layer; a melamine resin bonding layer, an algae mud active silicate thermal insulation layer and an acrylic waterproof layer are coated on the wall base layer from inside to outside in sequence; as the melamine resin bonding layer isadopted, the adhesion is good so that a thermal insulation coating is integrally firm and durable; through adoption of the algae mud active silicate thermal insulation layer, the heat transfer capability of a material declines or approaches the lowest limit so that the artificial stone composite board is a super thermal insulation material; as heat conduction is realized between an object and anobject through heat transmission, and the heat transmission capability of the heat transmission mode of the algae mud active silicate thermal insulation layer declines to a lowest degree, the seekingof people to the thermal insulation performance can be satisfied; and due to the existence of the waterproof layer, water can be very well prevented from permeating into the thermal insulation layer so that the thermal insulation layer can be effectively prevented from being destroyed by water.

Owner:秦春玉

Tank container for transport and storage of cryogenic liquefied gases

The invention relates to a tank container (100; 100′) for the transport and storage of cryogenic liquefied gas, comprising a framework (120) and a cylindrical vessel (110) connected to the frames work (120), wherein the vessel (110) is covered by a superinsulation arrangement (130) based on an aerogel composition, and the vessel (110) is connected to the framework (120) by a clamping device (30) which is adapted to allow for a relative movement between the framework (120) and the vessel (110) due to thermal expansion or contraction of the vessel (110).

Owner:ASPEN AEROGELS INC

A kind of preparation method of high temperature oxide nano-particles spaced vermiculite micro-nano sheets

ActiveCN113184866BControl granularityControl thicknessFireproof paintsMaterial nanotechnologyMicro nanoSlurry

The invention discloses a preparation method of vermiculite micro-nano sheets separated by high-temperature oxide nanoparticles, belonging to the technical field of thermal insulation and fireproof material preparation. In the invention, chemical modifiers are used to replace the ions between the vermiculite layers, and the interlayer bonding force is weakened by hydration to obtain a vermiculite-water slurry with weak interlayer bonding; high-temperature oxide nanoparticles are used to disperse in the vermiculite-water slurry. and adjust the consistency of the slurry; then through high-speed shearing and stirring, the vermiculite flakes are separated and highly dispersed in the nano-oxide slurry. The mixed slurry has high viscosity, and the vermiculite flakes are exfoliated into micro- and nano-thick lamellae, separated by nanoparticles, and stably suspended in the slurry. The method can control the particle size and thickness of the vermiculite flakes, and the peeling degree is better, and the prepared mixed slurry of vermiculite micro-nano flakes-nano oxide can be used as a fireproof coating for fire protection of flammable building materials. The nano-particle-spaced vermiculite micro-nano sheets obtained after the mixed slurry is dried can be used as a high-temperature nano-oxide powder-based super-insulation material in a dry process.

