Method for fixing super thermal insulation material of water beam stand column of heating furnace

A technology of thermal insulation material and heating furnace, which is applied to heat exchange equipment, pipeline protection through thermal insulation, thermal insulation, etc., can solve the problems of easy generation of hollowing, falling off, cracking of refractory thermal insulation materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is further illustrated by specific examples below.

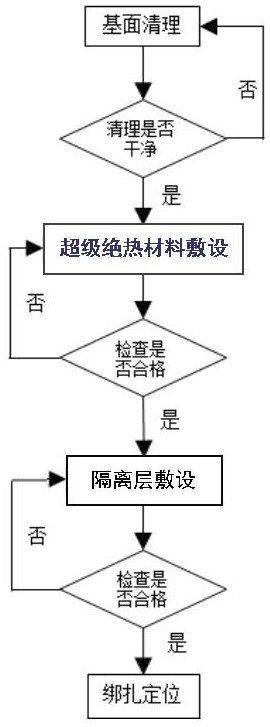

[0017] like figure 1 As shown, a fixing method of super-insulation material for a water beam column of a heating furnace, comprising:

[0018] Step 1. Base surface cleaning

[0019] First, check whether there are grease, welding slag, rust and other attachments on the surface of the water beam column. Use cotton yarn to clean up the grease attachments on the base surface. Use a pointed hammer to knock out the welding slag from the anchoring nails and other parts, and use a wire brush. Clean the rust on the base surface, and finally brush the asphalt-based release agent on the surface of the anchoring nail;

[0020] Step 2, laying insulation material

[0021] The super insulation material used in the water beam column is a blanket, which has a smaller thermal conductivity, higher density and thicker than the general floc insulation material. According to the spacing between adjacent anchoring n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com