Waste salt incineration heat preservation furnace body structure

A furnace body structure and furnace body technology are applied in the field of waste salt incineration and heat preservation furnace body structure, which can solve the problems of troublesome operation of replacing refractory bricks, and achieve the effects of good heat preservation effect and good heat preservation and heat insulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following is further described in detail through specific implementation methods:

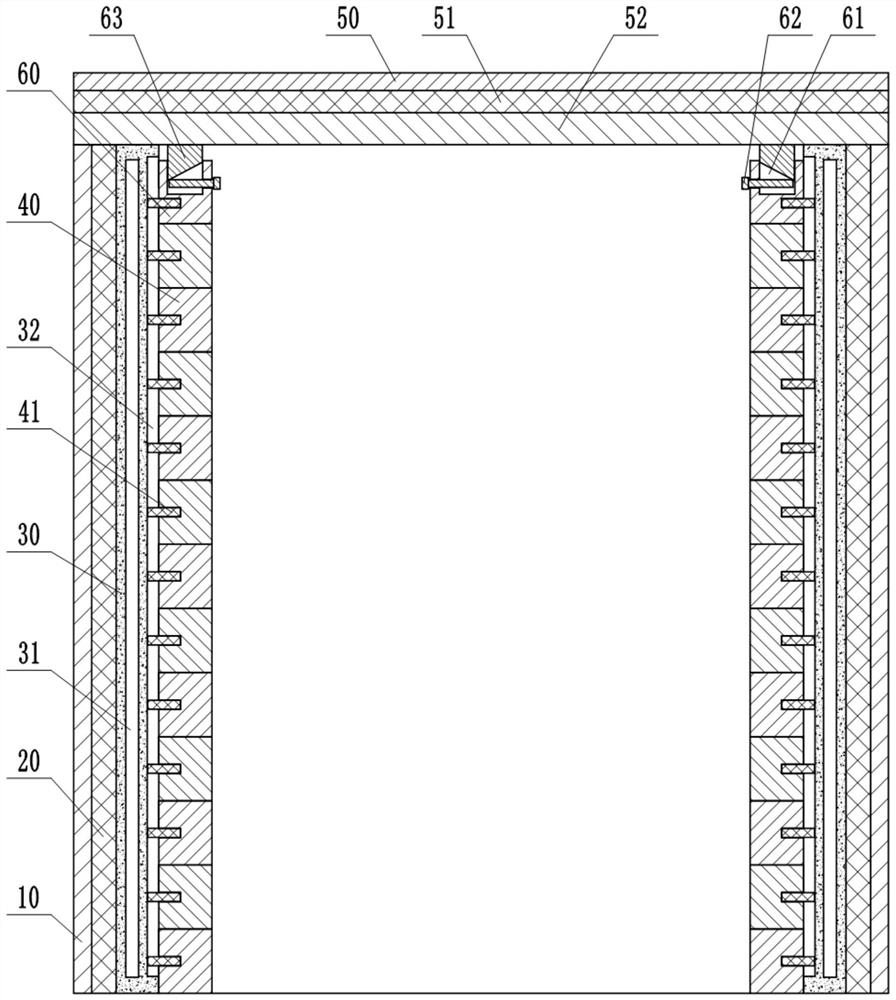

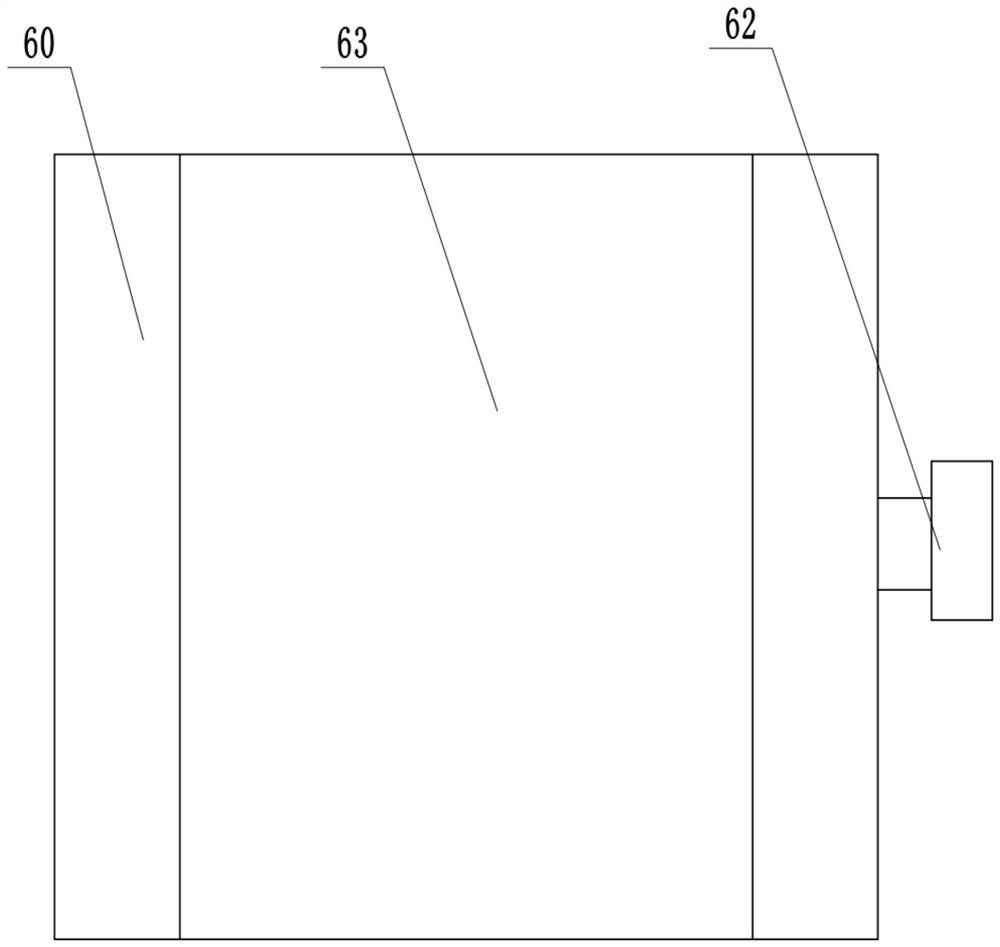

[0019] The reference signs in the drawings of the description include: outer wall layer 10, middle insulation layer 20, partition layer 30, cavity 31, slot 32, conventional refractory brick body 40, connecting column 41, outer layer 50, heat insulation layer 51 , refractory layer 52, upper refractory brick body 60, chute 61, push rod 62, regulating block 63.

[0020] This embodiment is basically as figure 1 , figure 2 Shown: The structure of the waste salt incineration heat preservation furnace body, including the furnace body, the furnace body includes side walls and upper walls, and the side walls include the outer wall layer 10, the middle insulation layer 20, the partition layer 30 and the corrosion-resistant layer from outside to inside. layer, in the present embodiment, the outer wall layer 10 is a concrete layer, the middle insulation layer 20 is a ceramic fiber board, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com