Owner:UNIV OF SCI & TECH BEIJING

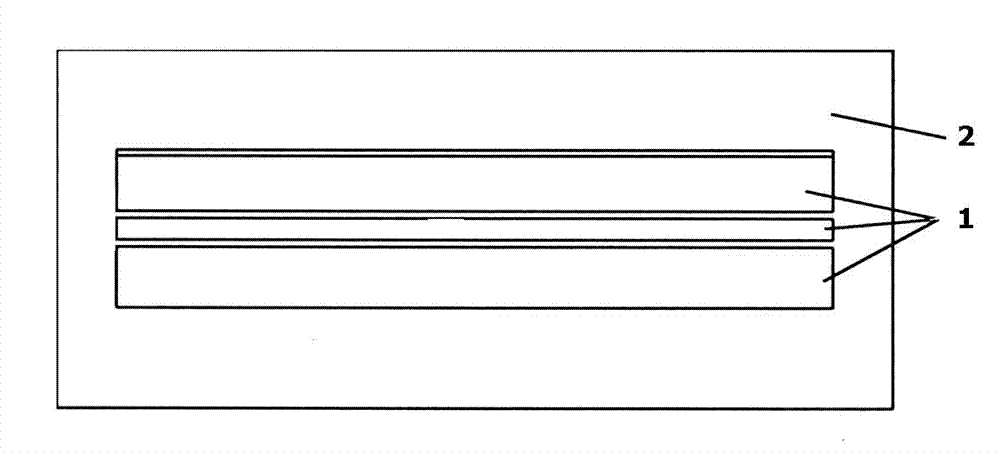

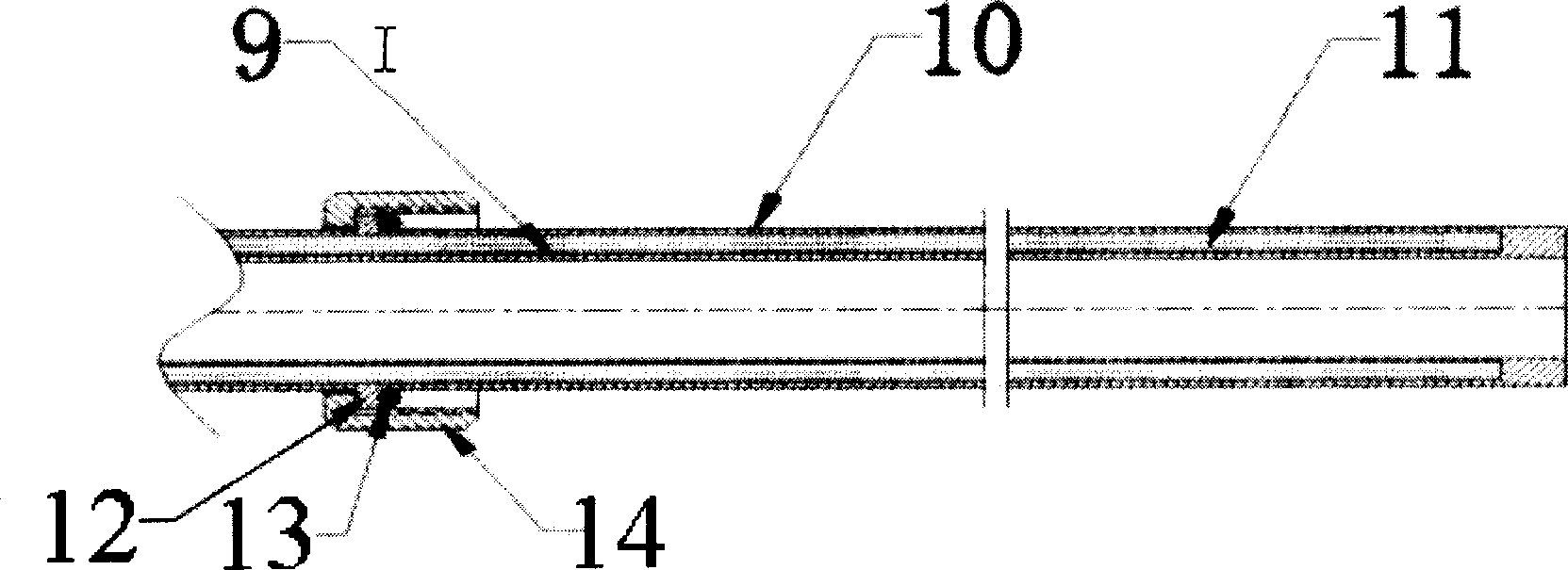

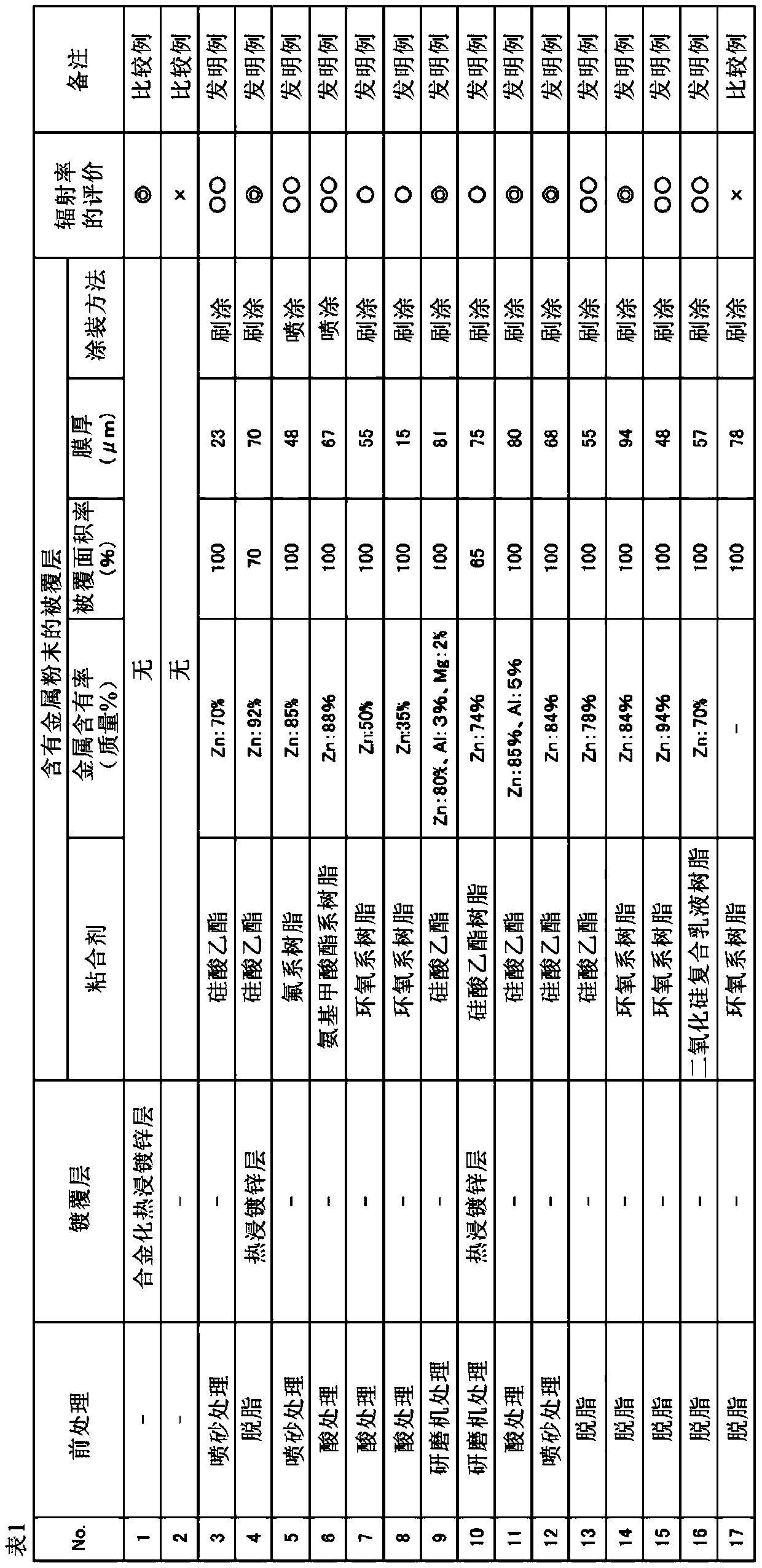

Thermal-insulated multiple pipe for superconducting power transmission

ActiveCN110709949AGood insulation performanceLow emissivitySuperconductors/hyperconductorsThermal insulationStraight tubeMetal powder

The present invention provides a thermal-insulated multiple pipe for superconducting power transmission having excellent thermal insulation properties, having highly suppressed heat incursion from outside caused by radiation, even when not using super insulation, and capable of being easily produced. The thermal-insulated multiple pipe for superconducting power transmission comprises a superconducting cable and a multiplex pipe housing the superconducting cable. The multiplex pipe comprises a plurality of straight pipes. At least one of the plurality of straight pipes has, on the surface thereof, a coating layer containing metal powder.

Owner:JFE STEEL CORP

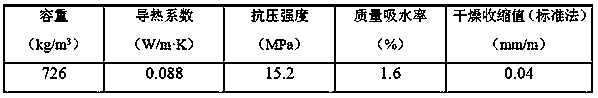

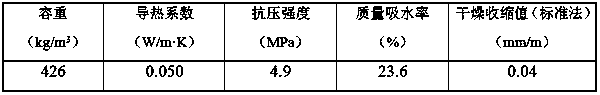

A kind of super heat insulation airgel foam concrete and preparation method thereof

Owner:NANJING WEICAI NEW ENERGY TECH

Cabin pipeline using super thermal insulation material and preparation method thereof

ActiveCN114593280AStrong impact resistanceExtended service lifeThermal insulationPretreated surfacesElectrochemical corrosionProtection layer

The invention discloses a cabin pipeline applying a super thermal insulation material and a preparation method thereof, and belongs to the field of marine oil and gas pipelines, the cabin pipeline comprises a conductive inner pipe, an anti-corrosion coating coated on the conductive inner pipe, a thermal insulation layer wound on the anti-corrosion coating and formed by the super thermal insulation material, and a resin sealing layer coated outside the thermal insulation layer. The cabin pipeline