High-strength nano-ceramic fiber anti-radiation heat insulating plate and preparation method of high-strength nano-ceramic fiber anti-radiation heat insulating plate

A technology of nano-ceramic fiber and ceramic fiber layer, which is applied in the field of refractory materials, can solve the problems that the crystal phase structure of refractory fiber is easily destroyed into powder, insulation, heat insulation, strength and other performance reduction, and the use temperature drops, so as to improve the effective Improvement of working capacity, thermal shock stability and high-temperature mechanical properties, and reduction of heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

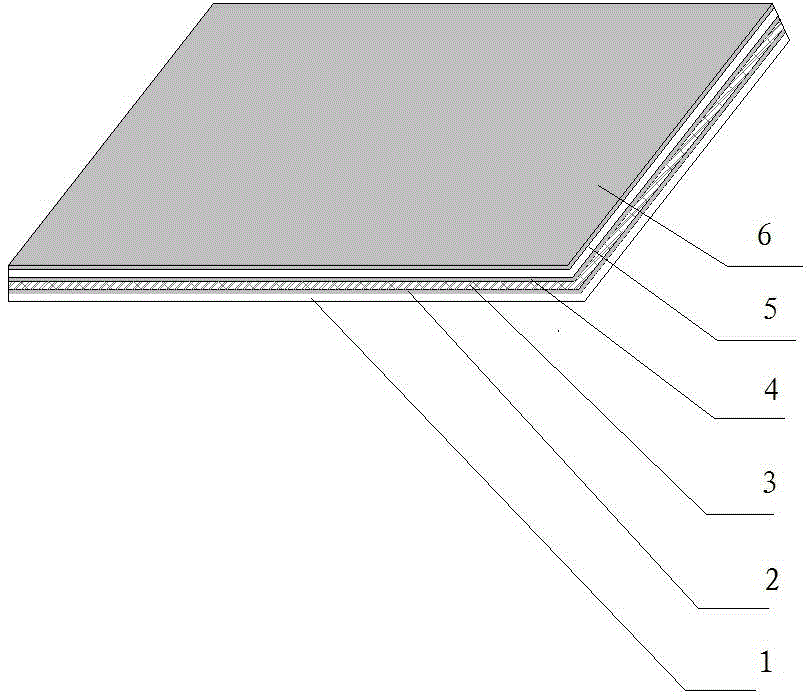

[0041] Such as figure 1 As shown, a high-strength nano-ceramic fiber anti-radiation insulation board is formed by three ceramic fiber layers through adhesives and cured by hot pressing. The ceramic fiber layer includes two heat storage layers 1 and an anti-radiation heat insulation layer 3, the anti-radiation heat insulation layer 3 is located between the two heat storage layers 1, and the heat storage layer 1 and the anti-radiation heat insulation layer 3 are respectively laid There are foils 2, 4, 6. The heat storage layer is a ceramic fiber blanket or a mixture layer containing ceramic fibers. The material components of the anti-radiation heat-insulating layer also contain inorganic non-metallic nanometer materials, metal oxides or non-metal oxides in addition to ceramic fibers.

[0042] The preparation method of the high-strength nano-ceramic fiber anti-radiation heat insulation board described in this embodiment adopts the following steps:

[0043] (a) Preparation of c...

Embodiment 2

[0067] Such as figure 1 As shown, a high-strength nano-ceramic fiber anti-radiation insulation board is formed by three ceramic fiber layers through adhesives and cured by hot pressing. The ceramic fiber layer includes two heat storage layers 1 and an anti-radiation heat insulation layer 3, the anti-radiation heat insulation layer 3 is located between the two heat storage layers 1, and the heat storage layer 1 and the anti-radiation heat insulation layer 3 are respectively laid There are foils 2, 4, 6. The heat storage layer is a ceramic fiber blanket or a mixture layer containing ceramic fibers. The material components of the anti-radiation heat-insulating layer also contain inorganic non-metallic nanometer materials, metal oxides or non-metal oxides in addition to ceramic fibers.

[0068] The preparation method of the high-strength nano-ceramic fiber anti-radiation heat insulation board described in this embodiment adopts the following steps:

[0069] (a) Preparation of c...

Embodiment 3

[0093] Such as figure 1 As shown, a high-strength nano-ceramic fiber anti-radiation insulation board is formed by three ceramic fiber layers through adhesives and cured by hot pressing. The ceramic fiber layer includes two heat storage layers 1 and an anti-radiation heat insulation layer 3, the anti-radiation heat insulation layer 3 is located between the two heat storage layers 1, and the heat storage layer 1 and the anti-radiation heat insulation layer 3 are respectively laid There are foils 2, 4, 6. The heat storage layer is a ceramic fiber blanket or a mixture layer containing ceramic fibers. The material components of the anti-radiation heat-insulating layer also contain inorganic non-metallic nanometer materials, metal oxides or non-metal oxides in addition to ceramic fibers.

[0094] The preparation method of the high-strength nano-ceramic fiber anti-radiation heat insulation board described in this embodiment adopts the following steps:

[0095] (a) Preparation of c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Normal temperature compressive strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com