applying the super thermal insulation material is high in impact resistance, long in service life and excellent in mechanical property and thermal insulation property. The conductive inner pipe is adopted and has excellent corrosion resistance to liquefied natural gas in a pipeline, and compared with a conventional steel pipe, the mass of the conductive inner pipe is obviously reduced, so that the carrying and mounting cost is saved, and the efficiency is improved; the protective layer formed by the anti-corrosion coating and the resin sealing layer can prevent the conductive inner pipe from being directly exposed in the environment due to long-time seawater infiltration or accidental damage of the outer layer, electrochemical corrosion is avoided, and the corrosion resistance is further improved.

Owner:中建材科创新技术研究院(山东)有限公司

Nano polyester superinsulation board

The invention provides a nano polyester superinsulation board. Nano vitrified microbeads are doped in premixed polyester in the mass ratio of 13%-15%, and a material A is prepared through low-speed stirring; besides, vitrified microbeads are doped in isocyanate in the mass ratio of 11%-14%, and a material B is prepared through low-speed stirring; the material A and the material B are mixed in theproportion of 1:(1-1.5) for a catalytic reaction, finally, molding is performed, and the board is obtained. The nano polyester superinsulation board has the benefits as follows: the use temperature ofthe nano polyester superinsulation board is subzero 100 DEG C to 250 DEG C, the fireproofing grade is grade B1, no pollution is caused during construction, the board is convenient and firm to mount,seamless joint of boards is realized, the heat conduction coefficient is smaller than or equal to 0.027 w / m.k, and the nano polyester superinsulation board can be placed in any special-shaped industrial structure for thermal insulation.

Owner:吕德欣 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com